A fully automatic needle threader

A threader, fully automatic technology, applied in the direction of cable installation devices, electrical components, and conveying filamentous materials, etc., can solve the problems of poor threading effect, easy knotting and slipping of outgoing lines, etc., so as to achieve easy knotting and low cost Inexpensive, non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

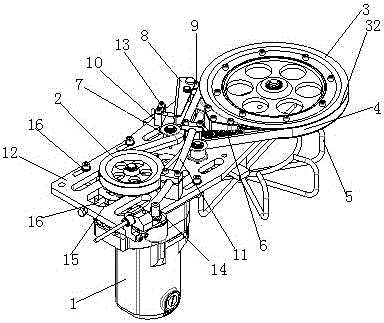

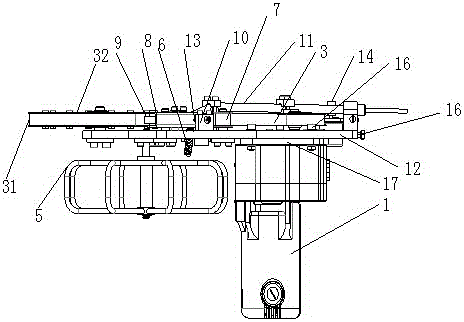

[0027] Such as Figure 1~2 As shown, a fully automatic threader includes a fixed plate 12, a motor 1, a synchronous pulley 3, and an adjustment mechanism; a motor is provided below the middle end of the fixed plate, and a motor plate 17 is provided on the motor. An adjustment plate 16 is fixed on the plate, and an adjustment plate hole is arranged on the fixing plate, and the adjustment plate can fit into the adjustment plate hole completely. A through hole is provided in the middle of the adjusting plate. The fixing plate and the adjusting plate are jointly provided with an adjusting channel, one end of the adjusting channel is located at the front side of the fixing plate, and the other end is adjacent to the through hole. The adjusting channel is provided with an adjusting member 16, the motor plate is provided with a through hole, the fixing plate is provided with a through hole corresponding to the through hole on the motor plate, and the adjusting member is penetrated in th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap