Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about "Filament handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Web material unwind apparatus

Owner:THE PROCTER & GAMBLE COMPANY

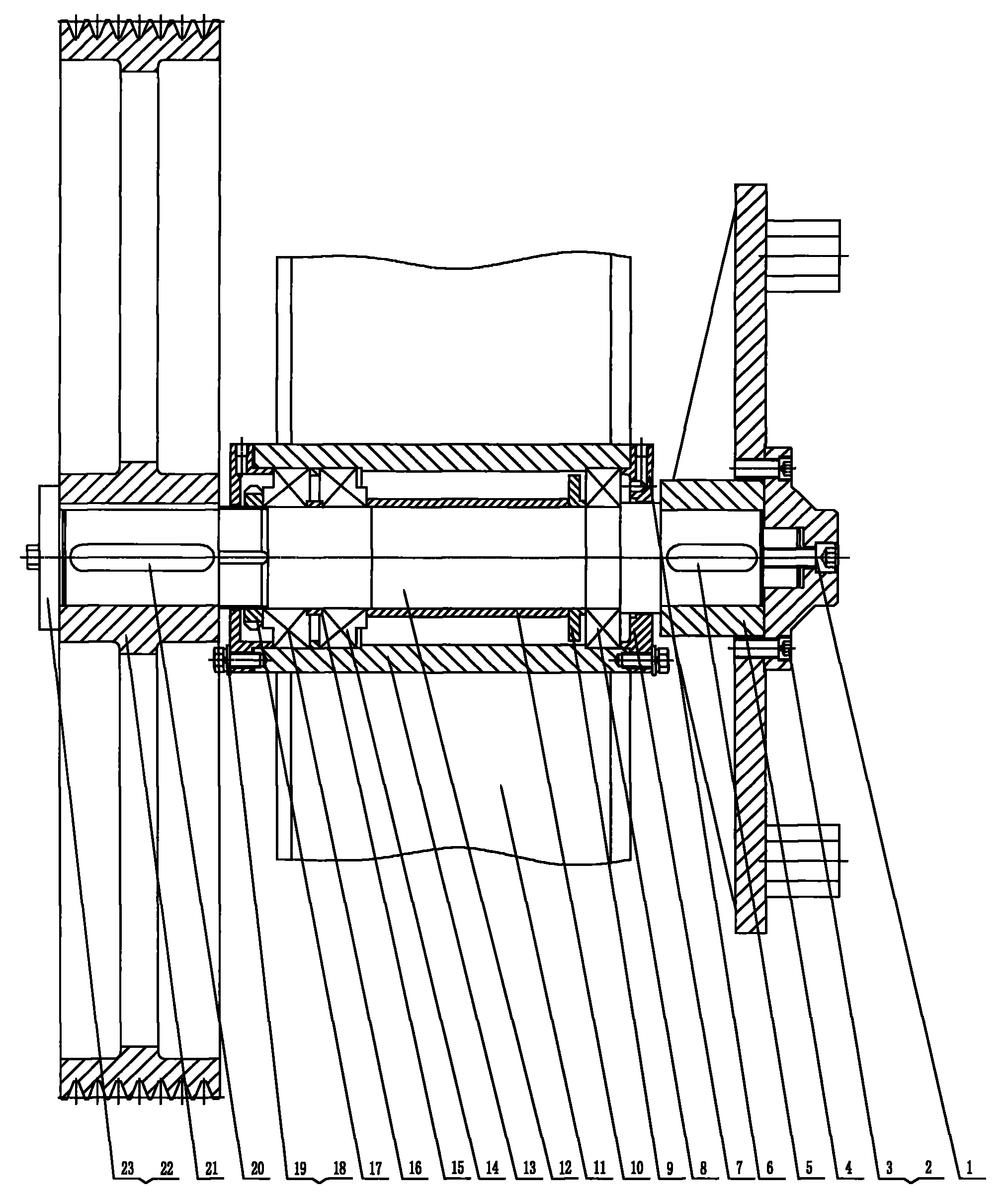

Bobbin-equipped wire take-up machine

Owner:WUXI PINGSHENG SCI & TECH

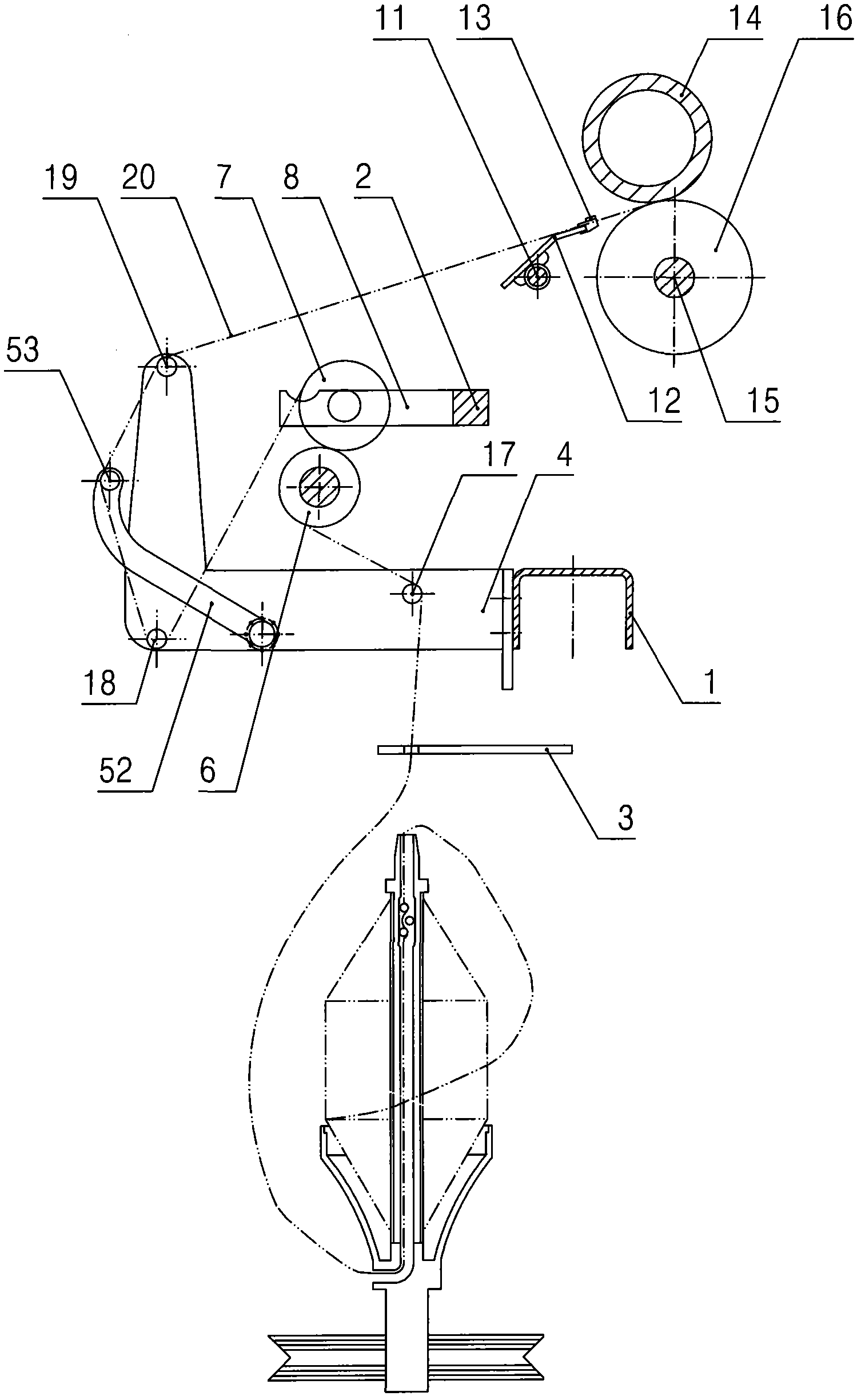

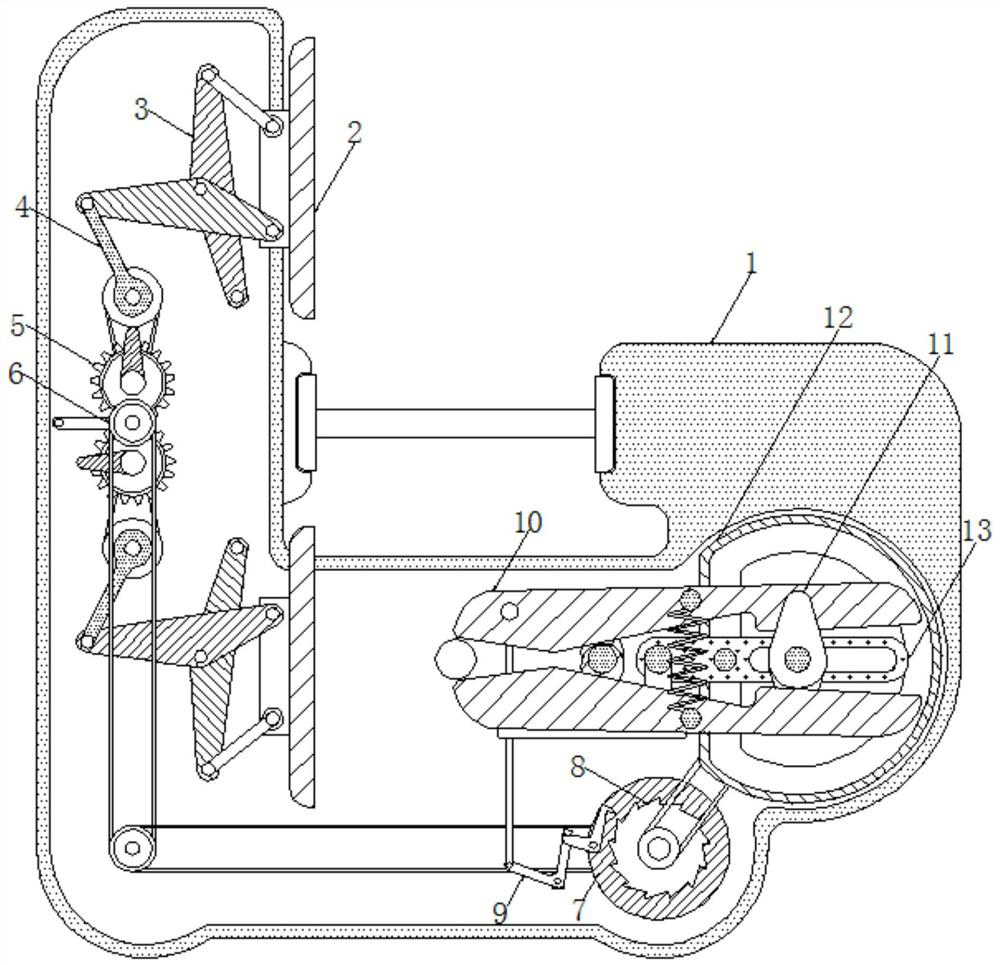

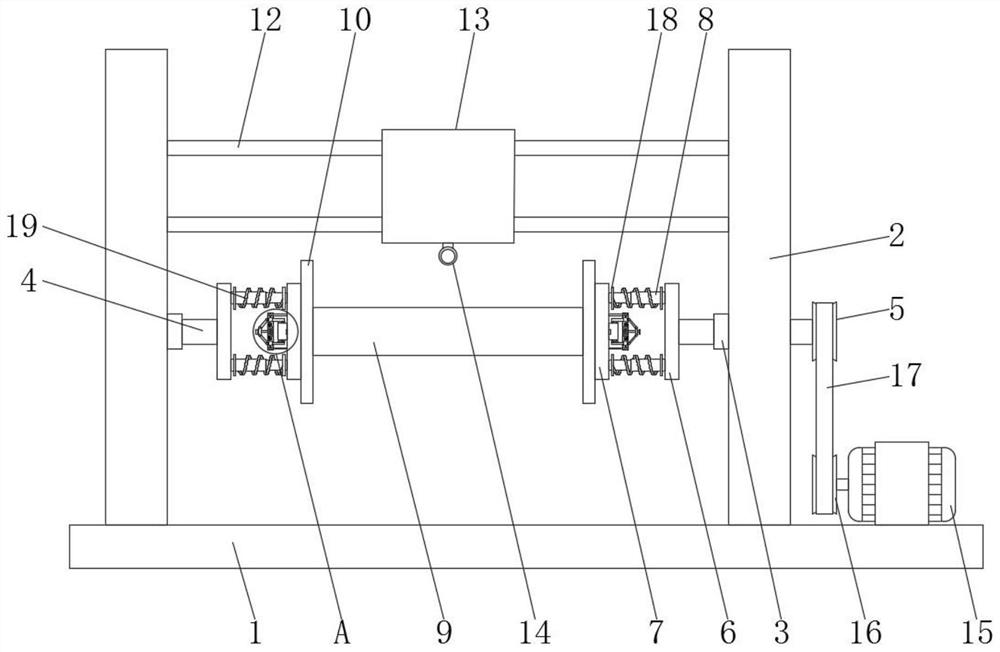

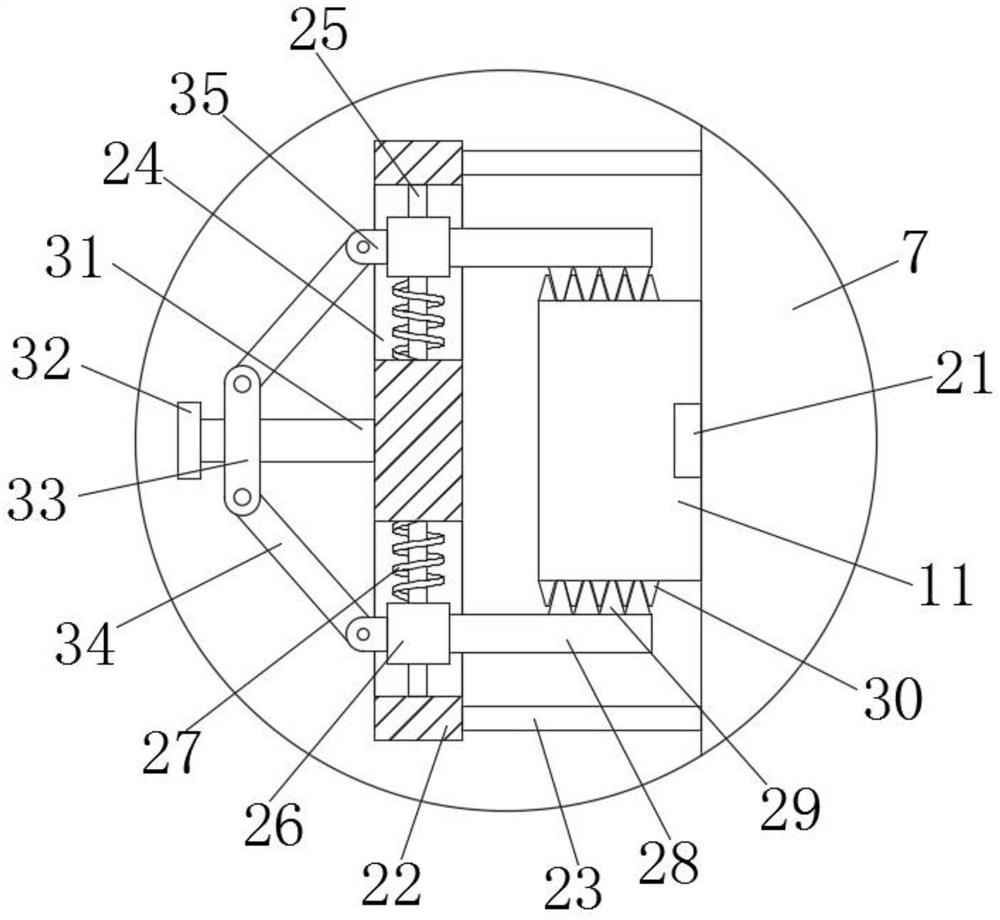

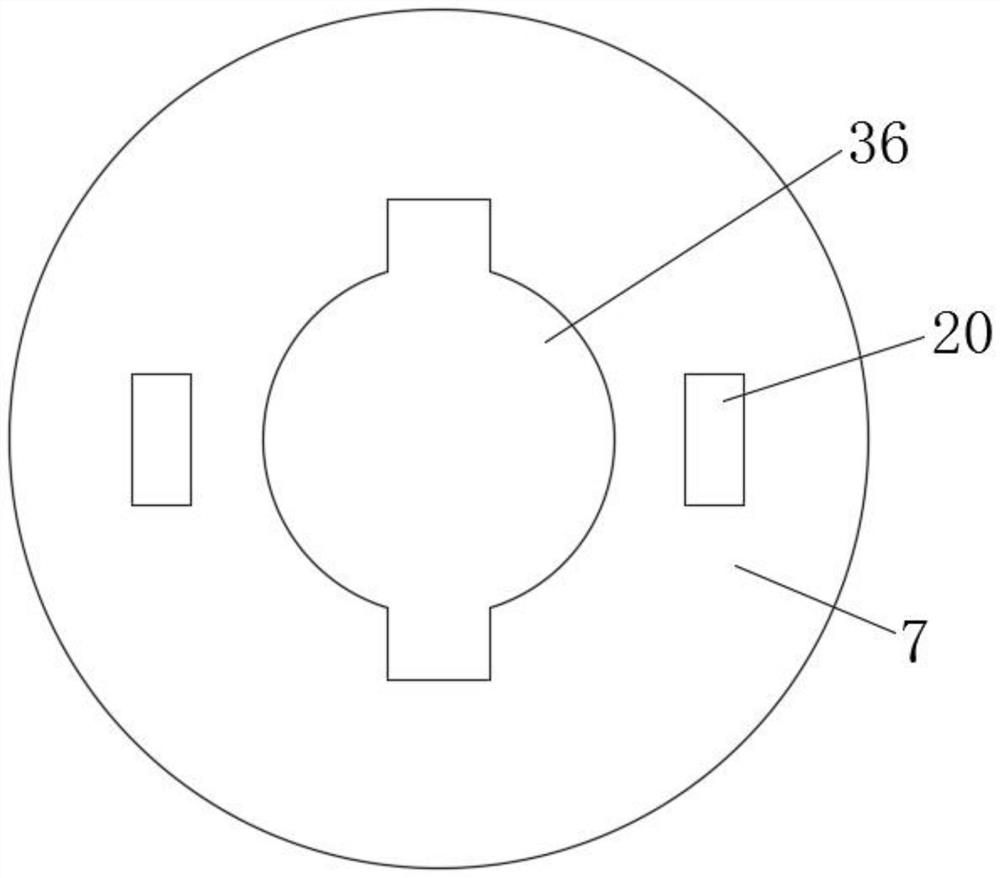

Cable tension adjusting device

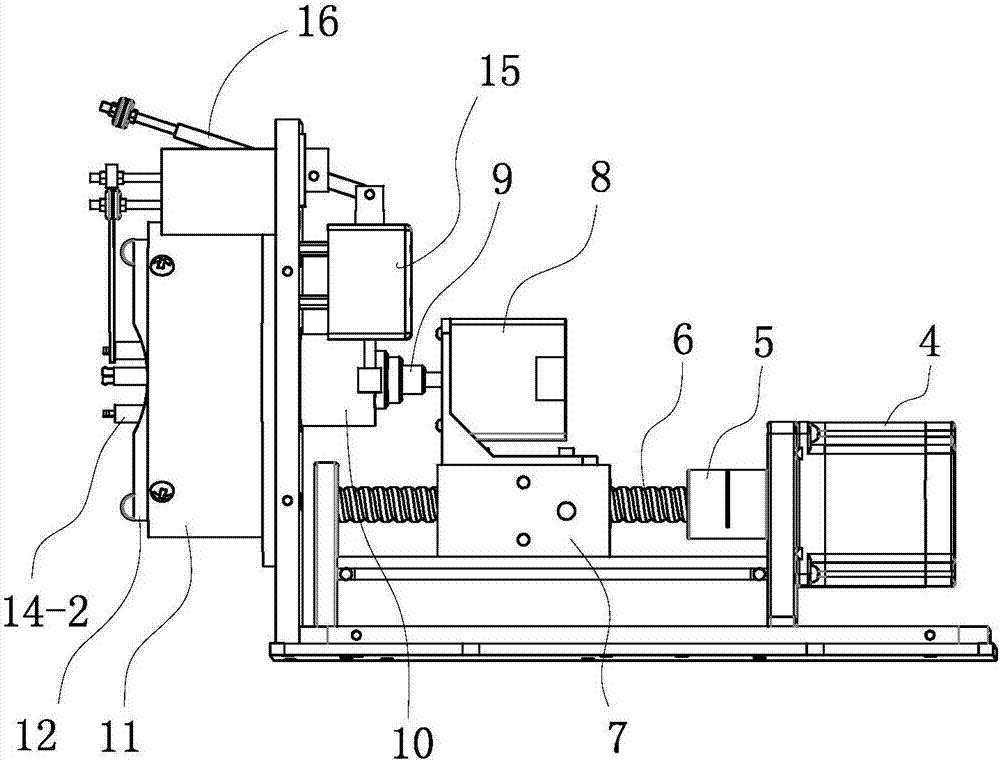

InactiveCN105060022AGuaranteed reliabilityEasy to processFilament handlingEngineeringMechanical engineering

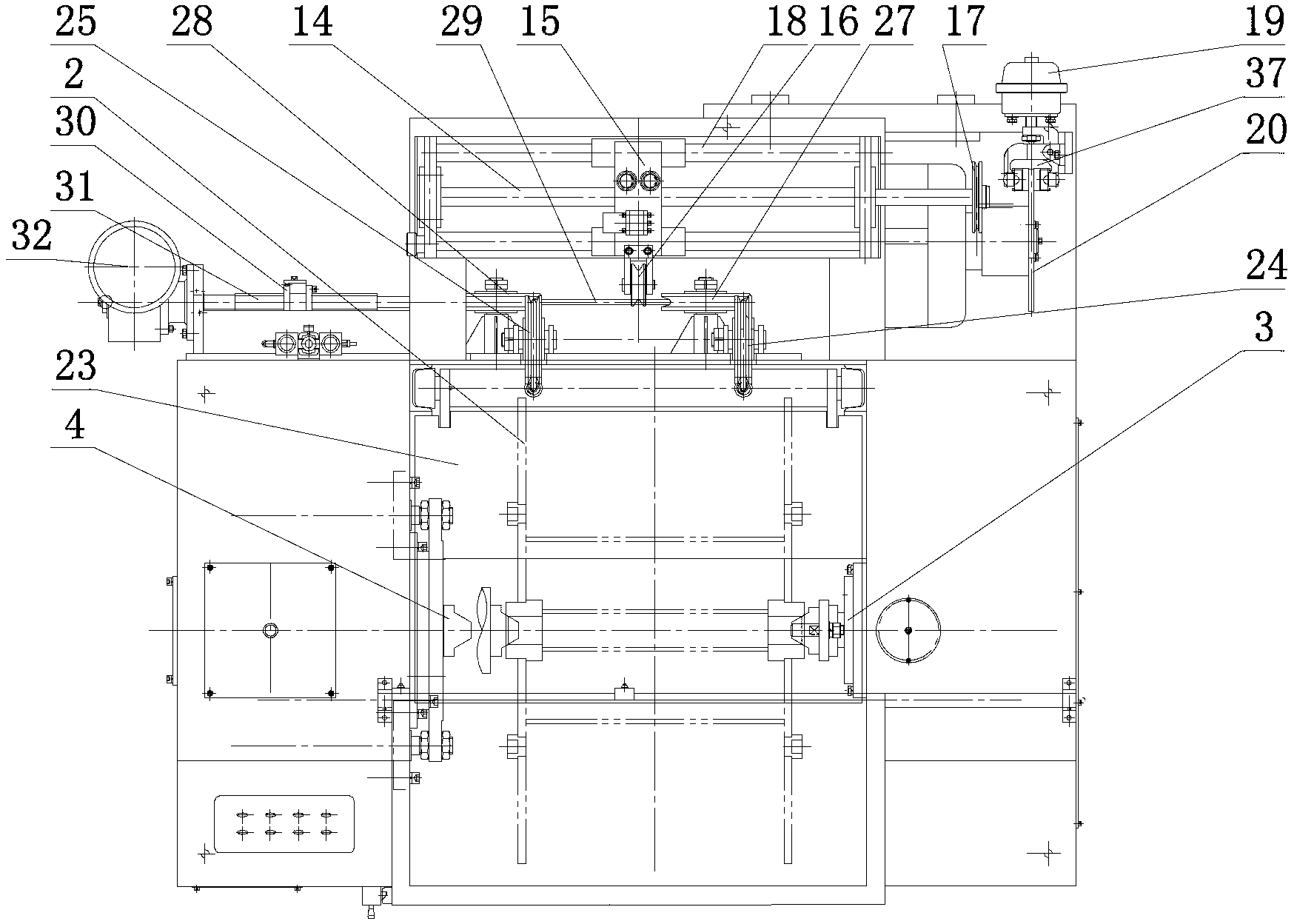

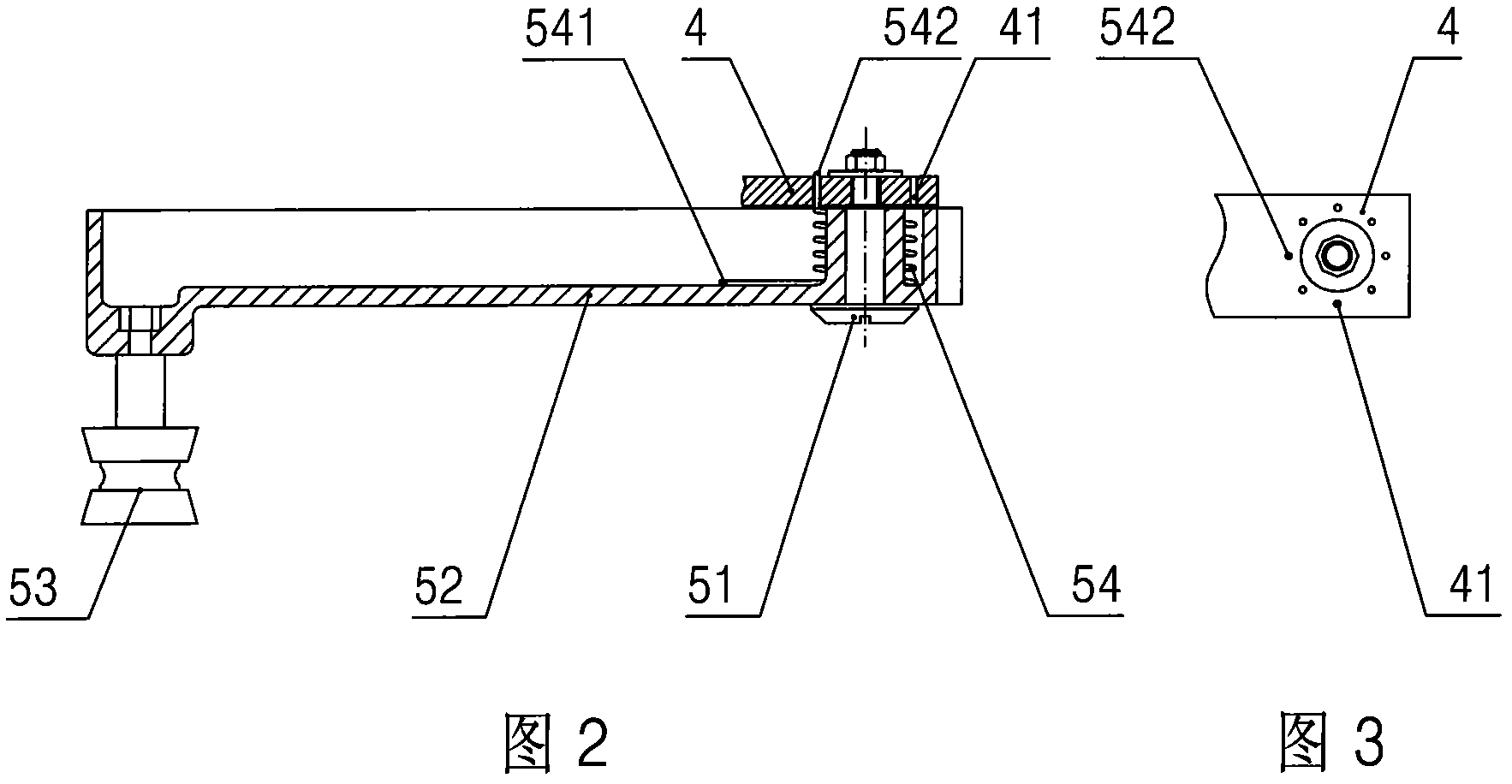

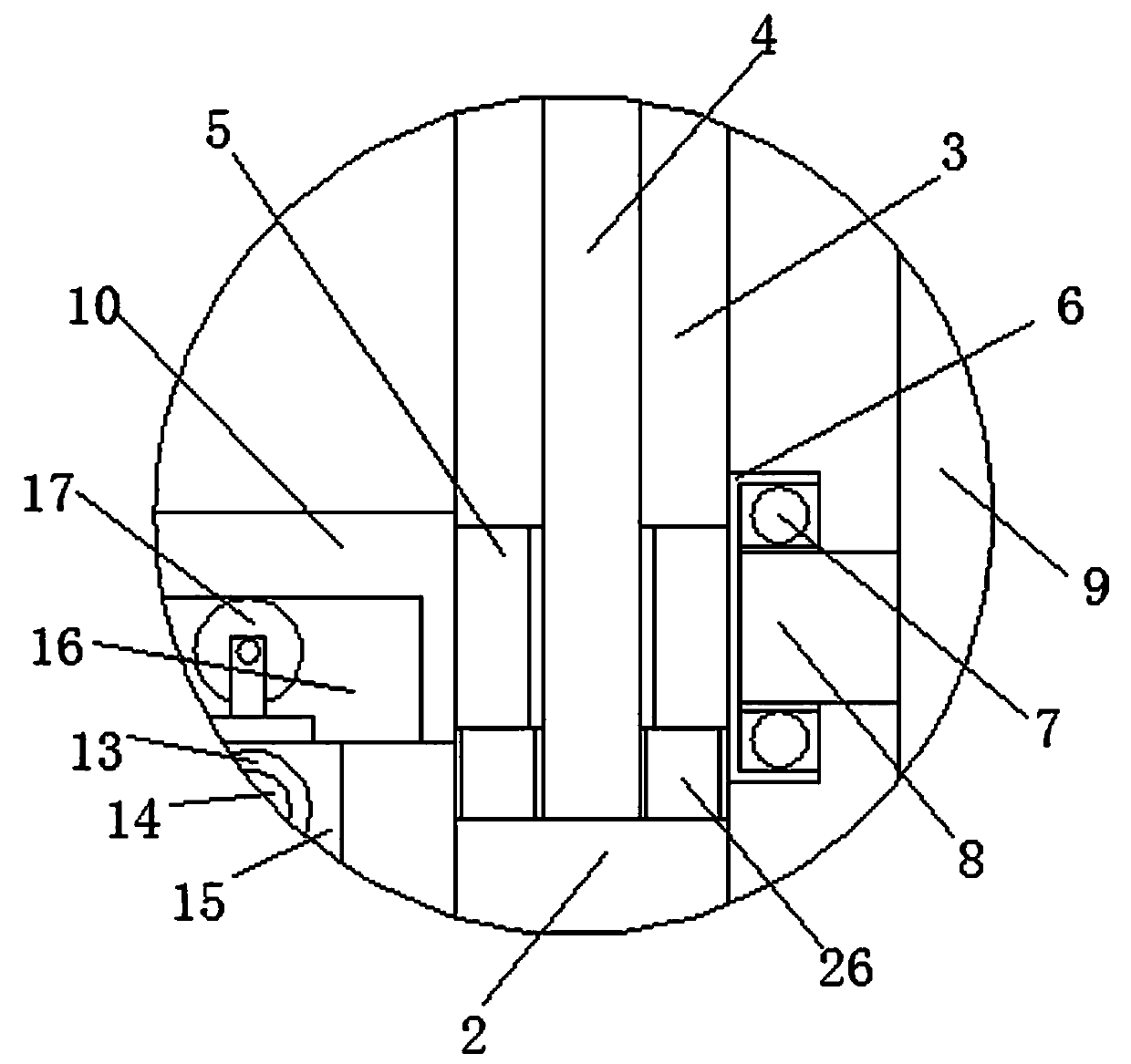

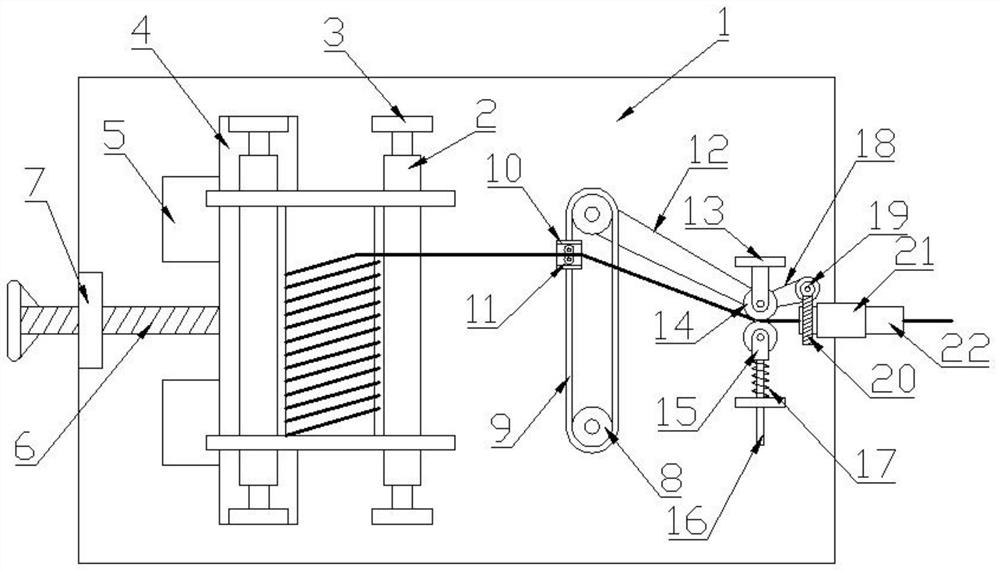

The invention relates to a cable tension adjusting device which is simple in structure, convenient to operate and convenient for tension adjustment. The cable tension adjusting device comprises a rack, a pay-off roller, a guide roller, a driving mechanism I, a driving mechanism II and a braking mechanism, wherein the rack is provided with a vertical plate I, a vertical plate II and a top plate, the pay-off roller and the guide roller are movably arranged between the vertical plate I and the vertical plate II, and the pay-off roller is positioned above the guide roller; the driving mechanism I comprises a driving wheel I, a driving wheel II and a support, and the driving wheel I and the driving wheel II are movably arranged on the support; the driving mechanism II comprises a driving wheel III, a hinge rod, a pull rod I and a pull rod II, the driving wheel III is connected to the hinge rod, and the hinge rod is hinge to the vertical plate II; the braking mechanism comprises a brake block and a brake disc, the brake disc is connected to the pay-off roller, and the brake block is connected to the pull rod II through a cross rod. The cable tension adjusting device has the advantages of being convenient to process and low in cost.

Owner:HUZHOU CHENFENG WIRE &CABLE CO LTD

Yarn winding machine with yarn breakage auto-stop function

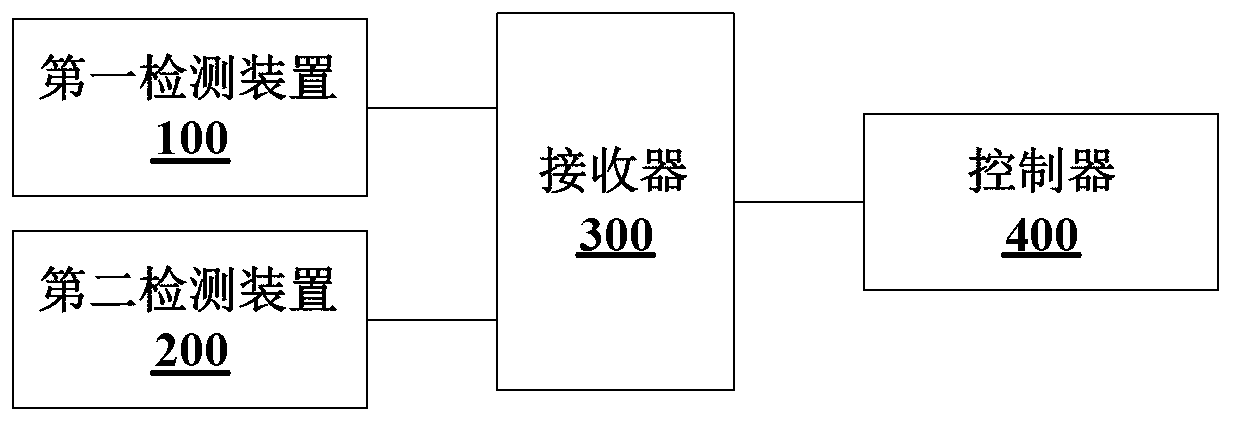

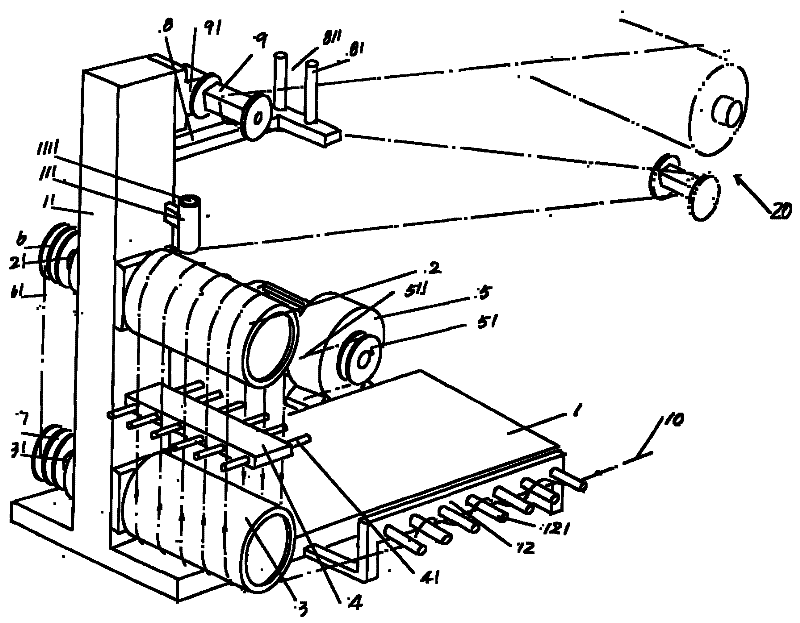

The invention discloses a yarn winding machine with a yarn breakage auto-stop function. The yarn winding machine comprises a bracket, a power device, a transmission device, yarn winding shafts and yarn reel loading parts, and further comprises yarn breakage auto-stop devices, wherein the power device, the transmission device, the yarn winding shafts and the yarn reel loading parts are mounted on the bracket; the yarn reel loading parts are used for loading of yarn reels; the power device is connected with and used for driving the transmission device; the transmission device is connected with and used for driving the yarn winding shafts; the yarn breakage auto-stop devices are arranged between the yarn winding shafts and the yarn reel loading parts, and comprise switches, detecting modules and processing modules; the detecting modules are electrically with the processing modules; the processing modules are electrically connected with the switches; the switches are connected in series with the power device; the detecting modules are used for detecting the status of yarns between the yarn winding shafts and the yarn reel loading parts, and feeding back signals; and the processing modules are used for controlling the on-off of the switches according to the signals. After a broken yarn is detected, the yarn winding machine disclosed by the invention is stopped in time, thereby preventing the continued running of the yarn winding machine and the waste of energy; and meanwhile, random yarn winding is avoided, the overall yarn quality is guaranteed, and the labor intensity of workers is reduced.

Owner:GUANGXI SISAL GRP SHANWEI SISAL PROD CO LTD

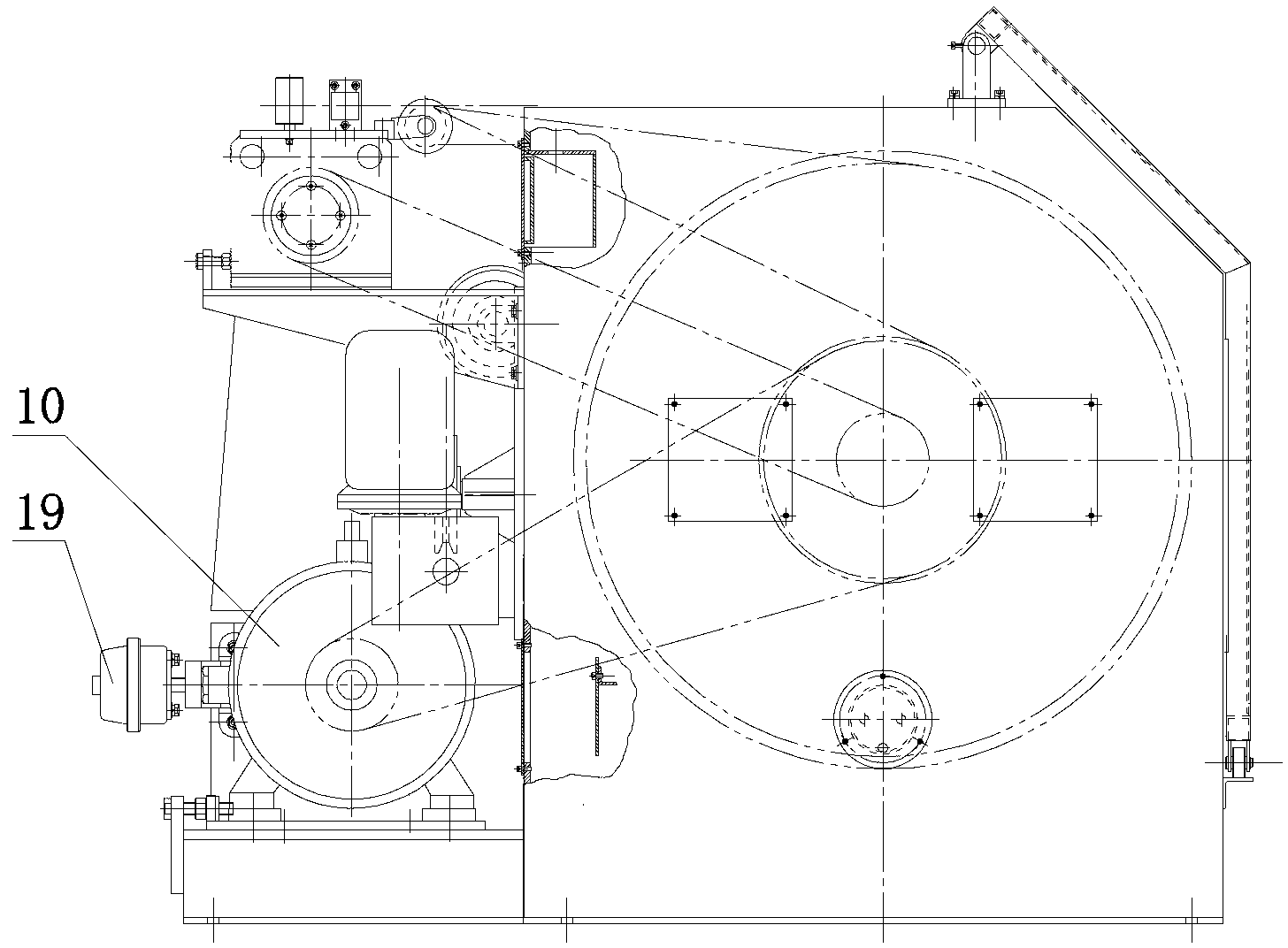

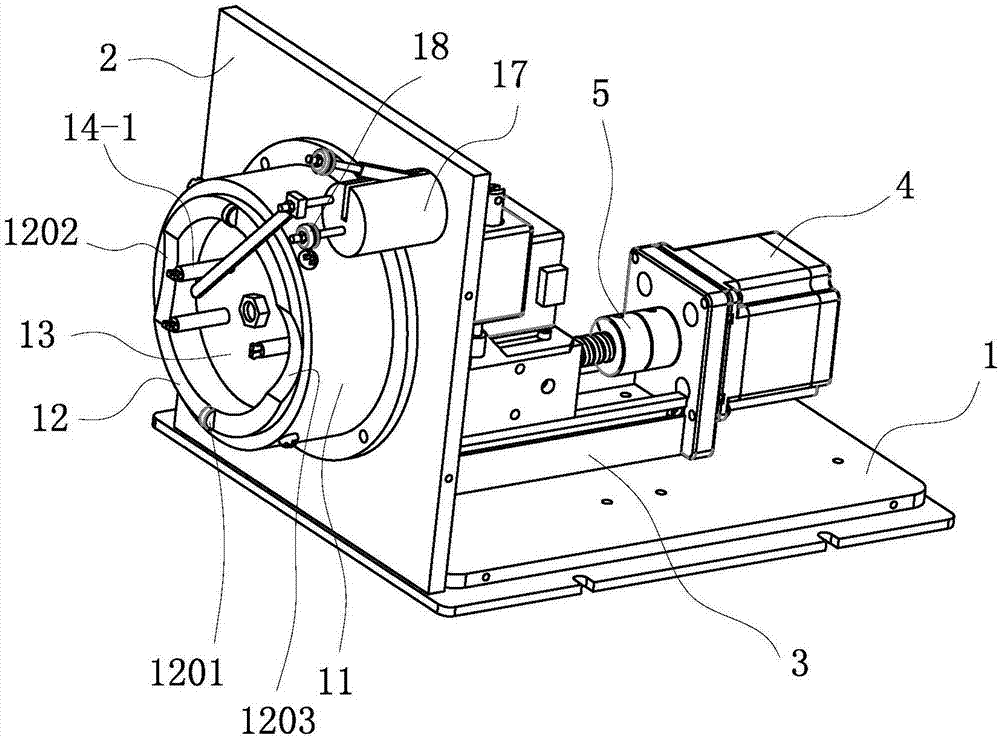

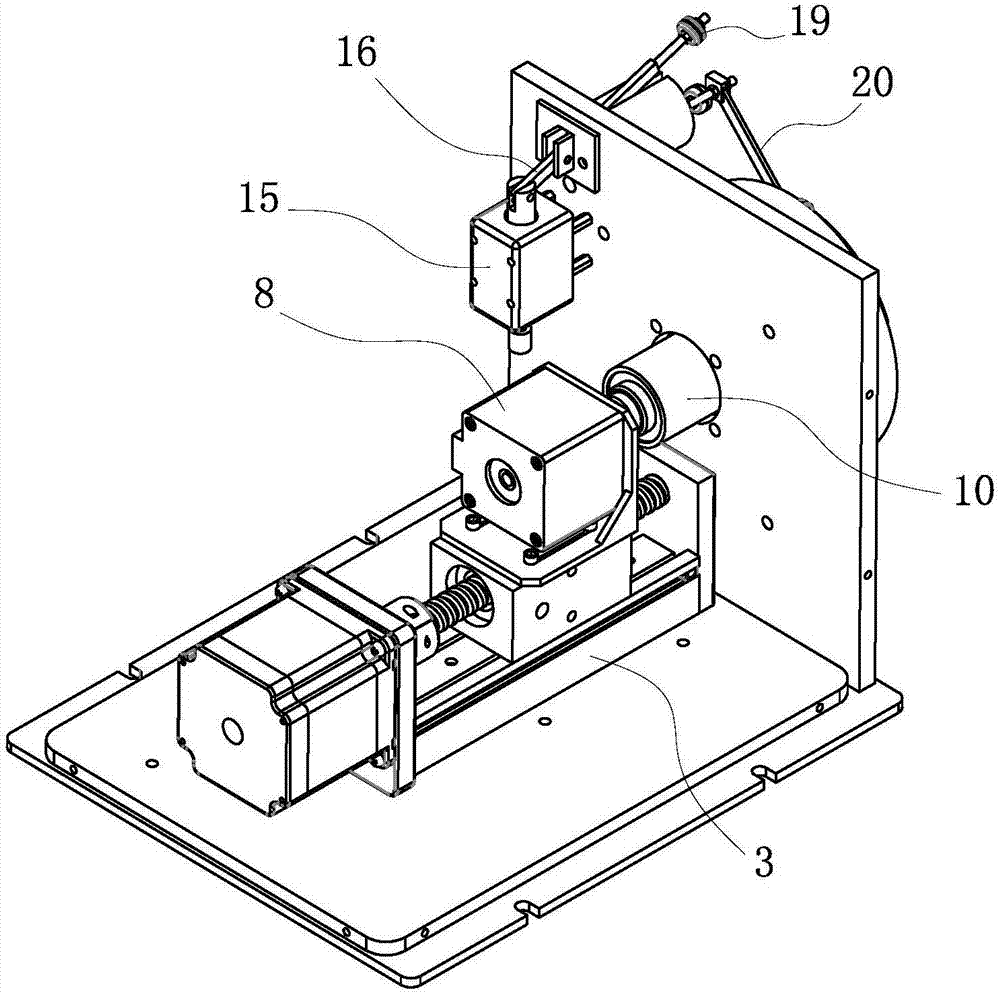

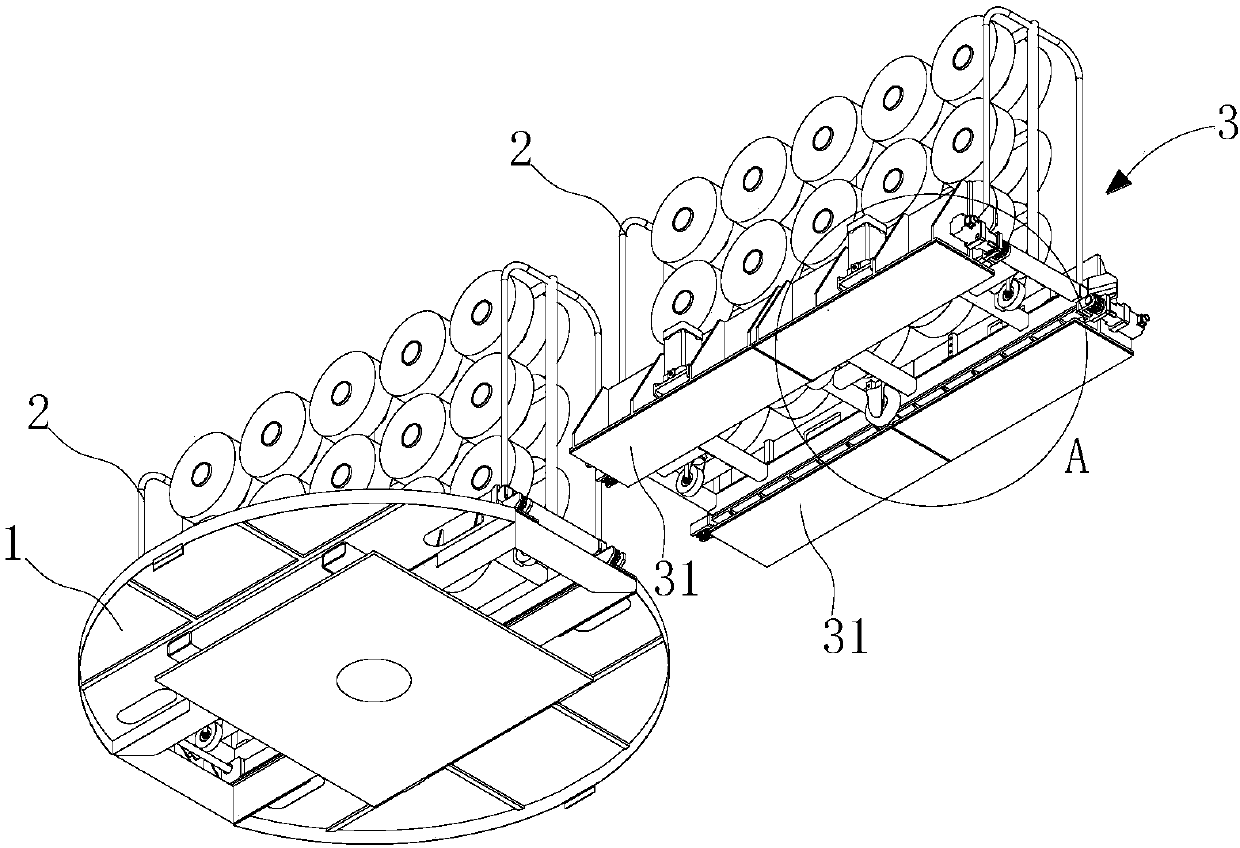

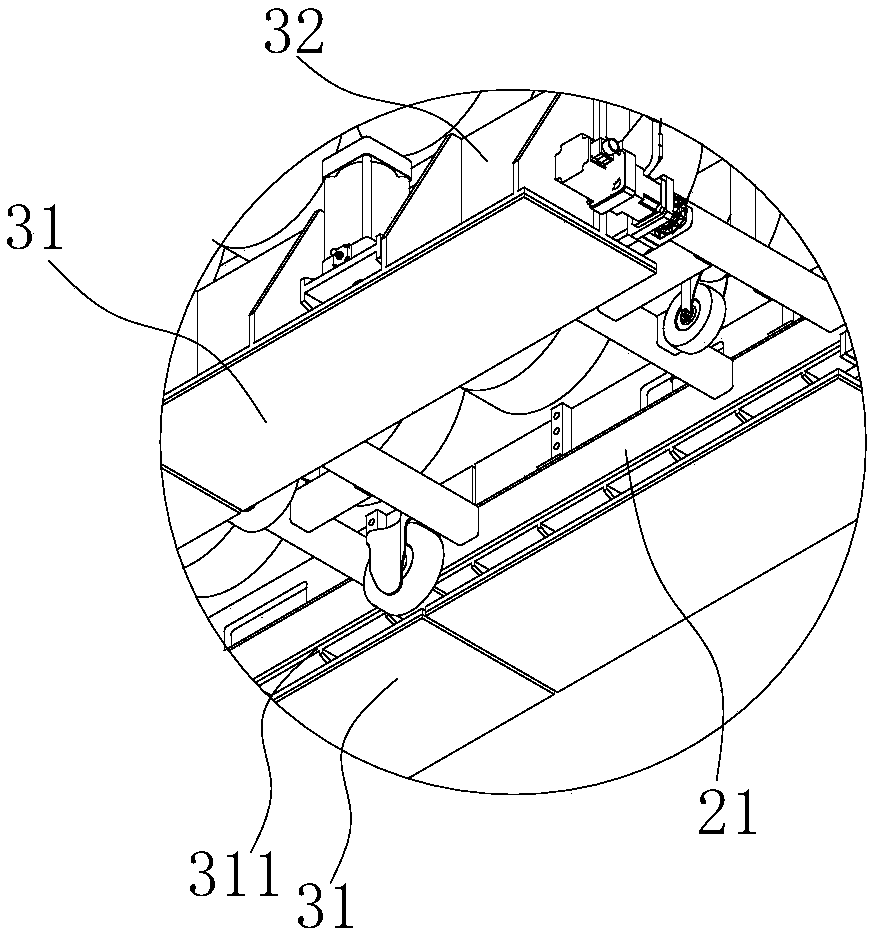

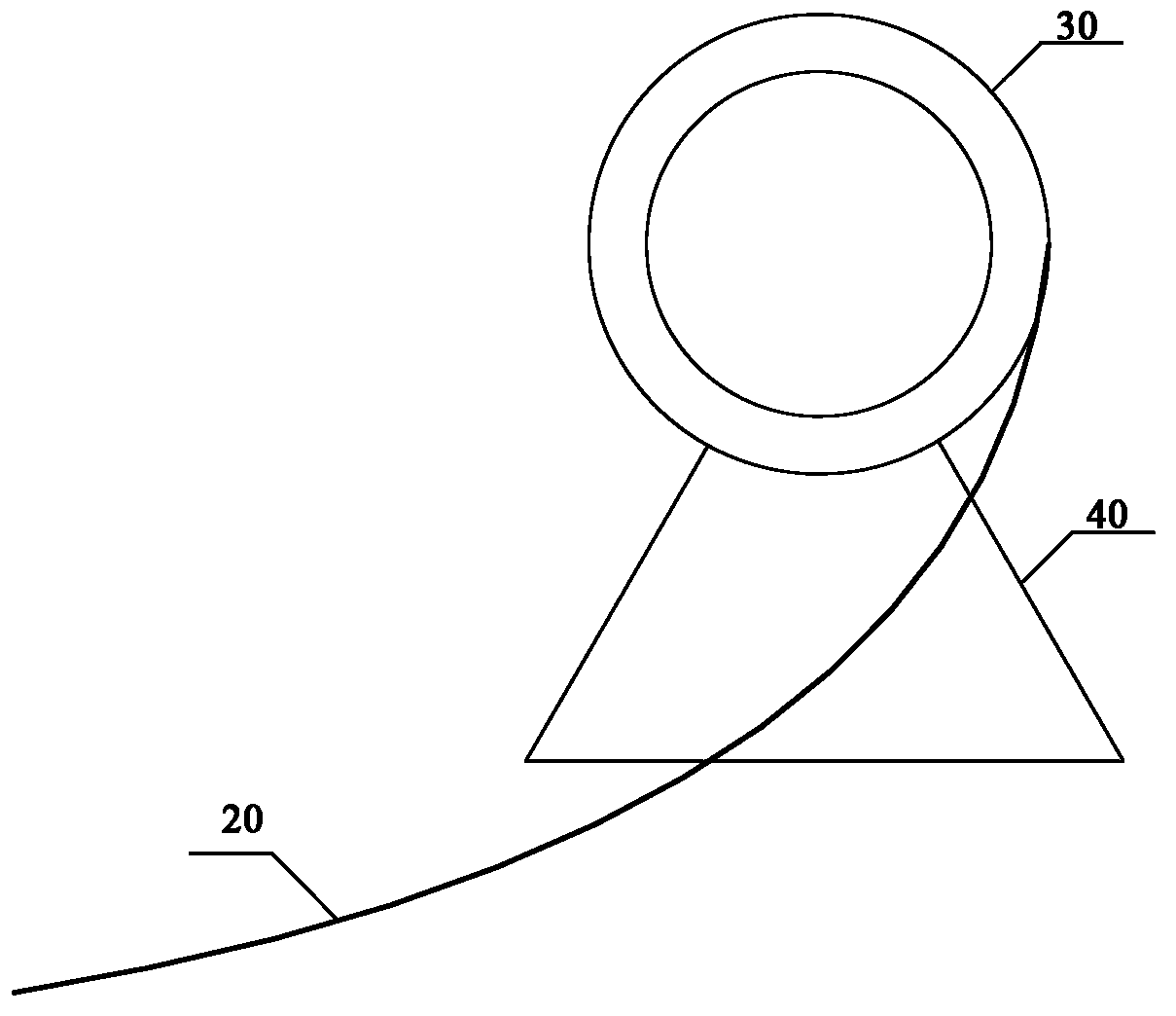

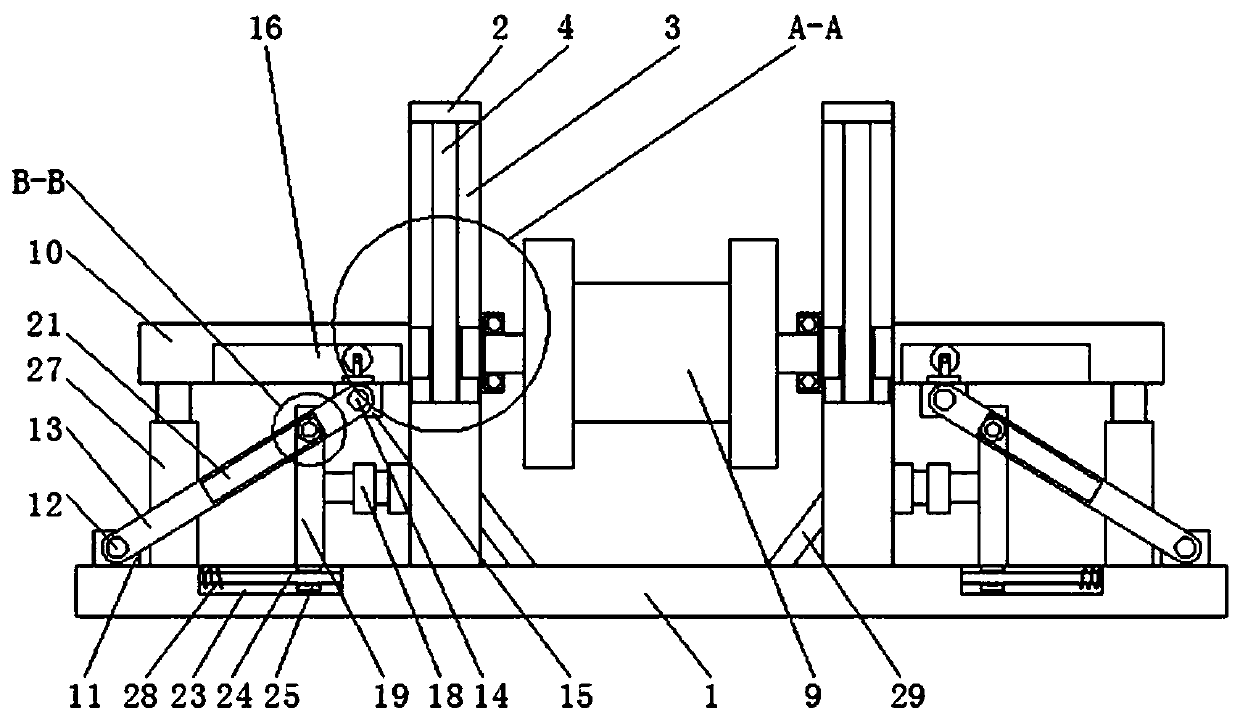

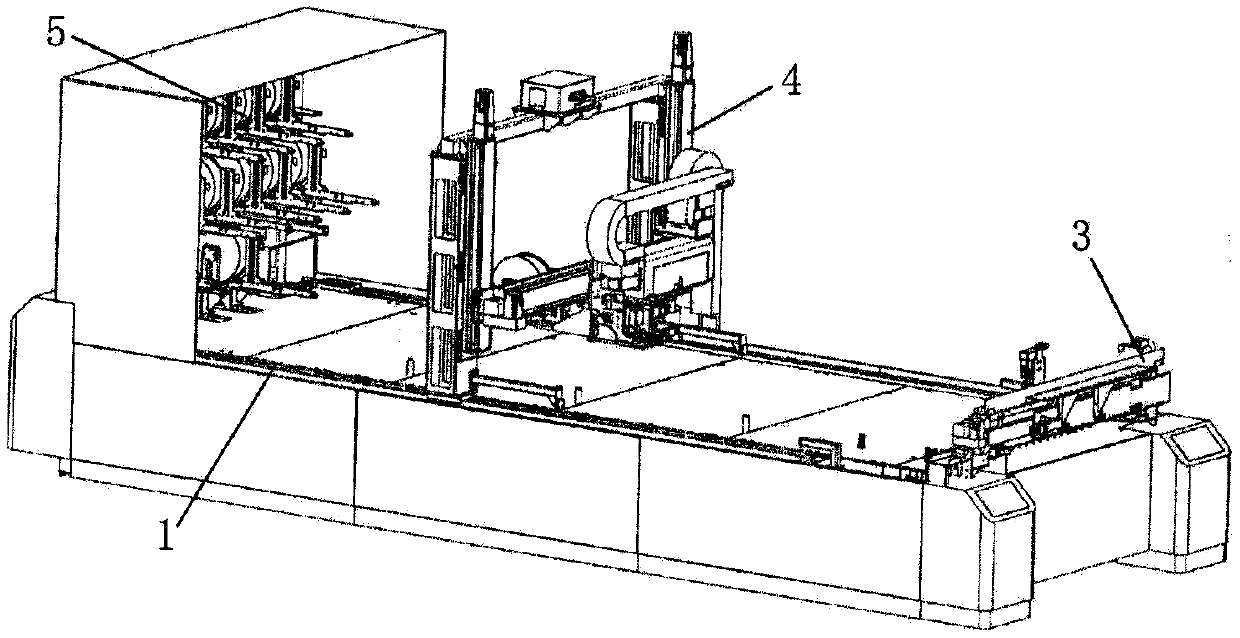

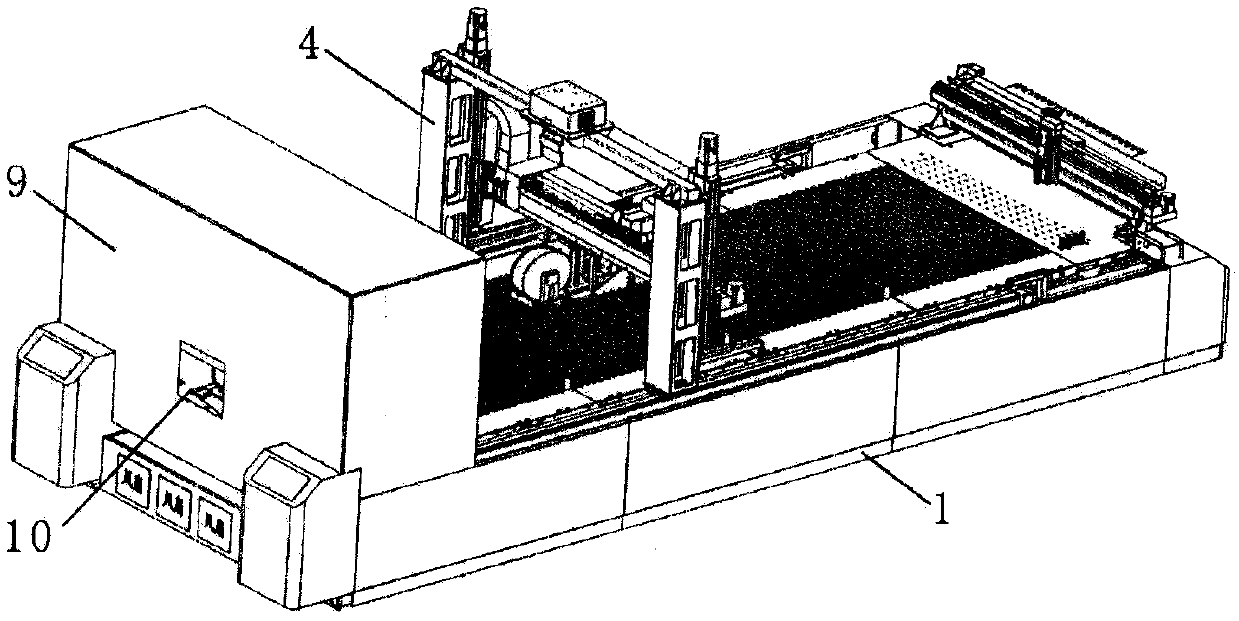

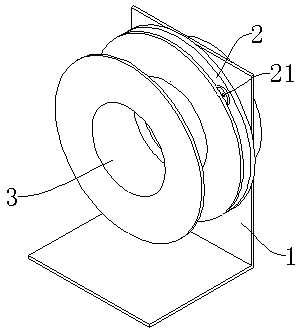

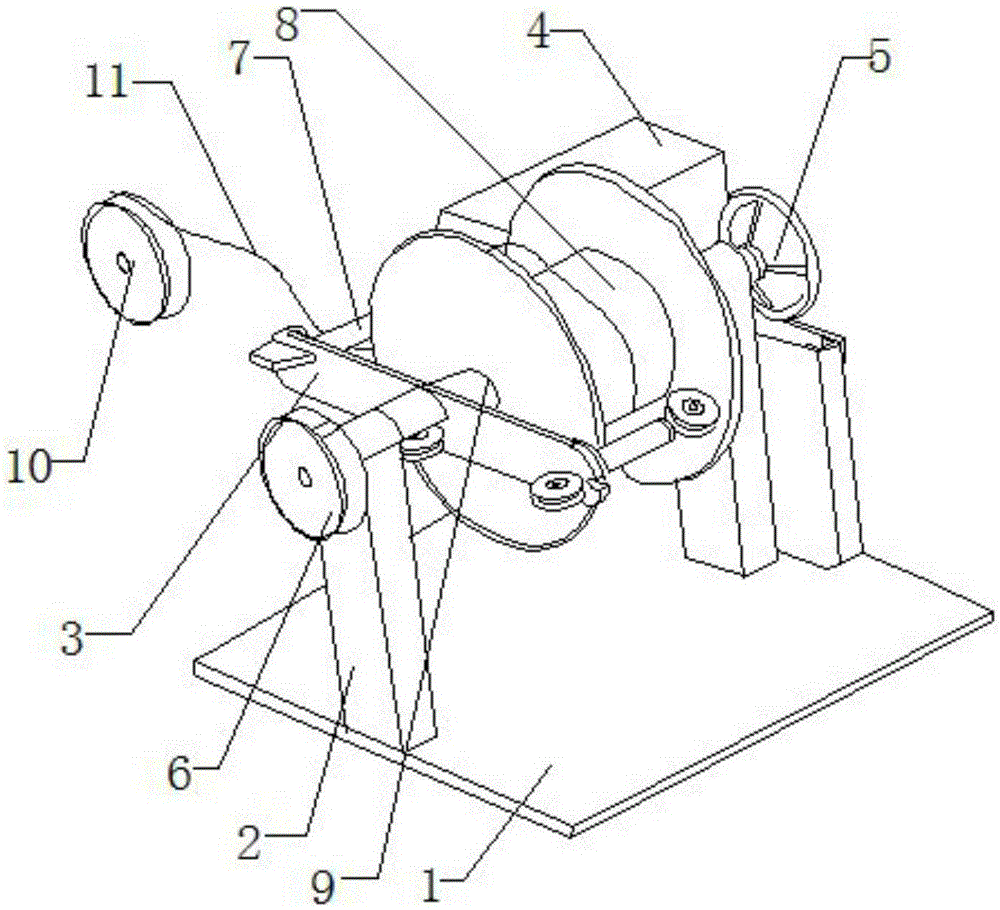

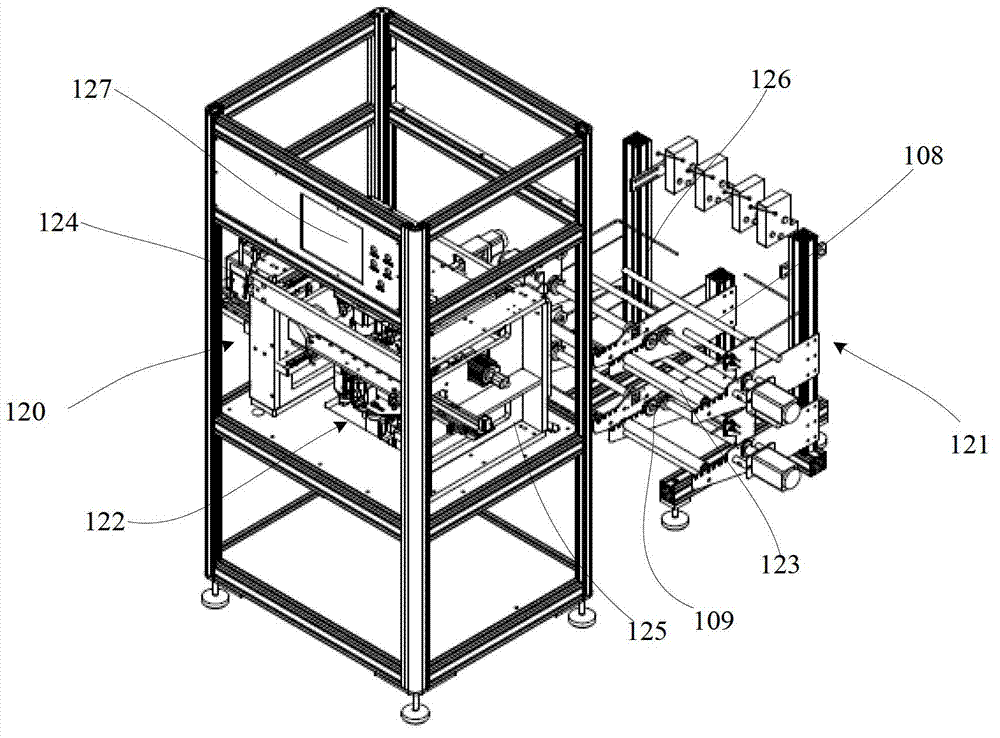

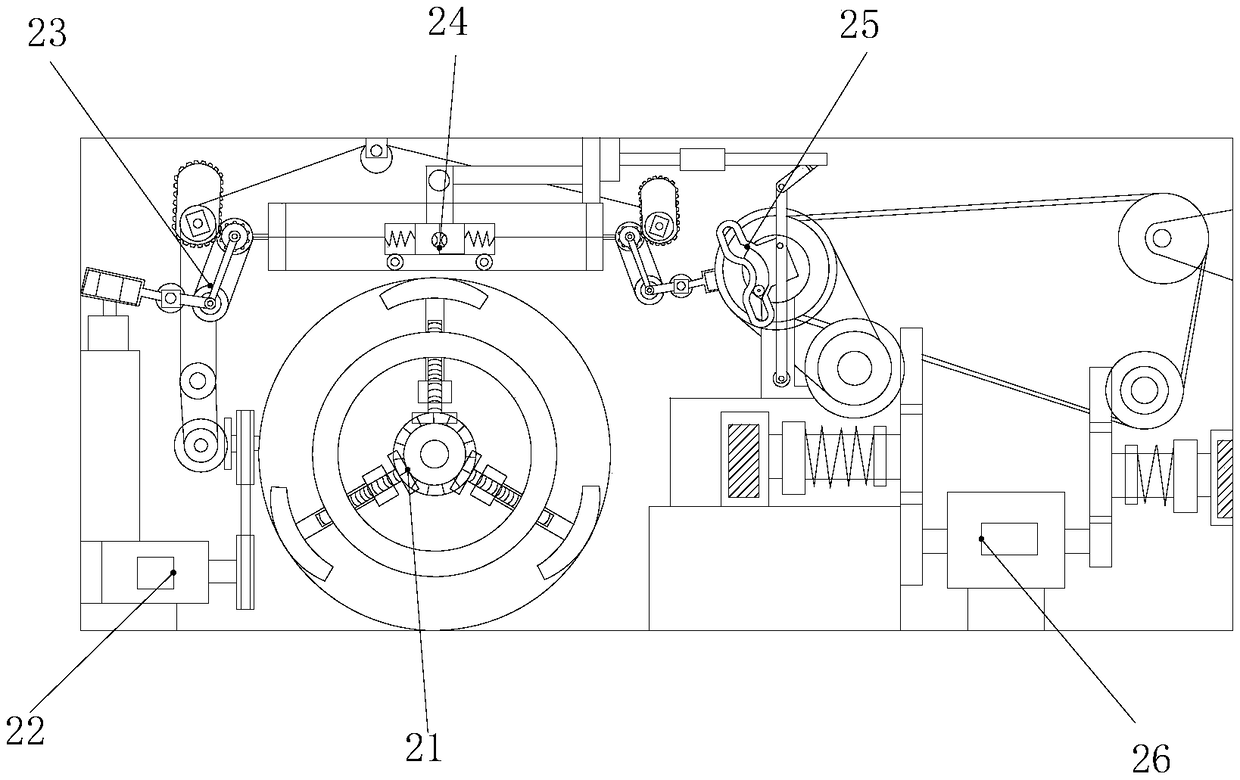

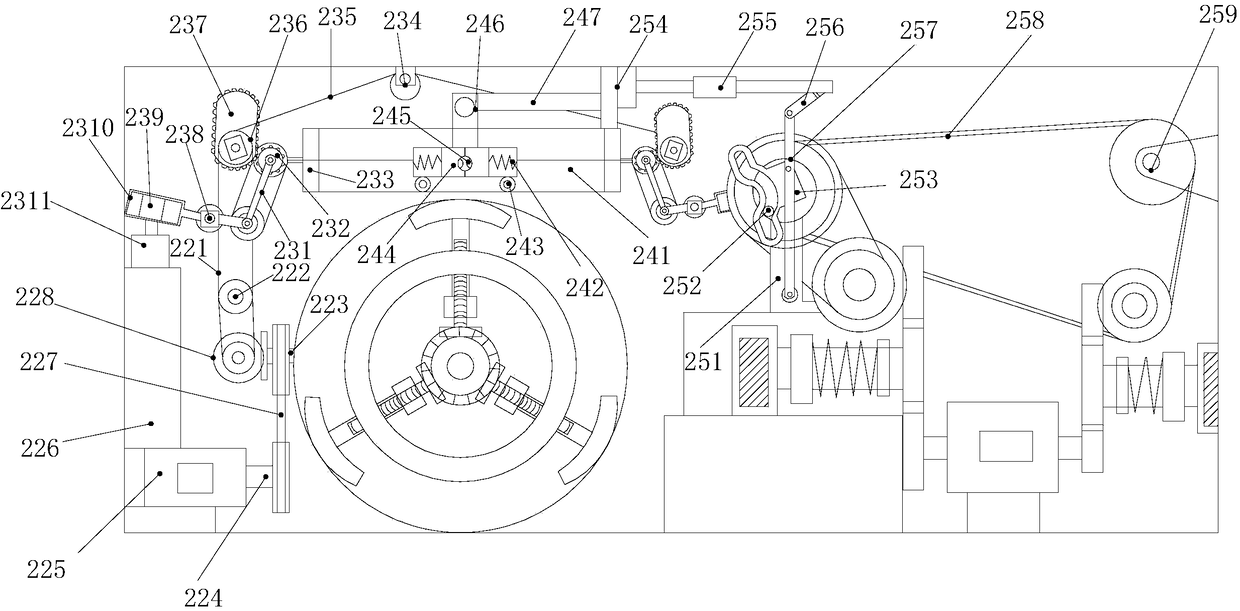

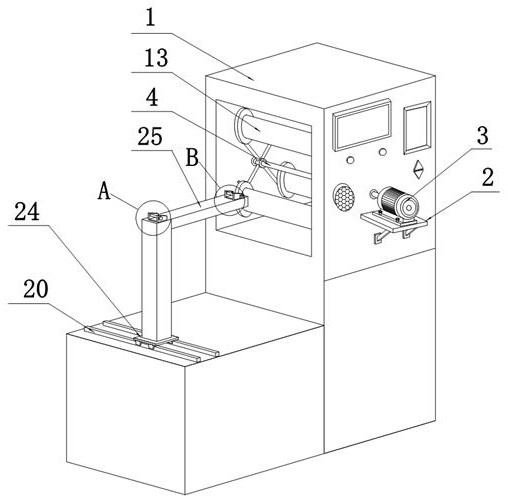

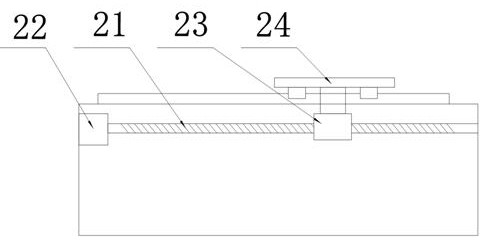

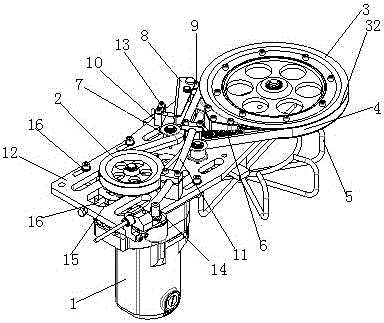

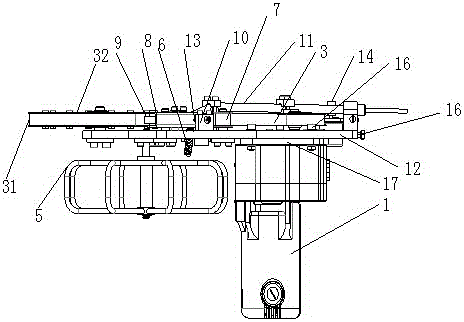

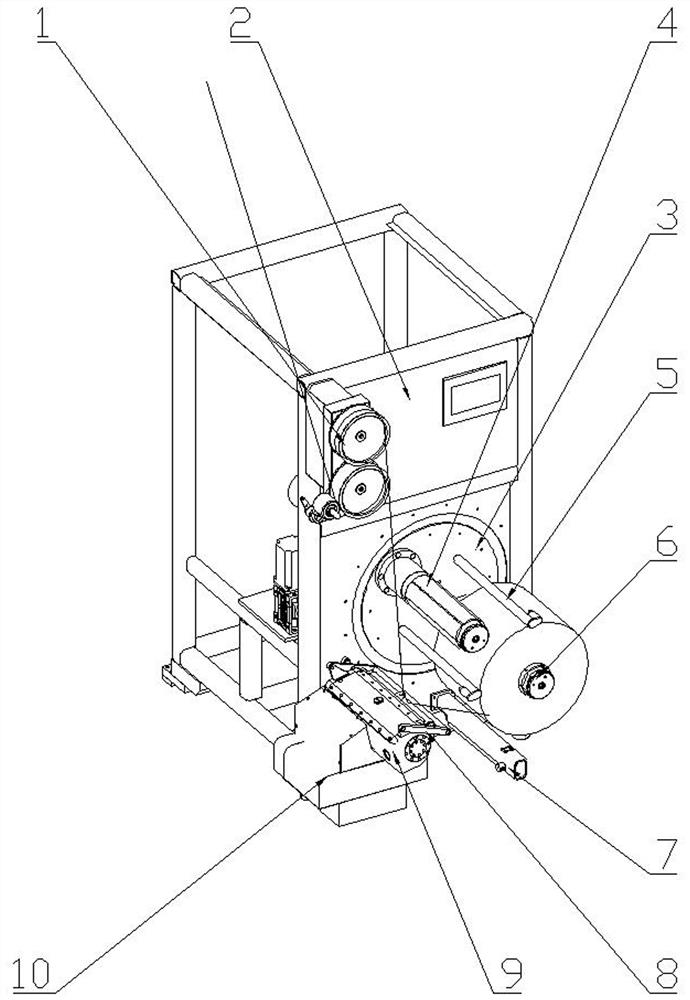

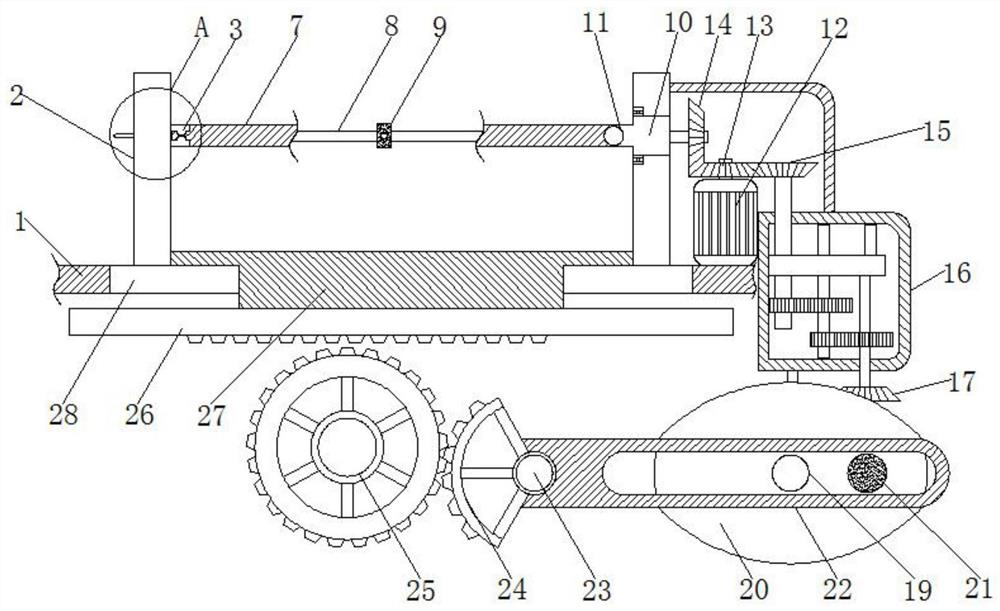

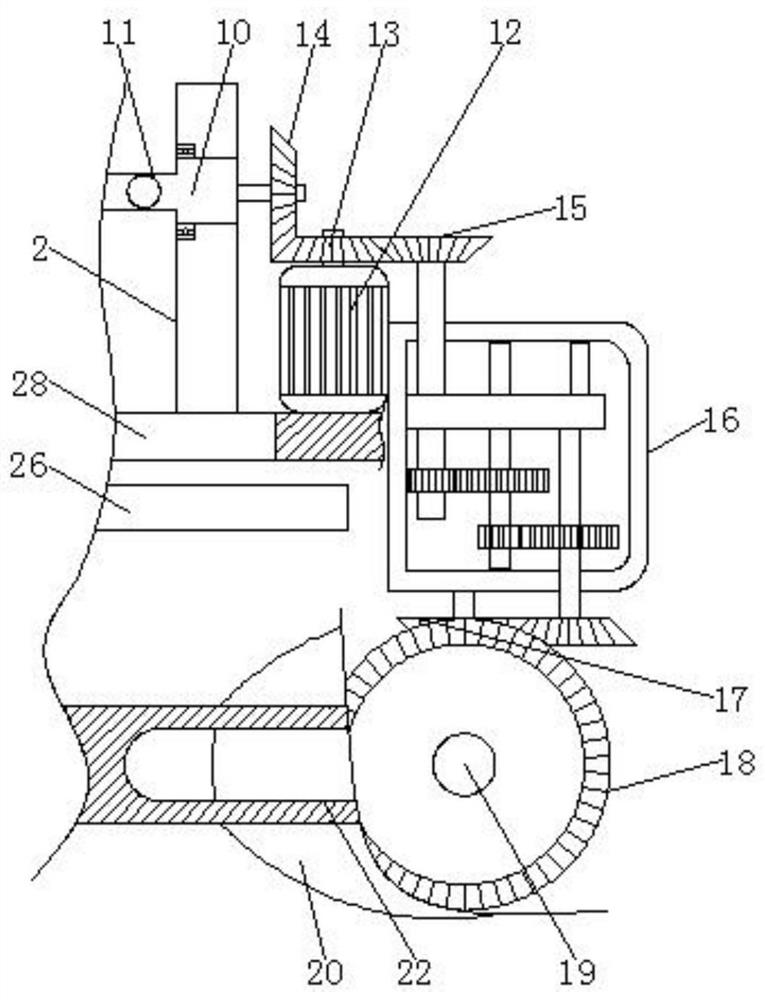

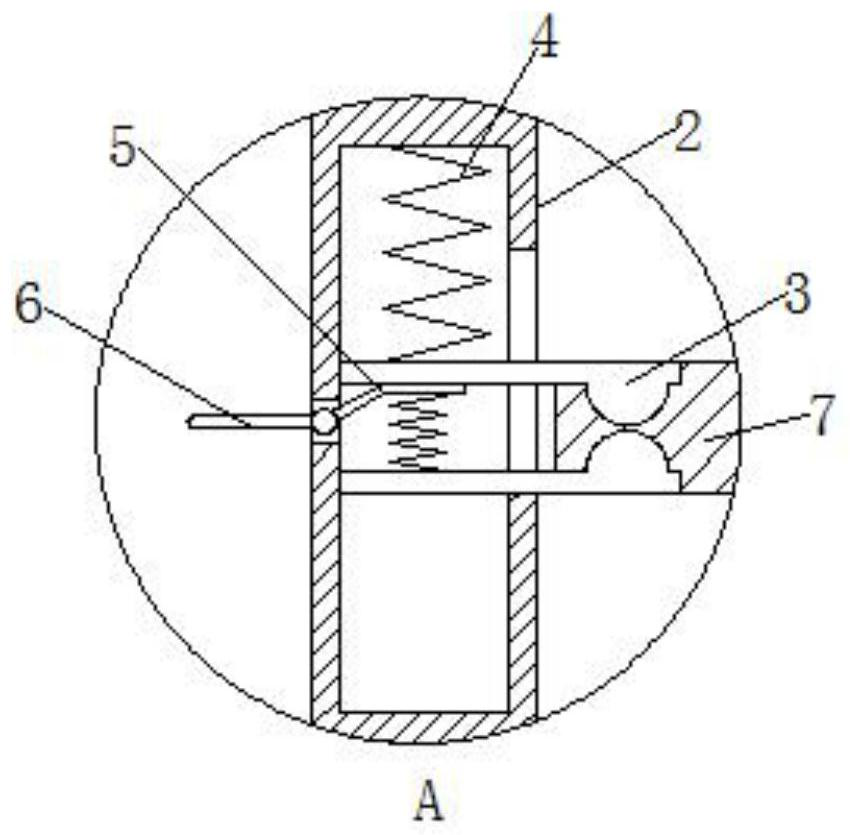

Suture winding machine and suture winding method

ActiveCN107265181ARealize automatic winding operationLow costFilament handlingWinding machineRotational axis

Owner:SHANDONG UNIV

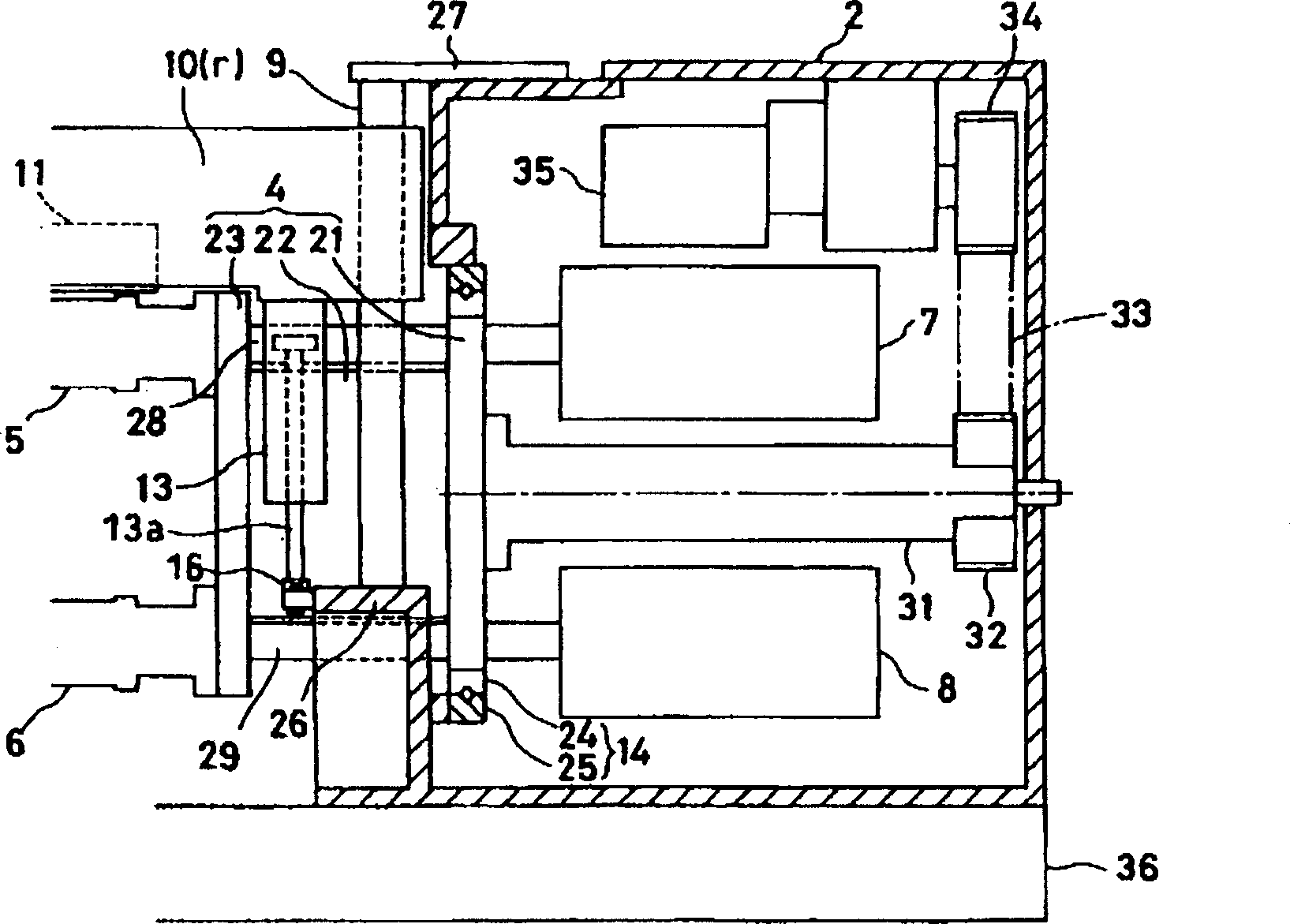

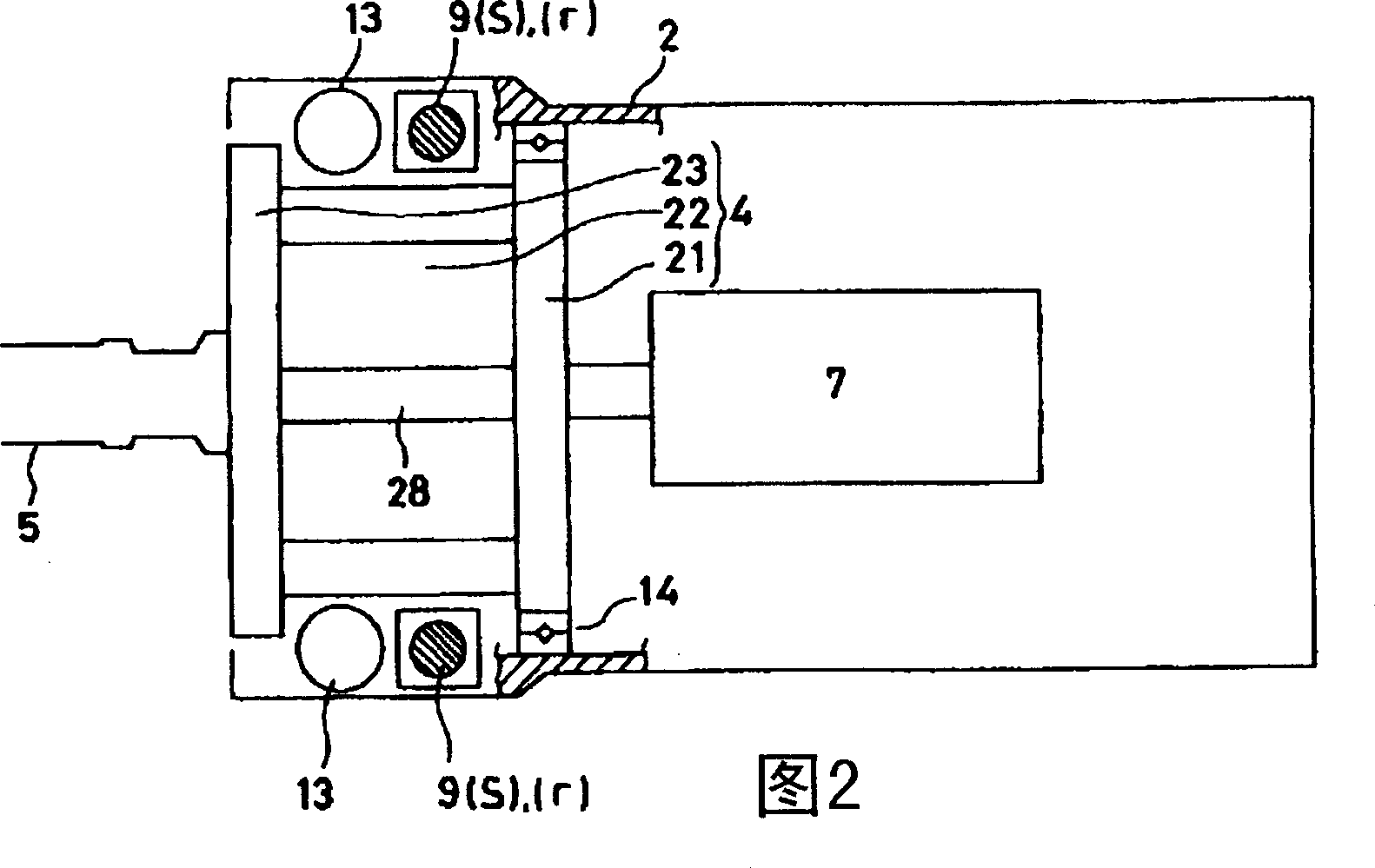

Spin winding machine

Owner:MURATA MASCH LTD

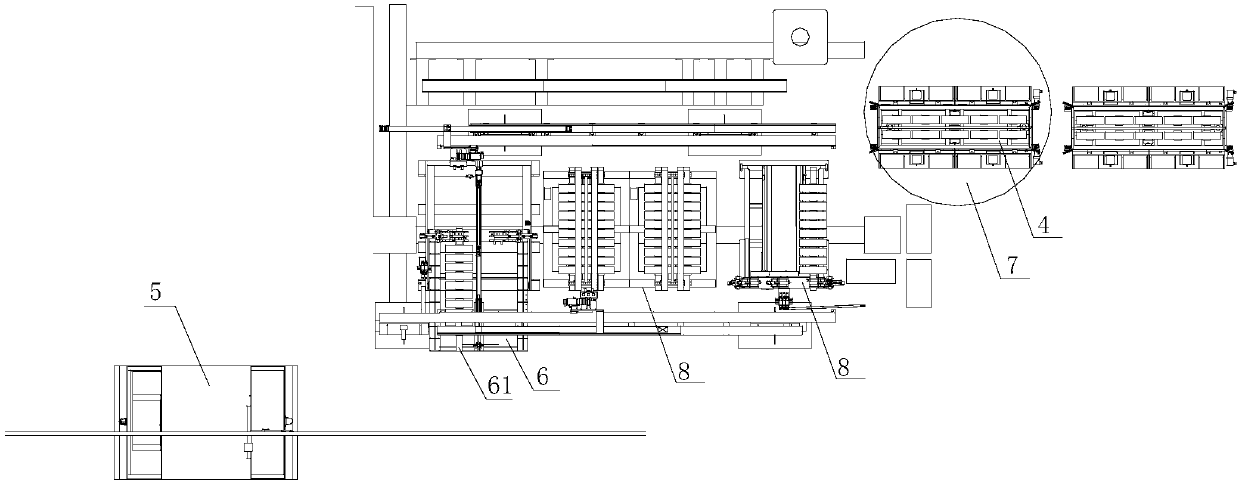

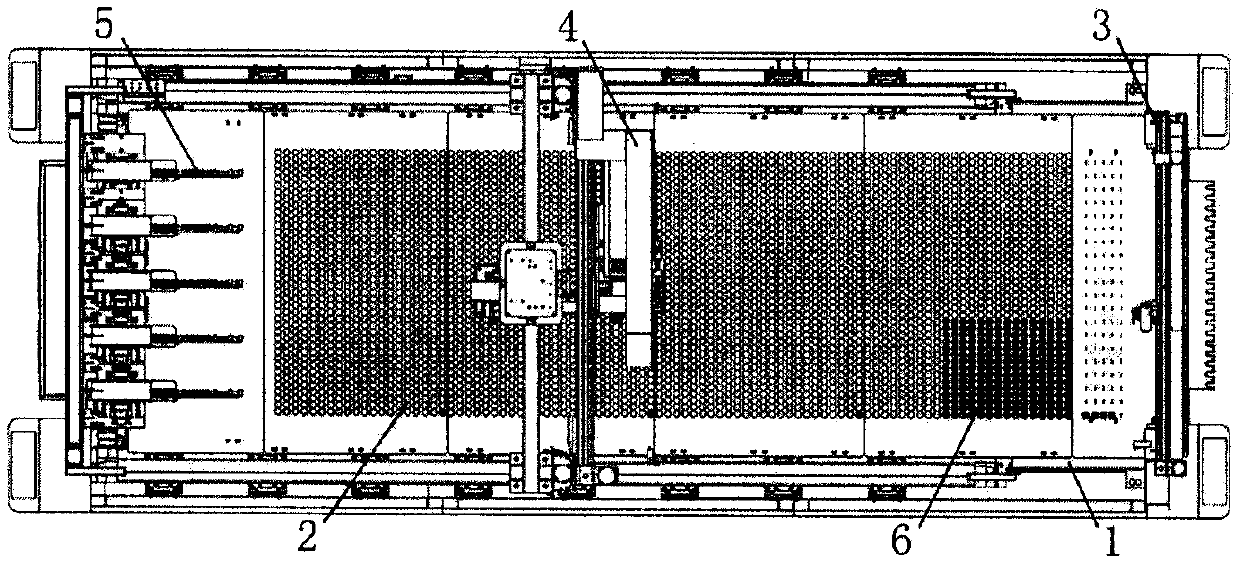

Doffing control system and automatic doffing control method

PendingCN107738957AImprove production efficiencyEasy to operateFilament handlingControl systemMechanical engineering

Owner:HANGZHOU RUIGUAN TECH

Winding balance device

Owner:ZHANGJIAGANG PANFENG TECH

Method and system for controlling cable drum

Owner:CHINA SHENHUA ENERGY CO LTD +1

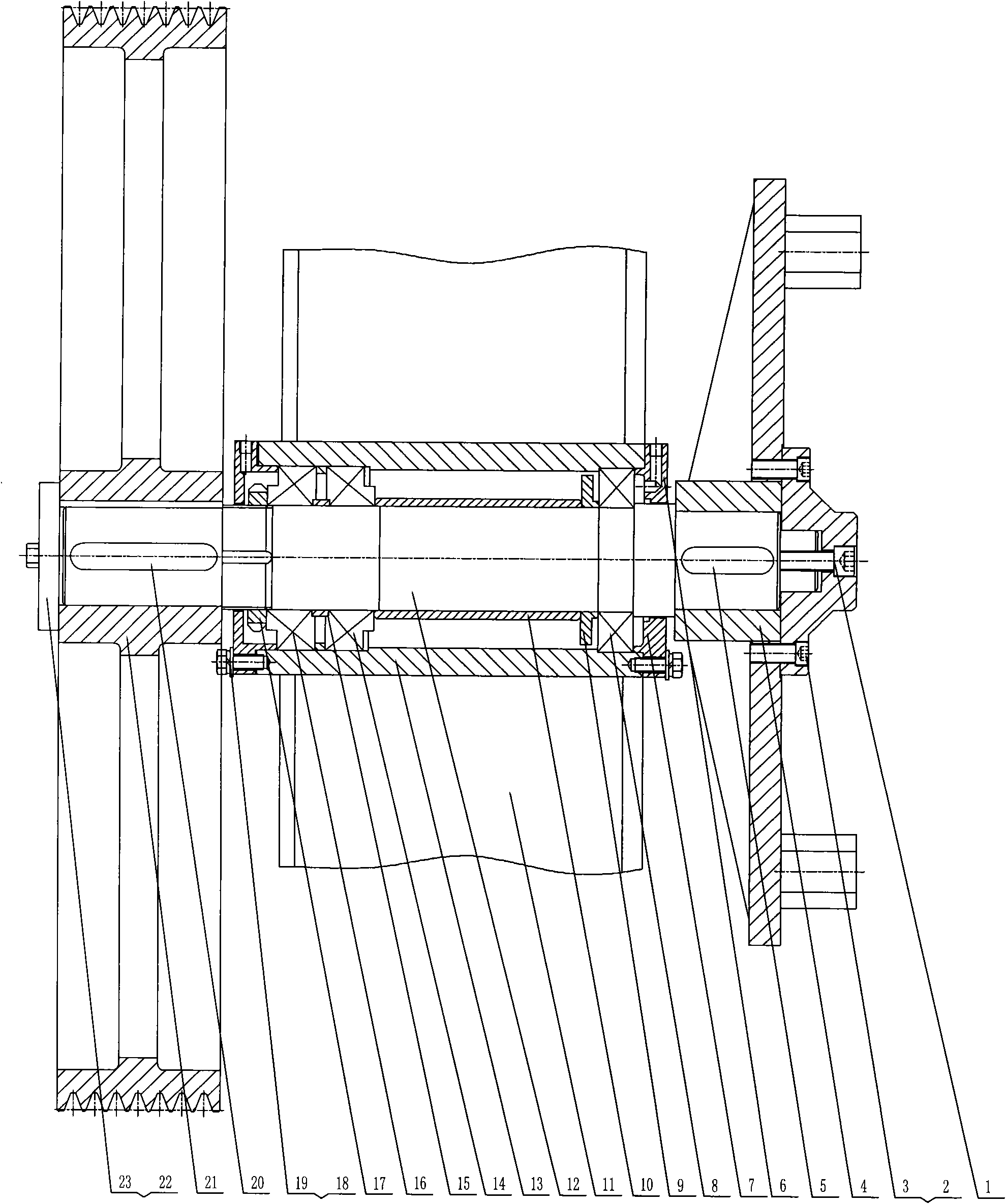

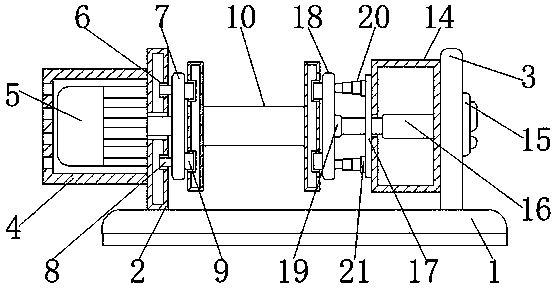

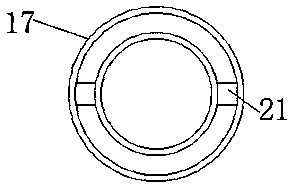

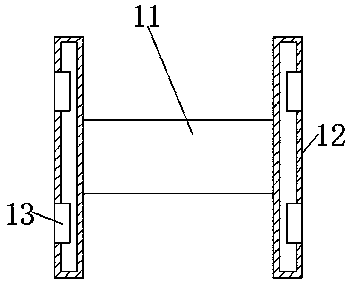

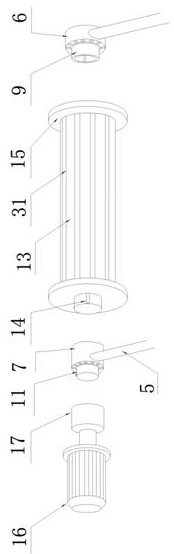

Main spindle part of spool wire-receiving machine

Owner:WUXI PINGSHENG SCI & TECH

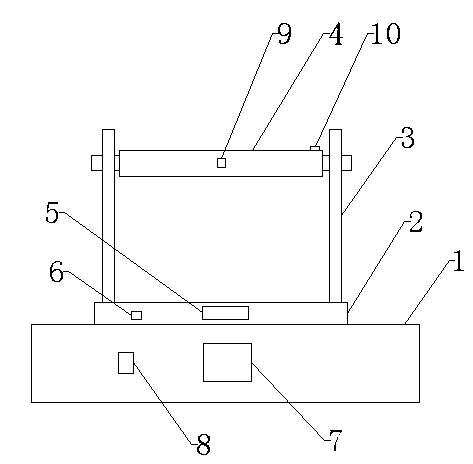

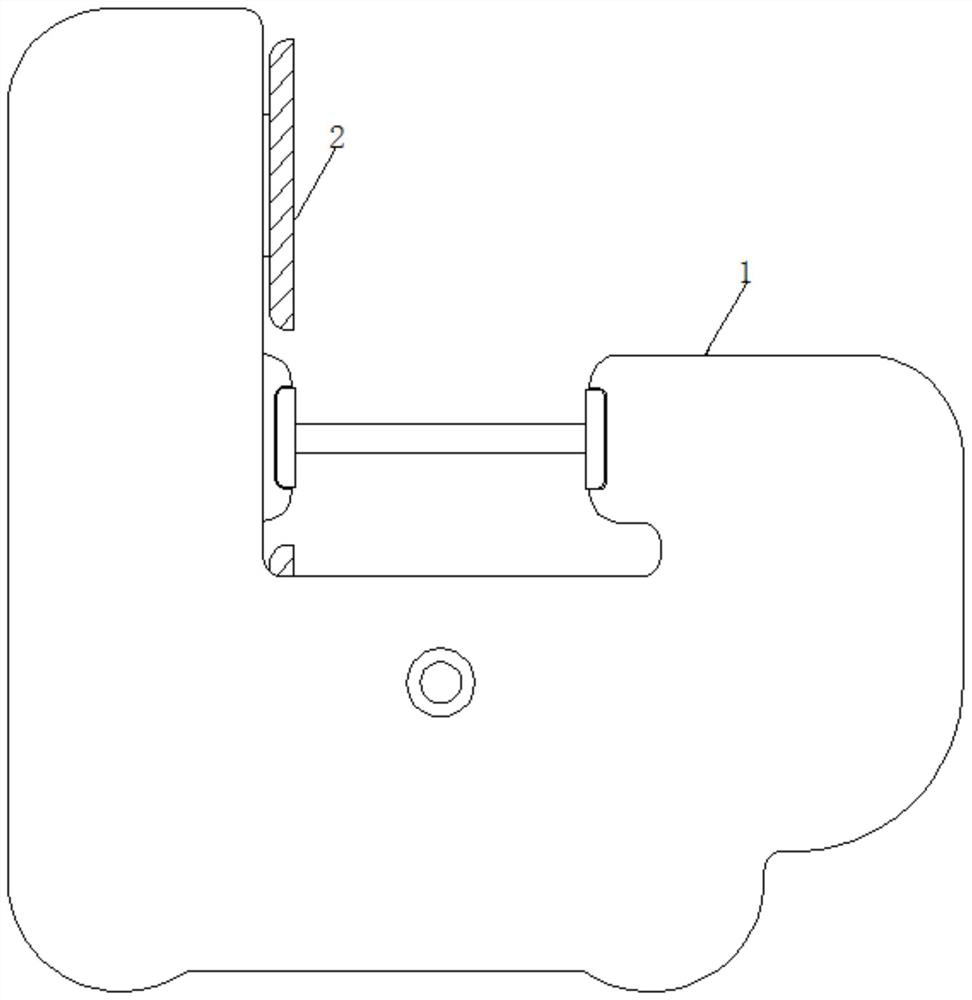

Pay-off rack with height conveniently adjusted for cable

InactiveCN111252617ASolve the inconvenience of height adjustmentEasy to adjustFilament handlingRotational axisElectric cables

Owner:桂林健威科技发展有限公司

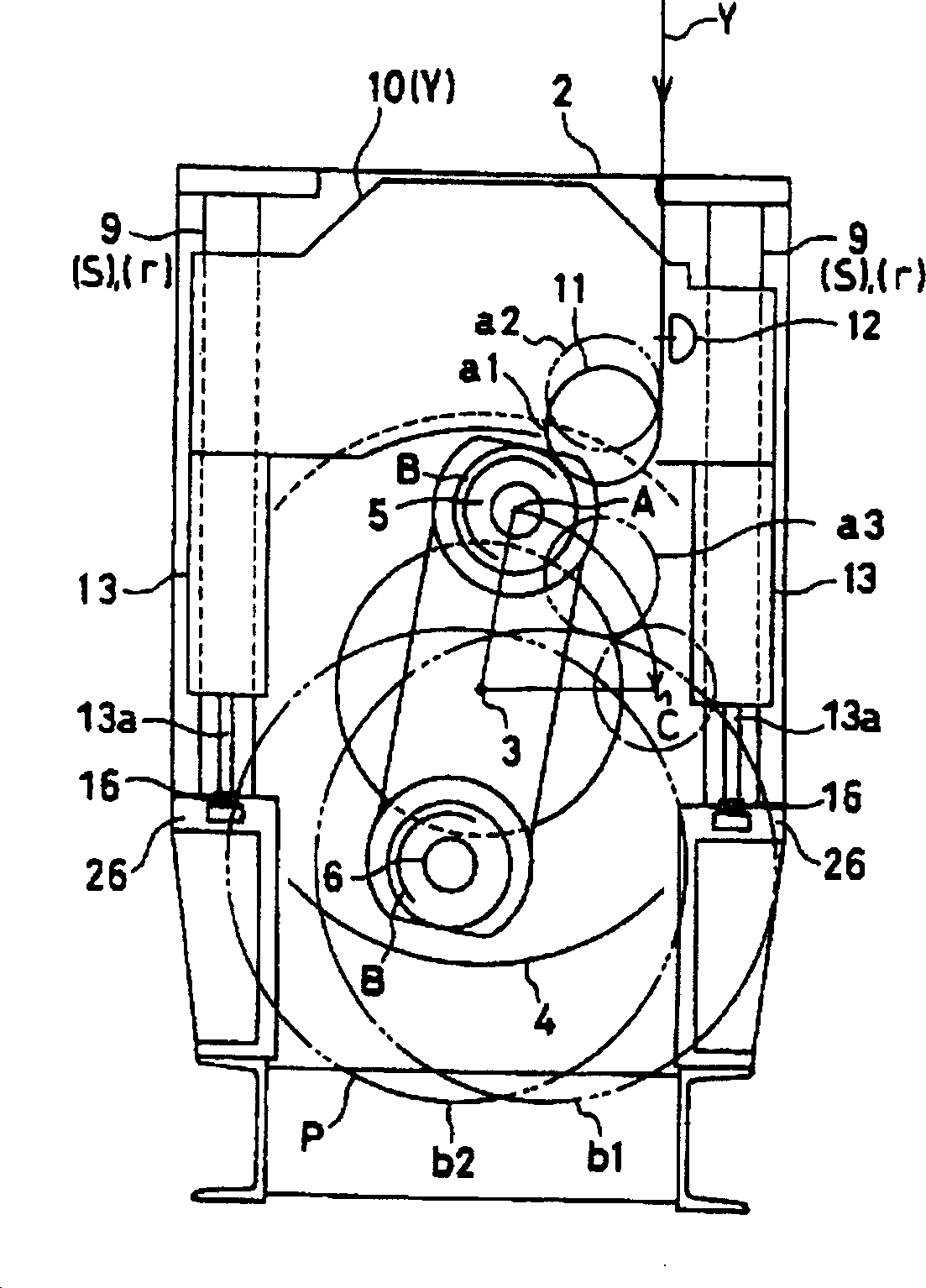

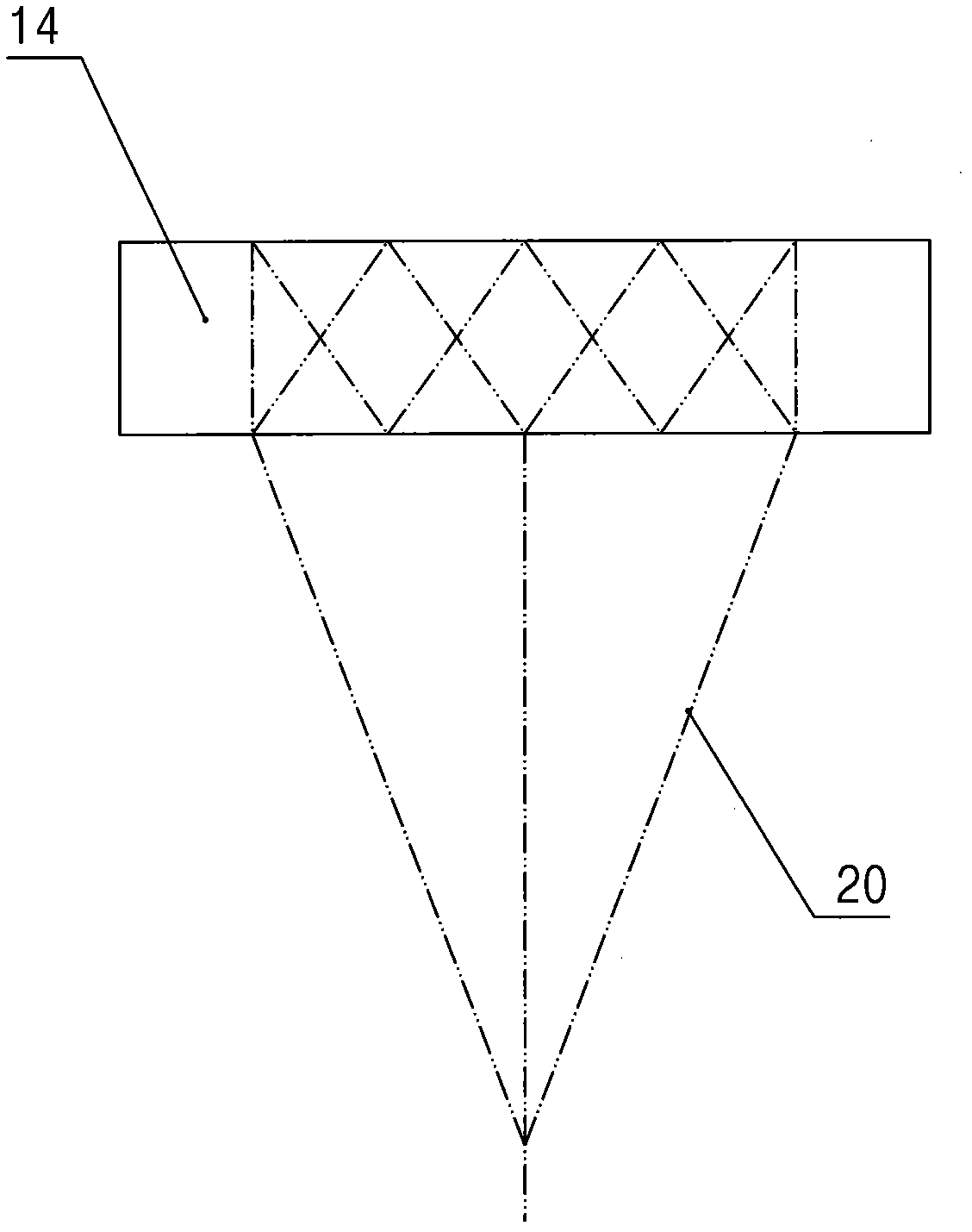

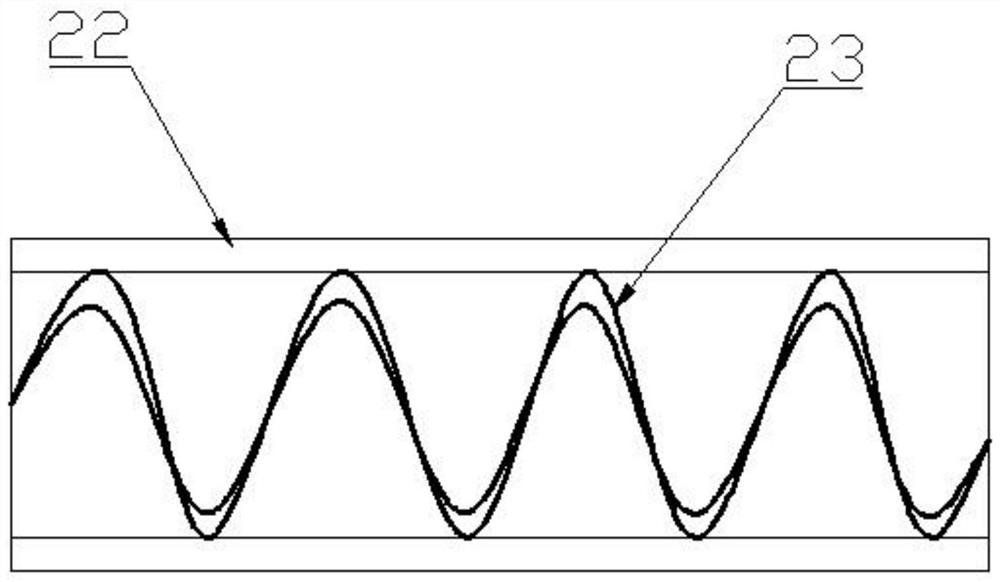

Method for manufacturing cross winding bobbin

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

Yarn separating mechanism for yarn separating machine

Owner:常熟市荣伟纺织有限公司

Automatic yarn winder

Owner:WUJIANG JIAYUN TEXTILE FINISHING

Intelligent wire harness machine

PendingCN111362050ARealize full automationSolve the cumbersome operationFilament handlingApparatus for removing/armouring cablesMechanical engineeringReliability engineering

Owner:北京风折科技有限公司

Winding device having automatic winding function and used for cable production

Owner:湖南新耒传导材料科技有限公司

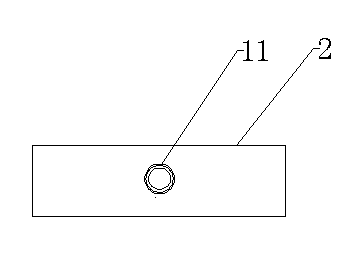

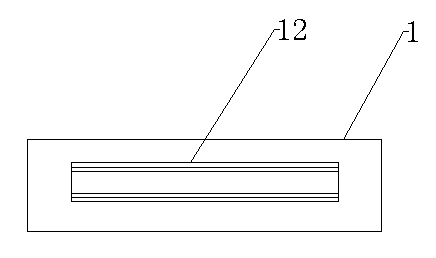

Unreeling device special for embedded silk thread

ActiveCN101531297ATroubleshoot specific issues with unwindingSimple structureFilament handlingEngineeringScrew thread

Owner:山东如意毛纺服装集团股份有限公司 +1

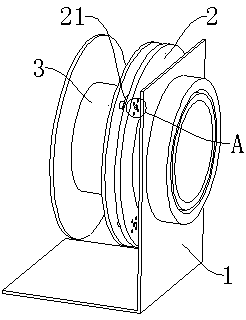

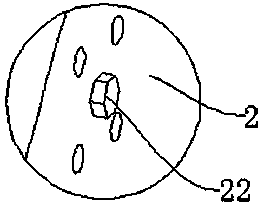

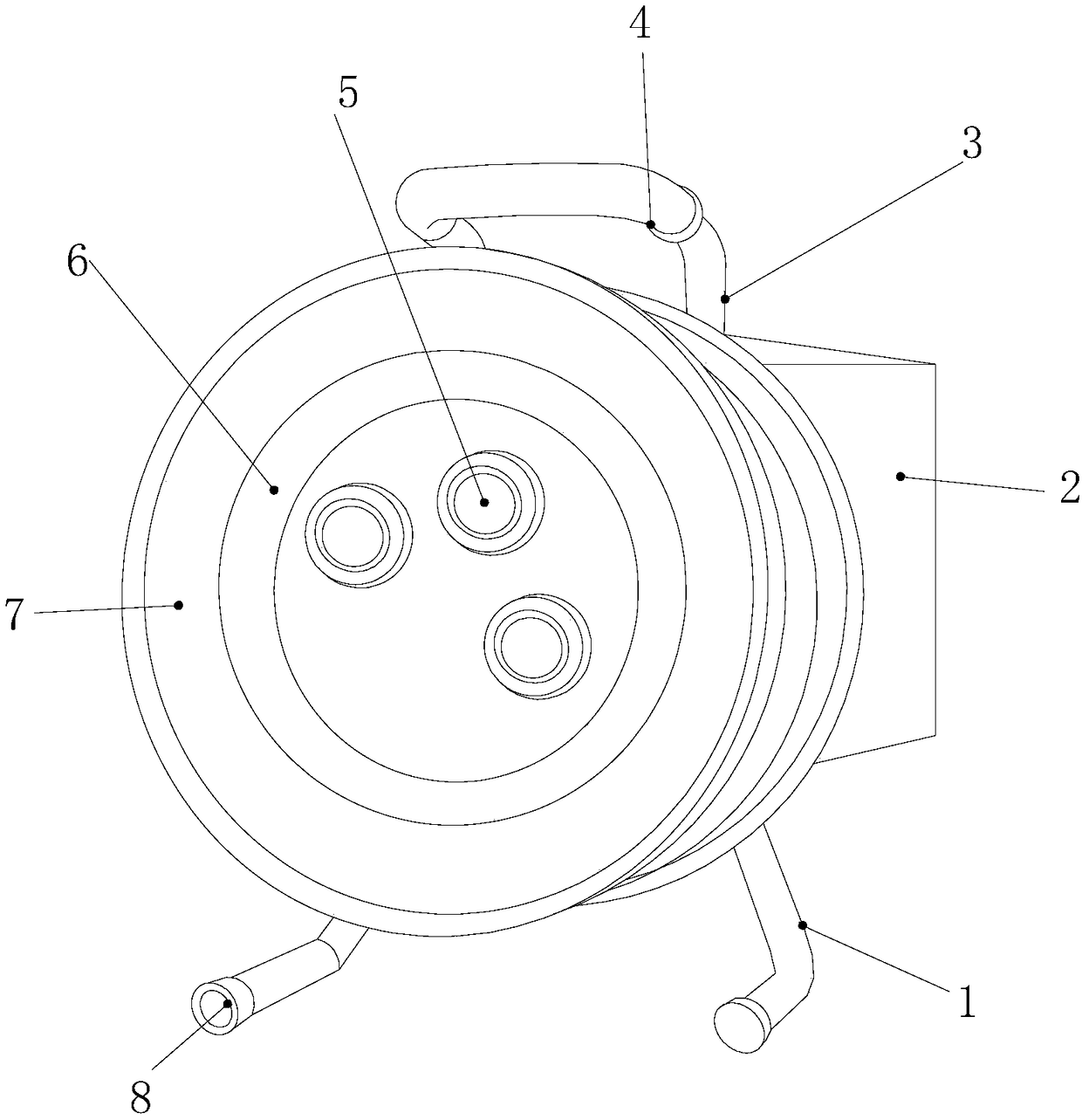

Pay-off reel supporting structure

Owner:泰州市犇源商贸有限公司

Textile machinery wire anti-winding protection device

Owner:江苏汤氏纺机集团有限公司

Double-shaft winding mechanism

Owner:SHIN YUAN ELECTRONICS PROD KUNSHAN

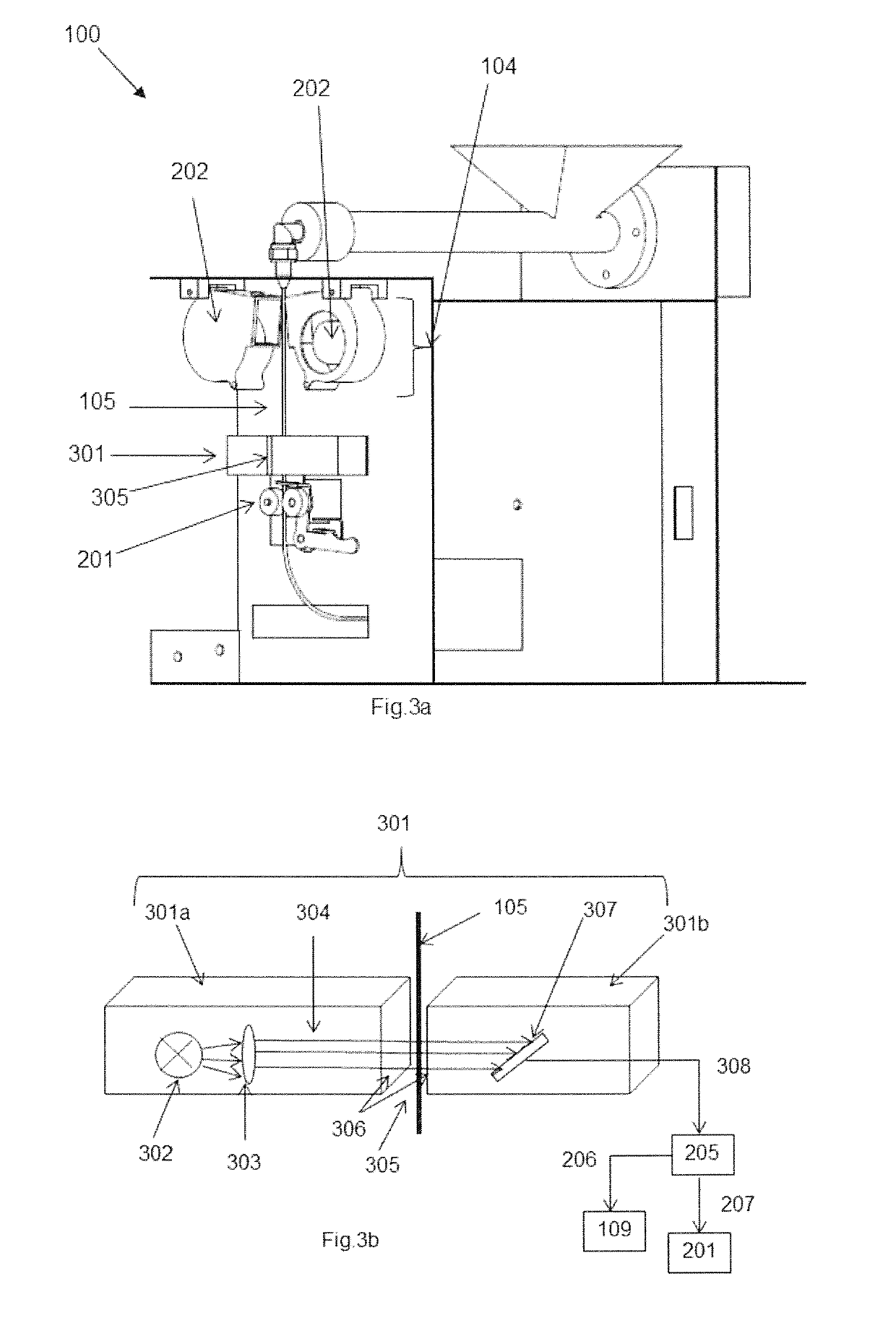

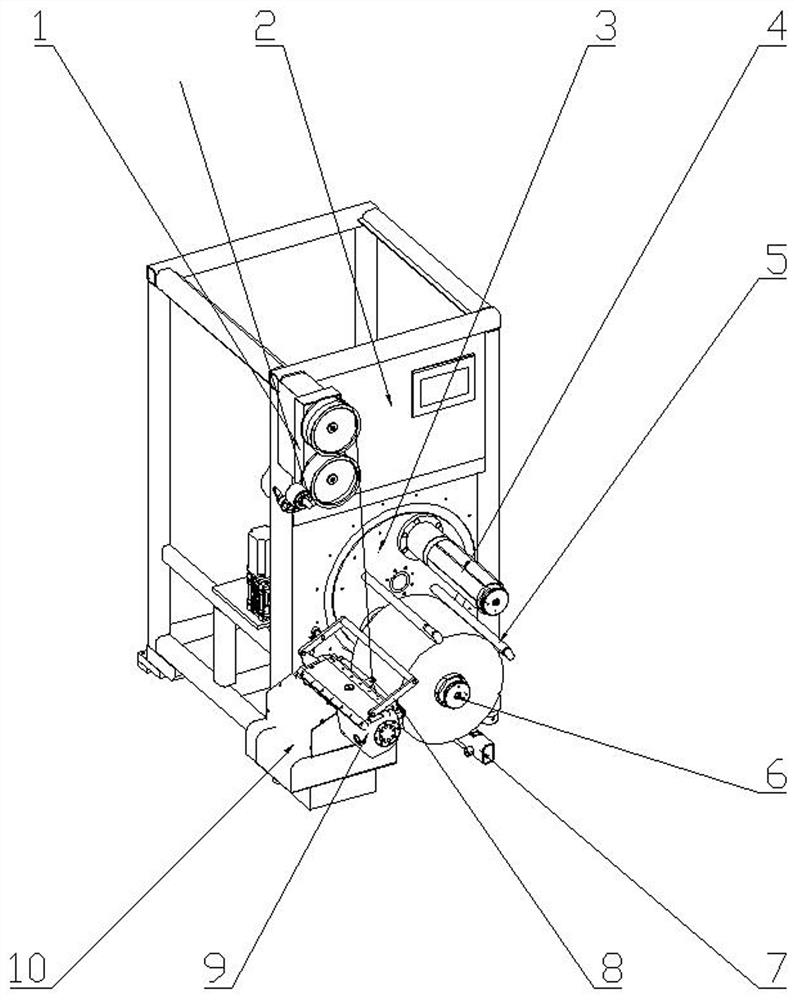

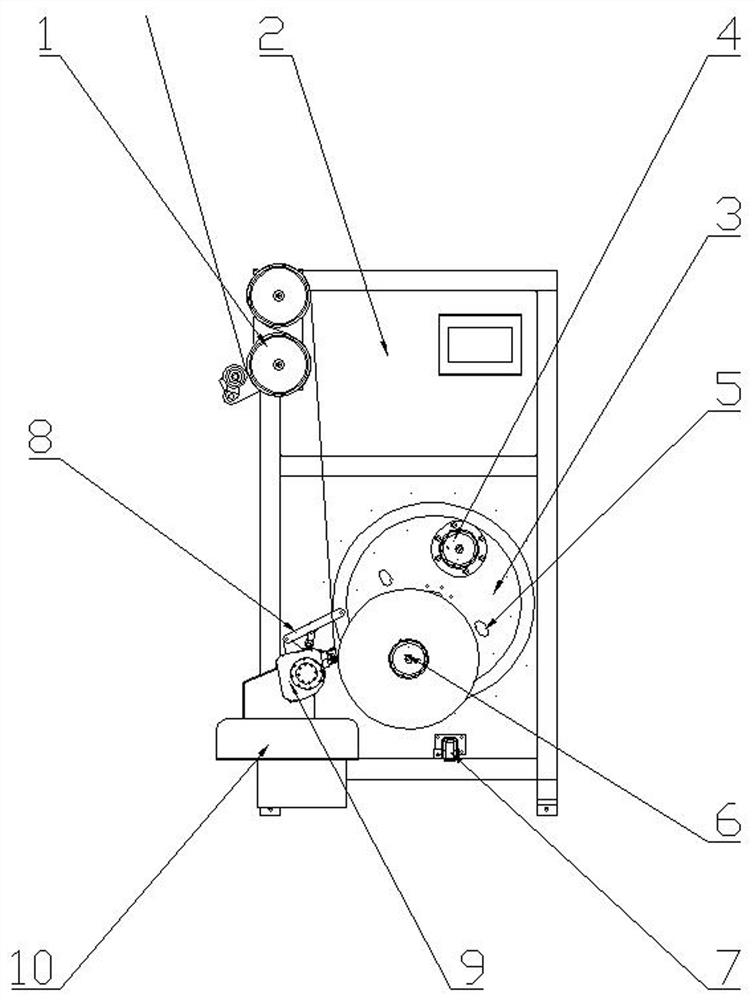

Fused Deposition Modeling Filament Production Apparatus

Owner:3DEVO BV

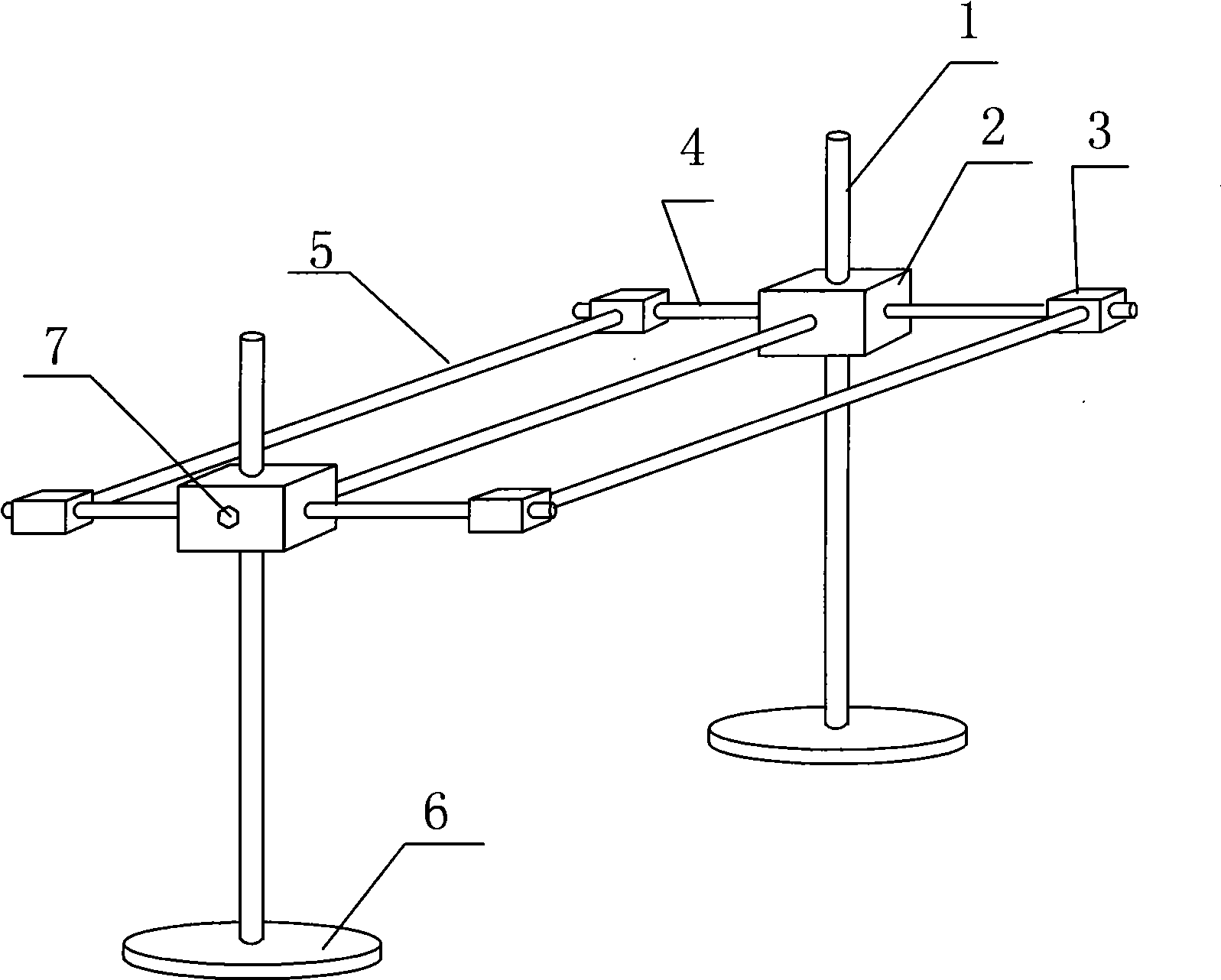

Auxiliary tool for making binding wire

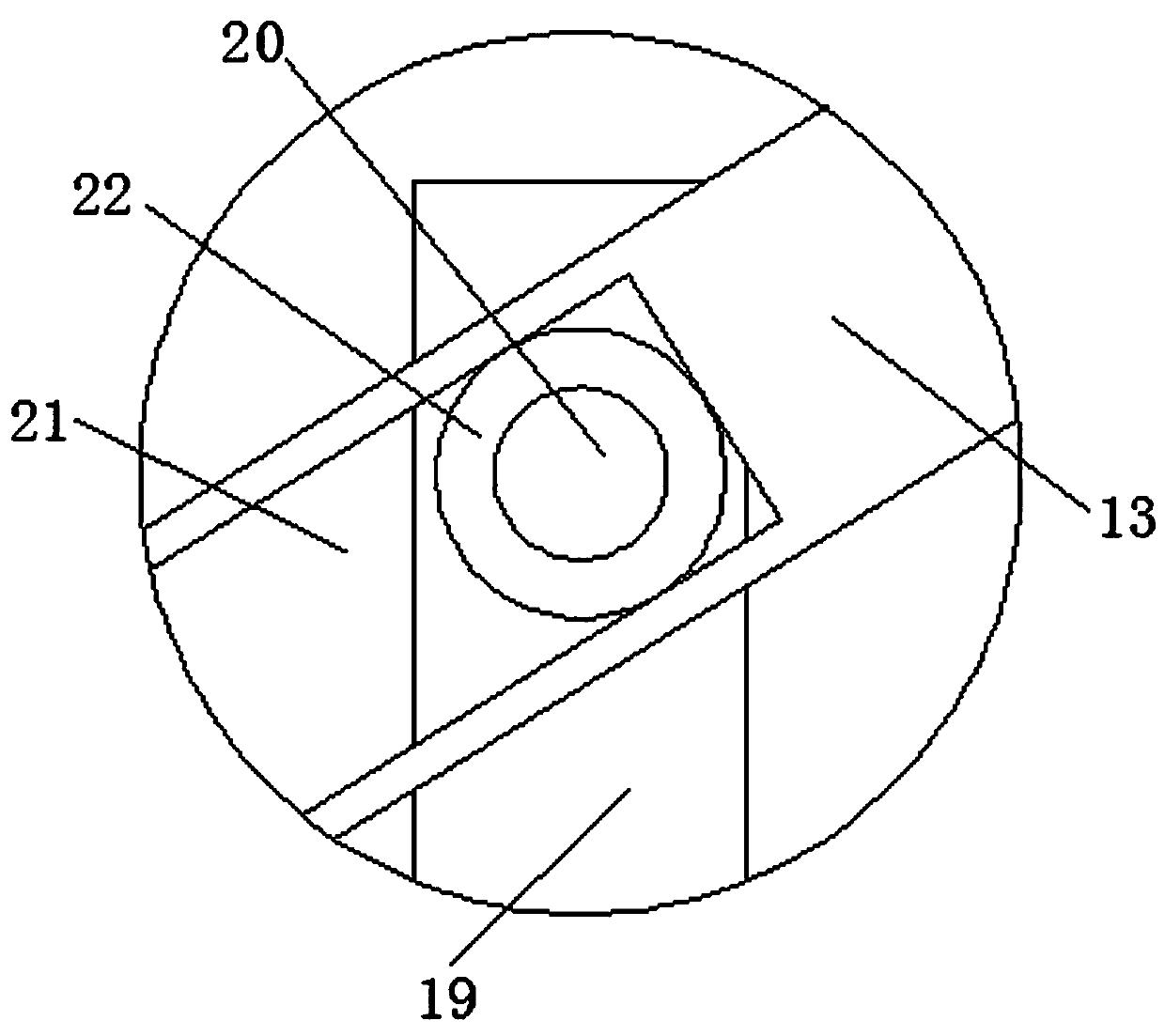

The invention relates to an auxiliary tool for making a binding wire, and belongs to the technical field of electric power circuit operation and maintenance. The auxiliary tool comprises a base, and a limiting plate is fixed to the base. The upper end of the limiting plate is connected with a wire winding bar through a rotating shaft. A wire through hole is formed in the wire winding bar. The wire through hole is connected with a set of wire outlets. The base is provided with a movable sliding rail. The movable sliding rail is provided with a supporting bar. A bracket used for supporting a stay wire is arranged at the top end of the supporting bar. A clamping groove is formed in the upper portion of the limiting plate, and the clamping groove is located above the bracket. The rotating shaft is provided with a motor, and the motor is provided with a counter. A wire coil fixing base is arranged on one side of the base, and a binding wire coil is installed on the wire coil fixing base. The auxiliary tool has the advantages that the binding wire can be wound automatically and adjusted according to the thickness of the stay wire, and reliable binding and accurate winding of the wire can be guaranteed.

Owner:YANGXIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Convenient-rectifying winding device for producing zippers

Owner:四会市世经拉链制品有限公司

Cable take-up and pay-off device for communication engineering

Owner:安徽莱特实业集团有限公司

A fully automatic needle threader

ActiveCN104767147BNot easy to slipNot easy to knotFilament handlingCable installation apparatusEngineeringFully automatic

Owner:谢位强

Automatic creeling winder and control method thereof

Owner:杭州天启机械有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap