Suture winding machine and suture winding method

A technology of suture and winding machine, applied in thin material processing, transportation of filamentous materials, transportation and packaging, etc., can solve the problems of difficult to guarantee product quality, low efficiency and high cost, and achieve low cost, high efficiency, Stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

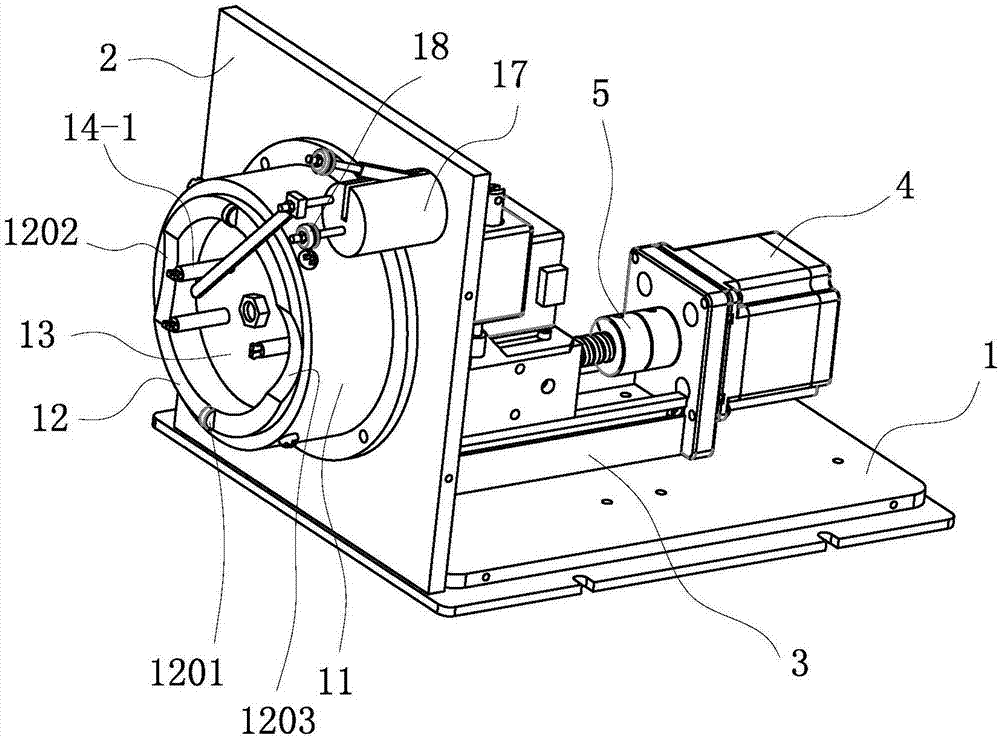

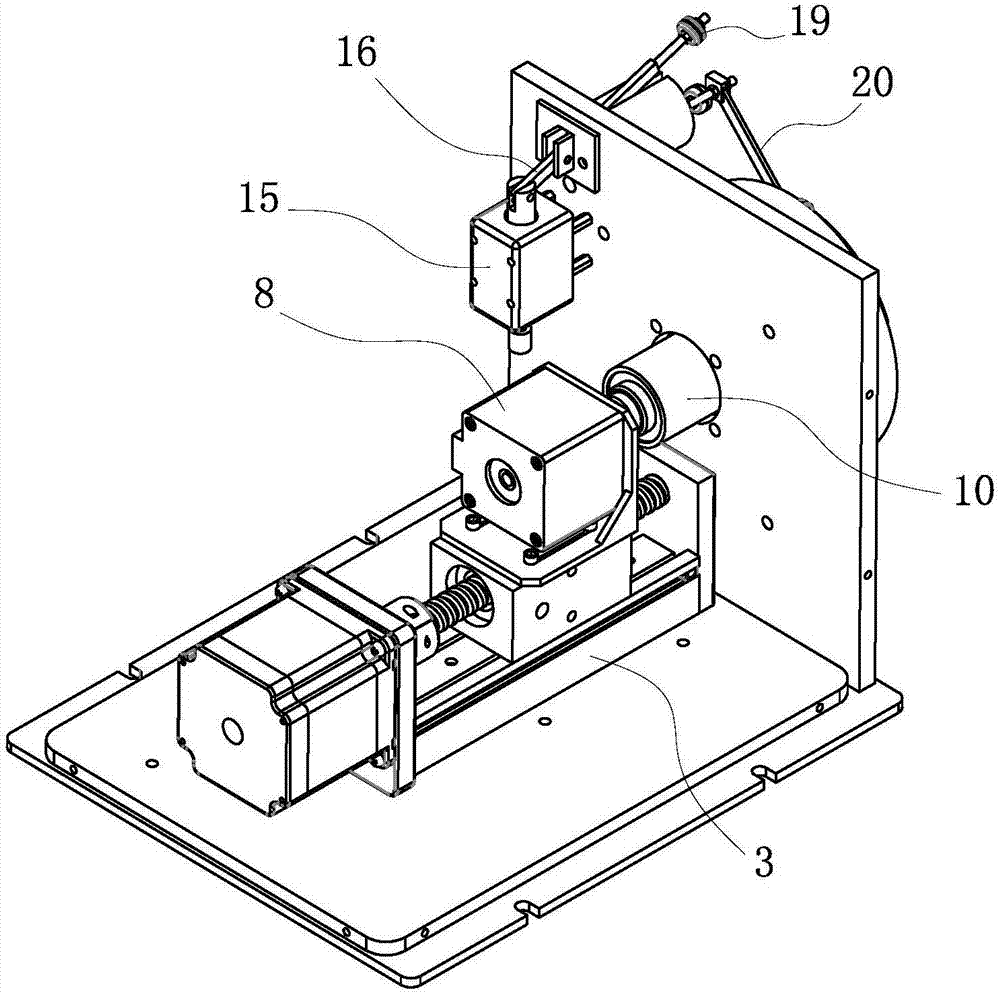

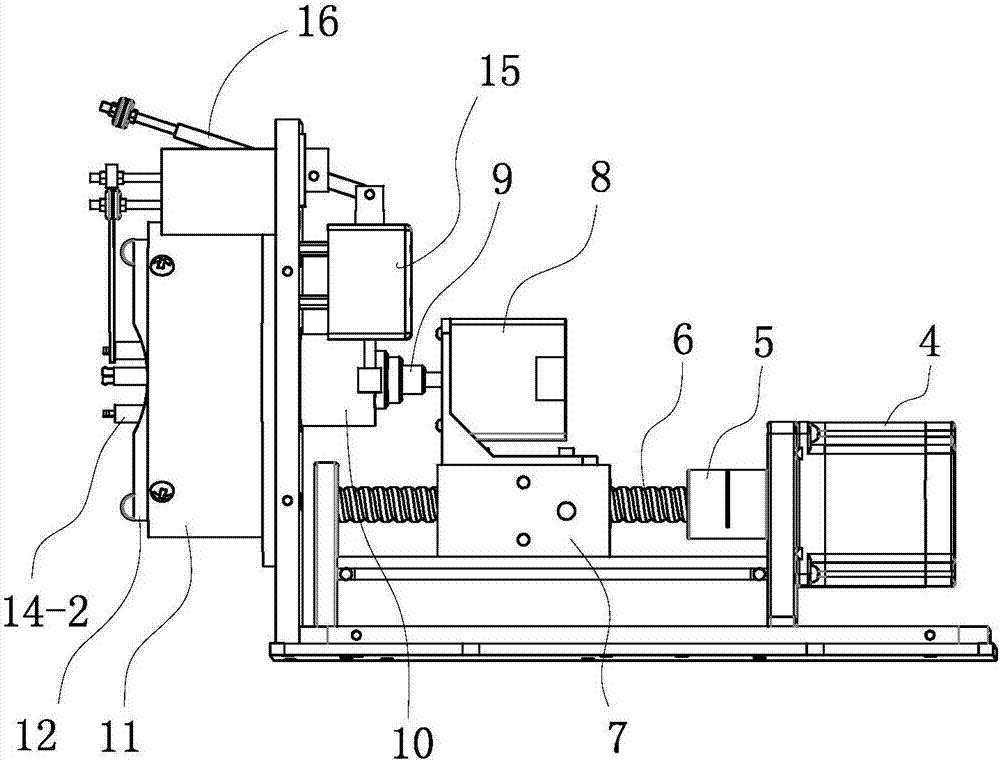

[0040] Such as Figure 1-5 As shown, the suture winding machine includes a base 1, a vertical plate 2, a track 3, a first stepping motor 4, a coupling 5, a screw rod 6, a slide table 7, a second stepping motor 8, and a claw shaft 9 , linear rotary bearing 10, bucket retaining ring 11, bucket bucket 12, rotation adjustment part 1201, first notch 1202, second notch 1203, claw plate 13, push-pull electromagnet 15, lever 16, tensioner connecting column 17. Fixed tension pulley 18, movable tension pulley 19, thread pressing rod 20.

[0041] The vertical plate 2 is vertically fixedly connected with the base 1 , the track 3 is installed on the base 1 , and the first stepping motor 4 is installed on the base 1 . The screw mandrel 6 is supported on the base 1 through a bearing, and one end of the screw mandrel 6 is connected with the rotating shaft of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap