Power shift gear box applied to engineering machinery

A technology for power shifting and construction machinery, which is applied in the field of shifting gearboxes and power shifting gearboxes. It can solve the problems of increased complexity and processing difficulty, more meshing pairs of transmission gears, and increased manufacturing and maintenance costs. Achieve the effect of improving power utilization, less parts involved in transmission, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

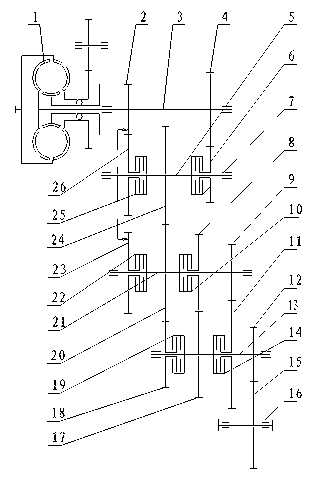

[0046] Examples such as figure 1 As shown, a power shift gearbox suitable for engineering machinery includes an input shaft 3 and an output shaft 16. One end of the input shaft 3 is connected to a torque converter 1. Between the input shaft 3 and the output shaft 16 The power transmission is carried out through three power transmission units. The three power transmission units include: the first intermediate shaft 5, which is connected to the input shaft 3; the third intermediate shaft 13, which is connected to the output shaft 16; the second intermediate shaft 21, which is connected to the input shaft 3 and the first intermediate shaft 5. The third intermediate shaft 13 is respectively connected by transmission.

[0047] The first fixed gear 2 and the second fixed gear 4 are fixedly connected to the input shaft, and the seventh fixed gear 15 is fixedly connected to the output shaft.

[0048] The first intermediate shaft 5 , the second intermediate shaft 21 and the third interm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap