Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Brick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brick is building material used to make walls, pavements and other elements in masonry construction. Traditionally, the term brick referred to a unit composed of clay, but it is now used to denote rectangular units made of clay-bearing soil, sand, and lime, or concrete materials. Bricks can be joined together using mortar, adhesives or by interlocking them. Bricks are produced in numerous classes, types, materials, and sizes which vary with region and time period, and are produced in bulk quantities. Two basic categories of bricks are fired and non-fired bricks.

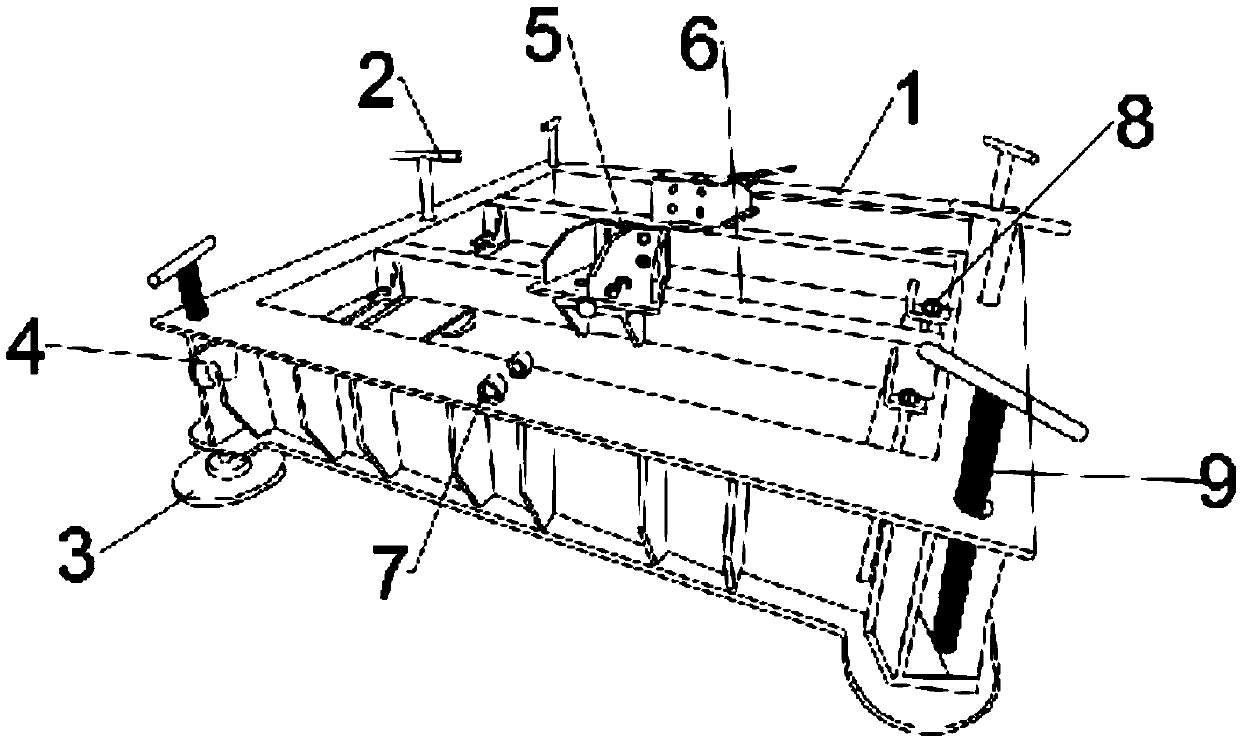

Bricklaying device and bricklaying robot

The invention discloses a bricklaying device and a bricklaying robot. The bricklaying device comprises a base, a brick transfer assembly, a brick feeding assembly and a plastering assembly. The bricktransfer assembly comprises a mechanical arm and a grabbing part. The mechanical arm is connected with the grabbing part to transfer bricks. The mechanical arm is movably arranged on the base and cando up-down lifting motion relative to the base. The brick feeding assembly comprises a bearing platform. The bearing platform is suitable for bearing the bricks. The bearing platform can do up-down lifting motion relative to the base, and the highest distance of the bearing platform relative to the base can be adjusted, so that the bricks are located within the grabbing range of the grabbing partall the time. The plastering assembly is arranged on the base and comprises a plastering head. The plastering head is used for plastering the bricks. The bricklaying device provided by the embodimentof the invention integrates brick transferring, brick plastering and bricklaying, can automatically complete the multiple working procedures, liberates manpower and accelerates the bricklaying progress; and shorter time required for brick taking is consumed, plastering and bricklaying can be quickly carried out after brick taking, the whole working procedure time is short, and the bricklaying efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

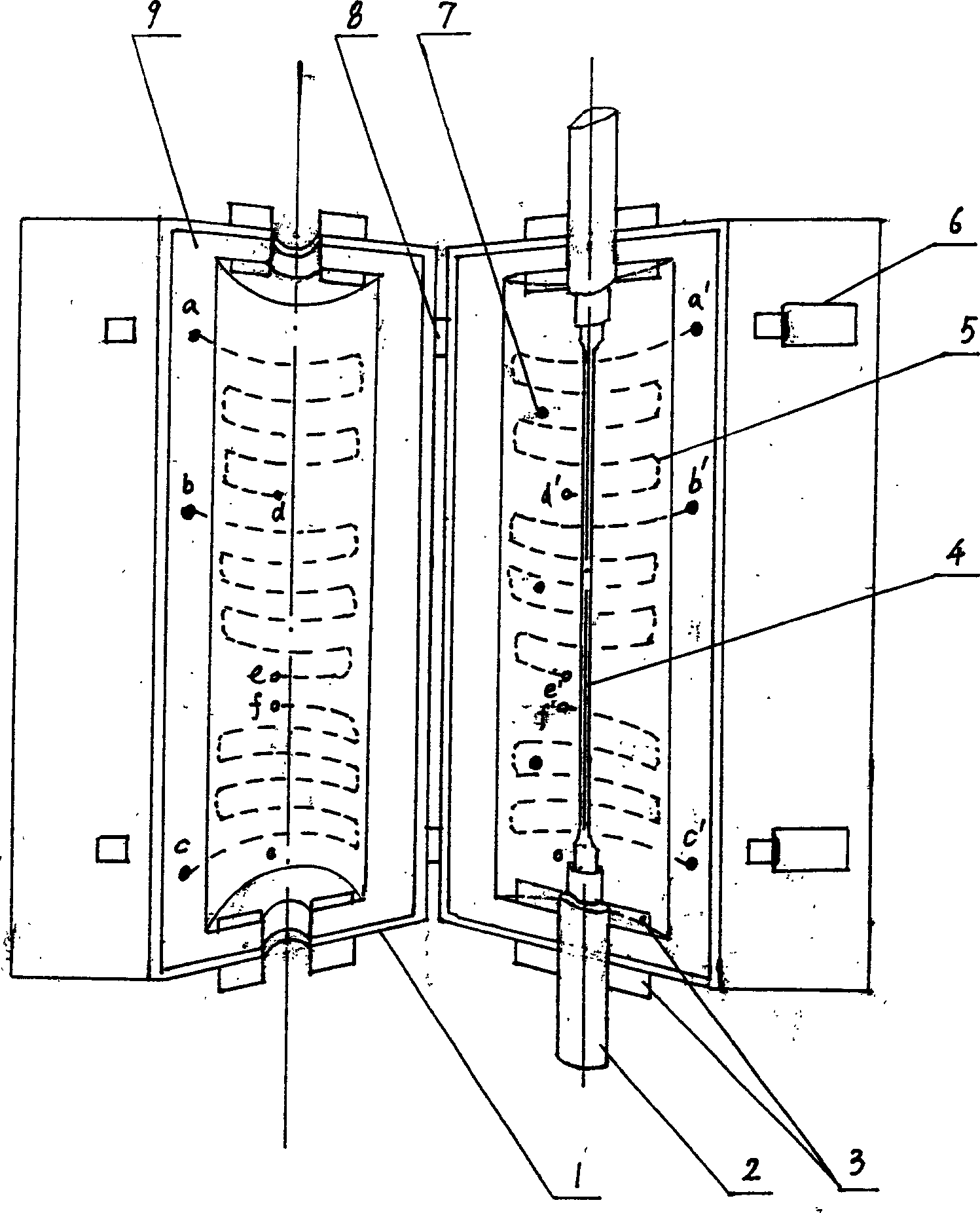

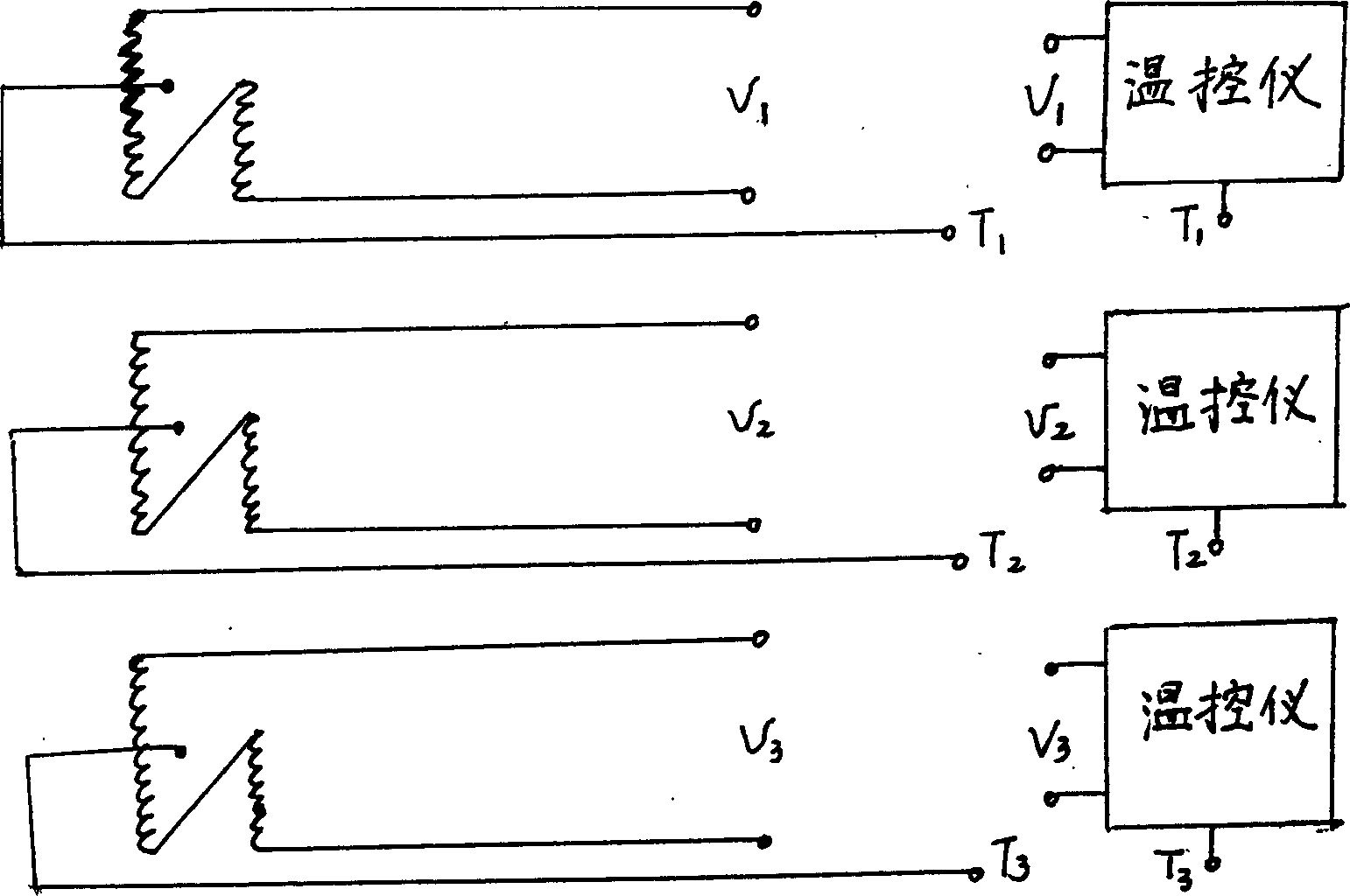

Three-segment opposite-opening type fatigue and high temperature test integrated furnace

InactiveCN1789441AUniform temperature riseEvenly heatedFurnace typesHeat treatment furnacesBrickThree stage

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

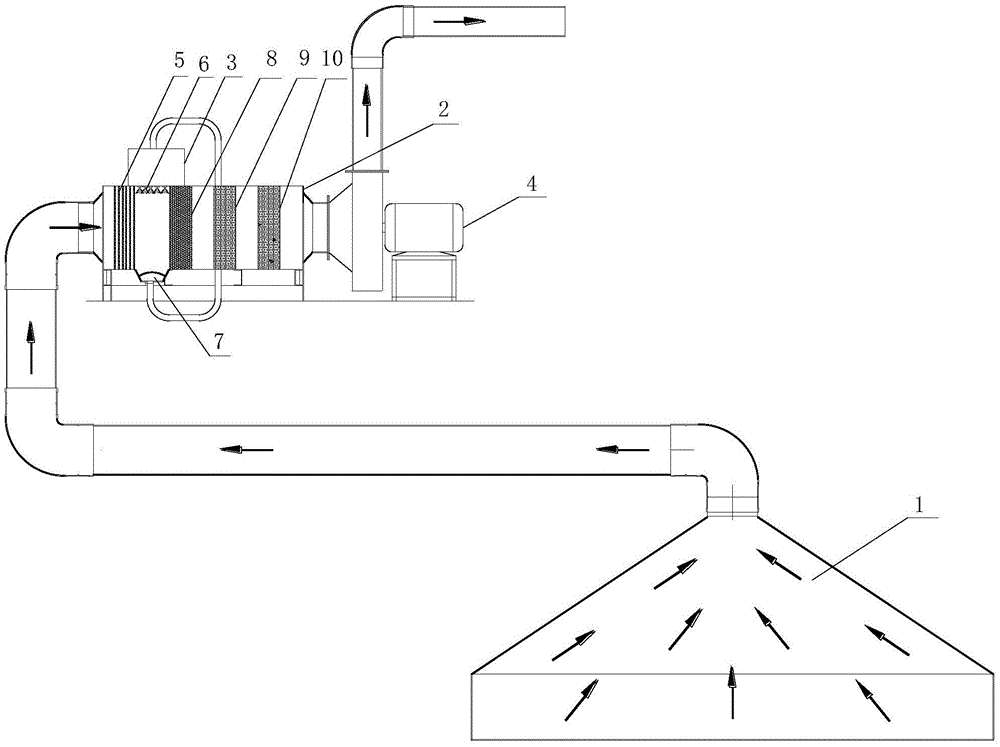

Dedusting apparatus

InactiveCN105597465AImplement coarse filteringFast absorptionCombination devicesBrickWater storage tank

Owner:ANHUI NINGHUO NEW MATERIAL

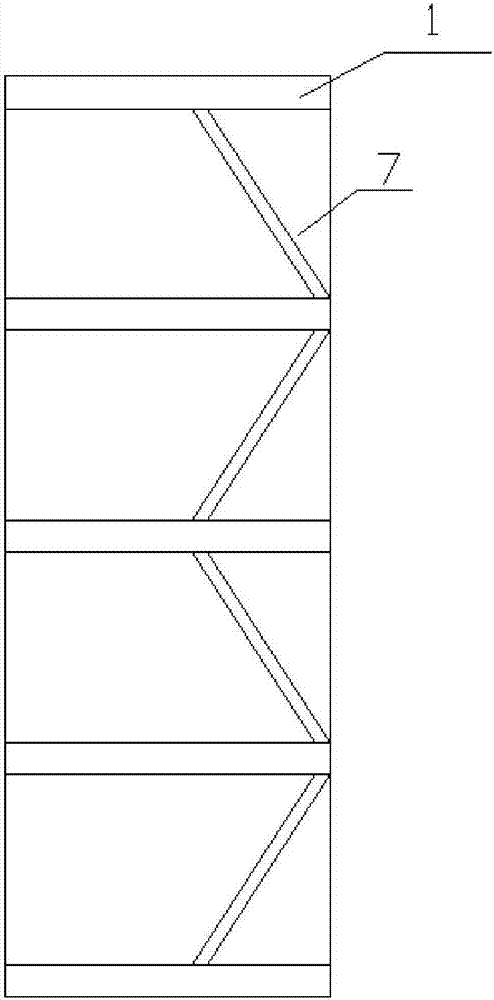

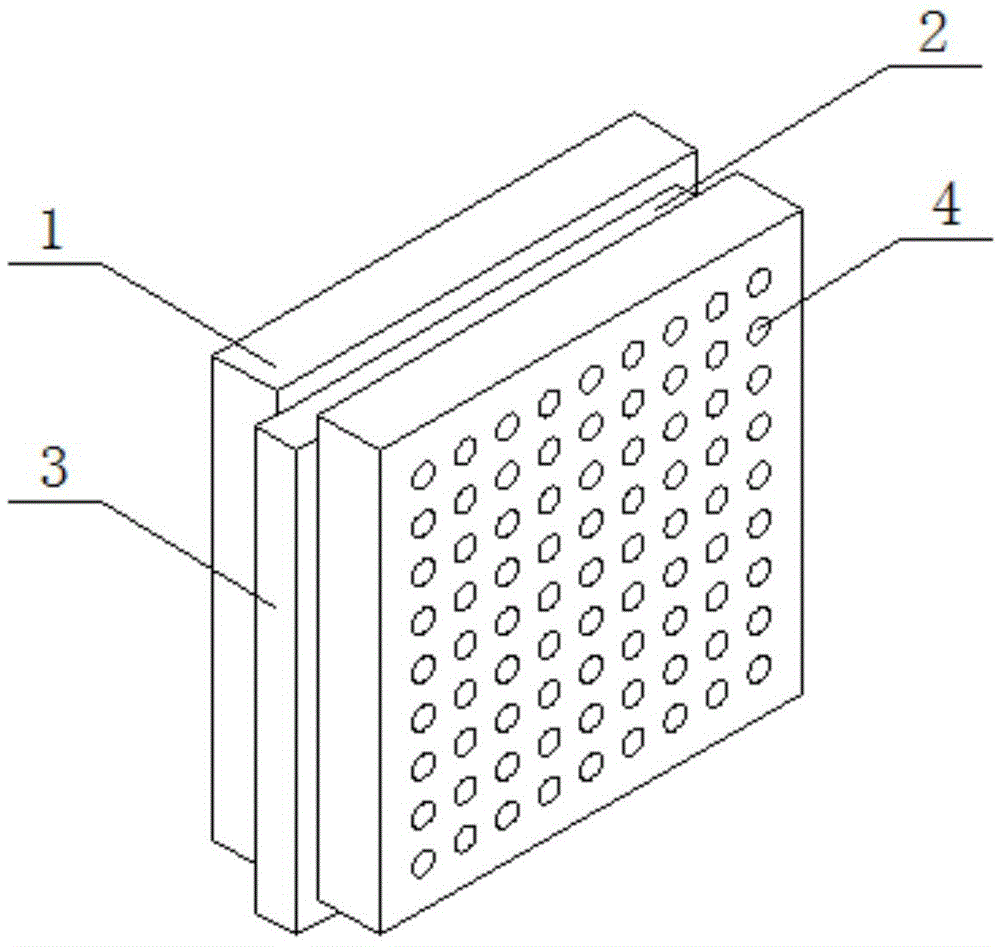

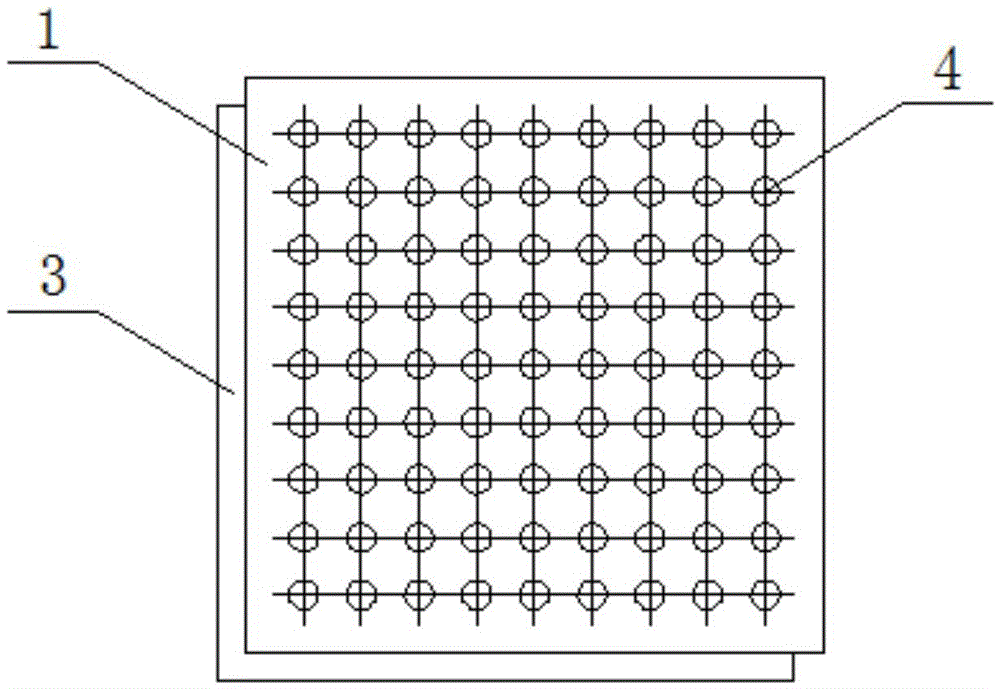

Shale-sintered hollow ganged brick

Owner:陈振杰

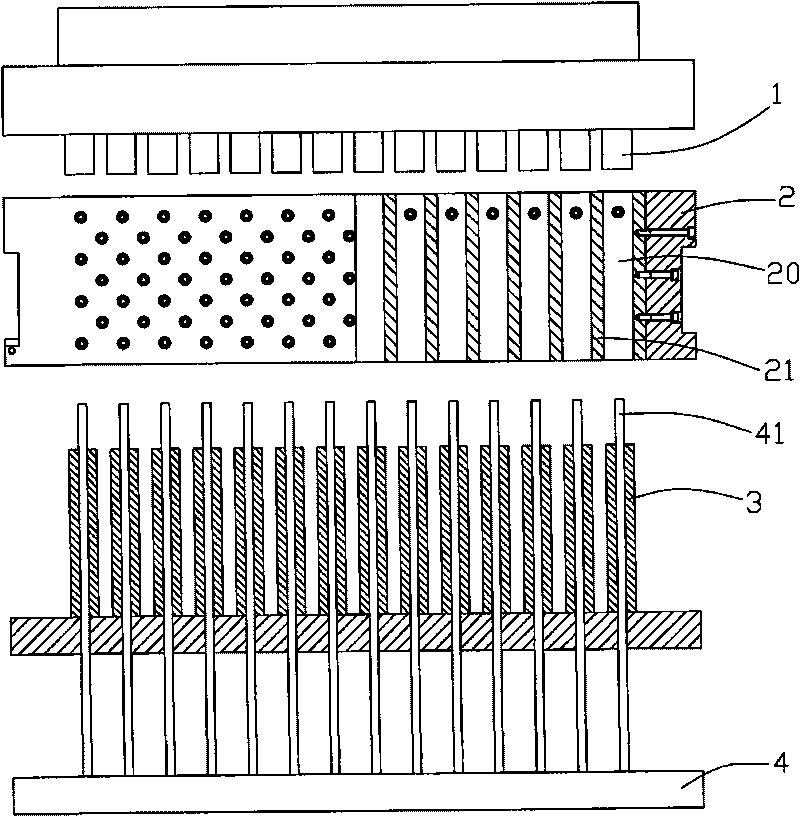

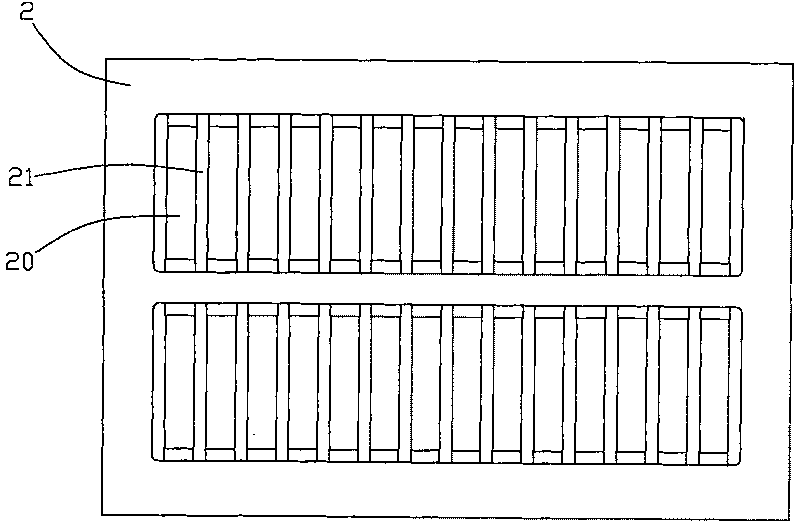

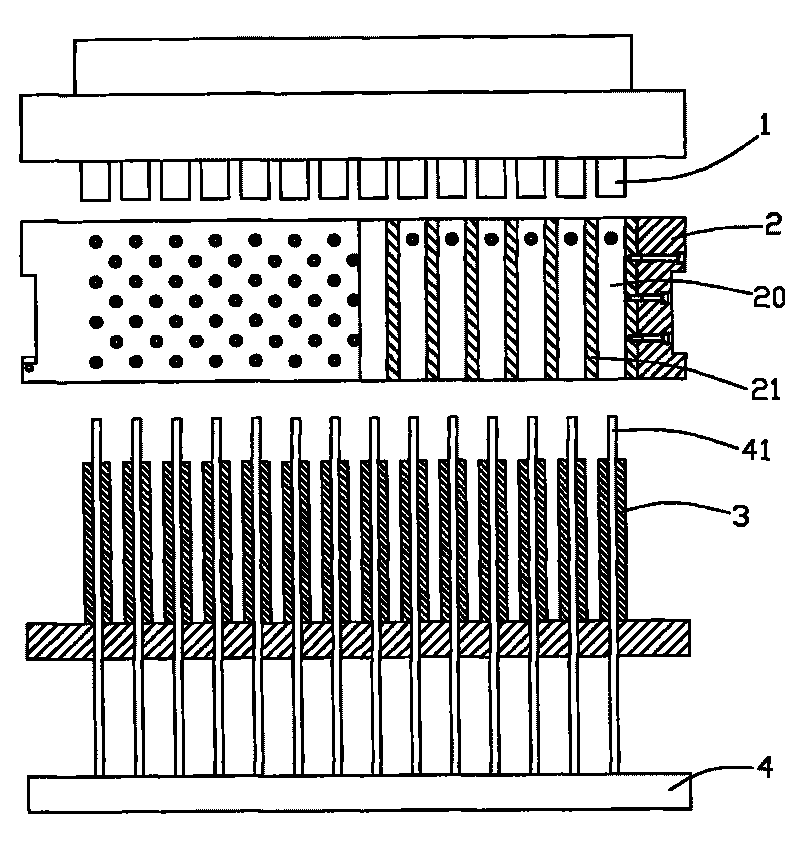

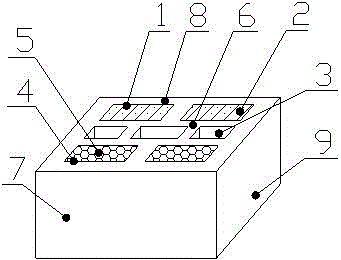

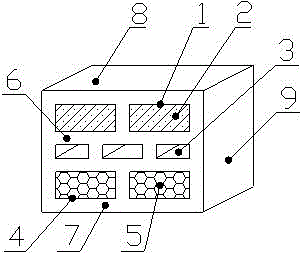

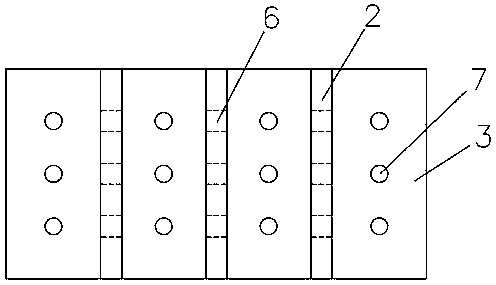

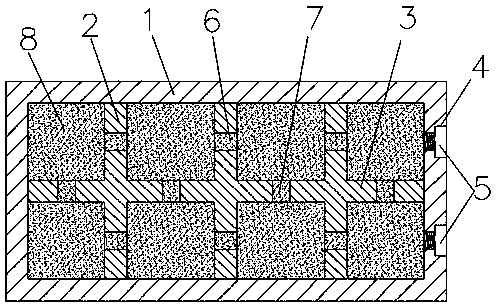

Full-automatic material distribution device and production process used for producing micro powder polished tiles

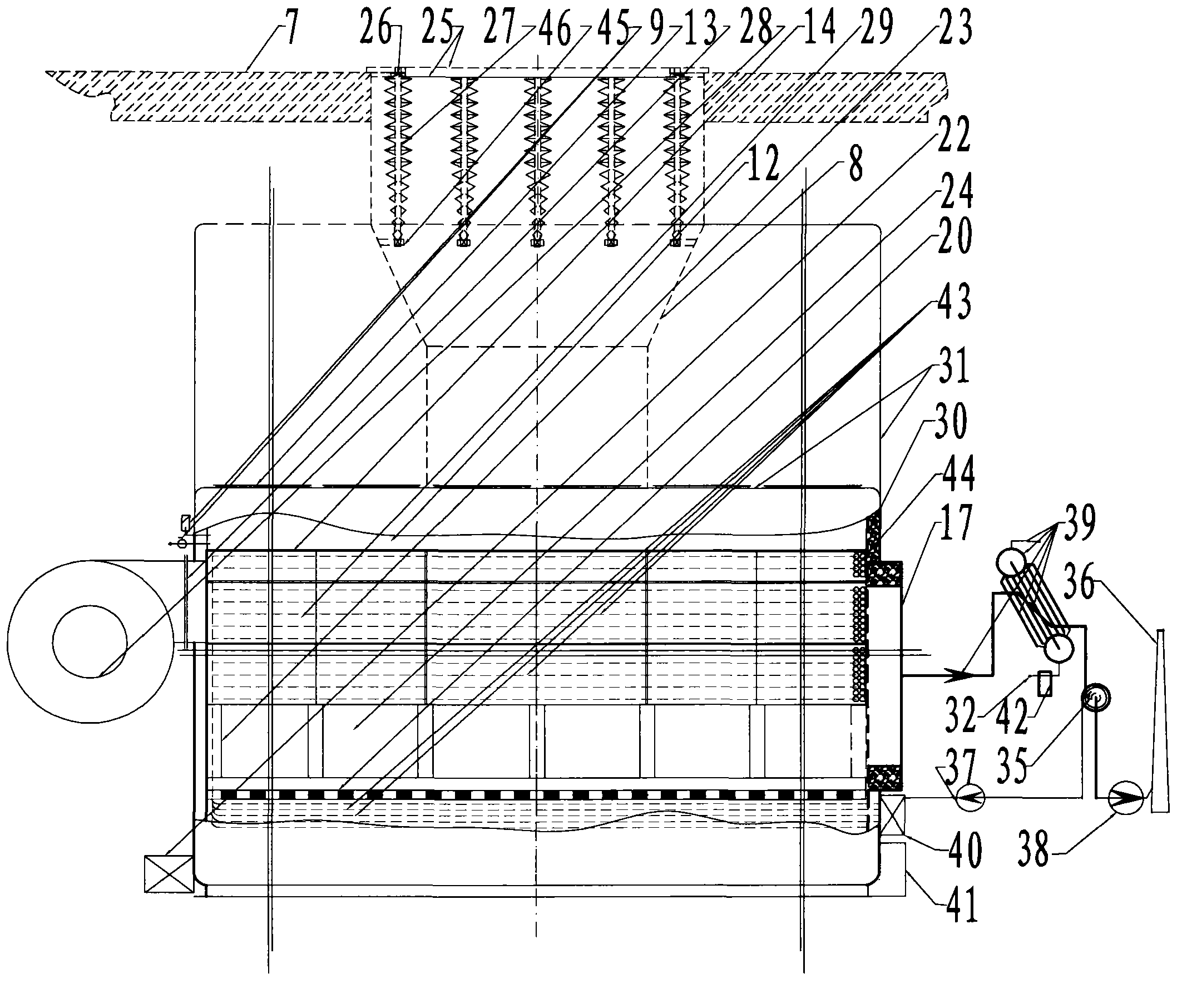

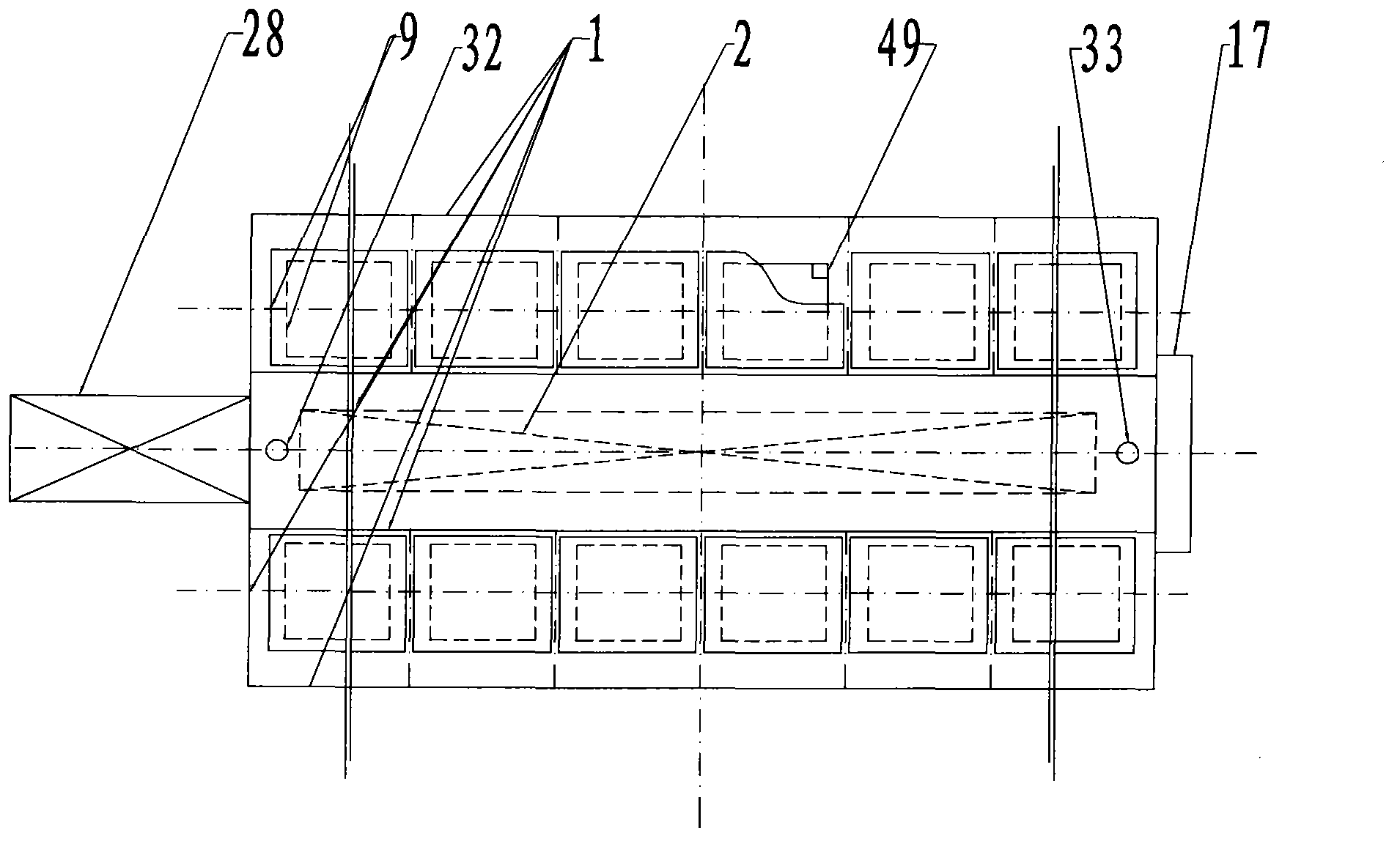

The invention discloses a full-automatic material distribution device and production process used for producing micro powder polished tiles. The full-automatic material distribution device comprises a main conveying belt for conveying micro powder, a line micro powder distribution mechanism, a material distribution mechanism, a material supplement mechanism, a grid feeding mechanism and an extrusion machine are sequentially arranged above the main conveying belt in the conveying direction, the line micro powder distribution mechanism, the material distribution mechanism and the material supplement mechanism sequentially distribute different types of powdery materials on the main conveying belt and then overlap the powdery materials step by step, and the grid feeding mechanism cuts the mixed powdery materials on the main conveying belt according to the specification of polished tiles and then feeds the materials into the extrusion machine for extrusion formation. The full-automatic material distribution device is ingenious and practical in structure. Ceramic micro power polished tiles produced through the full-automatic material distribution device are fine in texture, natural and vivid, the patterns of finished tiles are natural in transition, novel and irregular, and the decoration effect of ceramic micro powder polished tiles is greatly improved.

Owner:GUANGDONG HUIYA CERAMICS CO LTD

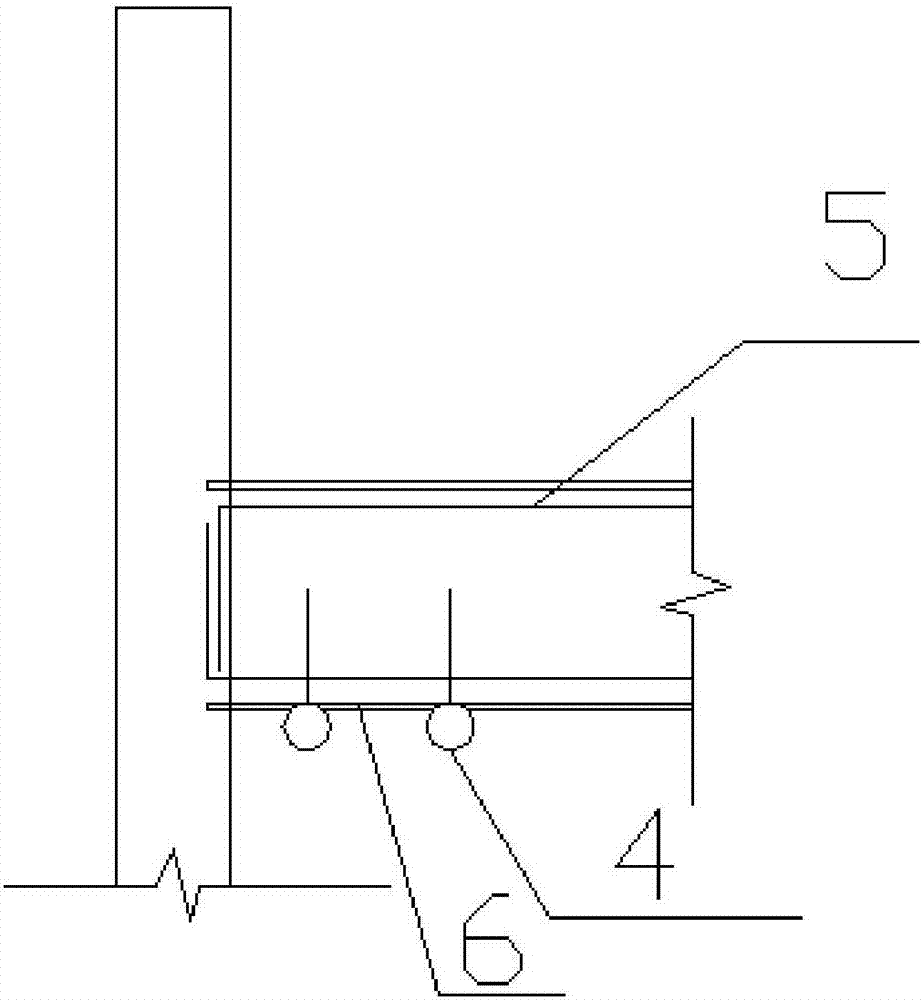

Core pulling molding device of pressure-type hollow brick machine

Owner:QUANZHOU FENGZE FUFAN MECHANICAL

Tunnel kiln brick-making method

ActiveCN104279865AReduce pollutionReduce consumptionFurnace typesIncreasing energy efficiencyAlkaneTunnel kiln

The invention provides a tunnel kiln brick-making method. A tunnel kiln comprises a preheating section, a sintering section, a cooling section, a fuel and combustion-assisting air conveying system, a temperature control system, a heat exchange system and a smoke discharging system. The tunnel kiln brick-making method includes that a mixture of smoke containing polluting gas like pyrolytic gas, volatile gas gas and alkane generated by the preheating section and combustion-assisting air is fed into the sintering section to be mixed with fuel for mixed combustion, wherein the polluting gas is fully oxidized and finally generate carbon dioxide, water and the like along with combustion smoke to be cooled through a heat exchanger and then discharged. Hot air generated by the cooling section directly enters the preheating section to serve as preheated air, or the hot air generated by the cooling section together with normal-temperature air is heated through the heat exchanger to be preheated air so as to achieve the objective of waste heat recycling. By the tunnel kiln brick-making method, energy utilization rate of the tunnel kiln in the prior art is increased further, pollution, to surrounding environment, of discharged smoke is reduced, and effect of energy conservation and emission reduction is realized.

Owner:DALIAN UNIV OF TECH

Decorative and thermal-insulation integrated novel lightweight walling material made from polishing brick waste

Owner:ZIBO YONGXU REFRACTORY MATERIALS

Granite concrete pavior brick and its manufacturing method

InactiveCN102337715ANot easy to residueNot crushableSingle unit pavingsClimate change adaptationBrickMaterial resources

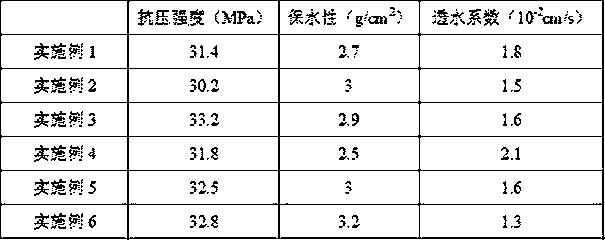

The invention discloses a granite concrete pavior brick and its manufacturing method. The method comprises the following steps: taking cement, mountain sand and broken stone as the bottom layer raw materials, taking cement, mountain sand and granite as the surface layer raw materials, then placing a double-layer die filled with surface layer mixed raw materials and bottom layer mixed raw materials into a 80 ton-110 ton of press machine for vibrating, pressurizing and forming to obtain the granite concrete pavior brick. The granite concrete pavior brick has the advantages of good wear resistance, high strength, uniform bearing, simple and fast construction, good draining performance, low cost and long service life. Comparing the tests under the same usage environment condition and same thickness of the brick, the service life of the granite concrete pavior brick is 2-3 times higher than that of a traditional concrete brick. And can be widely used for large load bearing roads, wharfs, squares, pavements, earth-retaining slopes, lawn roads and the like. Tests prove that the maintenance work is greatly reduced and the manpower and the material resources can be saved by using the pavior brick of the invention.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC +1

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

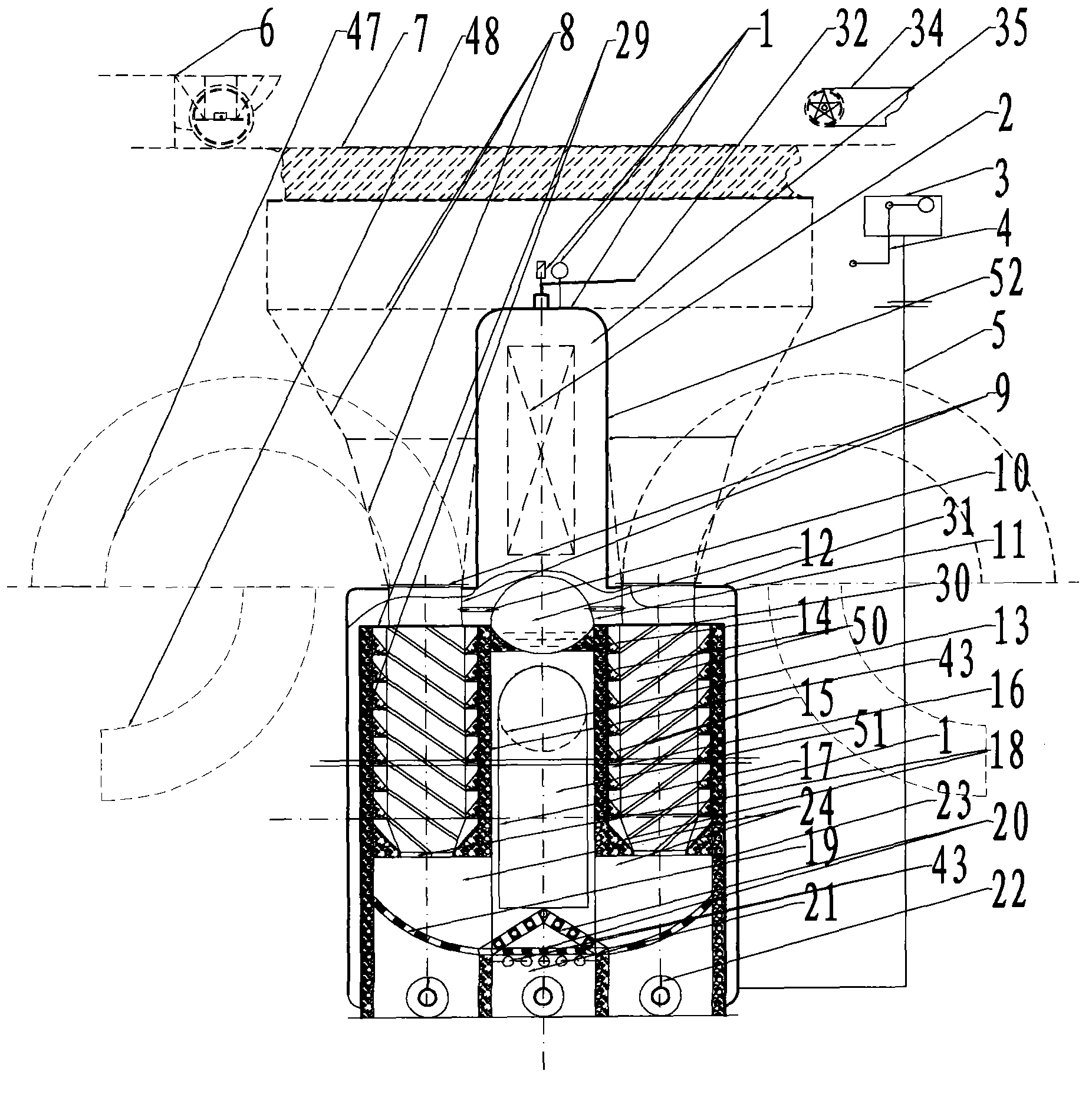

Water-based combustion-supporting straw particle boiler-kiln universal burner with fuel such as coal, gas and oil

InactiveCN104235832AKeep aliveResponse is continuous and stableCombustion using multiple fuelsCombustion using catalytic materialWater basedBrick

Owner:管理

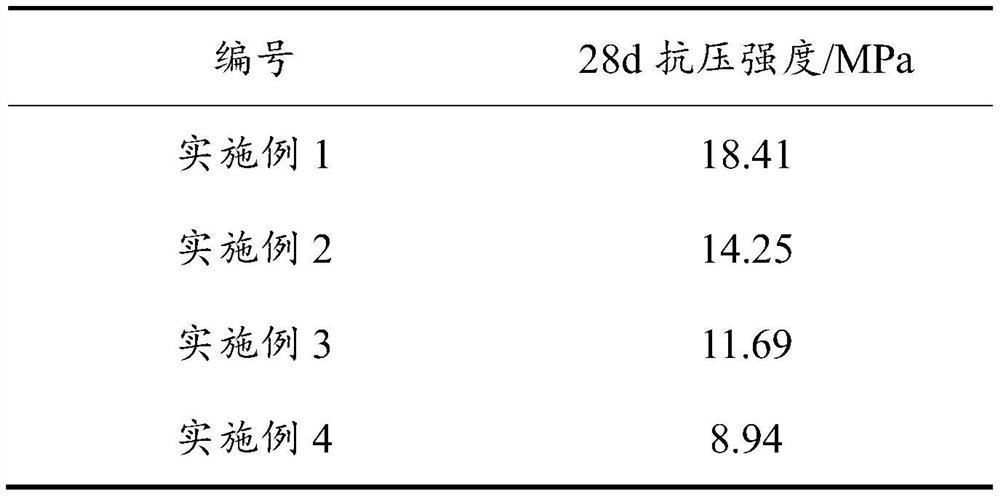

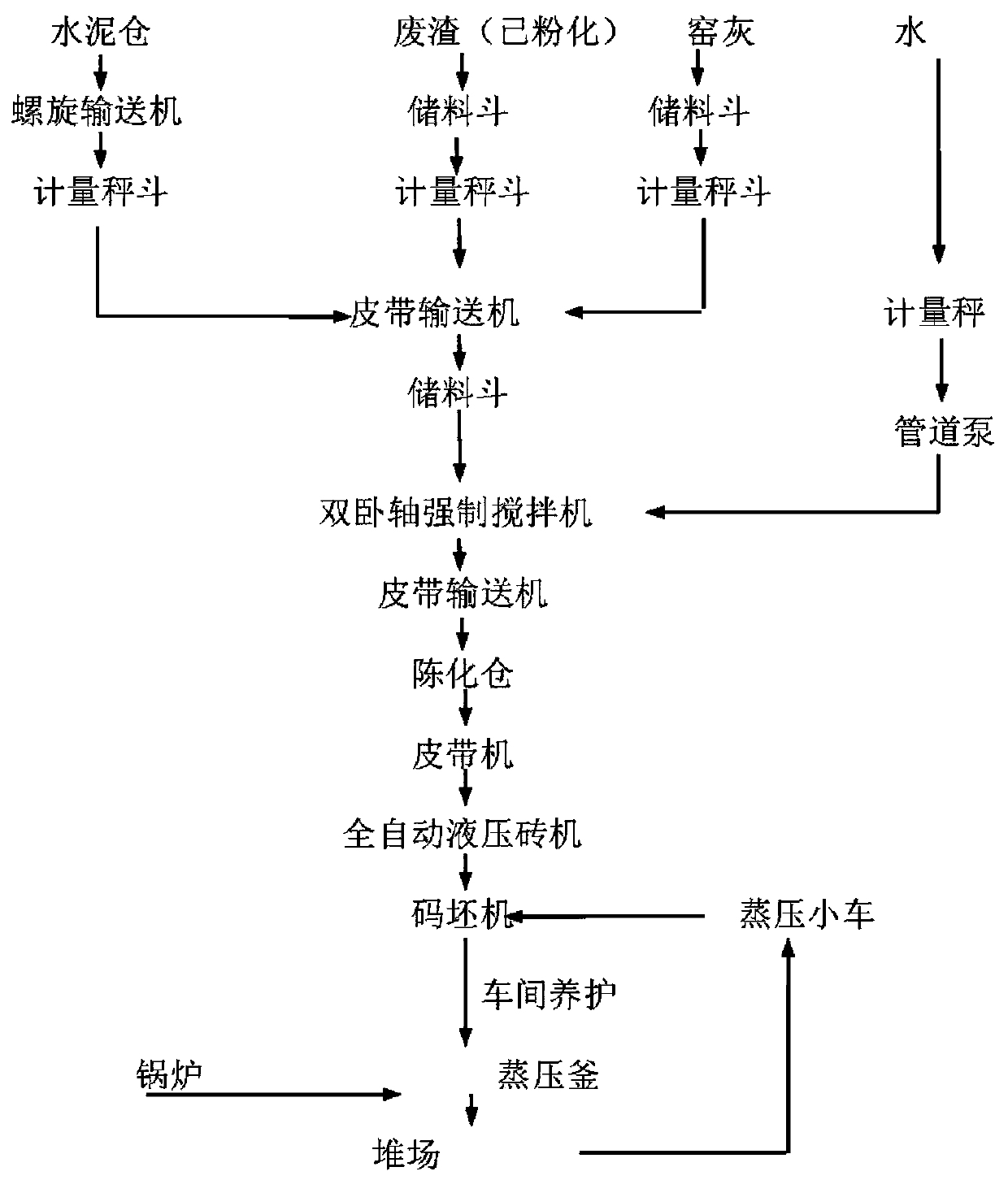

Autoclaved lime sand brick and production method thereof

InactiveCN104098312AStable expansion coefficientOvercome problemsSolid waste managementBrickMolding machine

The present invention discloses an autoclaved lime sand brick and a production method thereof, and solves the problems that in the prior art lime sand brick production cycle is long, the intensity is not high, the discrete degree is great and the like; the autoclaved lime sand brick is characterized in that: on the traditional basis of green sand and quick lime, a right amount stone chip is added, the quick lime is crushed, then the quick lime, the green sand and the stone chip are firstly mixed with water in an ash mixing machine, after 2.5 ~ 3 hours of hopper type digestion, secondary stirring is performed to make caking in the mixture broken and loose, the mixture is sent by a conveying system into a turntable type molding machine for pressing into green bricks, the pressed green bricks are sent by a traction machine into an autoclave for high temperature and high pressure autoclaving to produce the autoclaved lime sand brick with the strength more than 2 times of that of national standard of ordinary standard bricks.

Owner:HUANGGANG TONGKAI BUILDING MATERIALS CO LTD

Highly water-retaining water-permeable brick prepared from building recycled material and preparation method thereof

Owner:广东怡兴食品有限公司

Sliding construction method for building

Owner:郯城县经开区医药发展有限公司

Technology for making bricks from aggregate waste residues

Owner:华新新型建筑材料有限公司

One-column and one-pile construction method adopting hydraulic verticality-adjusting frame reversing building method

PendingCN109610441ASolve the construction problem of vertical adjustment of one column and one pileSimple construction processIncline measurementBulkheads/pilesBrickSlag

Owner:ZHONGTIAN CONSTR GROUP +1

Water-permeable soil-conservation revetment brick

Owner:ANHUI XIANGKAI NEW ENVIRONMENTAL CONSTR CO LTD

Thermal-storage, heat-insulation and sound-insulation hollow brick

InactiveCN104358342AReduce energy consumptionGood sound and heat insulationConstruction materialBrickStructural engineering

Owner:SOUTHWEAT UNIV OF SCI & TECH

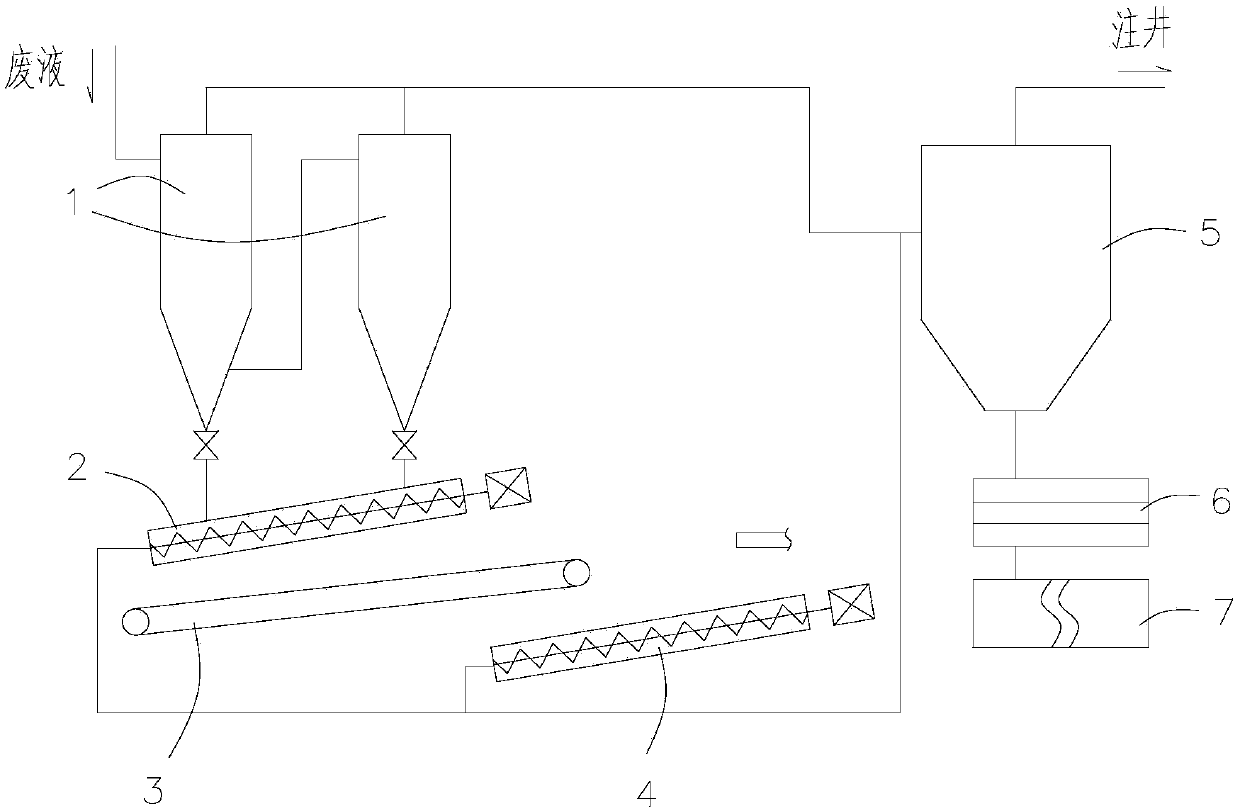

Reutilization method for alkali-making waste residue liquid and system using reutilization method

InactiveCN109570186AReduce pressure on environmental protectionReduce effluxSolid waste disposalTransportation and packagingBrickFilter press

Owner:湖北云应矿业技术开发有限公司

Civil automatic brick making device

InactiveCN112297194AConvenient collection workNo need for manual extrusionCeramic shaping apparatusBrickArchitectural engineering

The invention relates to a brick making device, in particular to a civil automatic brick making device. According to the civil automatic brick making device, slime is mechanically and automatically extruded into the shape of a brick, so that the surface layer of the slime is very smooth. The civil automatic brick making device comprises a bottom plate, a feeding mechanism, a rotating mechanism andan ejection mechanism, wherein a servo motor is arranged on one side of the top of the bottom plate; the feeding mechanism is arranged on one side, close to the top of the servo motor, of the bottomplate; the rotating mechanism is arranged on the other side of the top of the bottom plate; and the ejection mechanism is arranged in the middle of the top of the bottom plate. Slime can be automatically conveyed to an ejection mechanism part through the feeding mechanism, and workers only need to fill new slime used for making bricks when a feeding frame moves at intervals every time; and throughthe arranged rotating mechanism, the slime can be automatically extruded, manual extrusion is not needed, the extrusion force is consistent, and the formed bricks are smoother.

Owner:杨金鑫

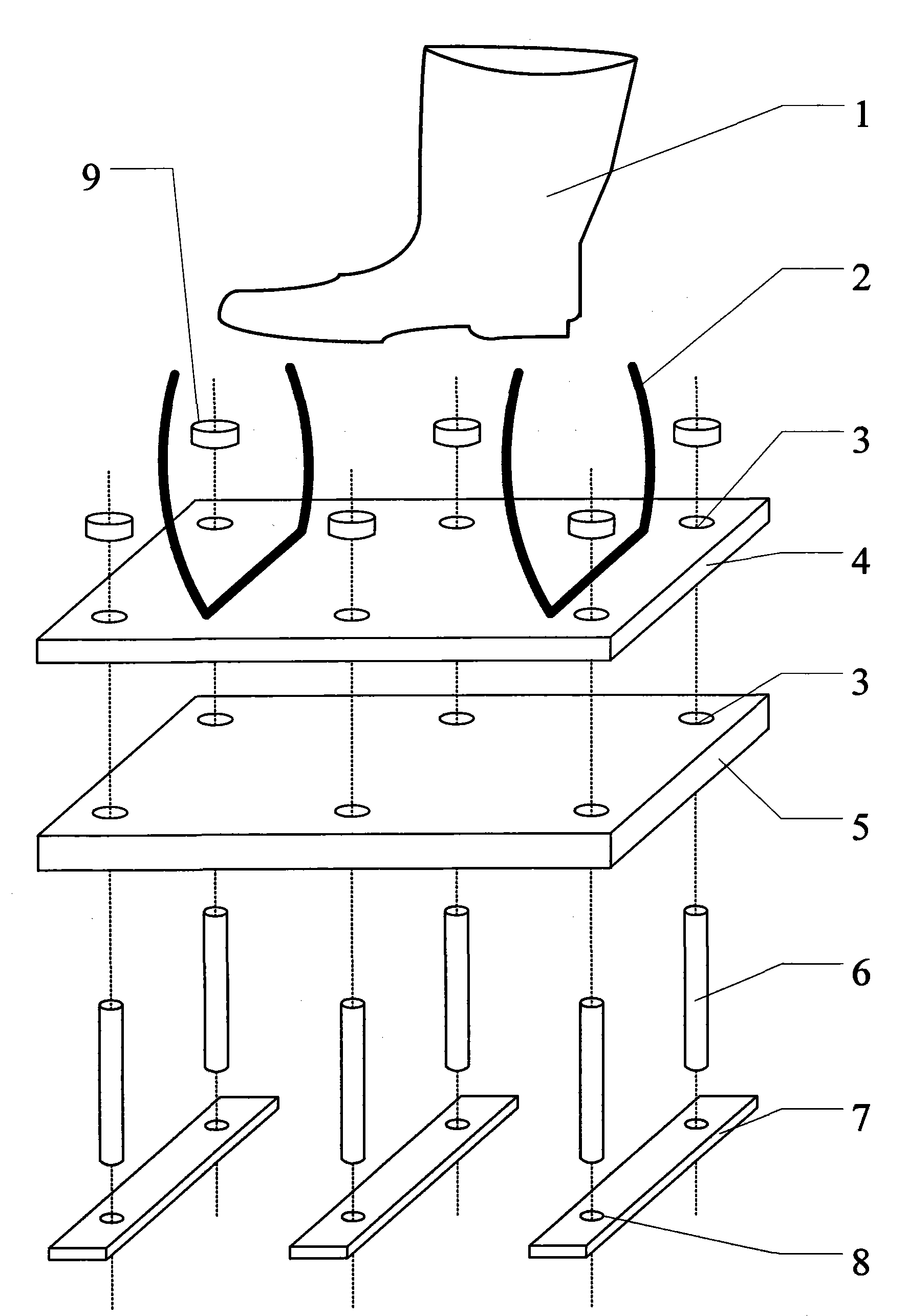

Brick layer boot

InactiveCN104018686AImprove work efficiencyImprove construction qualityBuilding material handlingBrickCushion

Owner:郭明

Hydrating molding process and raw material formula of concrete faux marble granite dry powder

ActiveCN103880345AHigh degree of simulationLow-carbon environmental protection and energy savingSolid waste managementBrickHigh pressure

The invention discloses a hydrating molding process and a raw material formula of concrete faux marble granite dry powder. The raw material formula comprises ceramic residue, mineral powder, cement and quartz sand; the molding process comprises the following steps: mixing color, agitating materials, storing materials, spraying powder by virtue of a computer, distributing by virtue of a plurality of pipelines, controlling a manipulator to adjust a pattern, spraying water at high pressure for hydrating, vibrating to mold, maintaining with steam, and polishing a surface. The raw material formula is on the basis of the ceramic residue and cement, and the molding process does not need any high-temperature firing, so that the advantages of low carbon, environmental friendliness and energy conservation are realized; in addition, a finished product molded through the process is high in simulation degree, the plate is 10 to 30mm in thickness, or a composite layer on the surface of a concrete faux marble granite composite plate is 3 to 8mm in thickness; all finished bricks are slightly different, have high sense of wholeness, and also show high naturalness while being applied to a specific scene; moreover, the problem of the current ceramic industry that a wall brick or a ceramic brick can only be molded by firing at a high temperature, which causes large energy consumption, serious pollution and treatment on lots of ceramic residues produced by the production of the wall brick or ceramic brick in the traditional ceramic industry, can be solved.

Owner:李庆洪

Method for producing environmentally friendly high-temperature fold-resistant high-strength high purity corundum bricks

InactiveCN105237003ASurprised by high temperature flexural performanceReduce dosageBrickMixed materials

Owner:长兴宏泰耐火器材有限公司

Refractory ceramic tile and preparation method thereof

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

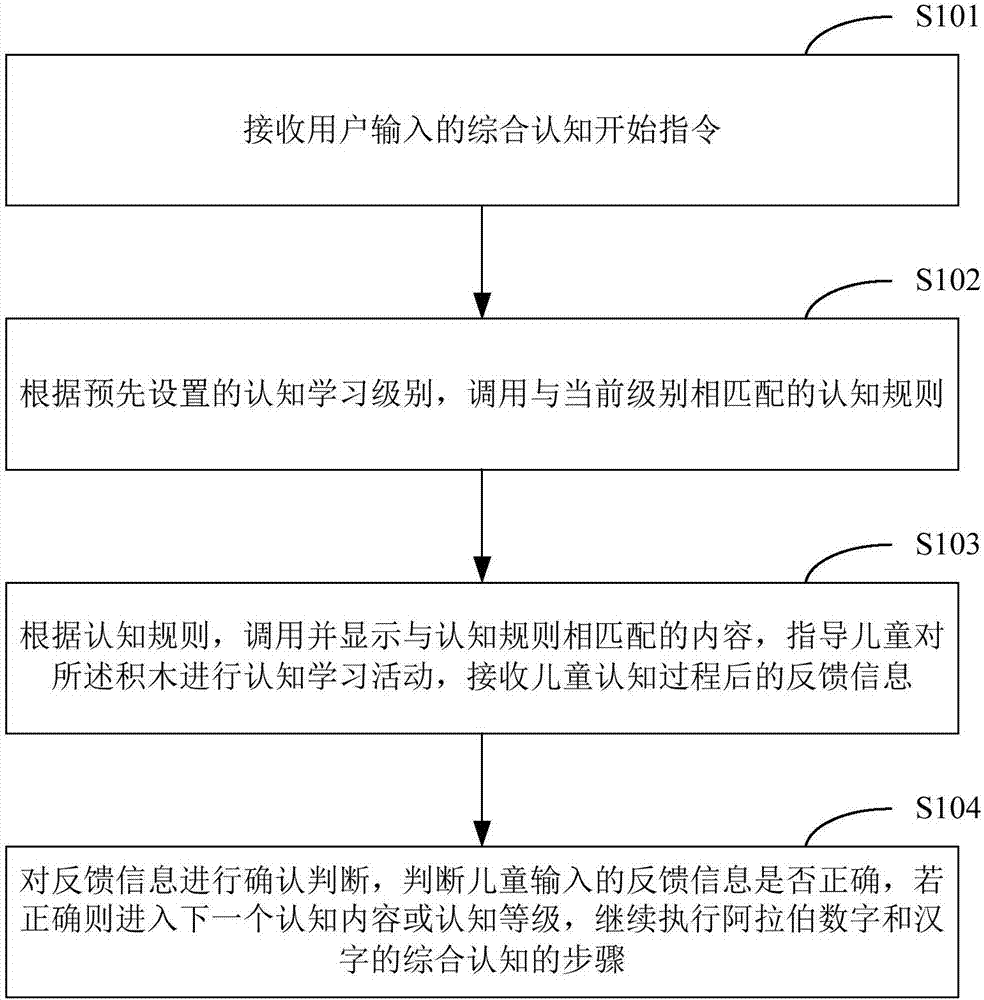

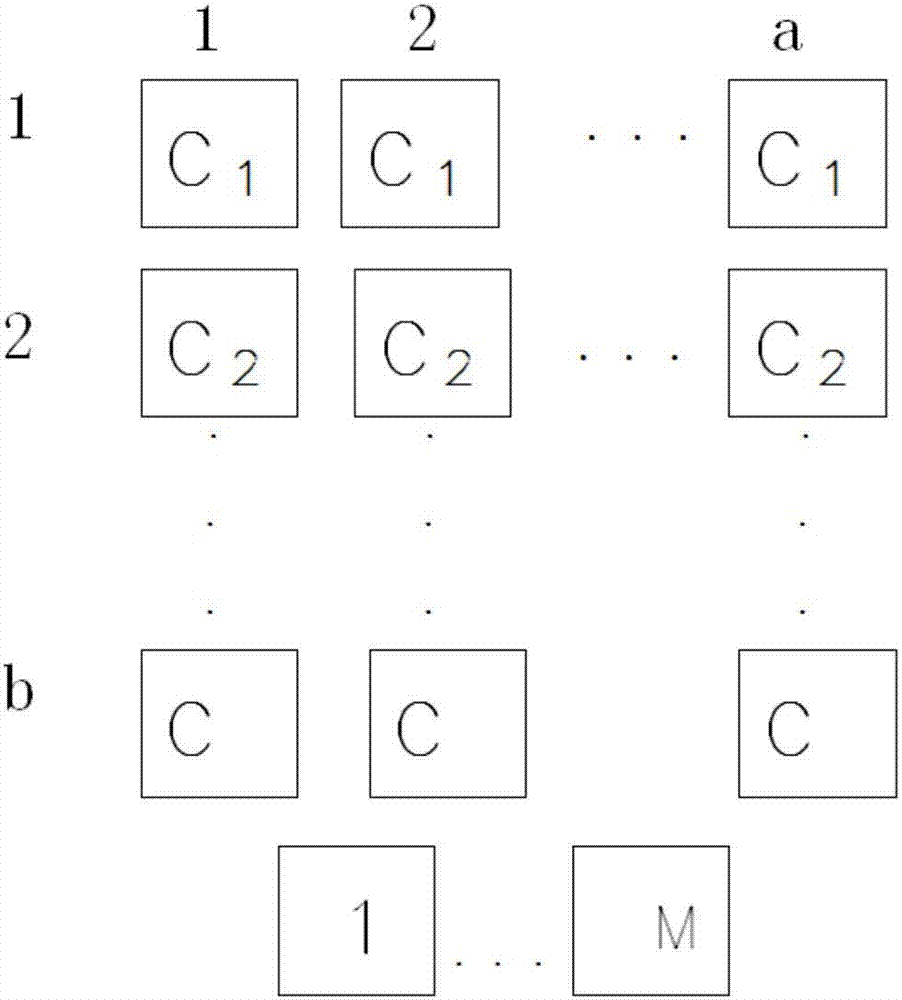

Comprehensive cognition method based on Arabic numerals and Chinese characters and system

InactiveCN106920428AGuaranteed healthy growthImprove interaction abilityElectrical appliancesChinese charactersArabic numerals

Owner:北京种月亮科技股份有限公司

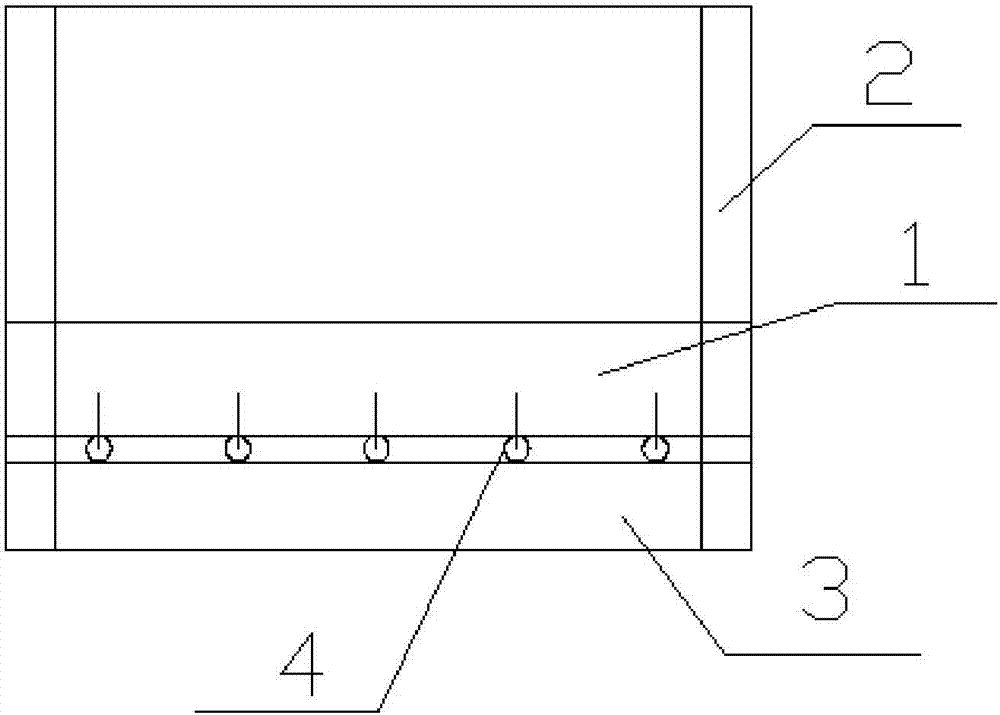

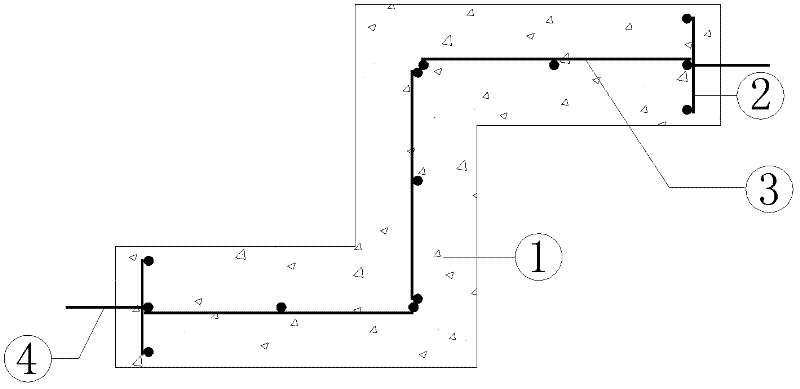

Latticed single-row reinforced Z-shaped sectional concrete column and making method

InactiveCN102561594AReduce dosageImprove shear resistanceStrutsBuilding reinforcementsBrickSteel bar

Owner:BEIJING UNIV OF TECH

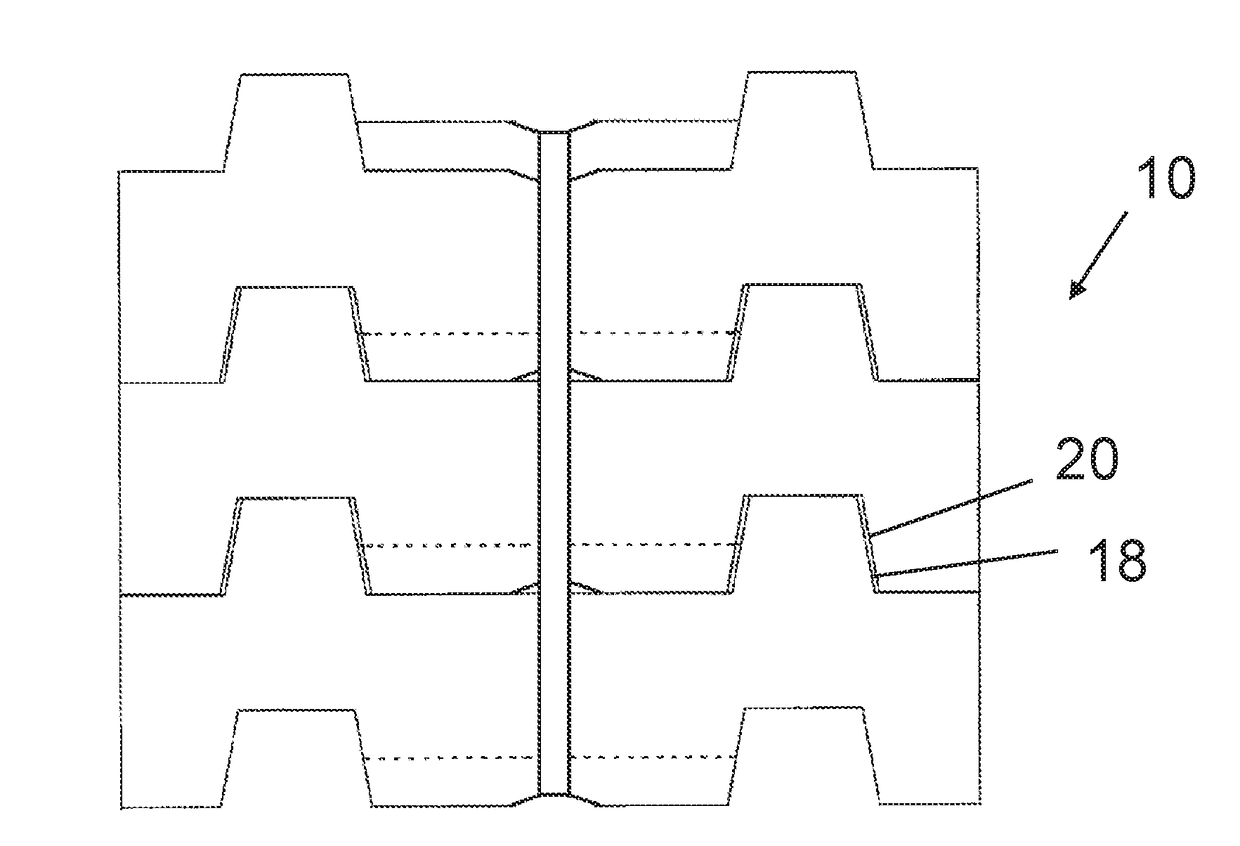

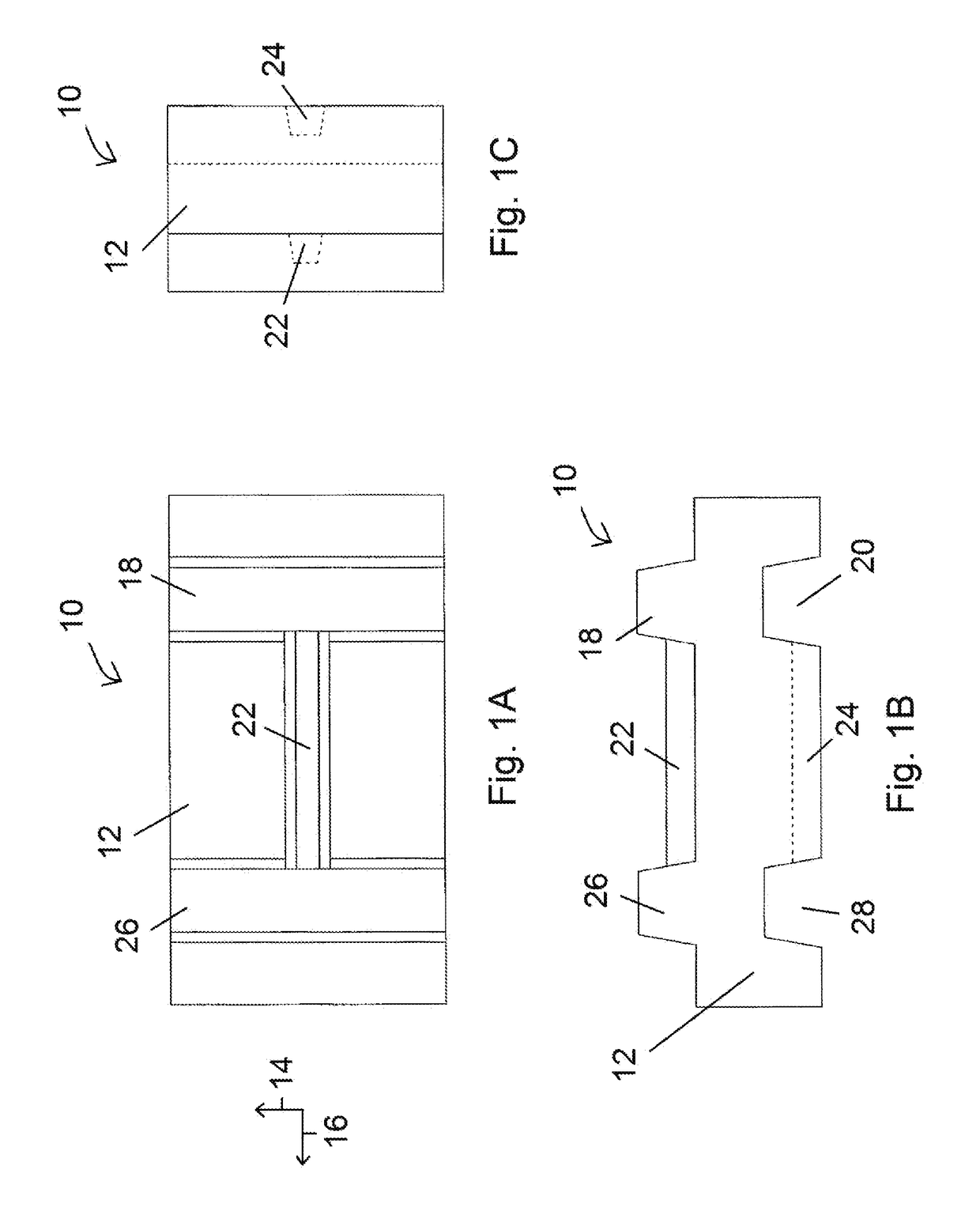

Pallet-less brick

ActiveUS20180244449A1Eliminate useTransported quickly and efficientlyRigid containersDamagable goods packagingBrickEngineering

Owner:BALL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap