Shell stripping device and method for crushing shells of bamboo shoots

A bamboo shoot and shell crushing technology, which is applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of unfavorable configuration and use of family workshops, and the large space occupied by the bamboo shoot device, so as to achieve compact structure, bamboo shoot meat Complete and clean, high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

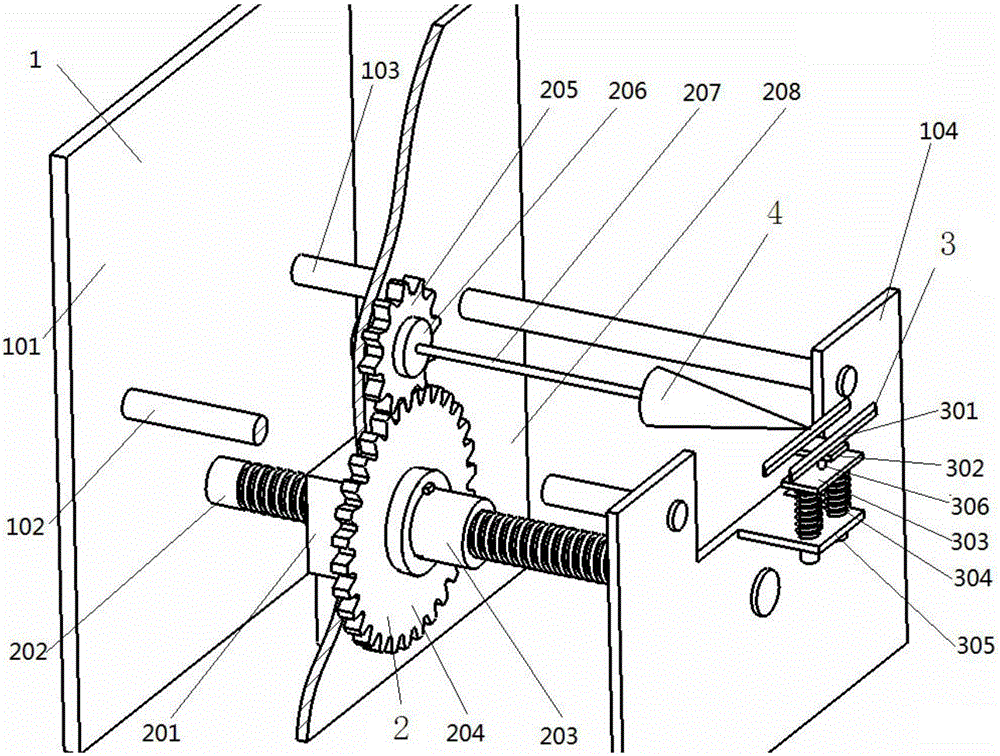

[0021] A kind of shelling device that makes the shell of bamboo shoots of present embodiment, as figure 1 As shown, it includes a large support 1, a driving device 2 and a tool contact device 3 that make the bamboo shoots rotate and produce reciprocating motion; wherein the large support 1 includes two left vertical plates 101 and right vertical plates 104 installed in parallel; The driving device 2 includes a small frame 208, a hollow motor 201 is installed on one side of the small frame 208, a reciprocating lead screw 202 is movably installed between the left vertical plate 101 and the right vertical plate 104, and the A lead screw nut 203 is installed between the reciprocating lead screw 202 and the small frame 208, and the lead screw nut 203 can freely rotate around its axis relative to the small frame 208; and the described lead screw nut 203 is connected with the hollow motor 201; A large gear 204 is installed between the other side of the small shelf 208 and the lead screw

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap