Deviation rectifying method for soil layer pile foundation

A pile foundation and soil layer technology, applied in the field of soil layer pile foundation deviation correction, can solve the problems of rising cost, time-consuming and laborious process of repositioning, and delay, and achieve the effect of increasing cost, reducing damage and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

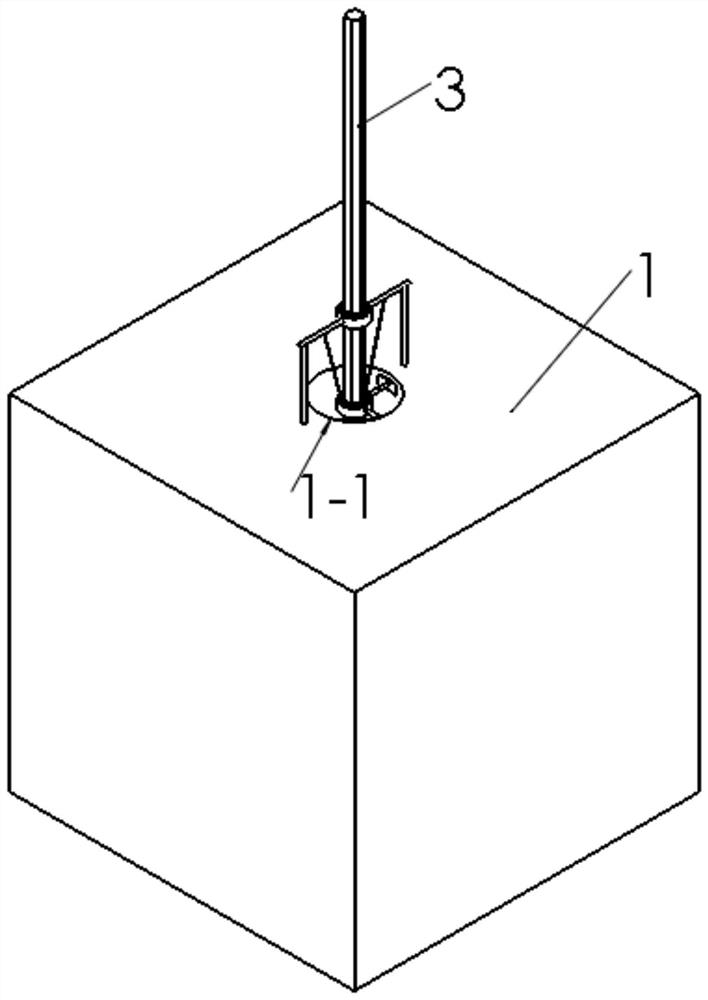

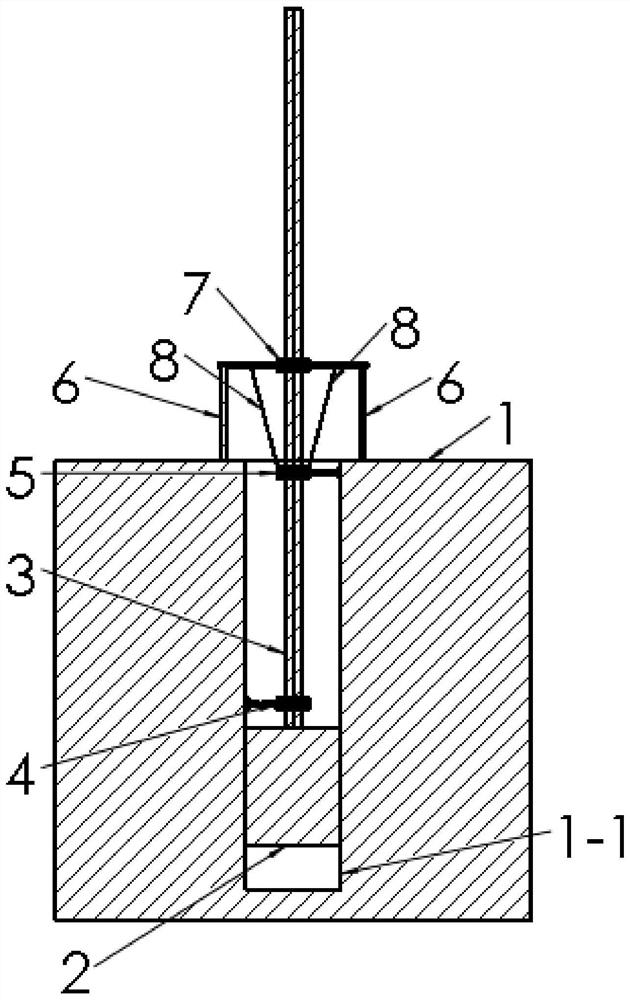

[0054] Implementation Example 1: Reference Figure 1 to Figure 7 , in order to ensure that the pile hole 1-1 is not inclined without increasing the cost and slowing down the progress of the project, the invention provides a method for rectifying the deviation of the pile foundation in the soil layer, and the method includes the following steps:

[0055] S01, drilling initial pile holes on soil layer 1;

[0056] S02, rotate and connect the first telescopic mechanism 4 and the second telescopic mechanism 5 at the drill pipe 3, the first telescopic mechanism 4 is perpendicular to the drill pipe 3, the second telescopic mechanism 5 is perpendicular to the drill pipe 3, and the second telescopic mechanism 5 is perpendicular to the first telescopic mechanism 5. The expansion and contraction directions of the telescopic mechanism 4 are opposite and parallel, and both the first telescopic mechanism 4 and the second telescopic mechanism 5 are located in the initial pile hole;

[0057] S0

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap