Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Avoid breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

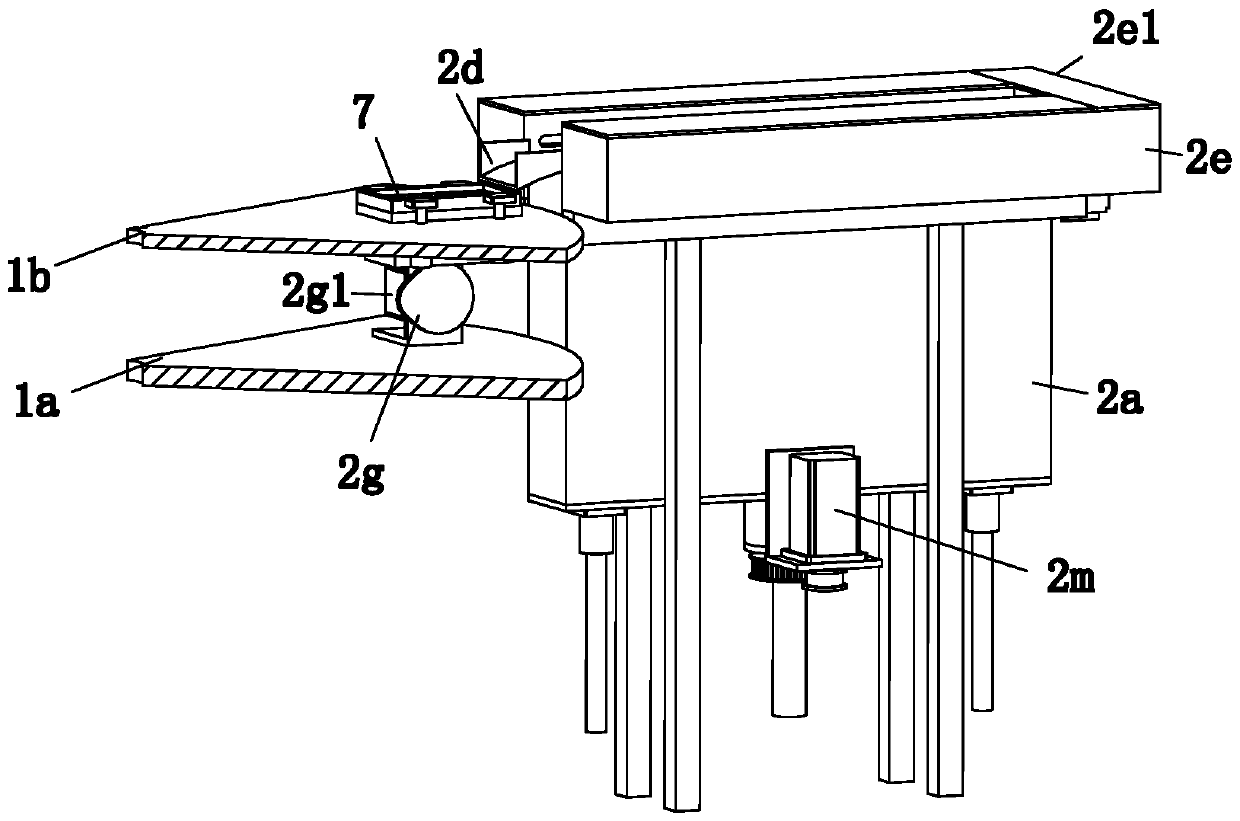

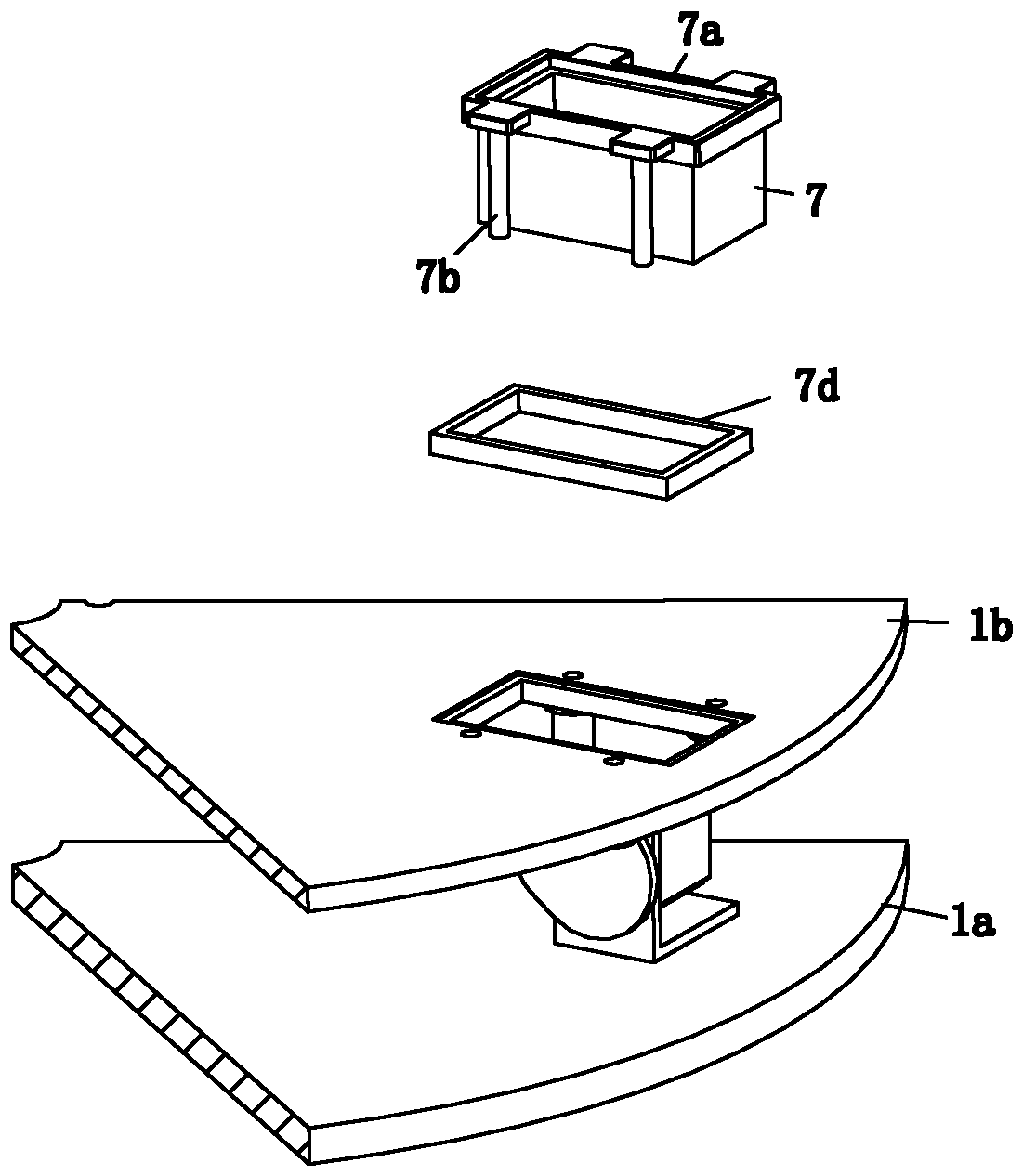

Intelligent control ground sweeping device

InactiveCN108742326AEffective protectionAvoid breakingCarpet cleanersFloor cleanersTerrainEngineering

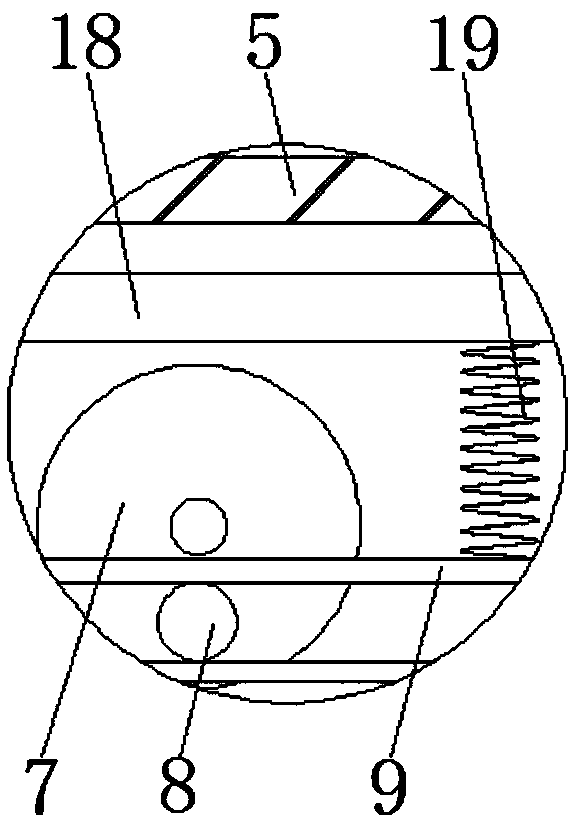

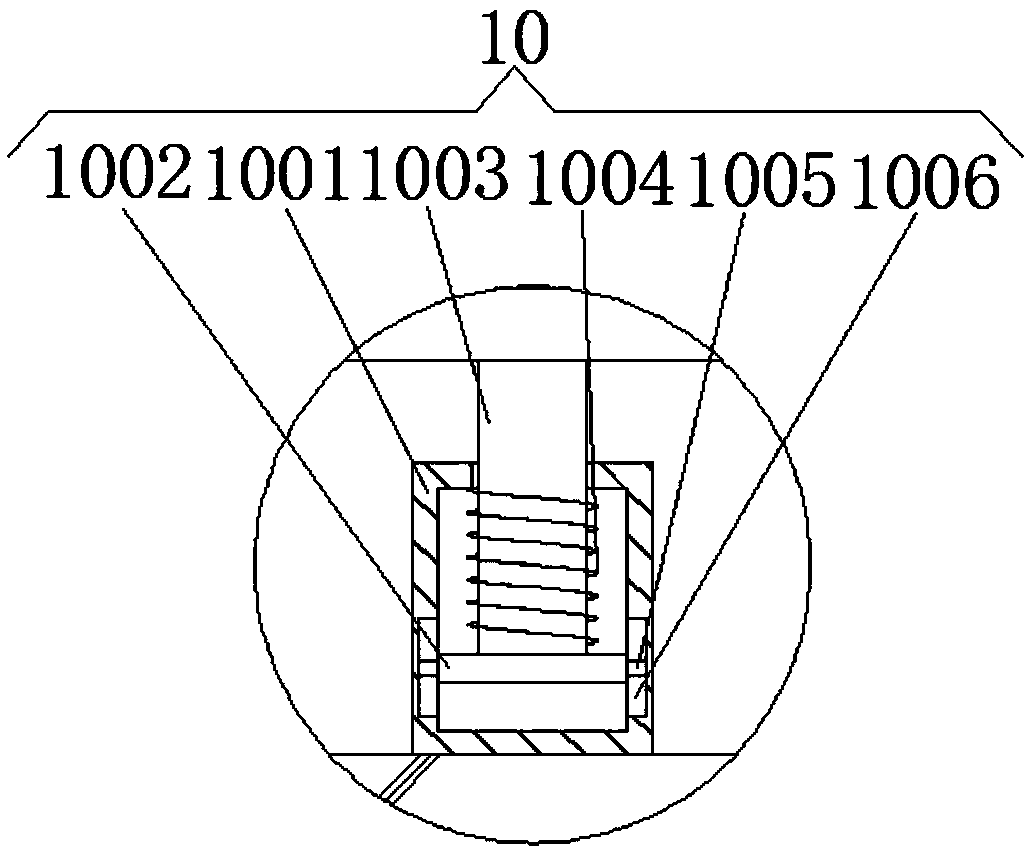

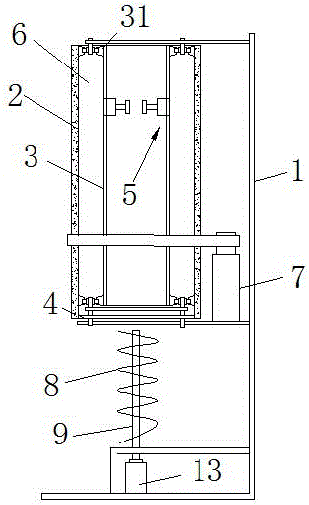

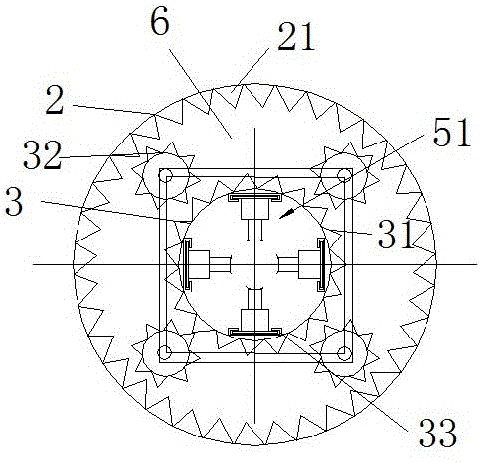

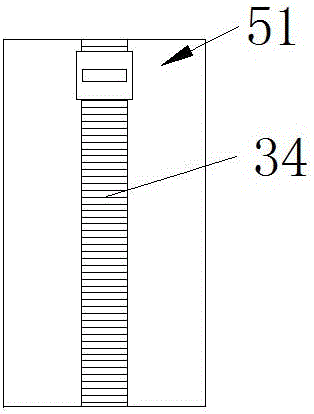

The invention discloses an intelligent control ground sweeping device. The intelligent control ground sweeping device comprises a sweeper body and a dust collection port, a spring structure is arranged on a fixed rod of a sweeping edge brush, the spring structure can contract according to the pressure borne by the edge brush when the sweeping terrain is changed, a passing path can be cleaned up inthe process of contraction, the edge brush can be effectively protected and is prevented from being stuck or breaking off, thereby prolonging the service life of a sweeper; the outer portion of a shell is provided with a layer of rubber protective pads, the rubber protective pads can exert a certain buffer function on the device when the device collides, thereby preventing inner precise elementsfrom being damaged and also preventing the shell from being scraped to leave traces and affect the appearance, the protective pads may be deformed or be broken somewhere due to frequent collisions after long-term use, a certain piece of the protective pads can be replaced, and the protective pad can be fixed by inserting a connecting head into a sliding groove, and four protective pads are arranged and can be replaced separately.

Owner:FOSHAN MOCHEN INTELLIGENT TECH CO LTD

Anti-collision access control gate

InactiveCN107119598AImprove securityAvoid accidental injuryTraffic signalsRoad signsEngineeringAccess control

Owner:陈云蕾

Low-density foaming cement and preparation method thereof

The invention discloses a low-density foaming cement, which comprises the following components in parts by weight: 60 to 120 parts of cement, 0.3 to 1.0 part of coagulant, 0.4 to 1.0 part of foam stabilizer, 0.5 to 1.2 parts of water reducer, 9 to 14 parts of foaming agent, 0.2 to 0.5 part of fiber, and 25 to 50 parts of water. The invention also discloses a preparation method of the low-density foaming cement. The low-density foaming cement is prepared through the following steps: evenly stirring dry powder, adding water to prepare cement slurry, adding a foaming agent under rapid stirring, casting to mould, and carrying out natural maintenance; and has the advantages of low dry density and low thermal conduction coefficient.

Owner:GUANGDONG JIANKE CONSTR CONSULTING CO LTD

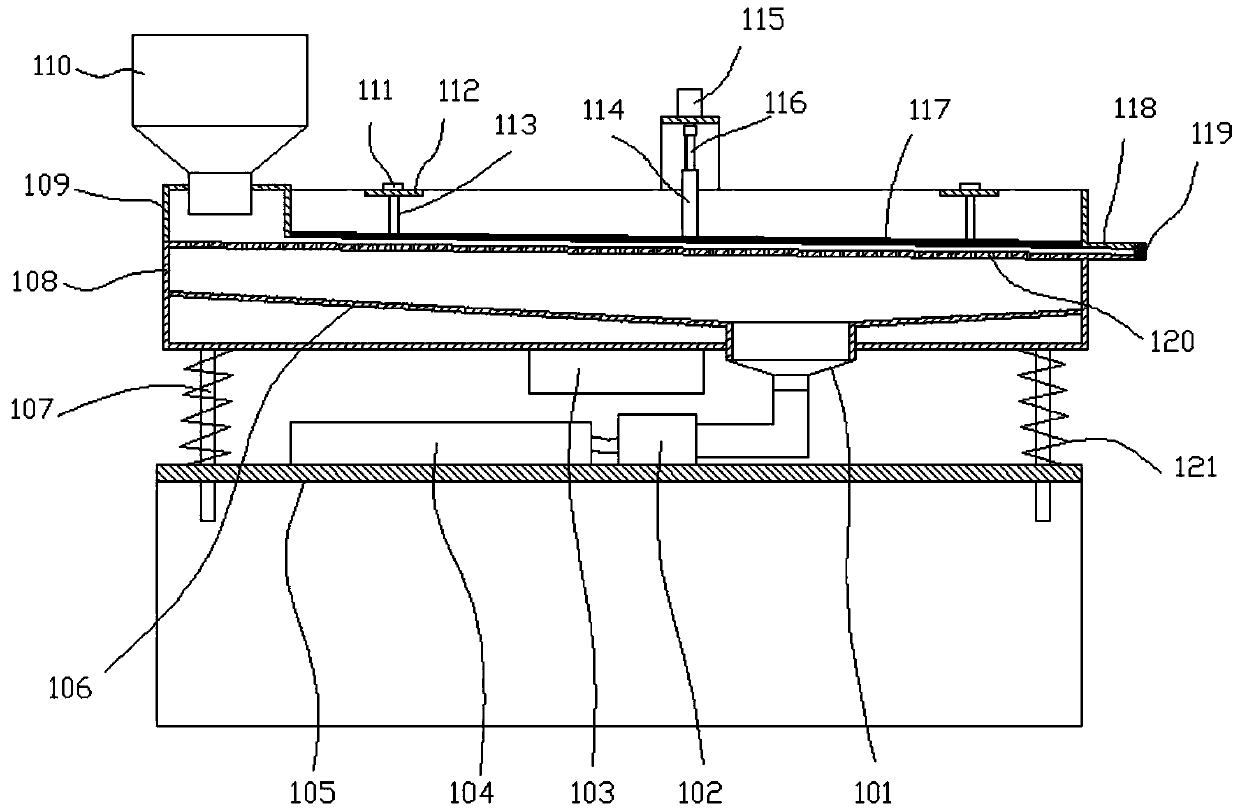

Feeding equipment of brick tea semi-automatic production device

Owner:湖南腾森生态农业开发股份有限公司

Impurity removal device and method for tea leaf processing

ActiveCN109570011AMaintain integrityAvoid breakingSievingPre-extraction tea treatmentAgricultural engineeringTea leaf

Owner:湖南会同宝田茶业有限公司

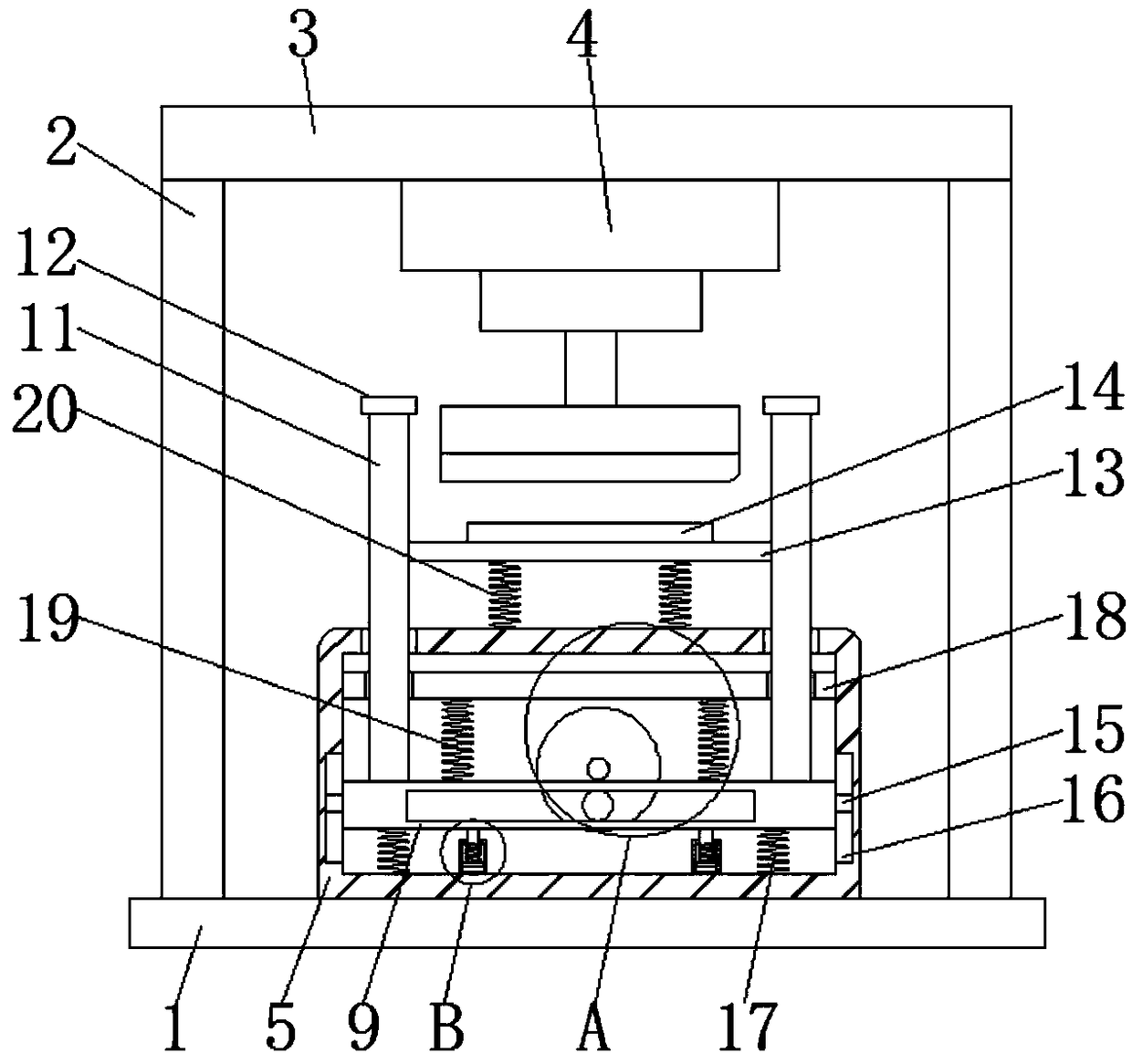

High-safety intelligent cutting device

ActiveCN109176686AAvoid breakingAvoid shakingMetal working apparatusNon-rotating vibration suppressionEngineering

Owner:泉州市华祥工业设计有限公司

Suction nozzle structure

Owner:SUZHOU JINGLAI OPTO CO LTD

Heating cable with invisible joint and manufacturing method thereof

InactiveCN101909373AImprove high temperature resistanceGood flexibilityHeater elementsHeating element shapesTemperature resistanceEngineering

The invention discloses a heating cable with an invisible joint and a manufacturing method thereof. The heating cable with the invisible joint comprises a heating segment and a lead segment, wherein the heating segment comprises a jacket layer, a shielding layer, an insulating layer, a high-temperature resistant insulating layer and a heating core; the lead segment comprises a jacket layer, a shielding layer, an insulating layer and a cold wire; the cold wire is connected with the heating core; and the jacket layer is provided with a joint mark. The manufacturing method comprises the following steps of: 1) manufacturing the high-temperature resistant insulating layer on the heating core; 2) cutting the heating core; 3) cutting the cold wire; 4) soldering the heating core and the cold wire; 5) finding out the joint; and 6) manufacturing the insulating layers, the shielding layers and the jacket layers. The heating cable with the invisible joint and the manufacturing method thereof have the advantages of: (1) improving the quality of the joint; (2) improving the high-temperature resistance of the cable; (3) improving the flexibility of the cable, so that the cable is difficult to break off when bent repeatedly; and (4) making the definite joint mark at the joint of the cold wire and the heating core.

Owner:LAIWU FUQIANG SPEICAL LINE CABLE

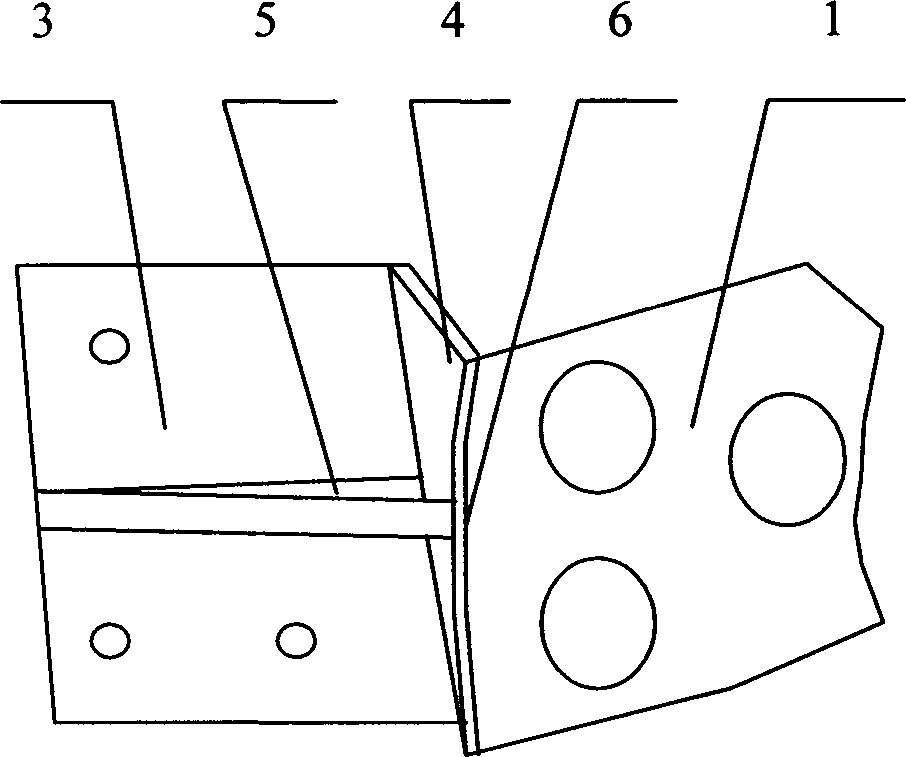

Electrode assembly, manufacture method thereof and lithium secondary battery

InactiveCN103887472AEasy to processExtend your lifeFinal product manufactureLi-accumulatorsLithiumEngineering

The invention discloses an electrode assembly which comprises a first polar plate, and two second polar plates, wherein active material layers are coated on two surfaces of the first polar plate, the first polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the first polar plate, an active material layer is coated on one surface of the second polar plate, each second polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the second polar plate, two surfaces of the first polar plate, coated with the active material layers, are respectively opposite to surfaces of the two second polar plates, coated with the active material layers, an isolating layer is arranged between the surfaces of the first polar plate, which are opposite to the second polar plates, and the first polar plate and the second polar plates are respectively provided with a contact region with connected leads. The electrode assembly is low in requirement of production equipment, is easy to process and manufacture, and is relatively prolonged in service life. The material utilization rate of the electrode assembly can be increased, the cost is lowered, and the energy density of a battery is improved, so that the volume of the electrode assembly is relatively reduced under the same capacity.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI +1

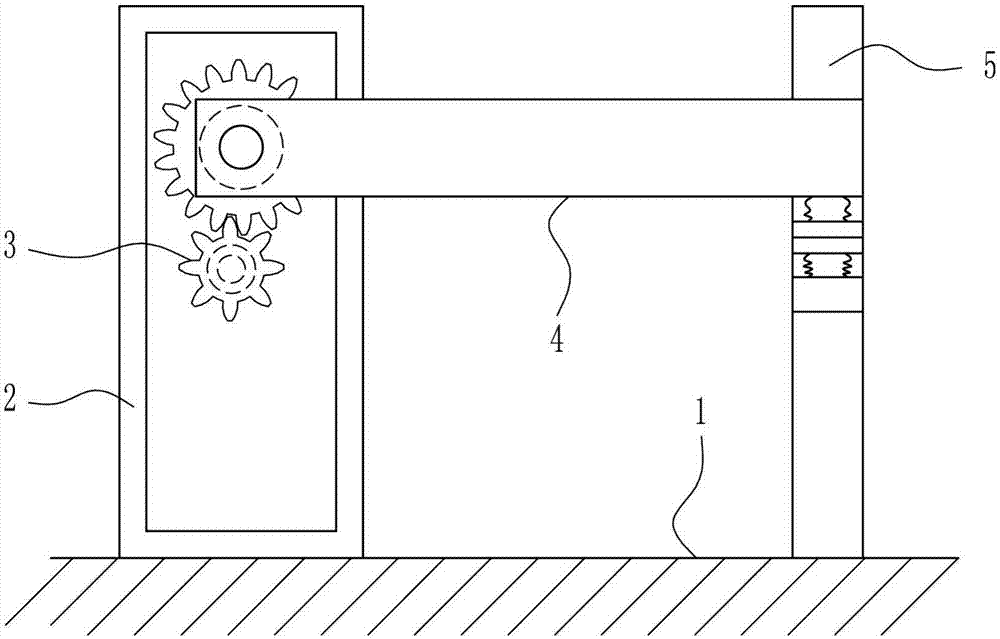

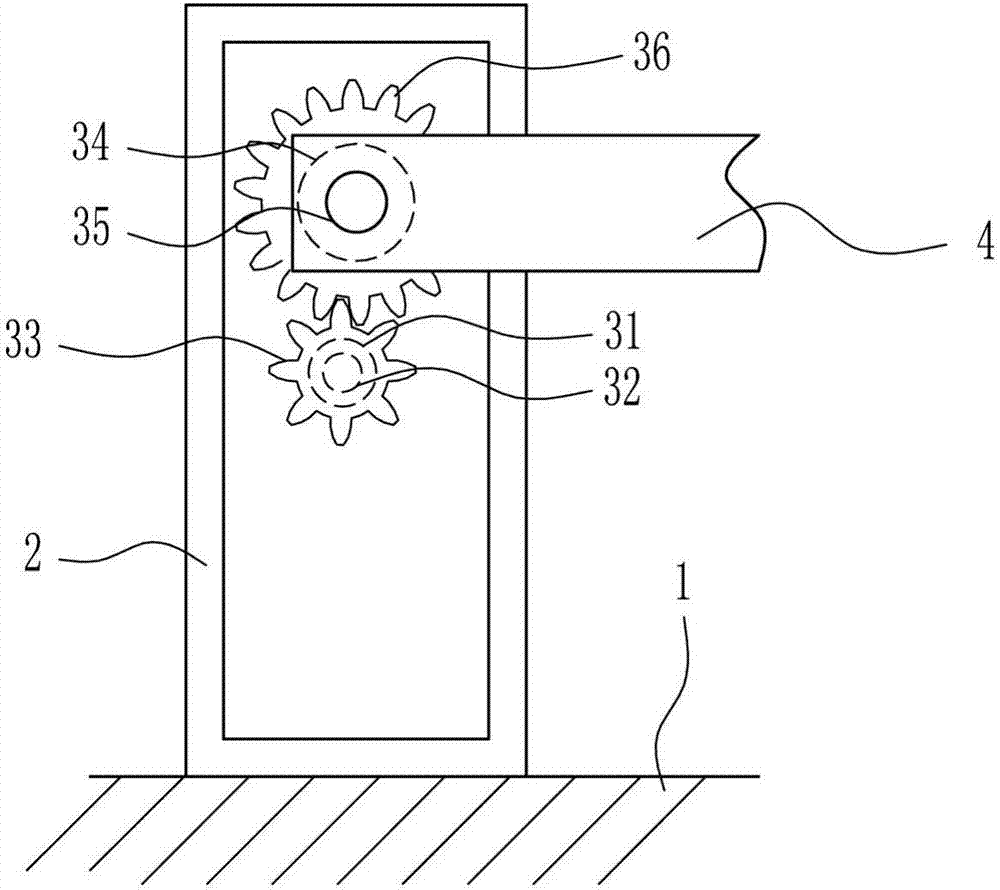

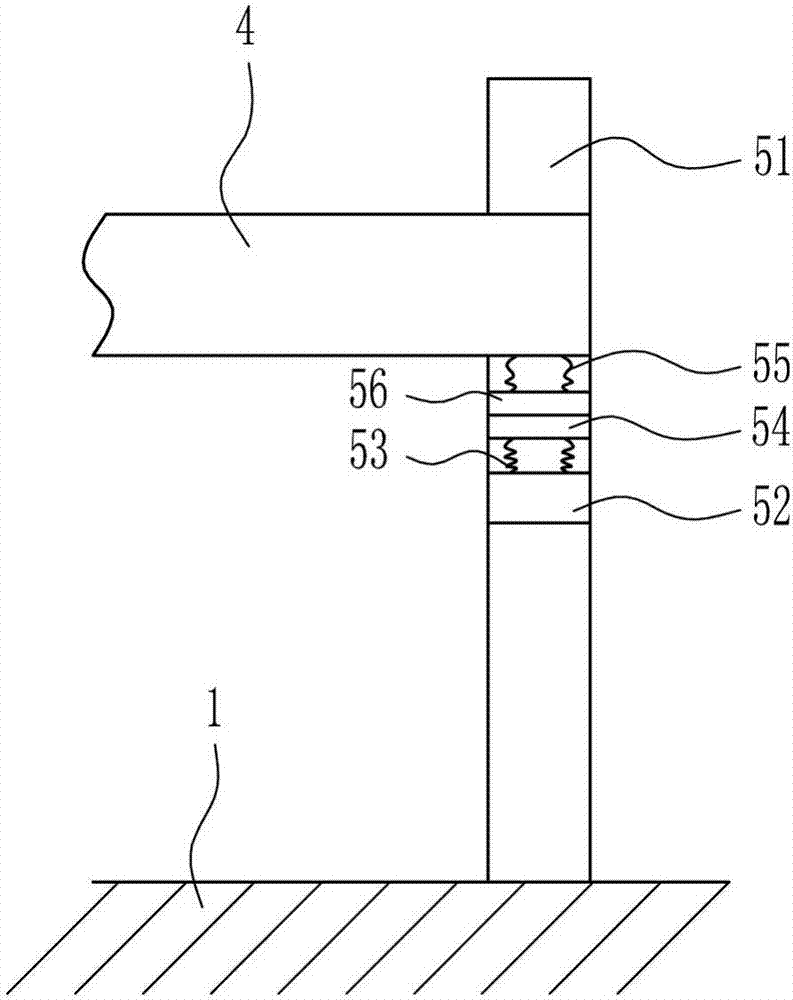

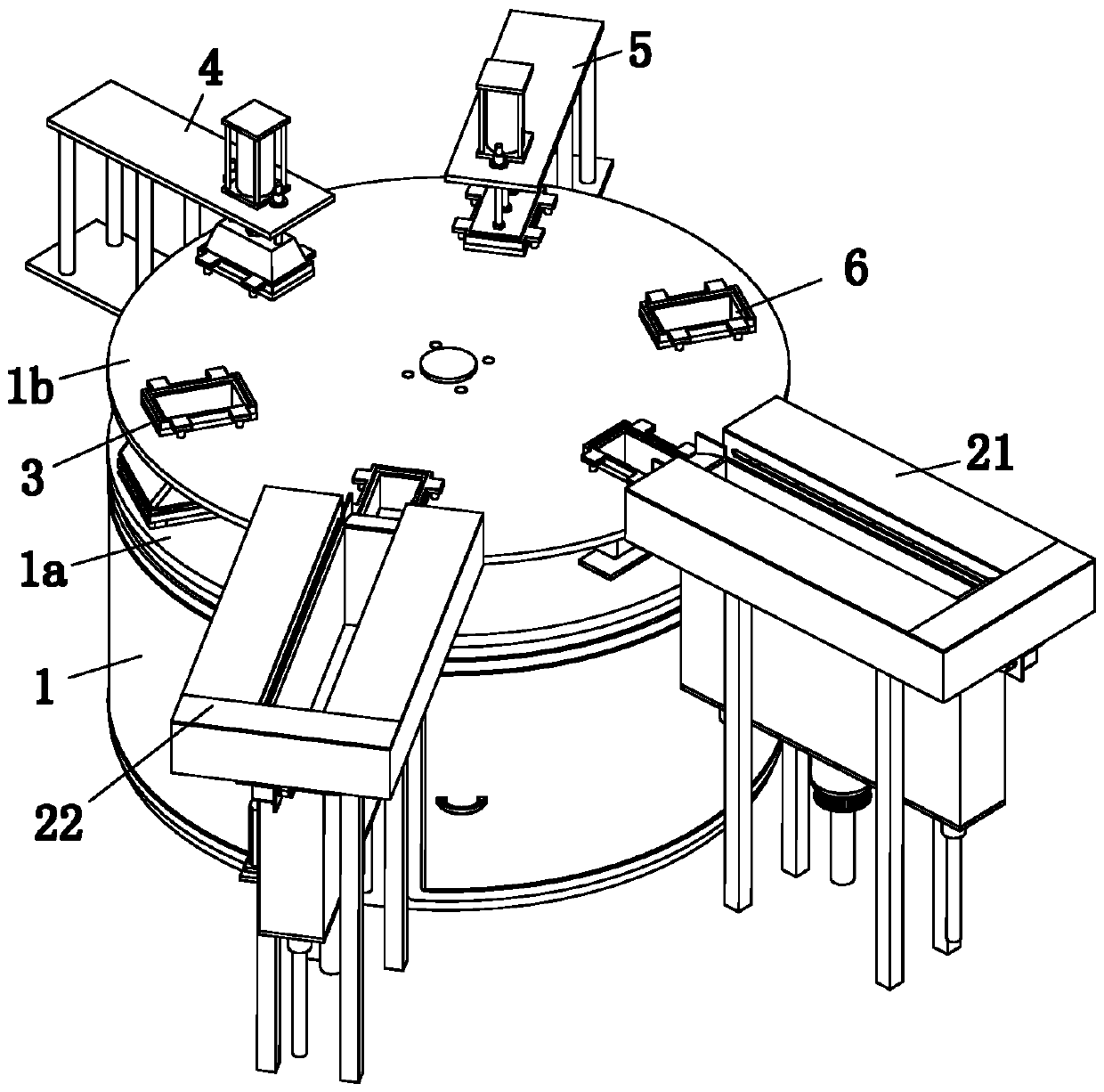

Improved plate turnover machine with quick turnover function

PendingCN113060519ASafe and reliable actionThe rotating structure is reasonable and effectiveConveyor partsRotational axisElectric machine

The invention belongs to the technical field of plate processing, and particularly relates to an improved plate turnover machine with a rapid turnover function. According to the improved plate turnover machine, through arrangement of a rotating shaft, a rotating plate, a motor pressing unit and an elastic plate unit on a driving motor, the purposes that plates are turned over quickly and stably, and are not prone to collide and damage are achieved. The improved plate turnover machine has the advantages that a rotating structure for plate turnover is reasonable and effective, and the plate clamping type rotating turnover action is safe and reliable; the plate is not prone to damage, and a plate pushing feeding and discharging structure is simple and efficient; the mode that an elastic plate unit is pressed to store energy firstly and then assists in pushing out the plate is flexible and ingenious, and the overall plate feeding and discharging structure is rapid, labor-saving, stable and accurate; and the whole turning plate structure is stable and compact, flexible, adjustable, energy-saving and economical.

Owner:ZHEJIANG YASHA DECORATION

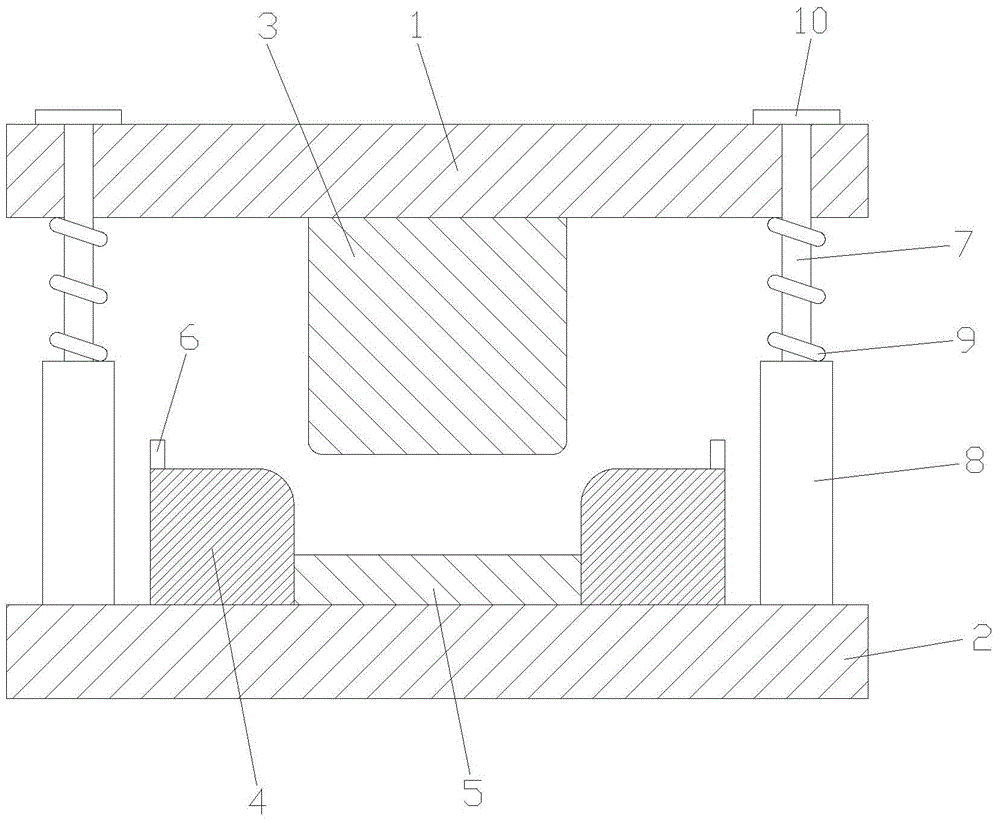

Metal plate stamping die

InactiveCN104384344AAvoid breakingGood stamping effectMetal-working feeding devicesMetal-working storage devicesEngineeringSheet metal stamping

Owner:吴中区光福华宇钣金厂

Hydraulic fixture based on progressive forming machine tool and sheet forming and feeding method thereof

ActiveCN108339886AAutomateAvoid breakingMetal-working feeding devicesMetal-working storage devicesEngineeringFastener

Owner:NANJING INST OF TECH

Clamp-breaking prevention scarification tooth

InactiveCN107178112AAvoid breakingExtended service lifeSoil-shifting machines/dredgersOrthodonticsScarification

Owner:HEFEI ZHUHANG ECOLOGY AGRI TECH CO LTD

Silicon wafer continuous extraction device

ActiveCN110797294AAvoid breakingSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:徐州博创建设发展集团有限公司

Rare earth polishing disc

Owner:珠海市吉昌稀土有限公司

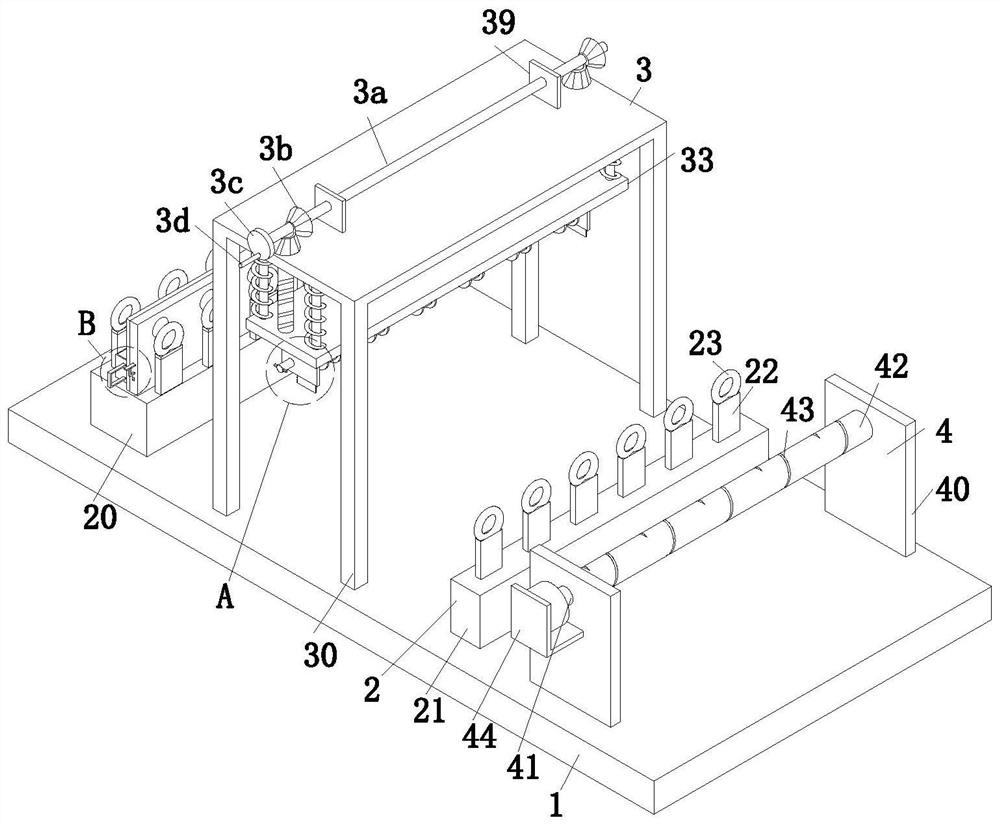

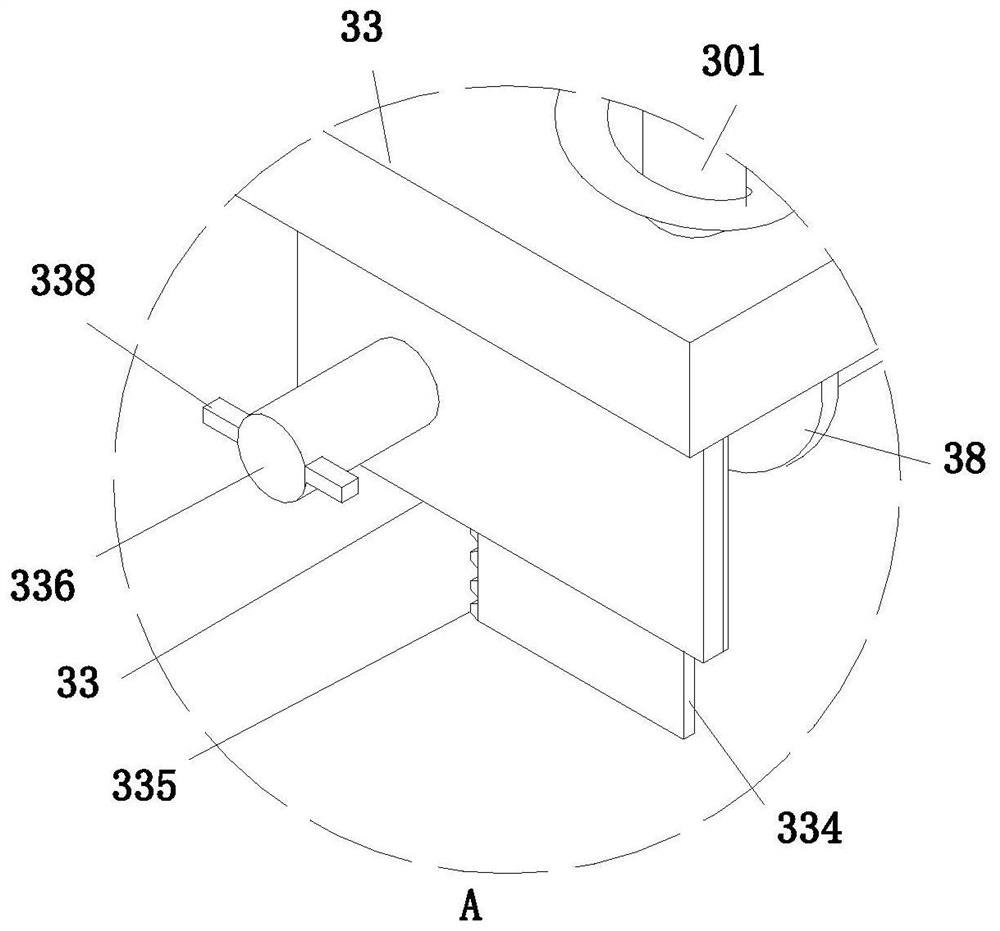

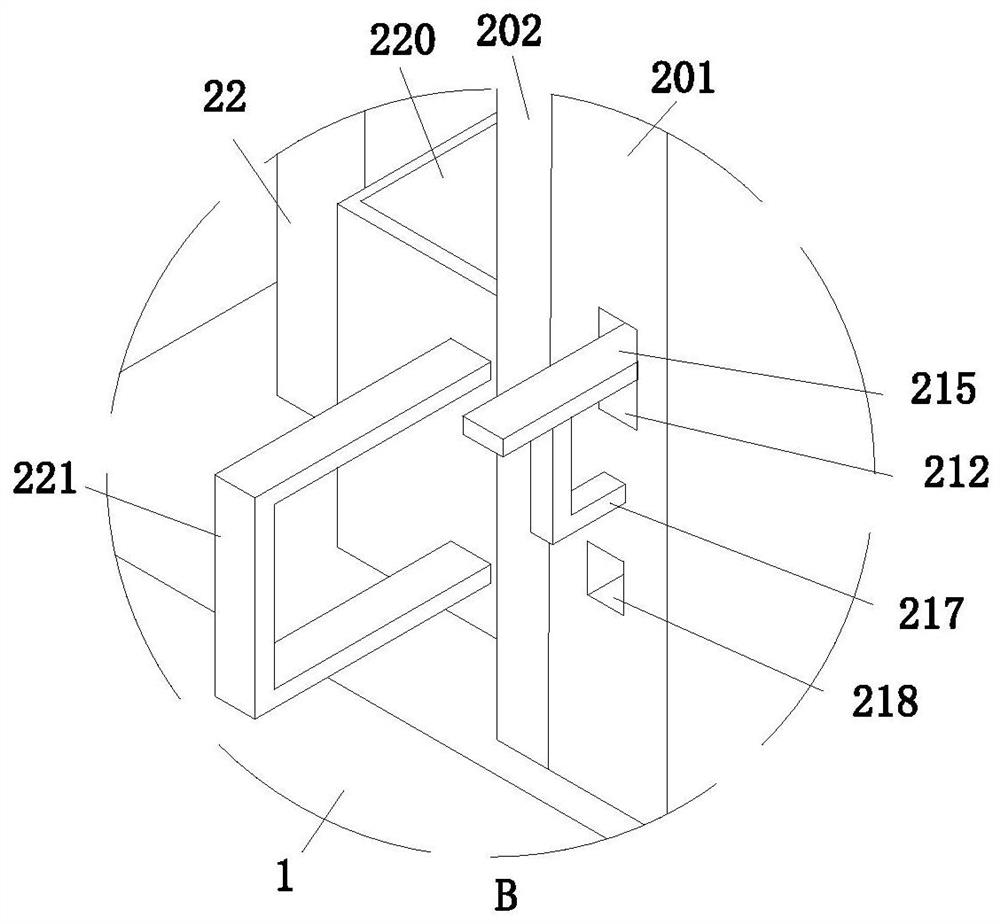

Textile yarn tensioning, adjusting and conveying integrated system

ActiveCN113148766AGuaranteed stabilityCause deadlockMechanical cleaningPressure cleaningTextile yarnStructural engineering

The invention relates to a textile yarn tensioning, adjusting and conveying integrated system. The textile yarn tensioning, adjusting and conveying integrated system comprises a workbench, a sleeving mechanism, a tensioning mechanism and a conveying mechanism, wherein the sleeving mechanism and the tensioning mechanism are installed on the upper end face of the workbench, and the conveying mechanism is arranged at the right side of the sleeving mechanism. According to the textile yarn tensioning, adjusting and conveying integrated system, the adopted tensioning mechanism drives yarns on rolling cylinders to move upwards to conduct primary tensioning, and then lifting plates move to enable the rolling cylinders to drive the yarns to conduct secondary fine adjustment tensioning, so that it is guaranteed that the yarns are not broken due to too large tensioning force; meanwhile, the yarns are tensioned, so that the stability of the yarns in the conveying process is guaranteed, and the phenomenon of conveying deviation or conveying failure caused by yarn looseness is avoided; and meanwhile, the conveying mechanism can convey the yarns in the corresponding grooves, so that the phenomenon that because the yarns are wound together, hard knots are caused is avoided.

Owner:山东杰瑞纺织科技有限公司

Four-point bending fixture of thin plate for high stress loading and loading method thereof

InactiveCN107607394AAvoid breakingPrevent falling offMaterial strength using steady bending forcesEngineeringHigh stress

Owner:武汉钢铁有限公司

Three-dimensional winding forming device for amorphous strips of amorphous three-dimensional wound core transformer

ActiveCN111627688AStable transmission speedStable tangential roll-up angleInductances/transformers/magnets manufactureTransformerClassical mechanics

The invention discloses a three-dimensional winding forming device for amorphous strips of an amorphous three-dimensional wound core transformer, and relates to the technical field of production and processing of amorphous strips. An adaptive transmission material storage unit can place the amorphous strips discharged by a discharging unit freely without constraint, the strips are avoided from break due to failure in high-frequency rapid discharging speed conversion of the discharging unit when a constant-tension relaxation control unit rapidly switches the spatial position of the wound stripsin the winding state of a three-dimensional winding unit, the constant-tension relaxation control unit can ensure that the conveying speed of the strips and the tangential strip winding angle are kept stable in the process that the amorphous strips are wound in a three-dimensional way in a rectangular single-frame inner tyre, and inconsistent fitting between layers of the strips or even crack ofthe strips due to non-uniform bearing of the wound strips when the winding speed and angle are changed is also avoided. An axial movement mechanism of the three-dimensional winding unit drives a driving rotation mechanism and a driven support mechanism to move synchronously and further to ensure stable three-dimensional winding of the amorphous strips.

Owner:JIHUA LAB

Indoor unit of air conditioner and rotary connecting structure of indoor unit

ActiveCN109708294AEasy to assemble and disassembleAvoid breakingLighting and heating apparatusSpace heating and ventilation detailsMechanical engineering

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Production device of spiral rhizoma dioscoreae slices

ActiveCN106690362ANot easy to breakImprove baking efficiencyMetal working apparatusFood treatmentEngineering

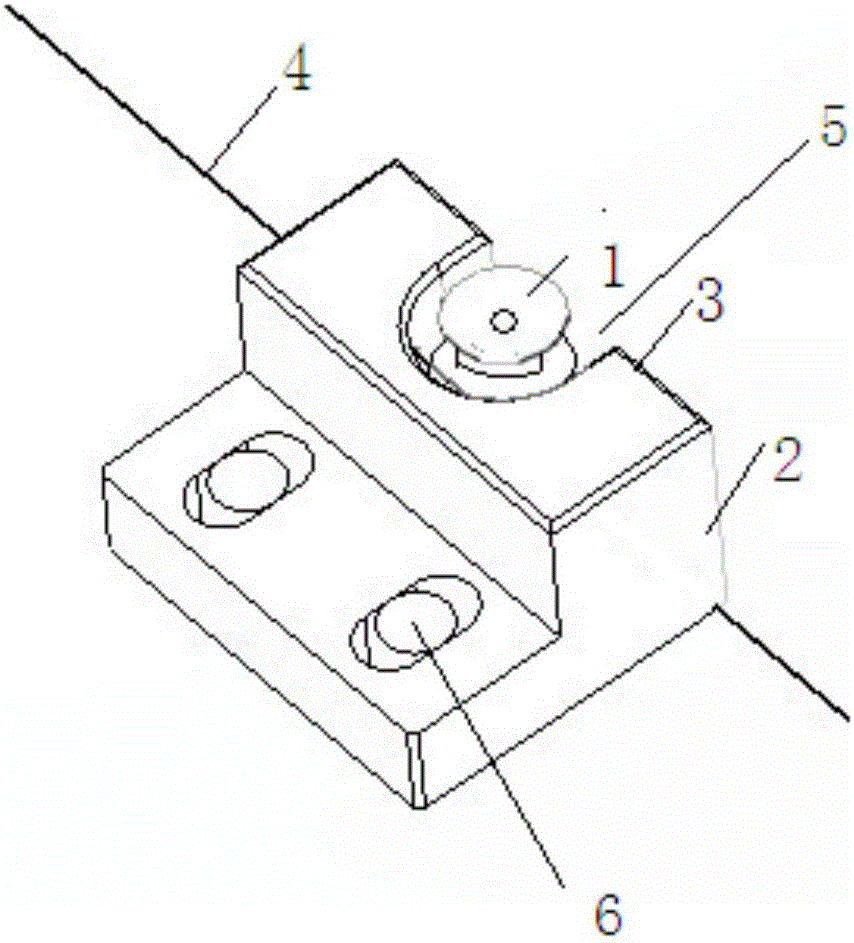

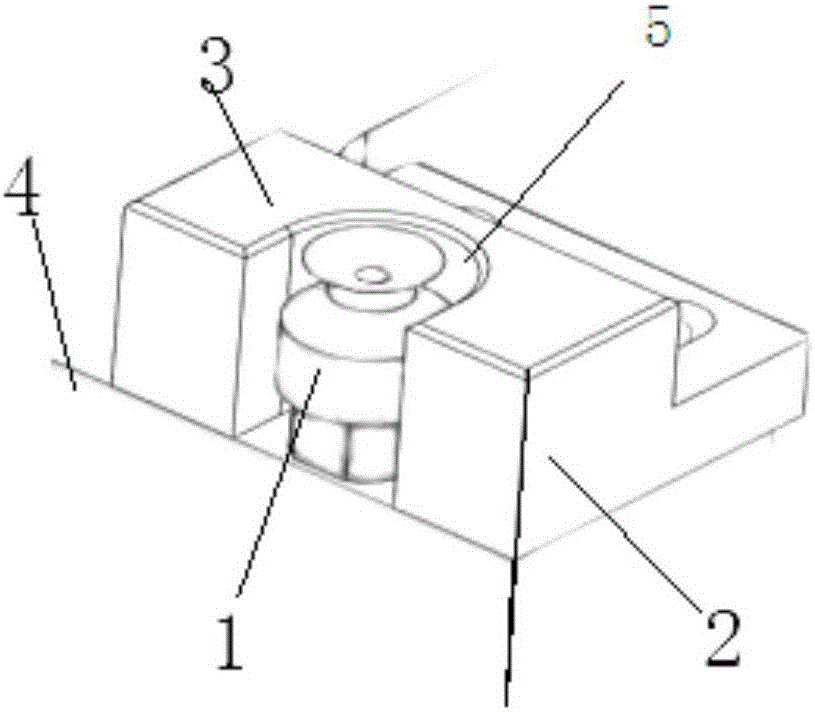

The invention relates to a production device of spiral rhizoma dioscoreae slices. The production device comprises a frame, a clamping mechanism, an outer circular tube, an inner circular tube and a circular blade, wherein the outer circular tube, the inner circular tube and the circular blade are concentric, the inner circular tube is nested into the outer circular tube, and an annular space is formed between the outer circular tube and the inner circular tube; four vertical grooves are formed in the inner lateral wall of the inner circular tube in a central symmetry manner; the inner bottom surface of each groove is provided with a rack; a sun gear sleeves the outer circumferential face of each of the upper end and the lower end of the inner circular tube, four planet gears are evenly arranged on the periphery of each sun gear and arranged on a planet carrier, and each planet carrier is fixedly connected with the frame; gear rings which mesh with the four planet gears sleeve the inner circumferential face of the outer circular tube; the clamping mechanism is matched with the grooves to slide vertically; the circular blade is horizontally arranged below the inner circular tube and fixedly connected with the inner circumferential face of the outer circular tube.

Owner:陈光钦

Preparation method of ready-to-eat baby squid product

ActiveCN102429262AGuaranteed ease of useReduce energy consumptionFood preparationReady to eatHeating time

The invention provides a preparation method of a ready-to-eat baby squid product. The preparation method comprises a stepped sterilization process; in a adopted heating and cooling process, water at different temperatures is sprayed to the outside of the flexible package of the processed baby squid; and the sterilization process comprises the specific procedures of sequentially spraying water at the temperature of 70 DEG C for 7 minutes, spraying water at the temperature of 90 DEG C for 4 minutes, spraying water at the temperature of 100 DEG C for 2 minutes, spraying water at the temperature of 121 DEG C for 1 minute, spraying water at the temperature of 90 DEG C for 4 minutes and spraying water at the temperature of 45 DEG C for 10 minutes. The stepped sterilization process and the spray-type heating and cooling process are adopted in the preparation method of the ready-to-eat baby squid product. Compared with the prior art, the preparation method has the beneficial effects that by adopting the spray-type heating and cooling process, the feasibility of the stepped sterilization process is ensured, and energy consumption and water consumption can be reduced; in addition, the totaltime of the sterilization process is shorter than that of the conventional sterilization process so as to prevent the obtained product from being damaged due to overlong heating time and high-temperature retaining time.

Owner:ZHEJIANG FUDAN TOURISM FOOD

Nutritional flavoring straw

The invention belongs to the technical field of living supplies, particularly relates to a nutritional flavoring straw for adding nutritional flavoring agents into flowing liquor. The nutritional flavoring straw comprises a straw, a filter tube and flavoring particles, wherein the filtering end of the filter tube is in sleeve joint with one end of the straw, the flavoring particles are arranged in the filter tube, the filtering end of the filter tube is provided with a filter screen, and the sucking end of the filter tube is connected with a filter plug. The nutritional flavoring straw is simple in structure and convenient to carry and use, and can be subjected to independent packing; in the process of using the nutritional flavoring straw, no pollution is caused to the liquid beverage; and by using the nutritional flavoring straw, the good combination of nutrition and taste can be ensured.

Owner:U S HEALTH WARMTH CARE

Green heat-preservation, heat-insulation and sound-absorption composite material and preparation method thereof

The invention belongs to the field of aerogel technology and organic fiber sound-absorbing composite materials, and relates to a green heat-preservation, heat-insulation and sound-absorbing composite material and a preparation method thereof. The green heat-preservation, heat-insulation and sound-absorbing composite material comprises an organic fiber felt and an aerogel material, the aerogel material is an aerogel material containing silicon aluminum or silicon aluminum titanium, and the mass ratio of the organic fiber felt to the aerogel material is 1: (2-12). The preparation method comprises the following steps of preparing a hydrophilic solvent with the surfactant concentration of 0.1-10%, spraying the hydrophilic solvent on the surface of the organic fiber felt, and drying the hydrophilic modified organic fiber felt at 80-150 DEG C after the hydrophilic solvent completely permeates into the organic fiber felt, and compounding a glass aqueous solution containing silicon-aluminum or silicon-aluminum-titanium components with the dried organic fiber felt to obtain a wet gel composite material, further putting the wet gel composite material into an ethanol solution for extraction and replacement, and drying the wet gel composite material after extraction and replacement to obtain a target product.

Owner:ZHEJIANG UGOO TECH CO LTD

Rapid drying and disinfecting device for glass culture dish

InactiveCN109458797AEasy to dryImprove the bactericidal effectDrying gas arrangementsDrying chambers/containersEngineeringBreathing

The invention discloses a rapid drying and disinfecting device for a glass culture dish. The rapid drying and disinfecting device comprises a box body, a box cover, a partition plate, a bottom plate,a placing unit, a hot air circulating device and a disinfecting device, wherein a box cover is movably connected to the top end of the box body, a partition board is arranged in the box body, a plurality of uniformly-disposed placing units are formed between the partition plate and the bottom plate, the hot air circulating device is arranged in the box body below the bottom plate, the hot air circulating device is connected with ventilation pipelines, ventilation holes are formed in the partition plate on the side wall of the box body, ventilation holes are communicated with the ventilating pipelines, the disinfecting device is arranged at the bottom end of the box cover. According to the drying and disinfecting device, rapid drying and disinfecting can be carried out on the culture dish,and the culture dishes with different sizes can be suitable for placement, meanwhile, effective protection can be provided for the culture dishes, the phenomena of crushing and the like of the culturedishes can be prevented, and unnecessary loss can be avoided.

Owner:王小改

Solution for treating steel core for aluminum-coated steel through water bath heating and method for treating steel core for aluminum-coated steel through water bath heating

InactiveCN106222378AMeet cold drawing processing requirementsIncrease surface tensionQuenching agentsWater bathsHazardous substance

The invention discloses a solution for treating the steel core for aluminum-coated steel through water bath heating and a method for treating the steel core for aluminum-coated steel through water bath heating. The solution for treating the steel core for aluminum-coated steel through water bath heating is a sodium polyacrylate aqueous solution with the concentration of 10% to 25%, and the temperature of the sodium polyacrylate aqueous solution is controlled to range from 85 DEG C to 95 DEG C. The method for treating the steel core for aluminum-coated steel through water bath heating comprises the following steps of (1) sending the steel core for aluminum-coated steel into a heating furnace to be heated till the temperature of the steel core ranges from 900 DEG C to 1200 DEG C, (2) directly conveying the heated steel core for aluminum-coated steel into the sodium polyacrylate aqueous solution with the temperature of 85 DEG C to 95 DEG C and the concentration of 10% to 25% for sorbitizing treatment. According to the solution for treating the steel core for aluminum-coated steel through water bath heating and the method for treating the steel core for aluminum-coated steel through water bath heating, sorbitizing of the steel core is realized in the sodium polyacrylate aqueous solution, the method has the advantages that the reaction effect is good, the efficiency is high, and no hazardous substances will be generated, and the method is an economic, high-efficiency and environment-friendly treatment technology, and can be widely applied to the field of sorbite treatment of steel cores.

Owner:HUANGSHAN CHUANGXIANG SCI & TECH

Switch socket apparatus

InactiveCN101350503AAvoid breakingSimple structureSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksInsulation layerEngineering

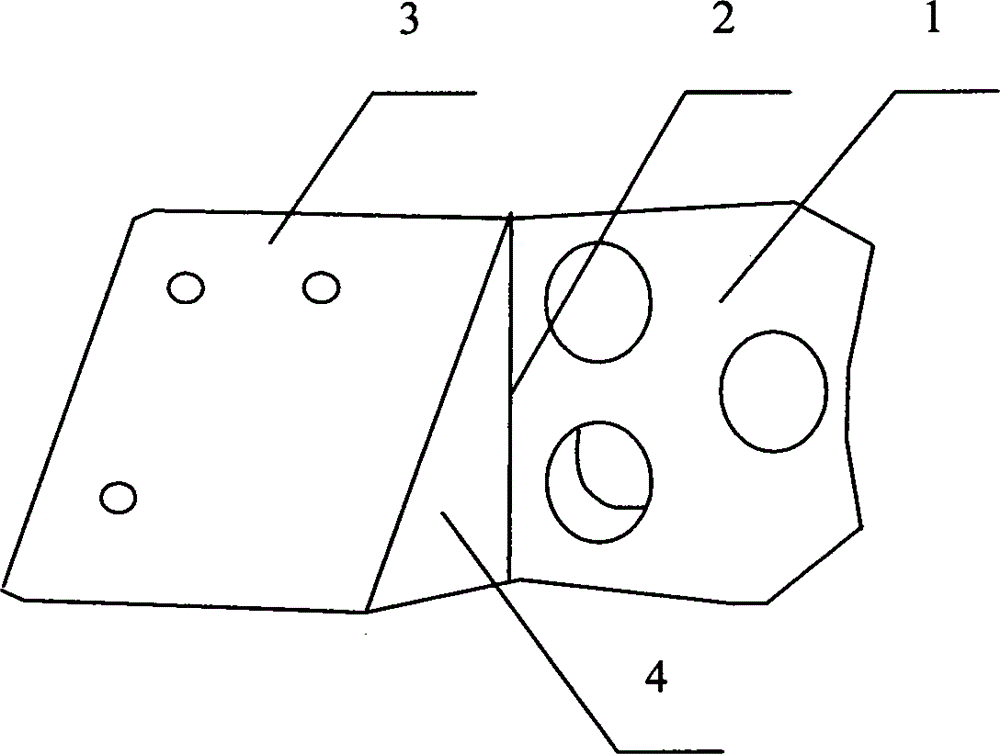

The invention discloses a switch socket device, comprising a base, functional parts on the base, a mounting box, etc. A bolt hole is arranged at the circle-center of the base, and the functional parts are arranged on the base. Locating teeth are arranged on the circumferential side-wall of the base, and tooth slots mating with the teeth are arranged on the inner wall of the mounting box; and a spacing member is arranged at the central part of the mounting box. A thread segment is arranged in the internal hole of the spacing member. The functional parts may be a power supply switch or various receptacles, and special elastic connection mechanisms are arranged on the functional parts and the base. The invention is easy to install, adjust and use, and is capable to avoid the accidents incurred by damage to the insulation layer of the wire.

Owner:吴侃武

Raymond mill scraper knife seat and manufacture method thereof

The invention discloses a Raymond mill scraper knife seat which is made of an A3 steel press forging piece. A manufacture method of the Raymond mill scraper knife seat comprises the following steps: (1) blanking; (2) calcining at the temperature of 850-1000 DEG C; (3) forging and pressing for forming; and (4) naturally cooling, and punching, or also comprises the step of (5) welding a reinforced plate between an auxiliary seat end at the back surface and a folding plate, or also comprises the step of (6) welding a positioning strip at a main seat end at the back surface and the bending part of the folding plate. Compared with a common casting in the prior art, the Raymond mill scraper knife seat has the advantages of being not prone to break, durable, low in cost, convenient to process, easy in quality control, stable in shape, convenient to install, and the like.

Owner:桂林永福恒达实业有限公司

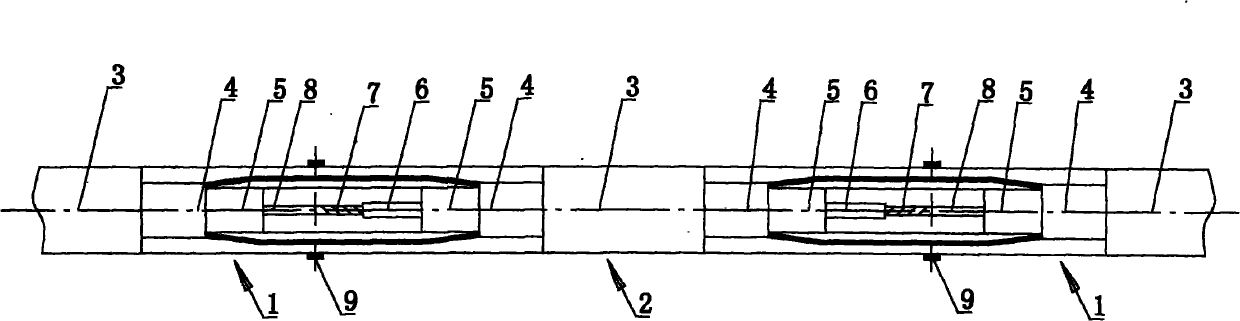

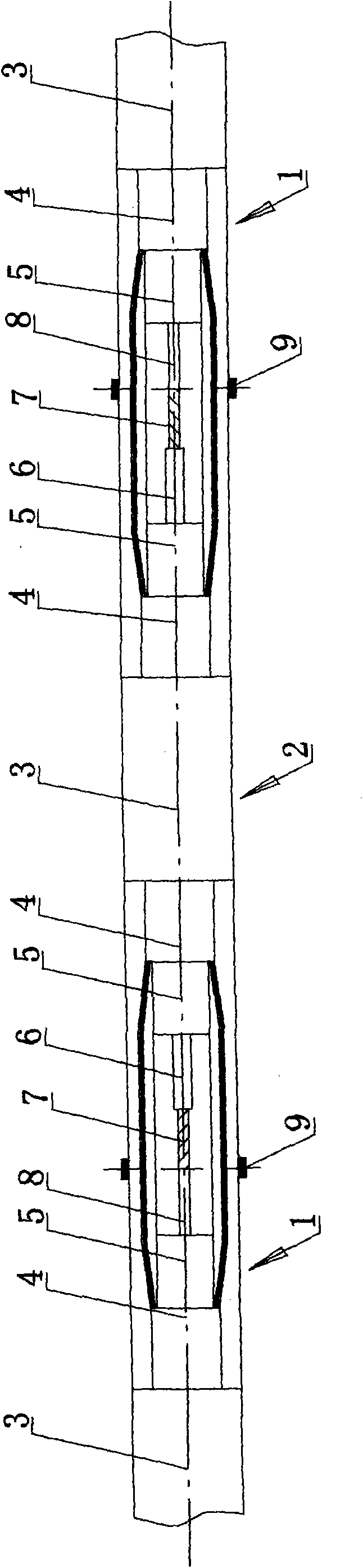

Horizontal well cable protection device and application method

PendingCN108798631AAvoid breakingAvoid contact frictionCable arrangements between relatively-moving partsSurveyCompressed airCorrosion

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

Steam-free hairdressing gel and preparation method thereof

The invention relates to a steam-free hairdressing gel and a preparation method thereof. The preparation method comprises the following steps of: heating and melting 2-8 parts by weight of cation conditioner; heating and melting 1-4 parts by weight of emulsifying agent, 1-5 parts by weight of mineral grease and 5-10 parts by weight of synthetic grease; sucking deionized water into an emulsification pot for heating; starting to mix when the temperature reaches 60-80 DEG C; adding 0.01-0.1 parts by weight of chelating agent, the melted cation conditioner, the melted emulsifying agent, the melted mineral grease and the melted synthetic grease into the mixture in sequence; cooling the mixture after the heat is preserved for 10-20min; adding 0.5-3 parts by weight of nutrient additives, 0.1-0.5 parts by weight of flavorings and 0.05-0.3 parts by weight of preservative when the temperature is cooled to 45-55 DEG C; and cooling the temperature to 30-45 DEG C. compared with the prior art, the steam-free hairdressing gel has the effects of deeply repairing and nourishing hair, strengthening, moisturizing and conditioning the hair, and keeping the hair smooth and bright.

Owner:SHANGHAI HUAYIN COMMODITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap