Automatic peanut shell and skin separator

A peanut shell and separator technology, which is applied in the direction of solid separation, separation of solids from solids with airflow, and shelling, etc. It can solve the problem of coating residues adhering to peanuts, reducing peanut processing efficiency, and using more equipment, etc. Problems, to achieve the effect of sufficient separation, improvement of practicality, and enhancement of sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

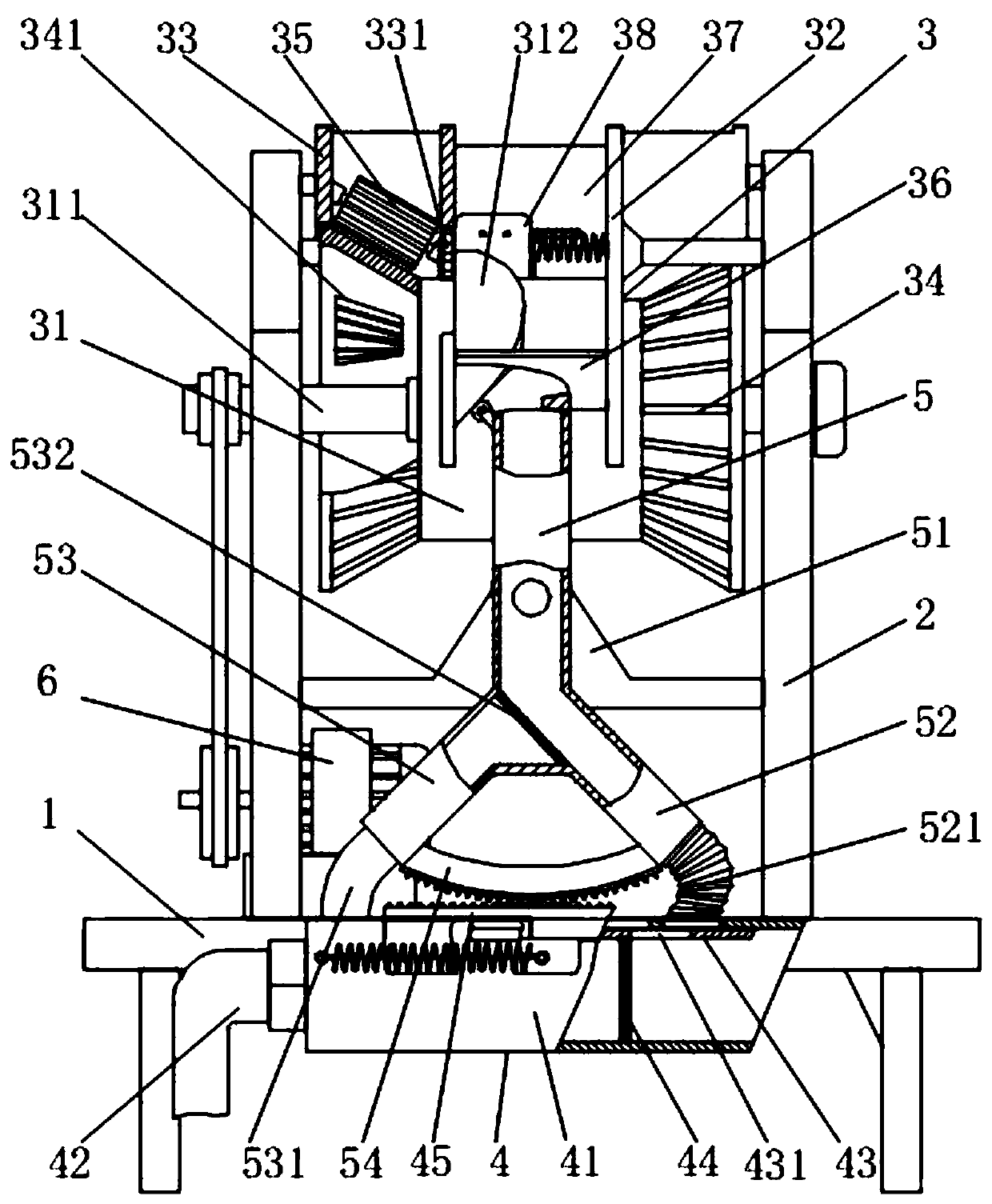

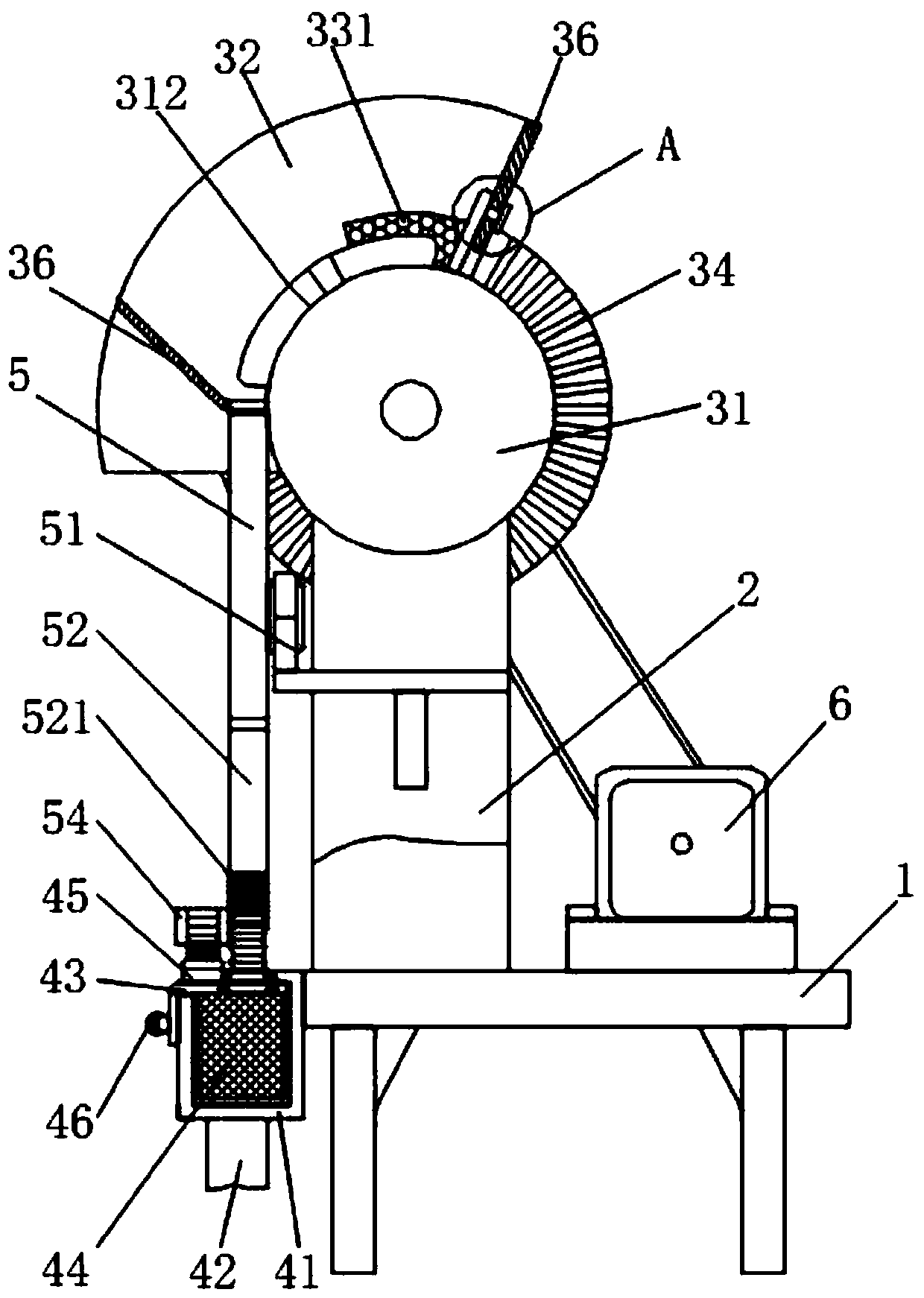

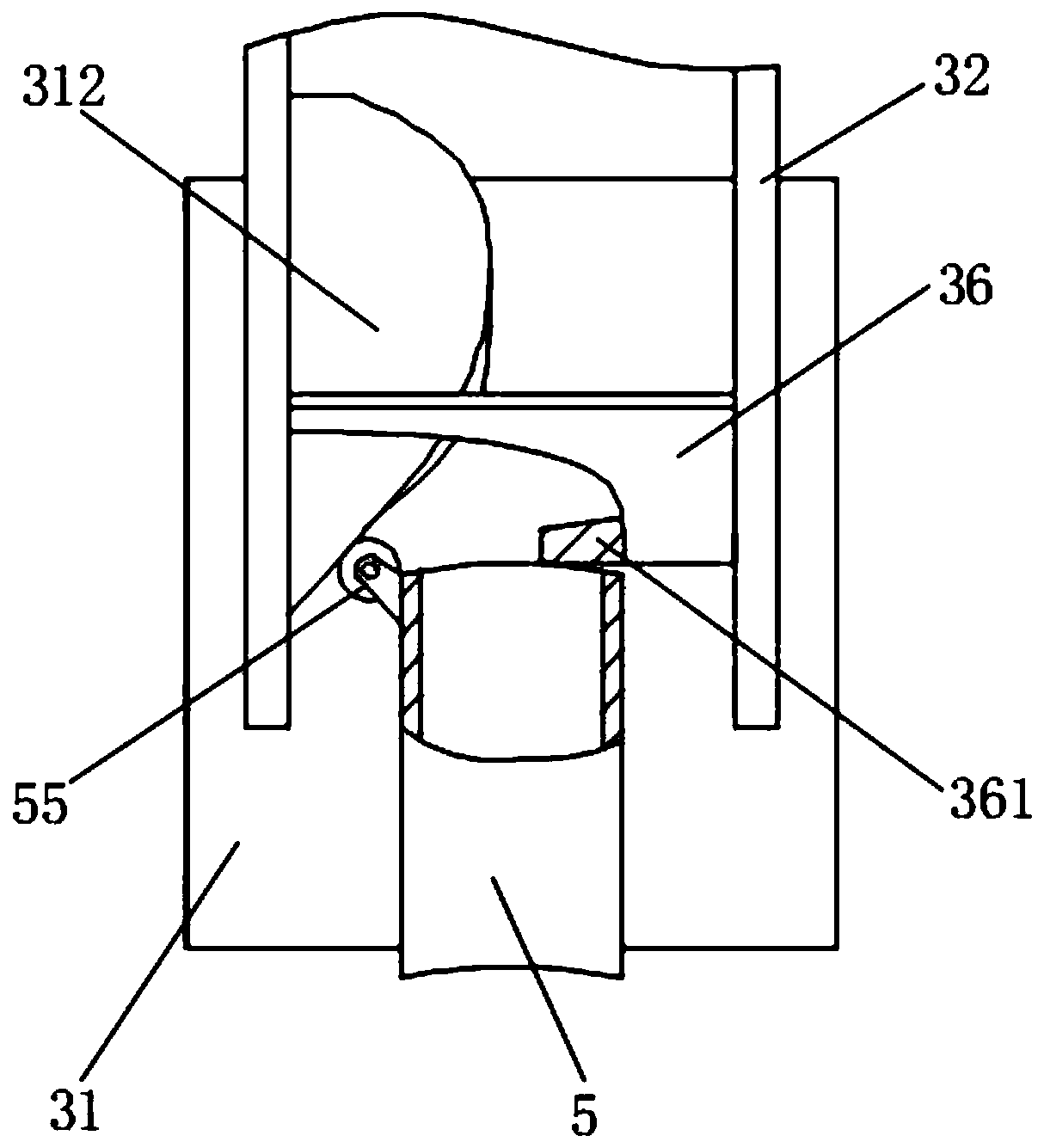

[0030] The present invention provides such as Figure 1-8A kind of peanut shell and skin automatic separator shown, including a base 1, the top of the base 1 is fixedly installed with a bracket 2, the inner side of the top of the bracket 2 is provided with a shell separation mechanism 3, and the bottom of one end of the base 1 is provided. An automatic unloading mechanism 4 is provided. The shell and skin separation mechanism 3 includes a rotating drum 31. Both ends of the rotating drum 31 are fixedly connected with a rotating shaft 311. The rotating drum 31 is rotatably connected to the top of the bracket 2 through the rotating shaft 311. On the inner side, a motor 6 is fixedly installed at one end of the top of the base 1 away from the bracket 2, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap