Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Logistics management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics is the management of the flow of things between the point of origin and the point of consumption to meet requirements of customers or corporations. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items. The logistics of physical items usually involves the integration of information flow, materials handling, production, packaging, inventory, transportation, warehousing, and often security.

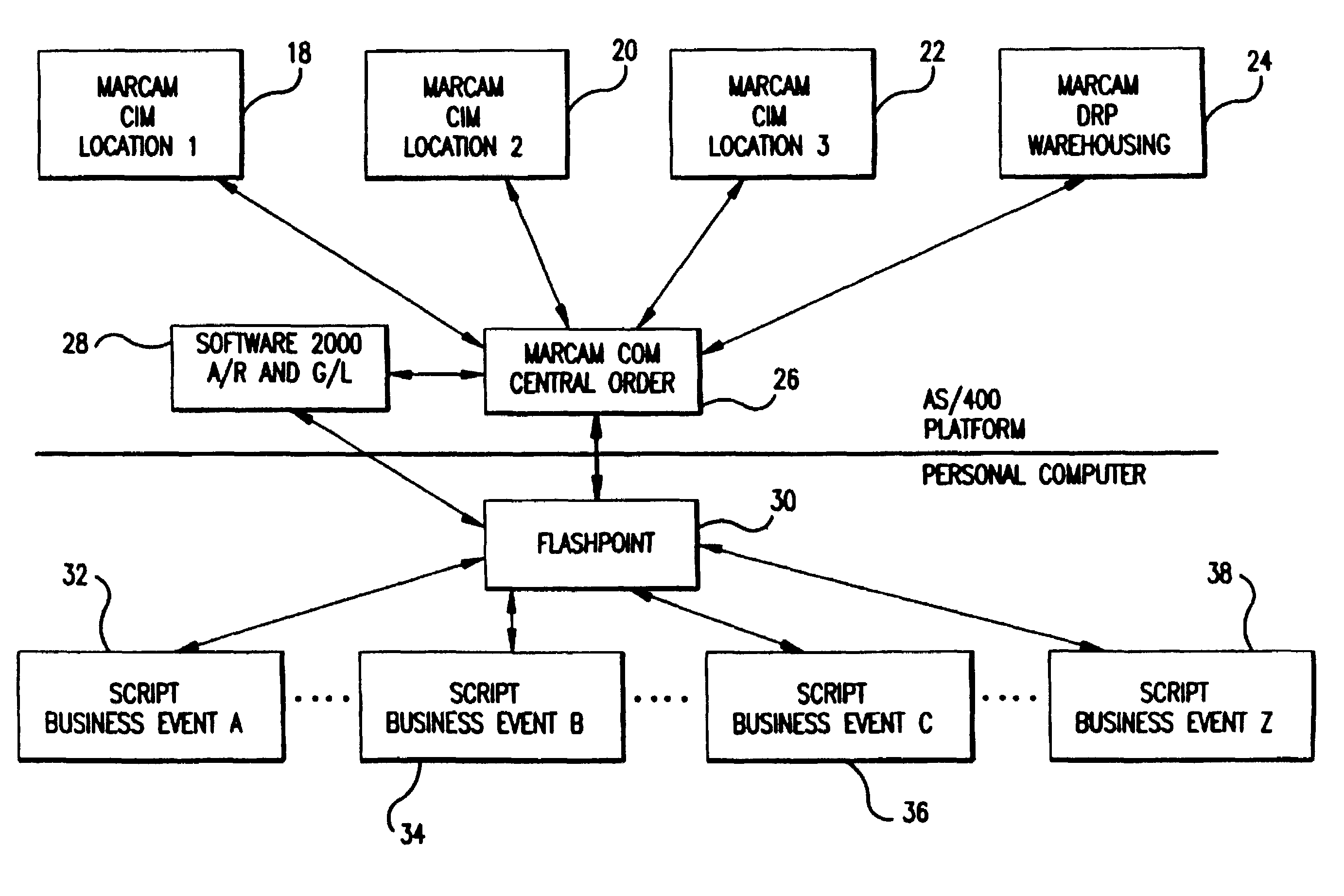

Computer method and apparatus for vessel selection and optimization

InactiveUS6983186B2Accurate dataFew typographical errorFinanceOffice automationLogistics managementComputer methods

Owner:ASPENTECH CORP

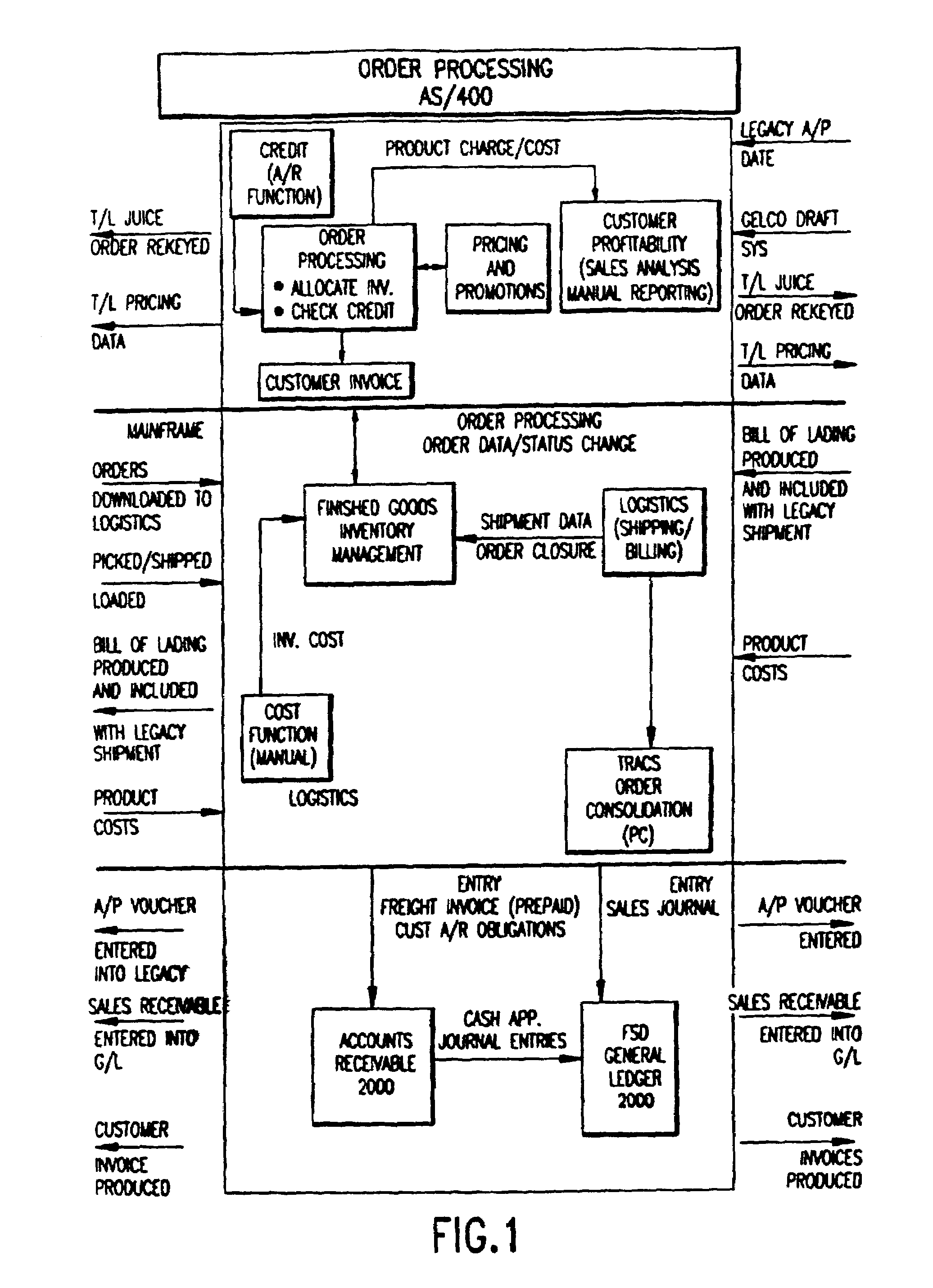

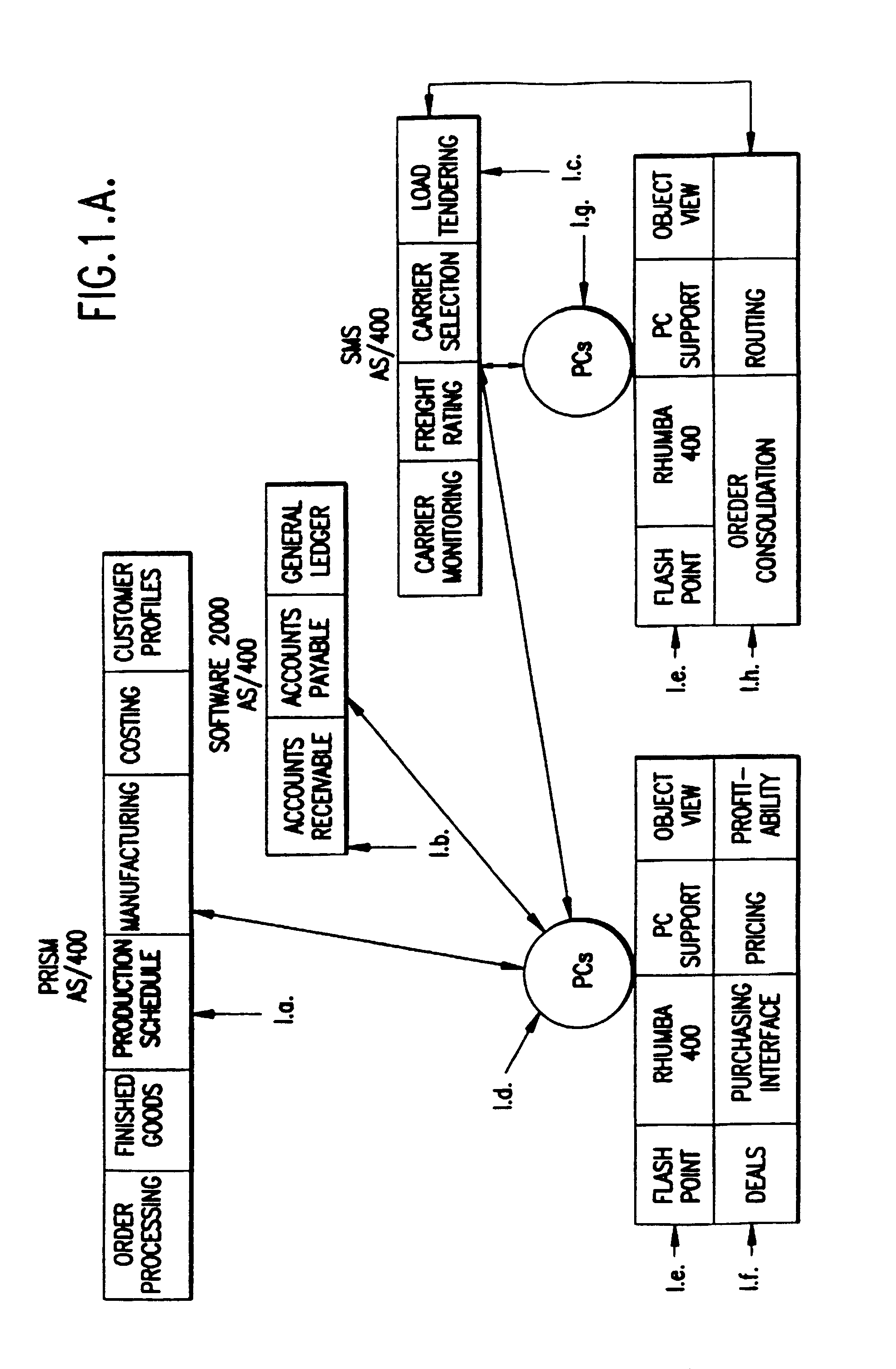

System for managing orders and method of implementation

InactiveUS7050995B2Efficient receptionDiscounts/incentivesFinanceCost effectivenessLogistics management

Owner:LYKES BROTHERS

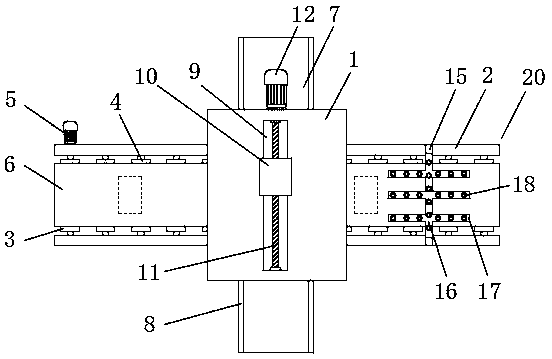

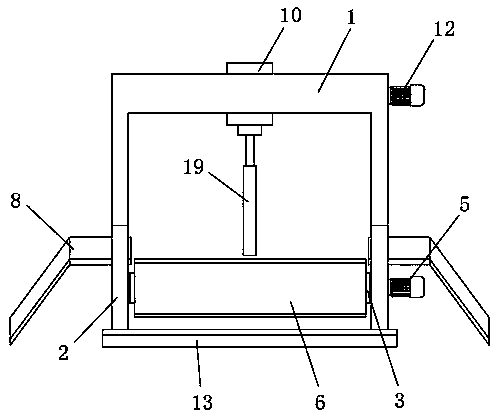

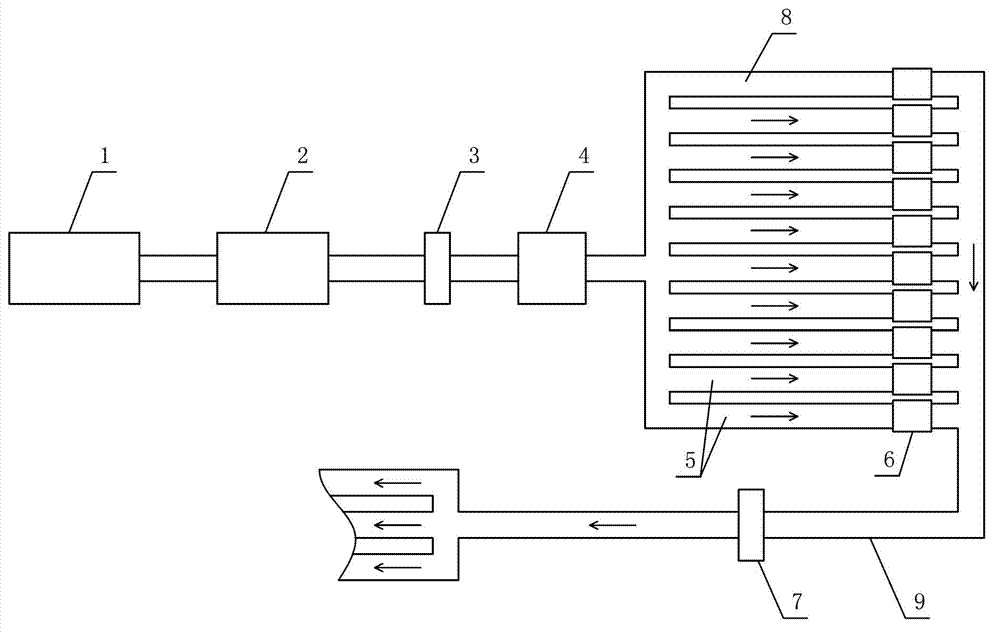

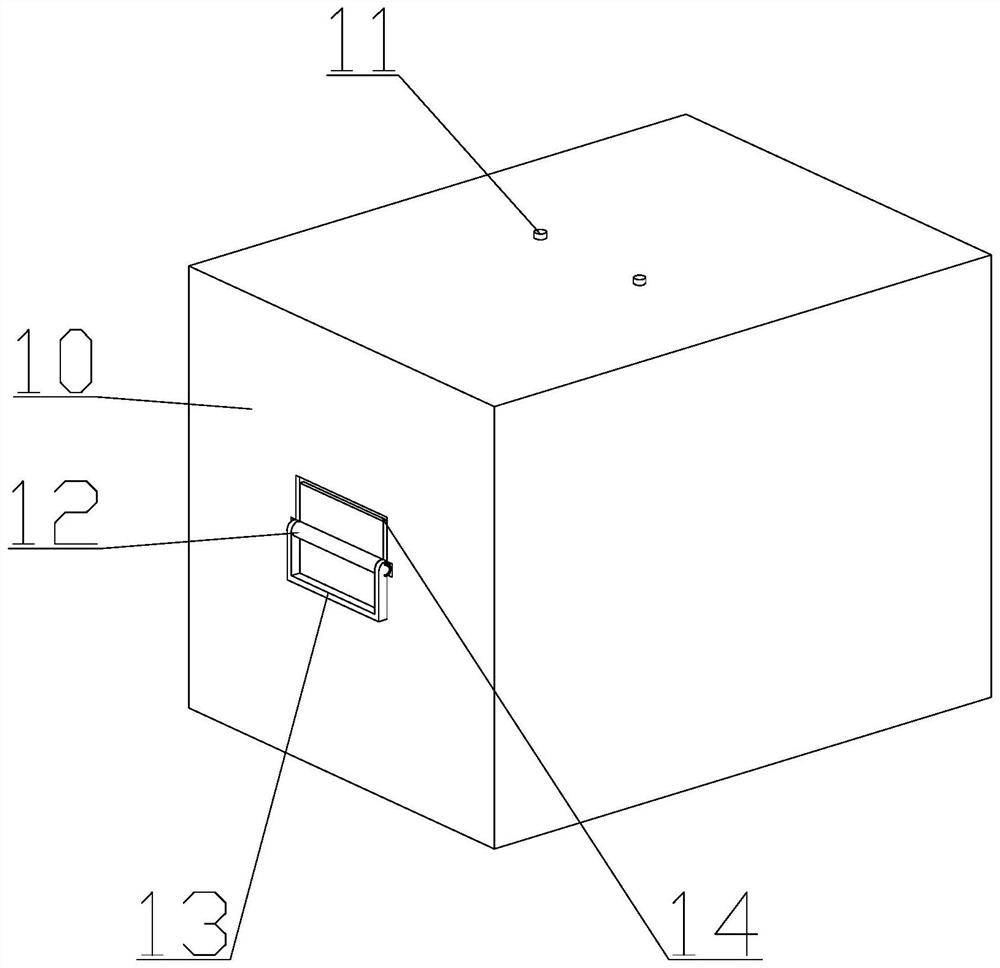

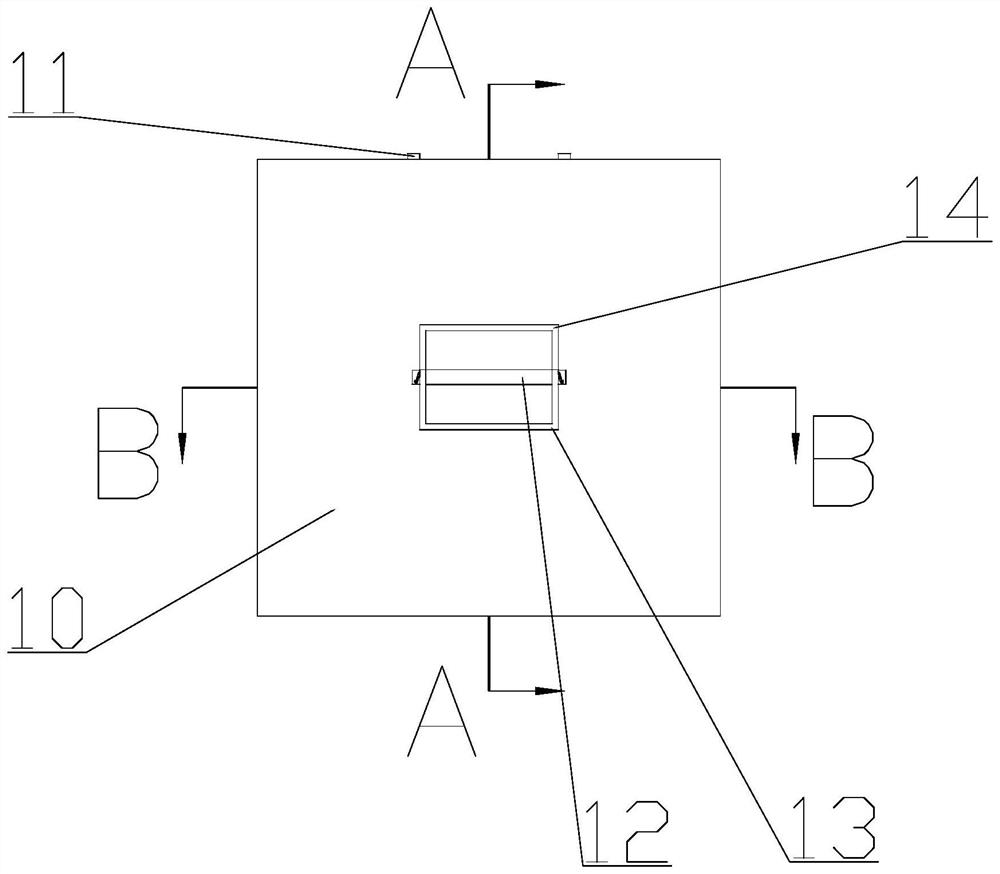

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

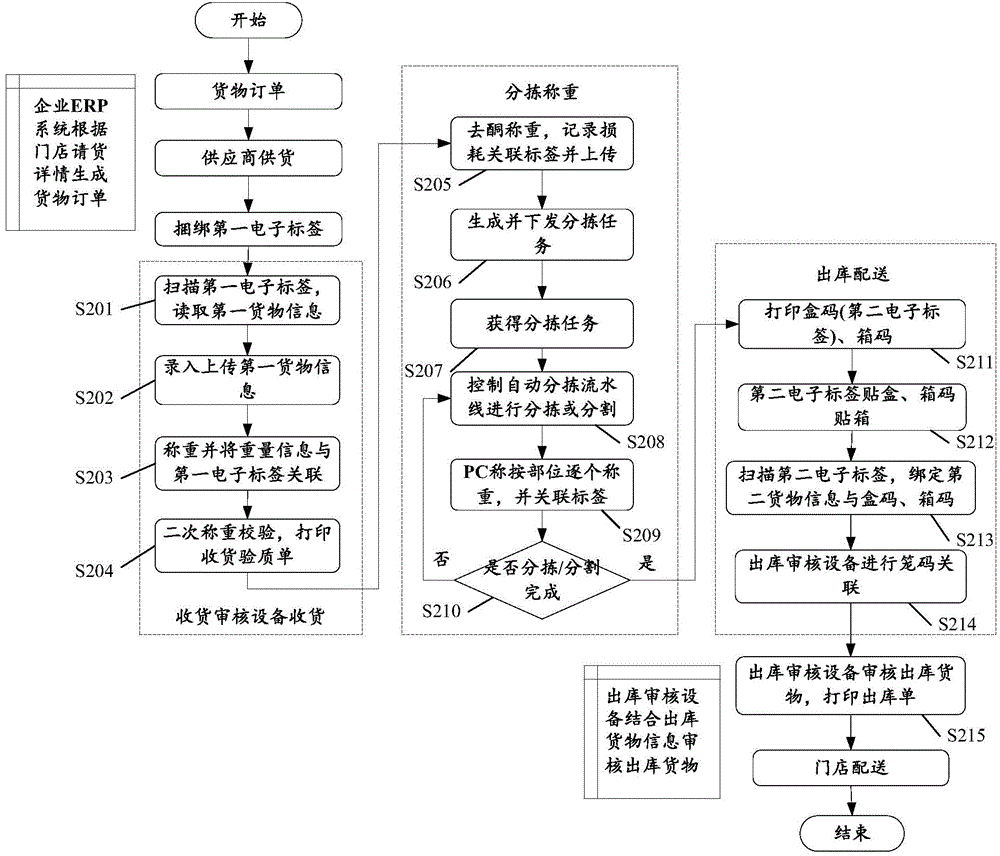

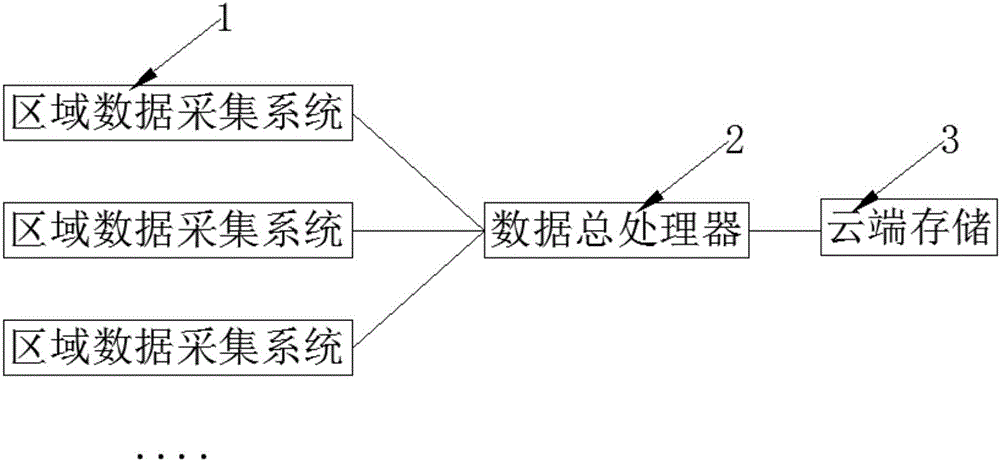

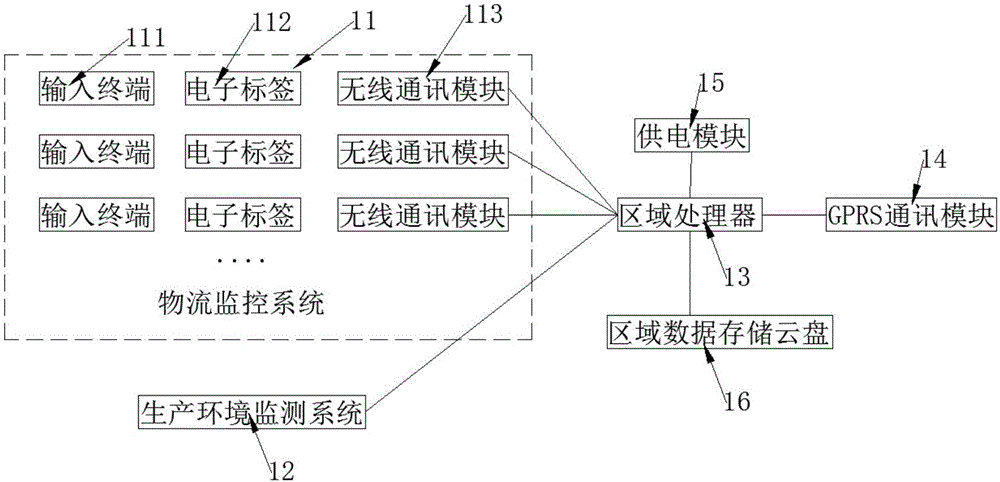

Internet of Things system for supply chain management

ActiveCN104463549AResolve accuracySolve efficiency problemsLogisticsLogistics managementAssembly line

Owner:武汉华工赛百数据系统有限公司

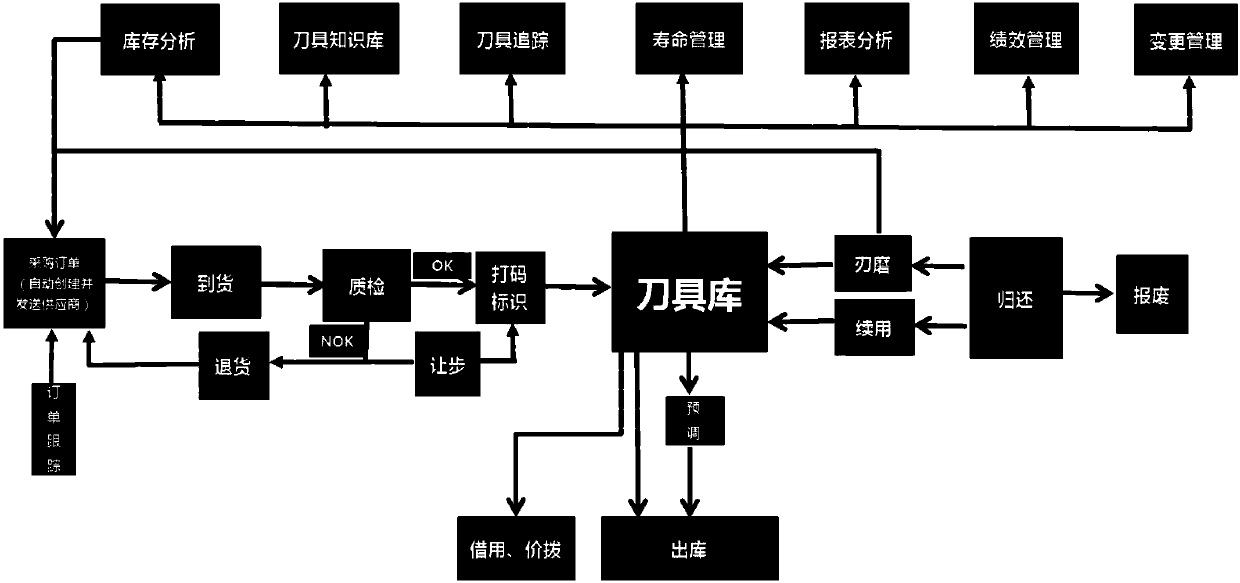

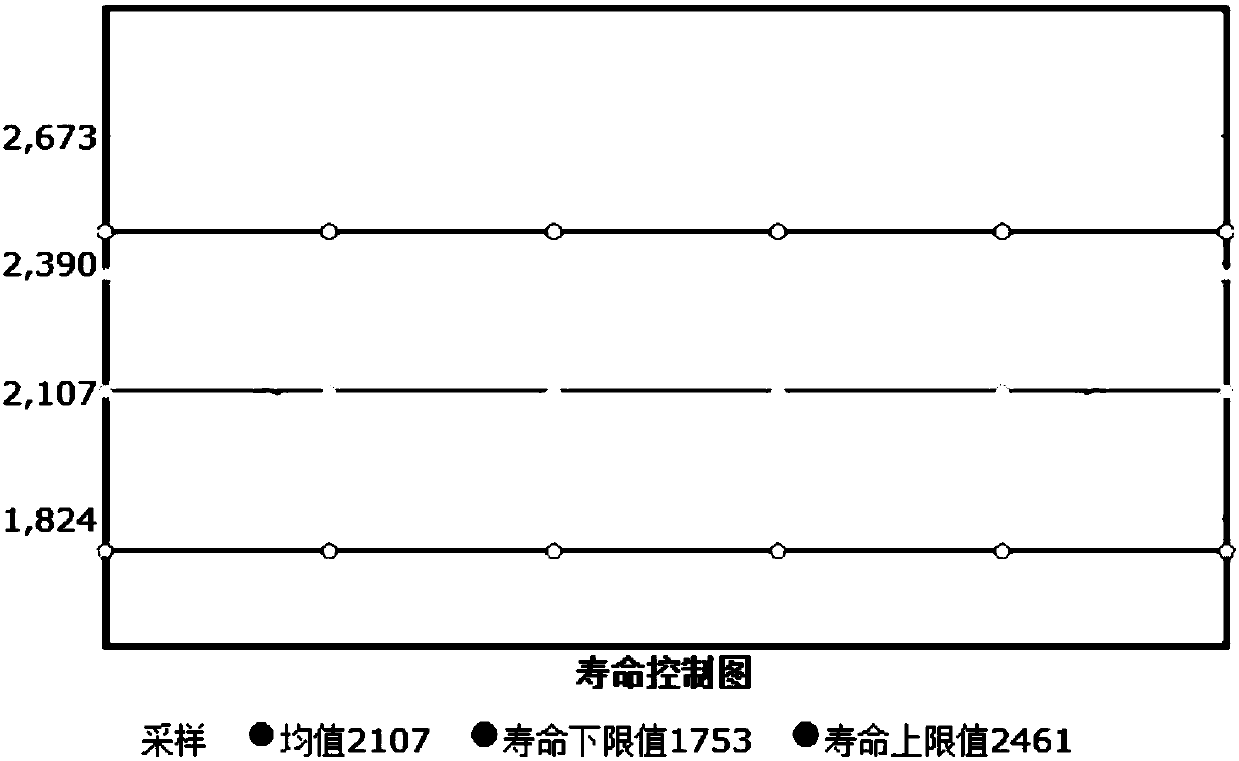

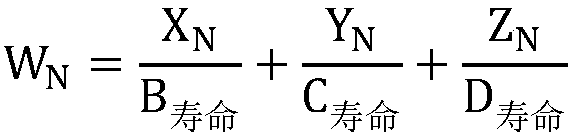

Tool management method

ActiveCN108492016ARealize "one item, one code" traceability managementReliable lifeResourcesLogisticsManufacturing cost reductionLogistics management

Owner:CSG TRW CHASSIS SYST CO LTD

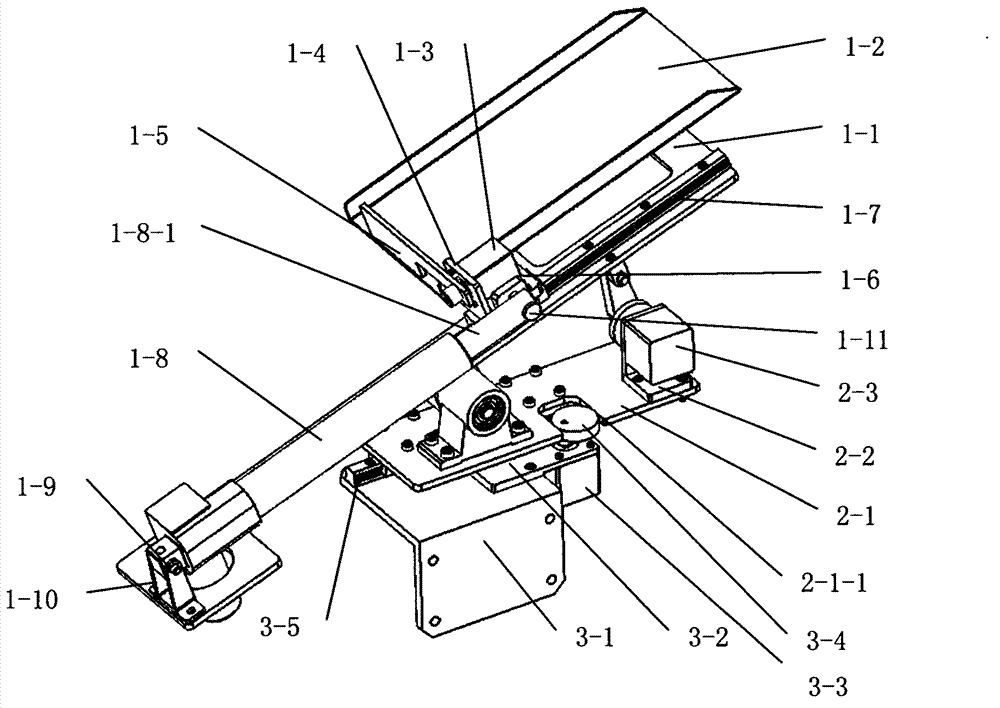

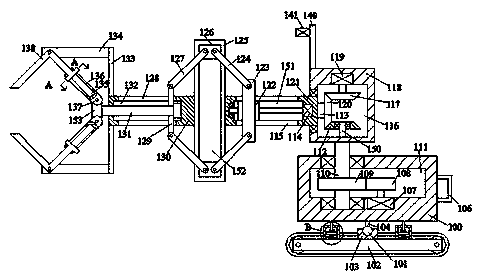

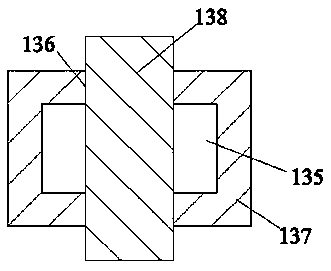

Telescopic belt conveyor changeable in amplitude and direction

ActiveCN106966116AFunction increaseExtended working hoursConveyorsLogistics managementClassical mechanics

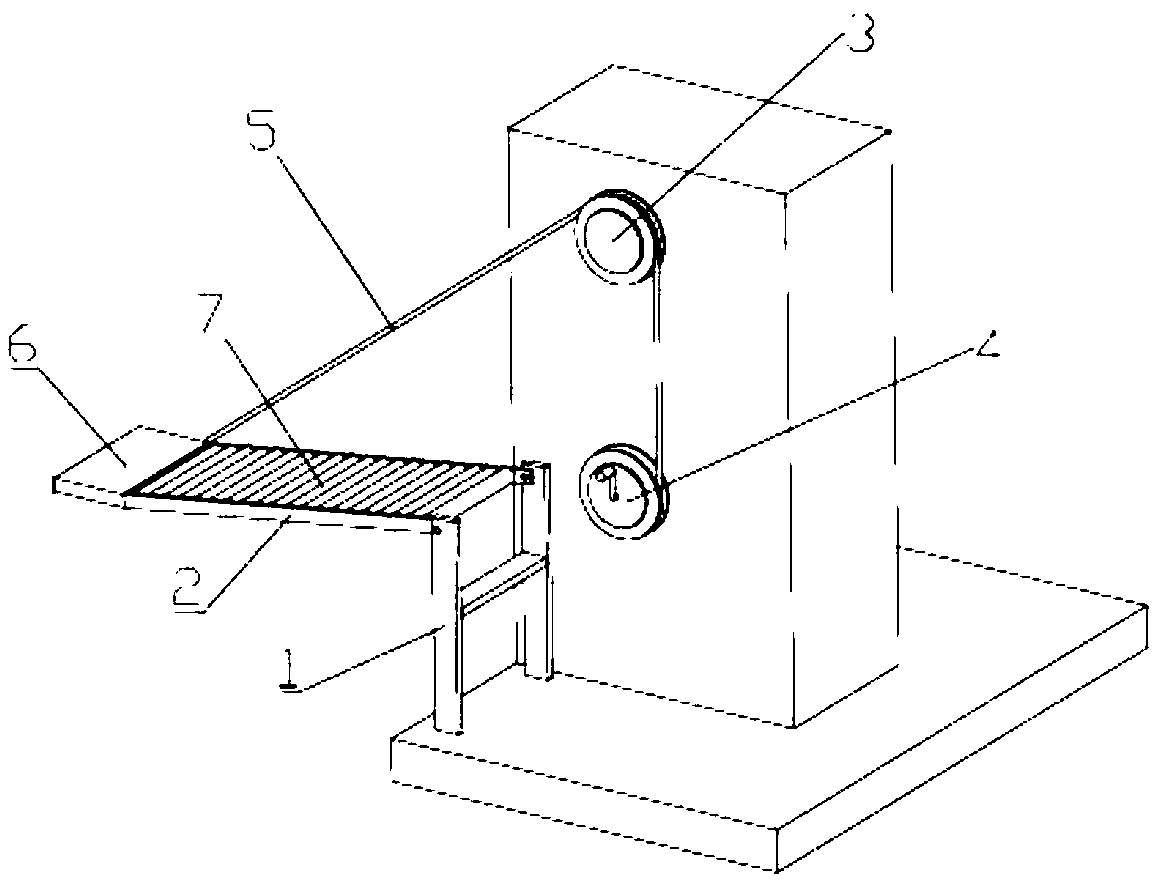

The invention discloses a telescopic belt conveyor changeable in amplitude and direction, and relates to the field of logistics transportation cargo handling mechanical equipment. The telescopic belt conveyor is composed of a three-section two-stage telescopic belt conveyor body with a telescopic function, an amplitude change mechanism with tilting and amplitude change functions, and a swing rotating mechanism with swing rotating and direction change functions. According to the telescopic belt conveyor changeable in amplitude and direction, a sleeved telescopic machine frame structure is adopted, and the elongation and shortening function, the tilting and amplitude change functions and the swing rotating and direction change functions of the belt conveyor are added by additionally arranging the amplitude change mechanism and the swing rotating mechanism; the conveying range is widened, along with conducting of the loading, unloading and conveying processes, under the condition that loading and unloading places of materials are changed, the conveying distance, height and direction are adjusted by driving and controlling a telescopic mechanism, the amplitude change mechanism and a direction change mechanism, and thus, the telescopic belt conveyor can adapt to change of the loading and unloading places; cargoes are directly delivered to the destination through only one time of loading and unloading, manual auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading efficiency is improved, and the loading and unloading carrying cost is reduced; and the working environment and the labor condition are effectively improved, and the effect that loading and unloading transport is economical, rapid, convenient and safe is ensured.

Owner:XIANGYANG ZHONGLIANG ENG MASCH CO LTD

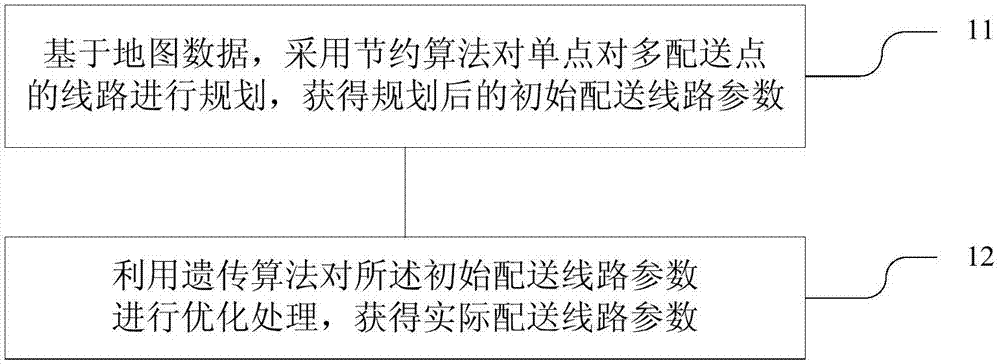

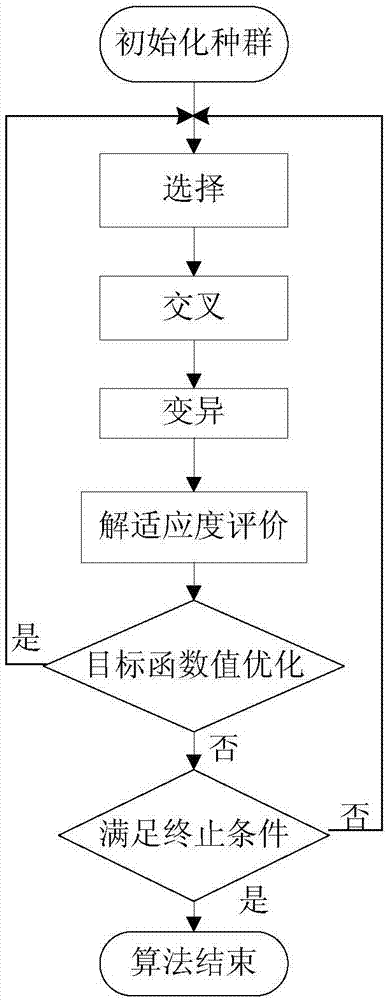

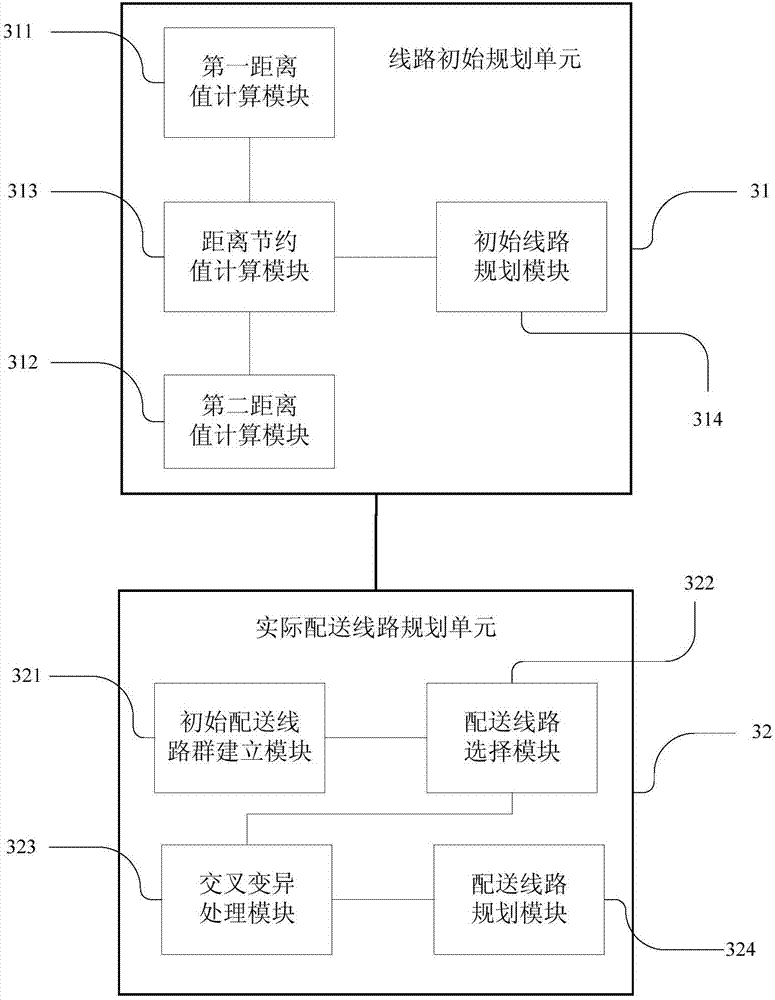

Single-vehicle multi-site distribution line processing method

PendingCN107358326AImprove distribution efficiencySequential calculation is reasonableForecastingLogisticsLogistics managementGenetics algorithms

Owner:SHENZHEN CARELAND TECH

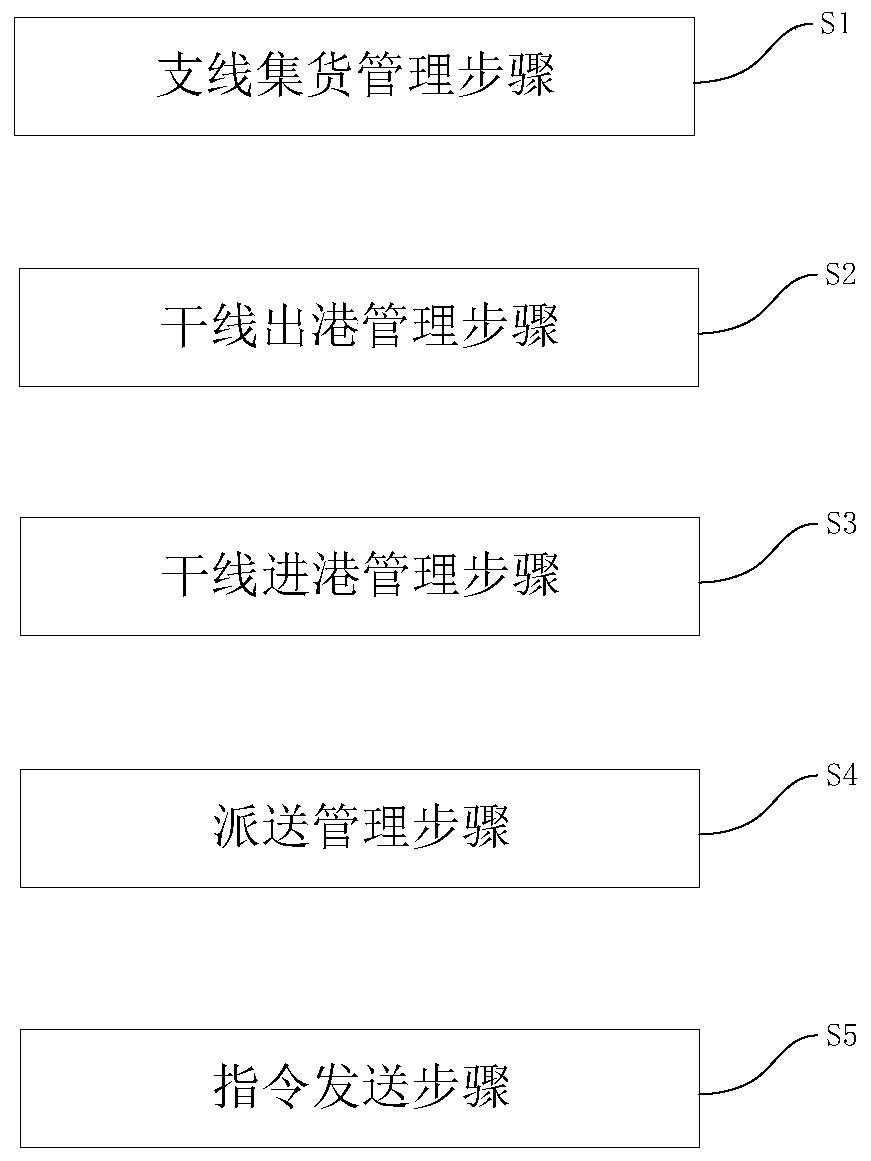

Intelligent logistics management method for allocation center

ActiveCN110348613AReal-time monitoring of operating conditionsReduce operating costsReservationsForecastingCustomer requirementsLogistics management

Owner:深圳市恒路物流股份有限公司

Large-size parcel sorting device used for logistics sorting

Owner:长沙佐迩信息科技有限公司

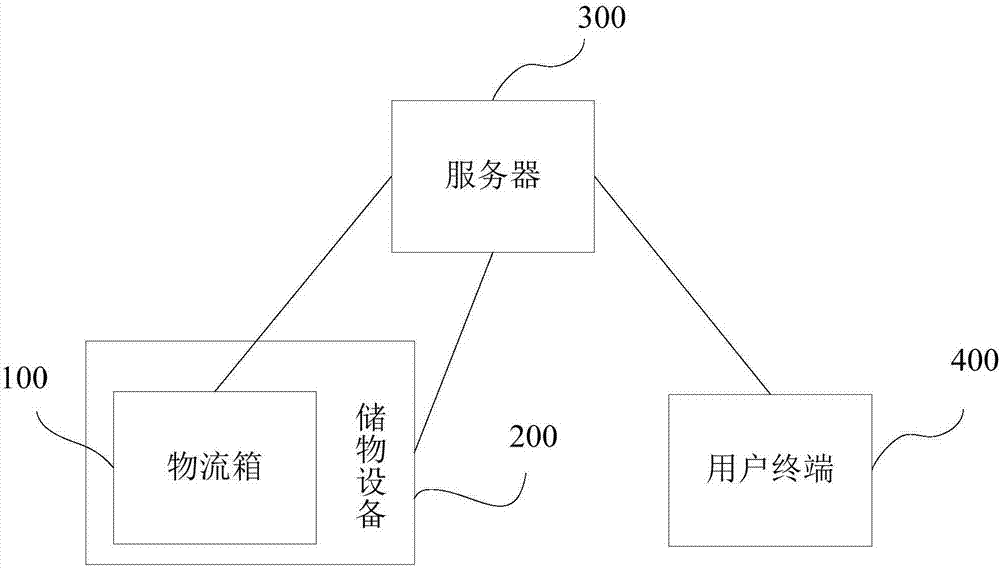

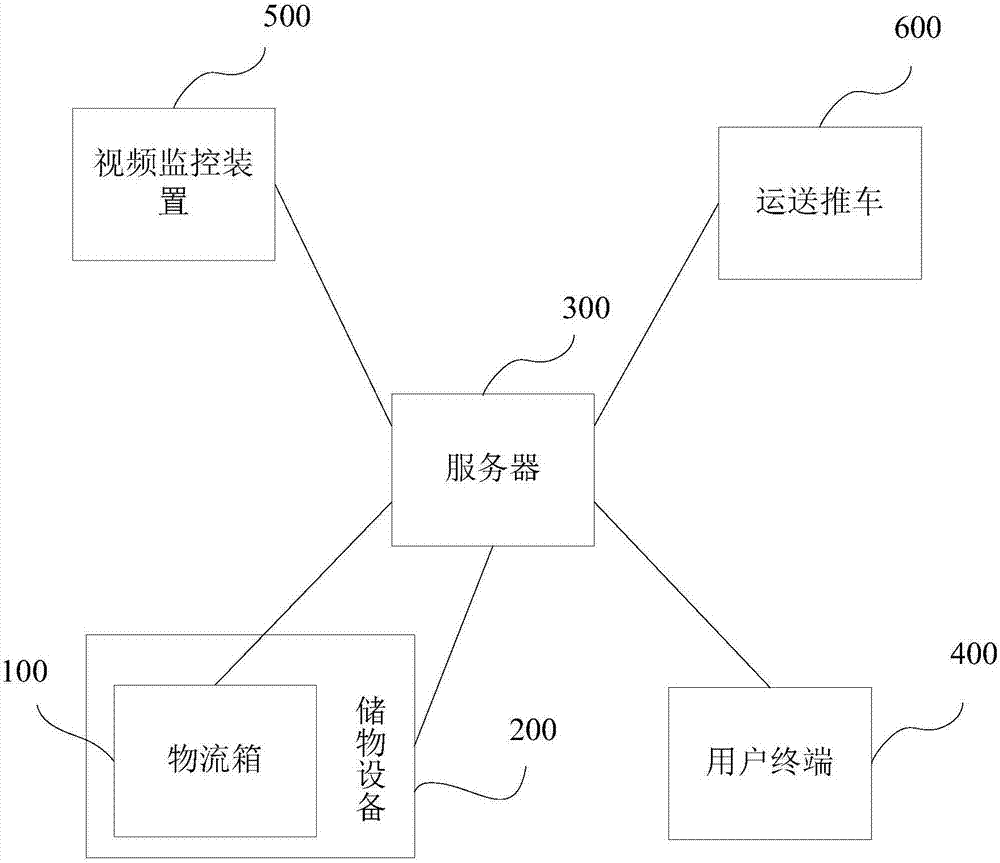

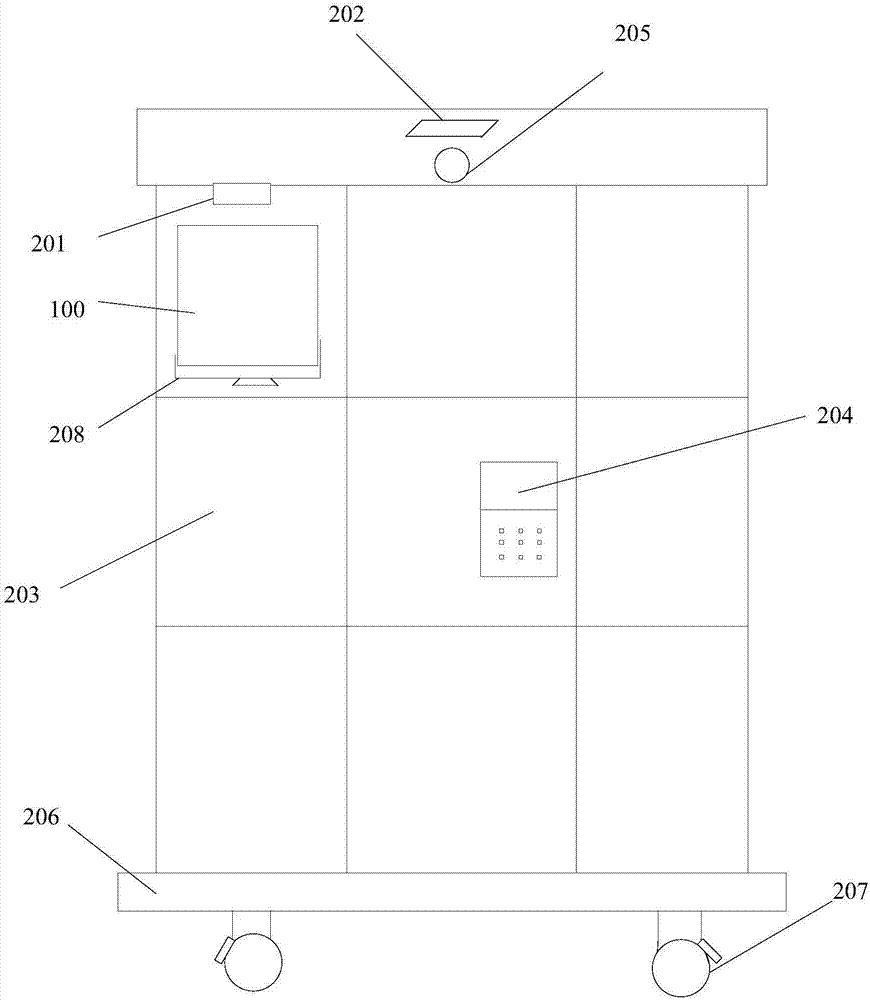

Management system and method of shared logistics box

Owner:HANGZHOU NAJIE TECH CO LTD

Container yard management mode on cloud

ActiveCN110510314ASolve the contradiction of tight land supplySolve the contradiction of the whole process informatization and transparency requirementsConveyorsLogisticsInformatizationLogistics management

The invention discloses a container yard management mode on cloud, and belongs to the technical field of container logistics. The container yard management mode on cloud involves a port information center, a container operator, a container yard, a CFS warehouse, a consolidated company and a consolidated truck driver. According to the container yard management mode on cloud, the contradiction between ground demands of the container yard and land tension of surroundings around the port, the contradiction between the empty-load transportation of devanning service empty container returning and theempty-load transportation of encasement service container despatching and the contradiction between traditional yard informatization island and logistics informatization demands are comprehensively solved. After containers are devanned, the containers are directly matched with the nearest container user, and when the container amount is insufficient, the containers are supplemented by the imported to-be-lightered containers, and then linkage supplemented by the container yard if insufficiency still exists. In the process, a cloud container yard platform realizes intelligent scheduling of thecontainers through big data cloud computing, and each qualified to-be-returned container is used as an inventory of the cloud container yard platform; meanwhile, the yard dispatching mode is transformed into a cloud container yard platform mode combining a distributed type, micro-inventory, direct-matching with fast-circulation; and finally, a traditional container yard is reserved and is used asan inventory and maintenance container.

Owner:SHANGHAI BOX CLOUD LOGISTICS TECH CO LTD

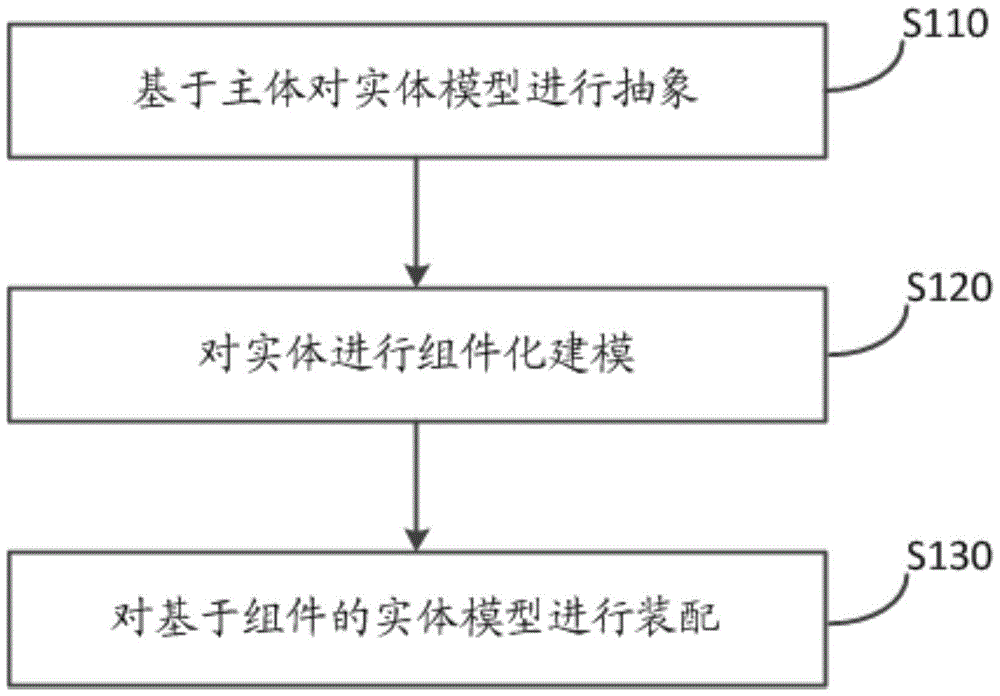

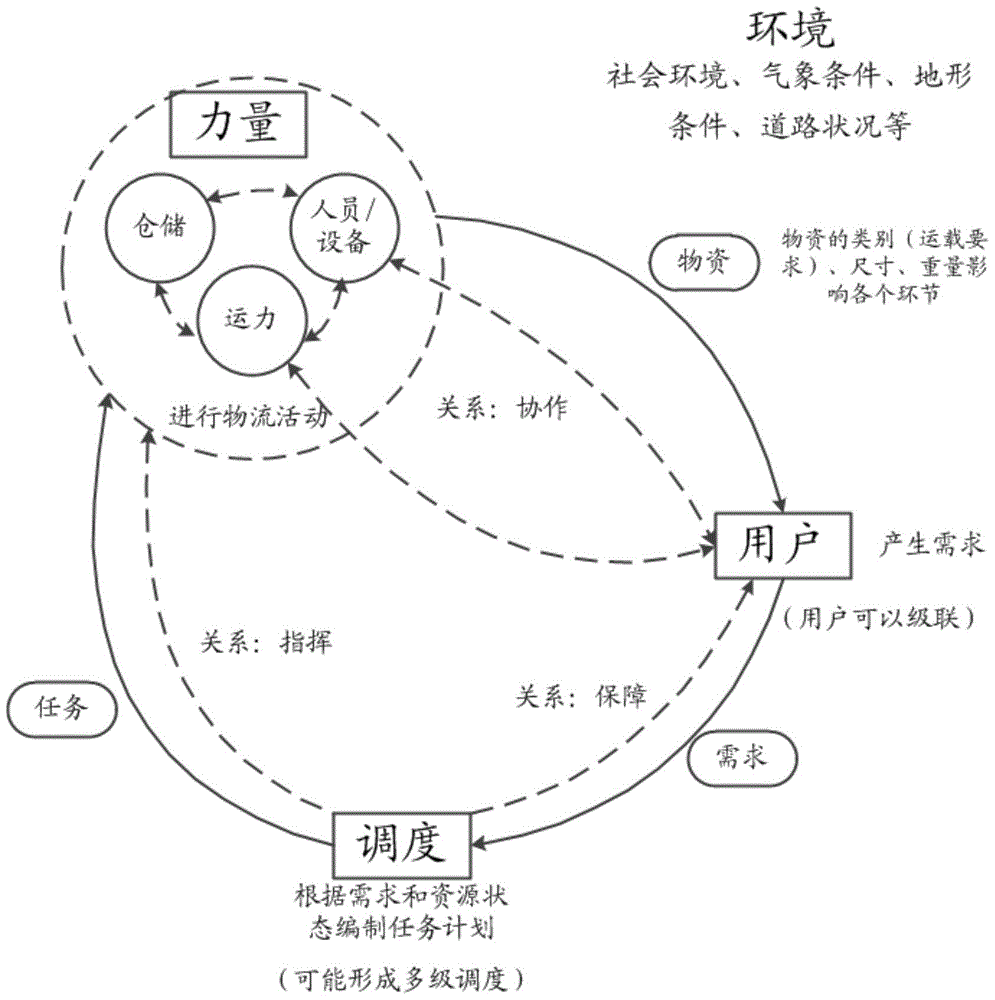

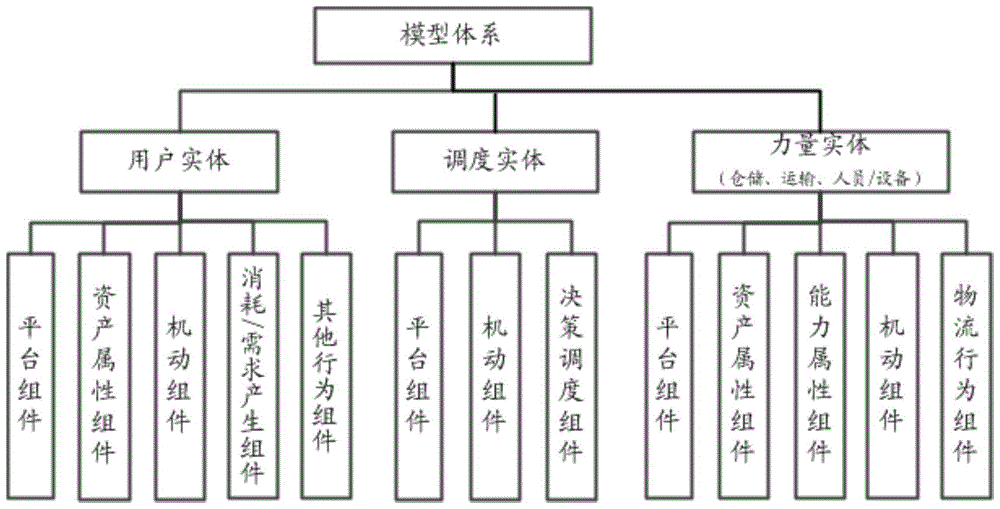

Agent-based modularized logistics system simulation computation method

ActiveCN105701273AUniversalImprove applicabilityLogisticsSpecial data processing applicationsEntity typeLogistics management

Owner:BEIJING HUARU TECH

Stocking-up system and method

InactiveCN102862809ASmall footprintImprove replenishment efficiencyConveyor partsLogistics managementStack machine

Owner:浙江省烟草公司绍兴市公司

Automatic sorting device for box-shaped articles

Owner:QILU UNIV OF TECH

Automatic sorting and processing assembly line of logistics warehouse

ActiveCN111545477AImprove work efficiencyIncrease sliding forceStacking articlesSortingLogistics managementProcess engineering

The invention relates to an automatic sorting and processing assembly line of a logistics warehouse. The automatic sorting and processing assembly line of the logistics warehouse comprises a sorting device and conveying and stacking devices, wherein the conveying and stacking devices are symmetrically arranged front and back on the left side of the sorting device, and the lower ends of the sortingdevice and the conveying and stacking devices are arranged on the existing working ground. According to the design concept of the sorting-stacking integrated structure, automatic sorting of goods inthe logistics warehouse is carried out, the adopted sorting device can be used for screening different specification types of packages in a uniform shape integrally, the screened goods can be rapidlytransported and stacked by the aid of the arranged conveying and stacking devices, and compared with a traditional manual sorting and arranging mode, the automatic cooperation operation mode between the sorting device and the conveying and stacking devices greatly improves working efficiency.

Owner:ZHEJIANG YIXINGDA WISDOM TECH CO LTD

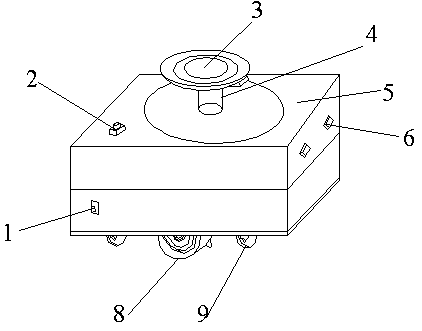

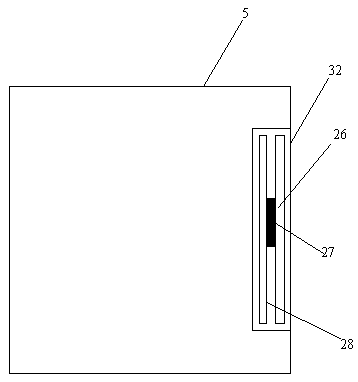

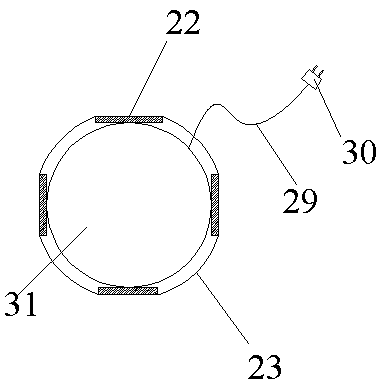

Storage transfer robot group with automatic charging function and wireless automatic charging method thereof

InactiveCN108512272ARealize automatic allocation and chargingImprove transportation efficiencyMobile unit charging stationsElectric powerLogistics managementLogistic management

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

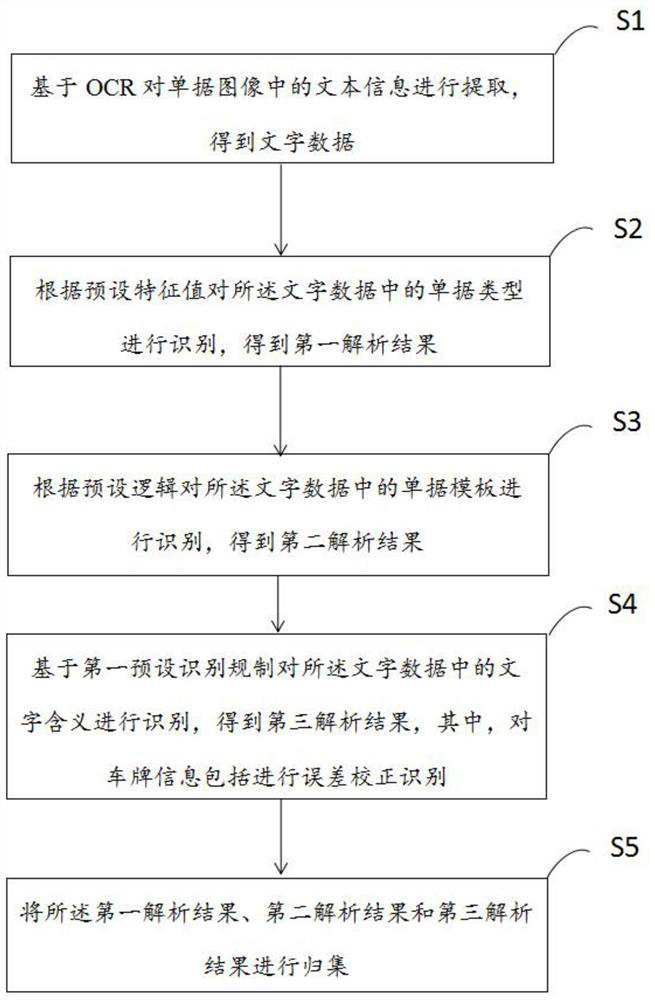

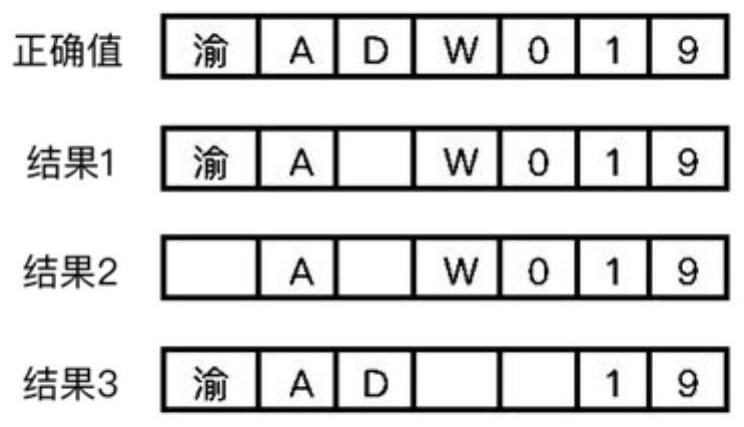

Receipt automatic identification method based on OCR

PendingCN111680679AQuick conversionMeet the needs of useCharacter and pattern recognitionNatural language processingText recognition

Owner:重庆数道科技有限公司

Mail distribution service robot

InactiveCN103736664AFully automatedAvoid adverse effects caused by sorting accuracySortingDrive wheelMail Distributions

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

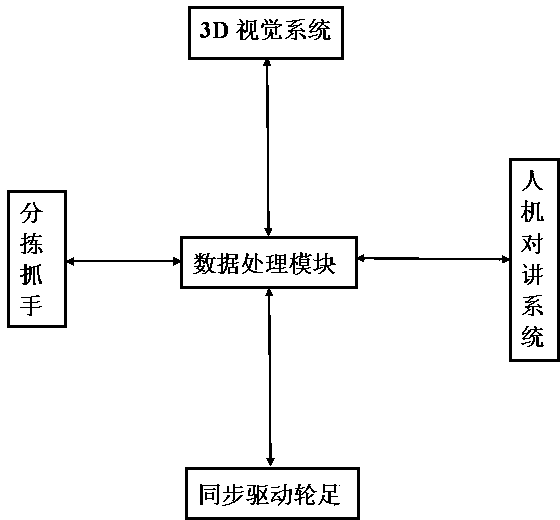

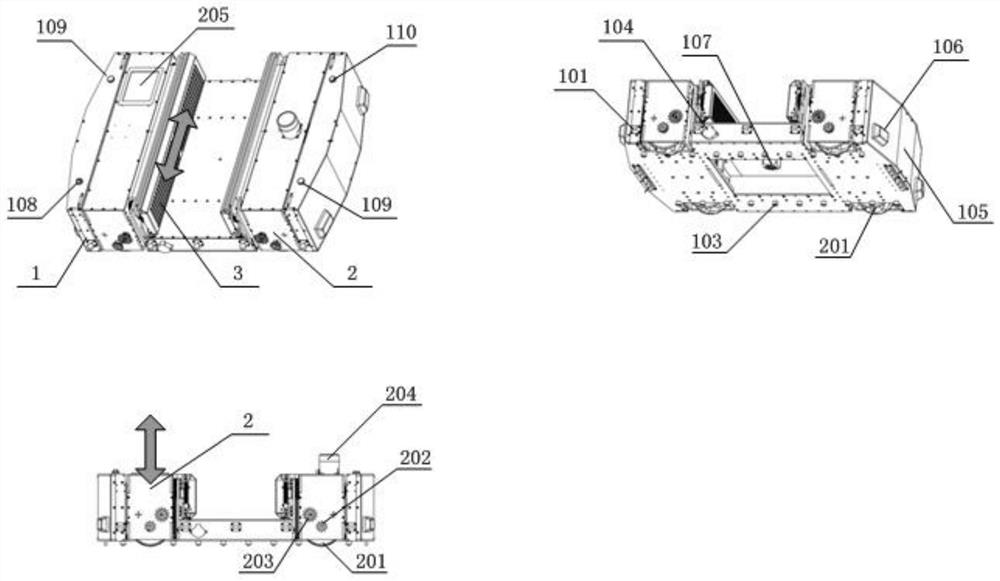

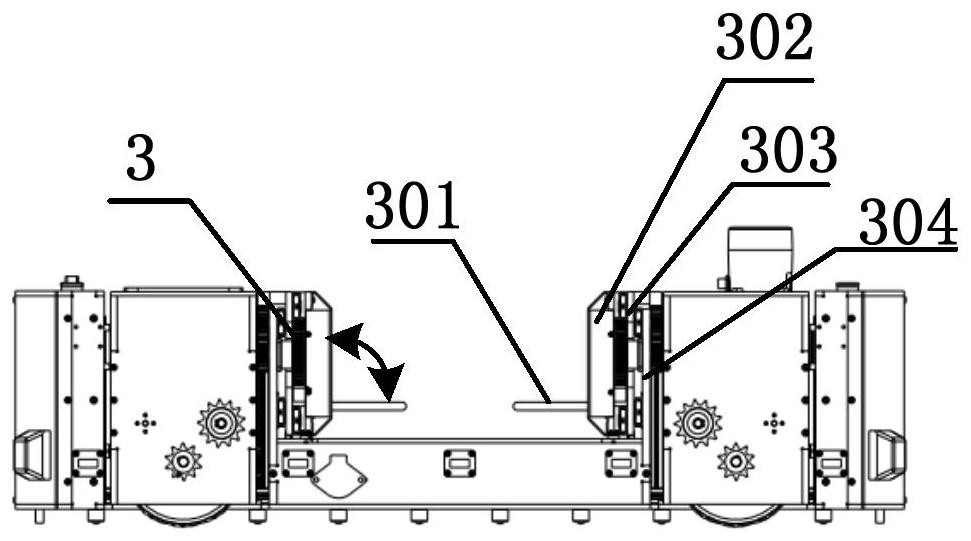

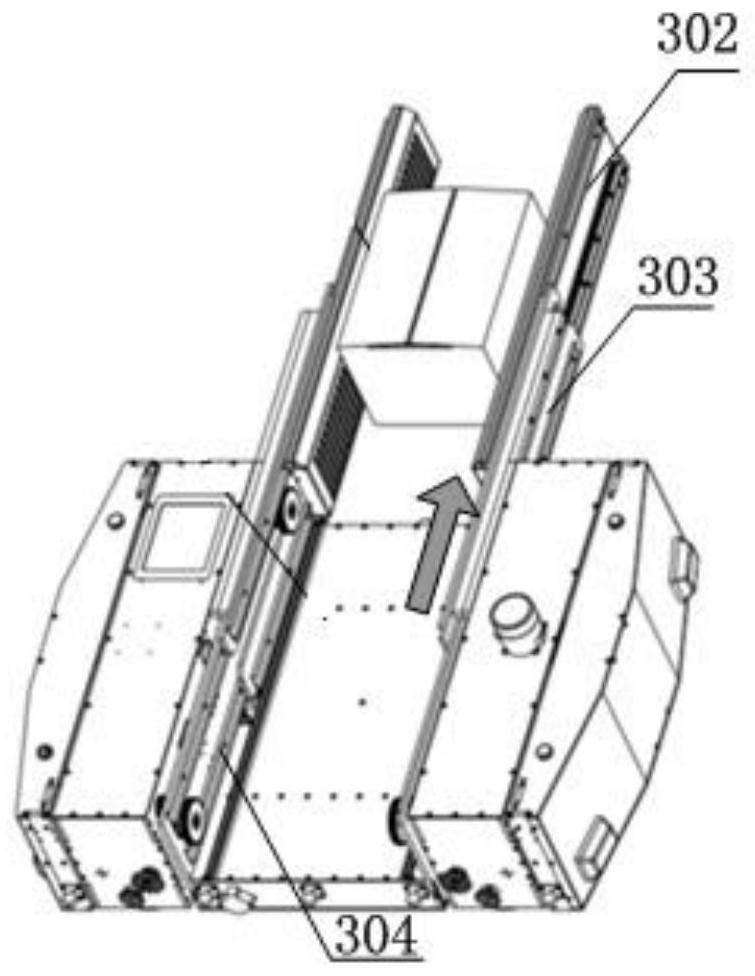

3D sorting logistics robot

ActiveCN112009926ATaking care of transportationIncrease working spaceStorage devicesLogistics managementStructural engineering

Owner:SHANGHAI AEROSPACE SYST ENG INST

Improved logistics transportation equipment

InactiveCN108861293AImprove work coordinationImprove transmission stabilityManual conveyance devicesLogistics managementTransport engineering

Owner:广州俊天科技有限公司

Intelligent logistics picking path combination method

ActiveCN109754203AReduce walking distanceReduce walking timeForecastingResourcesLogistics managementComputer science

The invention provides an intelligent logistics picking path combination method. The method comprises the following steps: simultaneously selecting according to a path and commodity frequency, the commodity frequency is obtained; selecting an initial picking roadway to calculate the number of task lists; when the number of the task orders does not meet the preset parameters, one adjacent roadway is added on the basis of the initial picking roadway, the number of the two roadway task orders is calculated, if the number of the two roadway task orders is not met, the roadway is added again untilthe number of the roadway is met, and the picking path combination method can enable a picker to walk on the shortest path to complete the most picking task and improve the picking efficiency.

Owner:WUHAN PROLOG INTEGRATED TECH CO LTD

Narrow belt type logistical sorting machine

InactiveCN110125011ASimple structureImprove stabilitySortingMechanical conveyorsLogistics managementWorking environment

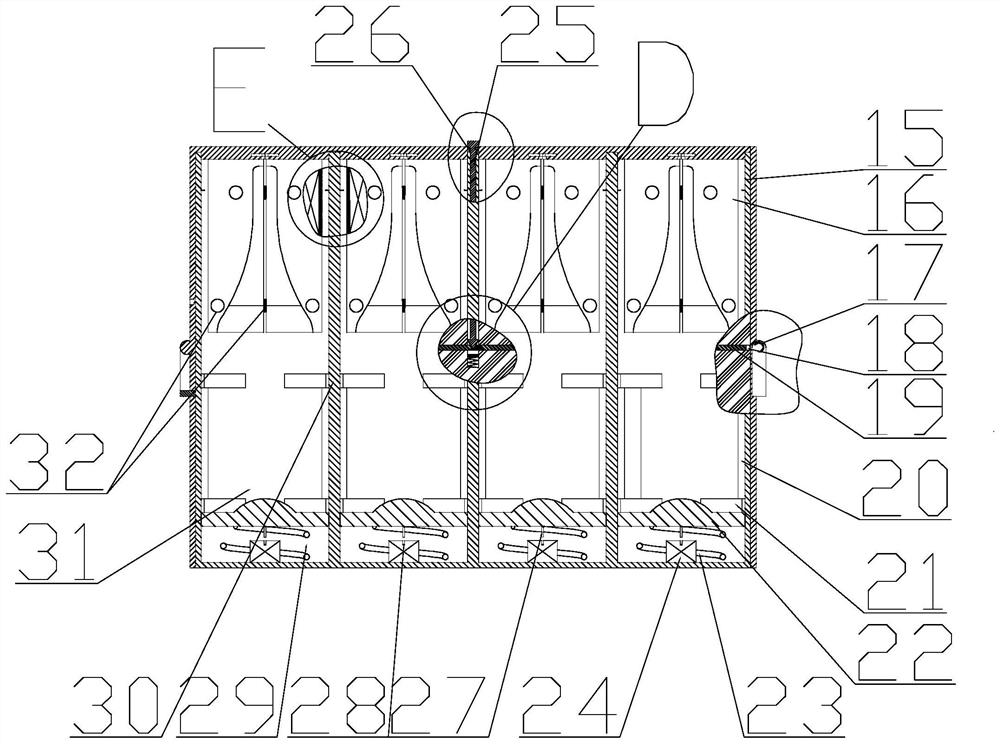

The invention discloses a narrow belt type logistical sorting machine. The machine comprises a rack, a forward moving driving device, a slide rail, a trolley and a guide structure, wherein the trolleycomprises a supporting frame, a conveying belt, a transmission assembly and a forward moving sliding assembly; the guide structure comprises a first rotating shaft, a second rotating shaft, a first cylinder, a second cylinder, a bottom plate, a first side plate, a second side plate, a first friction plate, a second friction plate, a first rotating frame, a second rotating frame, a first hinging seat, a second hinging seat, a third hinging seat and a fourth hinging seat; and the forward moving sliding assembly comprises a first pulley set, a second pulley set, a first inserting pin and a second inserting pin. Compared with the prior art, the machine has the advantages that a new structure is arranged; the trolley is free from a power structure, so that the structure of the trolley is effectively simplified, the stability is improved, and the cost is effectively decreased; a rubber chain is arranged and replaces a rigid chain in the prior art, so that the noise in running is effectivelyreduced, and the working environment is optimized.

Owner:CHANGSHA LIUZHU ELECTROMECHANICAL TECH CO LTD

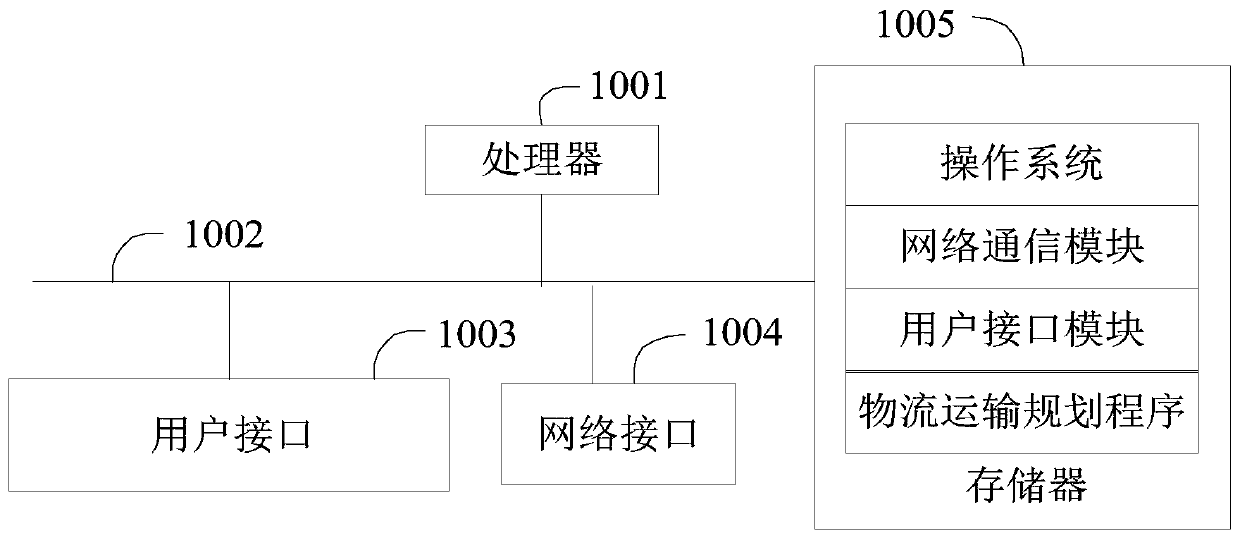

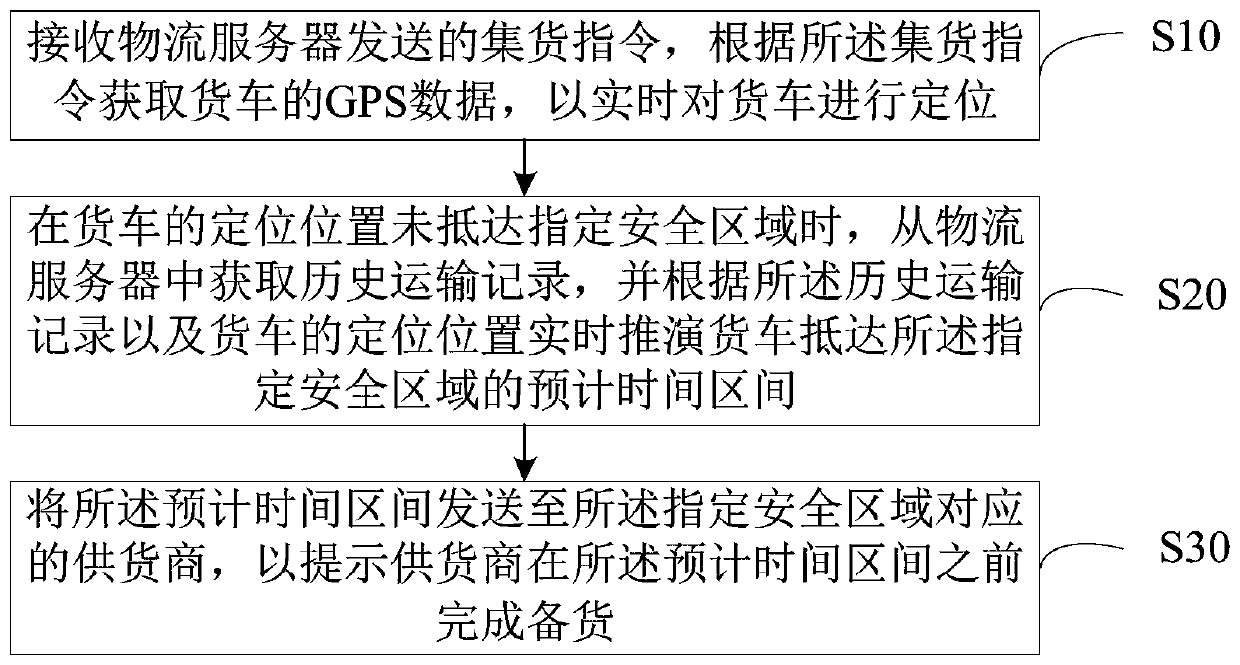

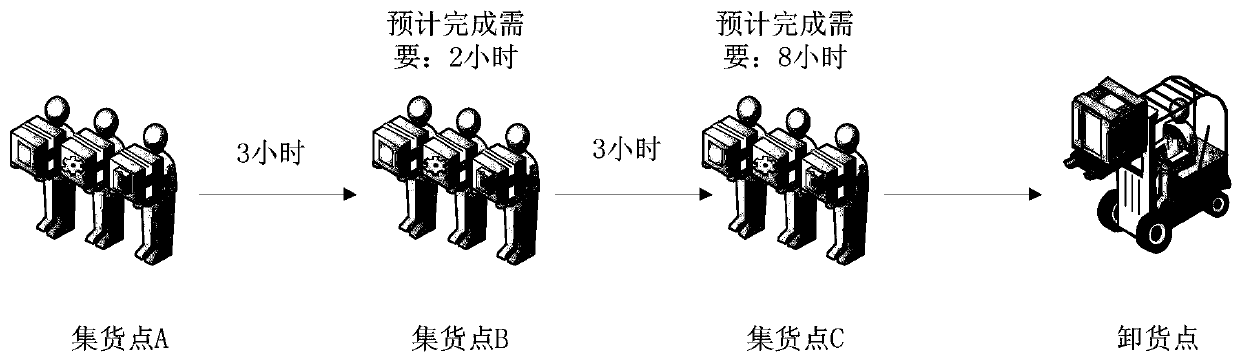

Logistics transportation planning method and system and computer readable storage medium

ActiveCN110969391APrevent shipping delaysLow costSatellite radio beaconingLogisticsLogistics managementTransportation planning

Owner:GAC TOYOTA MOTOR

Automatic sorting device for logistics packages

ActiveCN113275255AReduce consumptionImprove sorting efficiencySortingLogistics managementStructural engineering

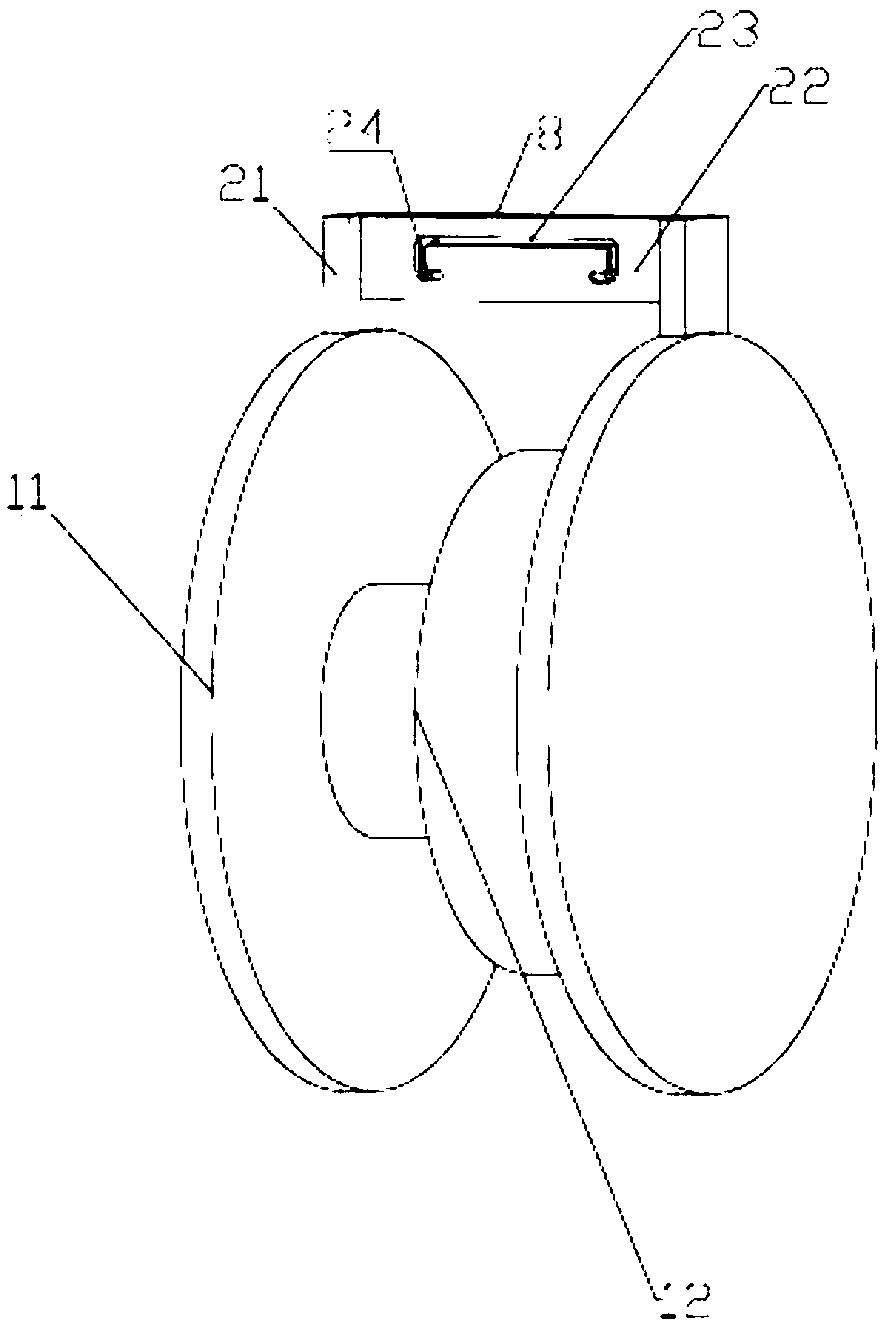

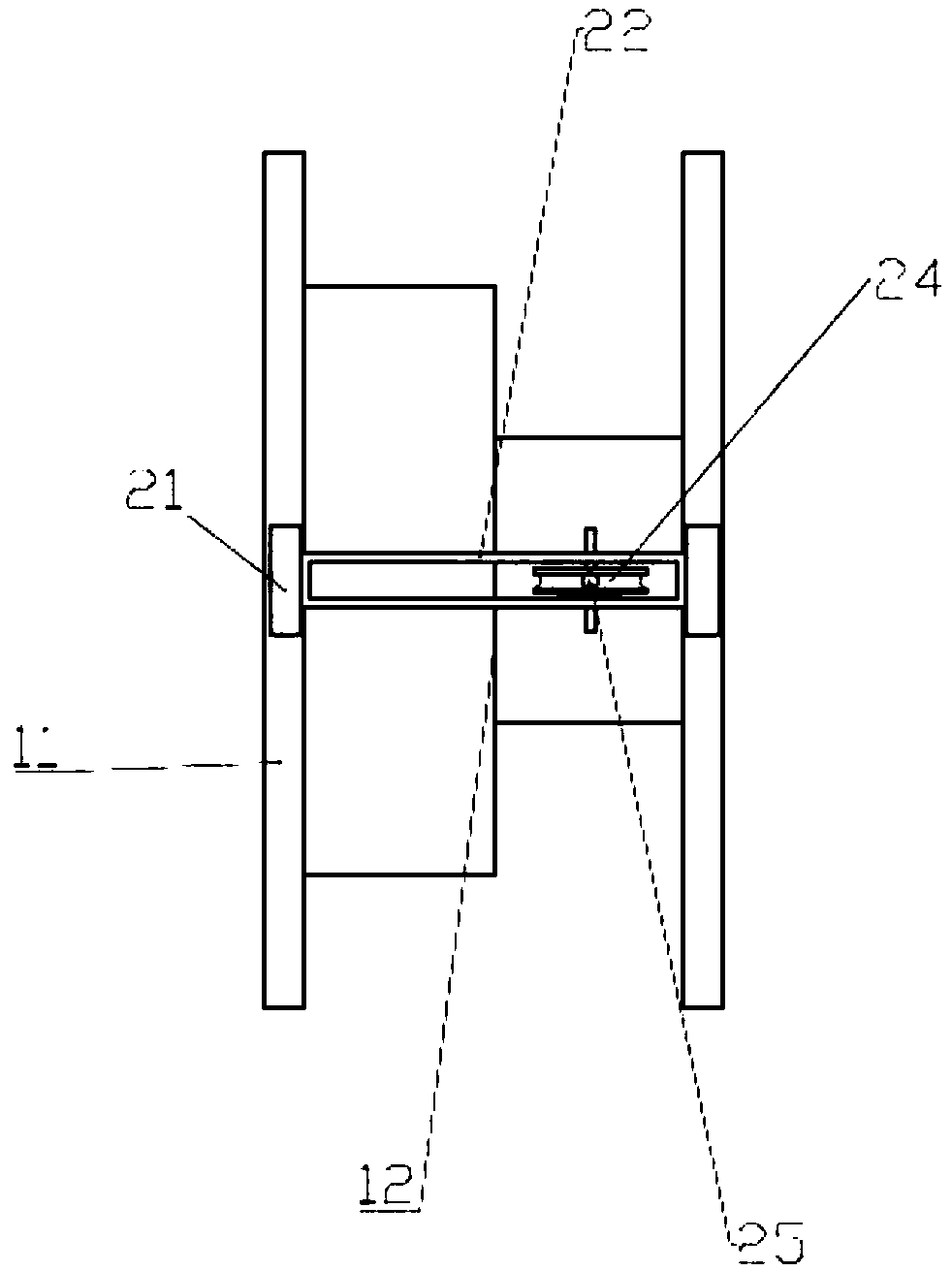

An automatic sorting device for logistics packages comprises a bottom plate, a power structure is arranged on the bottom plate, the power structure drives a first conveying belt and a second conveying belt corresponding to the first conveying belt, a pair of side plates is arranged at the upper end of the bottom plate, and the first conveying belt and the second conveying belt are rotationally connected with the side plates; the upper end of the first conveying belt is provided with a sorting structure capable of intermittently sorting and conveying out the packages, and the sorting structure comprises a sorting rotary disc rotationally connected with the side plates; the second conveying belt is provided with a plurality of stagnation plates with holes of different sizes, the stagnation plates comprise a first sorting plate and a second sorting plate corresponding to the first sorting plate, the first sorting plate and the second sorting plate are each provided with a pushing structure, and each pushing structure comprises a pushing rod; and the pushing rods can sort the packages stagnated at the front ends of the first sorting plate and the second sorting plate, so that the problems that in the logistics sorting process, manpower and material resource consumption is too large, and the sorting efficiency is low are solved.

Owner:DEZHOU JIAOTOU LOGISTICS DEV CO LTD

Goods shelf for logistics storage

InactiveCN113320864APrevent deformationPlay a buffer roleStorage devicesShow shelvesLogistics managementAgricultural engineering

The invention proposes a goods shelf for logistics storage, which comprises a goods shelf plate, a plurality of adjusting pieces are arranged on the goods shelf plate, the distance between any two adjacent adjusting pieces is adjustable, the two ends of the goods shelf plate are both connected with assembling plates, the assembling plates are connected with supporting rods in a penetrating mode and the assembling plates are in sliding fit with the supporting rods, sleeve blocks are arranged at the positions, below the assembling plates, of the supporting rods in a sliding and sleeved mode, locking pieces used for locking the sleeve blocks are arranged on the supporting rods, elastic buffering pieces are arranged at the positions, between the assembling plates and the sleeve blocks, of the supporting rods, and the elastic buffering pieces are respectively connected with the assembling plates and the sleeve blocks. According to the goods shelf for the logistics storage provided by the invention, the buffering effect can be achieved when goods are placed, the situation that the goods shelf plate deforms is prevented, the placing distance between the goods can be adjusted, and mutual extrusion between the goods is prevented.

Owner:CHUZHOU YOULIEN LOGISTICS EQUIP MFG CO LTD

Complete vehicle logistics order prediction method and device, logistics system and computer readable medium

PendingCN110309948AReduce production management costsLow costForecastingLogisticsLogistics managementProgram planning

The invention relates to the field of logistics, in particular to a complete vehicle logistics monthly order prediction method and device, a logistics system and a computer readable medium. The methodcomprises the steps of obtaining complete vehicle logistics order data of a historical month; extracting features to construct a learning sample set; according to the learning sample set, constructing a random forest model for training and evaluation, and obtaining a logistics monthly order prediction model of the complete vehicle; and inputting a to-be-predicted line, predicting a complete vehicle logistics order of the line in the future month according to the complete vehicle logistics monthly order prediction model, and outputting the complete vehicle logistics order. According to the complete vehicle logistics monthly order prediction method, device and system and the storage medium, prediction of the complete vehicle logistics monthly order is achieved, prediction efficiency and prediction accuracy are greatly improved, accurate information is provided for overall planning of transport capacity plans and warehouse management of transport companies, and then production managementcost is reduced.

Owner:ANJI AUTOMOTIVE LOGISTICS

Agricultural product supply and demand monitoring system based on big data

PendingCN107527241AAccurate outputAccurate supply and demandMarket predictionsBuying/selling/leasing transactionsAgricultural scienceLogistics management

Owner:江苏真格邦软件有限公司

Bottled wine transport case

PendingCN114132600APlay a protective effectGuaranteed use strengthContainers to prevent mechanical damageRigid containersLogistics managementTraffic accident

Owner:洪忠志

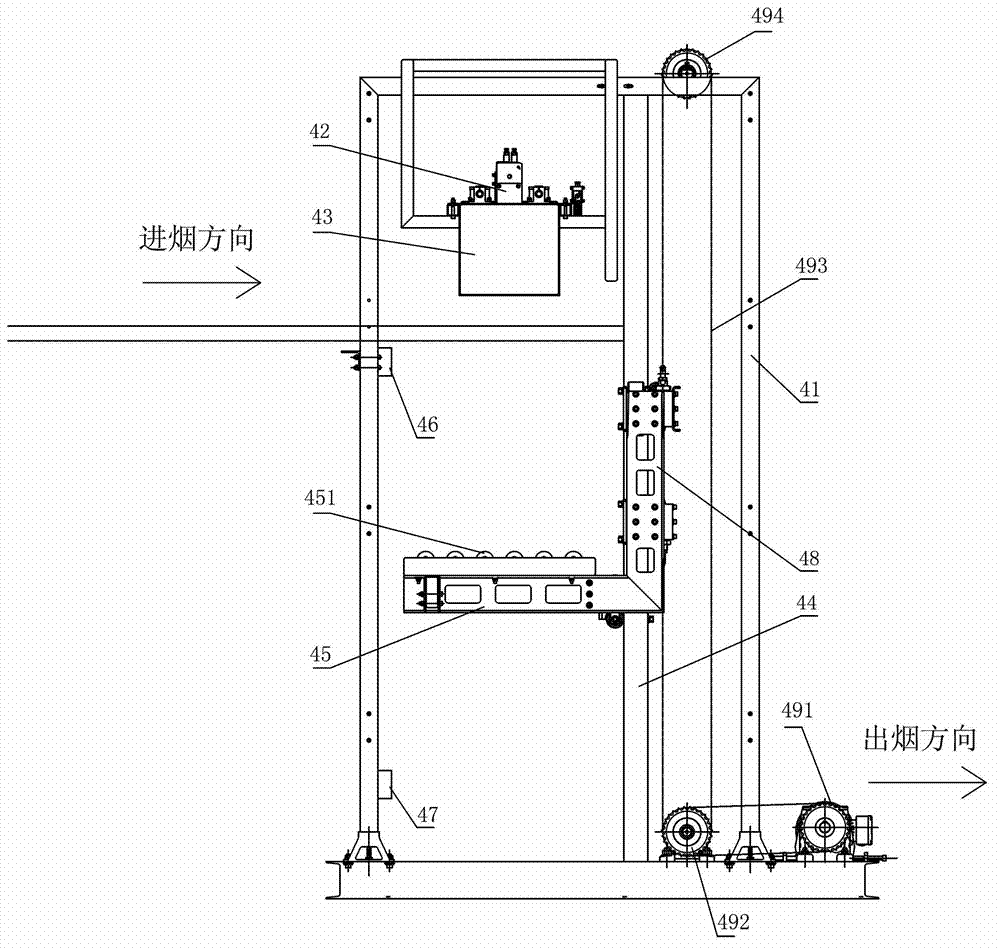

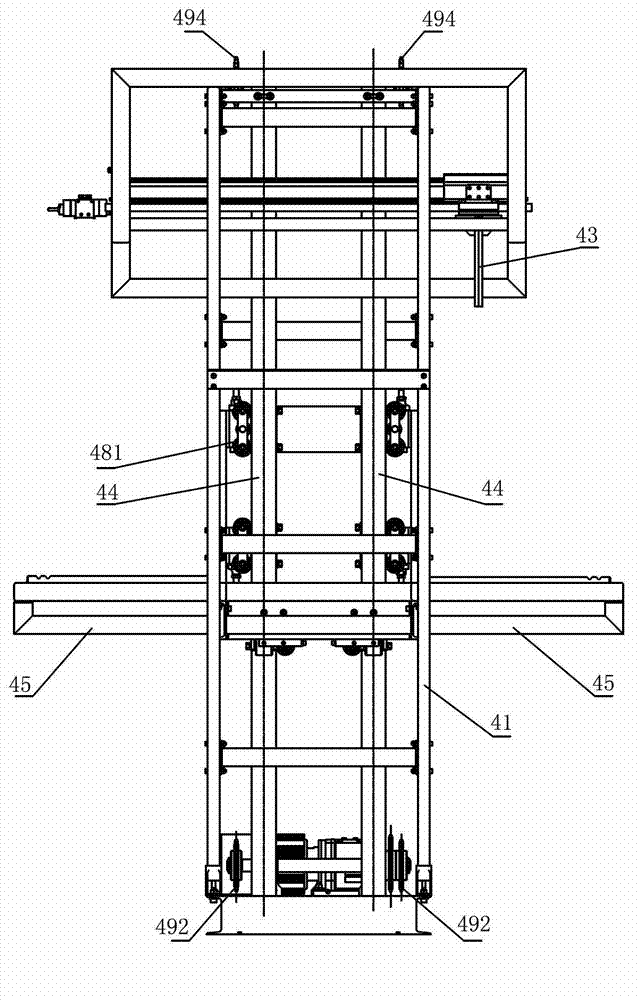

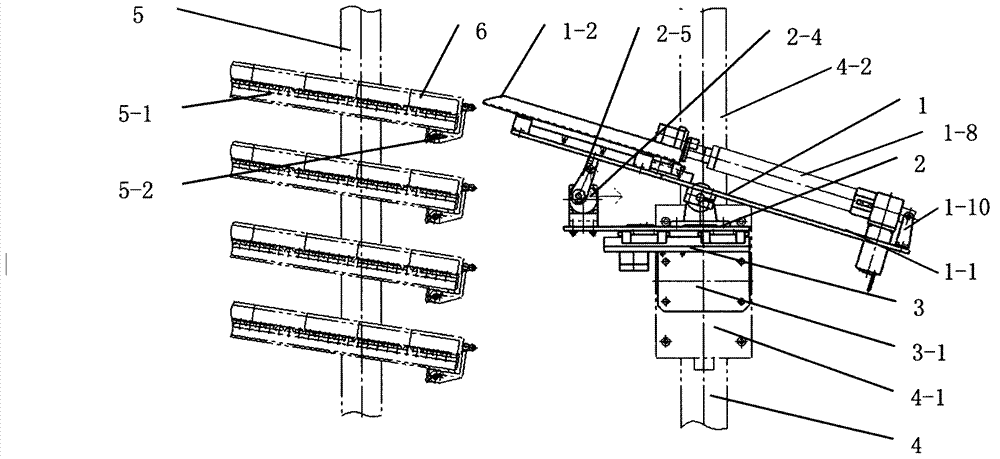

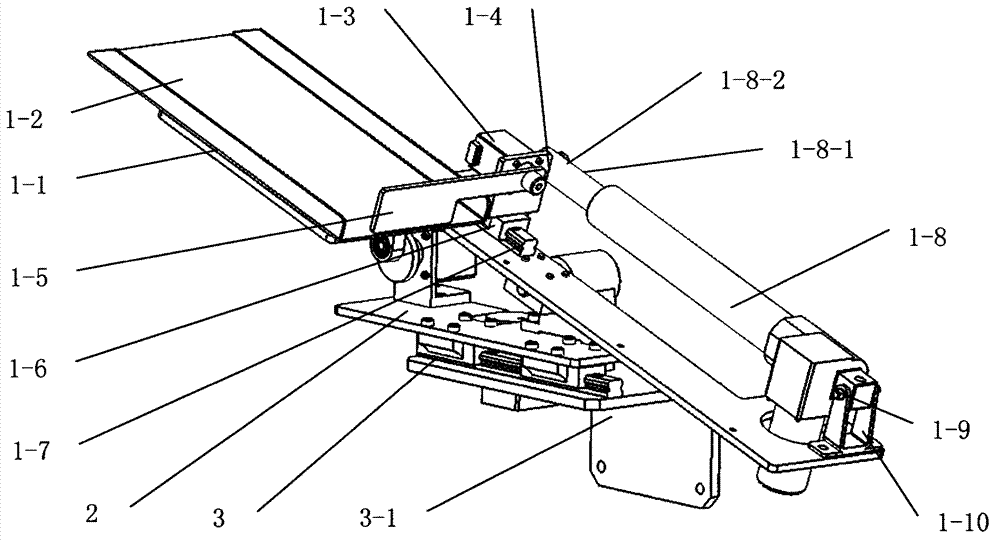

Novel platform cigarette truck loading device

InactiveCN108946216AReduce physical exertionReduce the time for handing over cigarettesWinding mechanismsLoading/unloadingLogistics managementEngineering

Owner:四川省烟草公司德阳市公司

Logistics management terminal control method and logistics management terminal

PendingCN111524297AEnsure safetyPrevent leakageApparatus for meter-controlled dispensingIndividual entry/exit registersLogistics managementLogistic management

The invention discloses a logistics management terminal control method and a logistics management terminal. The logistics management terminal comprises a main control unit, wherein the input end of the main control unit is electrically connected with the output end of a storage unit through a wire, the input end of the storage unit is electrically connected with the input end of a reading module through a wire, the input end of the reading module is electrically connected with the output end of a code scanning module through a wire, and the main control unit and a user login unit are in bidirectional connection through a wire. The invention relates to the technical field of logistics. According to the logistics management terminal control method and the logistics management terminal, the output end of the user login unit is electrically connected with the input end of a face recognition module through a wire, and a face recognition system is additionally arranged, so that the article safety of a client is well guaranteed, the verification code of the client is prevented from being leaked to let strangers get expresses, and the device can prevent the expresses of the client from being lost to cause certain economic loss.

Owner:冯建丽

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap