Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

583 results about "Electric machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

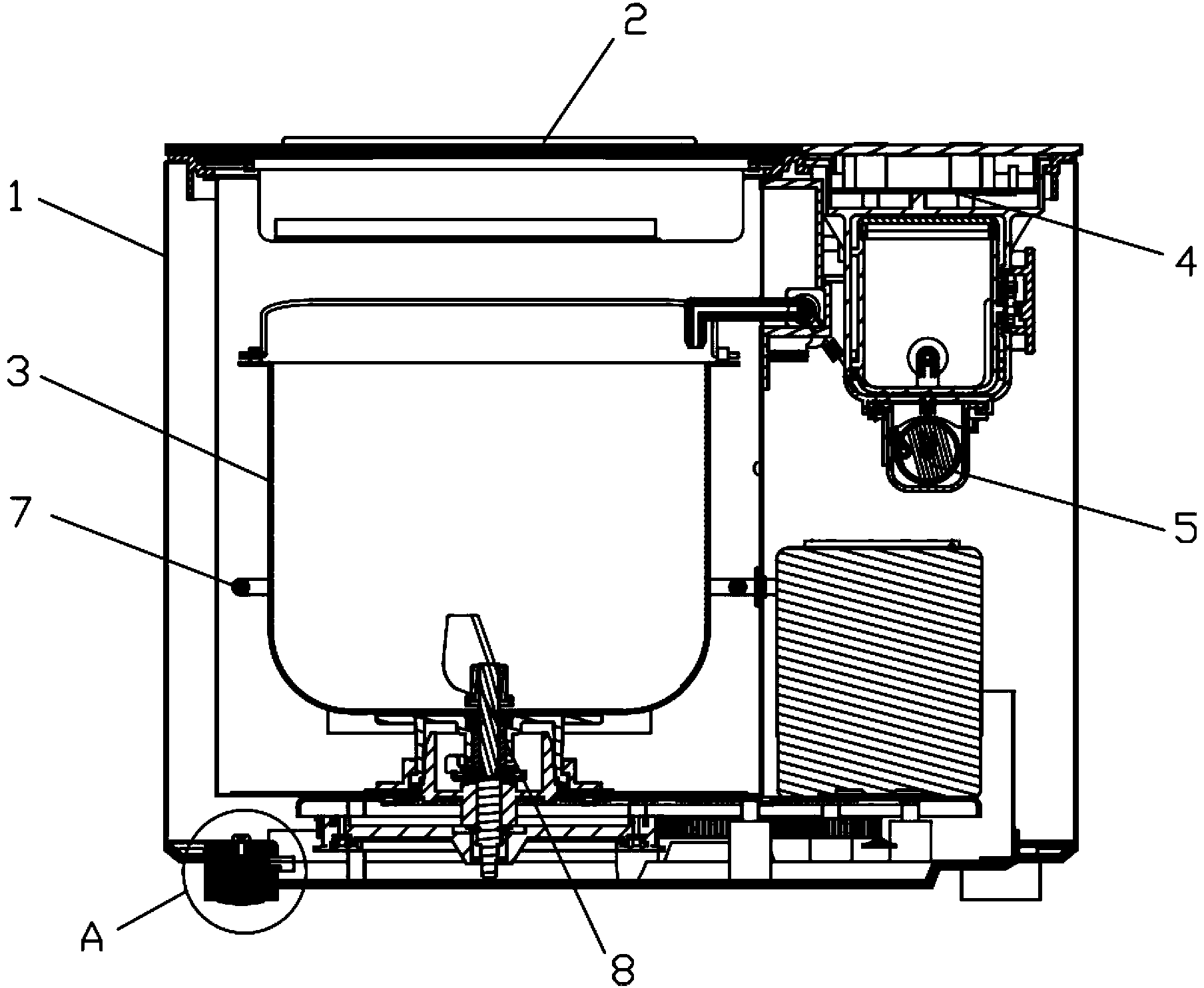

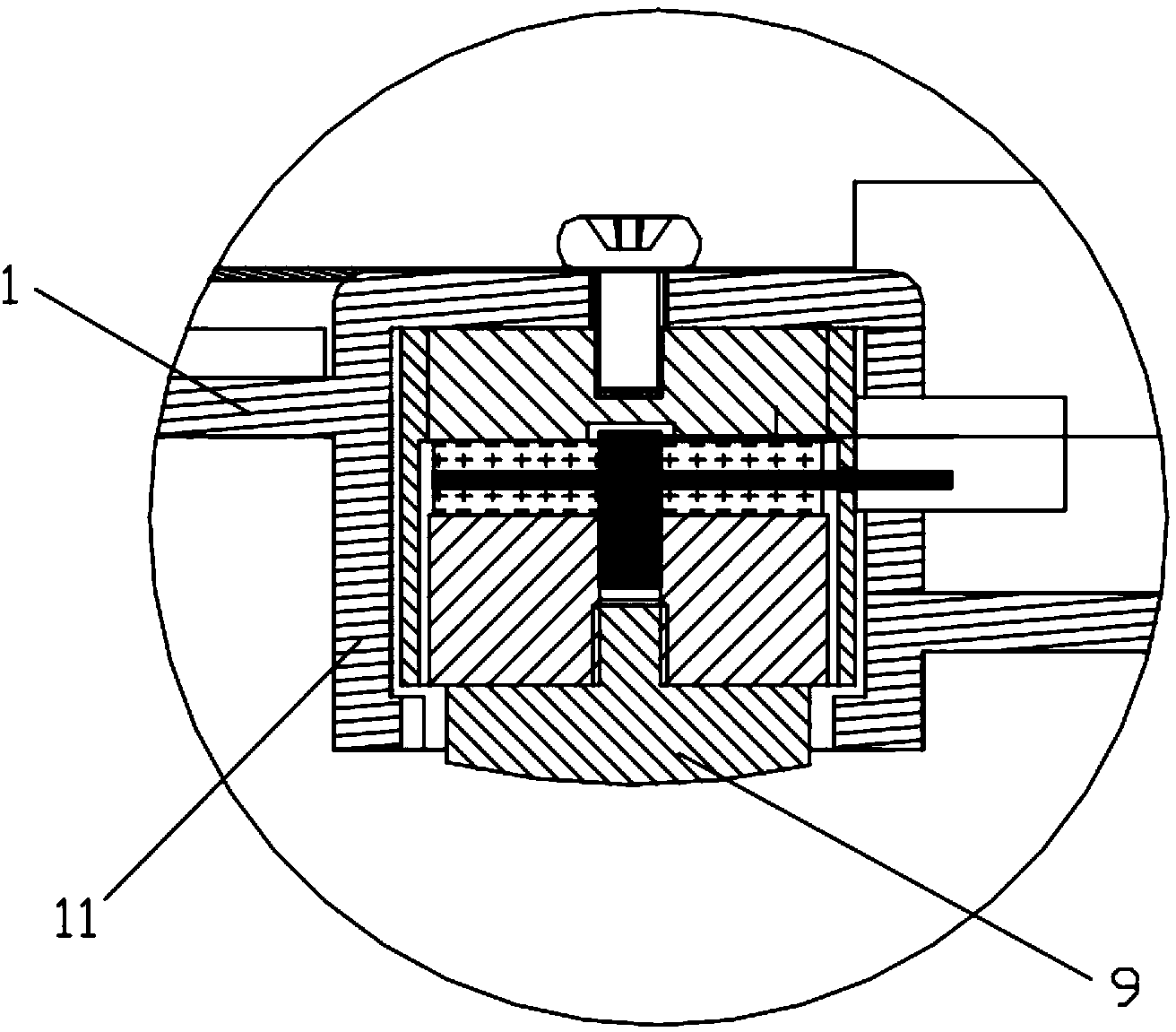

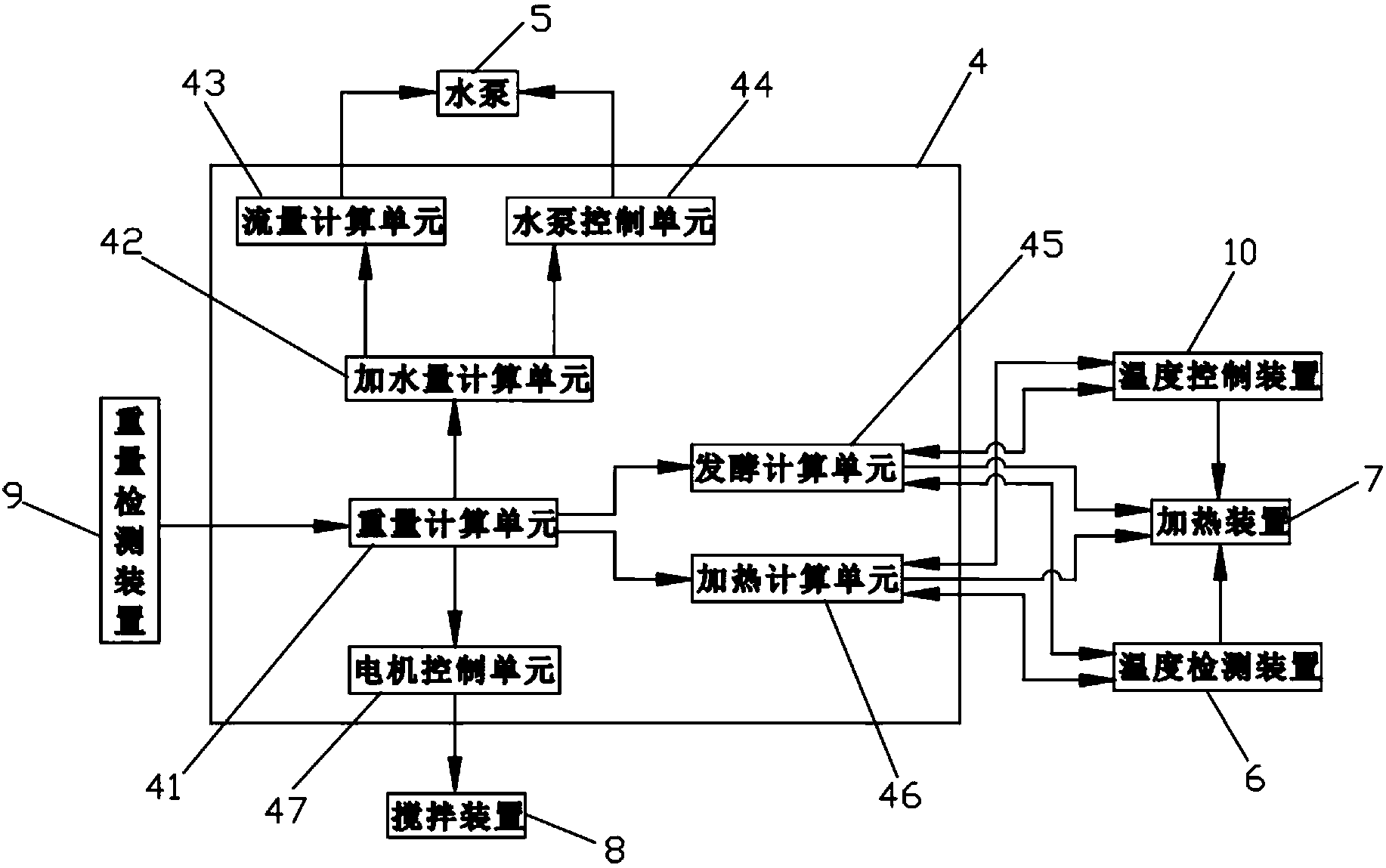

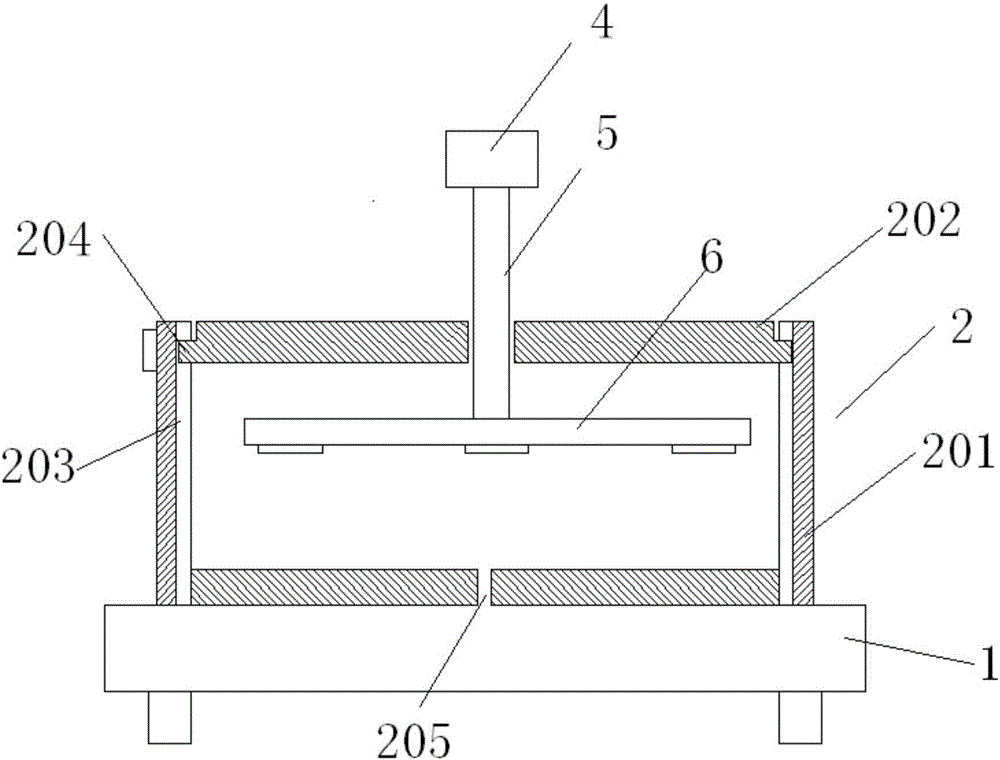

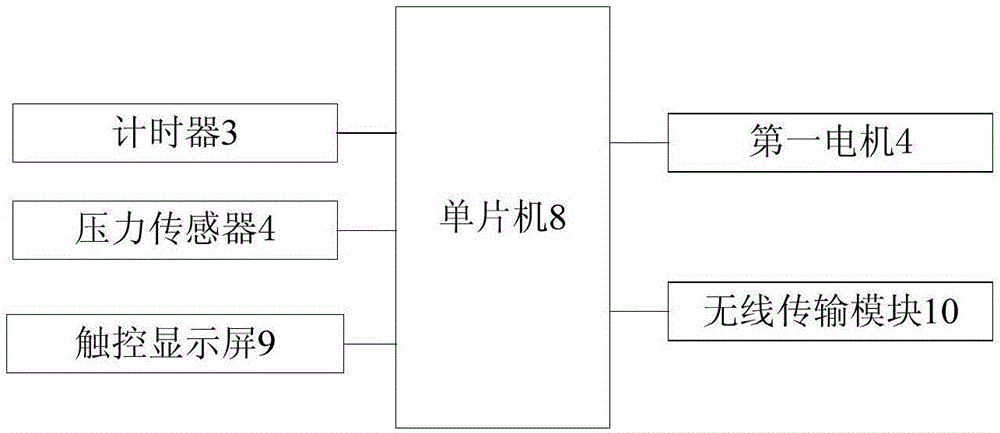

Intelligent bread machine and weighing control method thereof

ActiveCN103004917AManufacturing process intelligenceEasy to makeBakery productsSimultaneous control of multiple variablesElectricityHeating time

Owner:JOYOUNG CO LTD

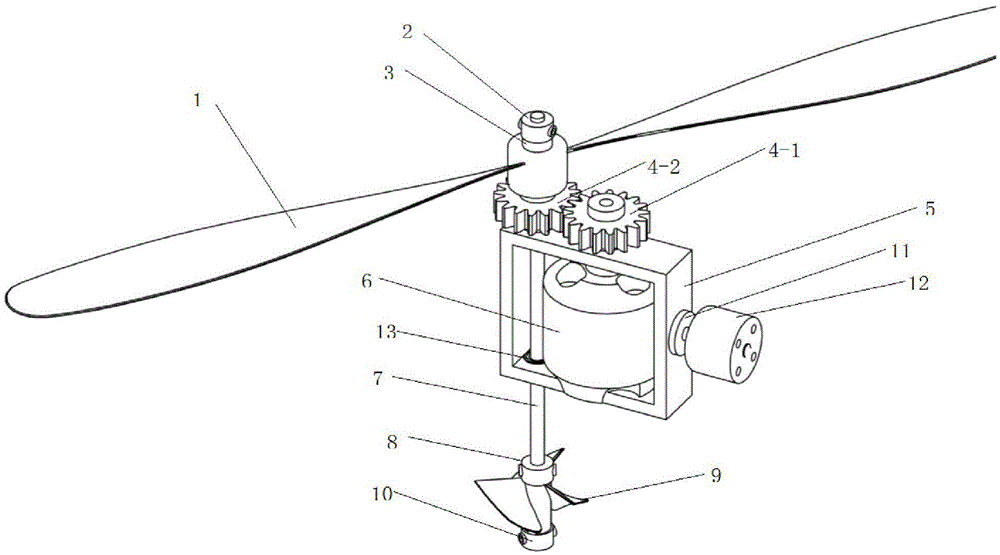

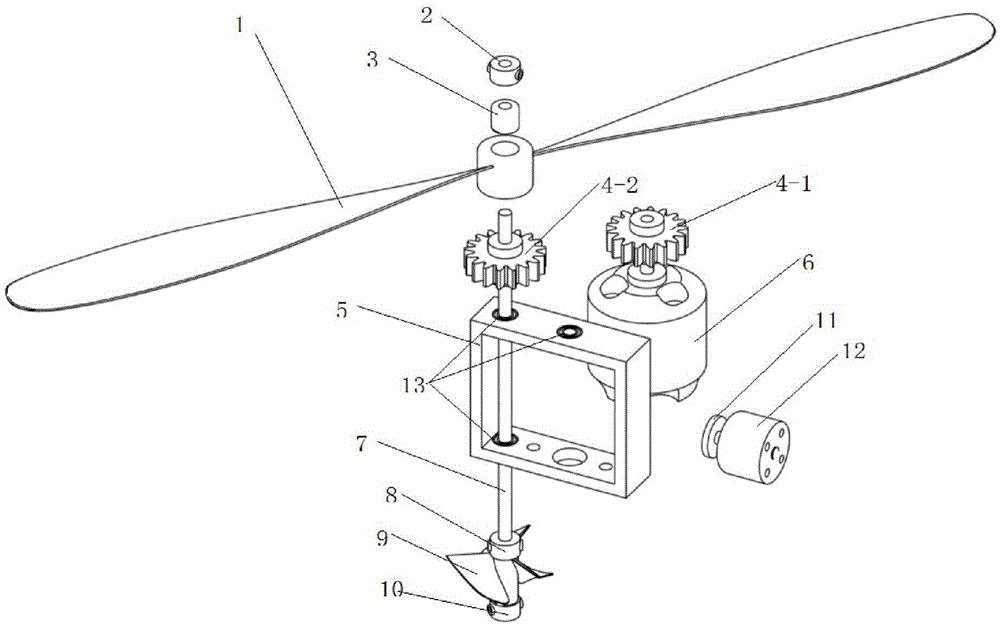

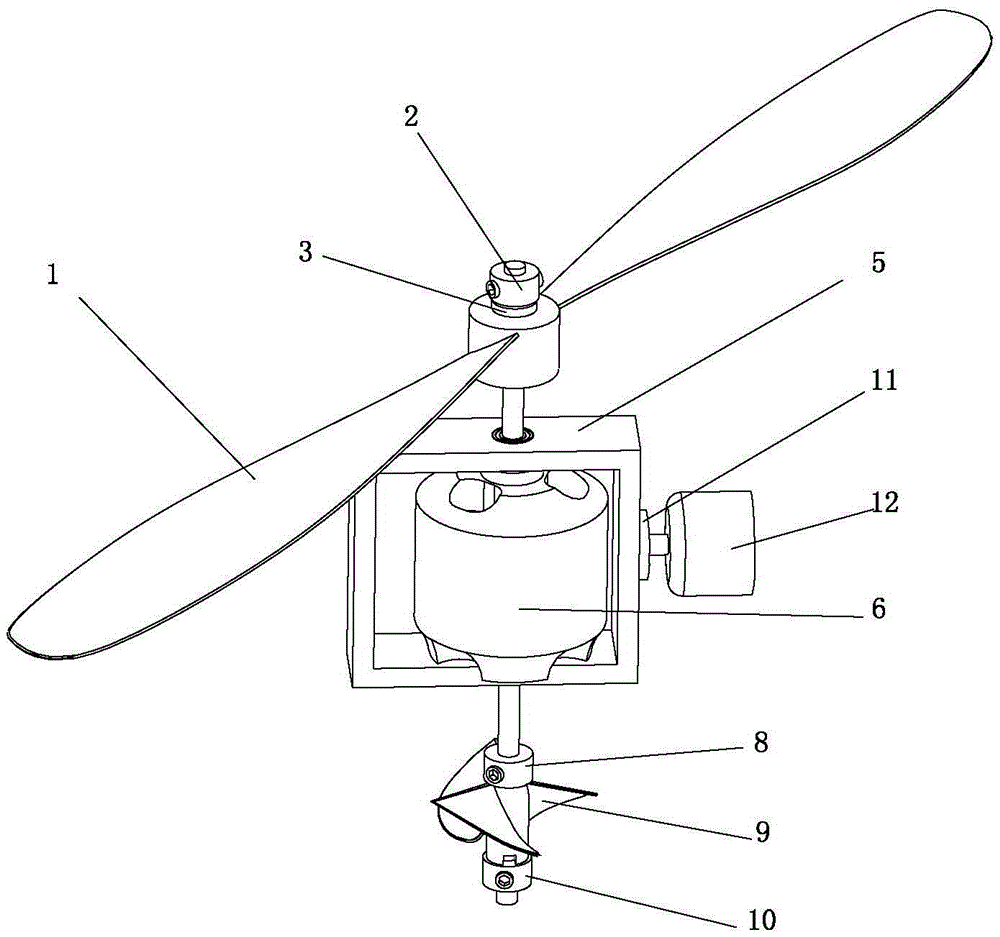

Amphibious power propulsion device suitable for sea and air and multi-axis aircraft

InactiveCN105539831AComplex structureReduce weightPropulsion power plantsOutboard propulsion unitsRotational axisFlight vehicle

Owner:SOUTH CHINA UNIV OF TECH

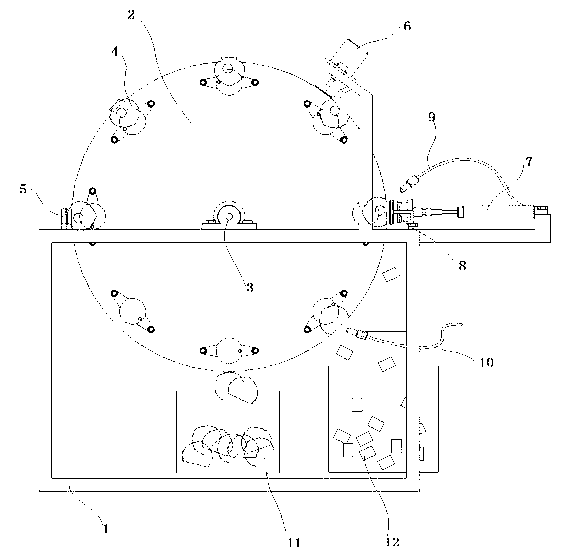

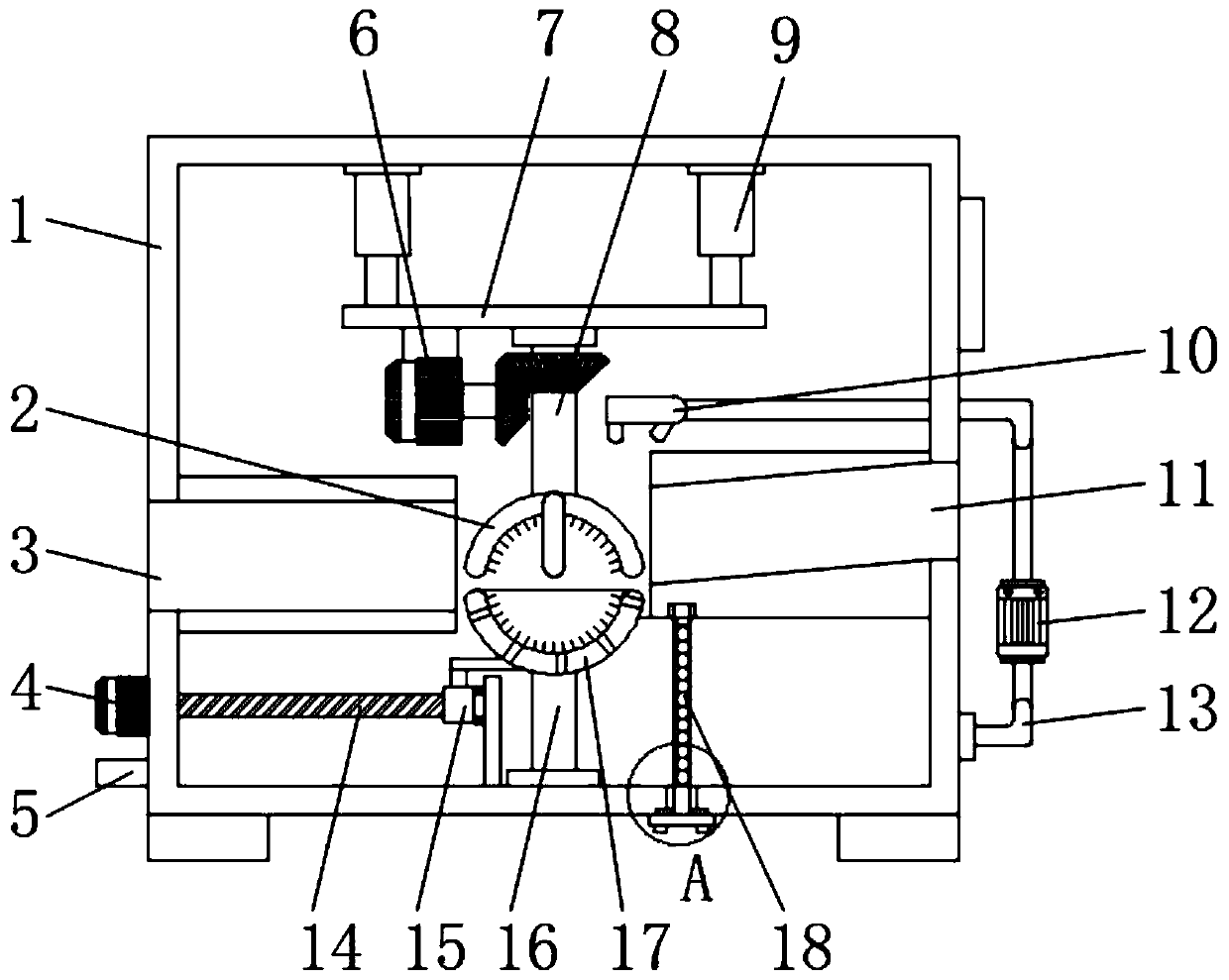

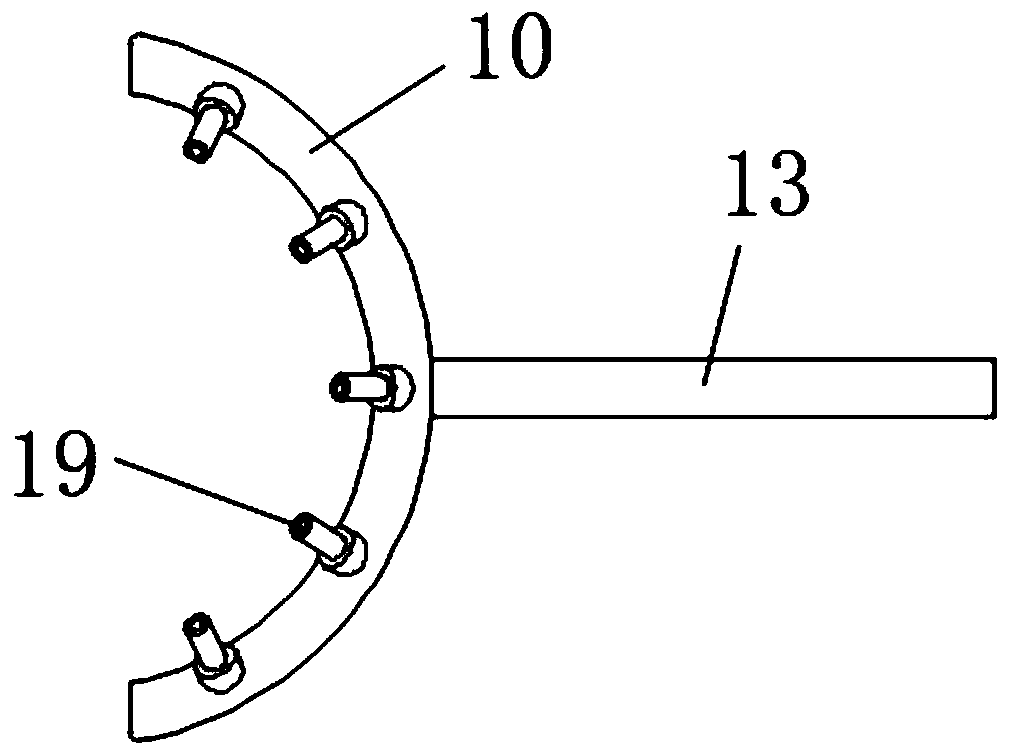

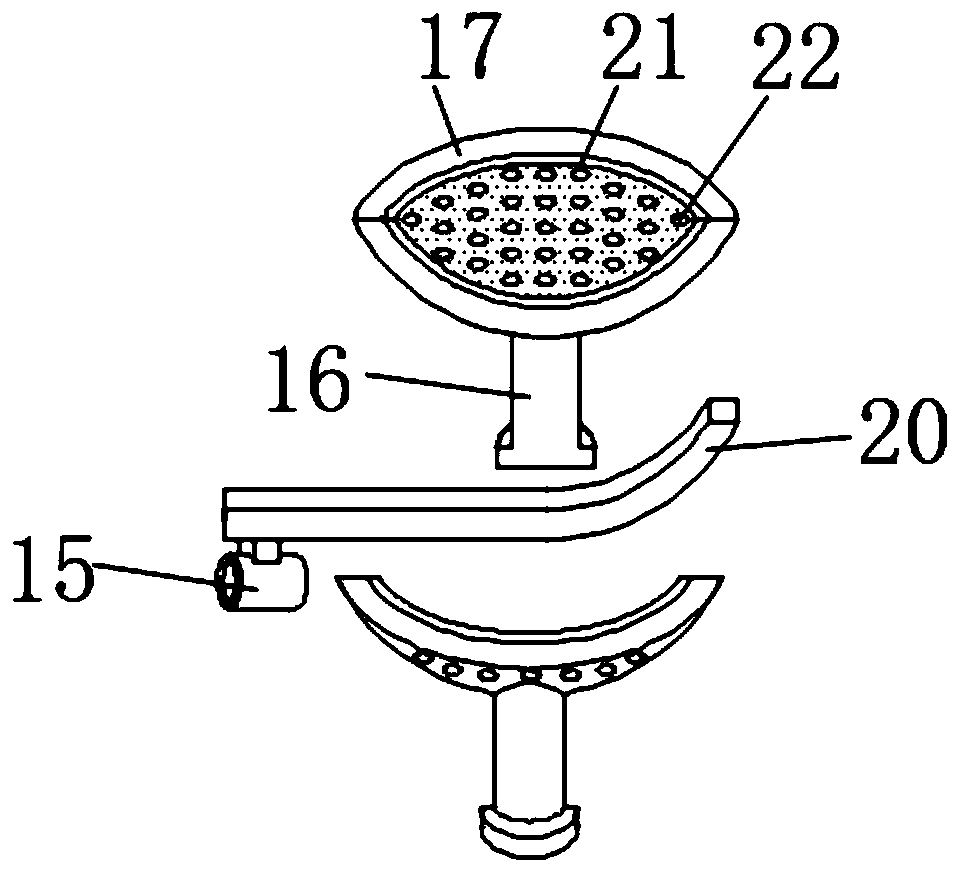

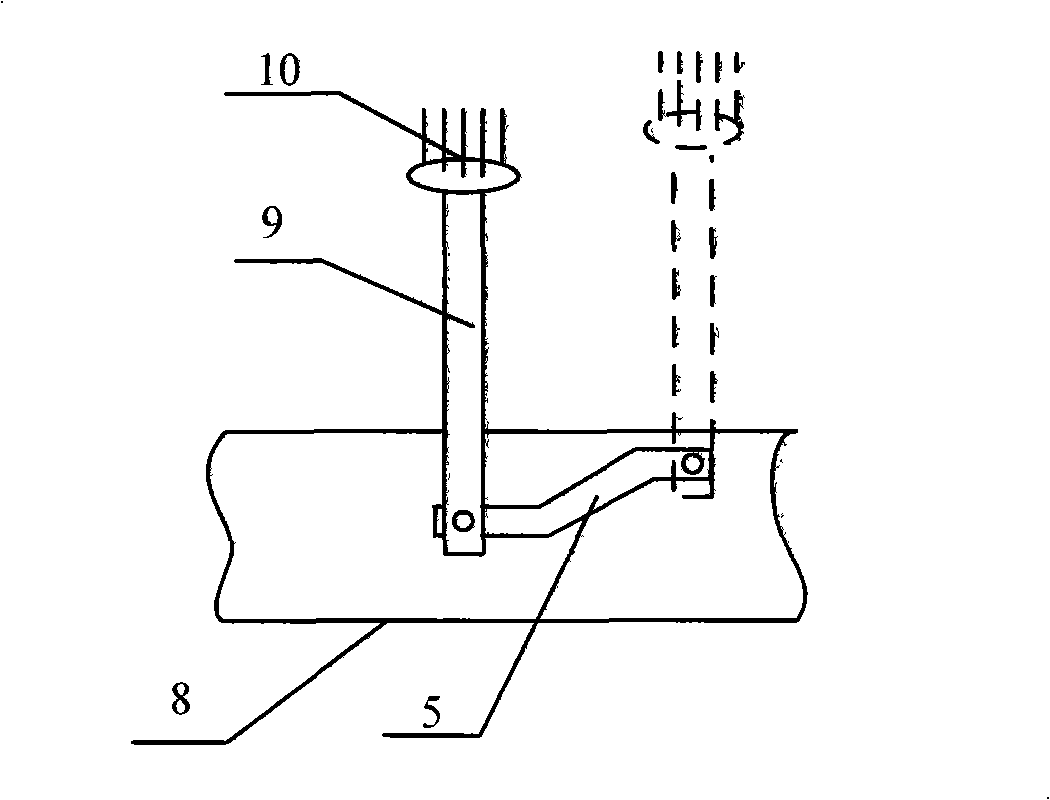

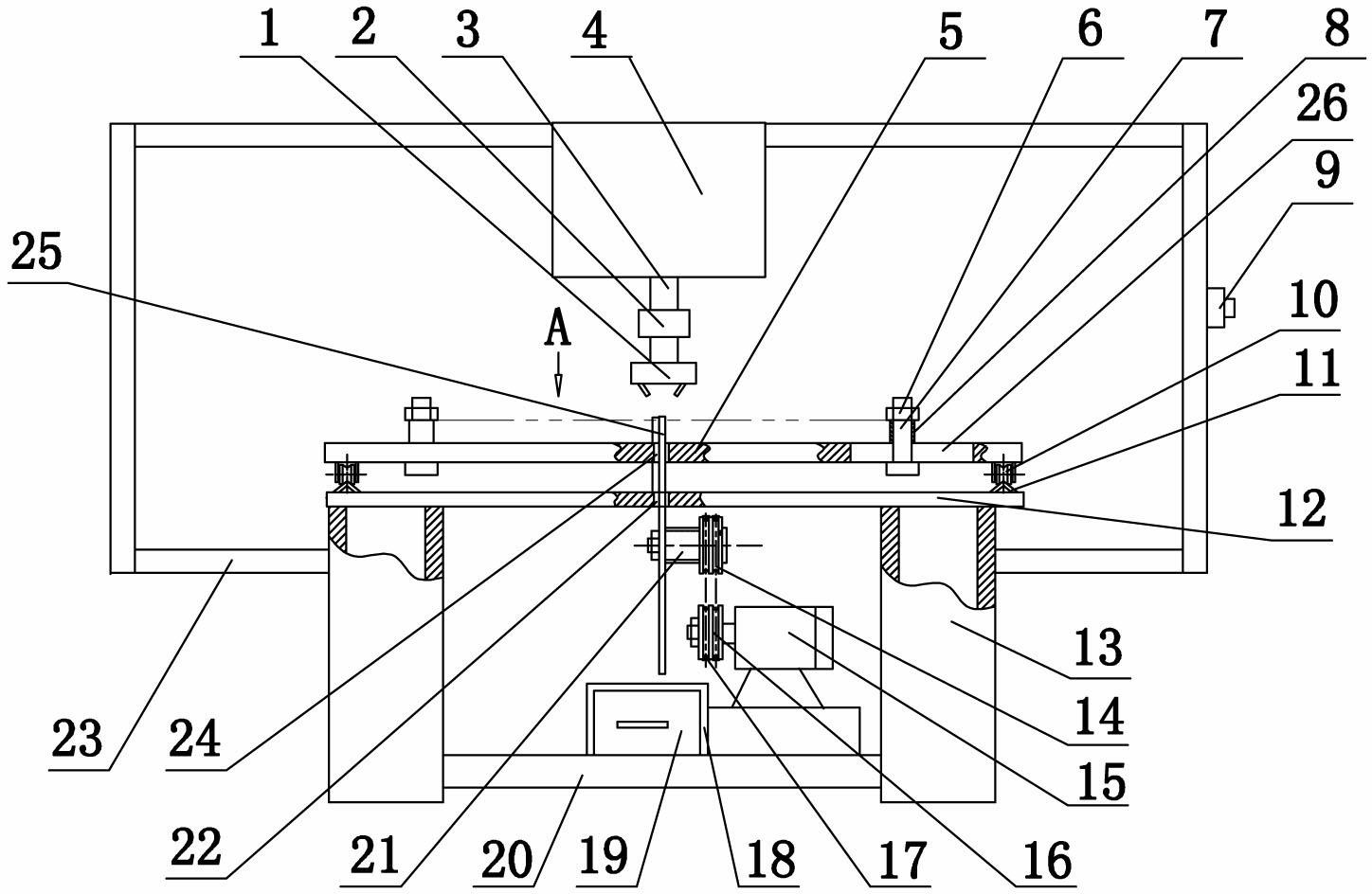

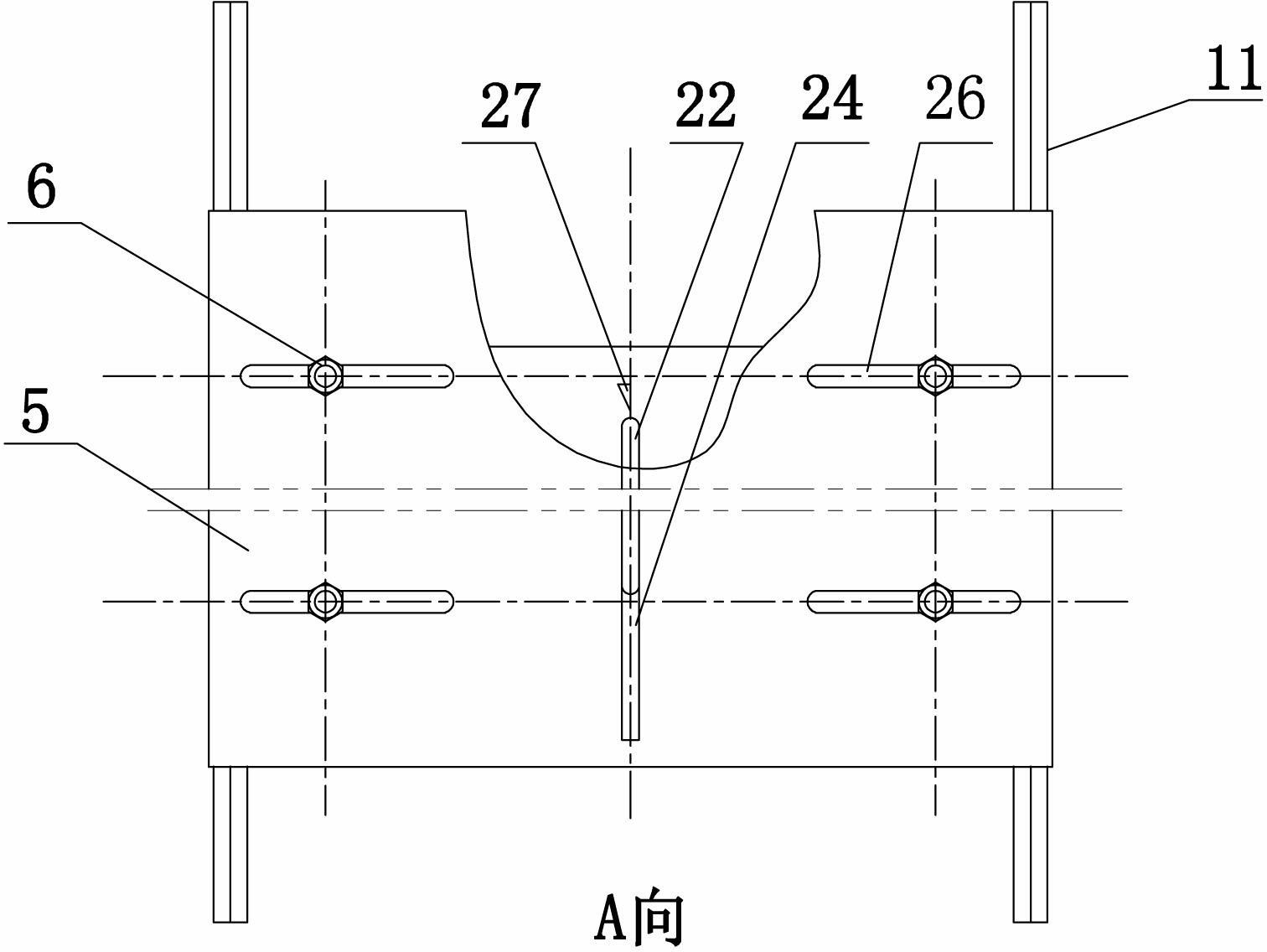

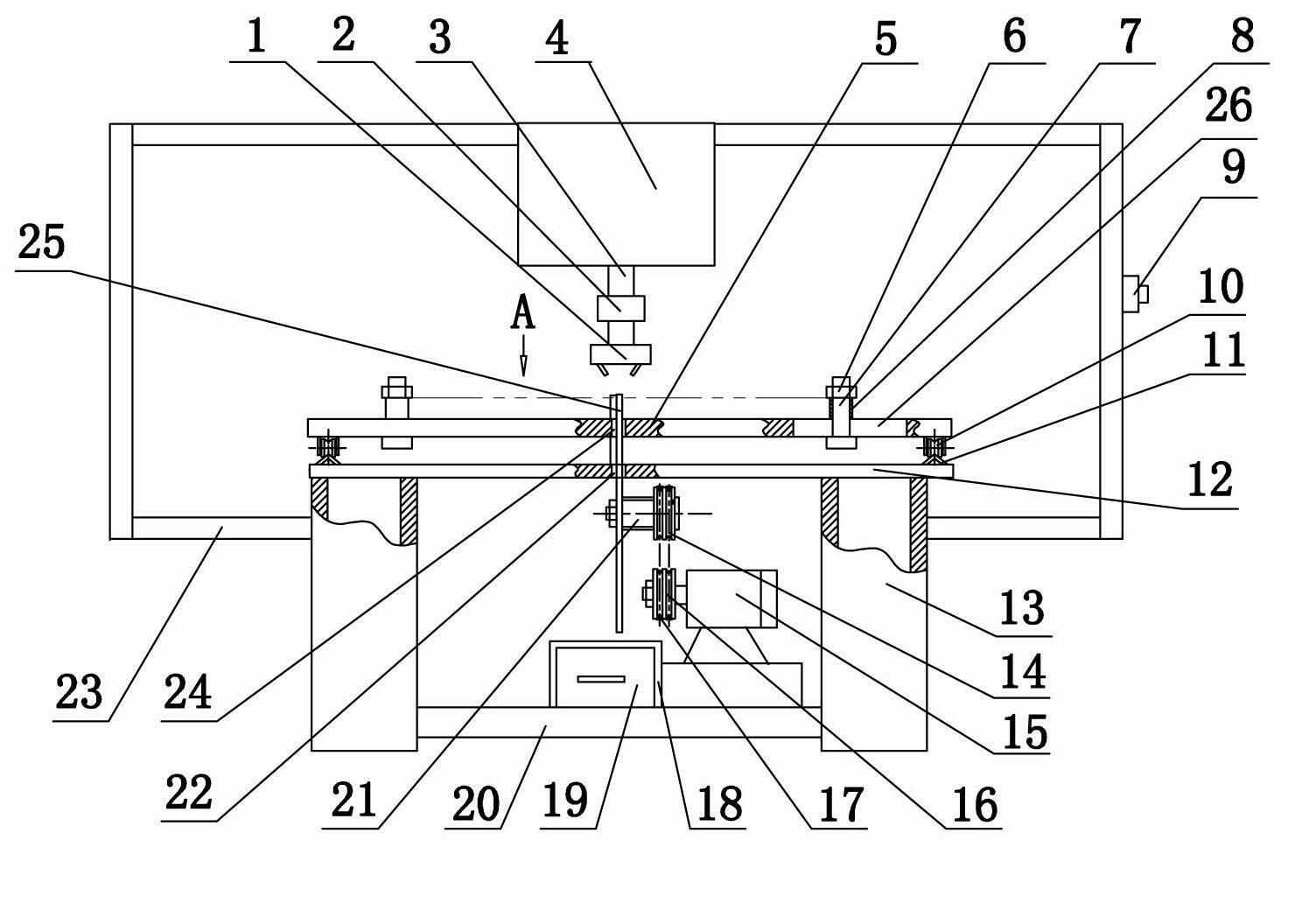

Device for taking scallop by opening scallop shell

Owner:HEBEI AGRICULTURAL UNIV.

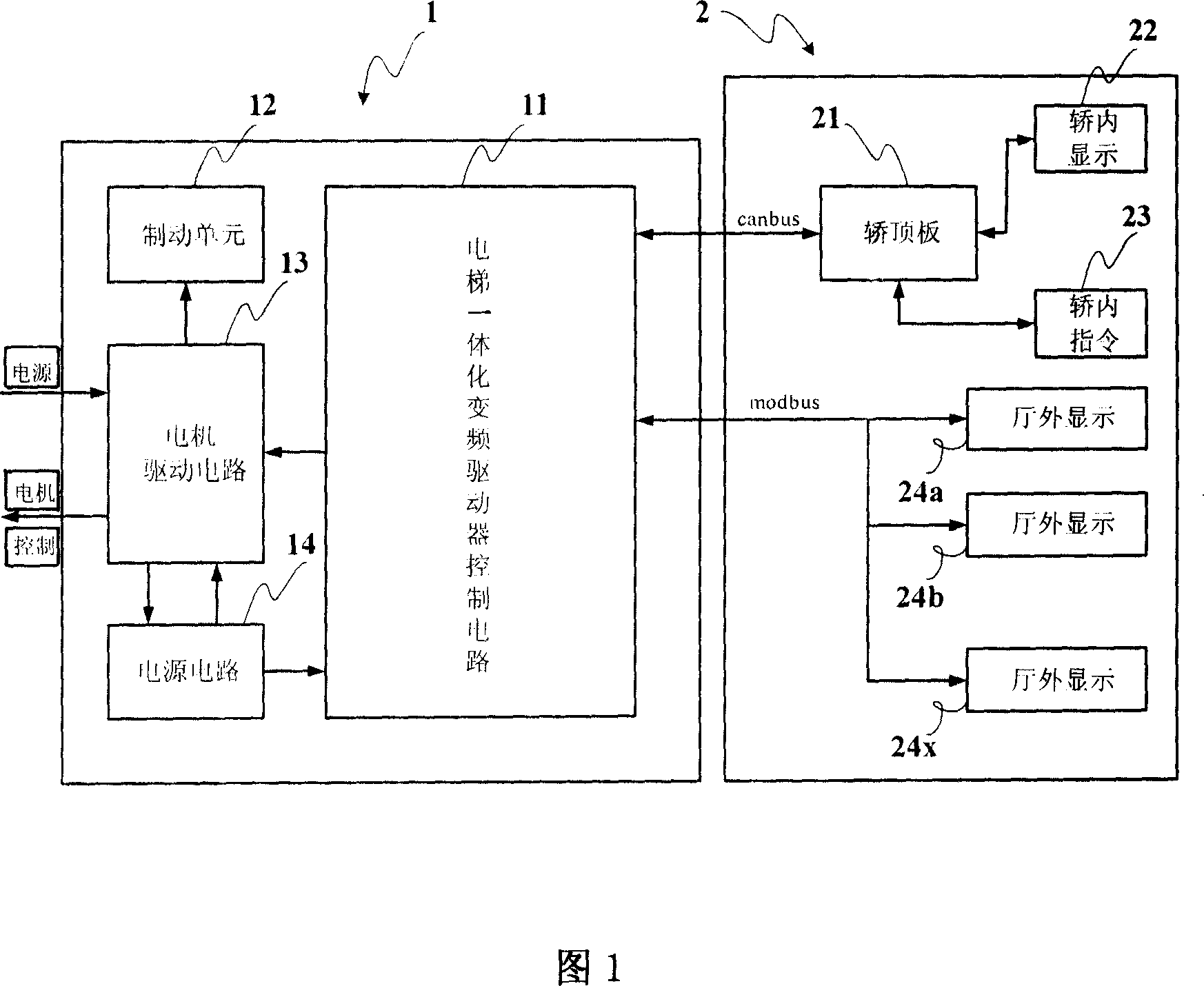

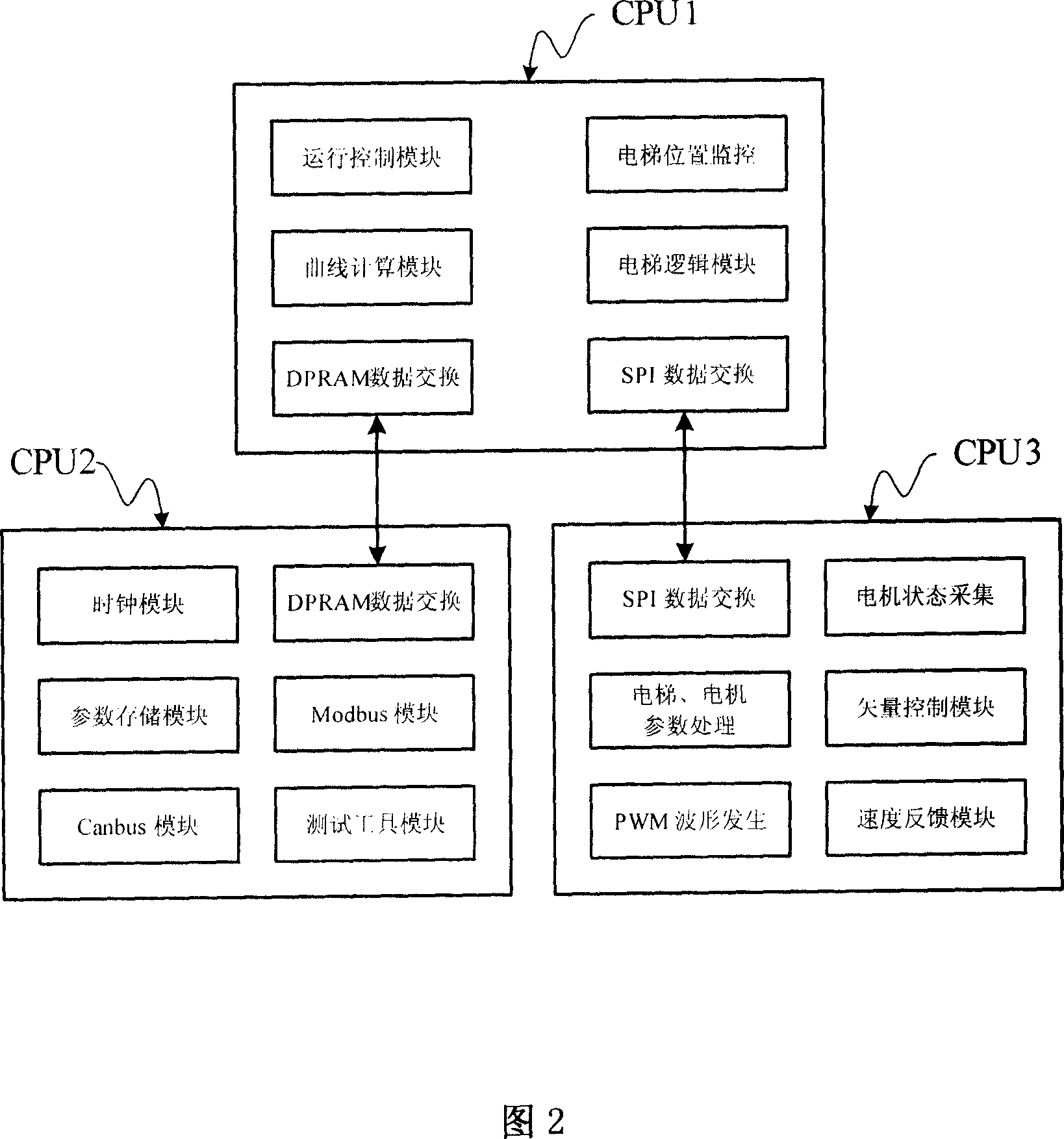

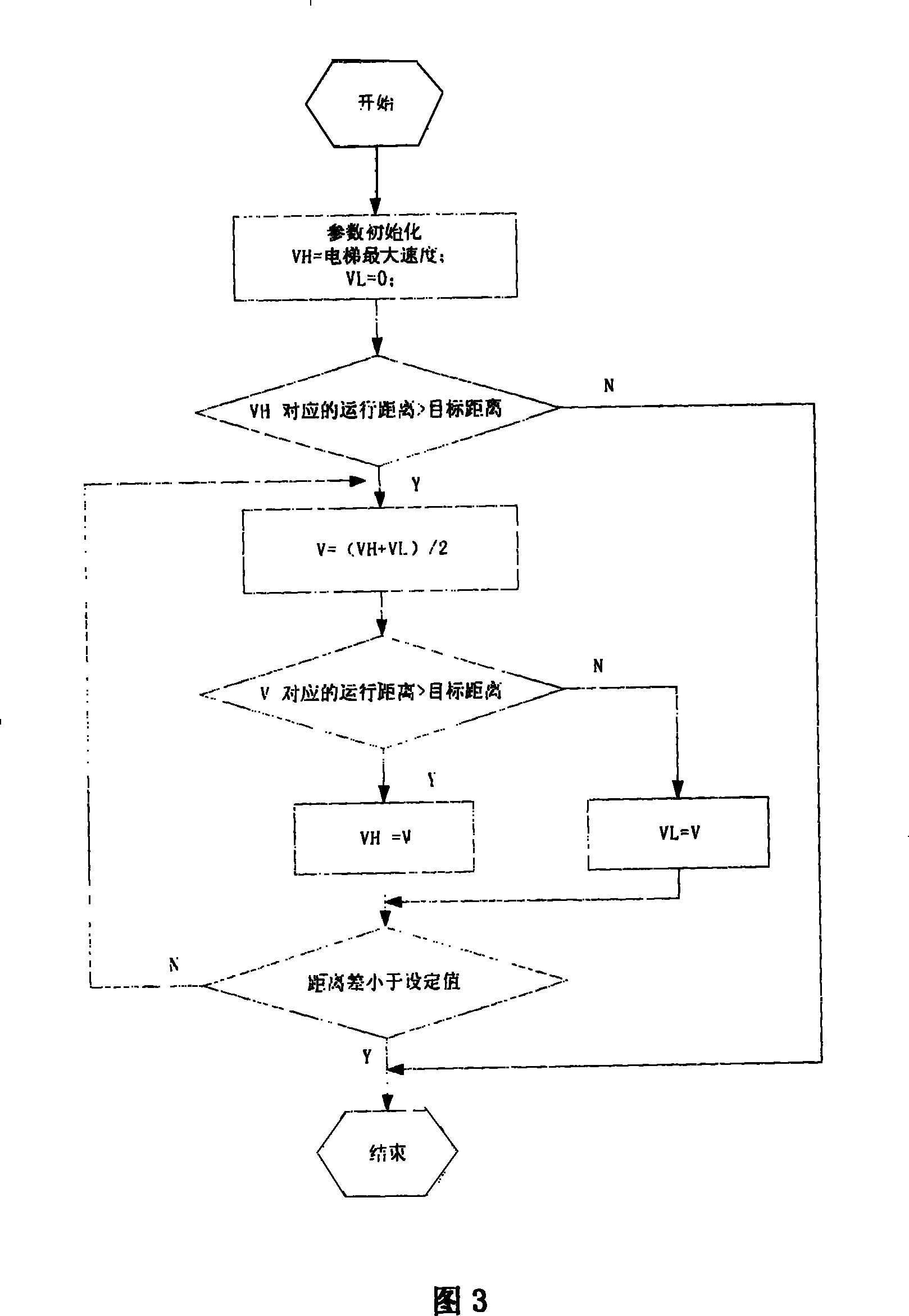

Integral frequency conversion controller for elevator

Owner:SUZHOU INOVANCE TECH CO LTD +1

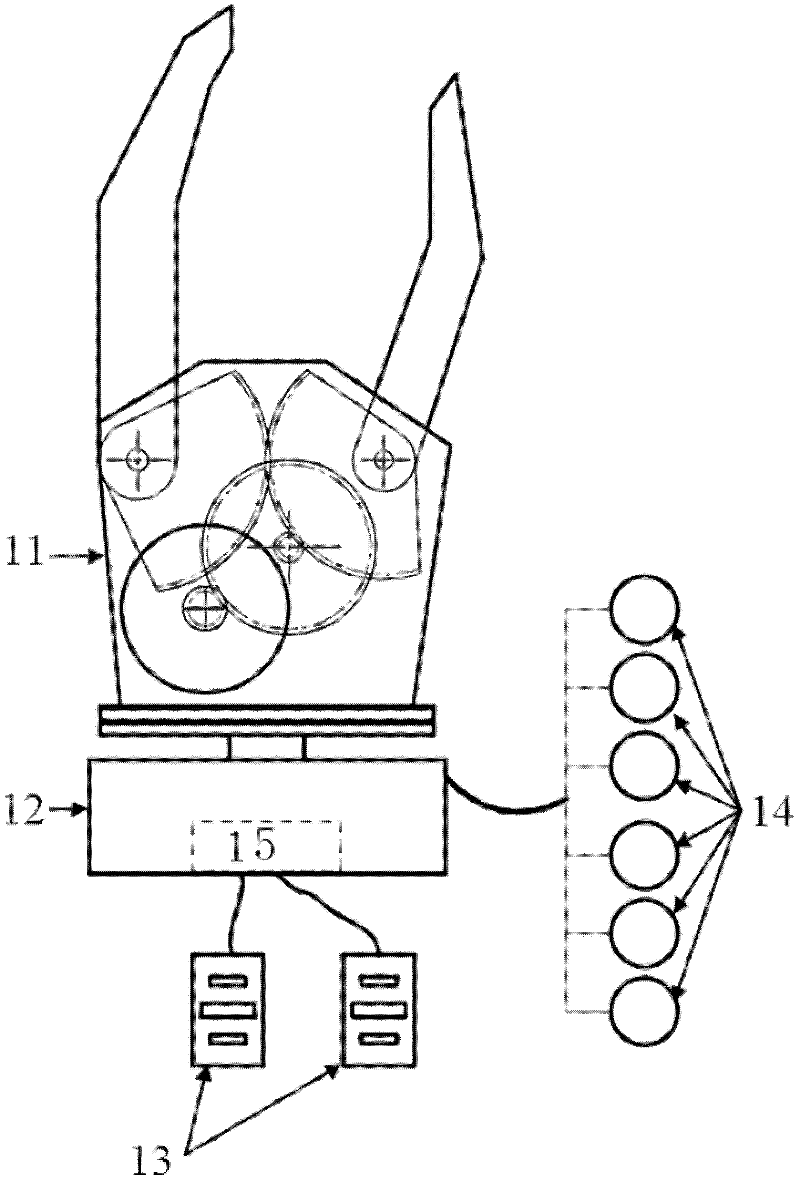

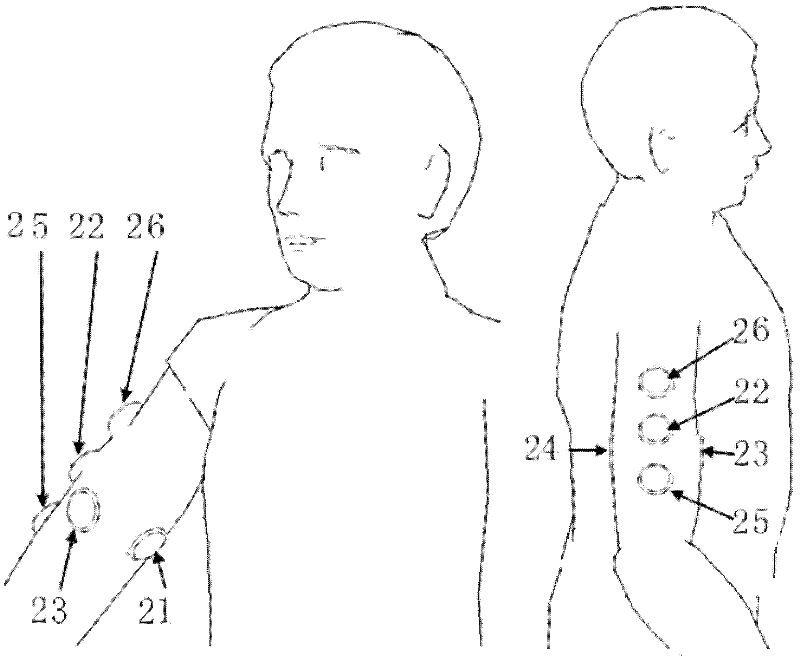

Myoelectric prosthetic hand force tactile feedback method and tactile feedback myoelectric prosthetic hand system

Owner:SOUTHEAST UNIV

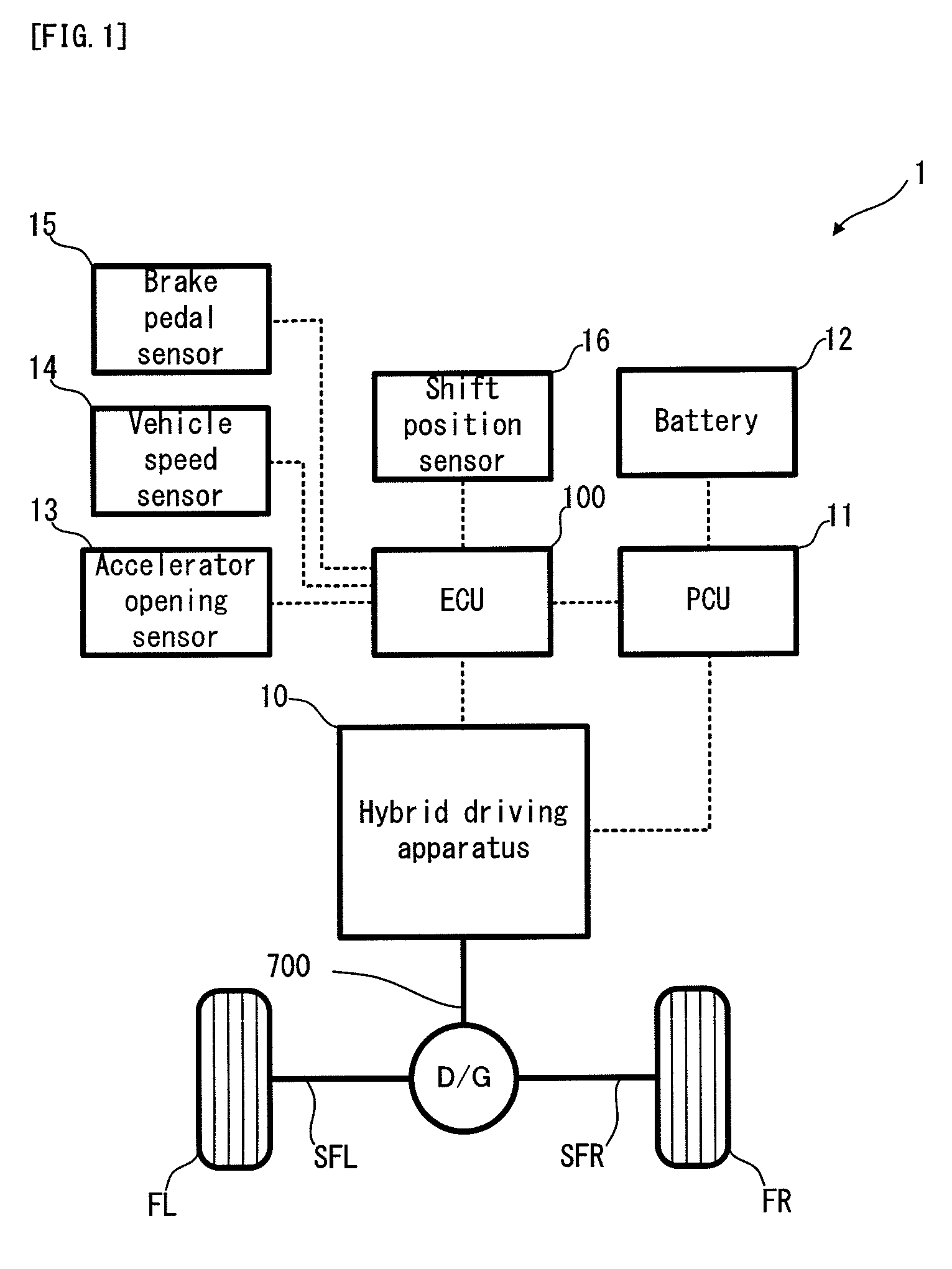

Vehicle control apparatus

ActiveUS20120053769A1Suppress sudden changesMitigate torque shockHybrid vehiclesDigital data processing detailsElectric machineryControl theory

Owner:TOYOTA JIDOSHA KK

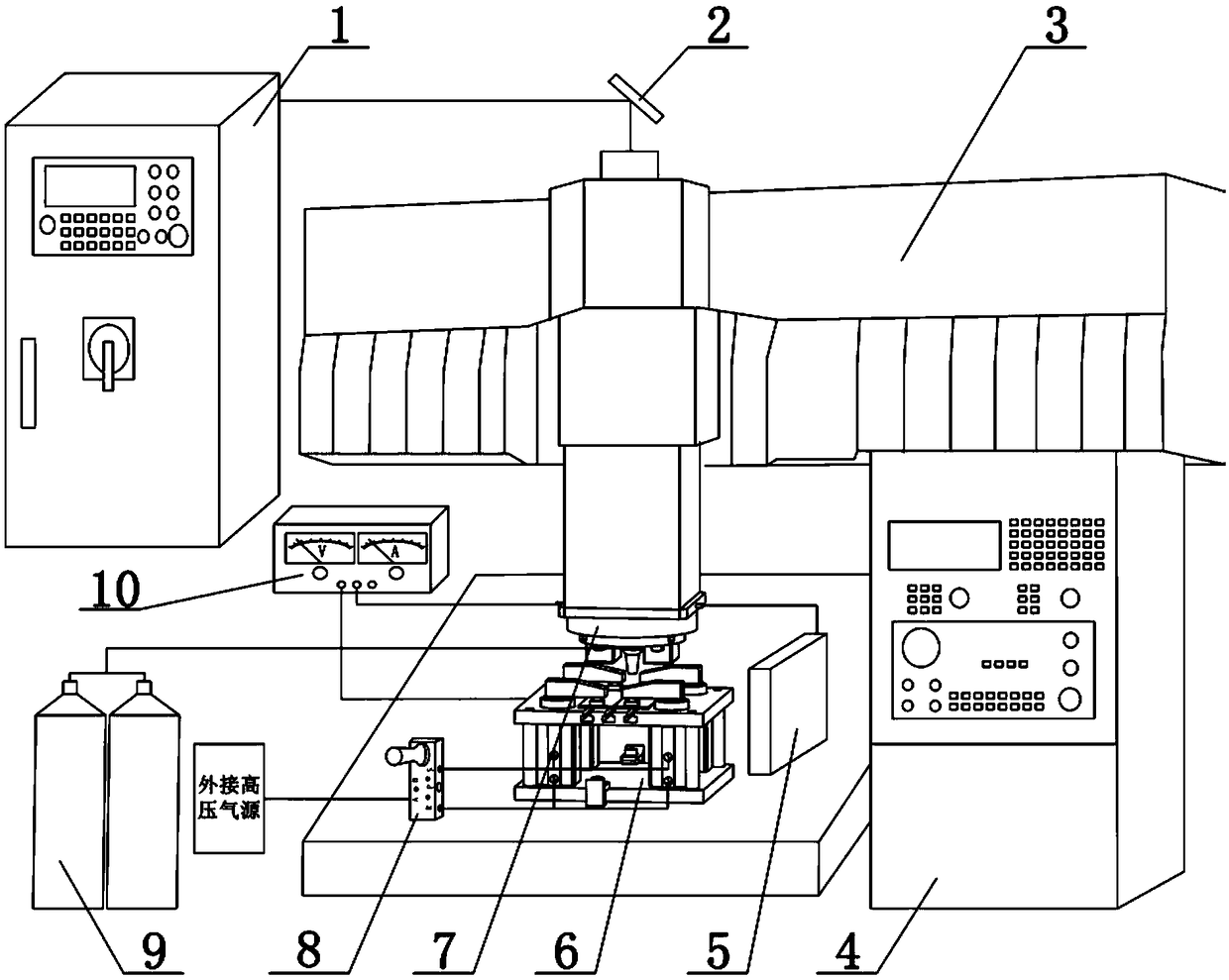

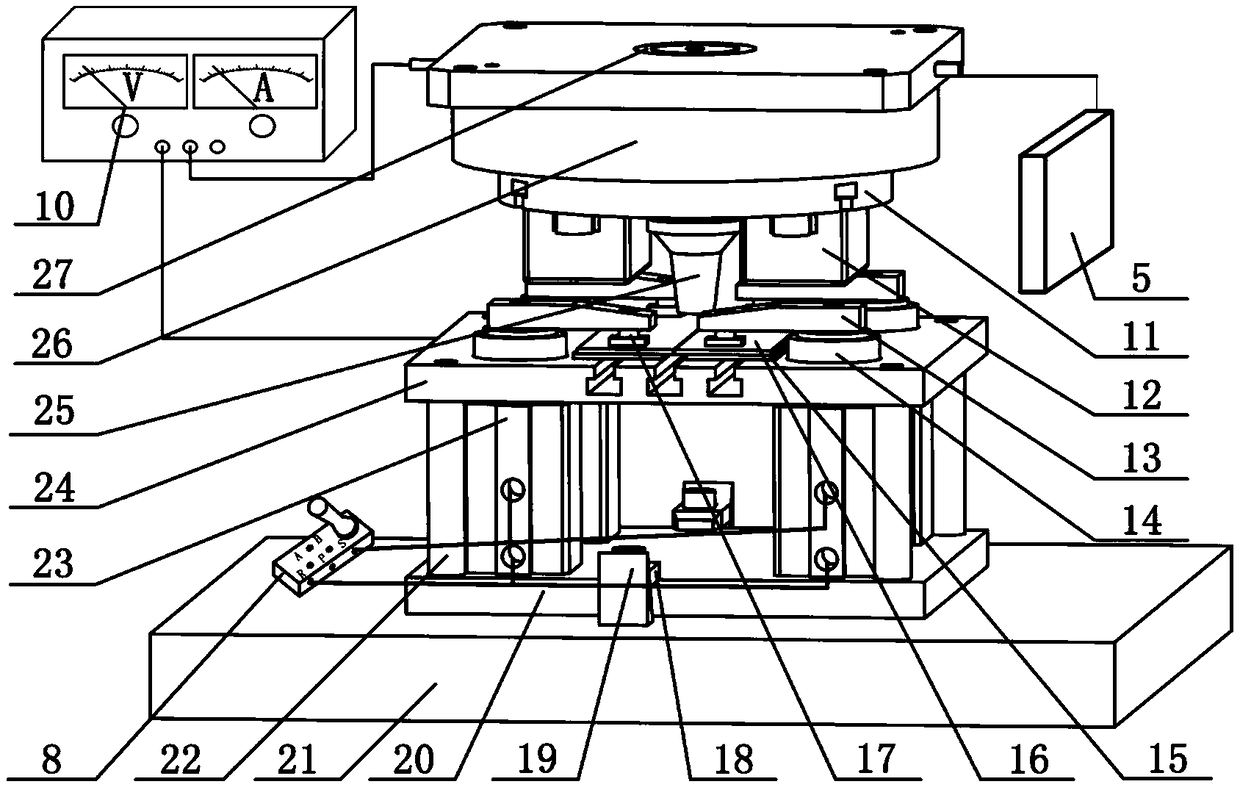

Equipment used for air sac test

InactiveCN106124140AMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesData transmissionElectric machinery

Owner:KUNSHAN HAOSHUO PRECISION MECHANISM CO LTD

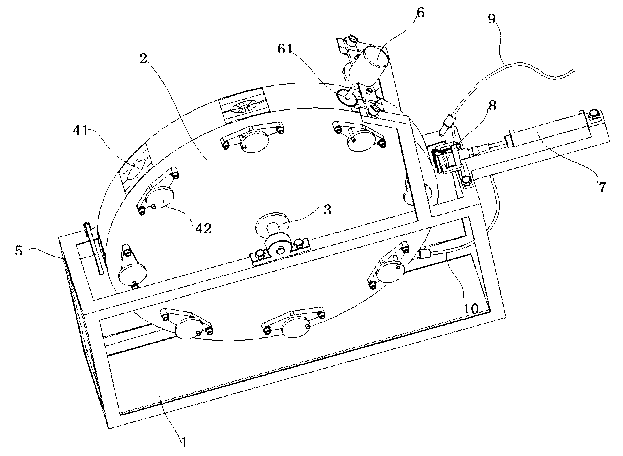

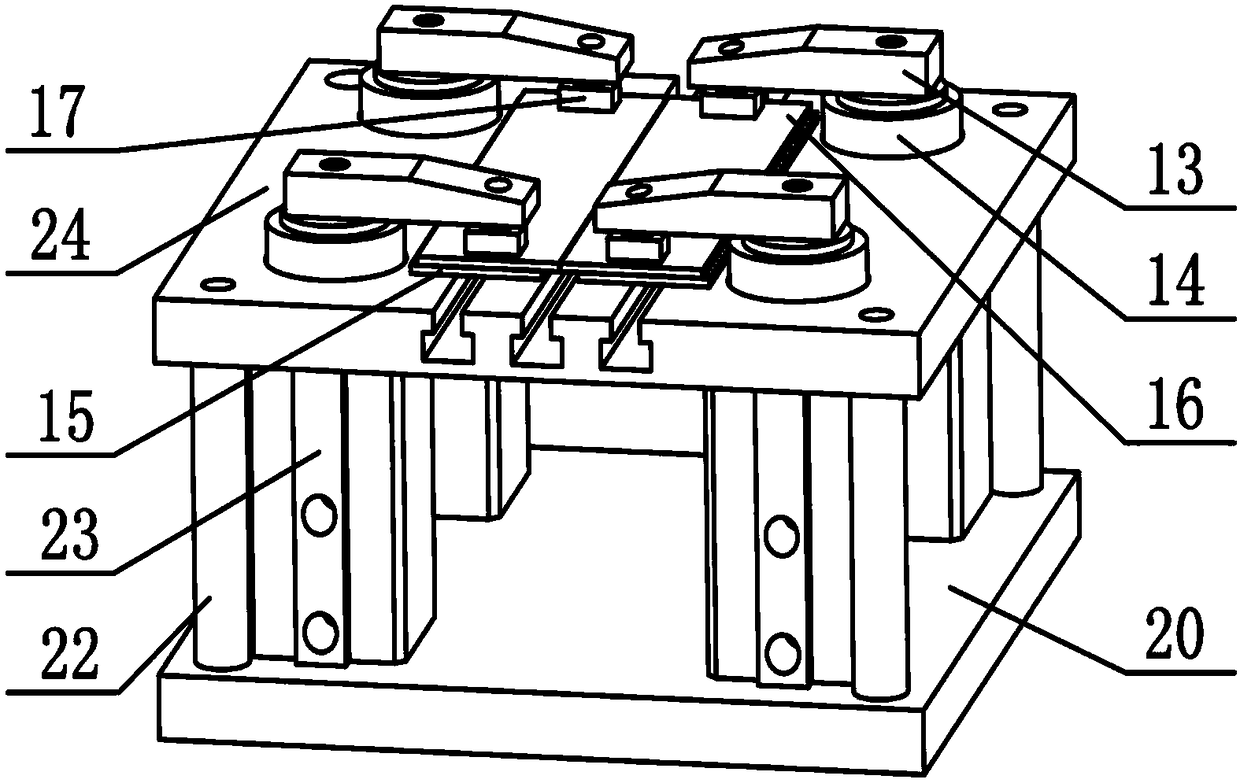

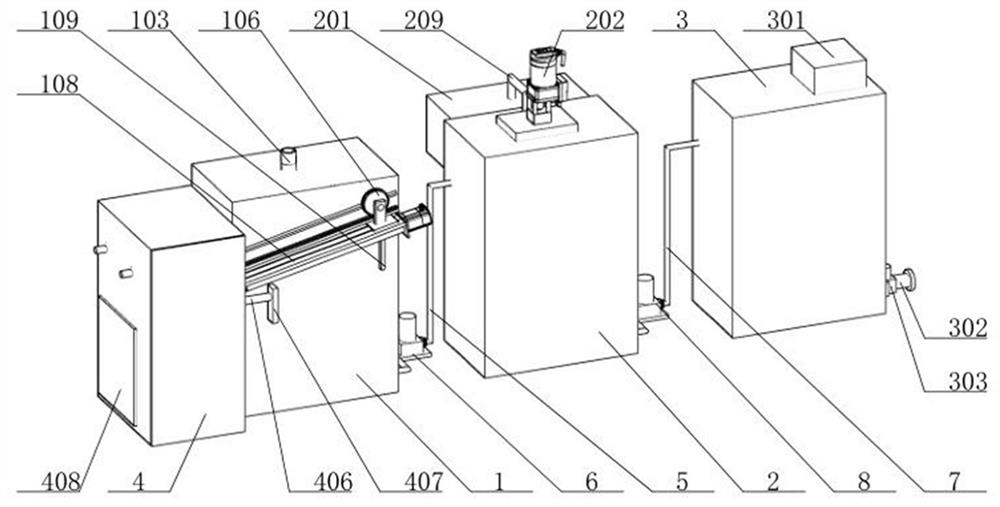

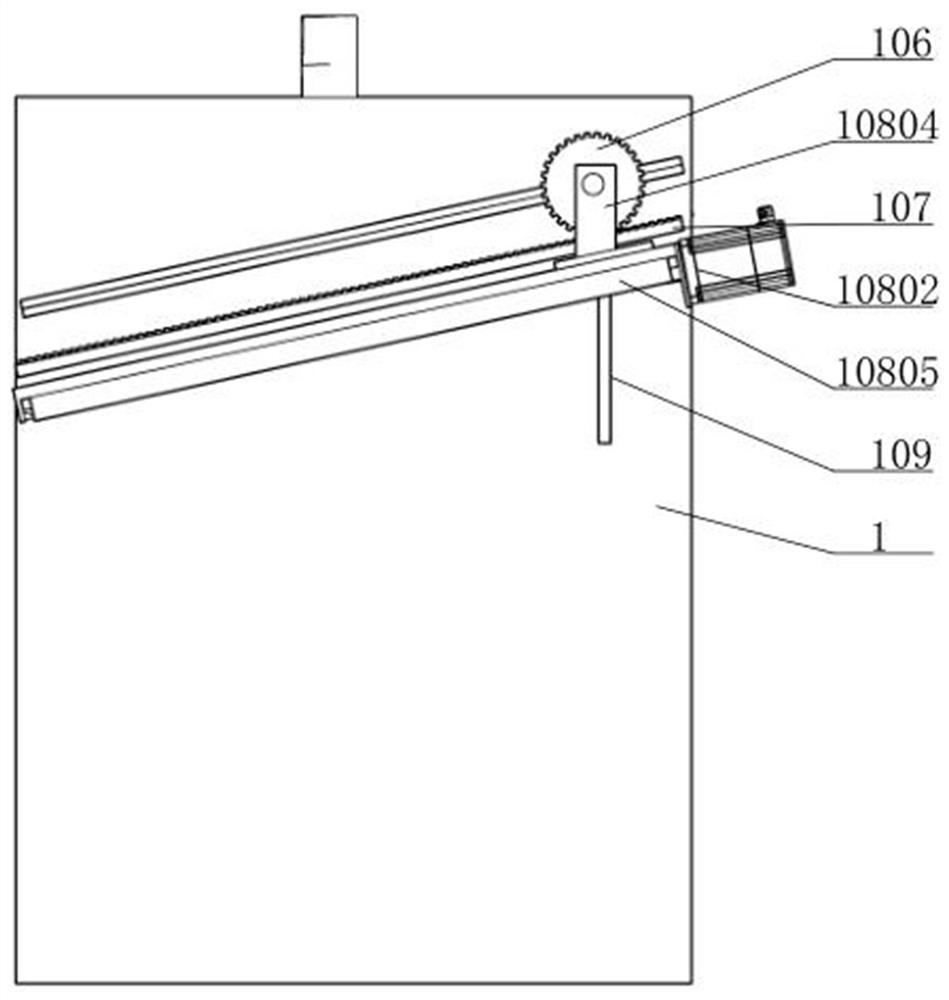

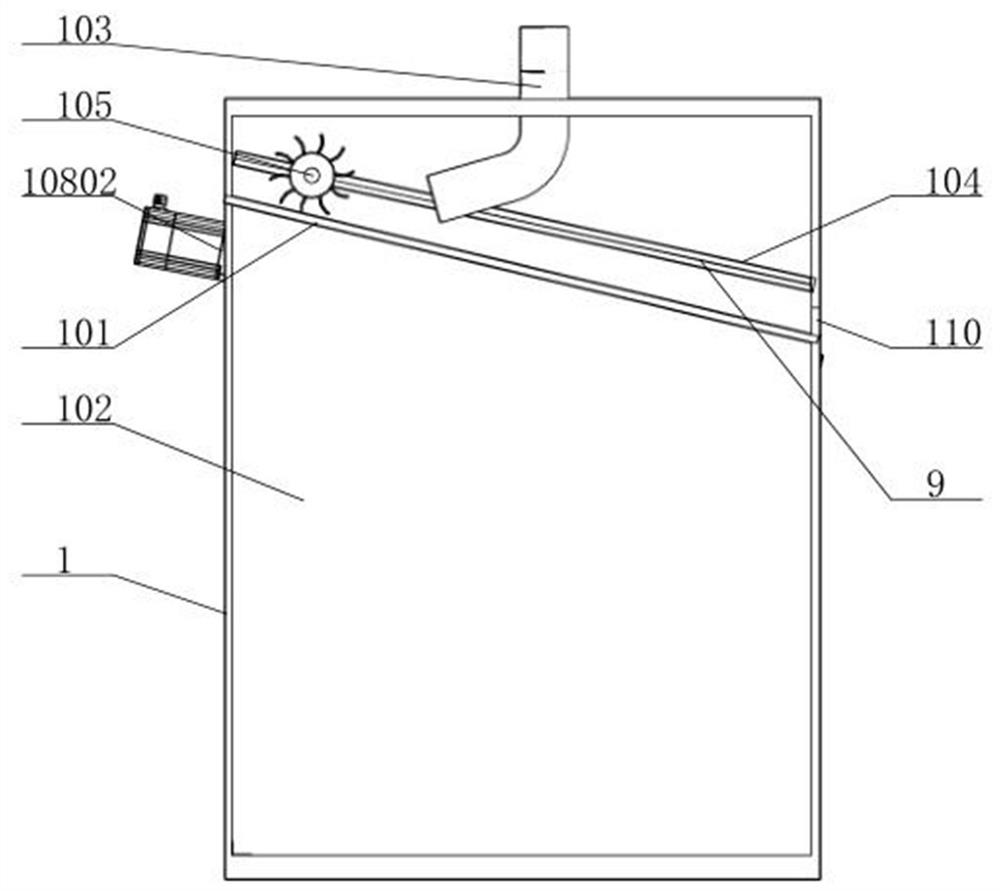

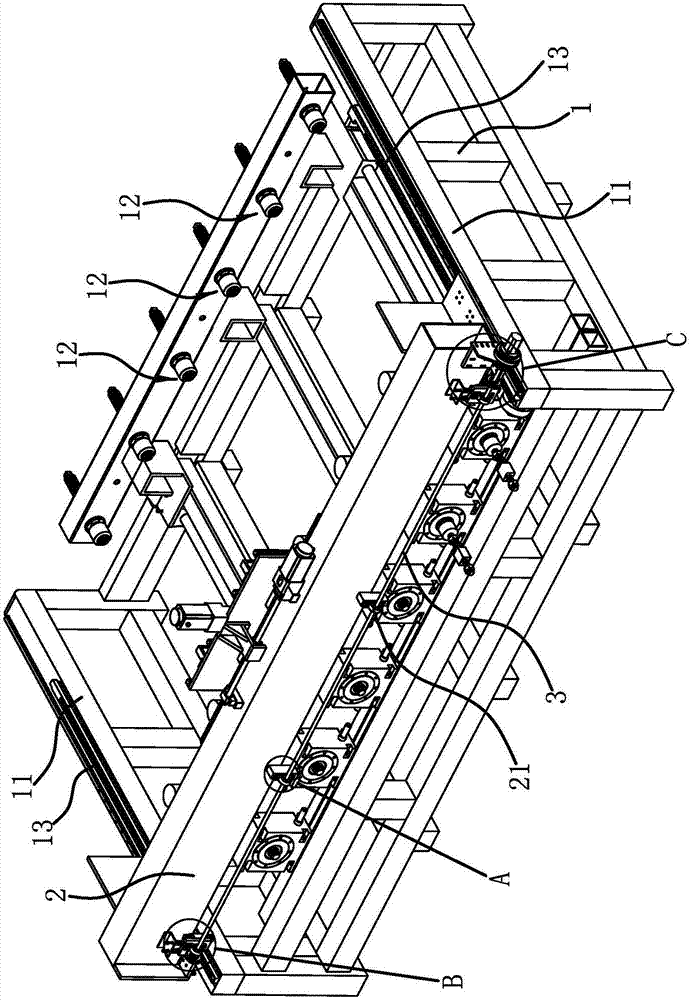

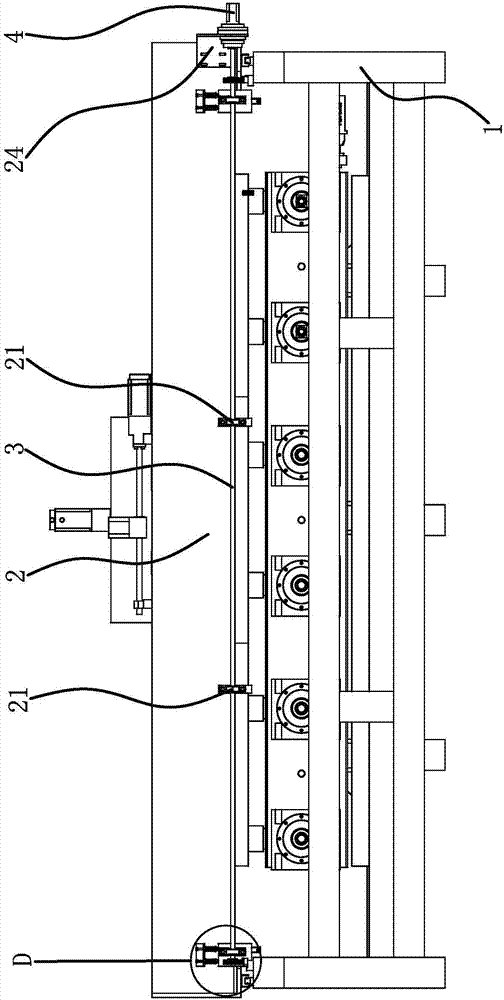

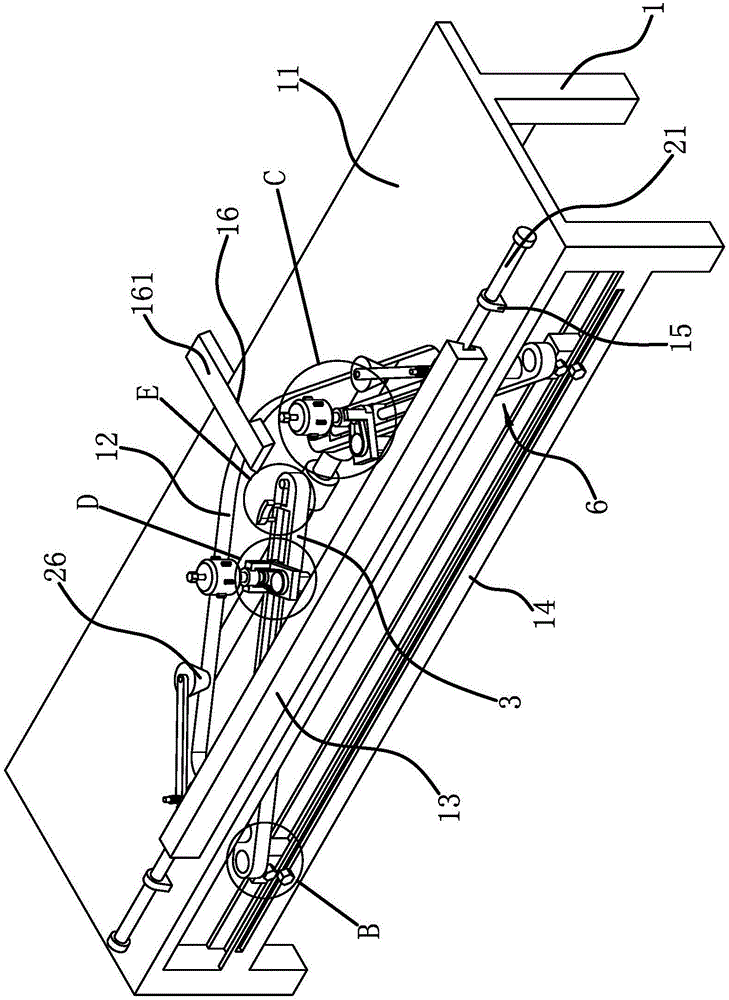

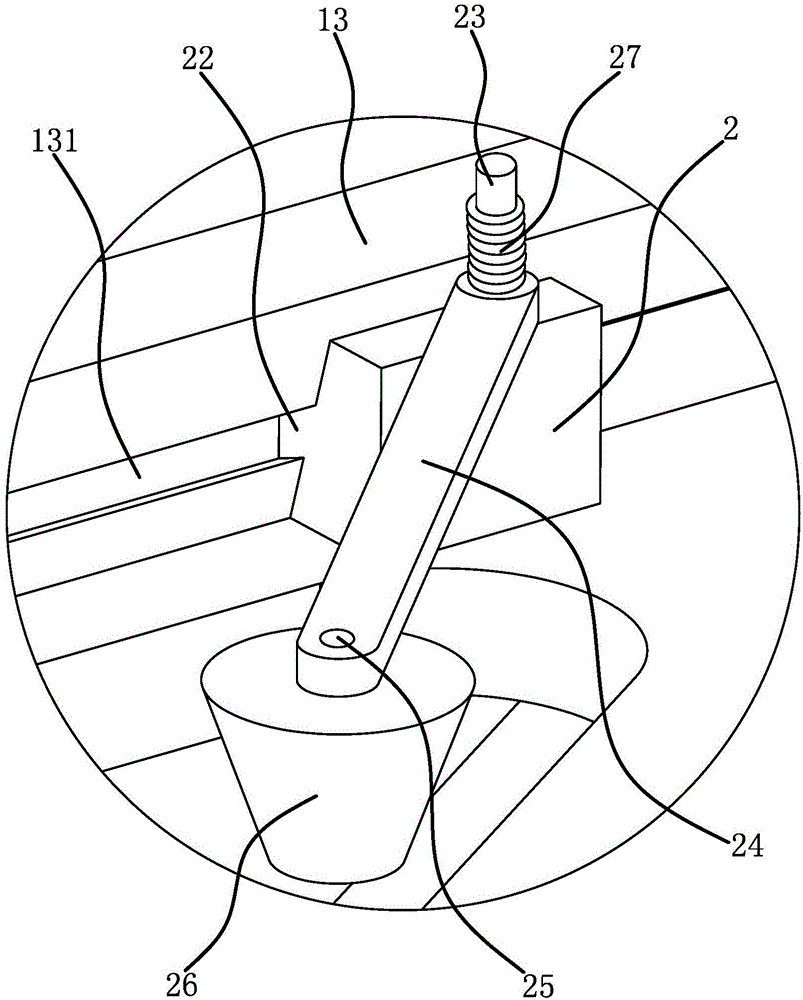

Deburring machine tool

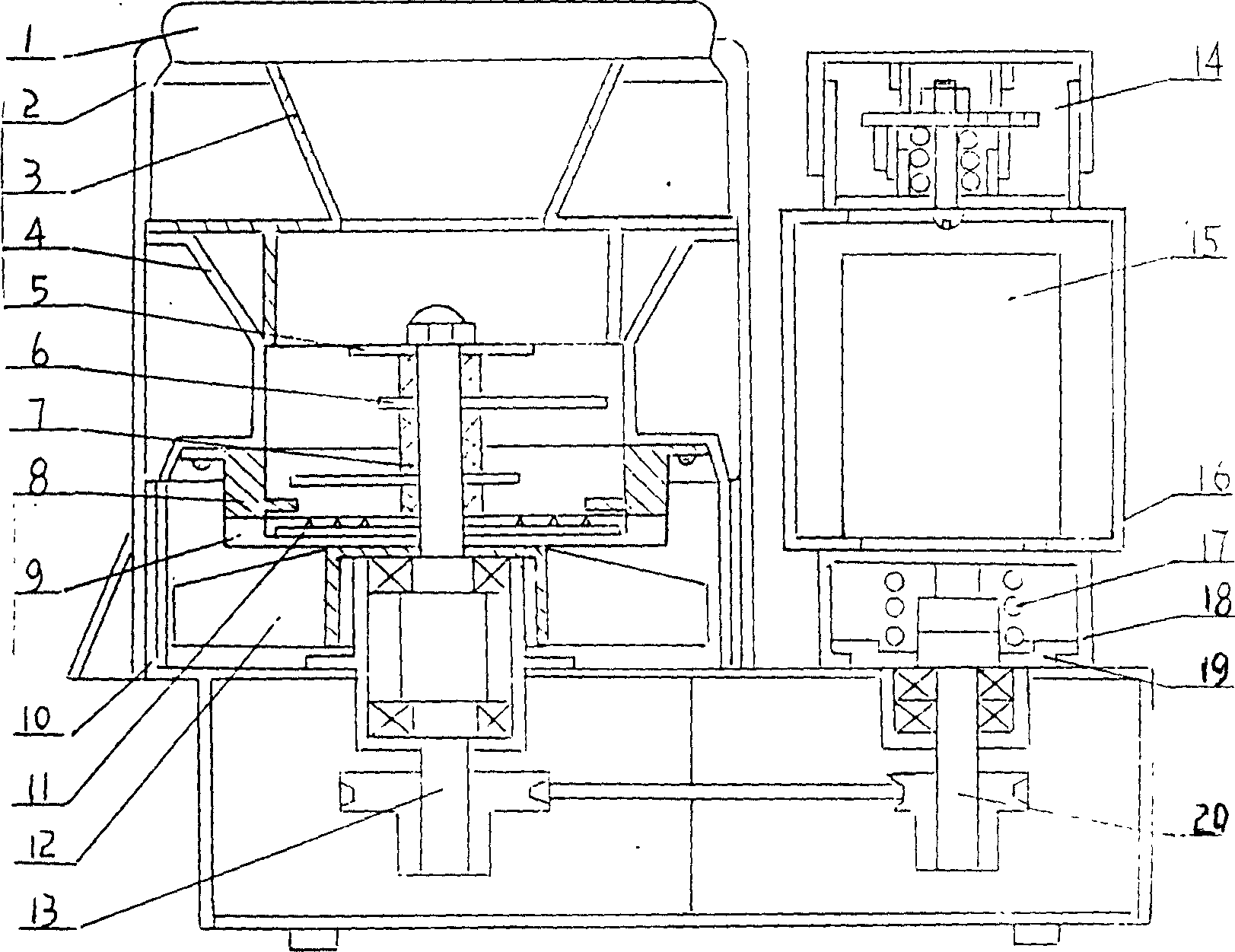

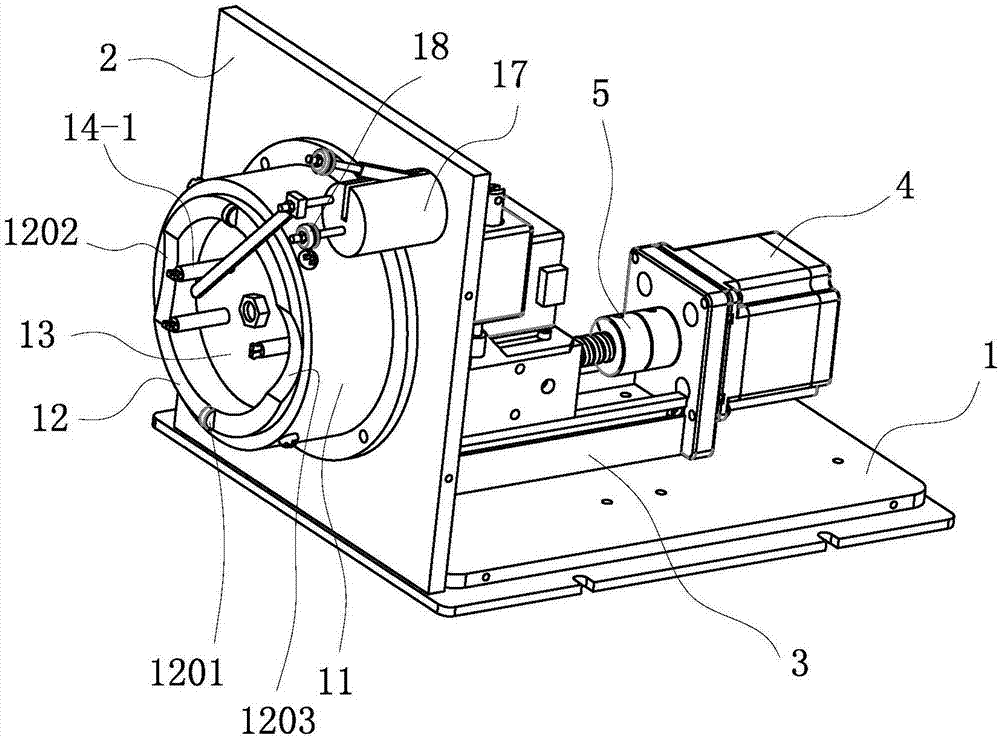

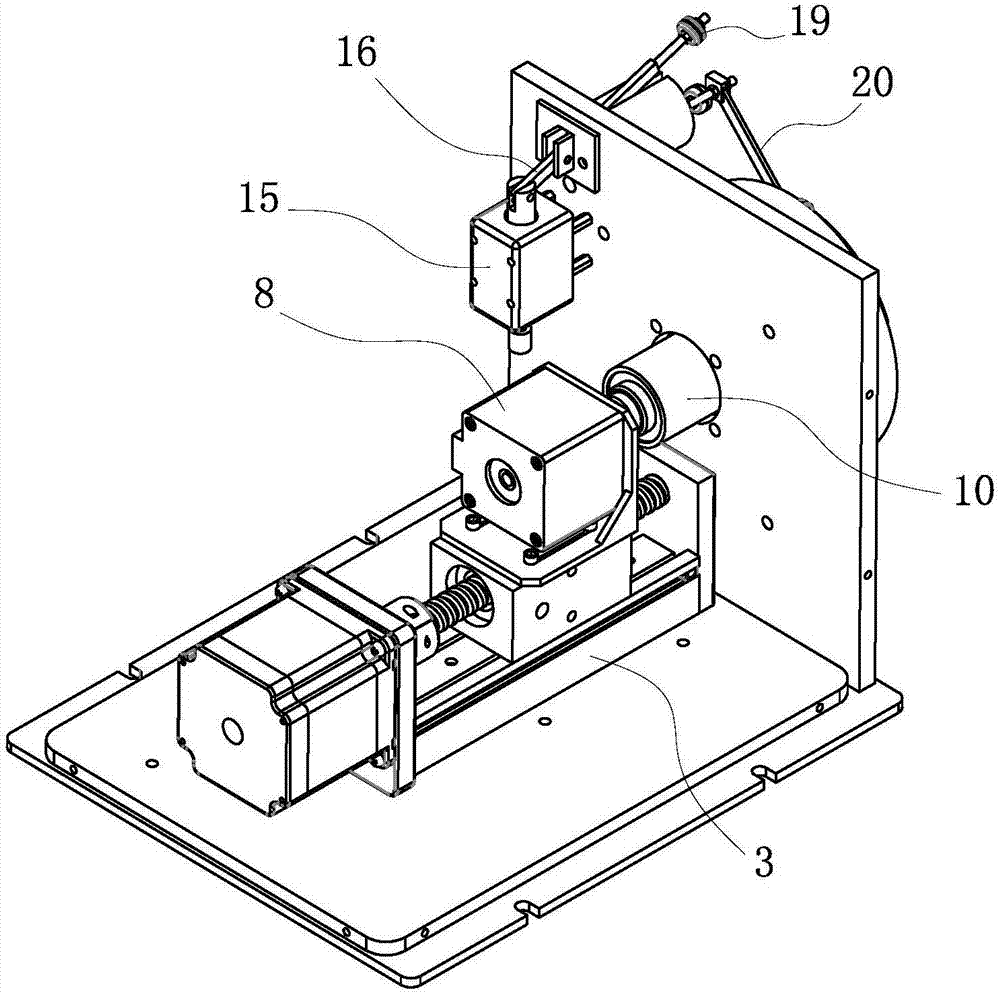

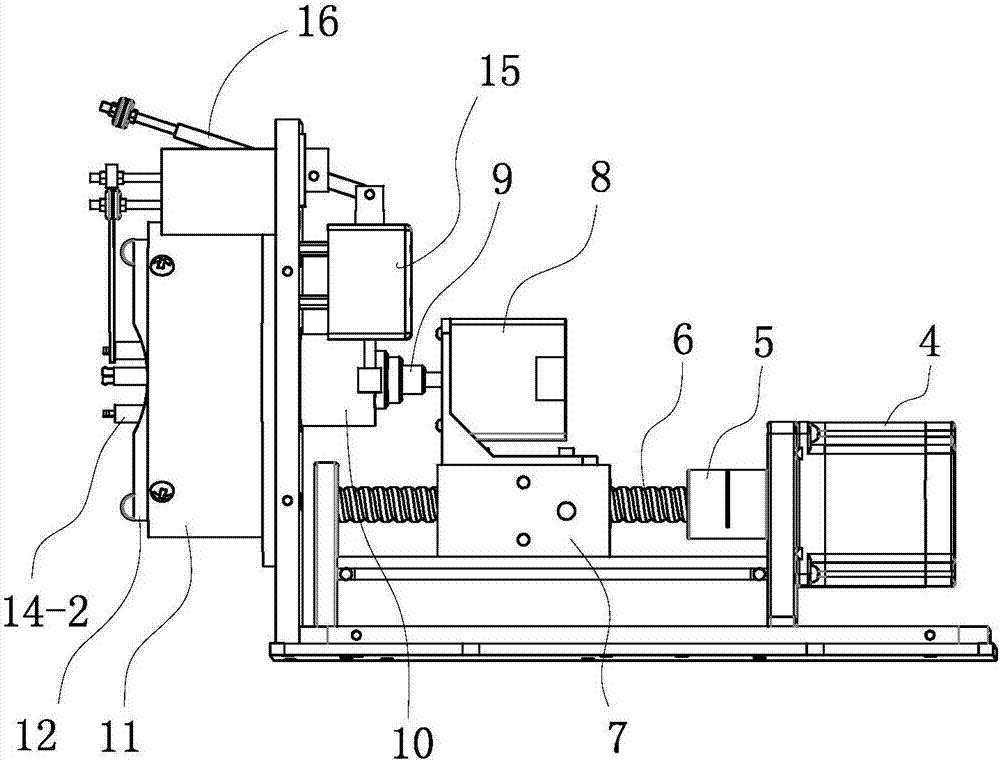

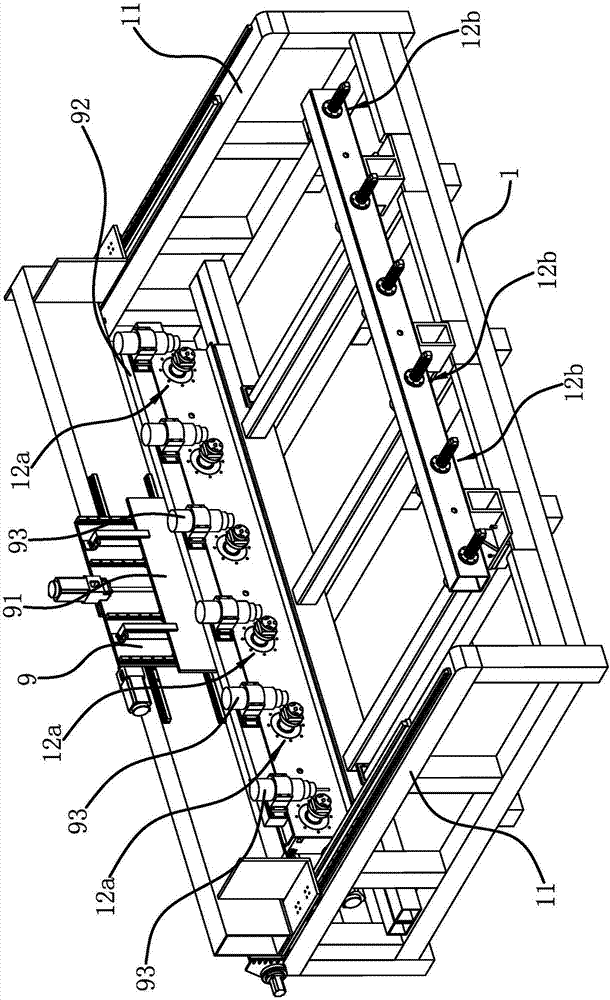

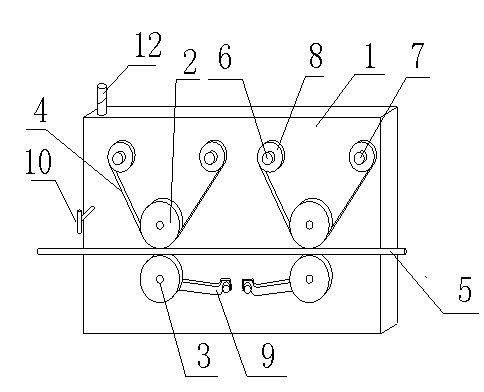

The invention discloses a deburring machine tool which relates to an excricle deburring machine tool of shaft parts, in particular to a machine tool used for deburring a straight flute, a transverse groove, a chute of an excircle of a pillar plunger core inside a plunger and barrel assembly. The deburring machine tool comprises a machine body, a fixture drive motor seat, a first micro motor, a fixture driving pulley, a first synchronous belt, a fixture driven pulley, a first flat key, a draw bar, a first compression spring, a supporting block, a clamping head top block, an elastic clamping head, an elastic clamping head seat, a first plane bearing, a space ring, a first deep groove ball bearing, a lower end cover, a rotary disk, a bush, a combination cap, a second micro motor, a horizontal motor support, a first disk type steel brush, a main shaft, a second flat key, a main shaft belt pulley, a second synchronous belt, a bearing seat, a second deep groove ball bearing, a bush, a space ring, a second plane bearing, a third plane bearing, a nut, a main motor support, a third micro motor, a coupler, a reduction box, a second flat key, a driving pulley, an inclined motor seat, a fourth micro motor, a second disk type steel brush, a vertical motor seat, a ninth outer hexagon bolt, a fifth micro motor and a third disk type steel brush.

Owner:JIANGSU REP MASCH TOOLS CO LTD

Rotary electric field and magnetic field synchronously assisted laser welding device and method

Owner:CHANGCHUN UNIV OF SCI & TECH

Basketball cleaning device for sports

Owner:义乌市裕晨科技有限公司

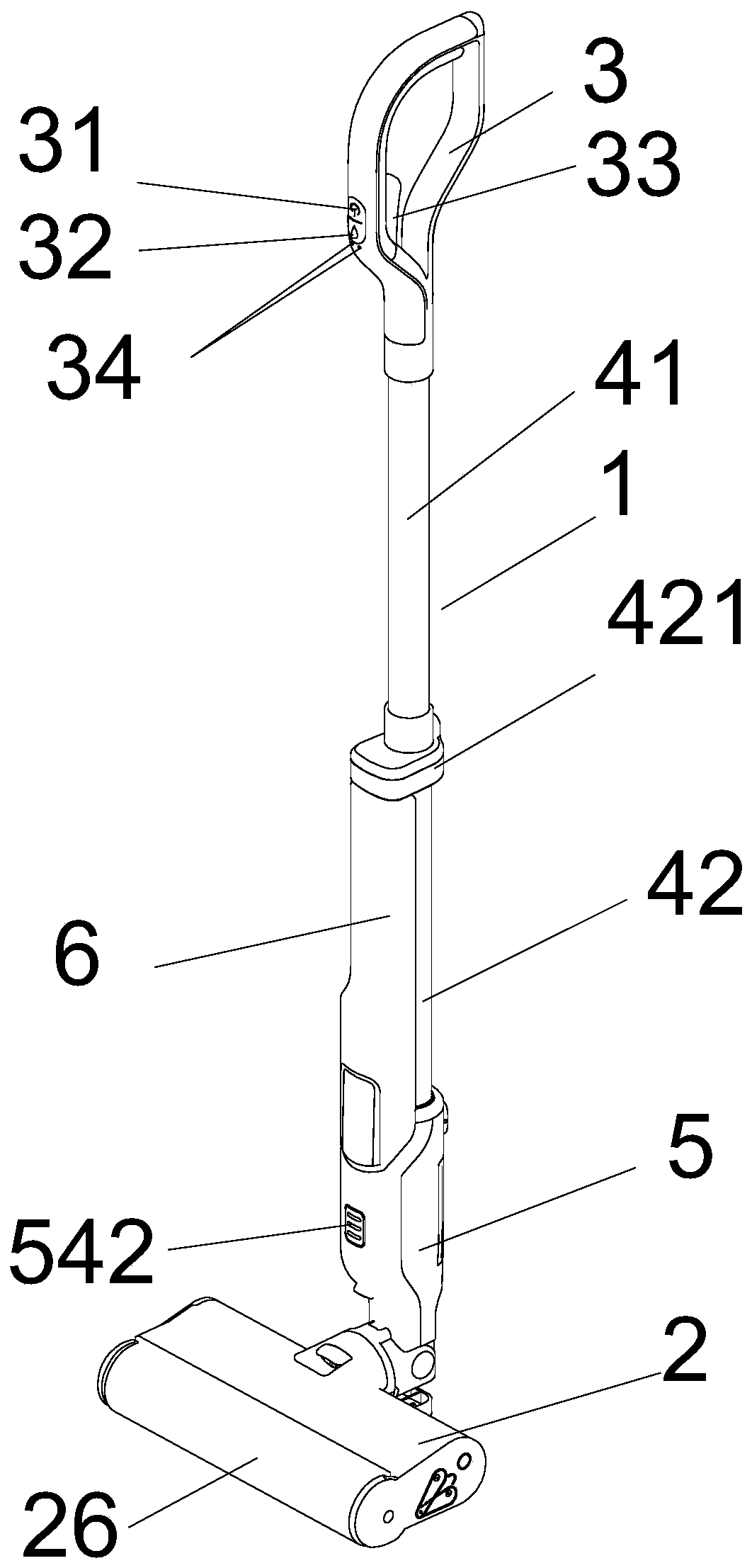

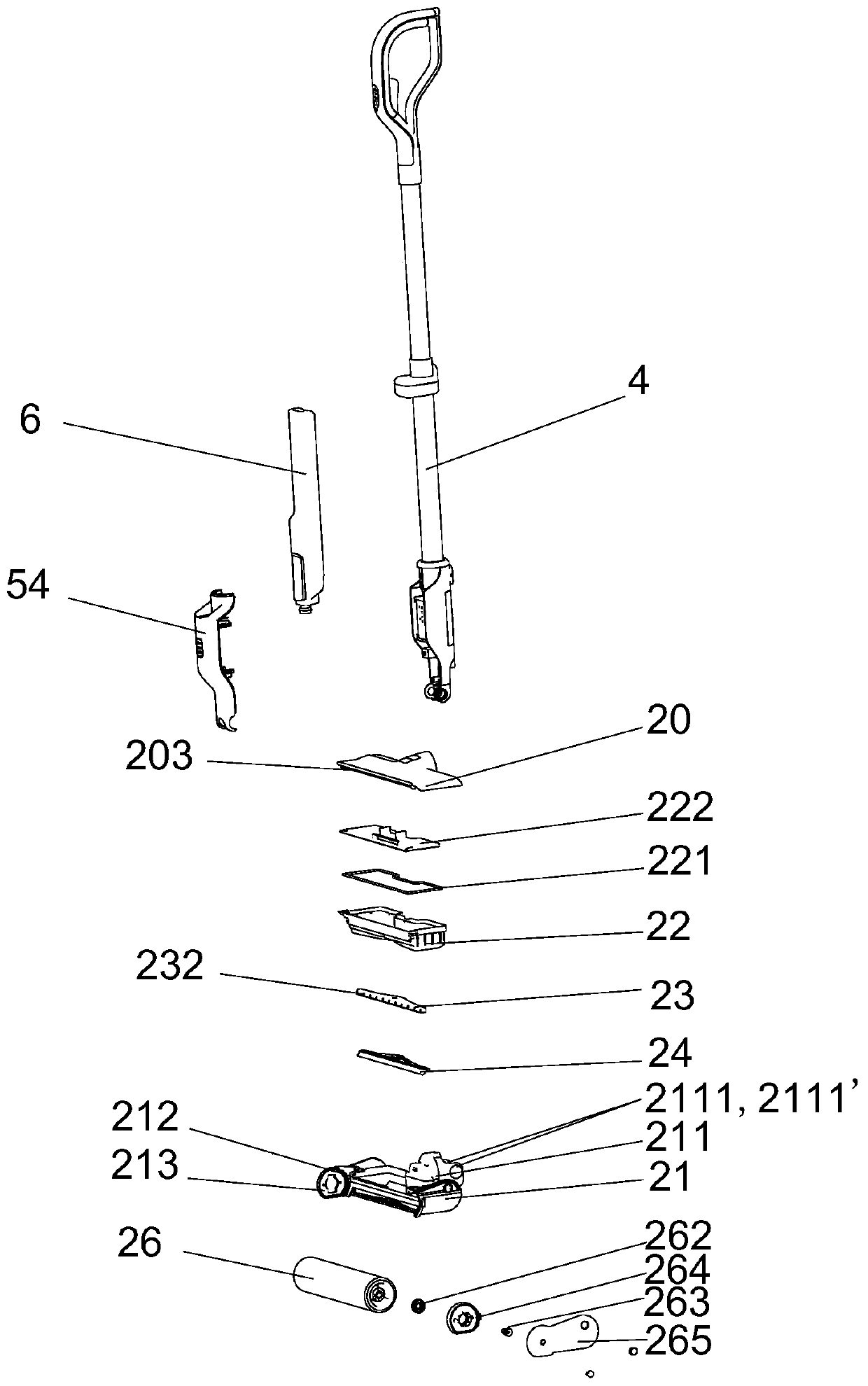

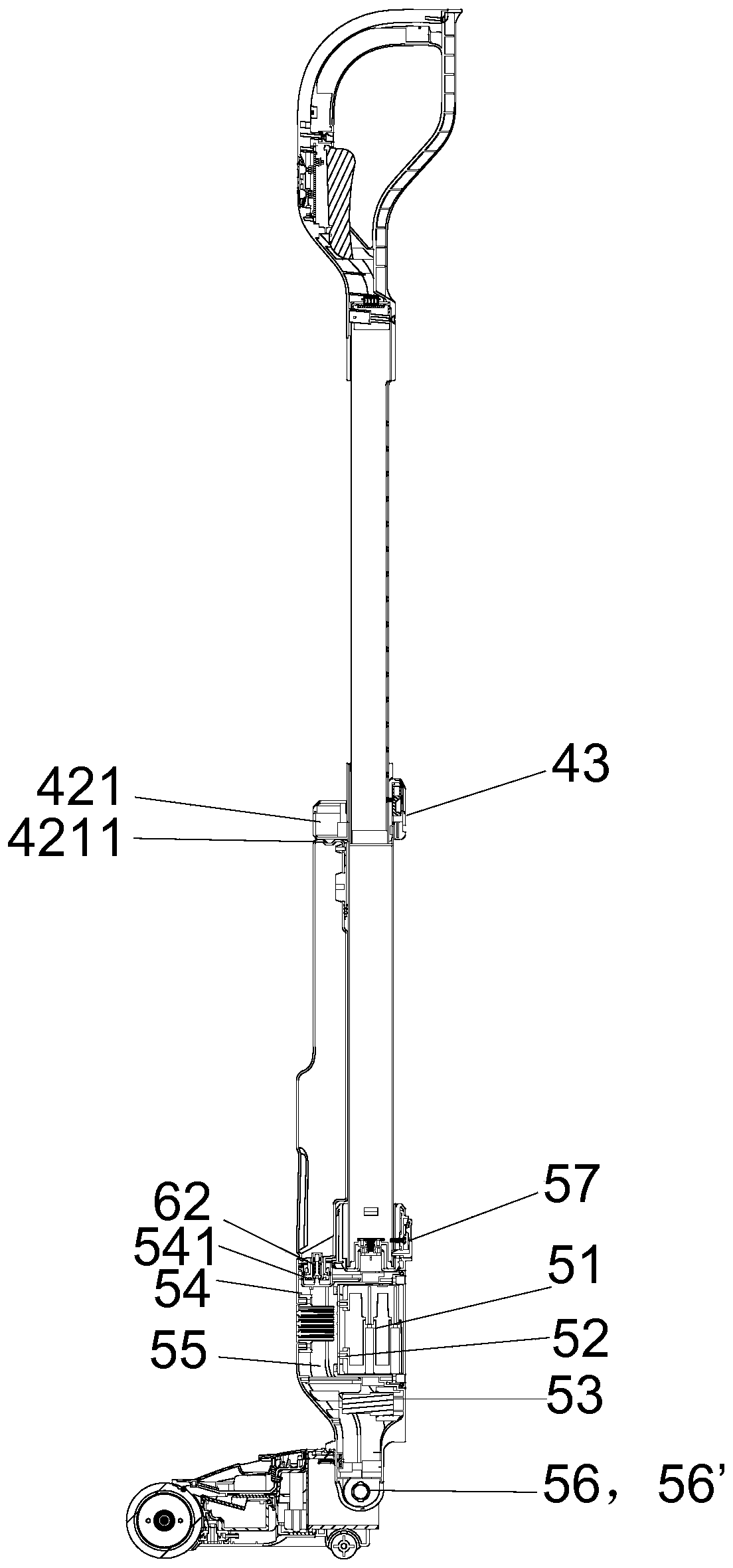

Floor brush assembly and vertical cleaning machine with same

Owner:SUZHOU CLEANPLUS ELECTRIC APPLIANCE

Tea leaf drying equipment

PendingCN107514879AReduce the impactRealize rolling back and forthPre-extraction tea treatmentTea dryingElectric machineryStructural engineering

Owner:池州市华茂茶业有限公司

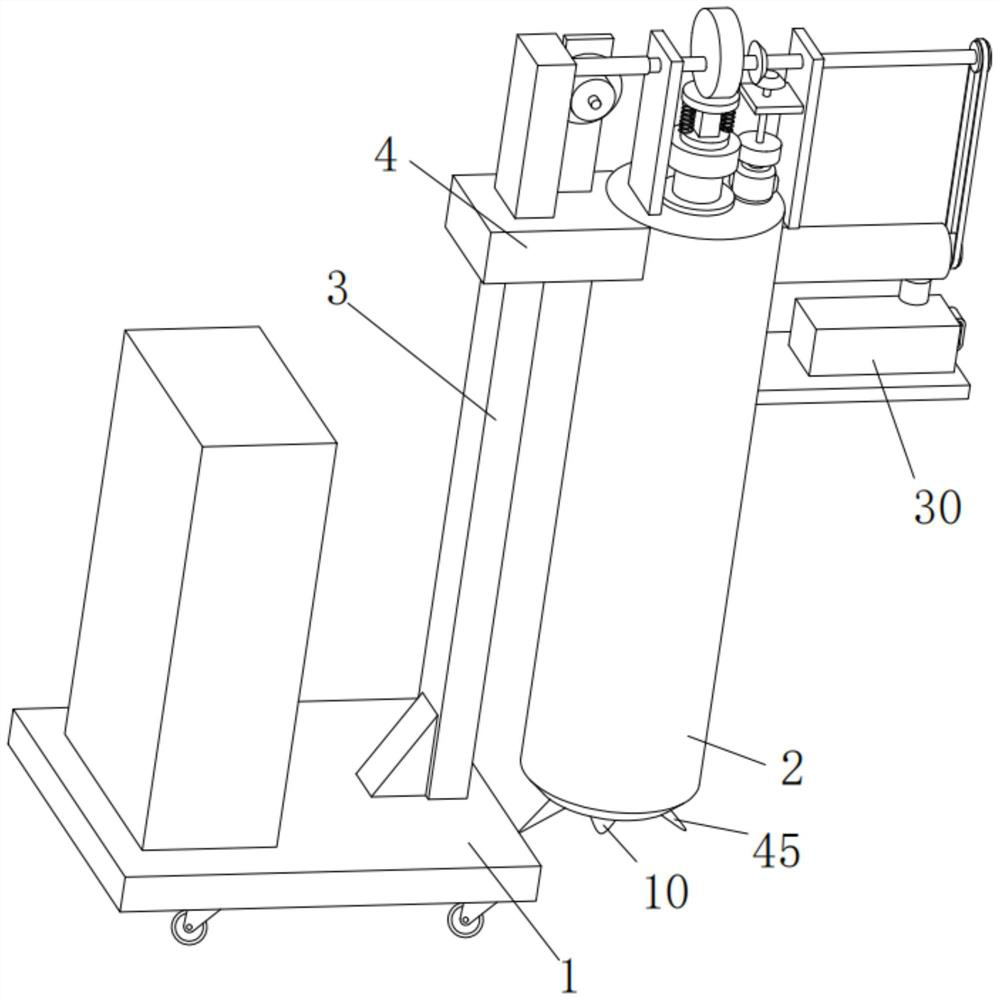

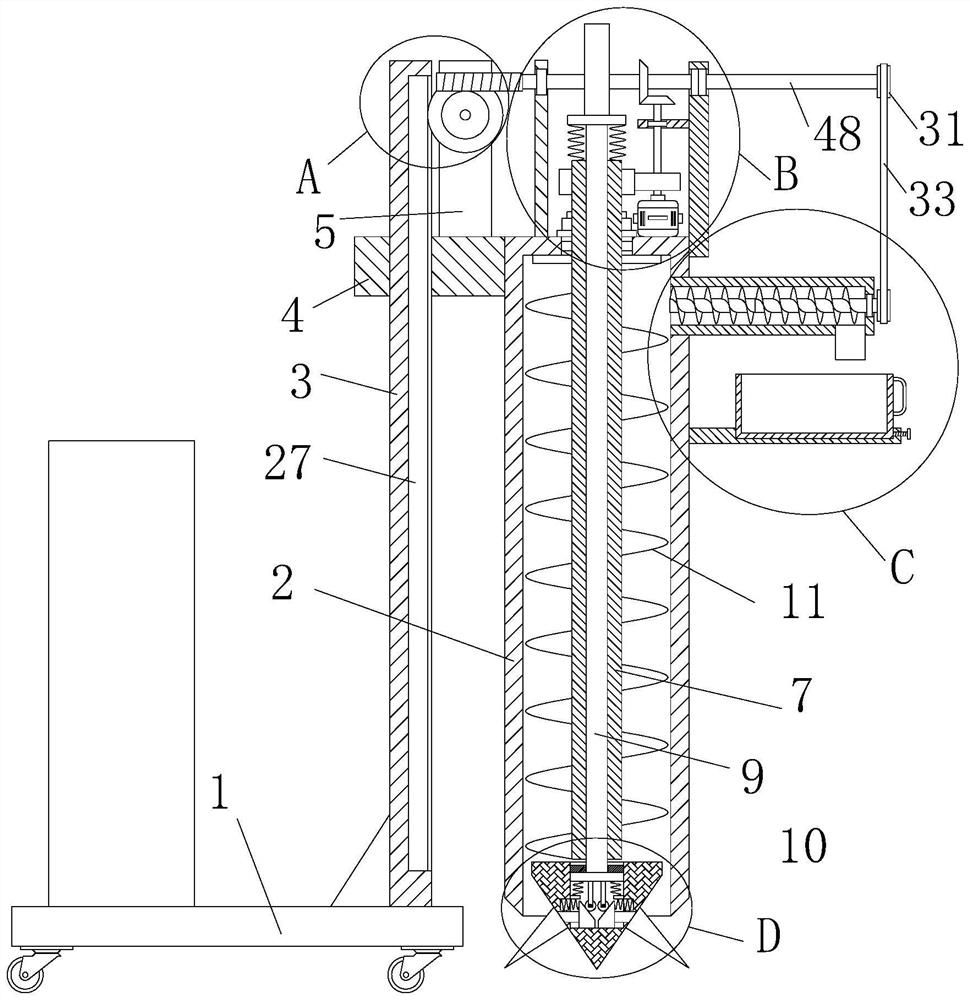

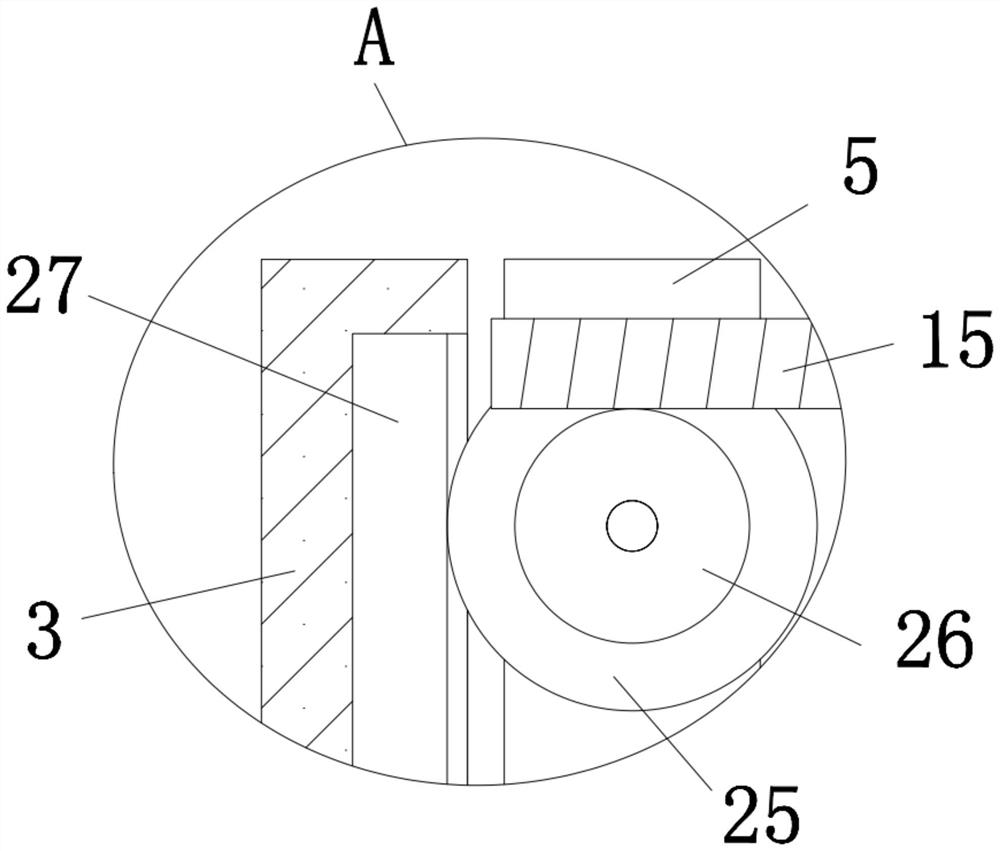

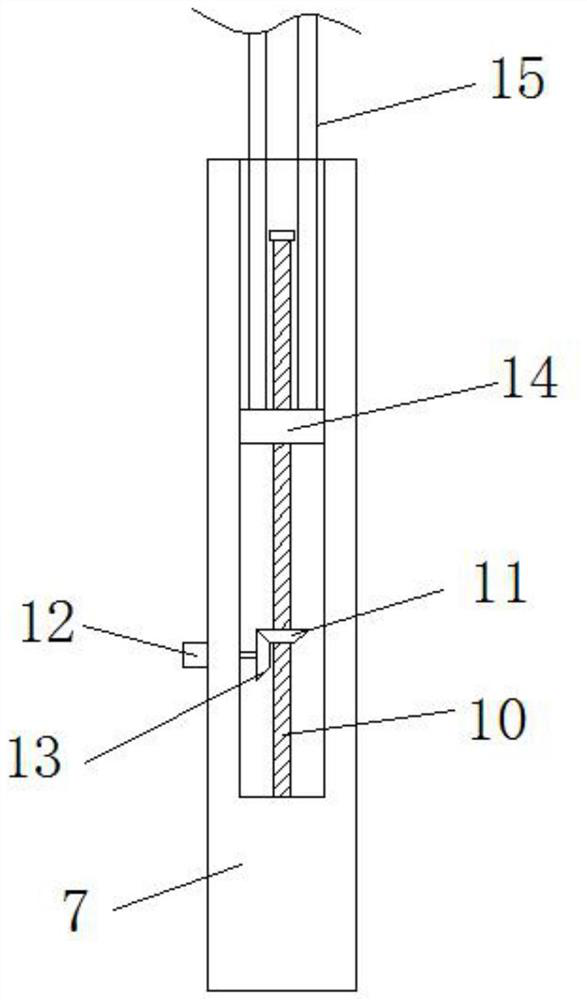

Soil sampling device for highway engineering road and use method thereof

PendingCN113404030AReduce manpower consumptionReduce difficultyIn situ soil foundationLow speedAgricultural engineering

Owner:谭小波

Industrial acidic sewage treatment equipment

ActiveCN112110572AAvoid dischargeEasy to handleWater treatment parameter controlSpecific water treatment objectivesElectric machinerySewage

Owner:山东万方板业有限公司

On-line automatic cleaning device for electro-chemistry glass electrode

Owner:HANGZHOU DIANZI UNIV

Adhesive tape cutting machine

Owner:ANSTEEL GRP MINING CO LTD

Suture winding machine and suture winding method

ActiveCN107265181ARealize automatic winding operationLow costFilament handlingWinding machineRotational axis

Owner:SHANDONG UNIV

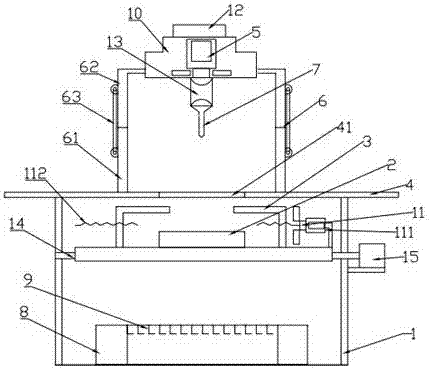

Carving machine

ActiveCN107089086AGuaranteed synchronicityDoes not affect rotationModel makingDrive shaftElectric machinery

Owner:玉环圣弘法数控雕刻设备有限公司

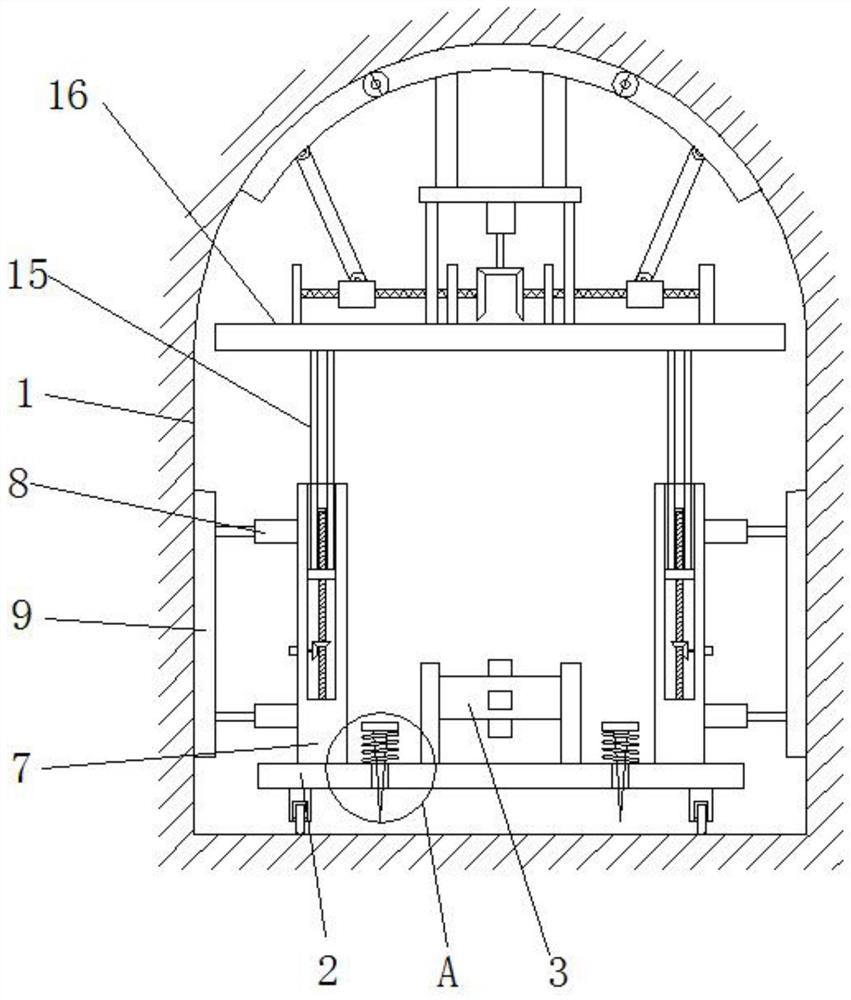

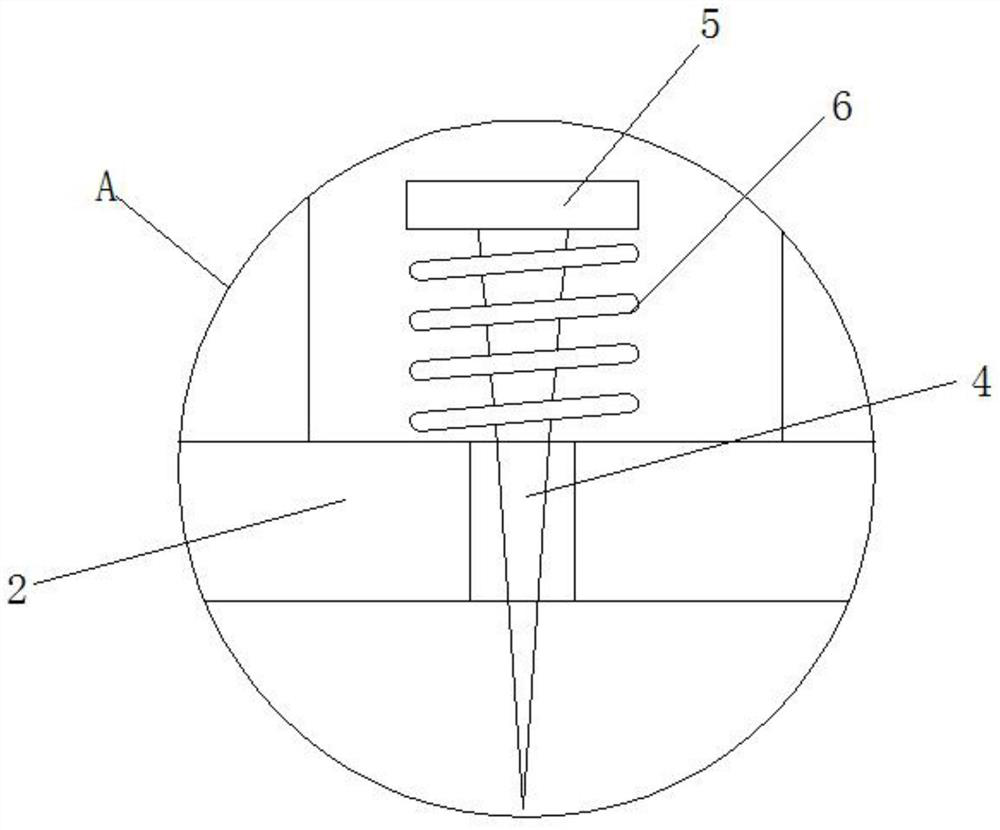

Reinforced supporting device for roadway

Owner:莱州汇金矿业投资有限公司

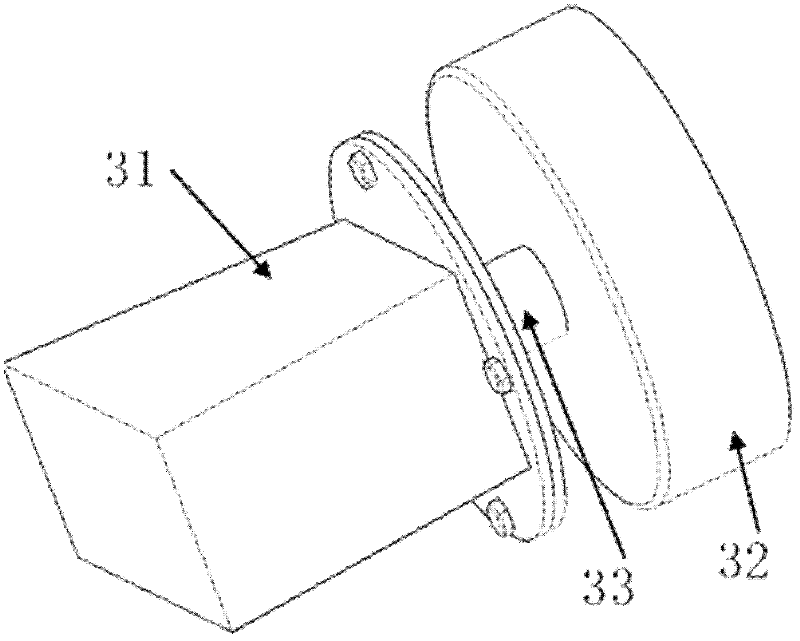

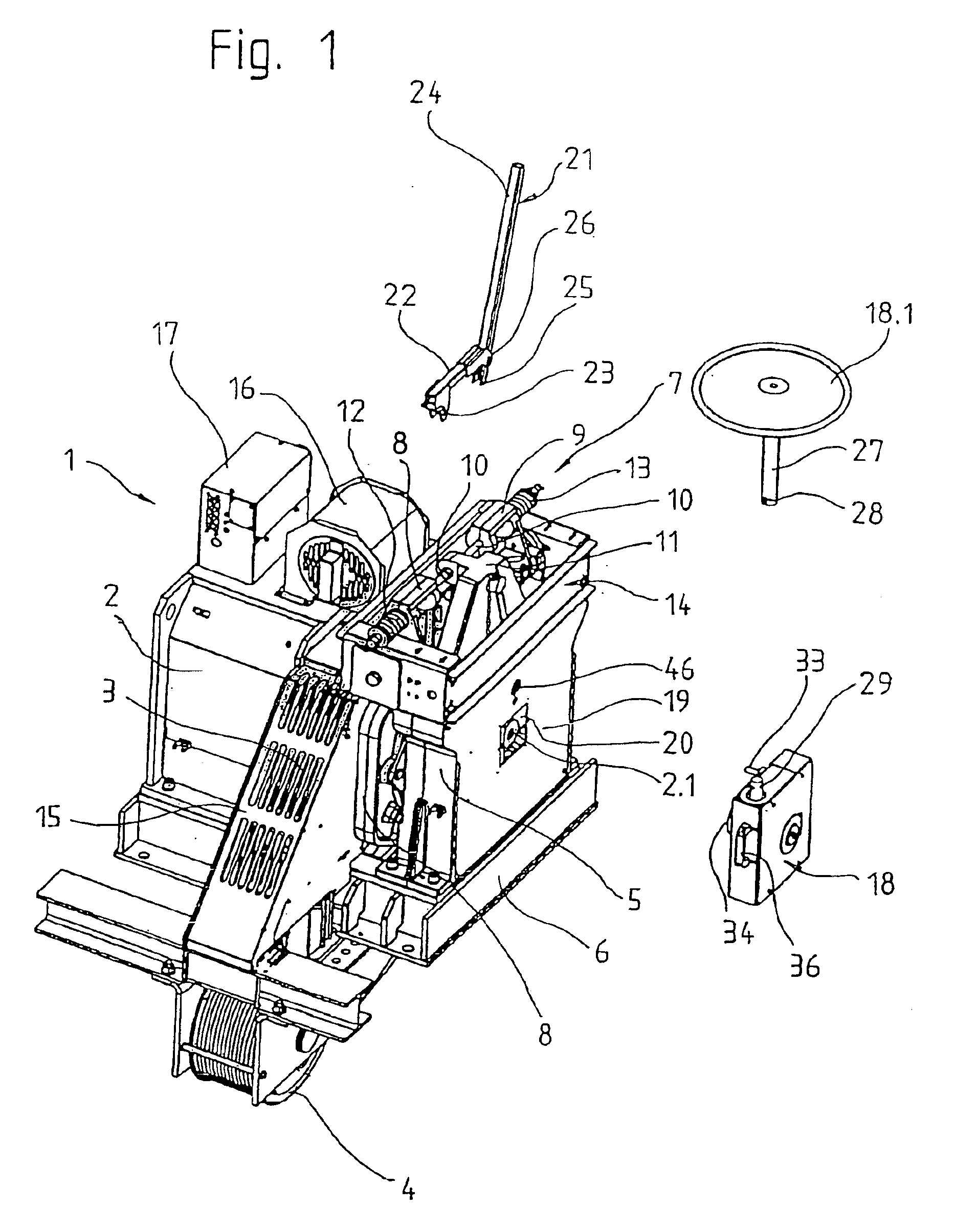

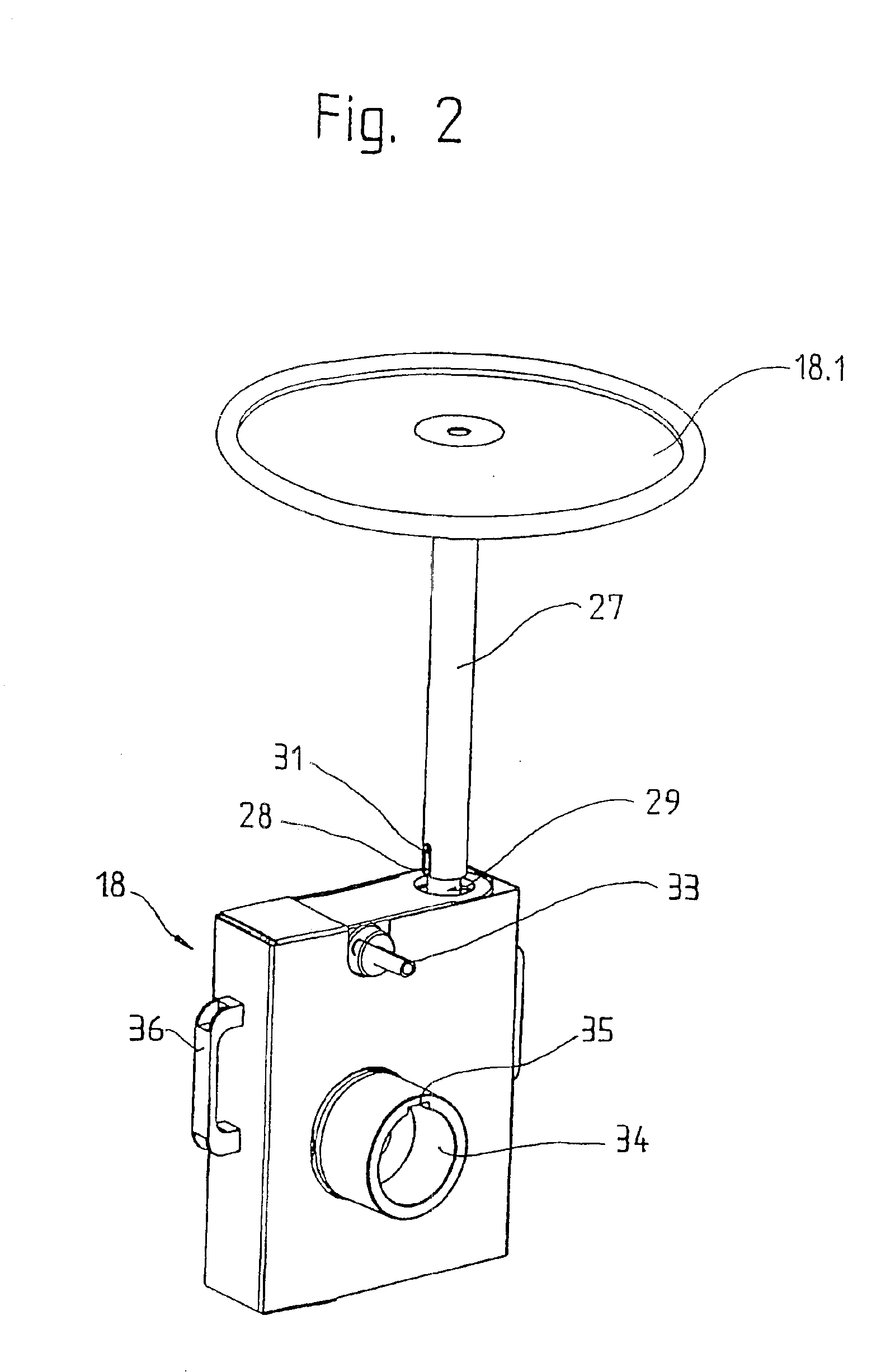

Actuating device for emergency operation of a gearless drive machine of an elevator

Owner:INVENTIO AG

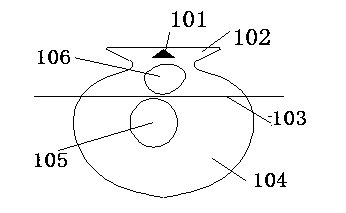

Coconut processing equipment

Owner:YANGTZE NORMAL UNIVERSITY

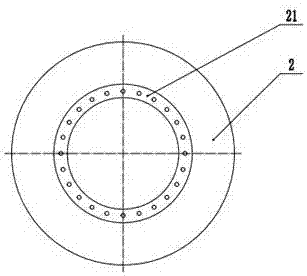

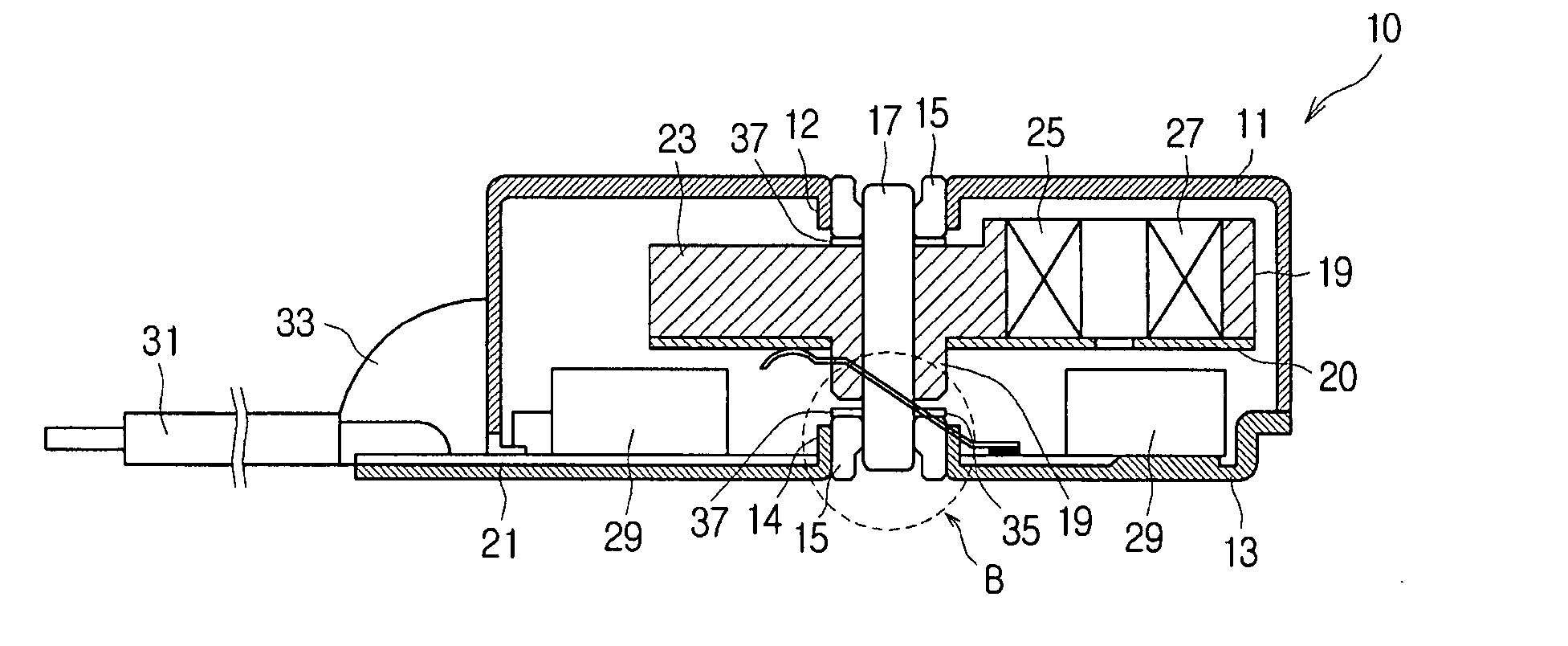

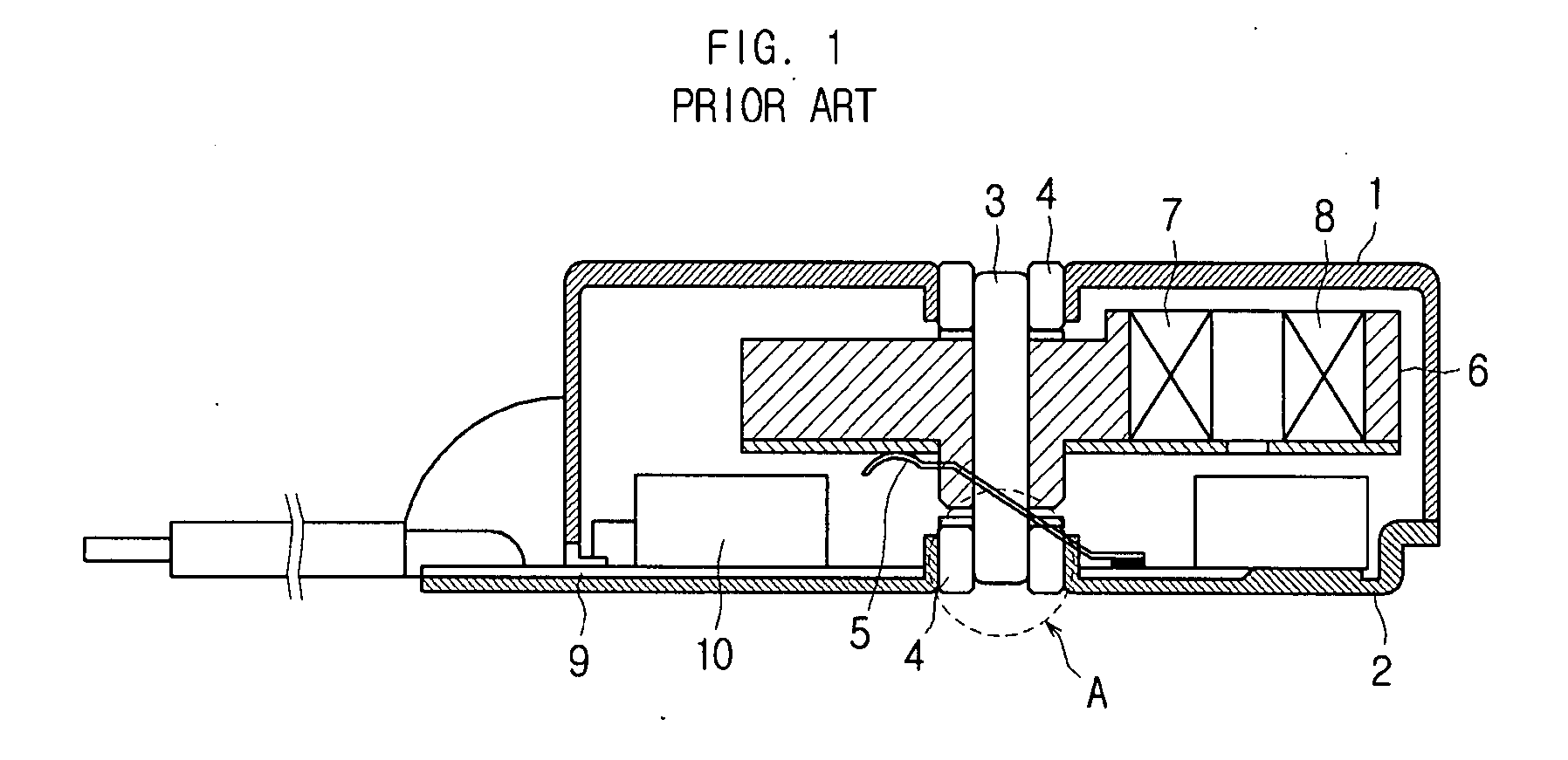

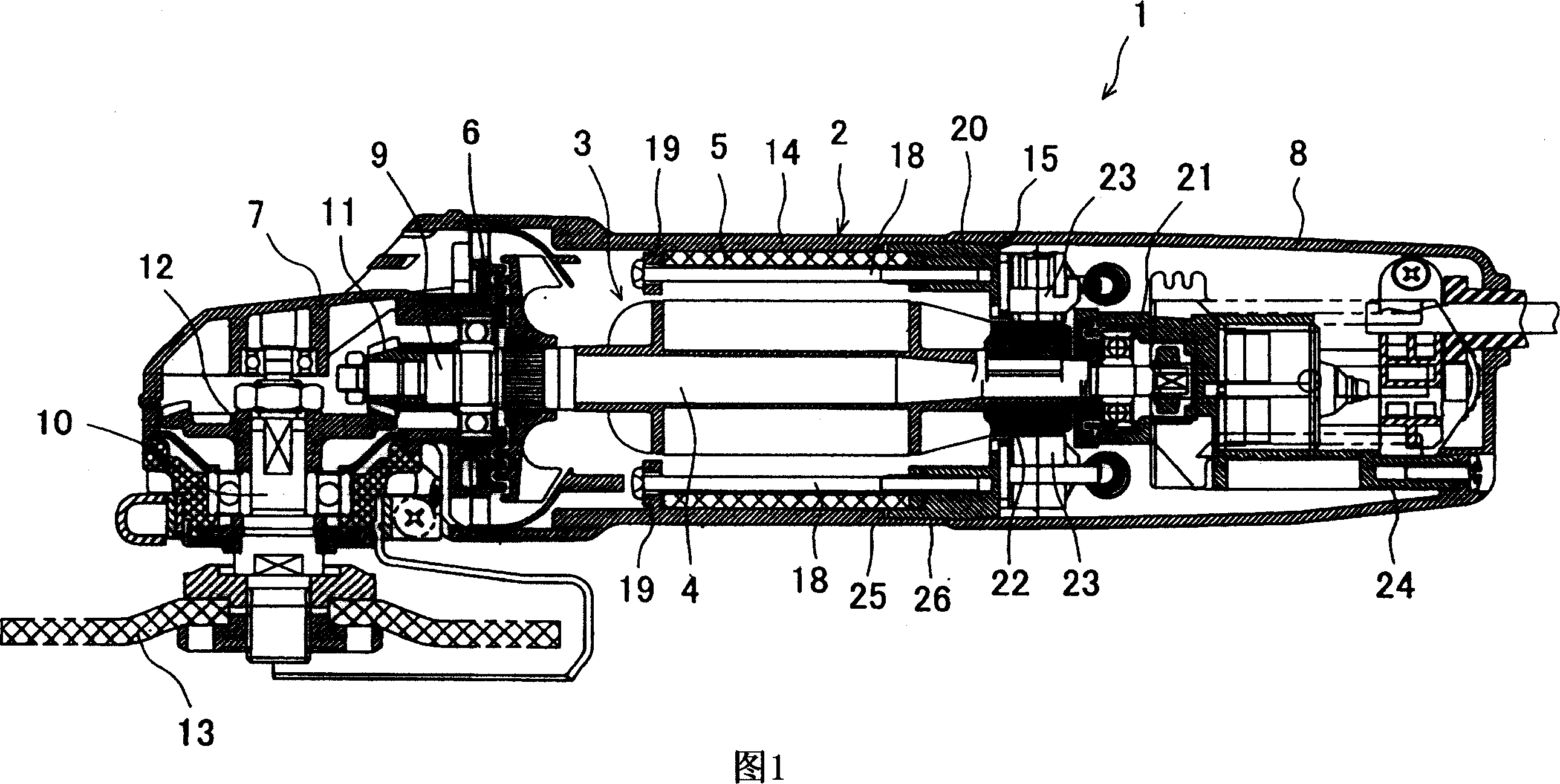

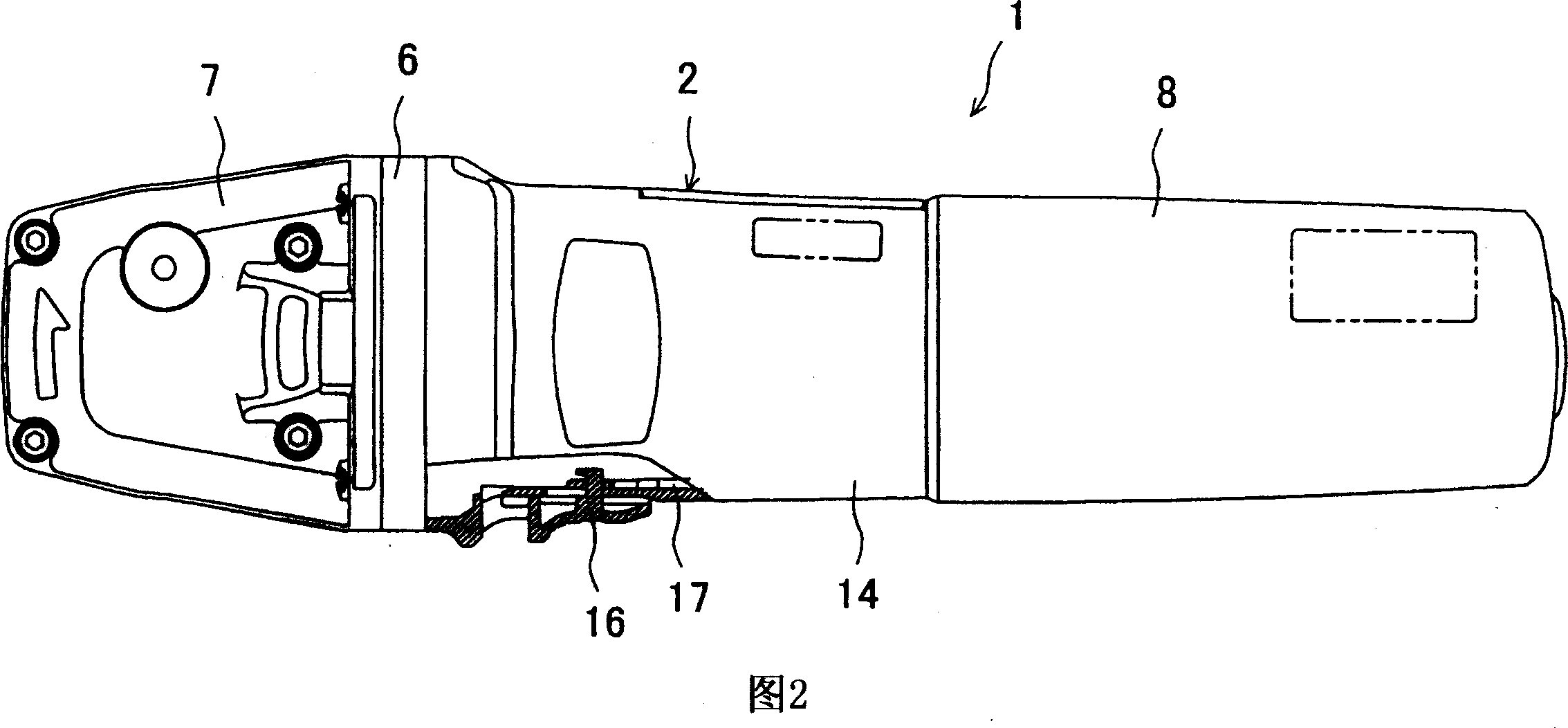

Vibration motor and oilless bearing

InactiveUS20070273224A1Improve propertiesReduce mechanical noiseManufacturing dynamo-electric machinesMechanical vibrations separationMotor vibrationElectric machinery

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

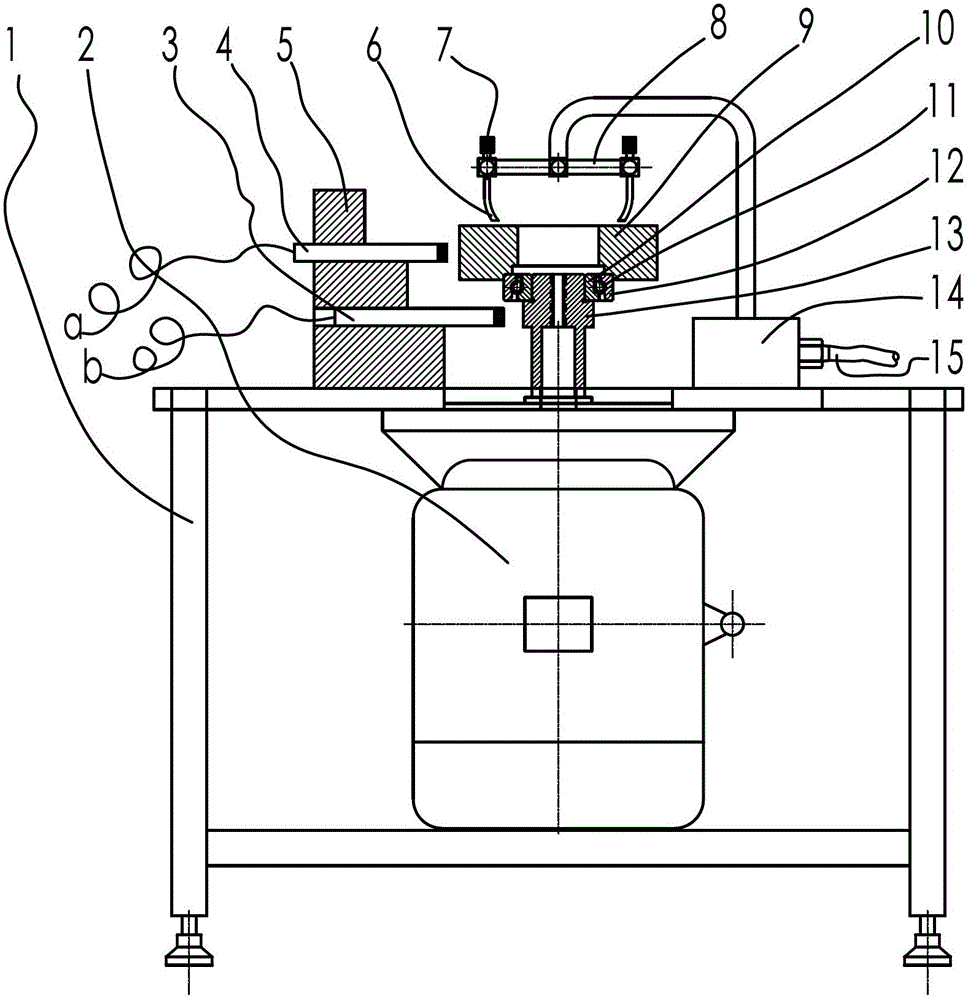

Computer controlled water column massage therapeutic equipment

InactiveCN101088485ASignificant effectIncrease local blood supplyMedical devicesMedical applicatorsElectric machineCurative effect

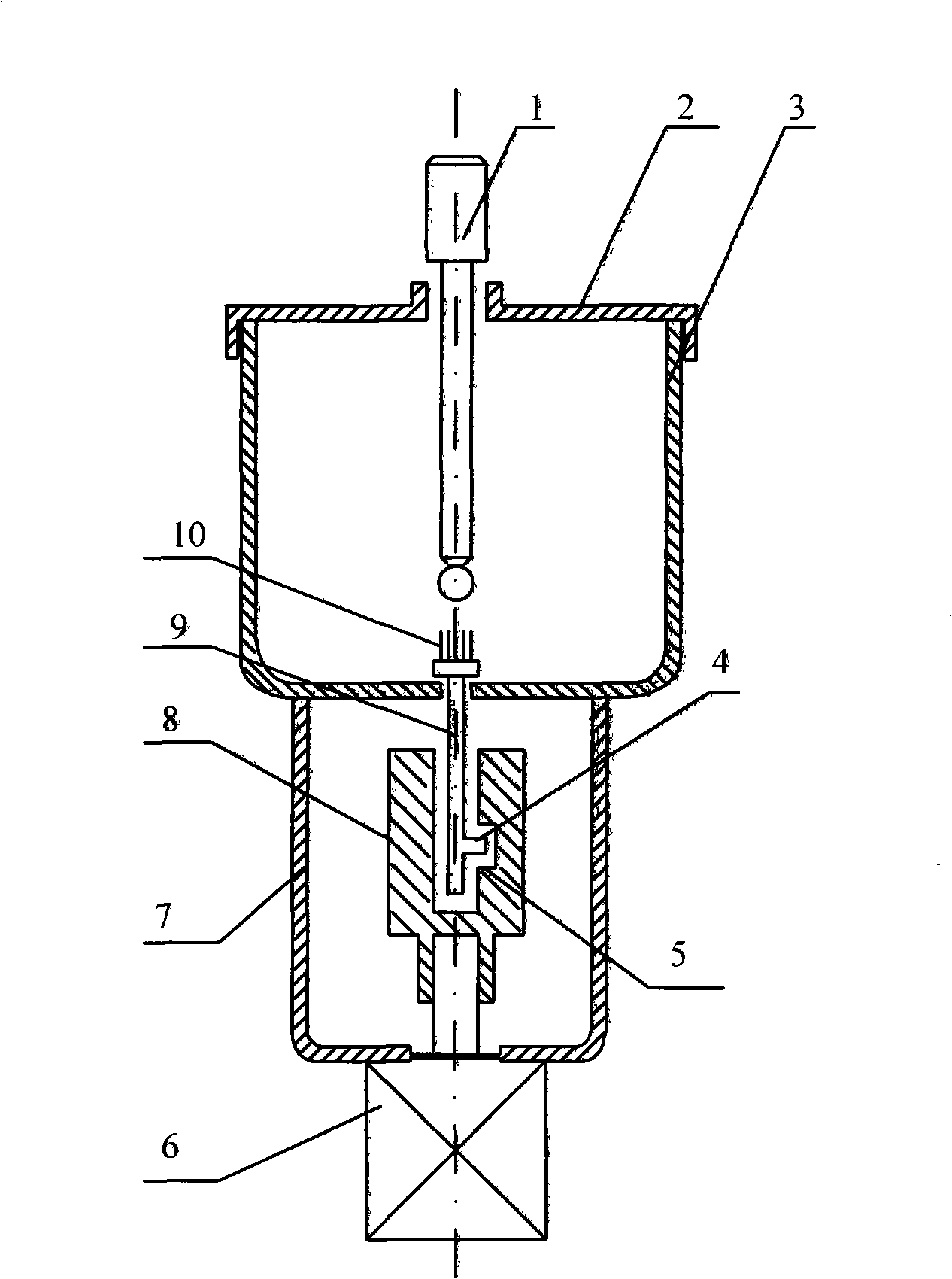

The computer controlled water column massage therapeutic equipment consists of one therapeutic bucket with water inlet pipe and water outlet pipe, one water column pressure and frequency controller, and one control cabinet. The therapeutic bucket has several water nozzles and one liquid level sensor; the water column pressure and frequency controller includes one control water valve array comprising flow rate sensors, step motor and rotary water valve, and one electromagnetic water valve for controlling the on-off frequency of the water columns; and the control cabinet consists of one control panel, one computerized control system and one sealed water heating tank. The water column massage therapeutic equipment has its water column pressure, direction, range and frequency automatically controlled, and thus obvious treating effect, simple operation and high use safety.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

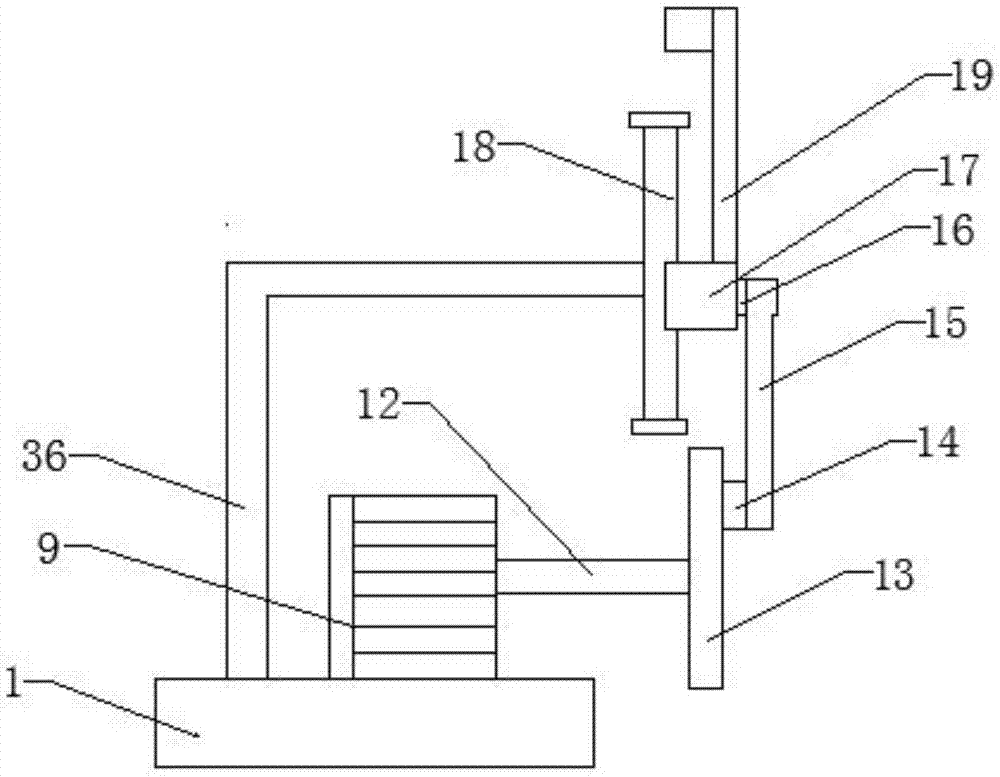

Electric control system of hydraulic experiment table

InactiveCN108087388AReasonable designGuaranteed uptimeFluid-pressure actuator testingServometer circuitsAutomatic controlControl system design

The invention discloses an electric control system of a hydraulic experiment table; the purposes of remote monitoring and control can be realized; the functions of voice alarm, statement output and the like are achieved; and automatic control of the system of the hydraulic experiment table is realized. The control system of the hydraulic experiment table is reasonable in design; hardware is selected properly; software is designed to achieve requirement meeting, high operability and powerful functions; detected scene sensor data is matched with actual data; control on a motor, a relay and the like is accurate and timely; and the whole system of the hydraulic experiment table is stable and reliable in operation and excellent in monitoring effect.

Owner:赵江涛

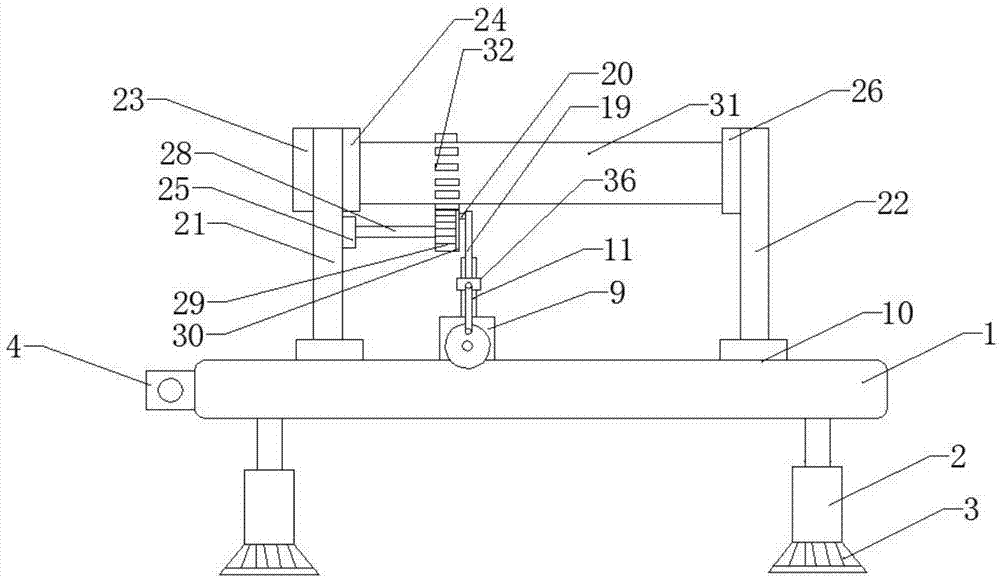

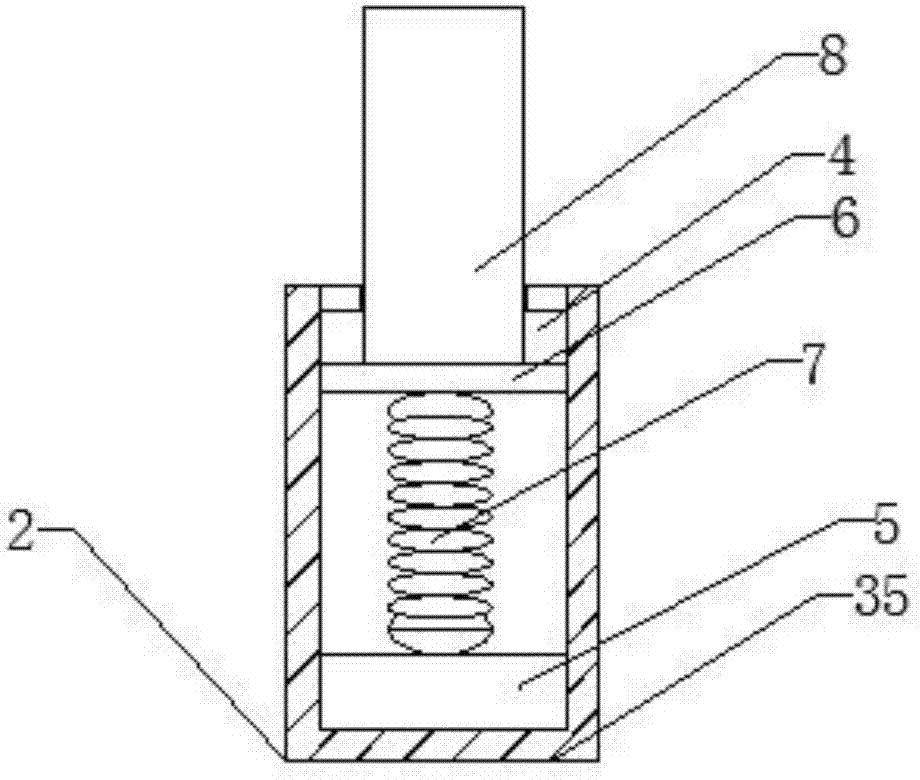

Method and device for measuring contact angle of ball bearing

ActiveCN102749063AEasy to operateAccurate and reliable measurement result dataMachine bearings testingElectric machineryEngineering

Owner:WUXI NO 2 BEARING

Trimming device for clothes hanger

Owner:重庆博视知识产权服务有限公司

Electric tool

Owner:MAKITA CORP

Multifunctional stirring device for biological pharmacy

ActiveCN112237881AWell mixedEasy to stir and mixTransportation and packagingMixer accessoriesPharmacyReciprocating motion

The multifunctional stirring device for biological pharmacy comprises a box body; a partition plate is fixedly connected to the upper end of an inner cavity of the box body, two feeding hoppers are fixedly connected to the left side of a top plate of the box body in a front-back symmetrical mode, and lower end openings of the feeding hoppers penetrate through the top plate of the box body and extend into the box body to communicate with upper end holes of feeding pipes; the lower opening of the feeding pipe penetrates through the partition plate and extends to the lower part of the partition plate; the top end of the left side wall of the inner cavity of the box body is fixedly connected with a motor; according to the invention, the motor drives a first rotating shaft to rotate, the firstrotating shaft rotates to drive a first connecting rod to rotate, then a first sliding block drives a second connecting rod to do left-right reciprocating motion, and further, the second sliding blockdrives the third connecting rod to swing with the second fixing rod as the axis, the check block synchronously swings along with the third connecting rod and is matched with the feeding hopper, and therefore raw materials are controlled to intermittently fall into the feeding pipe downwards.

Owner:XIAN TIANYI QINKUN PHARMA

Optical cable meter counting printing machine with alarm

Owner:成都亨通光通信有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap