Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Stacking articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

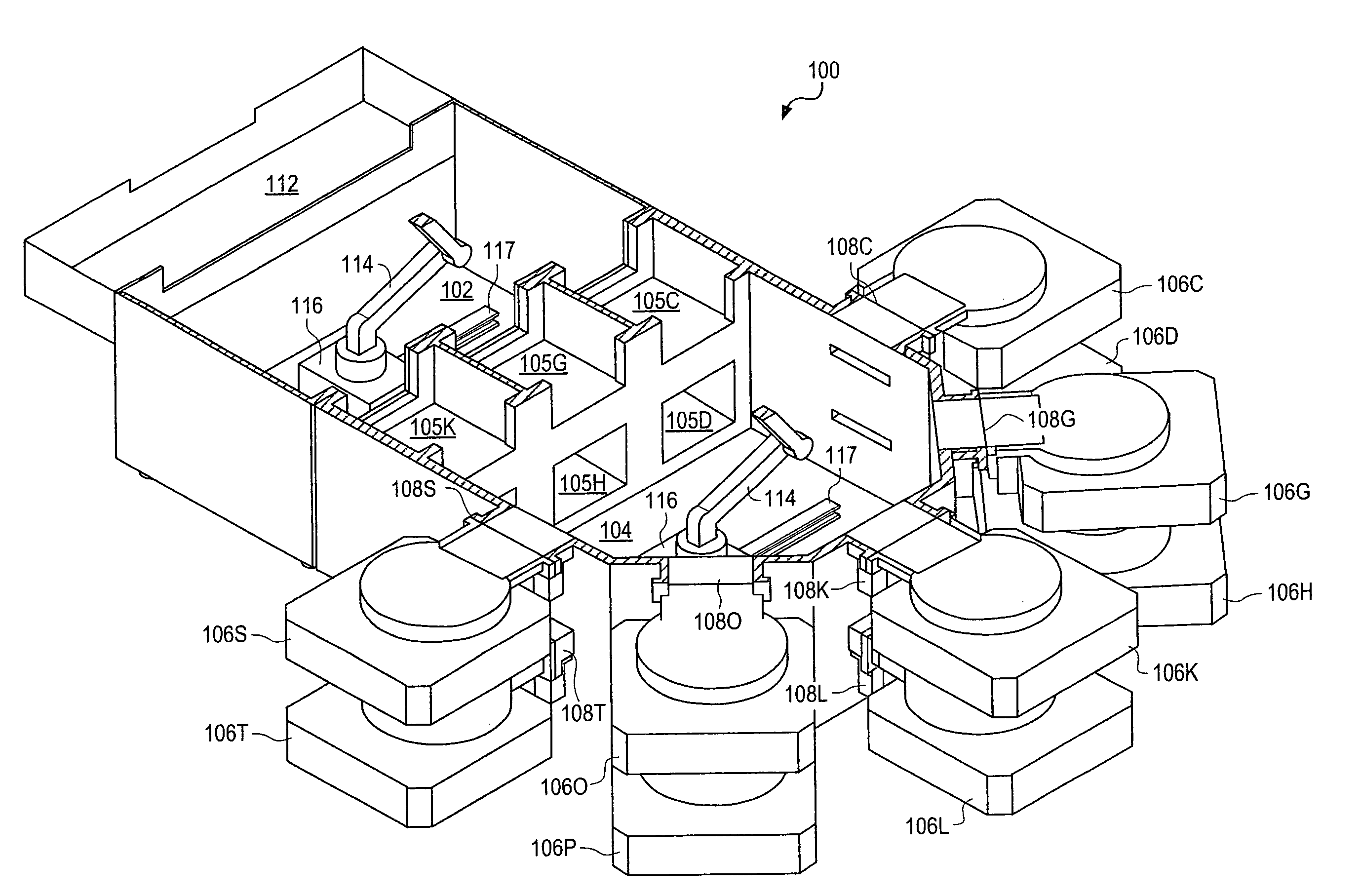

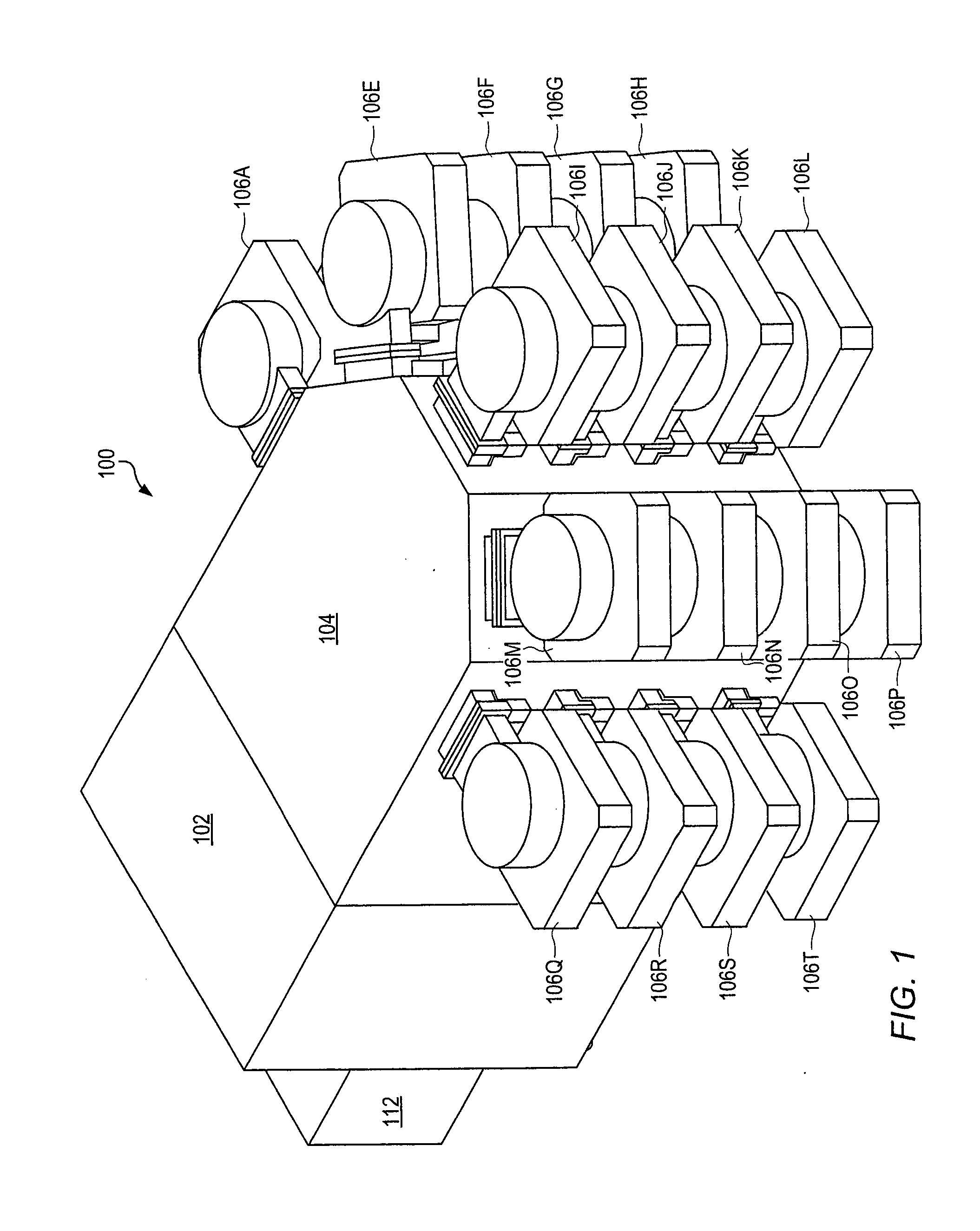

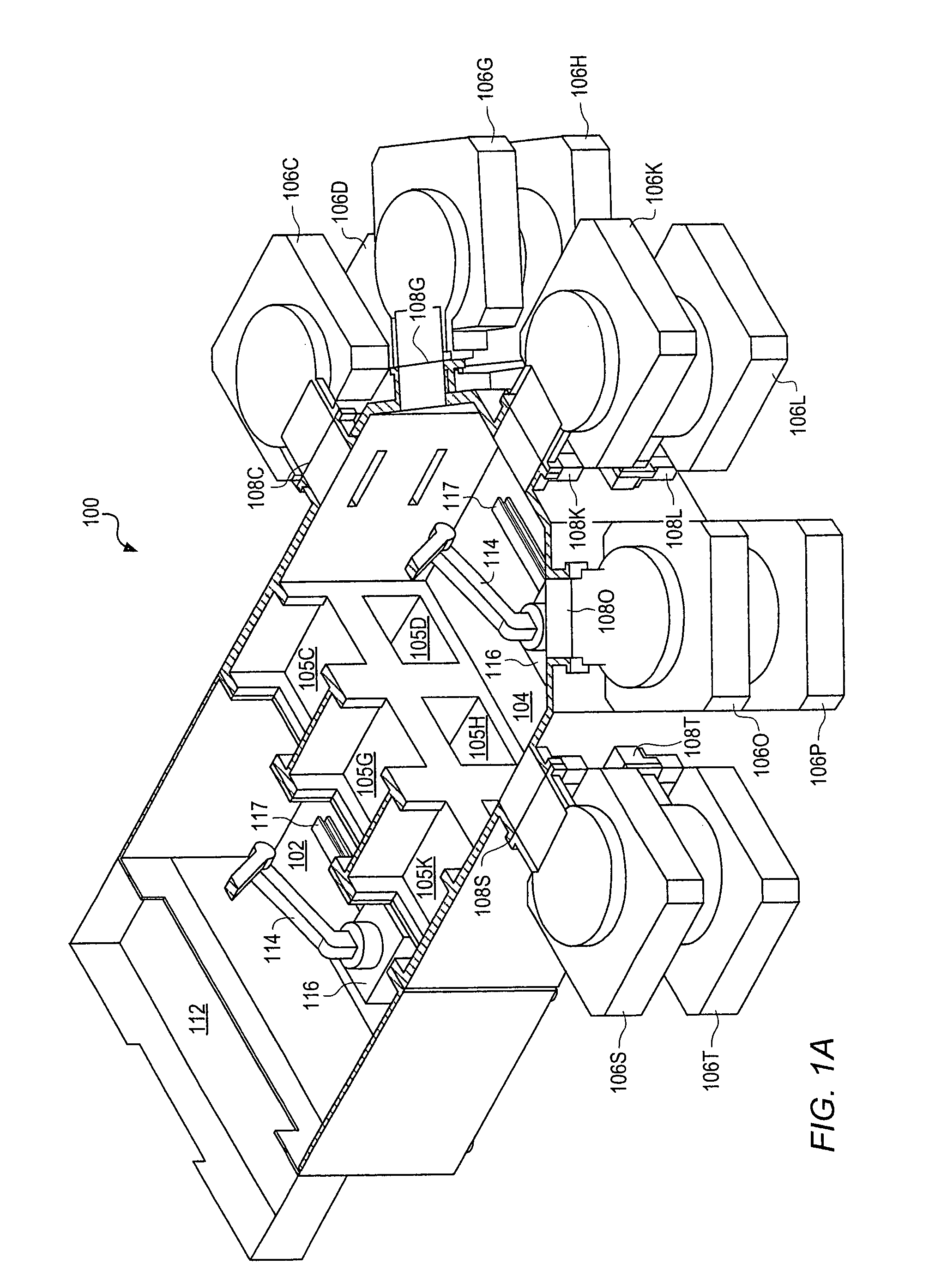

Magnetic media processing tool with storage bays and multi-axis robot arms

InactiveUS20080206036A1Semiconductor/solid-state device manufacturingPackagingMagnetic mediaMulti axis

Owner:SMITH JOHN M +2

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

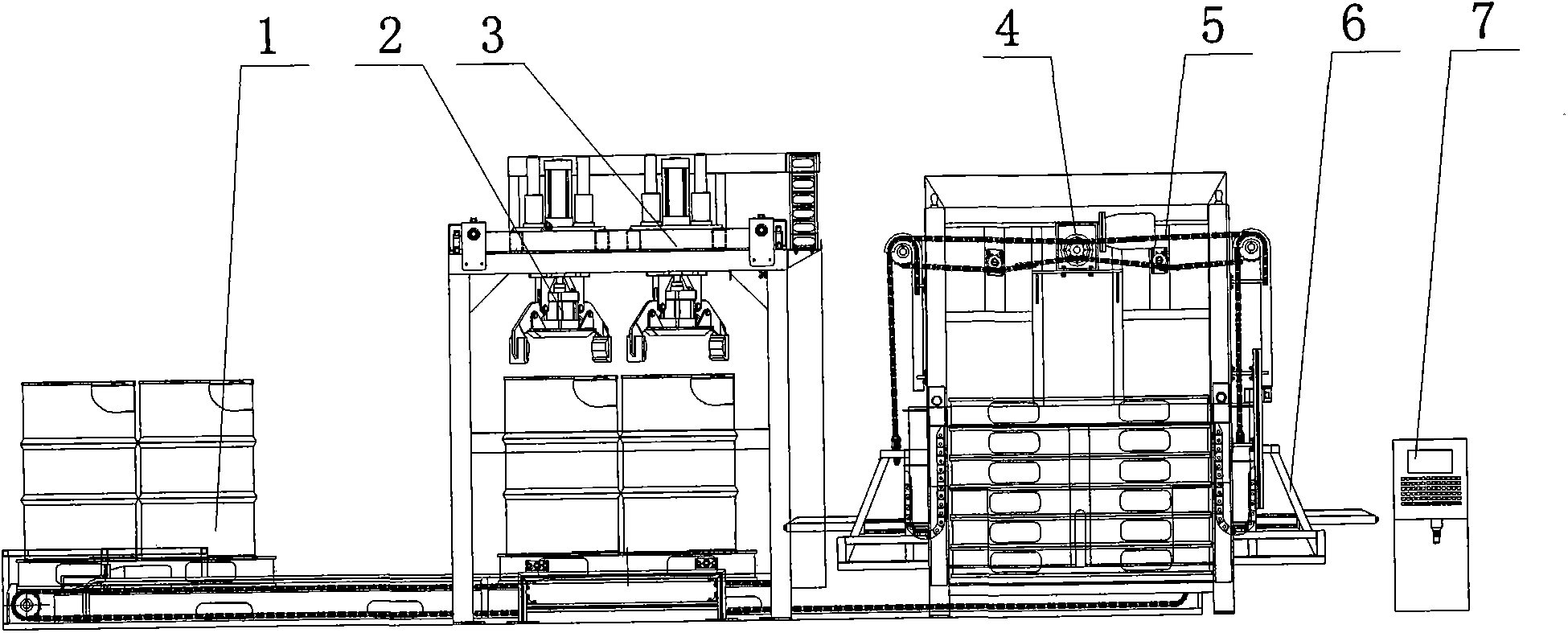

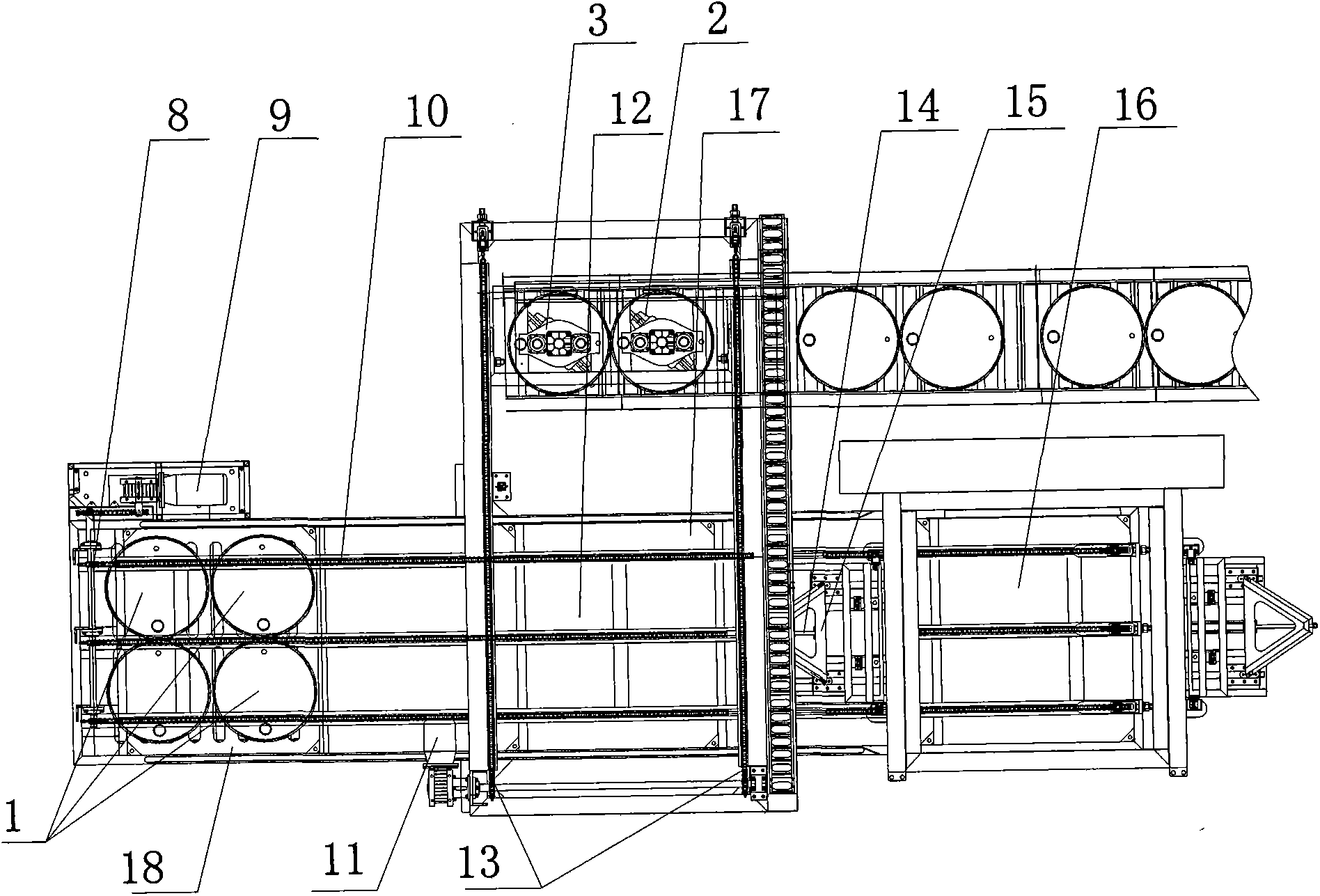

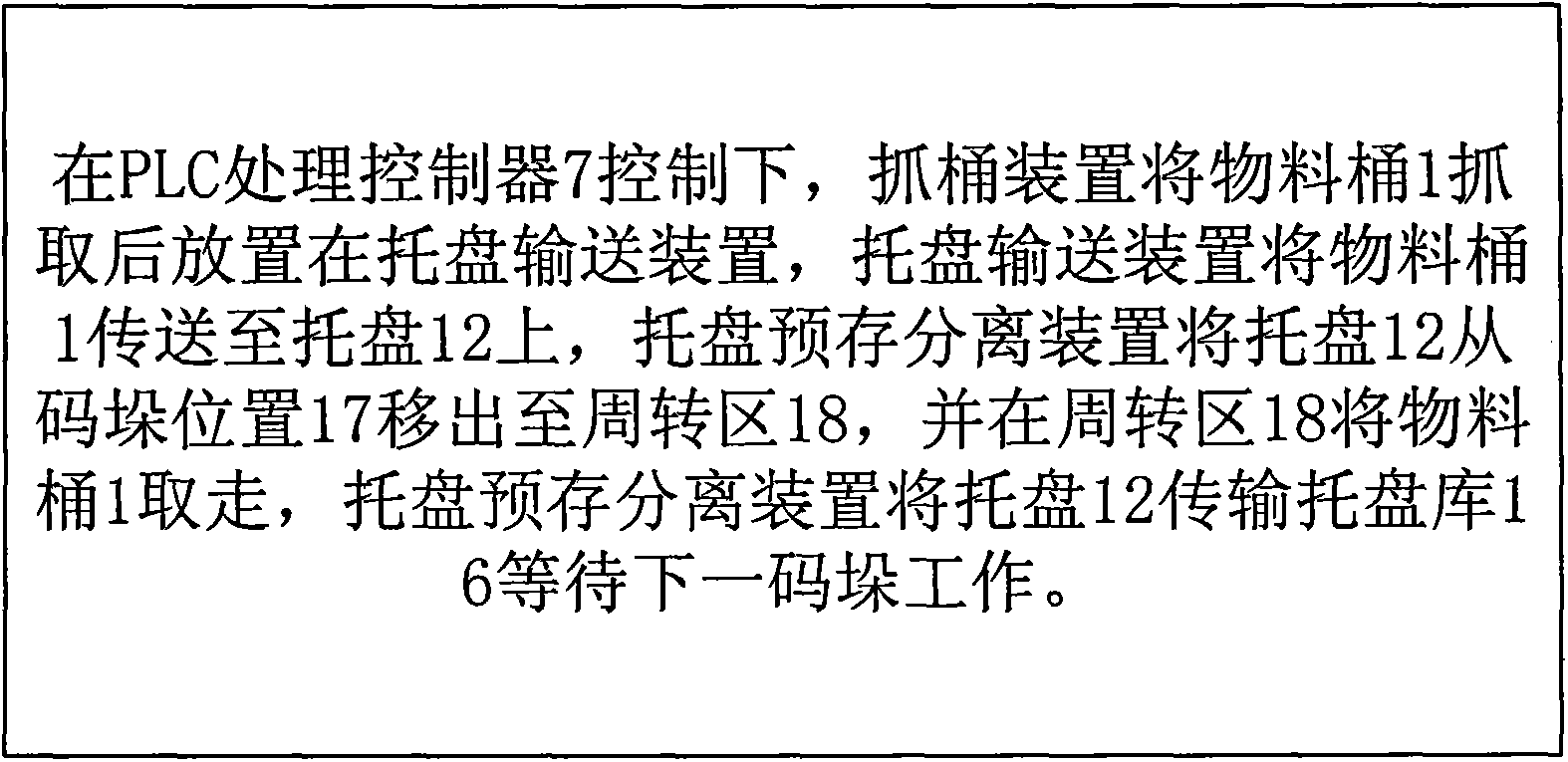

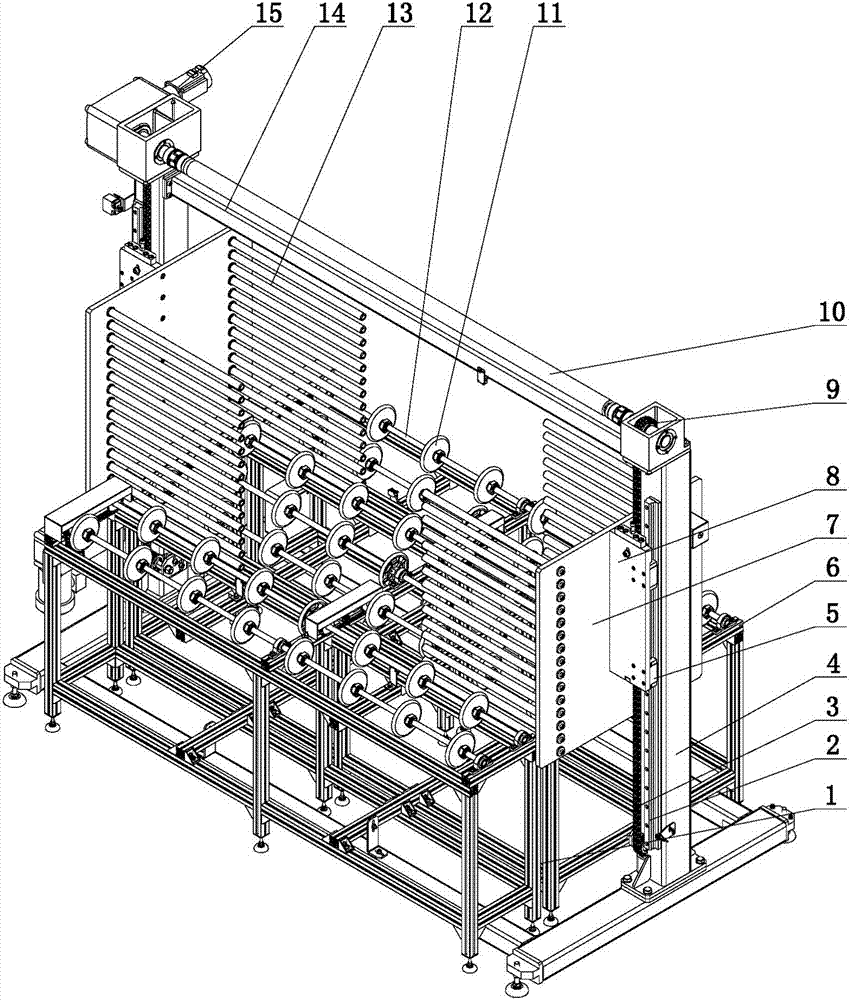

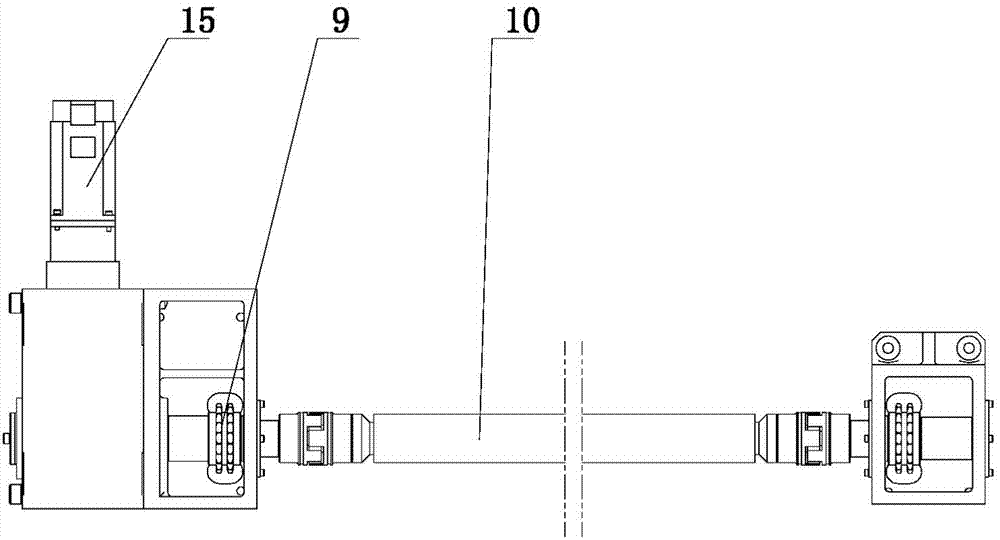

Full-automatic 200L steel drum transfer type stacking system and transfer stacking method thereof

Owner:CHANGCHUN BEIFANG INSTR EQUIP

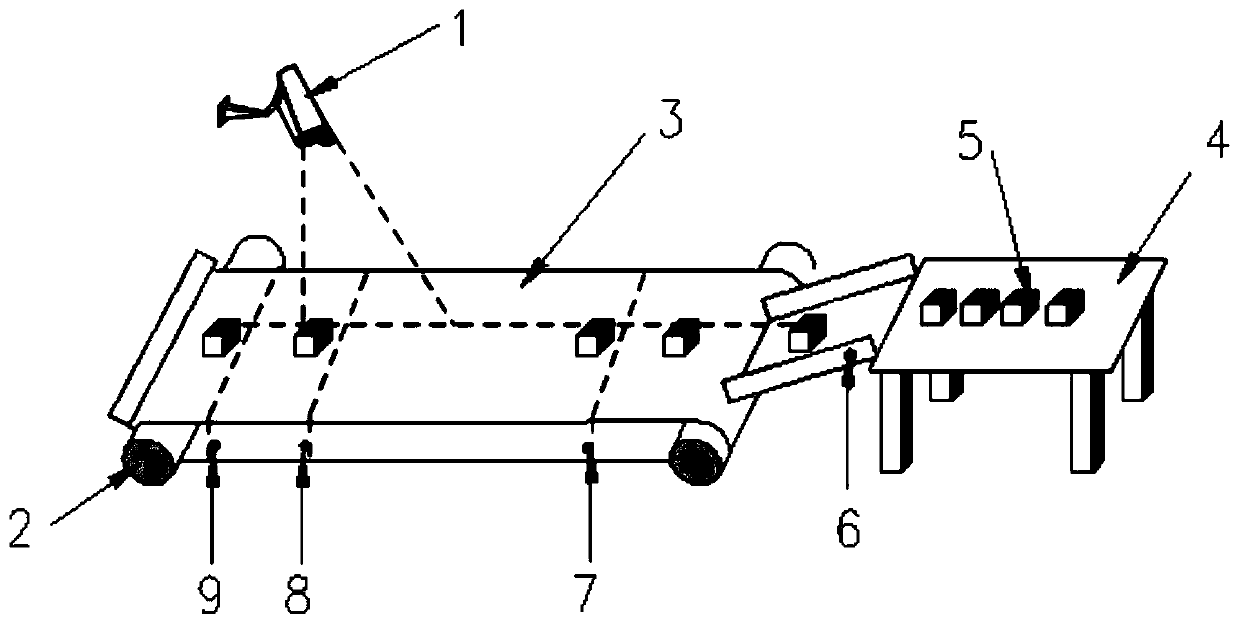

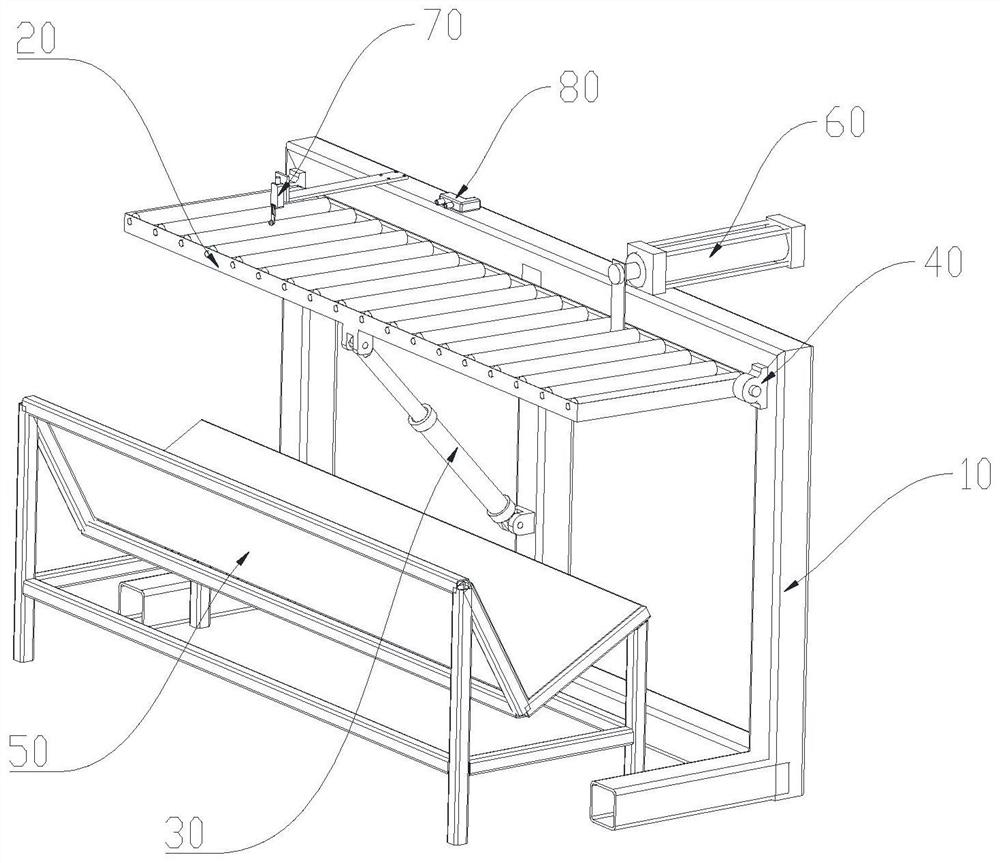

Automatic sorting and processing assembly line of logistics warehouse

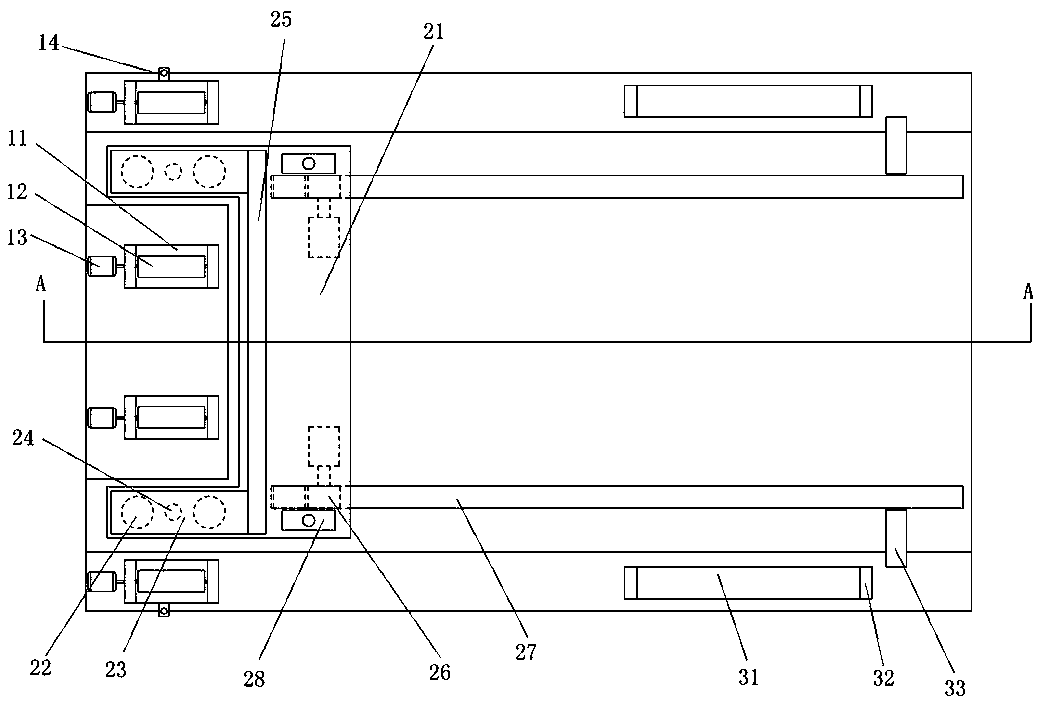

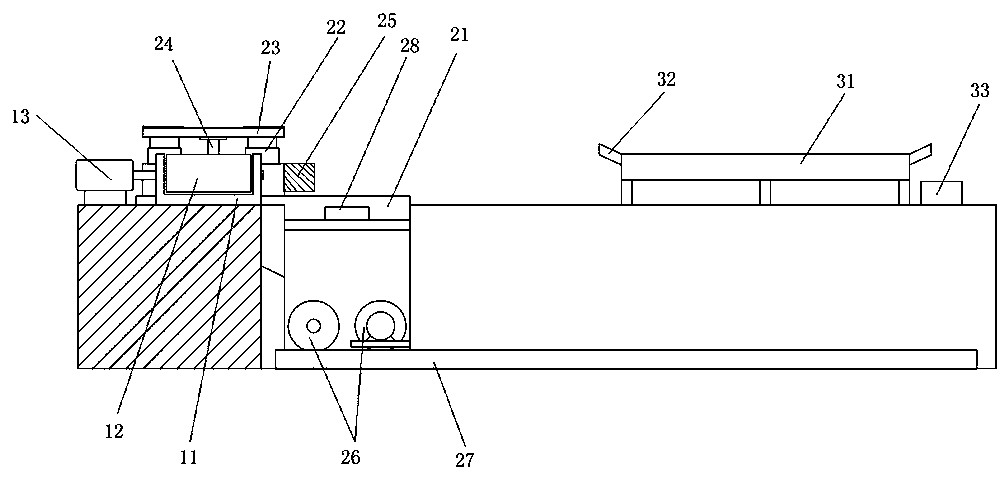

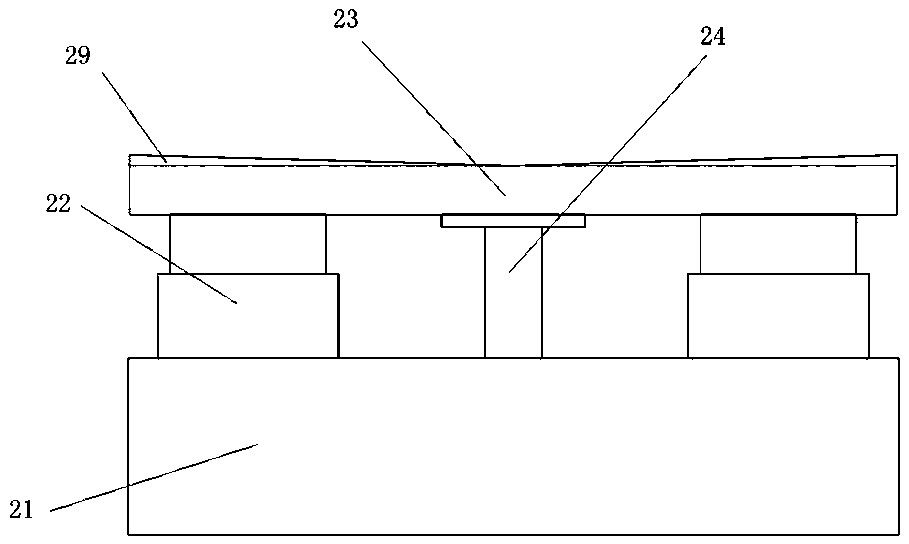

ActiveCN111545477AImprove work efficiencyIncrease sliding forceStacking articlesSortingLogistics managementProcess engineering

The invention relates to an automatic sorting and processing assembly line of a logistics warehouse. The automatic sorting and processing assembly line of the logistics warehouse comprises a sorting device and conveying and stacking devices, wherein the conveying and stacking devices are symmetrically arranged front and back on the left side of the sorting device, and the lower ends of the sortingdevice and the conveying and stacking devices are arranged on the existing working ground. According to the design concept of the sorting-stacking integrated structure, automatic sorting of goods inthe logistics warehouse is carried out, the adopted sorting device can be used for screening different specification types of packages in a uniform shape integrally, the screened goods can be rapidlytransported and stacked by the aid of the arranged conveying and stacking devices, and compared with a traditional manual sorting and arranging mode, the automatic cooperation operation mode between the sorting device and the conveying and stacking devices greatly improves working efficiency.

Owner:ZHEJIANG YIXINGDA WISDOM TECH CO LTD

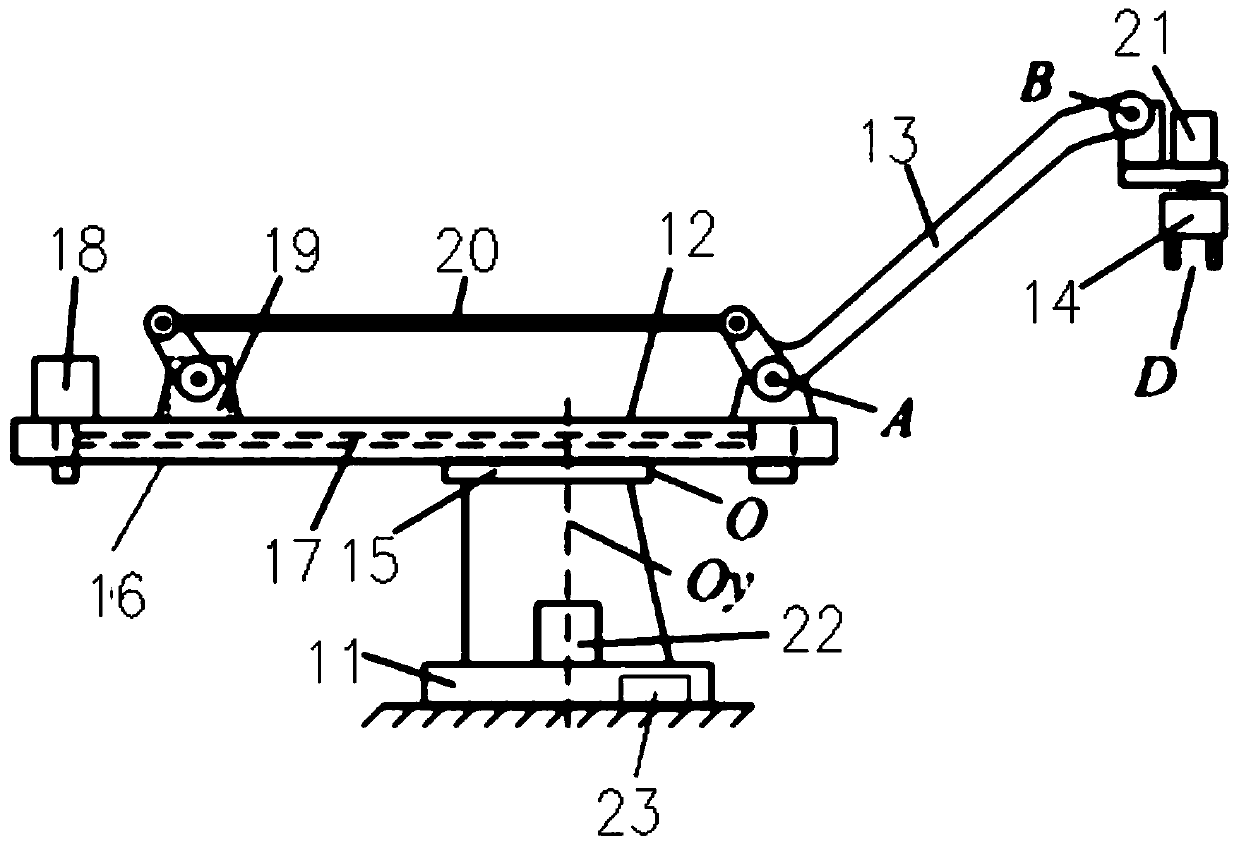

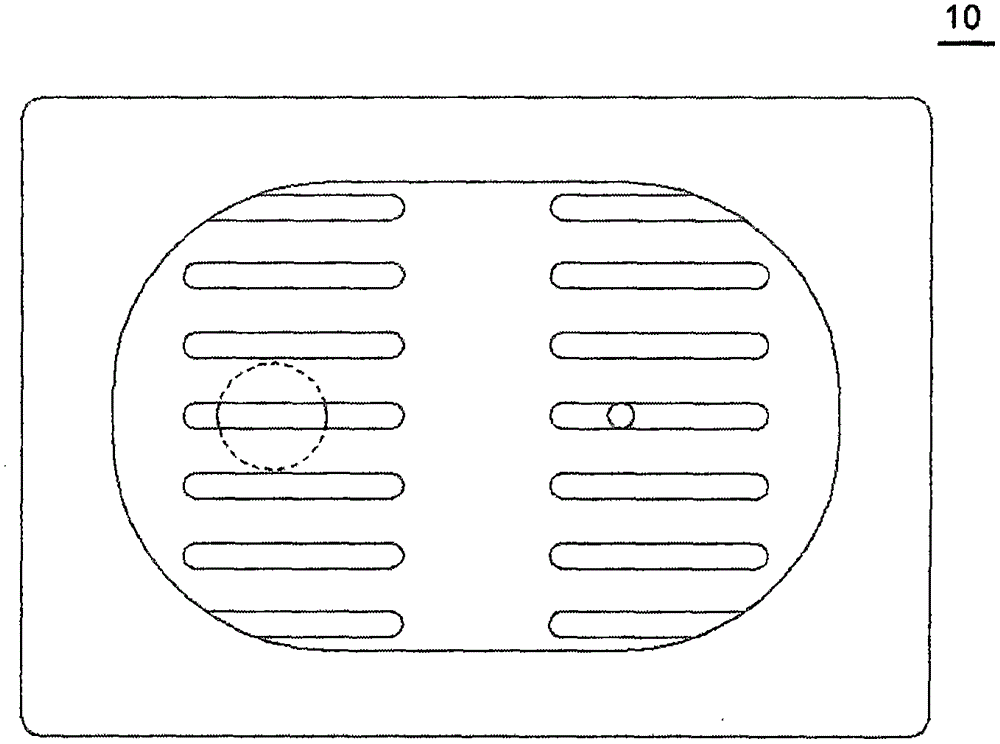

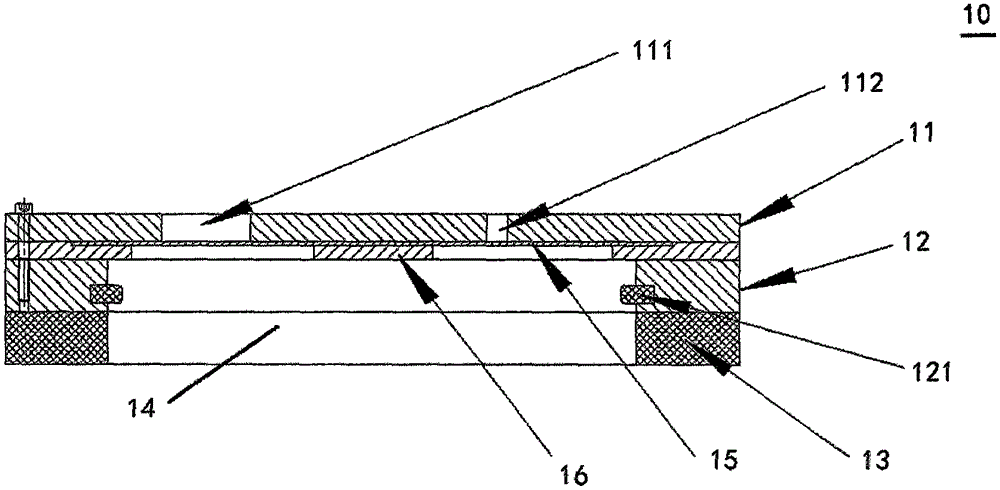

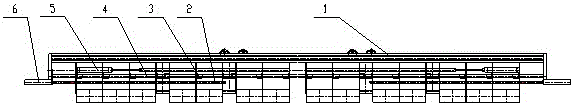

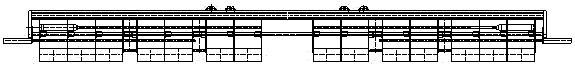

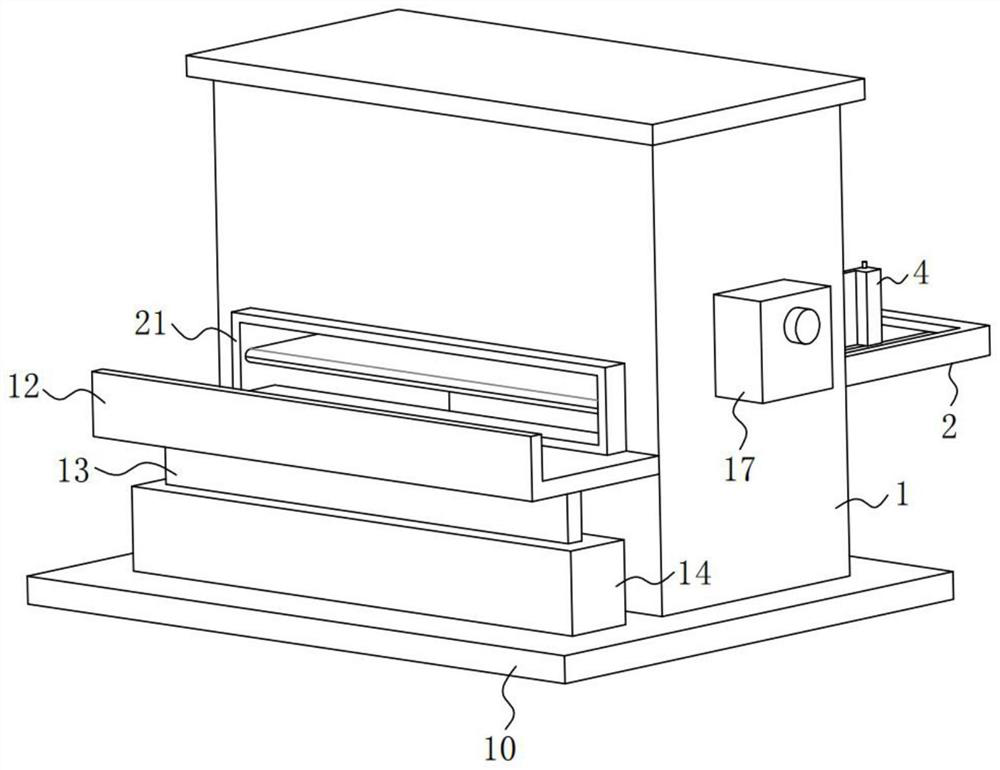

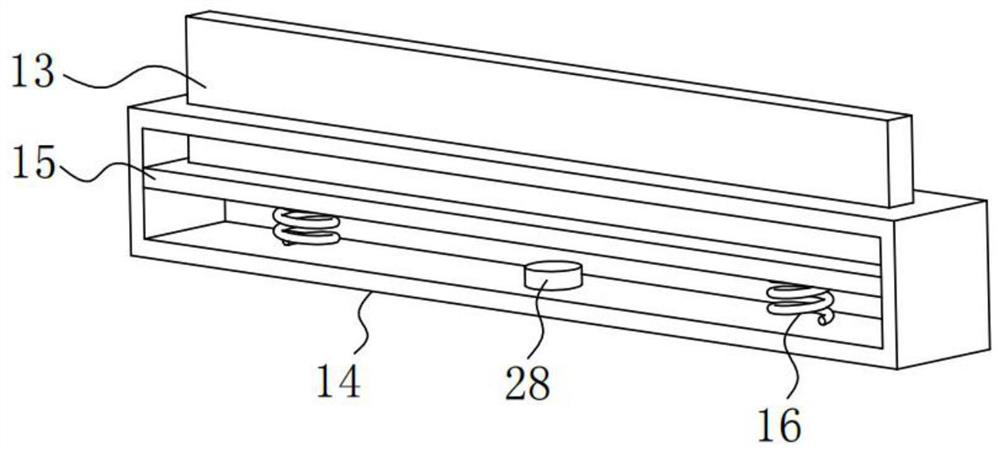

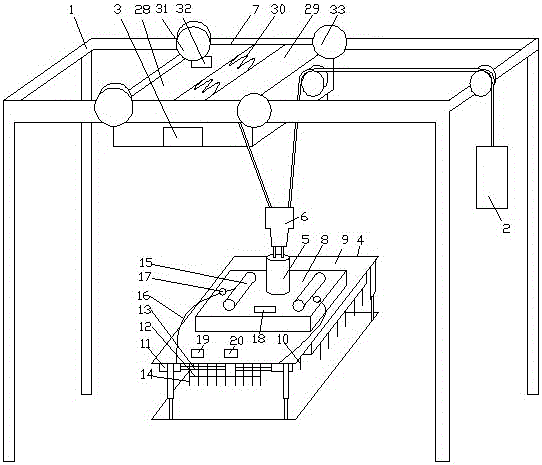

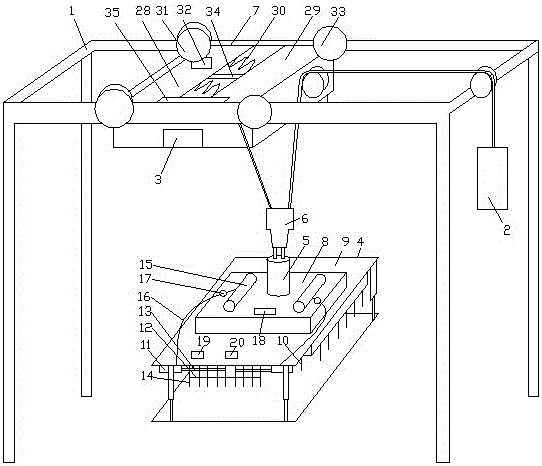

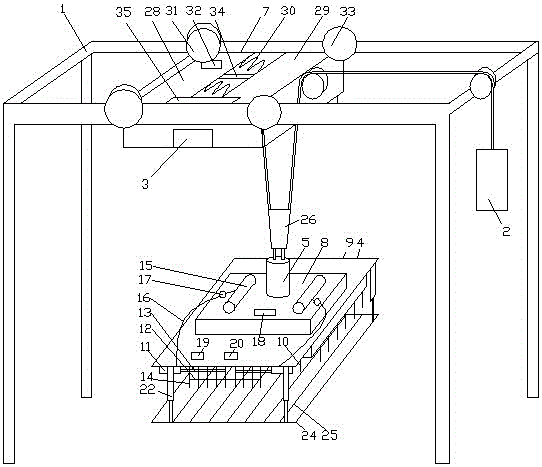

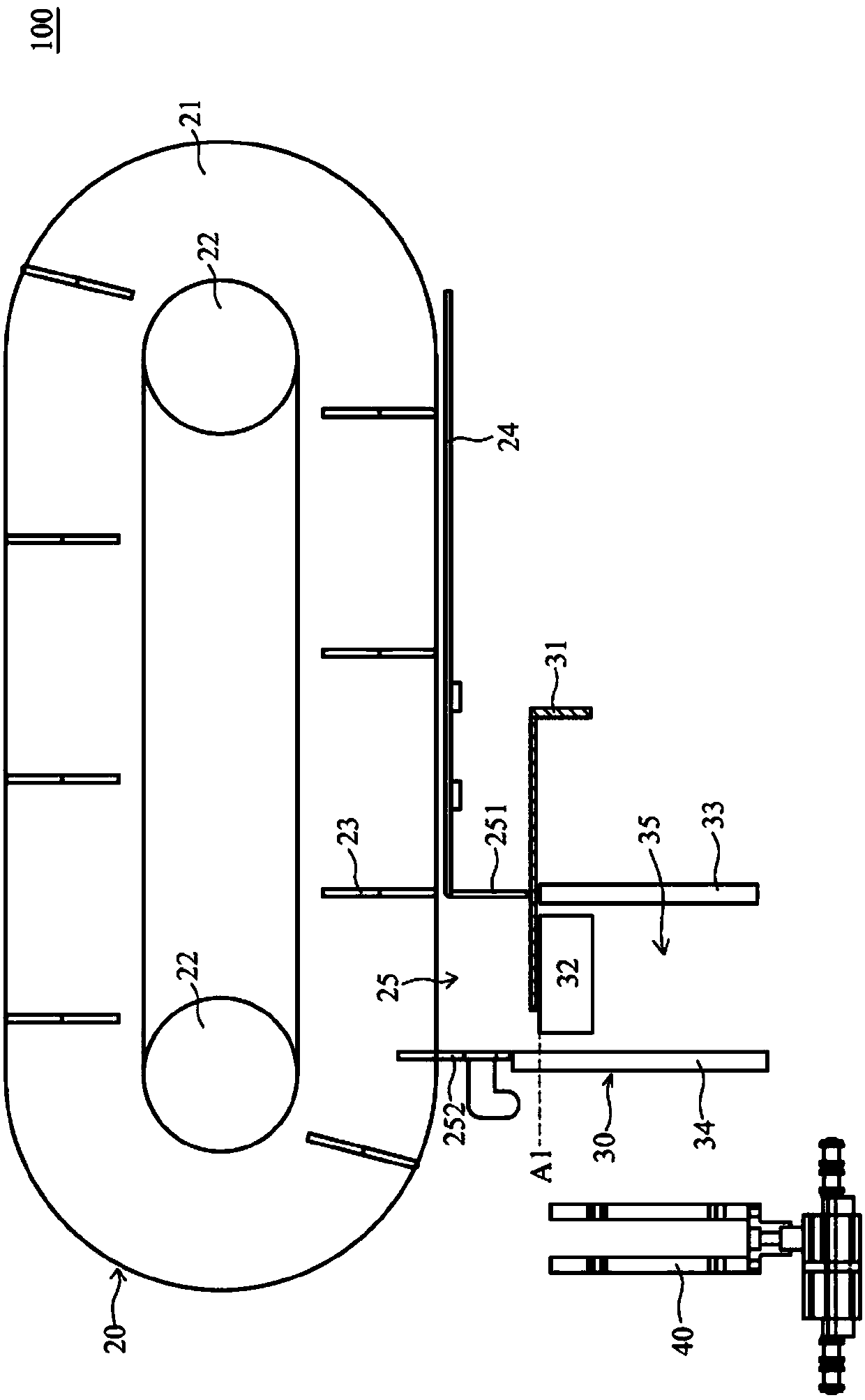

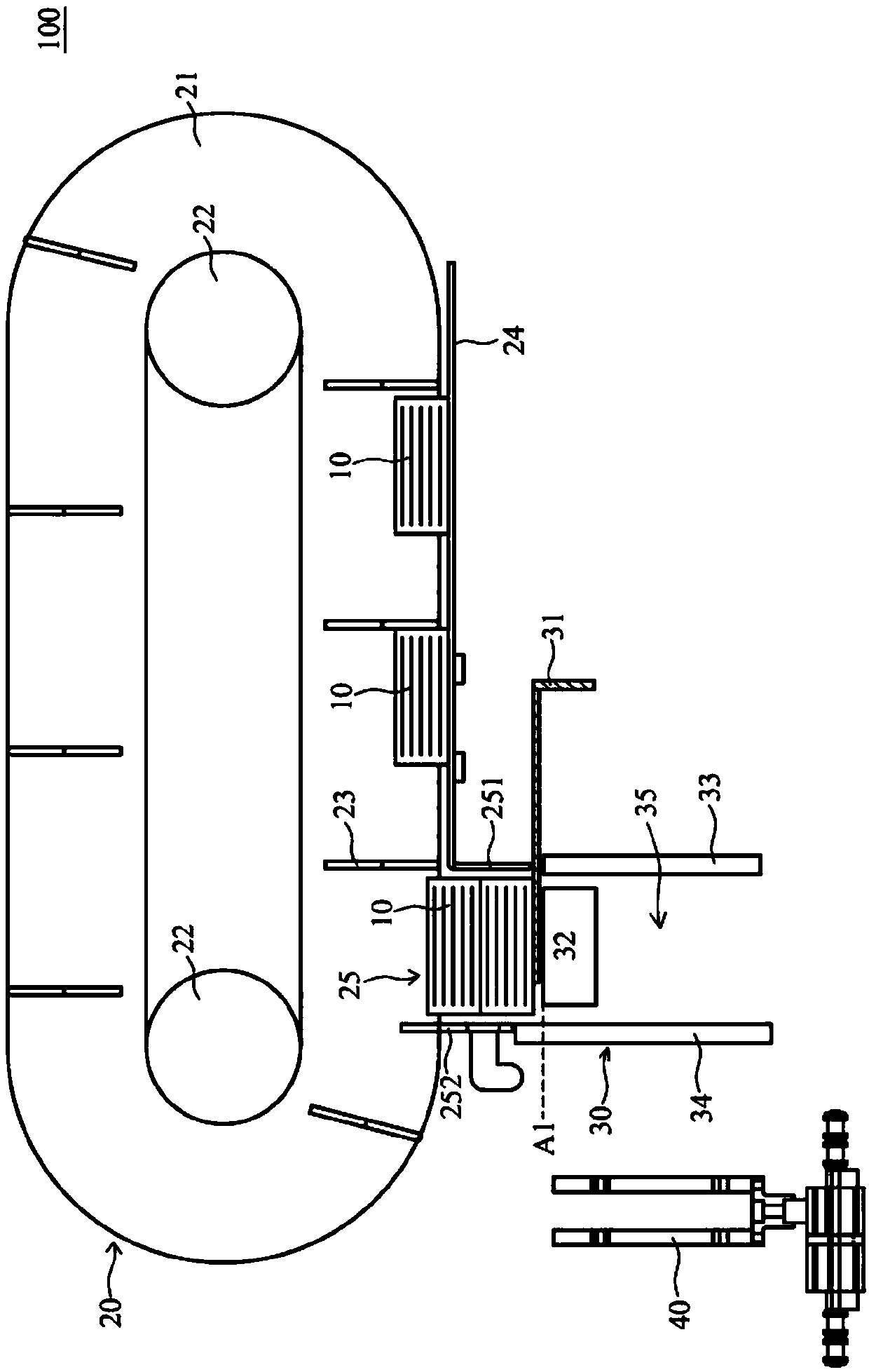

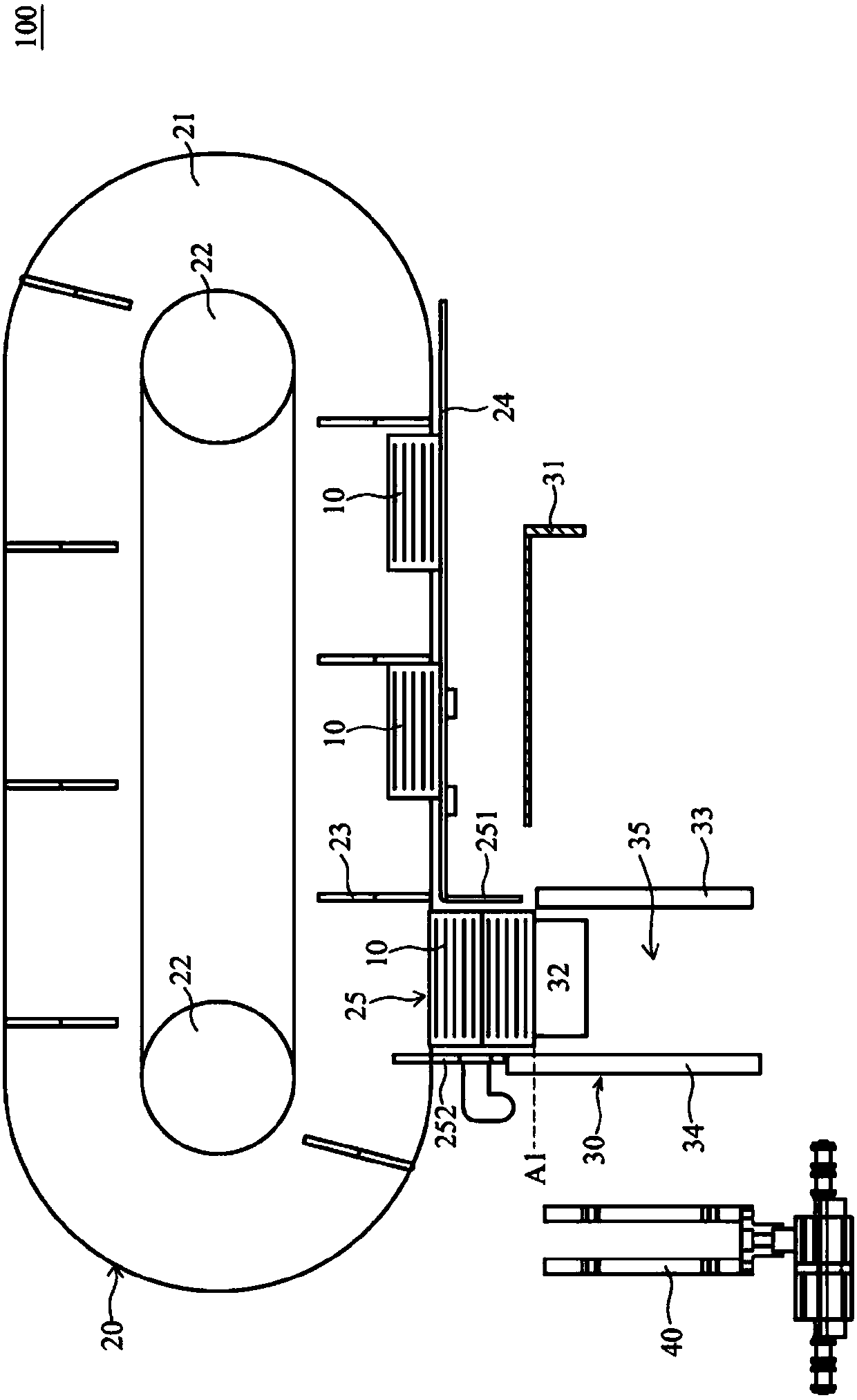

Solar cell assembly gantry storage stacking machine

The invention provides a solar cell assembly gantry storage stacking machine which belongs to automatic production devices in the field of photovoltaic and is stable in working and large in storage quantity. The solar cell assembly gantry storage stacking machine comprises a conveyor base and is structurally characterized in that the conveyor base comprises a frame, more than two conveying shafts are arranged on the frame, and conveying wheels are arranged on the conveying shafts. A gantry formed by a beam and columns is arranged above the frame. Vertical synchronous chains are arranged at two ends of the beam of the gantry and connected with lifting motors. Brackets are arranged on the two synchronous chains, and supporting columns corresponding to conveying shaft gaps are arranged on opposite sides of the two brackets.

Owner:YINGKOU JINCHEN MACHINERY

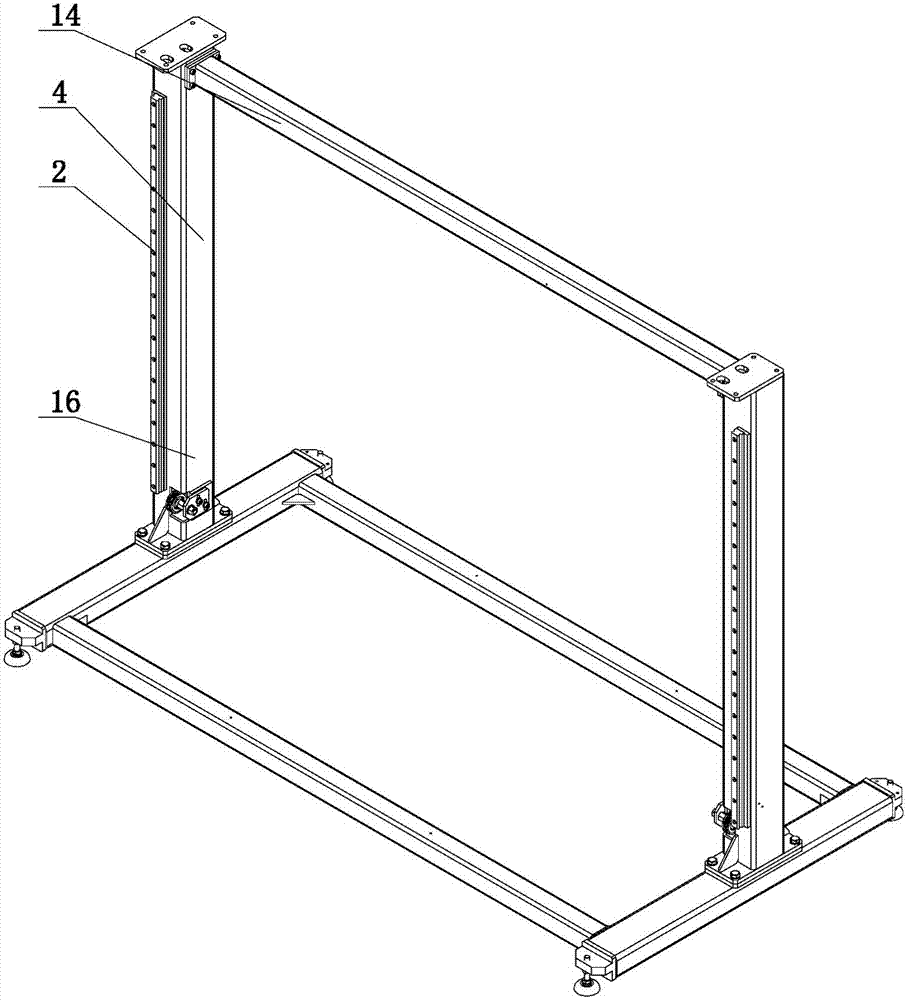

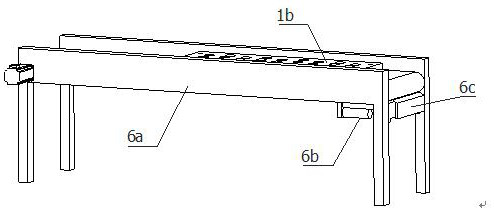

Tray stacking production line

InactiveCN107585583AHigh degree of automationSave human effortStacking articlesDe-stacking articlesProduction lineMechanical engineering

The invention relates to the field of a tray production devices, in particular to a tray stacking production line. The tray stacking production line comprises a first conveying belt, a tray taking andputting device, stacking and aligning devices, a second conveying belt and a control device. The first conveying belt is used for conveying trays and comprises tray grabbing positions. The second conveying belt comprises tray stacking positions, trays are stacked at the tray stacking positions to form tray stacks, and the second conveying belt is used for conveying the tray stacks. The tray taking and putting device is used for taking up the trays from the tray stacking positions of the first conveying belt and putting the trays at the tray stacking positions of the second conveying belt. Thestacking and aligning devices are located above the tray stacking positions and guide the tray stacks. The control device is used for controlling the first conveying belt, the tray taking and puttingdevice, the stacking and aligning devices and the second conveying belt. The tray stacking production line can complete tray stacking work without participation of excessive workers, save labor, canensure the stacking quality and guarantee the production safety.

Owner:广东精泽企业服务有限公司

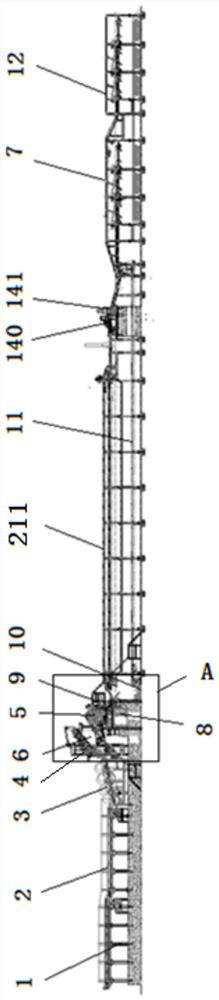

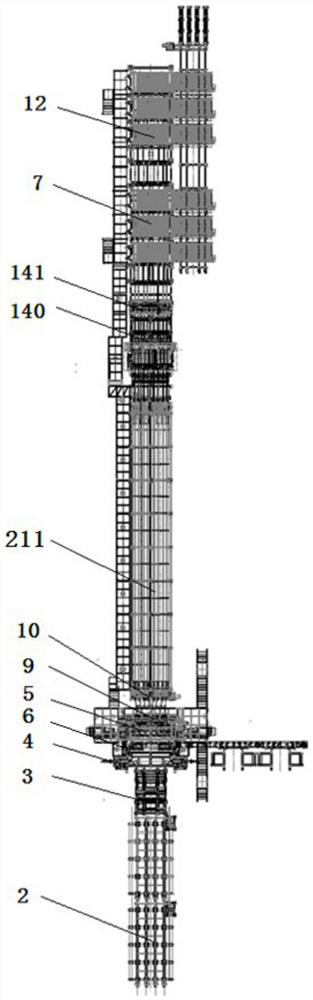

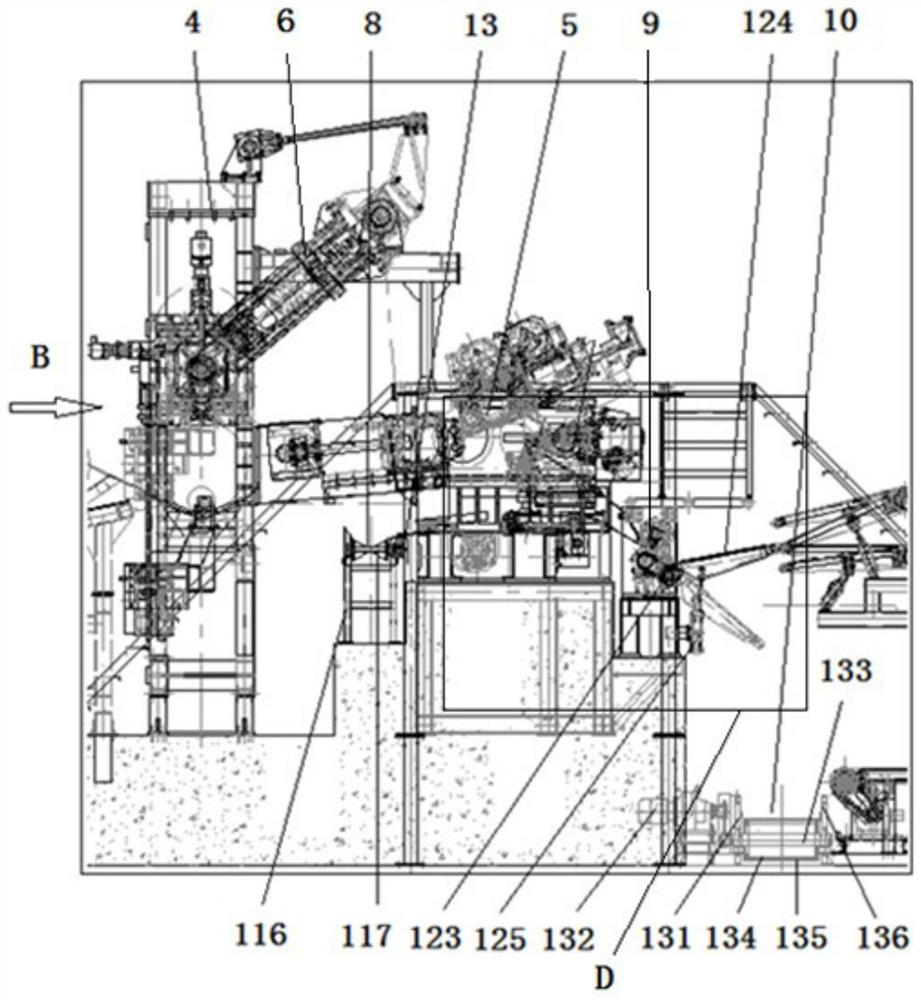

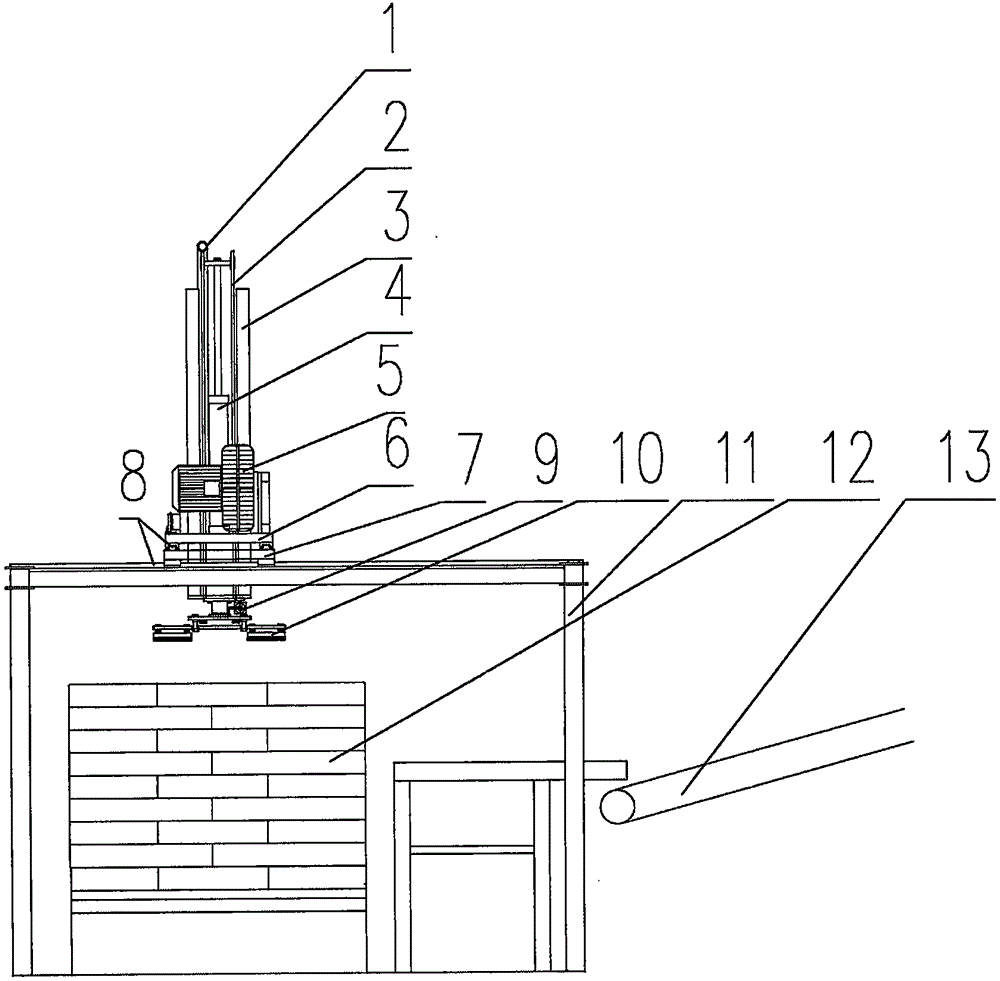

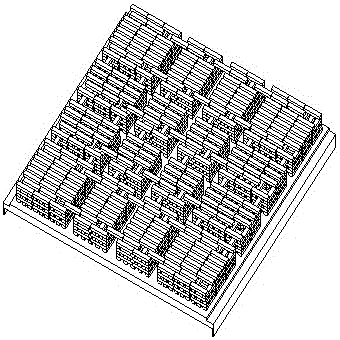

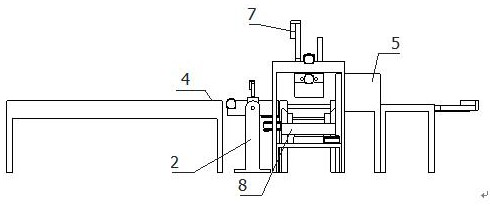

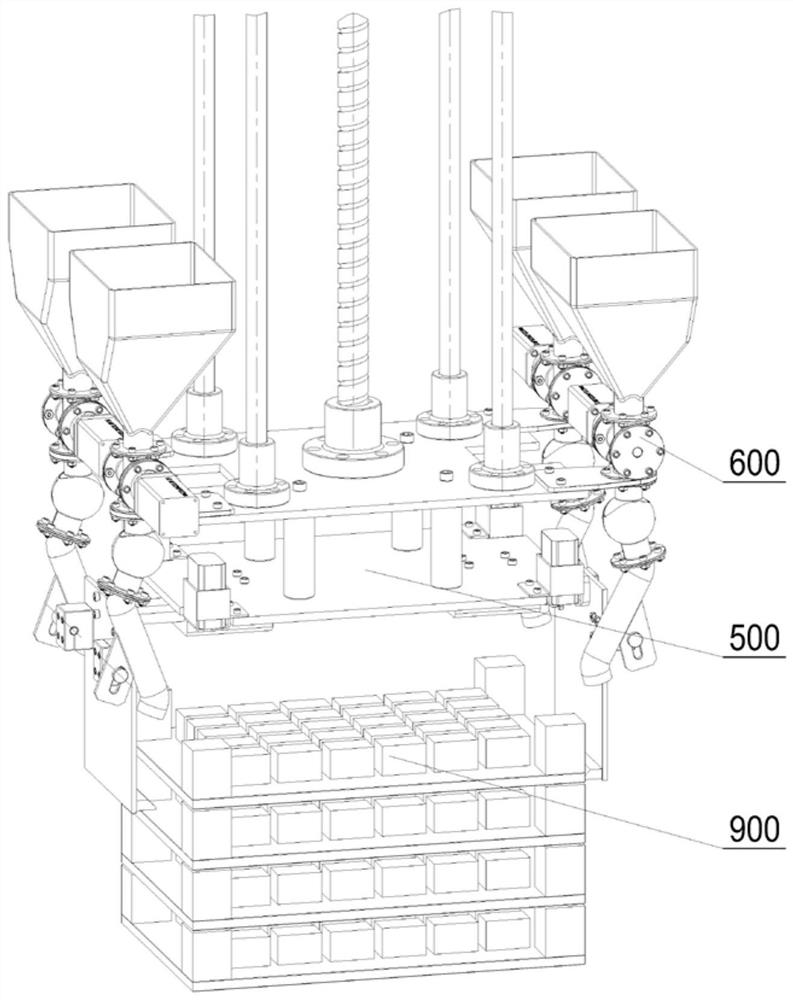

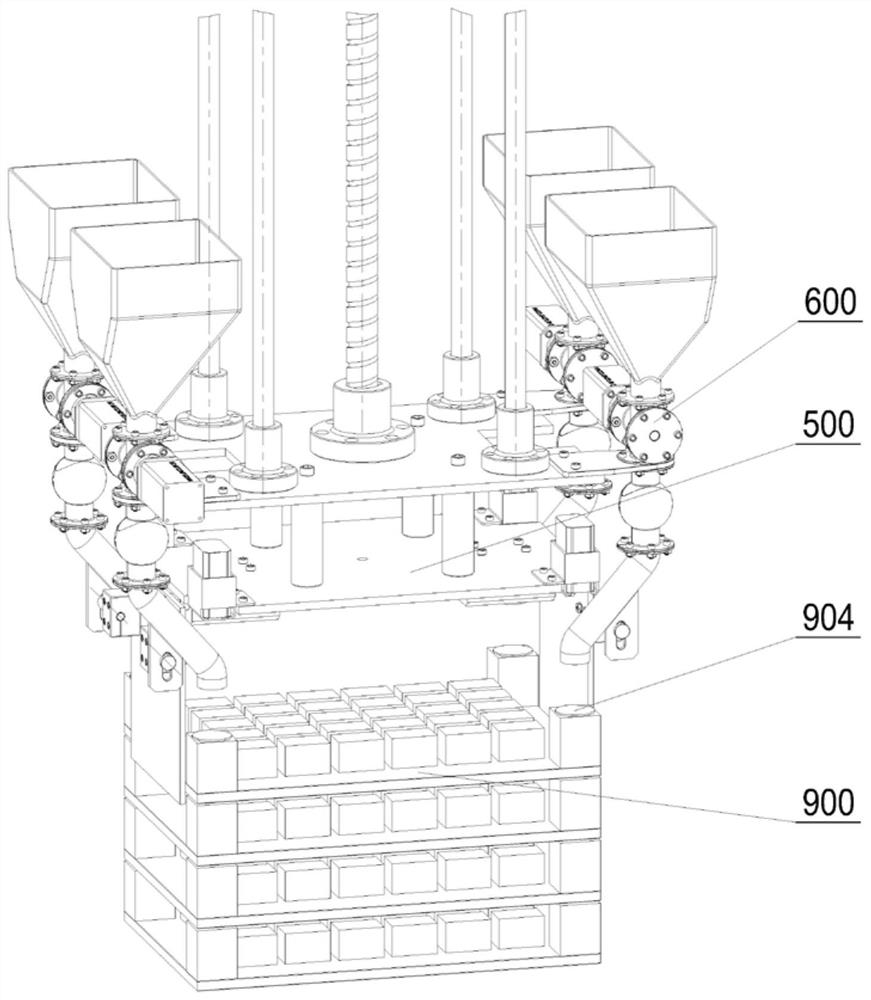

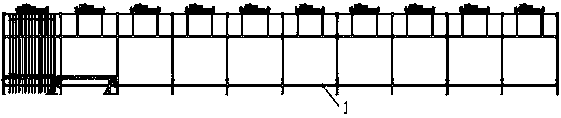

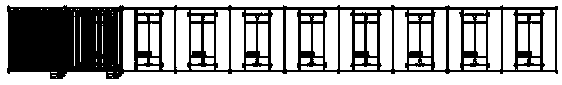

Building block off-line stacking system

The invention discloses a building block off-line stacking system. The building block off-line stacking system is characterized by comprising a finished product conveyor (2), a plate lifting machine (3), a supporting plate returning machine (4), a stack conveying machine (5), a stacking machine (6), a pallet separating machine (7) and a palletizing machine (8), the finished product conveyor (2), the plate lifting machine (3) and the supporting plate returning machine (4) are arranged in sequence, the stacking machine (6) is installed above the supporting plate returning machine (4), the stack conveying machine (5) penetrates through the lower portion of the stacking machine (6), the pallet separating machine (7) is arranged at one end of the stack conveying machine (5), one end of the supporting plate returning machine (4) is connected with the plate lifting machine (3), and the other end of the supporting plate returning machine (4) is connected with the palletizing machine (8). The building block off-line stacking system is a special stacking system which can operate independently and is suitable for stacking well maintained building blocks produced in factories, capable of improving the automation degree of building block production and relieving the labor intensity of workers, low in investment cost, high in working efficiency and suitable for large-scale popularization.

Owner:JIANGSU TENGYU MASCH MFG CO LTD

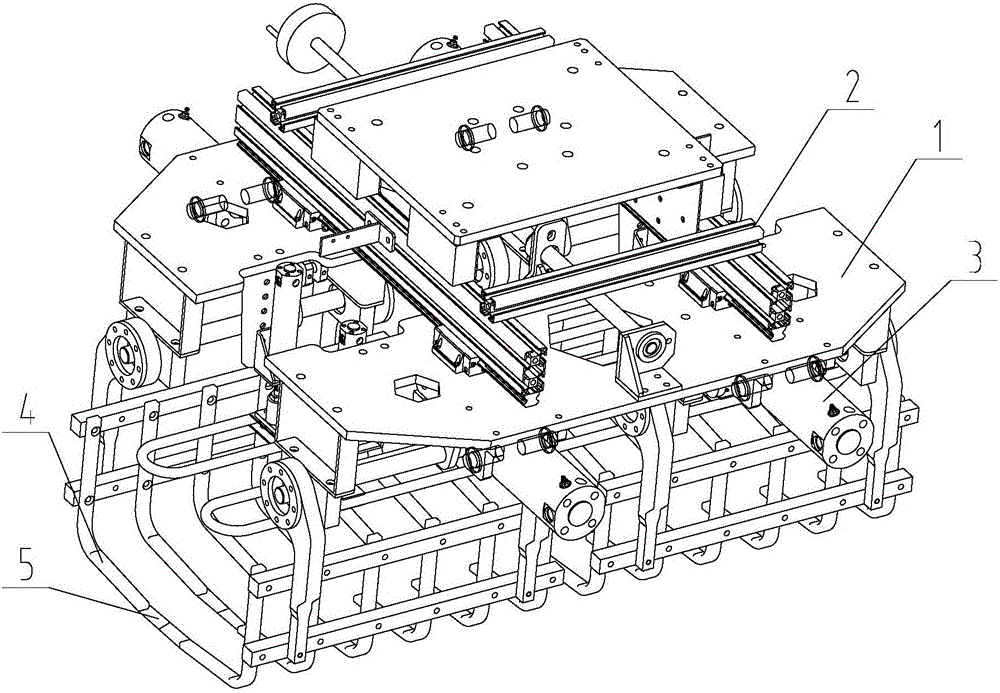

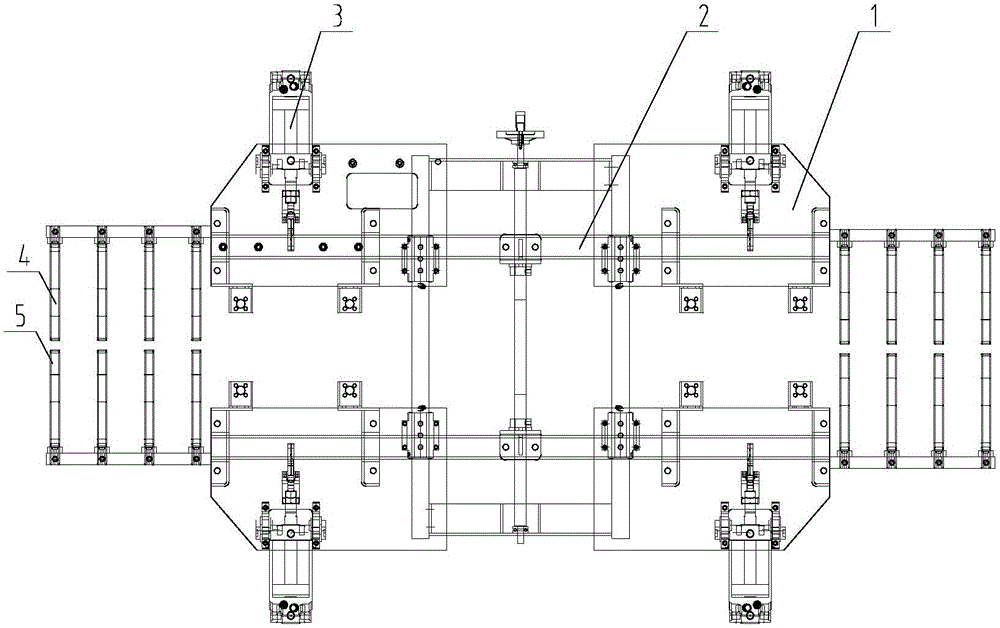

Intelligent robot gripper for stacking system

ActiveCN105084021AFree crawlingAchieve fixationProgramme-controlled manipulatorGripping headsRubber ringGlass fiber

Owner:东莞智动力电子科技有限公司

File sorting device

PendingCN112607288AGuaranteed stabilitySolve technical problems with uneven surfacesStacking articlesStorage devicesComputer hardwareEngineering

Owner:GUANGDONG UNIV OF TECH

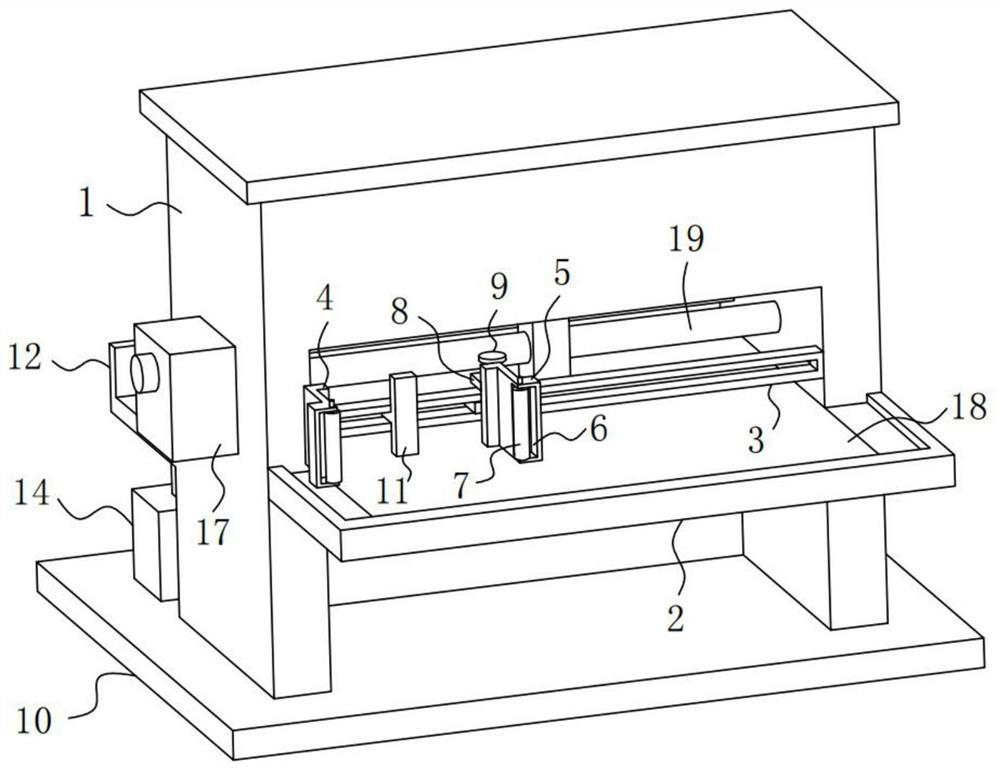

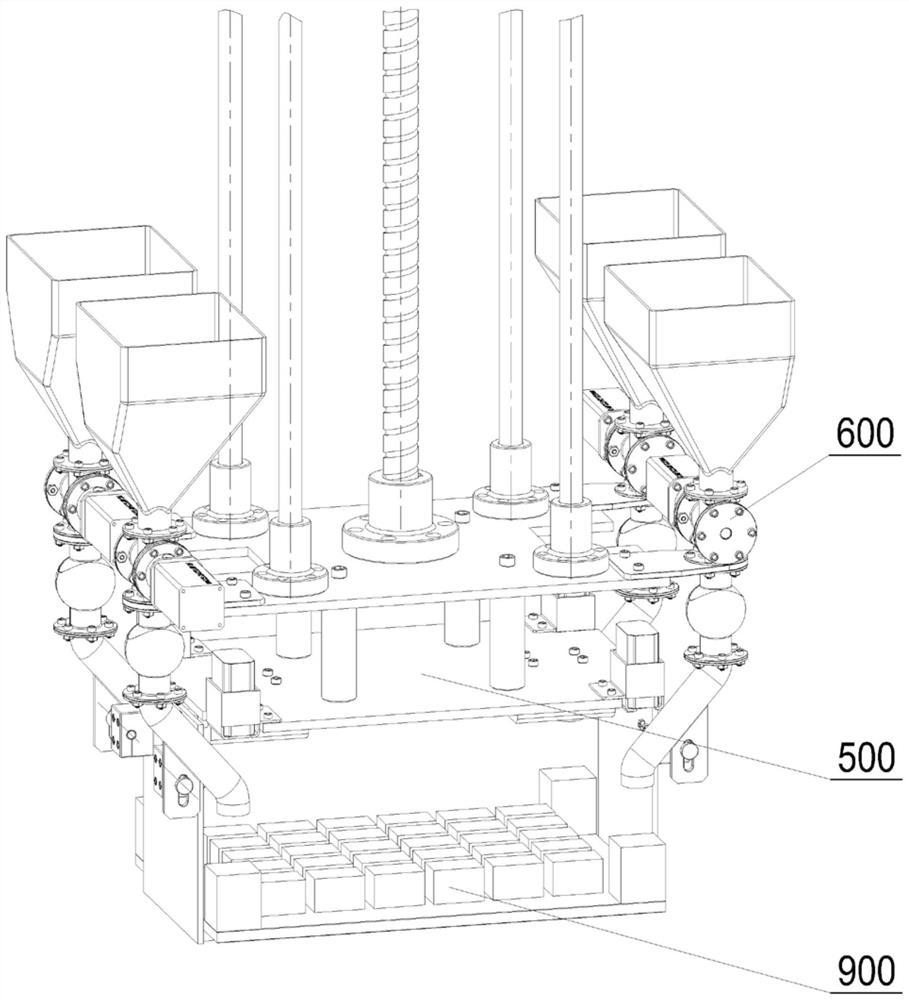

Automatic part taking system

ActiveCN113955506AHigh degree of automationRealize automatic box change functionEdge grinding machinesControl devices for conveyorsEngineeringMachining system

The invention relates to an automatic part taking system. The system comprises a first mechanical arm, a cooling device, a cinder ladle removing device, a deburring device and a second mechanical arm and further comprises an automatic box replacing device arranged at a box filling station and used for replacing part boxes and an automatic stacking device used for stacking the full part boxes. The automatic box replacing device comprises a conveying frame, a conveying roller set rotationally installed on the conveying frame and a driving part for driving the conveying roller set to rotate, and the box filling station is located on the conveying roller set. The automatic stacking device comprises a clamping mechanism used for clamping or loosening the part boxes and a stacking control mechanism used for controlling the clamping mechanism to move between the box filling station and a stacking station in a reciprocating manner and achieving stacking. The automatic part taking system has the effects that the work of replacing and stacking part boxes can be automatically carried out, and the automation degree of a part die-casting machining system is improved.

Owner:AIMI (SHANGHAI) TECH CO LTD

Full-automatic intelligent feeding, centering, rotary-cutting and stacking veneer processing production line

ActiveCN113771175AImprove work efficiencyQuality improvementConveyorsProfiling/shaping machinesStructural engineeringManufacturing line

Owner:SHANDONG BAISHENGYUAN GRP

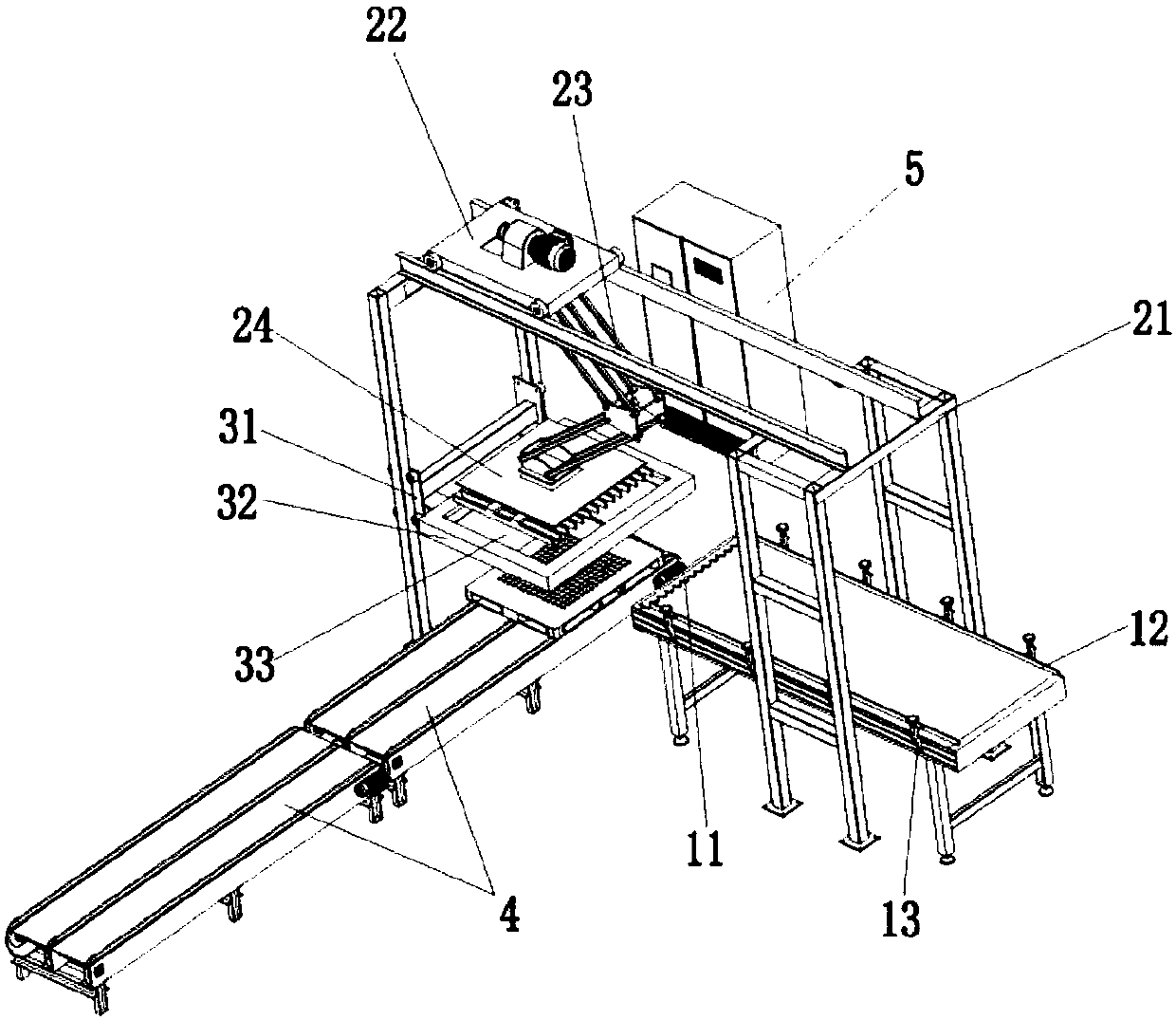

Sorting device of stacking robot based on computer vision

InactiveCN110681614AAccurate captureNovel structural designProgramme-controlled manipulatorStacking articlesRobot handPalletizer

Owner:NANTONG UNIVERSITY

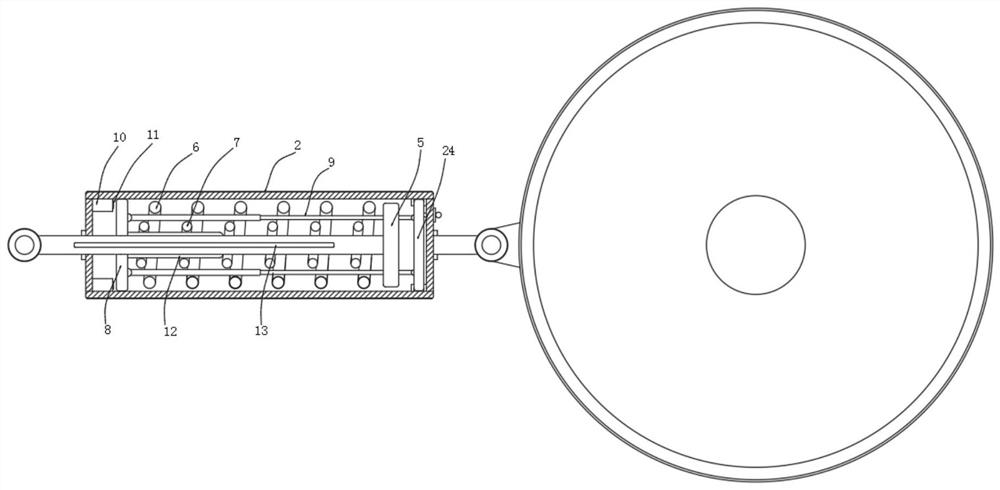

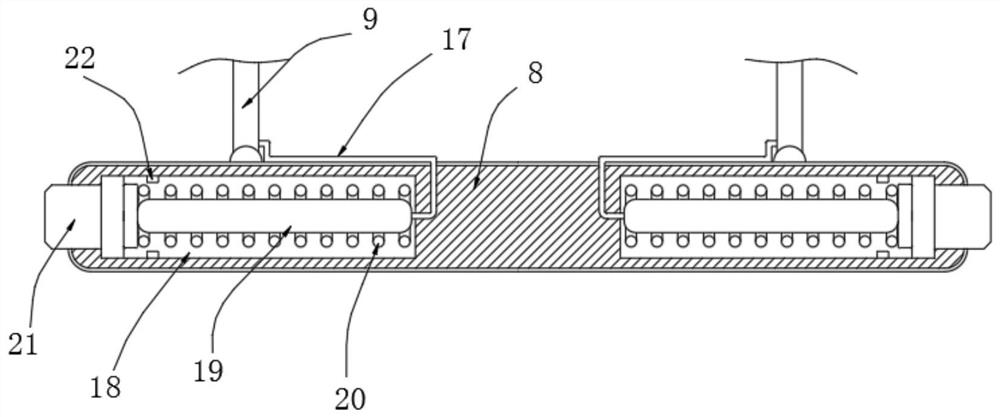

Suction cup for woven bag and unstacker with suction cup

ActiveCN105417184ASolve the long-term problem of manual unstacking and loadingSolve the problem of stack type identificationStacking articlesDe-stacking articlesEngineering

Owner:山东精瑞自动化设备有限公司

Bridge connecting mechanism for brick stacking

Owner:ZIYANG JINGGONG MECHANICS

Automatic stacking system for agricultural product packaging boxes

Owner:徐州斯塬网络科技有限公司

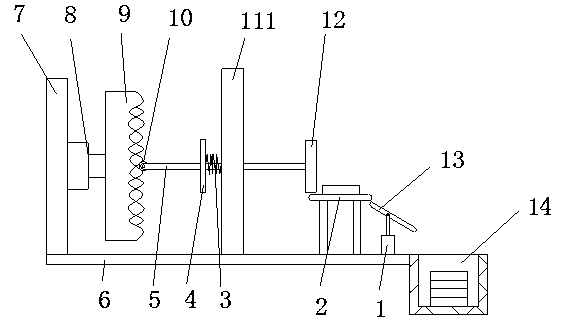

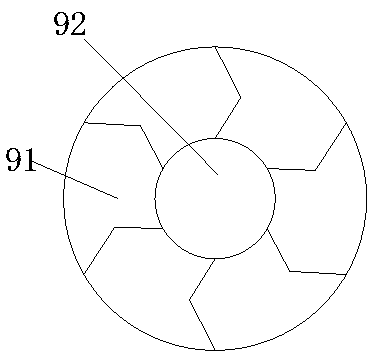

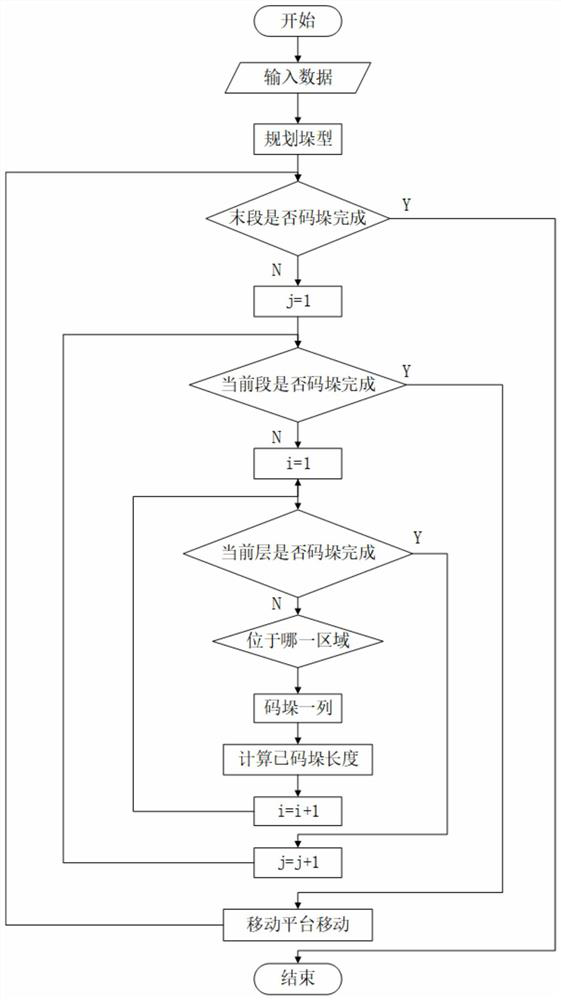

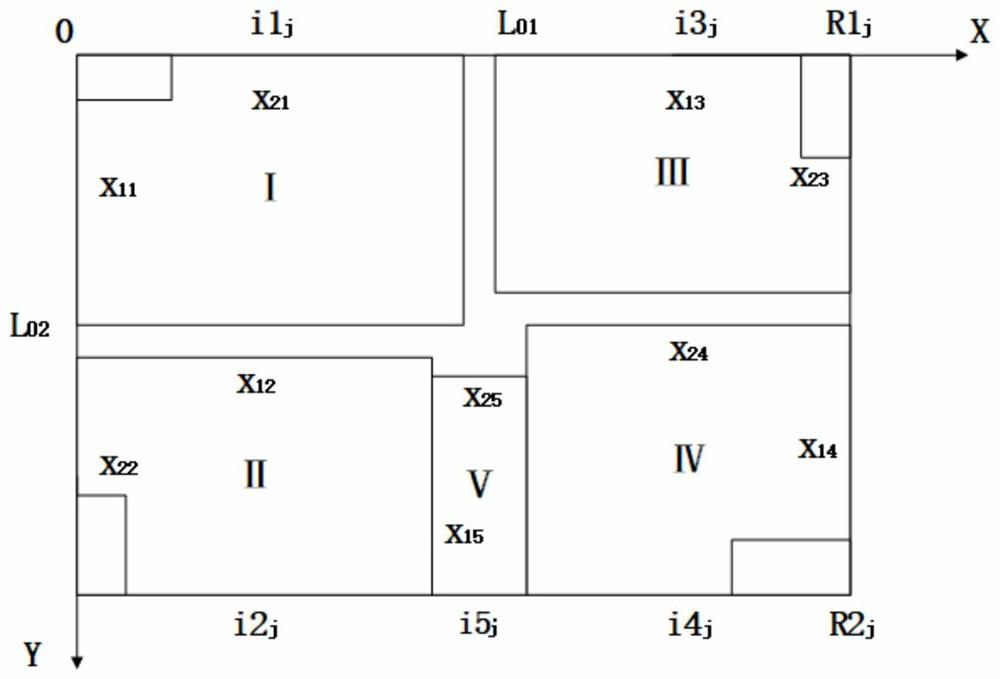

Segmented stepped stacking method based on staggered stacking planning

Owner:TIANJIN UNIV OF COMMERCE

Roll-in type automatic stacking machine

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

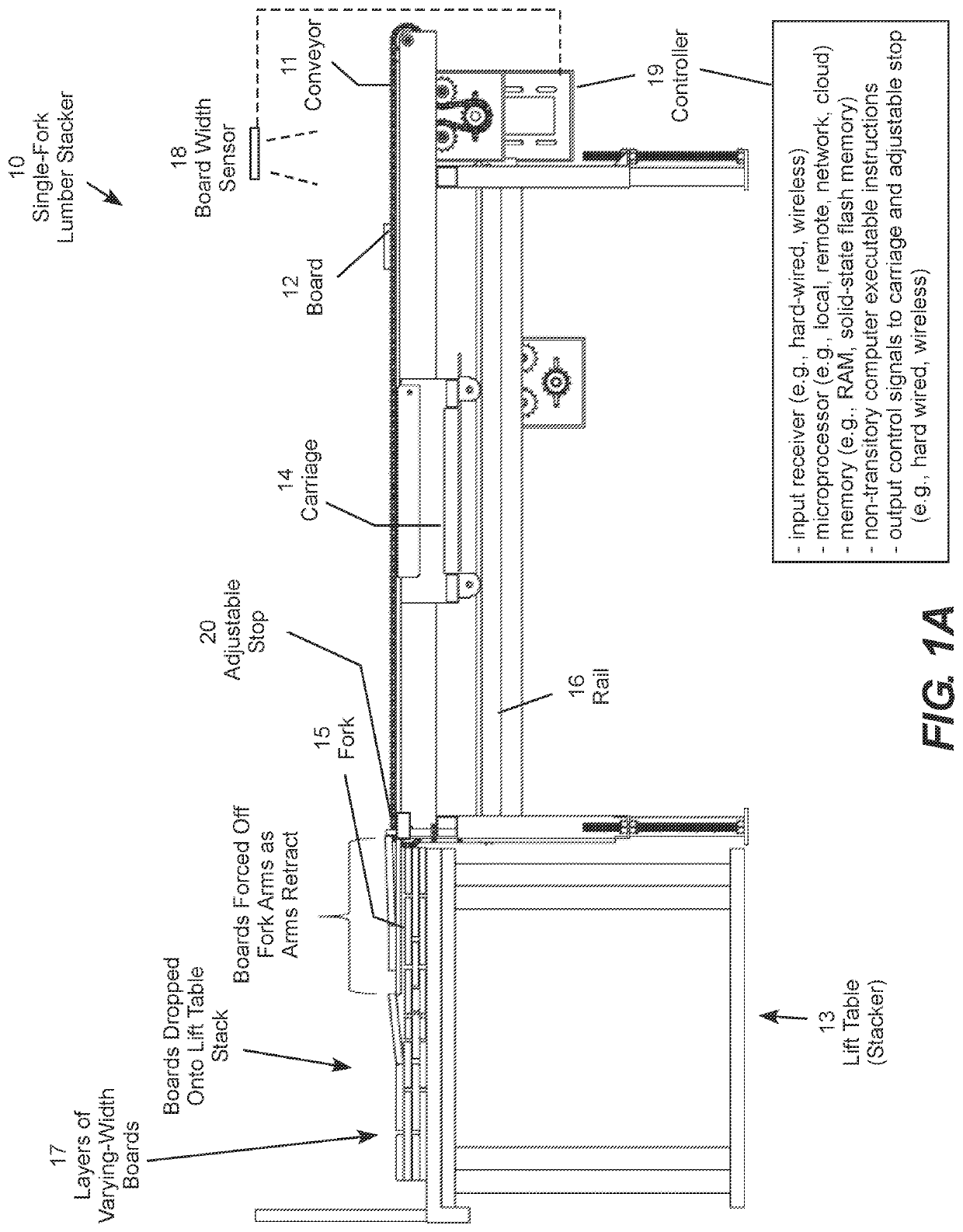

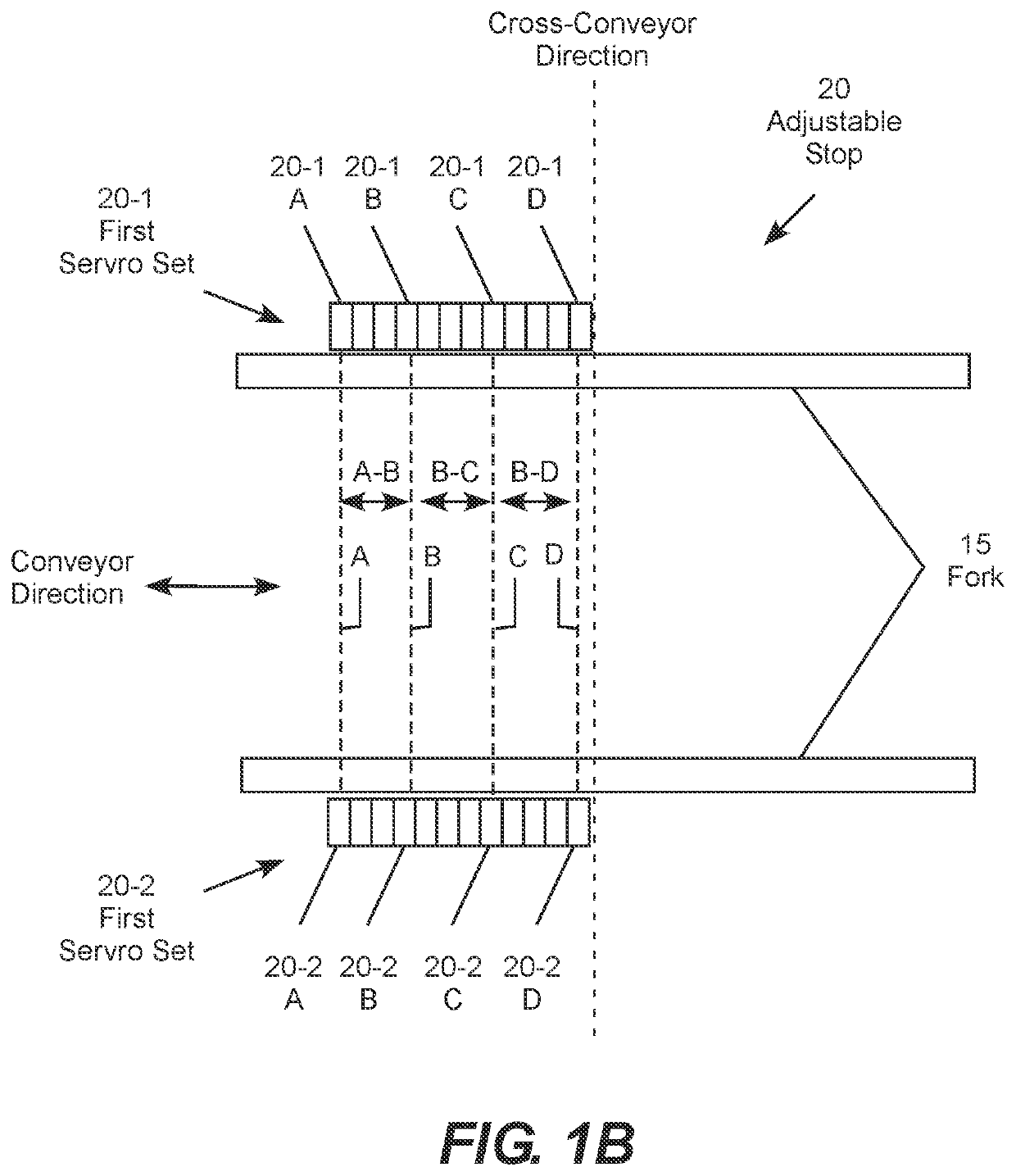

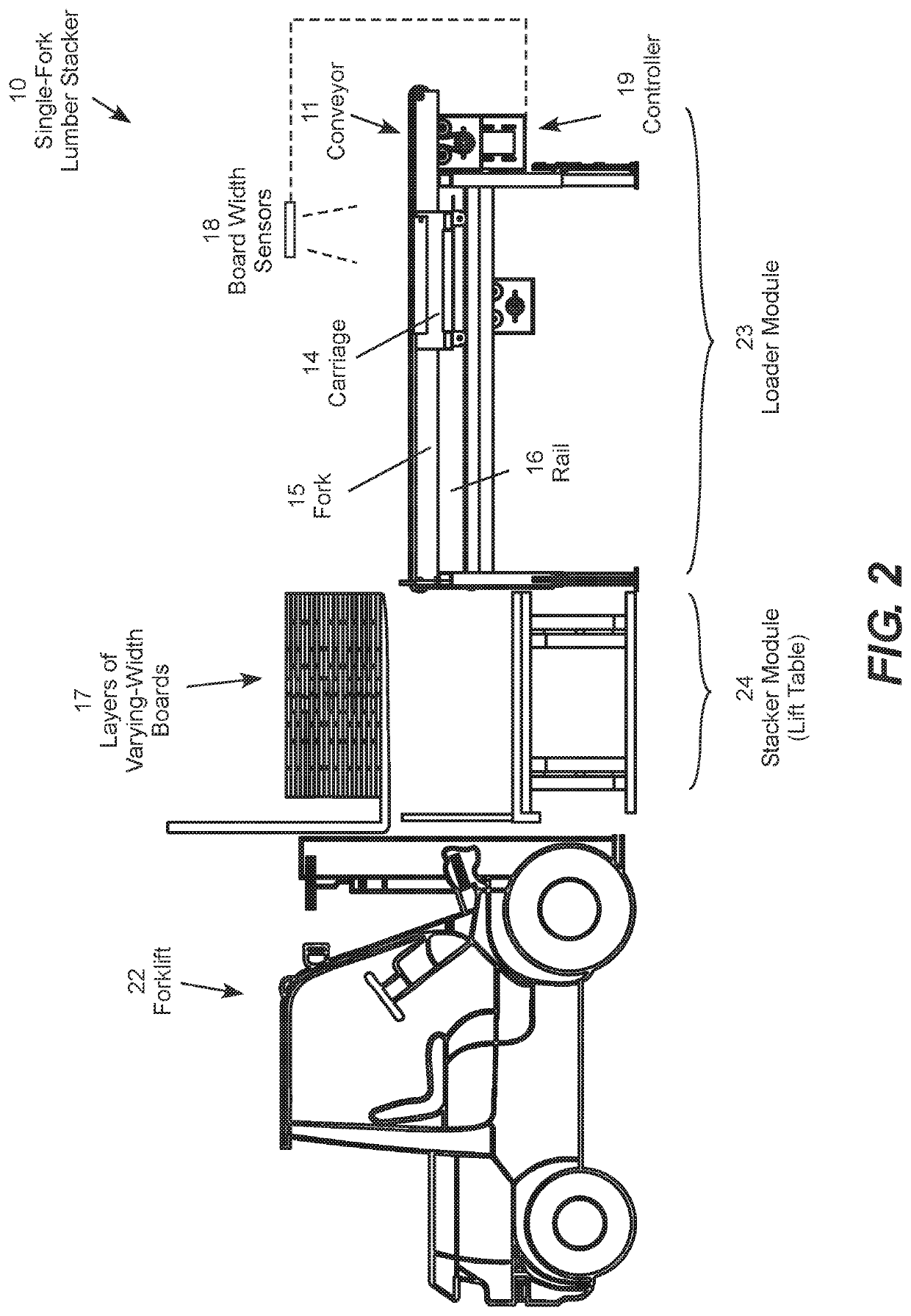

Modular Single-Fork Lumber Stacking Machine

ActiveUS20220063934A1Easy to relocateFacilitate repositioningConveyorsStacking articlesStructural engineeringForklift truck

Owner:WOODFLOW LLC

Balance cylinder and robot link integrated driving module

PendingCN112476482AEasy to installExtended service lifeStacking articlesDe-stacking articlesControl engineeringCylinder block

Owner:HEFEI GOODTIMES AUTOMATION

Robotic method for loading cases

The invention relates to a robotic method for loading cases on a packaging line from cases contained in a closed parallelepiped container and wherein it is proceeded with the loading of the packaging line, after opening of the container (Ca) by: / d / insertion of a first jaw (30) of the clamp between the first face (F1) of the container and the first case (Et1) of the row of cases and, insertion of a second jaw (31) of the clamp between the last case (Etd) of the row of cases and the second face (F2) of the container, and approach of the jaws until seizing up the row of cases, / e / piloting of the robotic arm so as to extract the row of cases from the container grasped by the motor-driven clamp (3) and load the packaging line (Lg) with the row of cases.

Owner:VELEC SYST

Plastic plate pushing and stacking device

PendingCN113200365ALabor savingLow costStacking articlesDe-stacking articlesTelescopic cylinderEngineering

The invention relates to the technical field of plastic plate production, in particular to a plastic plate pushing and stacking device. The plastic plate pushing and stacking device comprises a support, a movable frame and a telescopic cylinder, wherein the movable frame is movably connected with the upper end of the support; the telescopic cylinder comprises a telescopic end and a fixed end; the telescopic end is connected with the movable frame; and the fixed end is connected with the support. According to the plastic plate pushing and stacking device, the movable frame is movably connected with the upper end of the support, the telescopic cylinder comprises the telescopic end and the fixed end, the telescopic end is connected with the movable frame, and the fixed end is connected with the support; and plastic plates move forwards on the movable frame, then a hydraulic cutting knife cuts off the plastic plates, the telescopic cylinder works, the telescopic end shrinks to drive the movable frame to swing downwards, and the plastic plates fall onto a stacking assembly, therefore, the labor is saved, and the plastic plate pushing and stacking device is low in cost and high in practicability.

Owner:SHENZHEN JIMEI PLASTIC CO LTD

Printing machine with code spraying and up-and-down printing functions for cartons

Owner:浙江中包派克包装有限公司

Automatic setting machine

Owner:徐州博创建设发展集团有限公司

Grabbing device with automatic height adjusting function

InactiveCN113734775ARealize automatic crawlingAchieve releaseConveyorsStacking articlesLaser rangingPhysics

Owner:NANJING COLLEGE OF INFORMATION TECH

Sponge thin cushion airing storage warehouse

Owner:南通恒康数控机械股份有限公司

Conveying system for paper packages and layered stacking device

Owner:CHAN LI MACHINERY

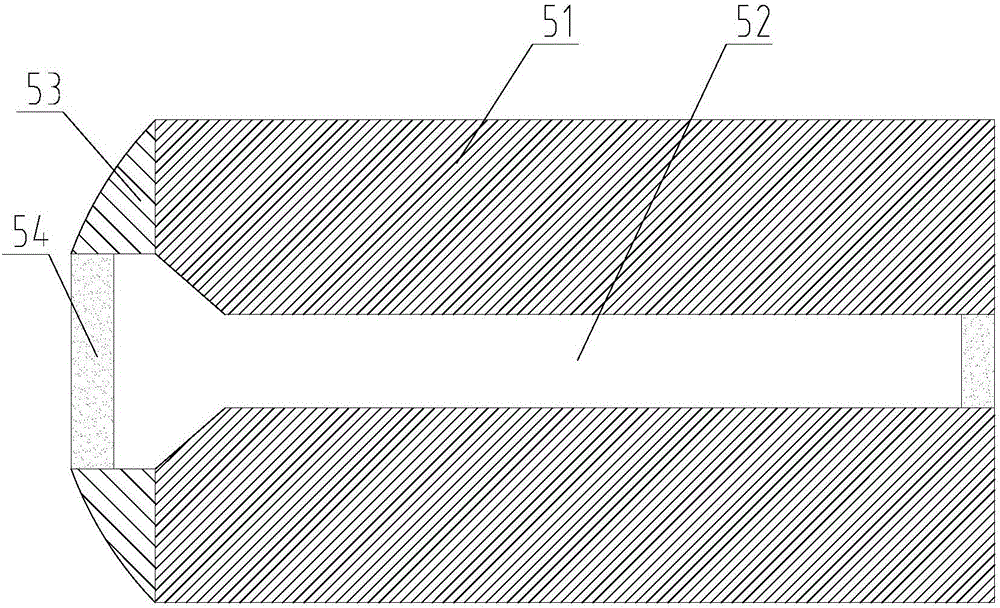

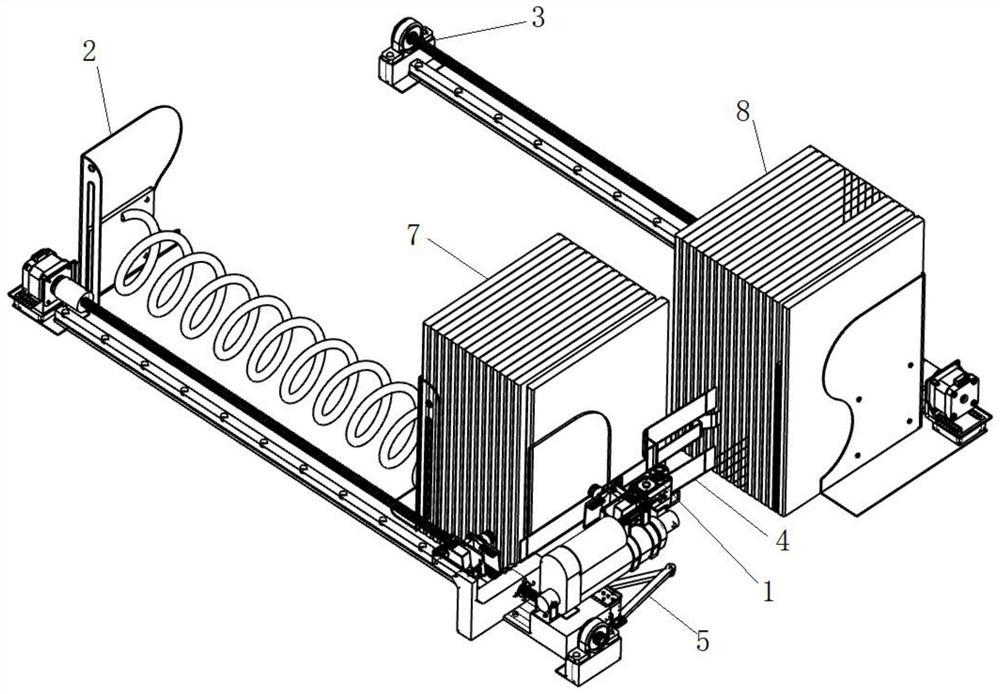

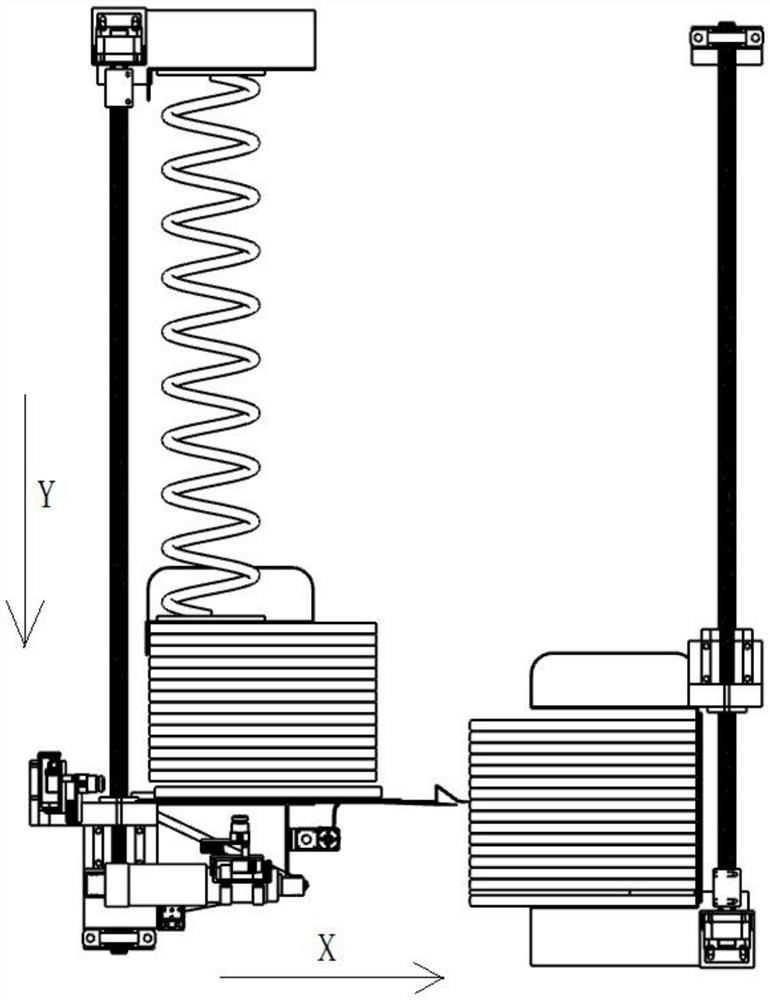

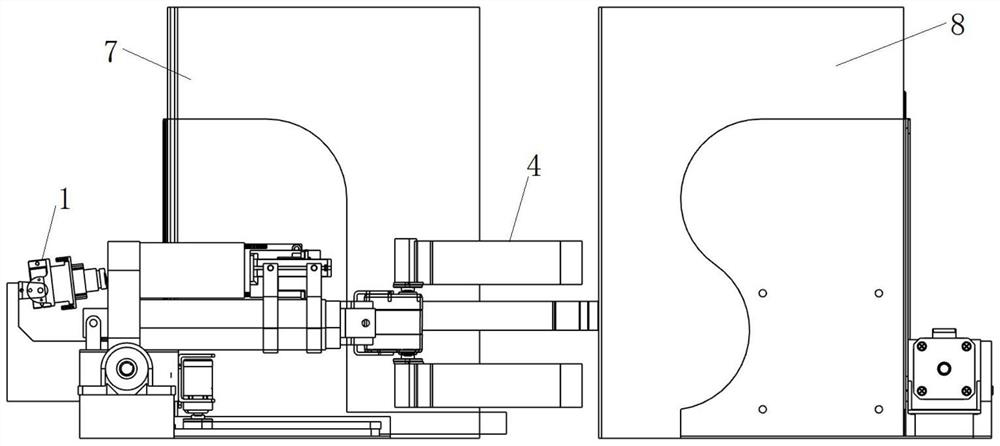

Variable-flame-path type blank stacking machine blank-clamping blank-drawing and blank-separating system suitable for micro-rectangular kiln car

Owner:武汉大通窑炉机械设备有限公司

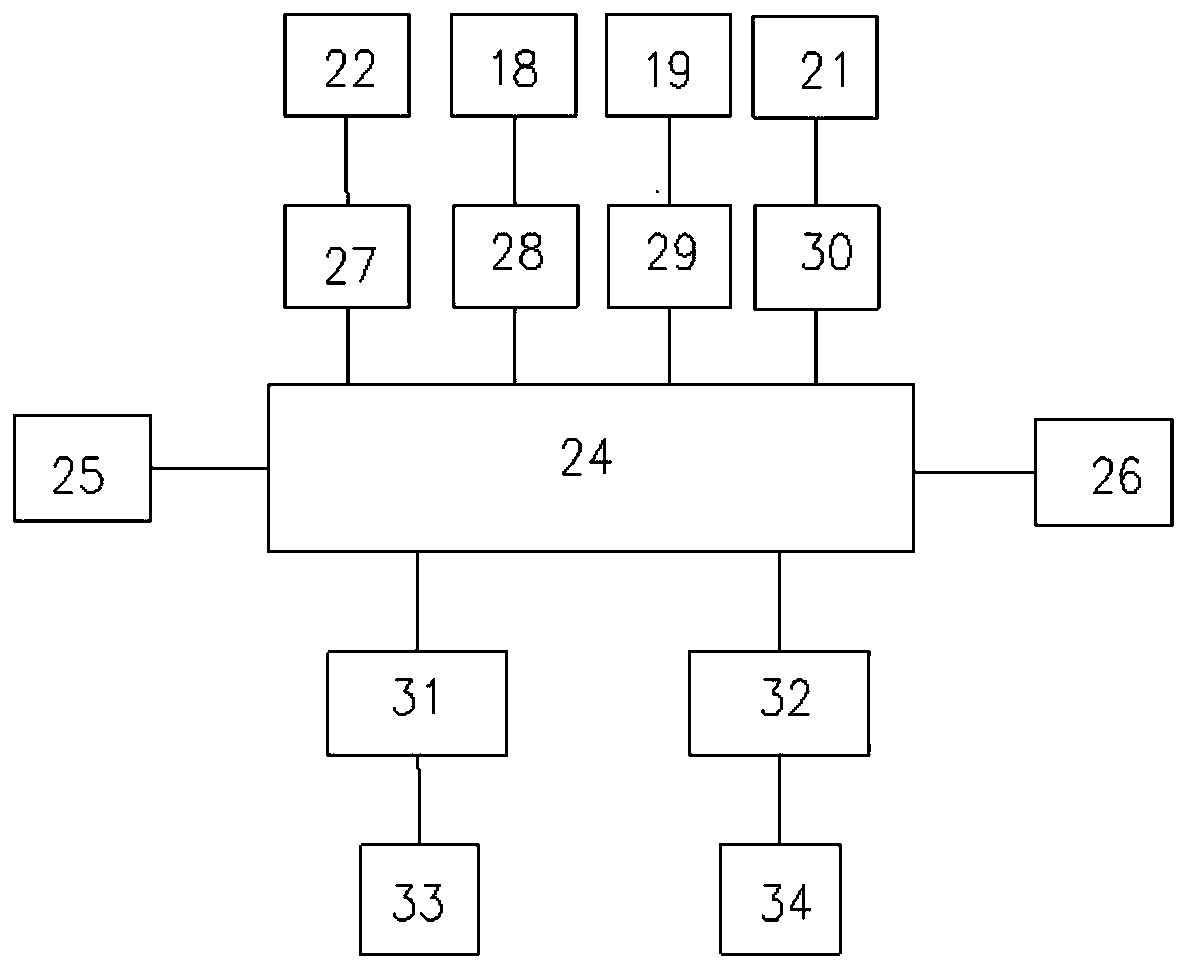

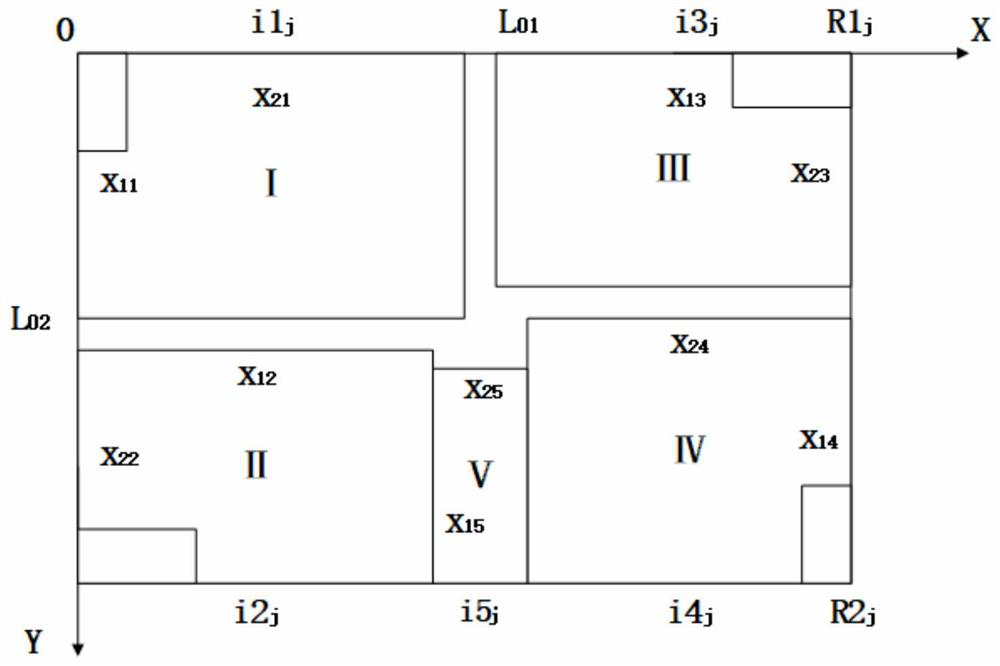

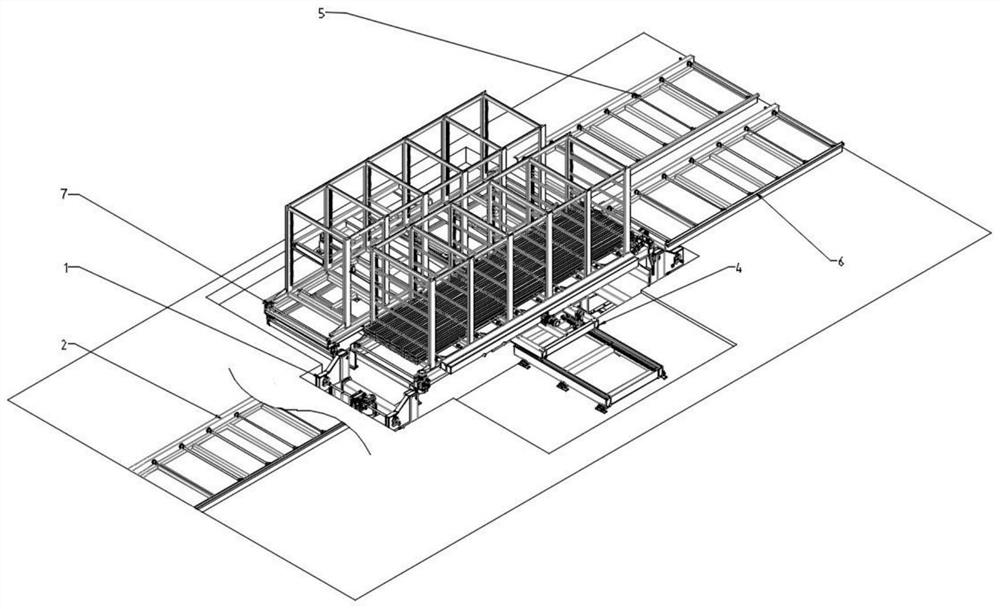

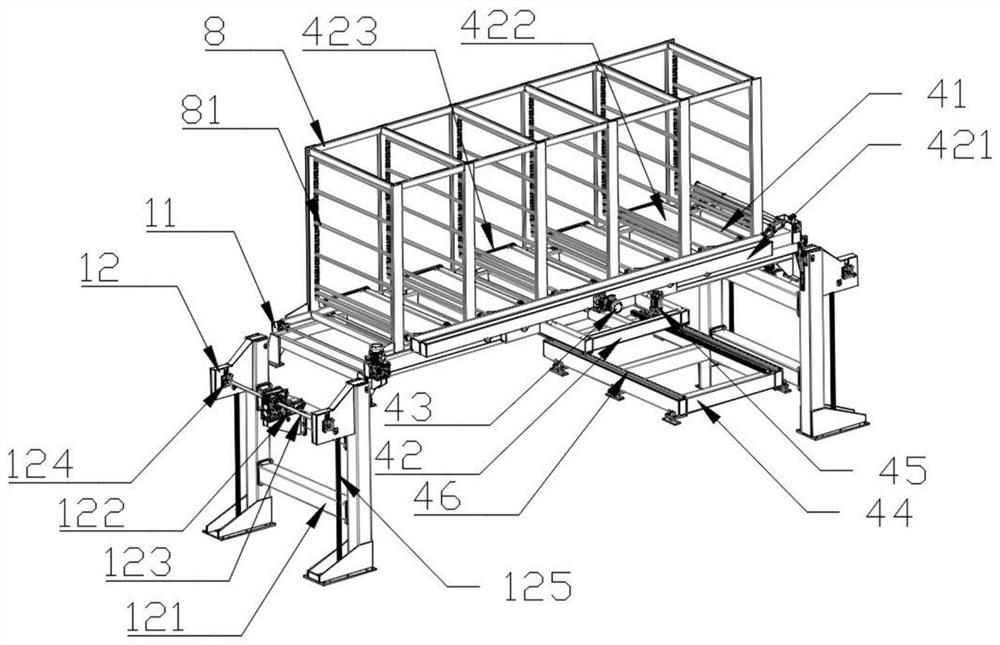

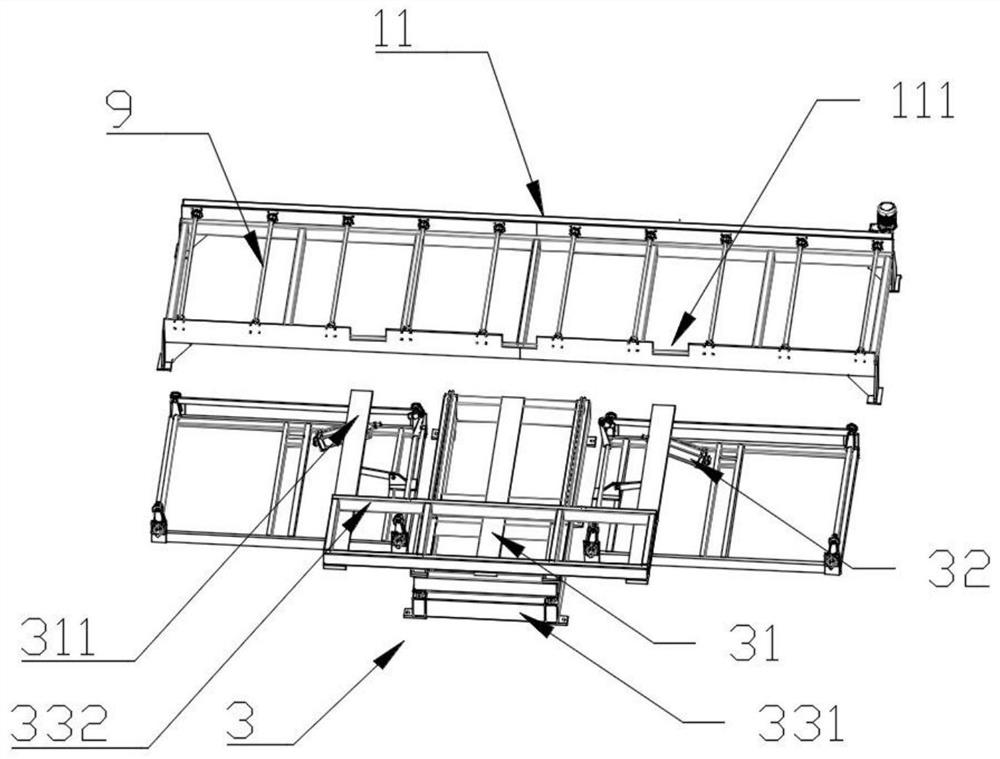

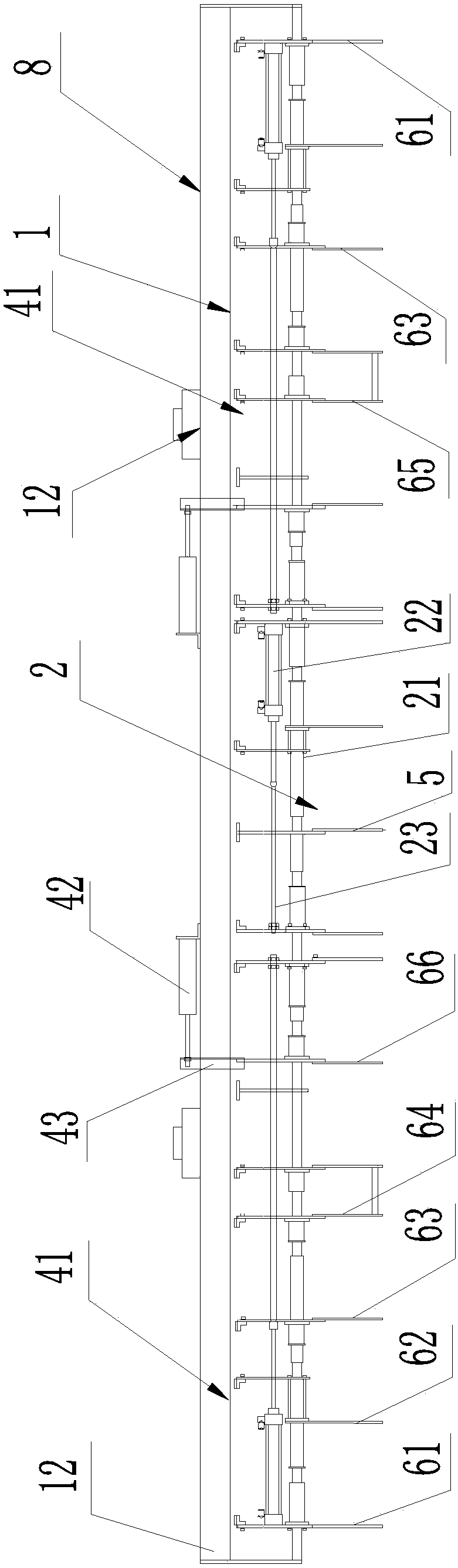

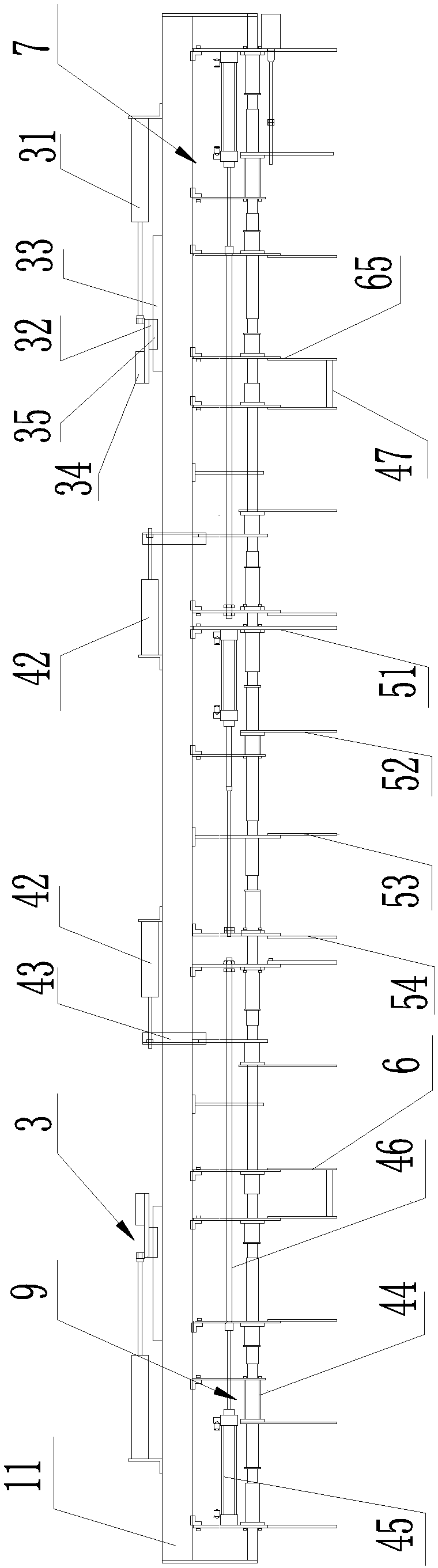

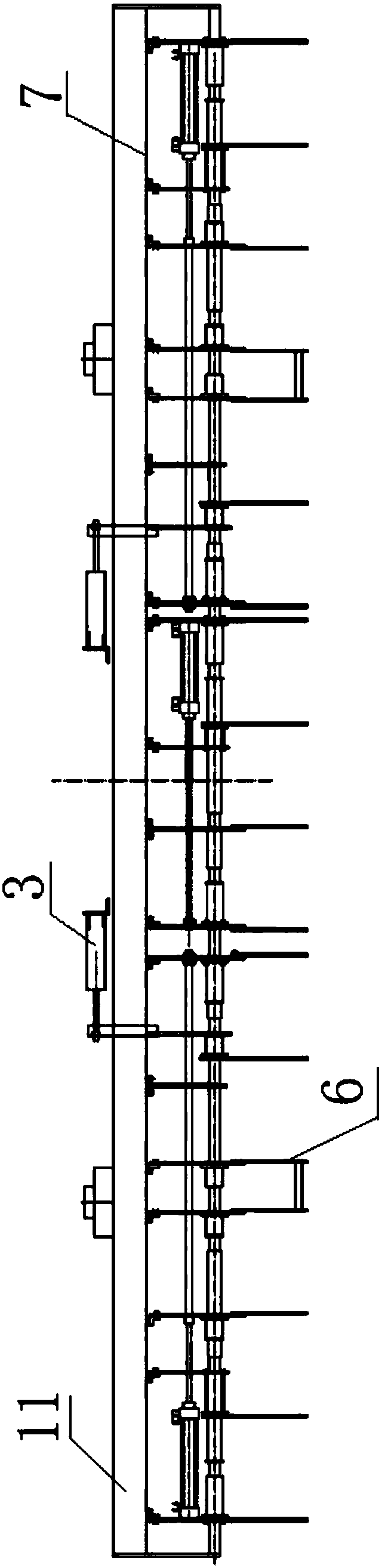

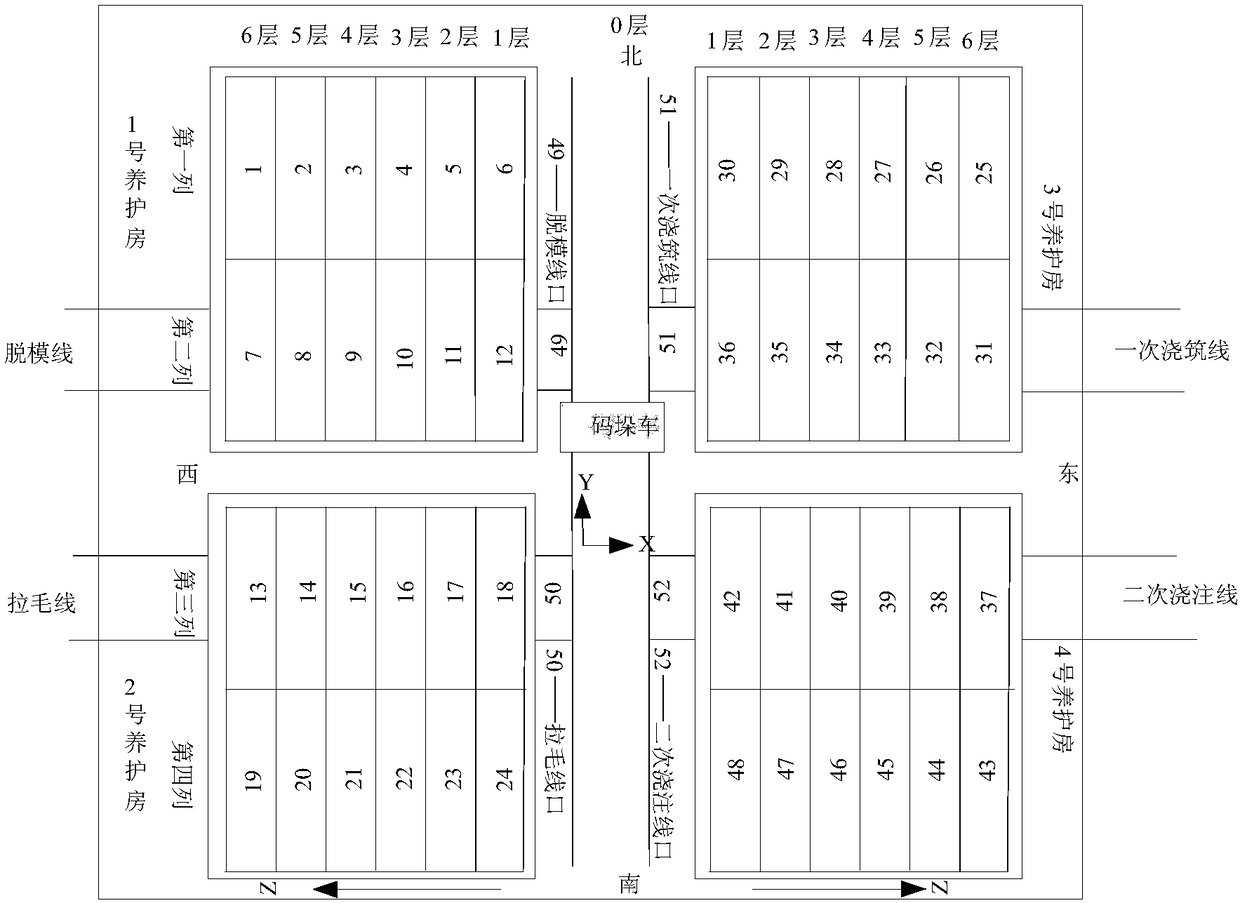

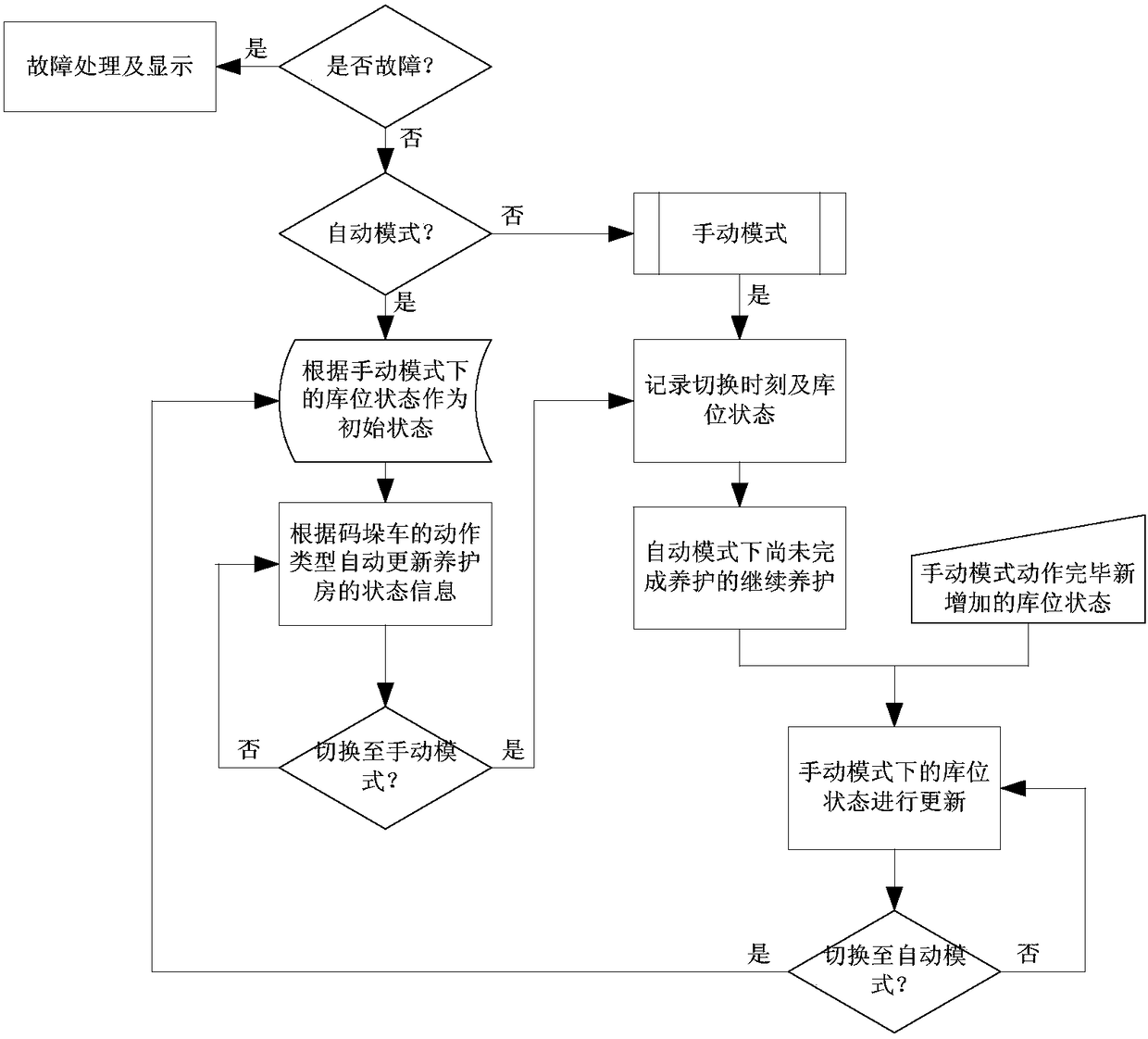

Maintenance state control system and control method in the maintenance room of the concrete precast slab production line

ActiveCN105739470BThe maintenance status is clear and controllableIncrease productivityControl devices for conveyorsStacking articlesProduction lineMode control

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Online steel pipe weighing and stacking device

PendingCN110745563AGuaranteed neatnessGuaranteed accuracyStacking articlesMechanical engineeringIndustrial engineering

Owner:ZHEJIANG KINGLAND PIPELINE & TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap