One-column and one-pile construction method adopting hydraulic verticality-adjusting frame reversing building method

A construction method and technology for adjusting the vertical frame, which are applied to sheet pile walls, infrastructure engineering, measuring devices, etc., can solve the problems of difficult operation, excessive consumption of manpower and material resources, etc. The effect of droop accuracy and speed advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

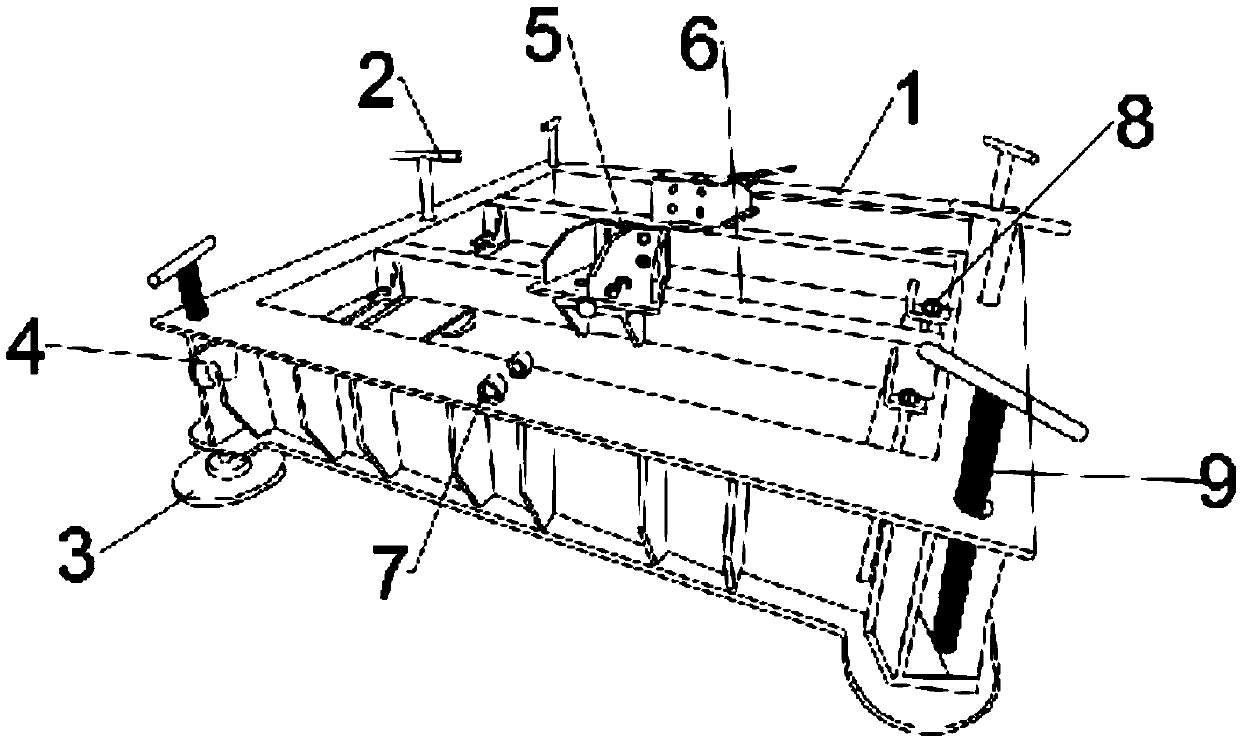

[0029] see figure 1, in an embodiment of the present invention, a hydraulic modulation platform, including a body 1, a unidirectional adjustment rod handle 2, a support base 3 and an adjustment support top 5, the four corners of the lower surface of the body 1 are fixed and welded to support the base 3, and the support The setting of the base 3 can support the body 1. The top of the inner wall of the body 1 is fixedly welded to connect the cross bar 6, and the connecting cross bar 6 is fixedly welded to the inner wall of the body 1. An adjustable support top 5 is installed on the top, and the adjustable support top 5 is slidingly connected with the connecting cross bar 6. The right end of the connecting cross bar 6 is also fixedly installed with front and rear movable end fixed wings 8, and the front and rear movable end fixed wings 8 The setting can play the role of limiting the adjustment support top 5, and the upper surface of the body 1 is axially evenly arranged with a plura

Embodiment 2

[0032] A construction method based on the hydraulic modulation platform described in Embodiment 1 using the hydraulic vertical adjustment frame reverse method, one column, one pile construction method, the steps are as follows:

[0033] S1, the whole site is hardened, the site needs to be fully hardened before construction: 300 thick brick slag leveling, tamping, pouring 200 thick C30 concrete surface, internally equipped with HRB335 grade φ12 threaded steel single-layer two-way distance of 200mm;

[0034] S2, setting out wires and laying casings;

[0035] S201. Lead out the pile position line from each axis, the allowable deviation is 5mm, mark the center point of the pile position with a nail, and use red paint to draw a control circle with the center of the pile position as the center and the radius of the pile as the radius, and indicate the pile number. On the hard floor, use an ink line to pop up the cross lines along the axial direction and the vertical axis direction, cut

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap