Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Cold medium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

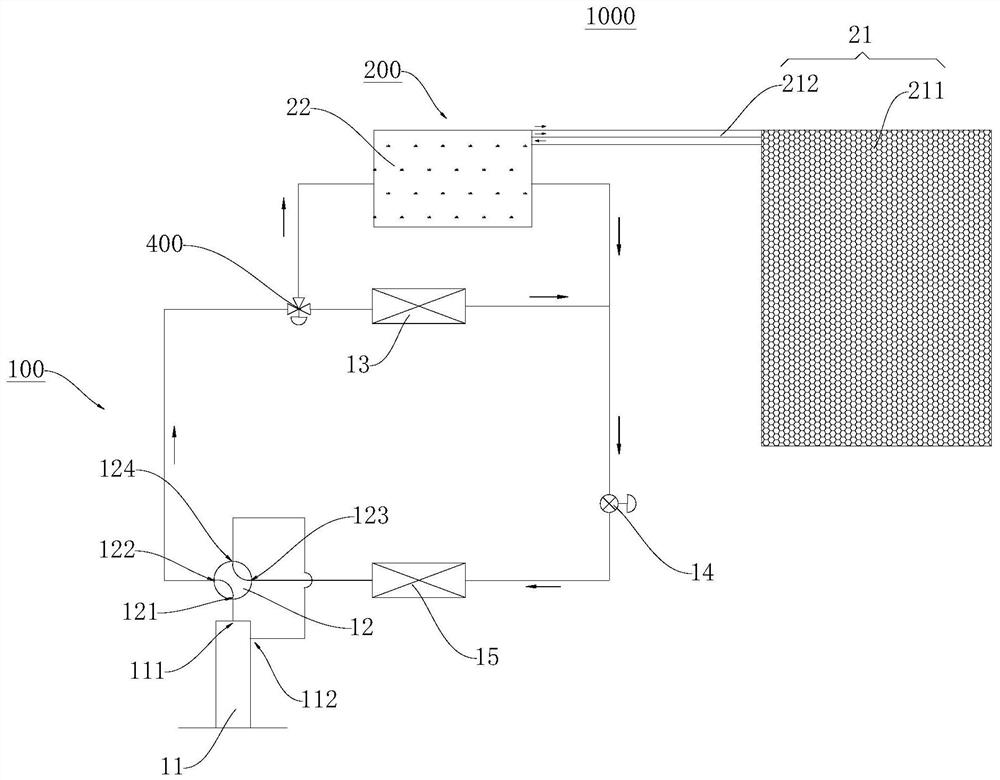

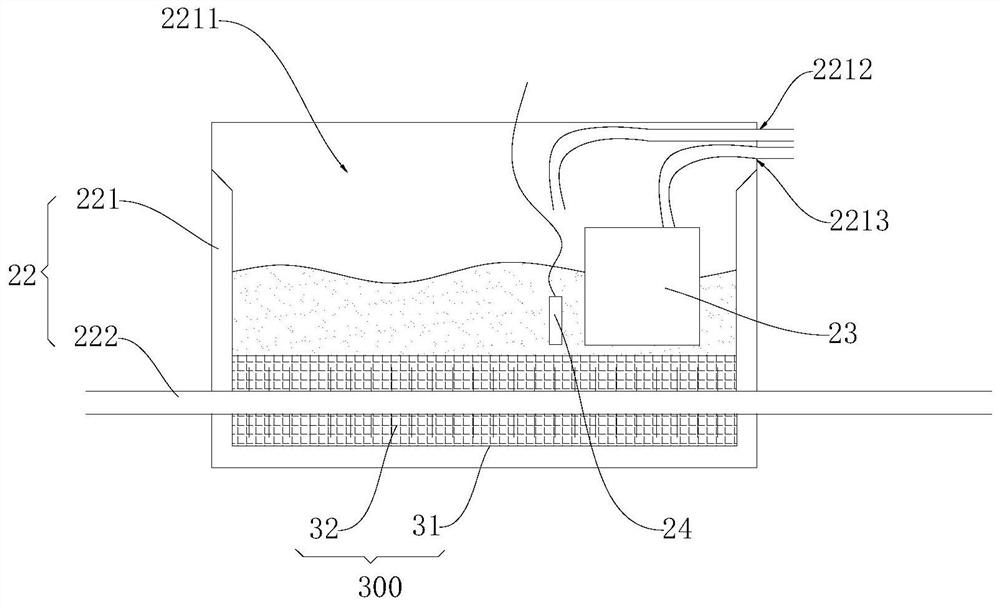

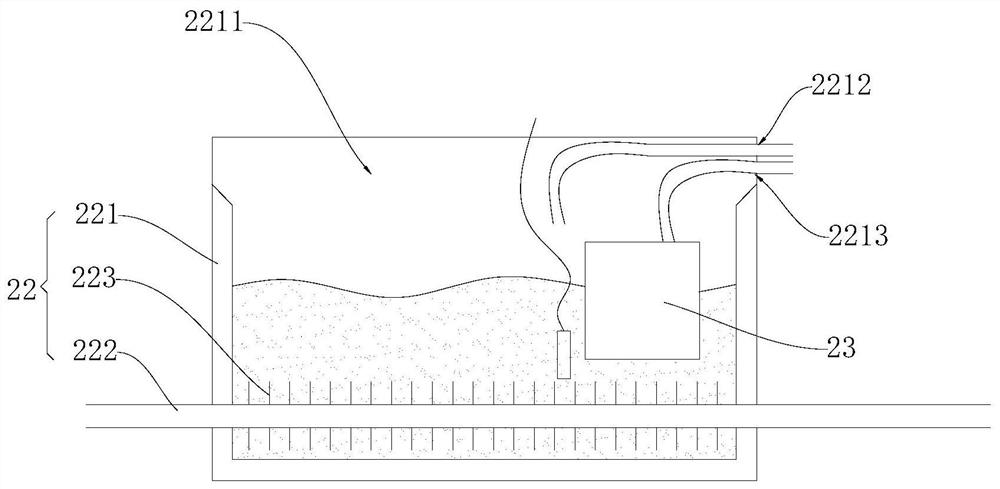

Air conditioner heat exchange pad system

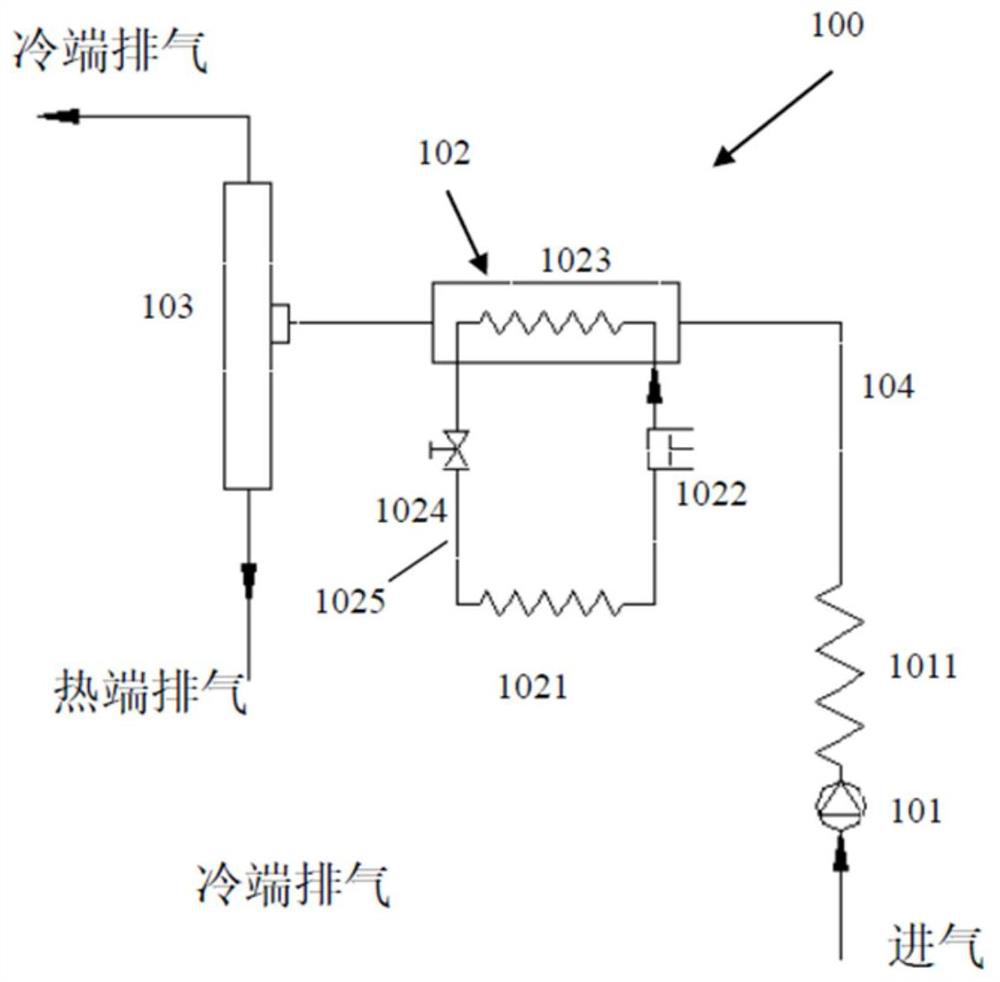

InactiveCN111692682AChange temperatureImprove comfort experienceFluid circulation arrangementAir conditioning systemsThermodynamicsRefrigerant

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

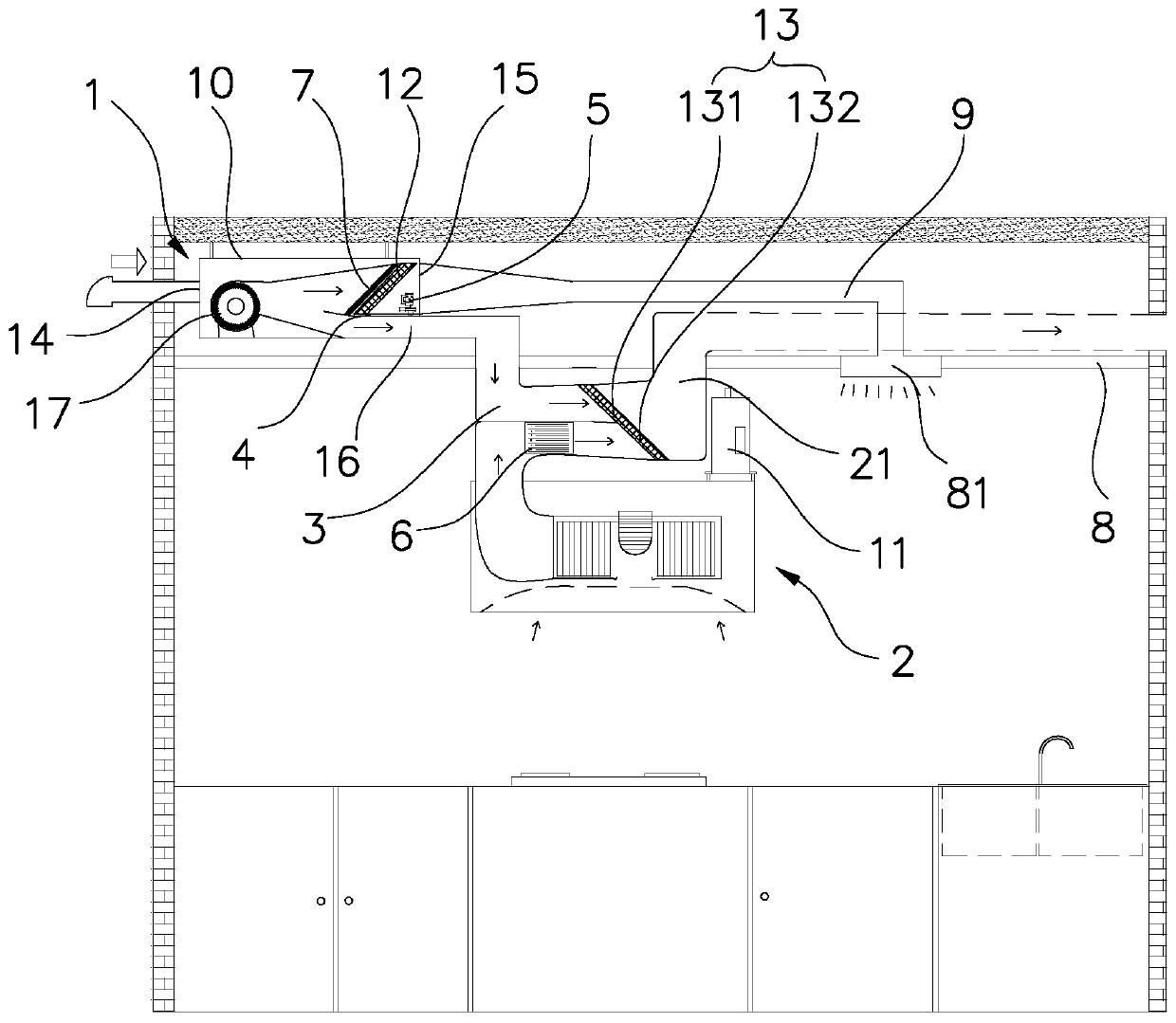

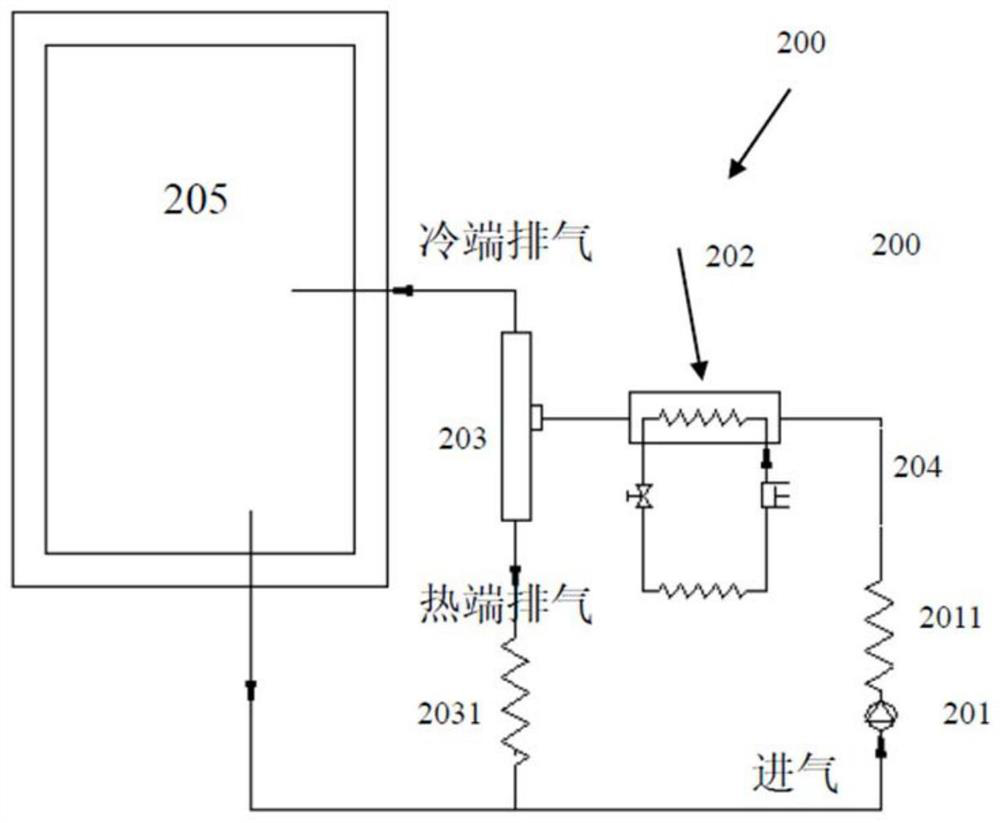

Kitchen air adjusting system

PendingCN110657523AImprove energy efficiencyFlexible useDomestic stoves or rangesMechanical apparatusAir volumeEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

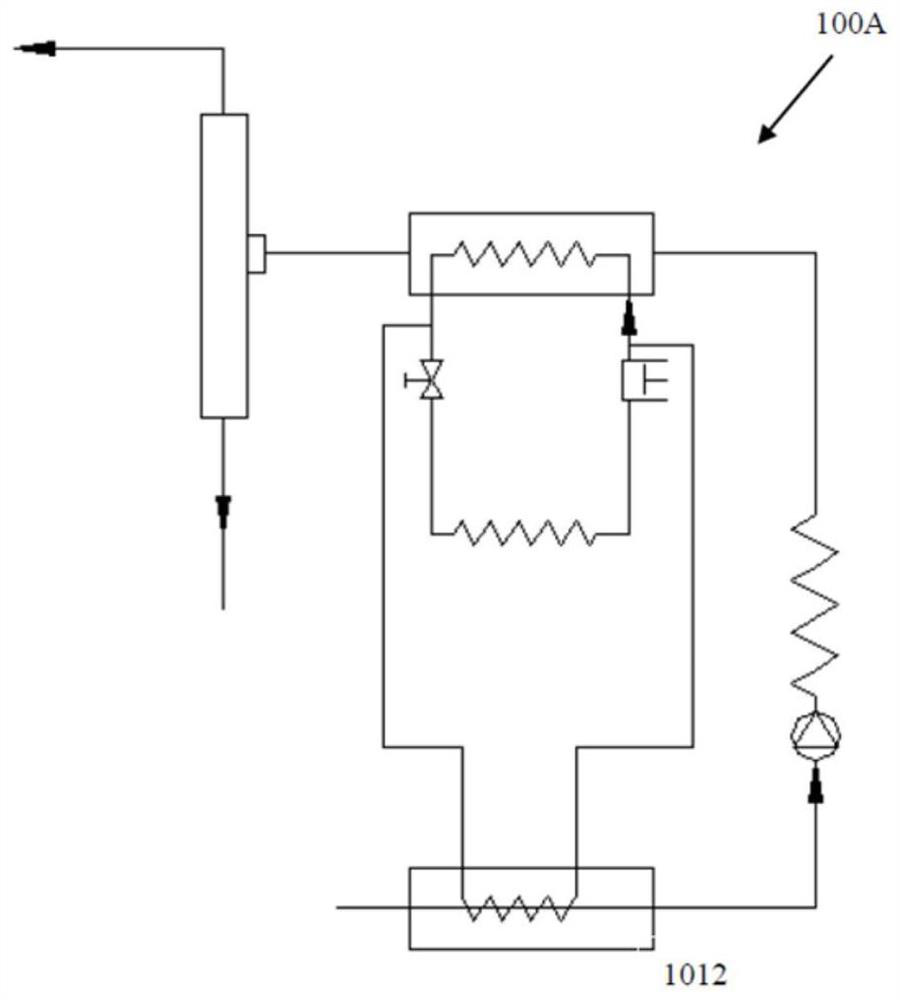

Low-temperature refrigeration method and system

Owner:湖南雅立科技开发有限公司

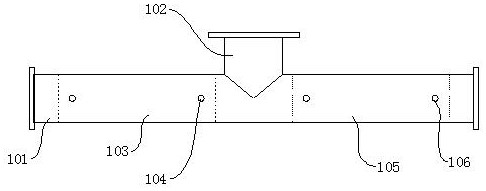

High-temperature flue gas heat energy recovery system

PendingCN113654379AEasy to separateIncrease surface areaHeat exchanger casingsStationary tubular conduit assembliesCold mediumEngineering

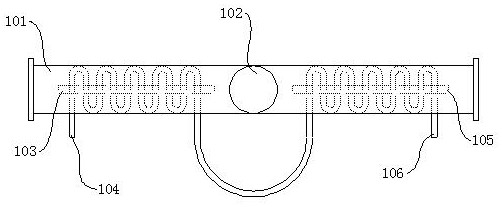

The invention discloses a high-temperature flue gas heat energy recovery system. The high-temperature flue gas heat energy recovery system comprises a gas inlet pipe and a gas outlet pipe, one end of the gas outlet pipe is fixedly connected with a position between the two ends of the gas inlet pipe, the gas outlet pipe communicates with the gas inlet pipe, a first partition plate is fixedly connected to the interior of the gas inlet pipe, the first partition plate is fixedly connected with a first heat exchange pipe, and the first heat exchange pipe is arranged in a snakelike mode along the central axis of the air inlet pipe. A cold medium is input into an inlet of the first heat exchange pipe, a hot medium is output from an outlet of the first heat exchange pipe, the cold medium becomes a hot medium after absorbing heat and is discharged from the outlet of the first heat exchange pipe, the outlet of the first heat exchange pipe is connected with a cleaning pool, water in the cleaning pool circularly flows through the first heat exchange pipe and absorbs the heat of high-temperature flue gas, recovery is carried out on the heat energy in the high-temperature flue gas, after the water in the cleaning pool is heated, sundries and oil stains adhered to the surface of a workpiece can be separated from the workpiece more quickly, and therefore the cleaning effect and the cleaning efficiency are improved.

Owner:宁波晟光金属制品有限公司

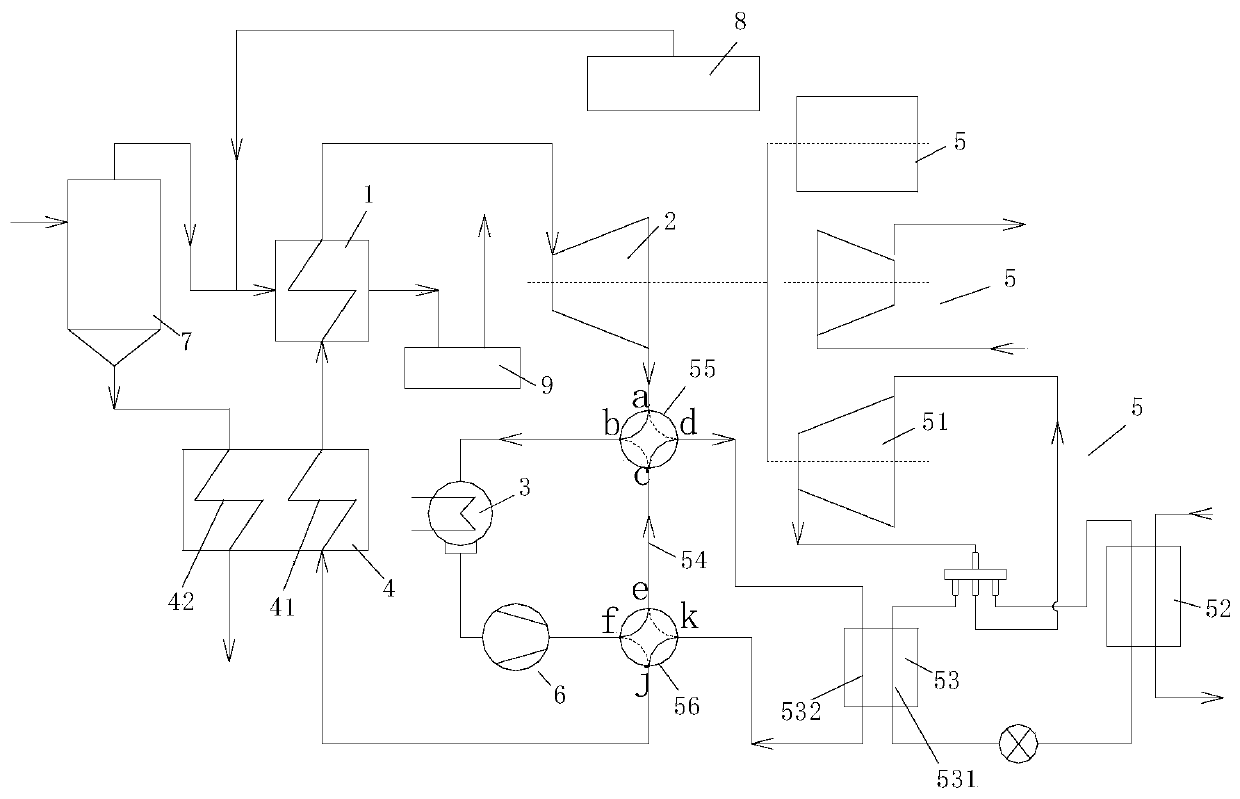

Thermal energy utilization system

Owner:GREE ELECTRIC APPLIANCES INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap