Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about "Toothed gearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

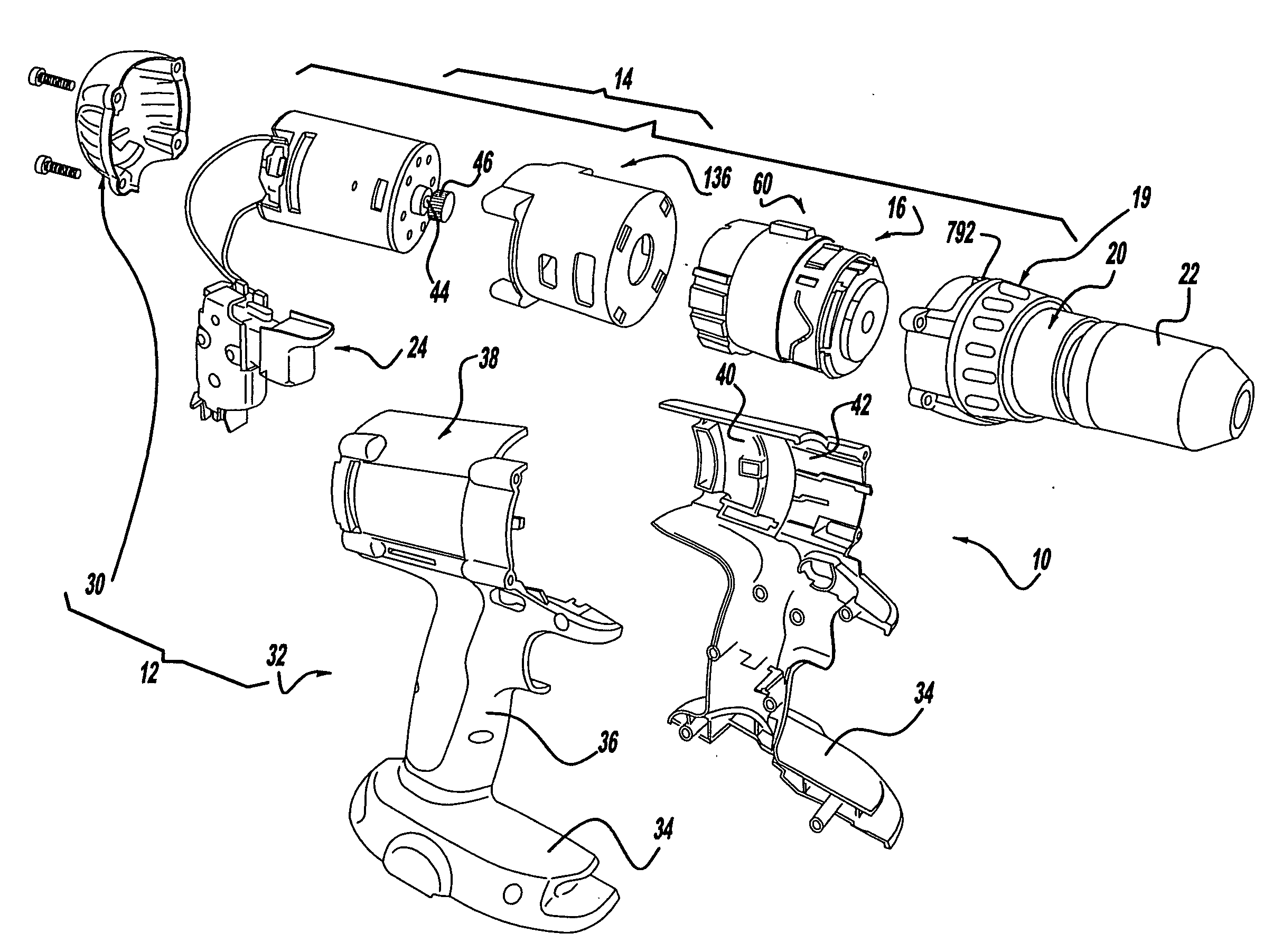

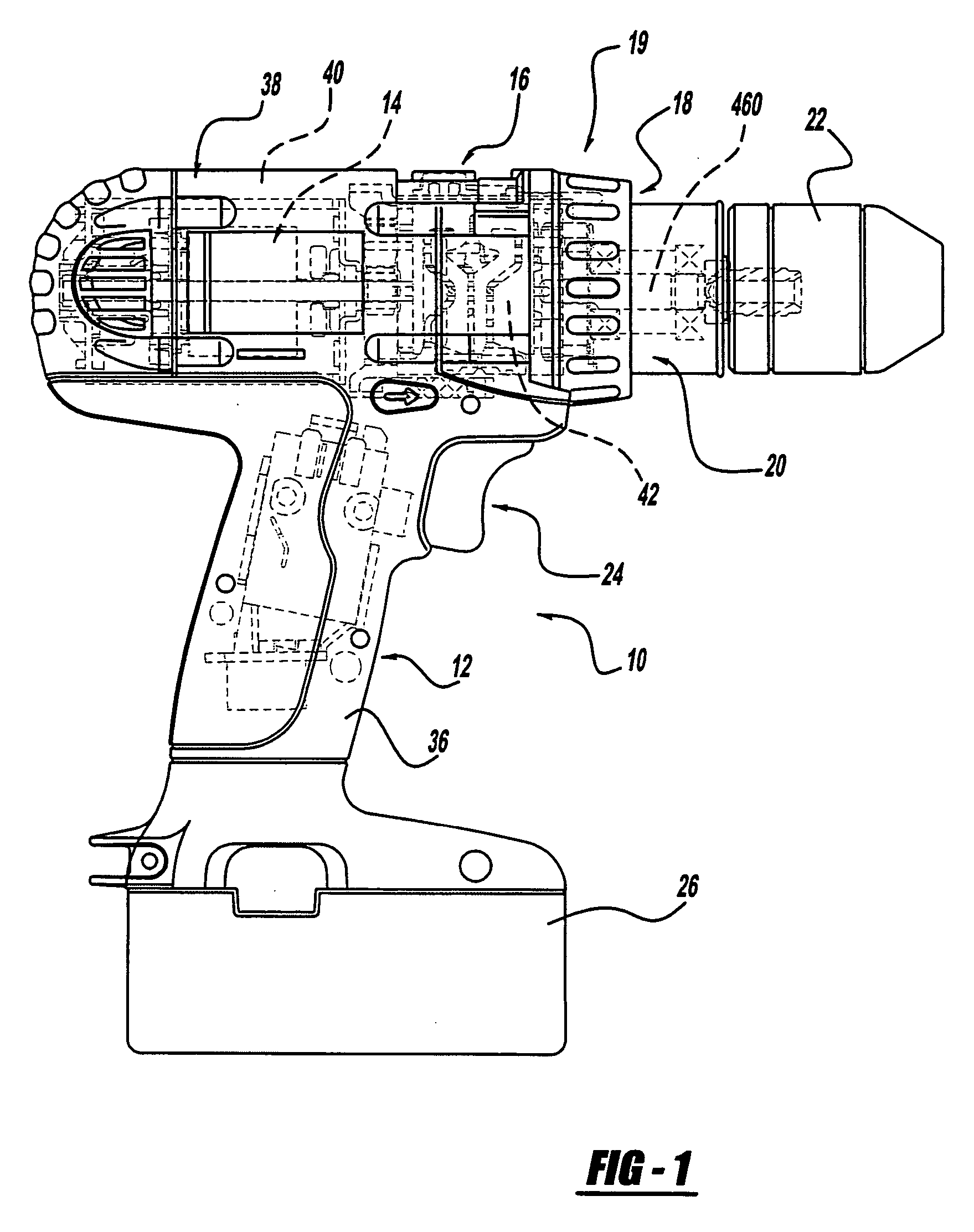

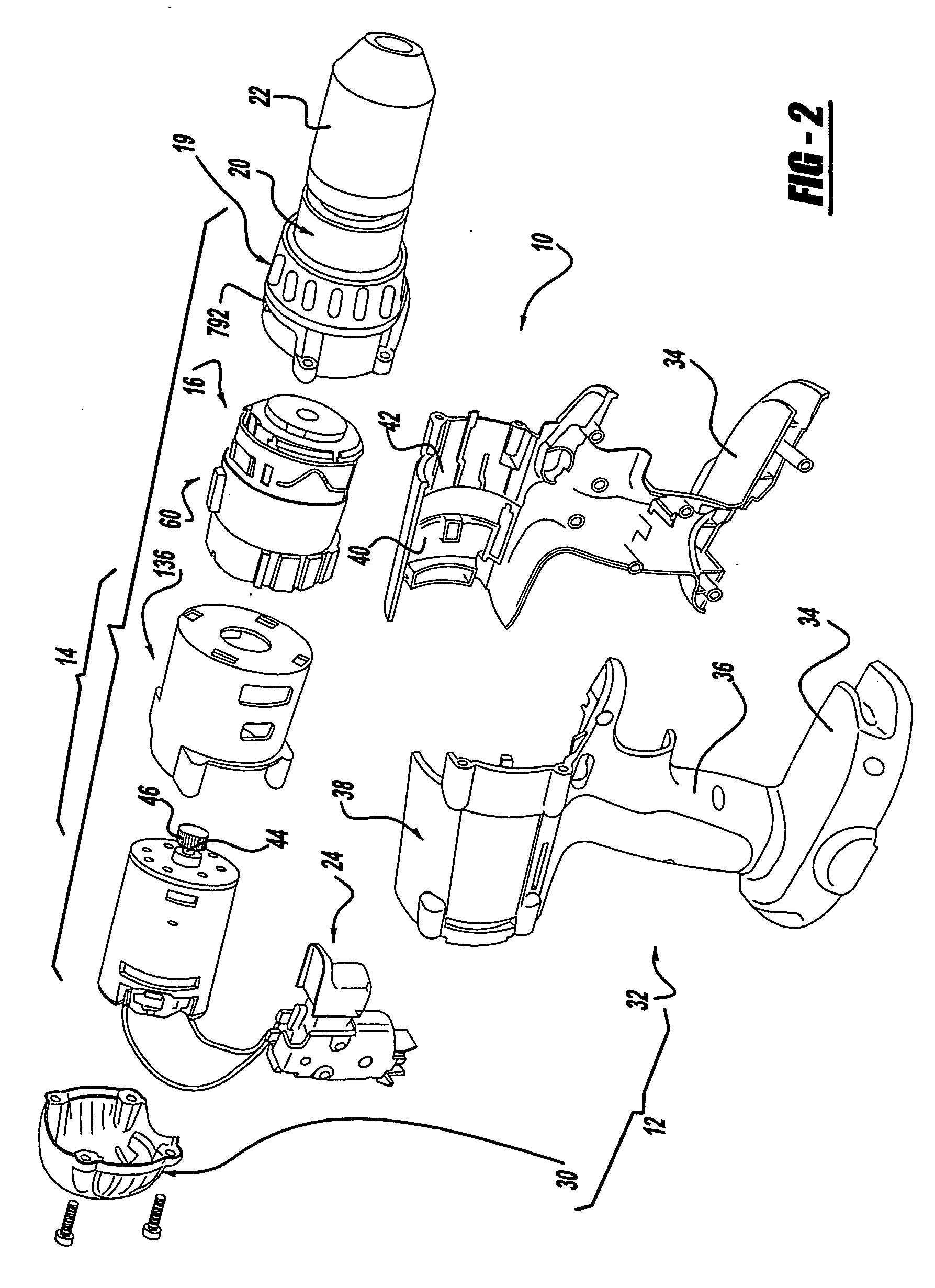

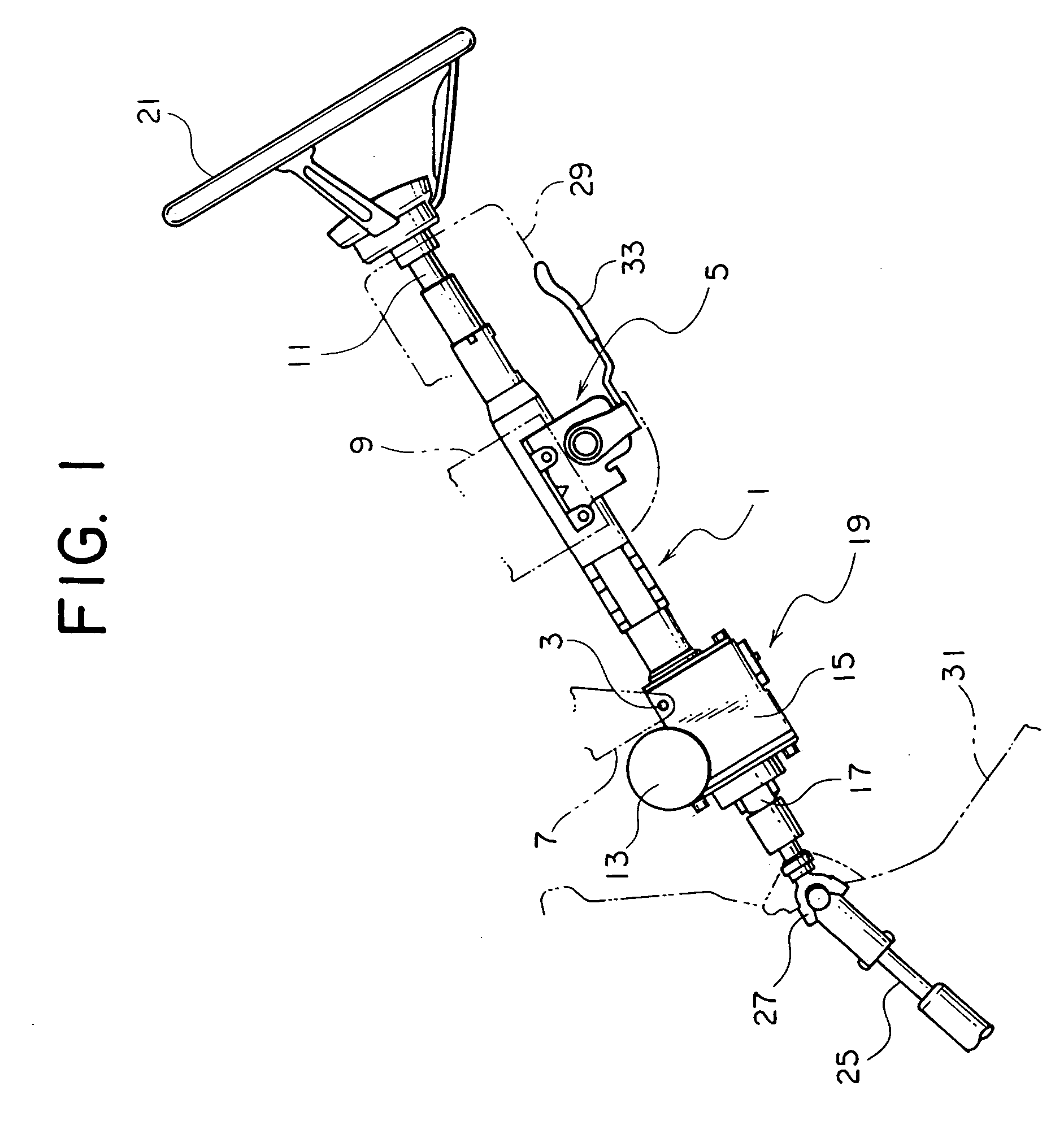

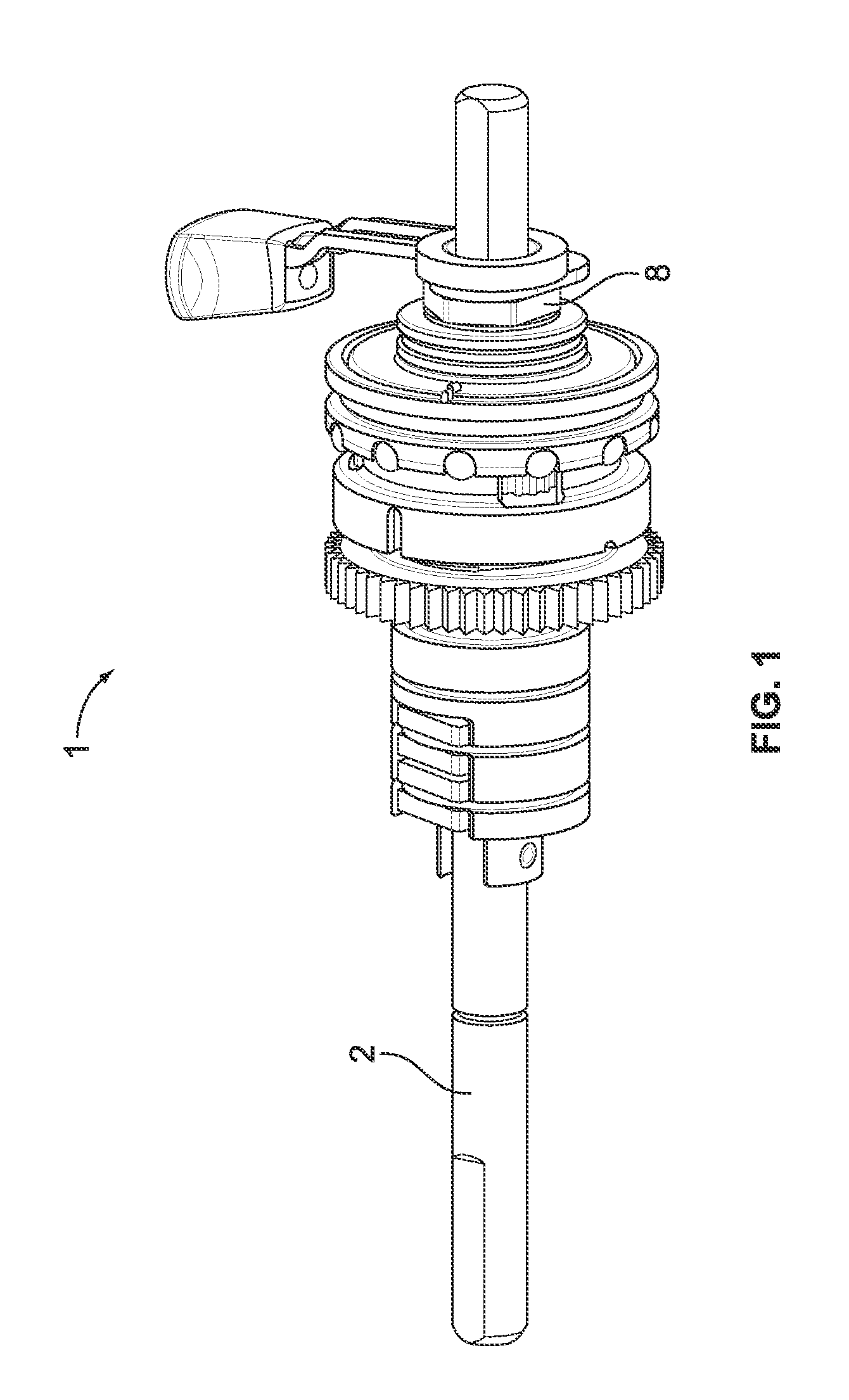

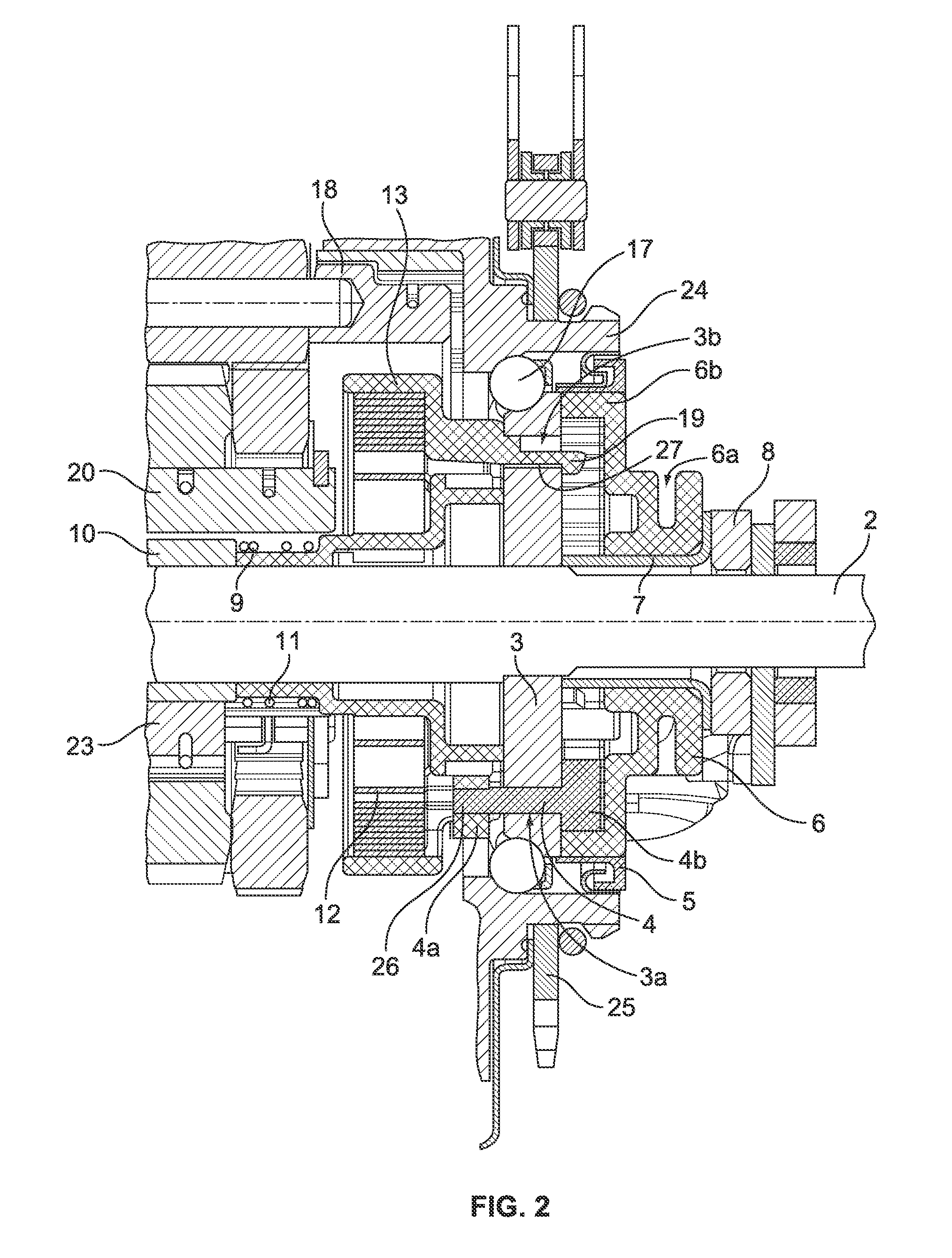

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

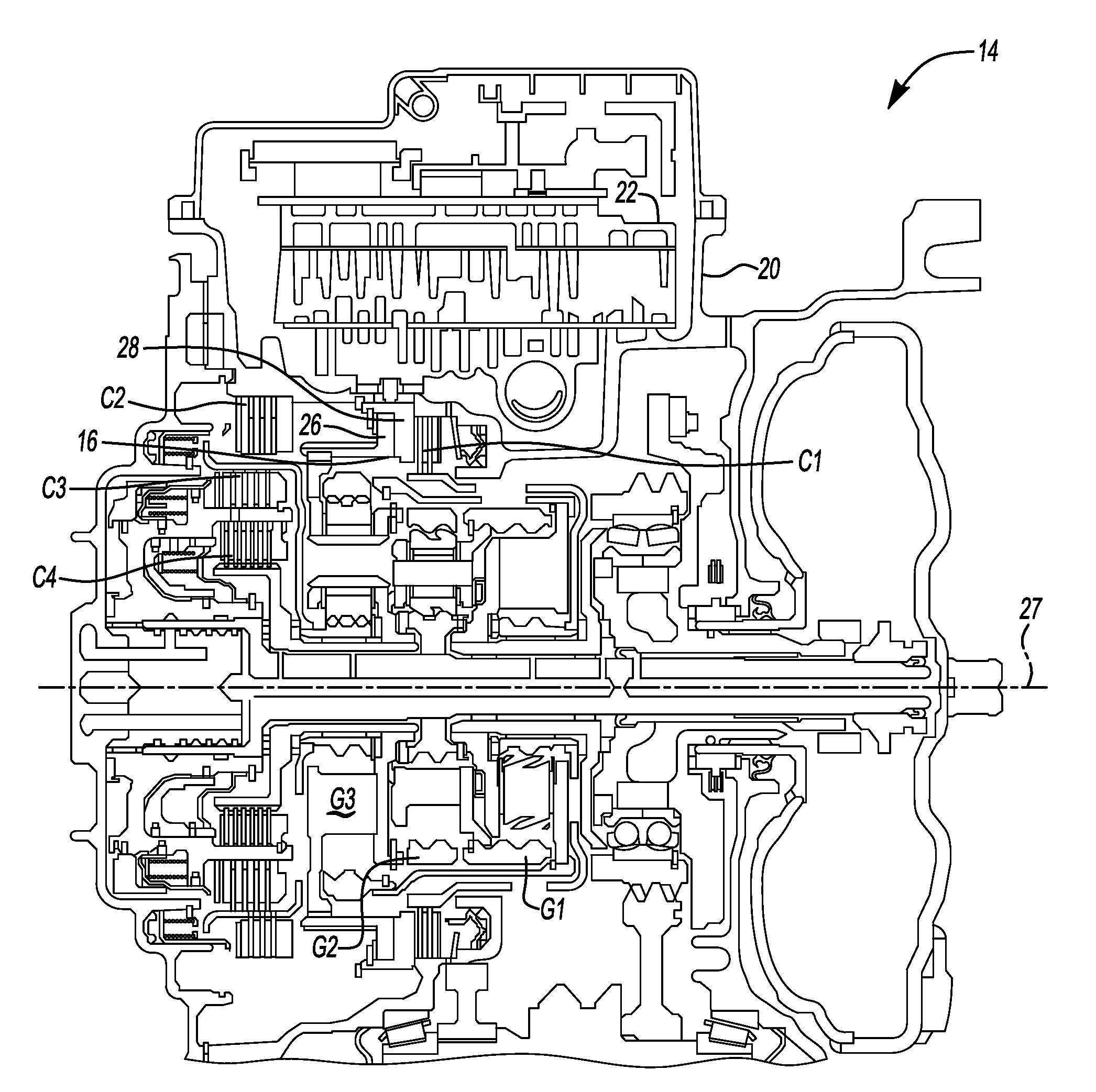

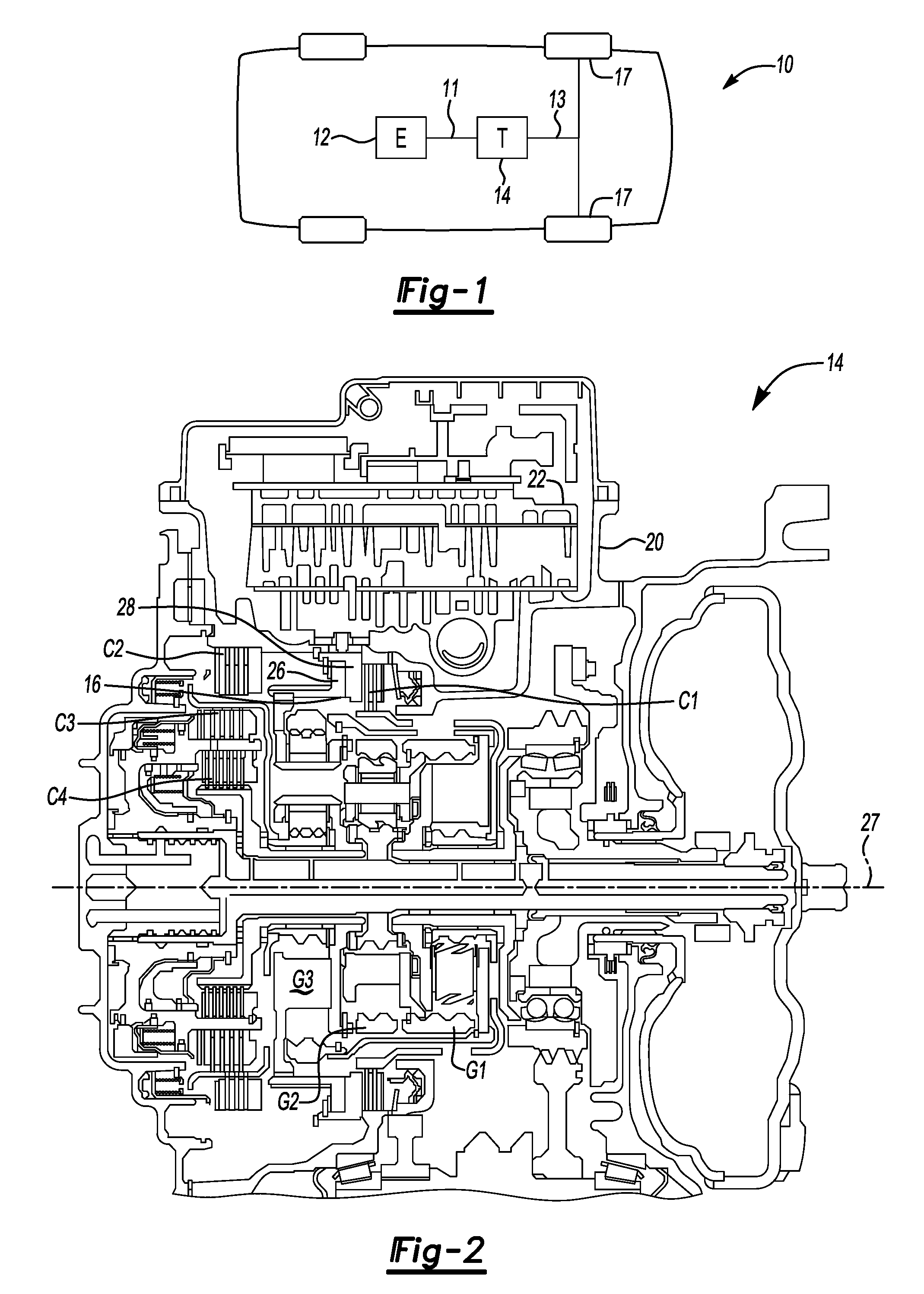

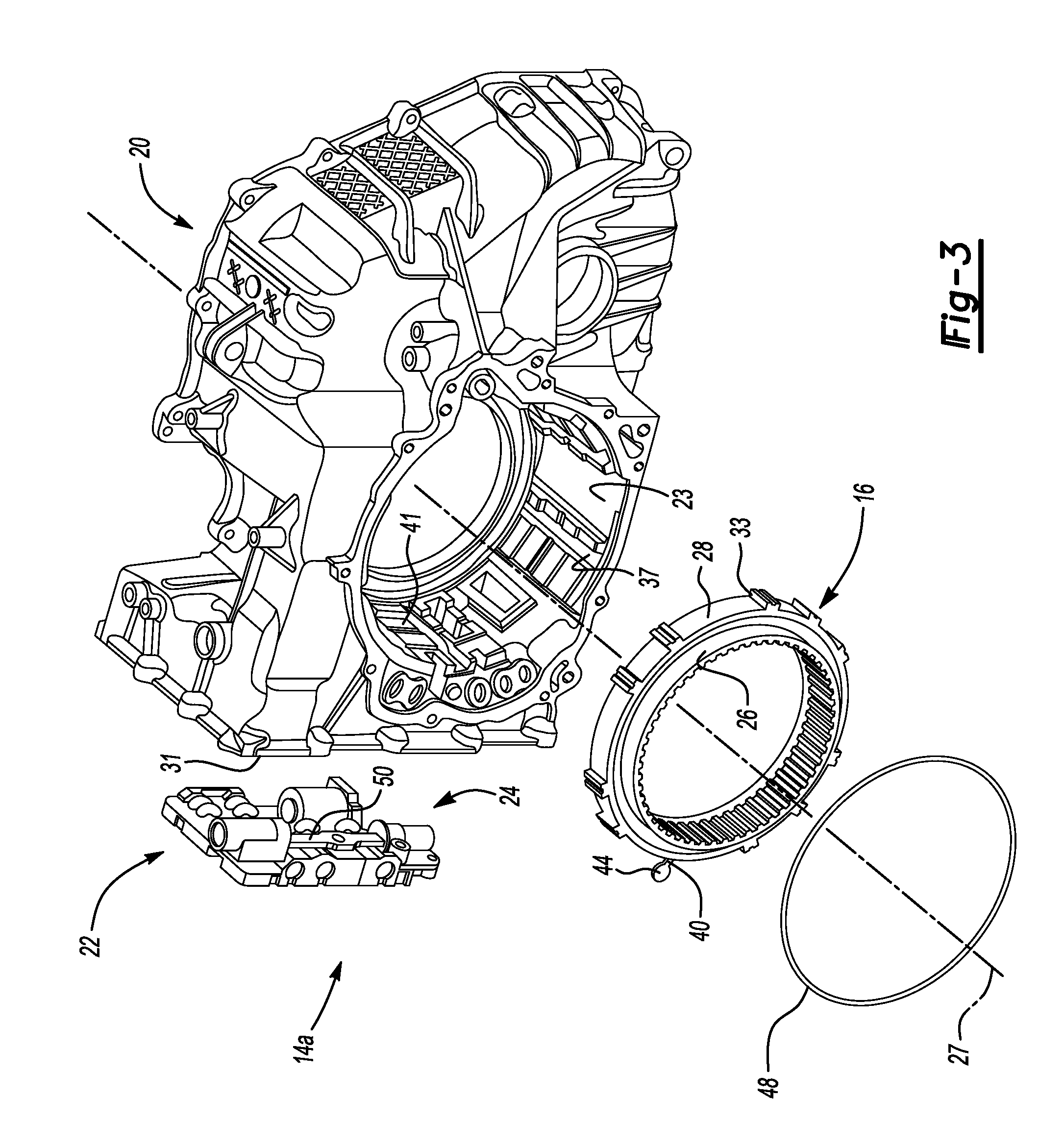

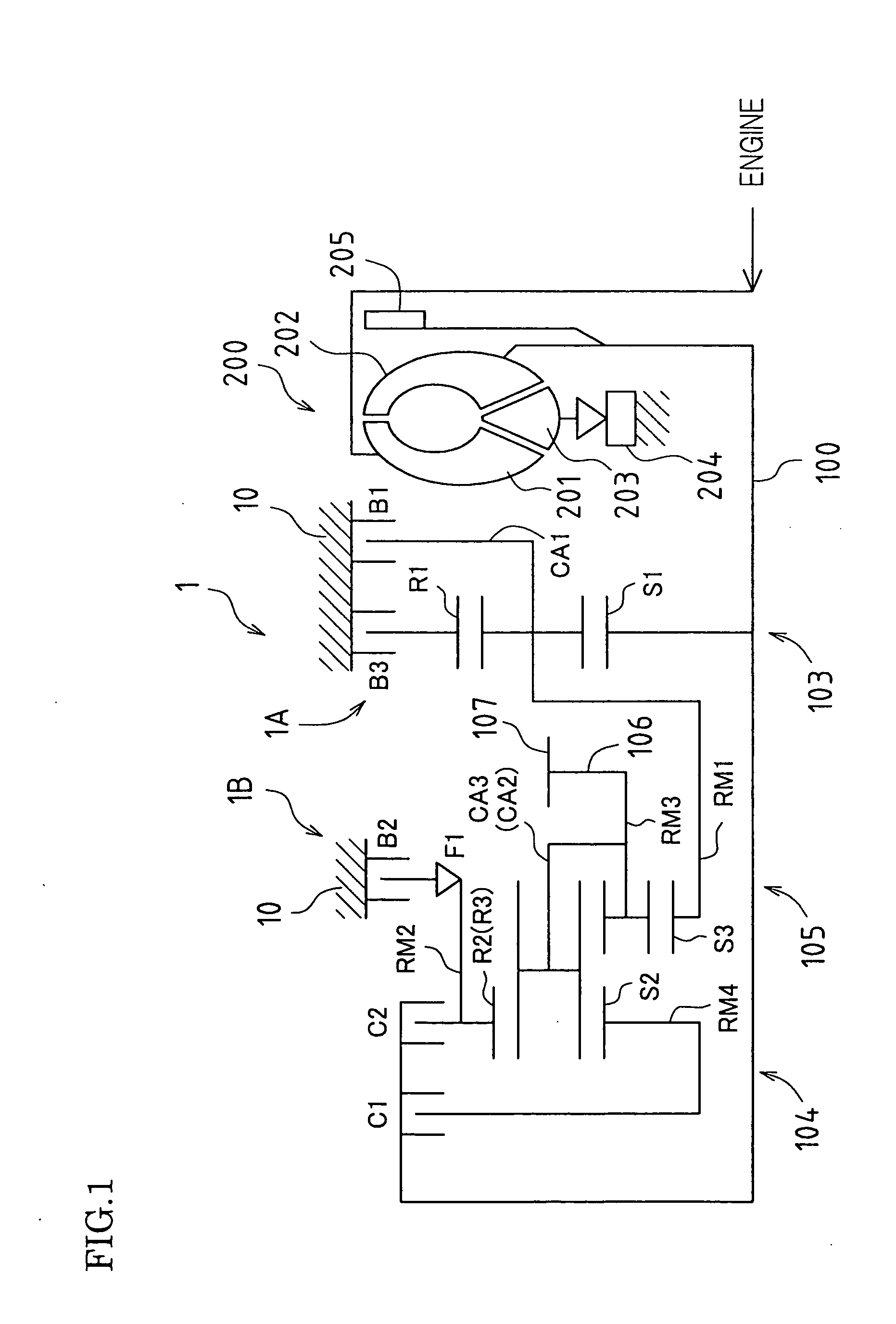

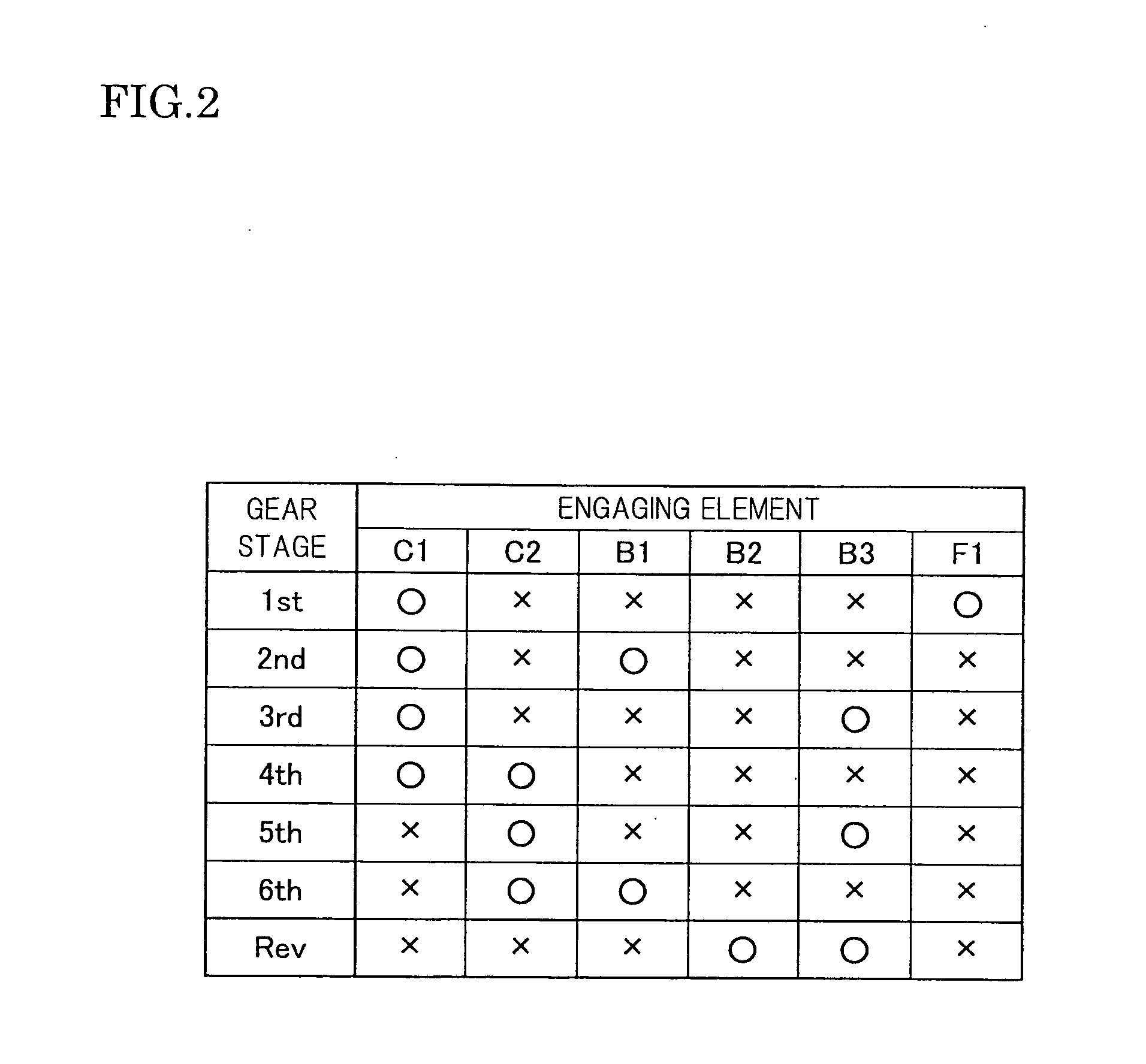

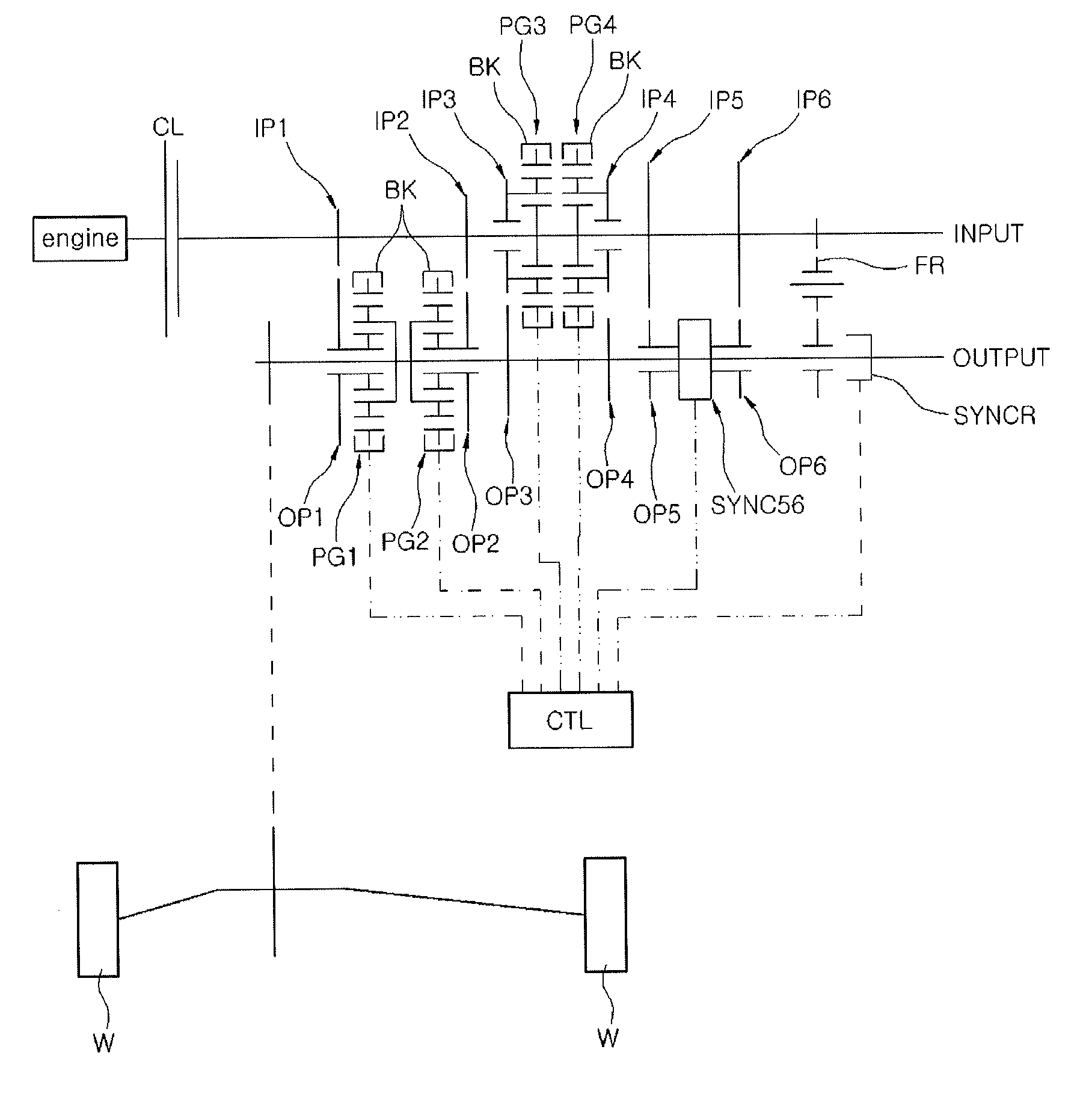

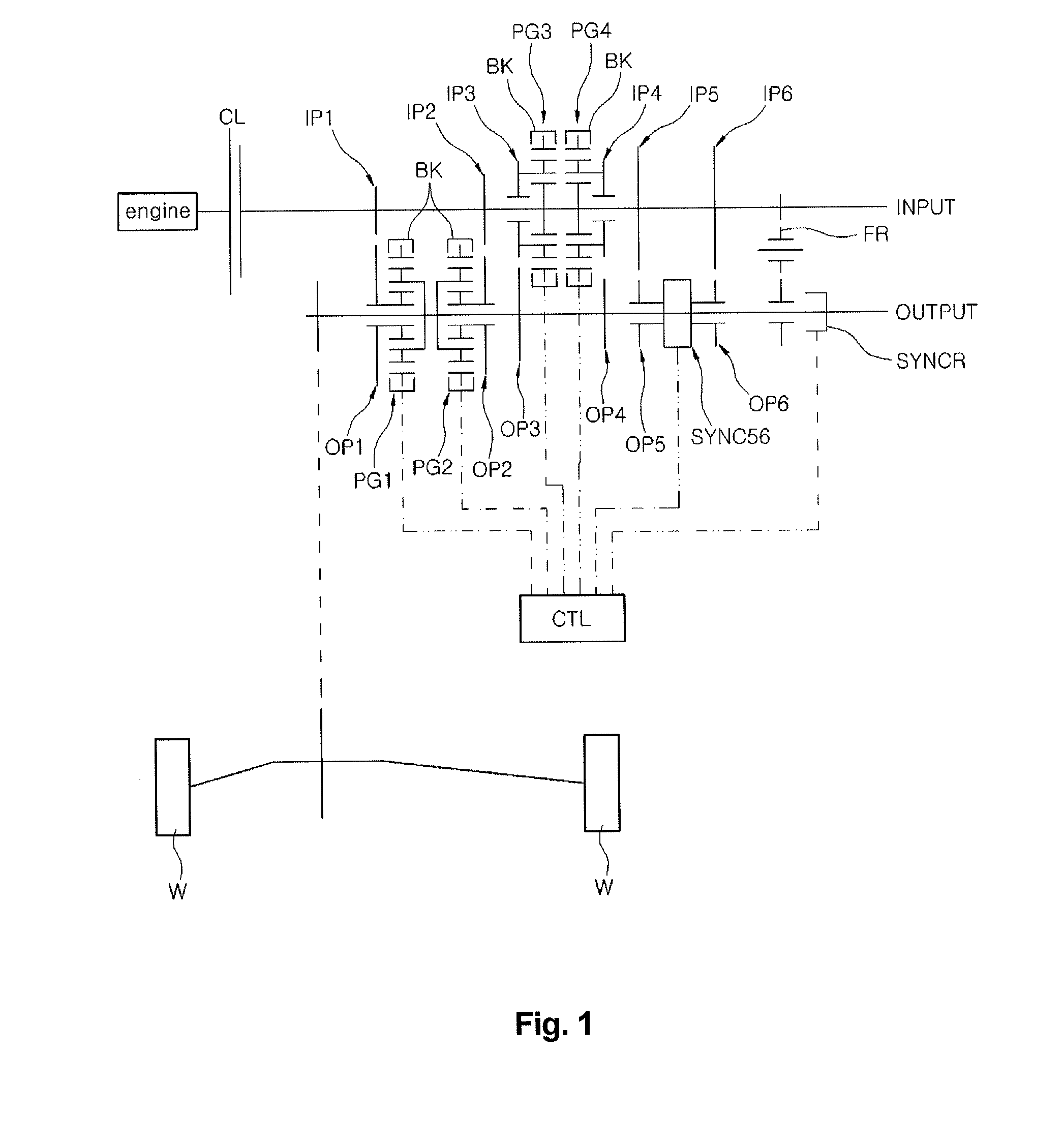

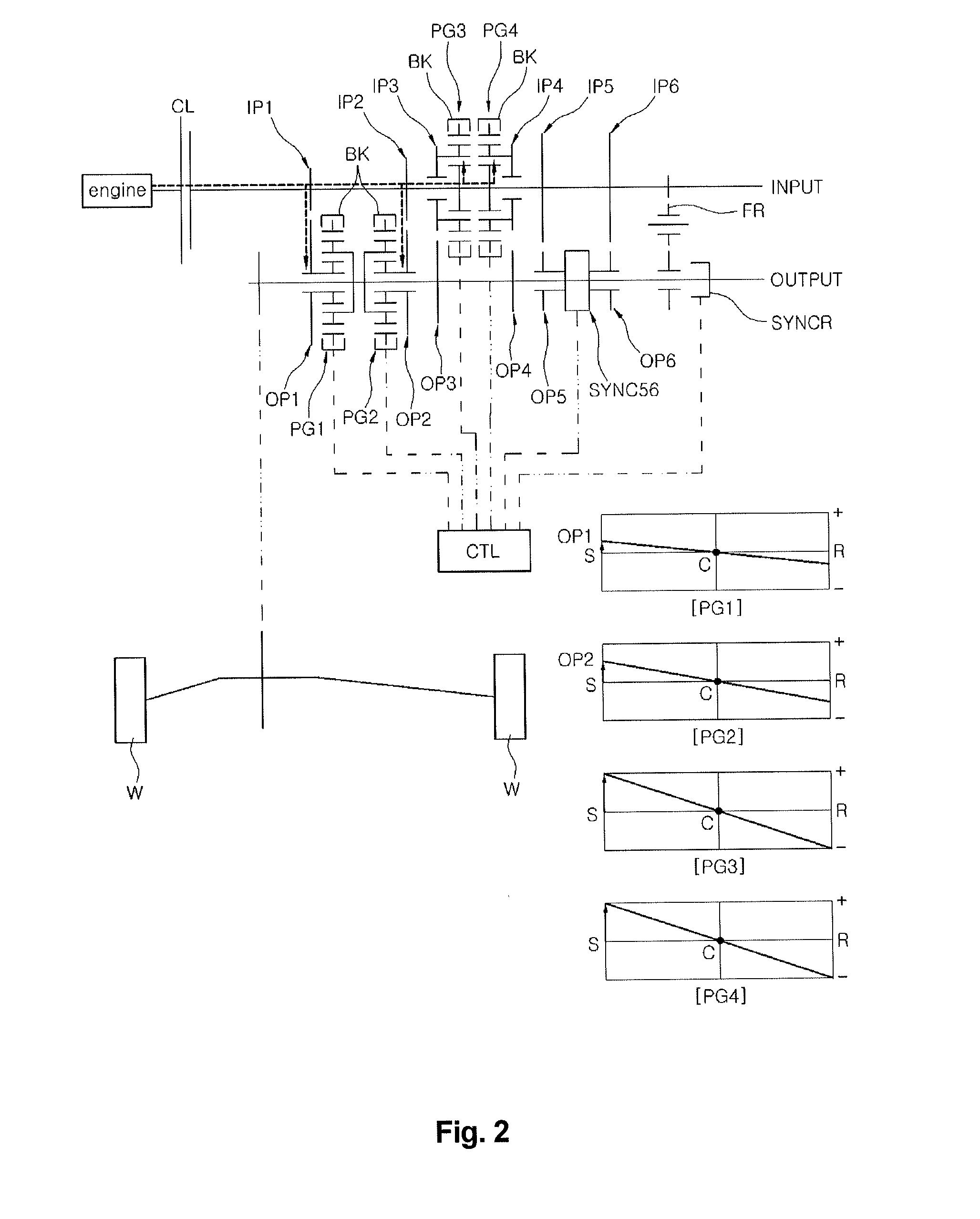

Front Wheel Drive Automatic Transmission with a Selectable One-Way Clutch

ActiveUS20100022342A1Reducing spin lossTransmission lossDigital data processing detailsToothed gearingsAutomatic transmissionOperation mode

Owner:GM GLOBAL TECH OPERATIONS LLC

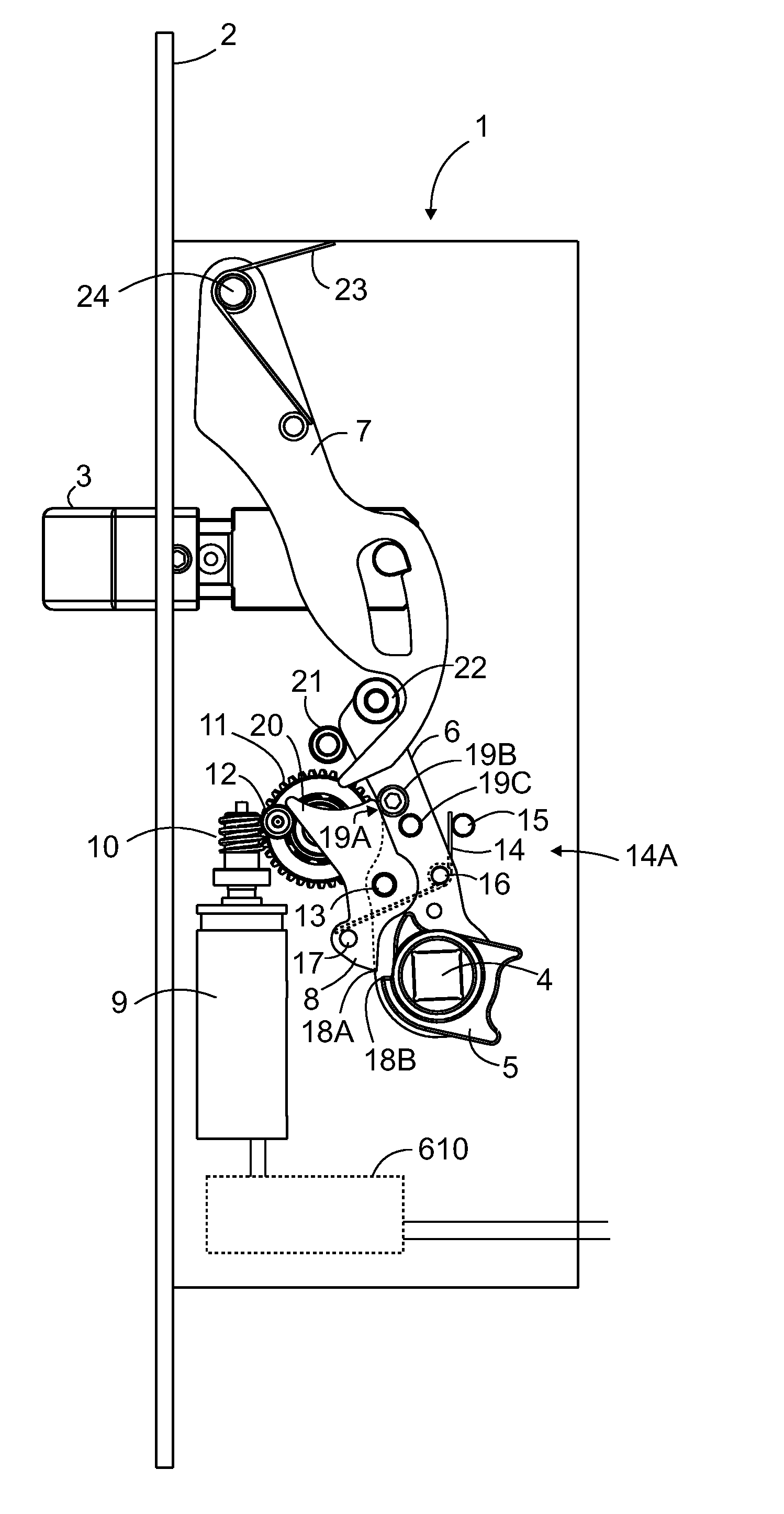

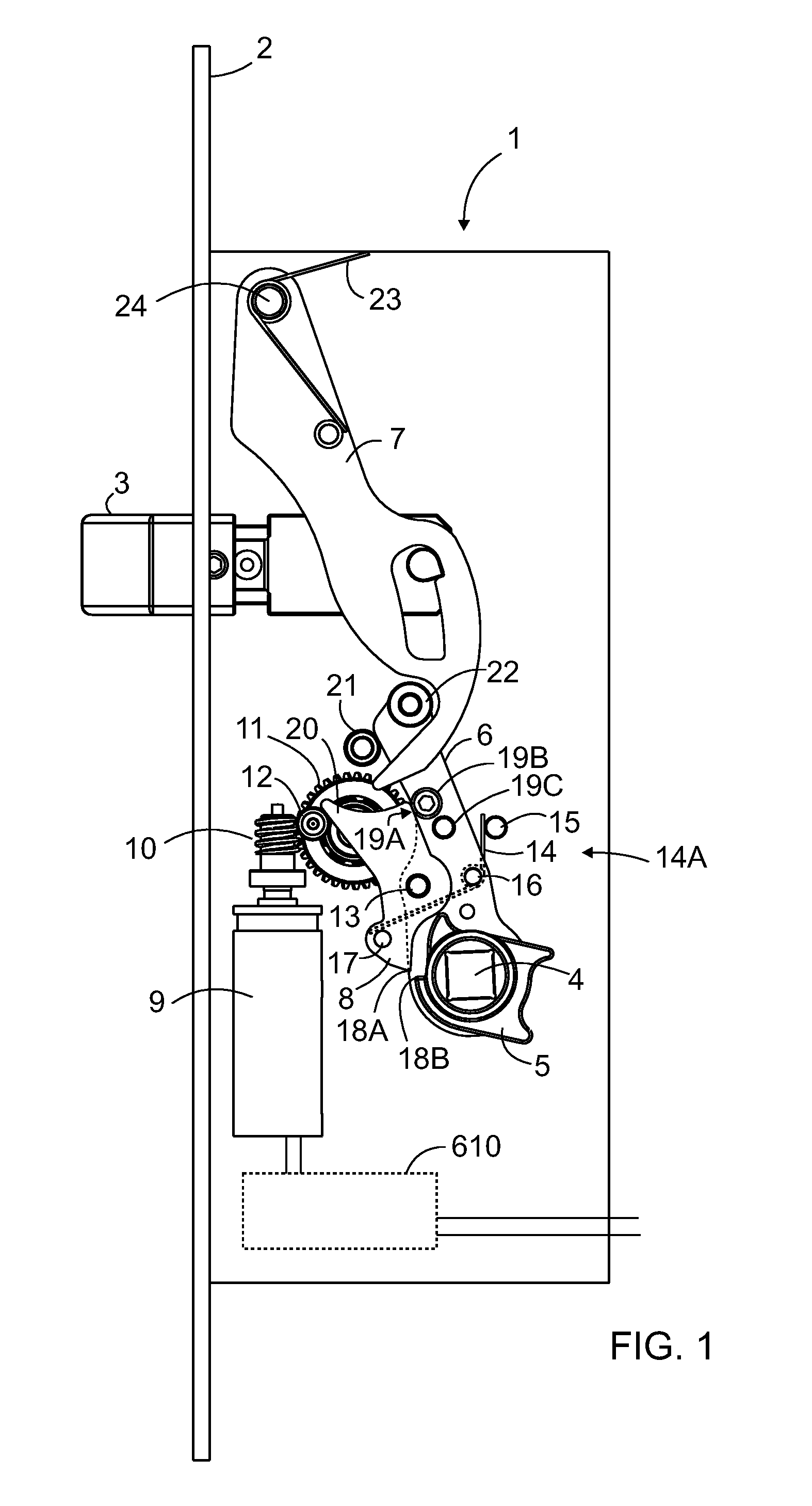

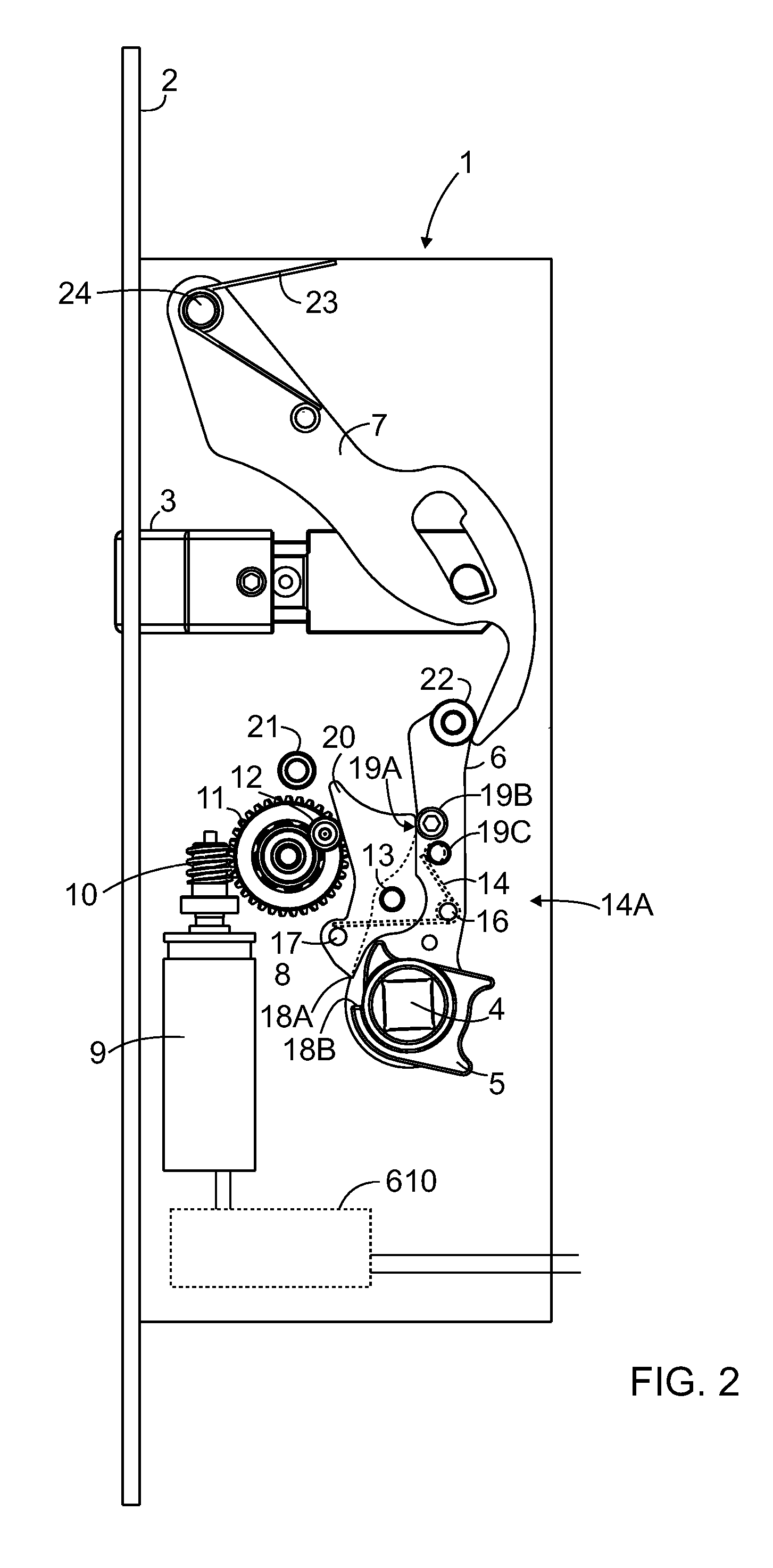

Lock body

Owner:ABLOY OY

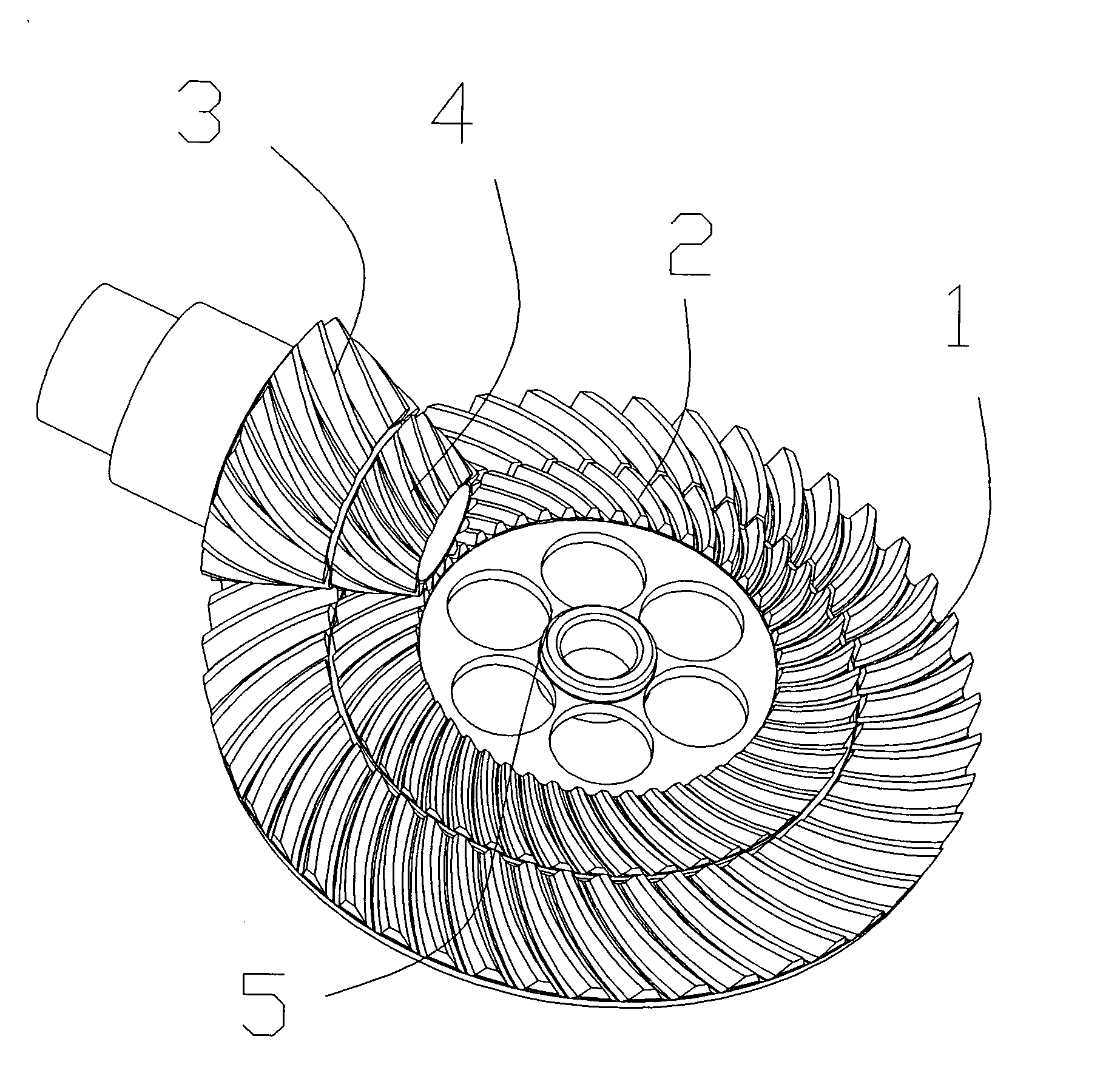

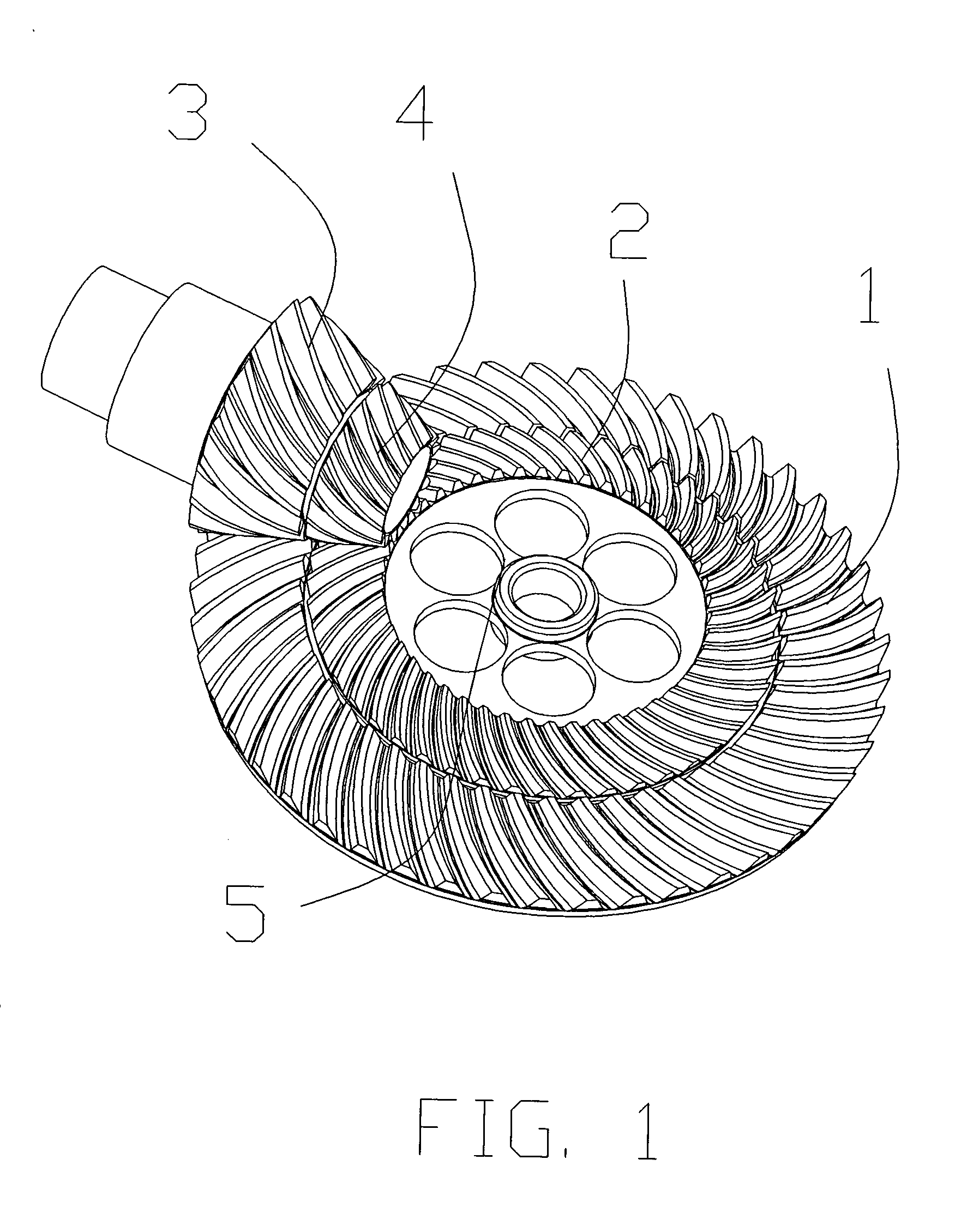

Gear reduction unit

InactiveUS20050028627A1Easy to useHigh contact ratioToothed gearingsTransmission elementsGear wheelEngineering

Owner:FLEYTMAN YAKOV

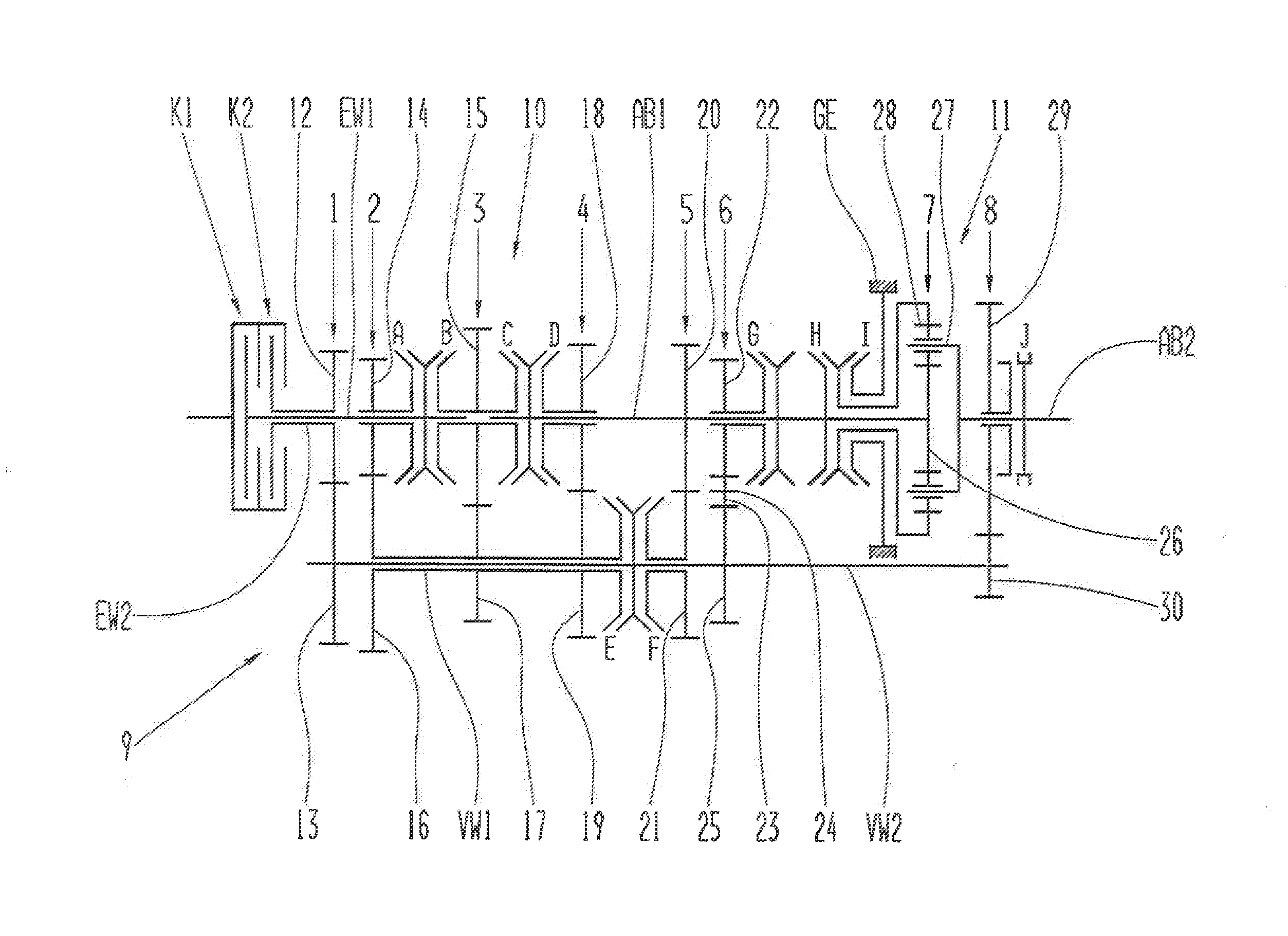

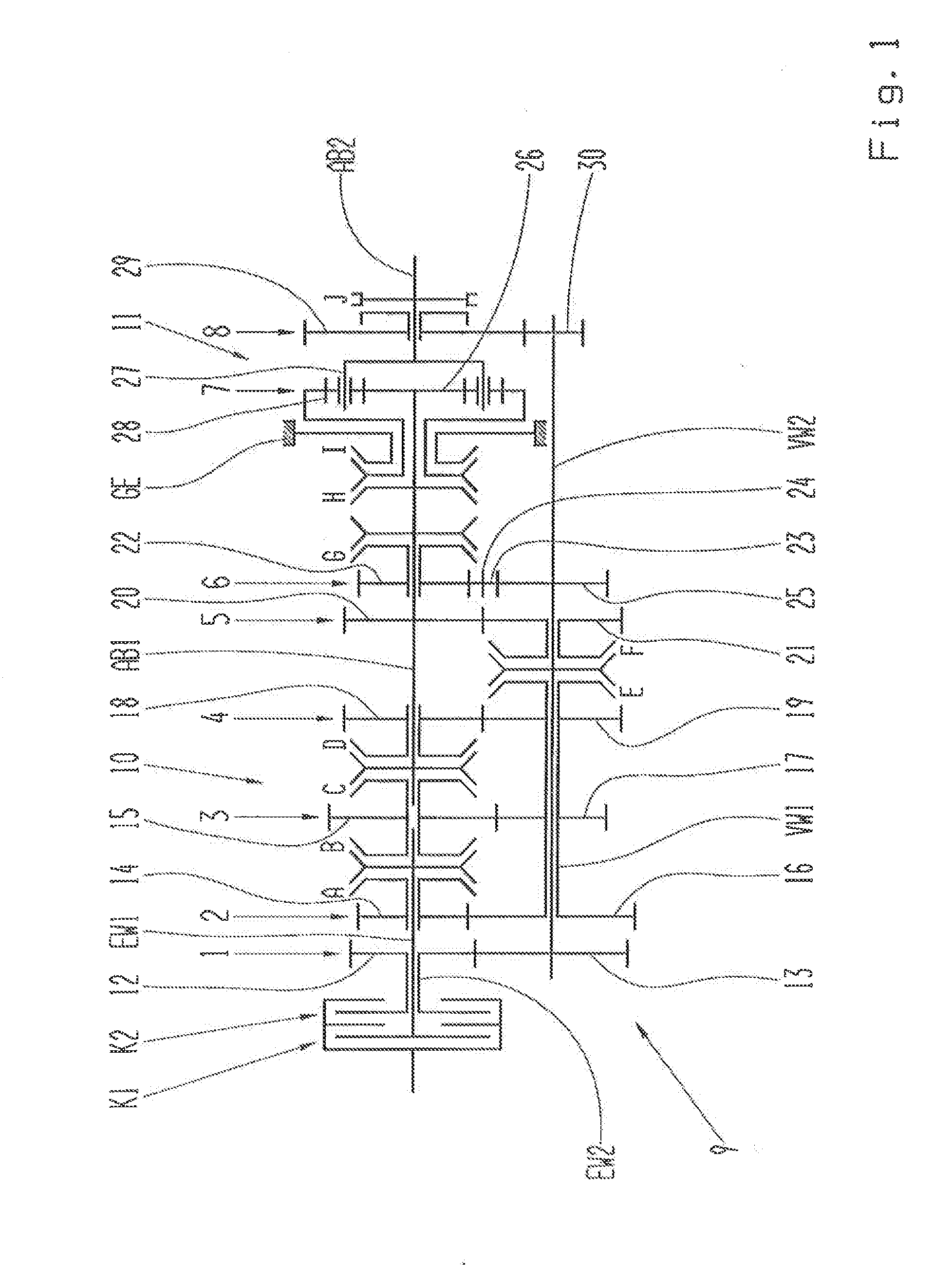

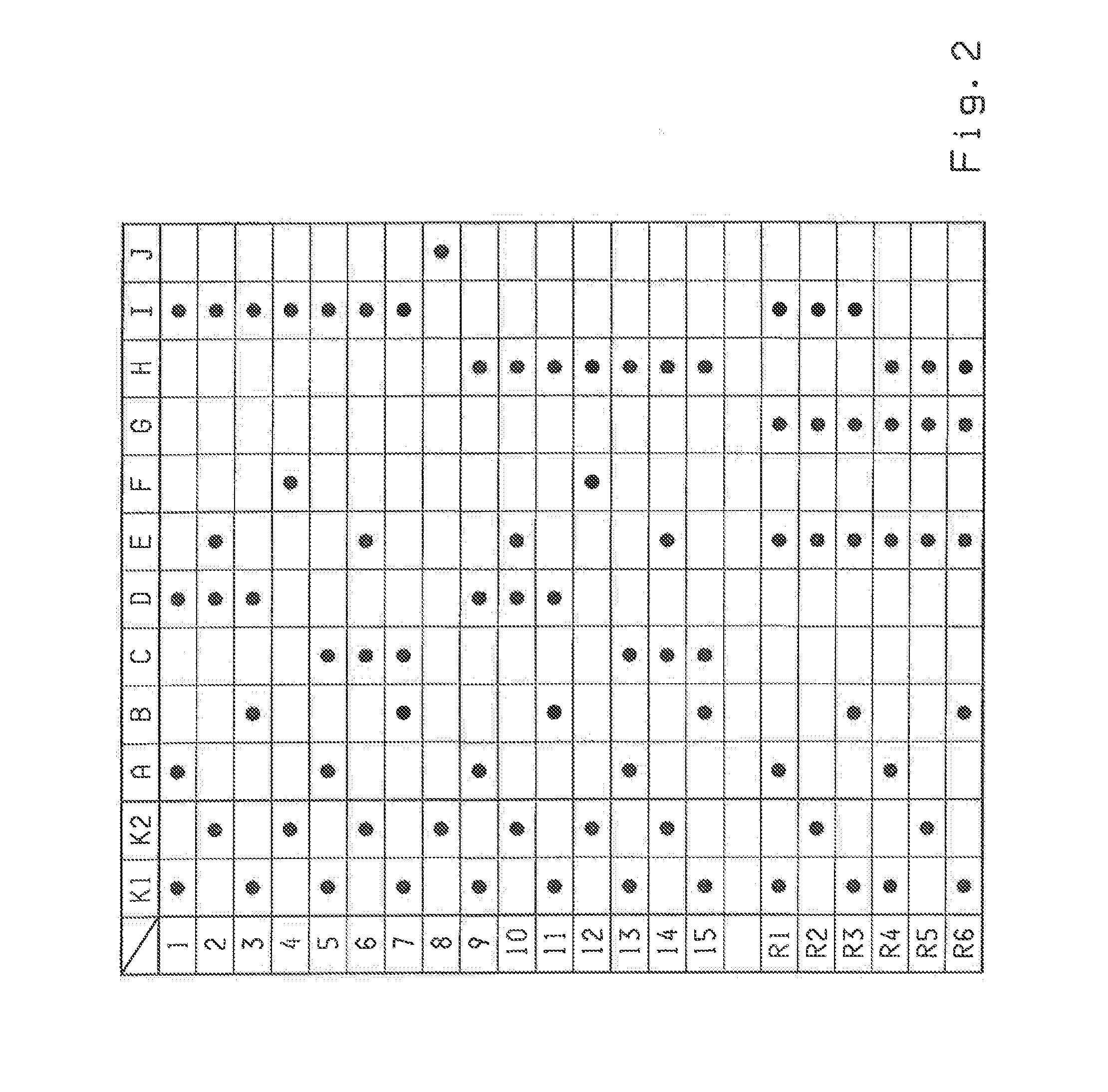

Dual clutch gearbox with countershaft design

Owner:ZF FRIEDRICHSHAFEN AG

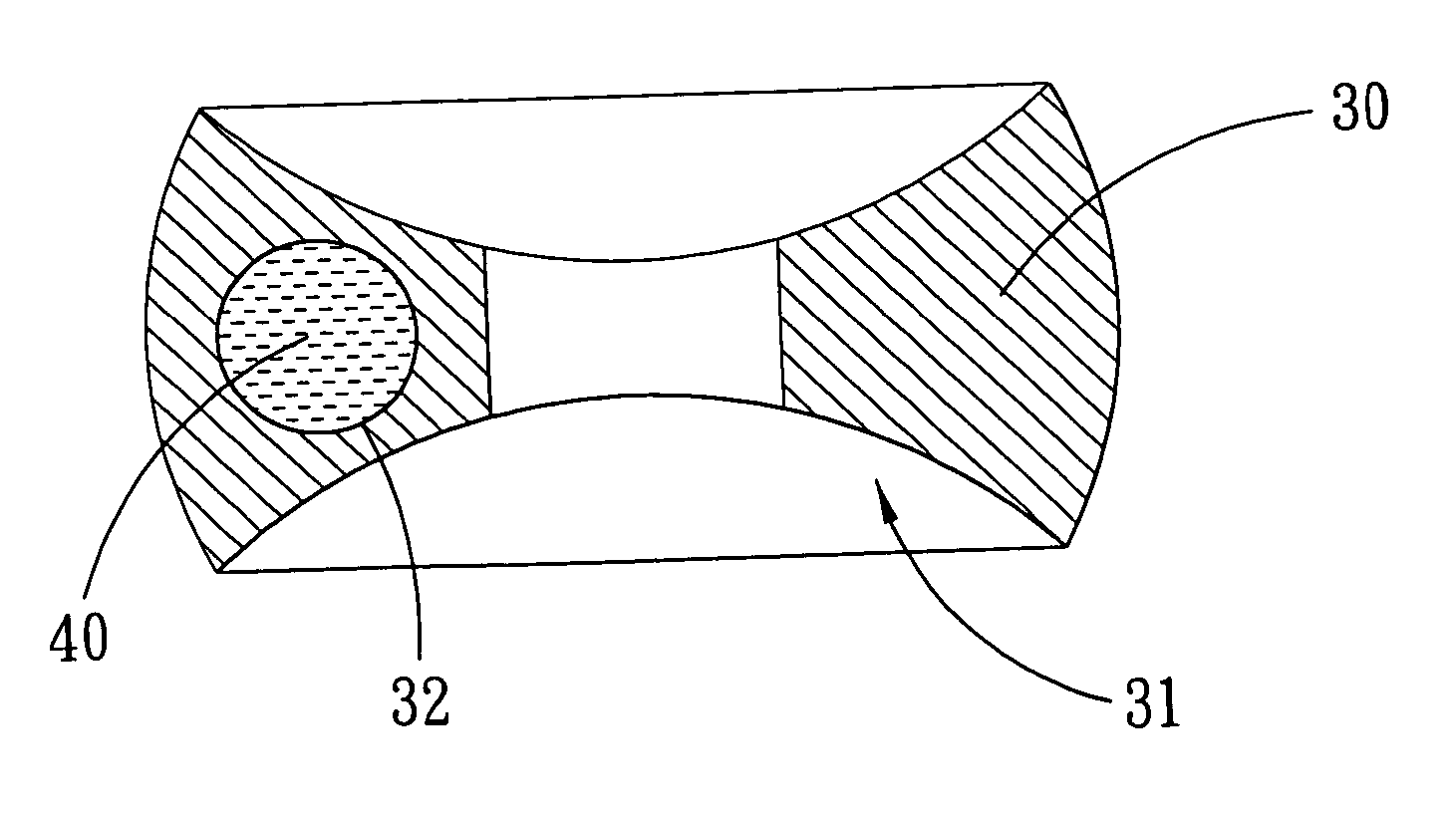

Worm wheel and method of manufacturing the same

InactiveUS20050247151A1High precisionPortable liftingToothed gearingsEngineeringMechanical engineering

Owner:NSK LTD +1

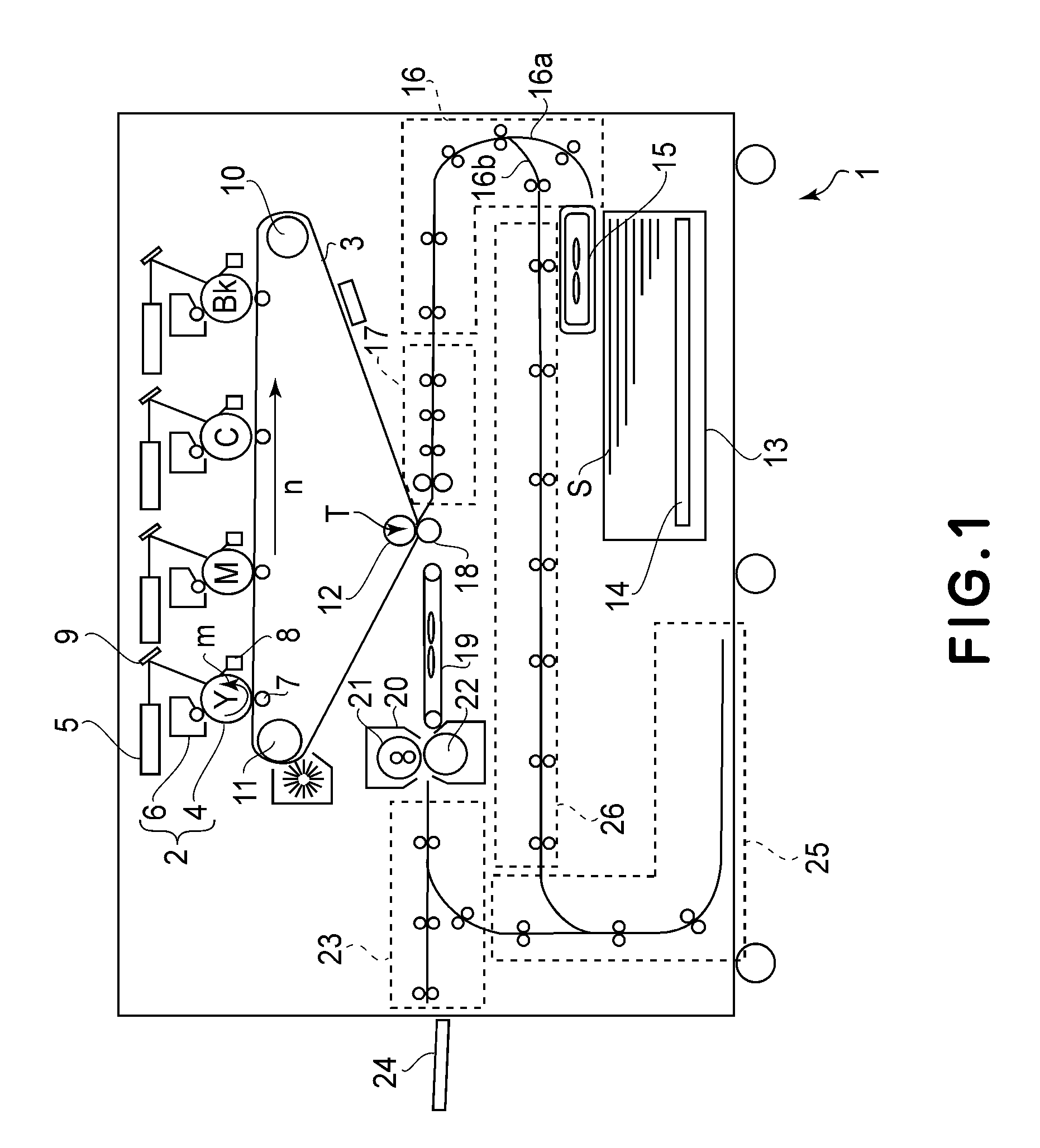

Control device and control method for powertrain, program for implementing the control method, and recording medium containing the program

InactiveUS20080153660A1Prevent change of directionReduce shockHybrid vehiclesDigital data processing detailsElectric machineExecution control

A shock caused due to a change in the direction of torque transferred to an output shaft is reduced. There is provided a control device for a powertrain including a drive power source that transfers torque to an output shaft connected to a wheel of a vehicle, and a rotary electric machine that transfers torque to the output shaft via a transmission. When electric power generation performed using the rotary electric machine is restricted, if torque that decelerates the vehicle is transferred from the drive power source to the output shaft, a control is executed so that torque that does not decelerate the vehicle is transferred from the drive power source to the output shaft, and a shift control over the transmission is executed.

Owner:TOYOTA JIDOSHA KK +1

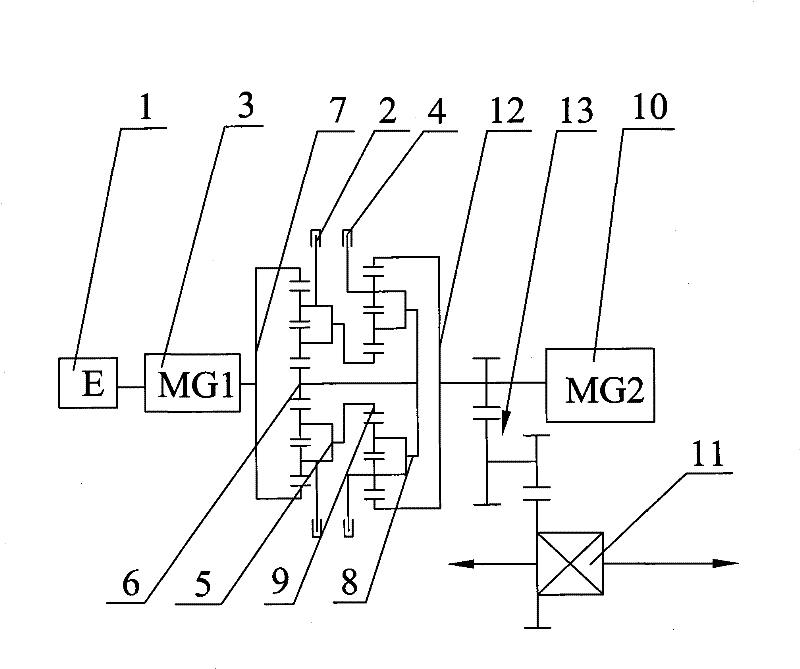

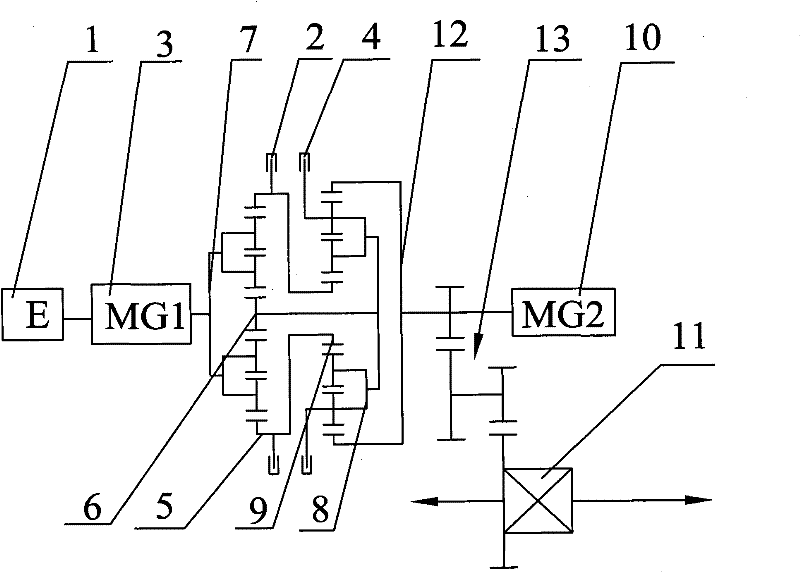

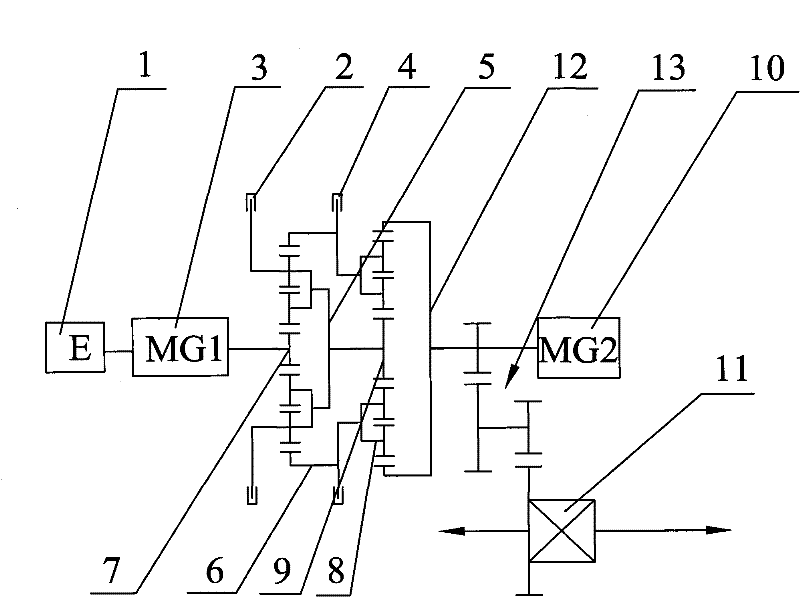

Hybrid driving system and vehicle including same

ActiveCN102343796AMeet the driving needs under different working conditionsEasy dischargeGas pressure propulsion mountingToothed gearingsLow speedInternal combustion engine

Owner:BYD CO LTD

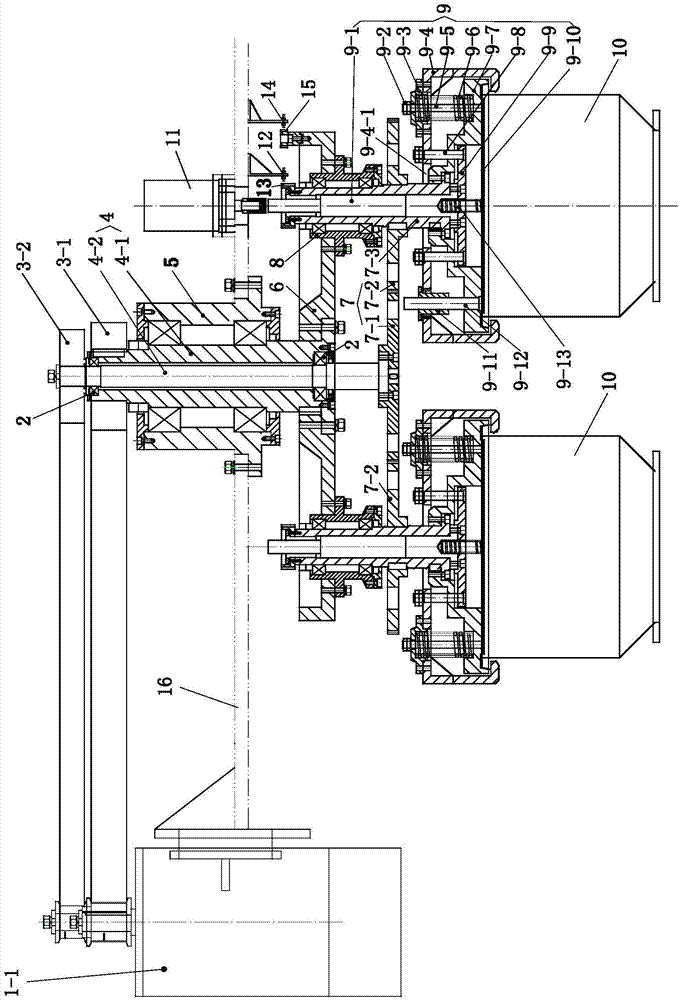

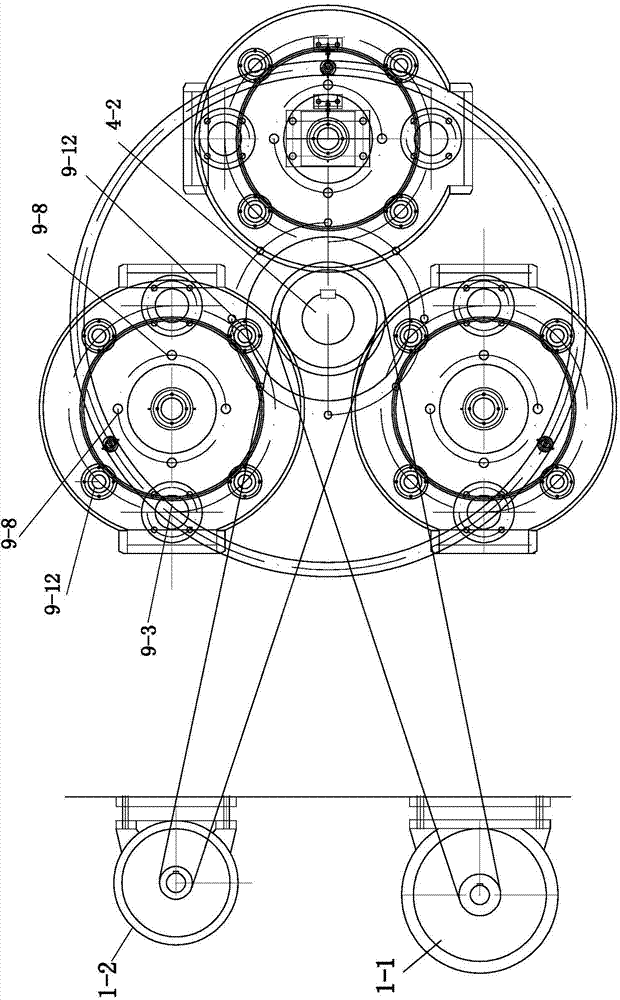

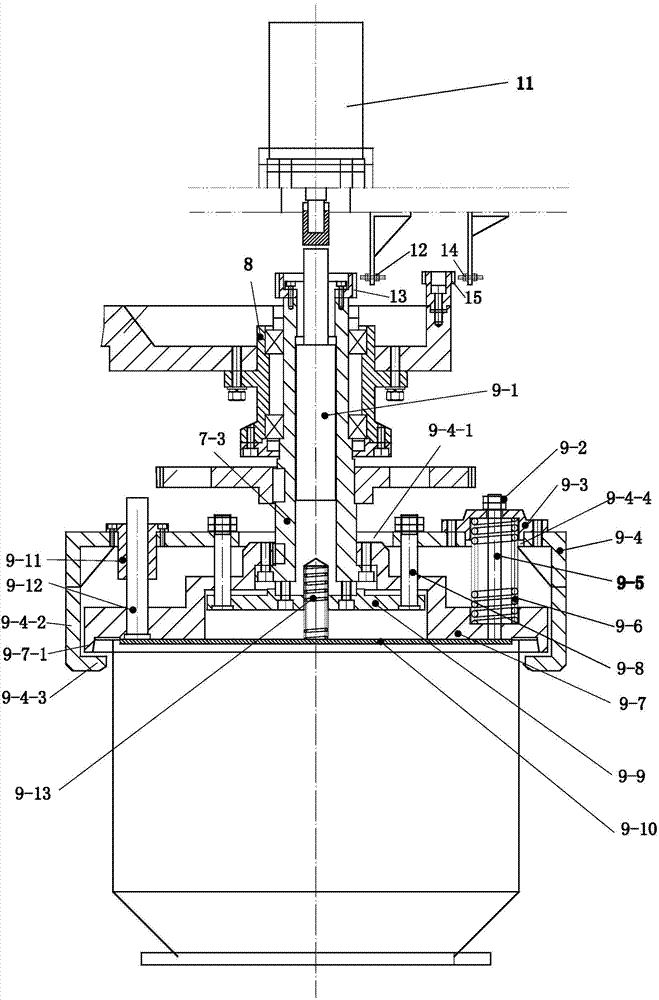

Planetary transmission device of coating machine

ActiveCN103934167AImprove coating qualitySave time at workLiquid surface applicatorsToothed gearingsEngineeringMechanical engineering

Owner:CHANGZHOU JUNHE TECH

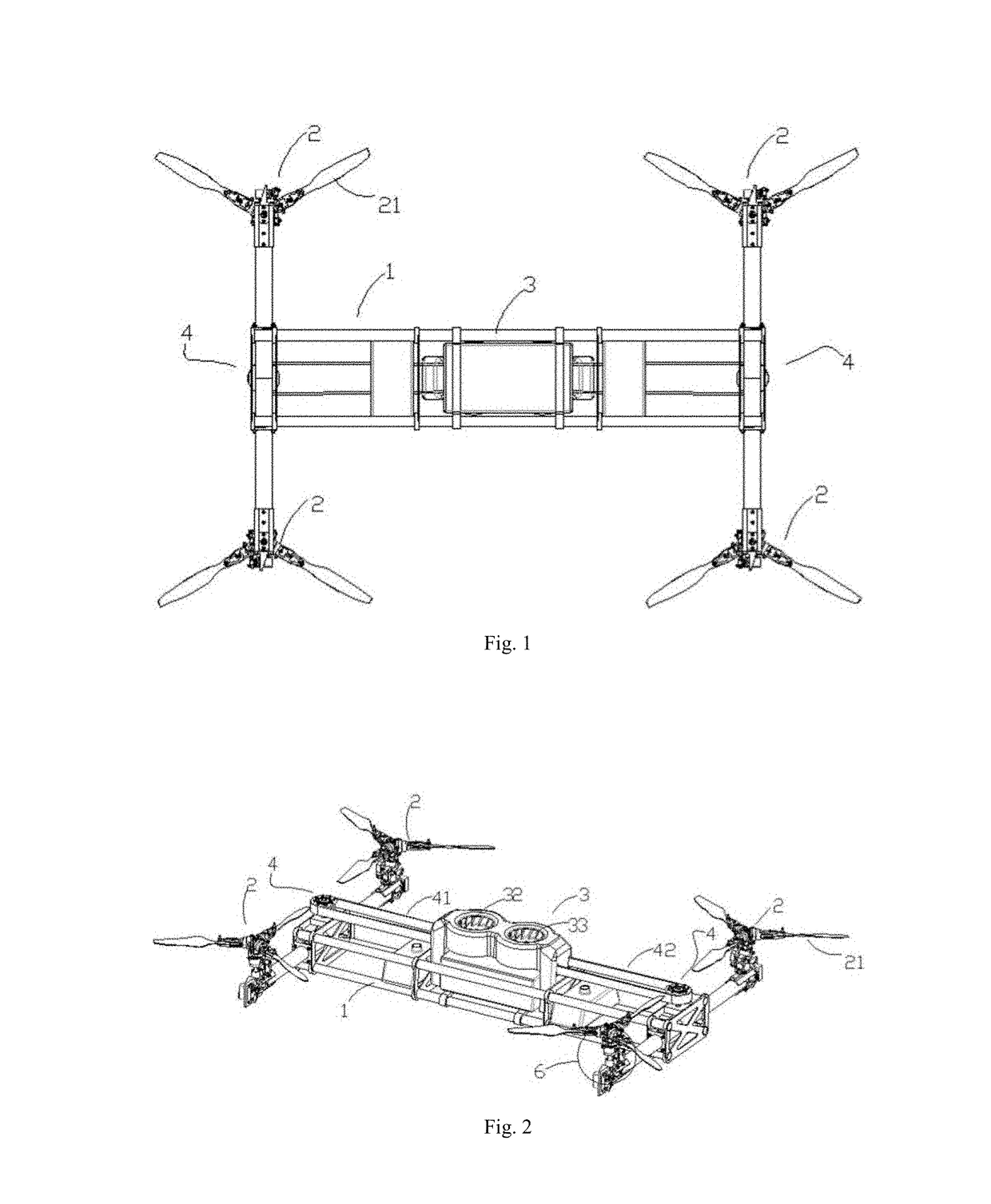

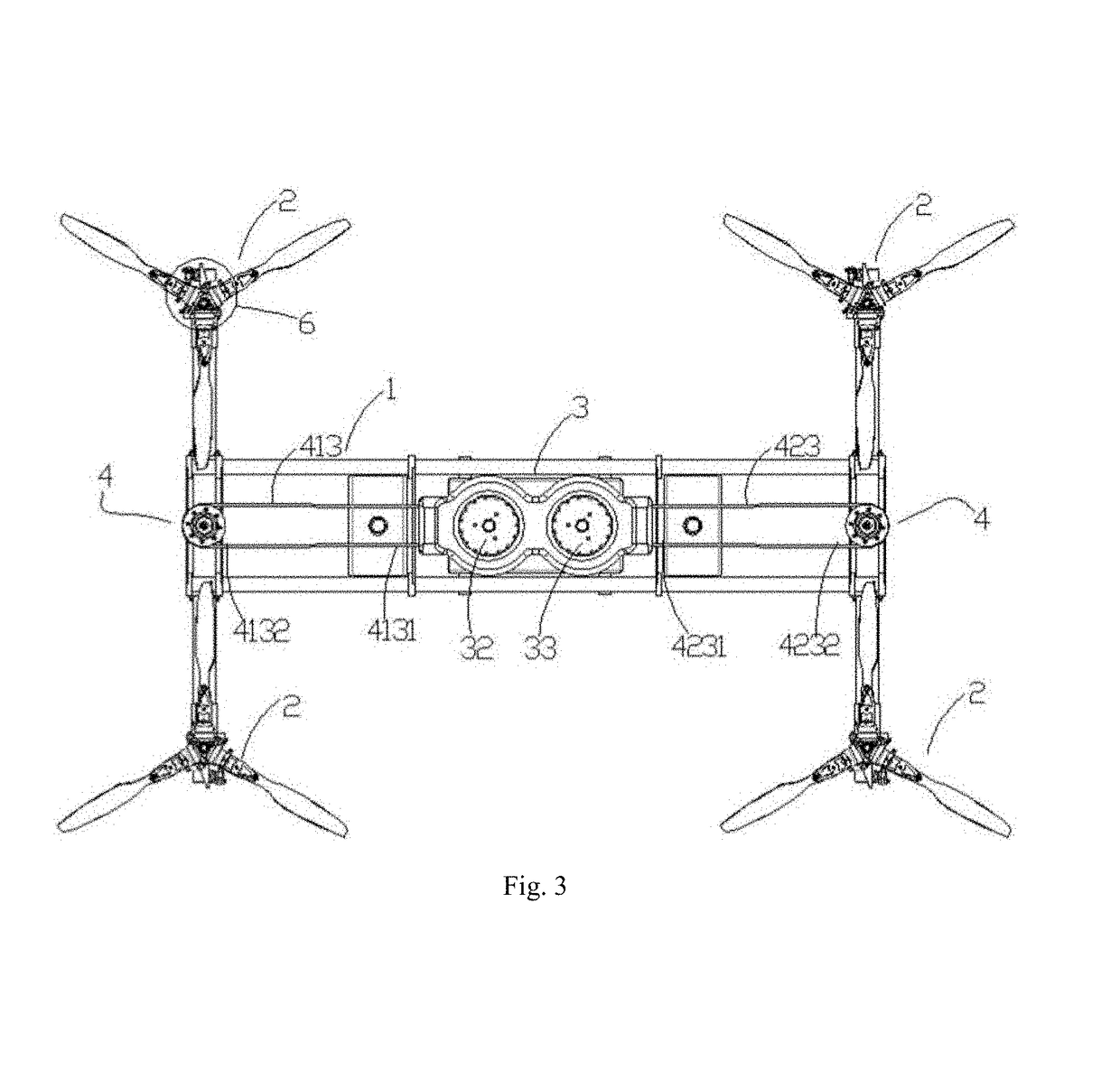

Multi-shaft power source unmanned flight equipment

InactiveUS20180030887A1Extended durationIncrease load capacityUnmanned aerial vehiclesCombination enginesCombustionUncrewed vehicle

Owner:EWATT TECH CO LTD

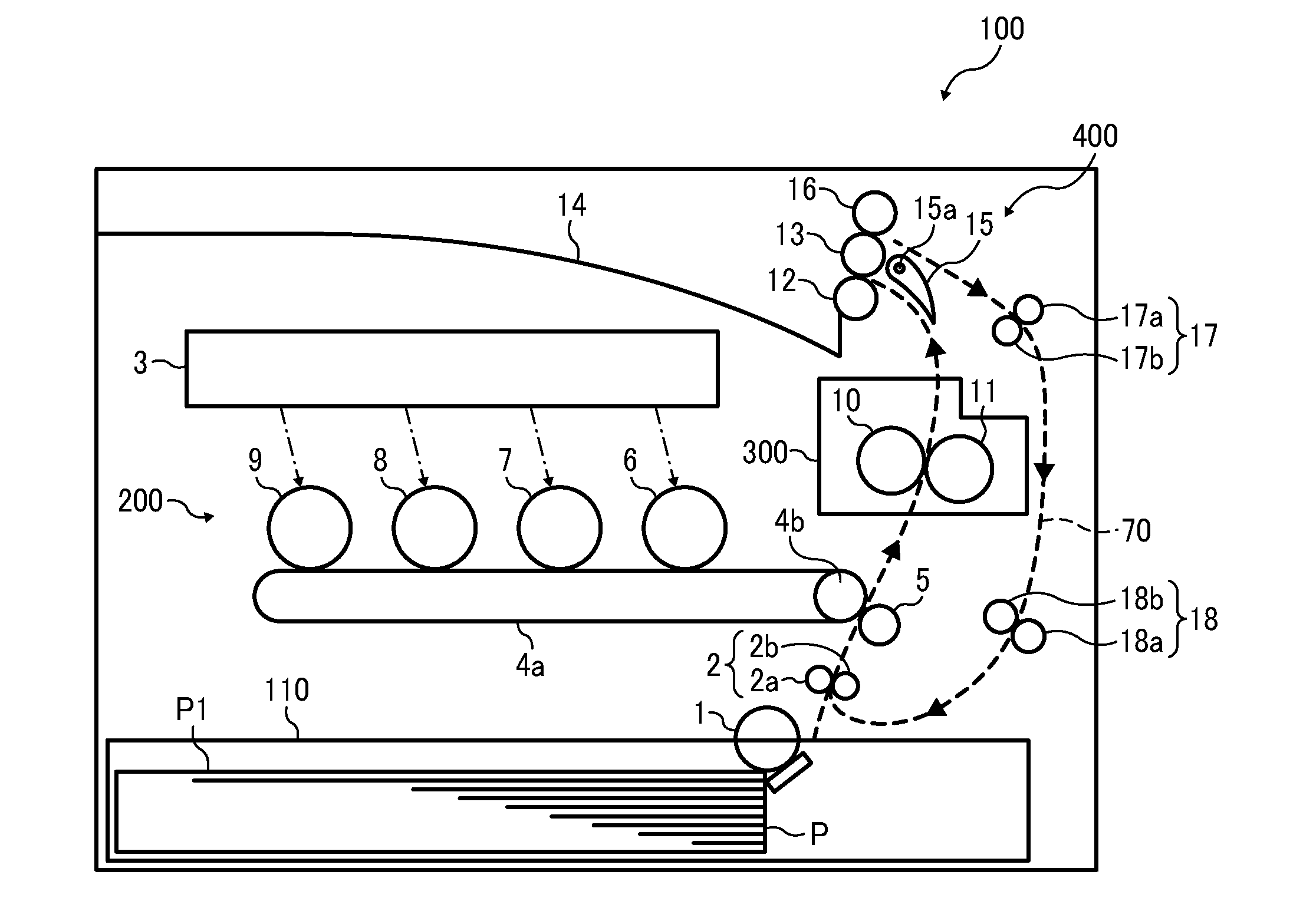

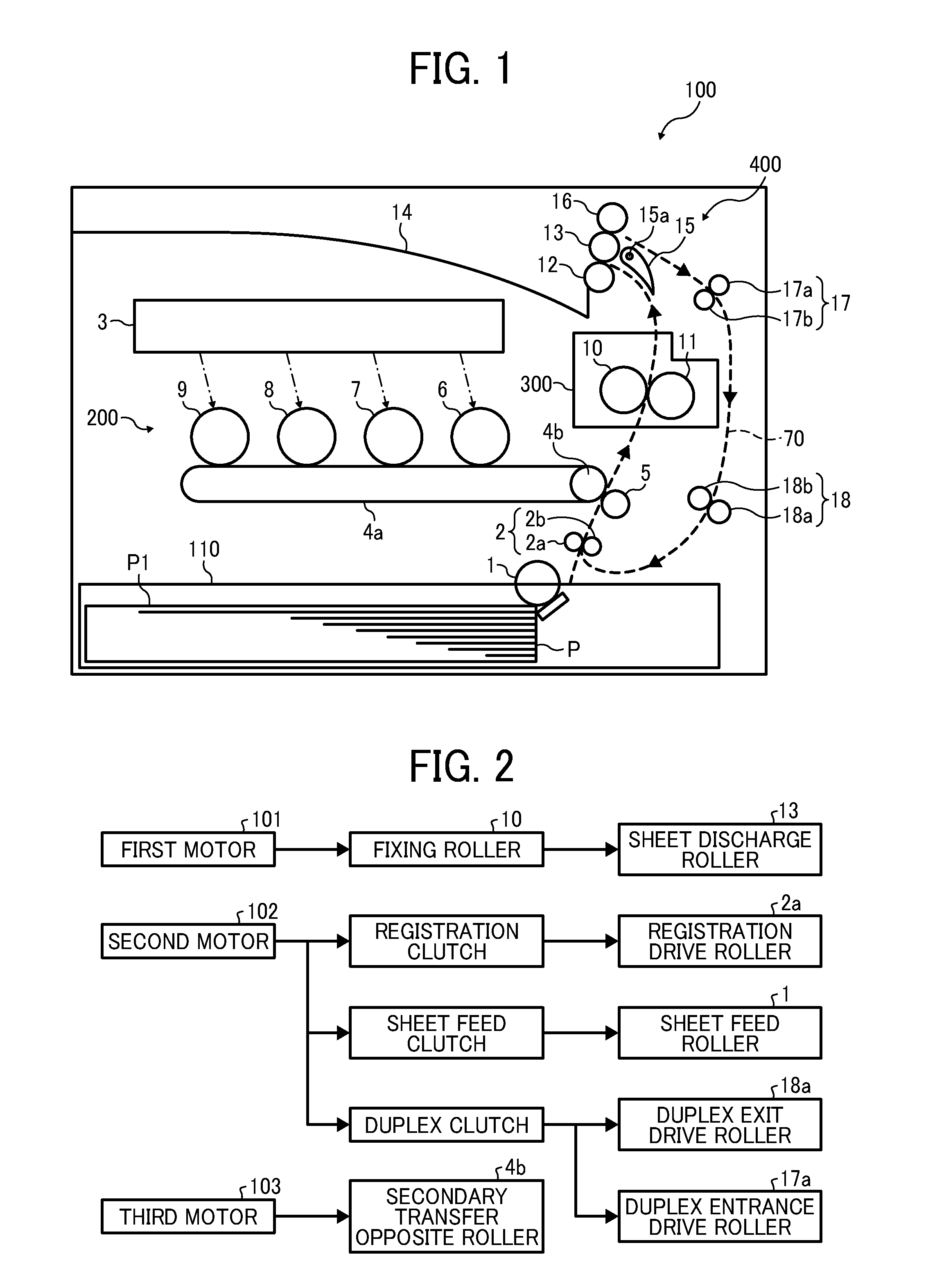

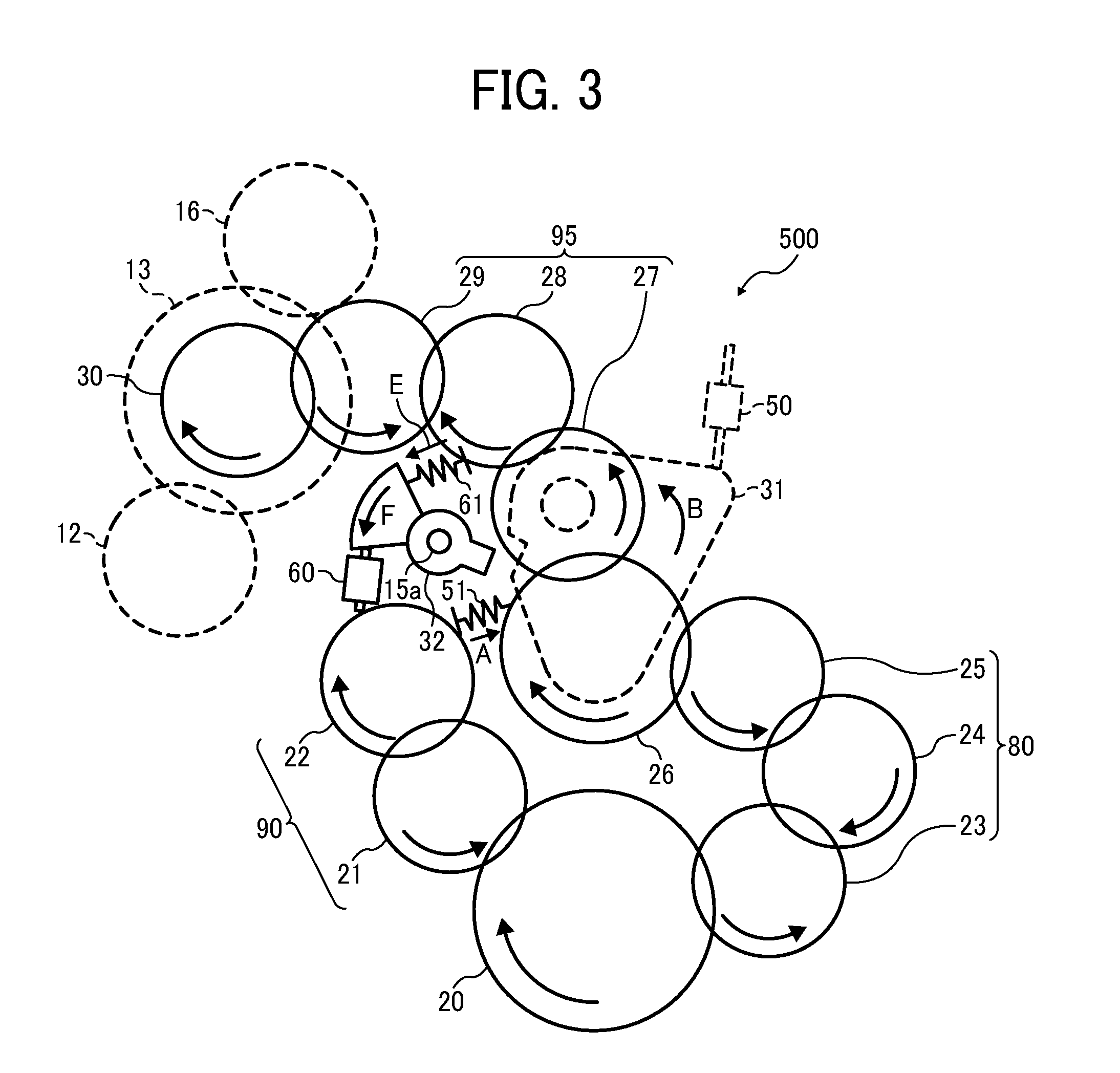

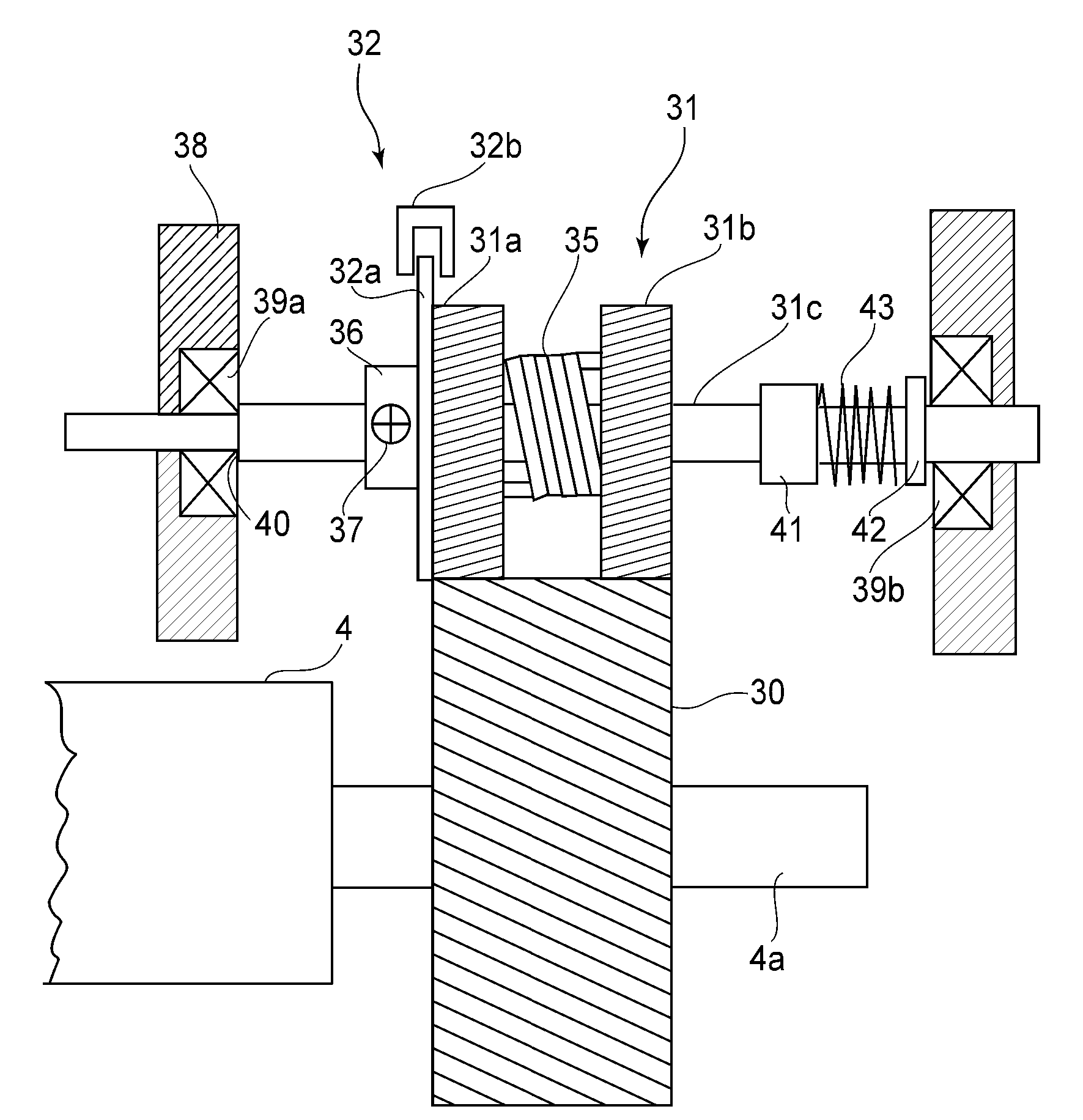

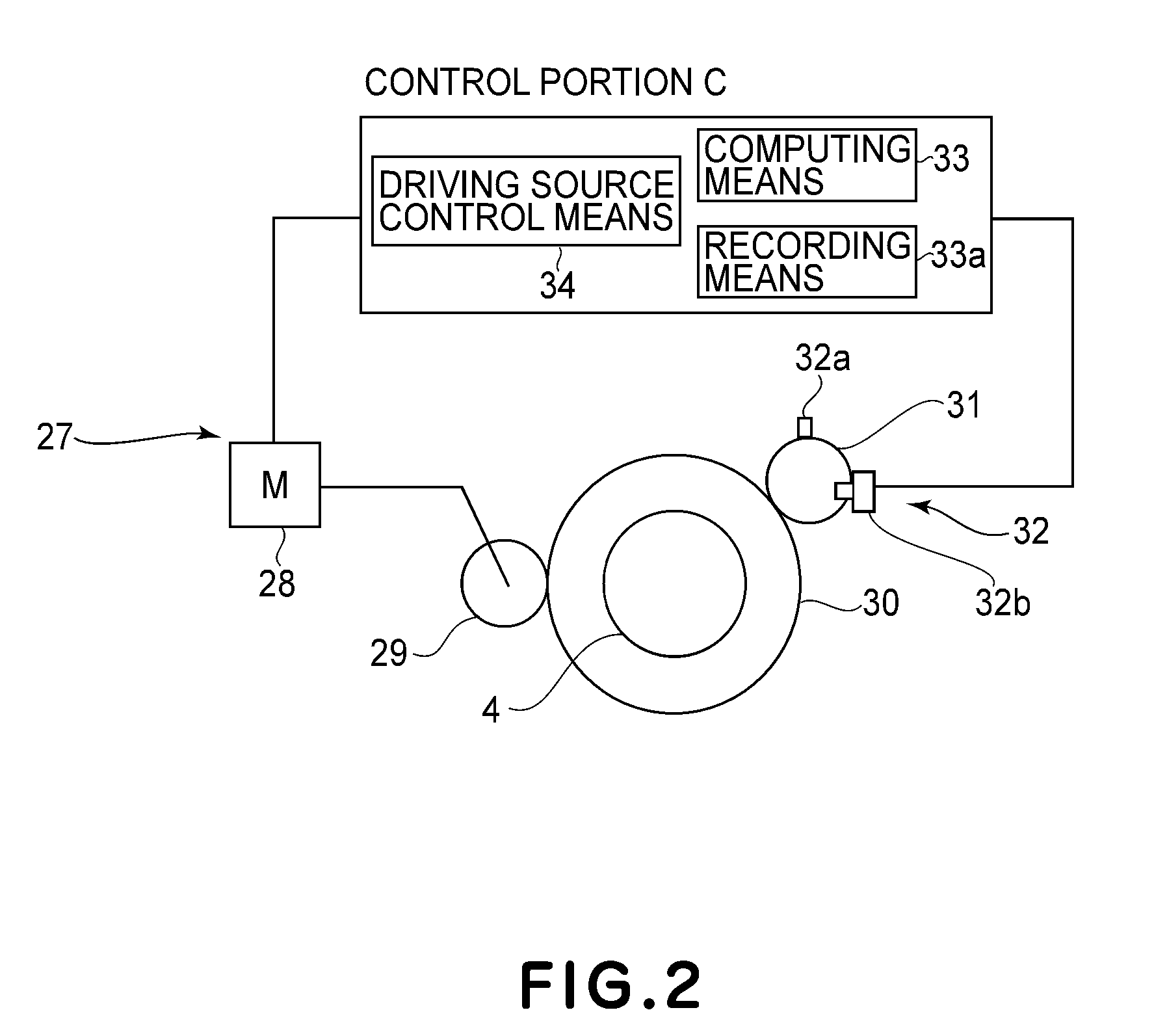

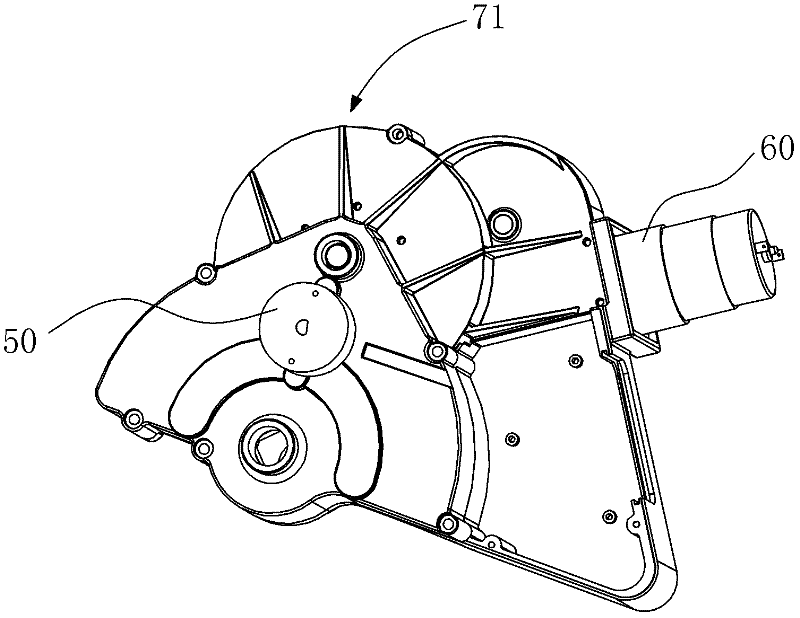

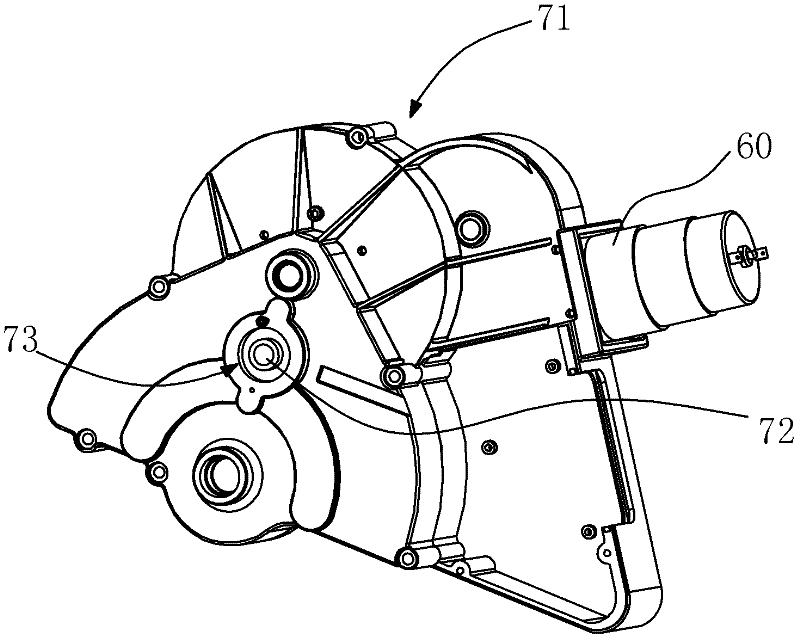

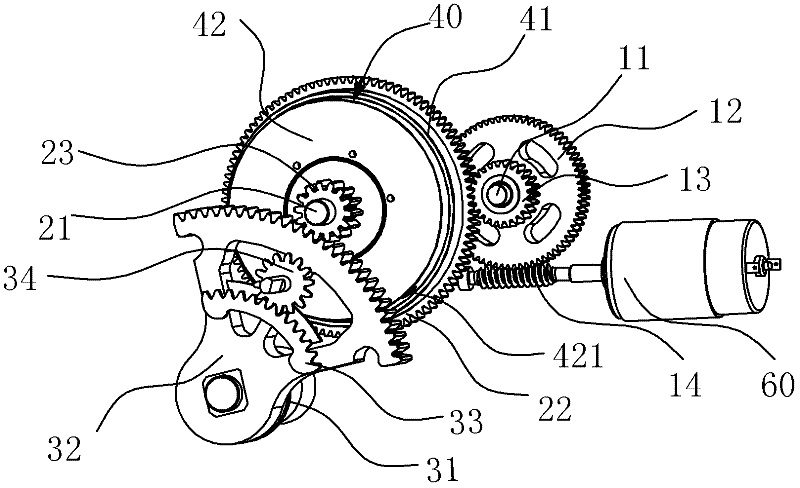

Driving device and image forming apparatus

InactiveUS20110017003A1Improve accuracyTaking imageGearboxesPortable liftingEngineeringMechanical engineering

Owner:CANON KK

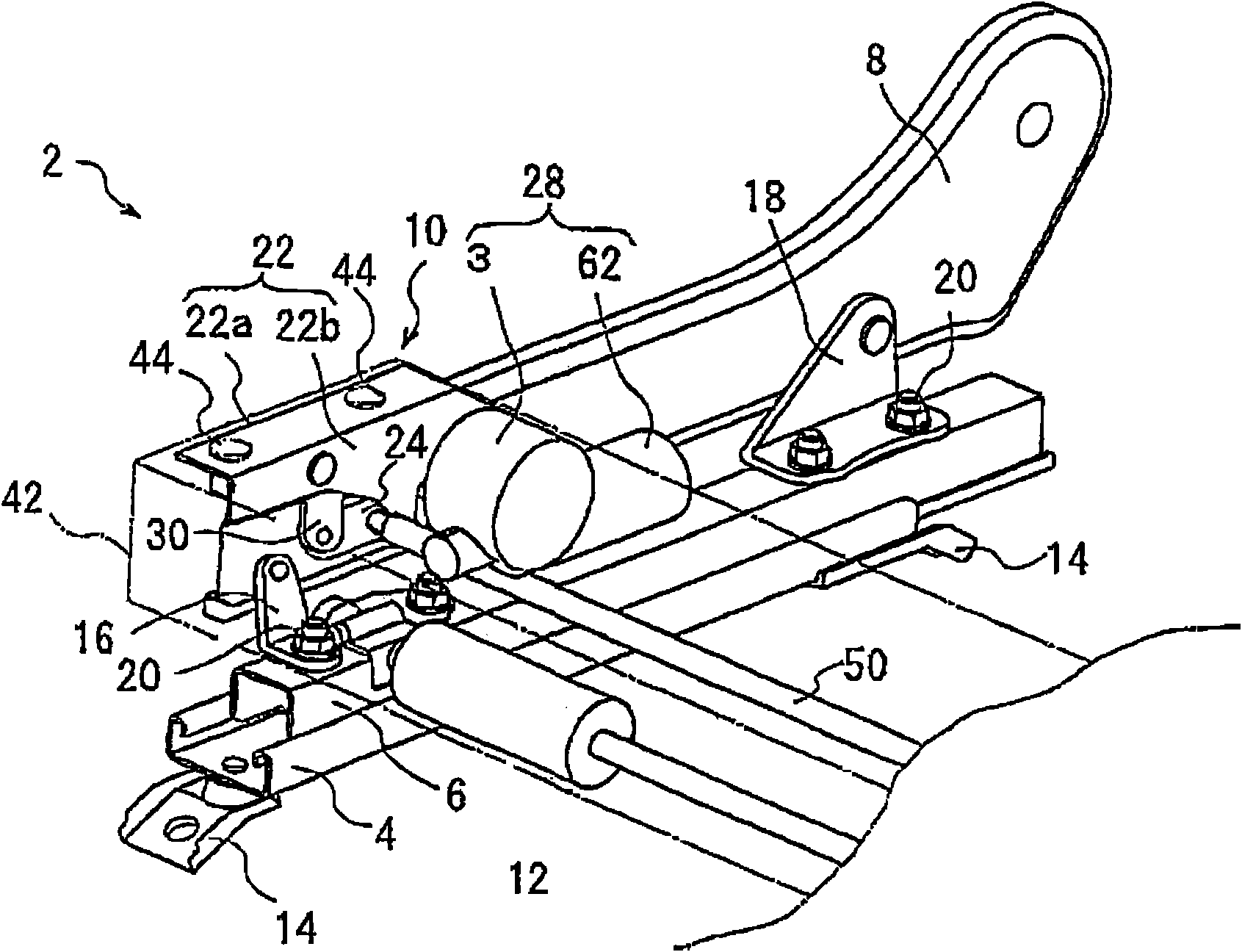

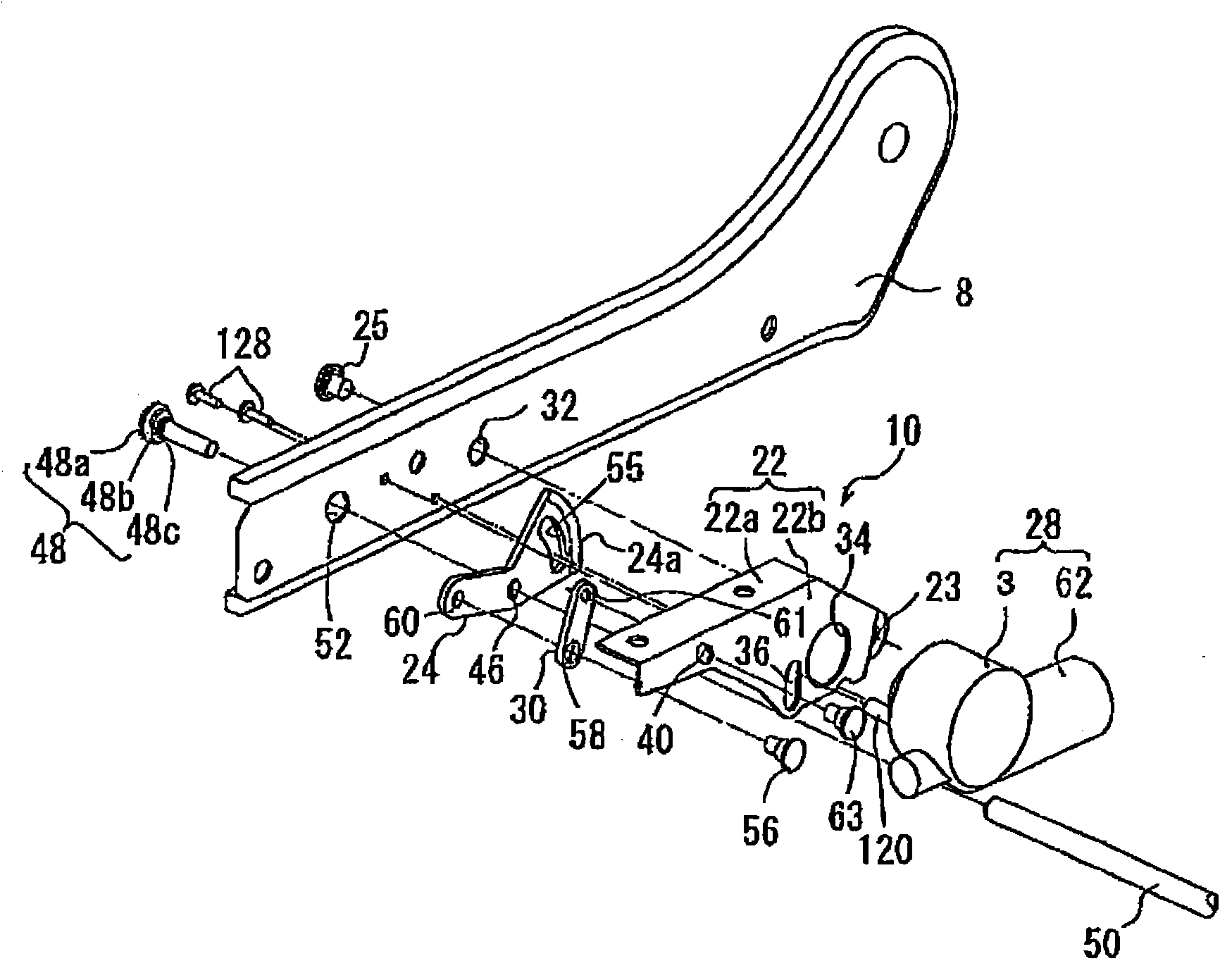

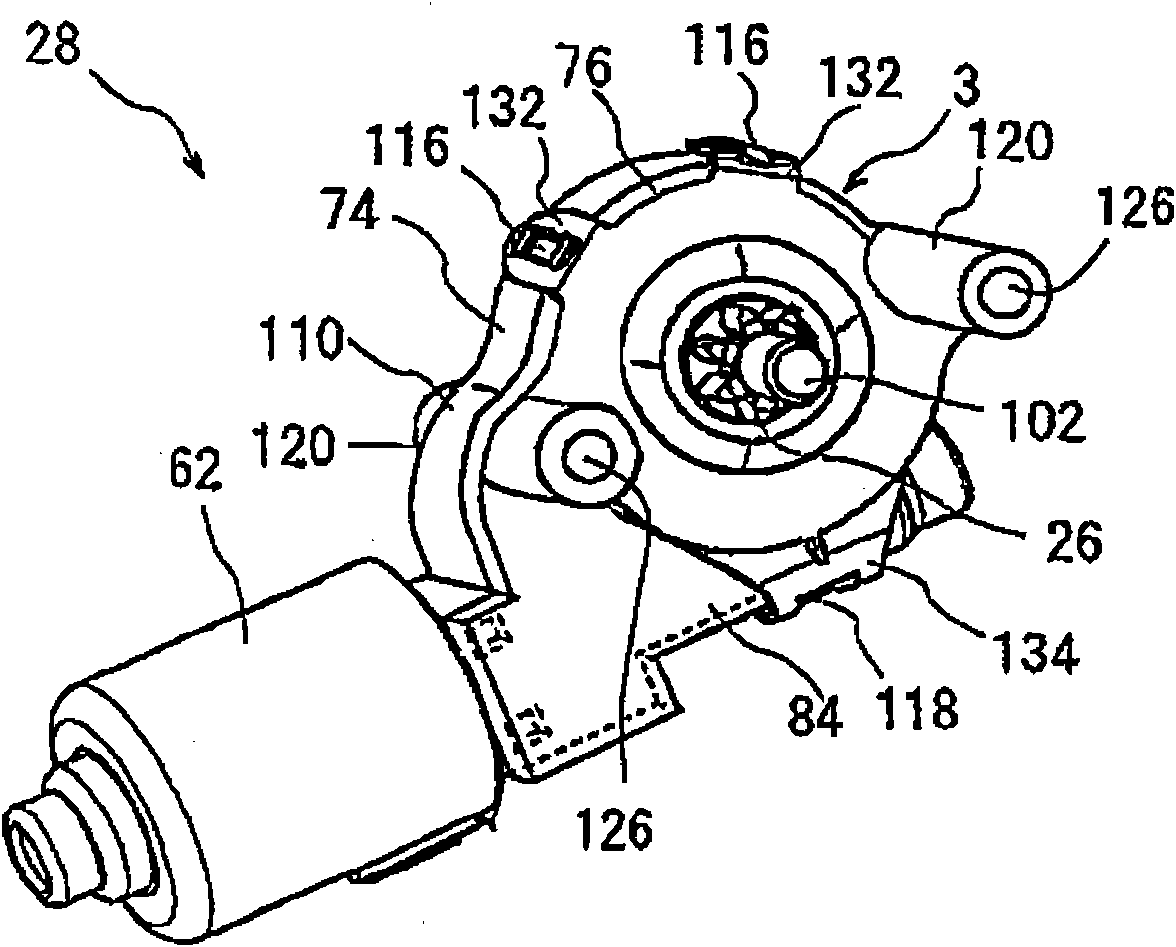

Seat slide apparatus for vehicle

Owner:AISIN SEIKI KK

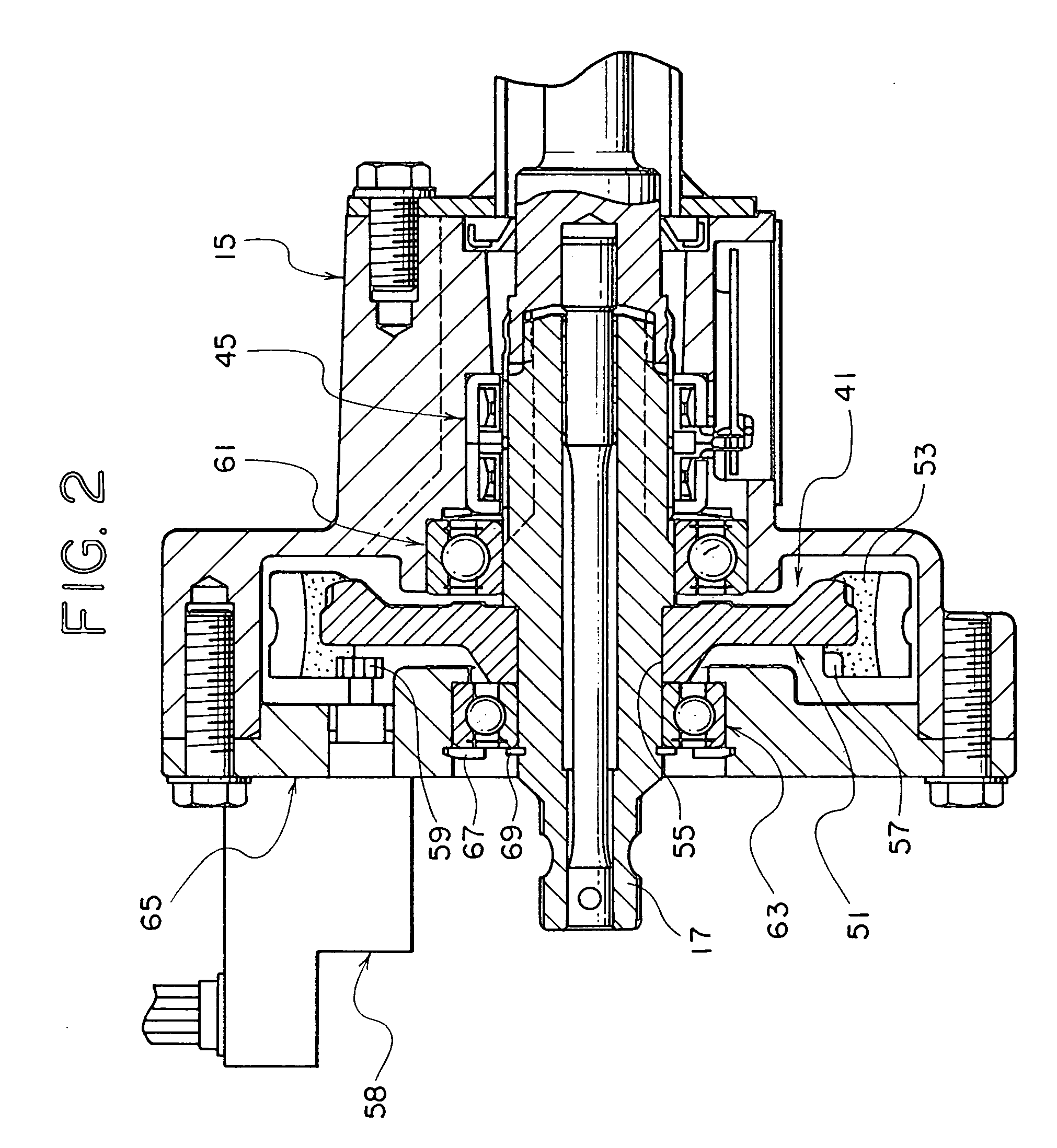

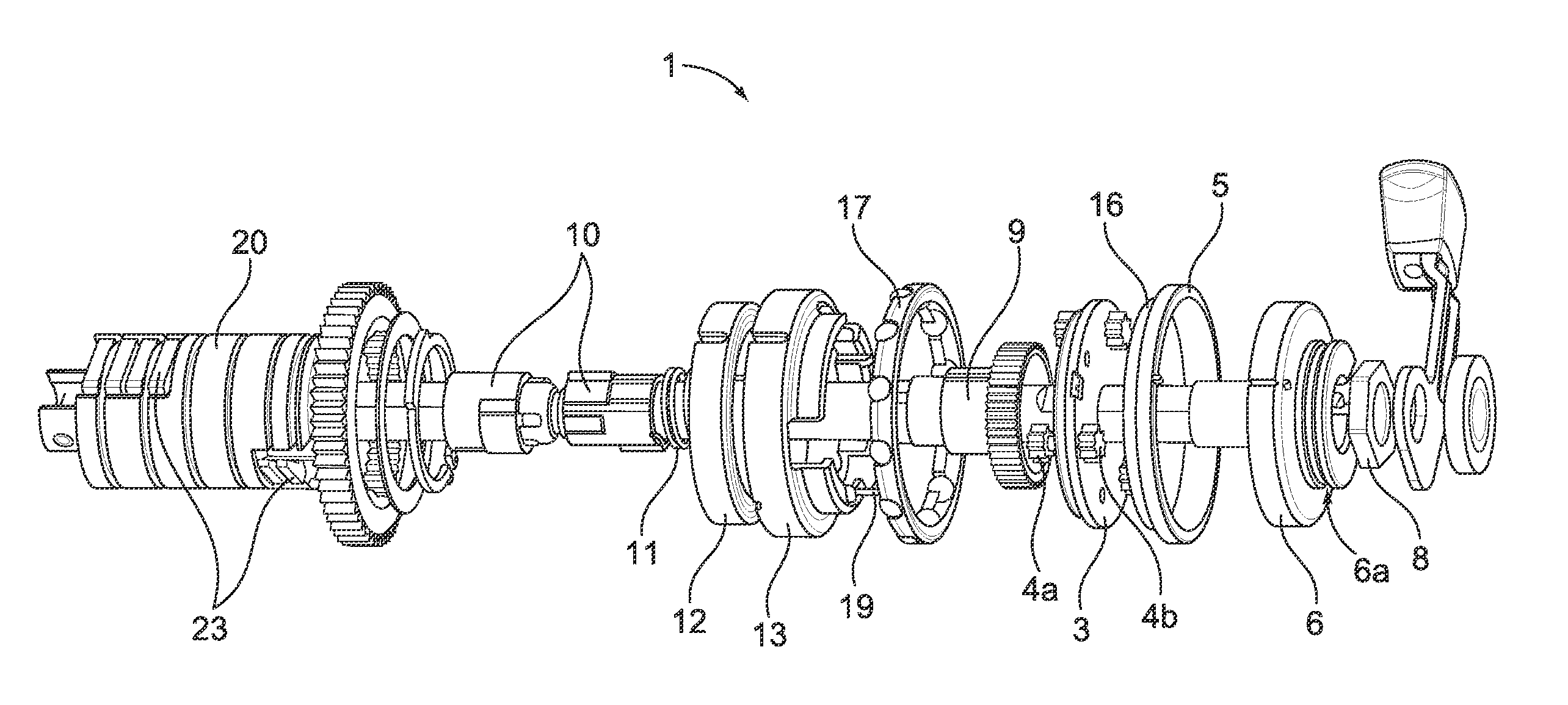

Operating mechanism for a bicycle multiple gear hub

ActiveUS20120277054A1Wheel based transmissionToothed gearingsElectrical and Electronics engineeringLinear motion

Owner:SRAM

Self-alignment spacer for a ball screw device

Owner:HIWIN TECH

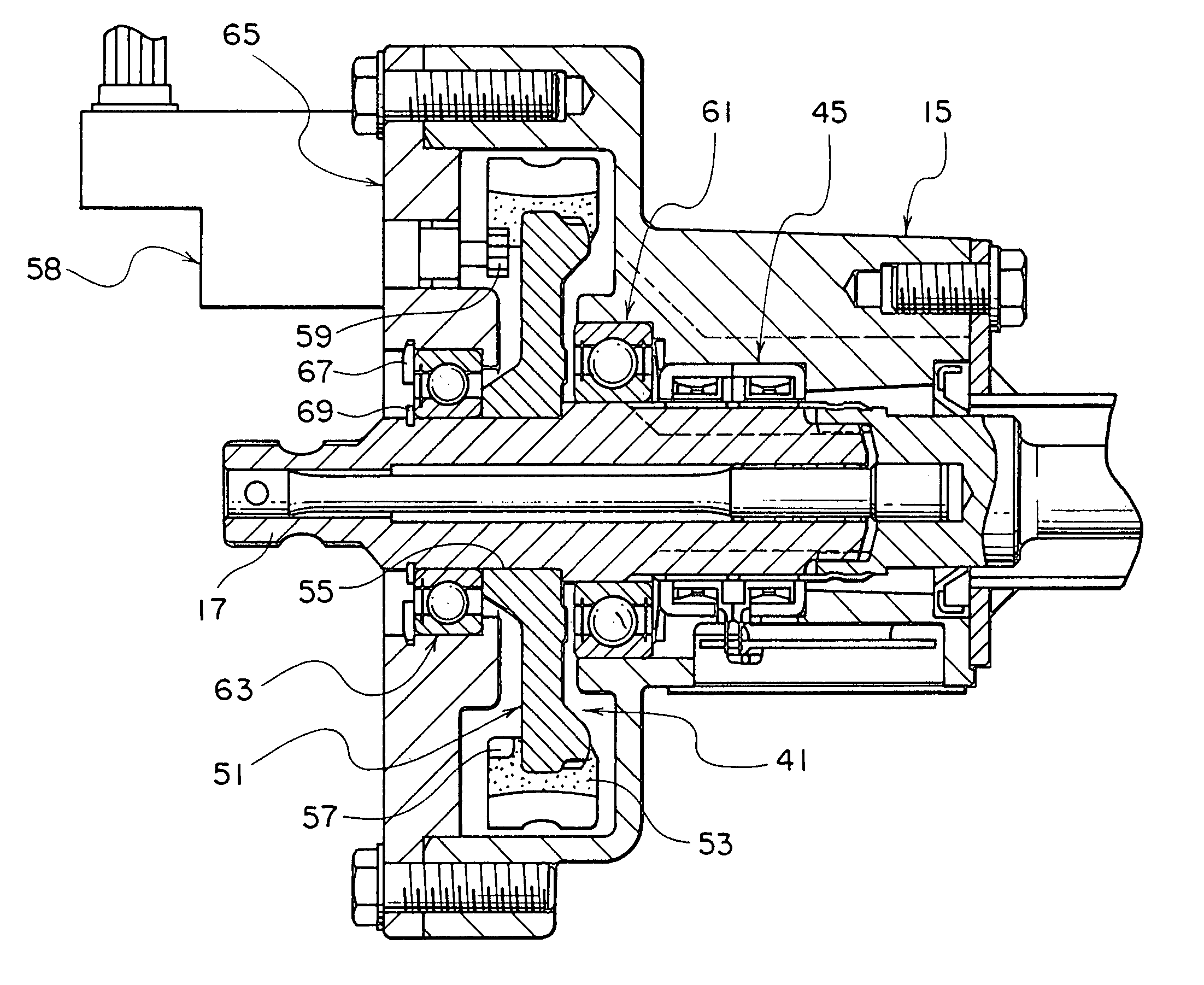

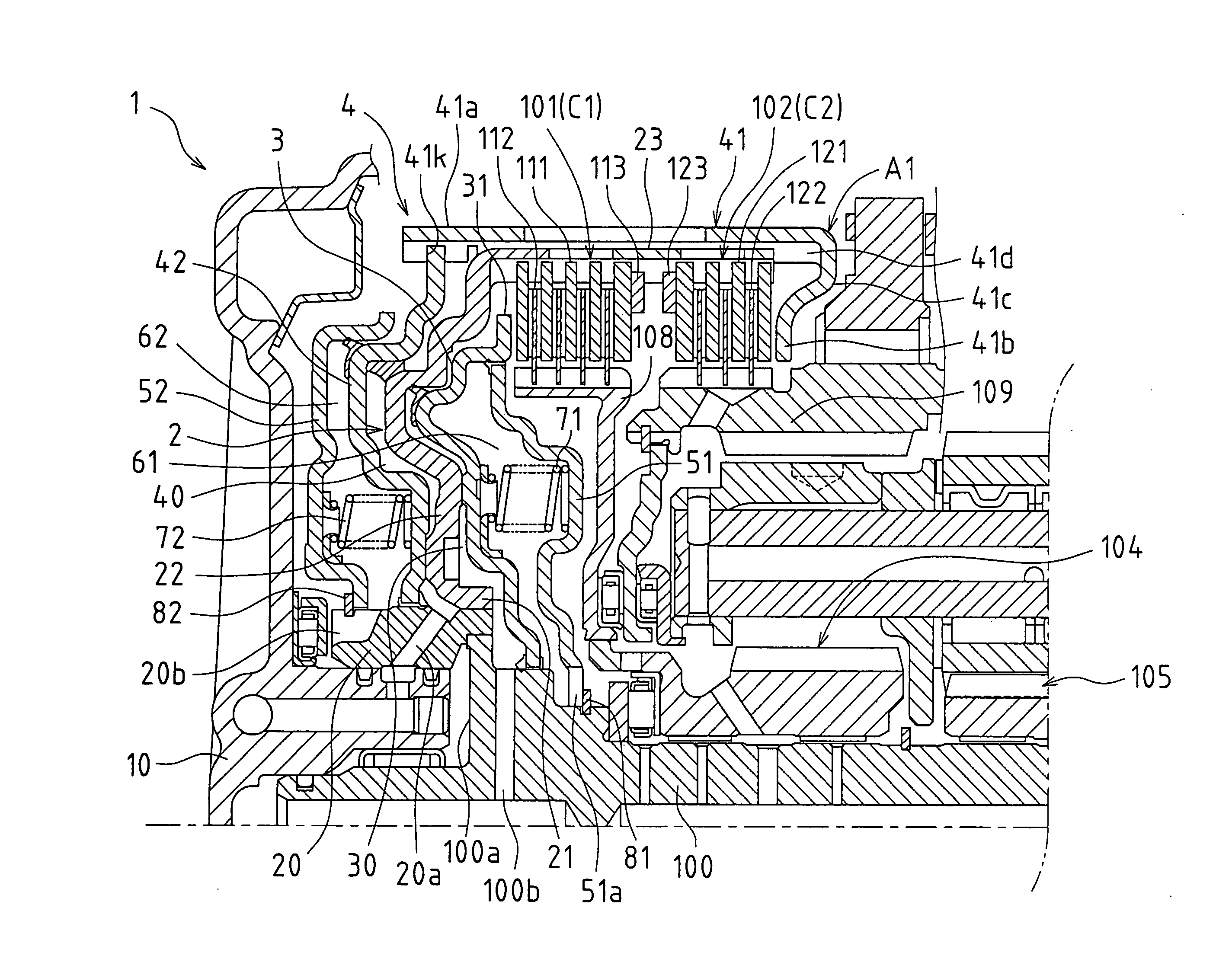

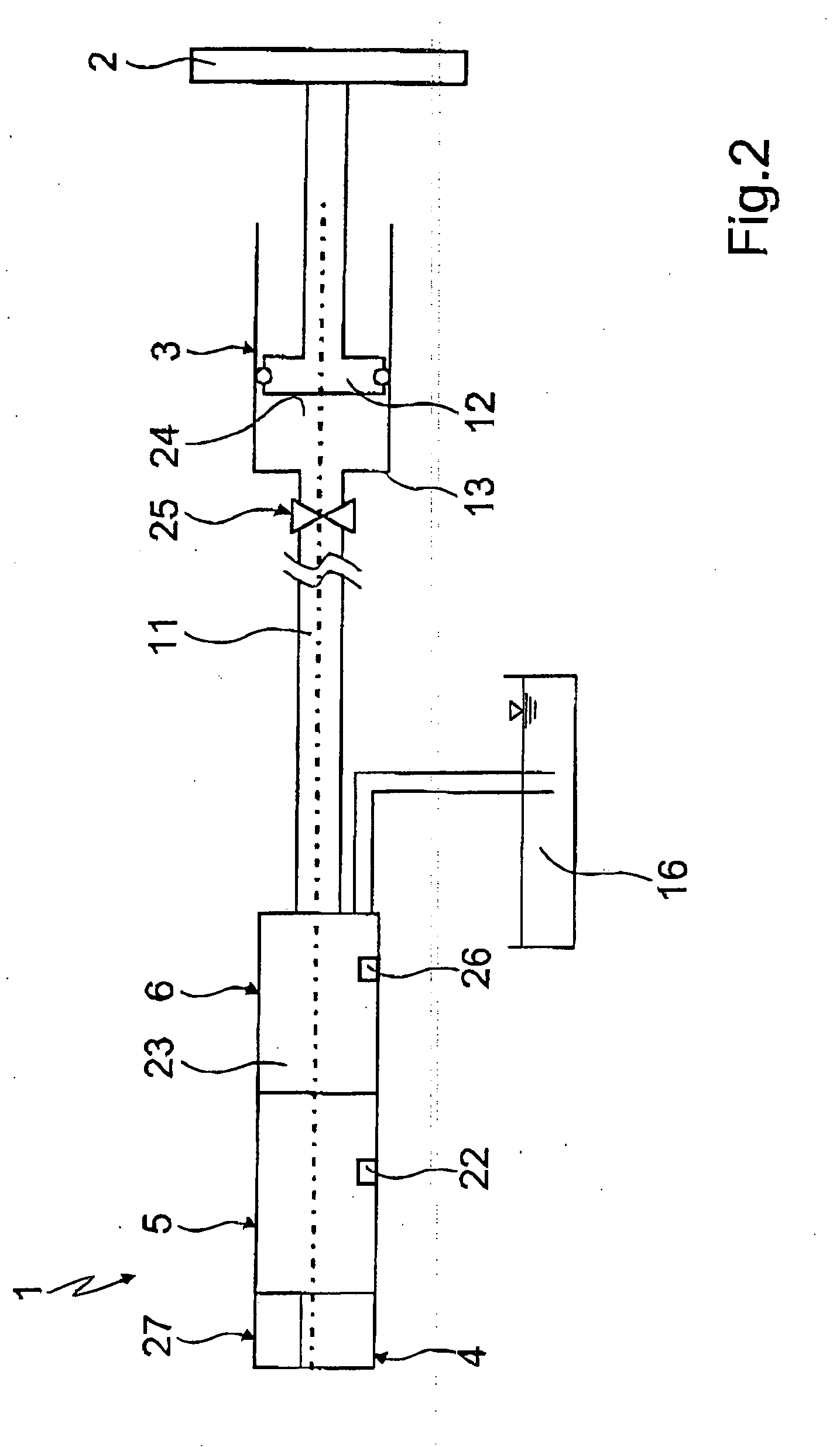

Piston apparatus of automatic transmission

InactiveUS20100140038A1Low costSmall sizeFluid actuated clutchesToothed gearingsAutomatic transmissionEngineering

Owner:TOYOTA JIDOSHA KK

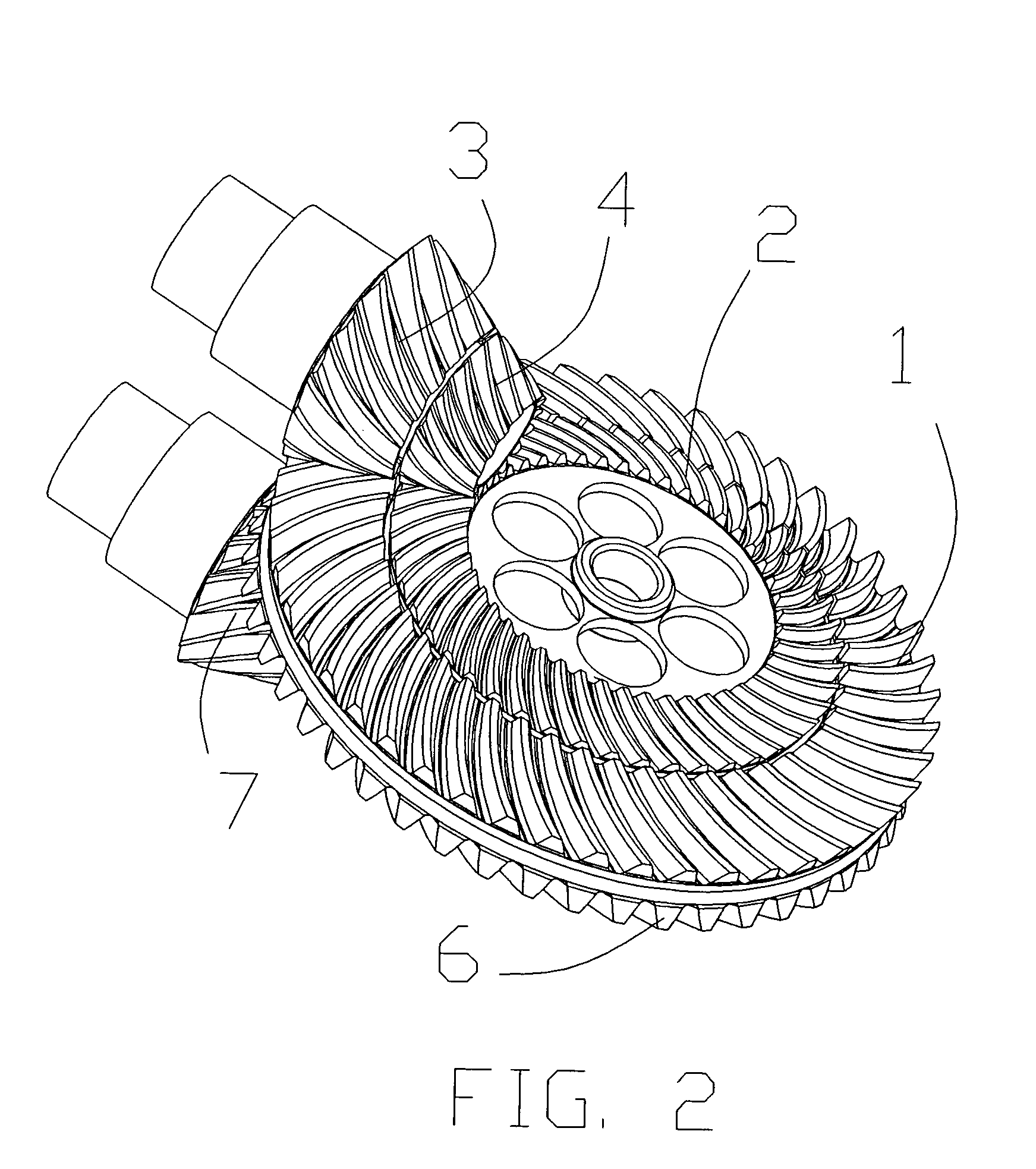

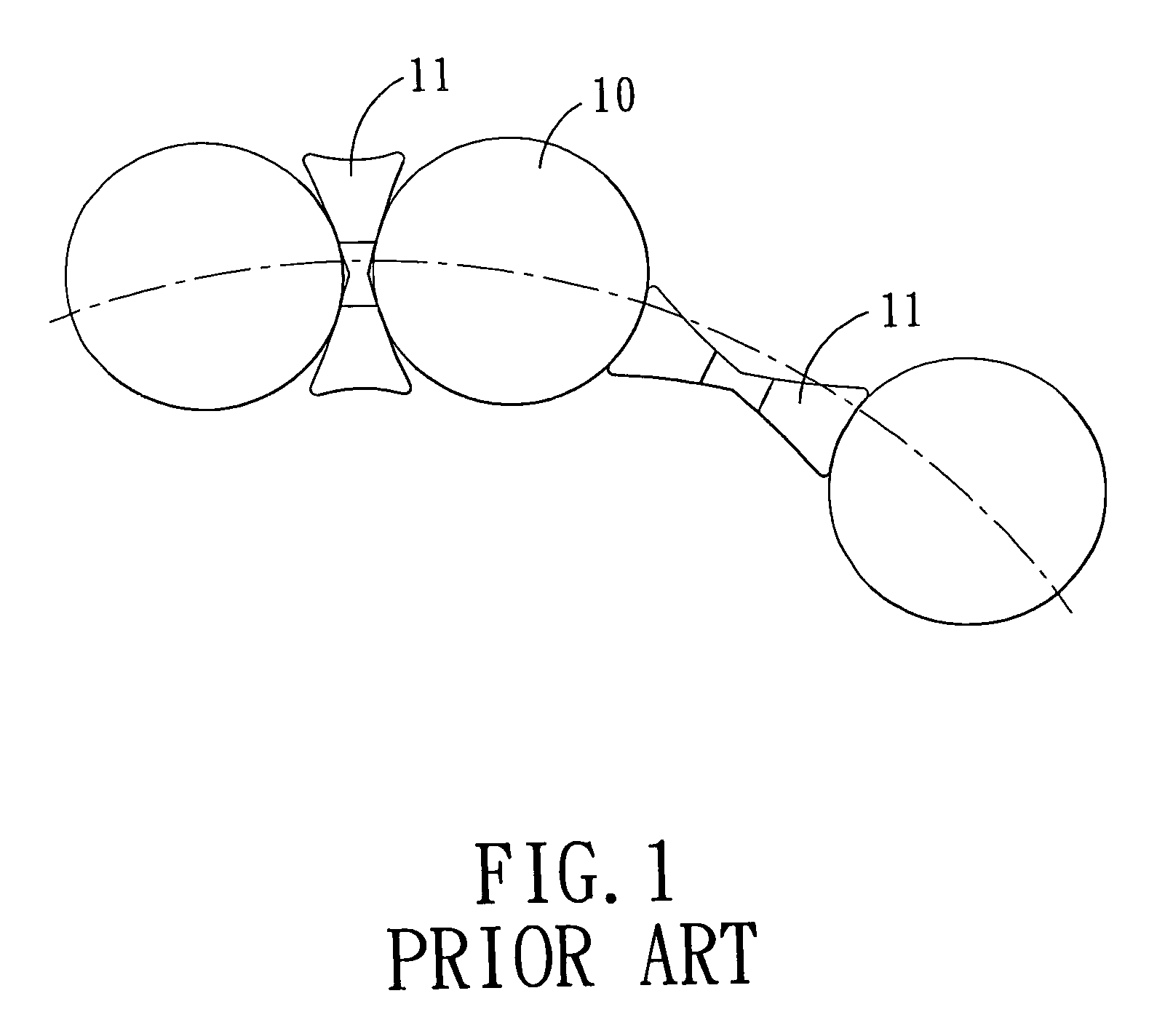

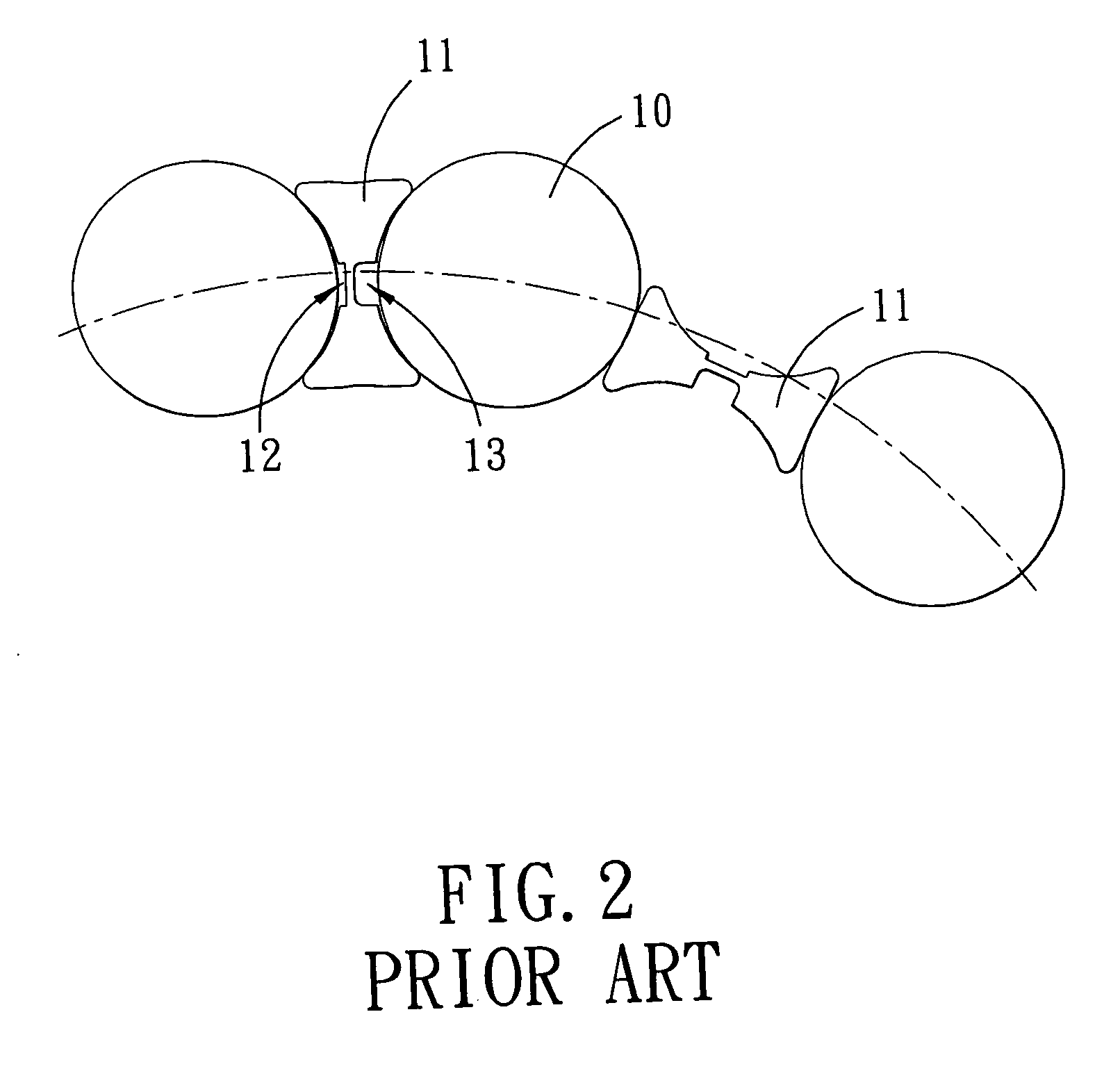

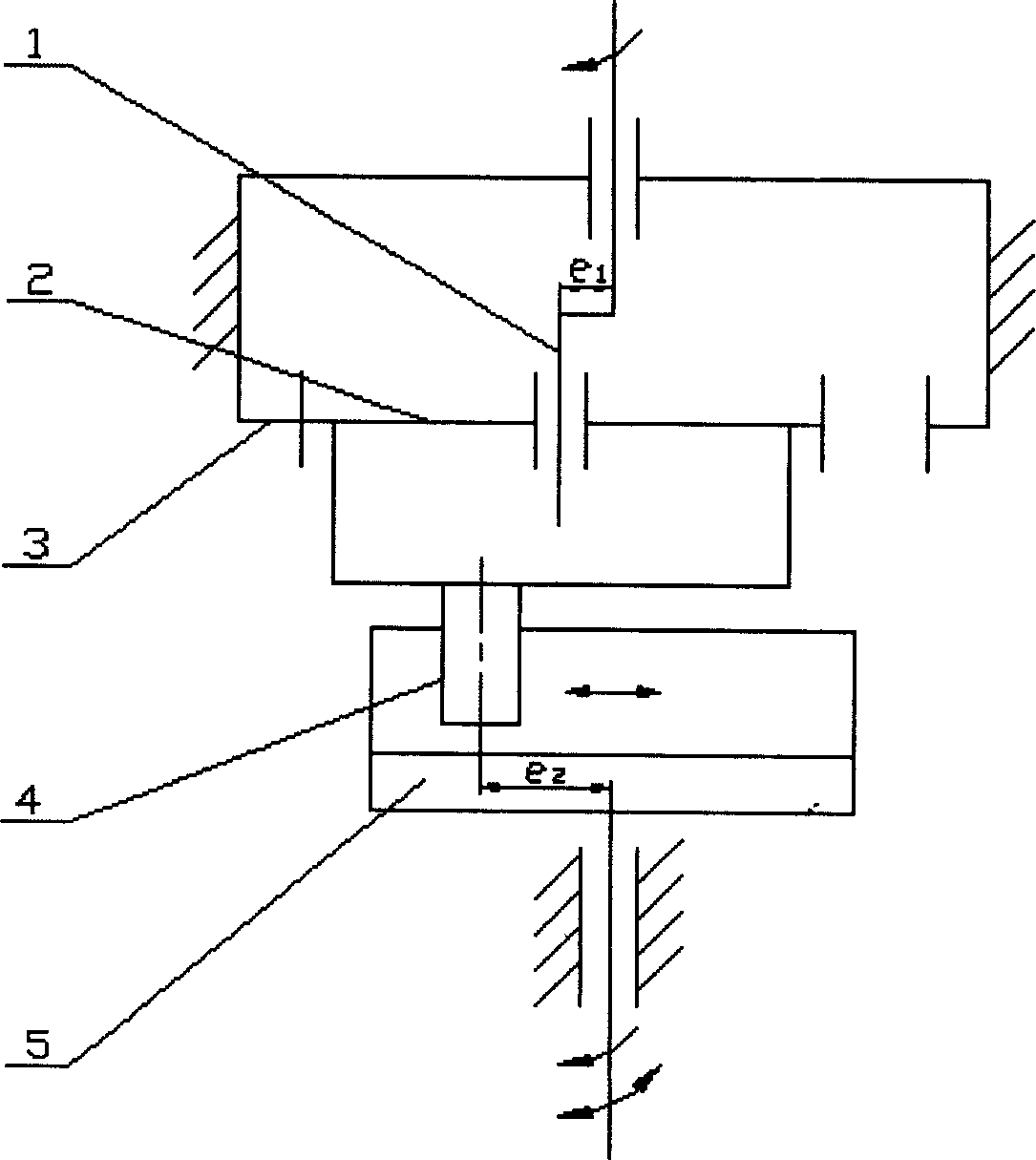

Gear configuration operable in various angles

A gear configuration allows force (torque) coming from a drive shaft to be transmitted to a driven shaft through two hemispherical gears that are placed at the end of the shafts and touch each other in variable, but constantly equal distance from the poles. This constant equal distance from the poles can be maintained through synchronization gears that are positioned against each other on both sides of U-shaped elements. These U-shaped elements also keep the shafts in position, where each U-shaped element on each of the shafts are connected by a ring formed hinge element, consequently keeping the hemispheres in connection

Owner:URGENC HASAN GOZDER

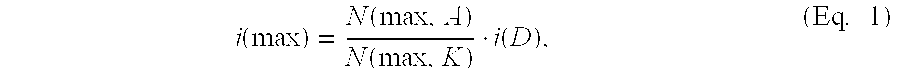

Speed reducer

ActiveCN102518753AMeet the transmission requirements of large reduction ratioSmall footprintToothed gearingsPower-operated mechanismThree stageReduction drive

Owner:CHERY AUTOMOBILE CO LTD

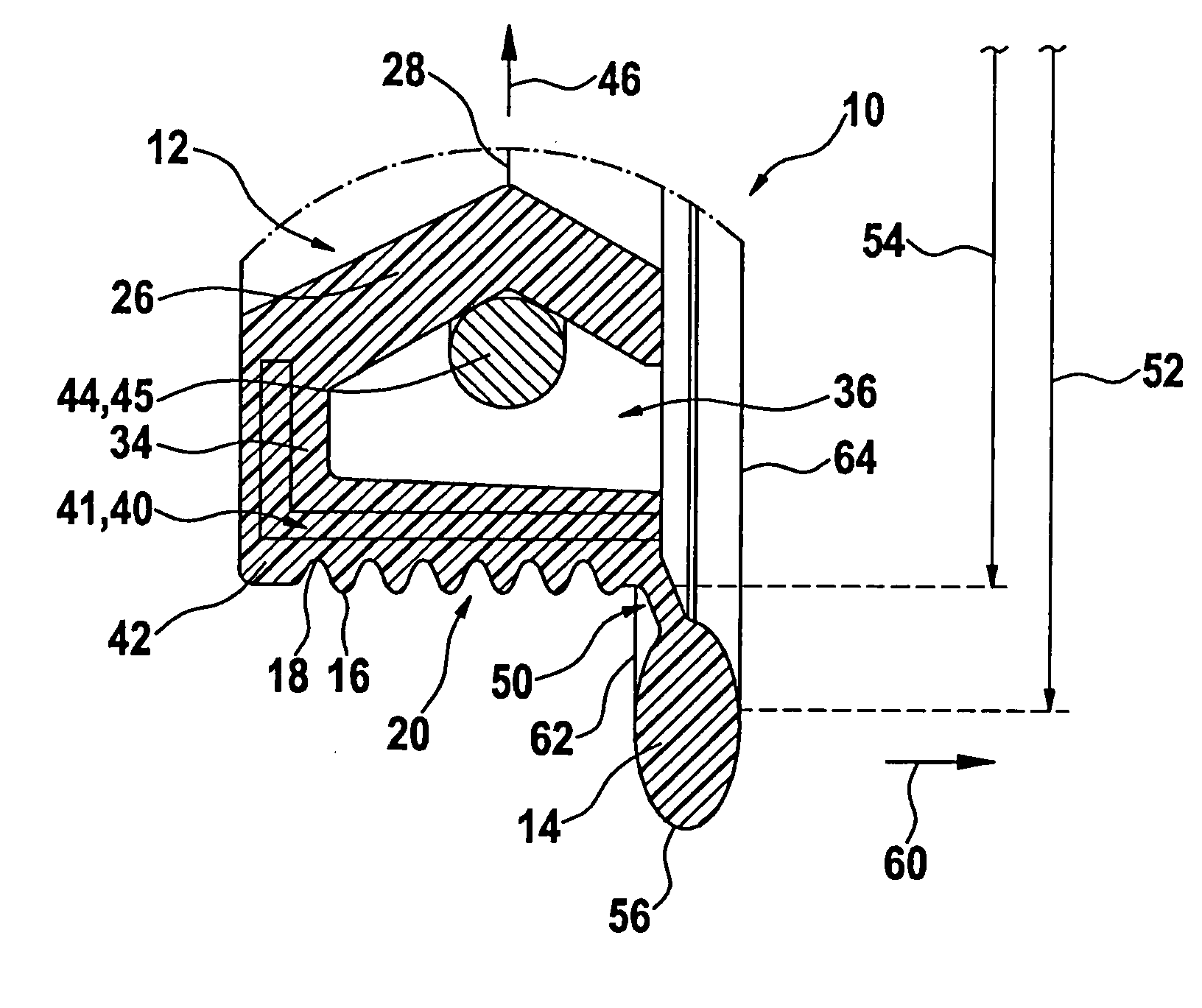

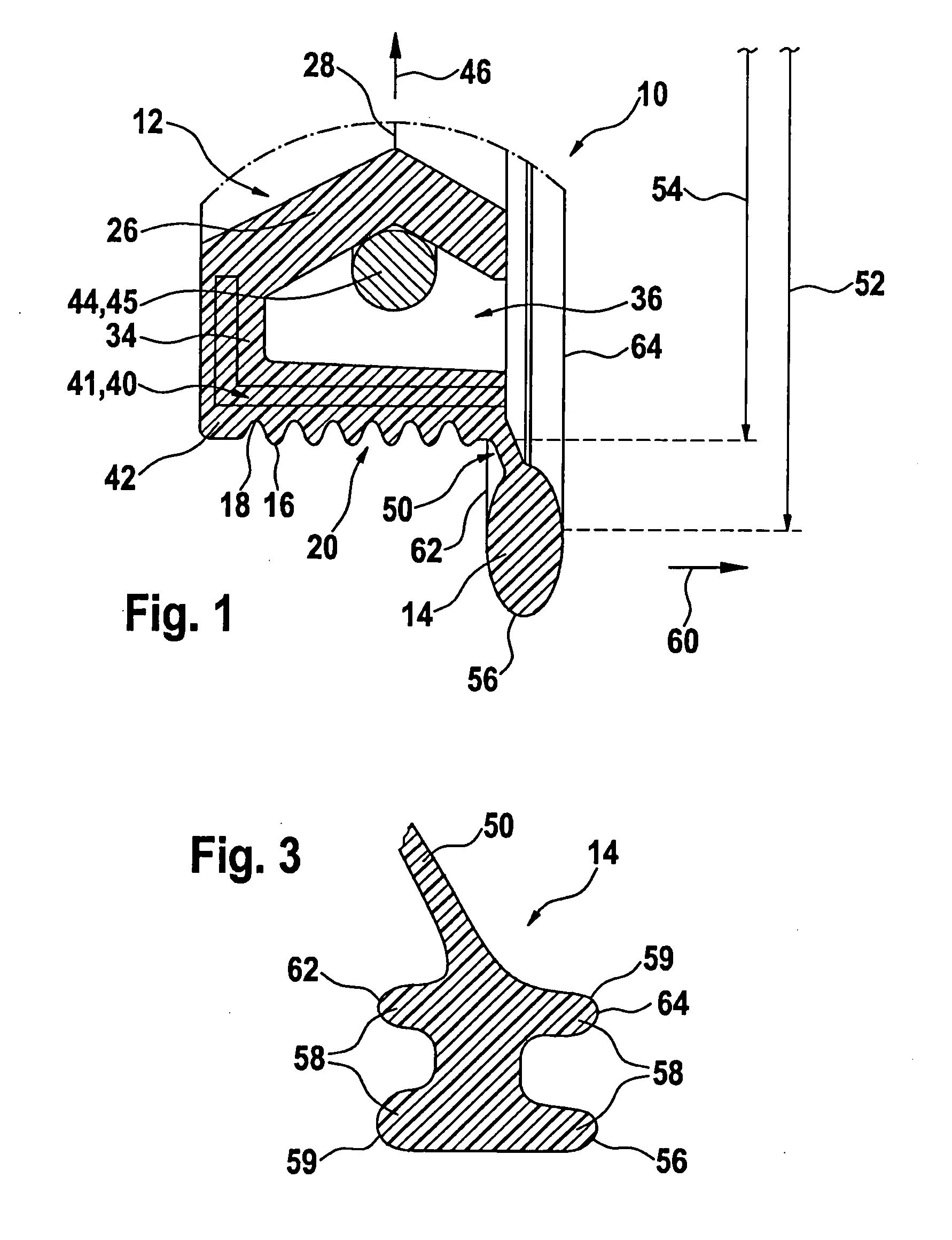

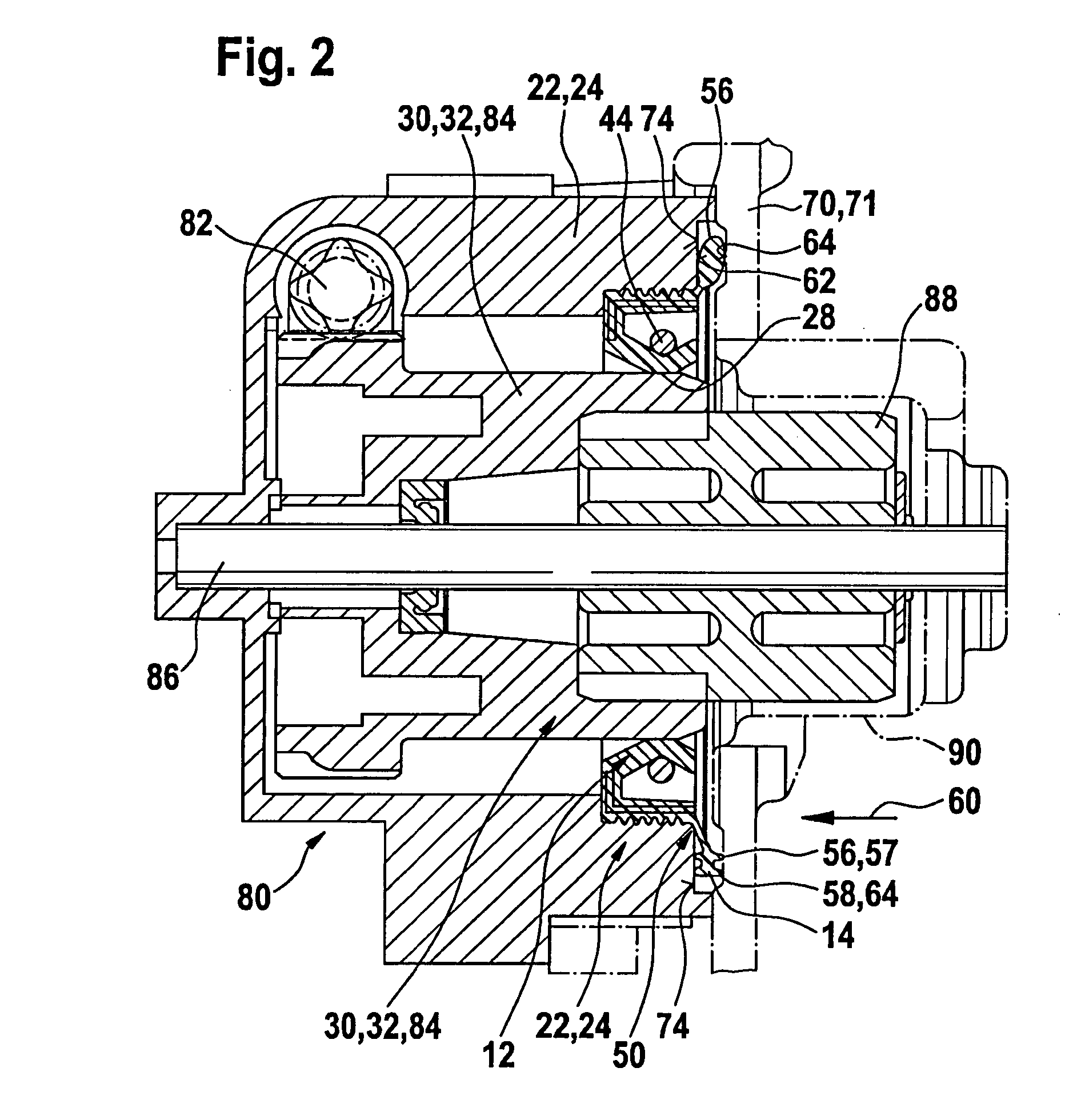

Sealing element, and drive unit containing a sealing element

Owner:ROBERT BOSCH GMBH

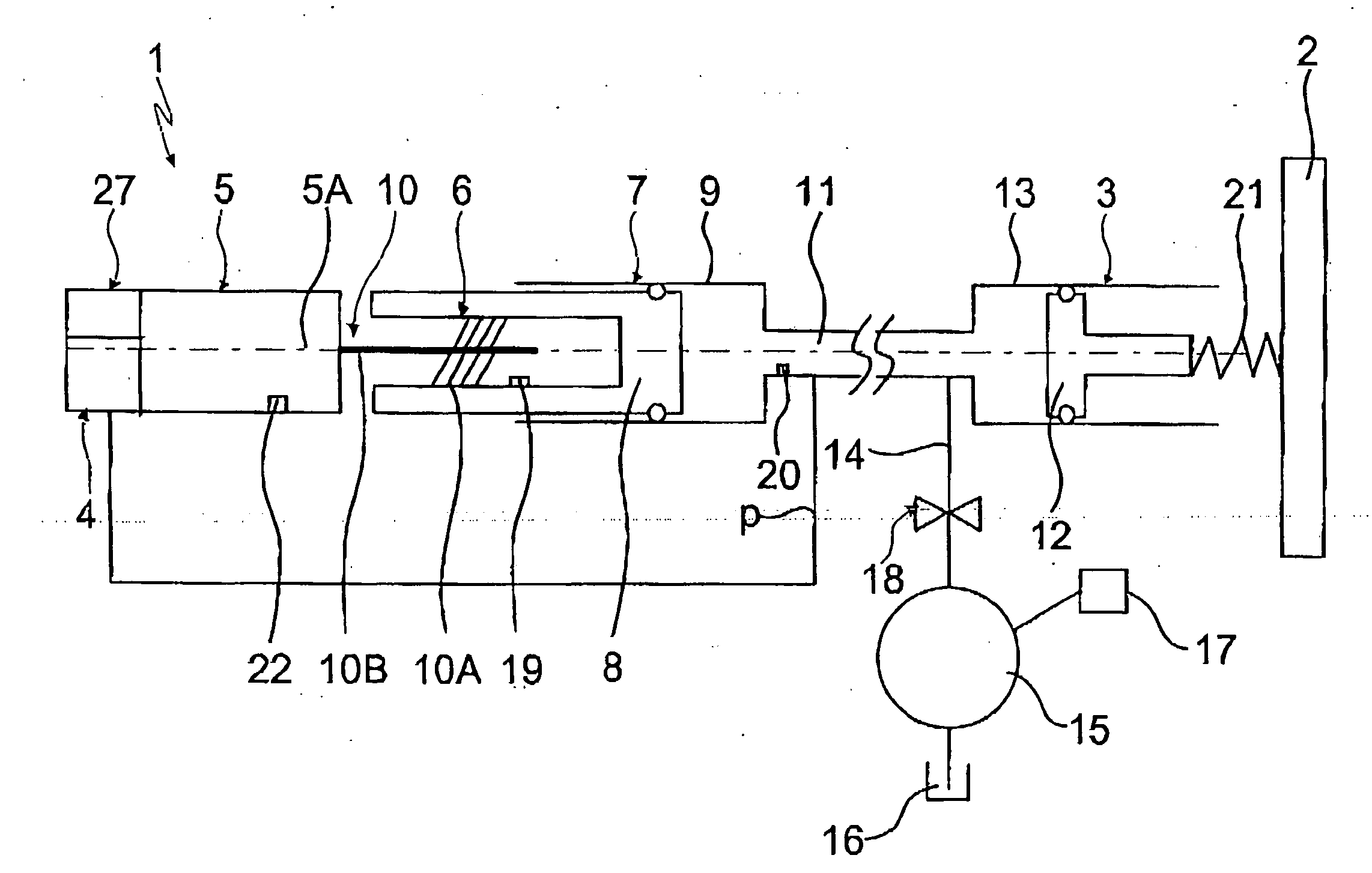

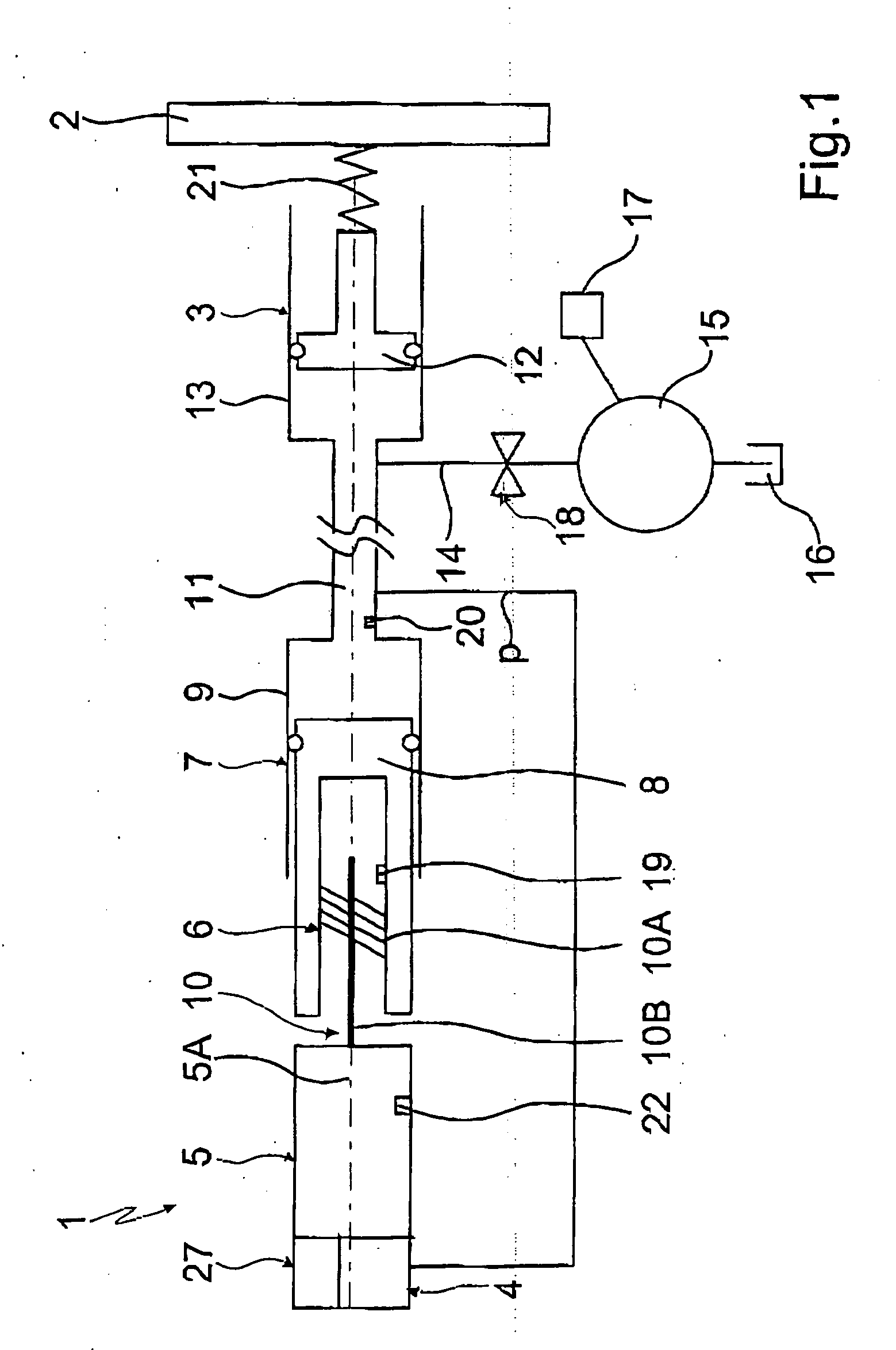

Device for controlling and/or regulating a hydraulically activatable shifting element of a gearing mechanism and a gearing mechanism

InactiveUS20070135258A1Reduce power consumptionImprove efficiencyGas pressure propulsion mountingToothed gearingsPiston cylinderEngineering

Owner:ZF FRIEDRICHSHAFEN AG

Automated manual transmission for vehicle

ActiveUS20140371022A1Smooth and reliable gear shift sensationImprove marketabilityToothed gearingsGearing controlGear wheelEngineering

Owner:HYUNDAI MOTOR CO LTD

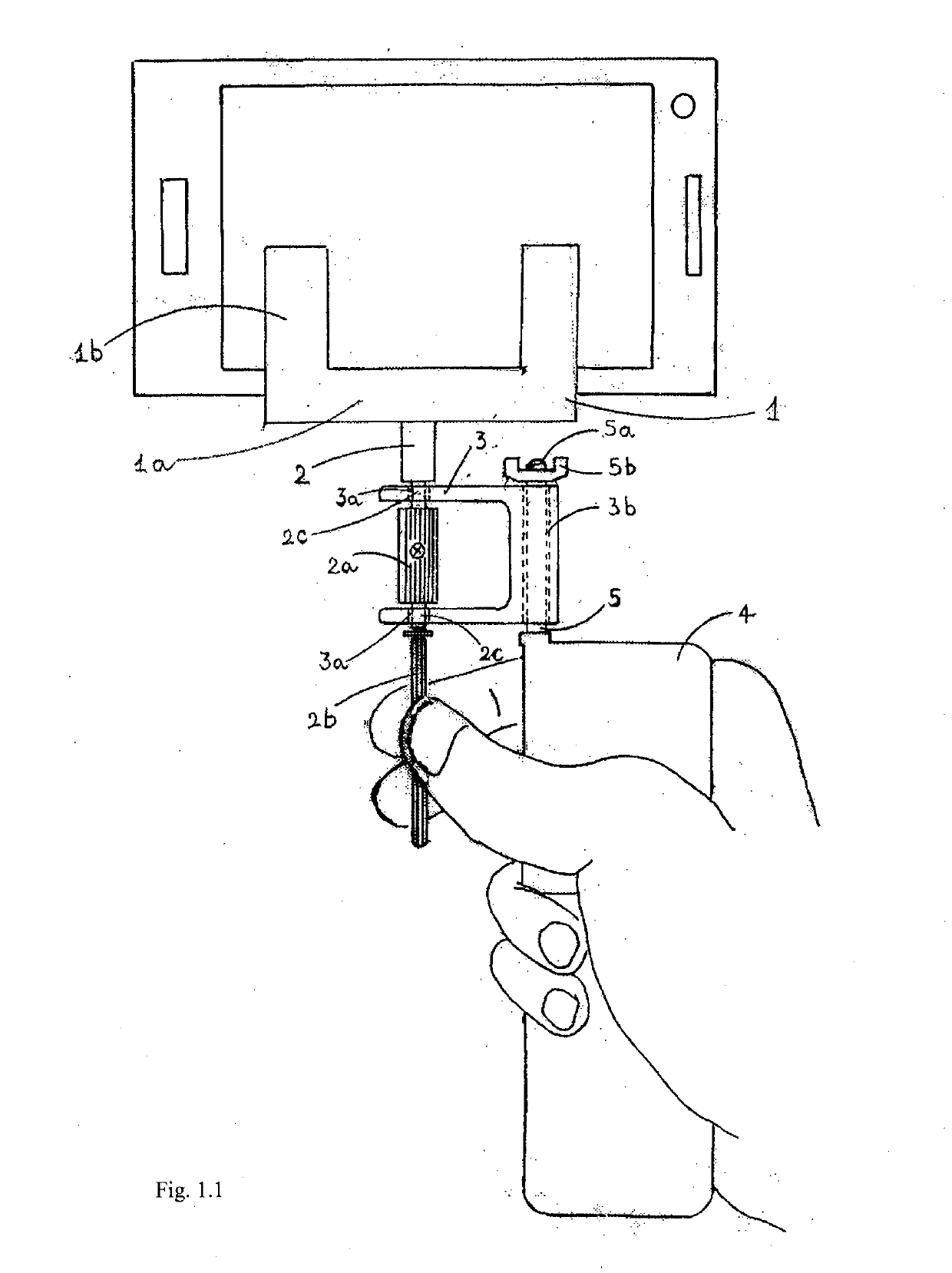

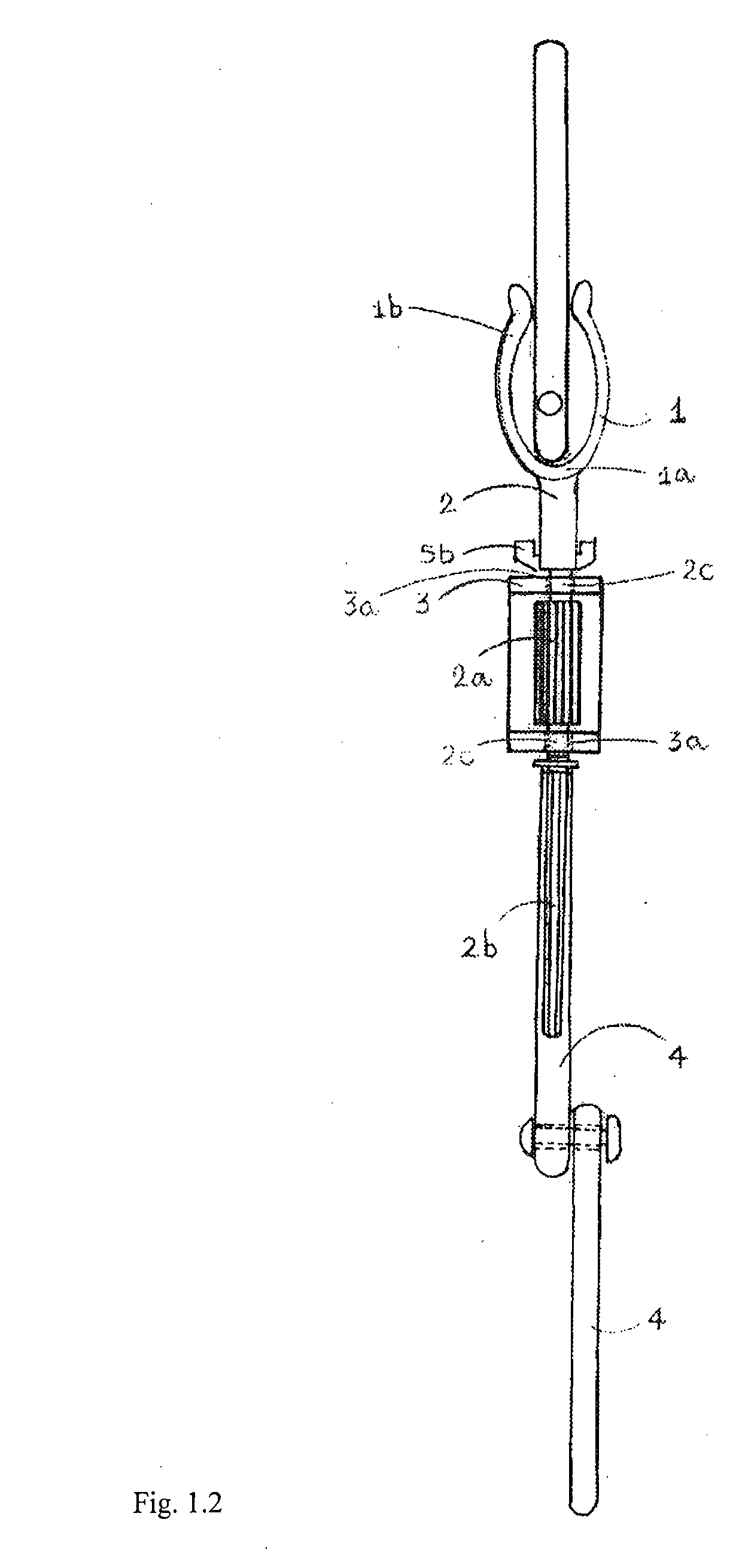

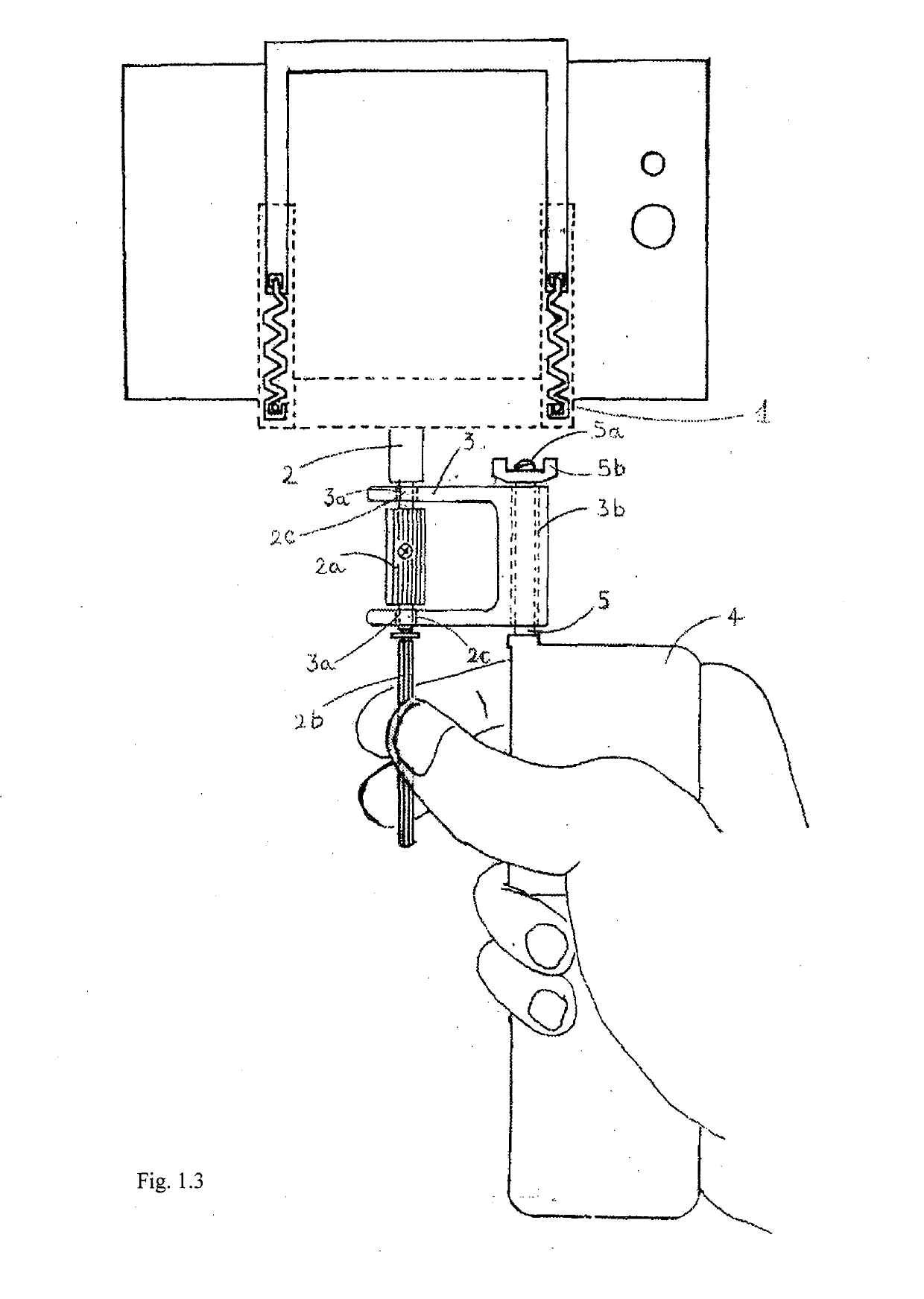

Finger-controlled 360° recording mobile phone rotary handheld device

InactiveUS20190195422A1Improve consistencyTelevision system detailsToothed gearingsFree rotationReciprocating motion

Owner:NHAN HUYNH CONG +1

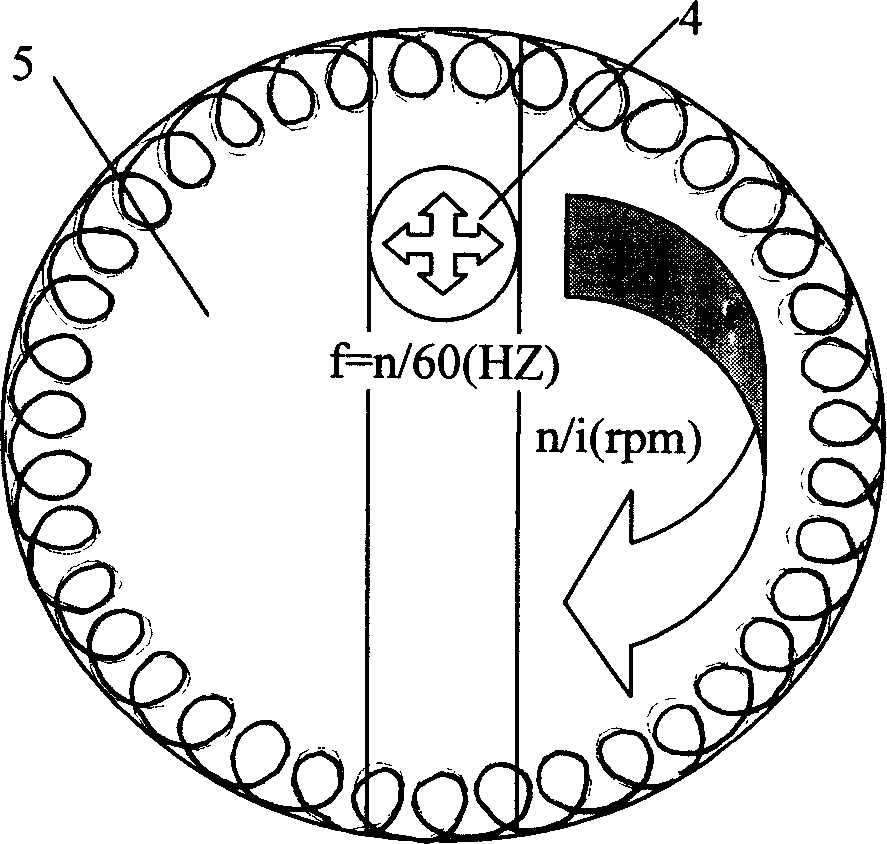

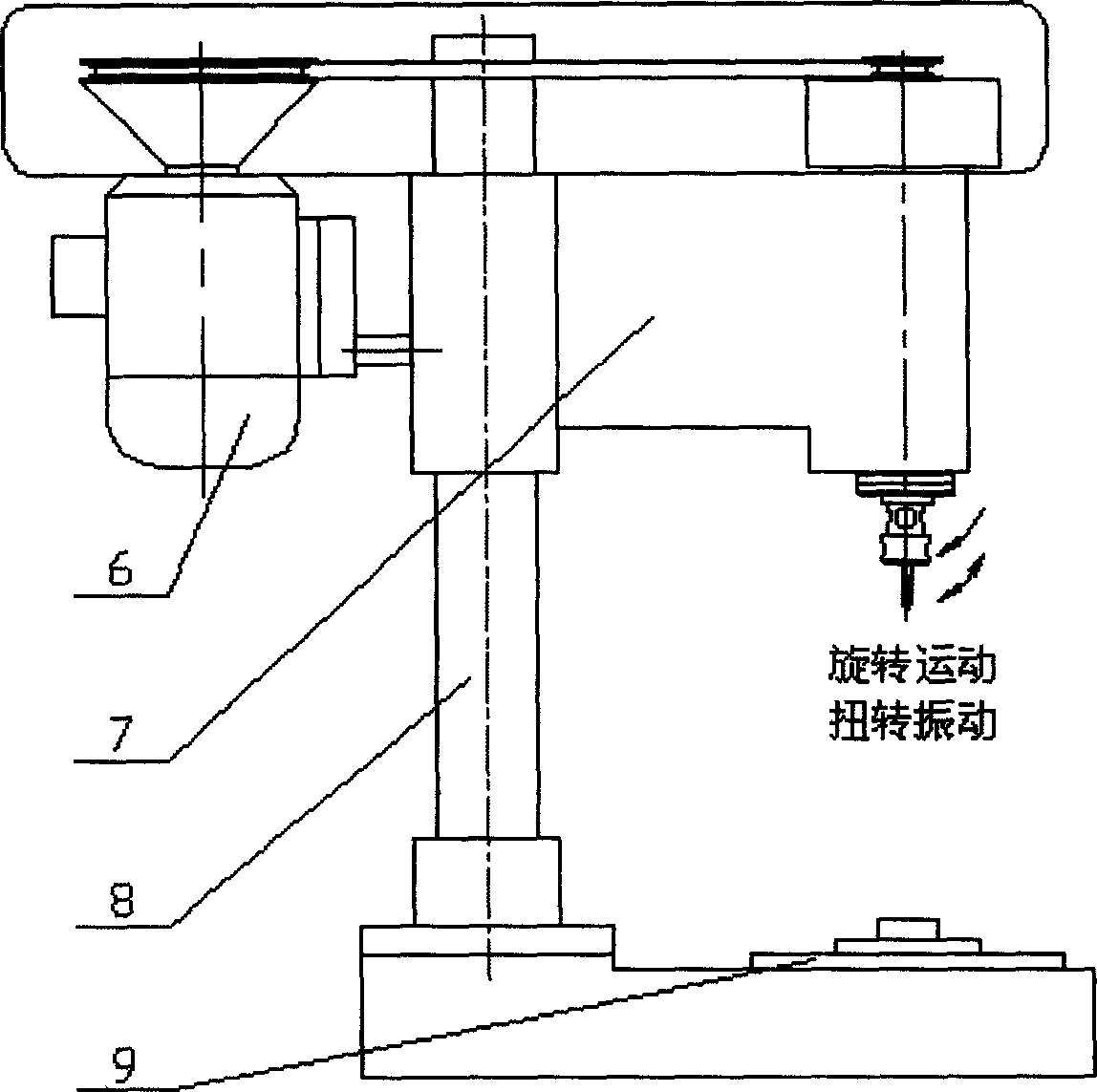

Rotation and torsional vibration compound movement mechanism based on planetary drive with small teeth difference

InactiveCN1632347ACompact structureEasy to assembleRevolution surface grinding machinesToothed gearingsLow speedRadius of gyration

Owner:XIAN UNIV OF TECH

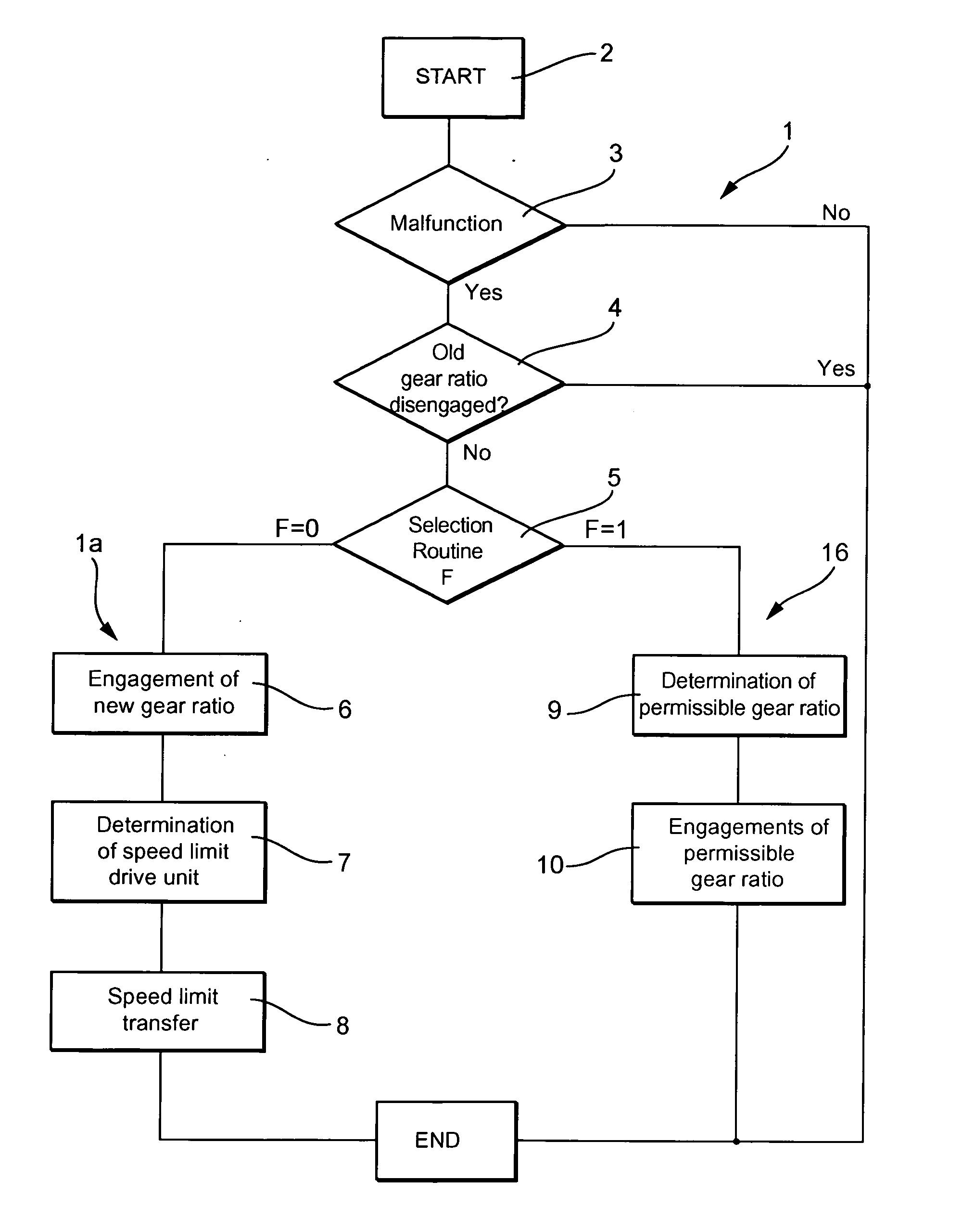

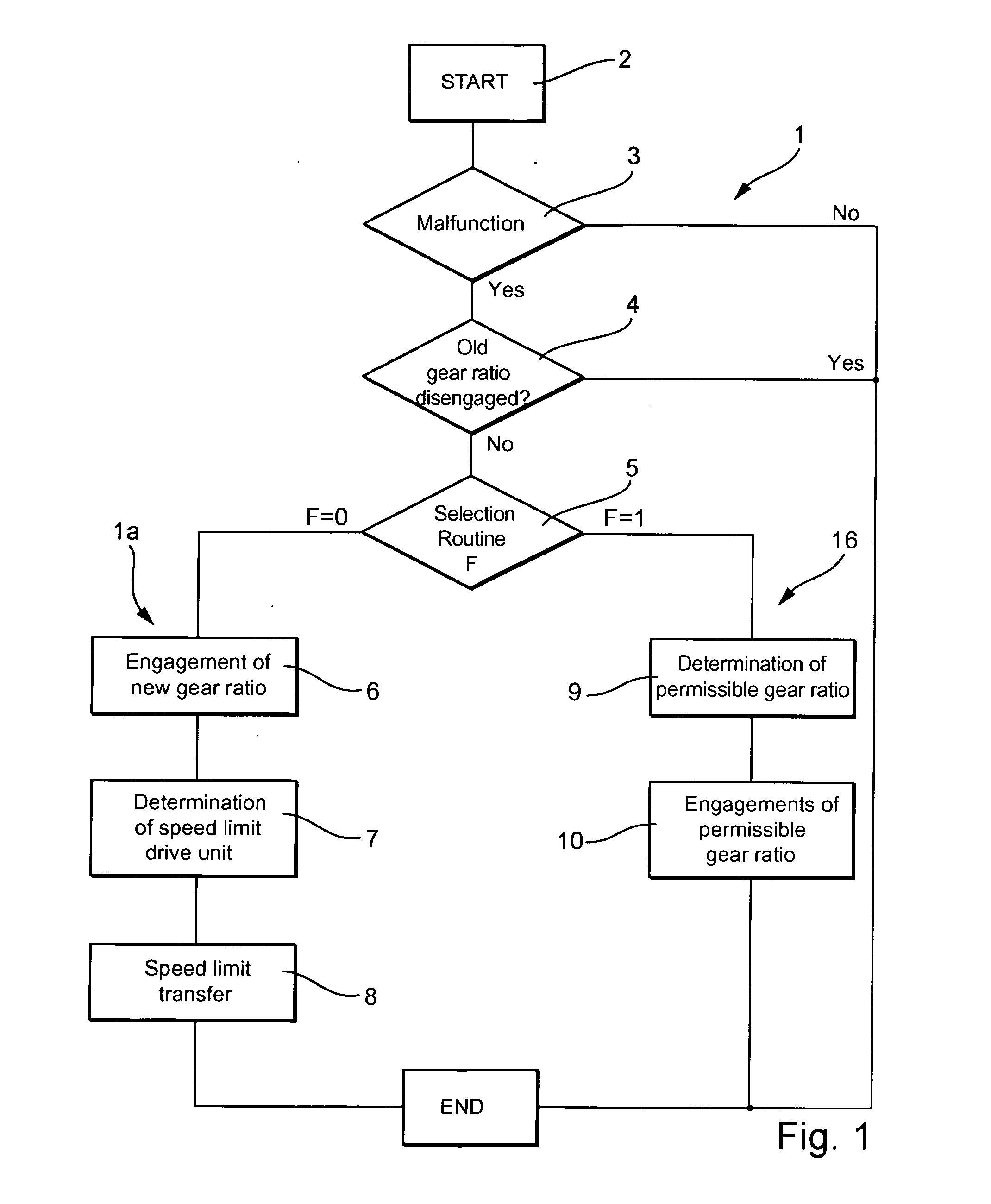

Parallel shift transmission and method for controlling it

InactiveUS20060089231A1Service life is prevented and reducedReduce and prevent situationToothed gearingsGearing controlEngineeringGear ratio

Owner:SCHAEFFLER TECH AG & CO KG

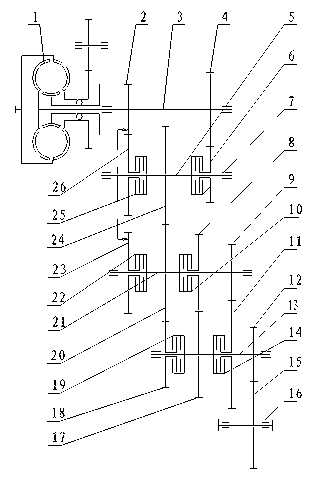

Power shift gear box applied to engineering machinery

Owner:QINGDAO LOVOL EXCAVATOR

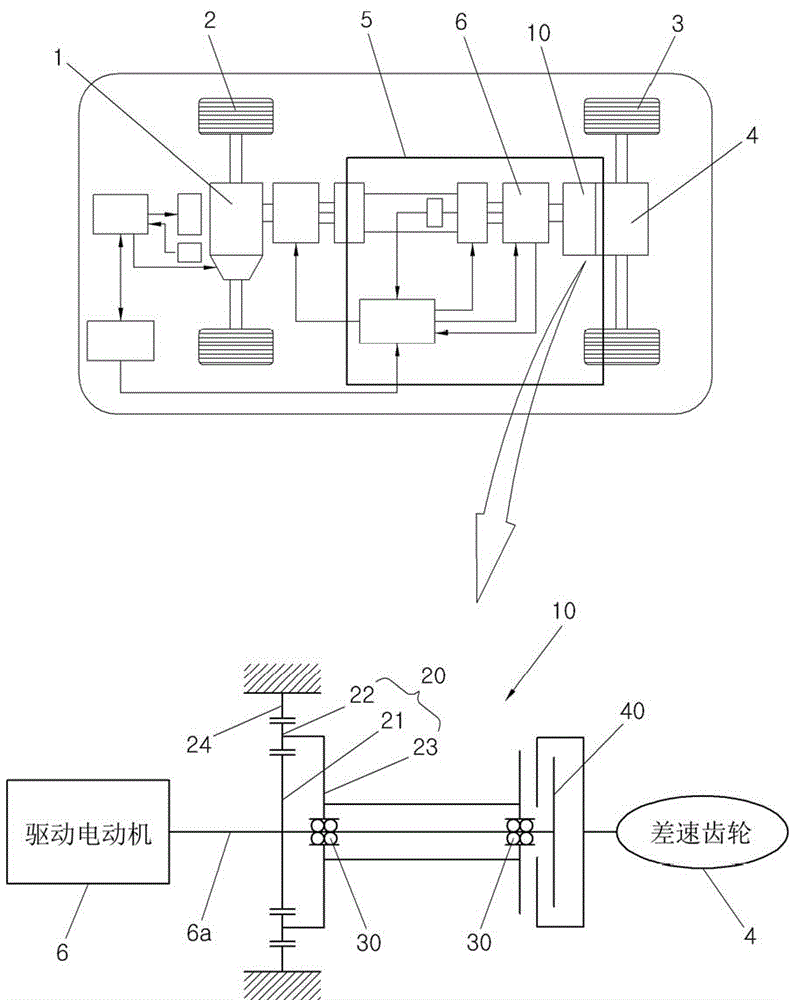

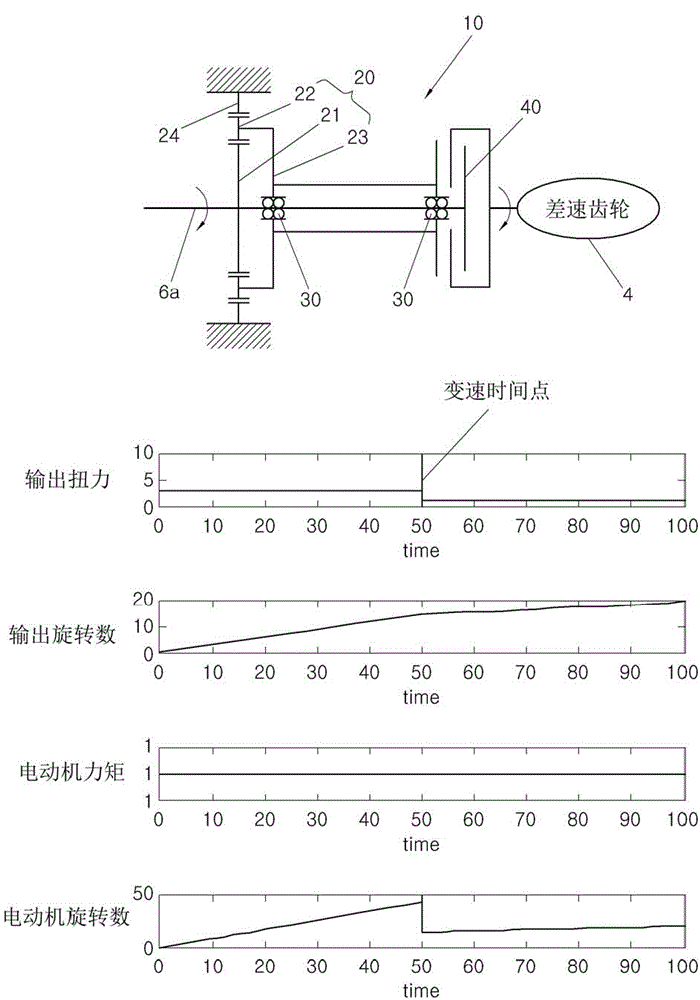

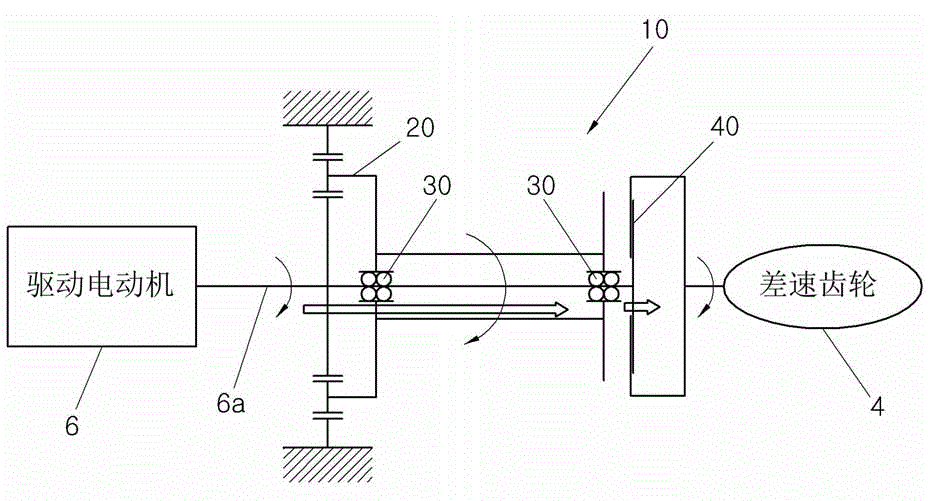

Stepless automatic transmission and vehicle

ActiveCN107664180AWide range of speed ratioImprove powerToothed gearingsGearing controlAutomatic transmissionDrivetrain

The invention provides a stepless automatic transmission and a vehicle, and relates to the technical field of vehicle power transmission systems. The stepless automatic transmission comprises a belt wheel transmission mechanism connected with an output shaft of an engine, and further comprises a planet gear mechanism, a differential, a transmission gear set and a clutch set, wherein the differential is connected with the planet gear mechanism, and comprises a transmission output shaft; the transmission gear set is in transmission connection with the output shaft of the engine and the planet gear mechanism; and the clutch set is connected with the planet gear mechanism and the transmission gear set, and comprises a first clutch and a second clutch. The stepless automatic transmission is provided with the planet gear mechanism connected with the differential and the clutch set connected with the planet gear mechanism and the transmission gear set; through change of working states of theclutches in the clutch set, the speed ratio range of the stepless automatic transmission is widened; the structure is simple; and the dynamic property and the economy of the vehicle are improved.

Owner:BAIC MOTOR POWERTRAIN CO LTD

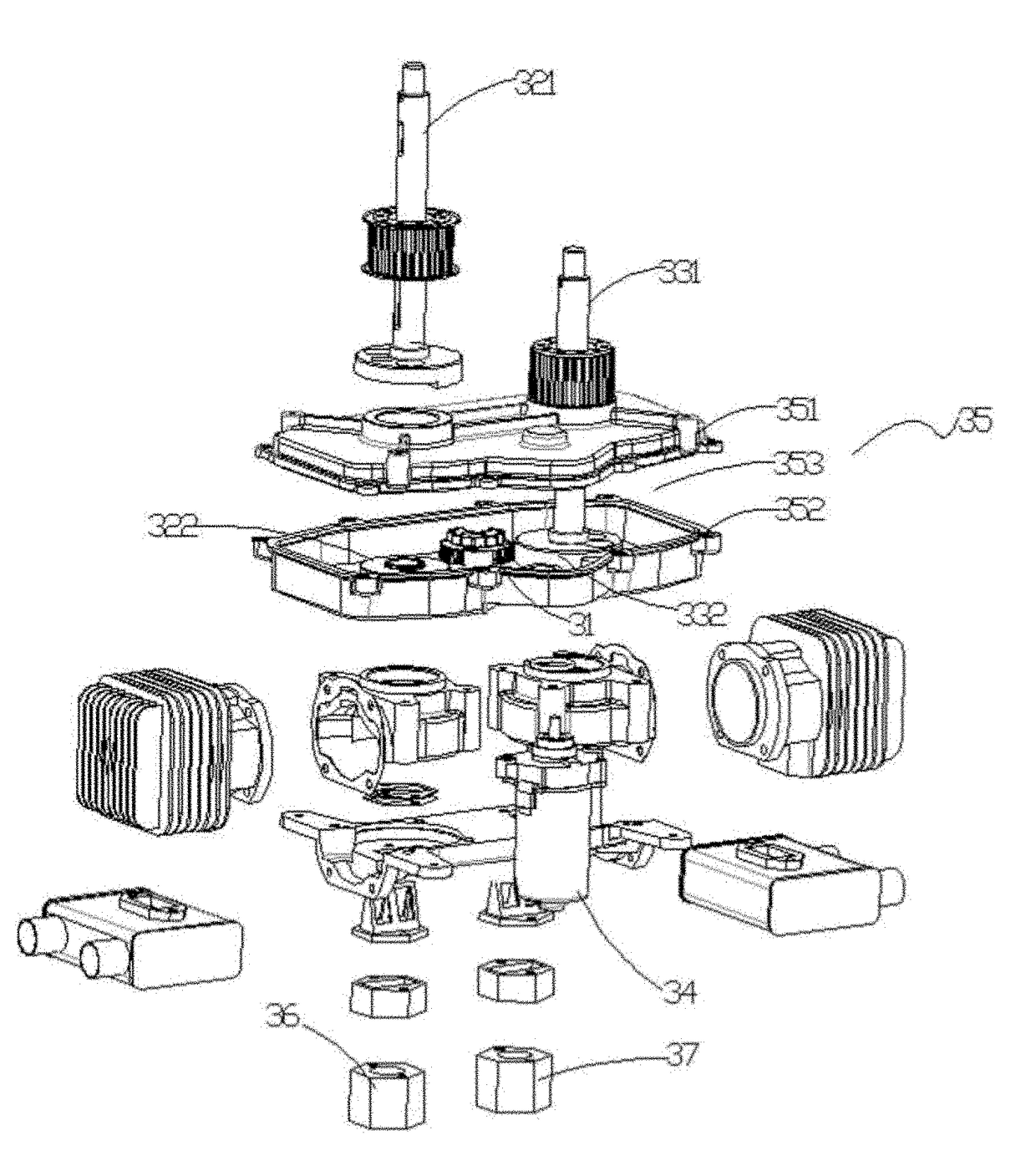

Wide-narrow row transplanting mechanism for two-stage non-conic bevel gear of high-speed rice transplanter

The invention discloses a wide-narrow row transplanting mechanism for a two-stage non-conic bevel gear of a high-speed rice transplanter. In a gearbox, the power is transmitted to a central shaft through a chain or a bevel gear; gear cases with the same inner transmission structures are fixed onto two shaft ends of the central shaft; a central non-conic bevel gear in each gear case is fixed onto each gear case through a tooth-type flange, and is meshed with a middle non-conic bevel gear fixedly mounted on the central shaft, so as to drive the other middle non-conic bevel gear coaxially mounted with the middle non-conic bevel gear to rotate; the other middle non-conic bevel gear is meshed with a planetary non-conic bevel gear; a transplanting arm part is fixed at one end, extending out of the gear case, of a planetary shaft; the shaft include angle, namely alpha, between the middle shaft and the central, and the shaft include angle, namely beta, between the planetary shaft and the middle shaft, are both sharp angles. The seedling needle has a better track and posture for wide-narrow row seedling; in the seedling taking process, the seedling is taken straight, the seedling setting port is small, the seedling is upright, and the wide-narrow row transplanting mechanism has the advantages of small size and simple structure.

Owner:ZHEJIANG SCI-TECH UNIV

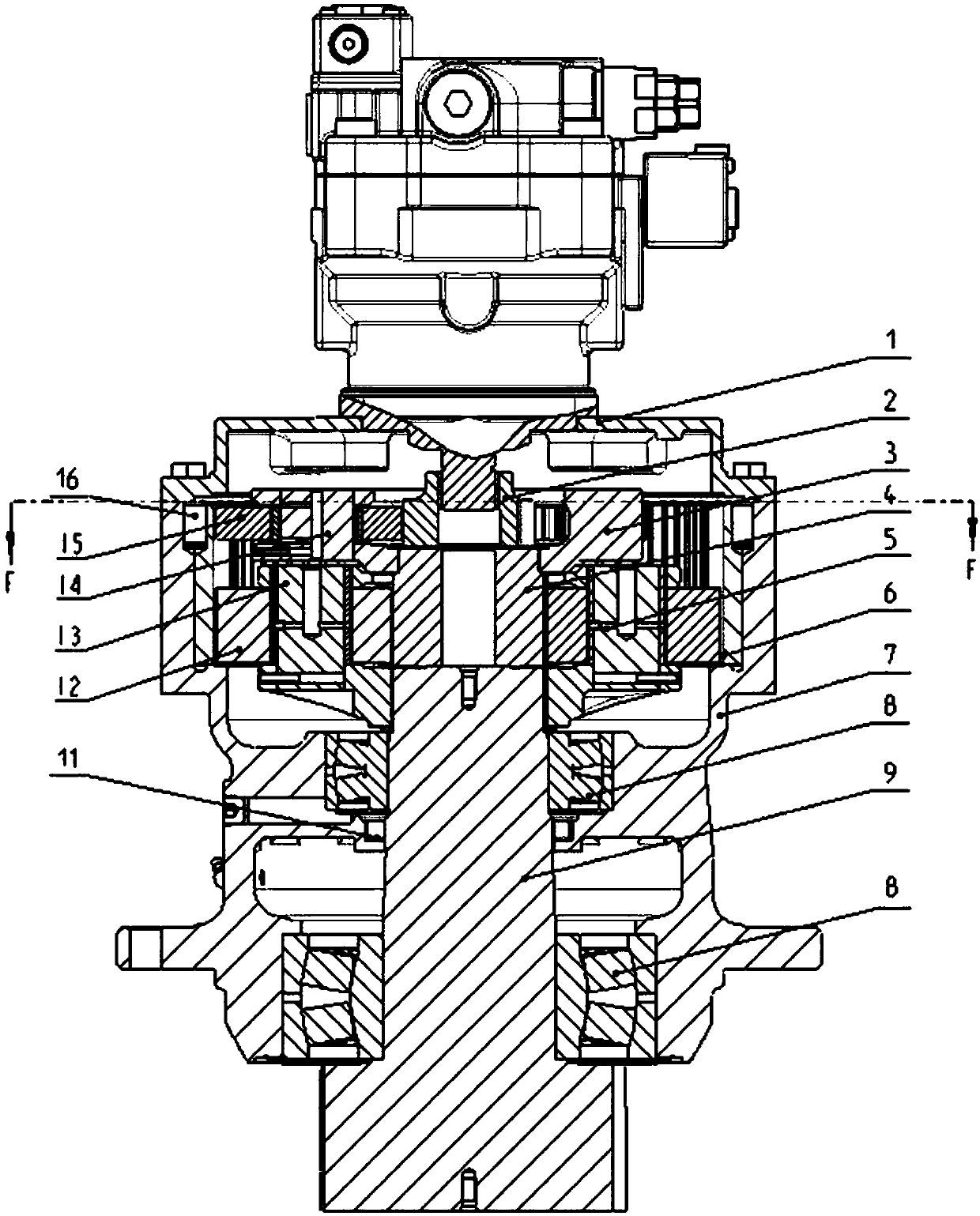

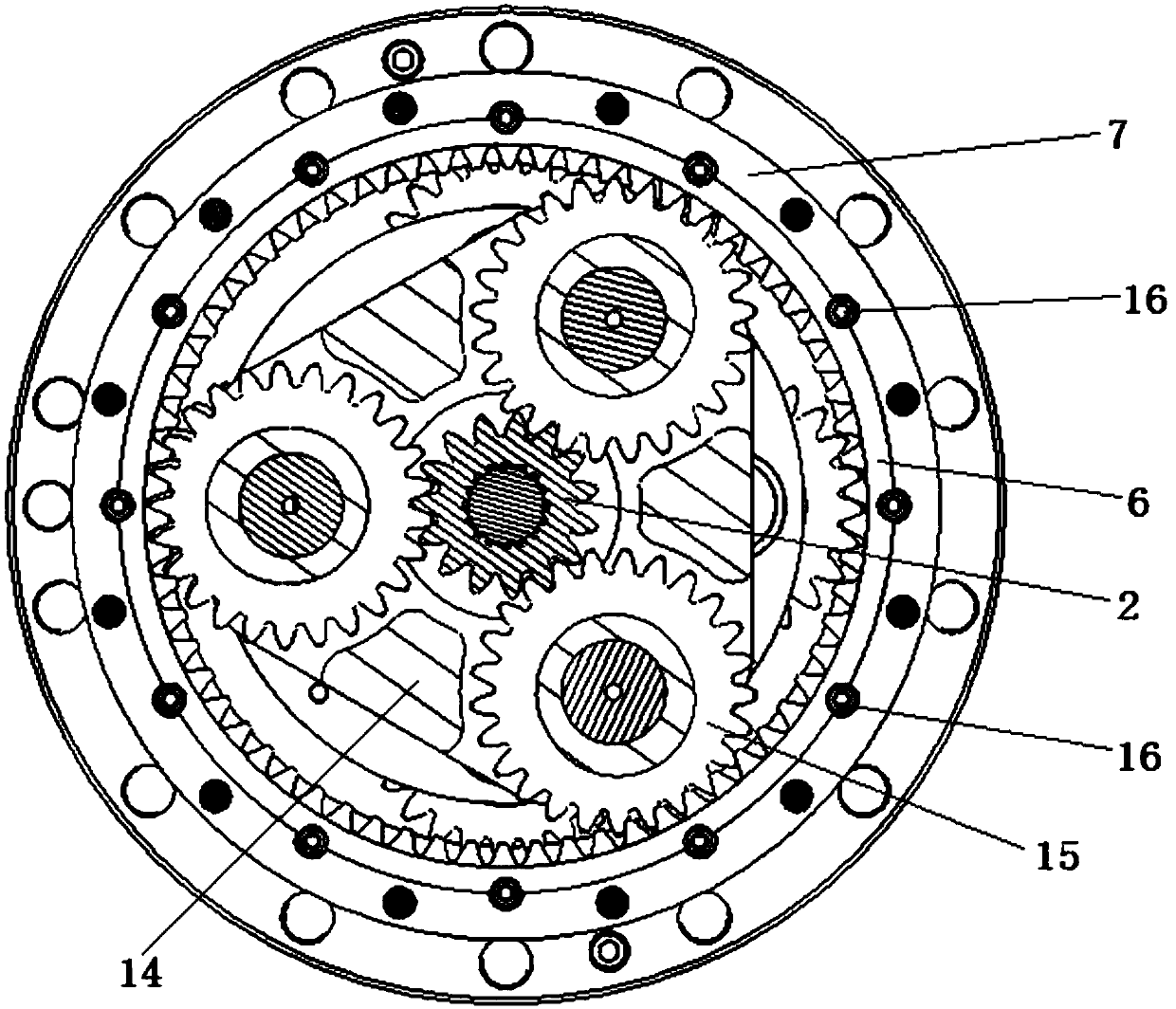

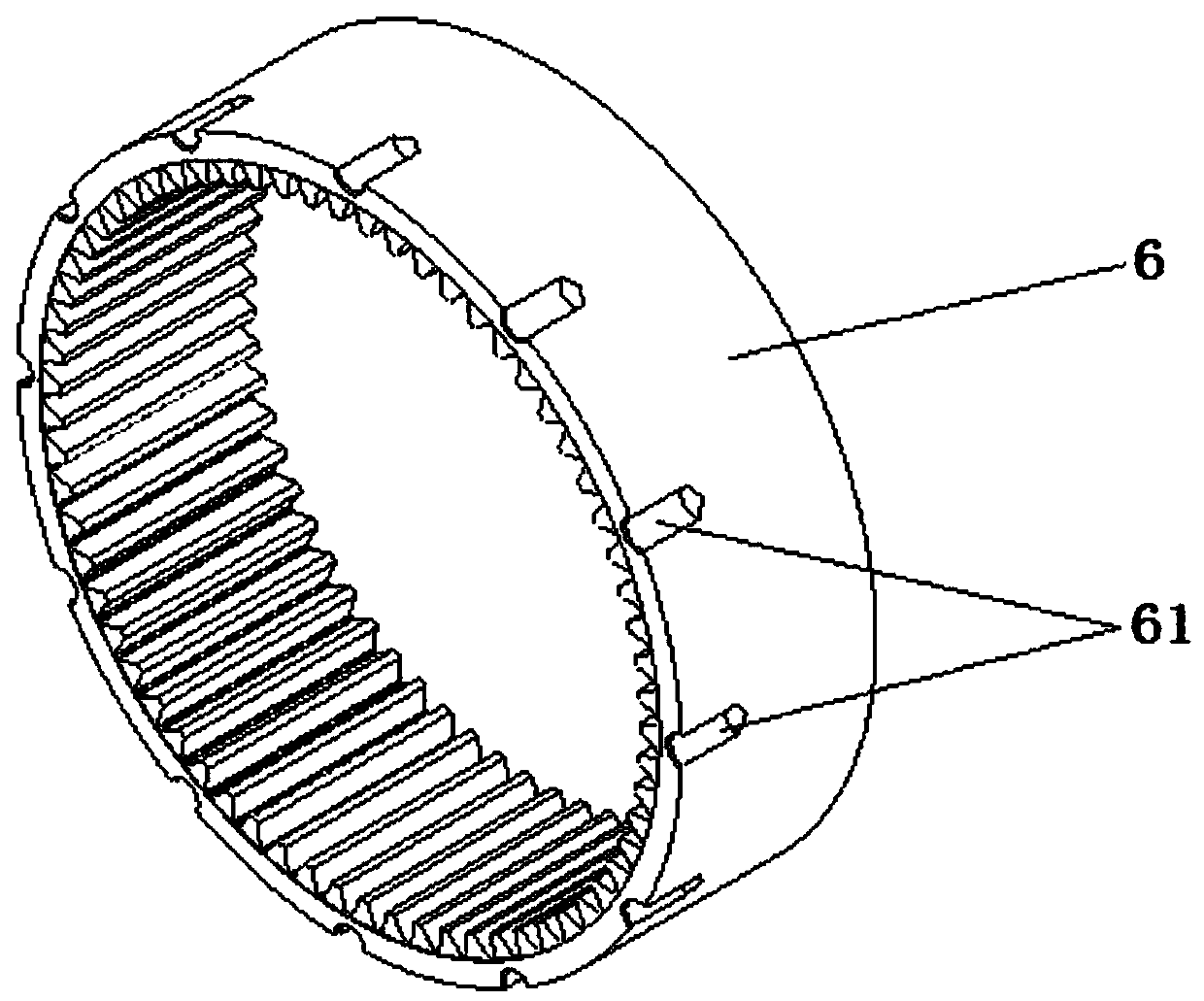

Planetary reducer

Owner:GUANGXI LIUGONG MASCH CO LTD

Four-wheel driving converter for electric automobile

InactiveCN102862477AAvoid damage phenomenonEasy to driveHybrid vehiclesElectrodynamic brake systemsConvertersRegenerative brake

Owner:HYUNDAI MOBIS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap