Bridge connecting mechanism for brick stacking

A technology of connecting bridges and bricks, which is applied in the field of bricks and bridges, which can solve the problems of low production efficiency and manpower consumption, and achieve the effect of guaranteed effect, reduced labor intensity and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

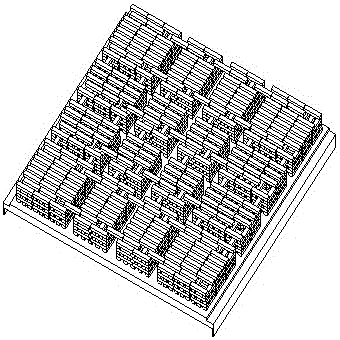

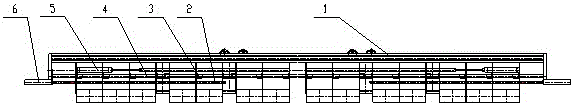

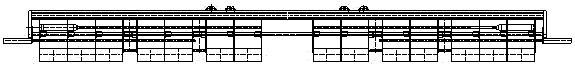

[0019] A bridge mechanism for stacking bricks, comprising a main frame 1, a pulling shaft 2, a linear bearing 3, a clamping shaft 4, a brick clamping cylinder 5 and a brick pulling cylinder 6, the clamping shaft 4 is fixedly connected under the main frame 1, and the Several groups of clamping plates are also arranged below the main frame 1, and the distance rods are fixedly connected between each group of clamping plates, and each clamping plate is installed on the clamping shaft 4 through a linear bearing 3 and horizontally sliding, and the pulling shaft 2 One end passes through each group of clamping plates horizontally and is fixed, the other end is connected with the output rod of the brick pulling cylinder 6, and the brick pulling cylinder 6 is fixedly arranged under the main frame 1, and the output end of the brick clamping cylinder 5 is connected through the connecting rod. lengthen, and then the two ends are fixedly connected with the outermost clamping plates of the sever

Embodiment 2

[0023] Such as figure 1 As shown, a brick-connecting bridge mechanism includes a main frame 1, a pulling shaft 2, a linear bearing 3, a clamping shaft 4, a brick clamping cylinder 5 and a brick pulling cylinder 6, and the clamping shaft 4 is fixedly connected under the main frame 1 , several groups of clamping plates are also arranged under the main frame 1, each group of clamping plates is fixedly connected by distance rods, and each clamping plate is installed on the clamping shaft 4 through a linear bearing 3 and horizontally slidable, so that One end of the pulling shaft 2 passes through each group of clamping plates horizontally and is fixed, and the other end is connected with the output rod of the brick pulling cylinder 6. The brick pulling cylinder 6 is fixedly arranged under the main frame 1, and the output end of the brick clamping cylinder 5 passes through the The connecting rod is lengthened, and then the two ends are fixedly connected with the outermost clamping plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap