Worm wheel and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, embodiments of the present invention will be described with reference to the drawings.

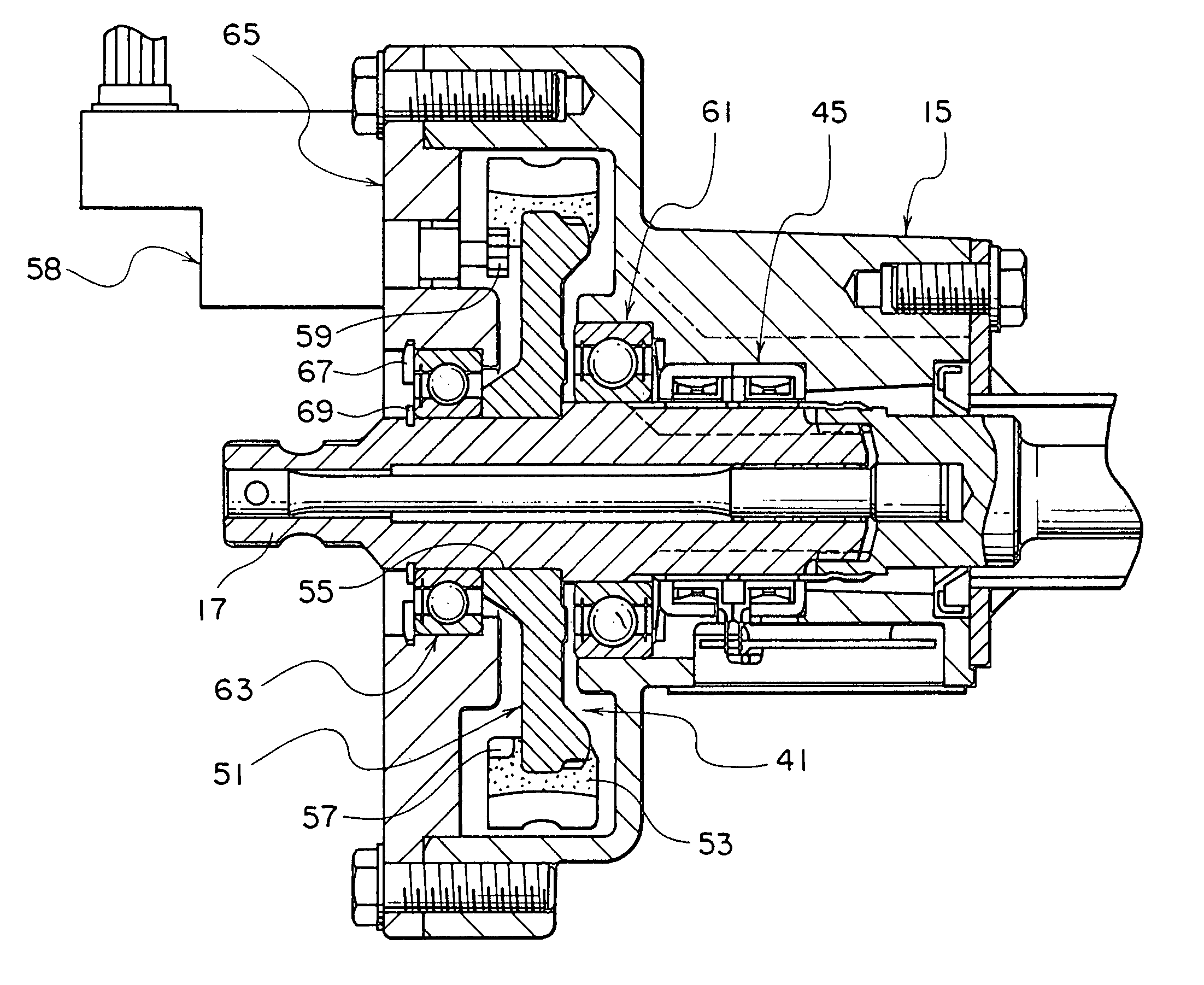

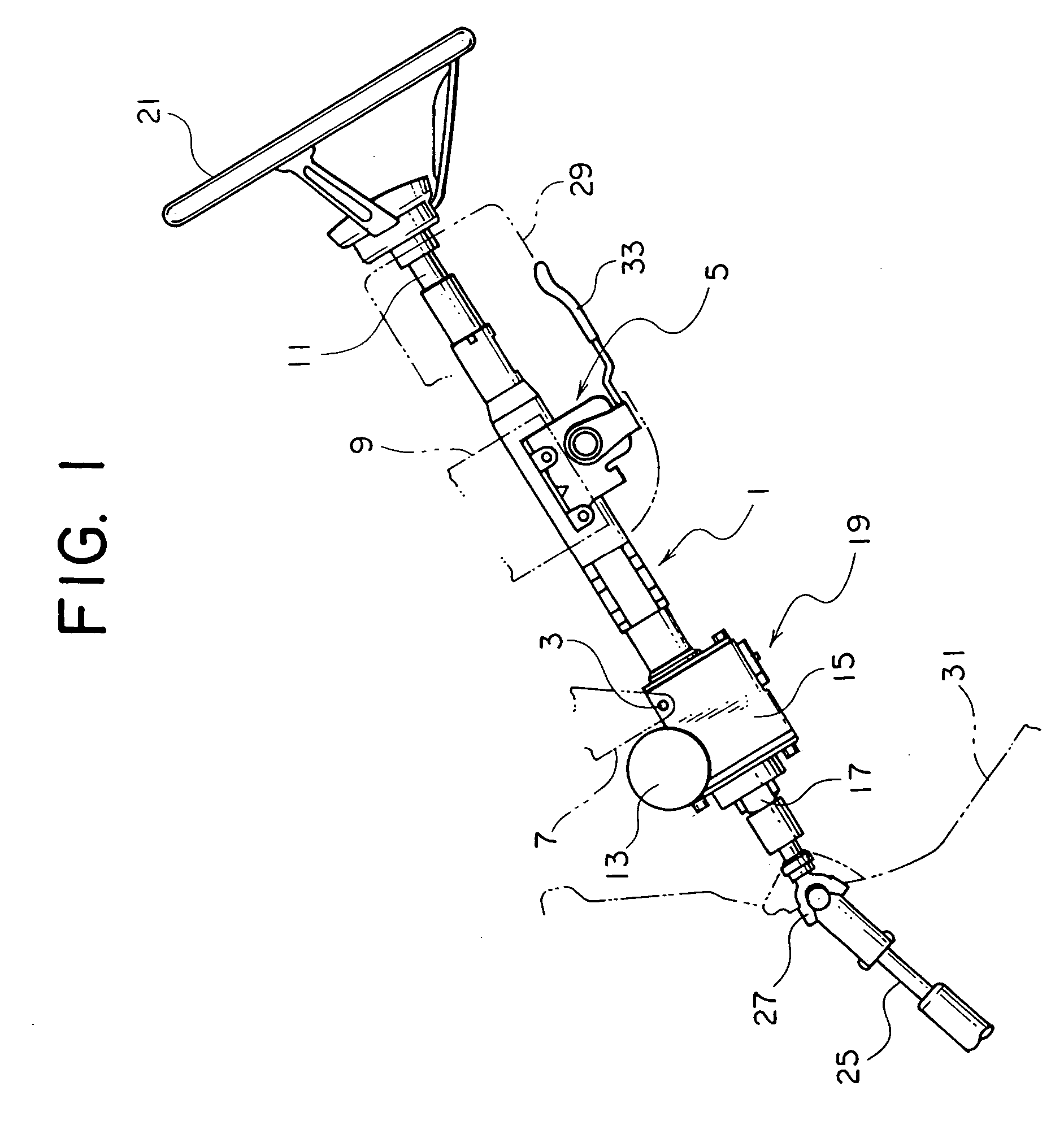

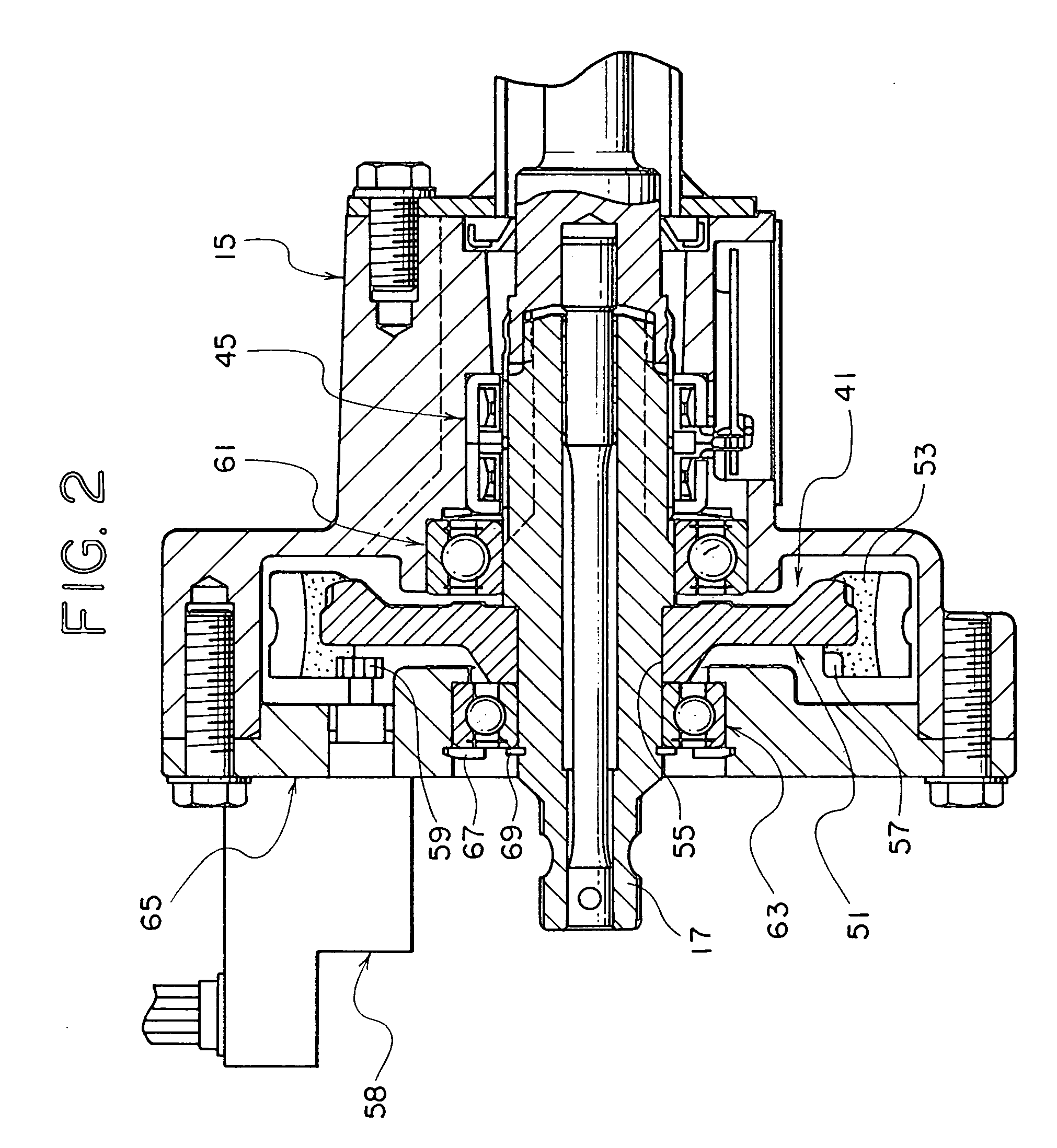

[0027]FIG. 1 is a side view showing the cabin side portion of a steering apparatus according to the first embodiment. In this drawing, reference numeral 1 designates a steering column. The steering column 1 is fixed to structural members 7 and 9 of a vehicle body by means of a pivot pin 3 and a tilt adjustment mechanism 5 respectively. Inside the steering column 1, a steering upper shaft 11 is rotatably supported, and an electric assist mechanism 19 composed of an electric motor 13, a gear housing 15 and output shaft 17 etc. is integrally formed on the steering column 1.

[0028] A steering wheel 21 is attached to the rear end of the steering upper shaft 11. When a driver turns the steering wheel 21, the rotational force is amplified by the electric assist mechanism 19 and transmitted to the output shaft 17. As shown in FIG. 1, a lower steering shaft 25 is connected to the fron

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap