Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about "Bulkheads/piles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

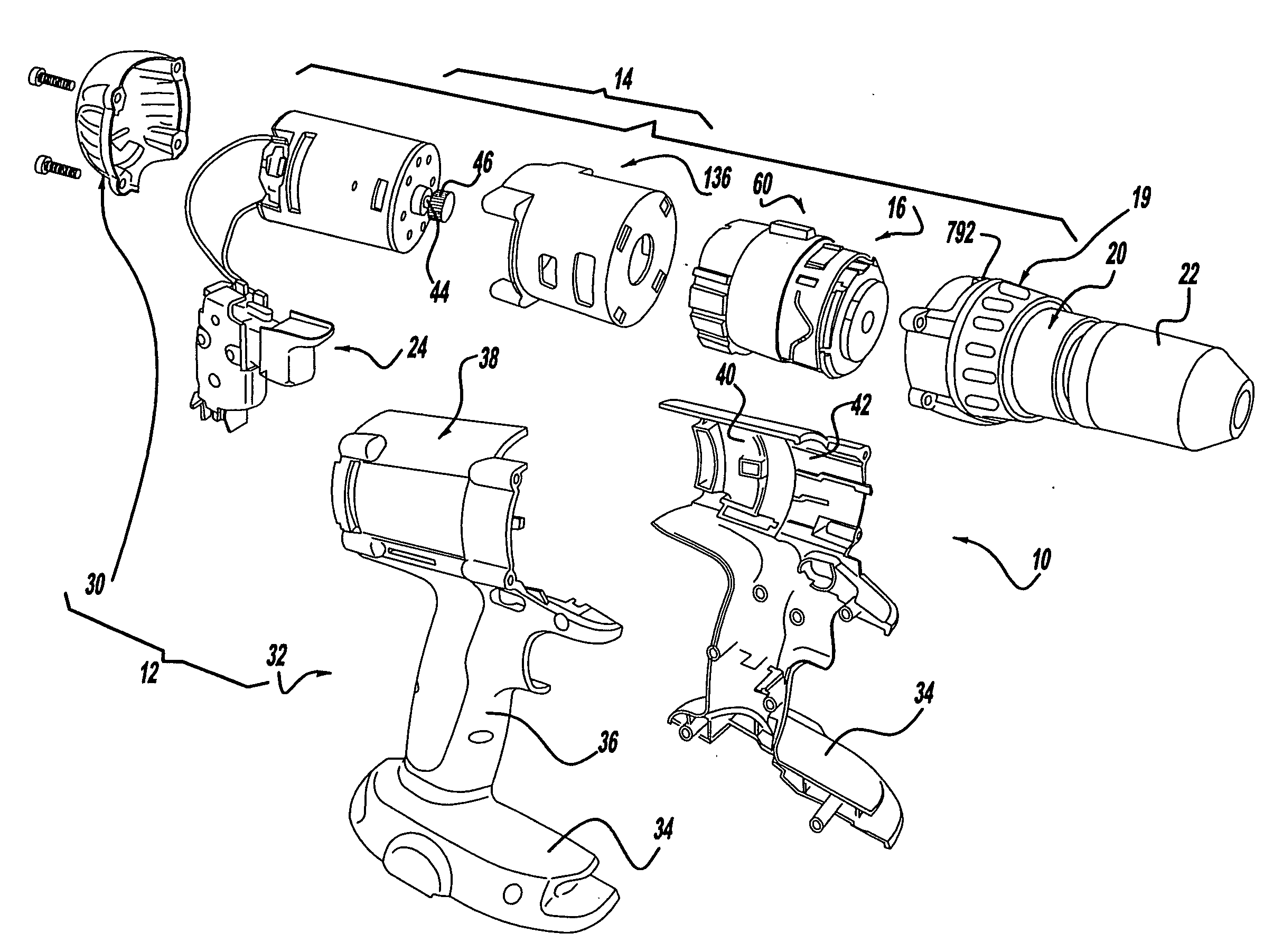

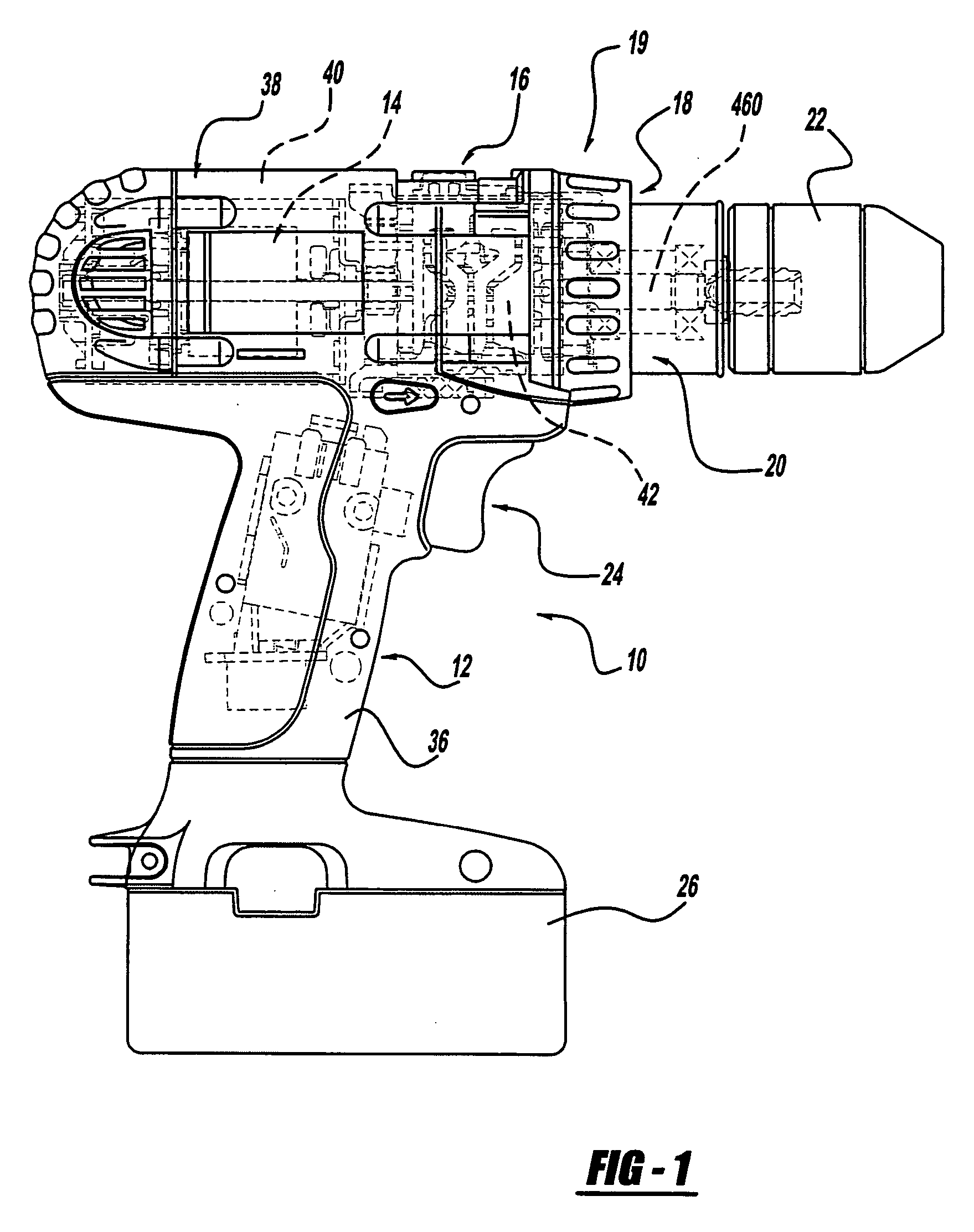

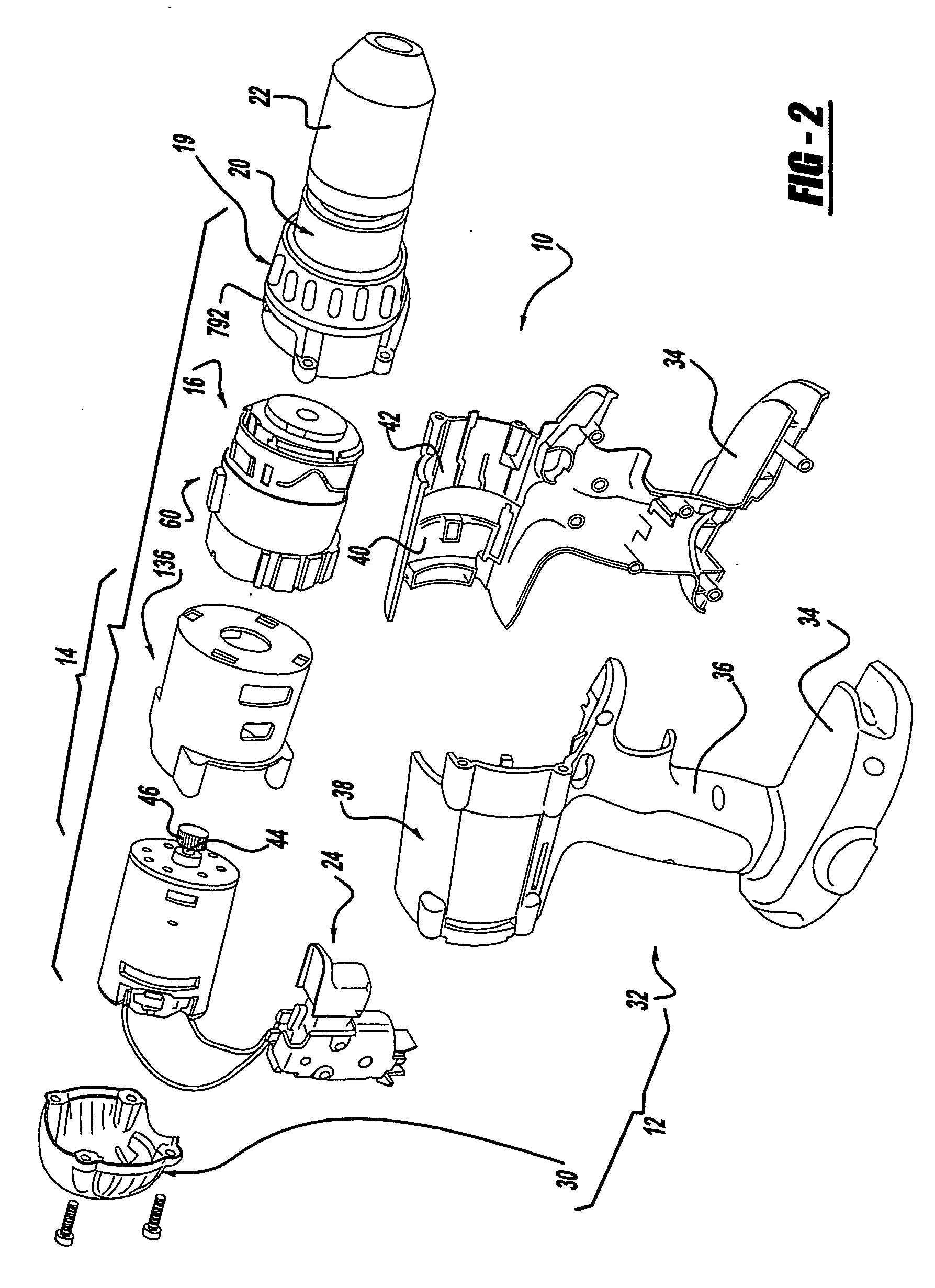

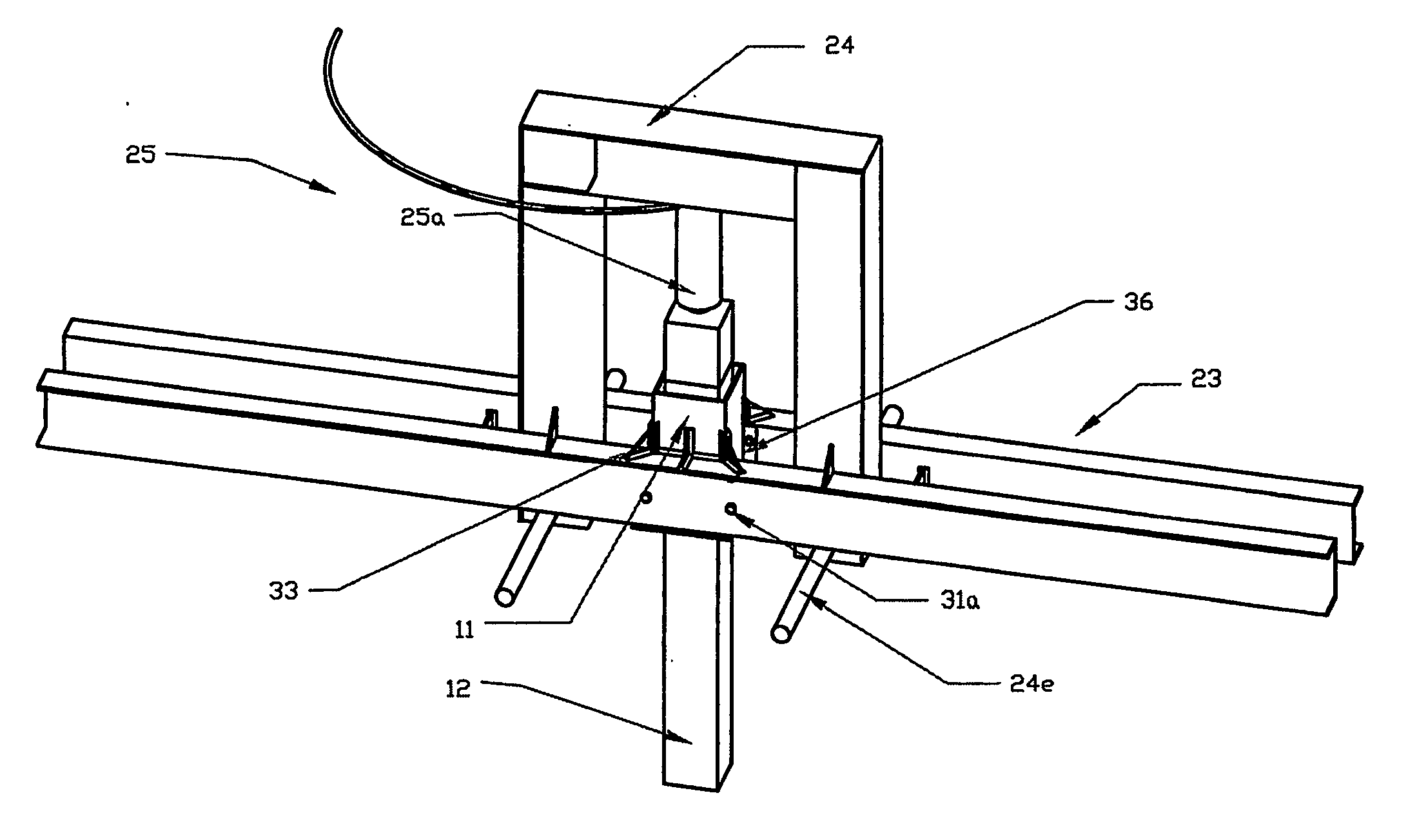

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

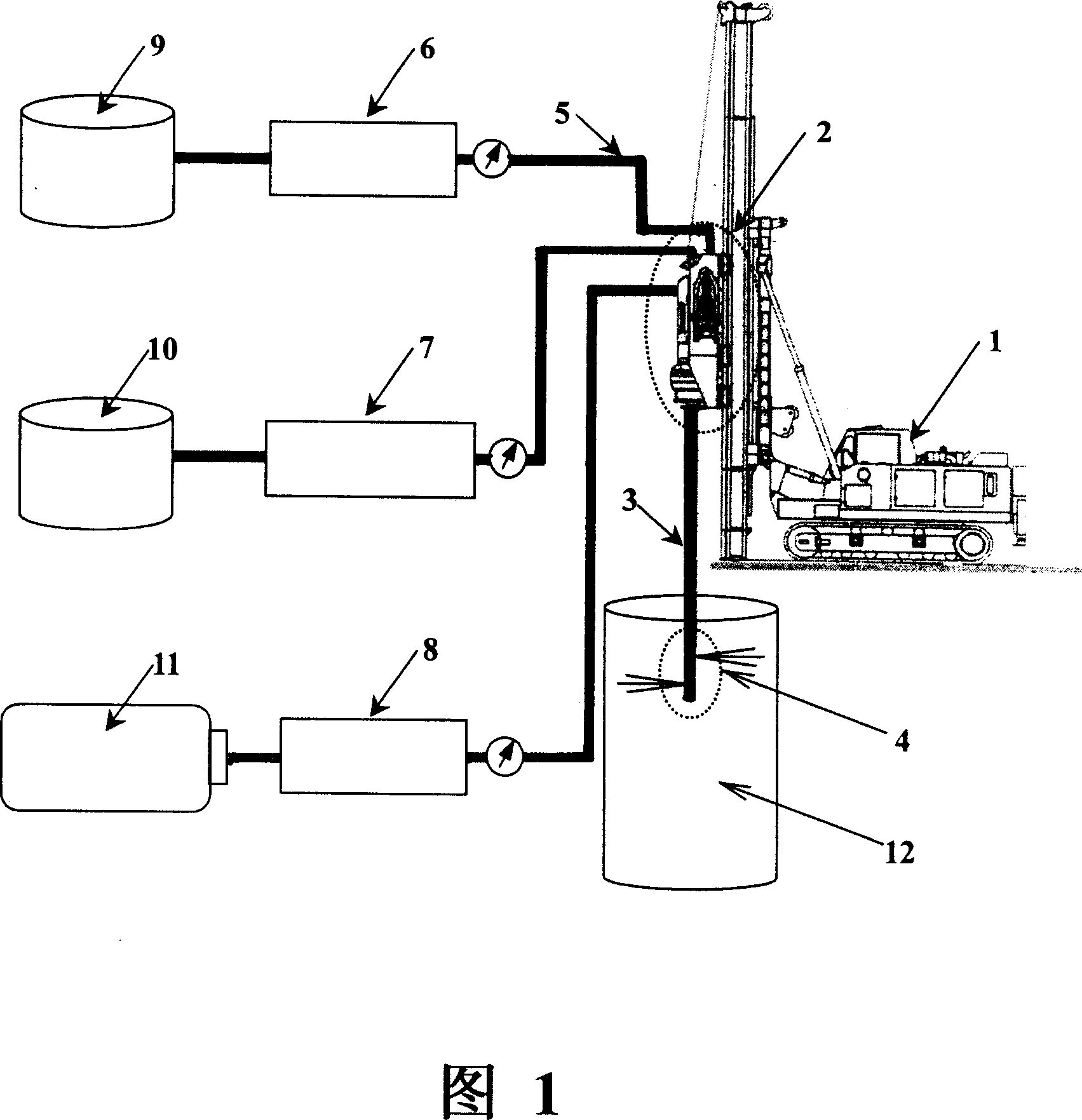

Three pipe double high pressure rotary jet sprouting reinforced construction method and its equipment

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

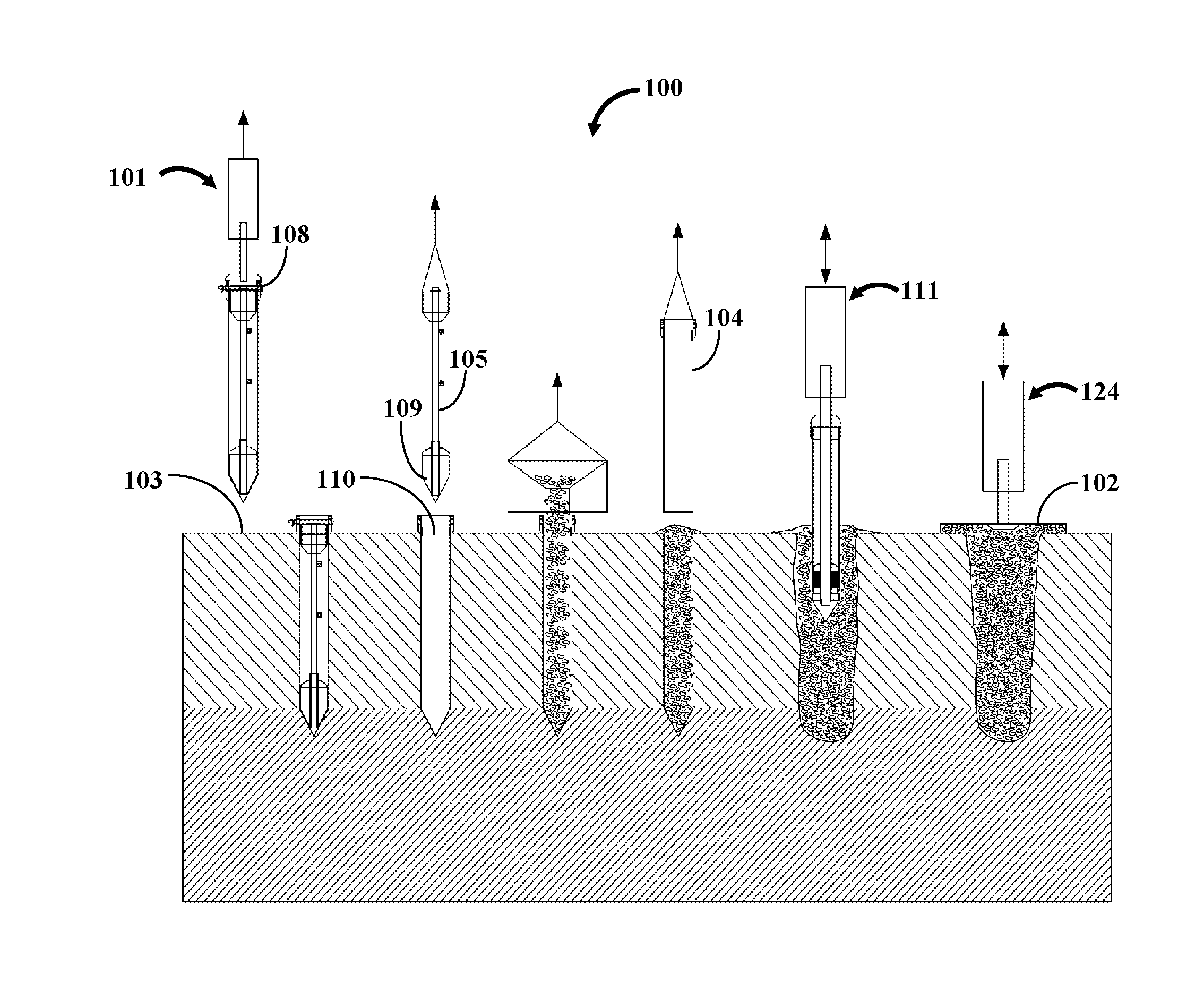

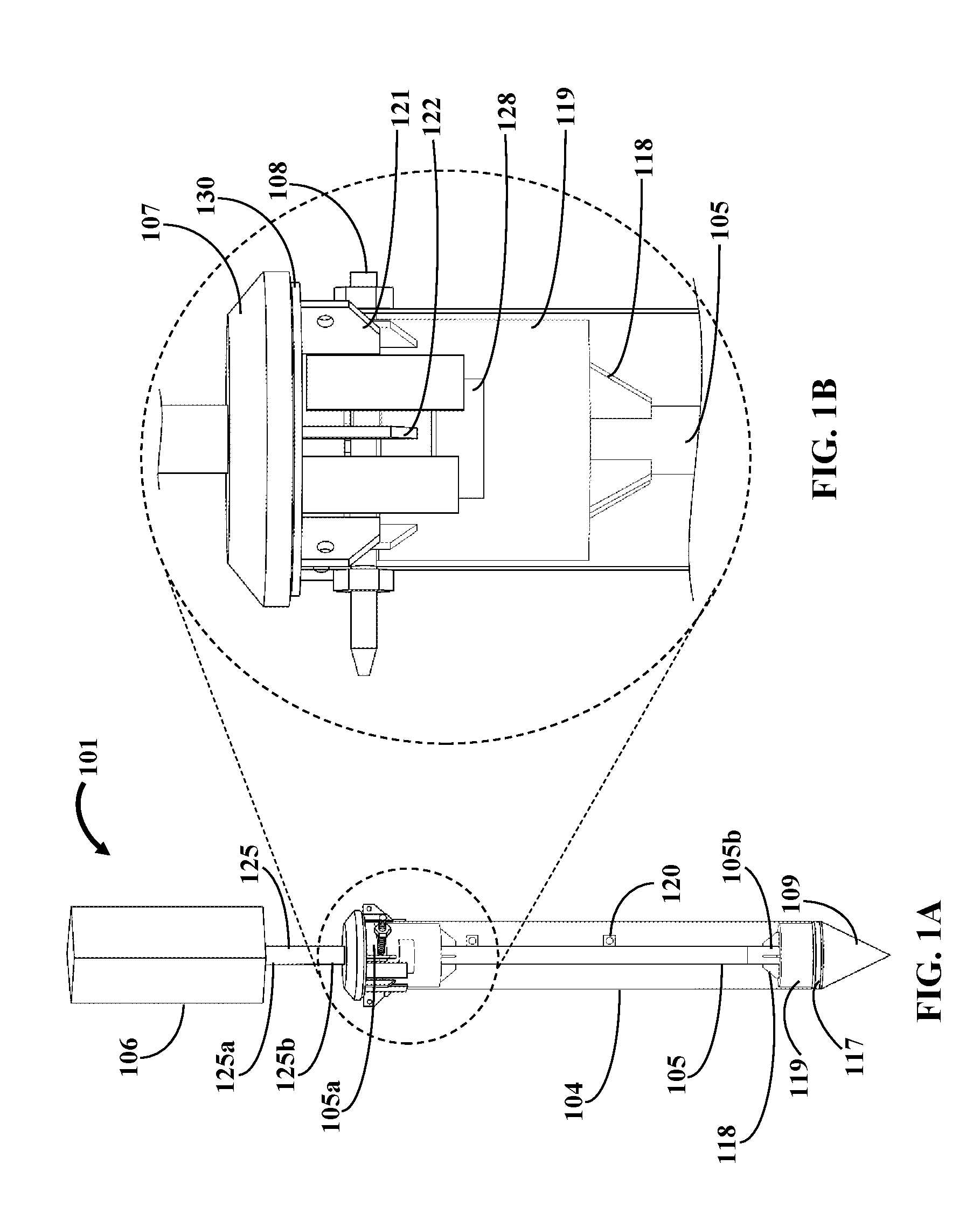

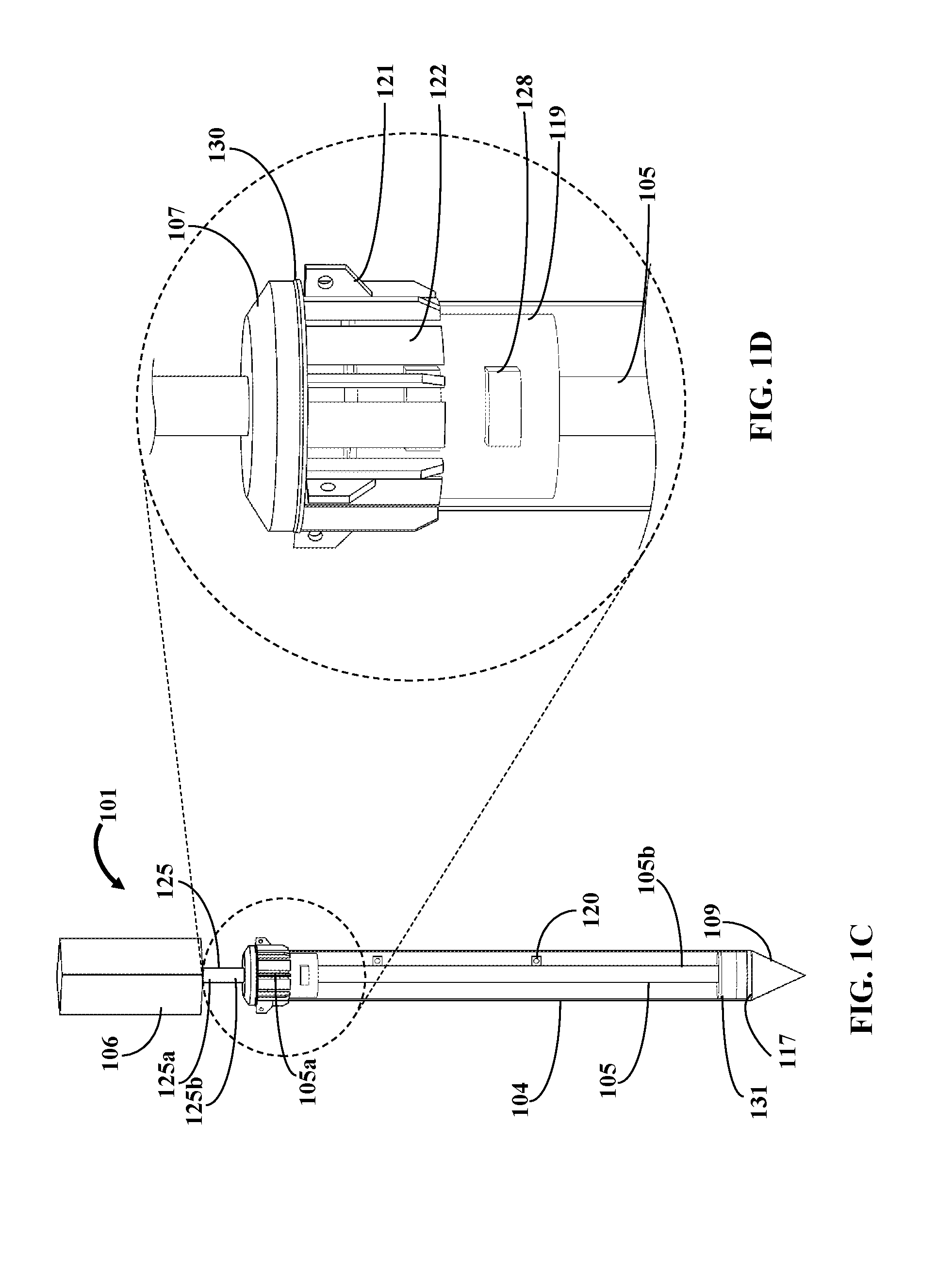

Mandrel for forming an aggregate pier, and aggregate pier compacting system and method

InactiveUS20170058477A1Easy to handleQuick implementationBulkheads/pilesSoil preservationEngineeringMechanical engineering

Owner:NIROUMAND BAHMAN

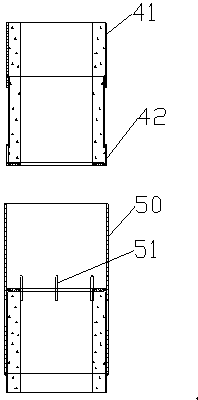

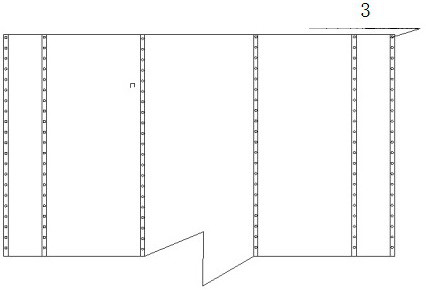

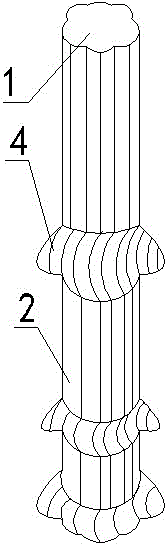

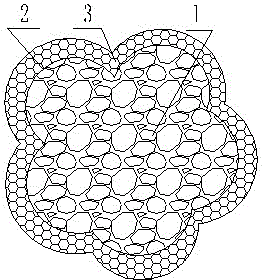

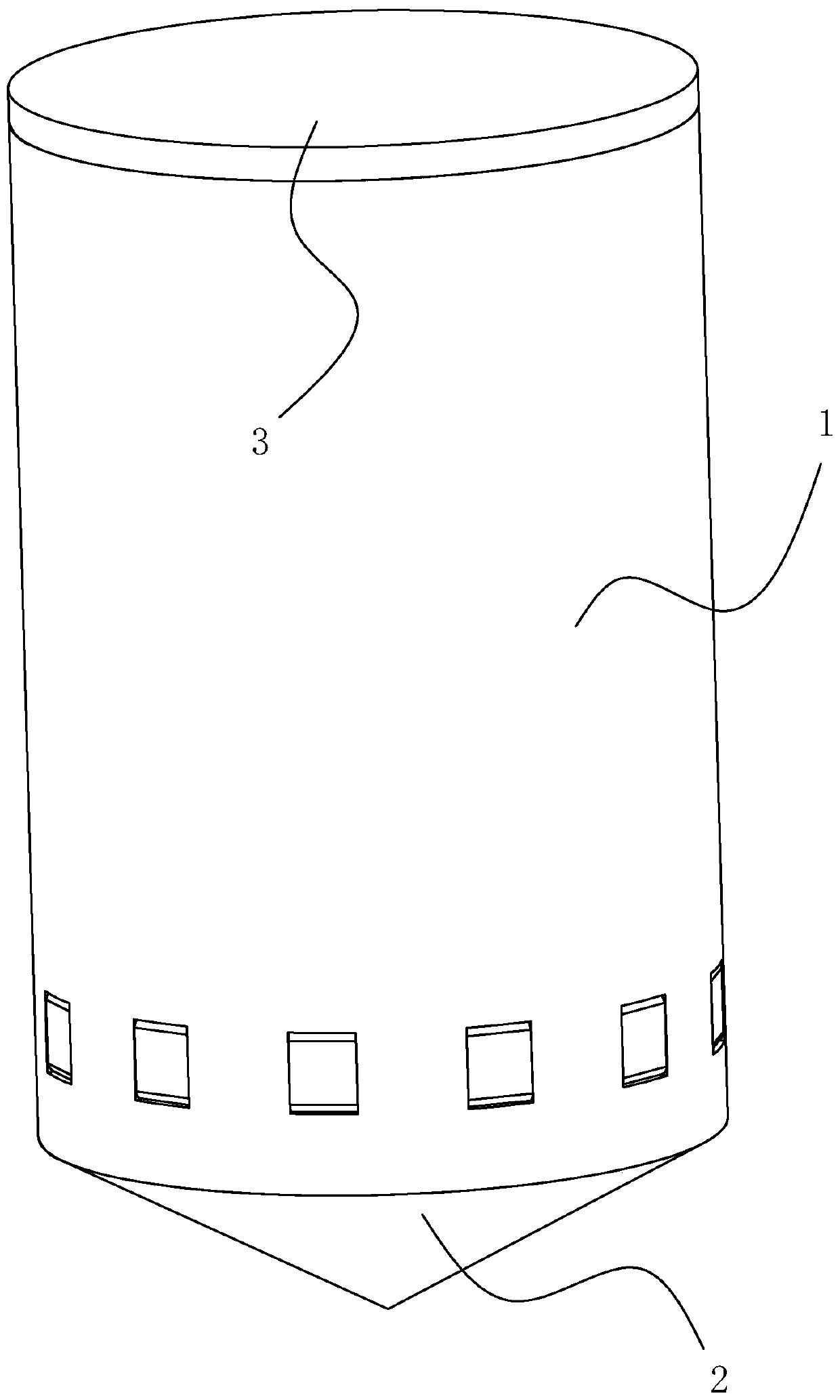

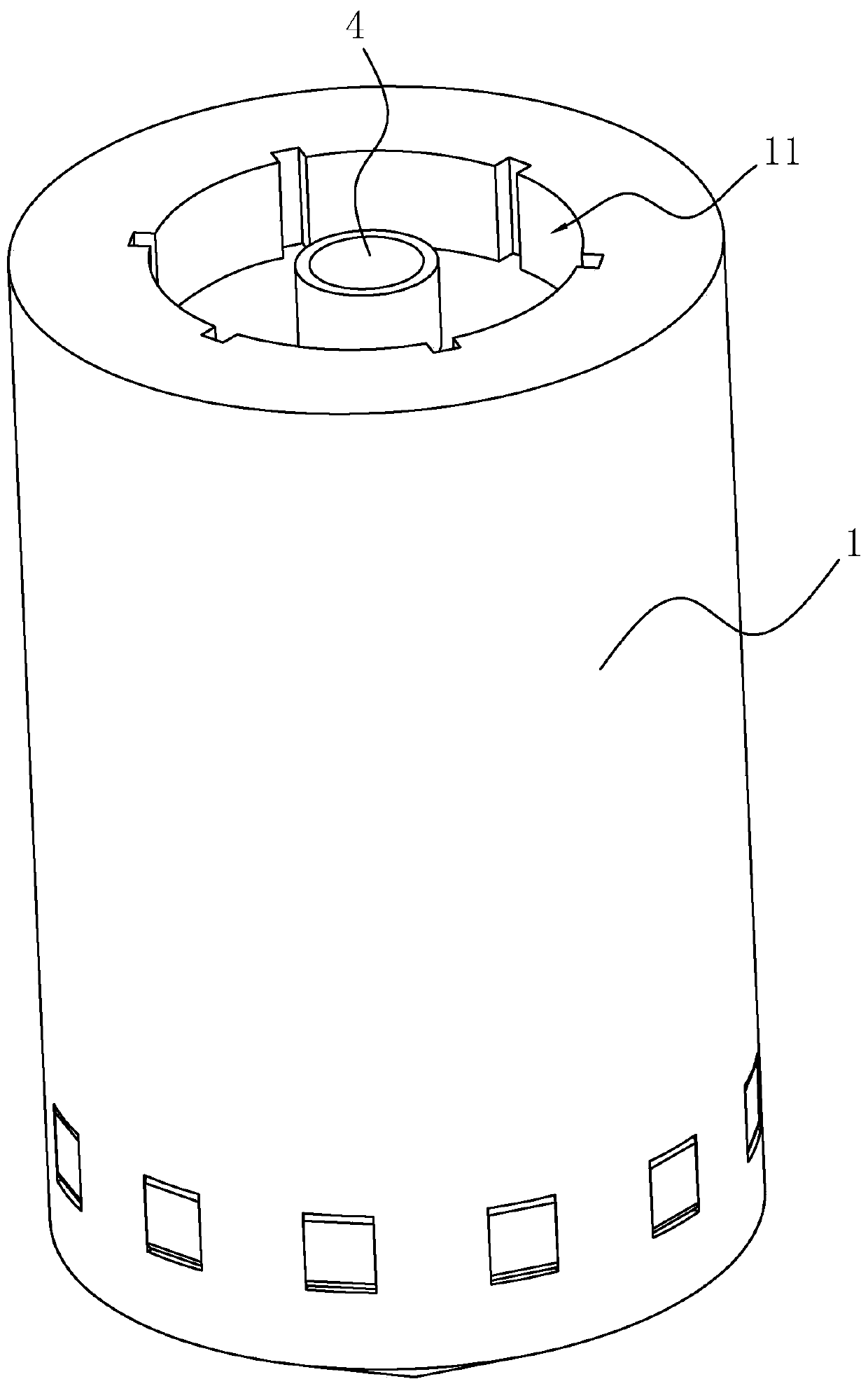

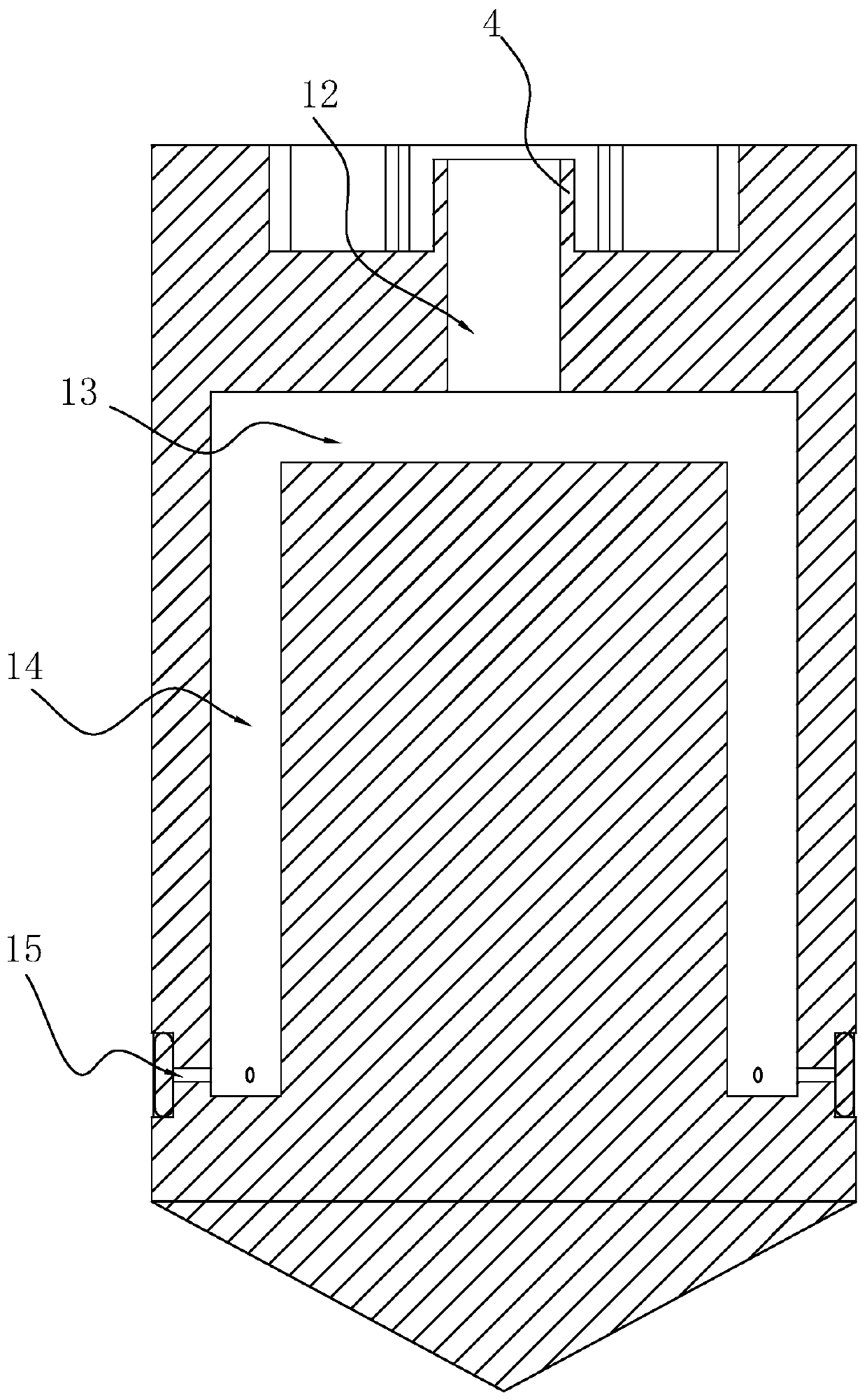

Openable skirt type steel reinforcement cage of reamed pile

The invention discloses an openable skirt type steel reinforcement cage of a reamed pile and belongs to piling building materials. According to the openable skirt type steel reinforcement cage, a reaming section of a pedestal pile has a horizontal expansion function, the reinforced concrete structure forms of the existing rotary expanding piles are changed, and the load capacity of the rotary expanding piles is increased; the steel reinforcement cage is unfolded at the bottom of a hole through a plurality of link mechanisms, the appearance of the unfolded steel reinforcement cage is basically similar to the contour of the reamed hole, the link mechanisms are simultaneously opened and are connected with an existing steel reinforcement cage through steel stranded wires, then, concrete is cast, the link mechanisms serve as steel reinforcement members, and thus, the strength of concrete members of rotary expanding pile bodies is enhanced.

Owner:XUZHOU LEHMAN MASCH TECH CO LTD

Pile anchor head for an underpinning pile and method of preloading the same

Owner:ONG CHIN CHAI

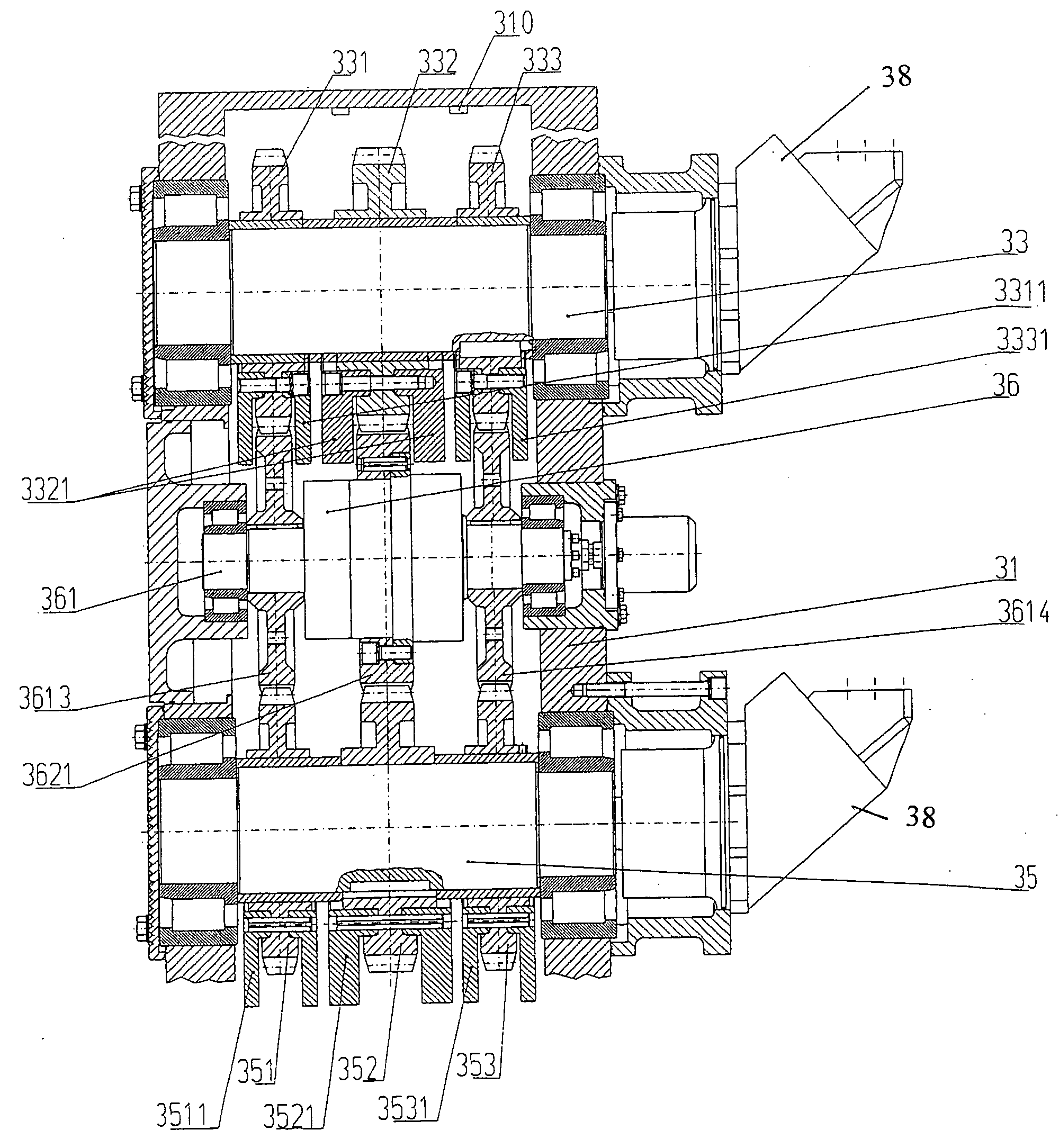

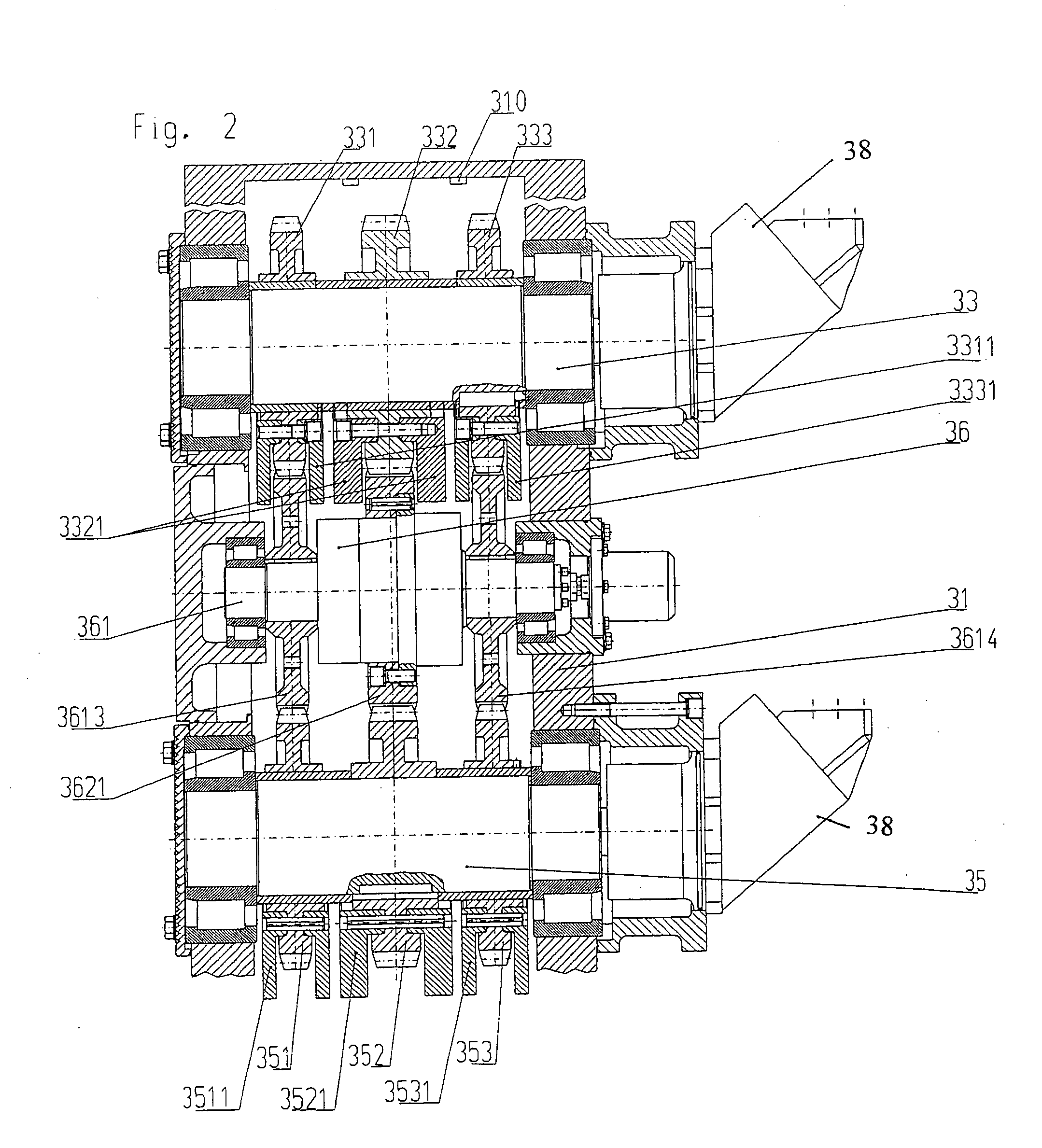

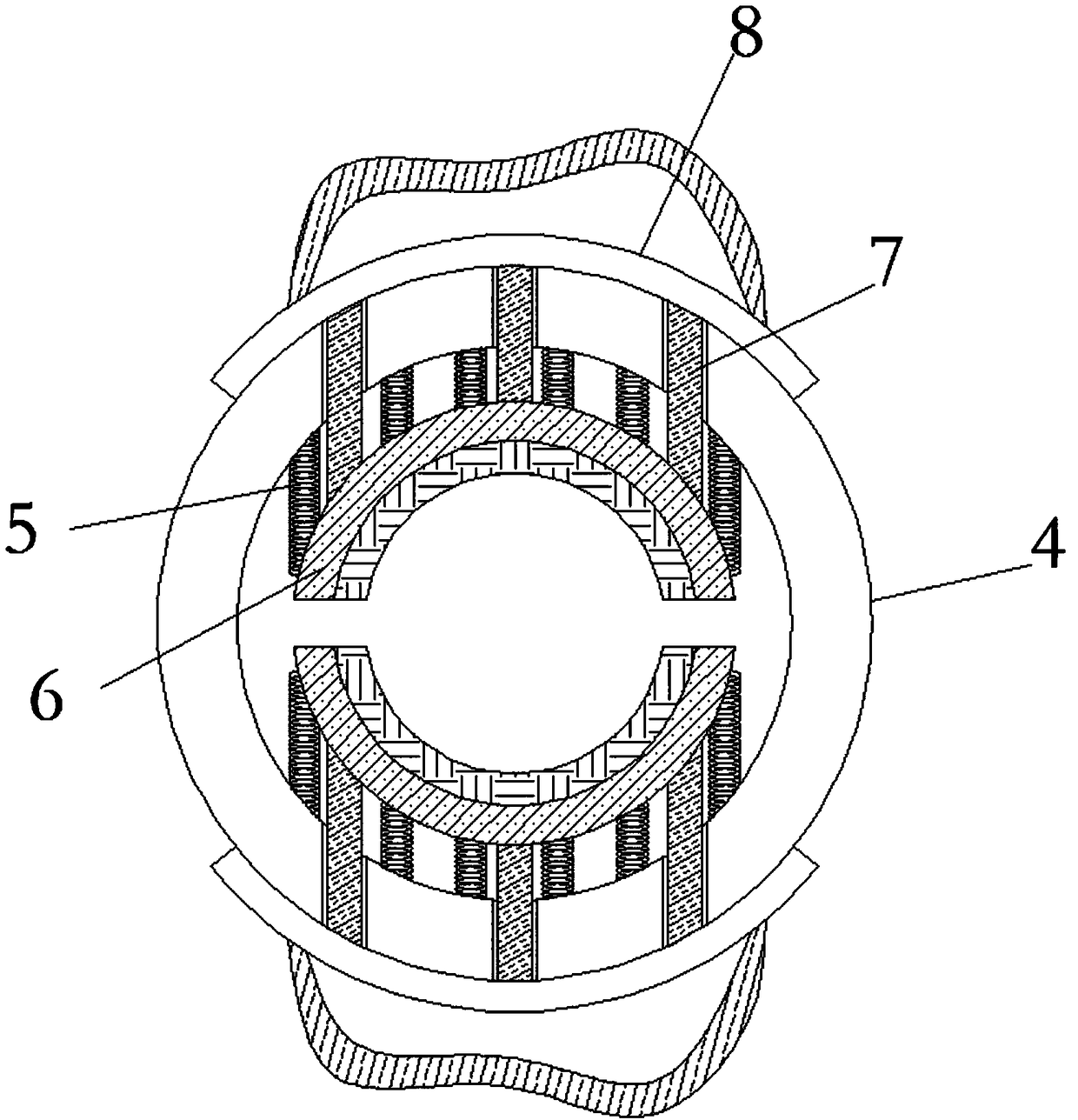

Vibration generator for a vibration pile driver

ActiveUS20090188687A1Reduce power lossRun energy savingReciprocating drilling machinesPortable percussive toolsData setEngineering

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

Lock catch steel pipe pile and I-shaped plate pile combined cofferdam structure and construction method thereof

Owner:CCCC SECOND HARBOR ENG +2

Building piling machine

Owner:CHINA MCC17 GRP

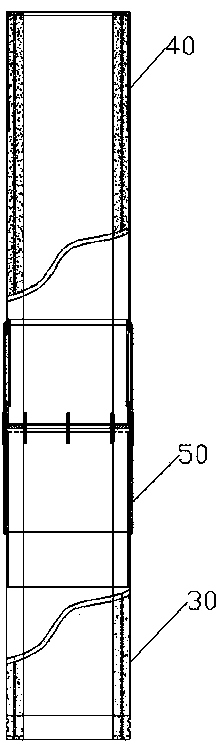

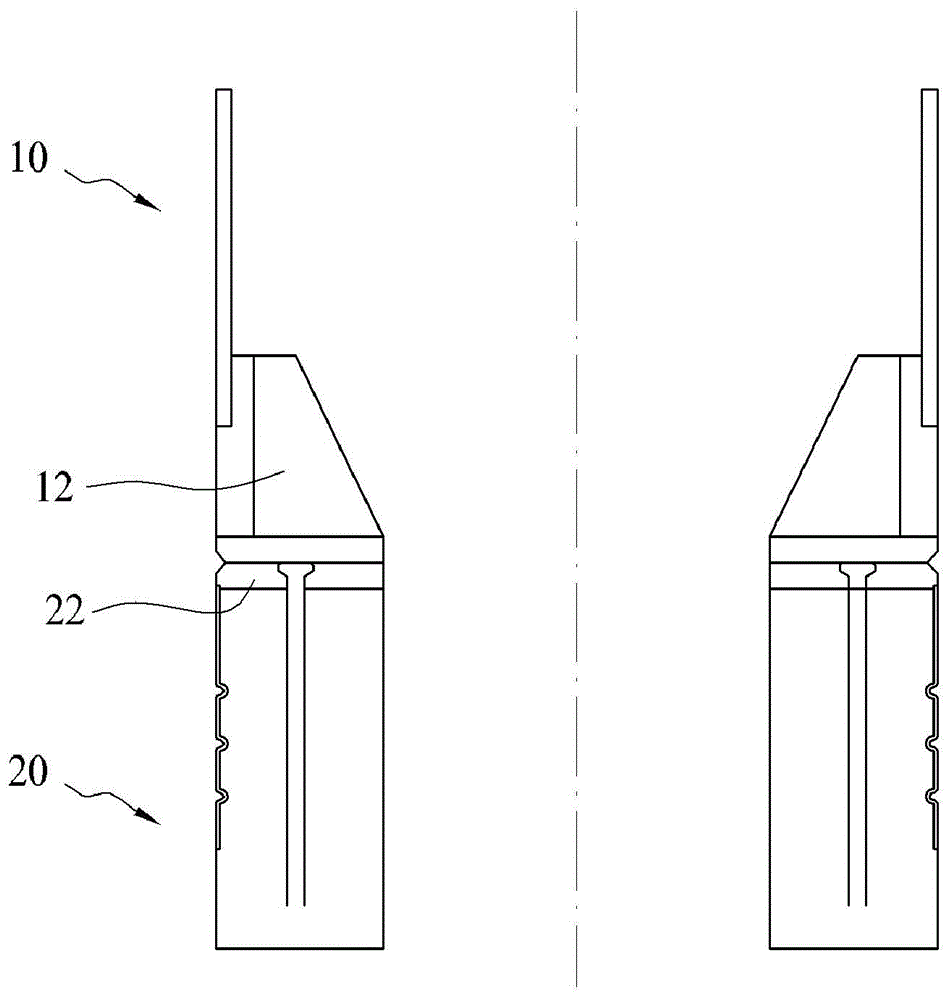

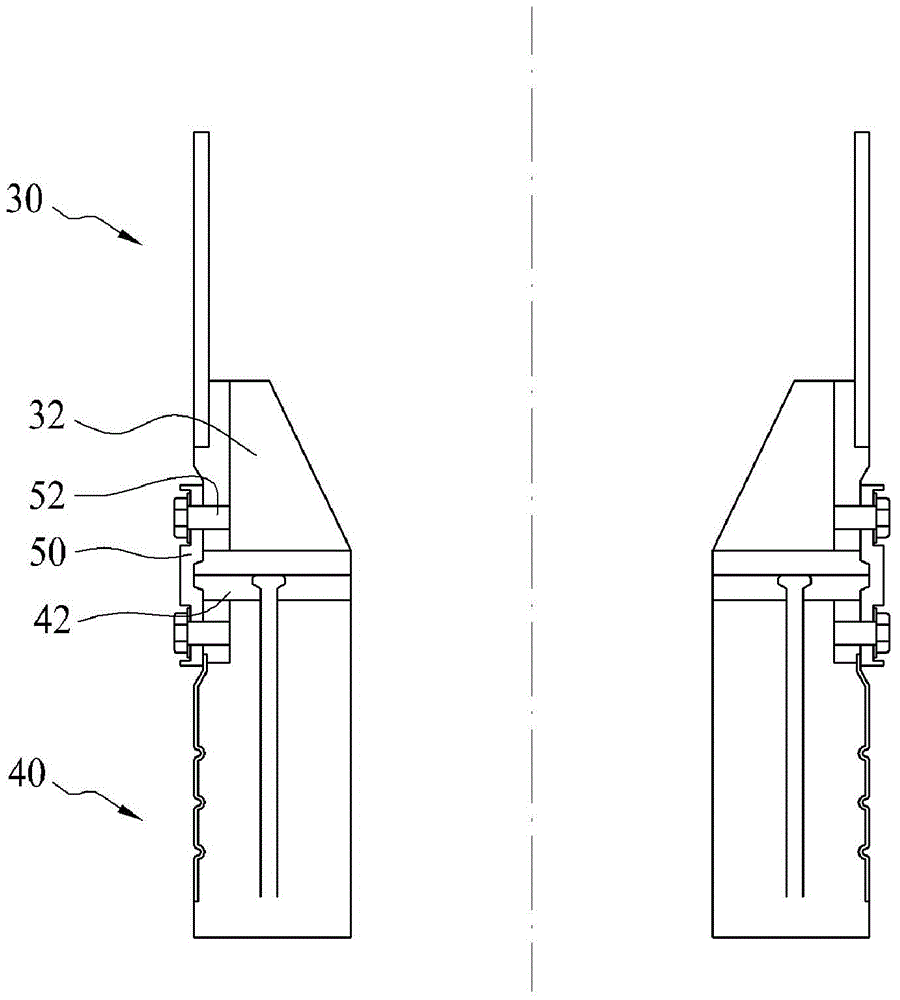

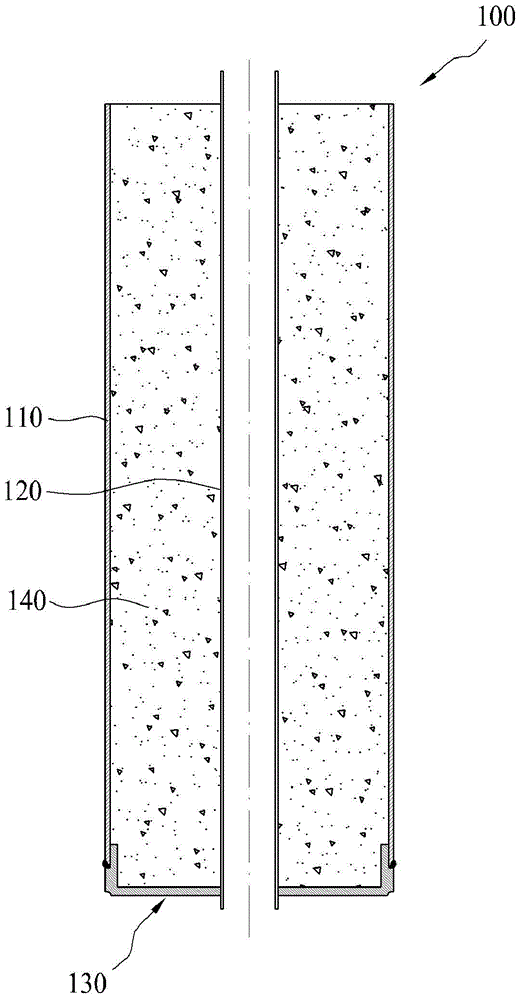

Combined splicing tubular pile and pile splicing method

Owner:国鼎(南通)管桩有限公司

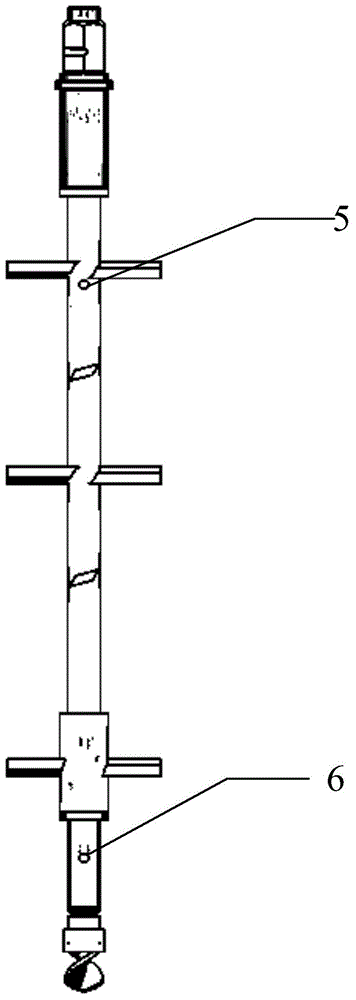

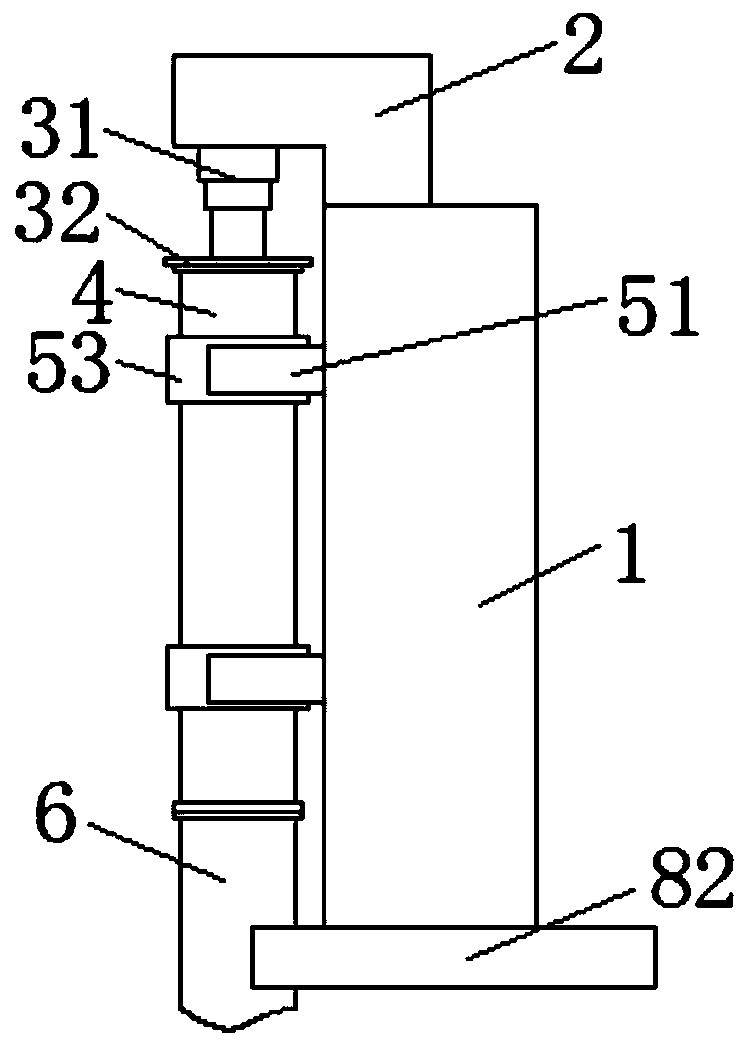

Material delivery pipe mechanism for bottom-mounted power drill rod

The invention belongs to the technical field of building, and relates to a material delivery pipe mechanism for a bottom-mounted power drill rod. The material delivery pipe mechanism comprises a drill rod and a length adjusting rod. A power mechanism is disposed between the drill rod and the length adjusting rod; the power mechanism is in driving connection with the drill rod, and is capable of driving the drill rod to rotate circumferentially. A delivery passage is formed within the drill rod, and a discharge hole is formed in the bottom of the drill rod and is communicated with the delivery passage. A slurry delivery pipe is disposed in the length adjusting rod, and extends into the power mechanism. A slurry delivery connecting pipe is disposed on the outer wall of the power mechanism, and one end of the slurry delivery connecting pipe is detachably connected to the slurry delivery pipe, while the other end of the slurry delivery connecting pipe is detachably connected to the delivery passage. The invention provides a delivery pipe mechanism capable of realizing bottom-mounted power of the drill rod, thereby guaranteeing that material can be delivered to the drill rod when power for the drill rod is mounted at bottom so as to obtain a high-strength cement soil mixing pile; no disturbance is produced for the power structure; and reliable and stable work is achieved.

Owner:ZHEJIANG ZHAODI TECH CO LTD

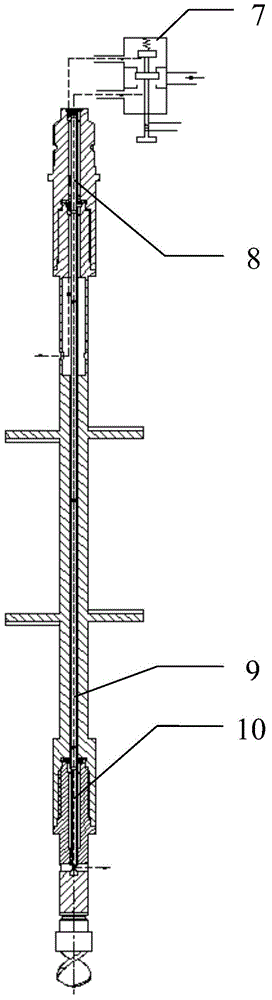

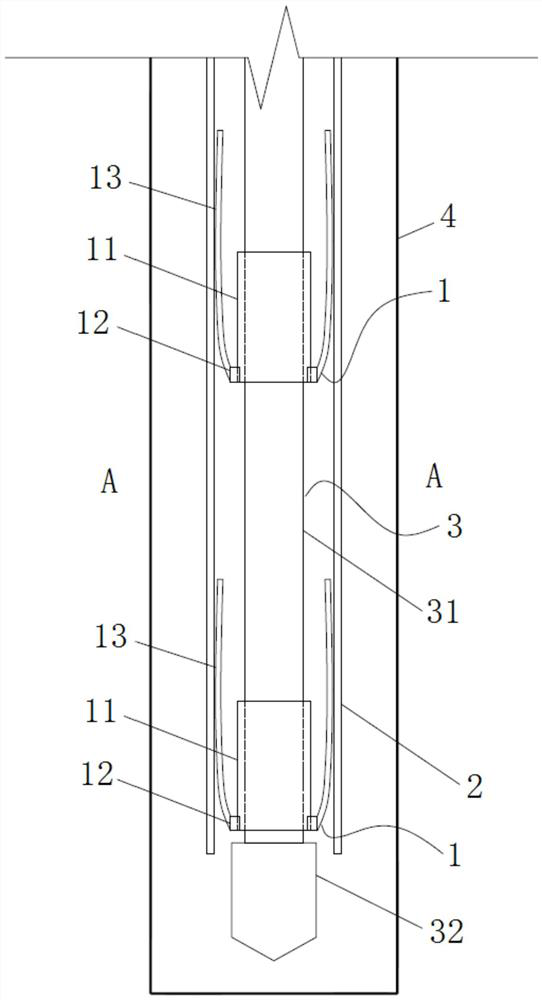

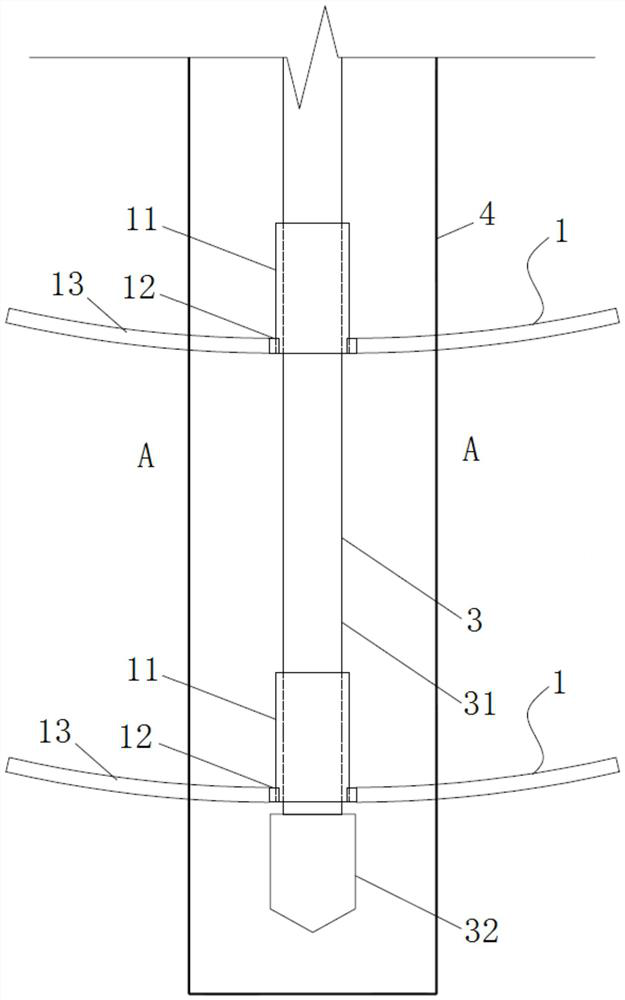

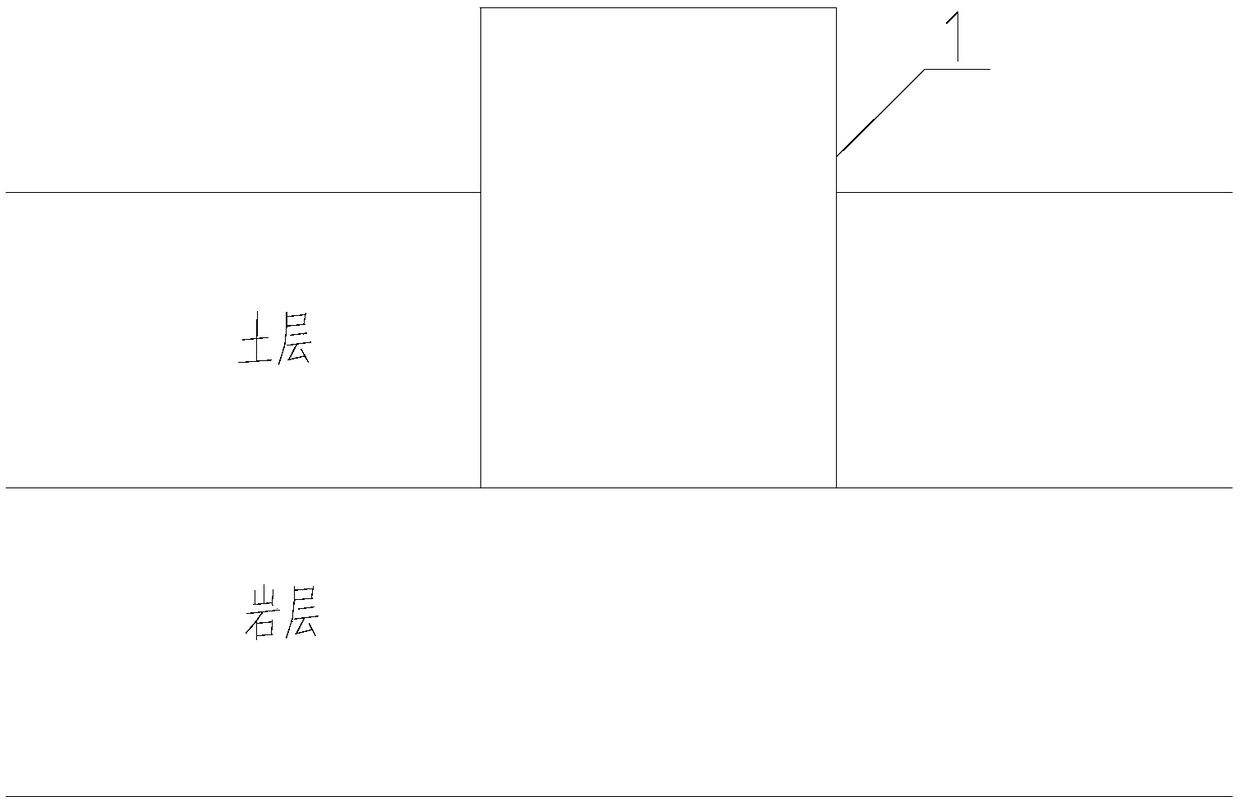

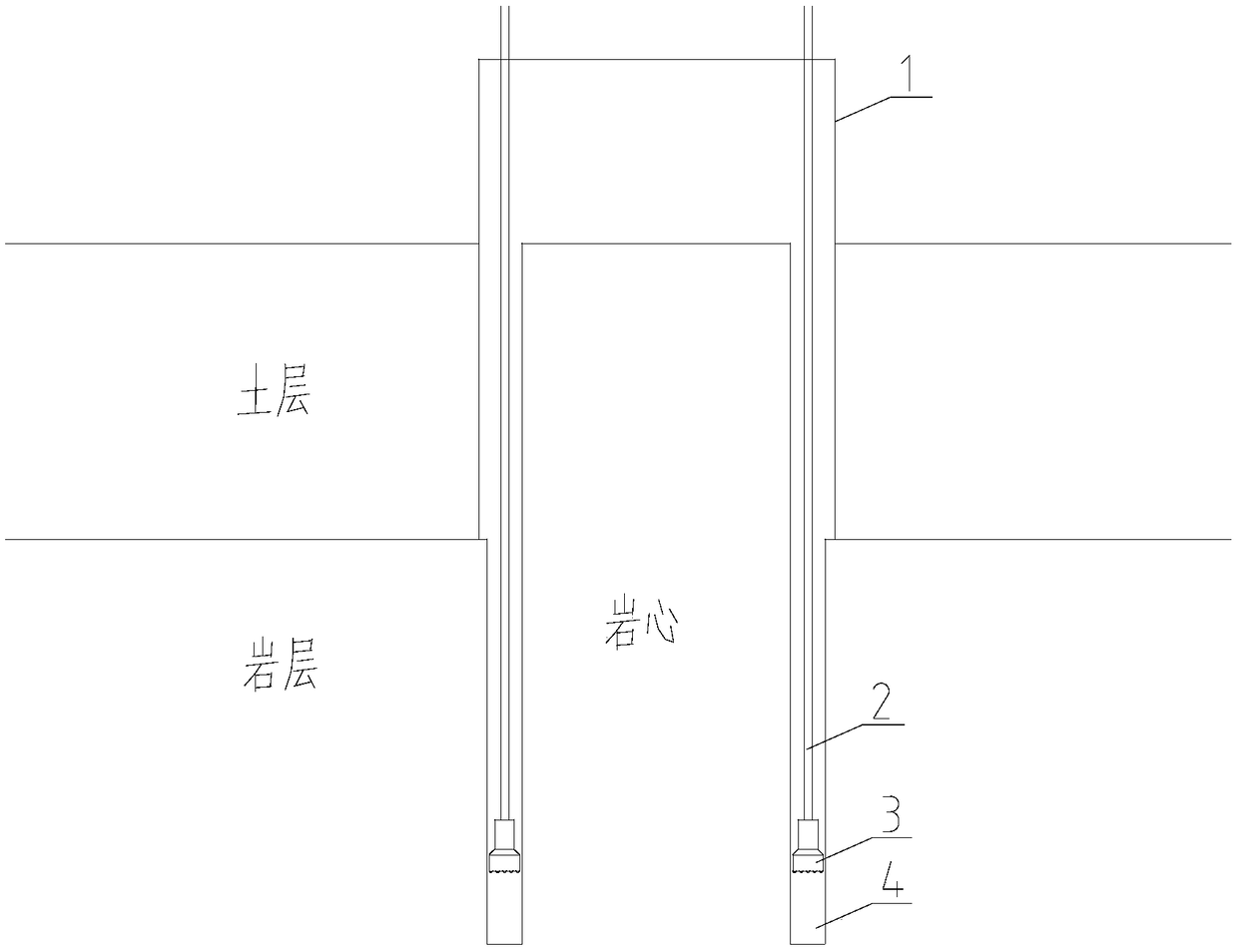

Down hole impacting rotary jetting mixing pile construction technology and device

ActiveCN106996105ASimple structureNo need to disassembleSolid waste managementBulkheads/pilesArchitectural engineeringHigh pressure

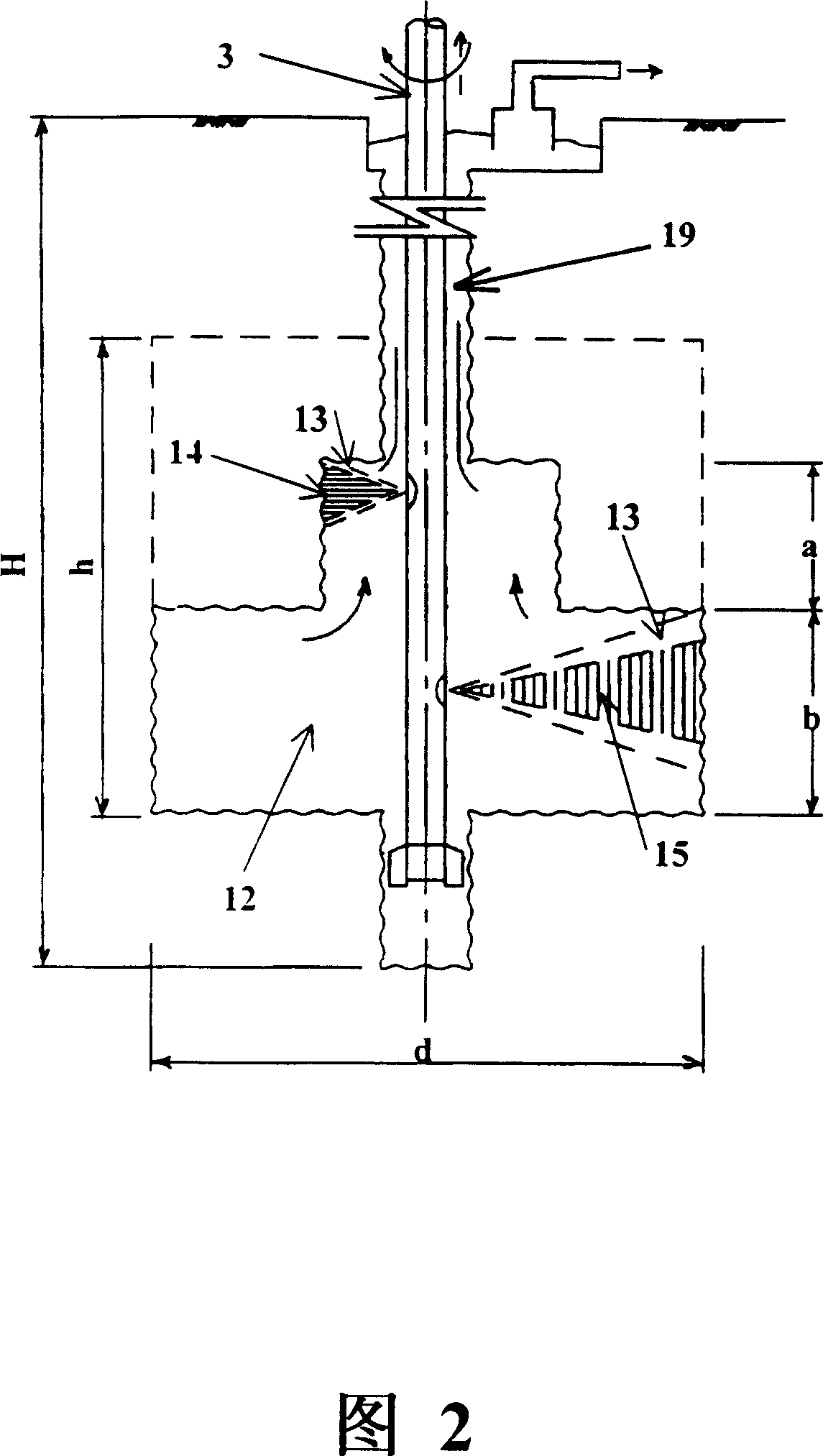

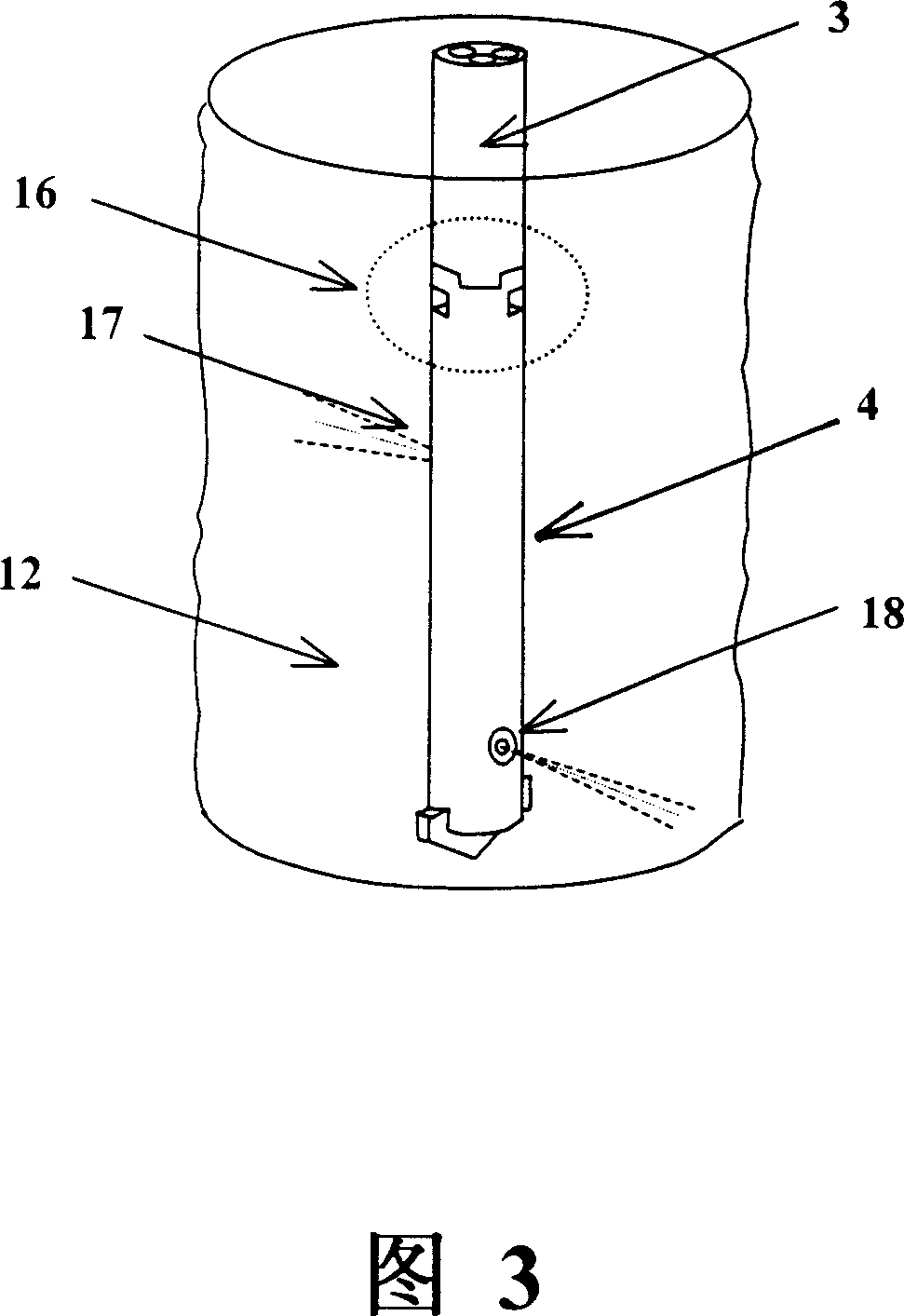

The invention provides a down hole impacting rotary jetting mixing pile construction technology and device. The down hole impacting rotary jetting mixing pile construction device includes a drill rod, a down hole impacting device arranged at the bottom end of the drill rod, a mixing device connected to the lateral side of the drill rod or the down hole impacting device, and a nozzle arranged on the lateral side of the down hole impacting device. A communicating high-pressure air passageway is arranged among the drill rod, the nozzle and the down hole impacting device. The above down hole impacting rotary jetting mixing pile is adopted in the down hole impacting rotary jetting mixing pile construction technology. By means of the down hole impacting rotary jetting mixing pile construction technology and device, the stratum adaptability is high, and pollution and influences of industrial production to the environment are reduced.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

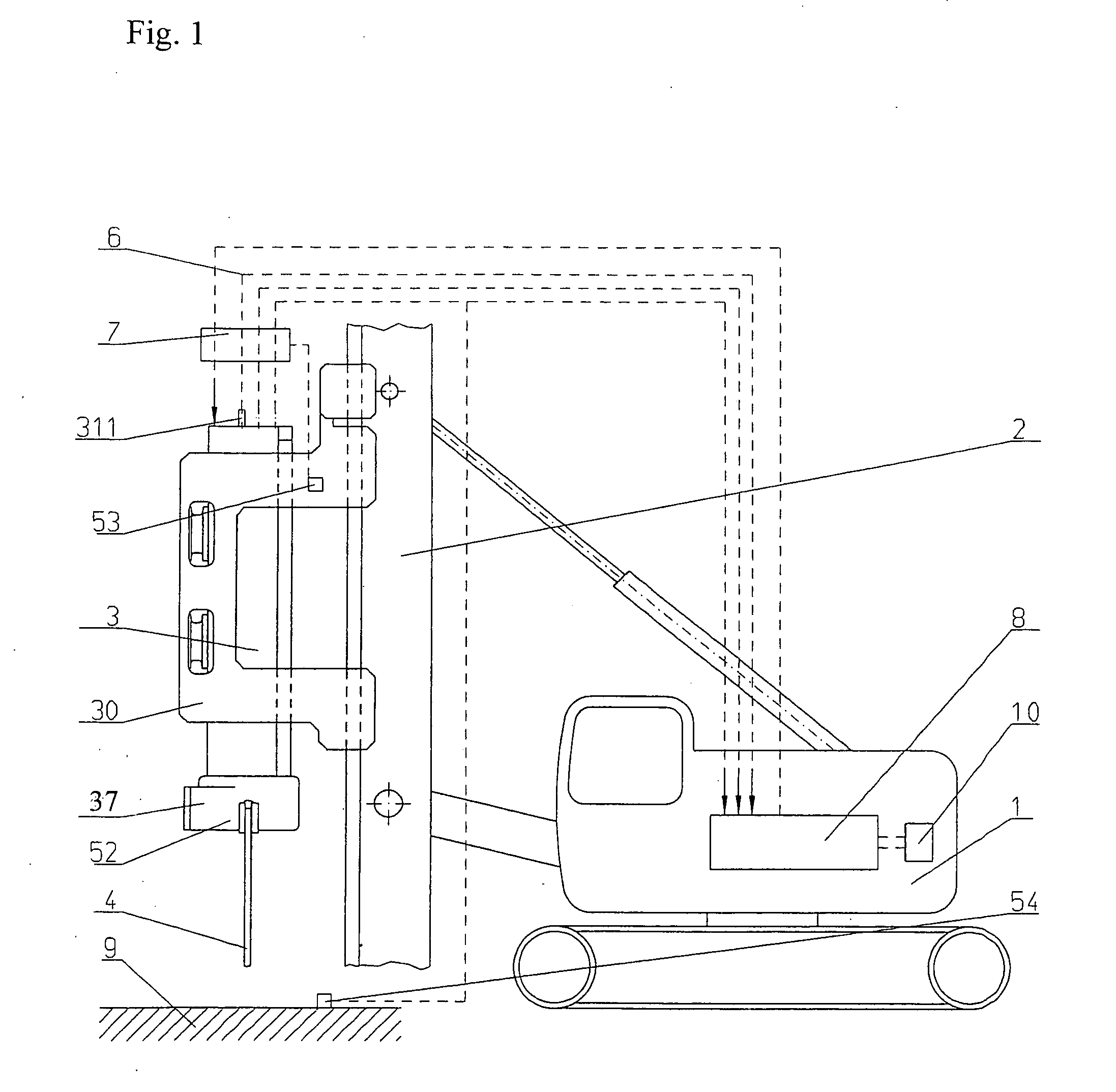

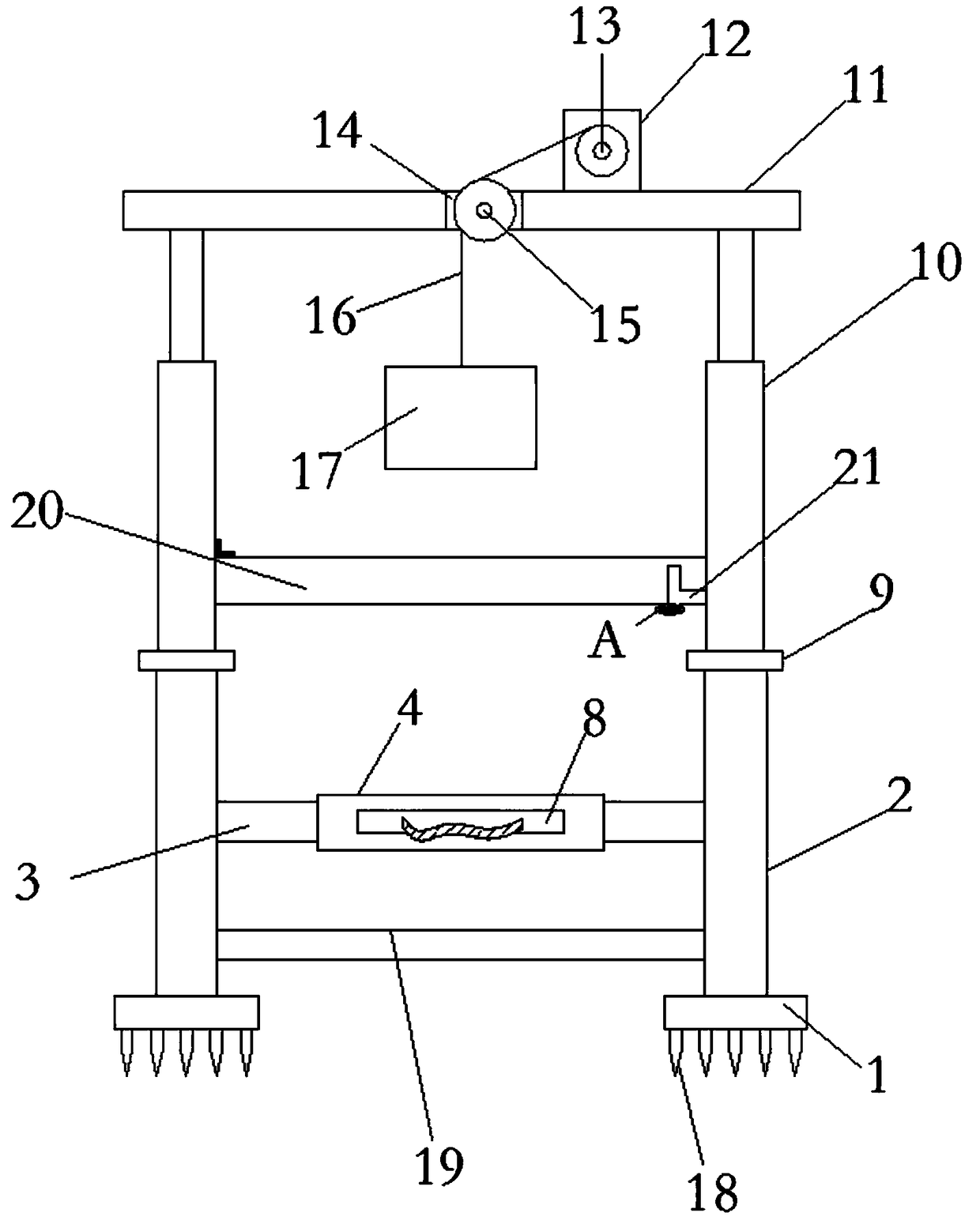

Multifunctional rotary drilling rig

InactiveCN103147689ALower purchase costImprove work efficiencyEarth drilling toolsDerricks/mastsFoundation engineeringWinch

The invention relates to a multifunctional rotary drilling rig and belongs to the field of foundation engineering construction equipment. The multifunctional rotary drilling rig comprises a chassis, an upper wagon mounted on the chassis, a diagonal bracing oil cylinder mounted on the upper wagon and a mast, wherein the mast is connected with a winch box and the diagonal bracing oil cylinder; the winch box is fixed at the front end of the upper wagon; a guide device is mounted at the tail end of the mast; and a soil remover is arranged above the guide device and also arranged on the mast. The multifunctional rotary drilling rig integrates functions of a rotary drilling rig, a CFG (Cement Flyash Gravel Pile) drilling rig and a screw pressure soil squeezing and filling pile drilling rig, and realizes multiple functions and construction by multiple construction methods; the cost for purchasing the drilling rig is saved; and the working efficiency is improved.

Owner:SHANDONG XINGUO HEAVY MASCH TECH CO LTD

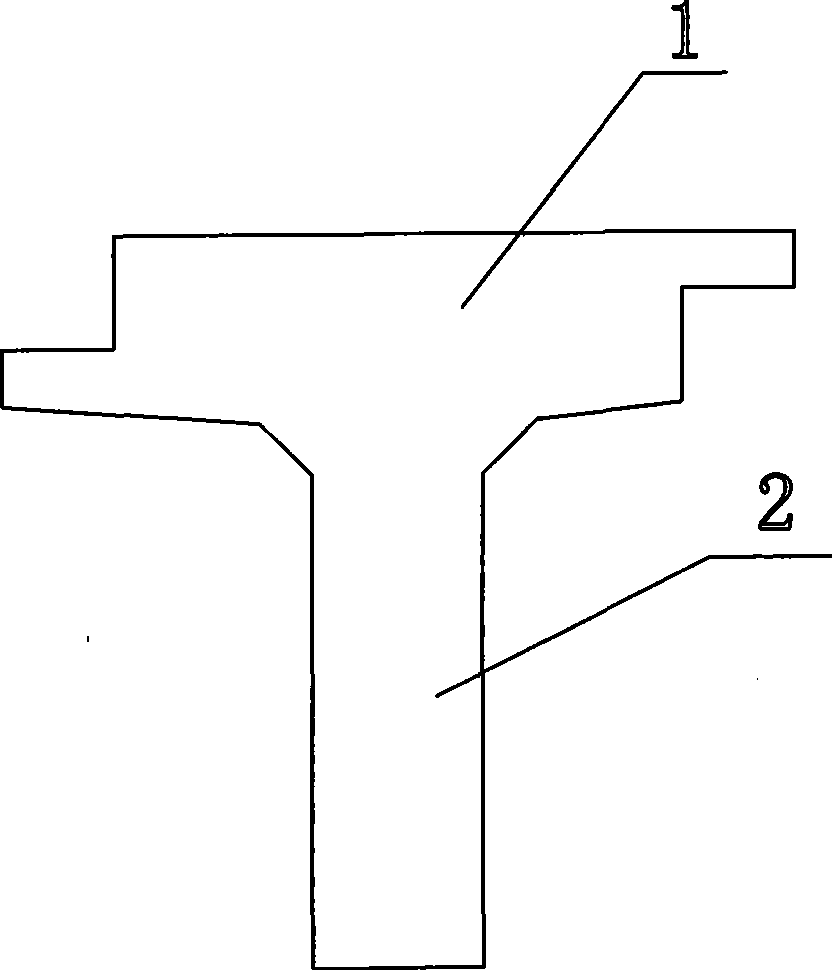

Revetment T shaped pile with tongue and groove

Owner:ZHEJIANG COMM CONSTR GRP CO LTD +1

Method for construction of pipe sinking cast-in-place pile in pebble bed, gravel layer and sand layer

A method for the construction of a pipe sinking cast-in-place pile in a pebble bed, a gravel layer and a sand layer, wherein firstly, a hole is drilled in a pile position and mud or coal ash slurry is simultaneously injected into the hole; and then the construction of the pipe sinking cast-in-place pile is performed through a process of hammering double sleeves; therefore, the purposes of no sediment at the bottom end of the pile and high bearing capacity of single pile are achieved. The method has the characteristics of high construction speed, no pollution on the spot, ensured quality, low construction cost, and ensured designed pile diameter and pile length.

Owner:刘清洁

Cement-soil mixing pile device capable of vertically converting for spraying slurry and operation method of cement-soil mixing pile device

InactiveCN104563124AImprove mixing uniformityShorten the mixing timeBulkheads/pilesSoil mixingEngineering

Owner:SHANGHAI CHENGDI CONSTR +1

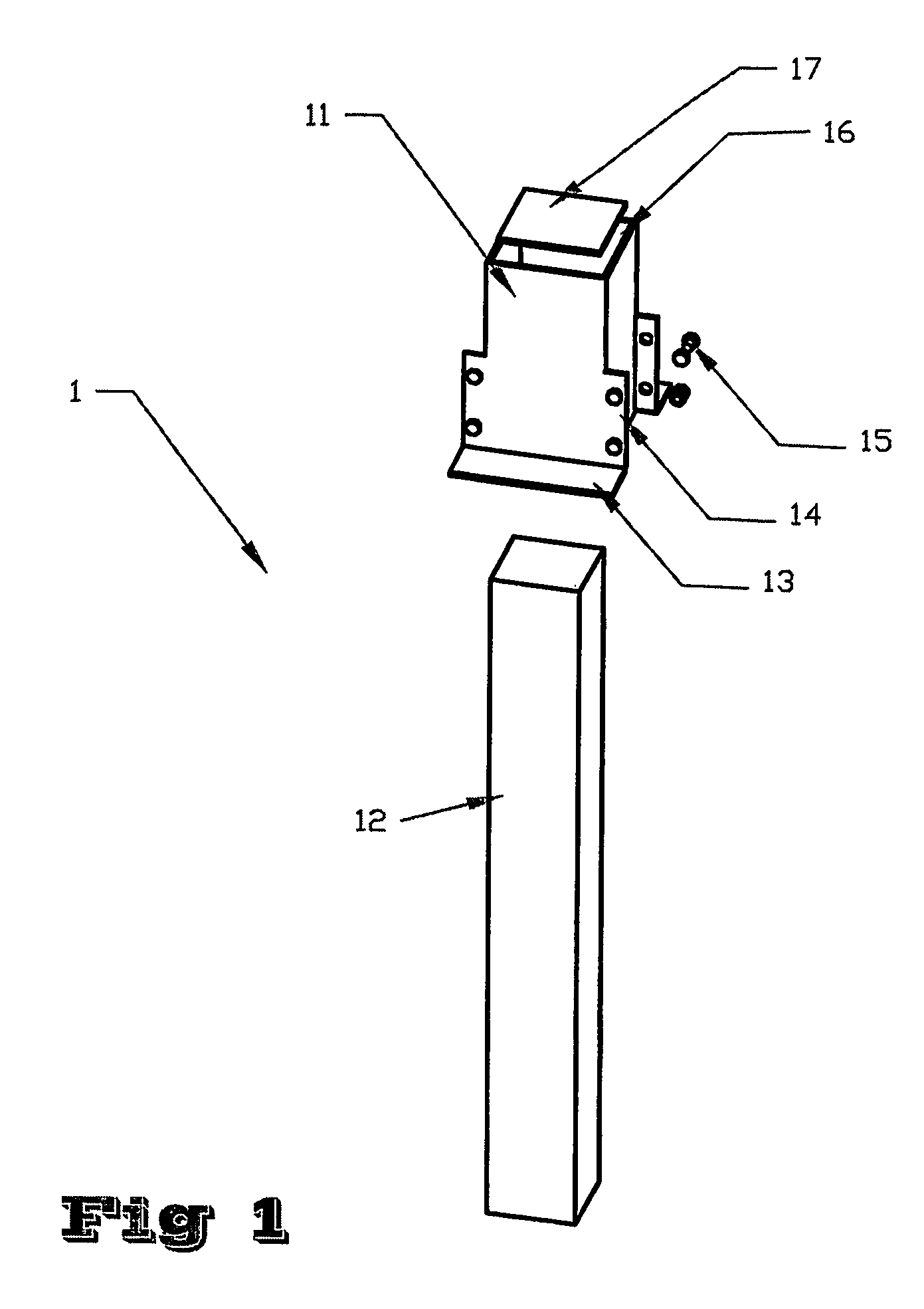

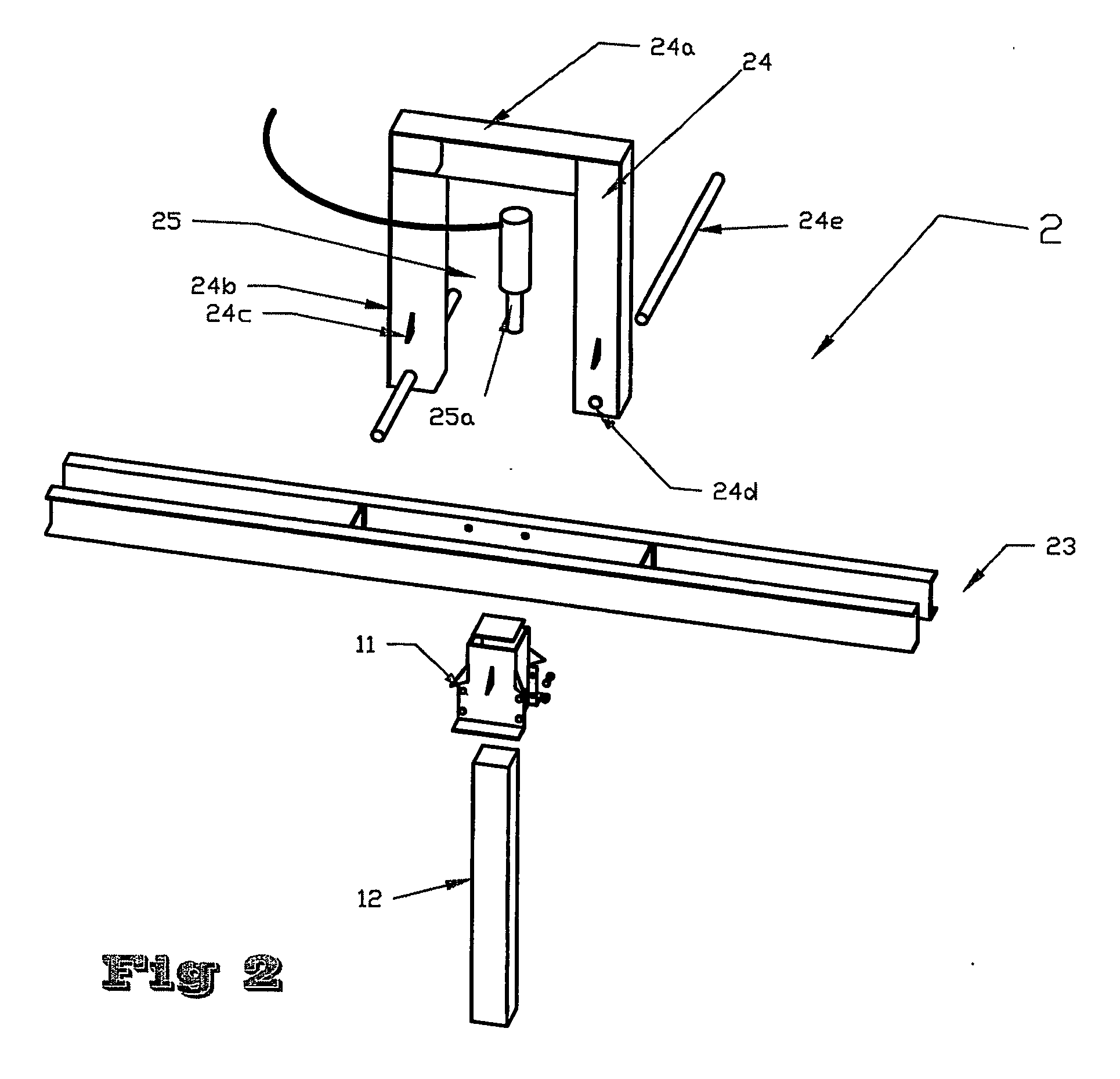

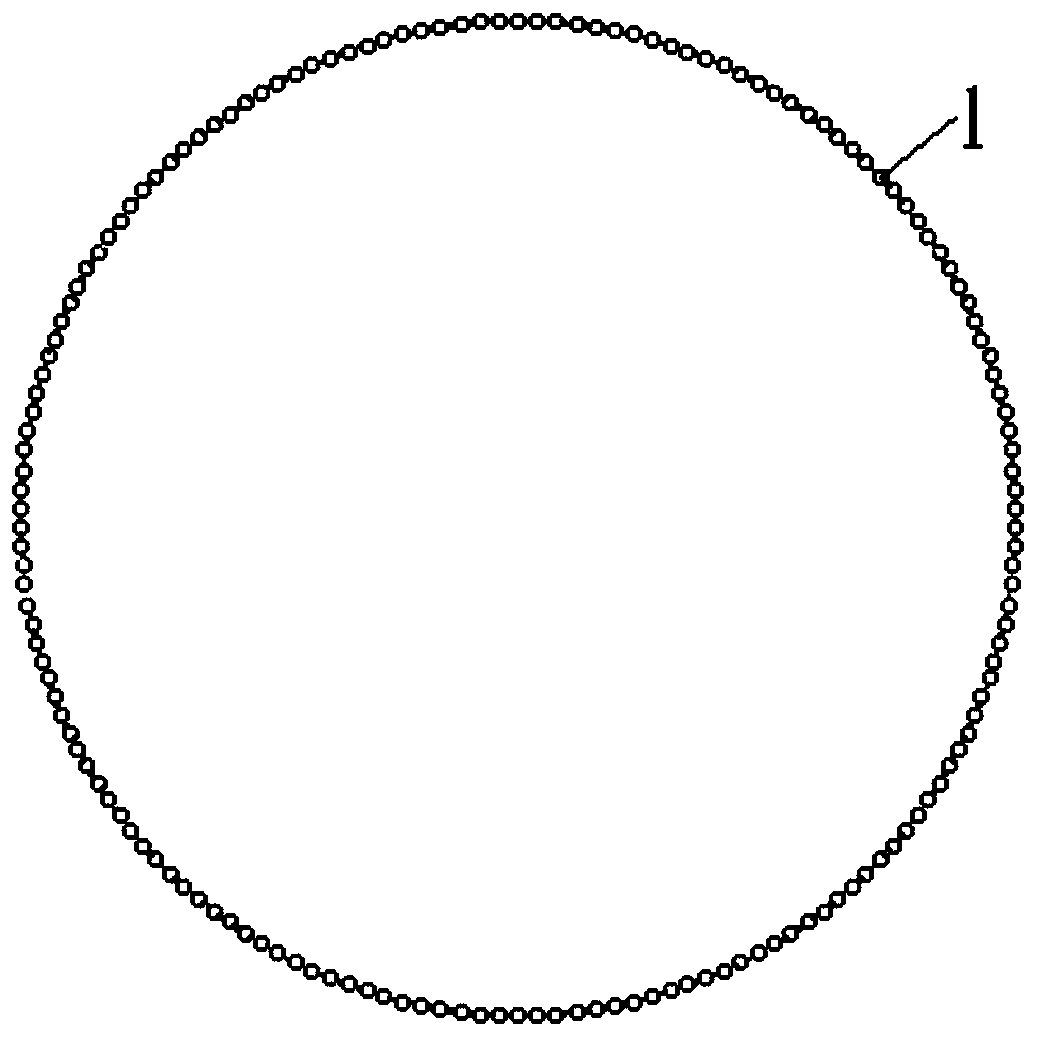

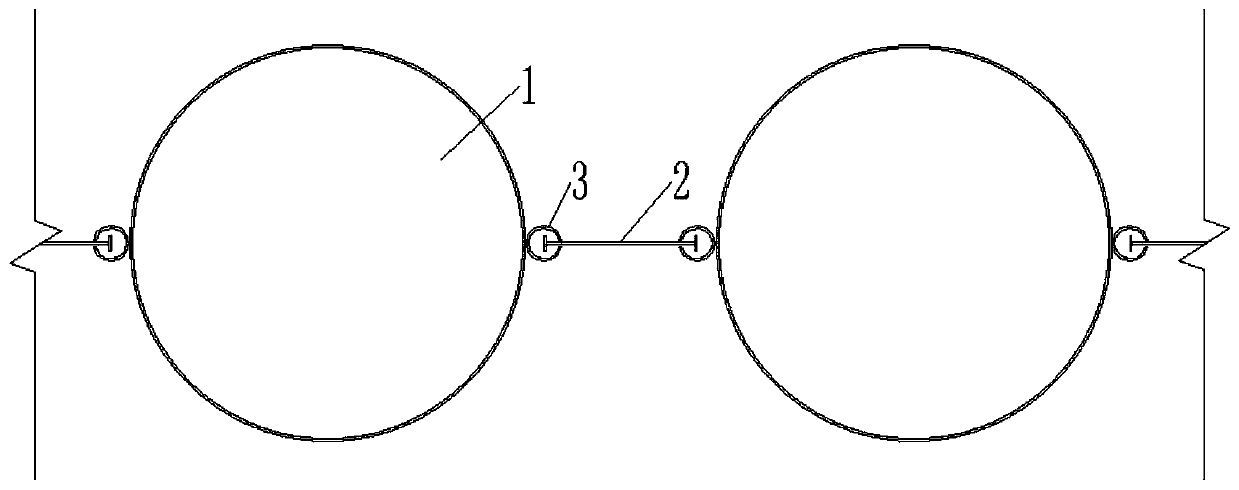

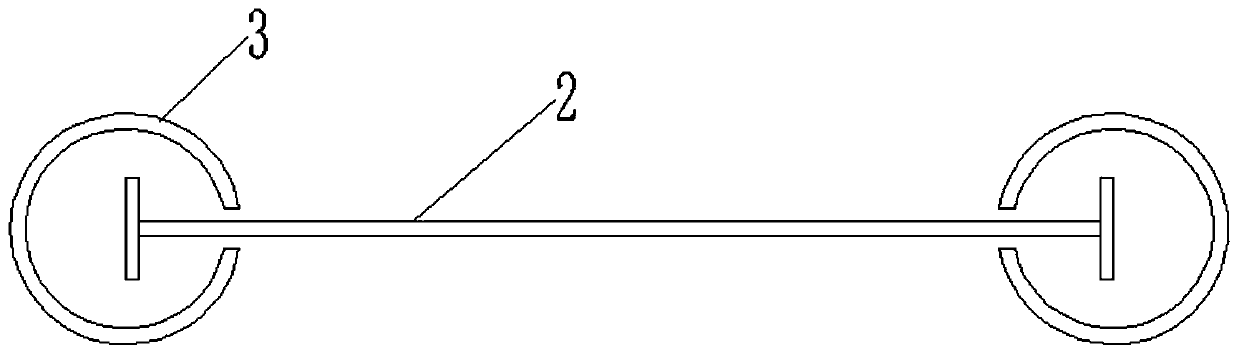

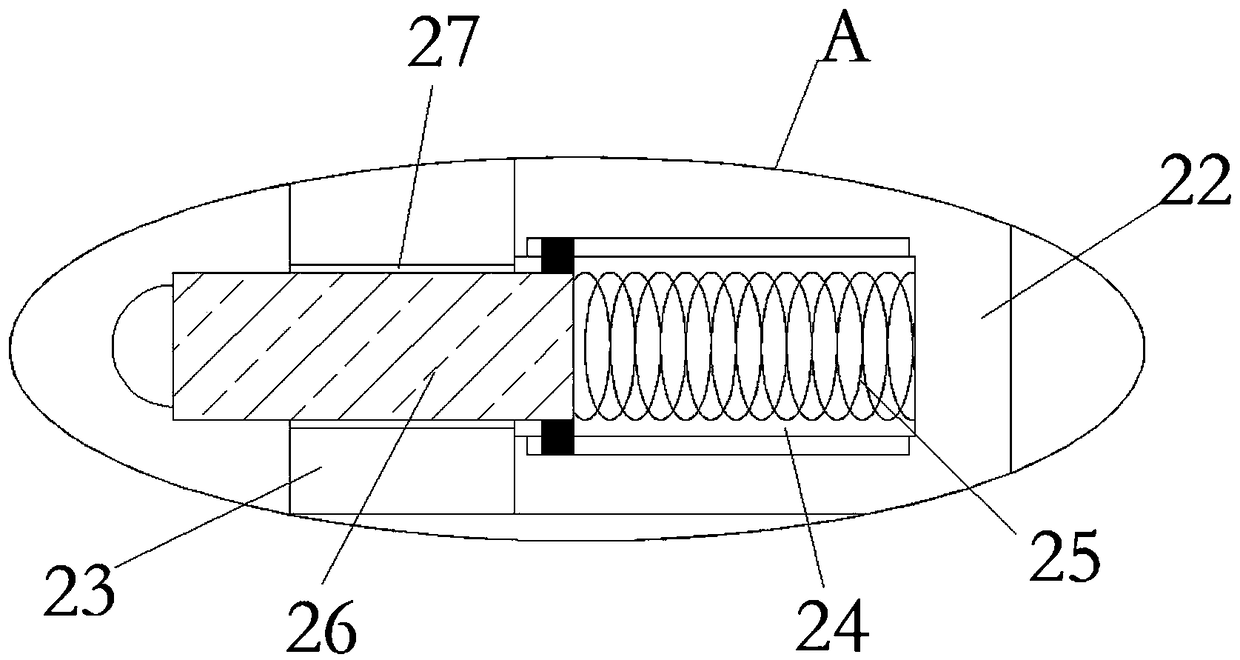

Fast anchoring assembly and quick anchoring structure

InactiveCN109235471AImprove construction efficiencyShorten the construction periodExcavationsBulkheads/pilesStructural engineeringMechanical engineering

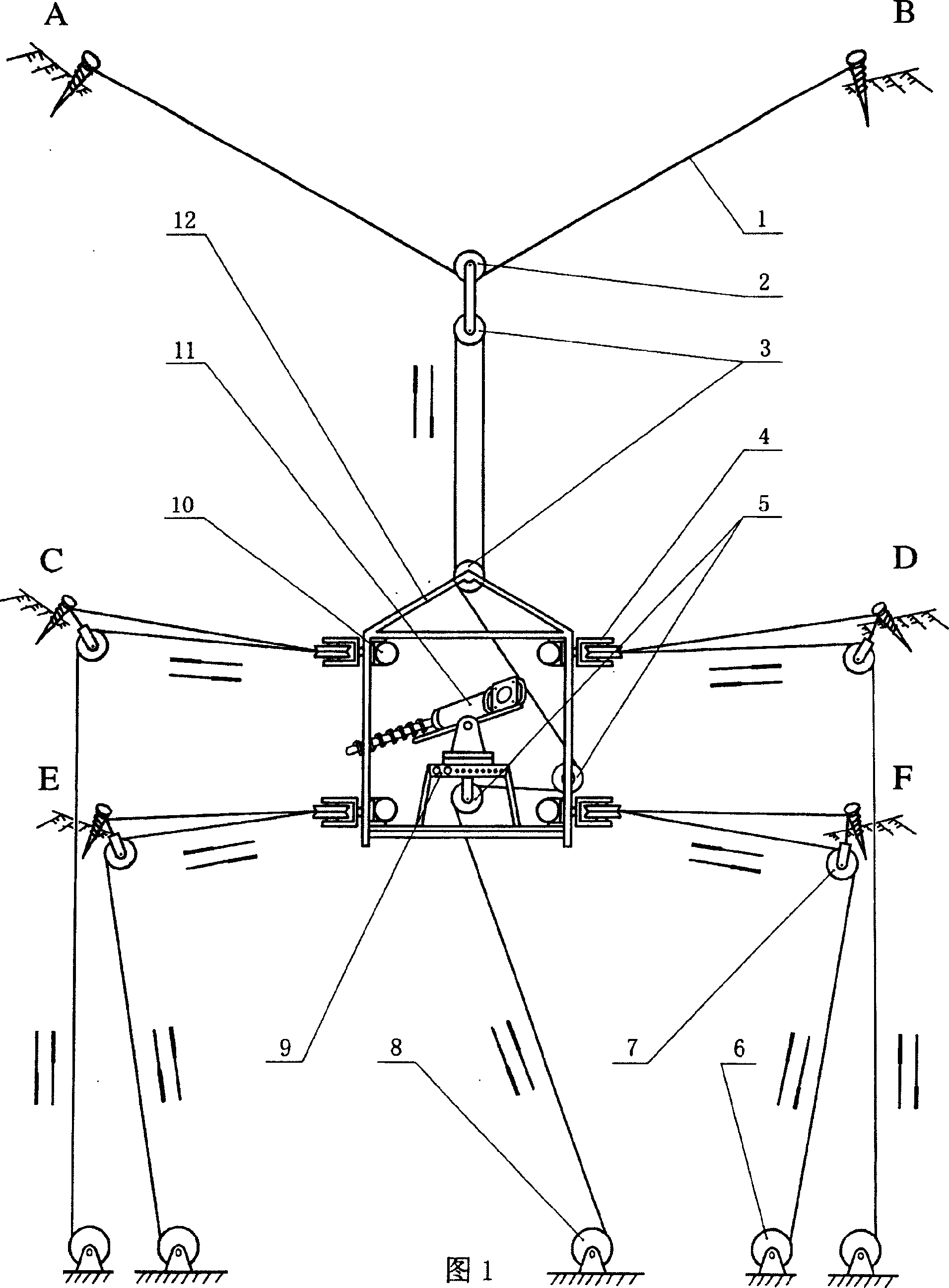

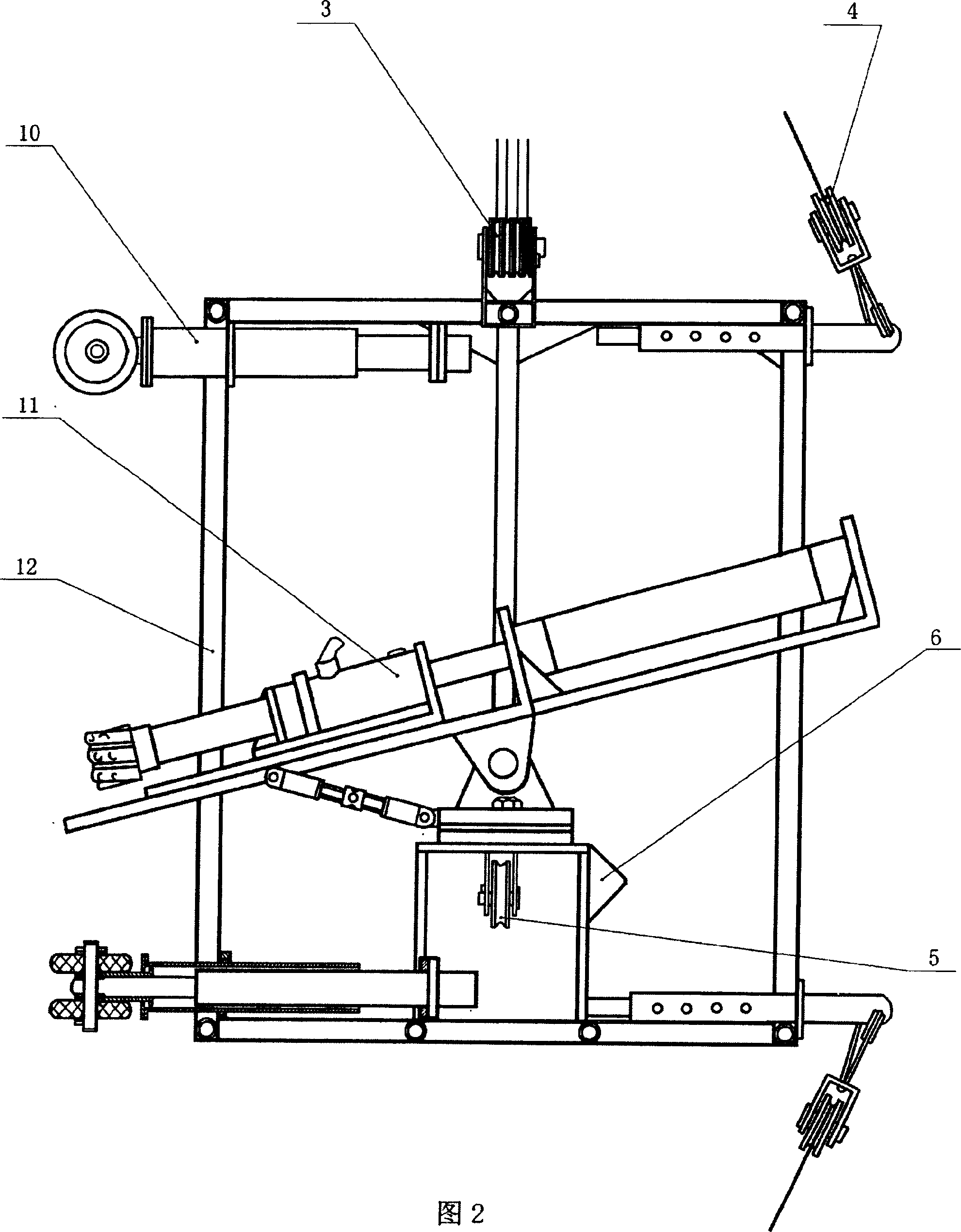

The invention discloses a fast anchoring assembly and a fast anchoring structure, belongs to the field of slope support engineering, and provides a fast anchoring assembly capable of fast anchoring aslope and a fast anchoring structure using the fast anchoring assembly. The fast anchoring assembly comprises a pair of pull pieces and an anchor head, wherein the anchor head comprises a bearing piece and at least one group of supporting units; one ends of the pull pieces is connected with the bearing piece; each group of supporting units comprises an elastic piece and two supporting pieces, andone end of each supporting piece is hinged on the bearing piece; two supporting pieces in the same group of supporting units are symmetrically distributed on two sides of the pull pieces; the two endsof the elastic piece are respectively connected with the middle parts of the two supporting pieces in the same group of supporting units. By using the fast anchoring assembly for performing the anchoring construction on the slope, the initial anchoring effect can be achieved by directly stretching before grouting into the anchor hole and anchoring, so that the construction period can be greatly shortened, and the anchoring construction efficiency can be accelerated.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Piling device for construction site tubular piles

InactiveCN110528521AFirmly connectedReduce the number of times to re-pileCleaning using liquidsBulkheads/pilesFixed frameArchitectural engineering

Owner:宁波青缇工业设计有限公司

Method for grouting and wall protection of a soft stratum pile foundation through steel casing

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP +1

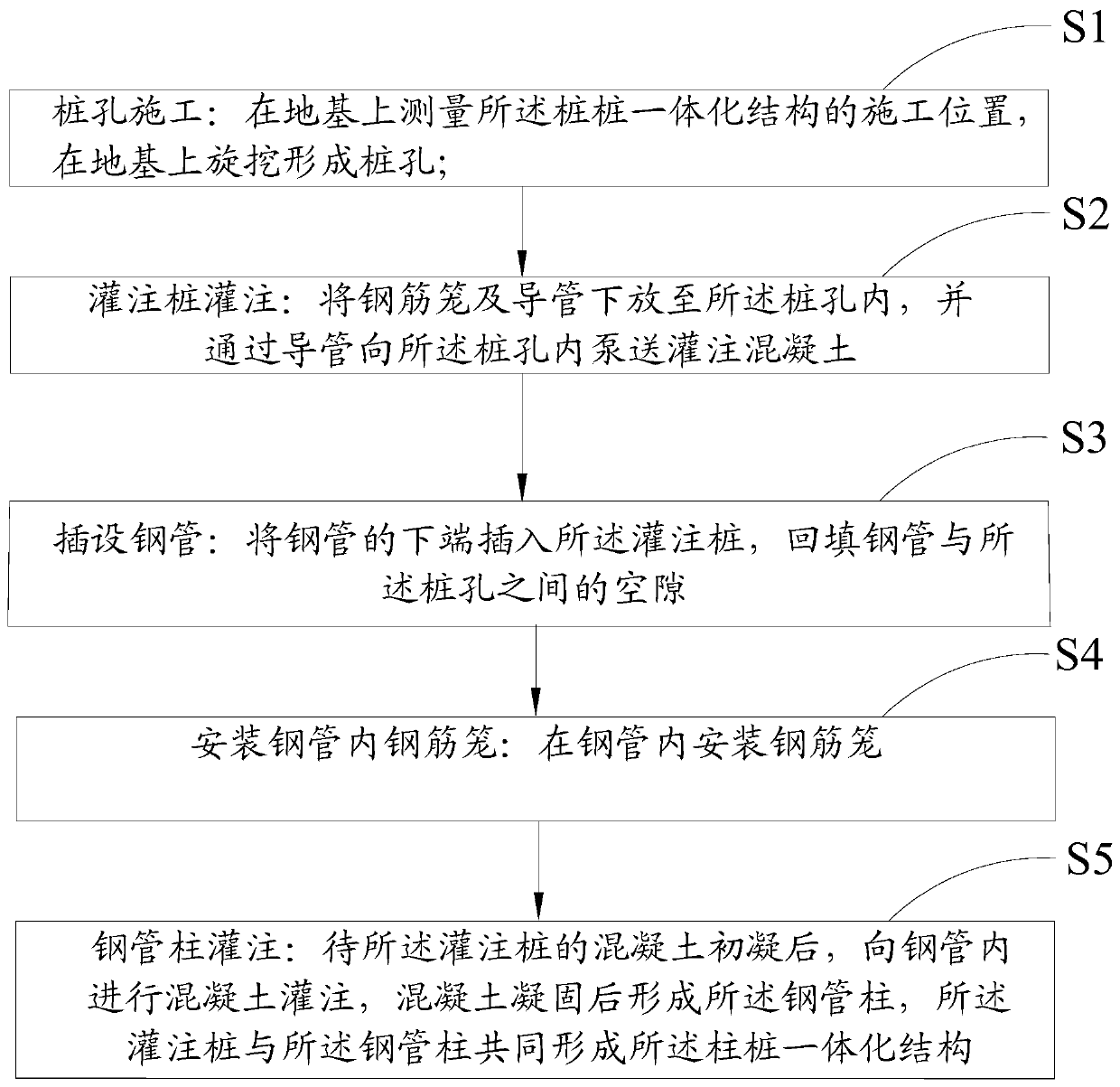

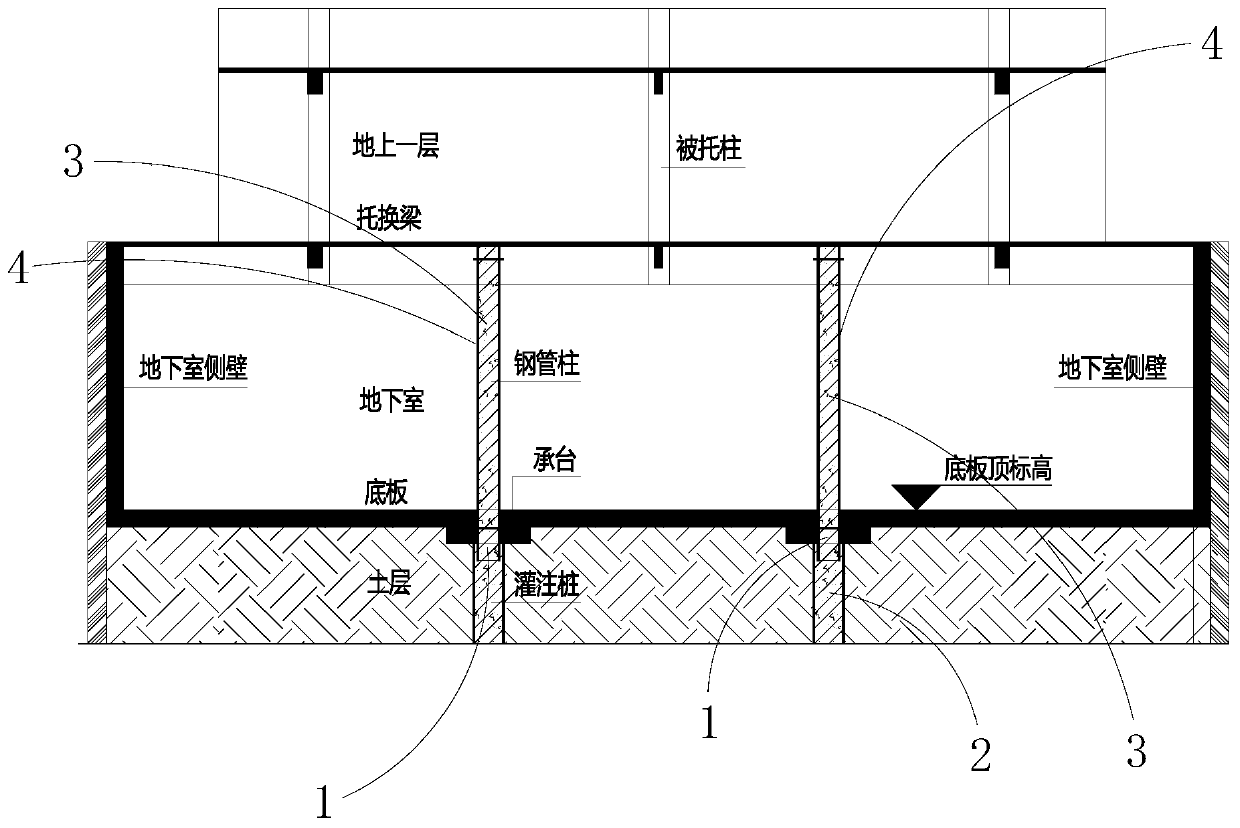

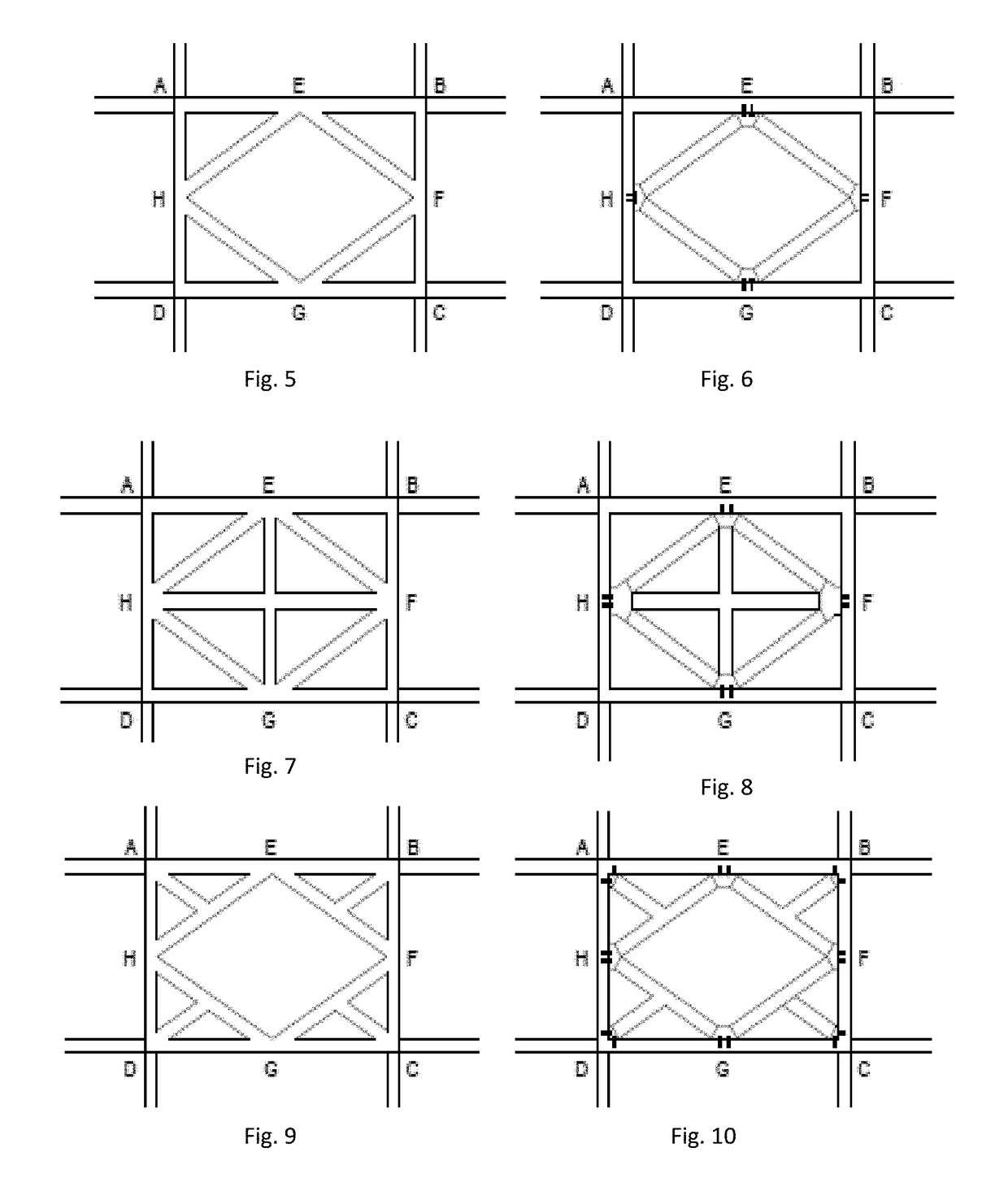

Construction method of pile-column integrated structure

Owner:SHENZHEN MUNICIPAL ENG +1

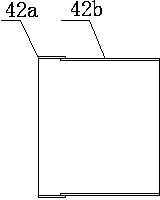

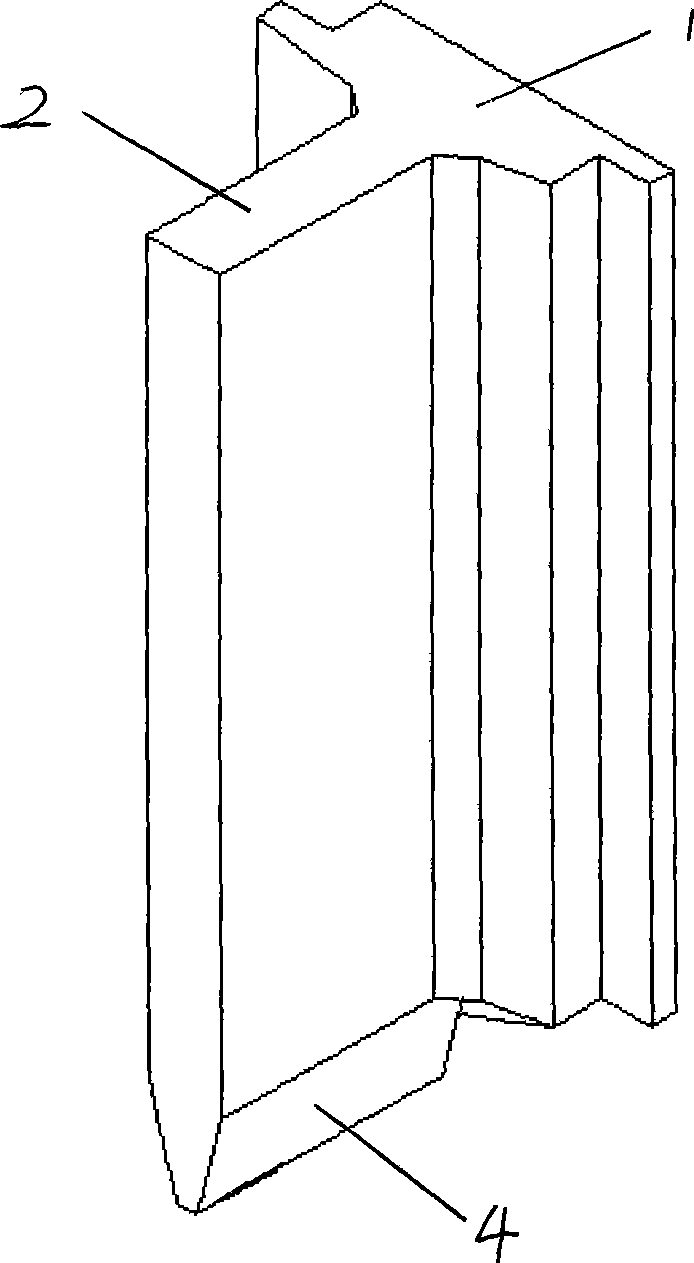

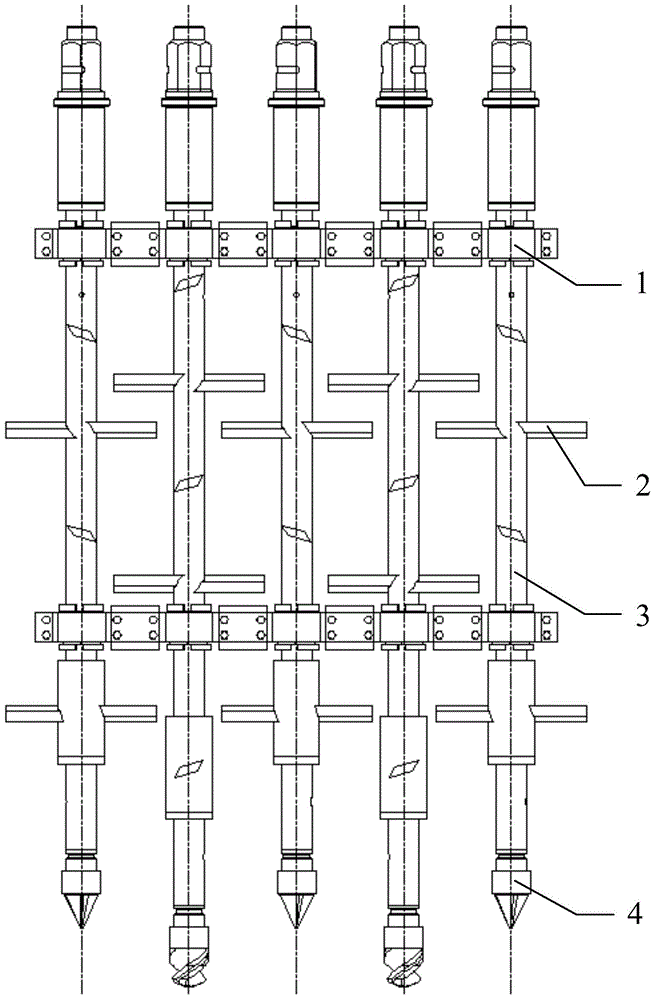

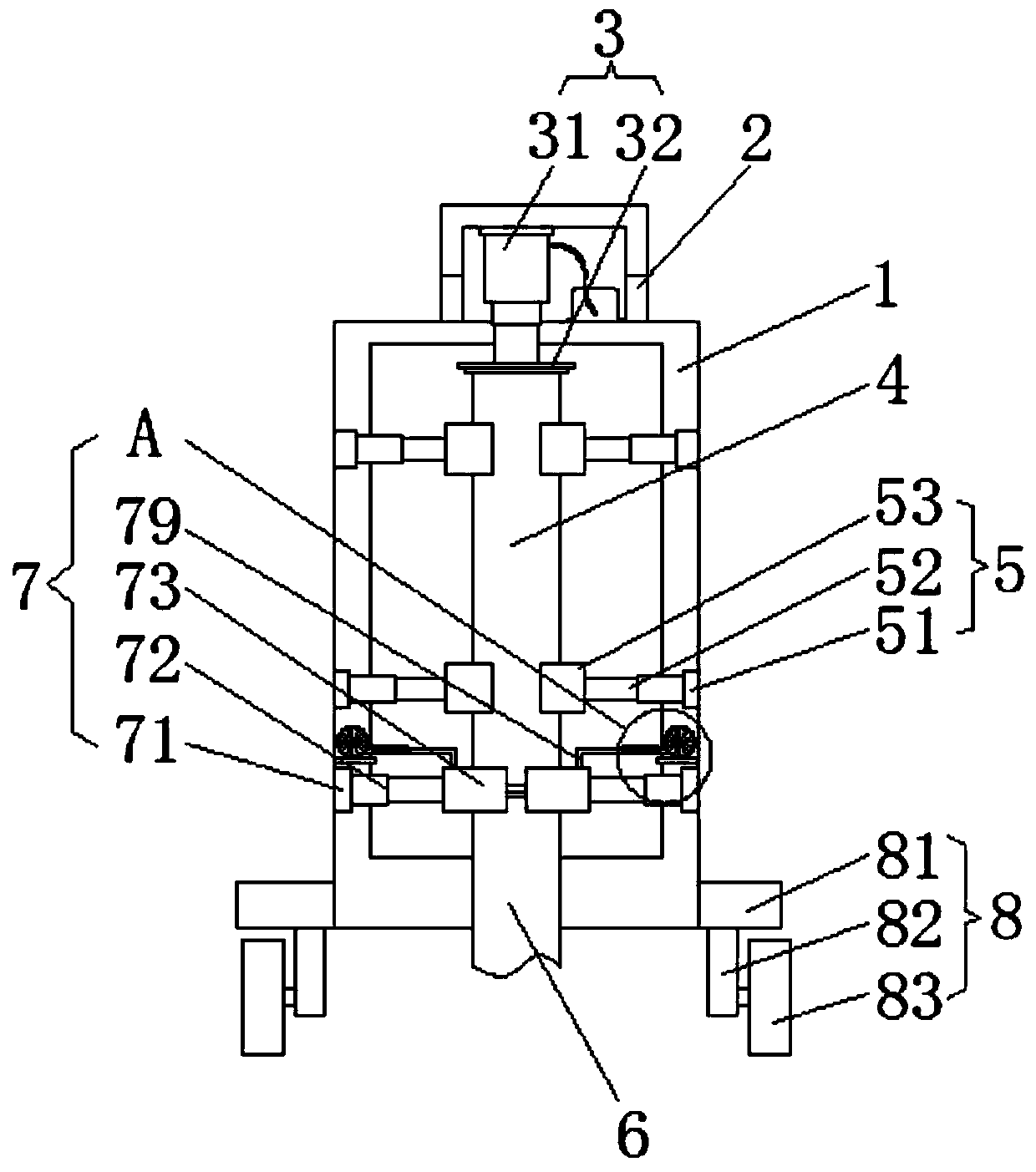

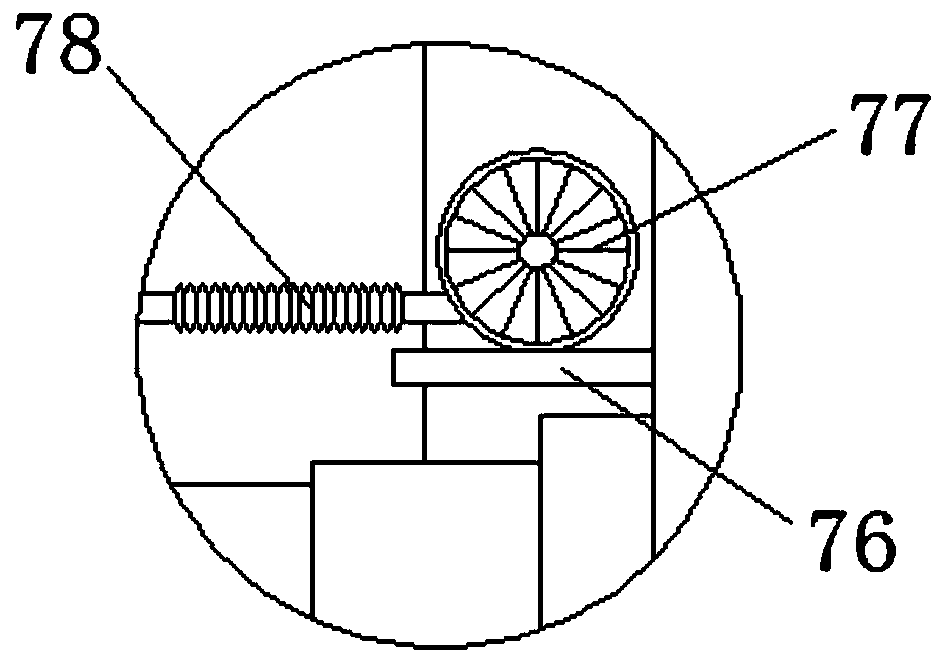

Compound jet grouting pile machine, compound jet grouting pipe and construction method for compound jet grouting pile

ActiveCN106948341AIncrease pressureAvoid the problem of poor construction stabilityBulkheads/pilesArchitectural engineeringHigh pressure

The invention discloses a compound jet grouting pipe machine which comprises a support (5), an outer sleeve (4), an inner core rod (3), a connecting device (2), a high-pressure pipeline (1) and a drill bit (14), wherein the high-pressure pipeline (1) is tightly connected with the inner core rod (3) through the connecting device (2); the inner core rod (3) is coaxially sleeved with the outer sleeve (4); the outer sleeve (4) is fixedly connected to the support (5); and the drill bit (14) is connected with the bottom end of the inner core rod (3), and comprises stirring drilling blades and a high-pressure nozzle (15) detachably mounted into a cylinder defined by the side wall of the drill bit (14). The invention further discloses a construction method for a compound jet grouting pile, and the compound jet grouting pile. According to the compound jet grouting pile machine, the pile is formed at a time, the stability is high, and the machine is suitable for soft and hard soil bodies, high in automation degree and capable of saving materials.

Owner:HUBEI DIGONG ZHANZHI CONSTR ENG CO LTD

A method of constructing earthquake resistant structure with reinforced foundation and wall structure

Owner:YASHRAJ MAHESH +1

Umbrella-shaped anti-floating anchor rod device and using method

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

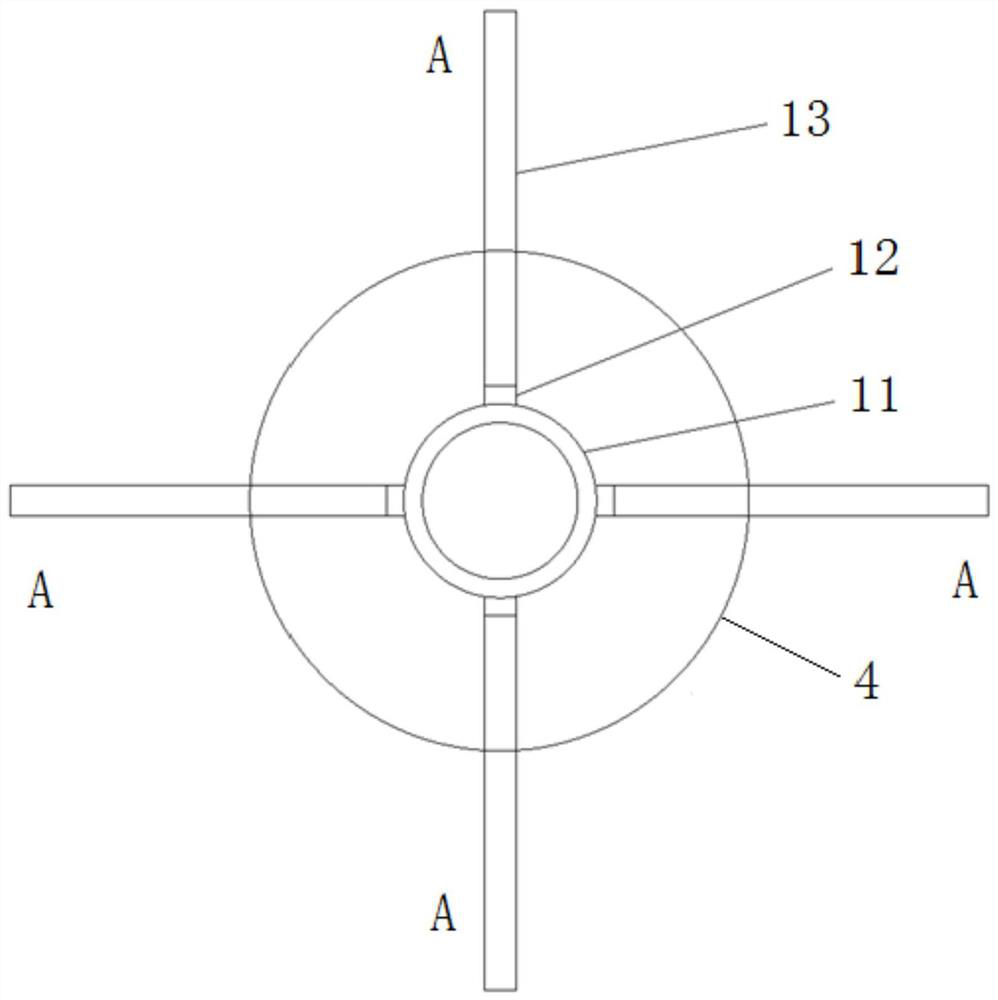

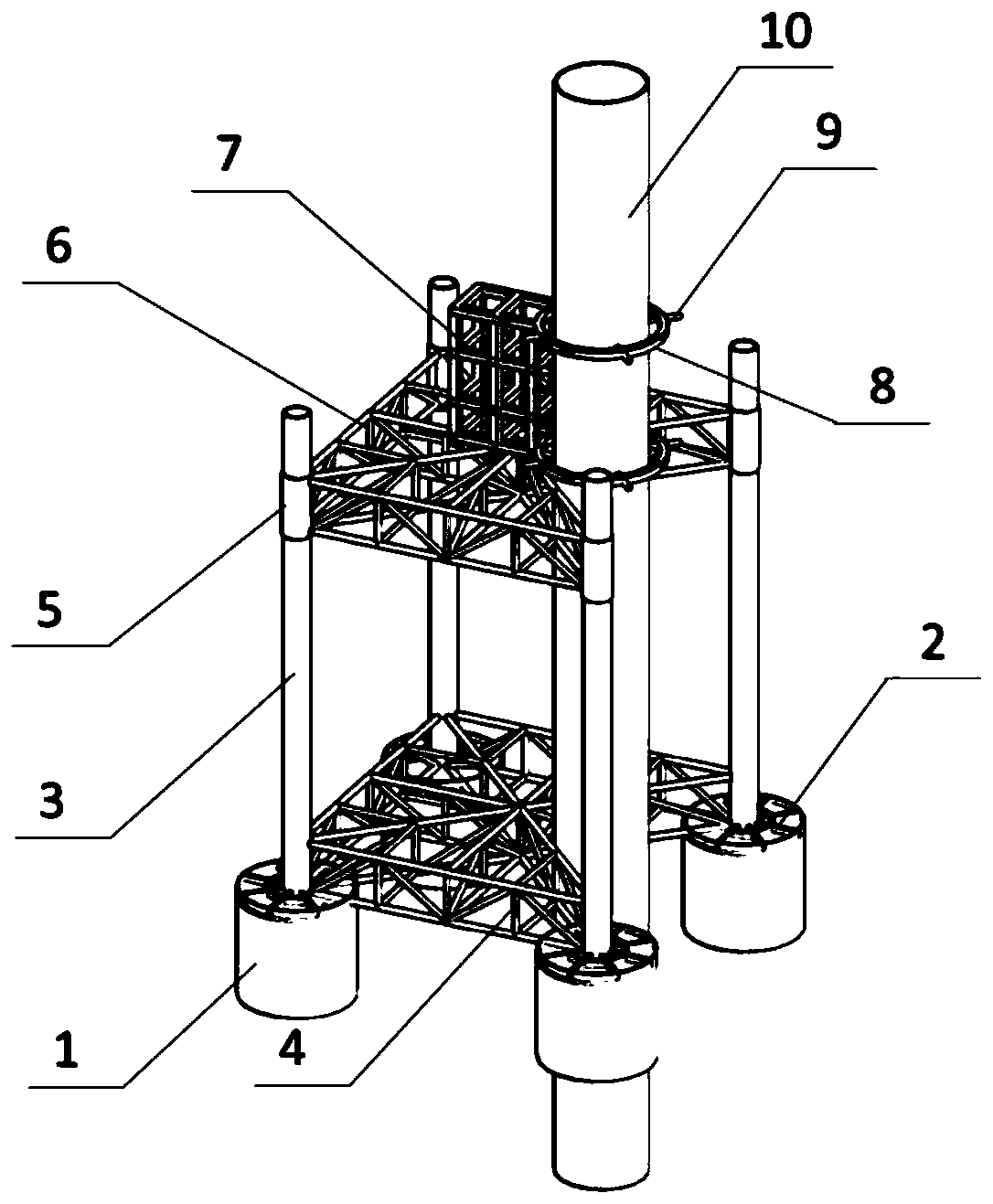

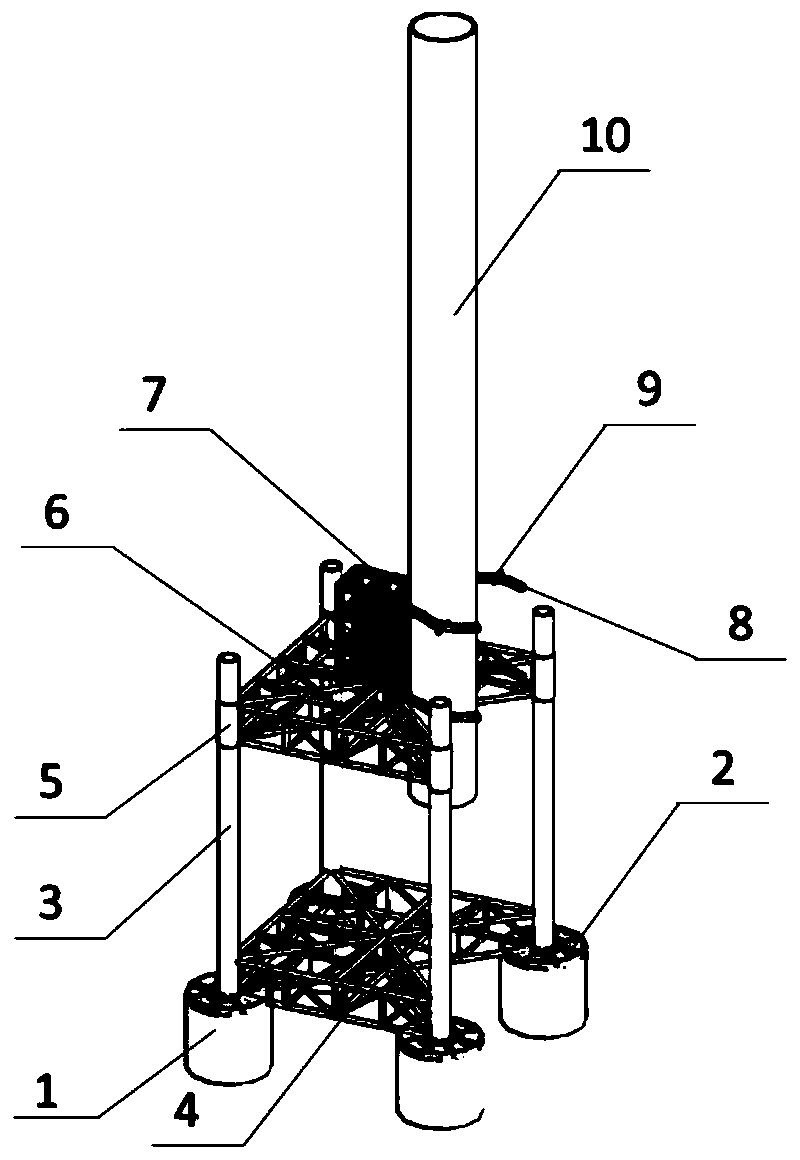

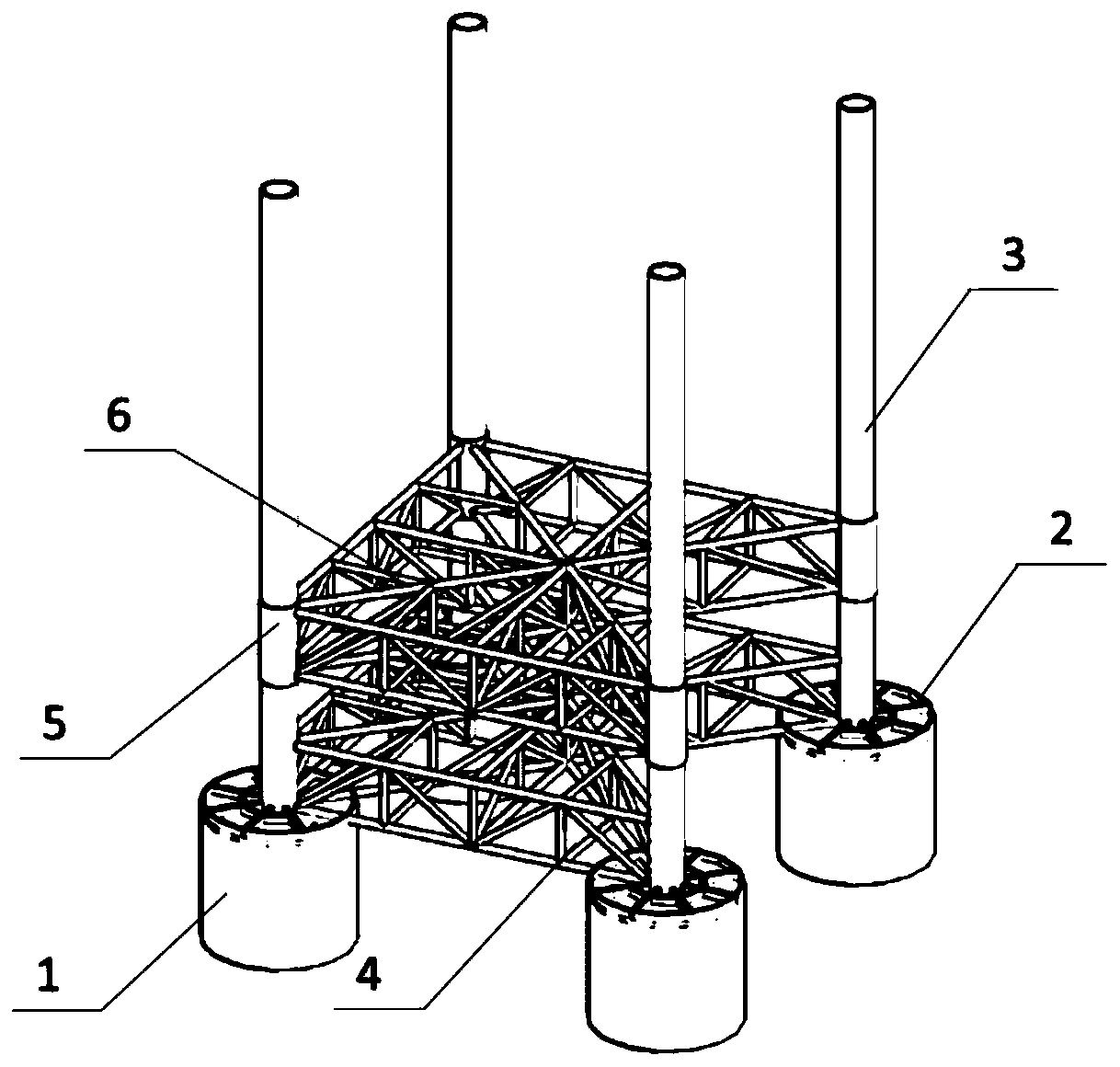

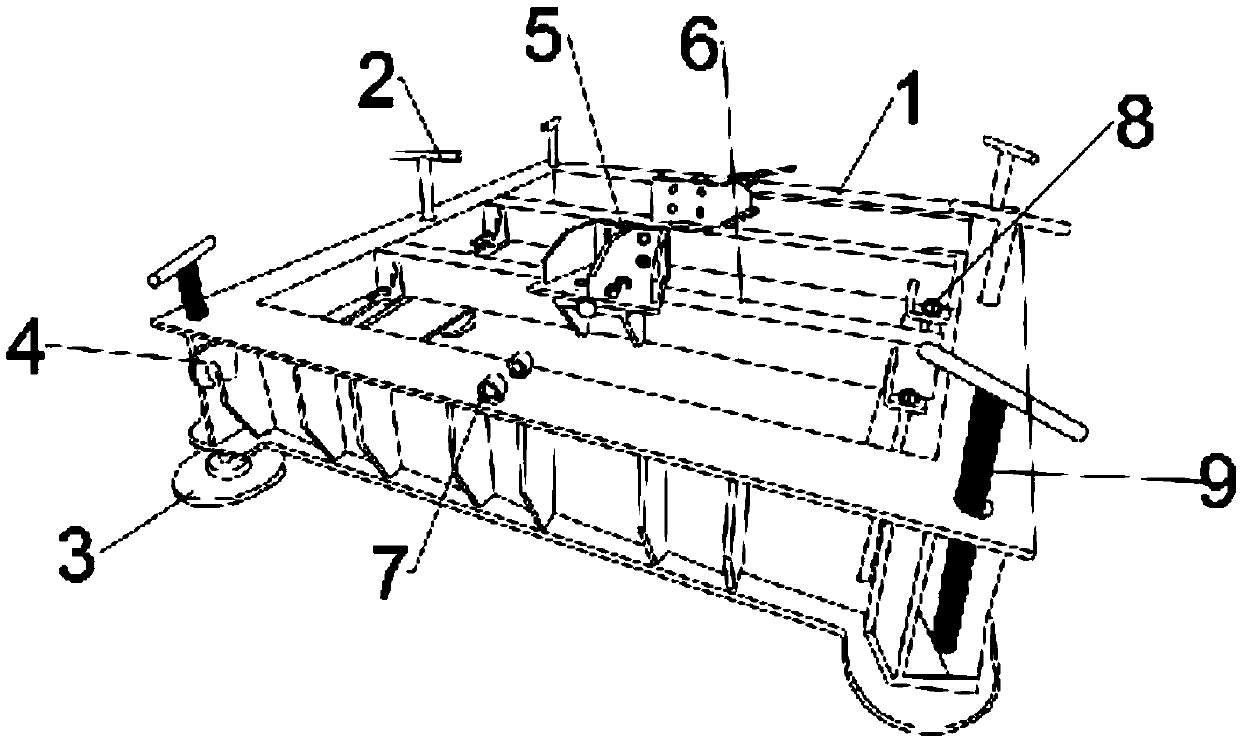

Construction method based on box-drum-type pile stabilizing platform

PendingCN110644487ASimple structureImprove horizontal bearing capacityArtificial islandsUnderwater structuresStable statusArchitectural engineering

Owner:天津港航工程有限公司

Building workshop pile foundation and building workshop piling technology applying pile foundation

ActiveCN110374099AImprove carrying capacityIncrease contact areaBulkheads/pilesCement slurryHigh pressure

Owner:东莞市建安桩基础工程有限公司

One-column and one-pile construction method adopting hydraulic verticality-adjusting frame reversing building method

PendingCN109610441ASolve the construction problem of vertical adjustment of one column and one pileSimple construction processIncline measurementBulkheads/pilesBrickSlag

Owner:ZHONGTIAN CONSTR GROUP +1

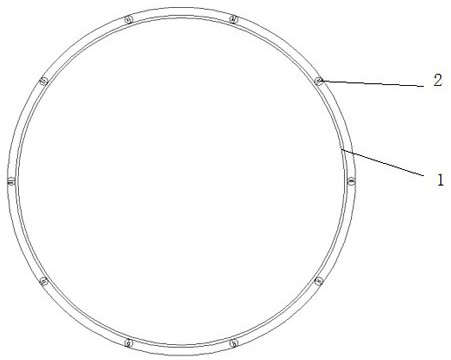

Construction method and equipment of circular bored socketed piles

Owner:天津港航工程有限公司 +1

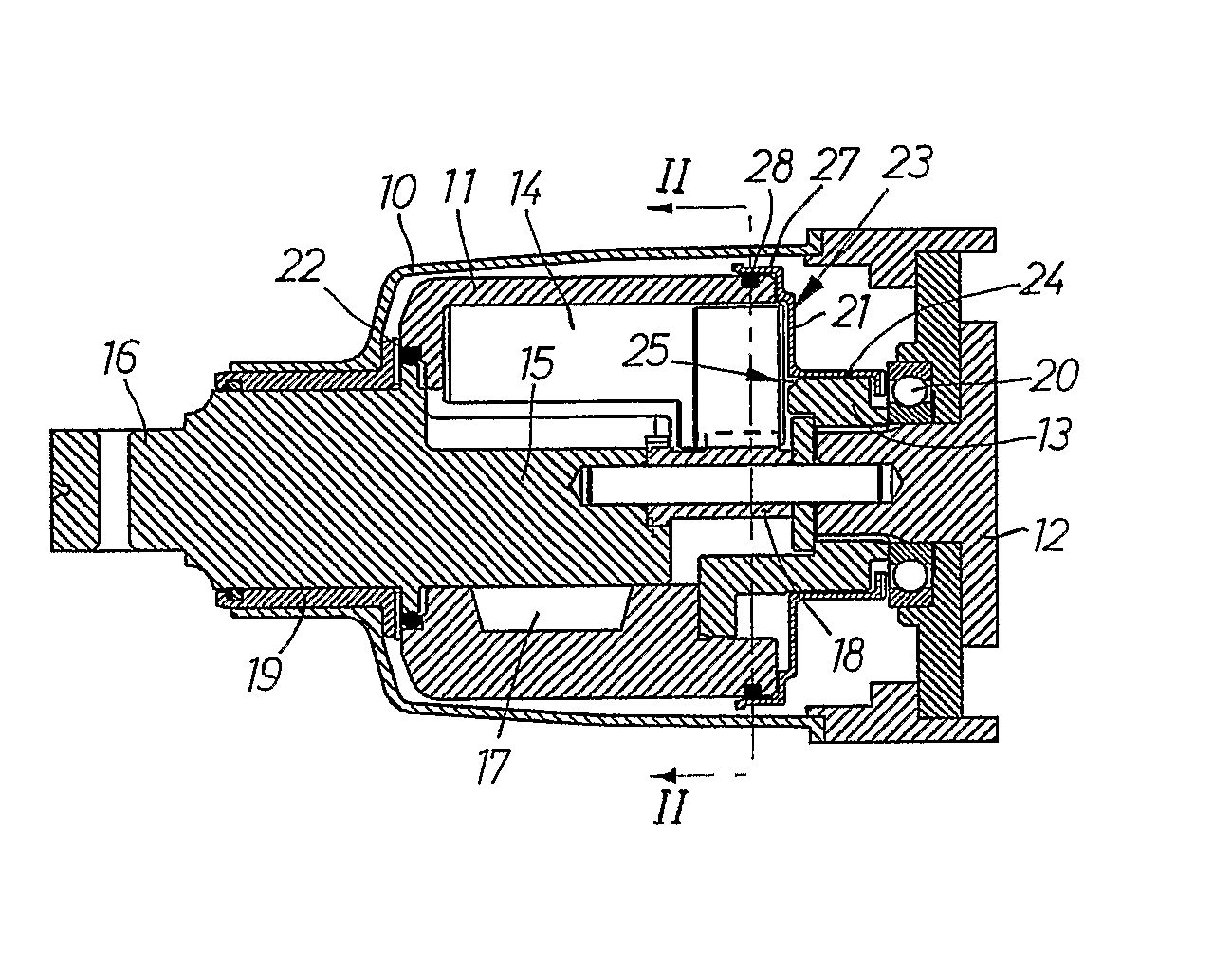

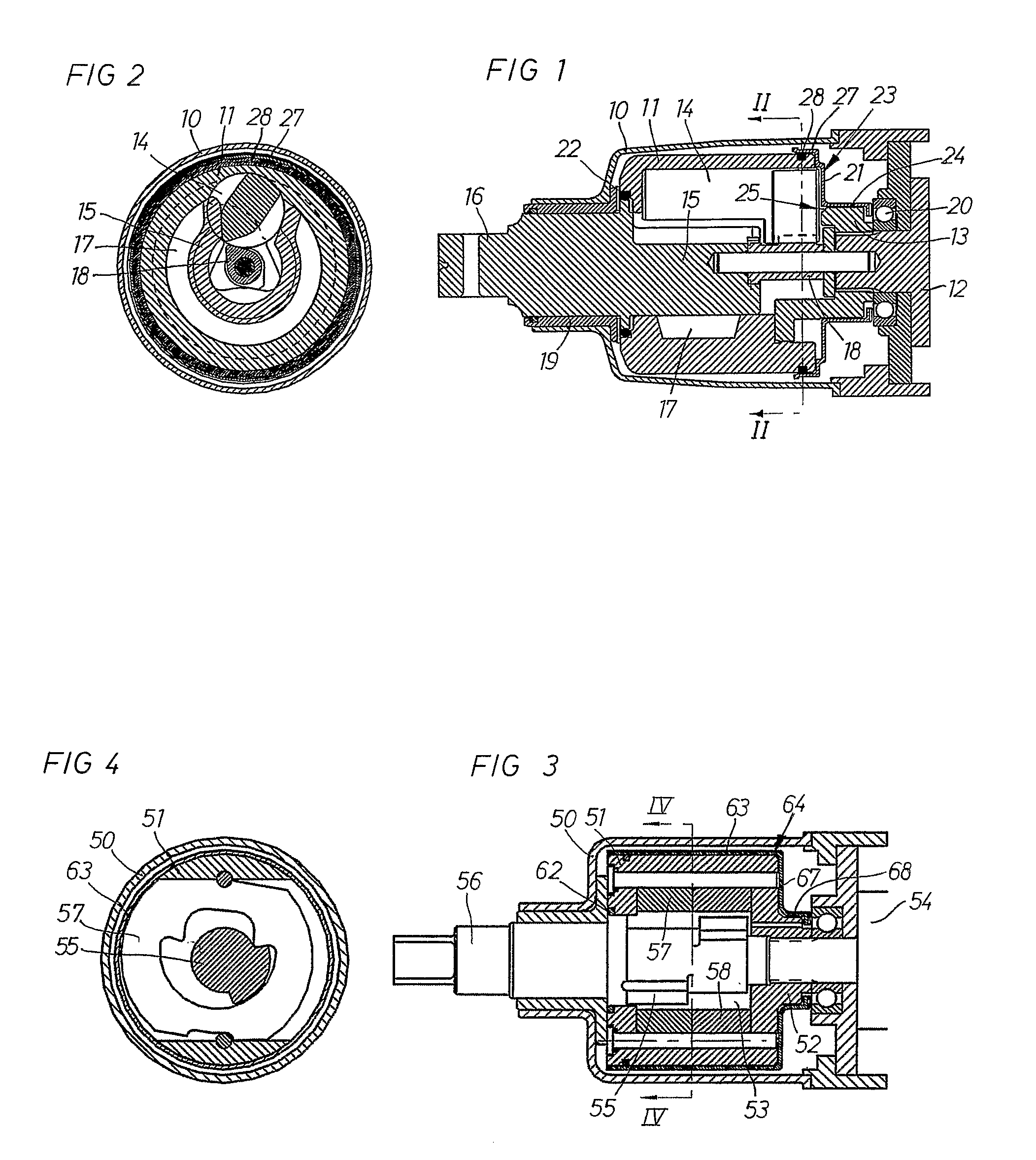

Impact wrench with a lubricated impact mechanism

Owner:ATLAS COPCO TOOLS AB

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap