Feeding equipment of brick tea semi-automatic production device

A production device and semi-automatic technology, which is applied in loading/unloading, food forming, transportation and packaging, etc. It can solve the problems of fragile tea leaves, a lot of manpower, and the inability to control the amount of tea leaves, so as to avoid broken effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

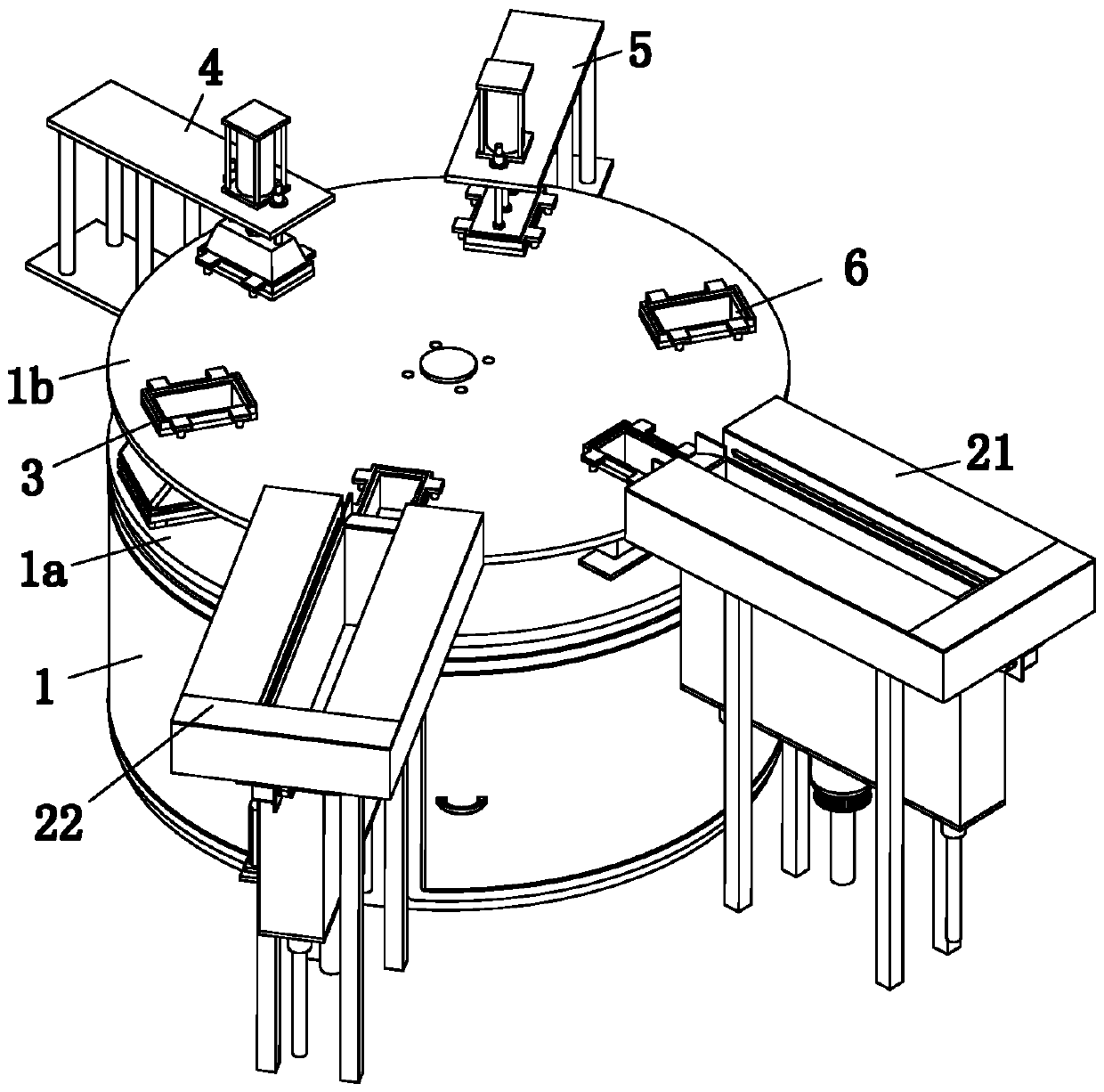

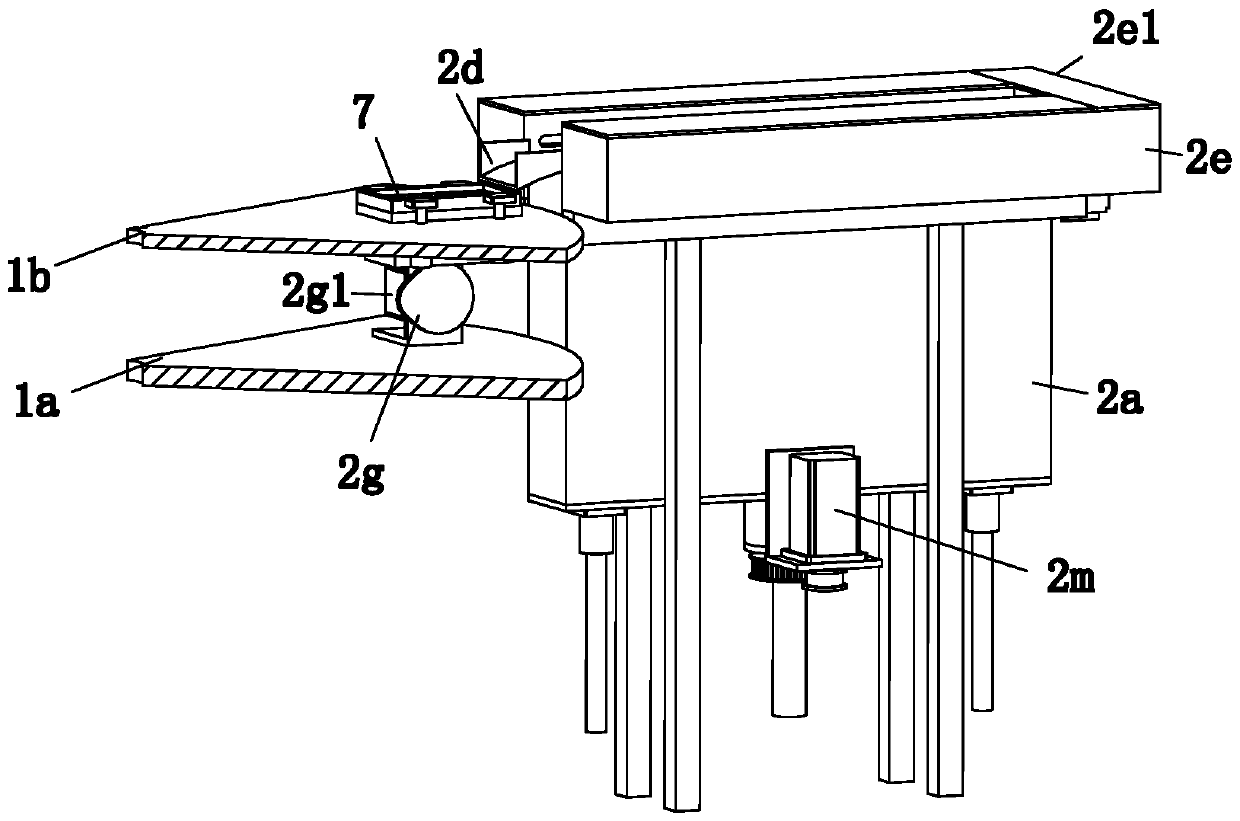

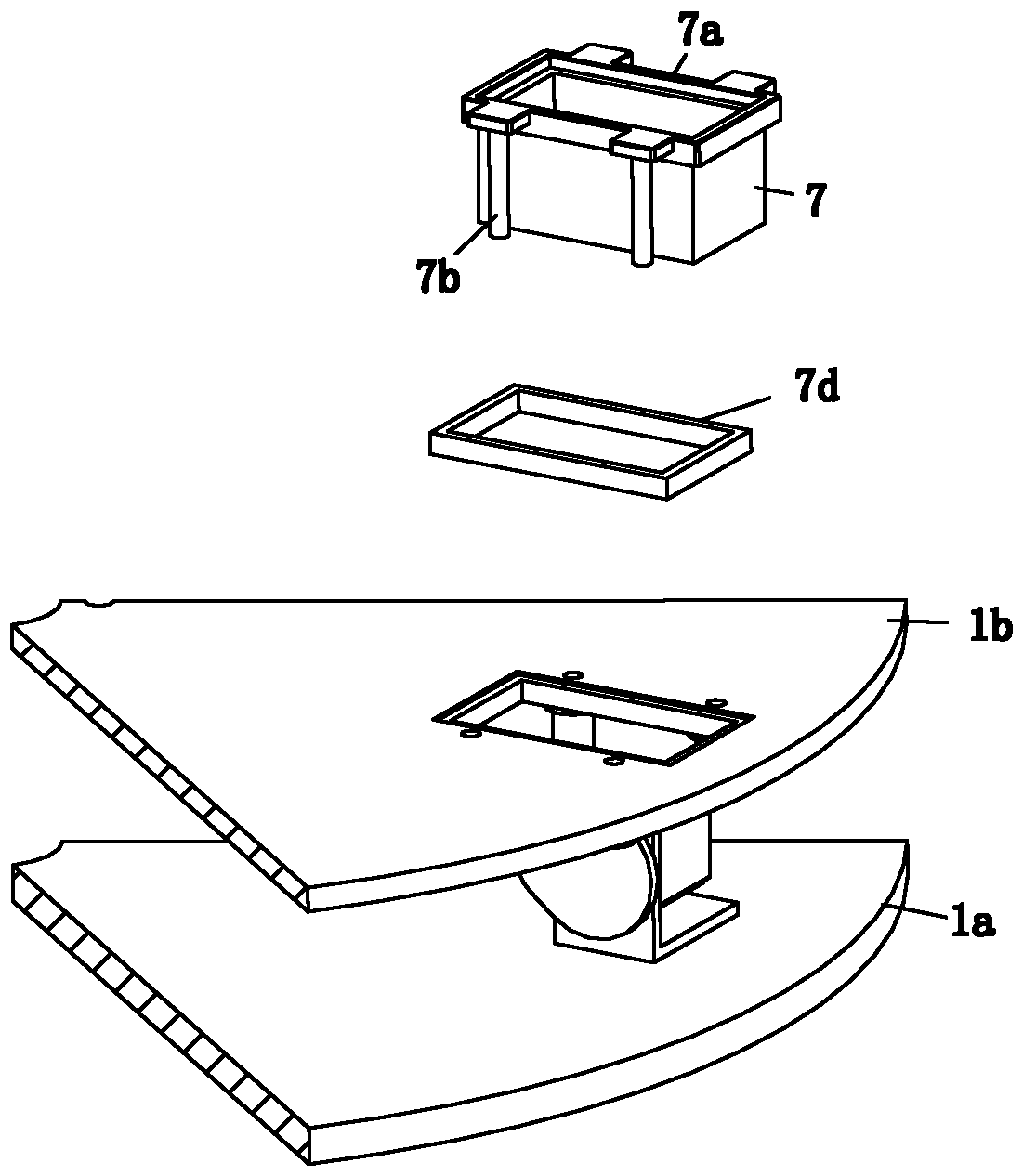

[0027] Reference Figure 1 to Figure 12 The shown semi-automatic tea brick production device includes a frame 1, a support plate 1a is arranged on the top of the frame 1, a turntable 1b is installed above the support plate 1a, and a stepping motor that drives the turntable 1b is installed inside the frame 1 A number of molds 7 are placed on the turntable 1b. The molds 7 are slidably fitted up and down with the turntable 1b. Around the turntable 1b is provided a first feeding station 21, a second feeding station 22, and raw materials. Calibration station 3, tea steaming station 4, pressing station 5, and unloading station 6. During production, the mold 7 on the turntable 1b is driven by the turntable 1b to pass through the first feeding station 21 and the feeding station in turn. The equipment on the first feeding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap