Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

641 results about "Industrial engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information, equipment, energy and materials.

Apparatuses and Methods for Managing Liquid Volume in a Container

InactiveUS20120097567A1Good for healthTable equipmentsOther accessoriesPotable waterProcess engineering

The present invention proposes an apparatus (100) and method for managing the liquid volume in a container. The apparatus (100) comprises a detector (101) for detecting liquid volume changes in said container during a first preset period, a first determiner (102) for determining whether said changes are lower than said first preset threshold value and a presenter (103) for presenting the first prompt information in the case of said changes being lower than said preset threshold value. The apparatus and method provided in the present invention can prompt people to drink drinkable liquids such as water in time, enable people to control their drinking intake and are beneficial to their health.

Owner:KONINK PHILIPS ELECTRONICS NV

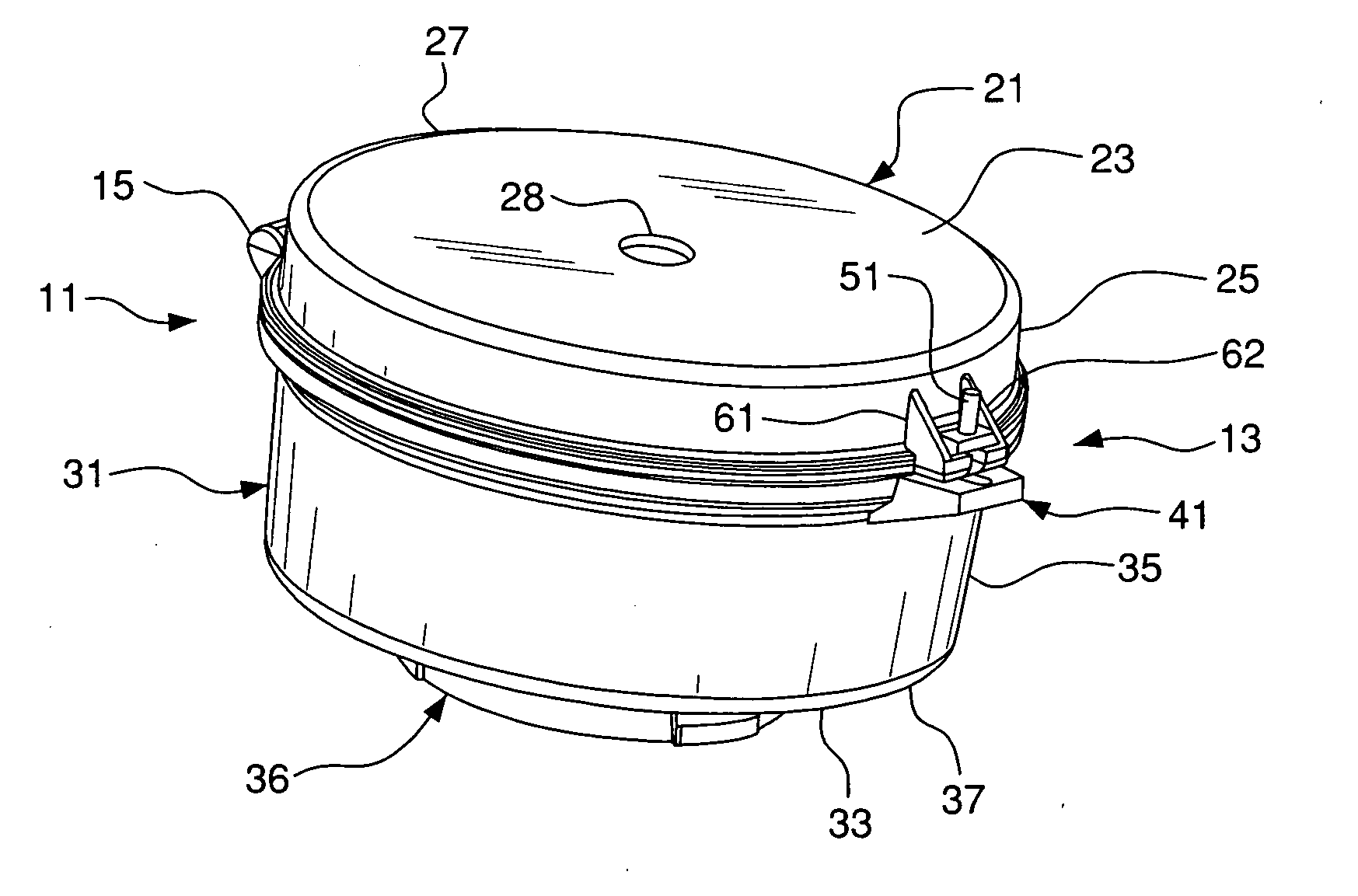

Full-period electric pressure cooker production control method

InactiveCN107713732AIncrease profitStrong targetingPressure-cookersIndustrial engineeringTechnical Guide

The invention discloses a full-period electric pressure cooker production control method. The method includes the steps that demand order data input by a customer is received, and a material ratio meeting electric pressure cooker production is automatically calculated and determined; an electric pressure cooker is produced according to the material ratio, and raw materials are weighed. In the full-period electric pressure cooker production control method, the electric pressure cooker is produced according to customer demands, the customer only needs to provide various demands such as food types and the product usage area when buying an electric pressure cooker, and then the electric pressure cooker which is needed by the customer and is suitable for food cooking and the product usage areacan be produced, which is like that an electric pressure cooker expert provides special technical guidance of electric pressure cooker production for the customer, so that the method has high pertinence to food cooking and the product usage area and is beneficial to increasing the electric pressure cooker utilization rate.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

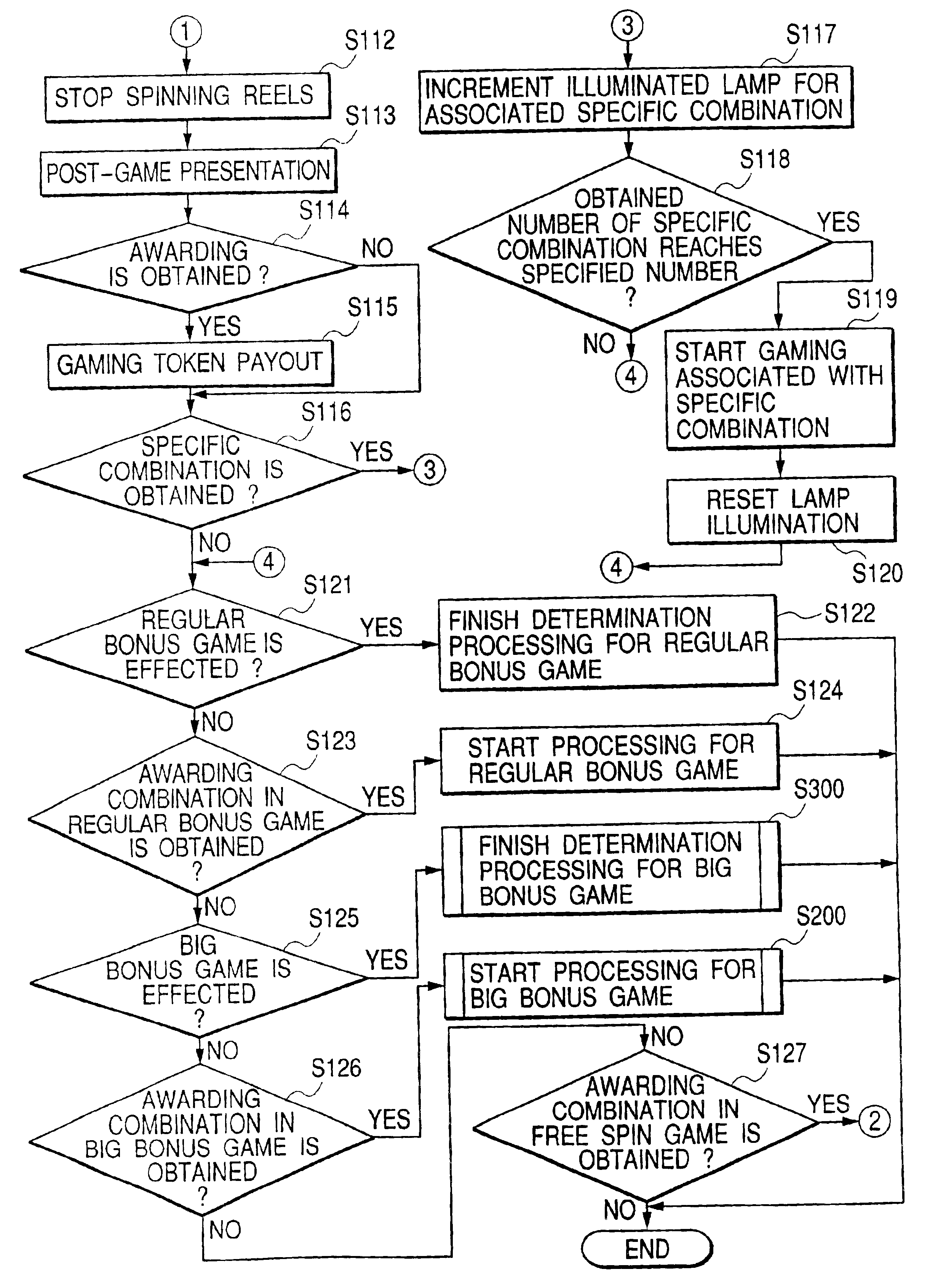

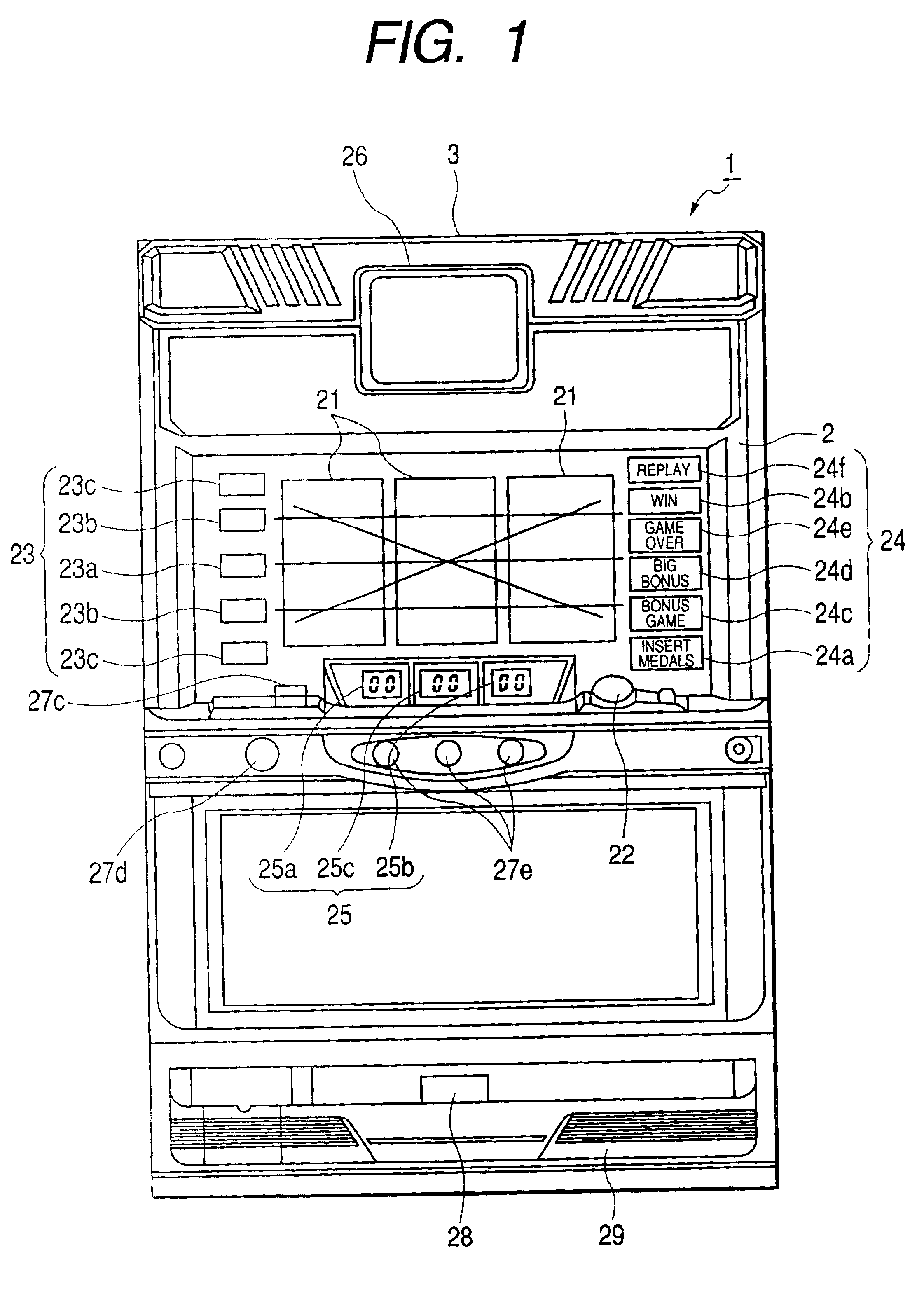

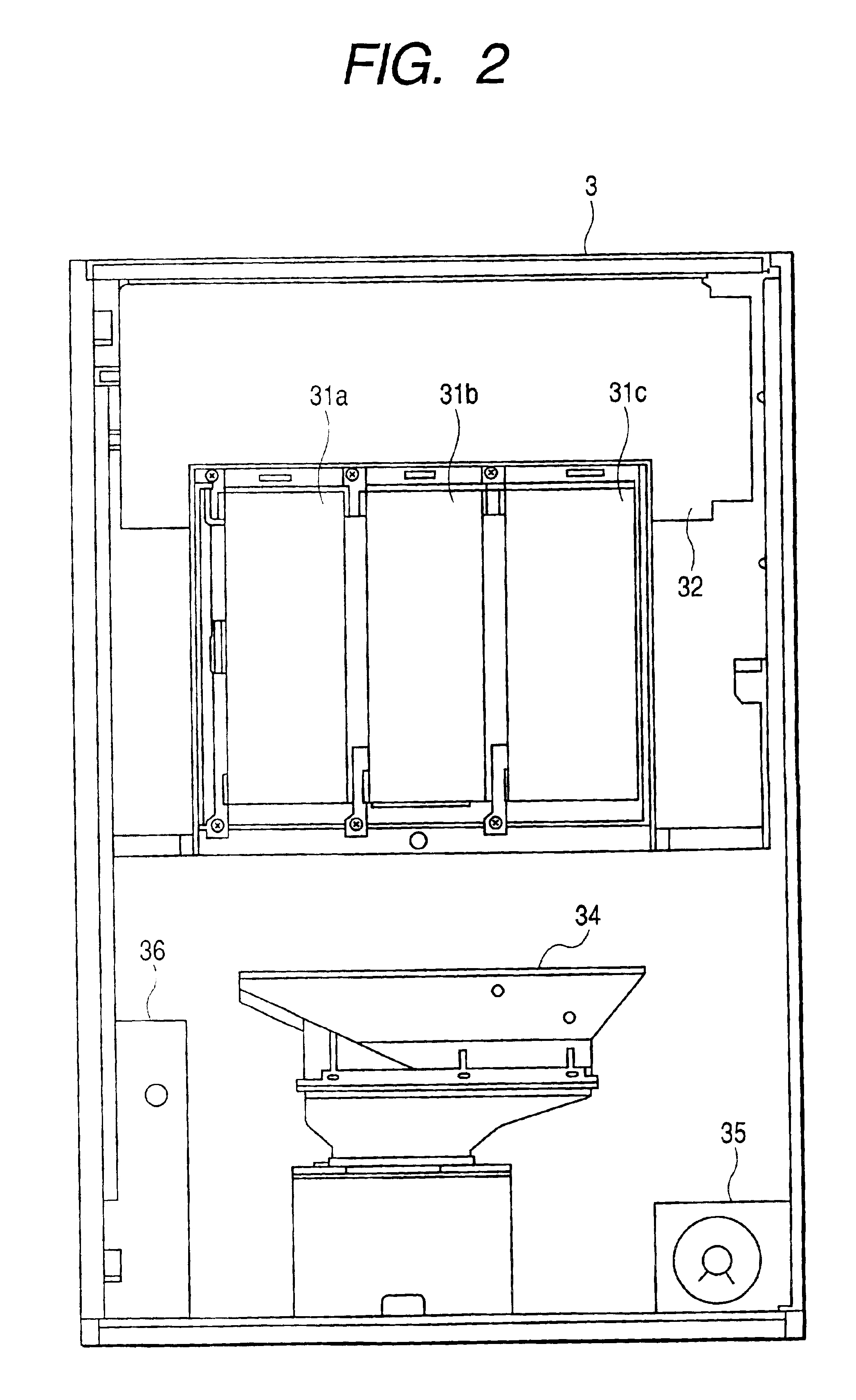

Gaming machine

InactiveUS6916243B2Enhance interestIncrease entertainmentRoulette gamesApparatus for meter-controlled dispensingAlgorithmDisplay device

Owner:KONAMI GAMING

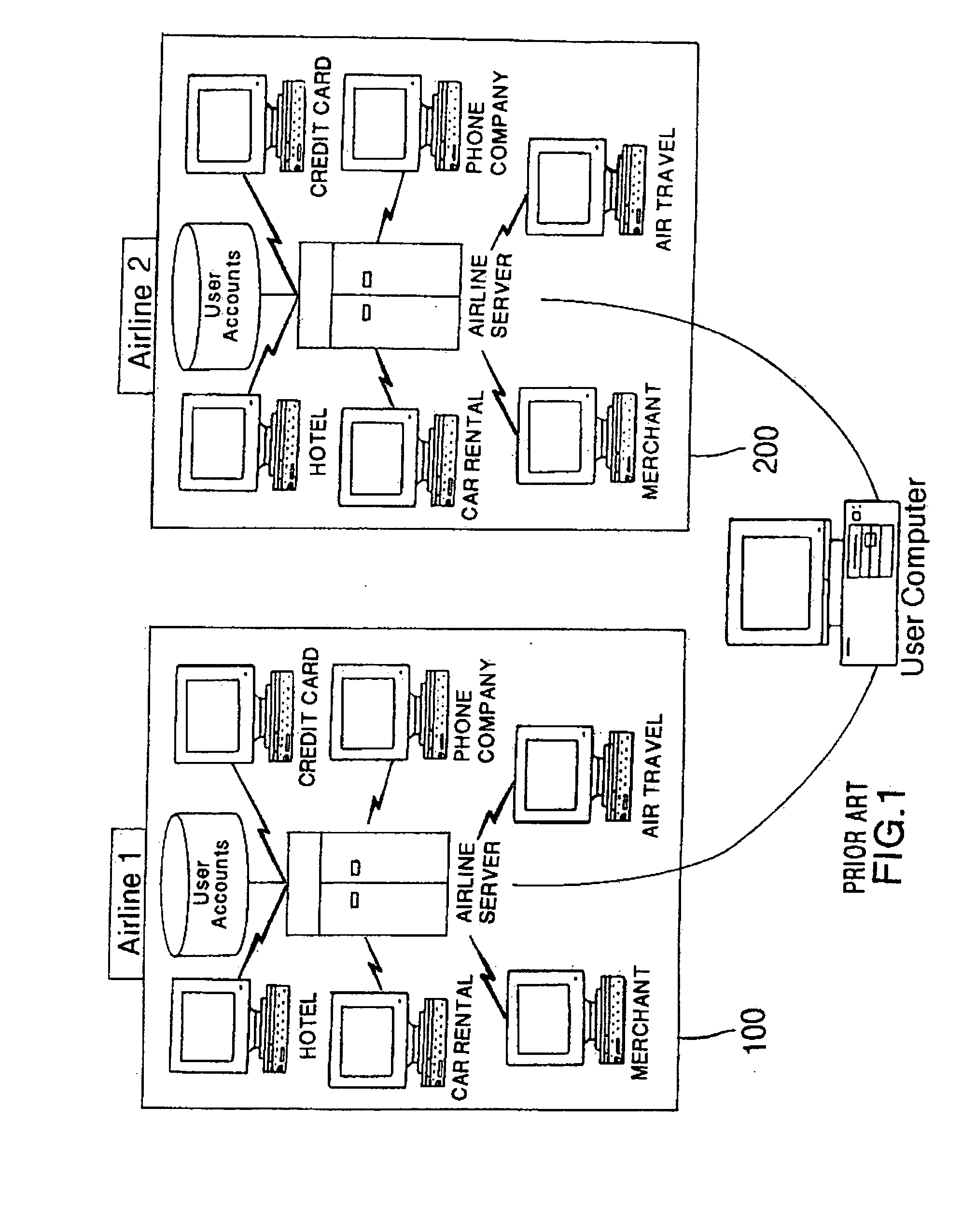

Method and system for using reward points to liquidate products

InactiveUS20060287943A1Eliminate liabilityReduce in quantityFinanceCash registersPaymentComputer science

Owner:POSTREL RICHARD

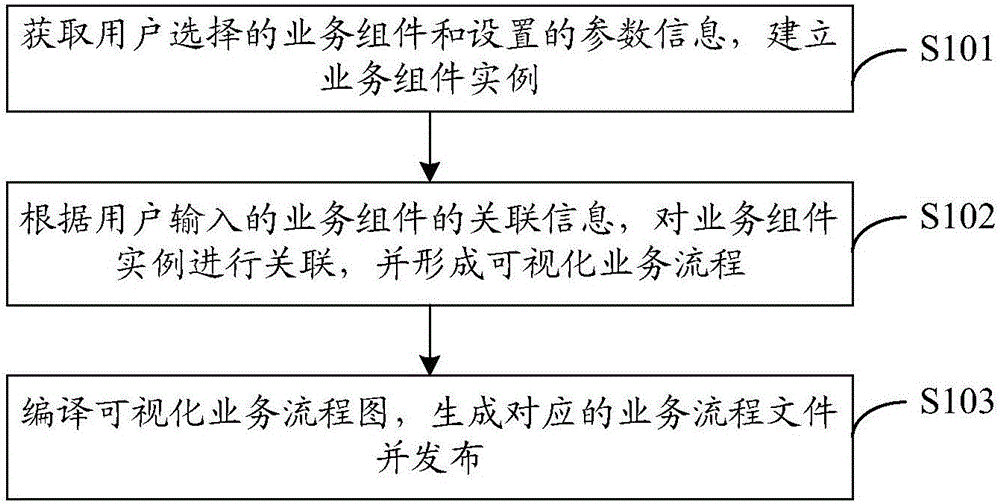

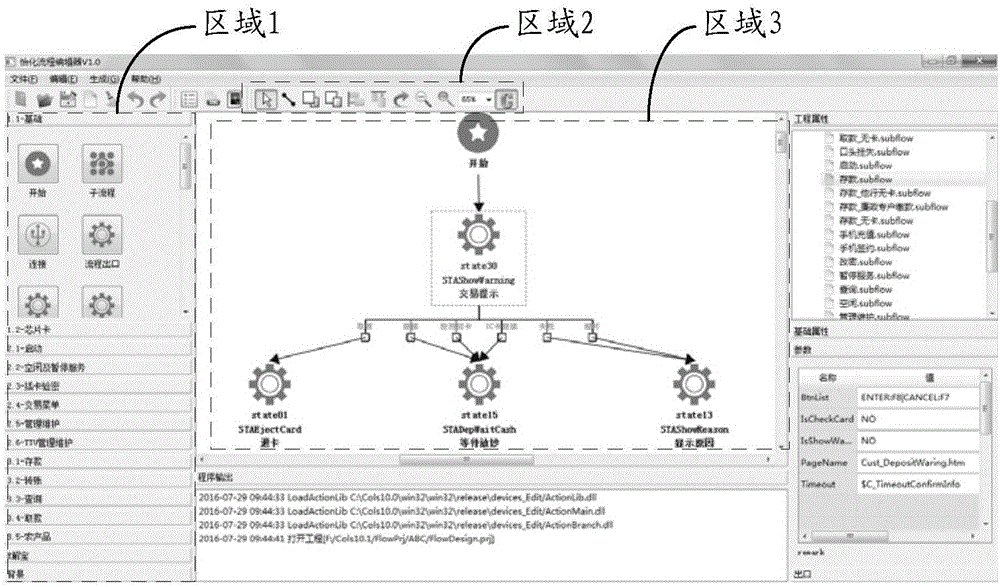

Method and device for service development

InactiveCN106648660AReduce development costsReduce maintenance costsOffice automationVisual/graphical programmingSoftware developmentService flow

The invention is applicable to the technical field of finance, and provides a method and a device for service development. The method and the device aim to solve the problem that financial service development and maintenance are high in cost, low in efficiency and low in reliability in the prior art. The method comprises the following steps: obtaining service components that a user chooses and set parameter information, and establishing service component living examples; associating with the service component living examples according to associated information of the service components that the user inputs, and forming a visual service flow chart; compiling the visual service flow chart, generating and issuing a corresponding service flow chart file. Through the technical scheme, financial service development can be simple like block stacking by using the service components, and complicated service becomes easily understood through a visual service flow chart customizing manner, so that the development difficulty can be reduced, the development efficiency is effectively improved, the software development and maintenance cost is greatly reduced, and the quality of software product is improved.

Owner:SHENZHEN YIHUA COMP +2

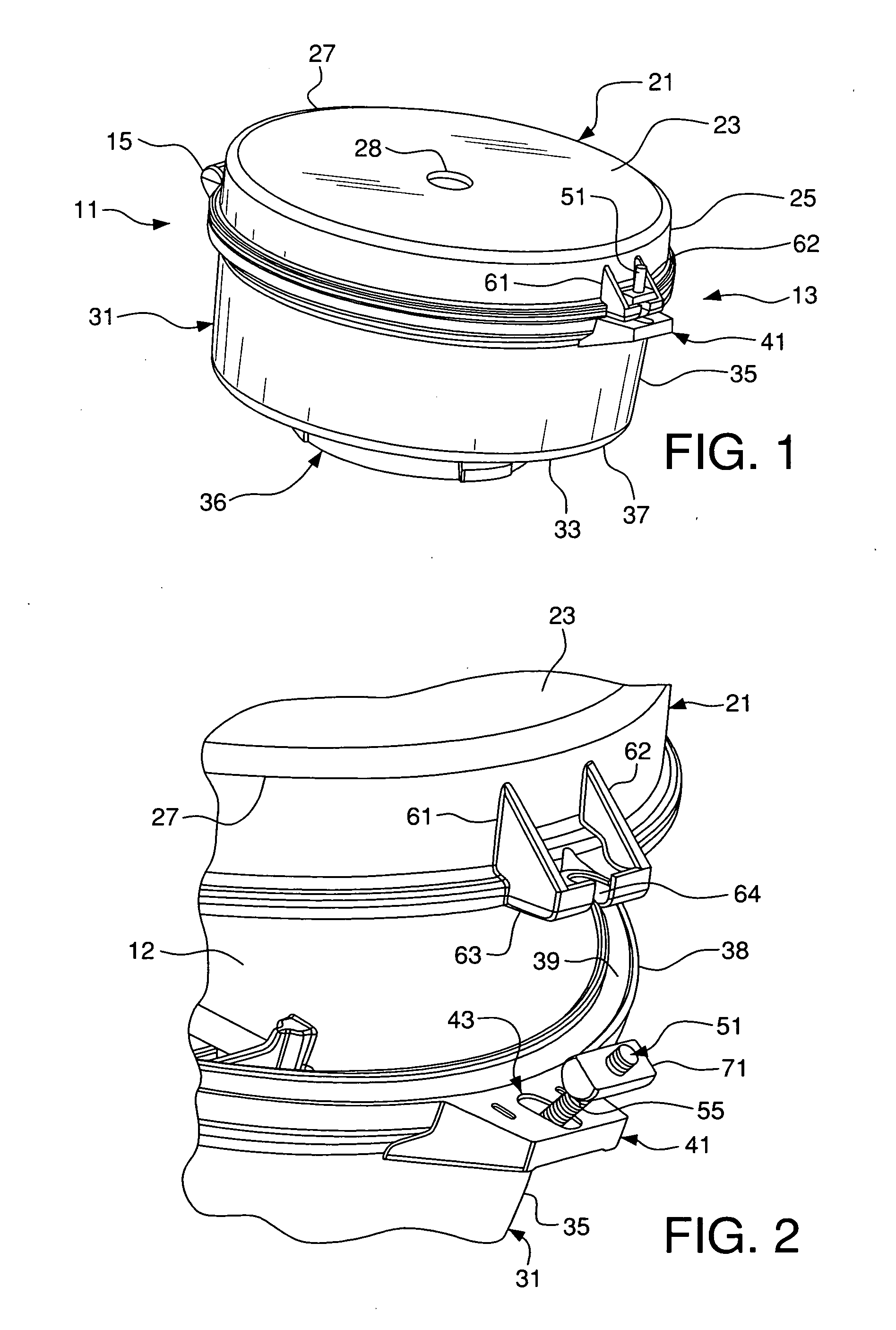

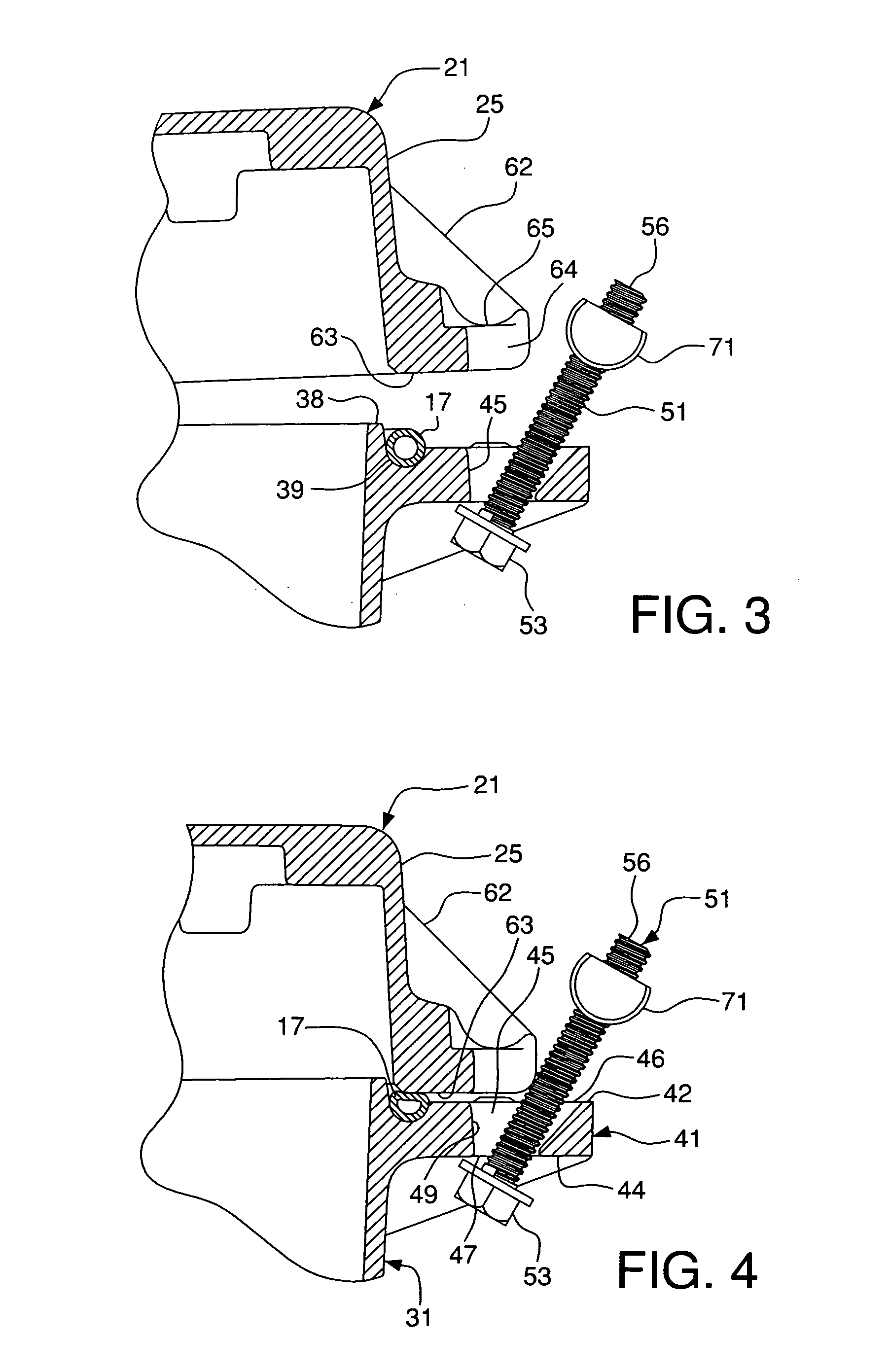

Locking assembly for ballast housing

ActiveUS20050205576A1Quick installationEffective installationLighting support devicesFuse disposition/arrangementScrew threadIndustrial engineering

Owner:HUBBELL INC

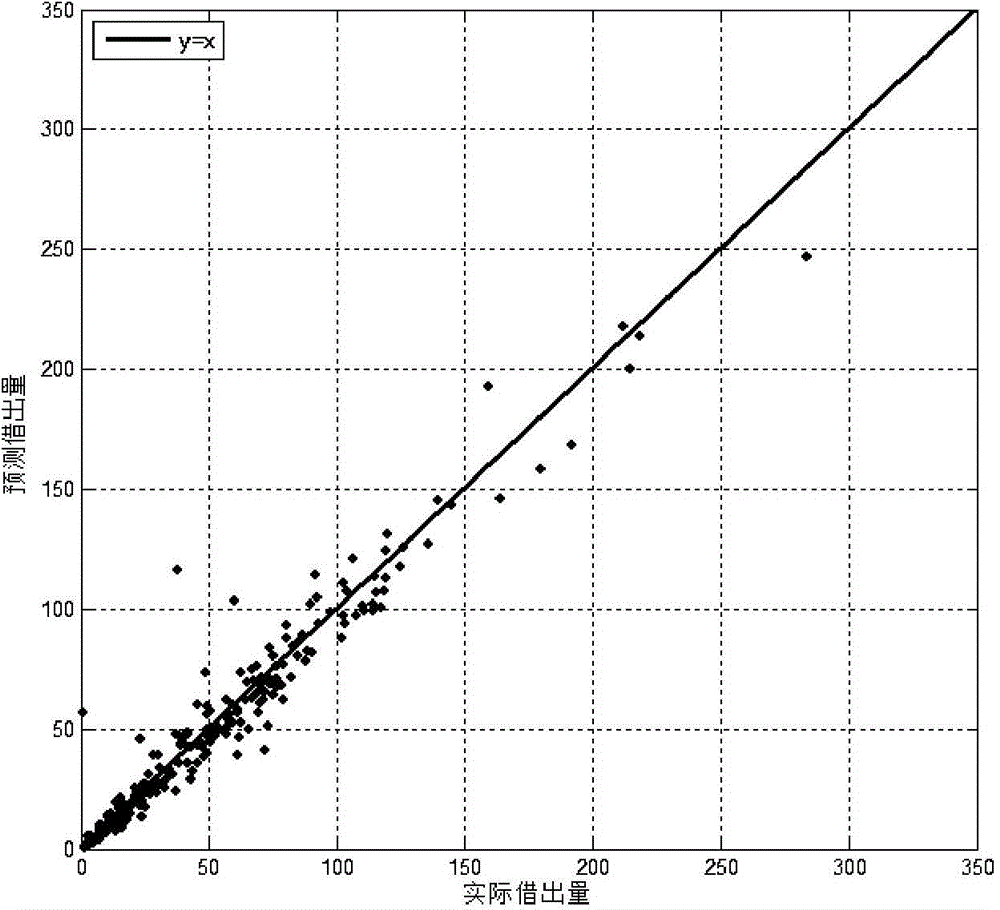

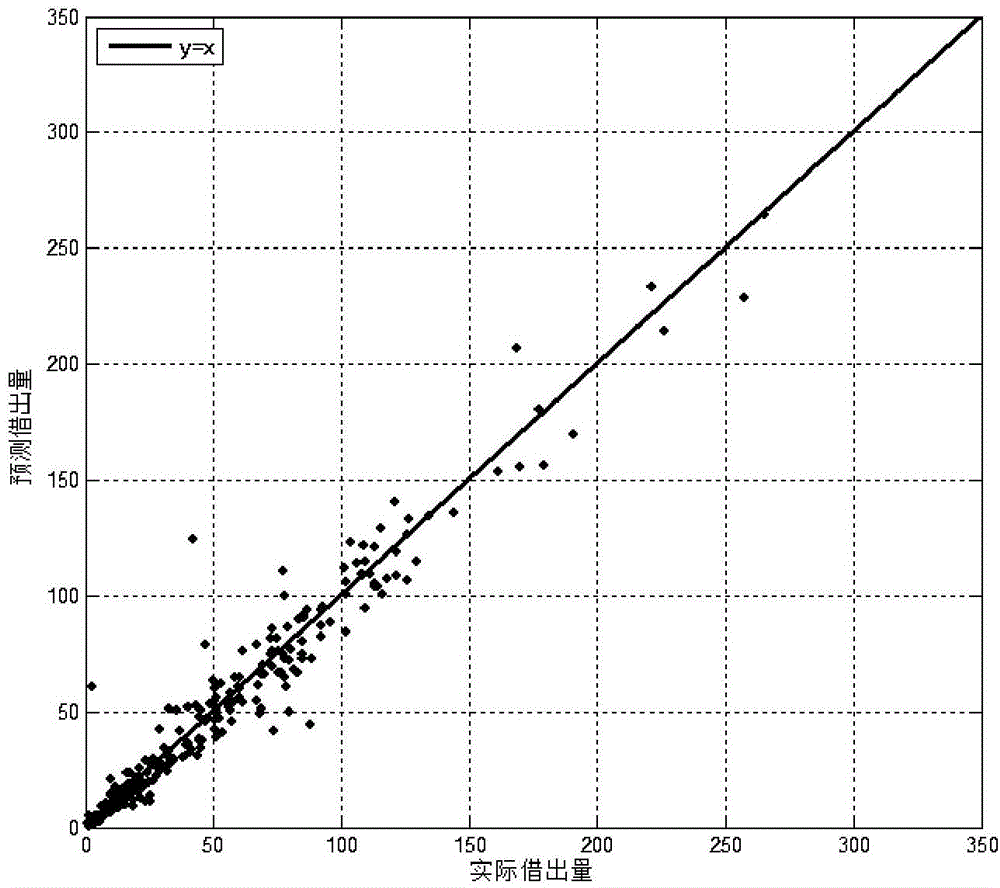

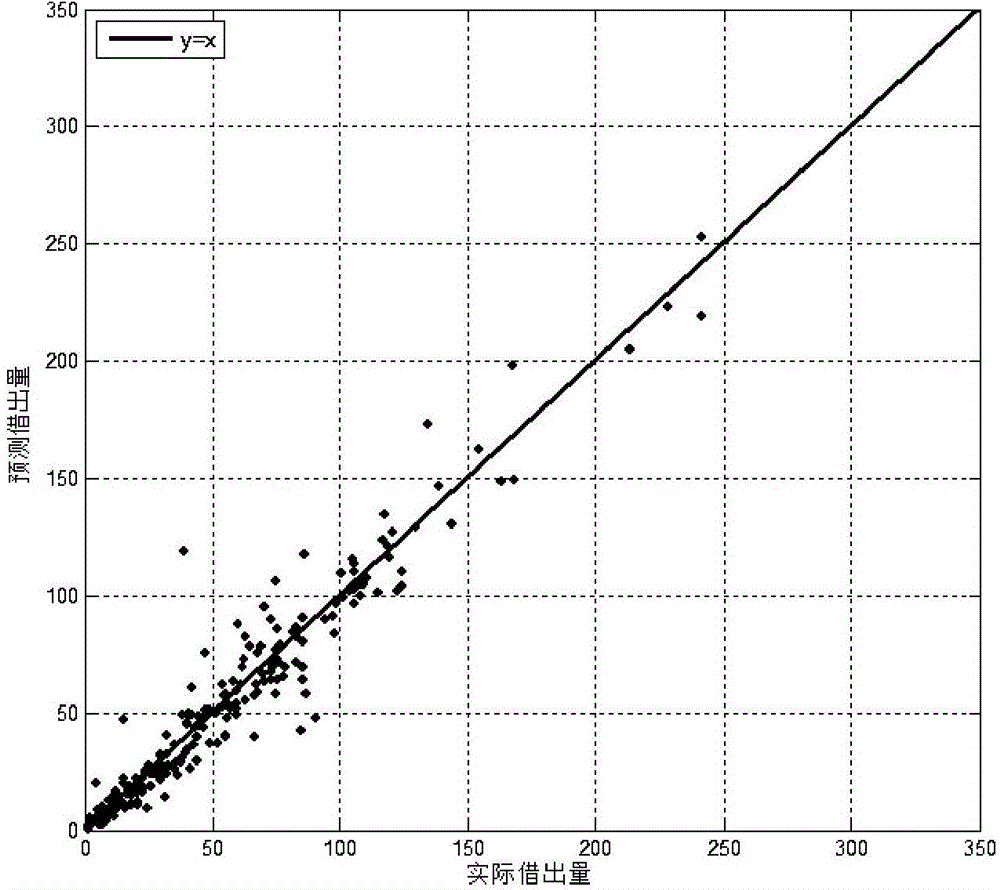

Public bicycle station supply and demand prediction method based on Markov chain

InactiveCN104636828AGood industry application prospectsMake up for the disadvantages of scientific inadequacyForecastingTransfer probabilityTransition probability matrix

Owner:SOUTHWEST JIAOTONG UNIV

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

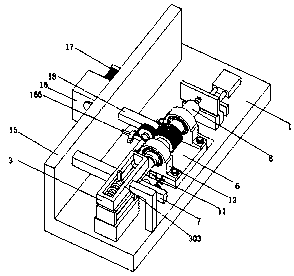

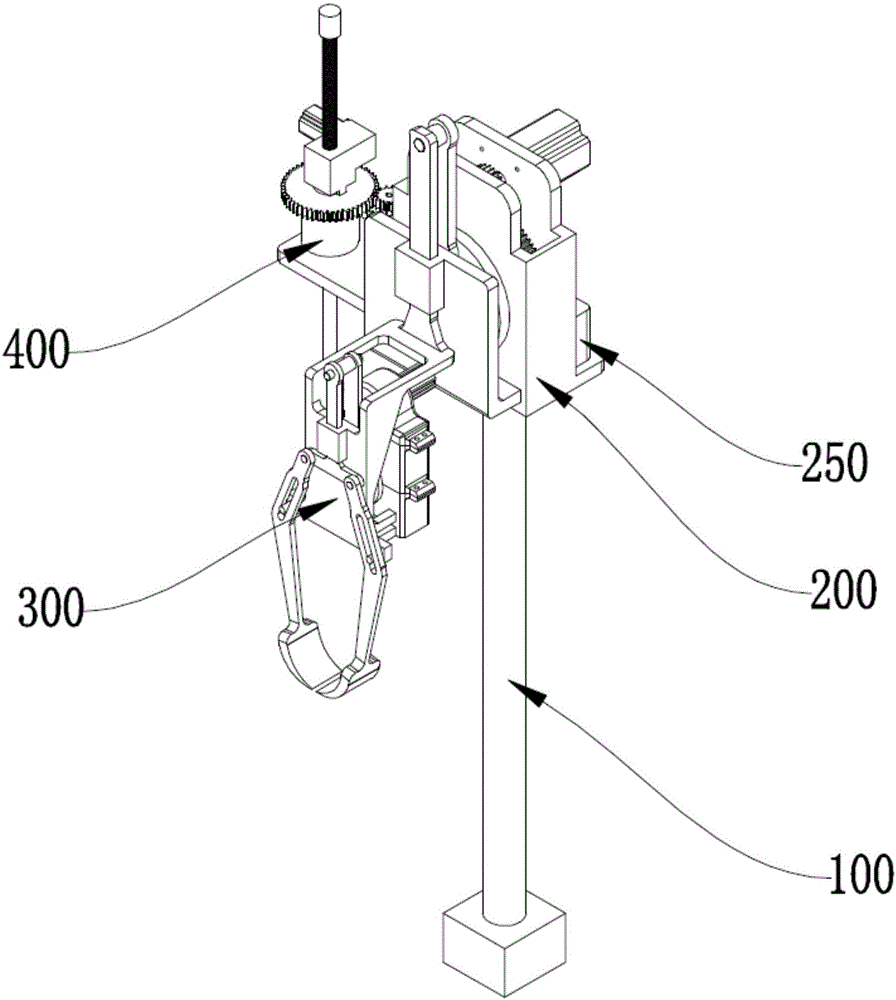

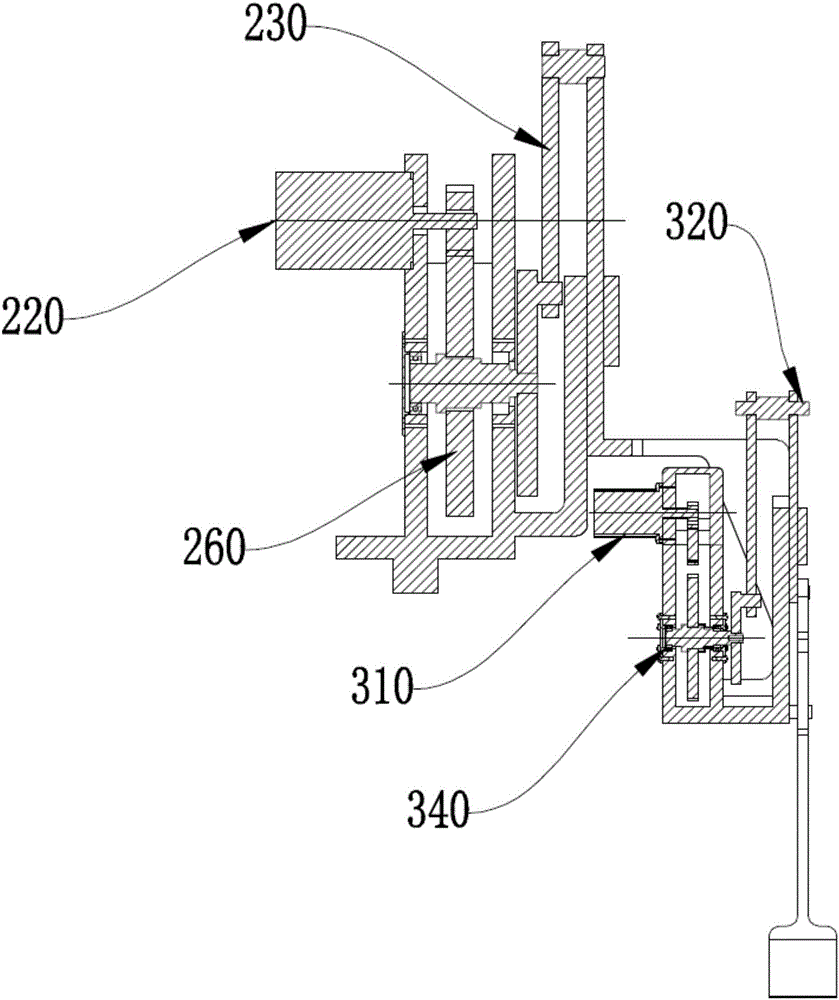

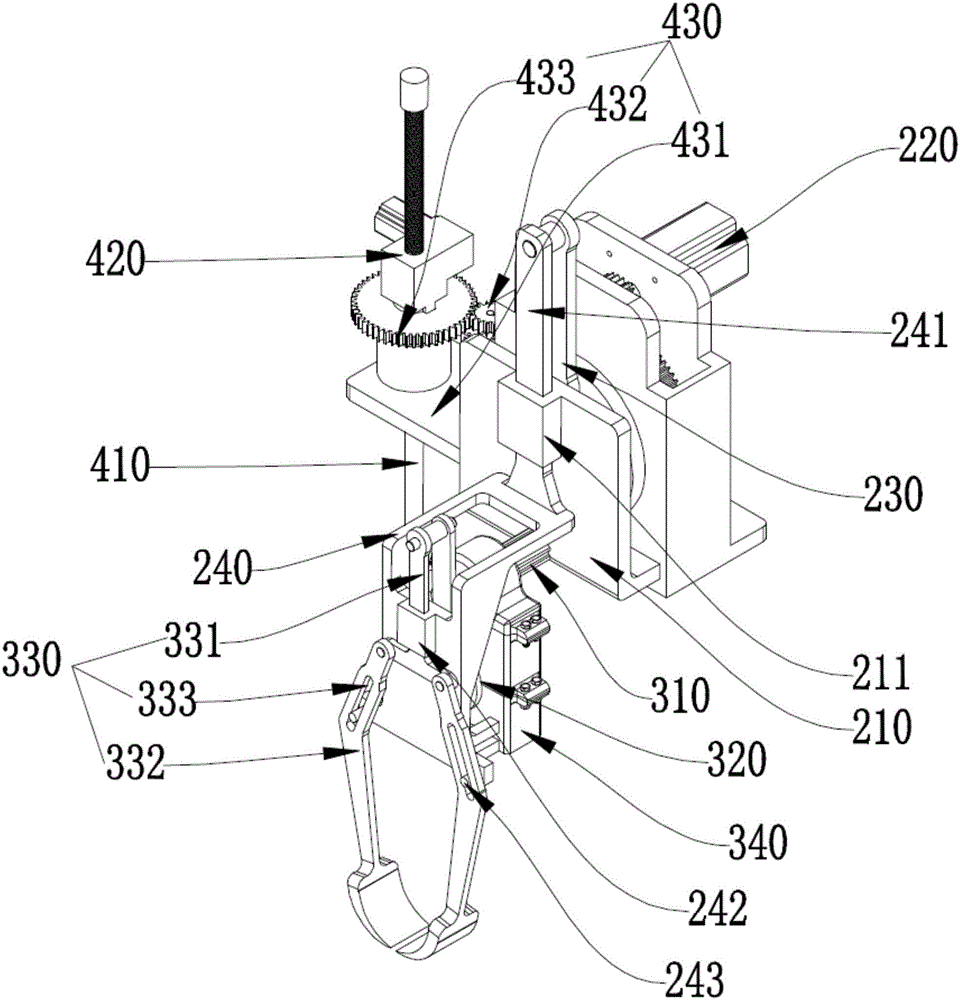

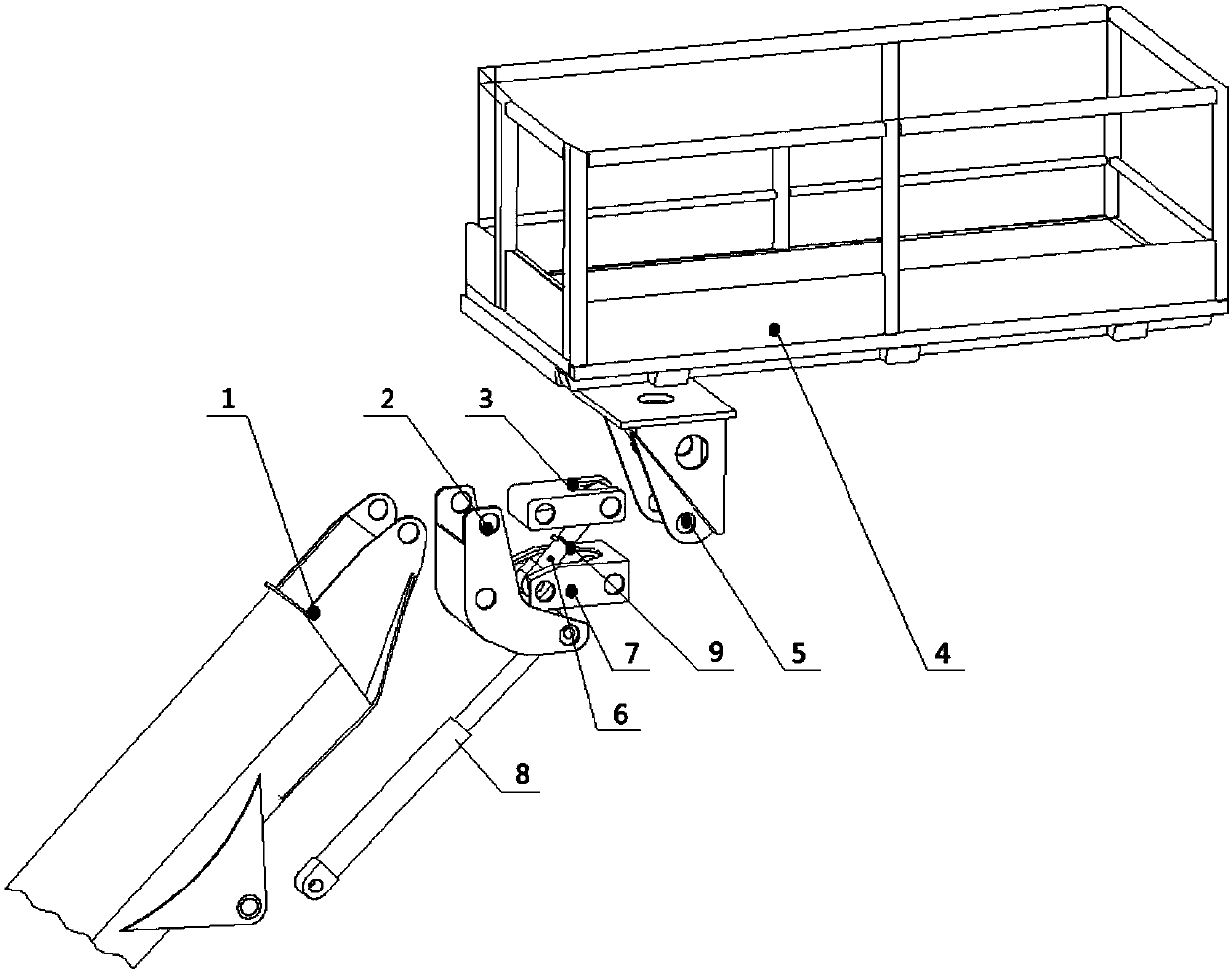

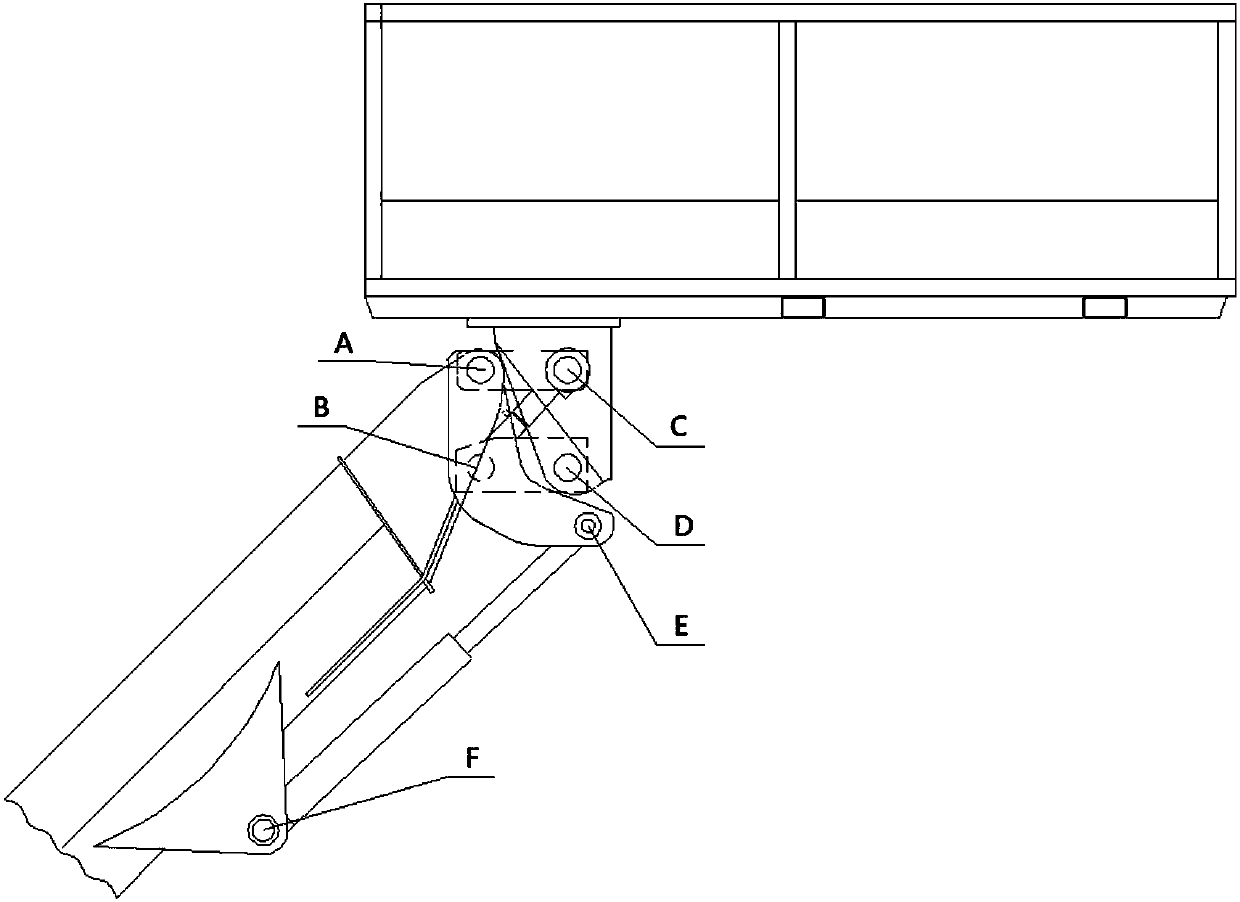

Bricklaying device and bricklaying robot

The invention discloses a bricklaying device and a bricklaying robot. The bricklaying device comprises a base, a brick transfer assembly, a brick feeding assembly and a plastering assembly. The bricktransfer assembly comprises a mechanical arm and a grabbing part. The mechanical arm is connected with the grabbing part to transfer bricks. The mechanical arm is movably arranged on the base and cando up-down lifting motion relative to the base. The brick feeding assembly comprises a bearing platform. The bearing platform is suitable for bearing the bricks. The bearing platform can do up-down lifting motion relative to the base, and the highest distance of the bearing platform relative to the base can be adjusted, so that the bricks are located within the grabbing range of the grabbing partall the time. The plastering assembly is arranged on the base and comprises a plastering head. The plastering head is used for plastering the bricks. The bricklaying device provided by the embodimentof the invention integrates brick transferring, brick plastering and bricklaying, can automatically complete the multiple working procedures, liberates manpower and accelerates the bricklaying progress; and shorter time required for brick taking is consumed, plastering and bricklaying can be quickly carried out after brick taking, the whole working procedure time is short, and the bricklaying efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

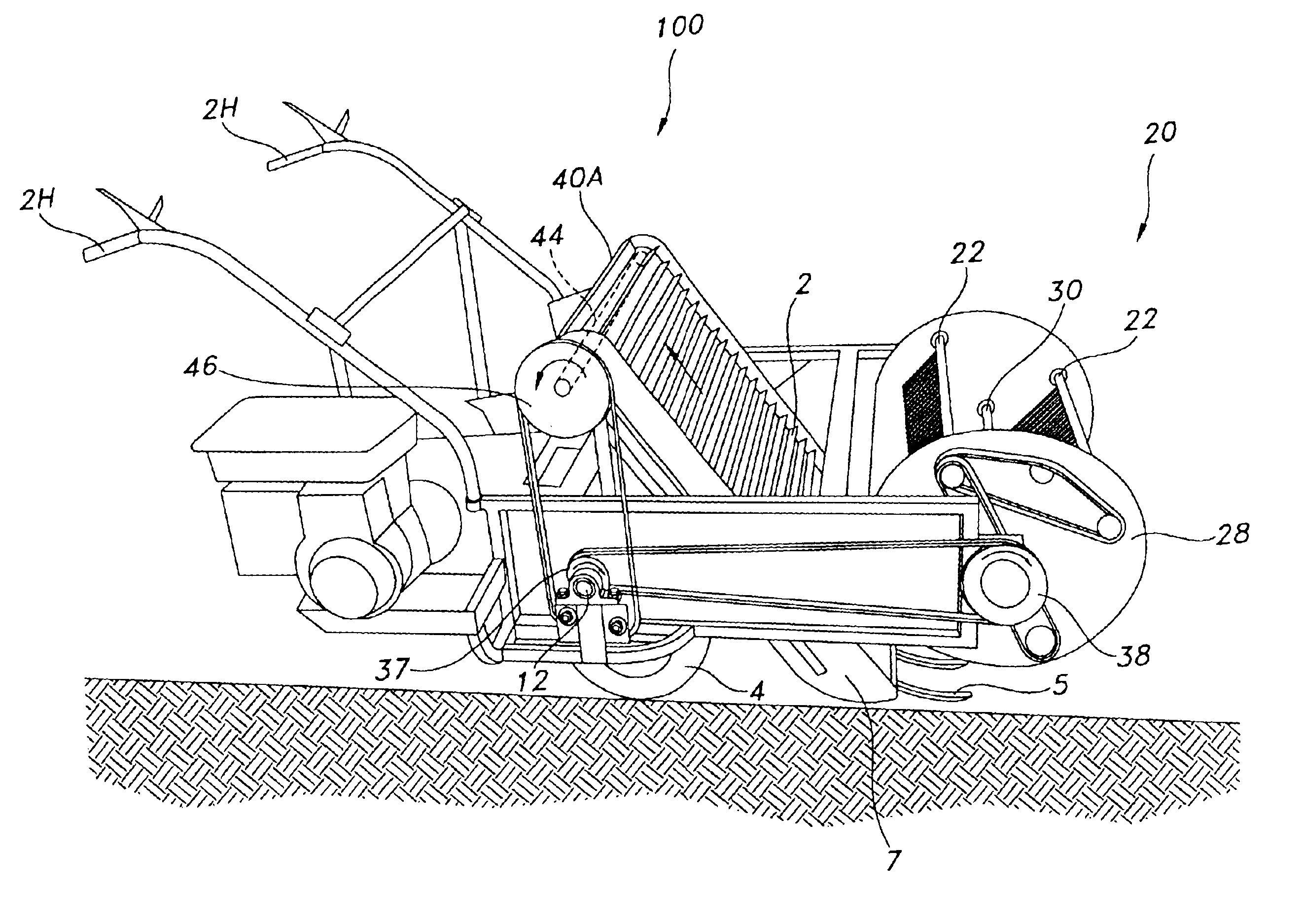

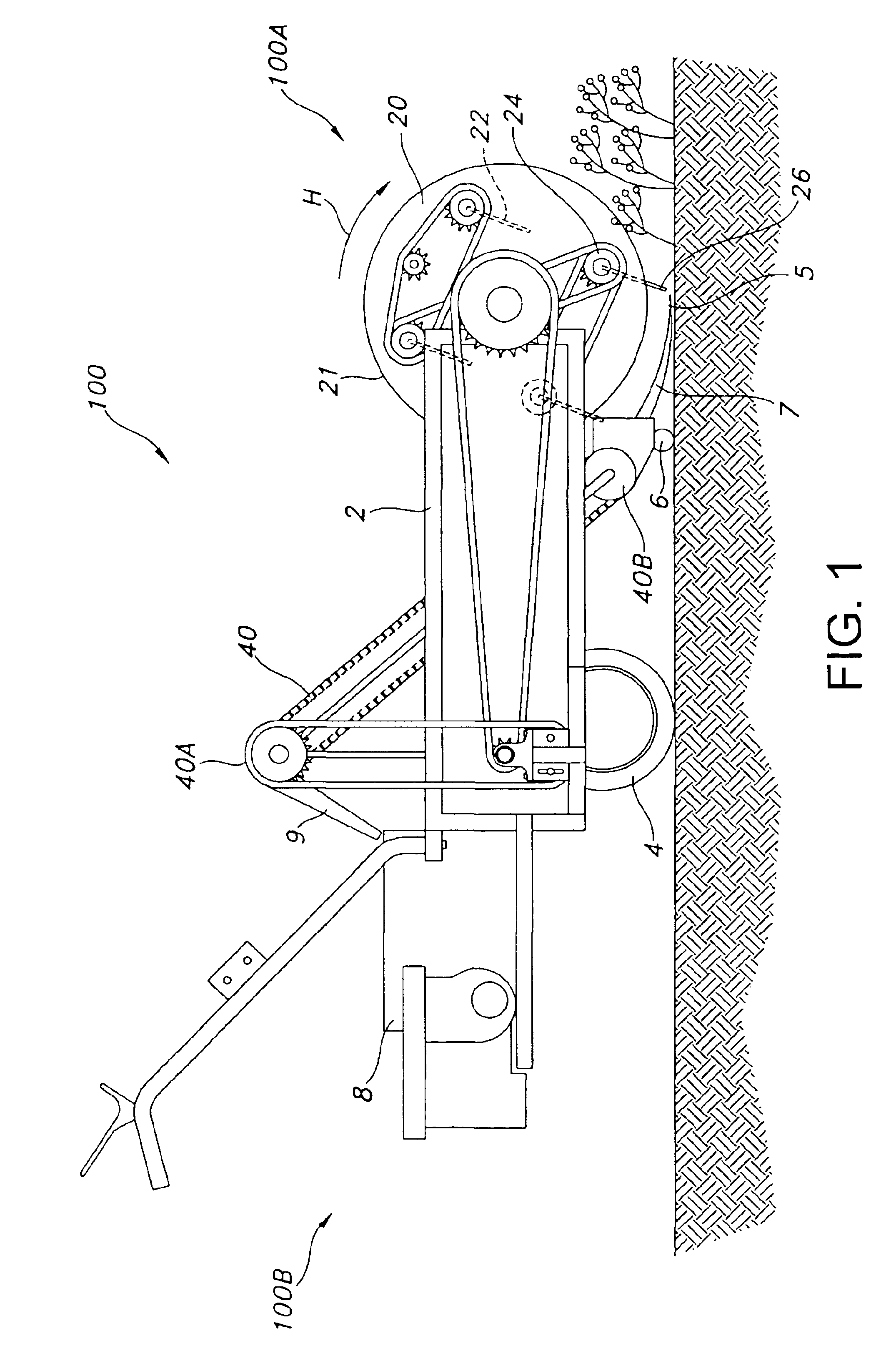

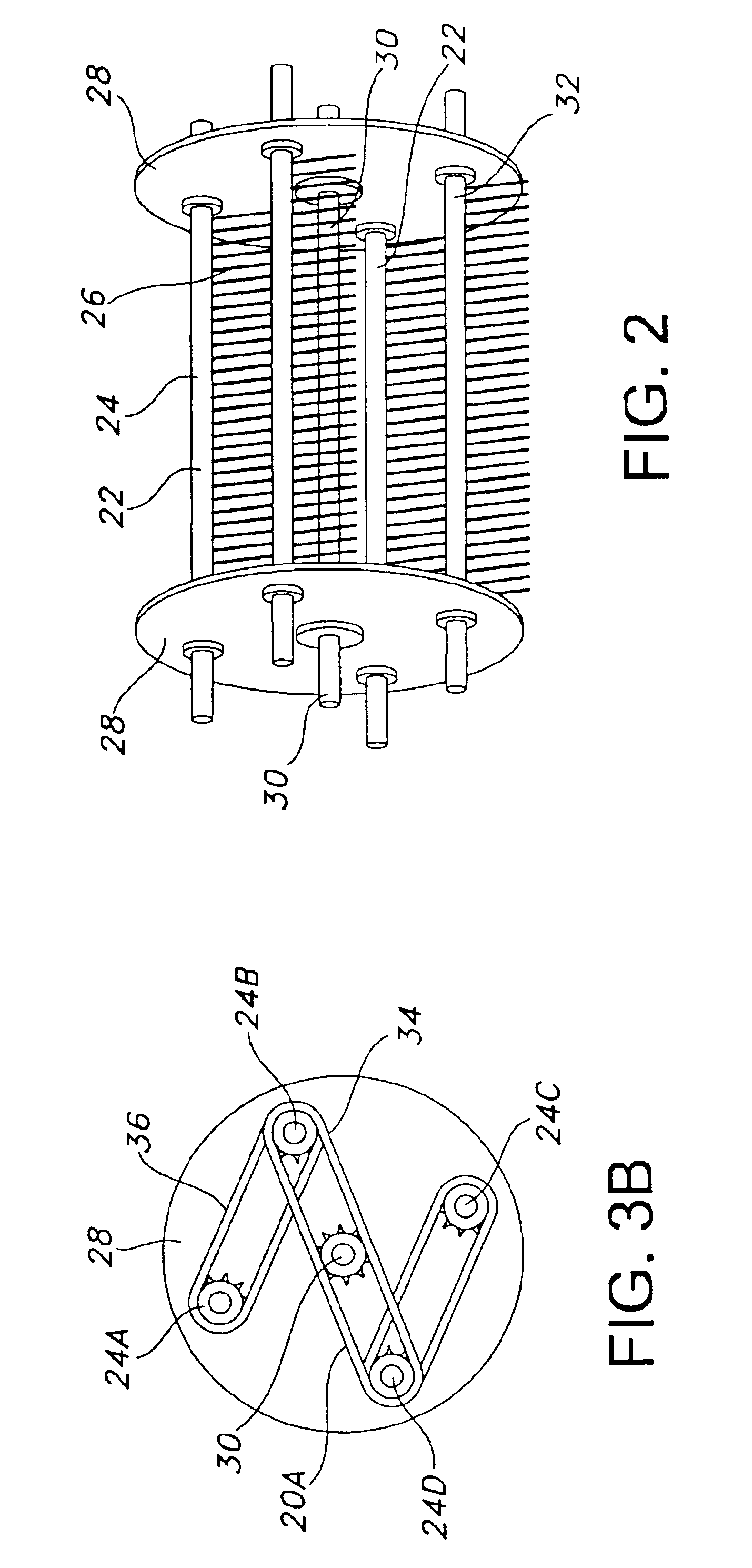

Berry harvester

Owner:EMERSON ZANE

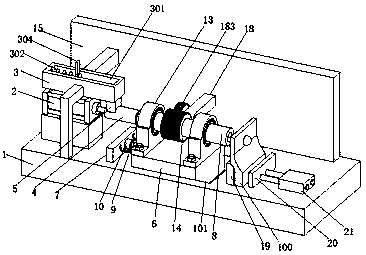

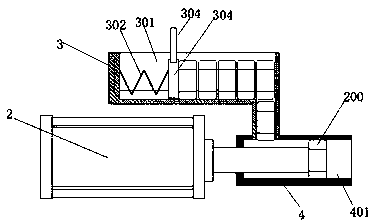

Horizontal sawing machine

ActiveCN107414182AIncrease profitReduce wasteMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention discloses a horizontal sawing machine. The horizontal sawing machine comprises a machine frame, a feeding supporting device, a saw bite discharging clamping device, a small sliding table feeding clamping device, a big sliding table feeding clamping device, a sawing travelling device and a sawing cooling system. The machine frame is provided with a sawing position. The feeding supporting device is arranged on one side of the sawing position and comprises two slideway supporting blocks arranged on the machine frame in parallel, and a supporting assembly located on the slideway supporting blocks. A feeding guide rail is arranged on the upper surfaces of the slideway supporting blocks. The feeding guide rail extends from the feeding end of the machine frame to the sawing position. The saw bite discharging clamping device is located on the other side of the sawing position. The big sliding table feeding clamping device is slidably connected to the feeding guide rail. The small sliding table feeding clamping device can clamp and fix blanks and is slidably connected to the feeding guide rail. The sawing travelling device is arranged on the machine frame and comprises a saw blade. Through the horizontal sawing machine, tailing materials are reduced, the blank utilization rate is increased, and the blanks with different lengths can be machined continuously.

Owner:DALIAN JIACHENG RITA TECH DEV CO LTD

Method for continuously cooking grass raw materials and equipment used in same

ActiveCN101906729ASmooth dischargeFinely-divided material pretreatmentBlack liquorPulp and paper industry

The invention provides a method for continuously cooking grass raw materials, comprising the following steps: (1) preparing the grass raw materials before dipping to obtain the prepared grass raw materials before dipping; (2) transferring the prepared fibrous raw materials into an impregnator through a screw feeder, adding impregnation liquid for dipping treatment, putting the prepared grass raw materials in a digester and adding impregnation liquid to the digester at the same time, and then adding hot black liquor for primary cooking to obtain the primarily cooked grass raw materials; and (3) adding cooking liquor to the primarily cooked grass raw materials for secondary cooking to obtain pulp of the grass raw materials. The method of the invention achieves the purpose of continuously cooking the grass raw materials with large liquor ratio, shortens cooking time, reduces energy consumption and improves uniformity of the pulp. The invention further provides cooking equipment used in the method.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

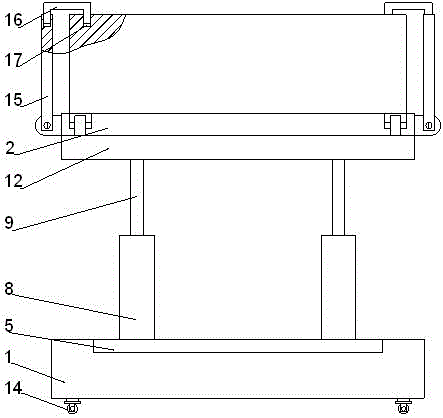

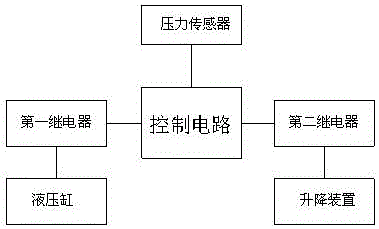

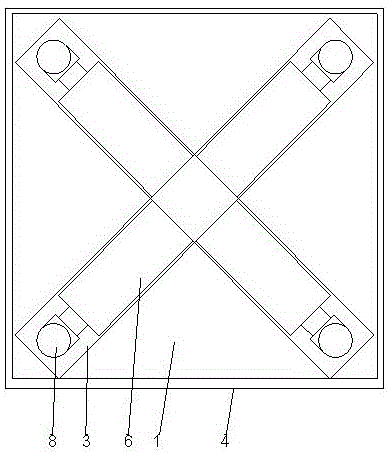

Electric power overhaul lifting platform

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LAIYANG POWER SUPPLY CO

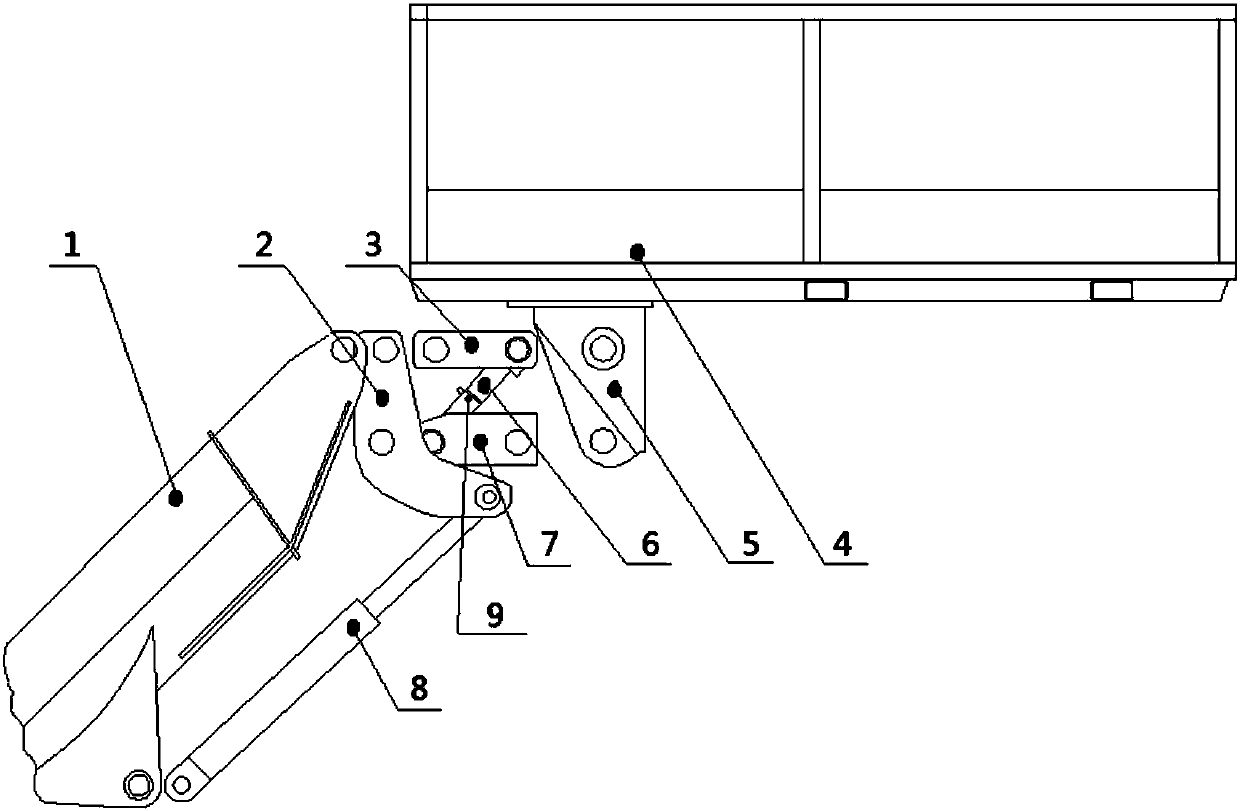

Hinge module for foldable type device

ActiveUS20200267856A1Simple componentsLow production costDigital data processing detailsCasings with display/control unitsDisplay deviceStructural engineering

The present invention relates to a hinge module of a foldable type device, which is connected to two casings for being relatively rotated for being in a folded status or in a unfolded status, each of the casings has a fixed outer casing and a moveable inner casing. The hinge module includes a base and two slide mechanisms. One end of a connection rod of each slide mechanism and one end of the linkage member are respectively pivoted to two pivotal parts at one end of the base; after each inner casing is driven to reversely displace, one end of each plate member is separated from each block part, so as to reversely swing and shift for forming an accommodation space allowing a bent central portion of a flexible monitor to be accommodated.

Owner:JARLLYTEC CO LTD

Intelligent climbing and fruit picking robot

InactiveCN106416625AReduce labor intensityCompact structureGripping headsPicking devicesSlide plateIndustrial engineering

The invention discloses an intelligent climbing and fruit picking robot which comprises eight crawler wheels, four wheel carriers, four first stepper motors, a bottom plate, a lower fixing claw, a second stepper motor, a rotary plate, a third stepper motor, a lead screw support, a lead screw, a slide plate, a fourth stepper motor, a lower rotary frame, a first electric cylinder, an upper rotary frame, a second electric cylinder, an upper fixing claw, a fifth stepper motor, a bag bracket, a fixing column, a fifth electric cylinder, a fixing plate, a sixth electric cylinder and hydraulic shears. The intelligent climbing and fruit picking robot has the advantages that the intelligent climbing and fruit picking robot is compact in structure, high in automation degree and applicable to various environments and is small, work for picking fruits from trees can be safely and efficiently carried out, the labor intensity can be relieved for workers to a great extent, and the work efficiency can be improved.

Owner:NANTONG NORTH BUND CONSTR ENG CO LTD

Continuous nut feeding device for automobile part processing

InactiveCN110788607AQuick assemblyRealize continuous assemblyMetal working apparatusIndustrial engineeringHydraulic pressure

Owner:含山县祥瑞运输有限公司

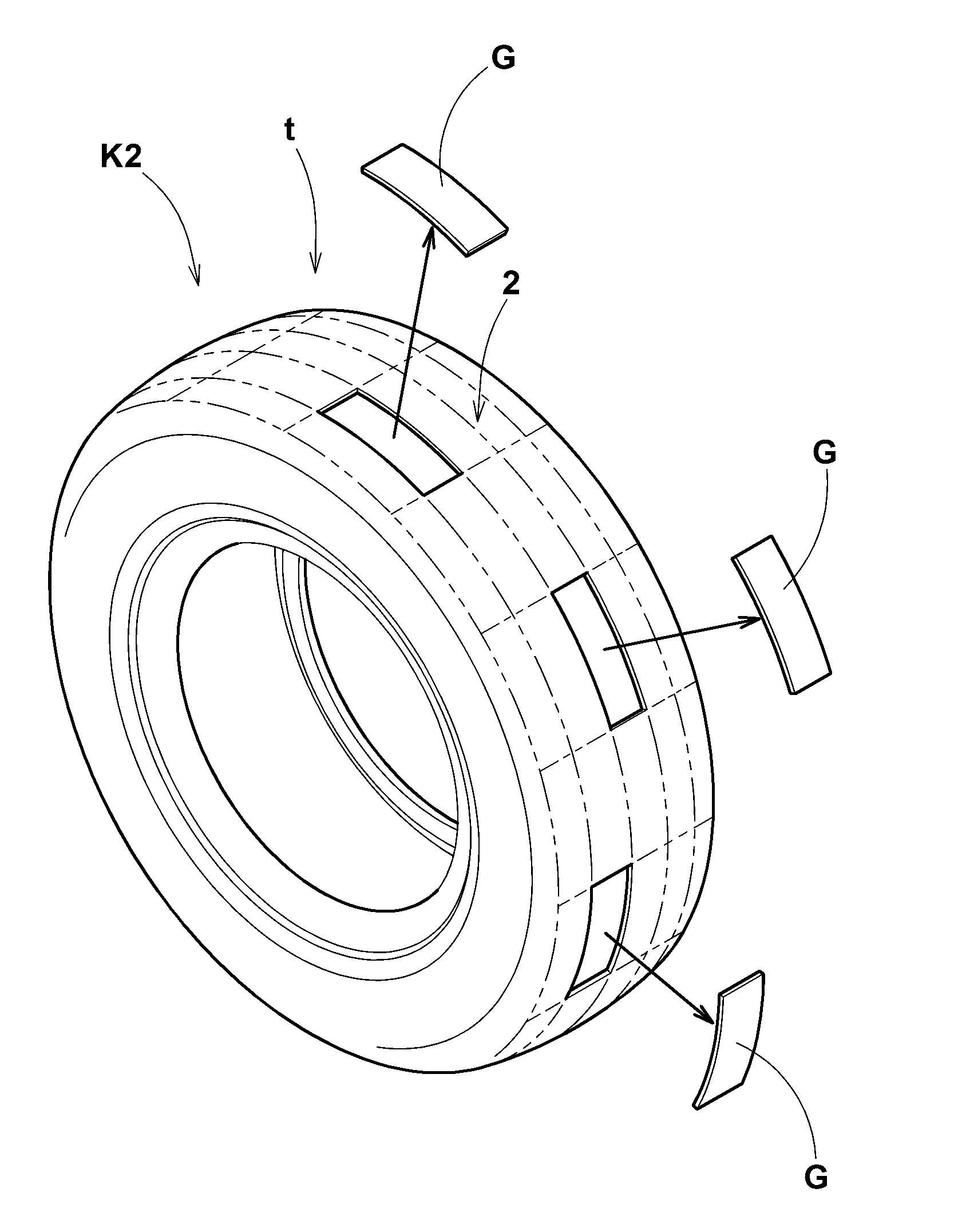

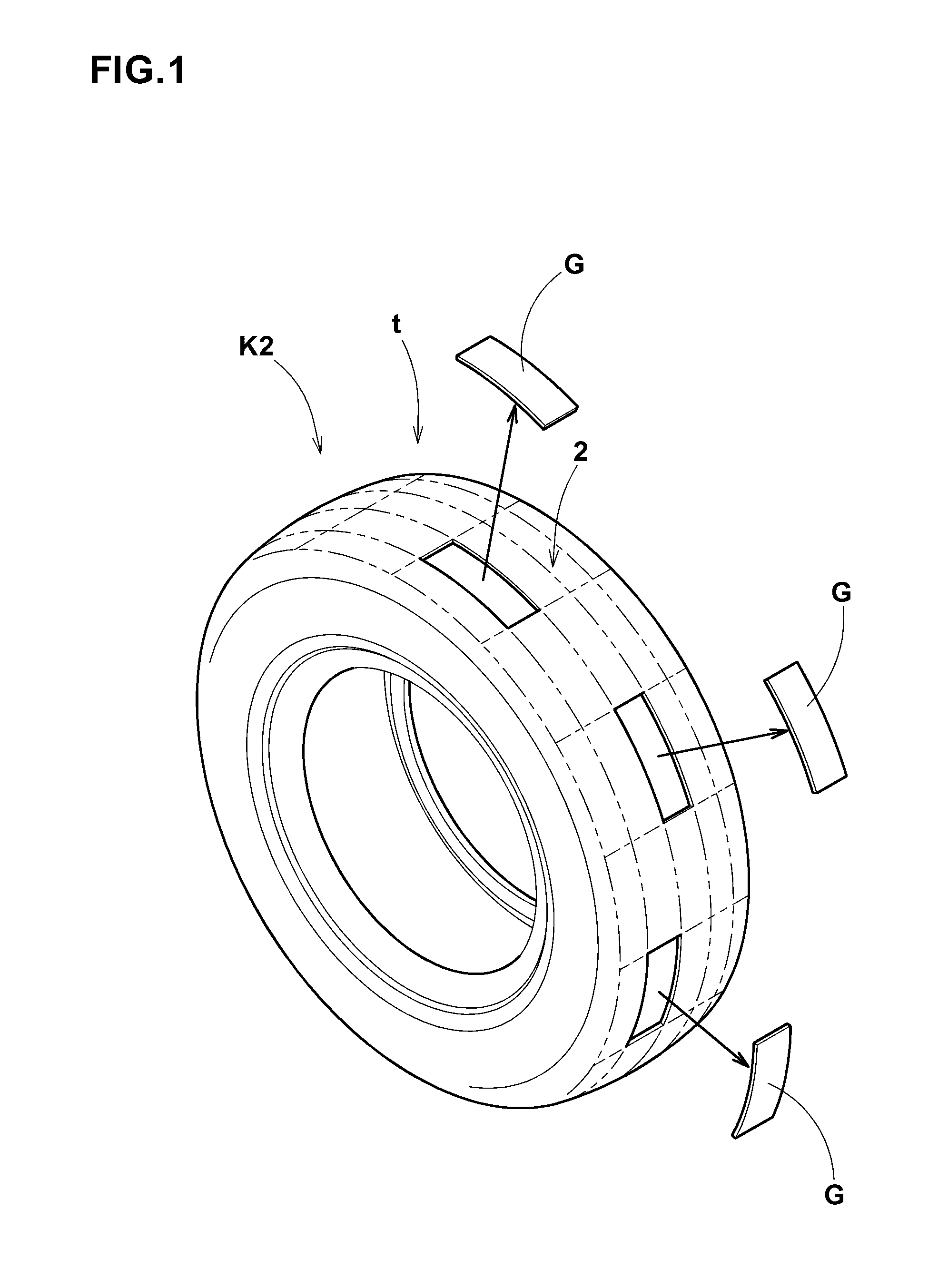

Method for estimating wear resistance of tread portion of tire

InactiveUS20130036790A1High correlationSamplingUsing mechanical meansWear testingIndustrial engineering

Owner:SUMITOMO RUBBER IND LTD

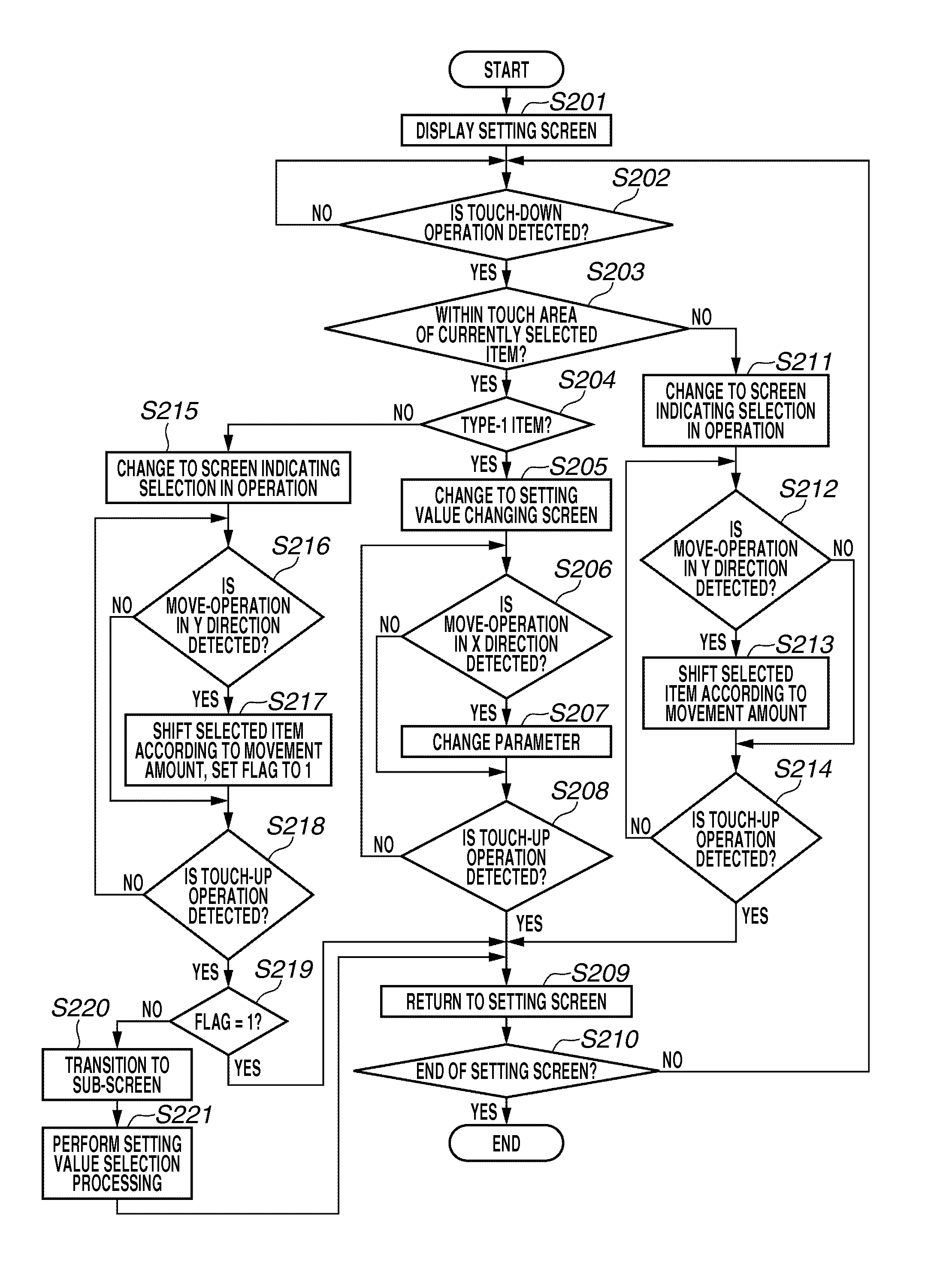

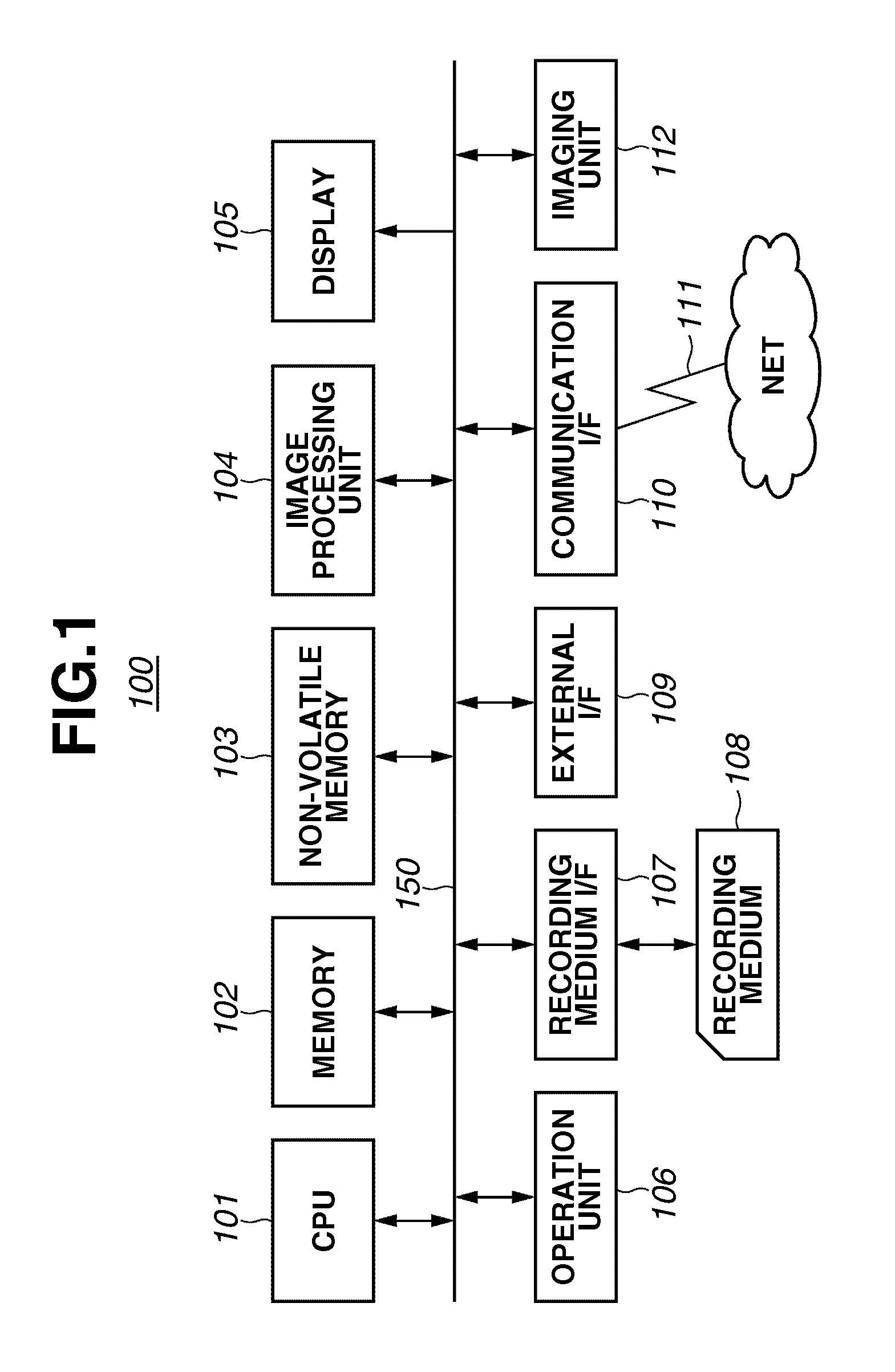

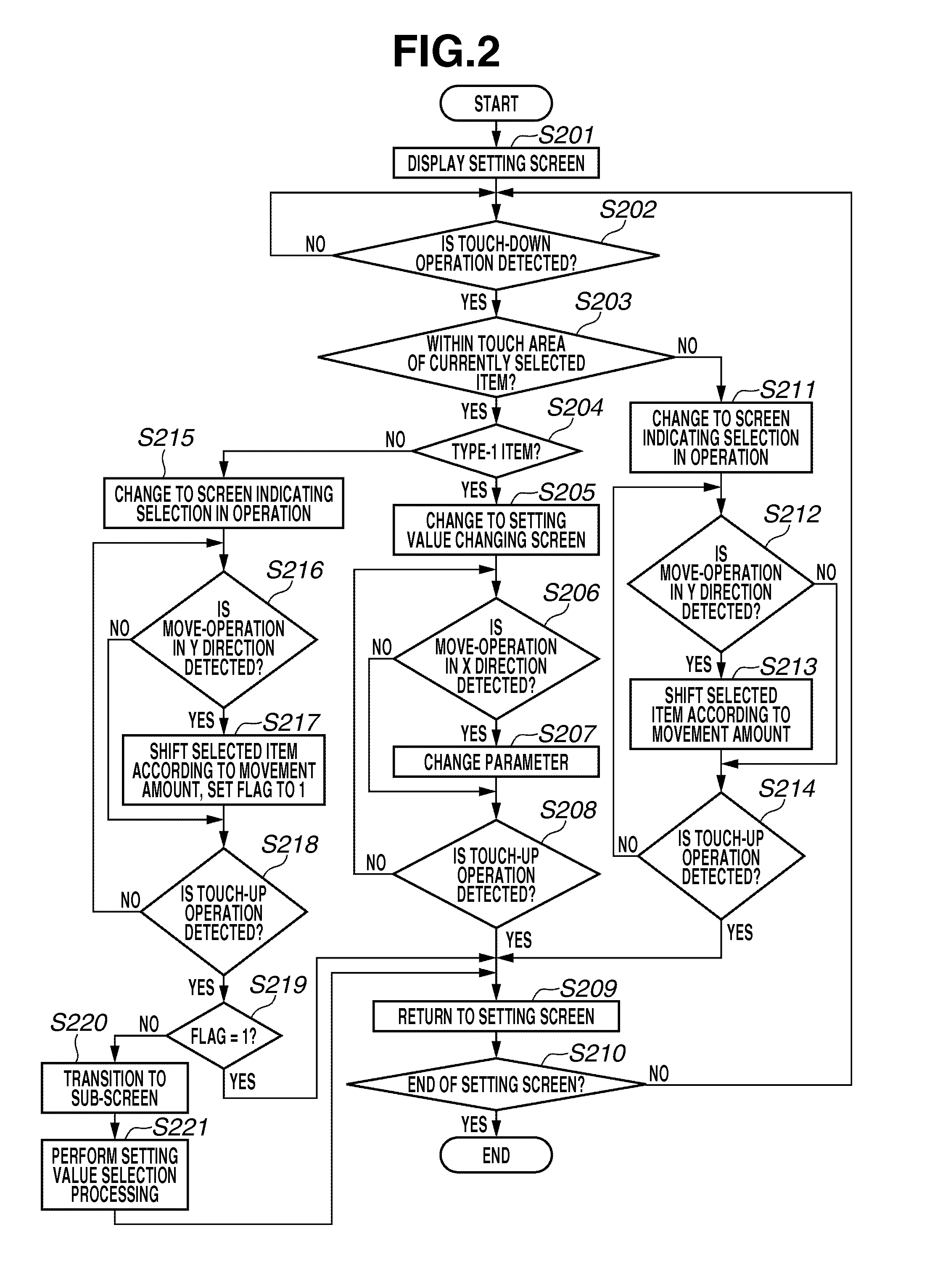

Display control apparatus and control method for the same

ActiveUS20130249829A1Easy to operateEasy to performCathode-ray tube indicatorsInput/output processes for data processingControl engineeringHuman–computer interaction

Owner:CANON KK

Coin processing apparatus and method

InactiveUS20030220064A1Easy to follow upImprove accuracyWrapping material feeding apparatusCoin countersCoinIndustrial engineering

A coin processing apparatus has an opening for receiving a plurality of coins of different types, a coin sensor adapted to determine a respective type of individual coins among the plurality of coins, a controller operatively coupled to the coin sensor, a coin separator operatively coupled to the controller and capable of separating the individual coins from the plurality of coins under control of the controller. Moreover, the apparatus has a coin packaging device comprising a coin inlet, a supply of packaging material and a packaging mechanism capable of producing a plurality of coin bags from the supply, so that at least two different coin types are packaged in the coin bags in a continuous operation.

Owner:SCAN COIN IND AB

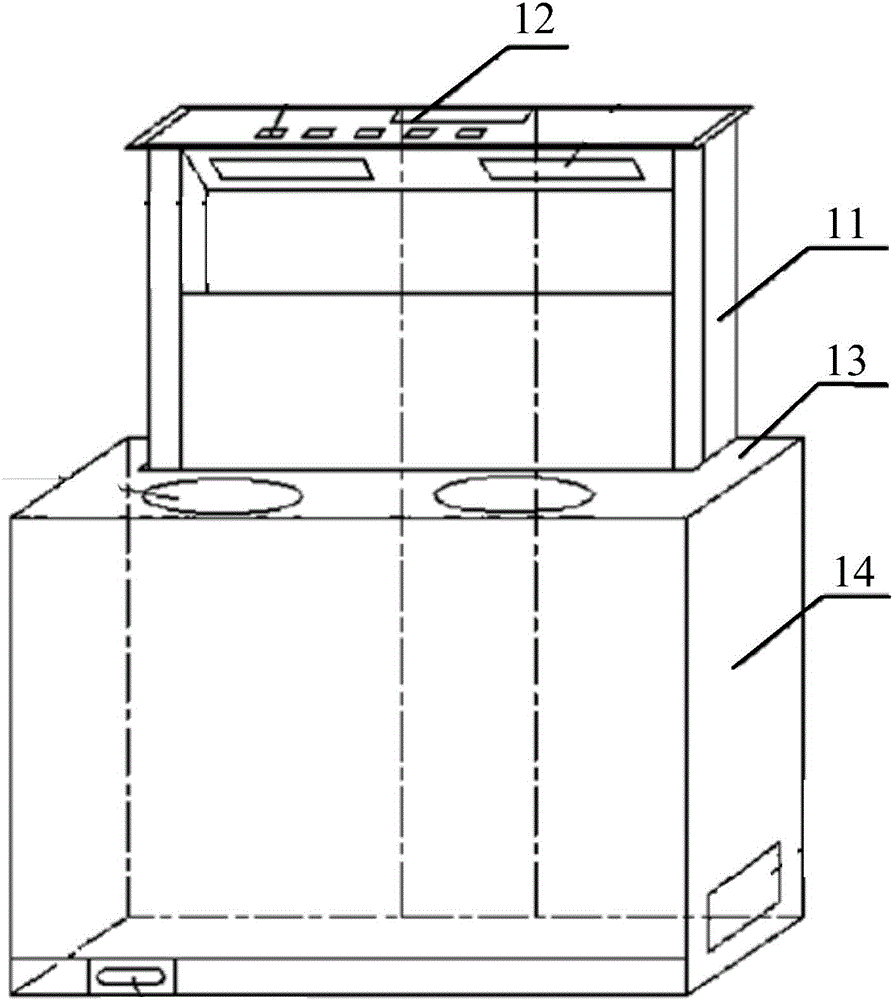

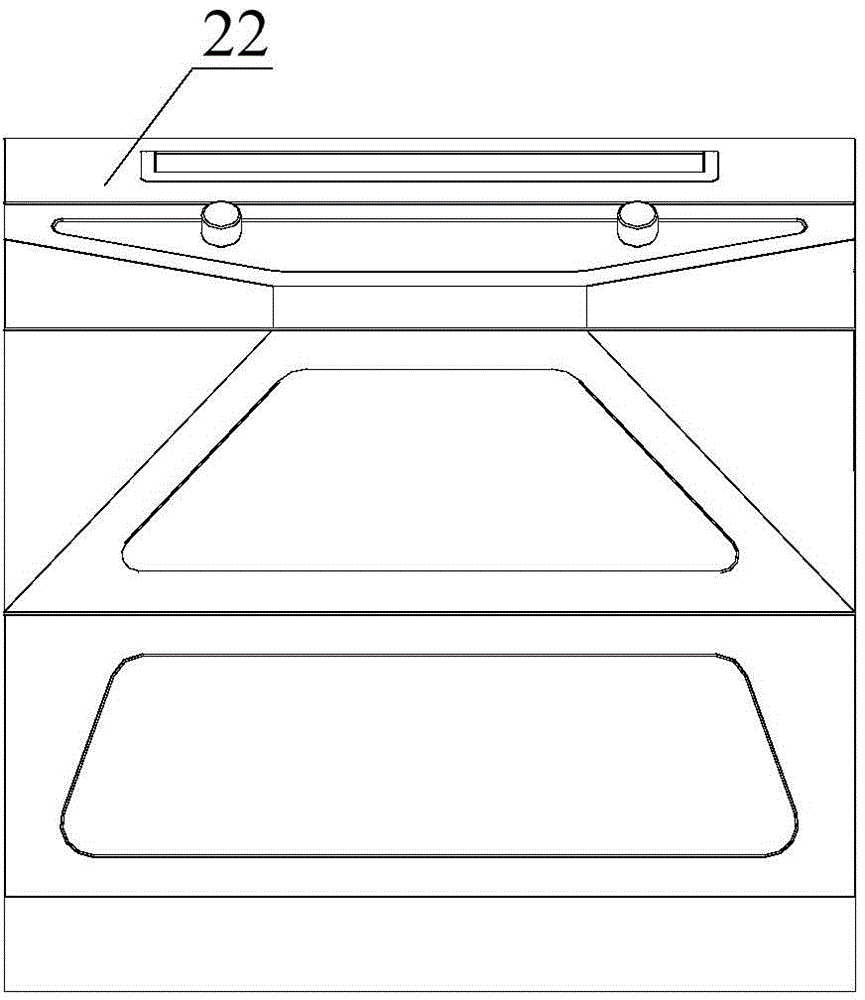

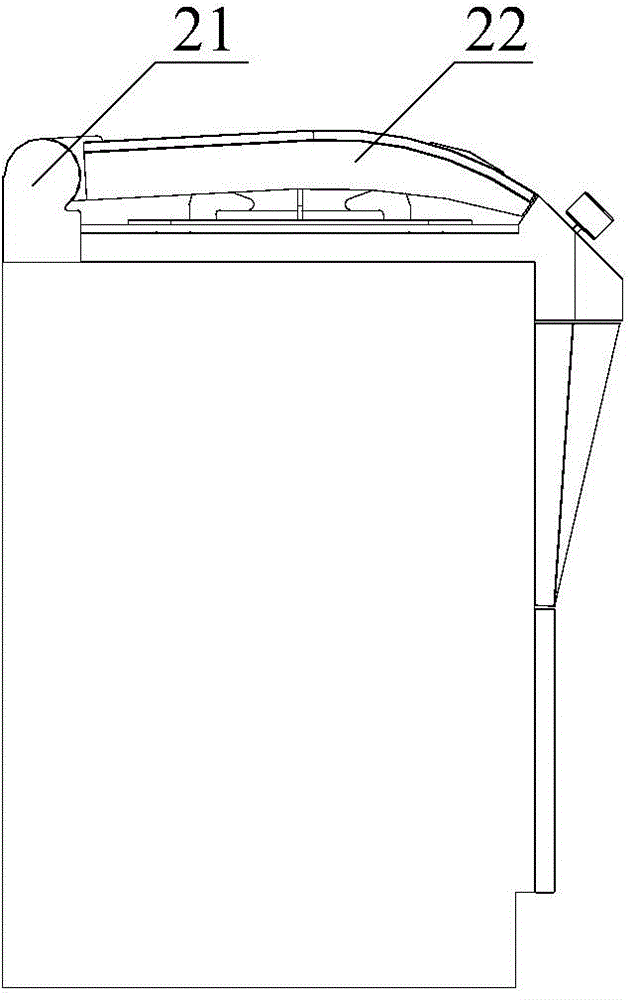

Flipping type integrated cooker

InactiveCN104456681AKeep clean and hygienicRealize the function of oil smokeDomestic stoves or rangesLighting and heating apparatusIndustrial engineeringCooker

Owner:ZHEJIANG AOTIN ELECTRIC APPLIANCE

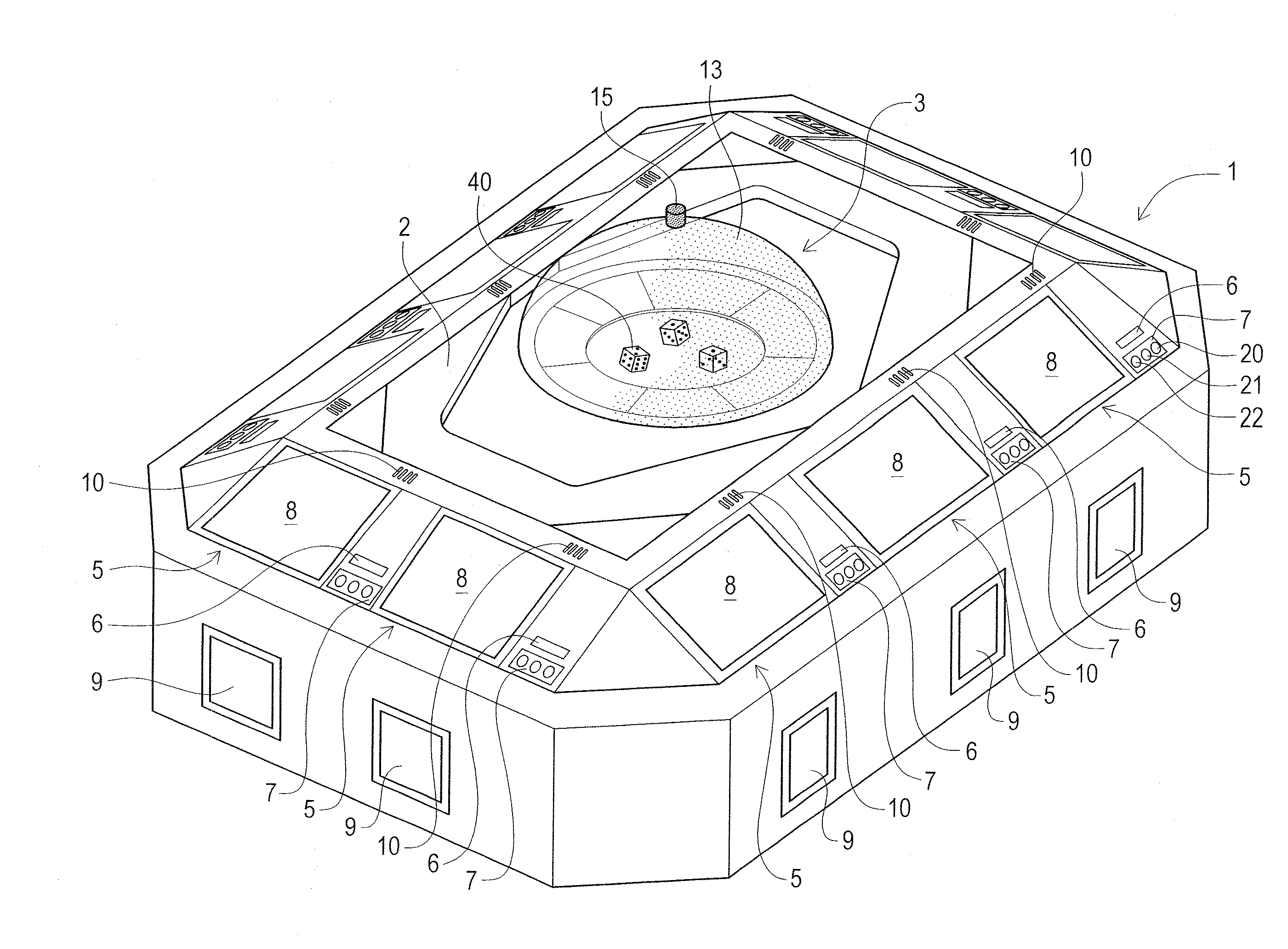

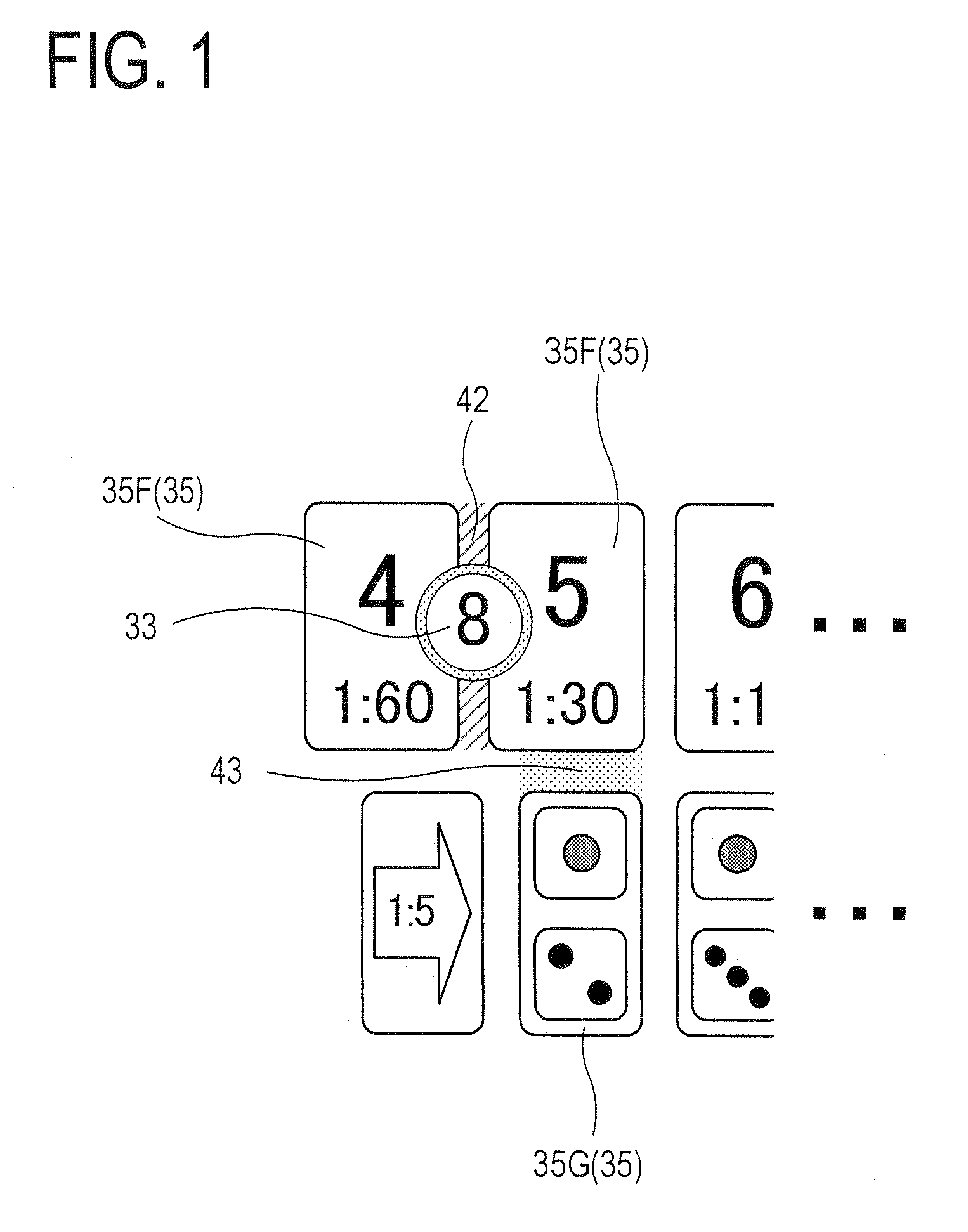

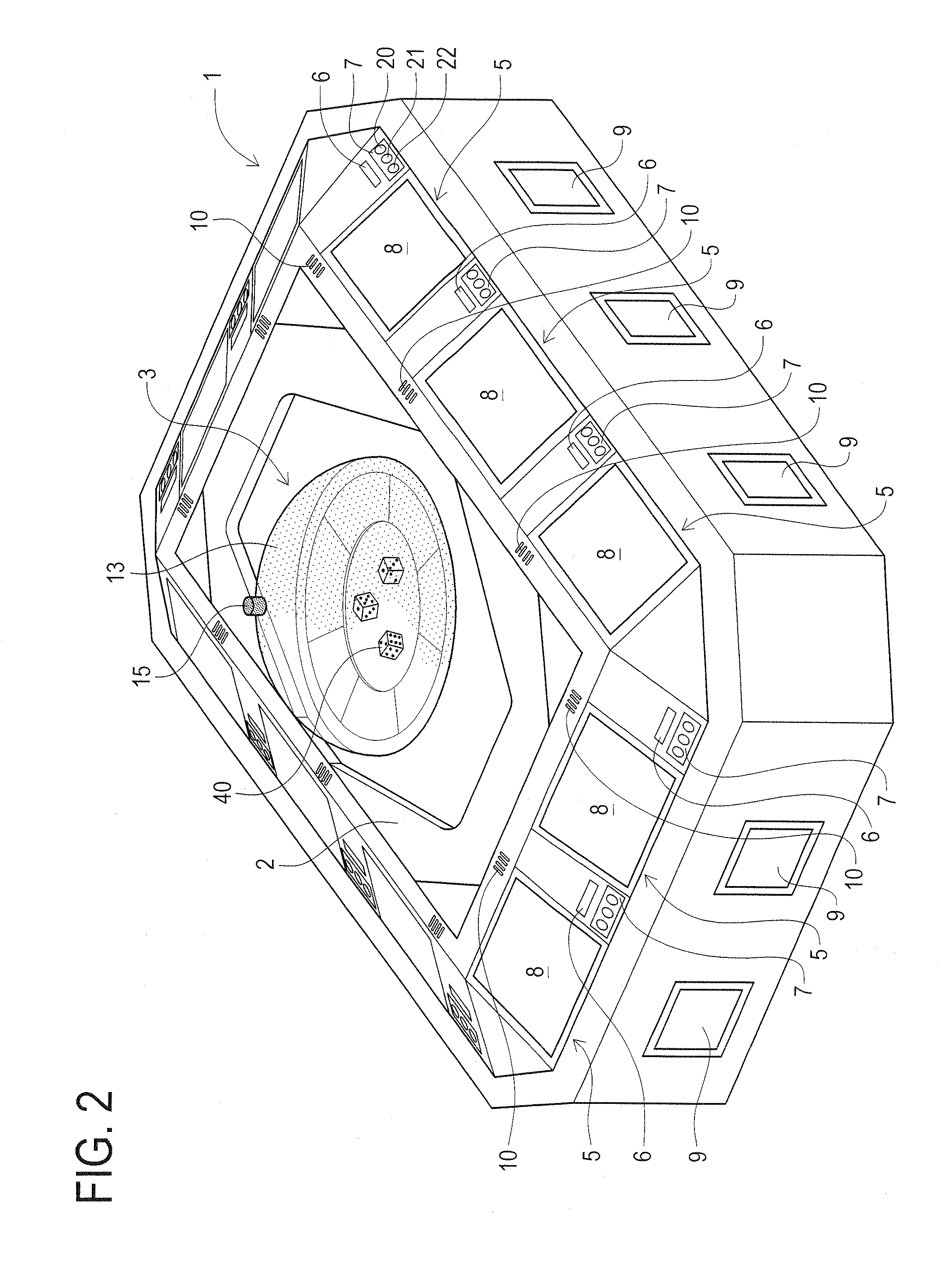

Dice Gaming Machine

ActiveUS20100069142A1Improve convenienceCard gamesApparatus for meter-controlled dispensingMagnificationIndustrial engineering

Owner:UNIVERSAL ENTERTAINMENT CORP

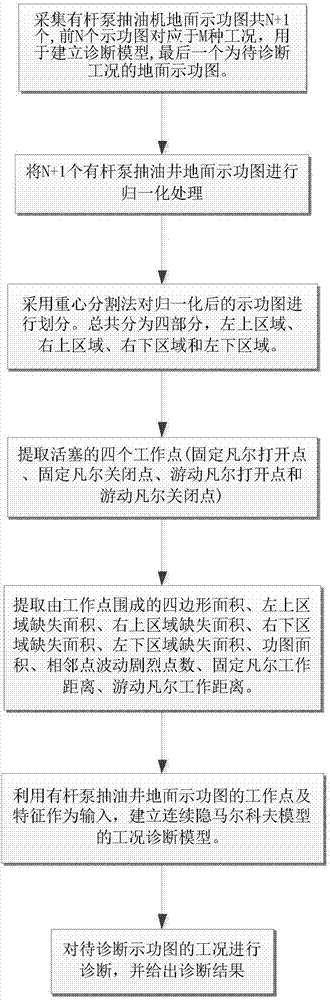

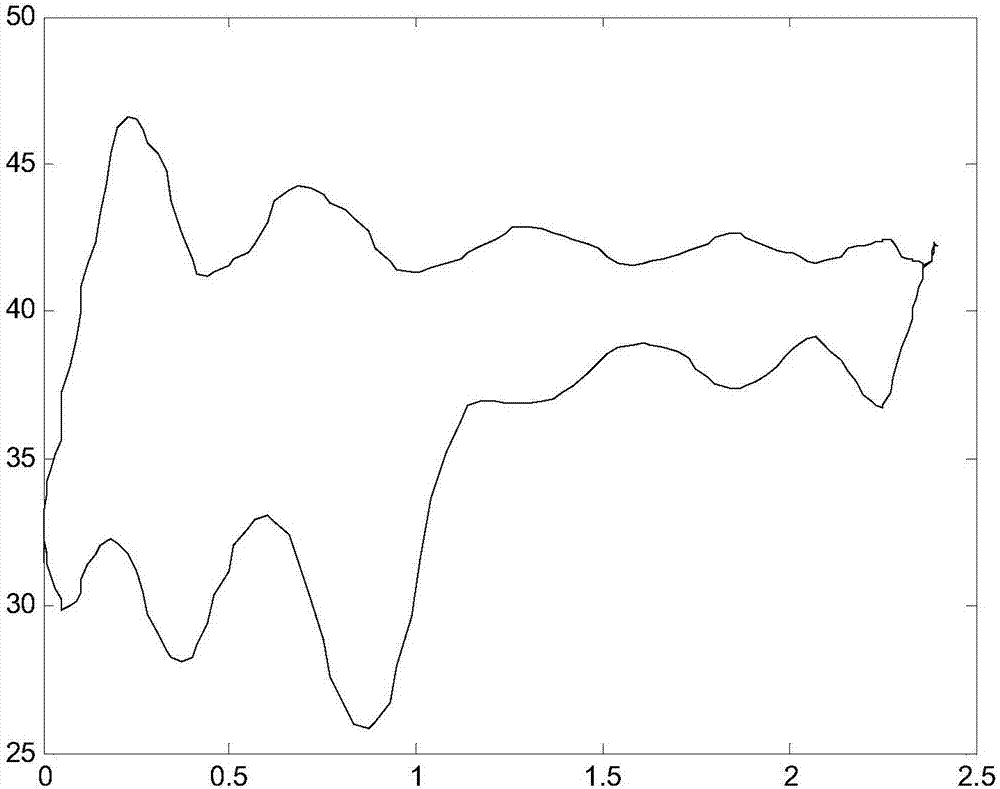

Downhole working condition diagnosis method for sucker rod pumping well based on valve working point

ActiveCN106951662AEnable real-time diagnosisReduce manufacturing costConstructionsDesign optimisation/simulationDiagnosis methodsGravity center

Owner:NORTHEASTERN UNIV

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

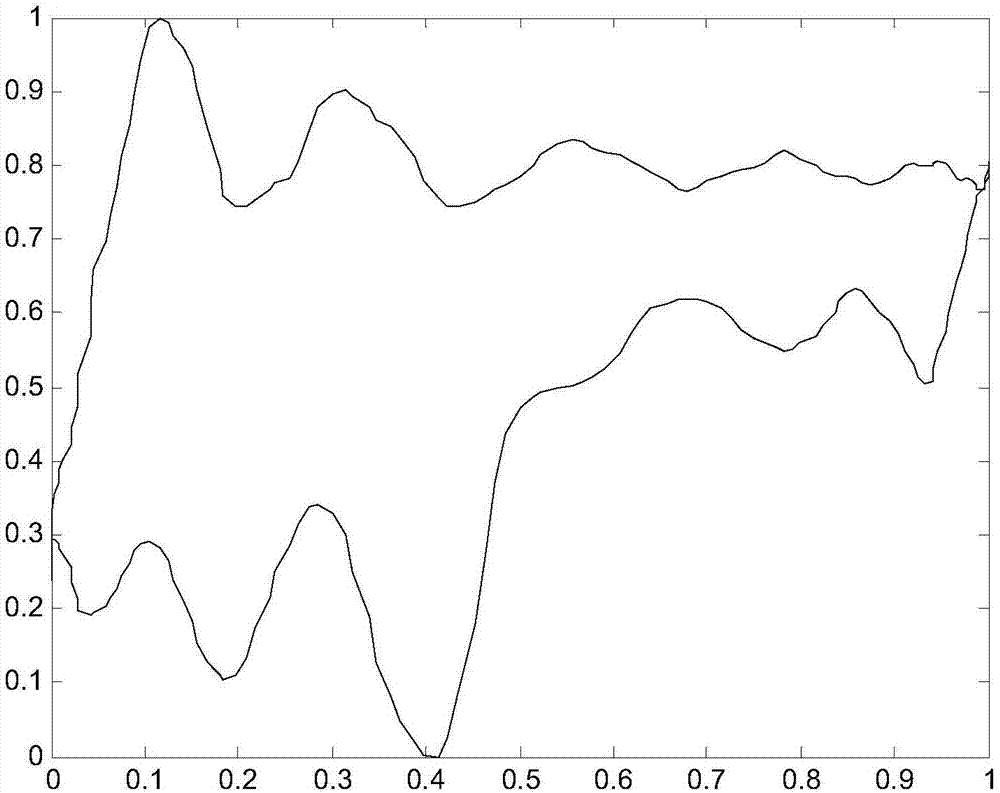

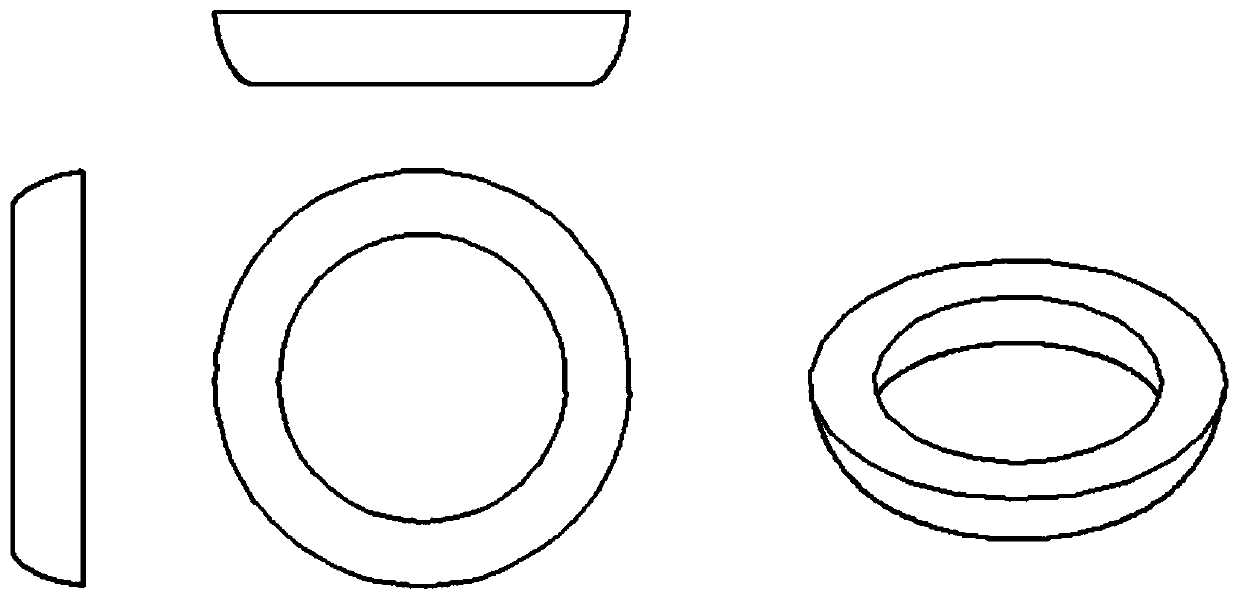

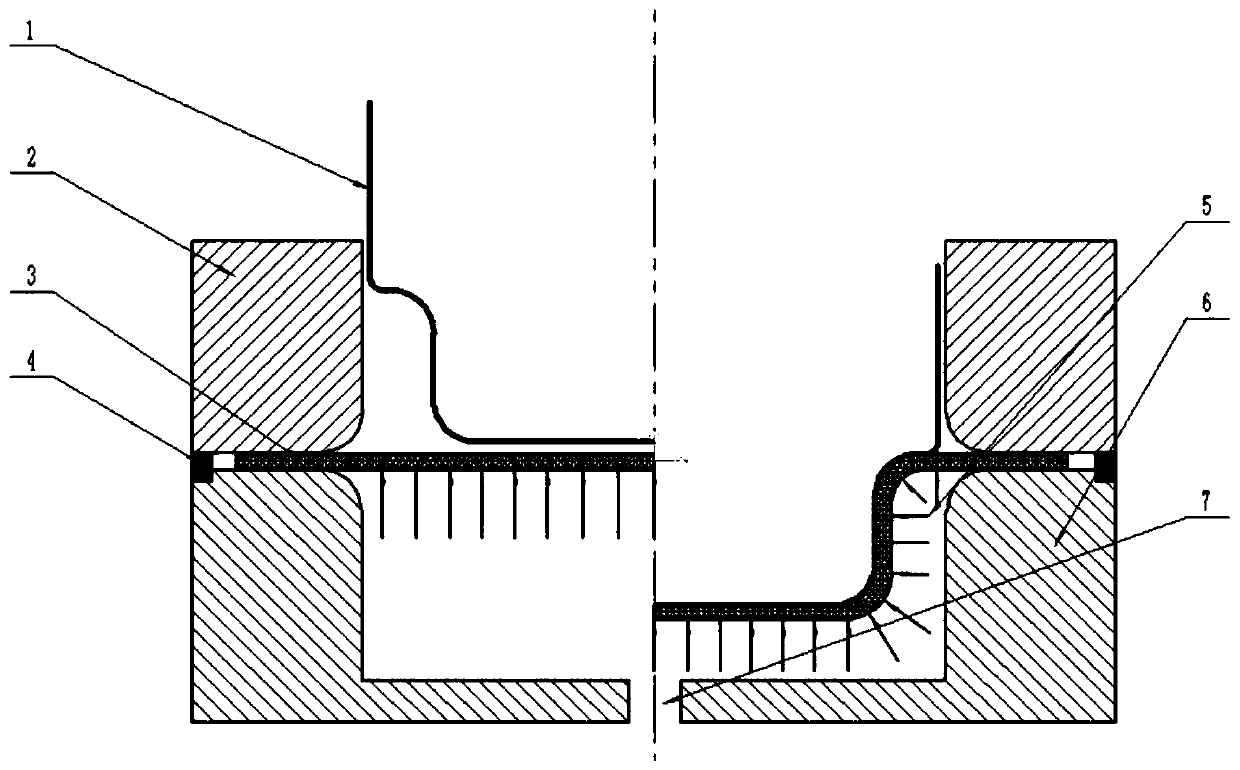

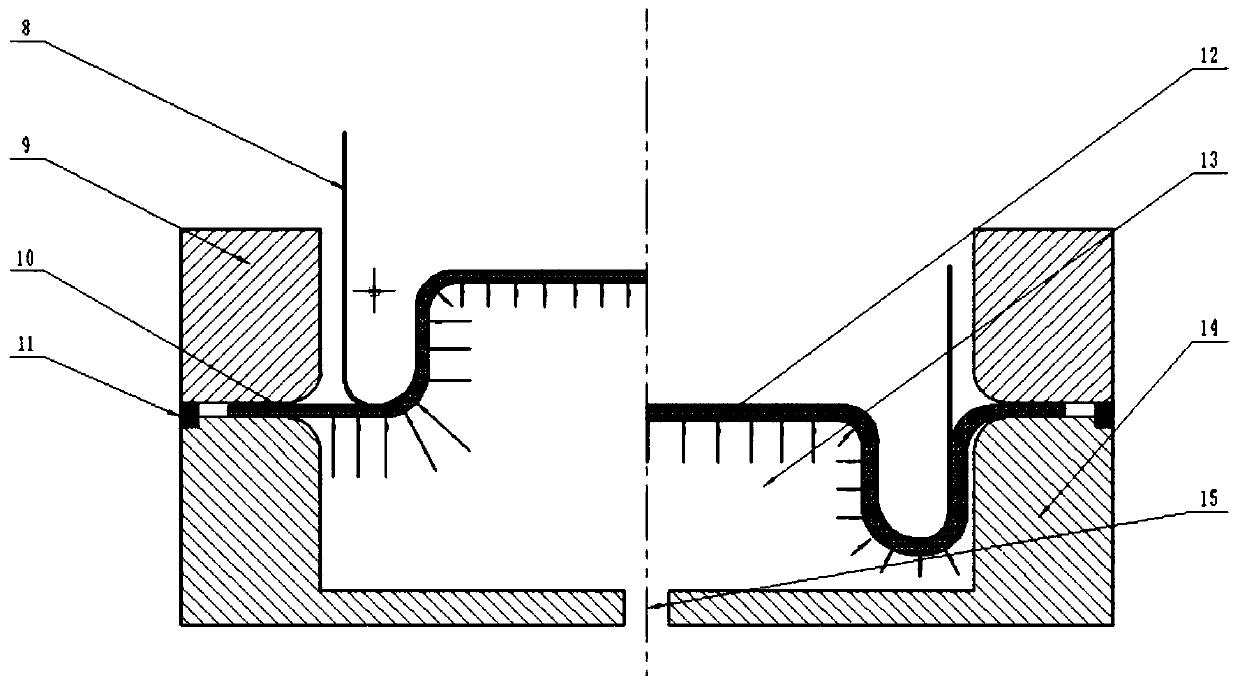

Integral liquid-filling forming method for large annular lip part

The invention provides an integral liquid-filling forming method for a large annular lip part, belongs to the technical field of aviation aerospace sheet metal forming, and can solve the problem thatlarge annular lip parts are difficult to integrally form. The method comprises the steps of design and manufacturing of a transition forming die and a final forming die, selection and debugging of technological parameters, post-processing and the like. According to the method, a novel technology of multi-step liquid-filling forming is carried out on the basis of guaranteeing integral forming of the lip parts; and the integral forming of the lip parts is realized through a two-sequence liquid filling forming process and a one-sequence shaping process. The method has the advantages of being highin forming limit, high in size precision, good in surface quality, low in cost and the like, and can effectively reduce the problems of uneven deformation, thinning or serious wrinkling in local areas, difficult elimination of resilience and the like in a traditional stamping mode, so that the local defects of the lip are reduced and the advantages are remarkable. Meanwhile, the technology can bepopularized to other parts with similar characteristics, and has good development potential.

Owner:BEIHANG UNIV

Tool changing trolley and PCB drilling and milling machine

PendingCN111586974AEasy to recycleRealize unmannedInsulating layers/substrates workingRobot handMachine

The invention belongs to the technical field of PCB processing, and discloses a tool changing trolley which comprises a trolley body, at least two layers of supporting plates arranged in the trolley body in a sliding manner, a tool box placing plate mounted on the supporting plate and sliding along with the supporting plate, a tool box fixed on the toolbox placing plate and used for placing a tool, and a manipulator arranged on the trolley body and used for taking and placing the toolbox. According to the tool changing trolley, at least two layers of supporting plates are arranged, so that atleast two layers of tool boxes can be placed, multi-layer placement of tools is achieved, the tool placing number is increased, and the working efficiency of the tool changing trolley is improved. Theinvention further provides a PCB drilling and milling machine with the tool changing trolley, unmanned, intelligent and flexible tool changing procedures can be achieved, a movable tool holder is matched with the tool changing trolley, tools can be changed while machining is conducted, the equipment utilization rate is increased, and recovery and grinding management of the tools are facilitated.

Owner:SUZHOU VEGA TECH CO LTD

Stir-frying mechanism of vegetable cooking equipment

Owner:FOSHAN POLYTECHNIC

Aerial work platform vehicle

InactiveCN107601383AAccurately reflectImprove securityLifting devicesSpecial purpose weighing apparatusAerial work platformIndustrial engineering

Owner:XCMG CONSTR MACHINERY

Technology for making double-layer knitted inner container thermal shirt

ActiveCN103960787AEnsure production efficiencyQuality assuranceWarp knittingNon-woven fabricsMechanical engineeringIndustrial engineering

Owner:苏州新超针纺织有限公司

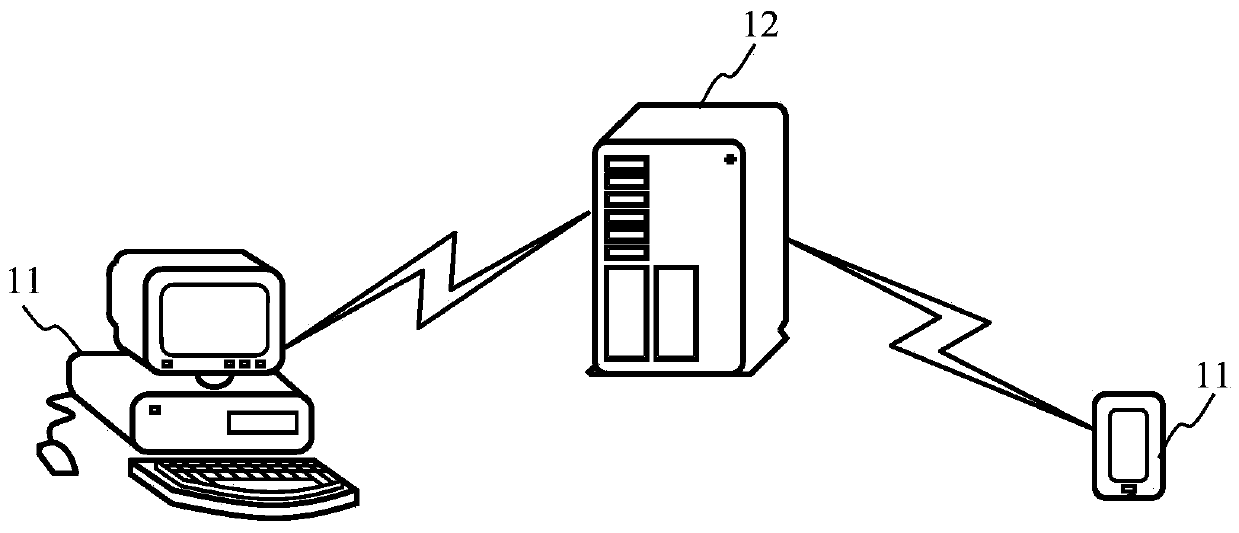

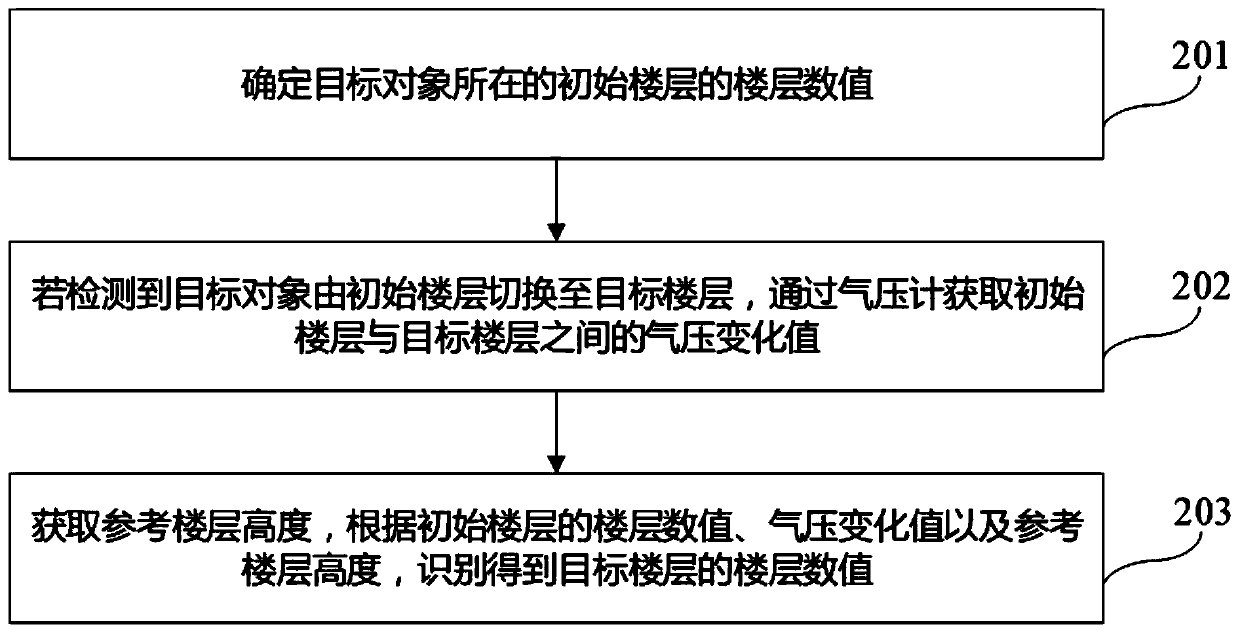

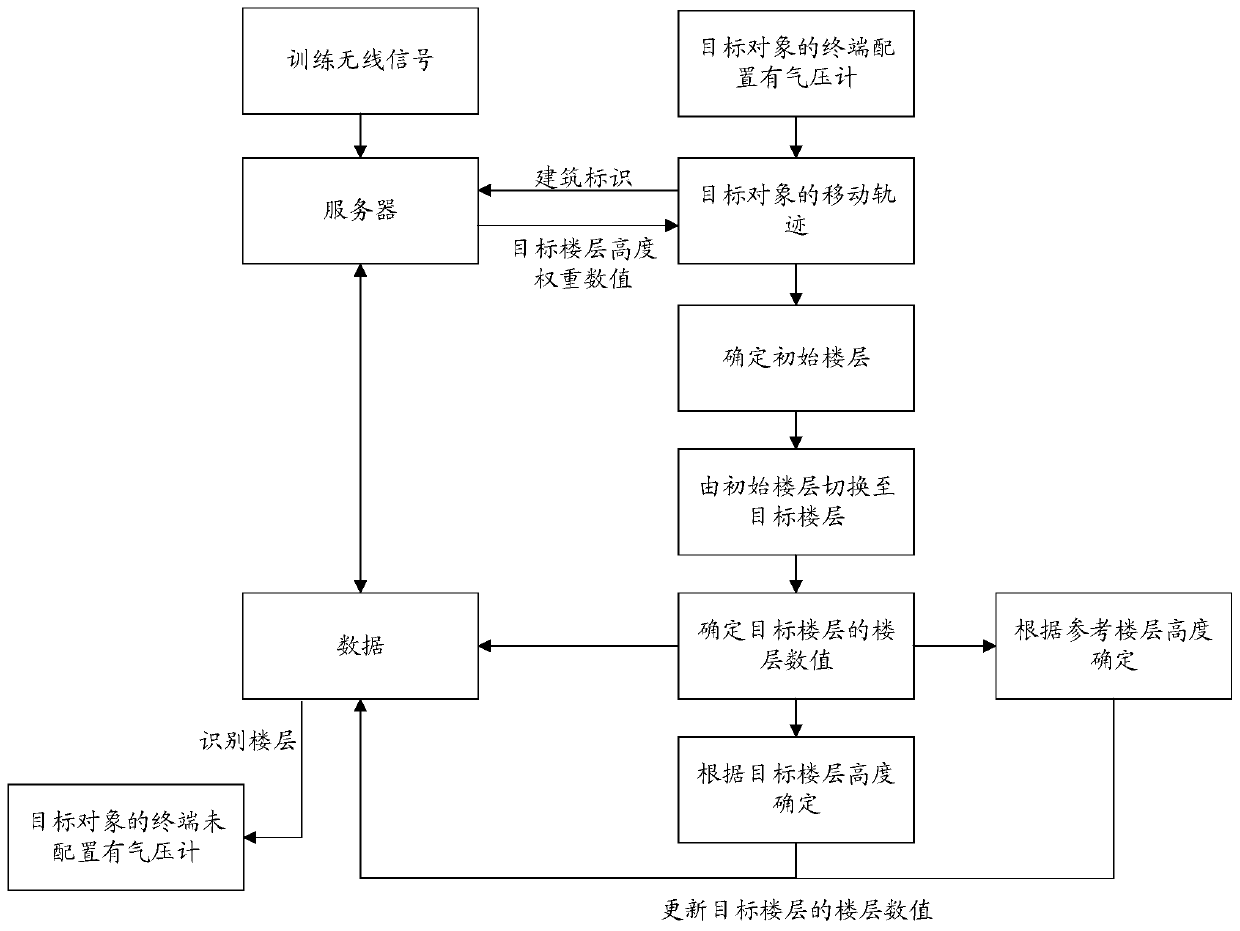

Floor recognition method and device, electronic equipment and storage medium

ActiveCN110926473ANavigational calculation instrumentsFluid pressure measurementMechanical engineeringIndustrial engineering

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

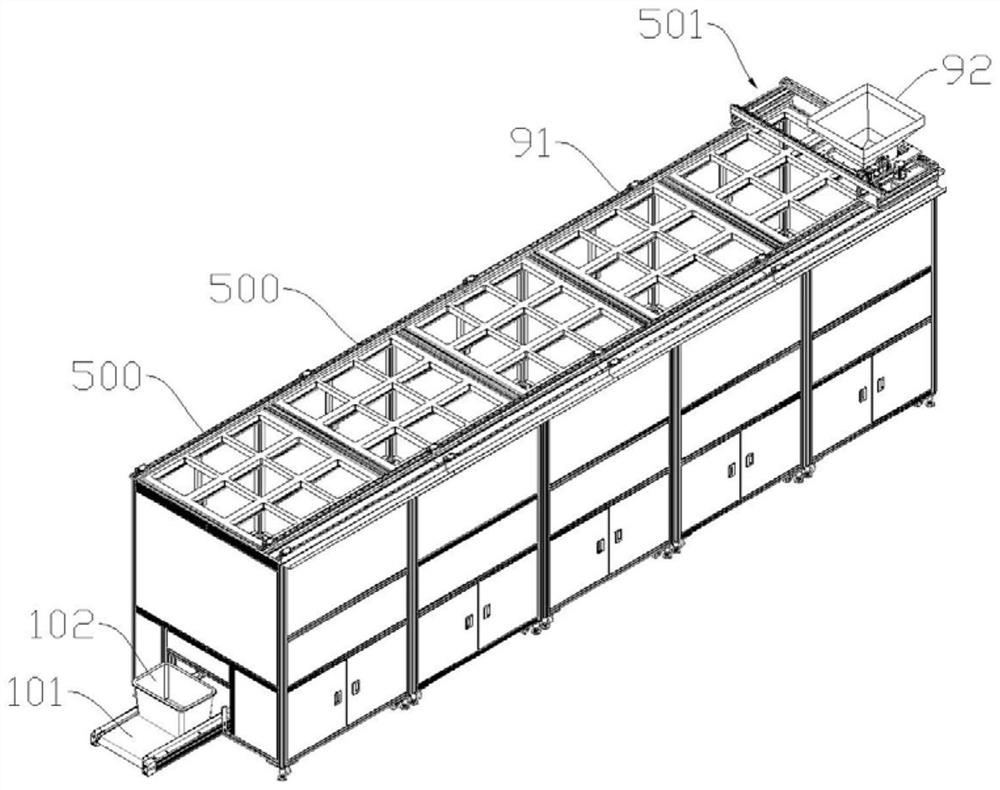

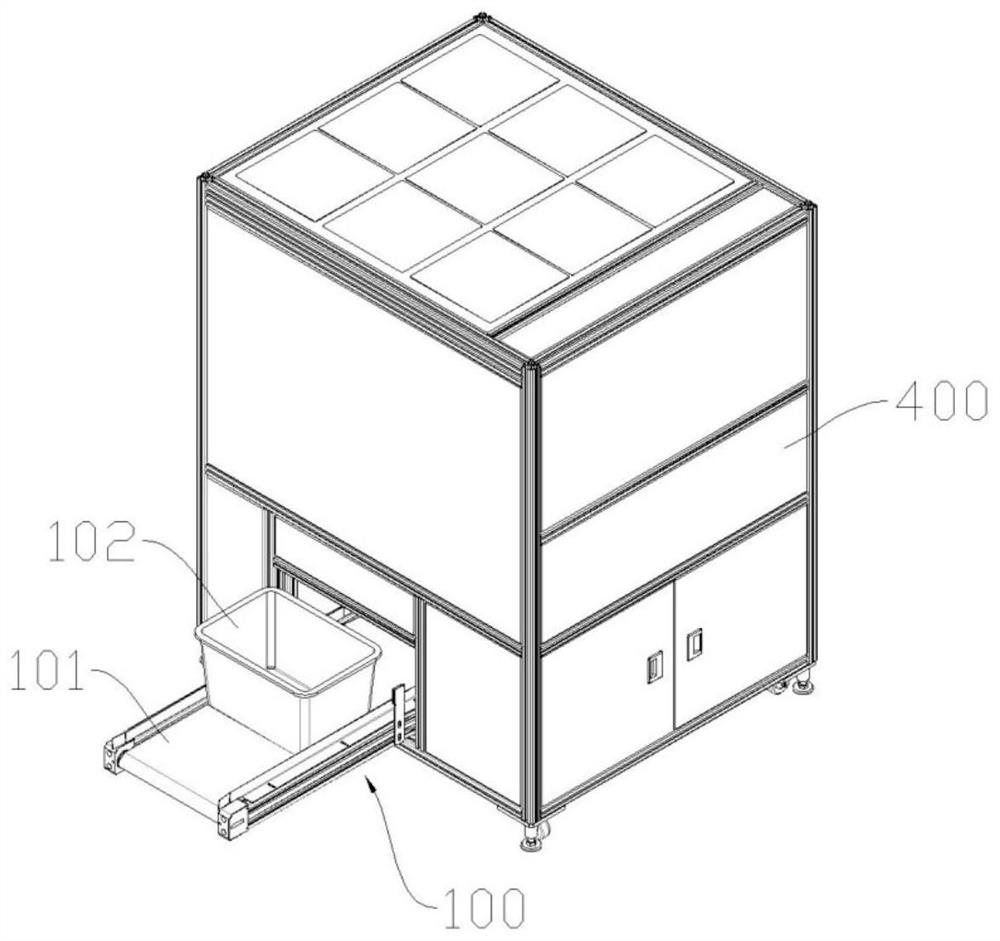

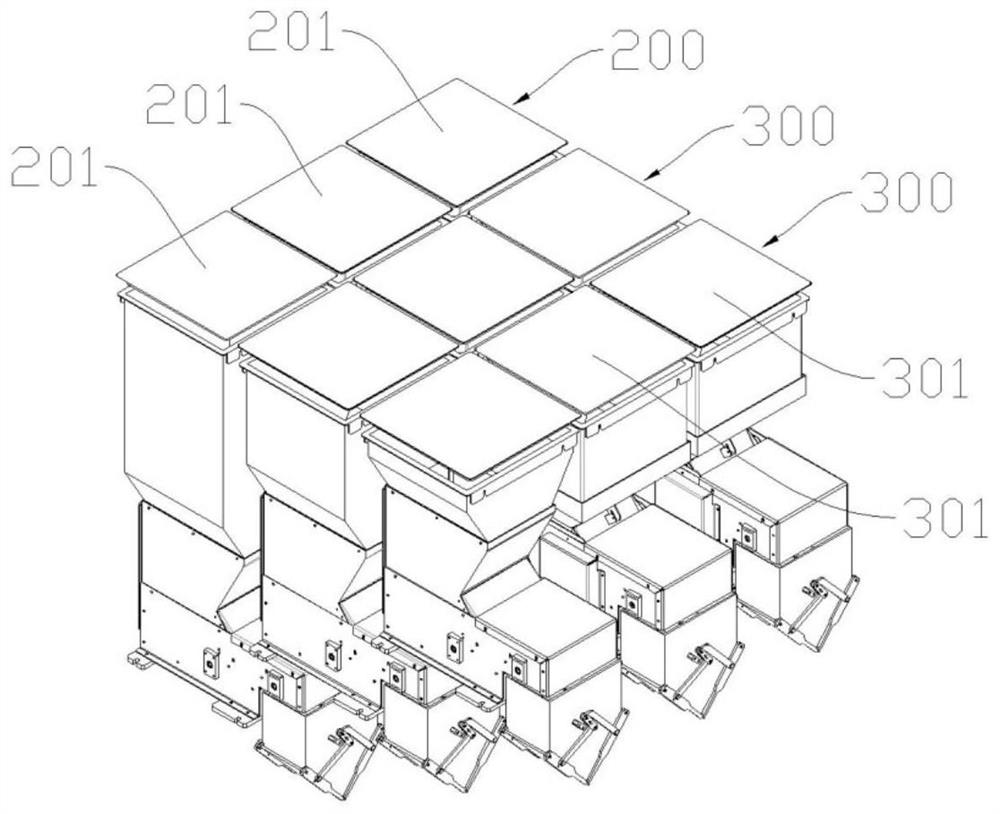

Automatic traditional Chinese medicine dispensing system

ActiveCN112722725AStable outputImprove adjustment efficiencyControl devices for conveyorsPackagingMedicinal herbsProcess engineering

Owner:SUZHOU IRON TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap