Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Foundation engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

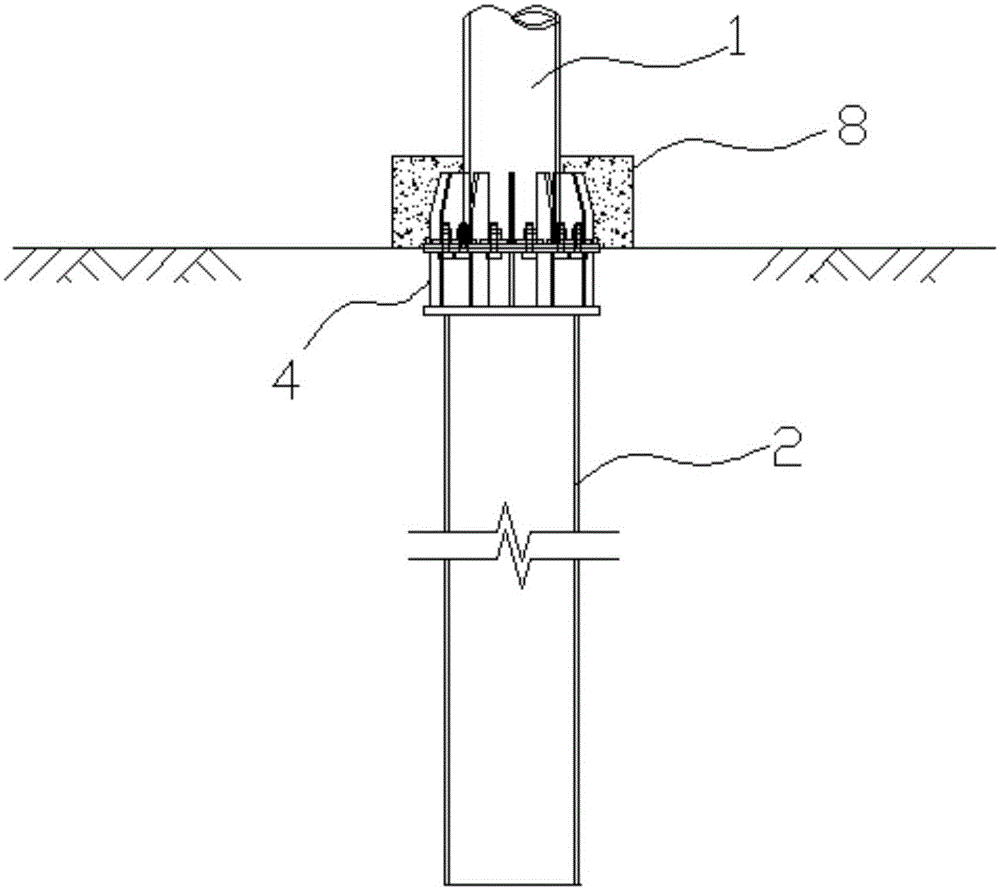

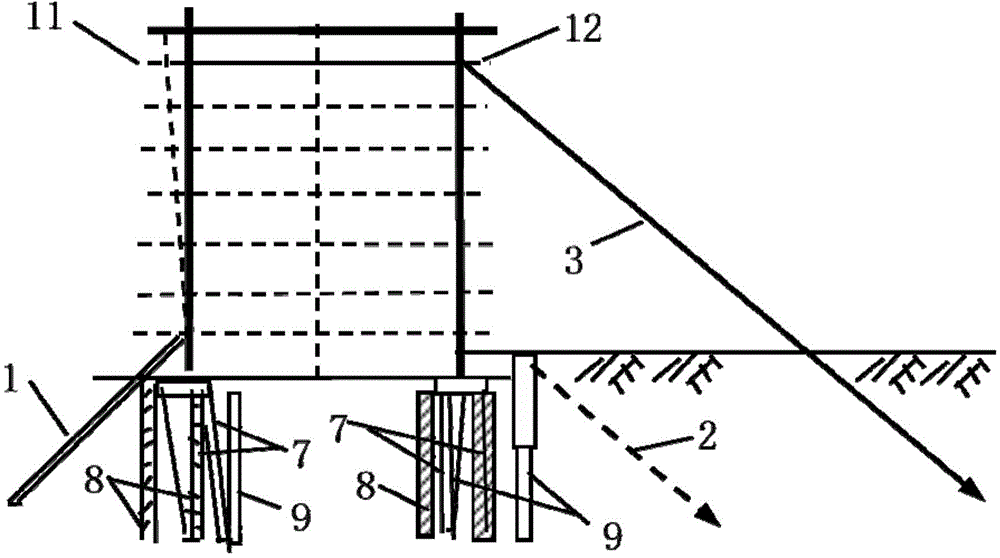

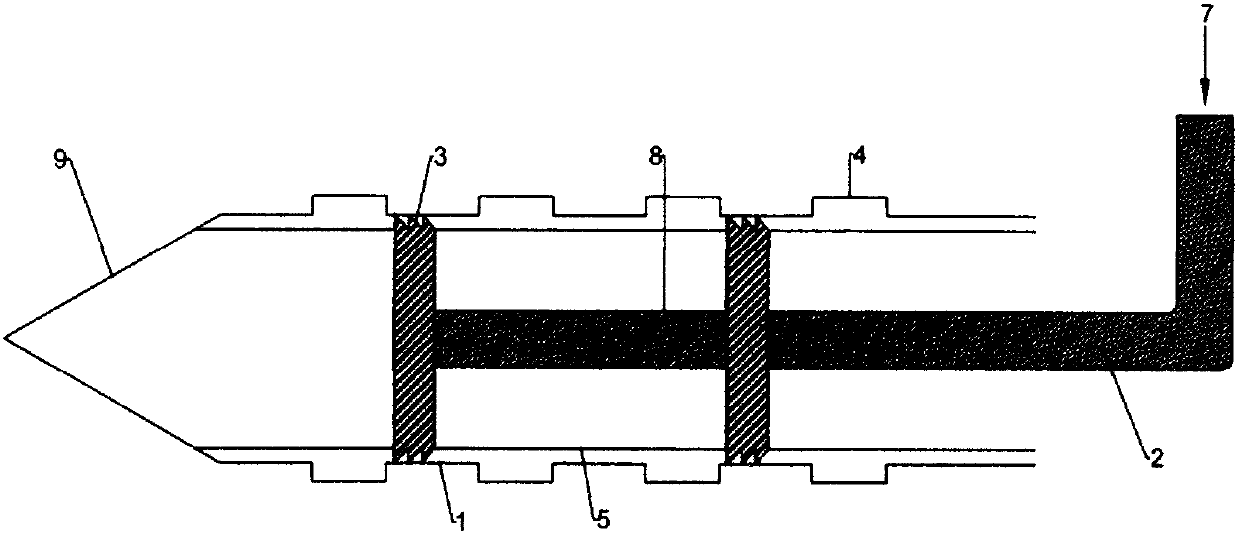

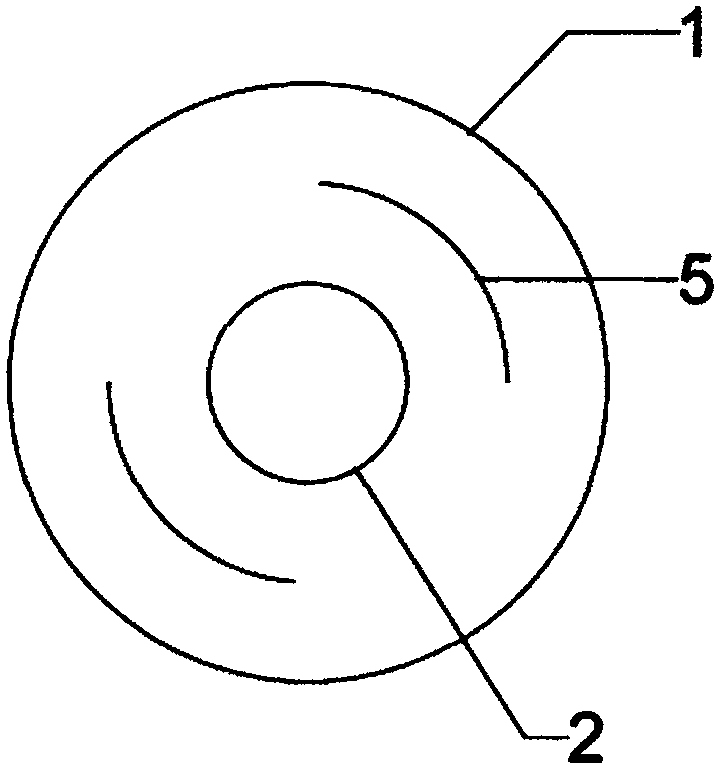

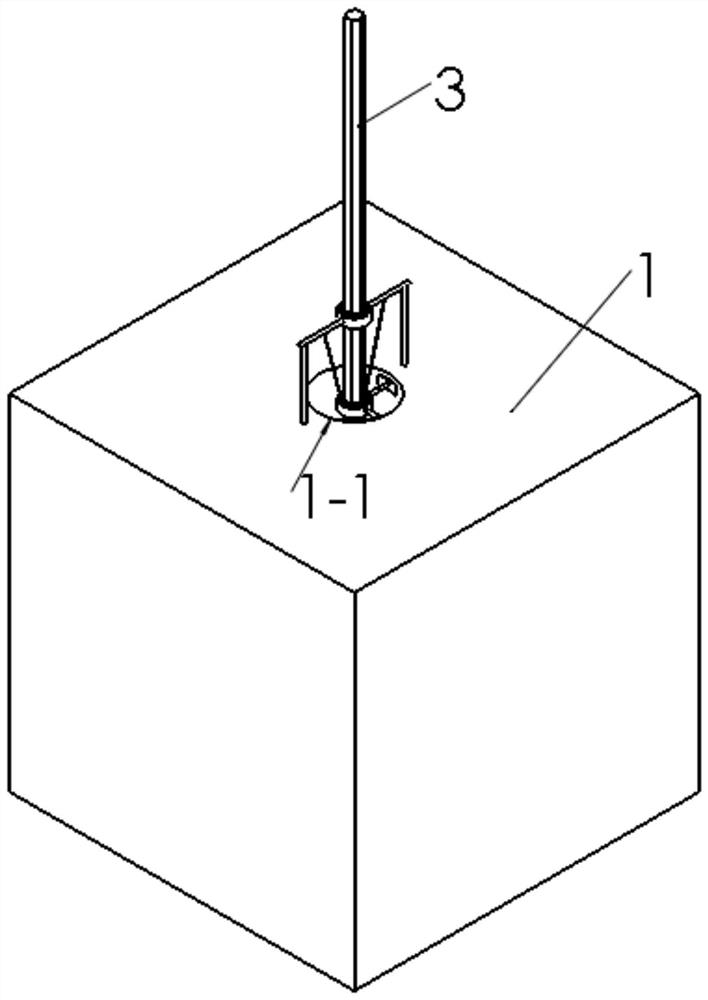

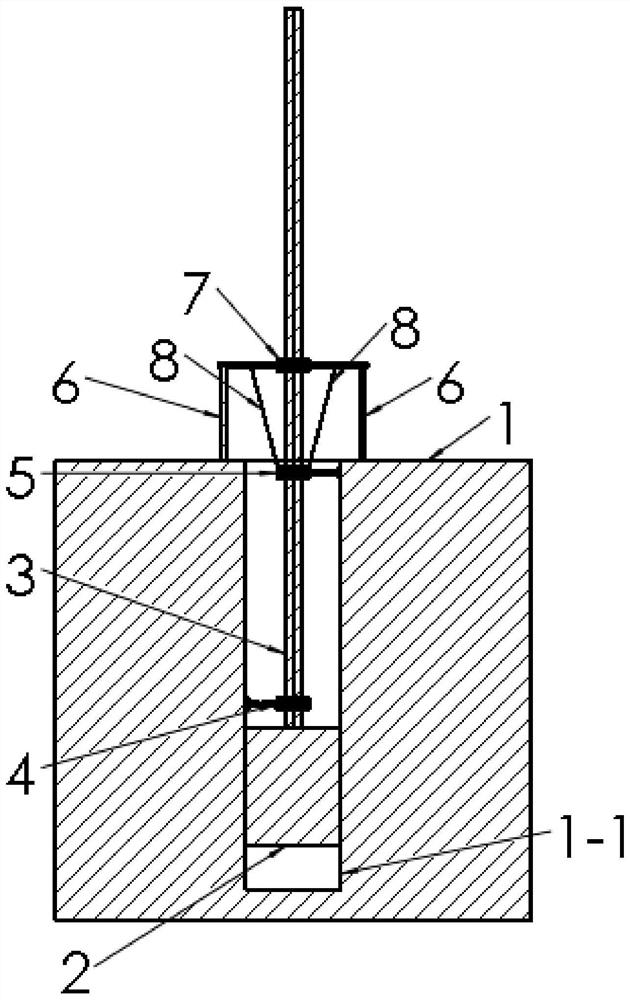

Auto-recovering reinforced column base and construction installation method thereof

PendingCN111075112AStrong self-resetting effectSolve the elastic resistance problemStrutsFoundation engineeringArchitectural engineeringSteel columns

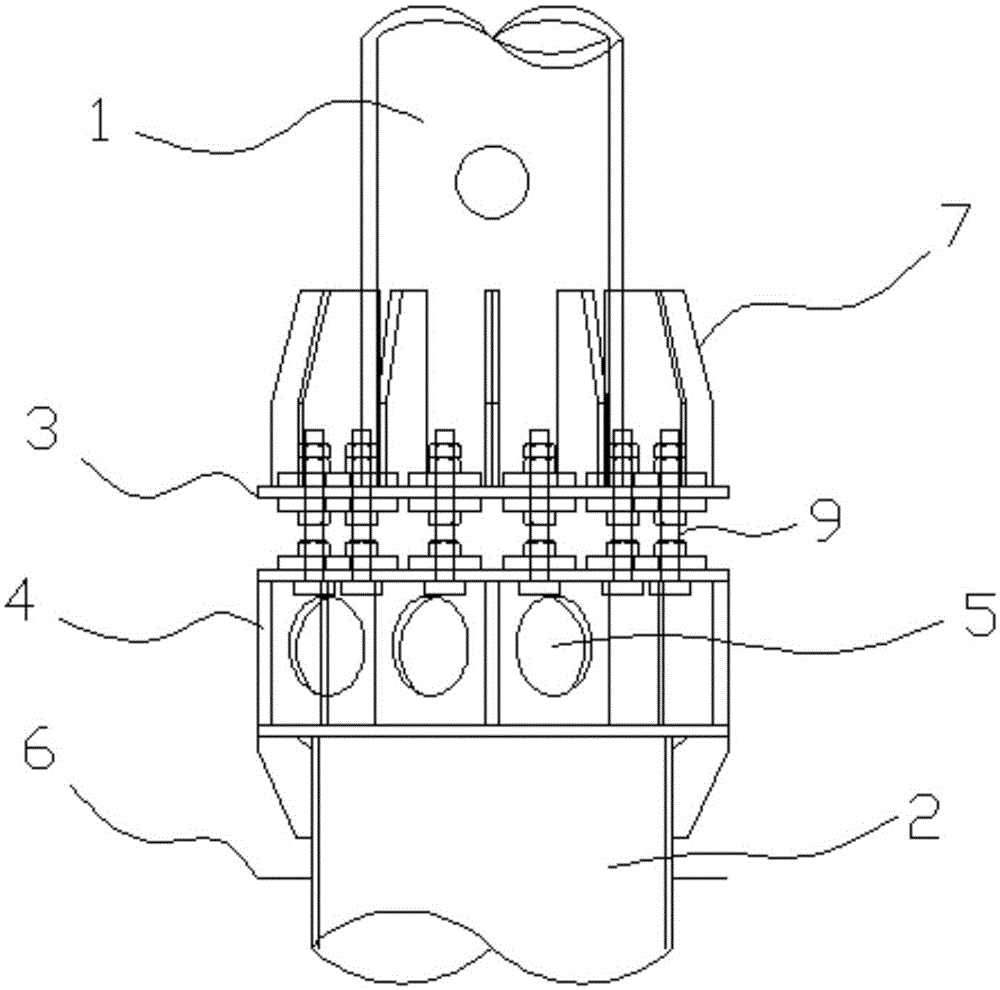

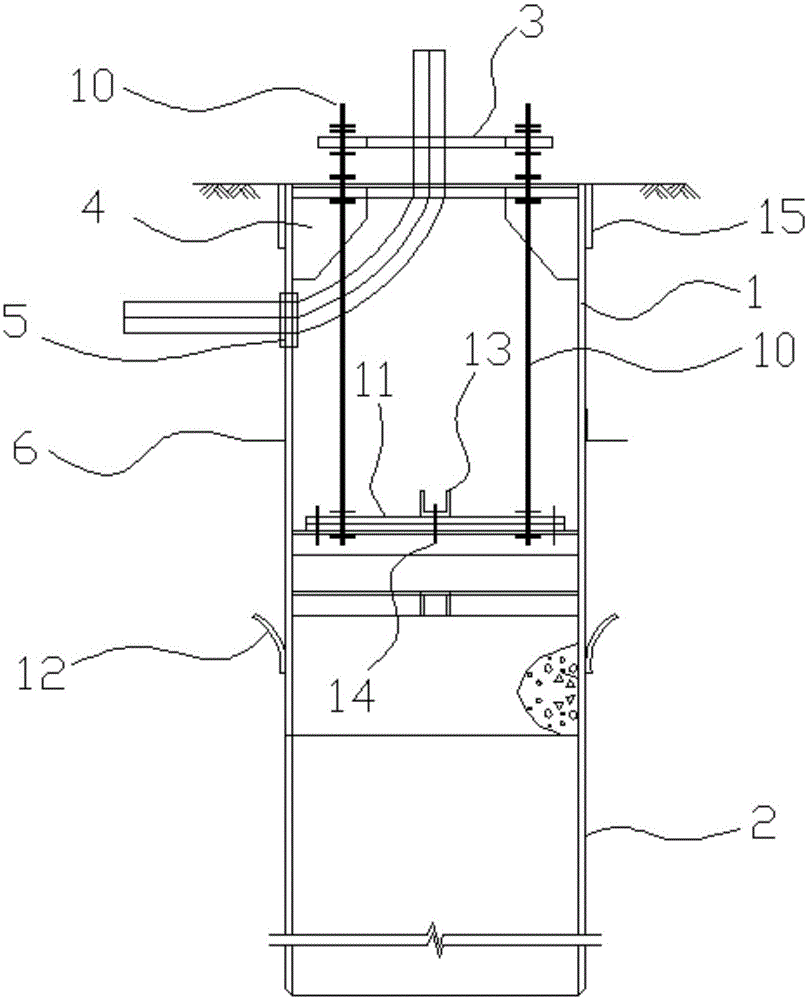

The invention discloses an auto-recovering reinforced column base and a construction installation method thereof. The auto-recovering reinforced column base is constructed on a foundation, and comprises a steel column, a high-strength pull rod, a cantilever plate, limiting devices, anchor rods and limiting base plates, wherein the steel column is inserted and connected to a limiting groove of thefoundation; the high-strength pull rod penetrates through transverse stiffening ribs of the steel column, and a first disc spring set is installed on the top end of the transverse stiffening ribs andthe high-strength pull rod for fixing; the cantilever plate is horizontally fixed on the outer side of the steel column; the limiting devices are fixed on the top surface of the cantilever plate; thebottom ends of the anchor rods are connected with the foundation, rod bodies penetrate through the cantilever plate and through holes of the limiting devices, and is provided with a second disc springset in a sleeved mode, and the limiting base plates and high-strength nuts are symmetrically installed at the two ends of the rod bodies in a sleeving mode. According to the auto-recovering reinforced column base, pre-pressure is applied to disc springs, so that the steel column has auto-recovering capability; and during a strong earthquake, the steel column swings to reduce the earthquake damage, after the earthquake, the auto-recovering function is achieved through the disc springs, and the device is clear in concept, convenient to construct and has a wide engineering application prospect.

Owner:HAINAN UNIV

Installation construction method of large coal pulverizer

ActiveCN103816983ANo pollutionReduce construction costsFoundation engineeringGrain treatmentsSocial benefitsCoal

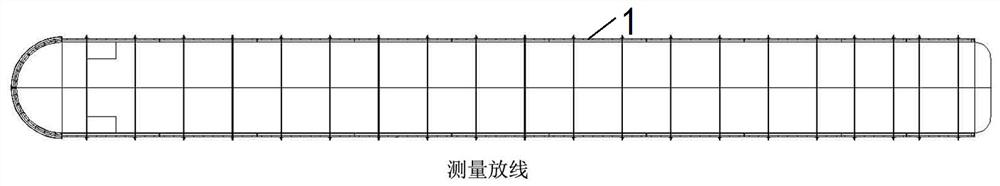

The invention discloses an installation construction method of a large coal pulverizer. The method comprises the following steps: 1, carrying out basic inspection and acceptance; 2, unpacking and inspecting an apparatus; 3, paying off a line; 4, installing an anchor bolt; 5, installing an apparatus pedestal; 6, installing a main bearing pedestal; 7, installing a main bearing; 8, installing a rotation portion; 9, installing a transmission portion; 10, installing a cylinder lining board and a feeding and discharging port lining board; 11, installing a gear cover and other accessories; and 12, carrying out test driving. The installation construction method allows an apparatus body and transmission mechanisms to be assembled on the ground, integral hoisting is carried out after the assembling of the apparatus body and the transmission mechanisms, and local adjustment is carried out to solve a series of problems of need of the arrangement of a full framing scaffolding on the apparatus, long use time of large tonnage cranes, low installation precision and the like are solved, and good economic and social benefits are realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

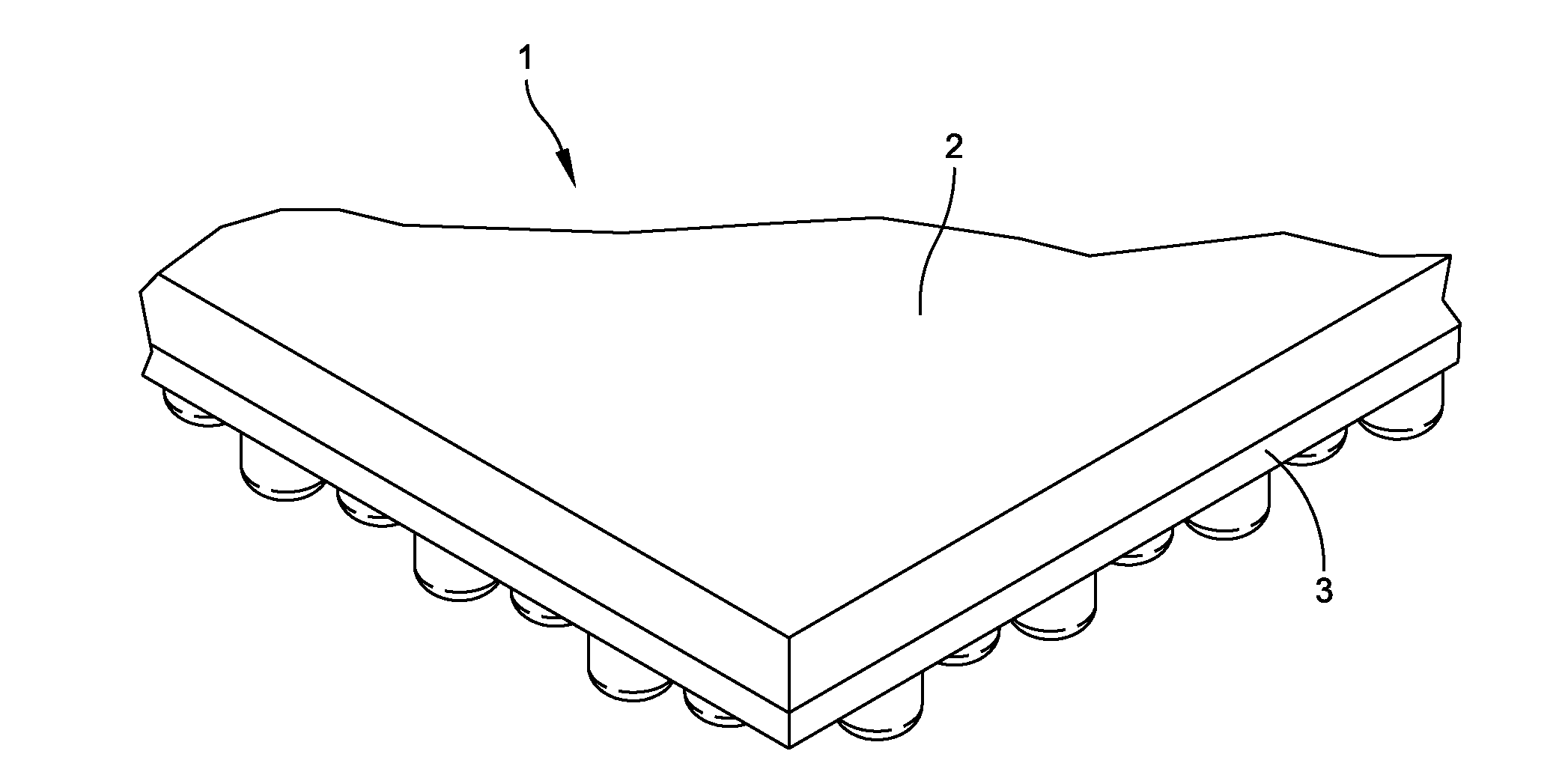

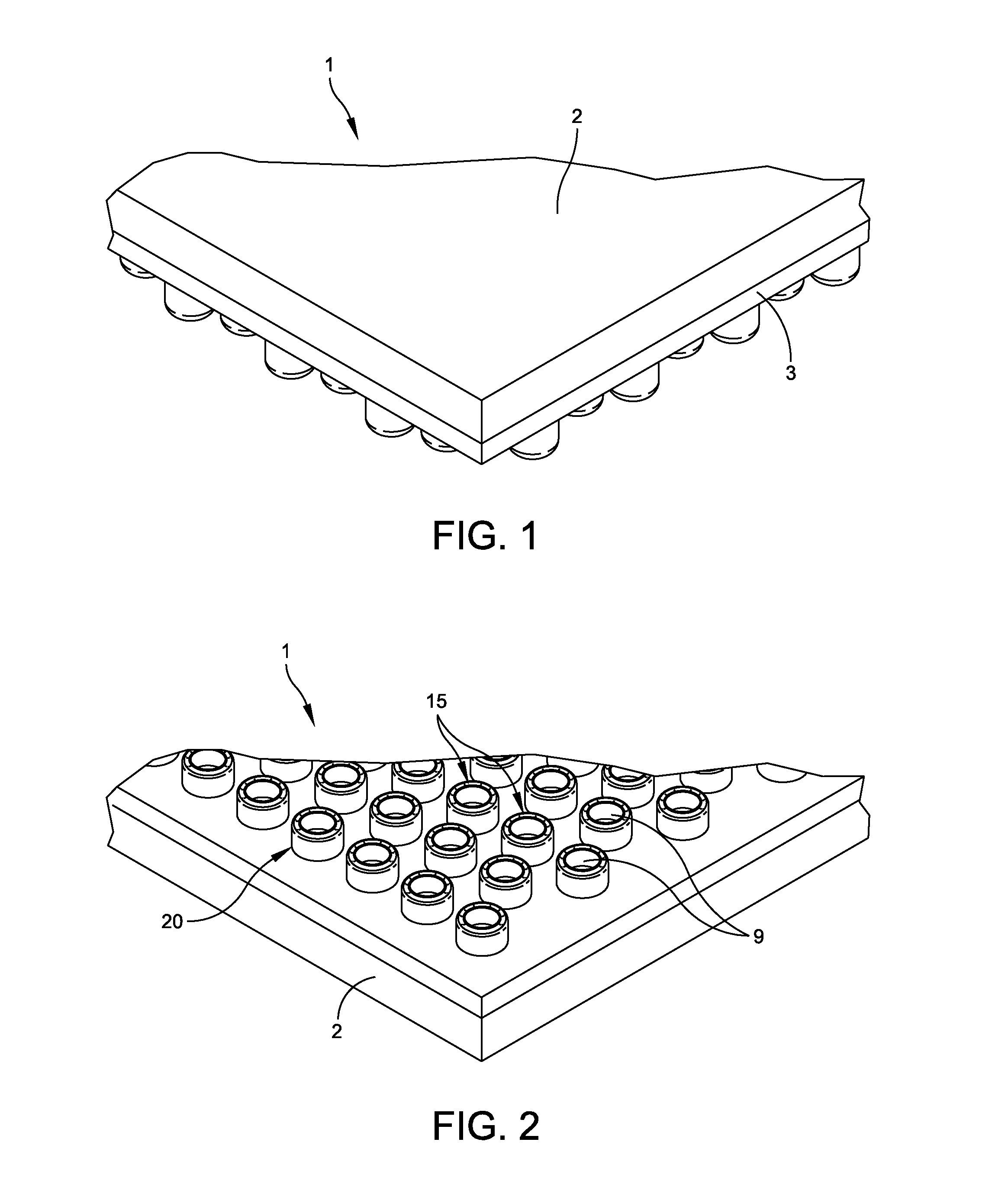

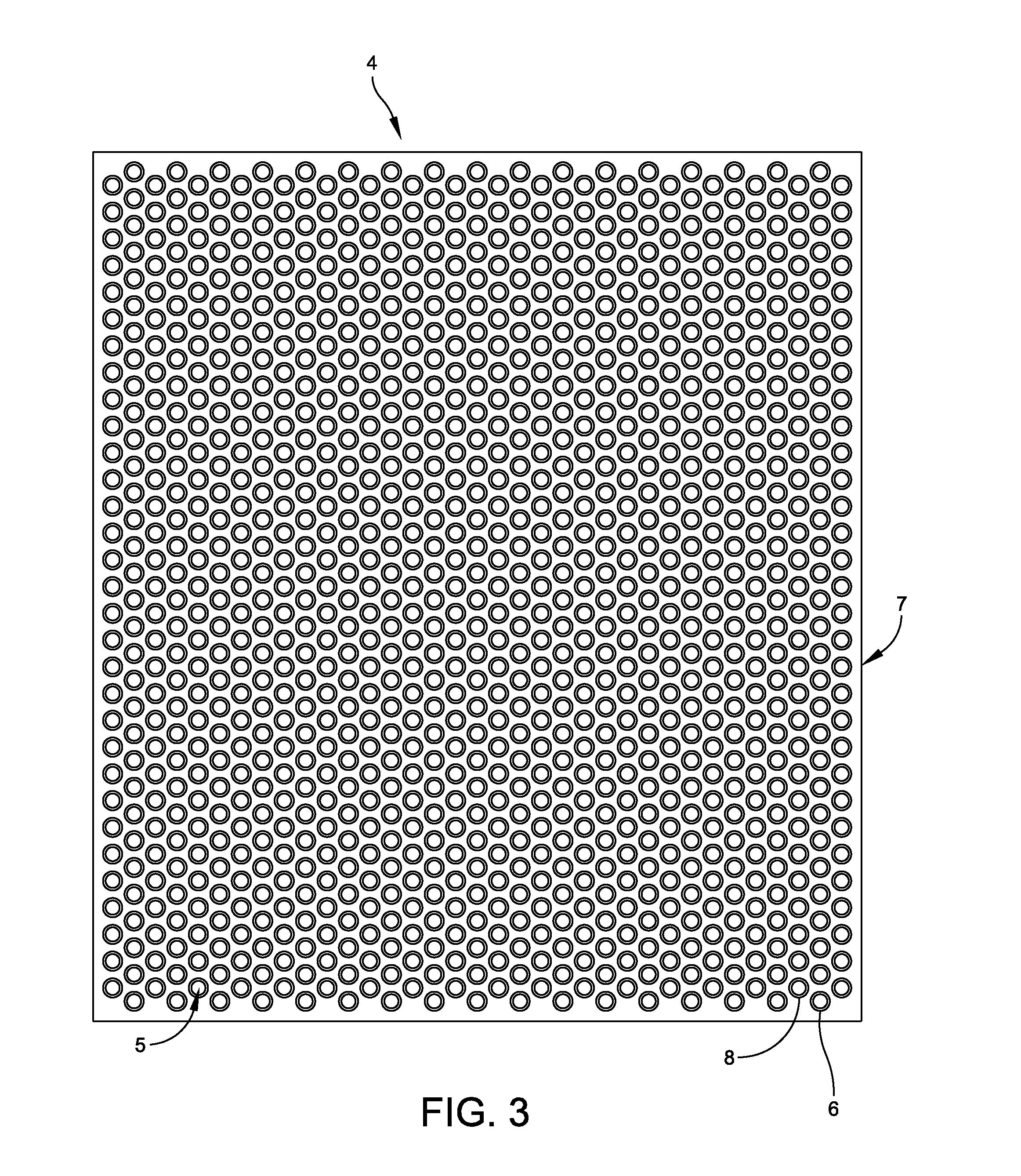

Adhesiveless decorative floor tile

InactiveUS20120324805A1Increase frictional resistanceFloorsFoundation engineeringAdhesiveSurface cover

Owner:GROWLIFE INC

Communication pole tower with steel tube pile as foundation

Owner:HUAXIN CONSULTATING CO LTD

Construction method of steel plate pile cofferdam concrete sealed bottom

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

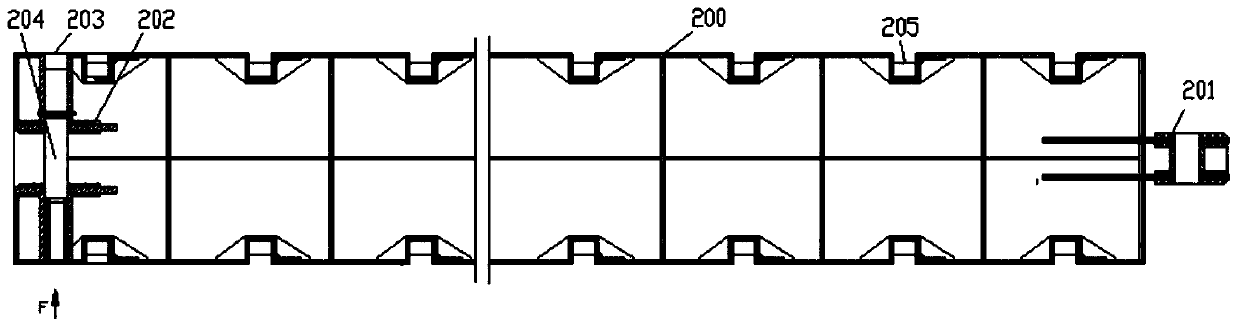

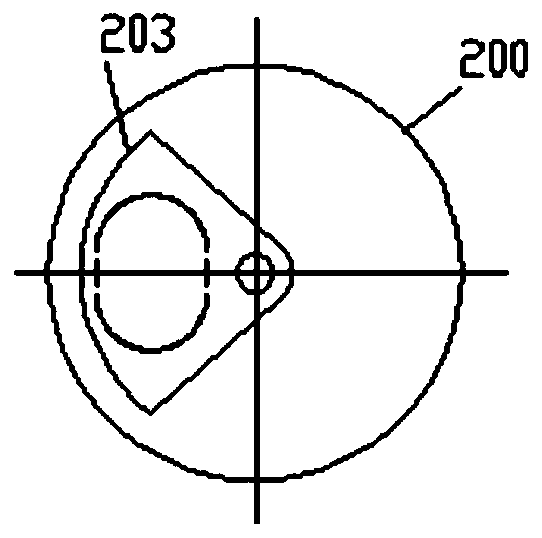

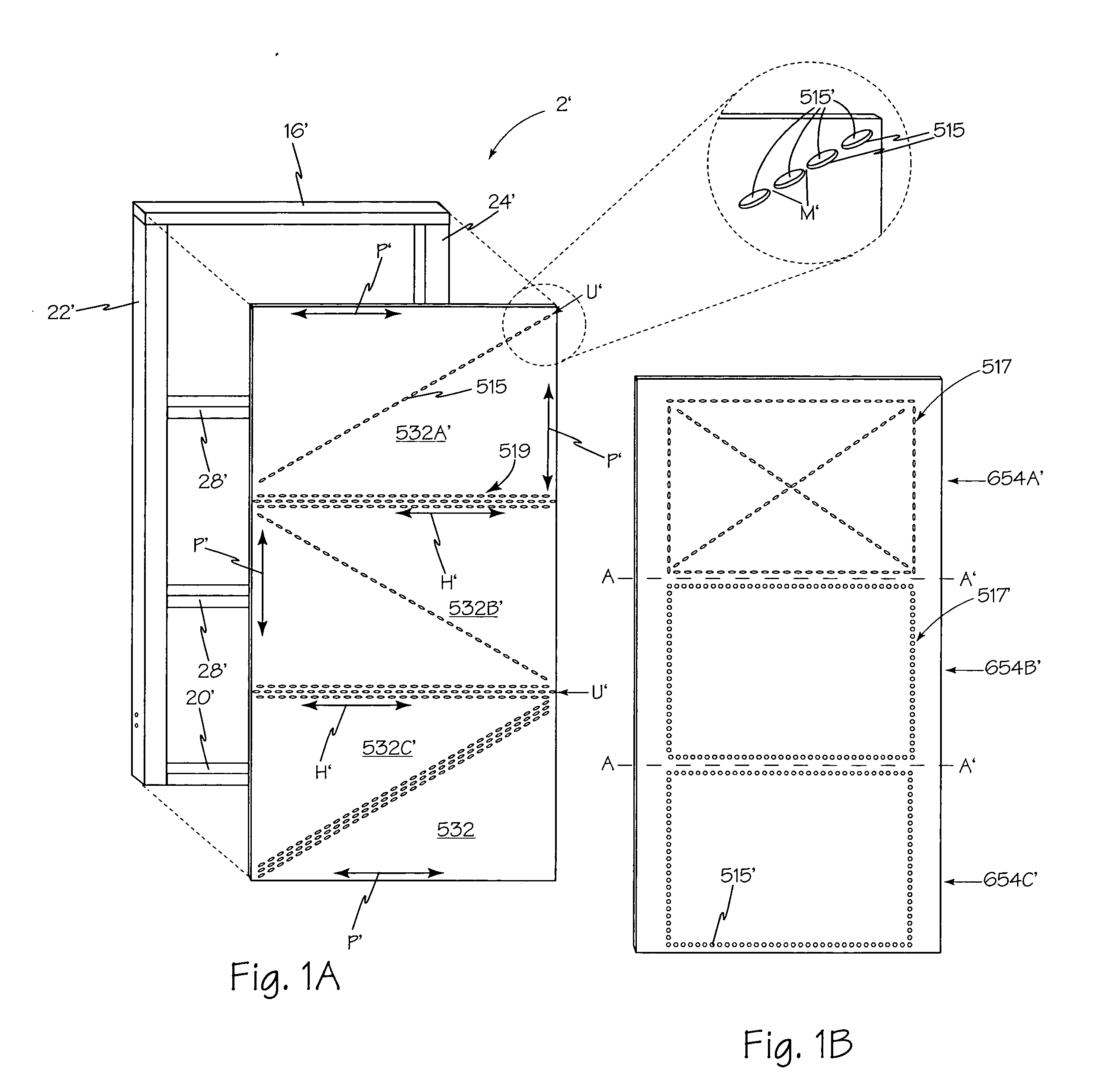

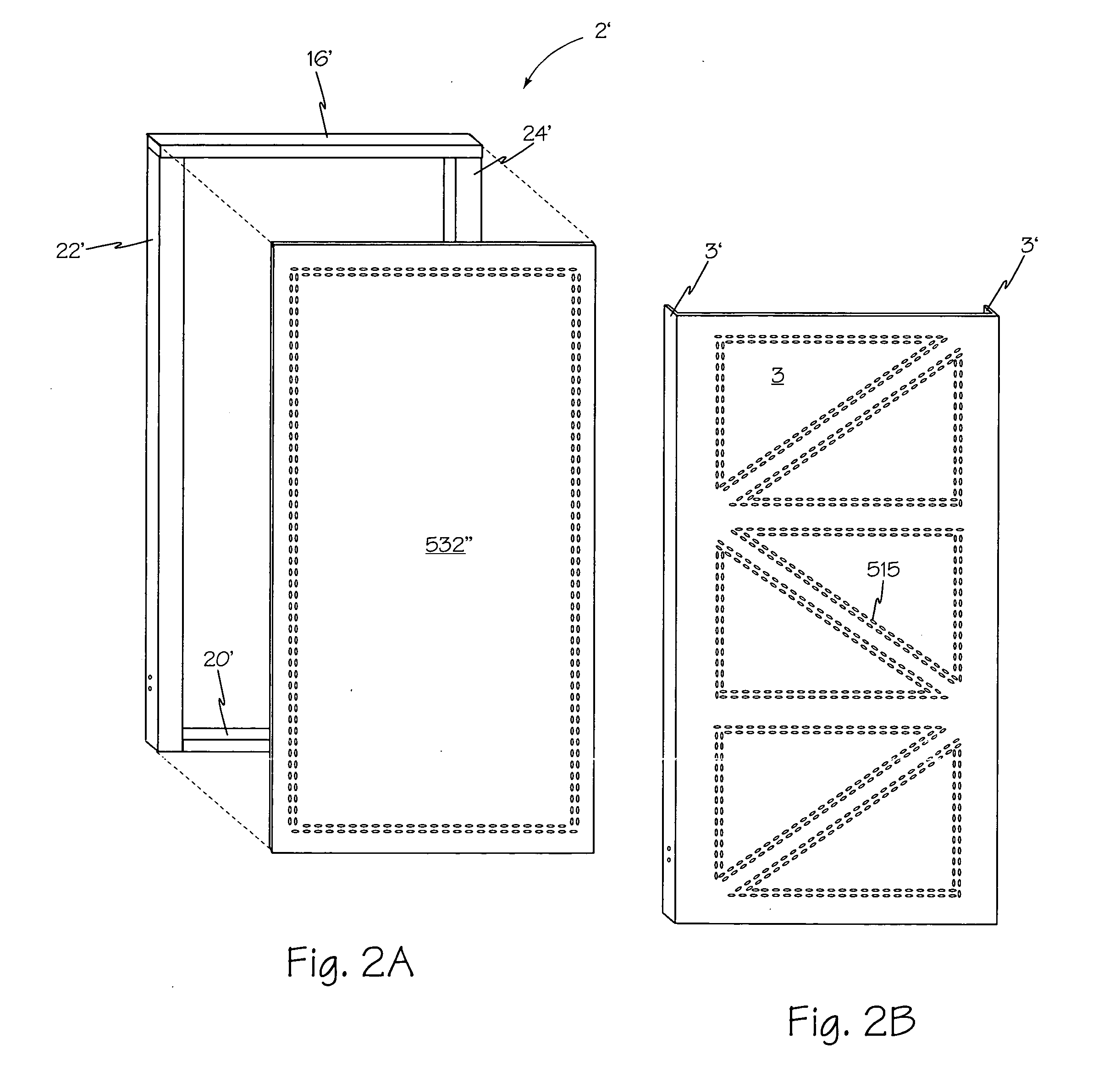

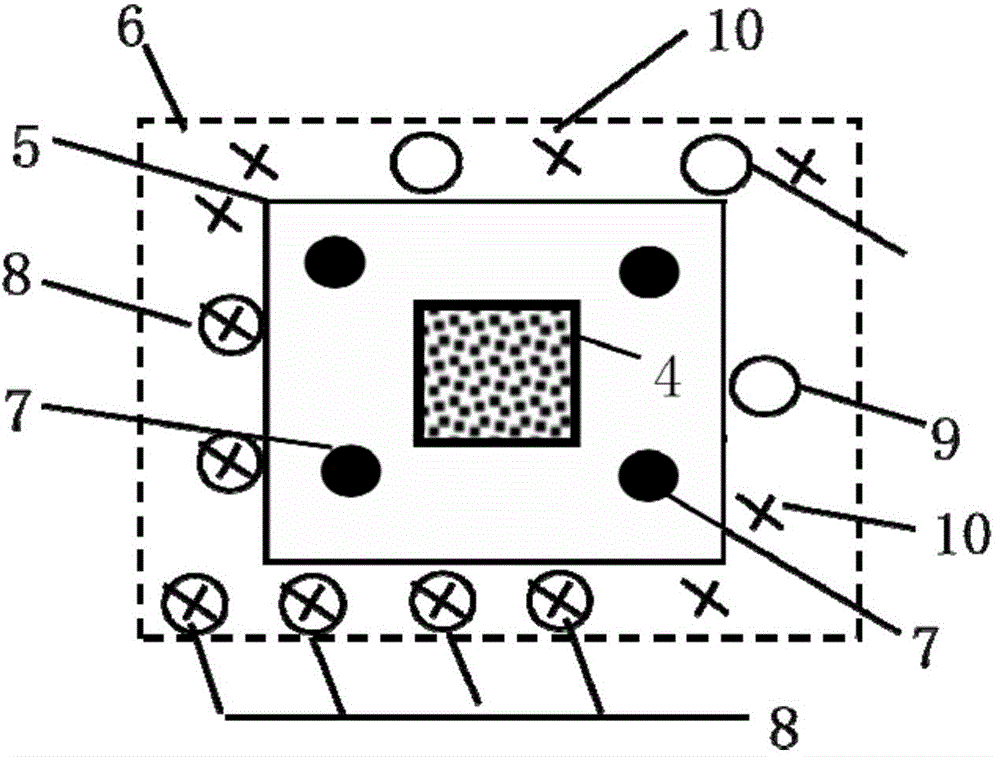

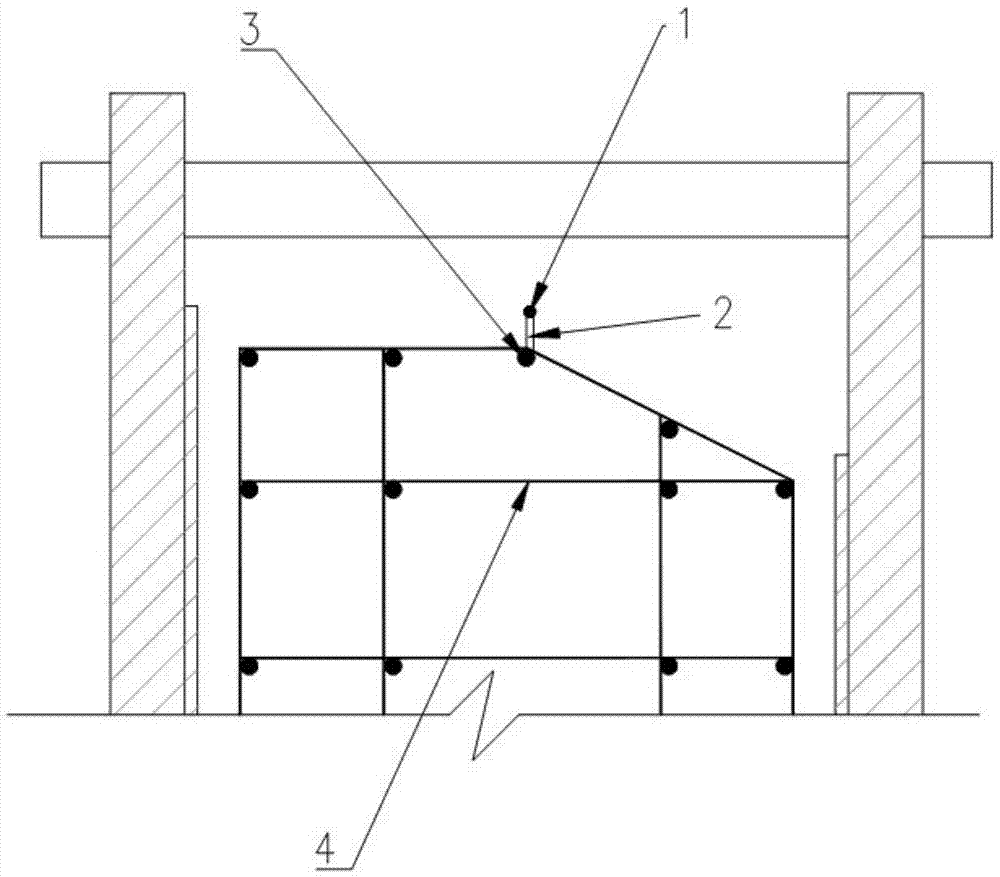

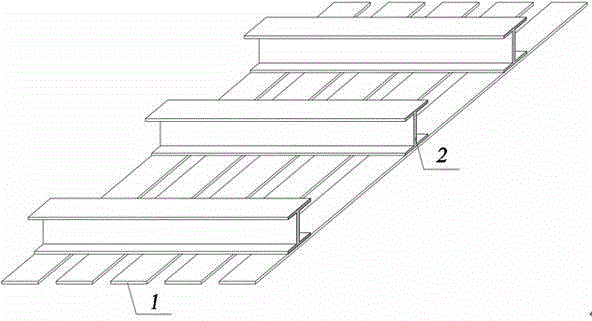

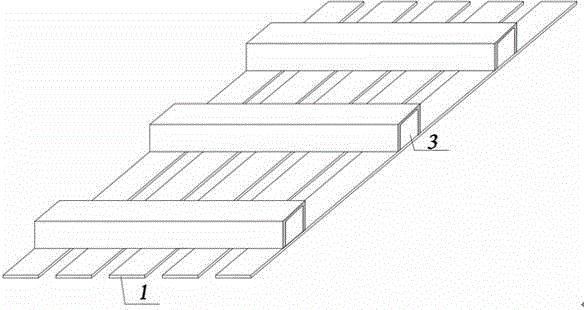

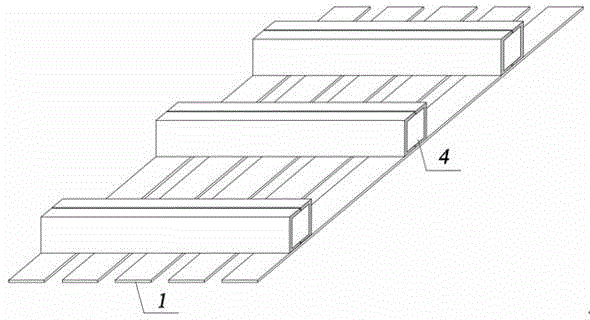

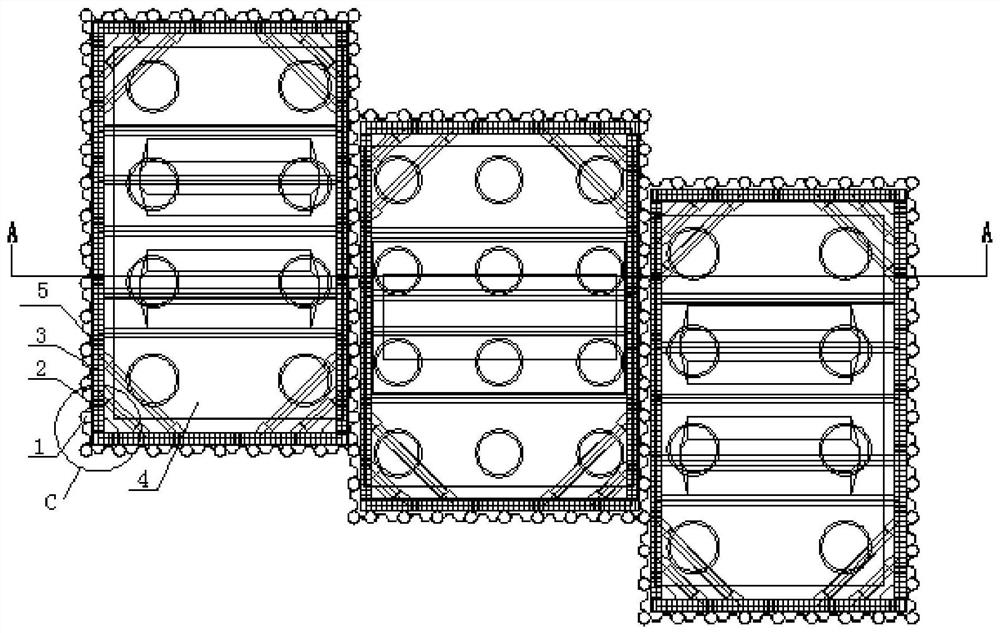

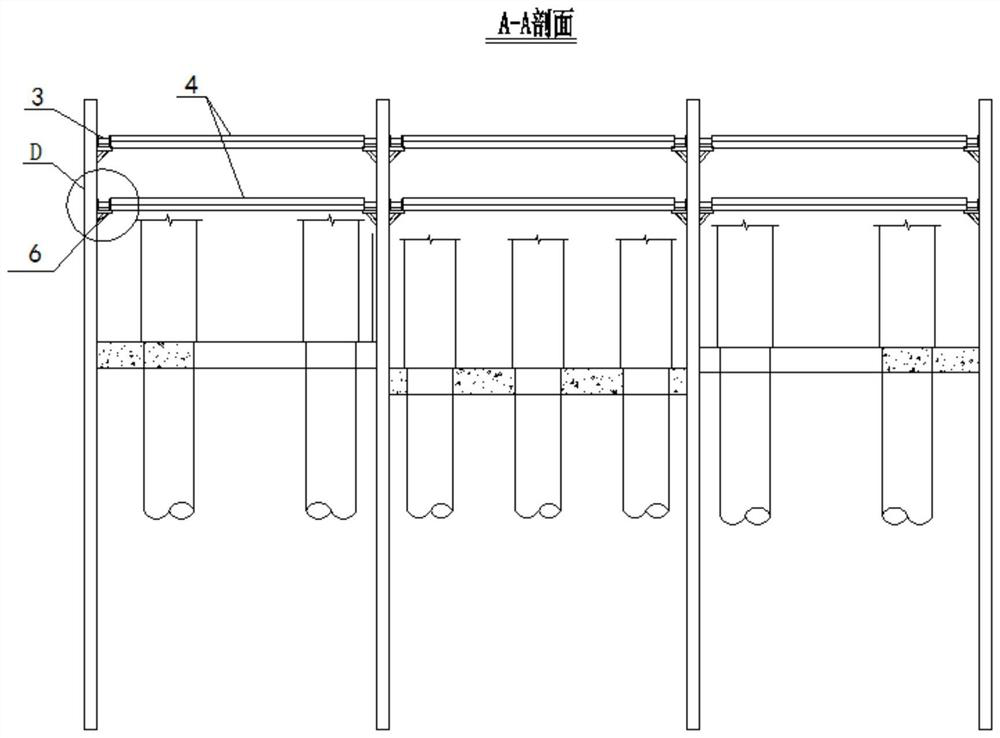

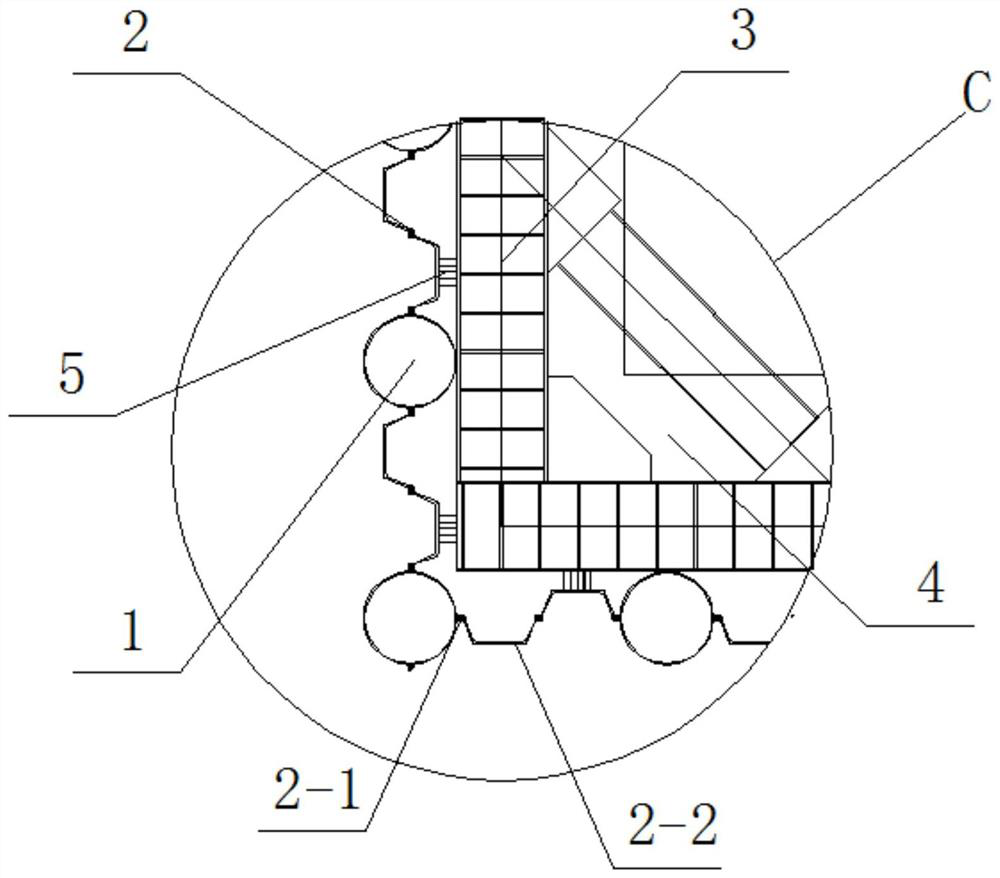

Installation type templates, installation type template group and set of installation type template devices

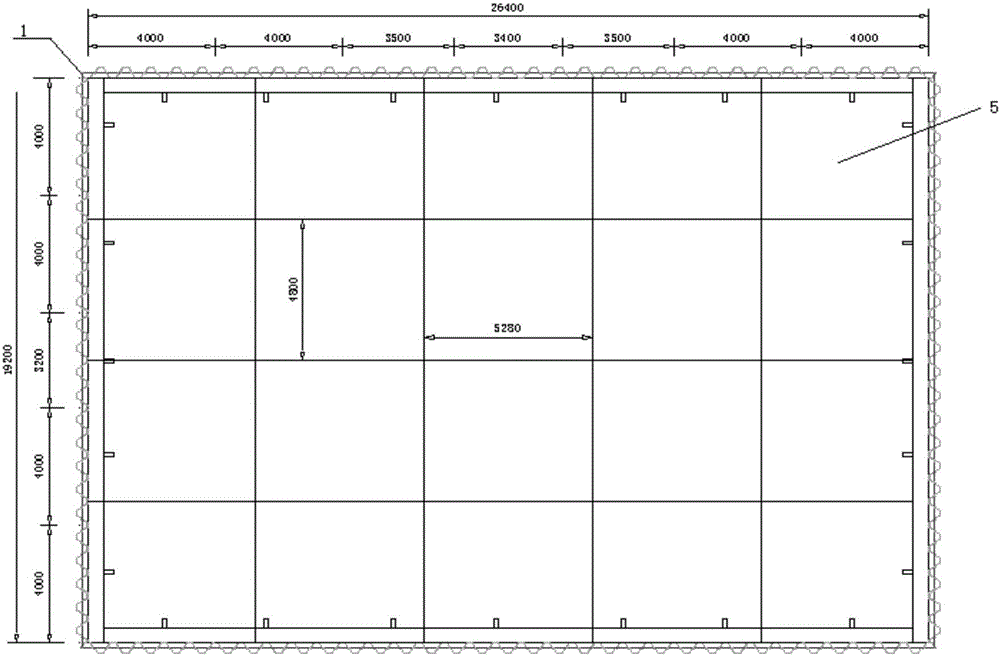

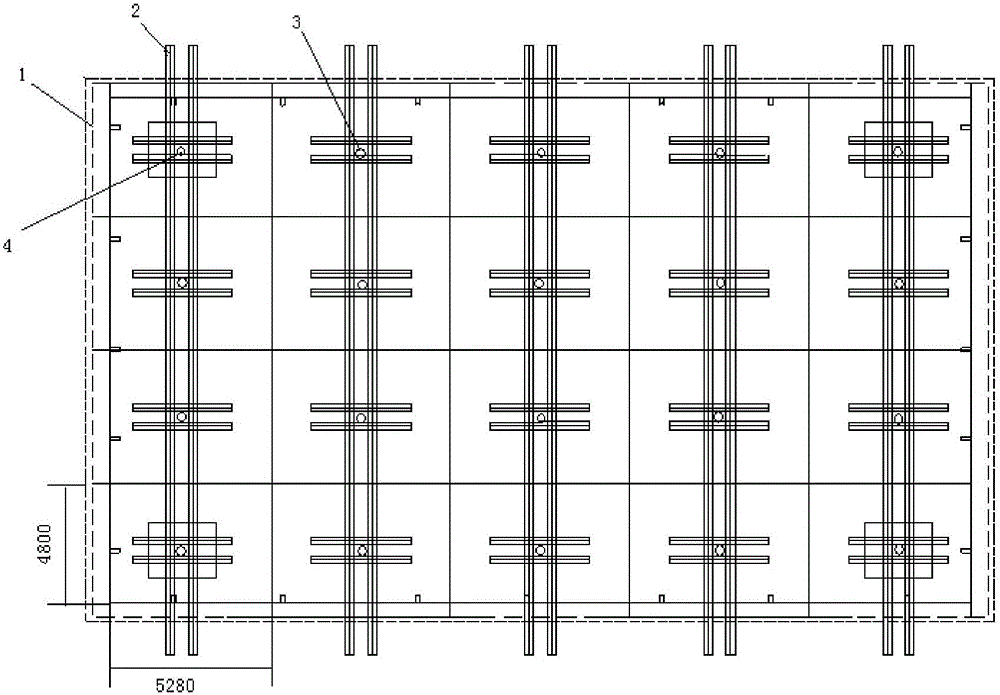

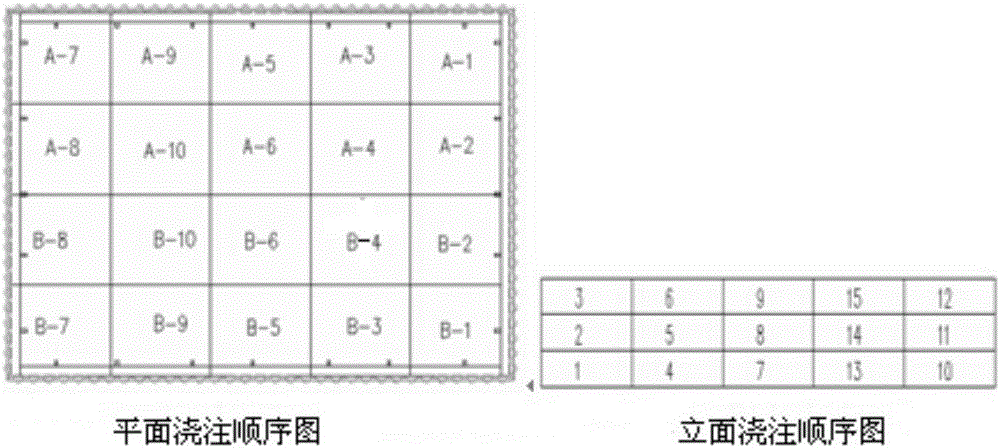

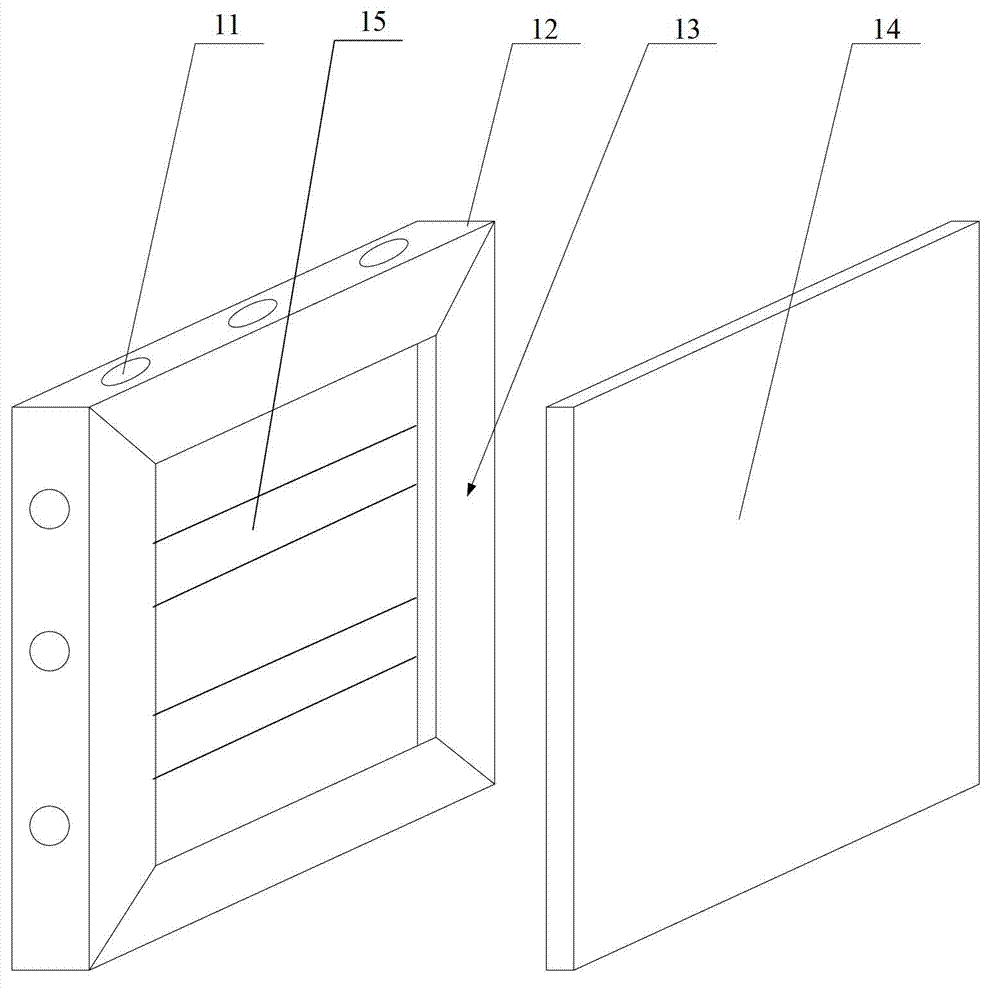

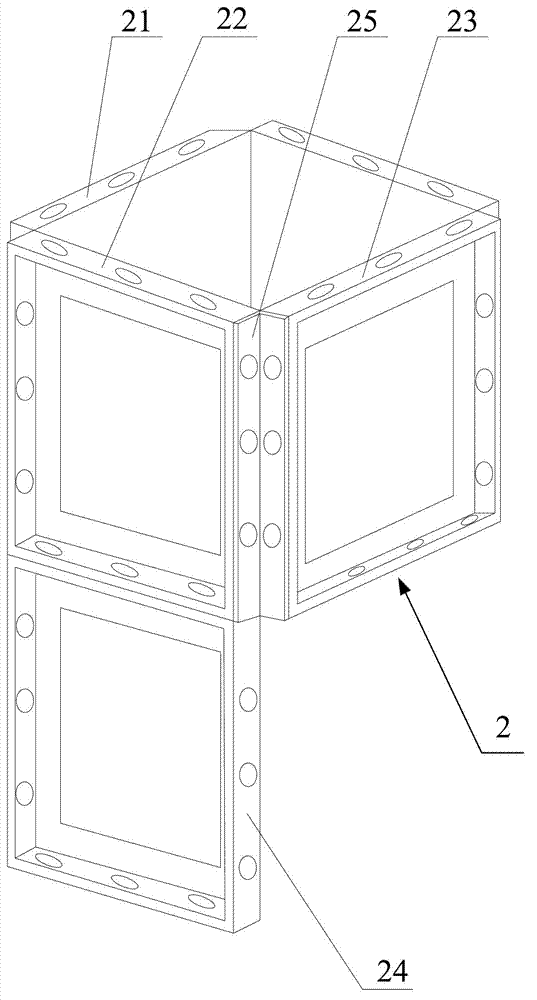

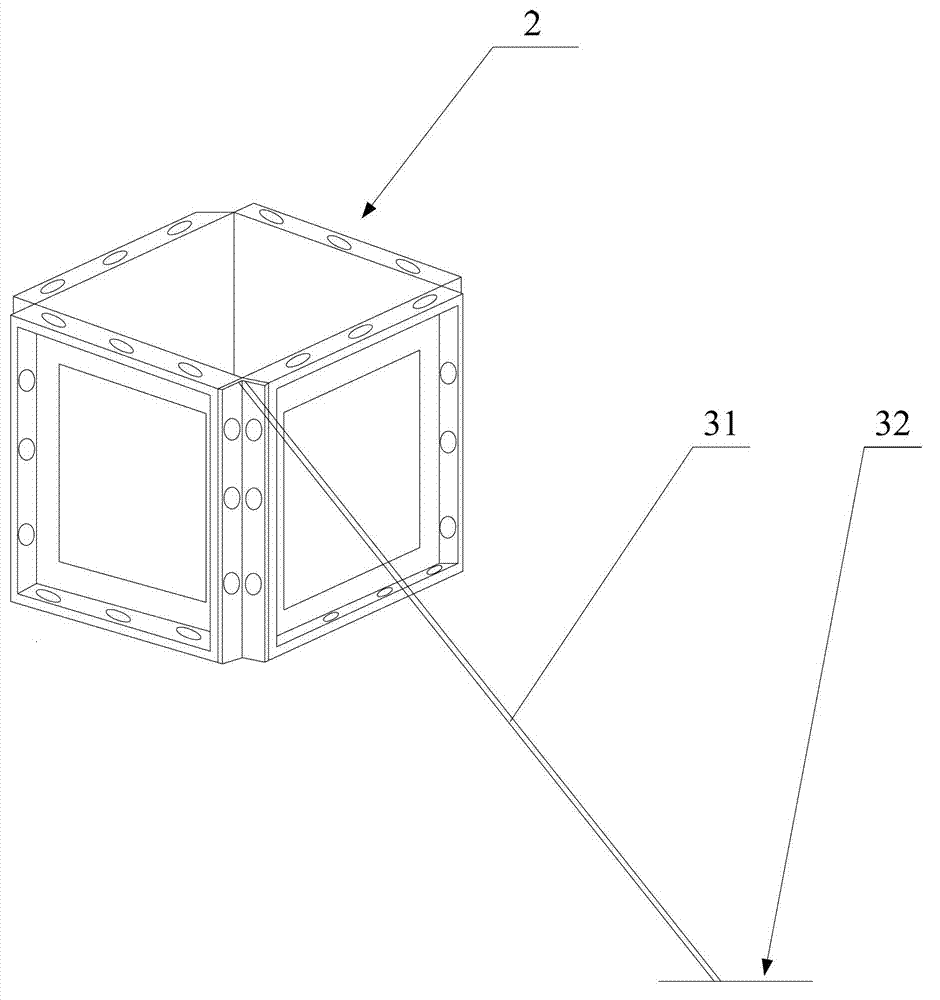

The invention discloses installation type templates which are used for foundation construction. Every installation type template comprises a main frame which comprises a front surface, a rear surface and four lateral sides, wherein a face plate is arranged on the front surface and the four lateral sides are provided with bolt holes. When installation type templates are used, the front surface faces inward, namely the face plate faces inward, four installation type templates are surrounded into a circle through bolts and sequentially connected with each other to form into vertical space to build a first subtemplate system, and a second subtemplate system is built in the same way. The first subtemplate system is fixedly connected with the second subtemplate system through the bolts on the bases of the first subtemplate system to build a template system with the required height. The installation type templates have the advantages of needing no supporting steel pipe, causing no damage to a basic body structure, being capable of being separated from a construction platform and enabling the template system to be not affected by construction loads, such as slurry downward, vibration and staff operation which are performed on the construction platform due to the fact that the template system is built in an assembling way.

Owner:STATE GRID CORP OF CHINA +1

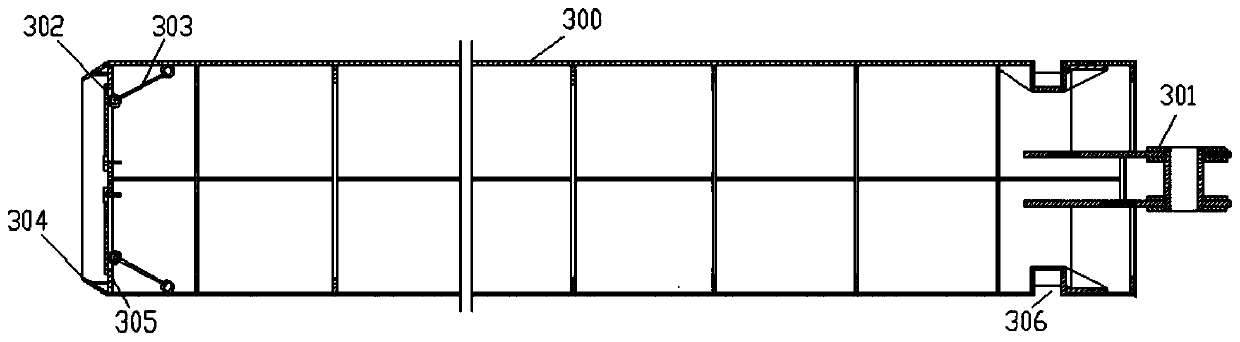

Prefabricated foundation assembly and splicing method thereof

The invention discloses a prefabricated foundation assembly which comprises at least two bases and a connecting transverse beam, wherein the at least two bases are arranged on the ground; the connecting transverse beam is used for connecting the adjacent bases; a steel structure module is fixedly arranged above each base; embedded screw studs are arranged at the upper top surface of each base; a connecting end plate is fixedly arranged at the bottom end part of each steel structure module; and connecting holes matched with the embedded screw studs are formed in the connecting end plate. Meanwhile, the invention also discloses a splicing method of the prefabricated foundation assembly. The bases and the connecting transverse beam are manufactured in advance in a prefabrication factory; during installation, all the bases are connected through the connecting transverse beam; and then, the steel structure module is arranged on each base. The pouring in a construction site is not needed; the fast splicing can be realized in the construction site; the construction period is shortened; and the work efficiency is improved.

Owner:ECONOMIC TECH RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

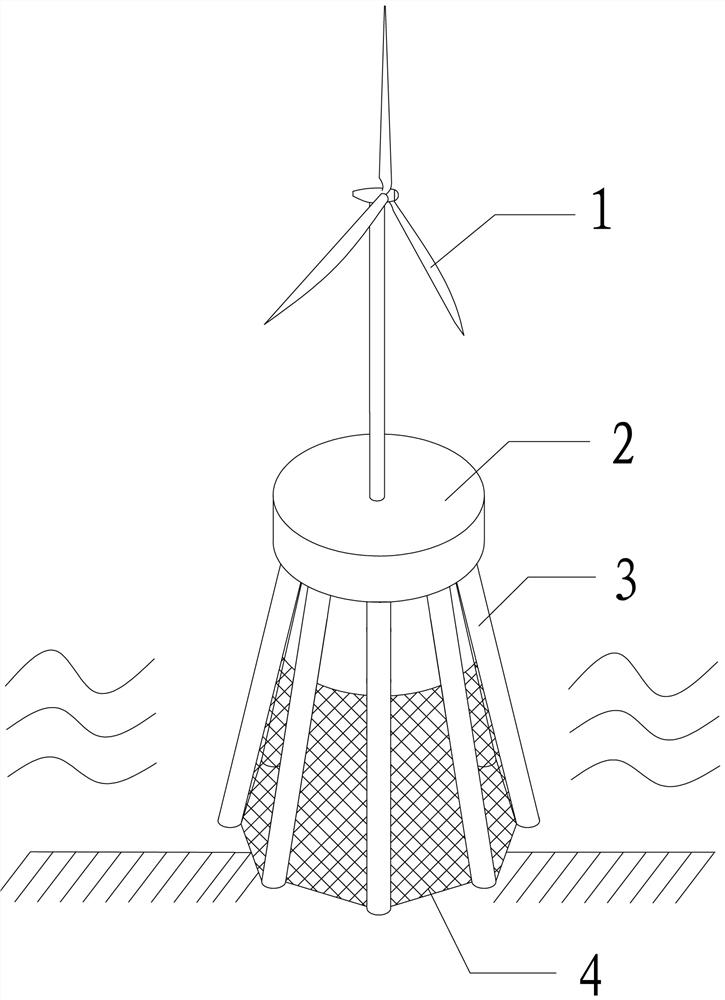

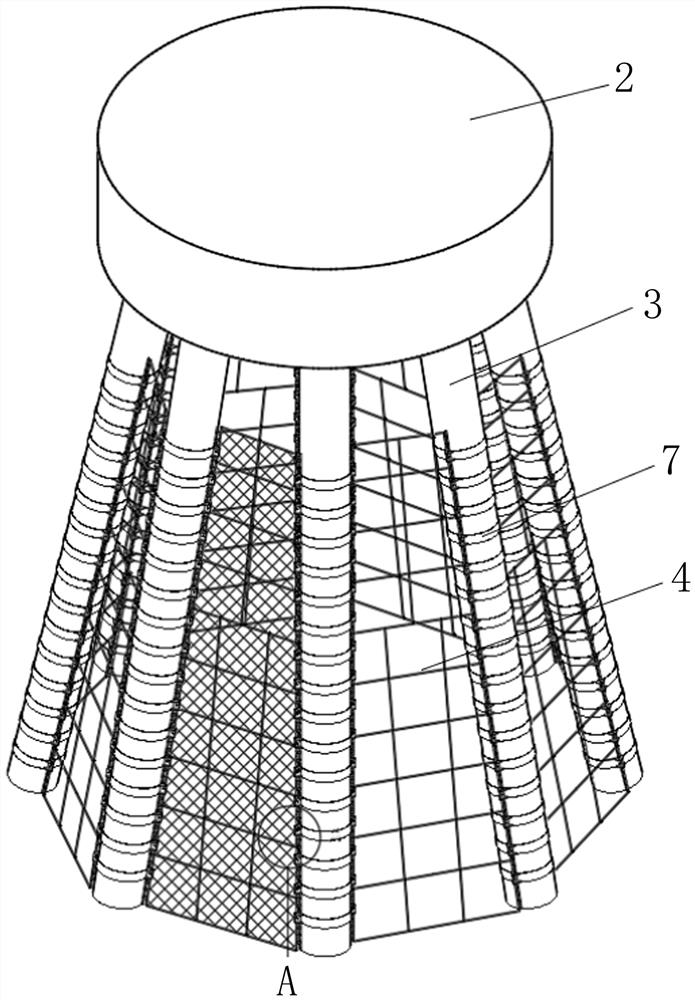

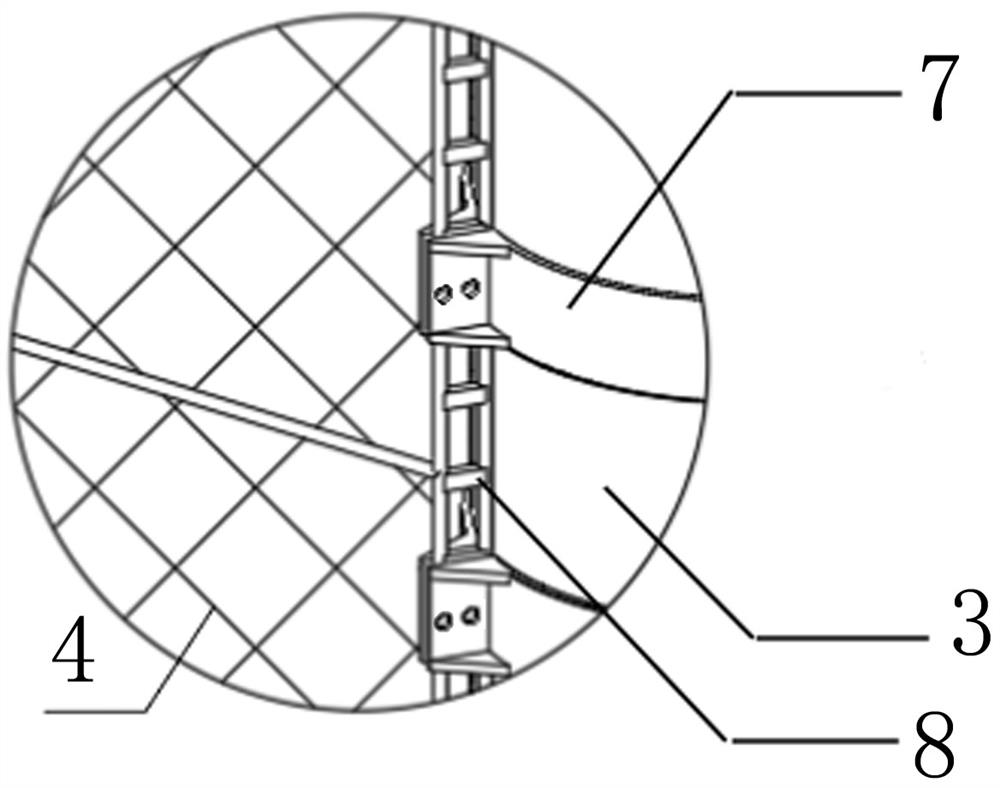

Construction method of aquaculture net cage based on built offshore wind power multi-pile bearing platform foundation

ActiveCN112049147AReduce difficultyLow costClimate change adaptationAgricultural fishingMarine engineeringArchitectural engineering

Owner:ZHEJIANG UNIV

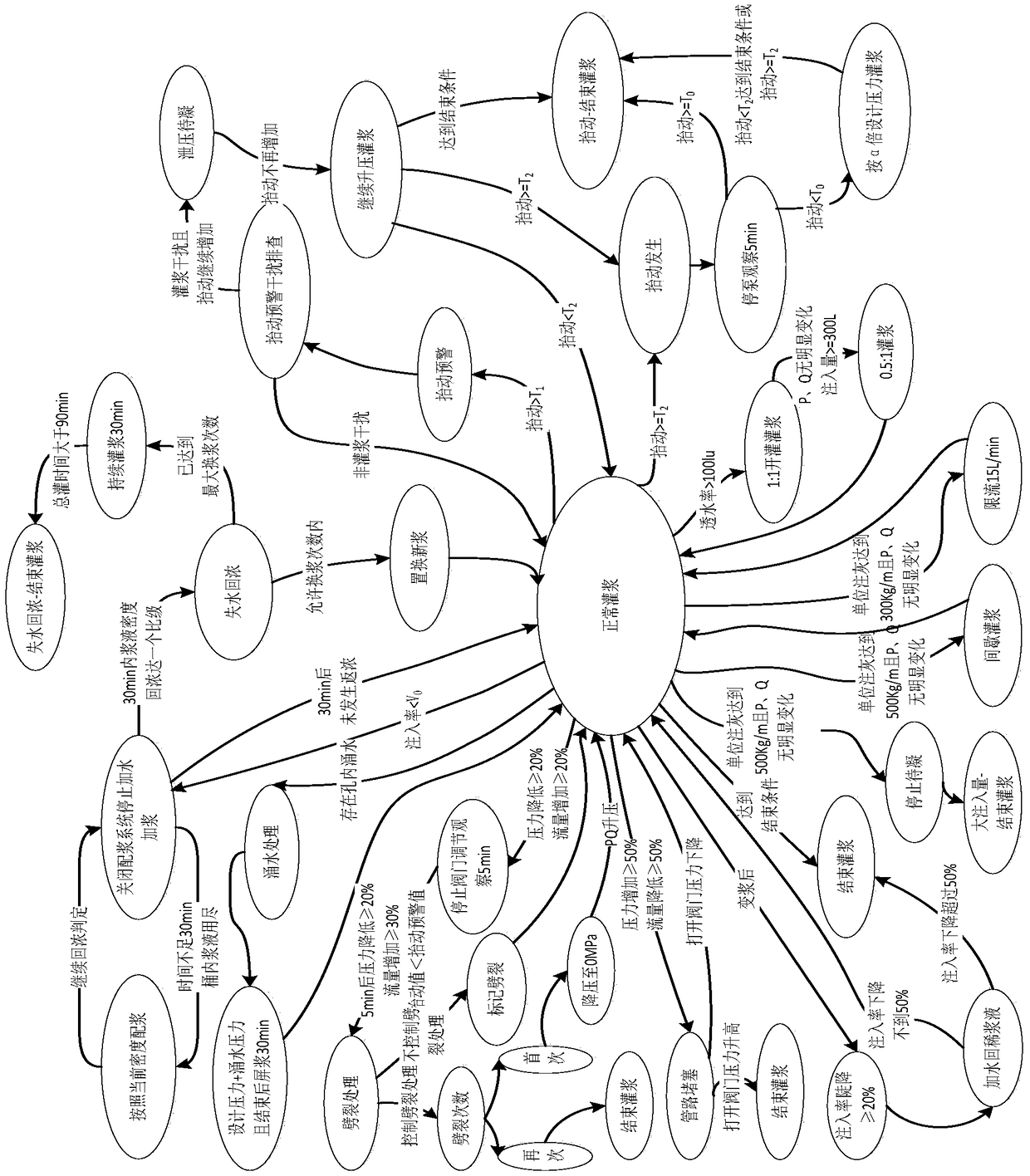

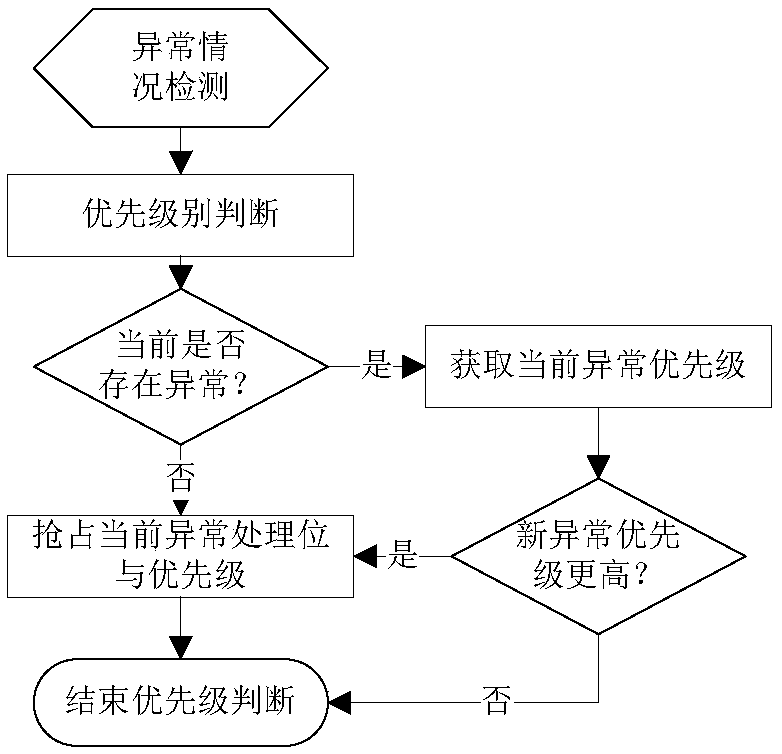

Grouting technology state switching method

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

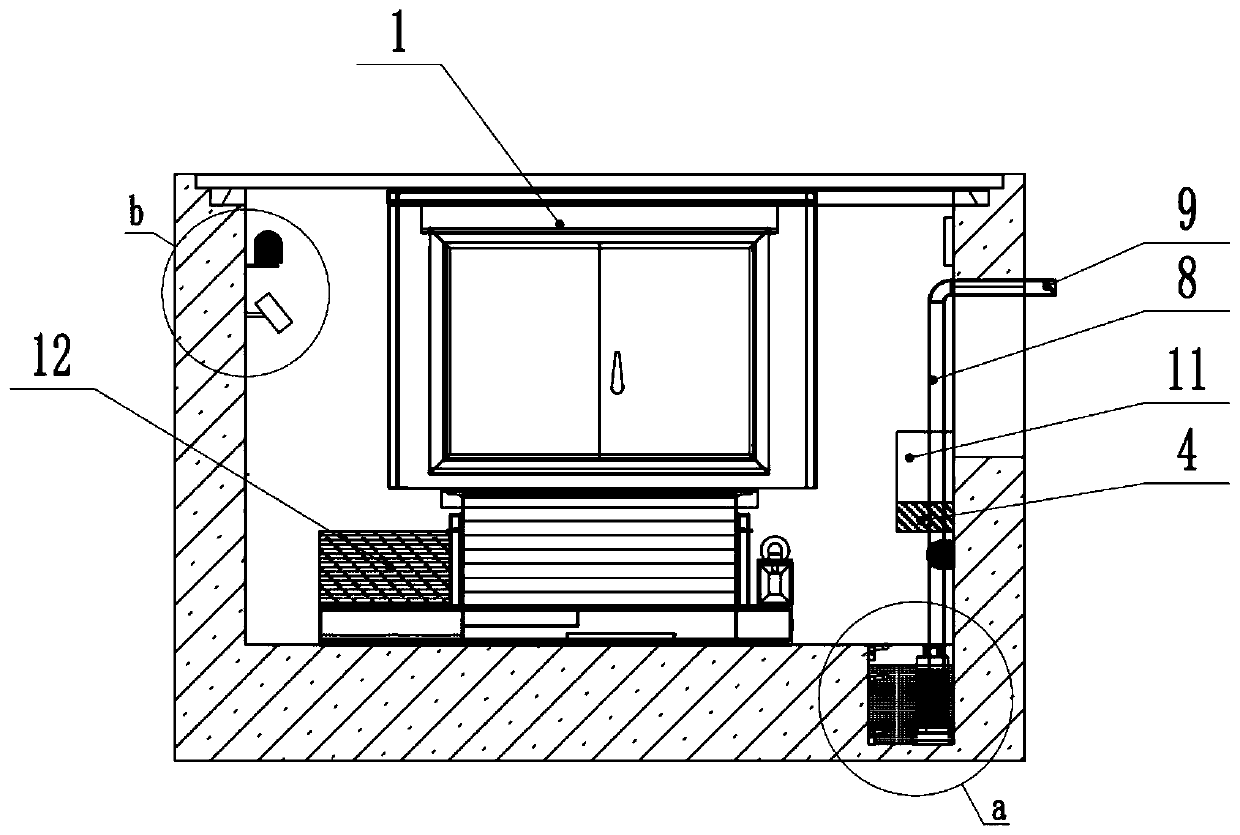

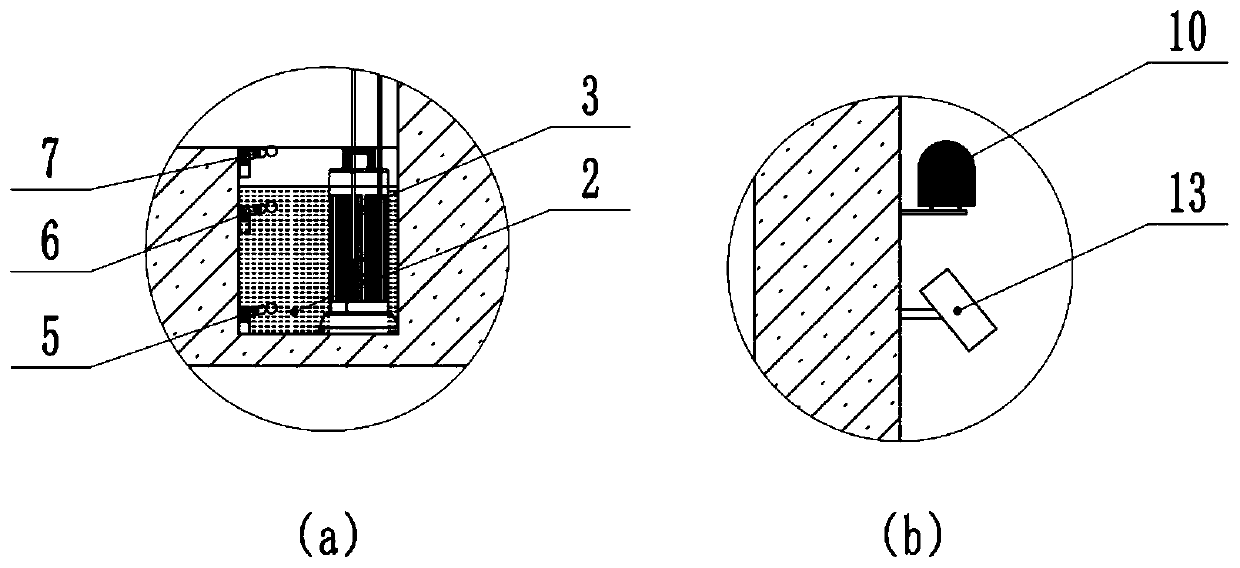

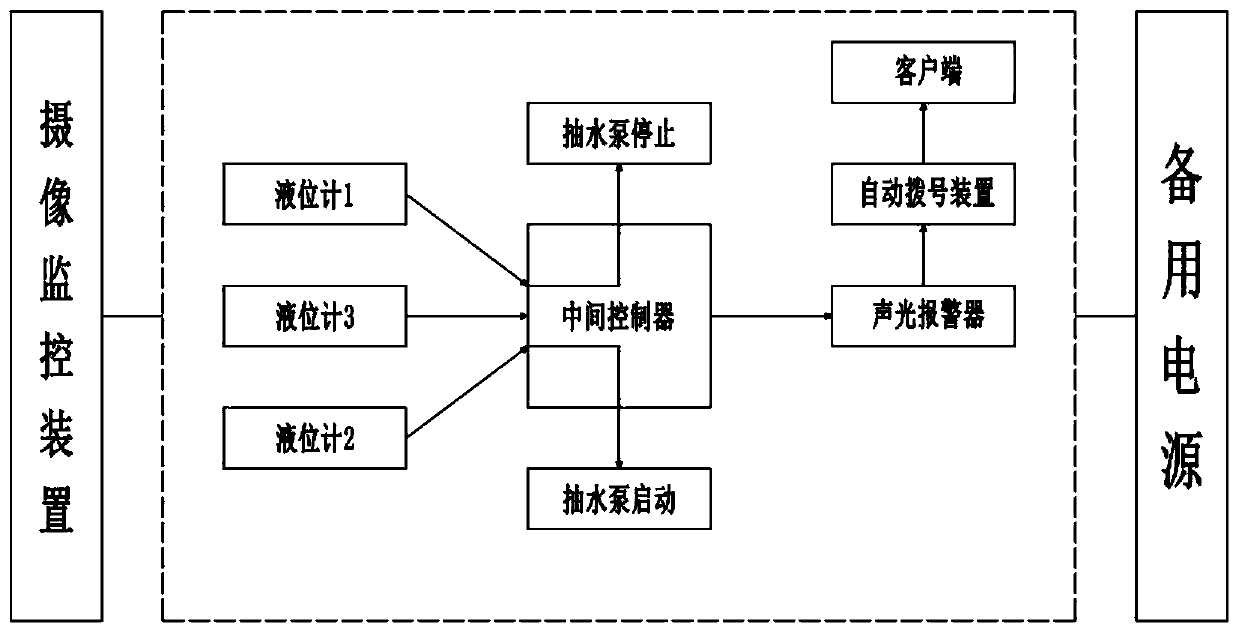

Lift type underground ring main unit based automatic water drainage system

PendingCN111206608ASolve the problem of damage to safety incidentsSimple structureFoundation engineeringStandby powerEnvironmental engineering

Owner:NANJING GAOLI CONSTR MASCH CO LTD

Method for preventing concrete of spillway tunnel of hydropower station from cracking

Owner:中国安能集团第一工程局有限公司

Connection method for wall sections of ultra-deep anti-seepage wall

ActiveCN111042060AFoundation engineeringMarine site engineeringGeotechnical engineeringStructural engineering

Owner:SINOHYDRO FOUND ENG

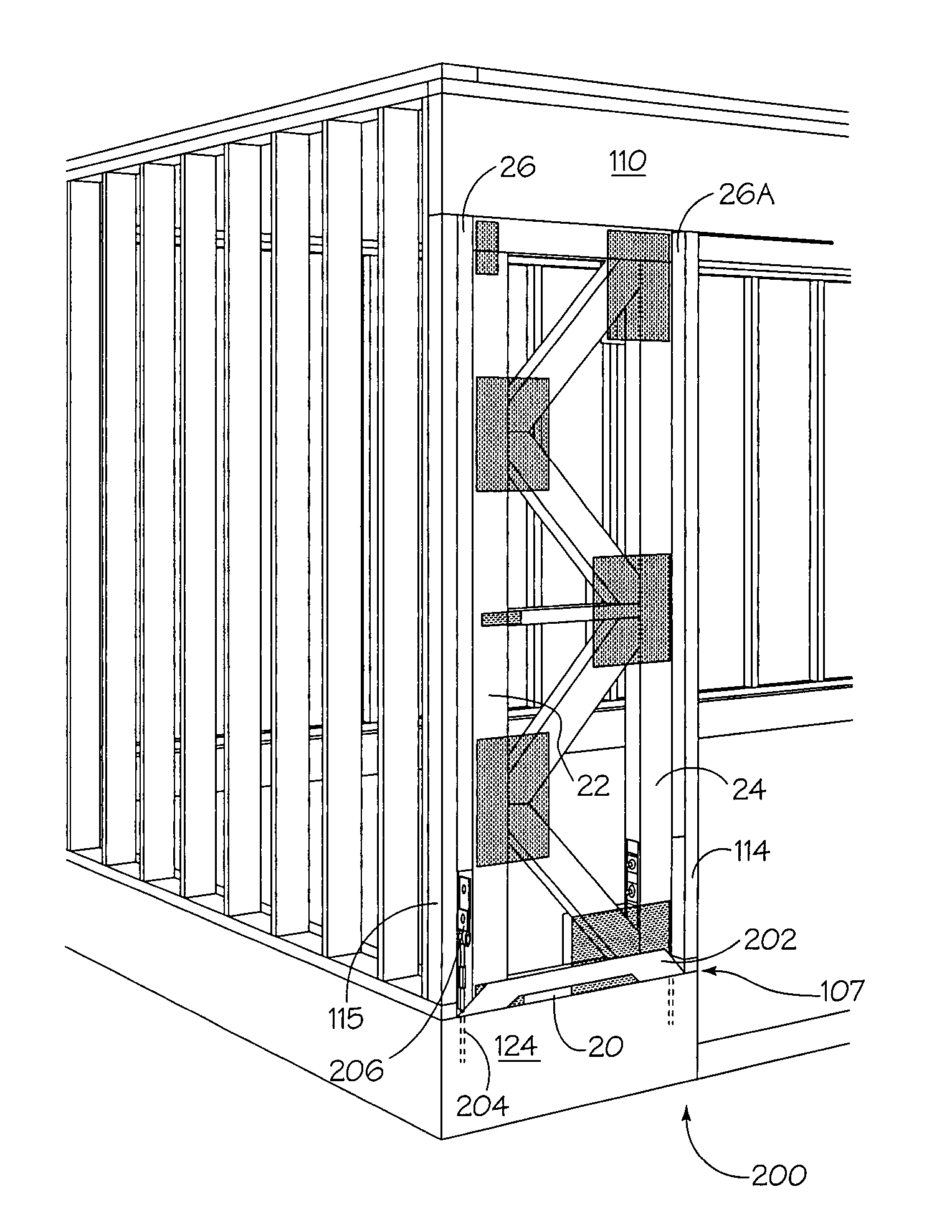

Lateral force resisting system

Owner:TIMMERMAN TIMOTHY L +1

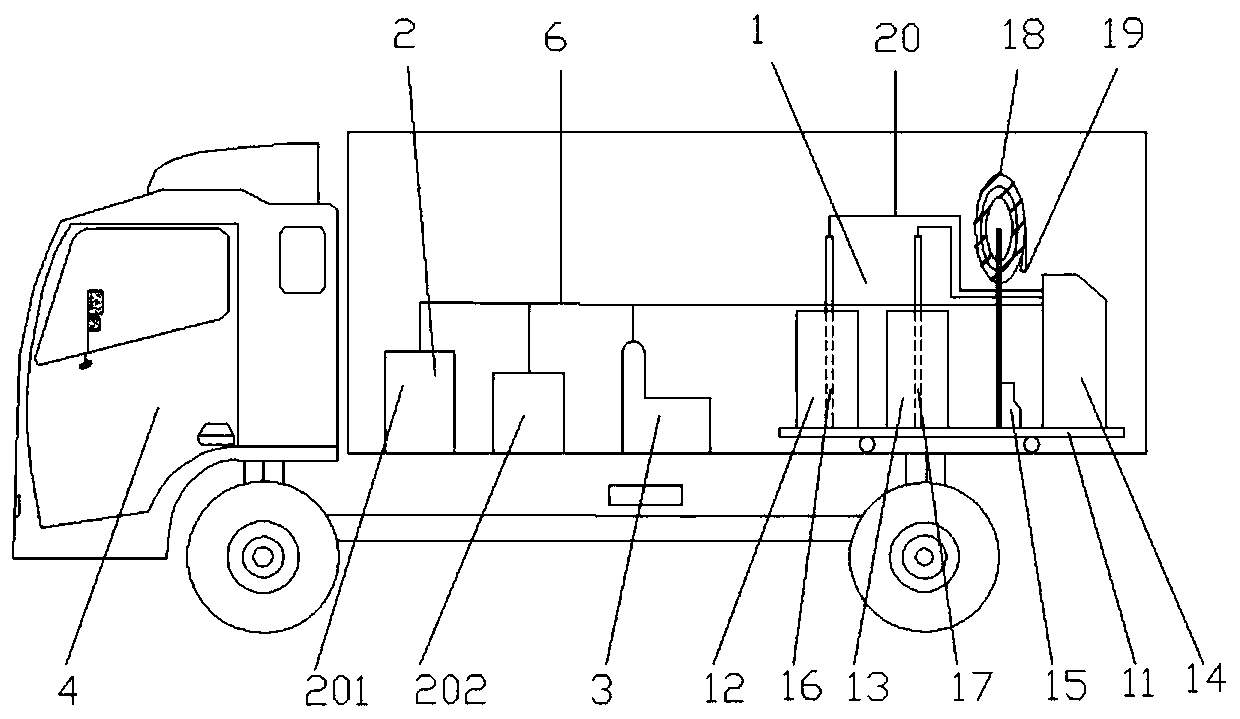

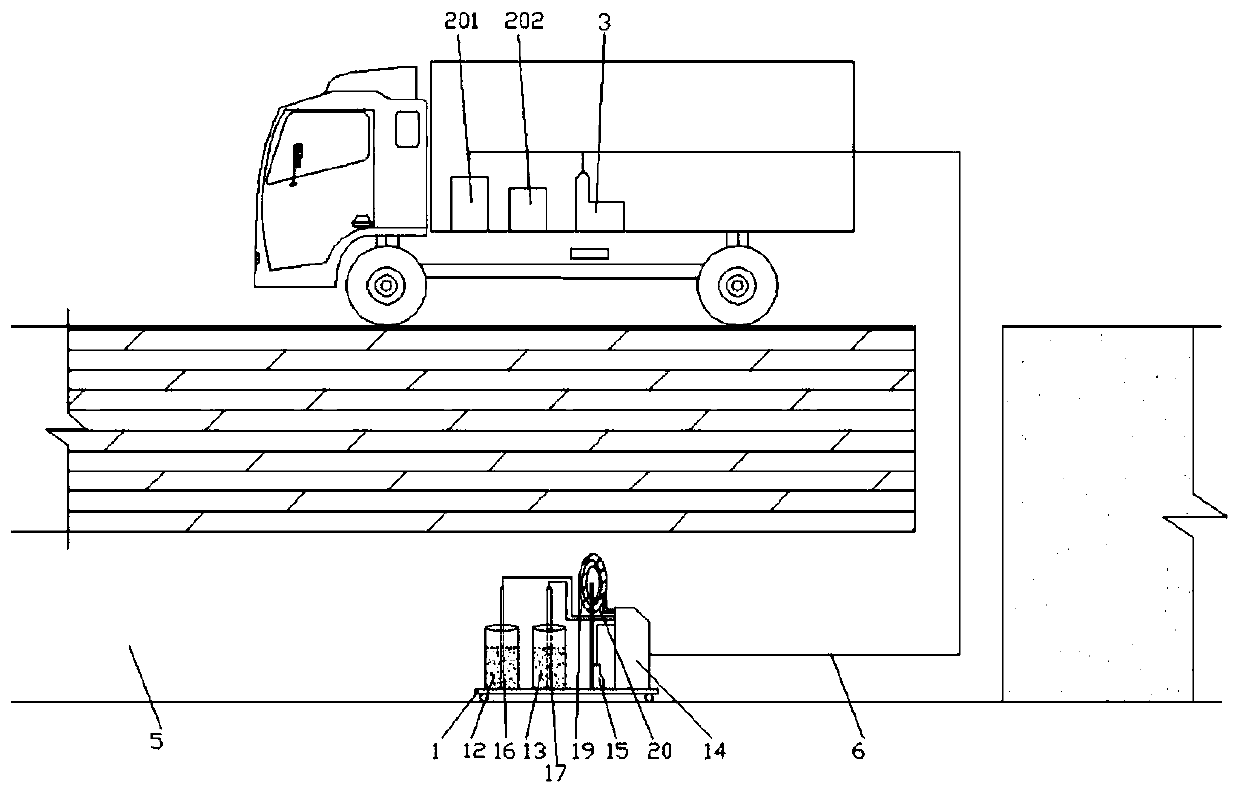

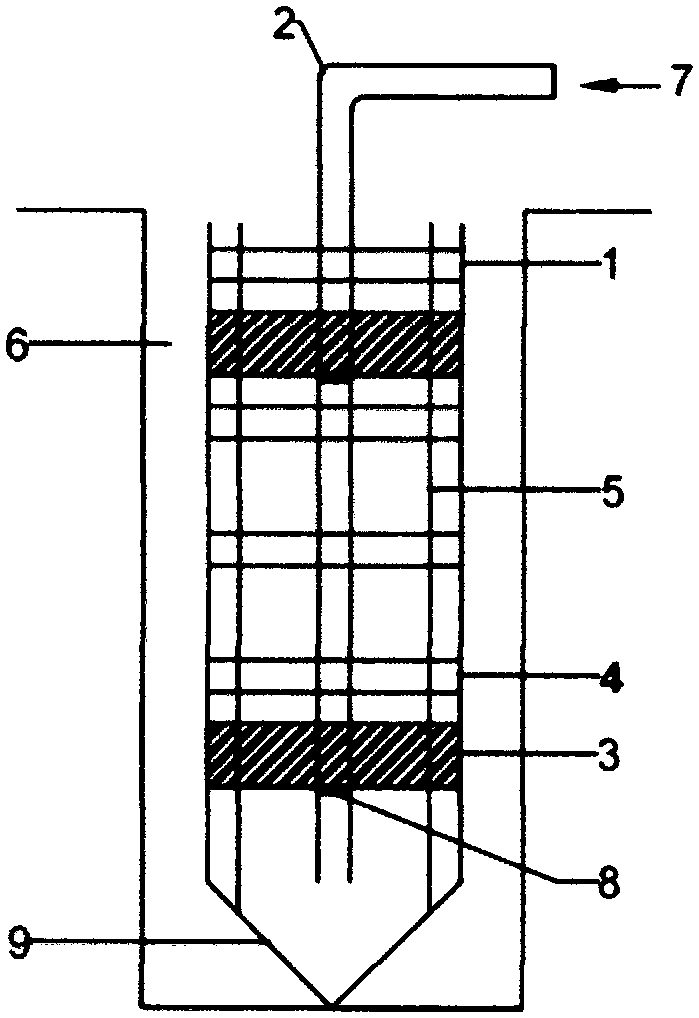

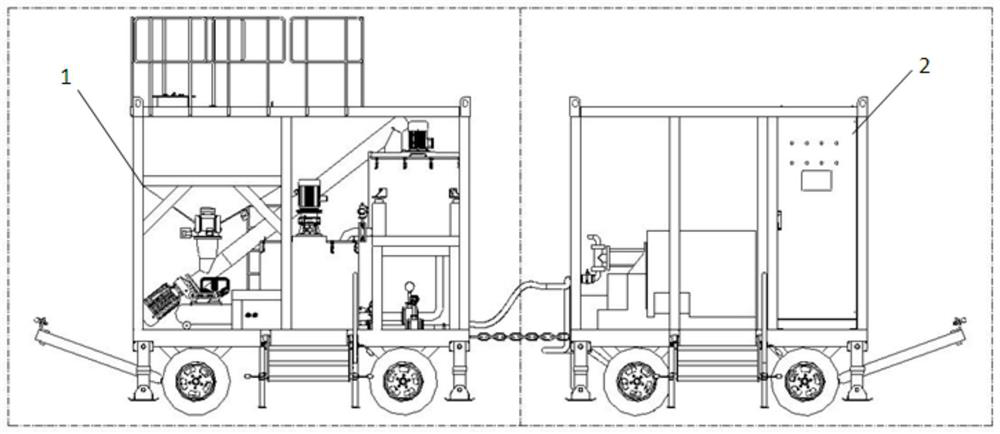

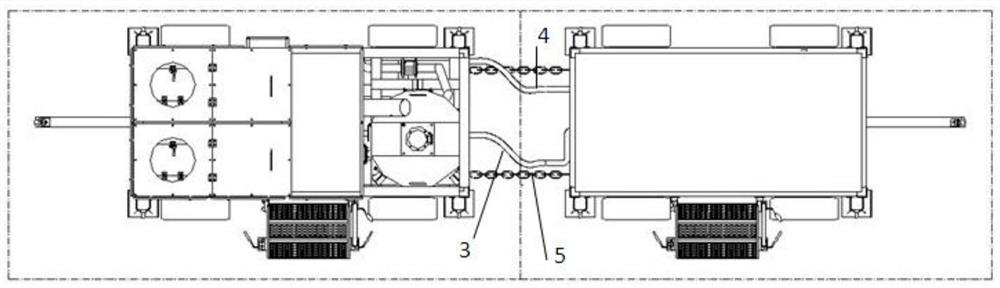

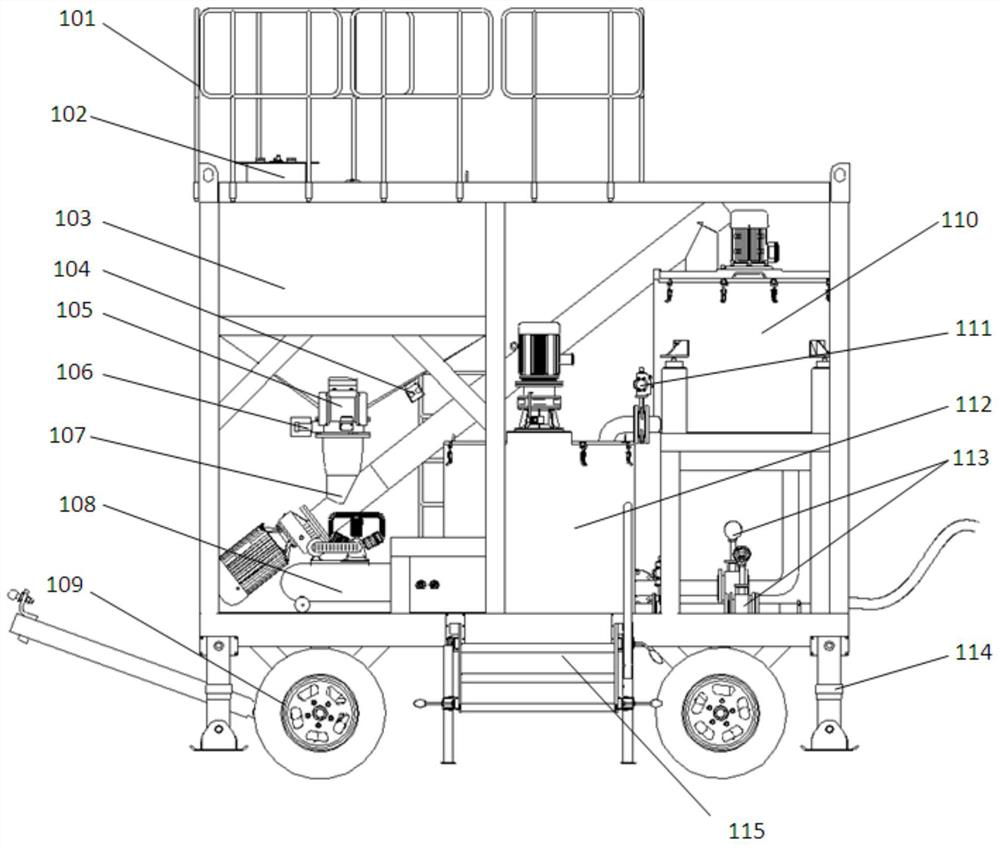

Portable grouting device and grouting vehicle

Owner:WELEAD INFRASTRUCTURE ENG TECH ZHENGZHOU LTD +1

Method for correcting building inclination caused by pile inclination

Owner:湖南征驰工程技术咨询有限公司 +1

Sleeve valve pipe for reinforcing pit bottom of water-rich pebble bed deep foundation pit and construction process

Owner:CHONGQING UNIV OF EDUCATION

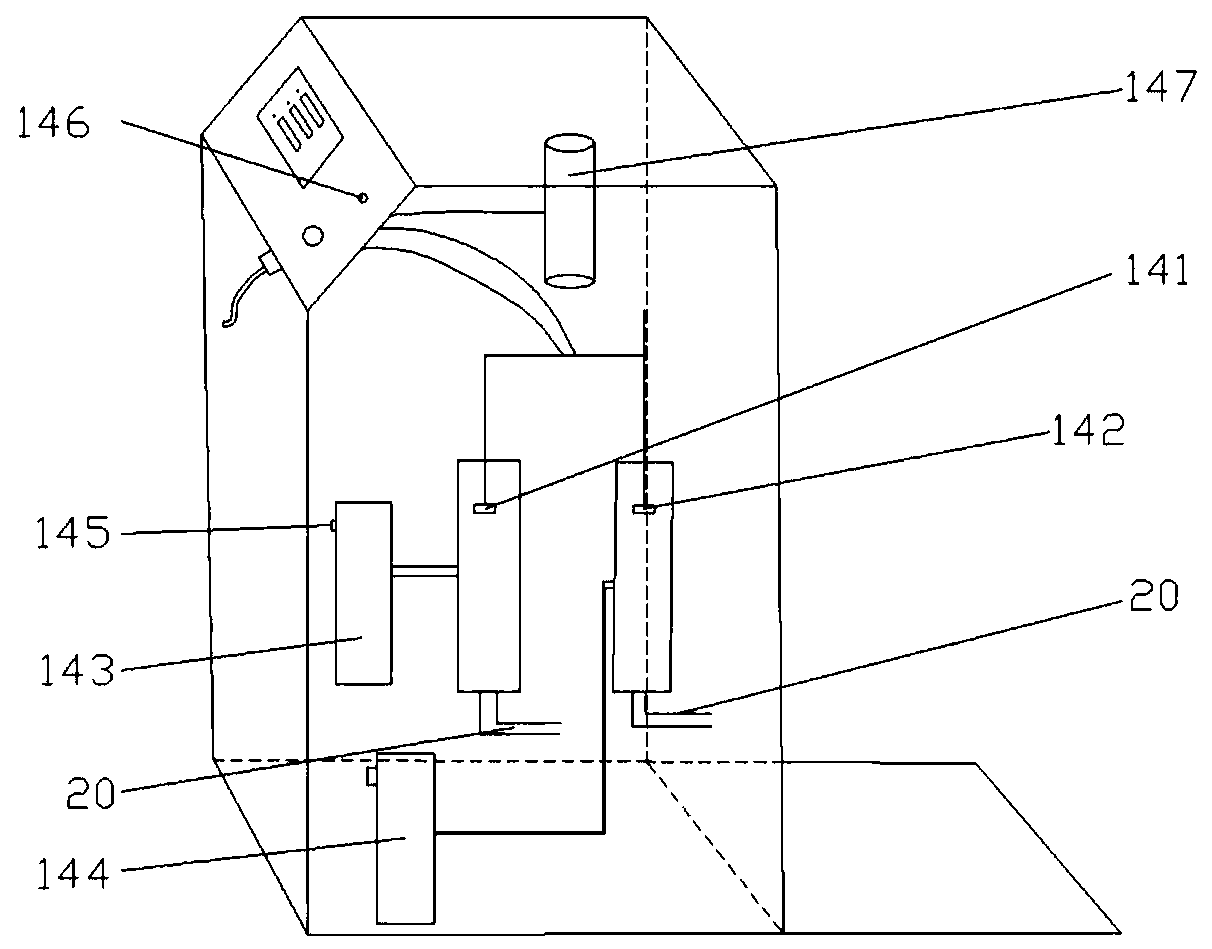

Movable grouting equipment

PendingCN112443341ASolving Dispersion ProblemsSolution volumeUnderground chambersMixing operation control apparatusControl cellCement grout

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

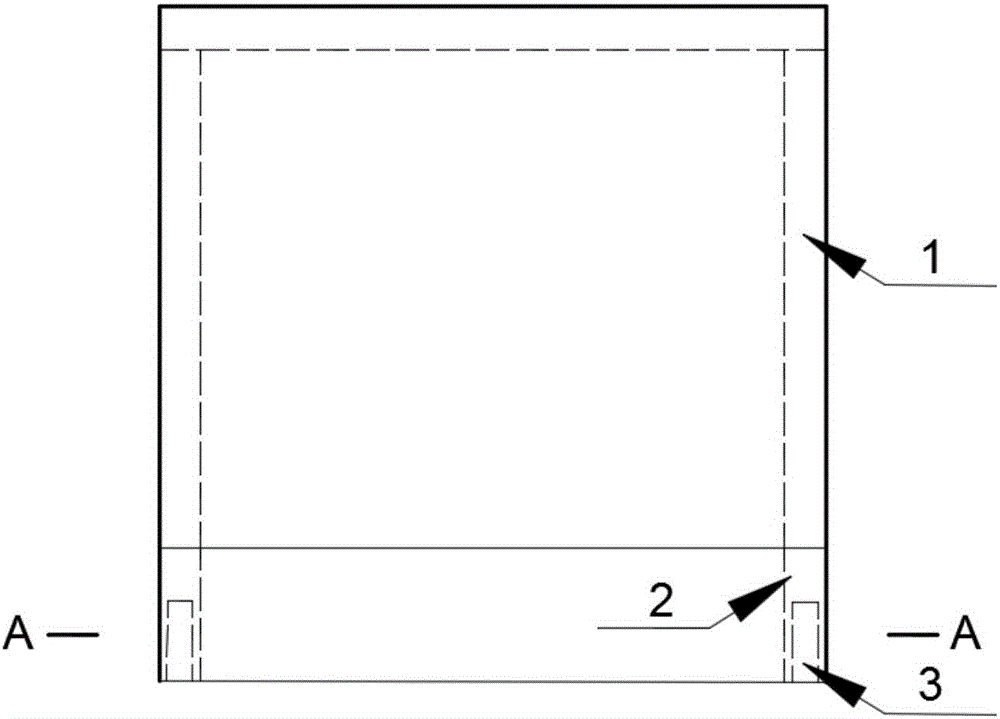

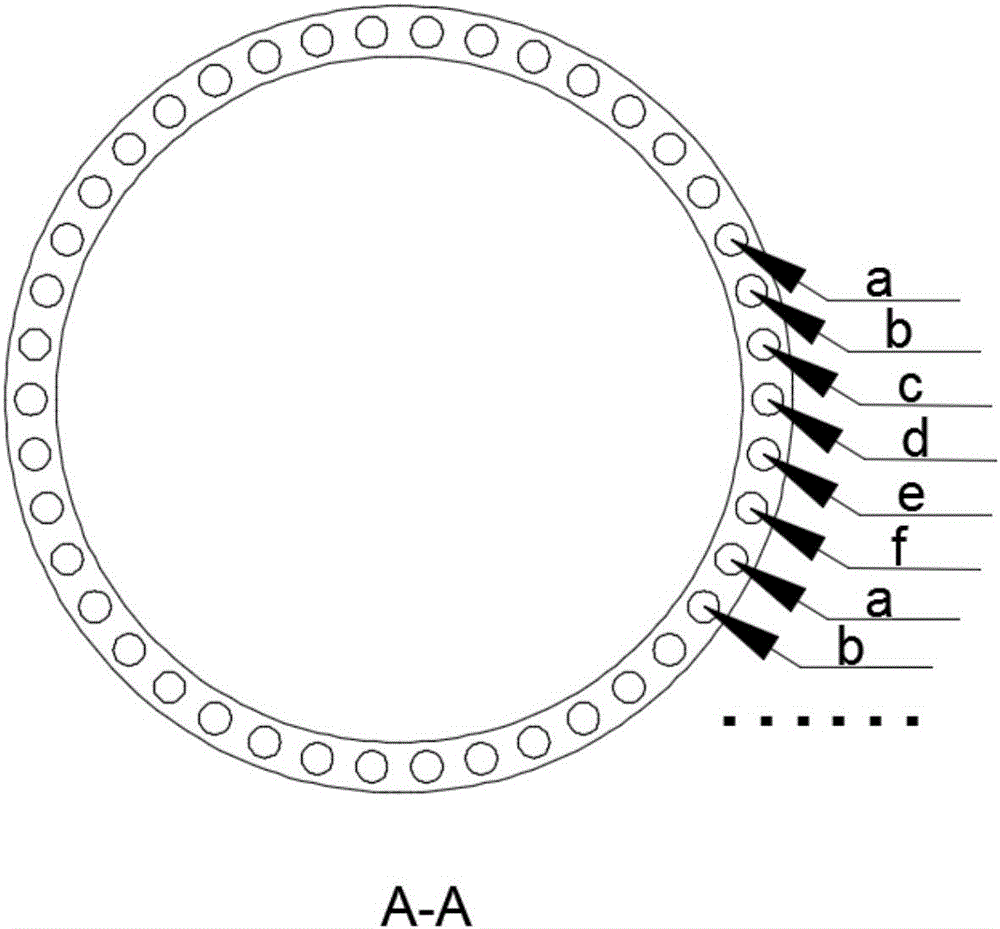

Application of positioning rib in large storage tank bearing platform ring wall foundation

Owner:SINOCHEM ZHOUSHAN XINGHAI CONSTR

Method for mounting and adjusting hammer crusher

InactiveCN103510536AGuaranteed installation accuracyReduce running vibrationFoundation engineeringButtressFree state

Owner:洛阳天信矿山机械制造有限公司

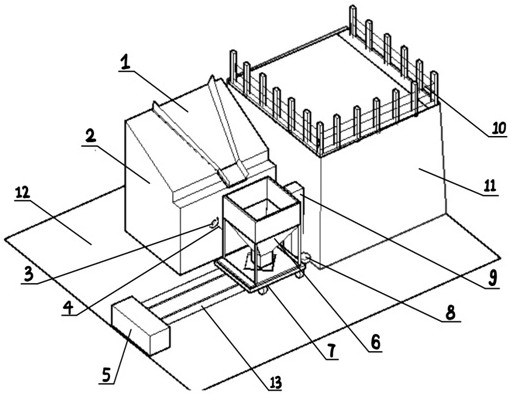

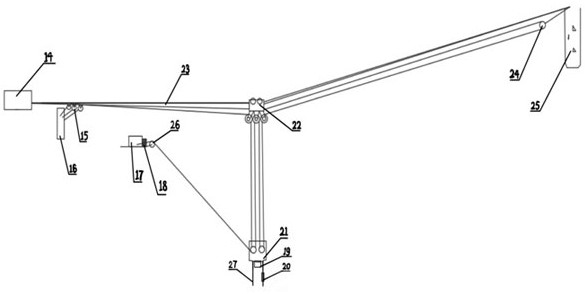

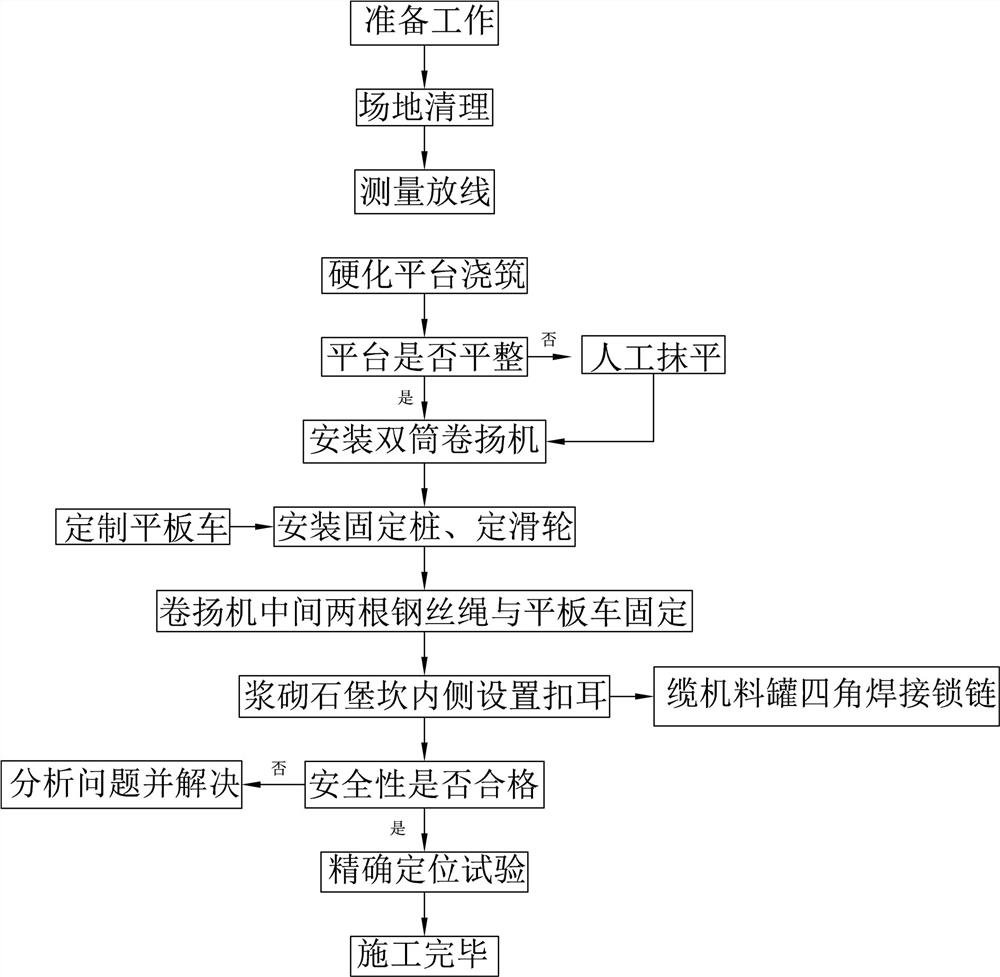

Concrete charging bucket landing anti-swing system and method for dam construction cable crane

ActiveCN112323802APrevent slippingReduce intensityFoundation engineeringWinding mechanismsControl theoryWinch

Owner:CHINA THREE GORGES UNIV

Novel quickly-disassembled-and-assembled combined cofferdam with slope-retaining gallery for river channel

Owner:河南传衡建设工程有限公司 +1

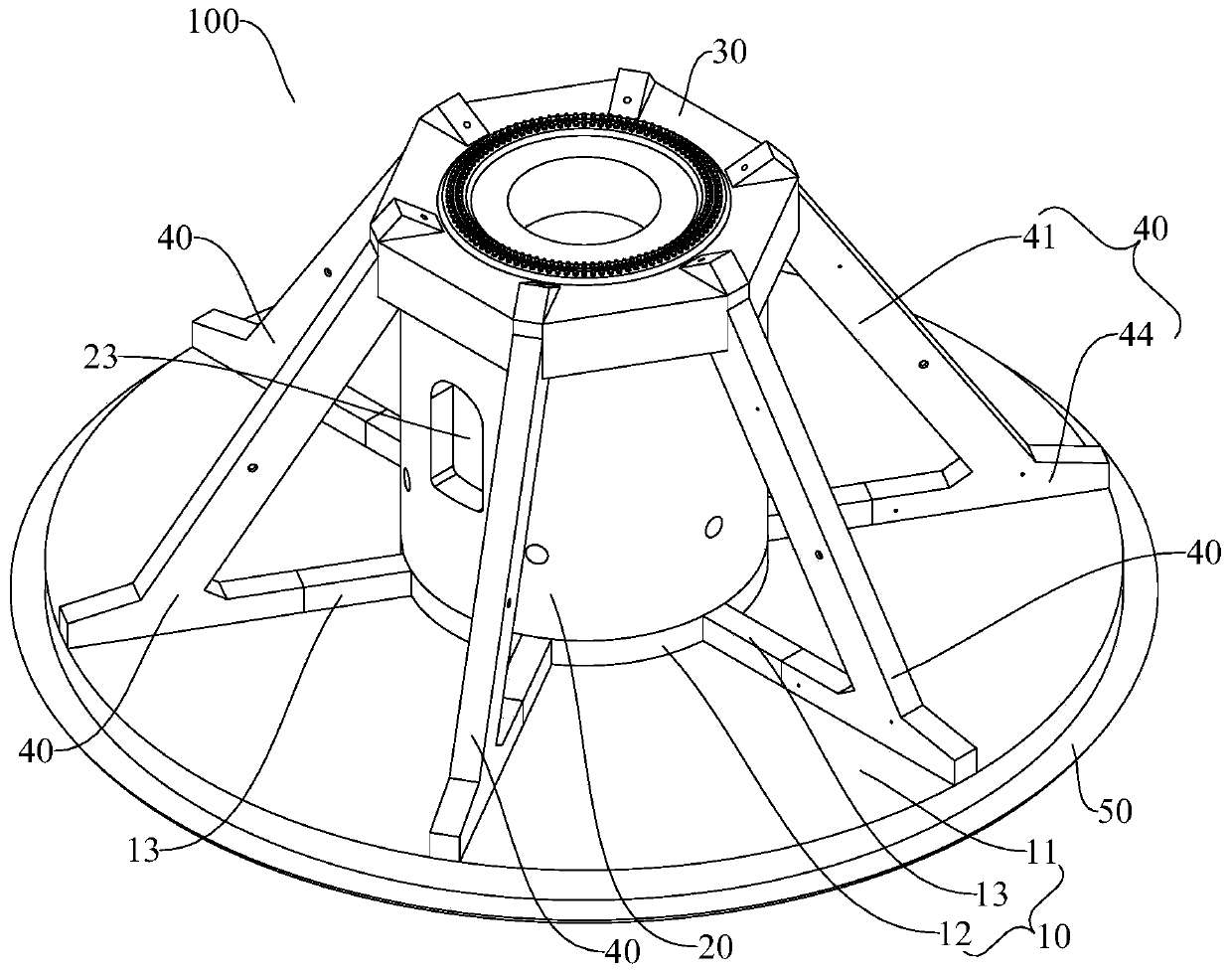

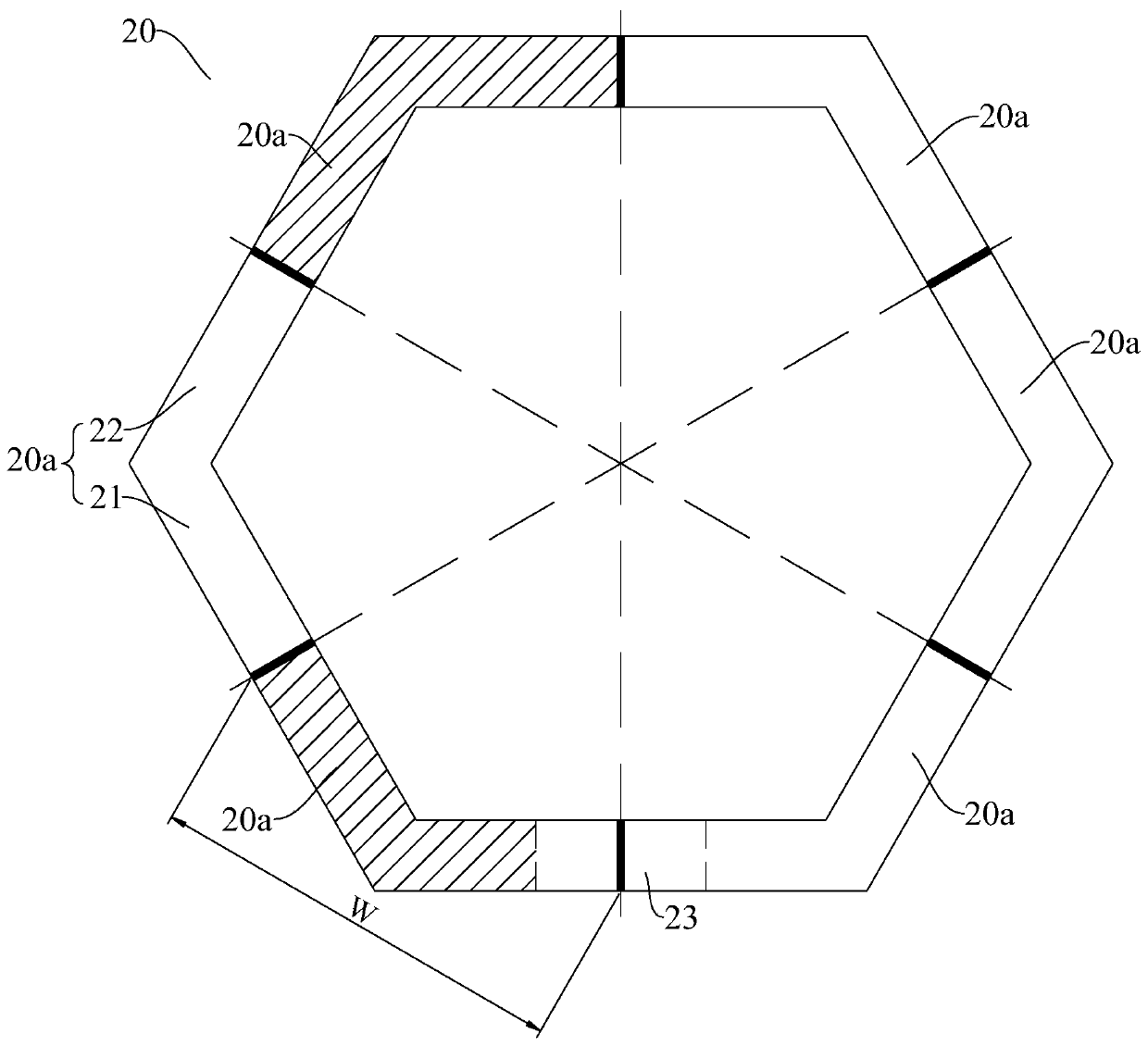

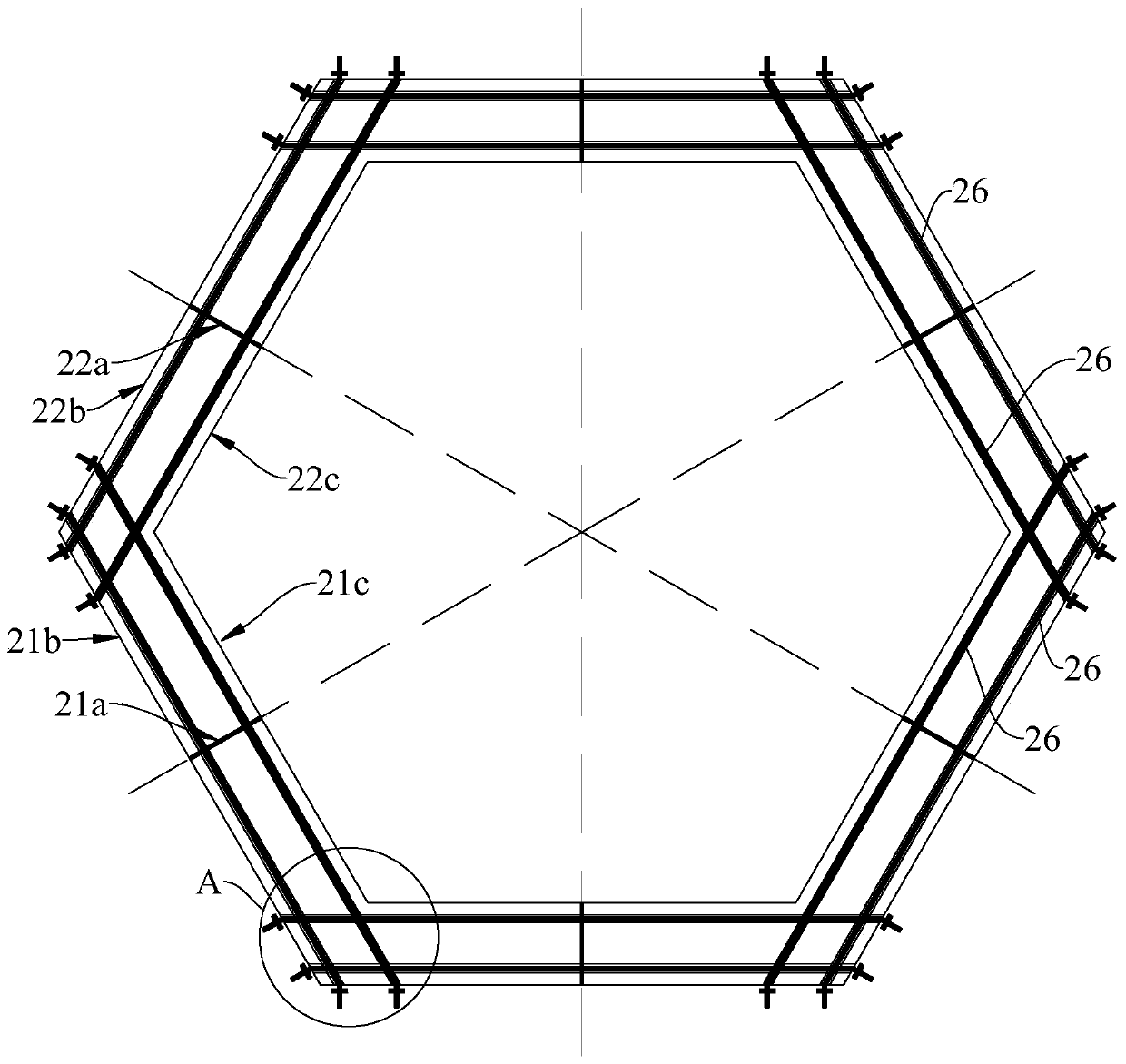

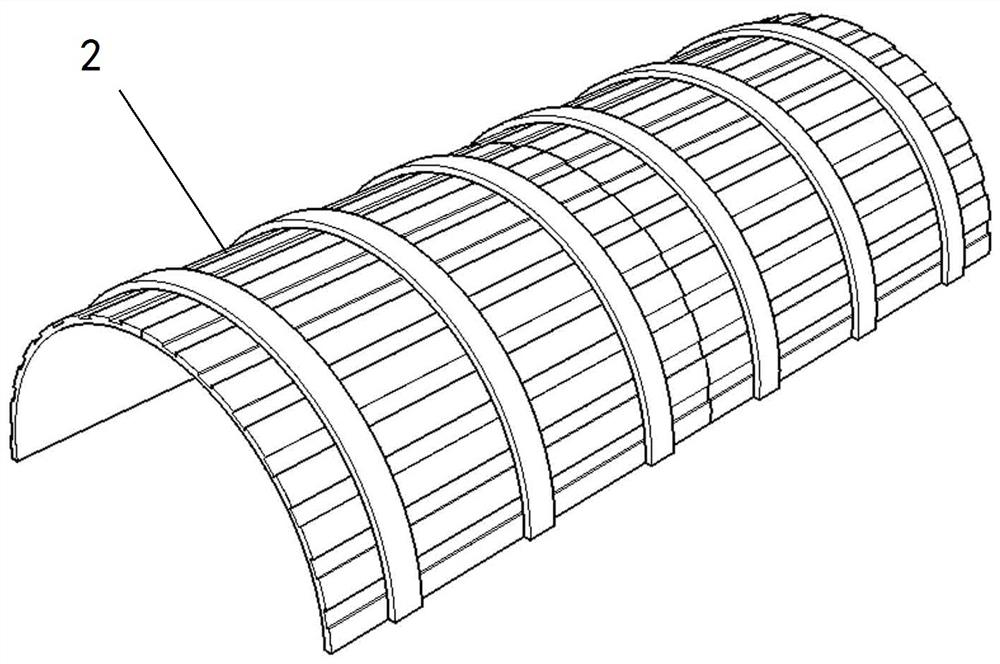

Center cylinder component, center cylinder and tower foundation

PendingCN111456074AOverall small sizeSmall widthWind motor supports/mountsFoundation engineeringArchitectural engineeringStructural engineering

Owner:深圳国金电力新能设计院有限公司

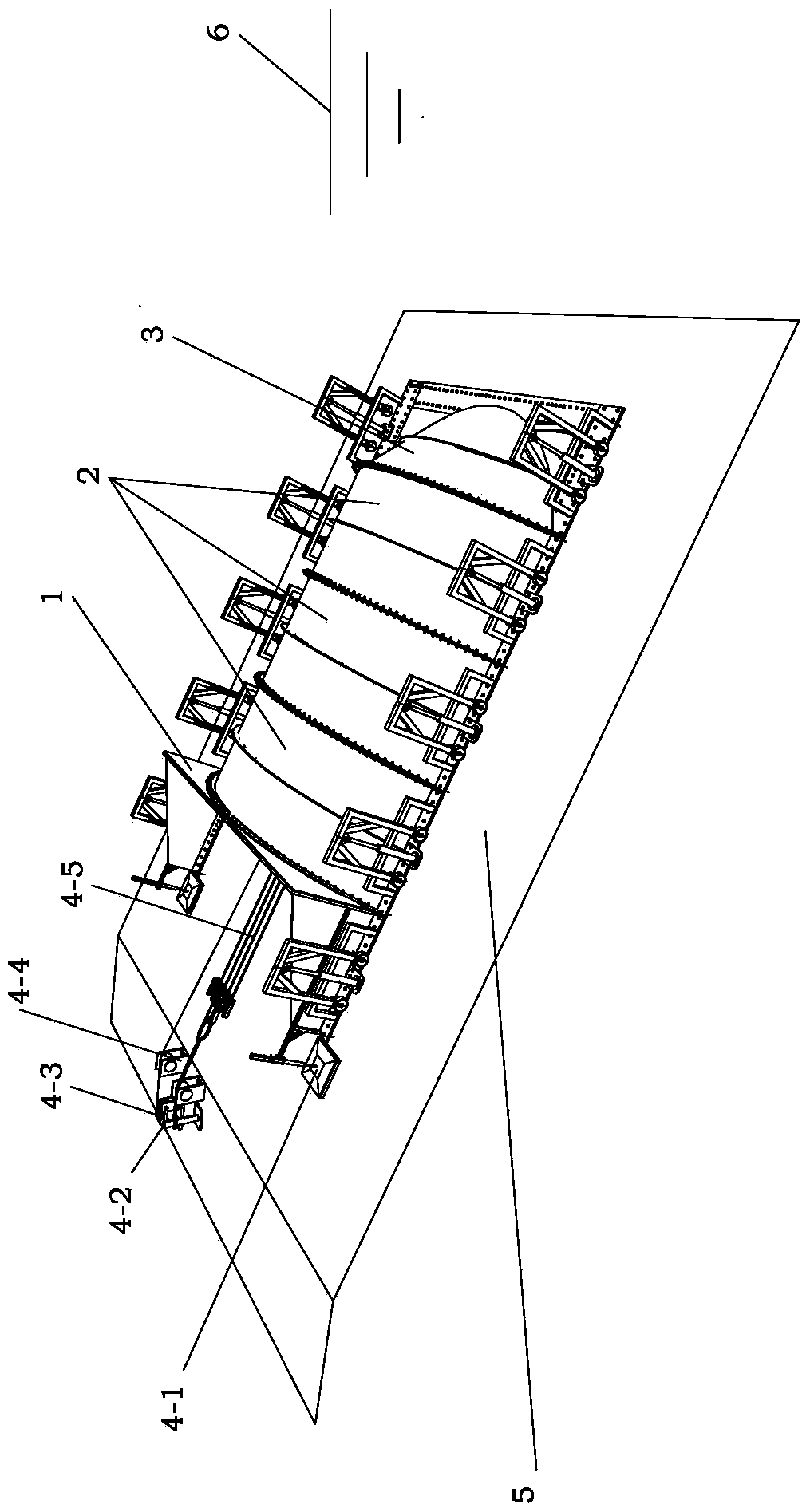

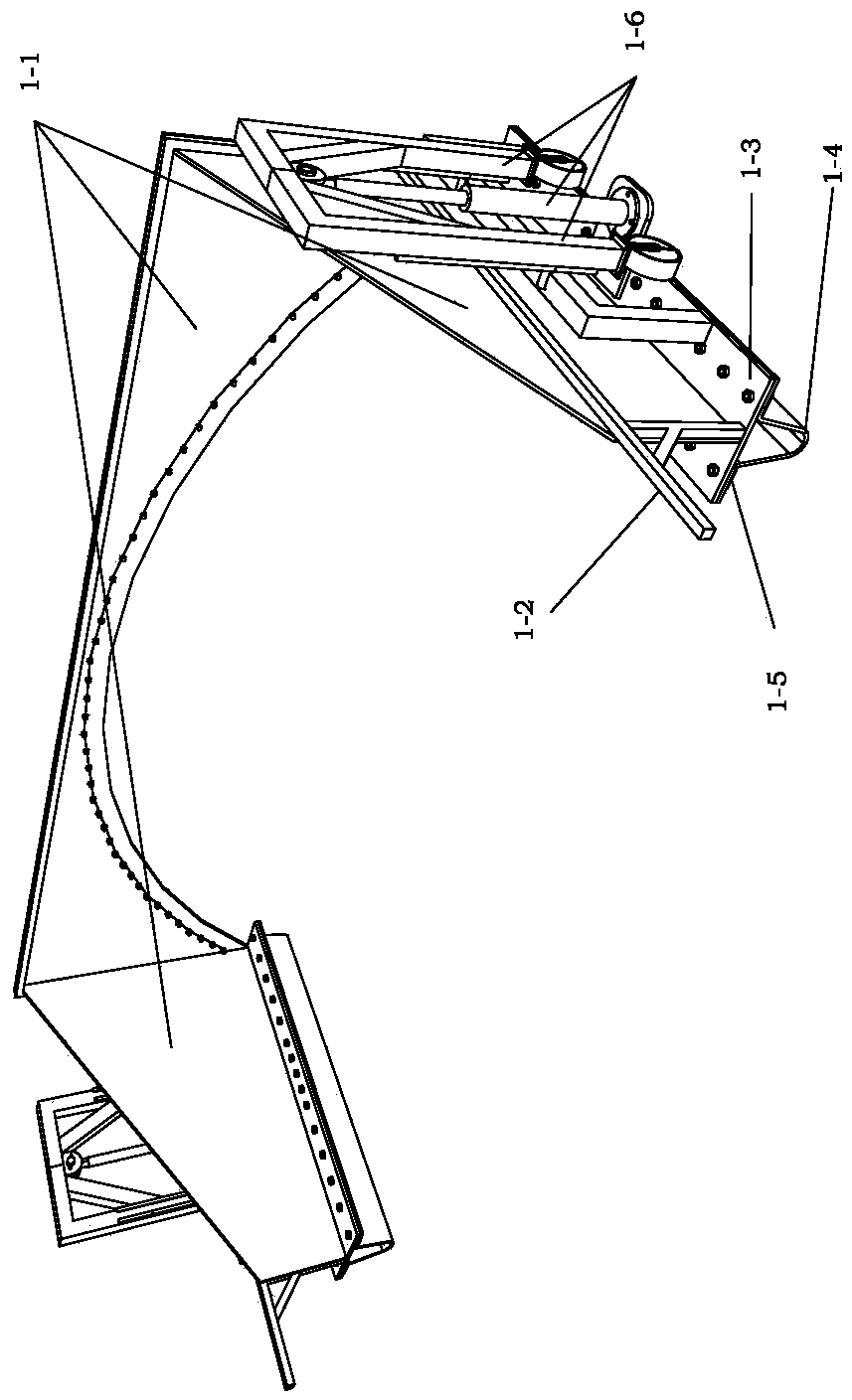

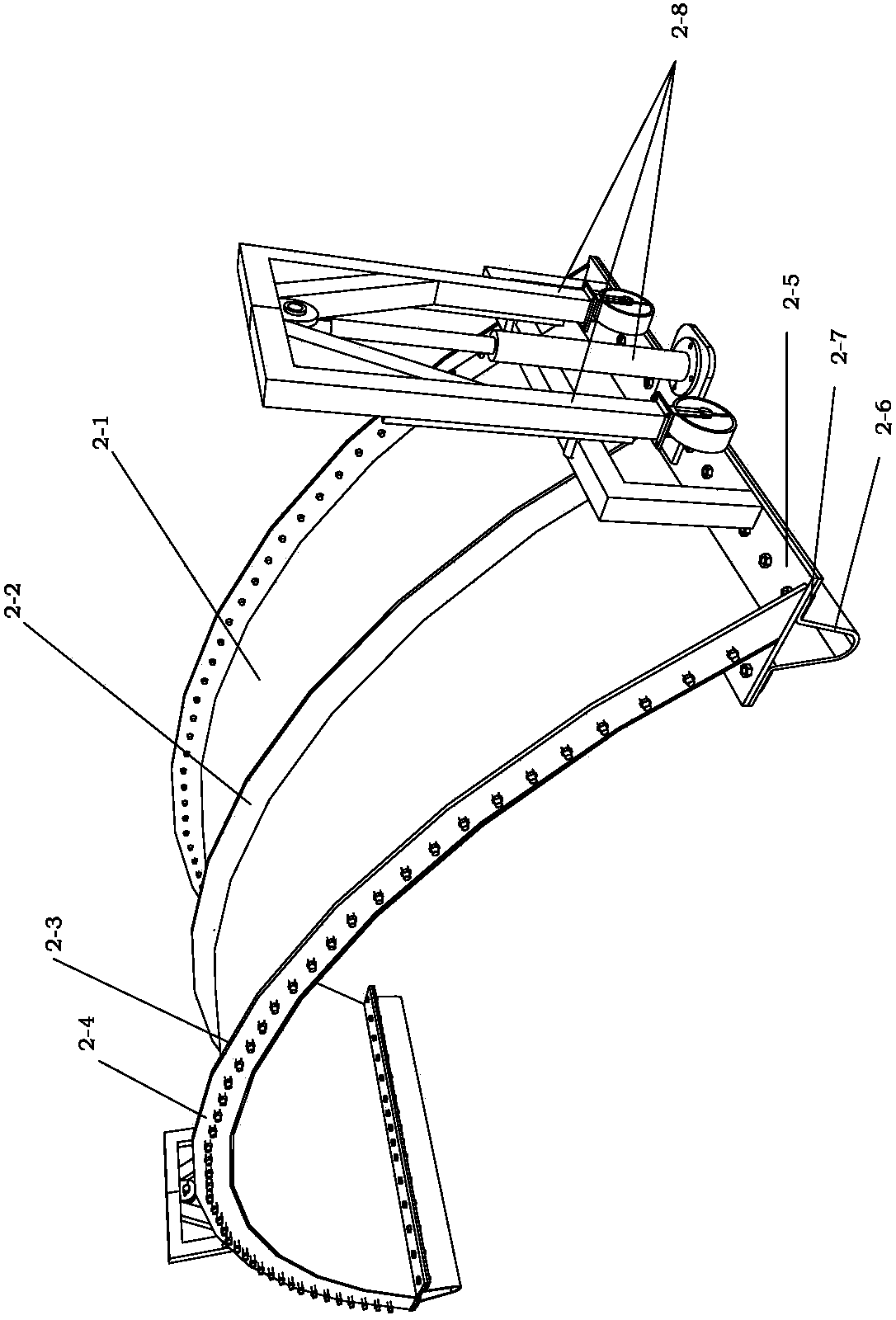

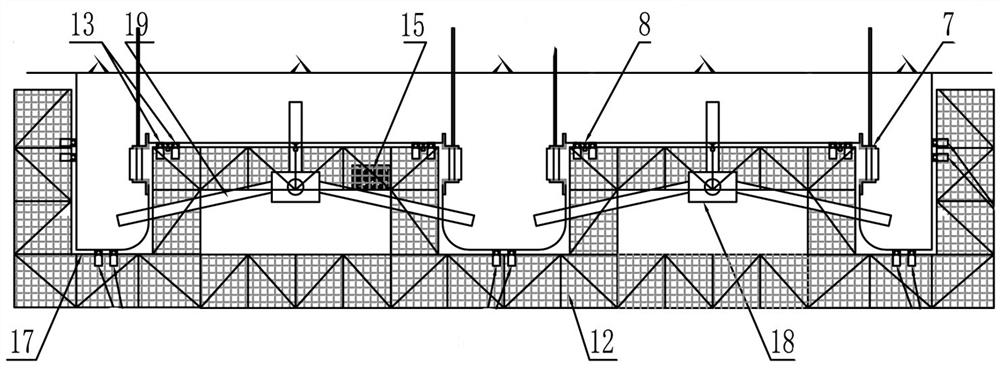

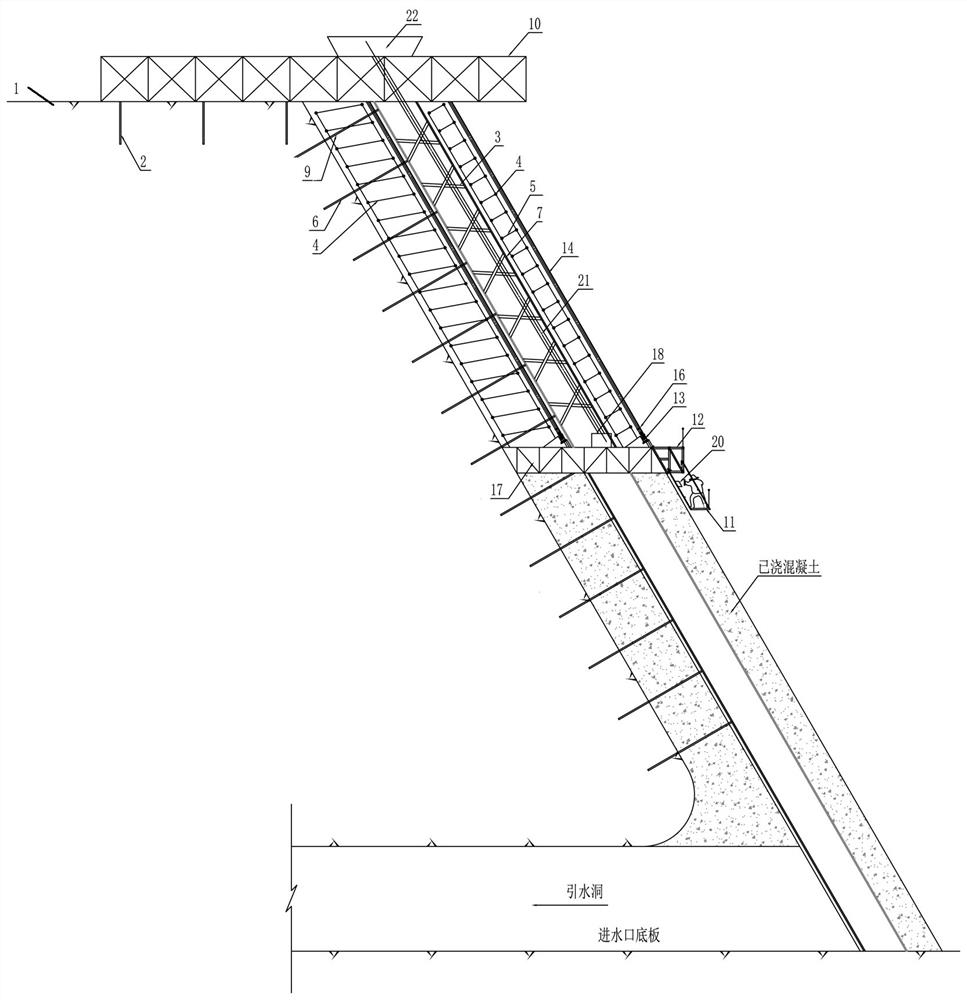

Large-dip-angle trash rack one-time forming suspension type sliding formwork and construction method

ActiveCN112095560AGuaranteed continuous constructionSimple structureWater cleaningFoundation engineeringControl systemRebar

Owner:CHINA INTERNATIONAL WATER & ELECTRIC CORPORATION +3

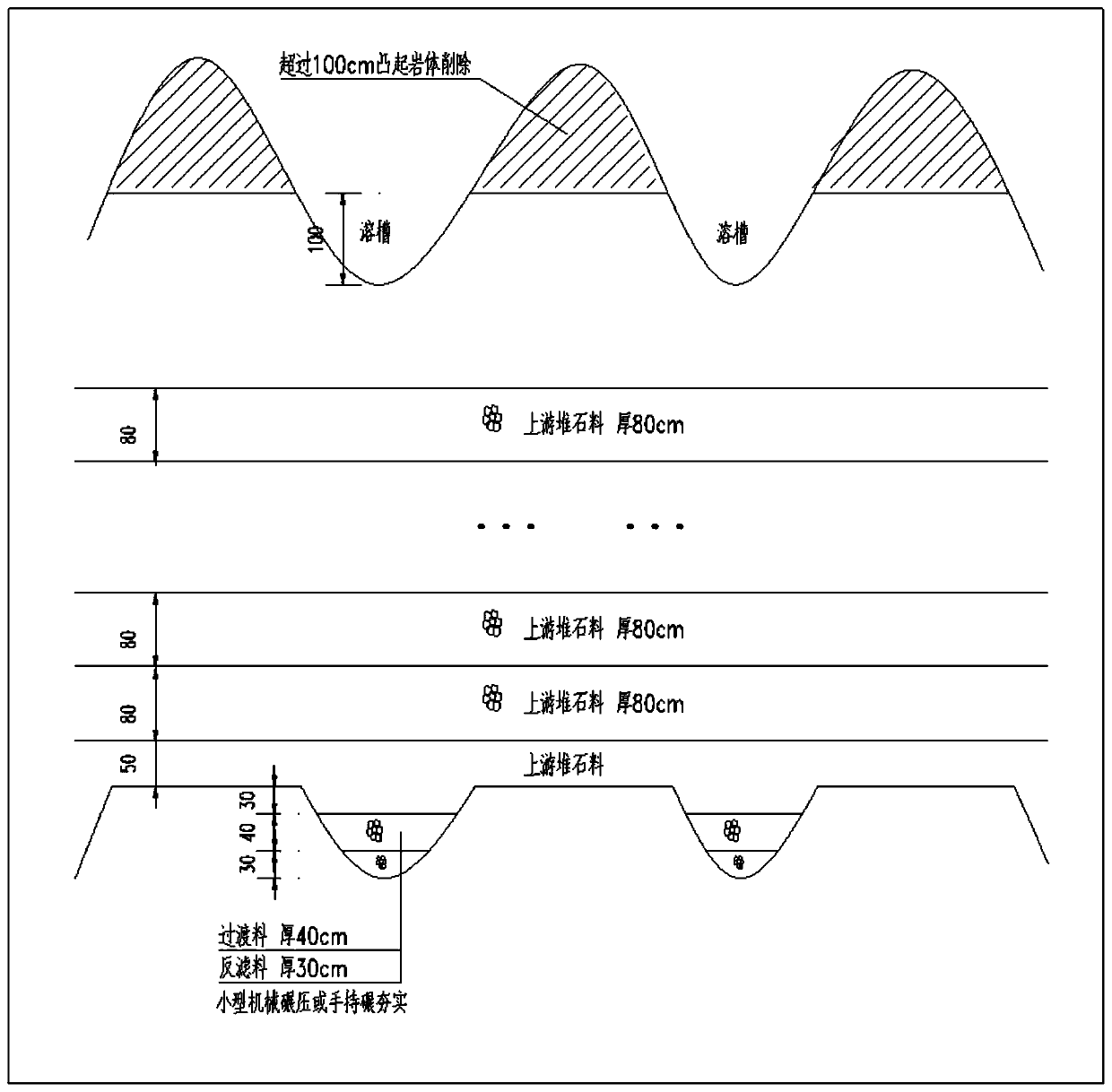

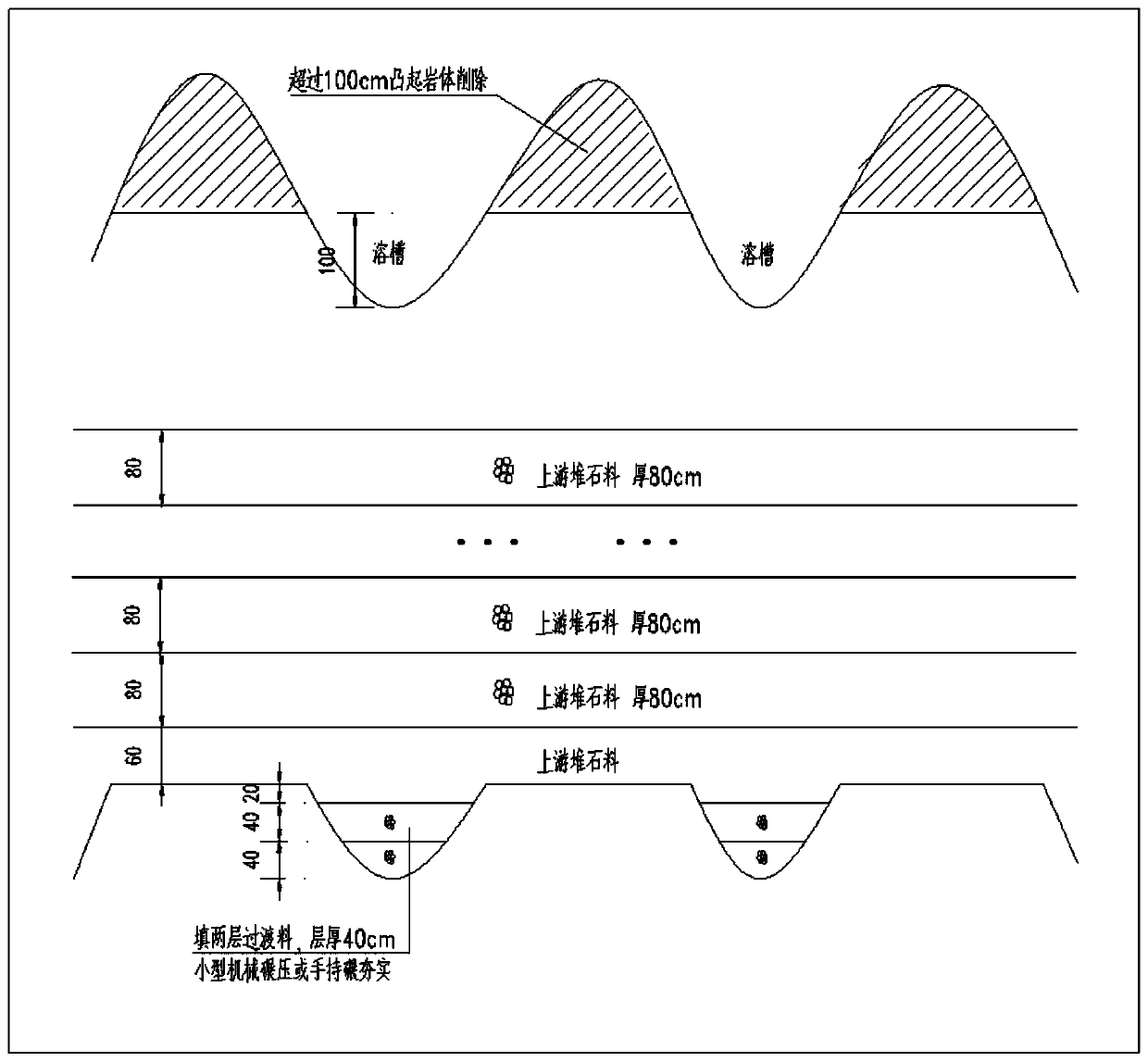

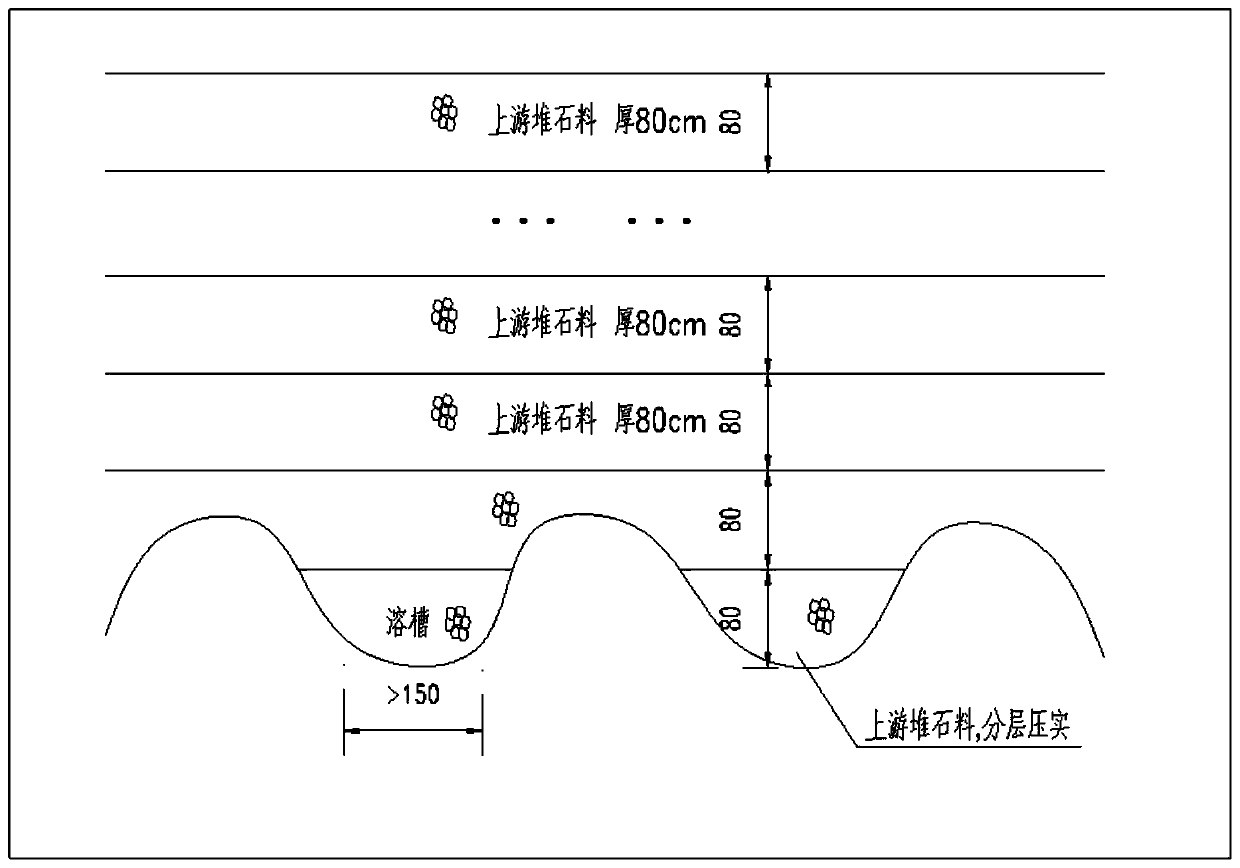

Building method of concrete faced rockfill dam in karst development region

Owner:STATE GRID CORP OF CHINA +2

Deviation rectifying method for soil layer pile foundation

Owner:GUIZHOU ELECTRIC POWER DESIGN INST

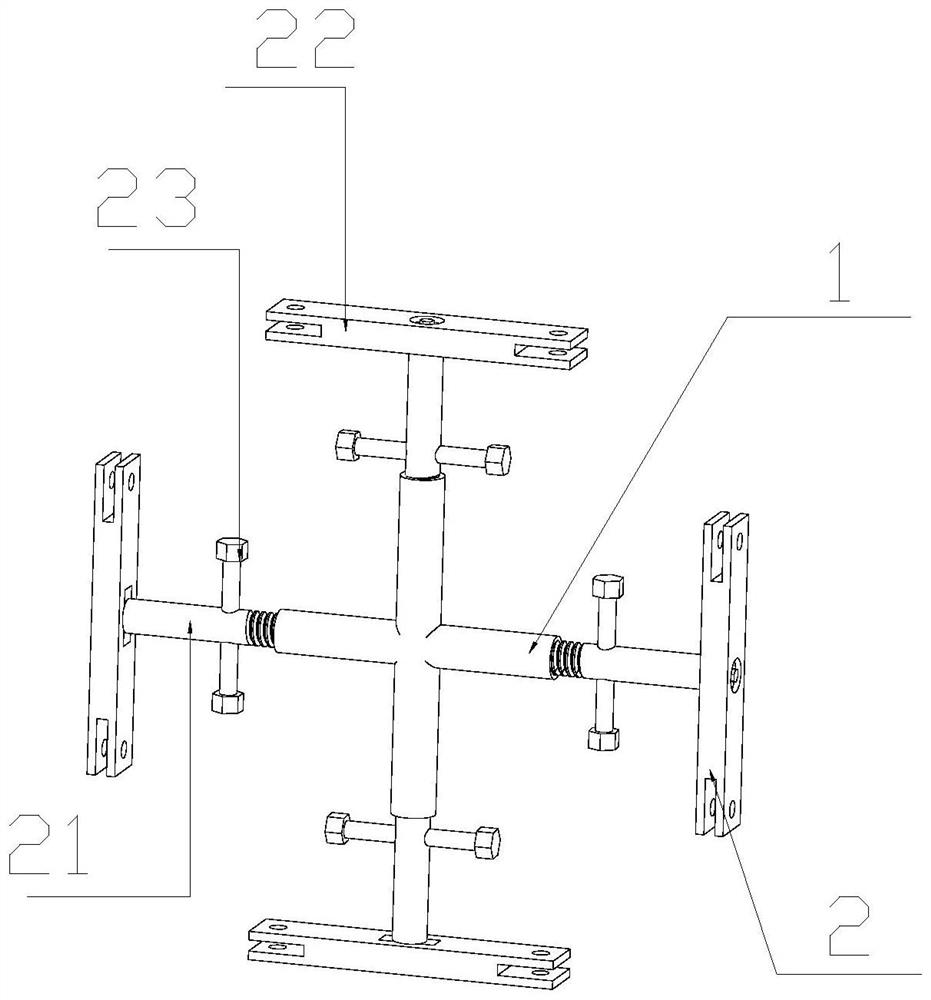

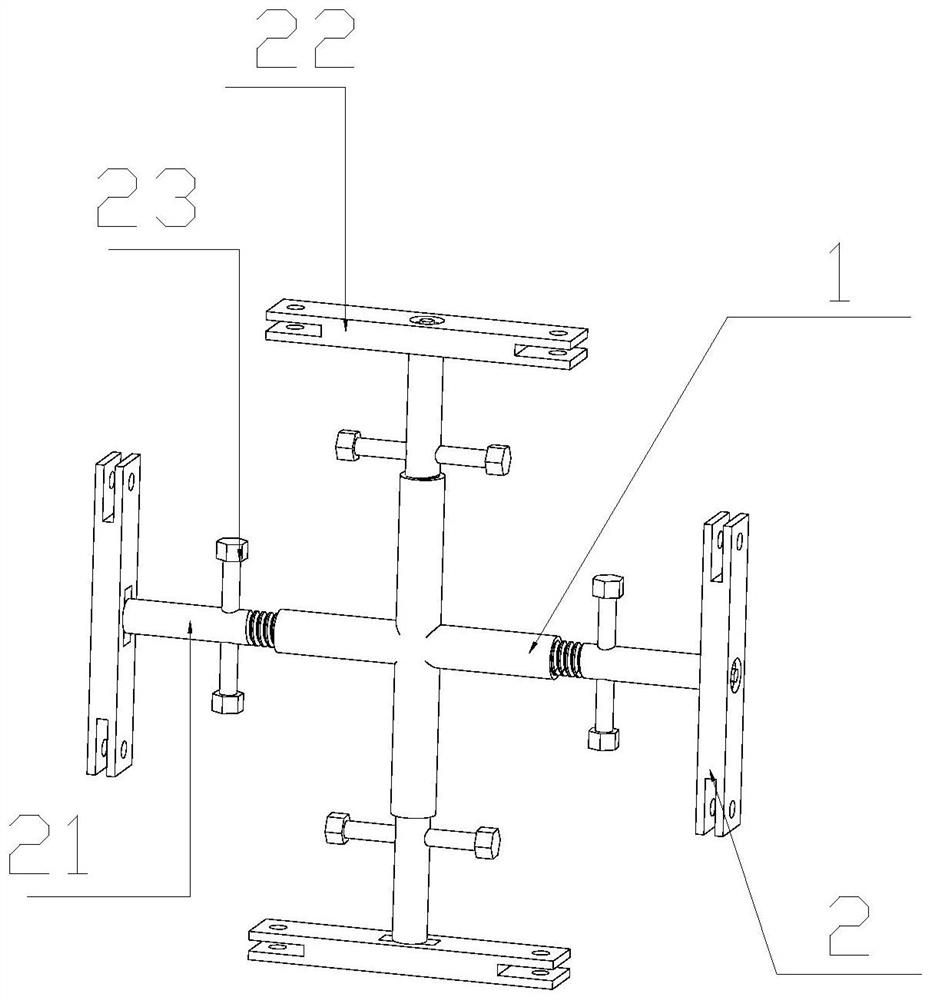

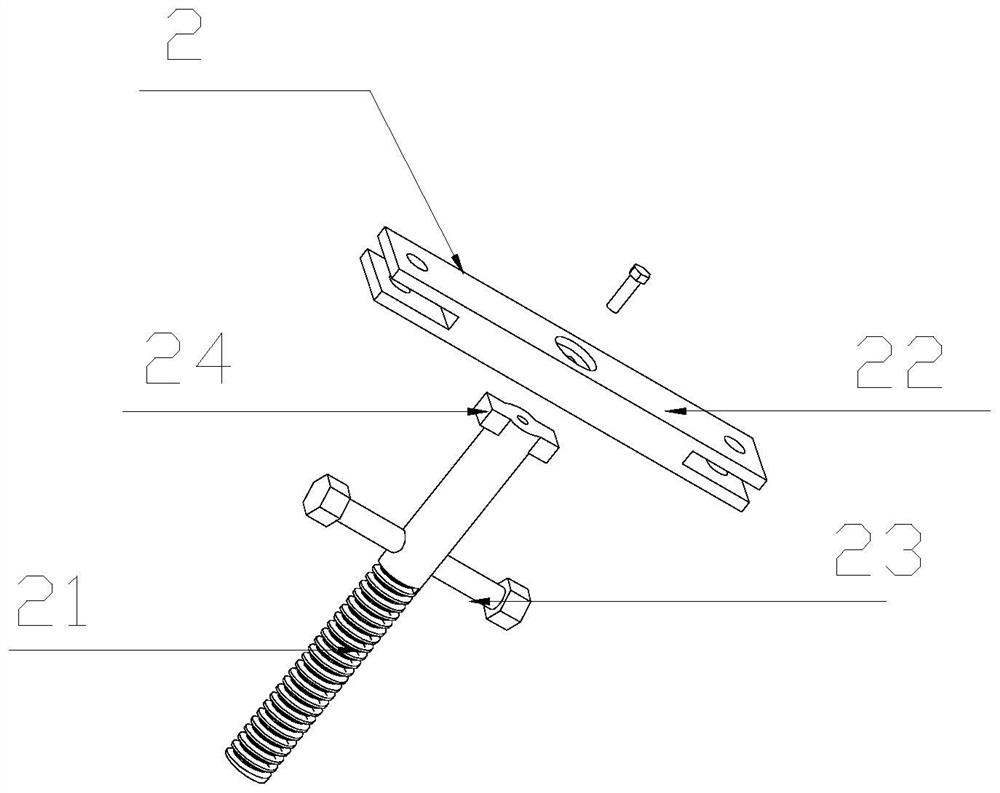

Adjustable portable template supporting device

PendingCN113958126AAdjustable support lengthAdjust the length of the supportFoundation engineeringForms/shuttering/falseworksEngineeringScrew thread

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

Rapid construction method for gate pier concrete high and large formwork

InactiveCN112900442AImprove construction efficiencyShorten the construction periodFoundation engineeringSupporting systemArchitectural engineering

Owner:GEZHOUBA GROUP FOUND ENG

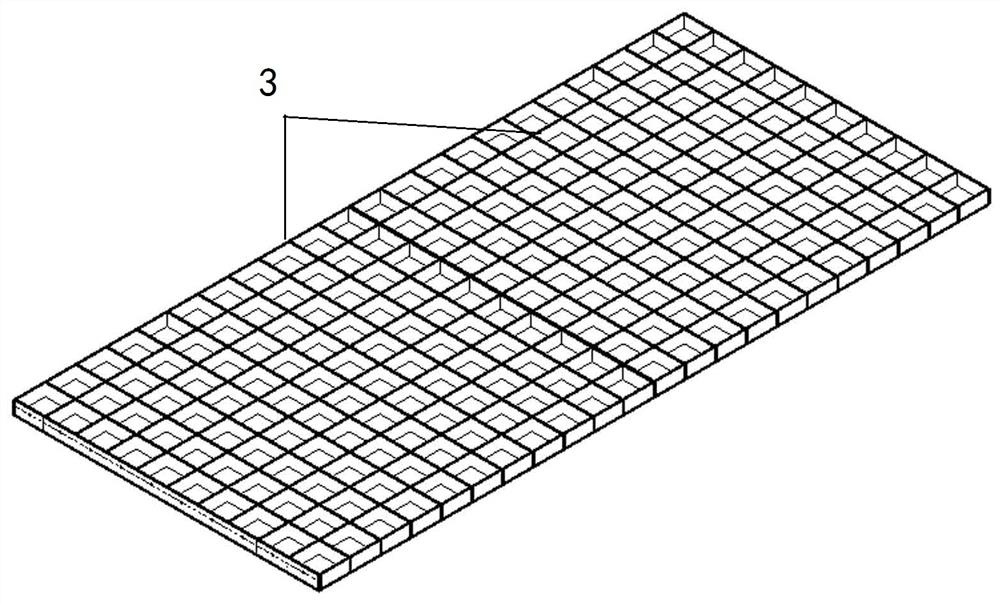

Composite type anti-settling plate basis with railing gaps in bottom plate and manufacturing method thereof

InactiveCN104631483ASimple preparation processGuaranteed stiffnessFoundation engineeringCarrying capacityEngineering

Owner:TIANJIN UNIV

Combined cofferdam suitable for offshore large-size bearing platform construction

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP NO 4 ENG +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap