Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limb training recovery device for fracture patient

Owner:南京捷科生物科技有限公司

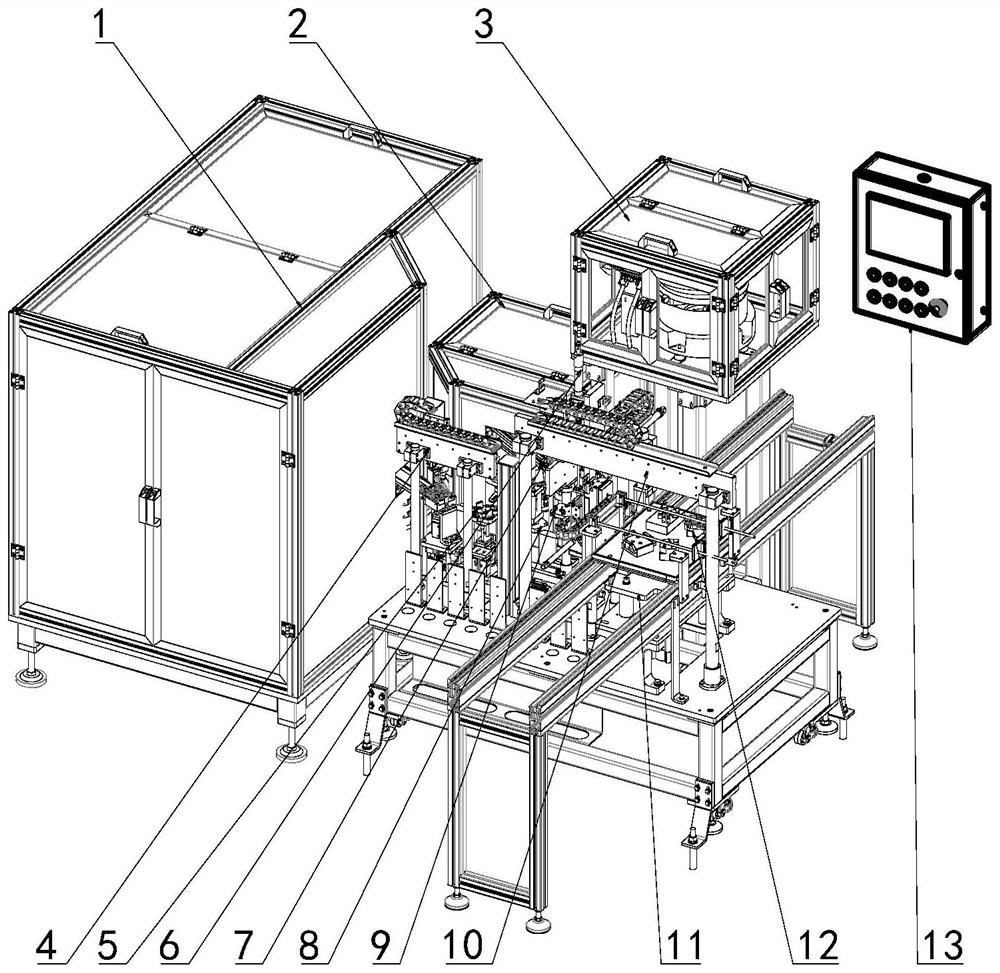

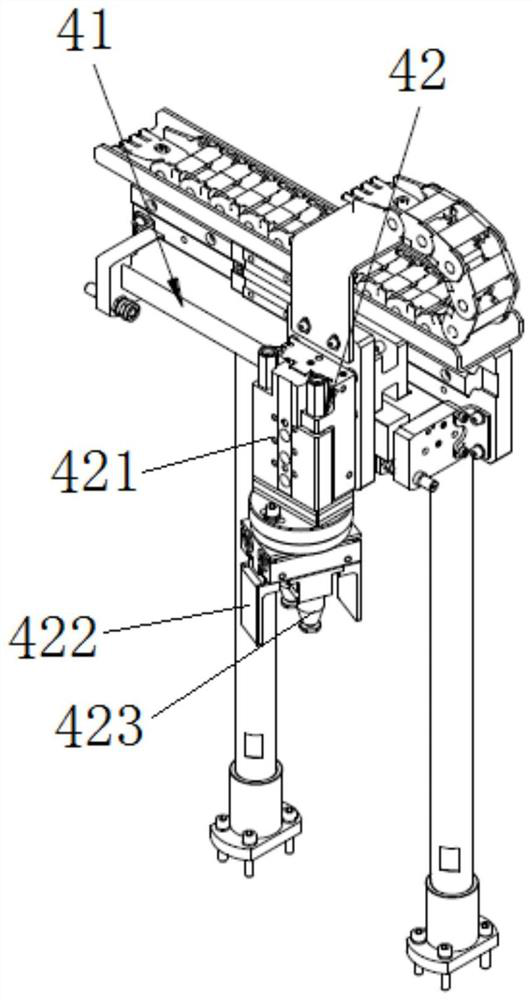

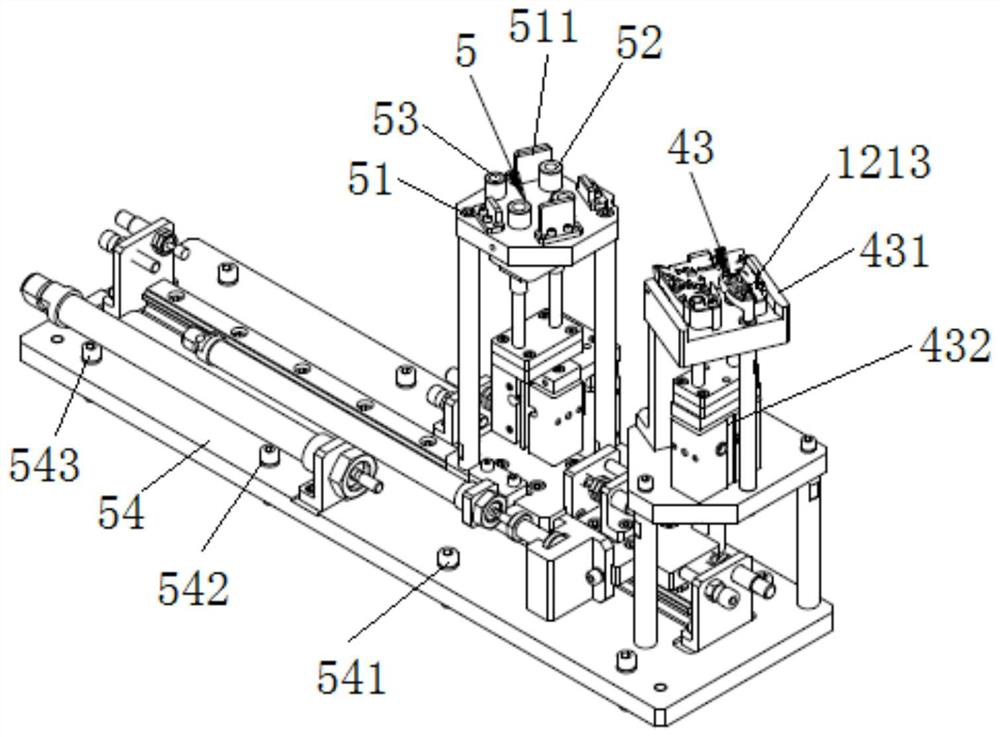

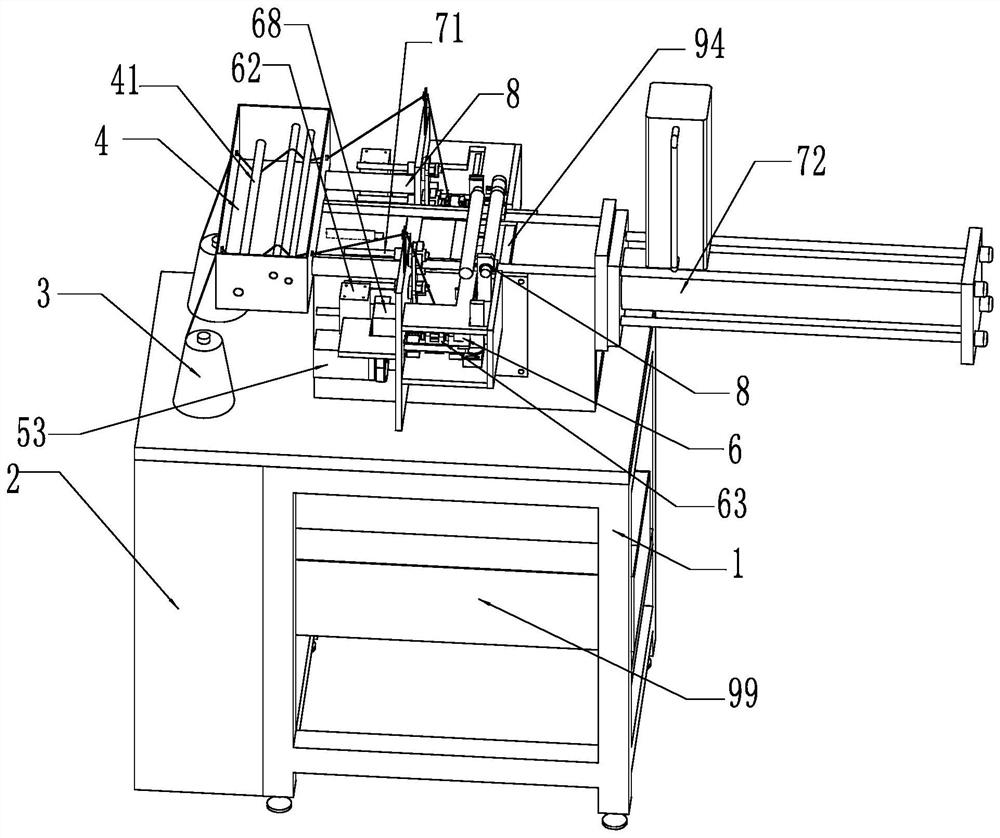

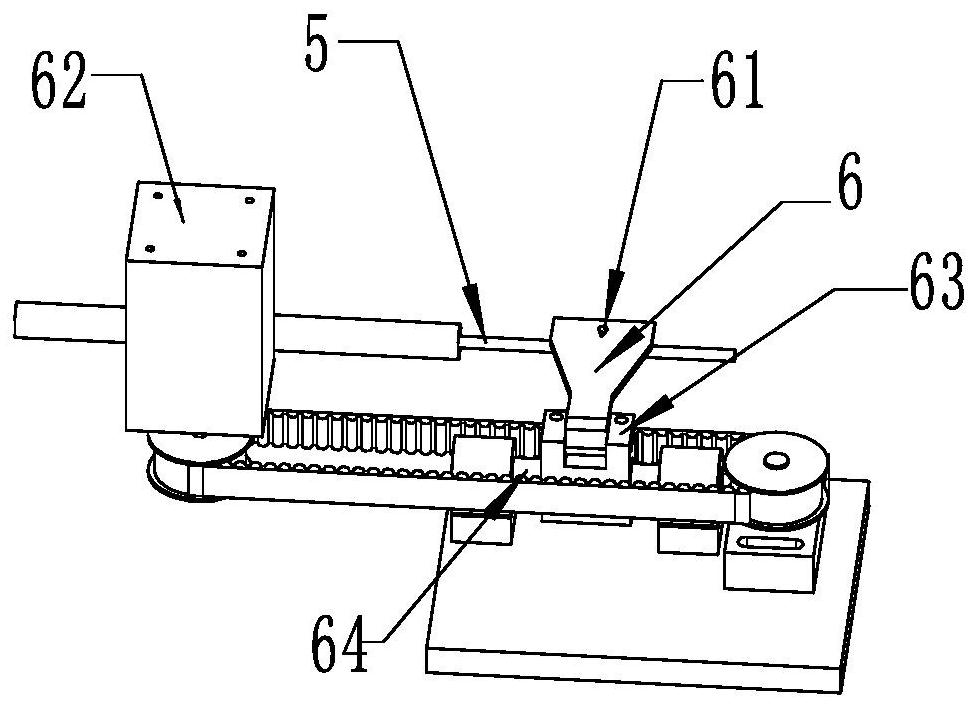

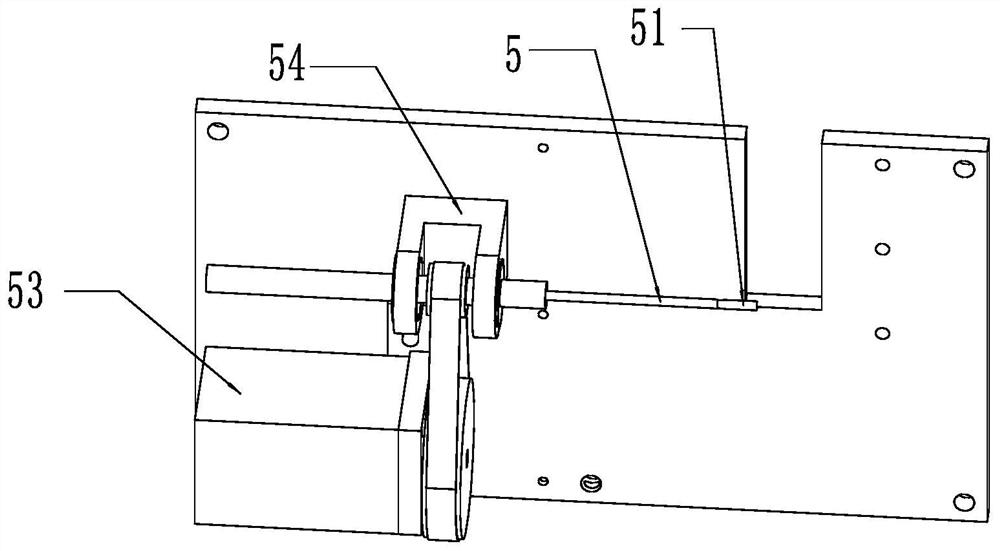

Automatic assembling equipment and assembling method for door lock shell assembly

ActiveCN114211246AImprove consistencyIncrease productivityAssembly machinesMetal working apparatusManufacturing engineeringRivet

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

Amplitude impedance calibrated three-dimensional package surface antenna

Owner:SOUTHEAST UNIV

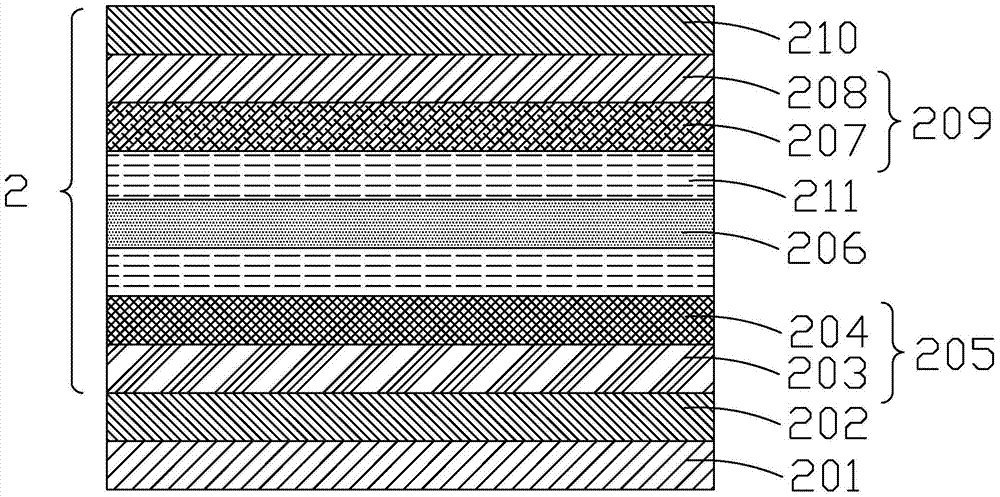

Production method of lithium-ion power battery improving battery consistency

InactiveCN102280665AImprove consistencyTotal weight controlCell electrodesFinal product manufacturePower batteryEngineering

The invention discloses a production method of a lithium ion power battery with consistency improved. According to the invention, anode sheets and cathode sheets are obtained through coating and cutting technologies, and are graded according to the weight of each sheet; a total weight of anode sheets in a single battery is controlled through steps that: a group of anode sheets with a total anode sheet number required by the single battery is weighed, wherein the anode sheets can be selected from a middle weight grade, or can be randomly selected from at least two weight grades; according to ameasured weight, anode sheets in the grade of a larger weight are replaced by anode sheets in the grade of a smaller weight, or anode sheets in the grade of a smaller weight are replaced by anode sheets in the grade of a larger weight; finally, the total weight of the anode sheets is controlled within a required total weight range. With the production technology modification provided by the invention, consistency of the lithium ion power battery is greatly improved, service life of the lithium ion power battery is prolonged, and application safety of the lithium ion power battery is ensured.

Owner:SHANDONG SHANGCUN ENERGY

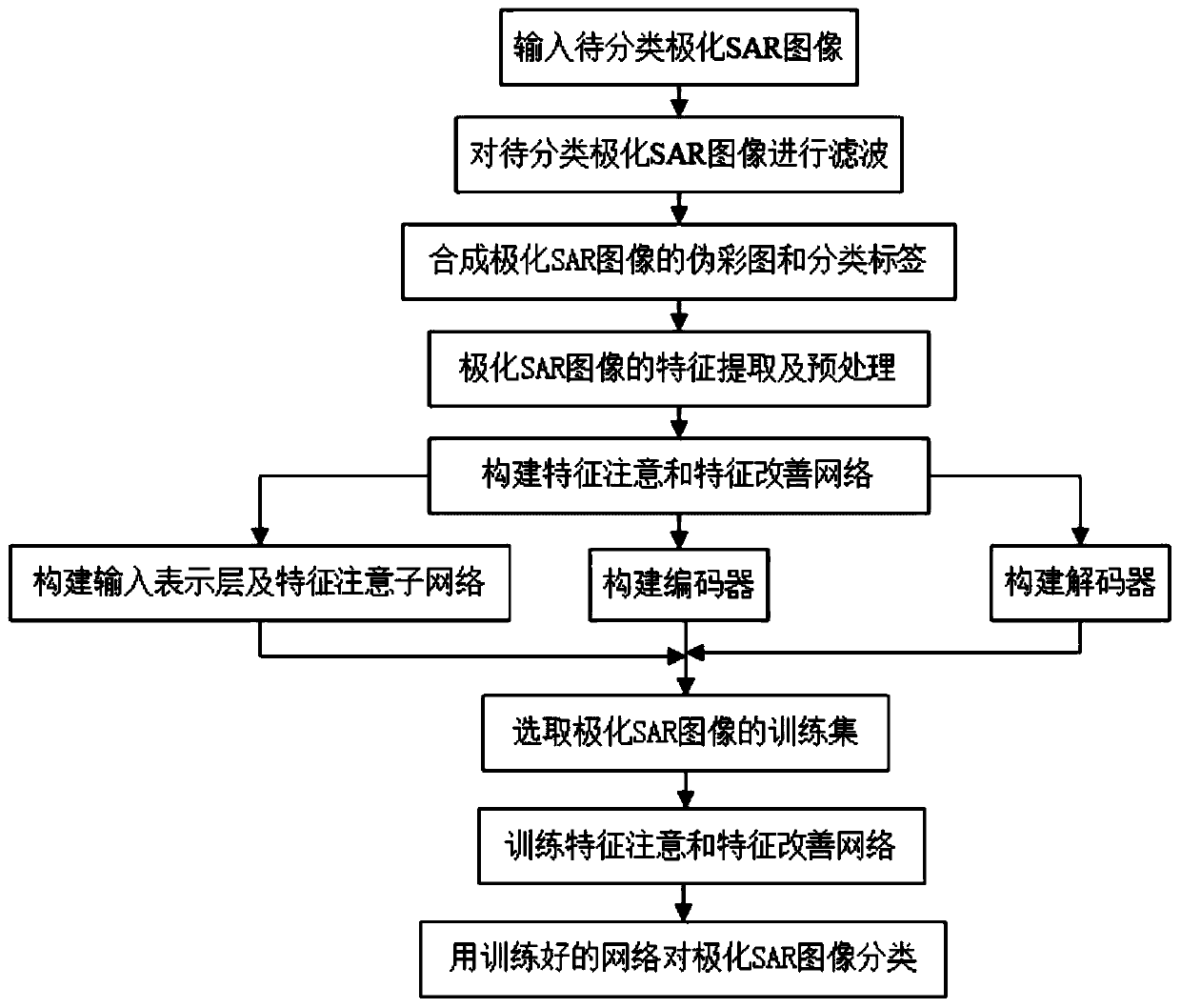

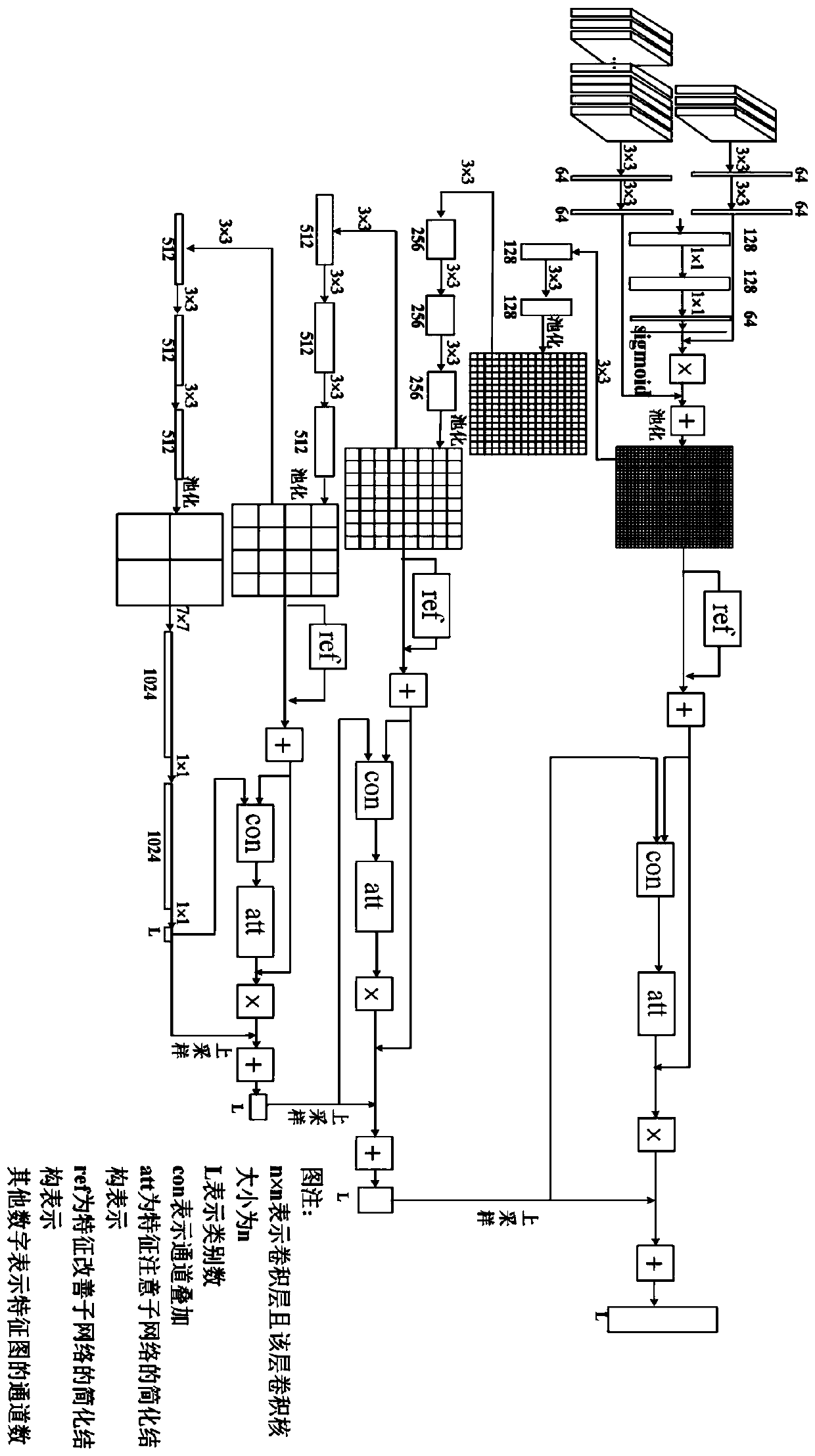

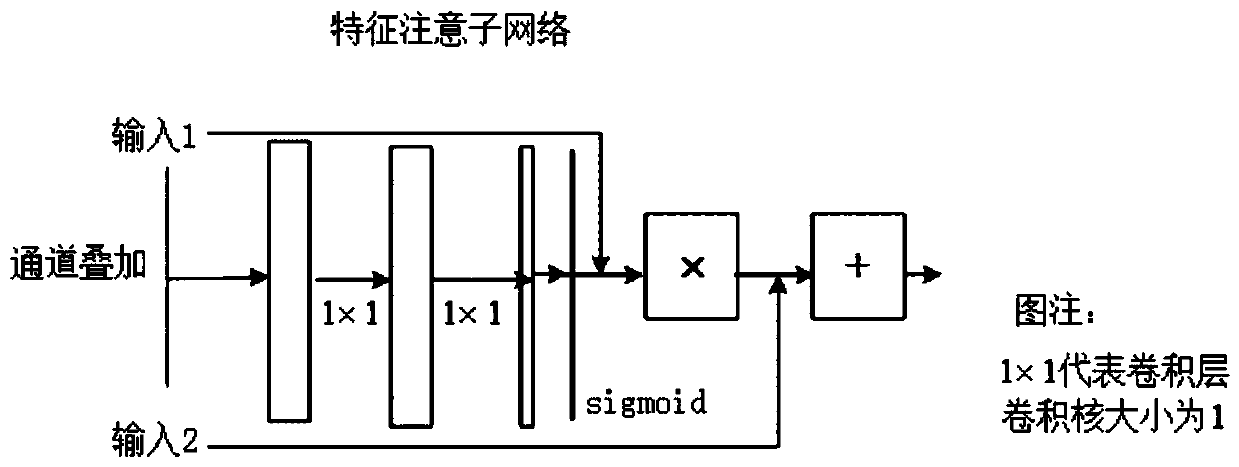

Polarimetric SAR image classification method based on feature attention and feature improvement network

ActiveCN110020693AImprove classification accuracyImprove consistencyCharacter and pattern recognitionImage analysisClassification methodsClassification result

Owner:XIDIAN UNIV

Micromechanical structure driving amplitude correction system and method

ActiveCN111780736ACorrecting electrical measurement errorsImprove consistencyMechanical oscillations controlTurn-sensitive devicesAmplitude correctionCapacitance

Owner:SENODIA TECH (SHANGHAI) CO LTD

Unmanned aerial vehicle automatic patrolling method for direct current single-circuit tension tower

InactiveCN109460054AImprove securityImprove consistencyPosition/course control in three dimensionsApparatus for overhead lines/cablesCrucial pointFlight direction

The invention discloses an unmanned aerial vehicle automatic patrolling method for a direct current single-circuit tension tower. The method comprises the steps that S1, key patrolling points of the direct current single-circuit tension tower are determined; S2, shooting key points and flight path key points in the patrolling process are selected, and a patrolling flight route is set; S3, manual patrolling is conducted according to the set patrolling flight route, and in the patrolling process, coordinates of the flight path key points, coordinates of the shooting key points and angles of thehead of an unmanned aerial vehicle and a cloud deck at the shooting key points are collected; S4, according to the data collected in the manual patrolling process, an automatic flight task and an automatic shooting task of the unmanned aerial vehicle are generated; S5, the generated patrolling tasks are uploaded to the unmanned aerial vehicle, the unmanned aerial vehicle is controlled to automatically fly completely according to the tasks, when the unmanned aerial vehicle arrives at the shooting key points, the flight direction of the head of the unmanned aerial vehicle and the angle of the cloud deck are automatically adjusted, after in-place adjustment, a camera is trigged to shoot, and the unmanned aerial vehicle returns to the taking off point until all the tasks are completed. The method effectively solves the problems that manual patrolling for the direct current single-circuit tension tower is large in stress, low in safety and not high in efficiency.

Owner:CHENGDU YOUAIWEI INTELLIGENT TECH CO LTD +1

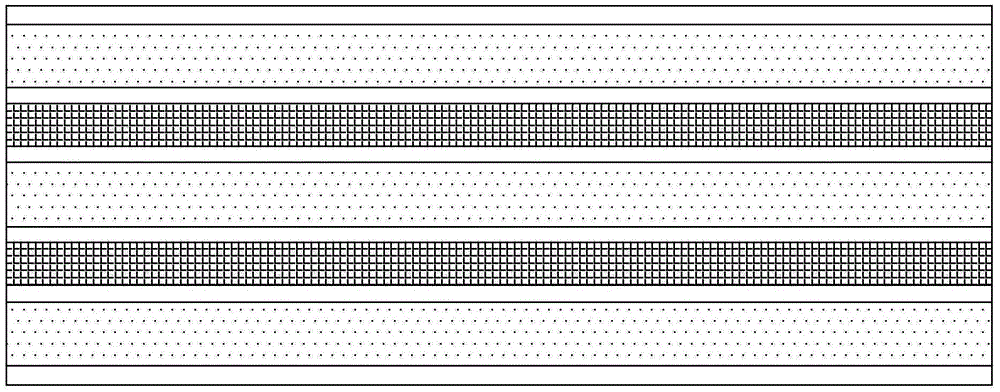

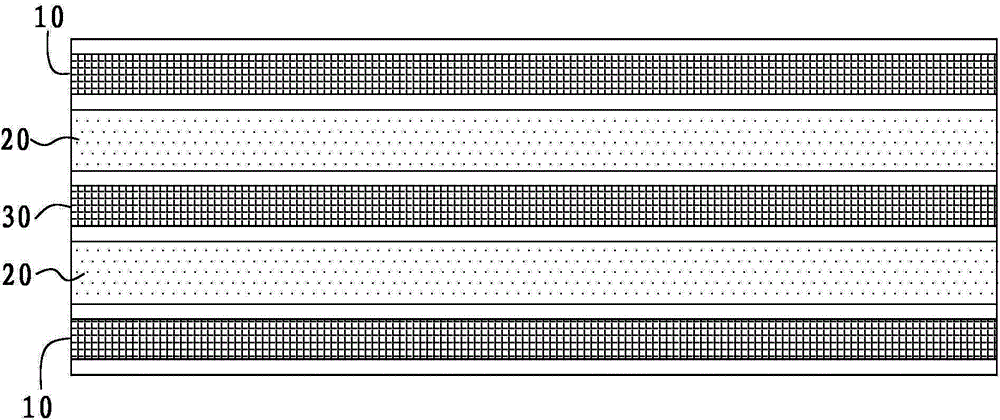

Printed circuit board and preparation method thereof

InactiveCN104159392ASmall expansion and contractionUniform media thicknessPrinted circuit detailsMultilayer circuit manufactureCopper foilElectrical impedance

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for adjusting inclination angle of light beams and illumination device for adjusting inclination angle of light beams

InactiveCN108107050AEasy to operateImprove consistencyOptically investigating flaws/contaminationCollimated lightField of view

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Miniature microphone and manufacturing method of miniature microphone

InactiveCN111770423AHigh sensitivityImprove yieldMicrophonesSemiconductor electrostatic transducersParasitic capacitorEngineering

The invention discloses a miniature microphone and a manufacturing method of the miniature microphone. The miniature microphone comprises a substrate which comprises a first cavity; a first sacrificial layer which is located on the substrate, wherein the first sacrificial layer comprises a second cavity; a vibrating diaphragm layer of which at least one part is supported by the first sacrificial layer, wherein the vibrating diaphragm layer located above the second cavity forms a vibrating diaphragm; a second sacrificial layer which is located on the vibrating diaphragm layer, wherein the second sacrificial layer comprises a third cavity; a back polar plate layer which is located on the second sacrificial layer of which at least one part is supported by the second sacrificial layer, whereinthe back polar plate layer located above the third cavity forms a back polar plate, and the back polar plate comprises at least one sound hole; a first passivation layer which is located between thevibrating diaphragm layer and the back polar plate layer, wherein the first passivation layer surrounds the inner side wall of the second sacrificial layer. According to the miniature microphone provided by the embodiment of the invention, the parasitic capacitance is reduced, and the problem of adverse influence of process deviation on the device performance is solved.

Owner:HANGZHOU SILAN MULTICHIP CO LTD

All-angle luminous LED light source and preparation method thereof

ActiveCN105552199AGood aperture consistencyImprove consistencySemiconductor devicesSolid-state devicesAnodeCathode

Owner:ZHEJIANG TWINSEL ELECTRONICS TECH CO LTD

Method for correcting position of solder ball for BGA package

ActiveCN109511234AAvoid reheating and reworkImprove consistencyPrinted circuit aspectsPrinted circuit assemblingCorrection methodEngineering

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS +1

Packaging method of SMD type LED with lens

The invention relates to a packaging method of an SMD type LED with a lens. Slice arrangement is directly carried out an electroplated SMD type LED patch support; adhesive dispersing is carried out on a die bonder to fix a chip; a fixed chip support box is placed in an oven and a crystal bonding adhesive is baked, so that the fixed chip support box is solidified; and then the solidified chip support box is placed in a welding wire machine and a gold wire or an alloy wire are employed to enable a P / N junction of the chip to be bonded with the support; and the bonded support is directly discharged into a moulding die with a lens and a press machine is utilized to inject a silicon resin or a silica gel into the moulding die, so that one-time injection moulding of an SMD type LED with a lens is completed. According to the packaging method of the SMD type LED with a lens in the invention, an injection method is utilized to produce the SMD type LED with a lens; and the output is high and the consistency is high; besides, the LED has high surface smooth finish and is free of air bubbles; a bonding force between materials is good; and injection and moulding can be completed once.

Owner:HUBEI KUANGTONG ELECTRONICS

Embedded software interface design method with shared memory

InactiveCN106484386AImprove consistencyImprove work efficiencySpecific program execution arrangementsApplication layerComputer control

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Tank body pressure intensity distribution test method and tank body internal pressure intensity test device of tank truck

InactiveCN111076857AImprove accuracyImprove securityFluid pressure measurementClassical mechanicsTank truck

The invention relates to the technical field of special vehicles and particularly provides a tank pressure distribution test method and a tank internal pressure test device for a tank truck. The testmethod comprises the following steps: (1) setting a sampling area in a tank body, fixing pressure sensing devices for acquiring pressure data in the sampling area, and setting a data acquisition device in signal connection with the pressure sensing devices to acquire the pressure data; and (2) injecting liquid into the tank body to enable each pressure sensing device to be immersed into the liquid, starting the tank truck to drive the tank body to move, and obtaining and processing test data. The pressure distribution at an end socket is obtained in a real test environment, the accuracy of test data can be improved, technicians are helped to master the pressure intensity distribution in the tank body when the vehicle runs, effective data support is provided for the structural design of thetank body in the future, and great help is provided for improving the safety of the whole vehicle.

Owner:ZHENGZHOU YUTONG HEAVY IND

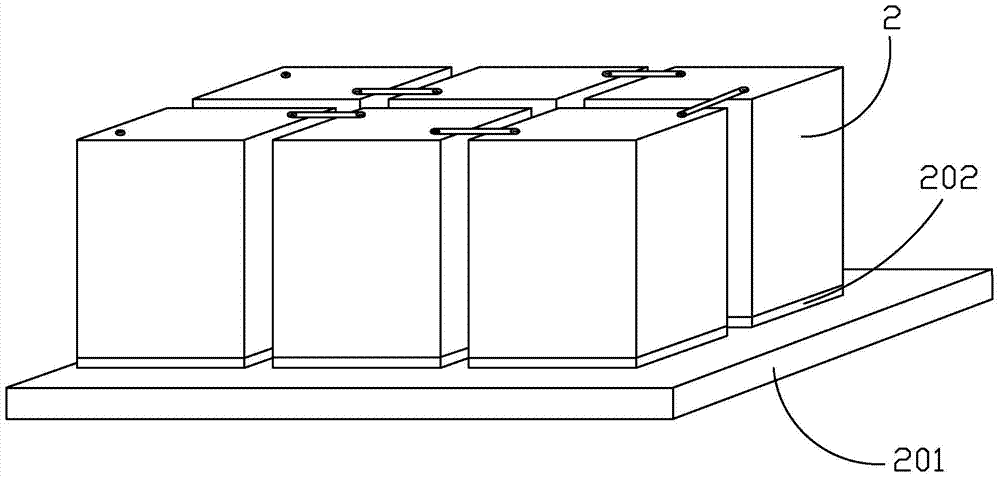

Battery module

PendingCN109980145AStable structureImprove cooling and heating effectSecondary cellsCell component detailsElectrical batteryHeat conducting

The invention provides a battery module. The battery module comprises a plurality of battery units arranged side by side, two end plates respectively butted against two ends of the battery units and two side plates butted against two sides of the battery units. Each side plate comprises a substrate and a plurality of heat conducting plates vertically connected to the surface of one side of the substrate, wherein the substrate is internally provided with a heat conducting pipe, the heat conducting plates are arranged at intervals, and each heat conducting plate is clamped between each two adjacent battery units. The battery module provided by the invention has the advantages of the stable structure, the good battery temperature consistency and the good heating and refrigerating effect.

Owner:HUZHOU XINYUAN BATTERY SYST TECH CO LTD

Automatic charging and discharging equilibrium device for battery pack

InactiveCN103647327AExtended service lifeImprove consistencyBatteries circuit arrangementsElectric powerBattery packCharge and discharge

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Thermal correction method of titanium alloy special-shaped tubular casting

ActiveCN108620452AAvoid secondary crackingImprove efficiencyShaping toolsTitanium alloyMachine press

The invention aims to solve the problems that the temperature of a traditional gas flame correcting and heating process is not uniform, secondary cracking is easily generated, the efficiency is low are solved, an induction heating mode is adopted, a special-shaped movable induction coil is designed according to the section shape of a titanium alloy special-shaped tubular casting, the heating rateand the heating temperature are controlled, the integral heating is carried out on the local part of the casting, and the secondary cracking tendency caused by heat concentration is prevented. A tool,a clamp and a mold are designed, and a deformation part is subjected to plastic deformation through a hydraulic press, so that the casting is corrected. The method is suitable for the thermal state correction of the titanium alloy tubular casting with the wall thickness less than or equal to 20 mm, and the heat correcting efficiency of the casting is greatly improved.

Owner:SHENYANG RES INST OF FOUNDRY

Automatic curved surface coating apparatus

InactiveCN102424162ASufficient athletic abilityAccurate cloaking actionLabelling machinesManipulatorComputer control

The invention belongs to the technical field of curved surface coating, and especially relates to an automatic curved surface coating apparatus which can automatically complete a curved surface coating process. The automatic curved surface coating apparatus comprises a material conveying device and a film paper conveying device which are mounted on a frame; the material conveying device comprises a manipulator for clamping a material, and a manipulator motion mechanism for driving the motion of the manipulator; the film paper conveying device comprises a film paper frame for fixing the film paper, and a film paper horizontal motion mechanism for driving the motion of the film paper; a position measuring device is disposed on the motion tracks of the material conveying device and the film paper conveying device, and is fixed on the frame; the film paper conveying device is disposed in a water tank; the material conveying device, the film paper conveying device, and the measuring device are connected with a computer control device, and are controlled by the computer control device; an activator spraying device is disposed on the frame. The invention provides a curved surface coating apparatus which can perform material curved surface coating in an automatic production mode.

Owner:赖万明

Light source mode measuring instrument

ActiveCN111337126AScience of Evaluation CompetencePersuasivePhotometry using electric radiation detectorsPhotovoltaic detectorsEngineering

The invention discloses a light source mode measuring instrument. The light source mode measuring instrument comprises a light source adapter (601), a beam expanding concave lens (5), an inner lens cone (603), an annular mode selection mirror (21), a guide rail (605), a photoelectric detector PD (3), transmission plate glass (607), a holophote (4), an outer lens cone (609), a battery bin and circuit assembly (610) and an angle ruler (611). The annular mode selection mirror and the photoelectric detector (PD) (3) can move towards the same direction, and in the moving process, light of multiplemodes emitted by the multimode light source is different in emergent angle corresponding to different modes and finally can be sequentially reflected to the photoelectric detector (PD) (3). That is tosay, the power of the multimode light source in all propagation modes can be sequentially collected and recorded by the photoelectric detector (PD) (3), and all light propagation modes of the light source can be measured by corresponding to the emergent angle shown by the angle scale on the outer lens cone. The measuring instrument is simple in structure, accurate in measurement and low in cost.

Owner:ANHUI UNIV

Injection hole structure capable of improving thermal shock test of square lithium ion battery

PendingCN106410070AGood sealing effectStable structureSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsThermal shockLithium electrode

The invention discloses an injection hole structure capable of improving a thermal shock test of a square lithium ion battery. An injection hole in a cover plate of the battery is sealed by using an LDPE high polymer material, so that the injection hole in the battery is in a closed state at low temperature, and a good sealing effect can be achieved; the injection hole is in an open state at high temperature, gas and heat inside the battery outflow from the injection hole, and the phenomenon of short circuit of the battery is inhibited. According to the injection hole structure, the sealing property of the injection hole can be guaranteed, liquid leakage of the battery is avoided, the problems, such as battery fire and explosion, caused by thermal abuse, of the battery are also solved, the using performance and safety performance of the battery are effectively guaranteed, and the injection hole structure has great production practical significance.

Owner:SINOWATT DONGGUAN

Assembling and welding fixture for forklift overhead guard

ActiveCN107825047AImprove quality and efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an assembling and welding fixture for a forklift overhead guard. The assembling and welding fixture comprises a base, a front support positioning device used for positioning the front support of the overhead guard, a rear support positioning device used for positioning the rear support assembly of the overhead guard and a top frame positioning device used for positioning the top frame assembly of the overhead guard, and the front support positioning device, the rear support positioning device and the top frame positioning device are all arranged on the base. By adoptingthe assembling and welding fixture for the forklift overhead guard, accumulated error caused by multiple times of assembling and welding can be effectively reduced; product quality and production efficiency of the overhead guard are improved; the homogeneity of welded products is good; and production cost is lowered.

Owner:WUHU RUICHUANG FORKELEVATOR

Coreless bottom line winding and shaping automatic all-in-one machine and method thereof

Owner:DONGYANG TAIJI PRECISION MFG

Production method of large-NA (large numerical aperture) aspherical cylindrical lens

The invention discloses a production method of a large-NA (large numerical aperture) aspherical cylindrical lens; the production method comprises the steps of placing, in a clean environment, a glass preform in a high-precision smooth metal film which is made of copper and is 10-14 mm in thickness and 20-10 in surface gloss; dropping ultraviolet glue the same as the glass preform in refractive index into a gap between the glass preform and the metal film; applying, by piezoelectric ceramic, positive pressure to the outer surface of the metal film so that the metal film, the glass preform and the ultraviolet glue are in full contact, and performing ultraviolet curing by ultraviolet or low temperature heating. The production method has the advantage of good simplicity.

Owner:CHANGSHA QINGBO PHOTOELECTRIC TECH CO LTD

Efficient grinding method for waterproof sealing strip

ActiveCN111993242AImprove grinding efficiencyIncrease contact areaGrinding drivesGrinding machinesElectric machineEngineering

The invention provides an efficient grinding method for a waterproof sealing strip, and belongs to the technical field of rubber product processing. A corresponding positioning screw is selected according to the size of the waterproof sealing strip. The depth of a first guide groove in the positioning screw is required to be less than the thickness of the waterproof sealing strip. Outward pullingis conducted from the end portion of the waterproof seal strip wound around a discharge wheel. Winding is conducted on a discharge screw along a second guide groove by a plurality of rings, then penetrating into a first guide groove is conducted from one end of the positioning screw, then traction onto a winding wheel is conducted from the other end of the first guide groove, a grinding wheel abuts against the waterproof sealing strip on the middle section of the first guide groove, a driving motor, a winding motor and an air pumping motor are started, the discharge screw and the grinding wheel rotate synchronously, the positioning screw is static, the waterproof sealing strip slides in the first guide groove relative to the positioning screw at a uniform speed, and all portions of all waterproof sealing strips wound on the discharge wheel are caused to be sequentially subjected to rough grinding, fine grinding and polishing. The efficient grinding method has the advantages of being capable of continuously performing high-efficiency grinding on the single side of the waterproof sealing strips and the like.

Owner:HUBEI UNIV OF SCI & TECH

Stainless steel part grinding tool for numerical control flat grinder

PendingCN111195842AQuality improvementImprove efficiencyGrinding machinesGrinding work supportsNumerical controlMachine parts

The invention relates to a stainless steel part grinding tool for a numerical control flat grinder. The stainless steel part grinding tool for the numerical control flat grinder comprises a magnetizedbottom plate closely fixed to a flat magnetic disc of the numerical control flat grinder, two supporting plates fixed to the two ends of the magnetized bottom plate respectively and a top plate whichis horizontally fixed to the top ends of the two supporting plates and provided with a horizontal working face, and the horizontal working face is used for fastening and containing a to-be-machined part. Compared with the prior art, the stainless steel part grinding tool for the numerical control flat grinder has the advantages that the flat machining precision of workpieces is high, the servicelife is long, the structure is simple, operation is convenient, the quality is stable and reliable, and the economical efficiency is good.

Owner:TIANZHONG METAL PROCESSING SHANGHAI CO LTD

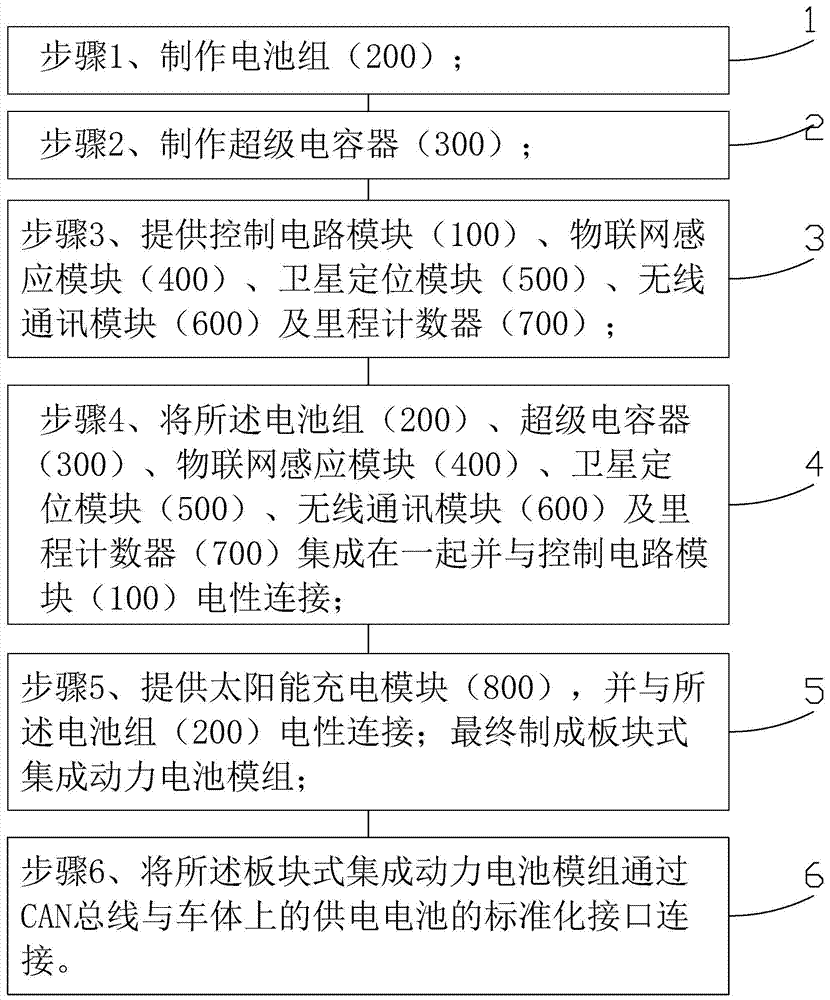

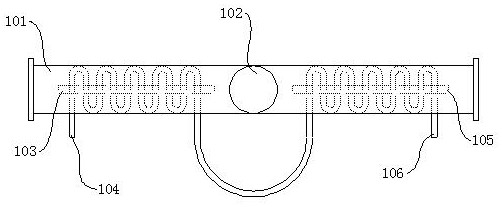

Manufacturing method of plate type integrated power battery module

ActiveCN104377380BImprove consistencyHighly integratedBatteries circuit arrangementsFinal product manufactureSatelliteInternet of Things

Owner:SHENZHEN HONGYUAN BODE NEW ENERGY TECH DEV

Electro-pneumatic brake control device and brake control system

PendingCN110949350AImprove consistencyImprove operability and application securityAerodynamic brakesBraking action transmissionAutomotive engineeringBrake control

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

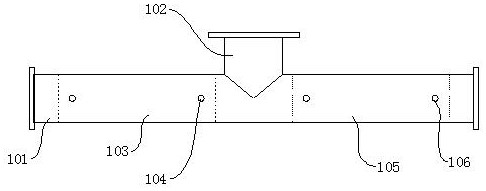

High-temperature flue gas heat energy recovery system

PendingCN113654379AEasy to separateIncrease surface areaHeat exchanger casingsStationary tubular conduit assembliesCold mediumEngineering

The invention discloses a high-temperature flue gas heat energy recovery system. The high-temperature flue gas heat energy recovery system comprises a gas inlet pipe and a gas outlet pipe, one end of the gas outlet pipe is fixedly connected with a position between the two ends of the gas inlet pipe, the gas outlet pipe communicates with the gas inlet pipe, a first partition plate is fixedly connected to the interior of the gas inlet pipe, the first partition plate is fixedly connected with a first heat exchange pipe, and the first heat exchange pipe is arranged in a snakelike mode along the central axis of the air inlet pipe. A cold medium is input into an inlet of the first heat exchange pipe, a hot medium is output from an outlet of the first heat exchange pipe, the cold medium becomes a hot medium after absorbing heat and is discharged from the outlet of the first heat exchange pipe, the outlet of the first heat exchange pipe is connected with a cleaning pool, water in the cleaning pool circularly flows through the first heat exchange pipe and absorbs the heat of high-temperature flue gas, recovery is carried out on the heat energy in the high-temperature flue gas, after the water in the cleaning pool is heated, sundries and oil stains adhered to the surface of a workpiece can be separated from the workpiece more quickly, and therefore the cleaning effect and the cleaning efficiency are improved.

Owner:宁波晟光金属制品有限公司

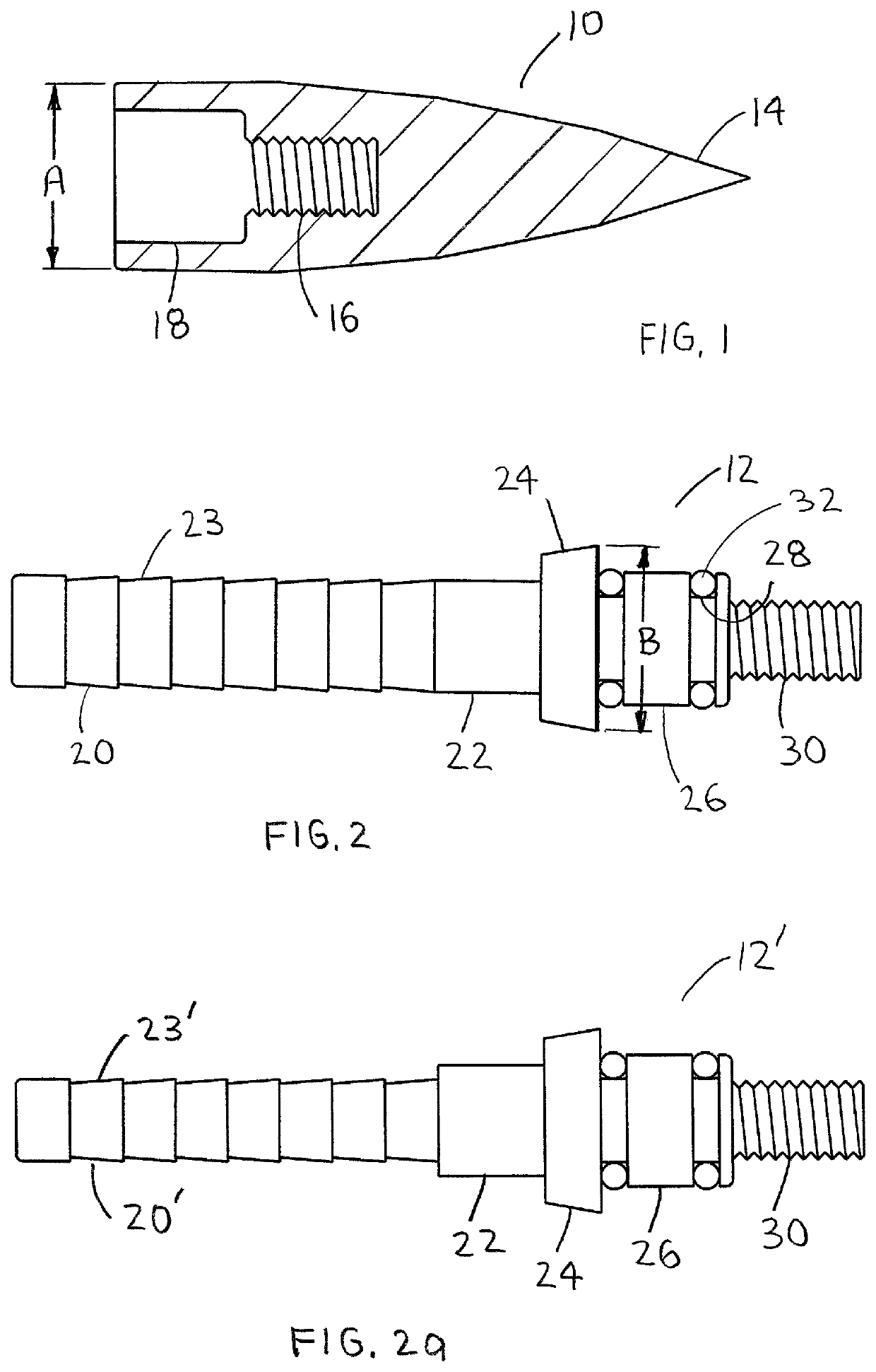

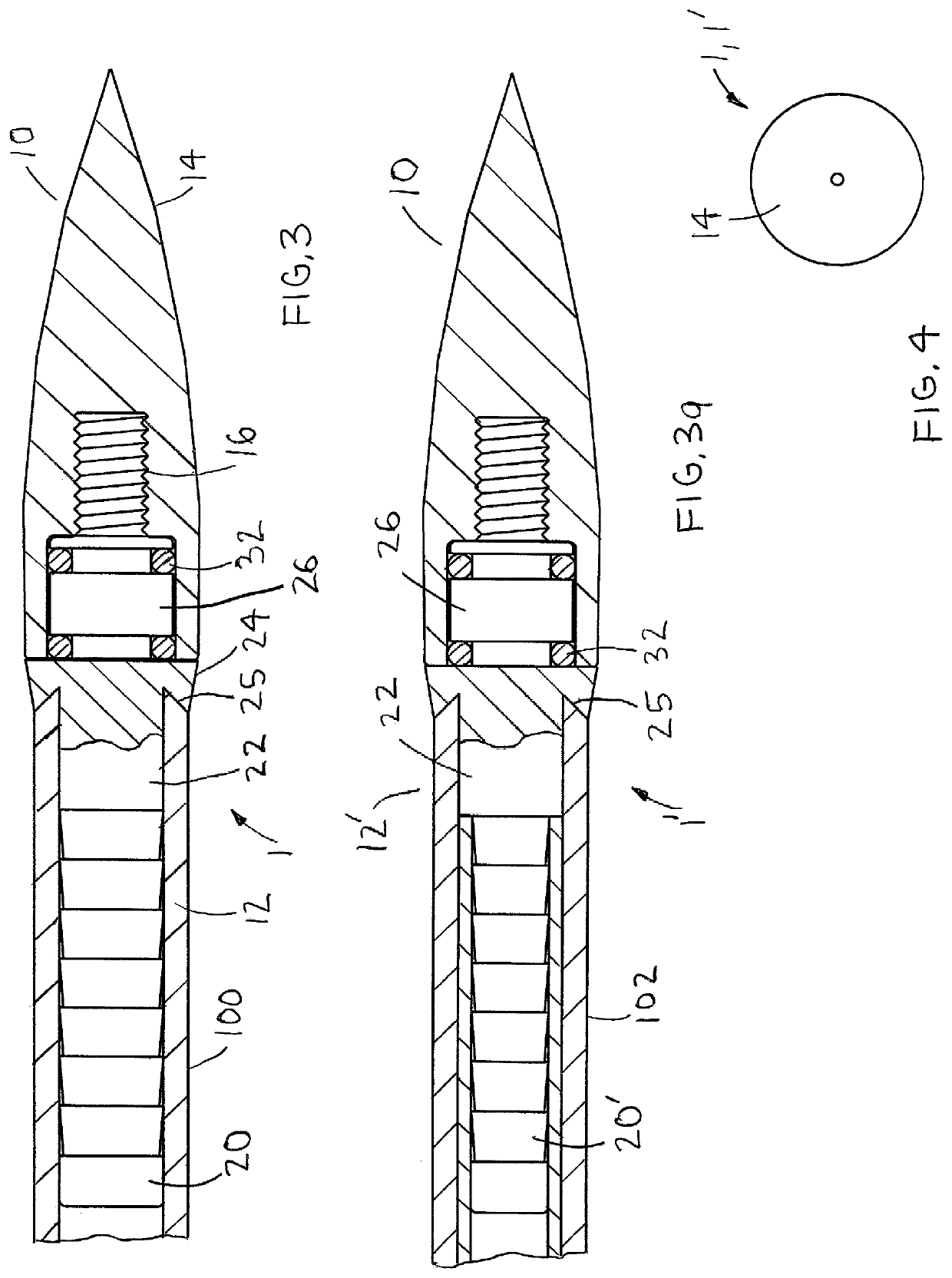

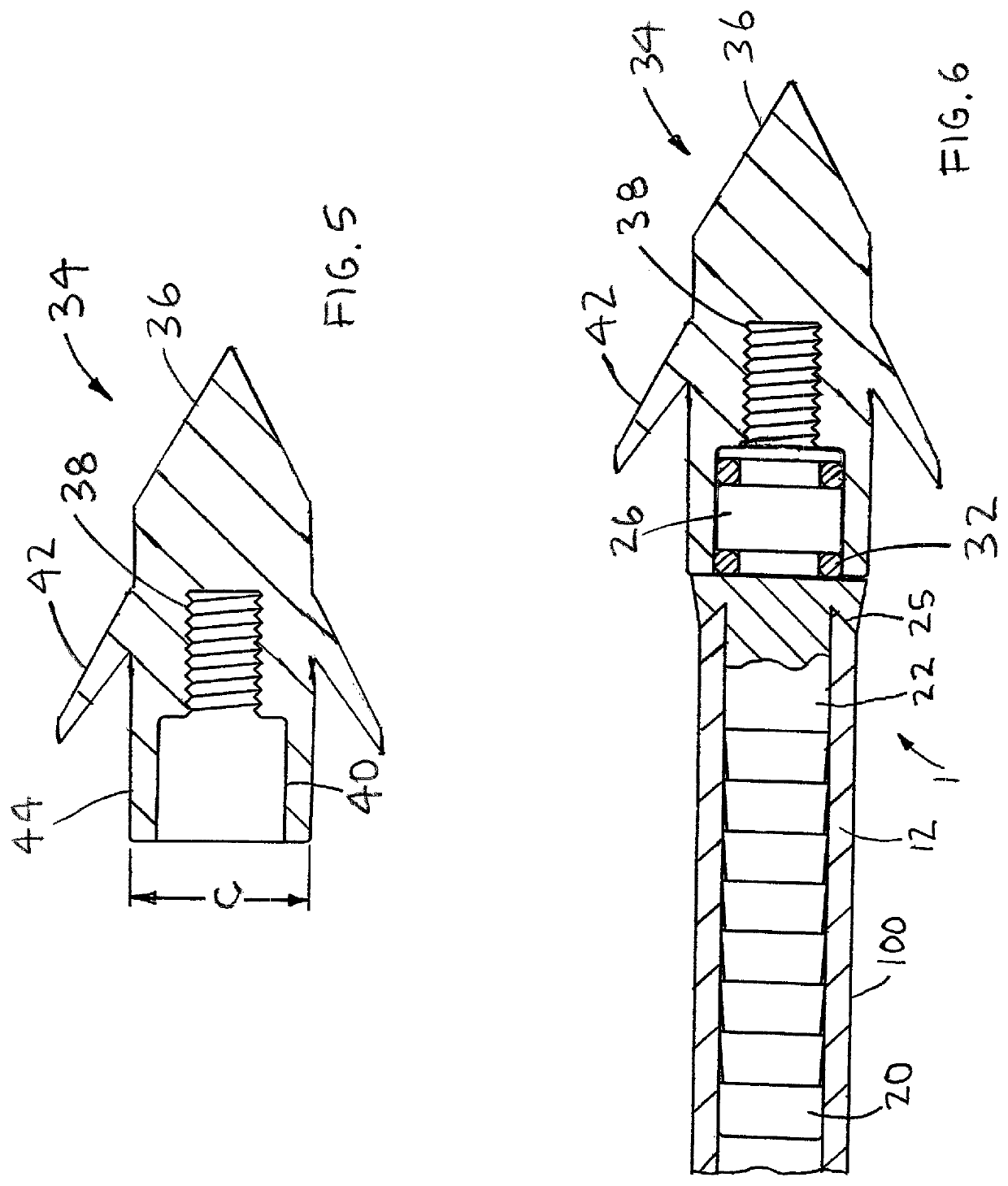

Arrow insert with threaded stem for retaining an arrow tip

Owner:HUANG DORGE O

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap