Velour-like pile articles and pile surface structures and methods of making

a technology of pile articles and pile surfaces, applied in the direction of textiles and paper, synthetic resin layered products, floor coverings, etc., can solve the problems of high carpet cost, large amount of pile yarn, and separation of tufts, and achieves low torsional stability, good elasticity, and easy guide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Moldable Automotive Construction Based on Thermoplastic Backing and Strand

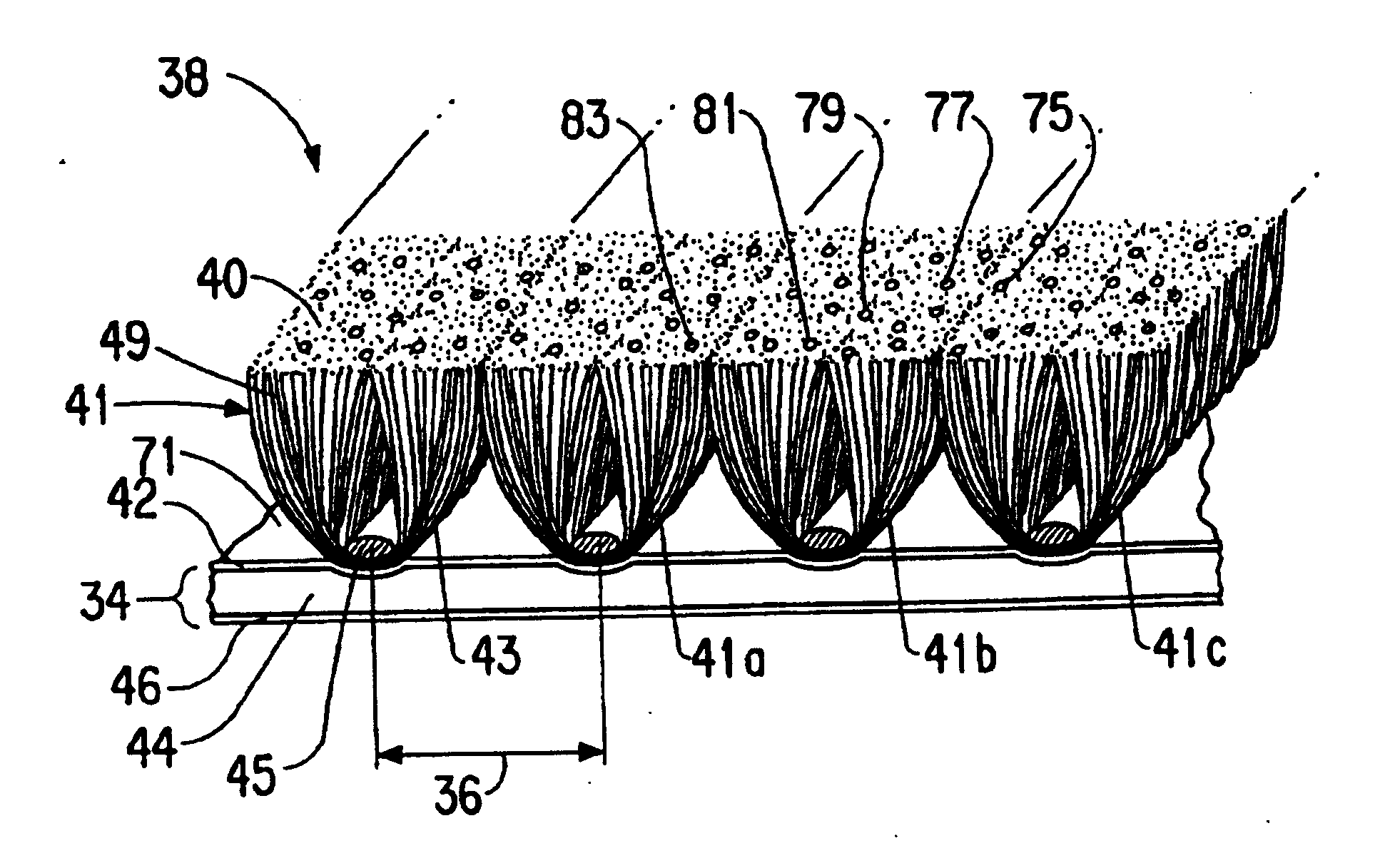

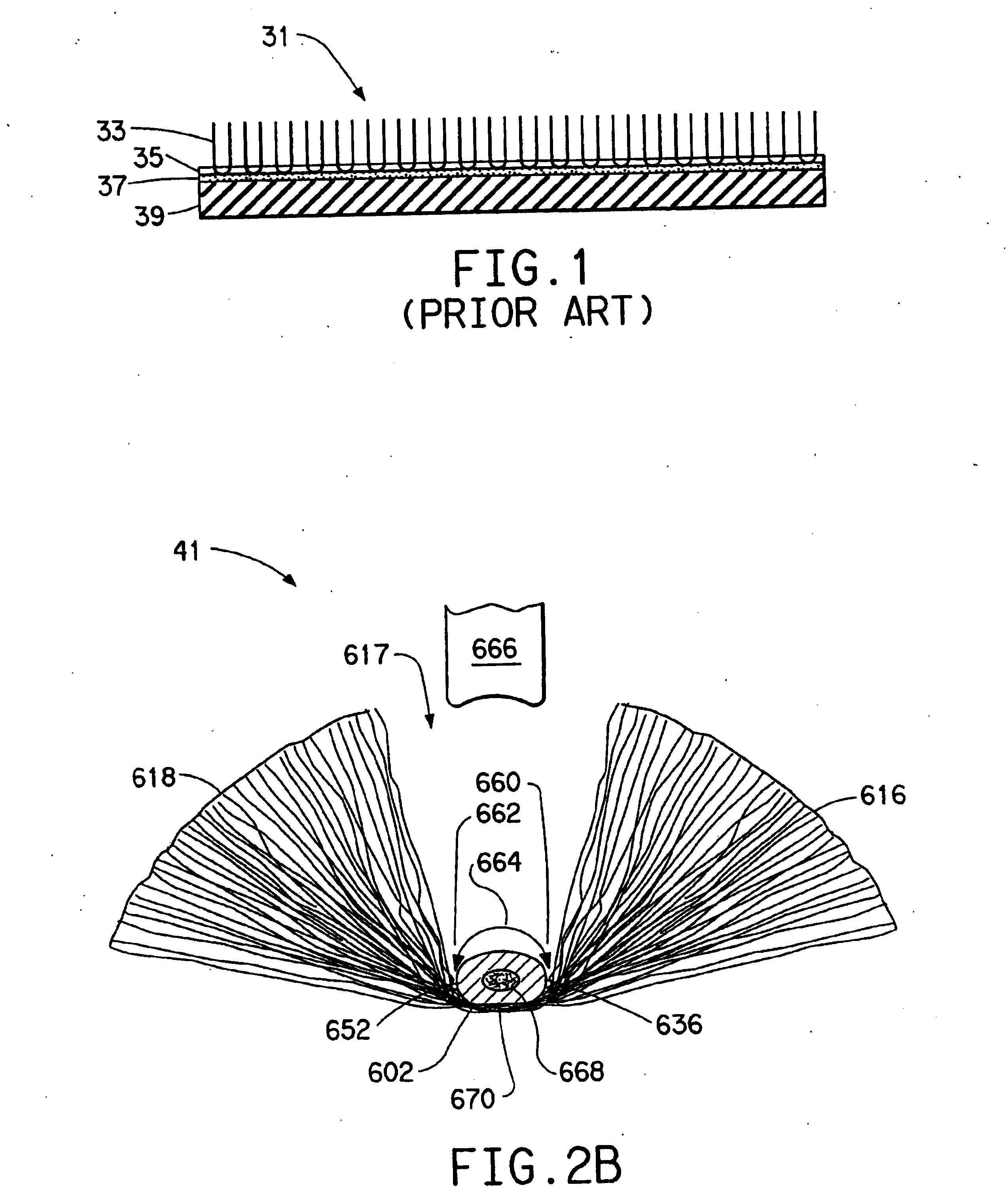

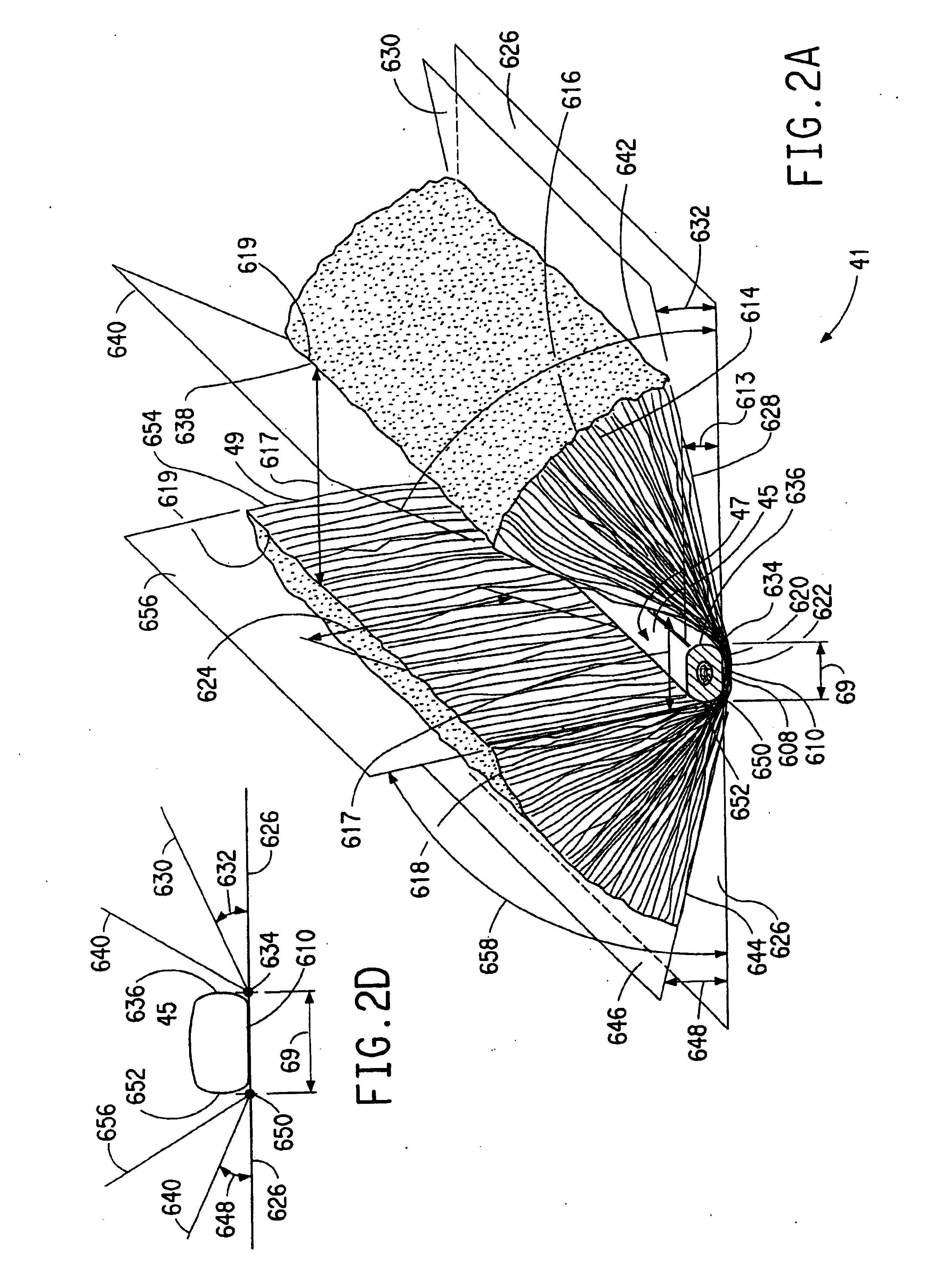

[0135] A carpet structure was fabricated in the following manner: first, a tuftstring was fabricated on a triangular mandrel similar to that shown in FIGS. 5 and 6. The tuftstring was formed at 1.8 meters (2 yards) per minute by wrapping two strands of 1546 dtex total (1405 total denier), producer colored, bulked continuous multifilament nylon 6,6 yarn, produced commercially by the E. I. du Pont de Nemours and Company, around the triangular mandrel. A monofilament sheath / core strand was used for the tuftstring strand. The ultrasonic power used to bond the pile yarn to the strand was 30 watts and the ultrasonic tool loading on a 19.1 mm ({fraction (3 / 4)} inch) long tool was approximately 10,500 kg / sq m (15 psi). There were 10.2 (26) single wraps of the 1546 dtex (1405 denier) yarn per centimeter (inch) of strand used to create the tuftstring. A disc knife cut the yarn immediately after bonding to release it

example 2

[0143] Sheath / Core of 50 / 50 wt. composition; core: Crystar 1995 polyethylene terephthalate, sheath: Capron® 1590 Nylon 6 / 66 copolymer. Approximate strand sheath melting point is one hundred sixty five (165) degrees C.

example 3

[0144] Nylon 6,12 monofilament comprising a copolymer of nylon 6,12 / Novolac / Capron® 1590 (60 / 20 / 20% by weight, respectively). The Novolac is a poly-phenol polymer additive available from Schenectady Chemical Co. and is useful in this blend to lower the melt temperature and improve adhesion of nylon 6,12 in the strand to the nylon 6,6 pile yarn. Approximate strand melting point is two hundred fifteen (215) degrees C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap