Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about "Yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

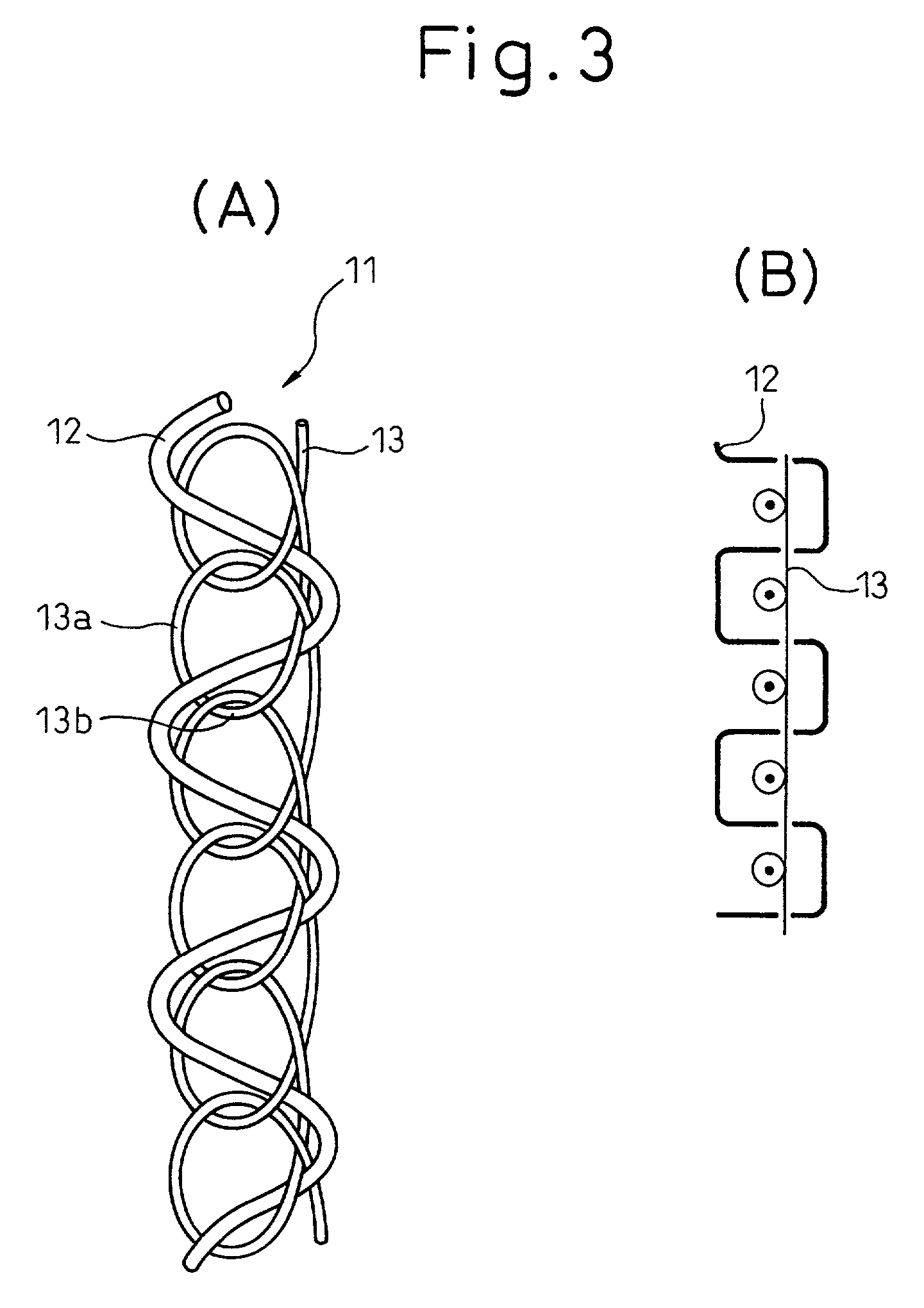

Polytrimethylene terephtalate conjugate fiber and method of preparing the same

InactiveUS20050233140A1Filament/thread formingConjugated synthetic polymer artificial filamentsPolytrimethylene terephthalatePolyethylene terephtalate

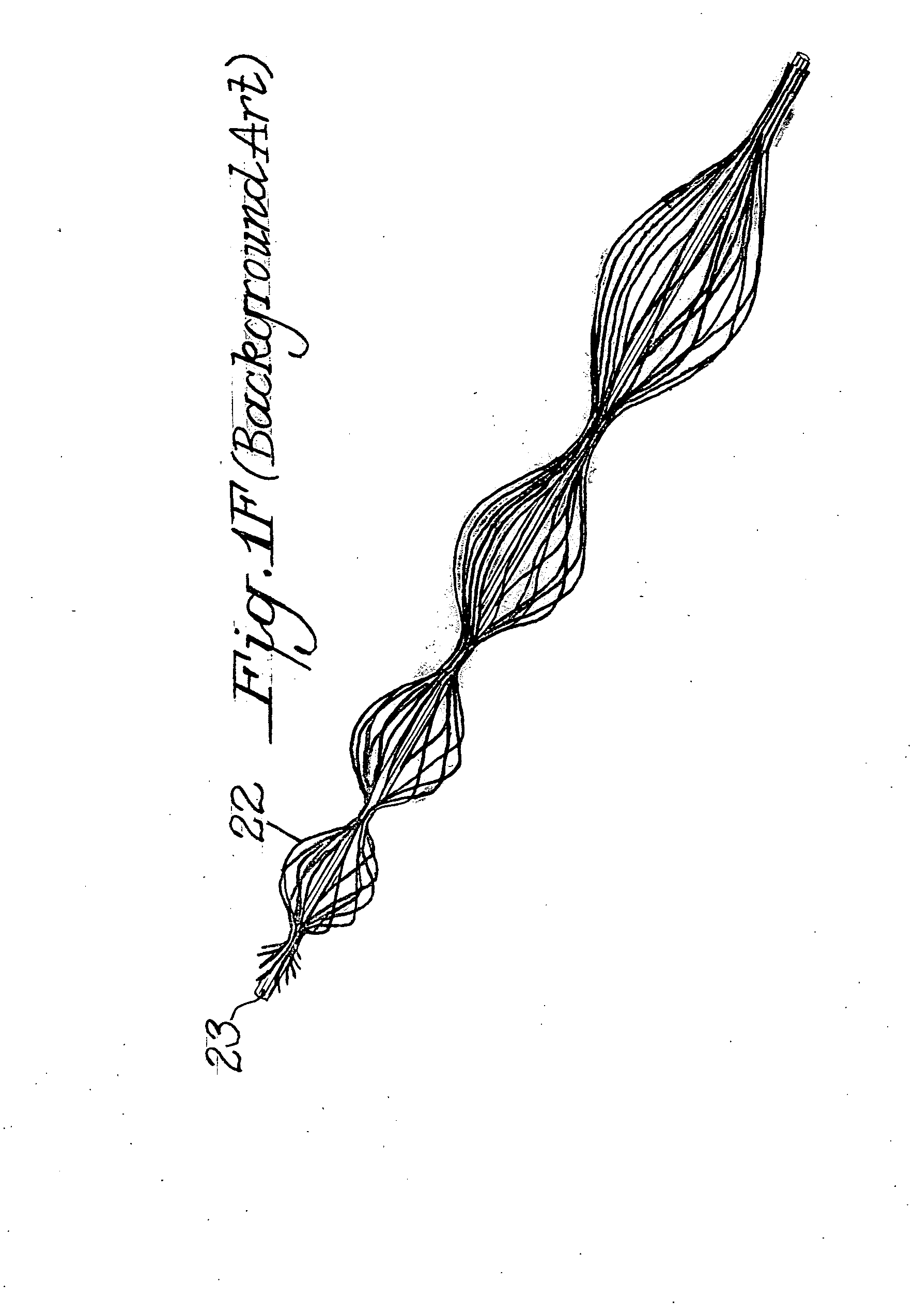

Disclosed is a polytrimethylene terephtalate conjugate fiber having high self-crimpability, which is prepared by conjugate-spinning two types of polytrimethylene terephtalates having different intrinsic viscosities in which a difference between the intrinsic viscosities ranges from 0.05 to 0.15 into a side-by-side fiber. Also, the polytrimethylene terephtalate conjugate fiber prepared by the conjugate-spinning undergoes a false twisting process, leading to development of three-dimensional high self crimpability and sufficient bulky property in the resulting fiber.

Owner:HUVIS CORP

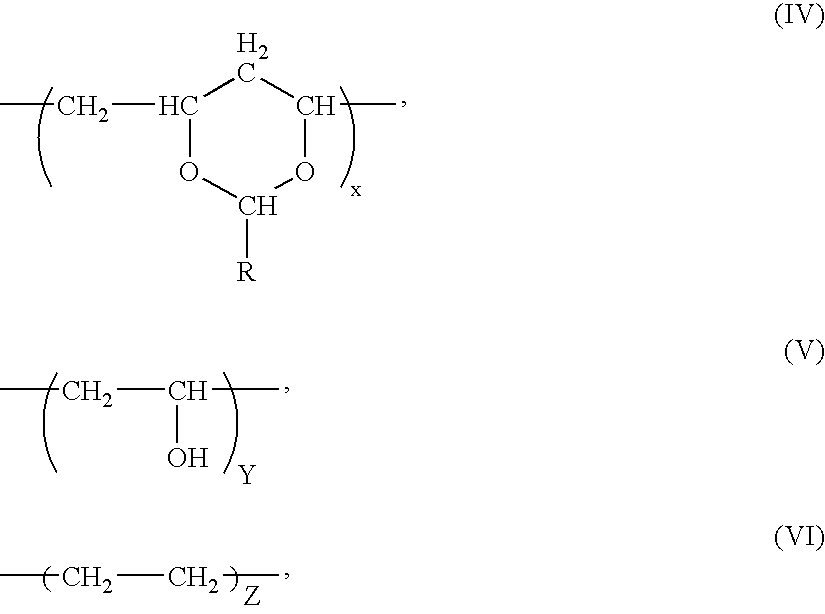

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

Owner:EI DU PONT DE NEMOURS & CO

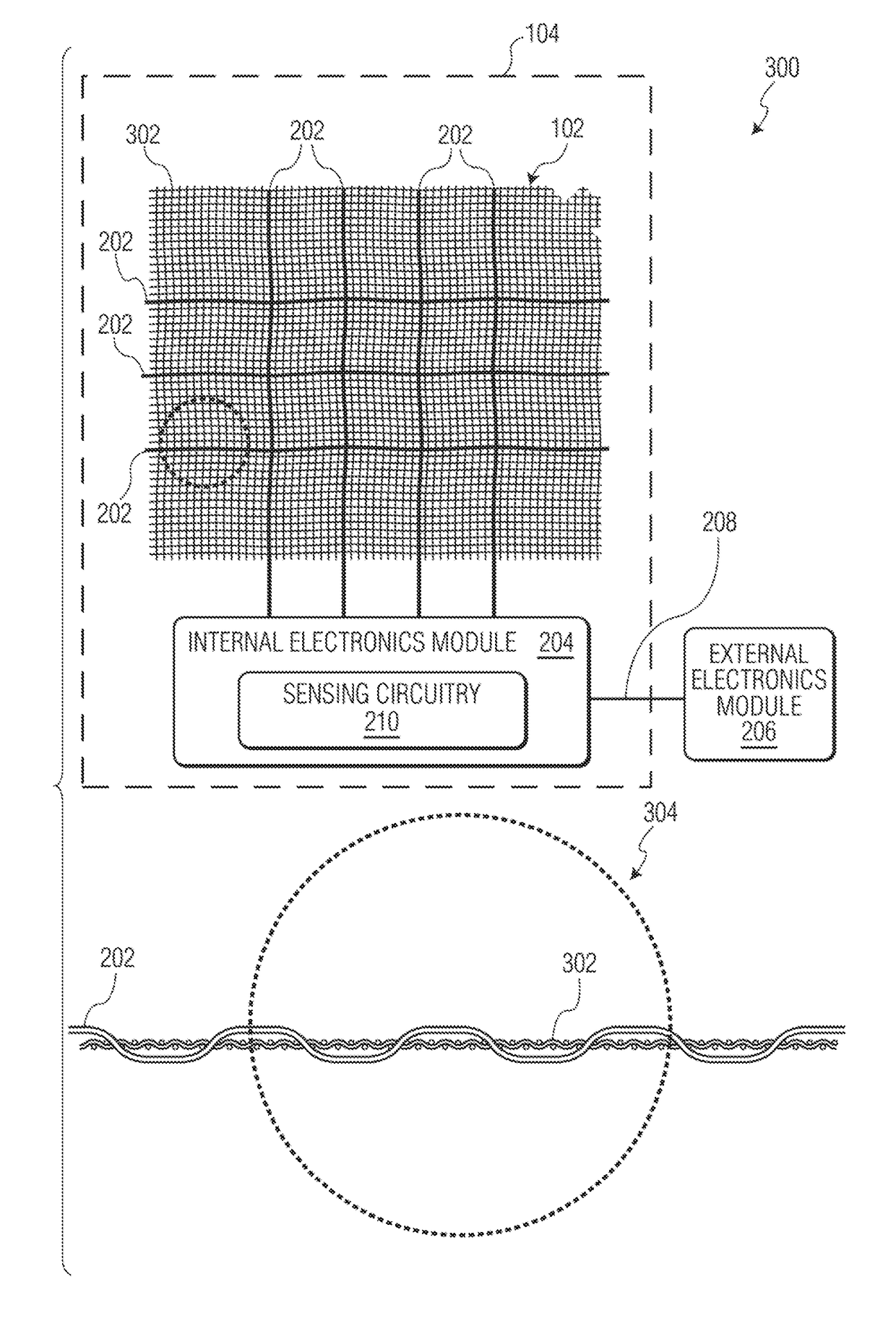

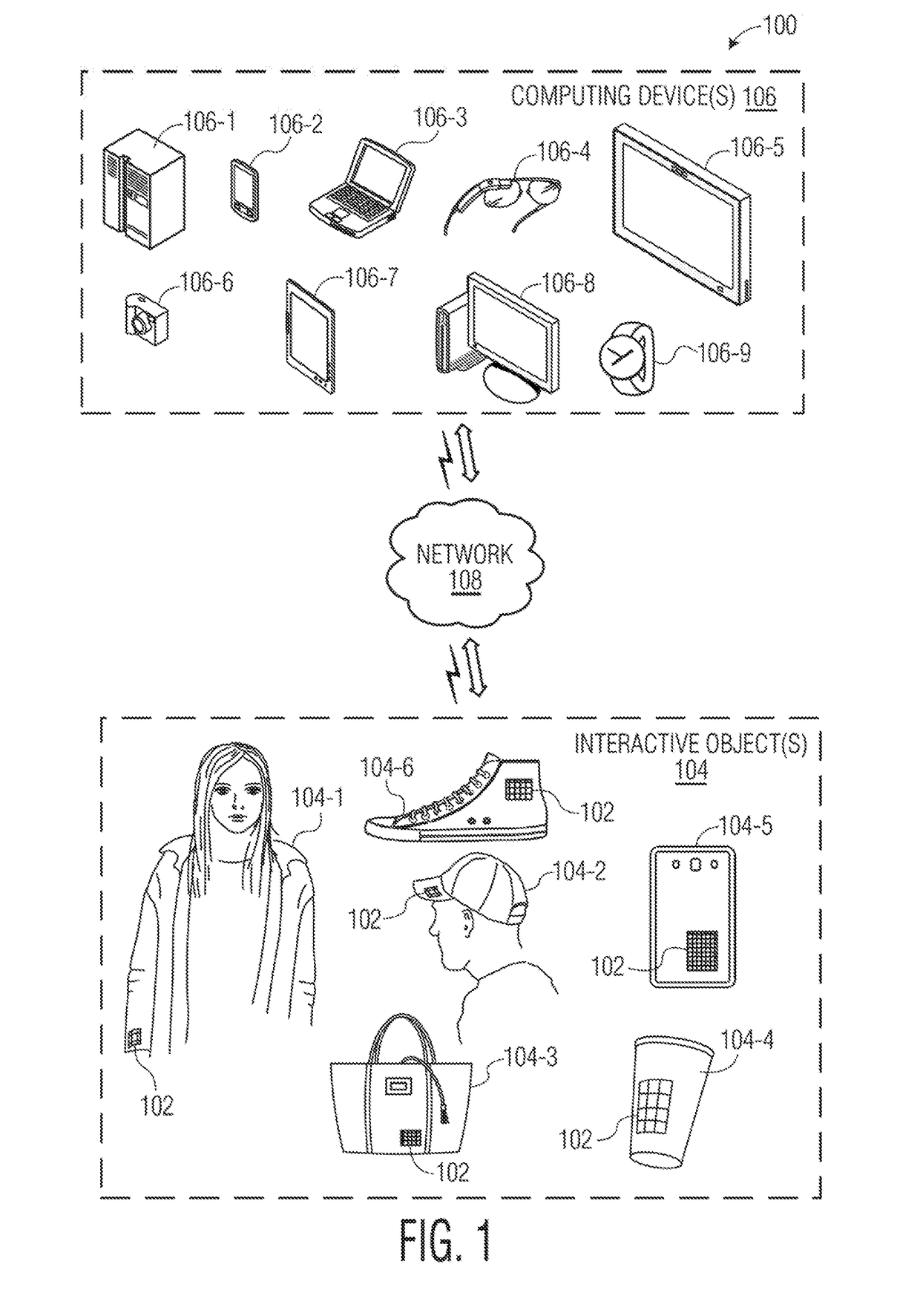

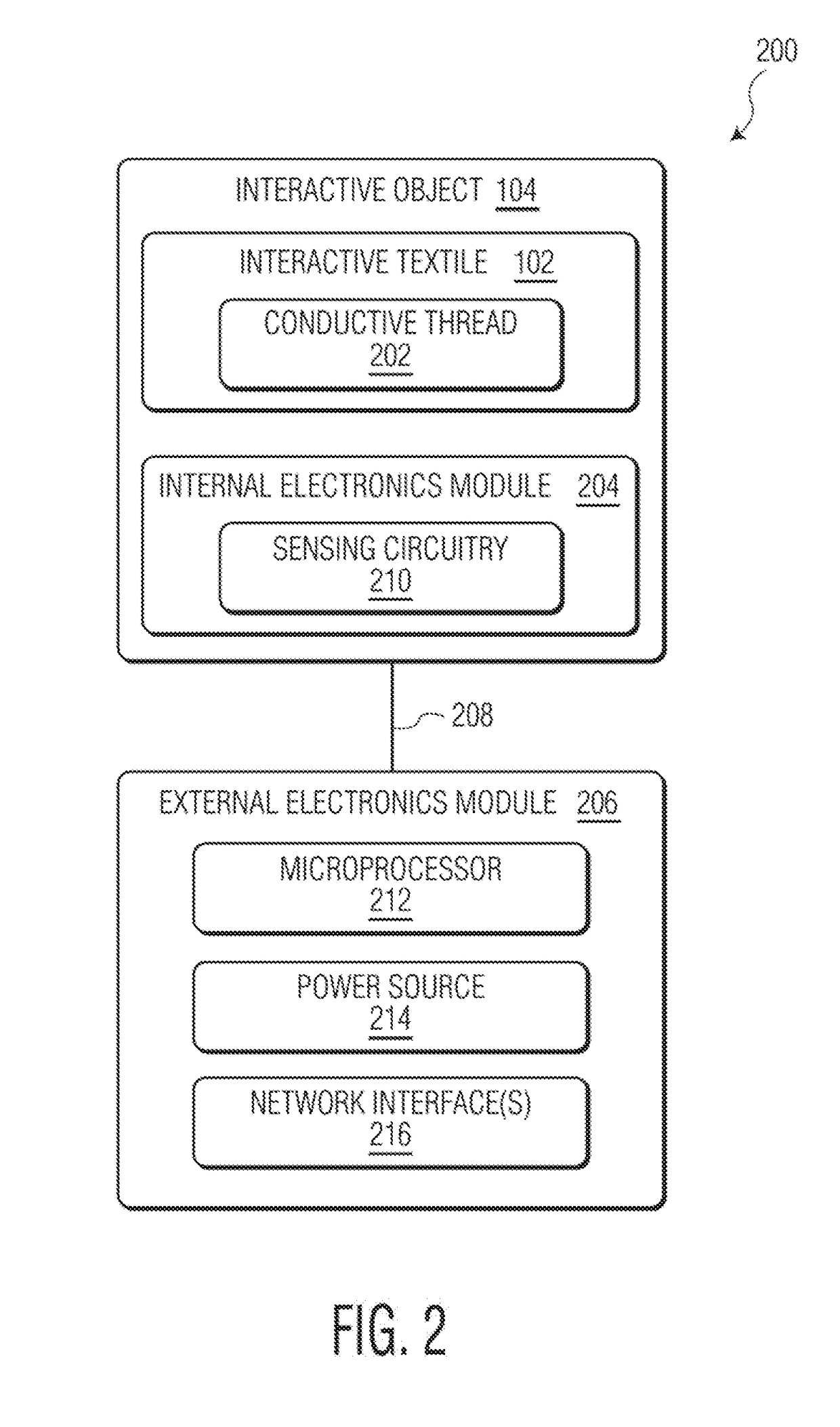

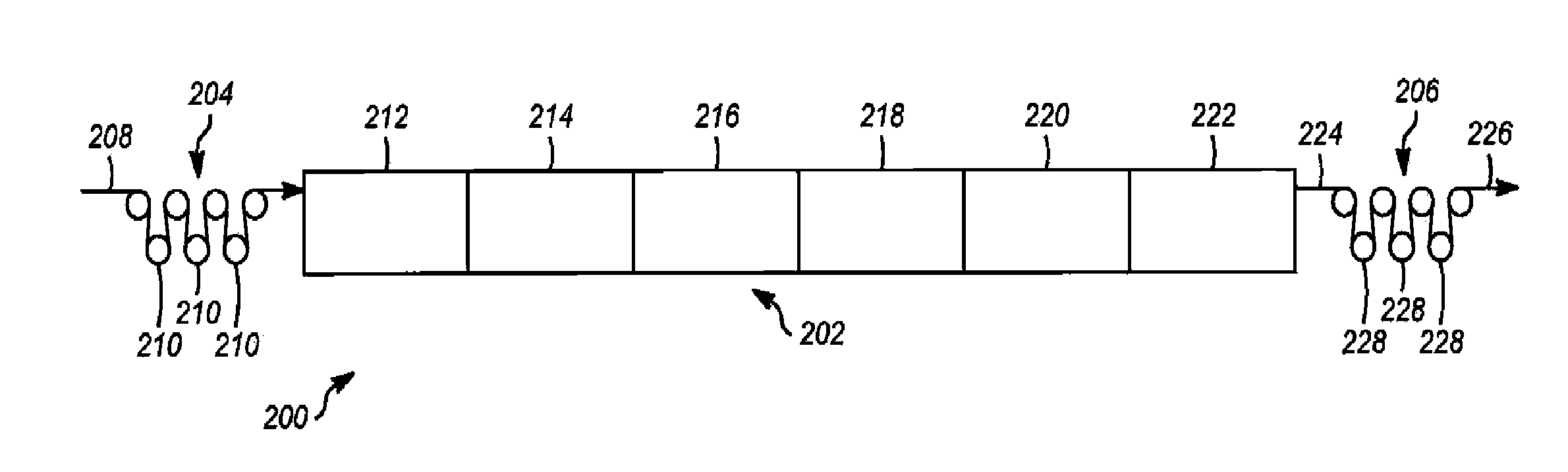

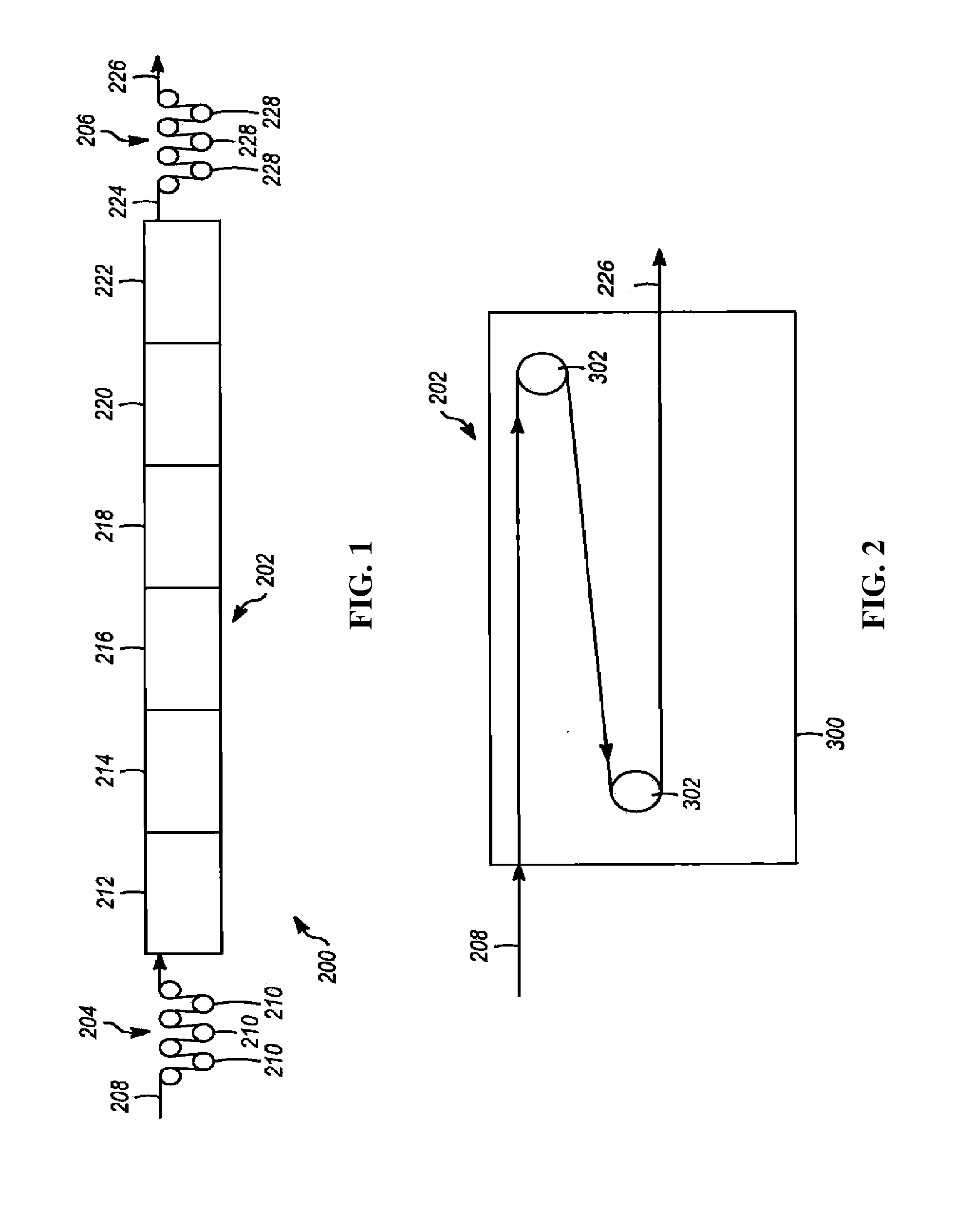

Connector Integration for Smart Clothing

ActiveUS20180260052A1Provide strain reliefPrinted circuit aspectsOvergarmentsCommunication interfaceComputer module

Owner:GOOGLE LLC

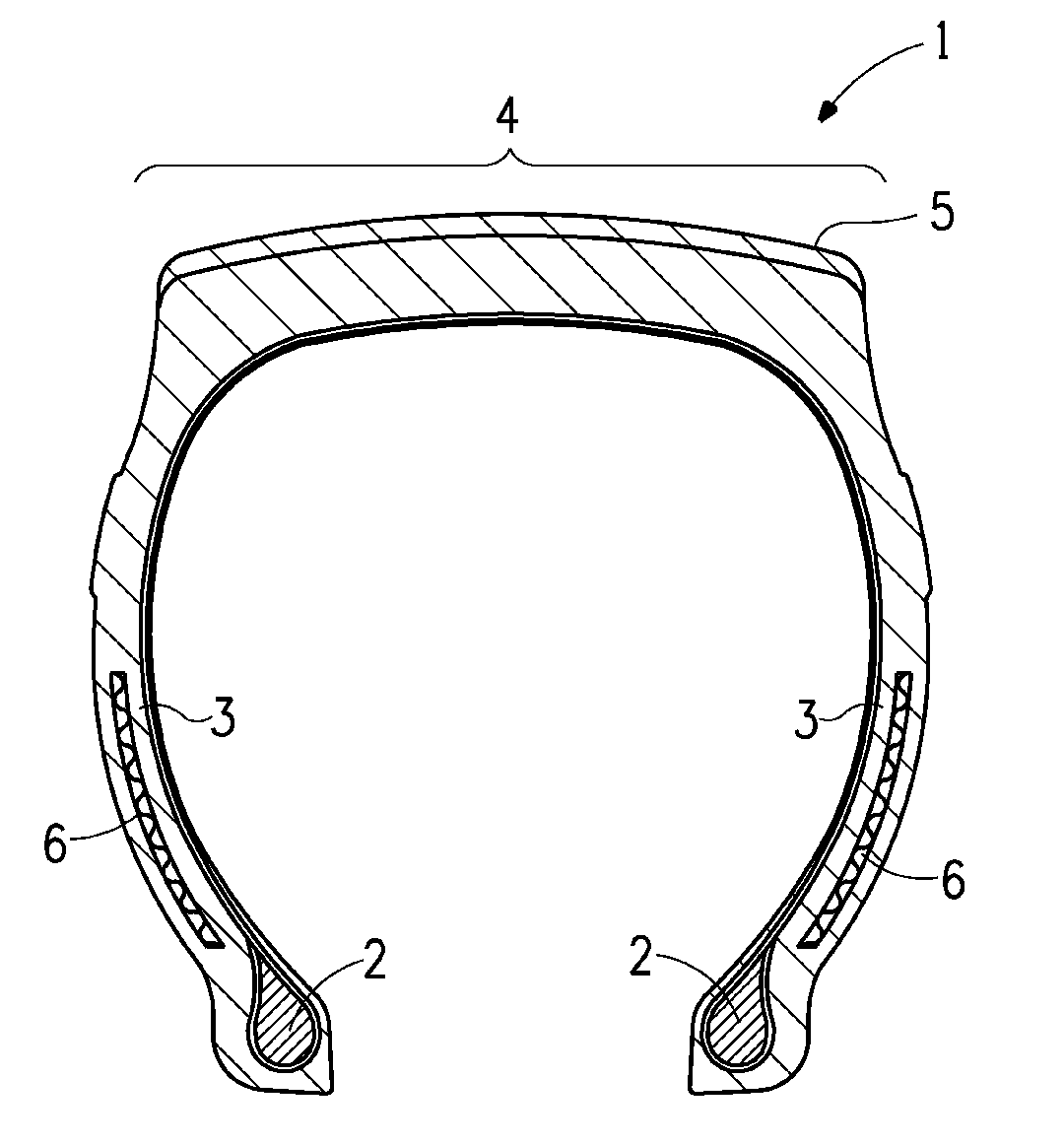

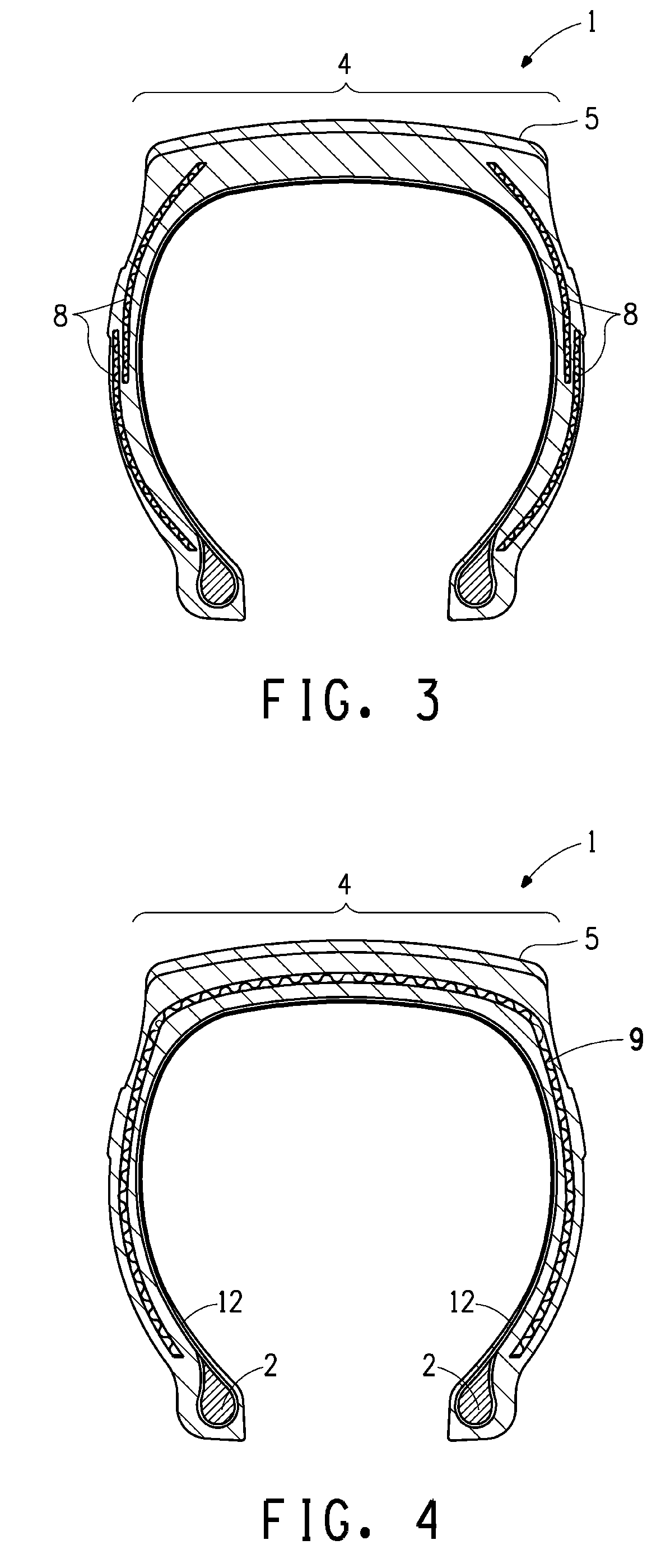

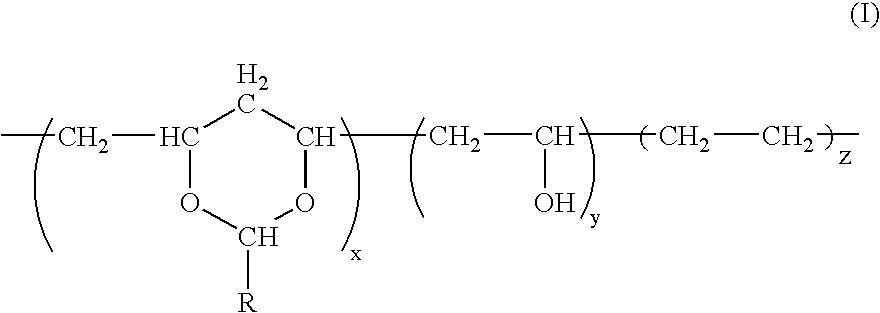

Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same

InactiveUS20100108218A1Improved adhesion of fabricLayered productsPneumatic tyre reinforcementsYarnFiber

Owner:EI DU PONT DE NEMOURS & CO +1

Novel uhmwpe fiber and method to produce

Owner:HONEYWELL INT INC

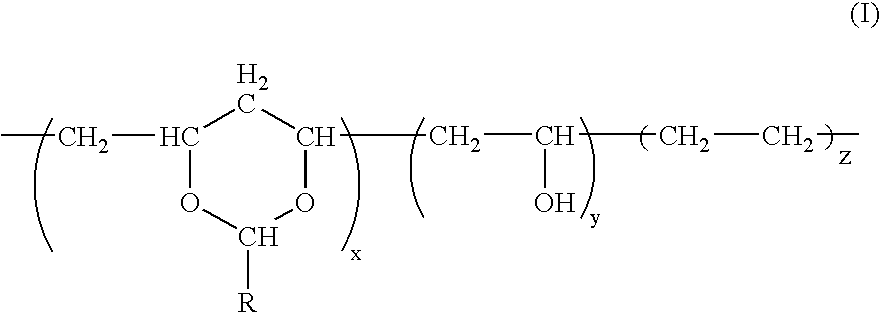

Enhanced oxygen barrier performance from modification of ethylene vinyl alcohol copolymers (EVOH)

Owner:CRYOVAC INC

Cashmere and stretched wool blended yarn and manufacturing method thereof

Owner:CONSINEE GRP CO LTD

Size-covered composite yarns and method for making same

InactiveUS20050124245A1Appealing tactile propertyIncrease speedWarp knittingSynthetic resin layered productsYarnFiber

Owner:INVISTA NORTH AMERICA R L

Method for producing high-count yarns from vinylon and polyester fibers, and cotton by blending

Owner:JIHUA 3509 TEXTILE

Fabric with water absorption and air permeability and production method thereof

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Skin-care permanently-antibacterial DP finishing liquid for shirts and finishing method

InactiveCN106436329AImprove antibacterial propertiesGood non-ironing effectBiochemical fibre treatmentLiquid/gas/vapor removalN dimethylformamideSkin care

Owner:阜阳市豹子头服饰科技有限公司

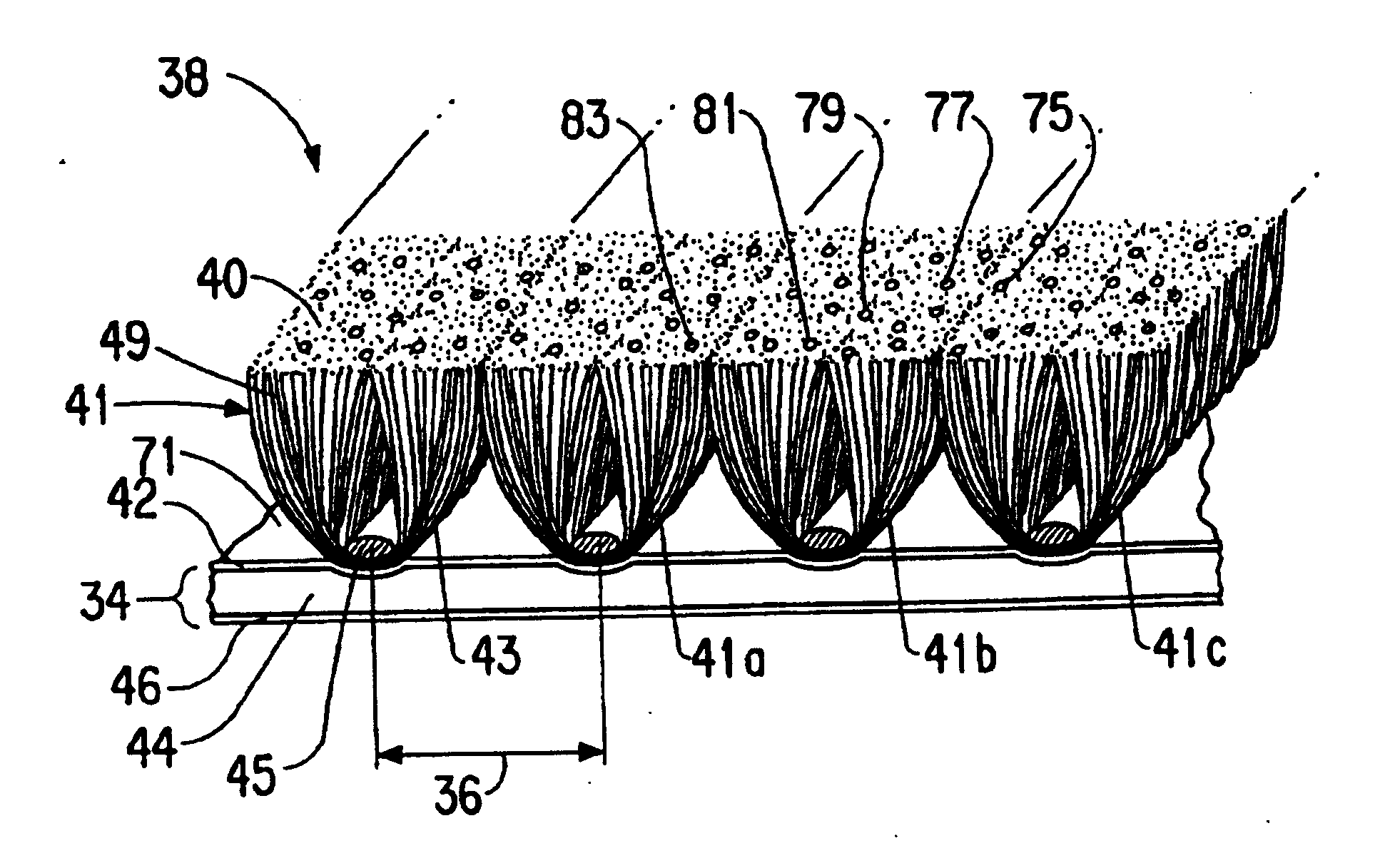

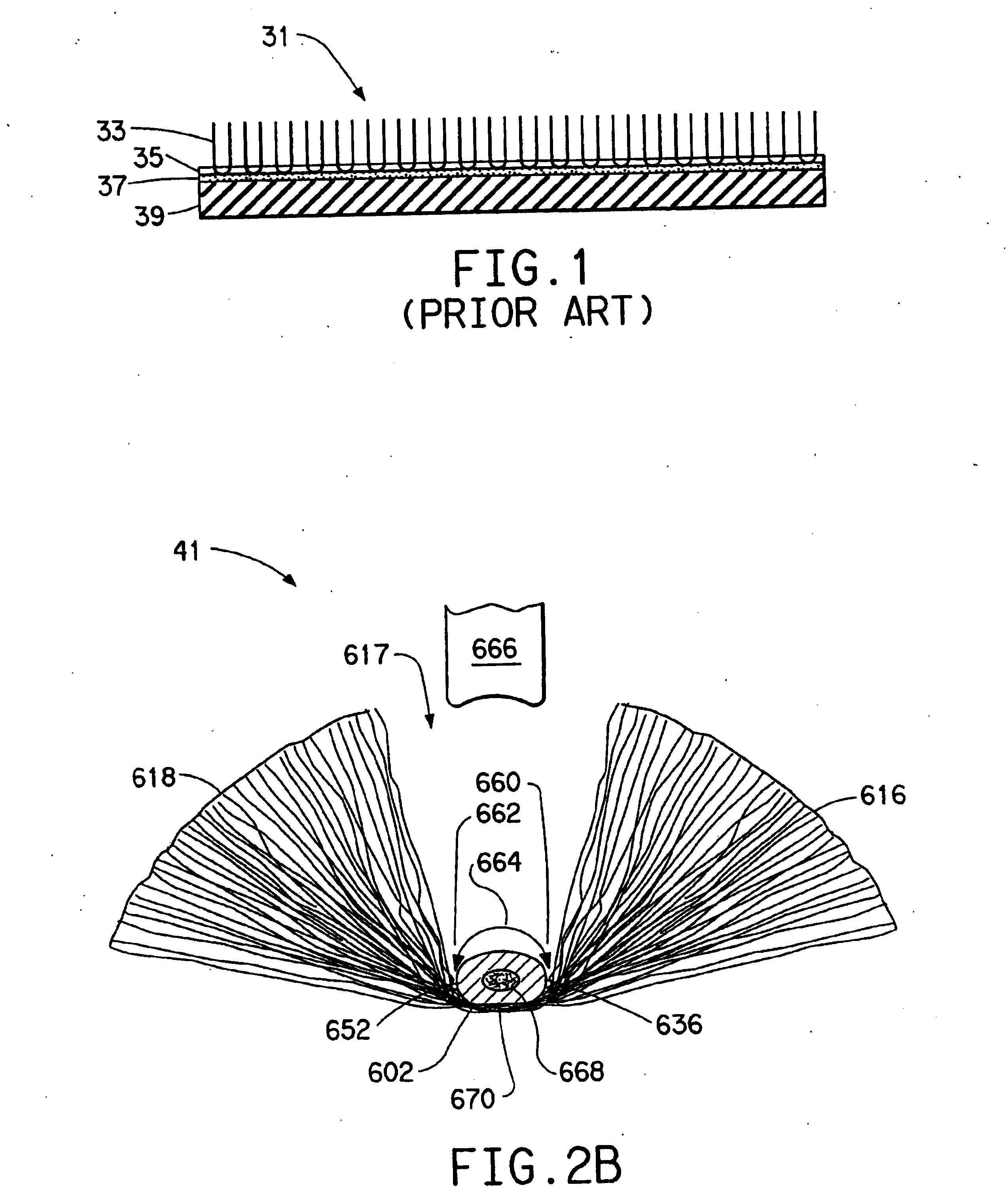

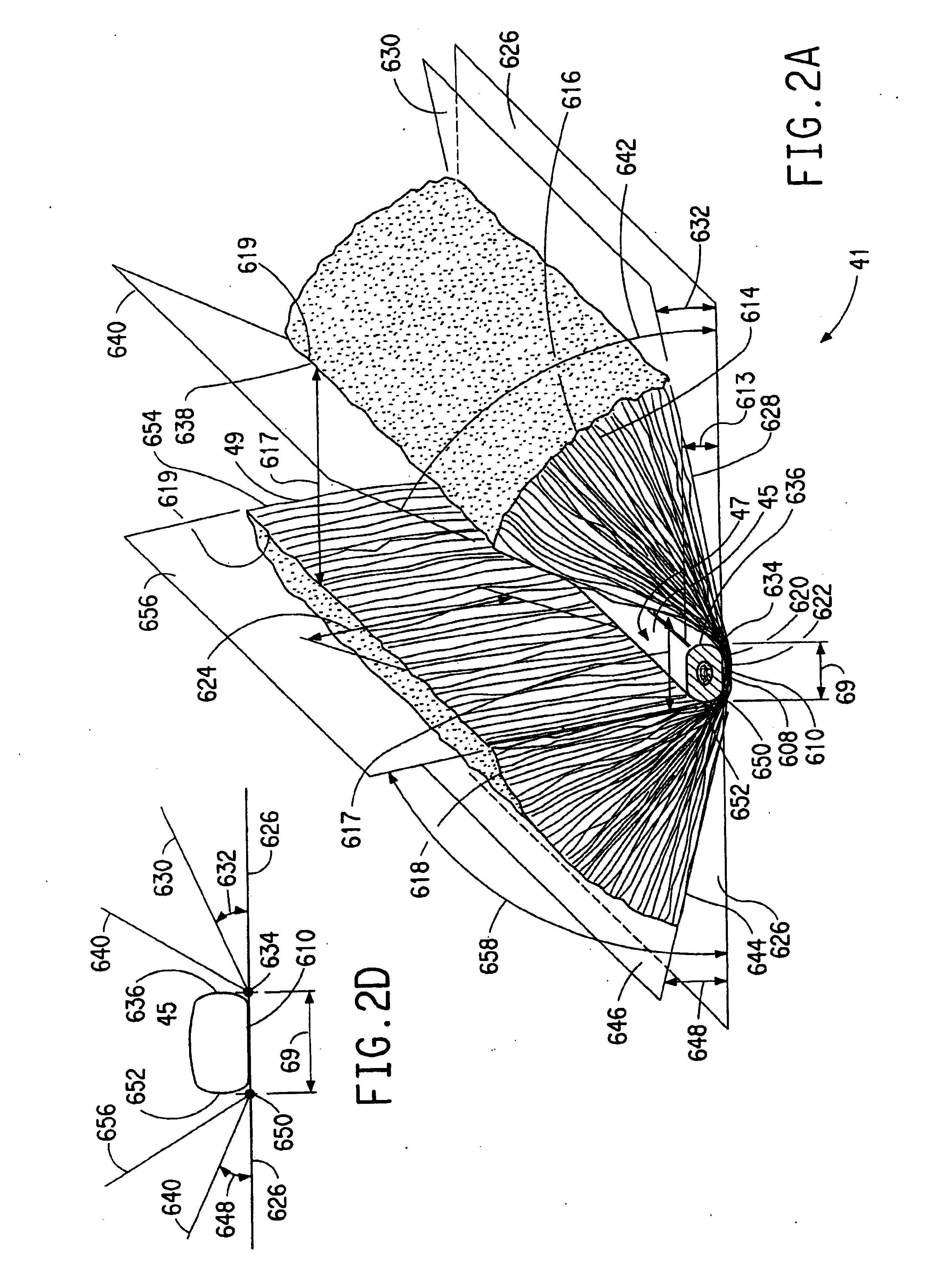

Velour-like pile articles and pile surface structures and methods of making

InactiveUS20050129905A1Convenient guidanceLittle torsional stabilityVehicle arrangementsSynthetic resin layered productsYarnStructural engineering

Owner:INVISTA NORTH AMERICA R L

Natural bamboo fibers modified by nano-cellulose whiskers and preparing method of natural bamboo fibers

Owner:中山华沙利科技有限公司

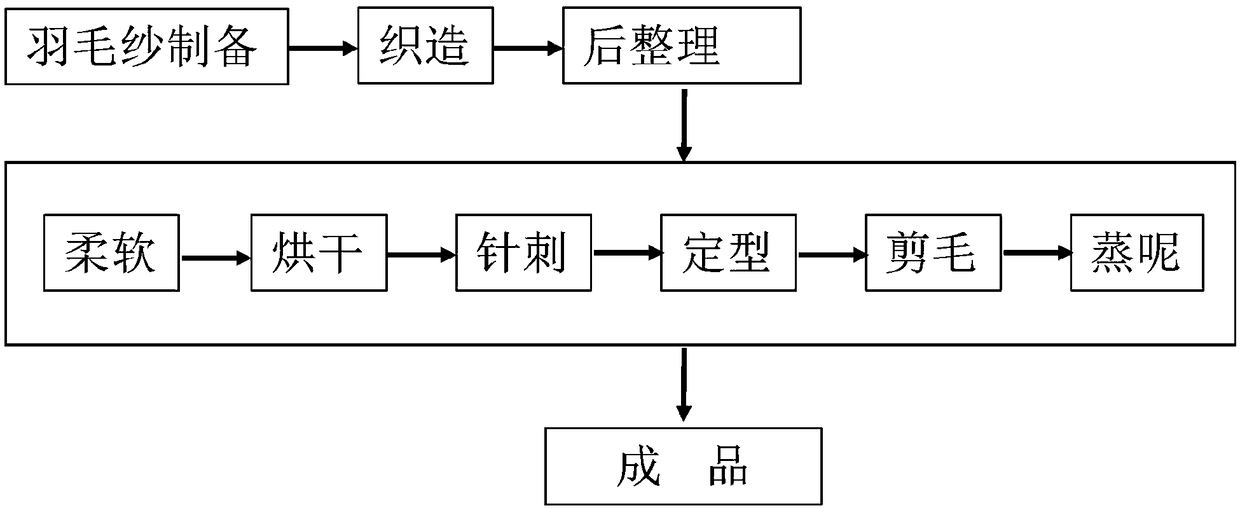

Production technology of weft-knitted flight down feather

Owner:江苏润玖纺织有限公司

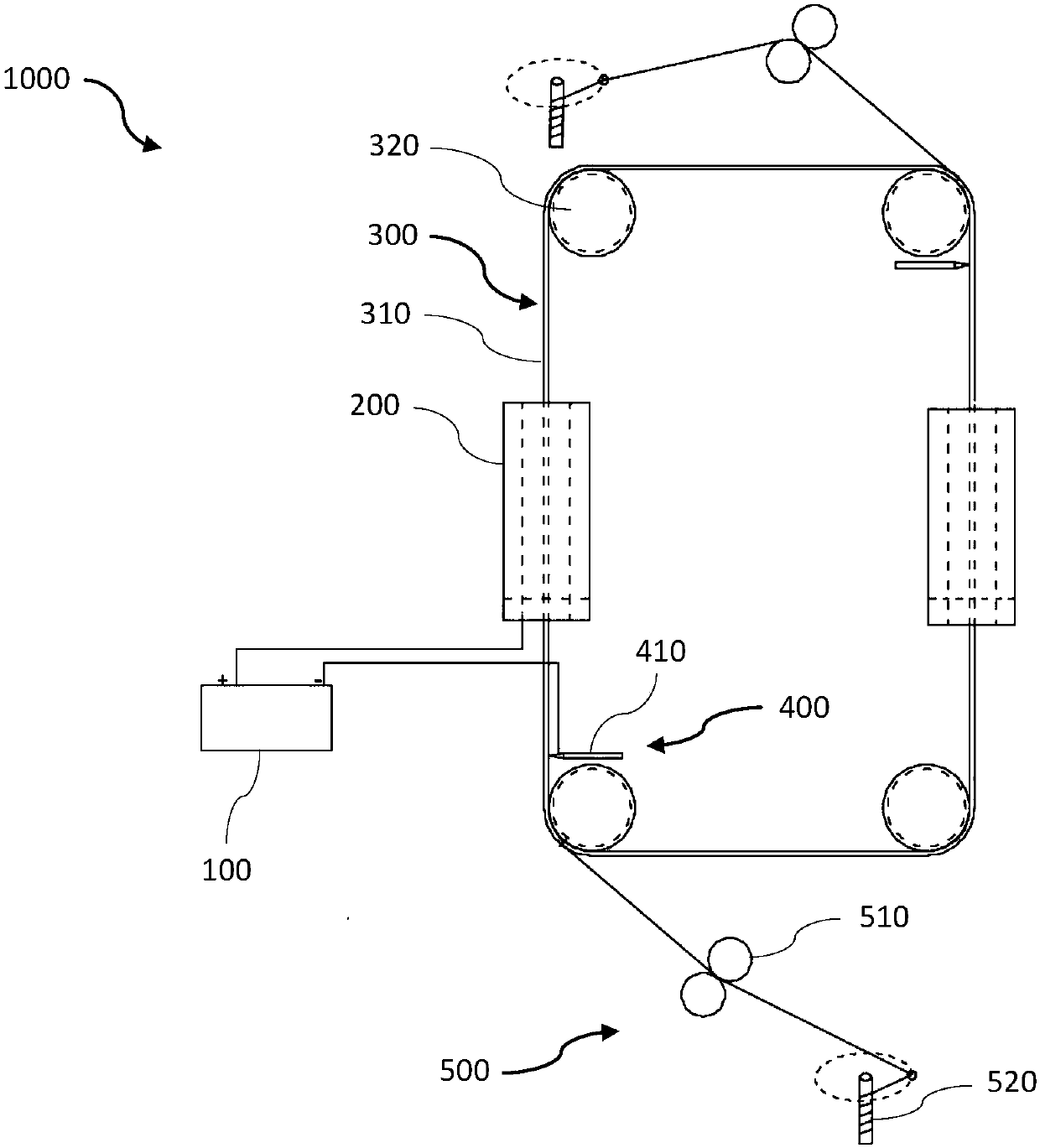

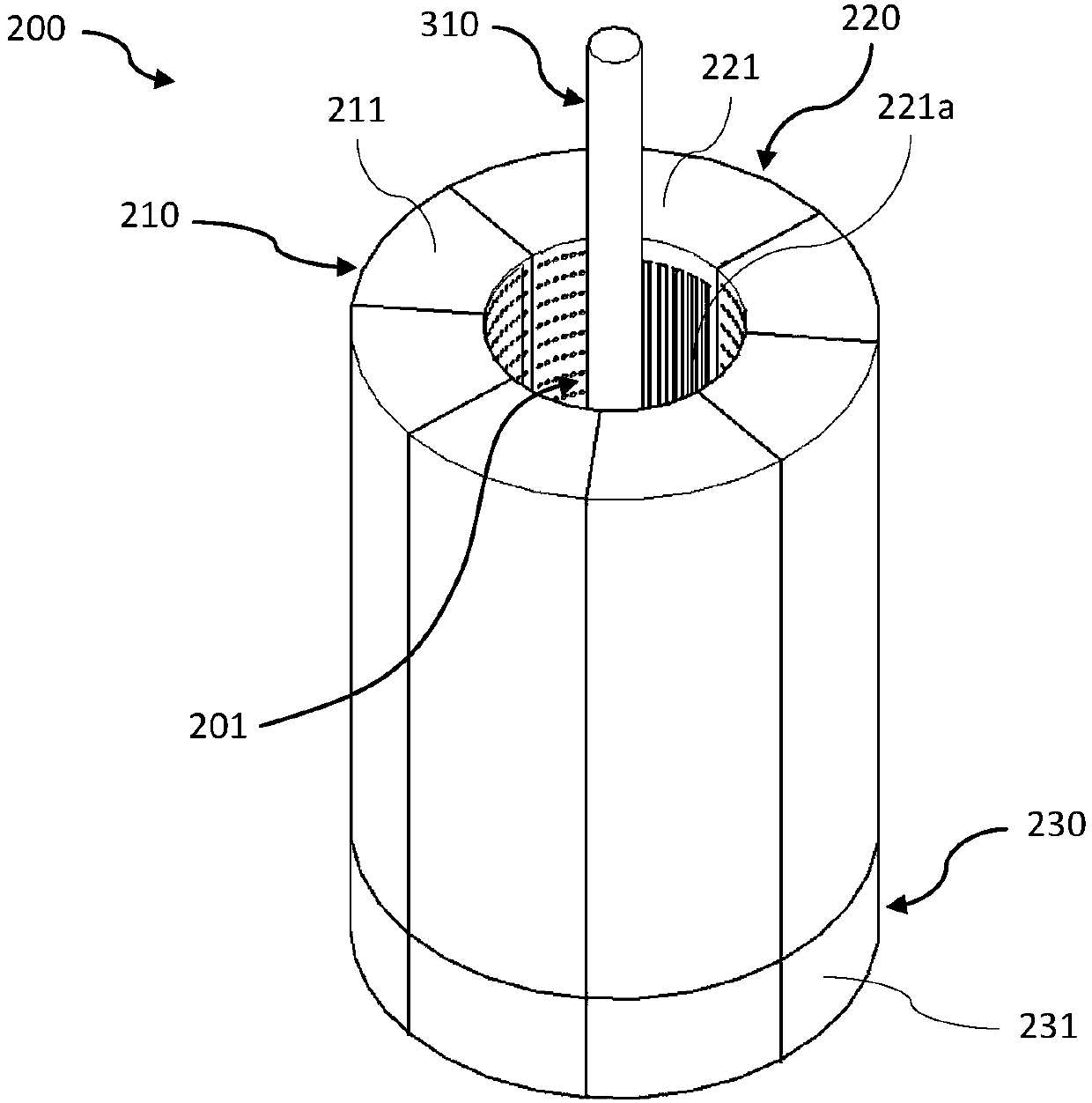

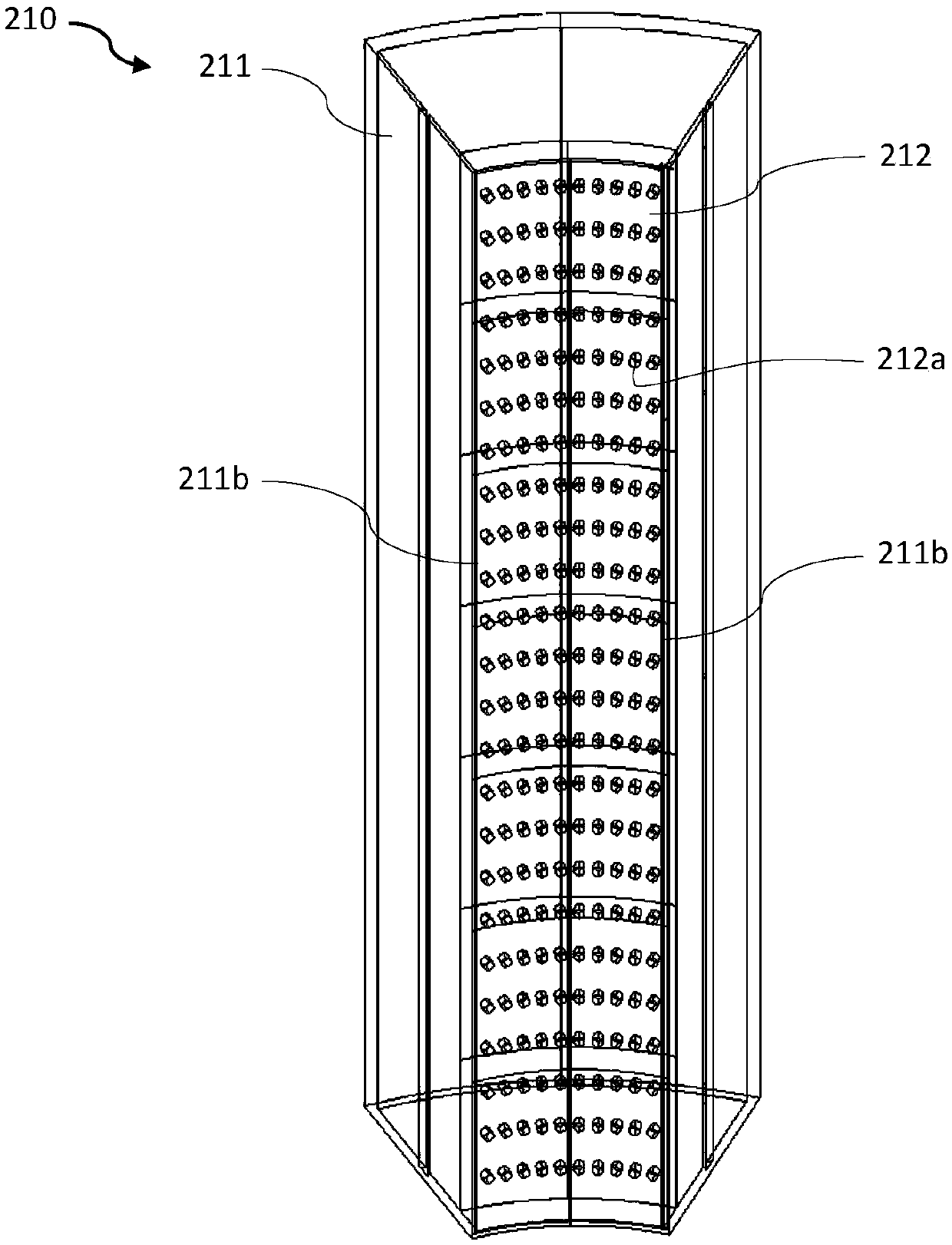

Annular-spraying electrostatic spinning machine and application

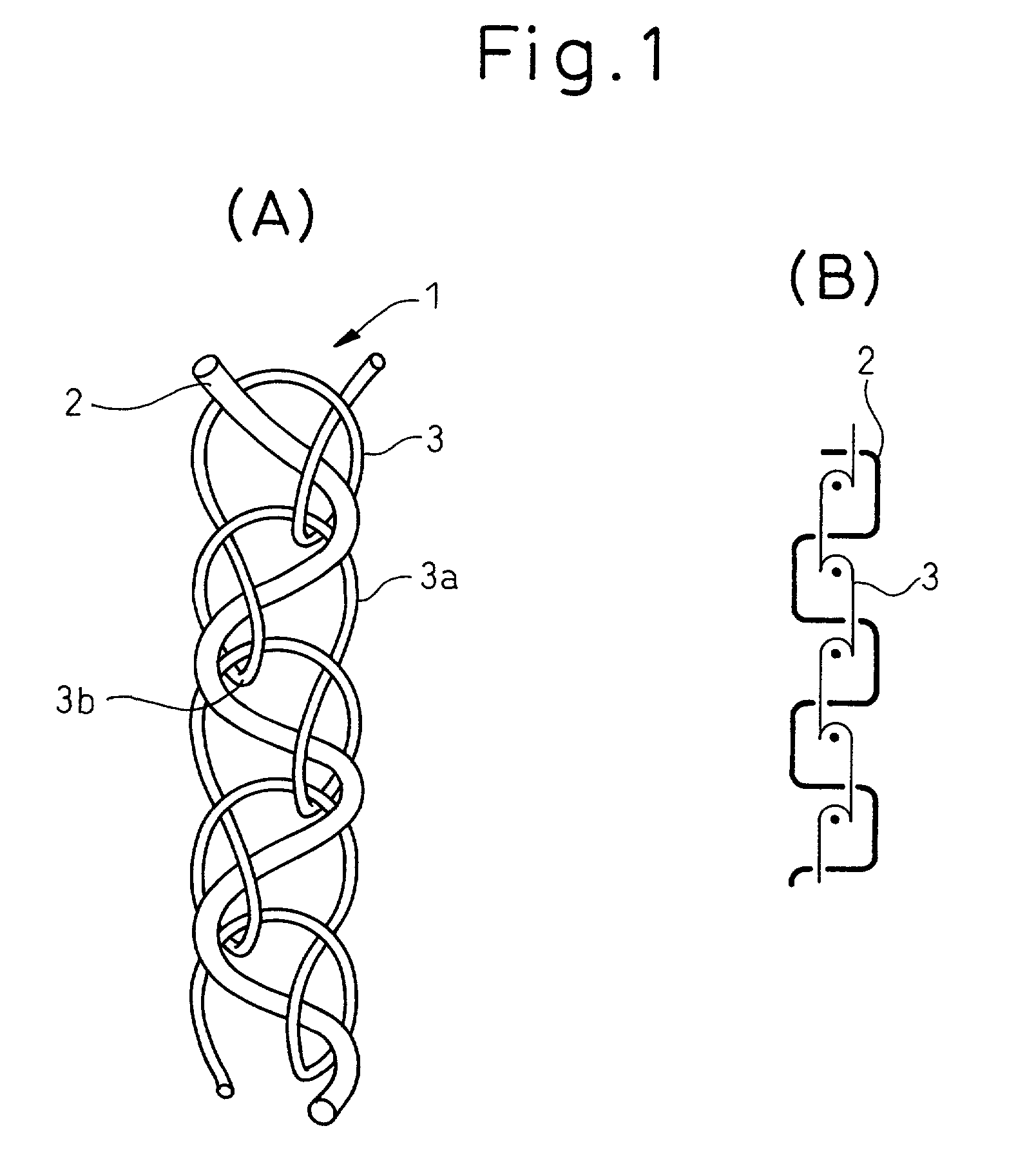

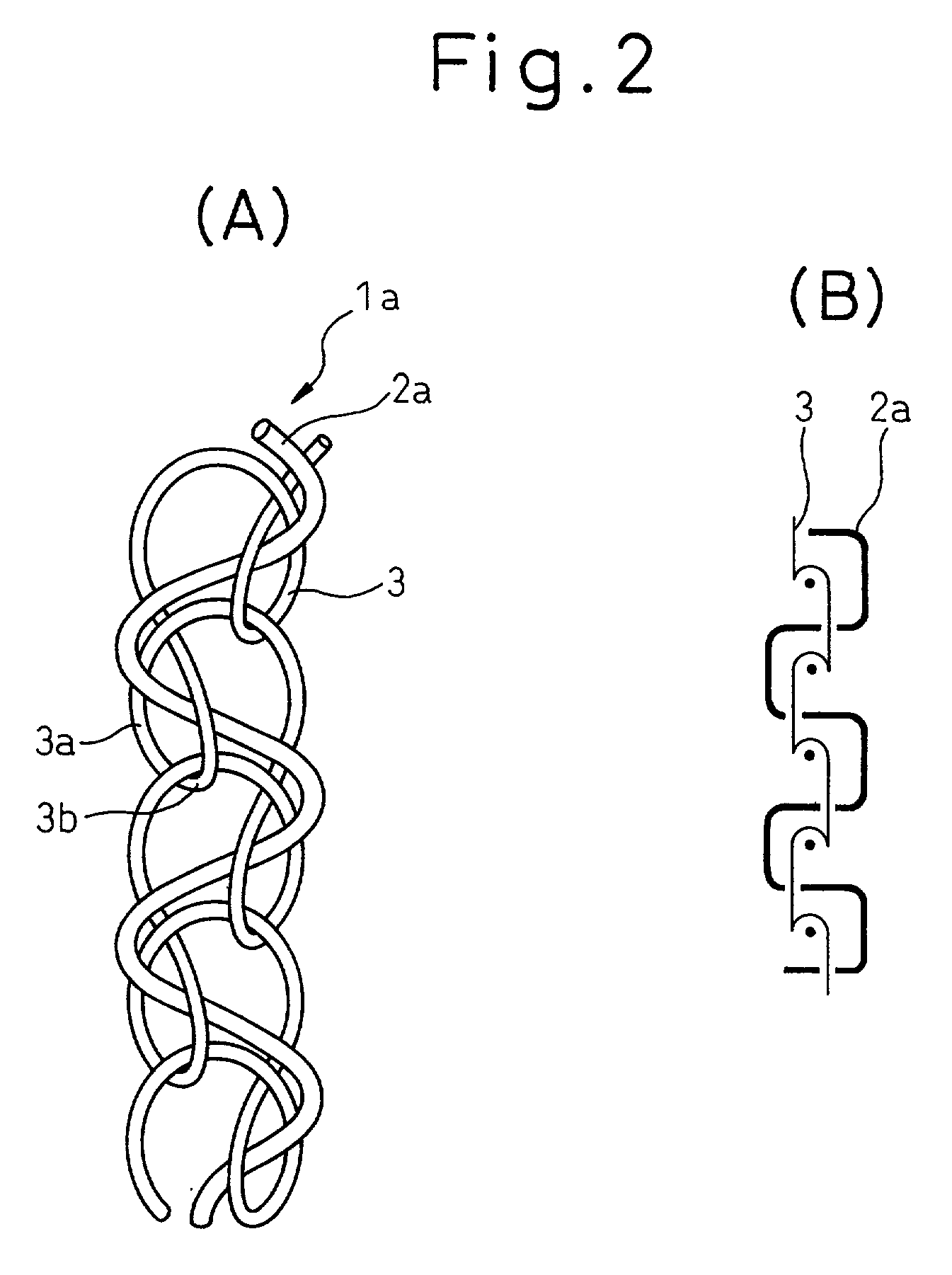

InactiveCN107557943AIncrease diversityEase of mass productionFilament/thread formingYarnPre treatmentYarn

The invention provides an annular-spraying electrostatic spinning machine. The annular-spraying electrostatic spinning machine comprises a high-voltage direct-current power source, m thread spraying devices, a thread spraying receiver, a striping device and a traction twisting device, the thread spraying devices are mutually independent, have hollow cavities and used for performing thread sprayingon spinning liquid to form fiber, the thread spraying receiver has a receiving lead penetrating the hollow cavities and used for receiving and transferring the fiber, the striping device is used forstripping off the fiber wrapped on the receiving lead, and the traction twisting device is used for drawing and twisting the fiber striped off the receiving lead to form yarn; each thread spraying device comprises n thread spraying units and pretreatment units which are arranged in an annular closed manner to form a hollow cavity, at least thread spraying hole is formed in one sides, facing the hollow cavity, of the thread spraying units, and a positive electrode of the high-voltage direct-current power source is connected with the thread spraying units while the negative electrode of the sameis connected with the receiving lead. The invention further discloses application of the annular-spraying electrostatic spinning machine direct spinning processing of core spun yarn through electrostatic spinning.

Owner:SHANGHAI UNIV OF ENG SCI

Production method of suede elastic fabric

Owner:JIANGSU SUNSHINE GRP CO LTD

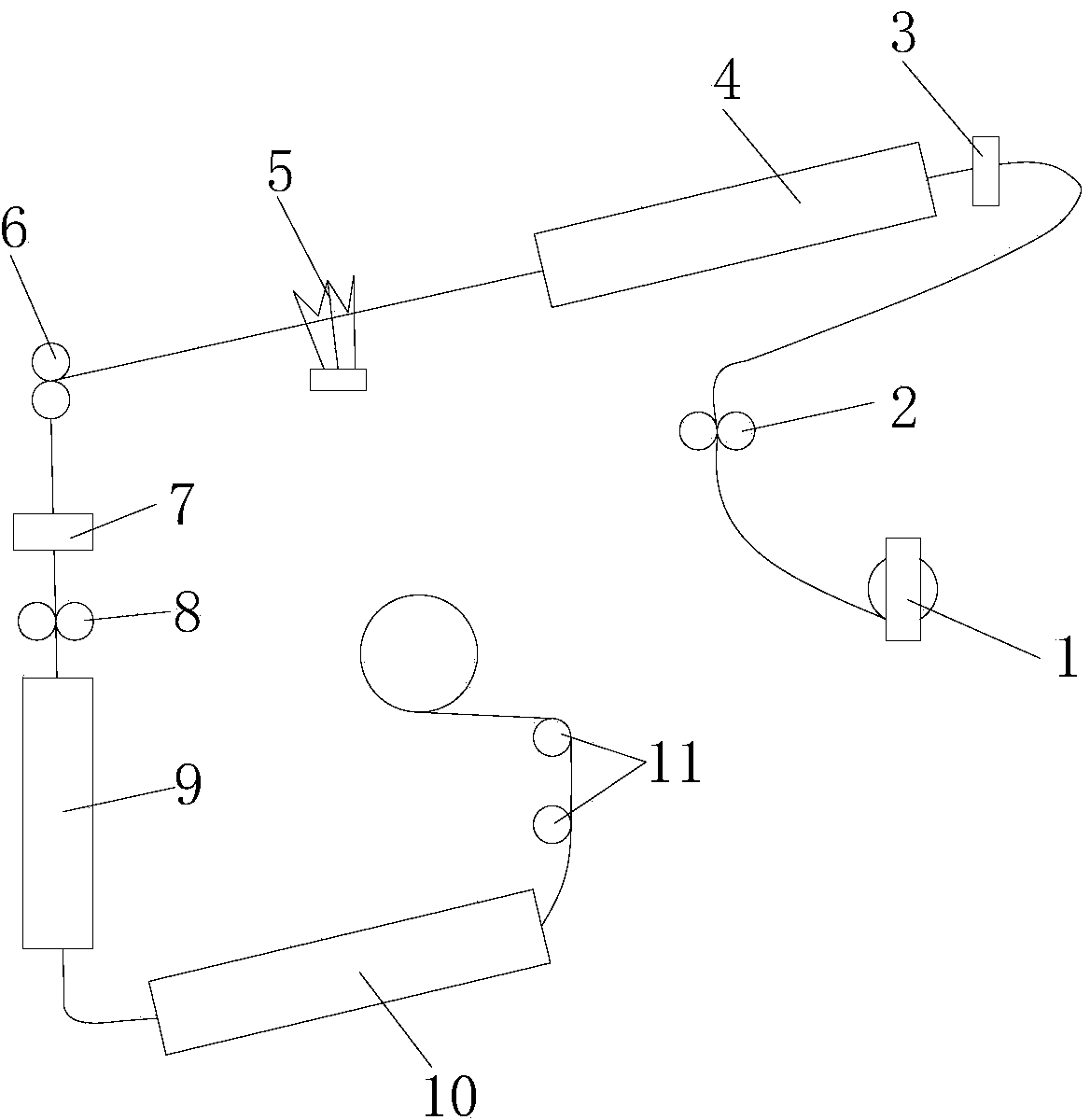

Doubling machine for metallic threads

The present invention discloses a tinsel yarn assembler. It contains payoff frame, annealing furnace and yarn-rewinding mechanism. The top portion and bottom portion of said payoff frame are respectively equipped with disk shaft and ceramic ring. The described yarn-rewinding mechanism contains supporting frame, the upper portion and lower portion of each of two sides of said supporting frame are respectively equipped with yarn-guiding wheel and yarn-rewinding disk, and the upper portion and lower portion of said annealing furnace are respectively with yarn tension controller and spindle. Said invention also provides the working principle of said tinsel yarn assembler and its operation method.

Owner:陈惠良

Antibacterial finishing agent, antibacterial yarn and preparation method and application of antibacterial yarn

InactiveCN107217481AHas antibacterial propertiesPrevent mildewBiochemical fibre treatmentGrip property fibresYarnWater based

Owner:湖南莎丽袜业股份有限公司 +1

Production method of elastic yarn or high elastic yarn in polyester or nylon production

Owner:ZHEJIANG KAICHENG TEXTILE MACHINERY

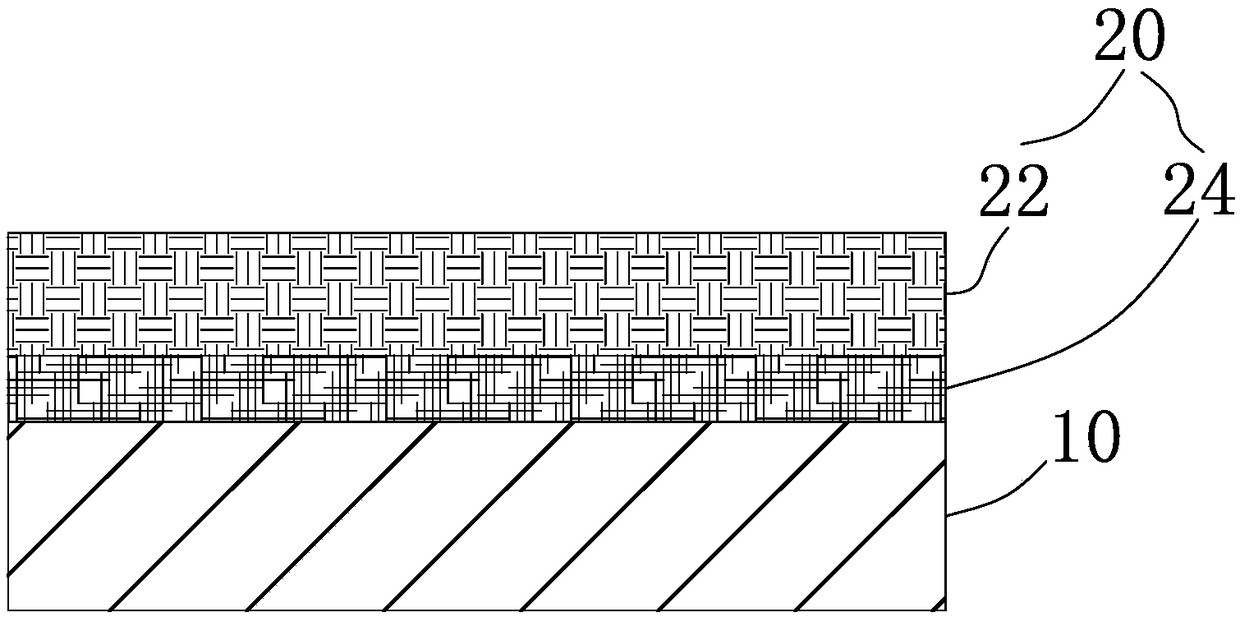

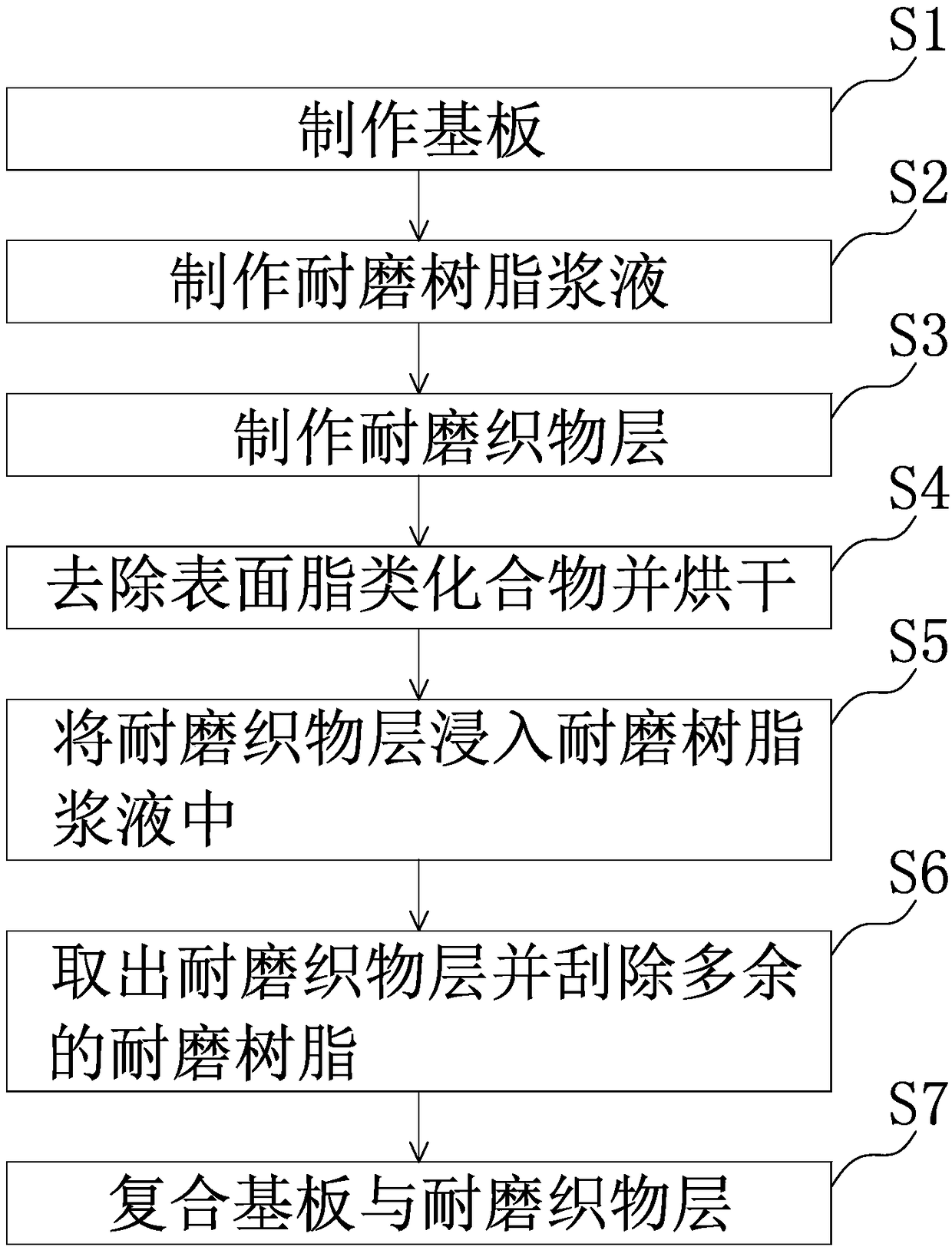

Wear-resistant non-metal composite board and production method thereof

ActiveCN108437585AReduced carrying capacityExtended service lifeLamination ancillary operationsSynthetic resin layered productsPolyesterEpoxy

Owner:JIASHAN CSB PLASTIC BEARING TECH CO LTD

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

Novel blended yarn

The invention relates to a novel blended yarn. The blended yarn is made of cotton fibers, seaweed carbon fibers, silkworm protein fibers and bamboo fibers. The blended yarn is characterized by comprising the following raw materials, by weight, 10-20 parts of the cotton fibers, 50-80 parts of the seaweed carbon fibers, 15-30 parts of the silkworm protein fibers and 15-30 parts of the bamboo fibers. The blended yarn has the advantages that the blended yarn is capable of emitting far infrared rays and generating anions, good in air permeability, moisture absorption and drapability, comfortable in hand feeling, high in wear resistance, and good in dyeing property, has the natural anti-microbial, anti-bacteria, snail killing, odor-resistant and uvioresistant functions, and can meet requirements of people.

Owner:邹雪芬

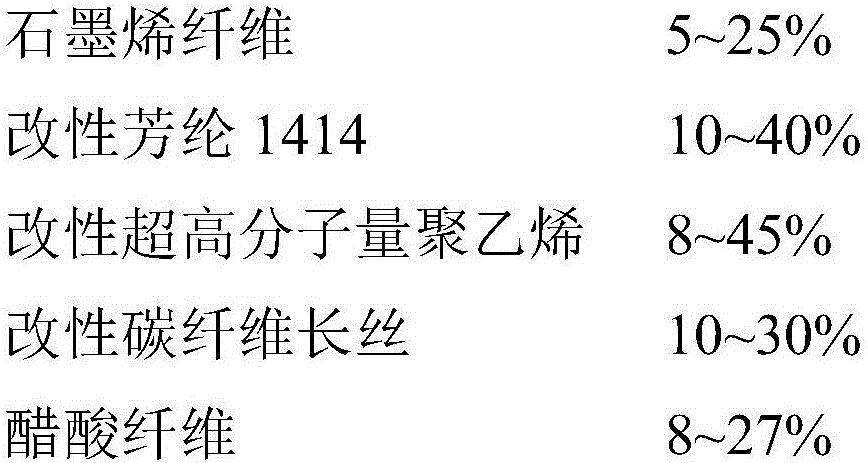

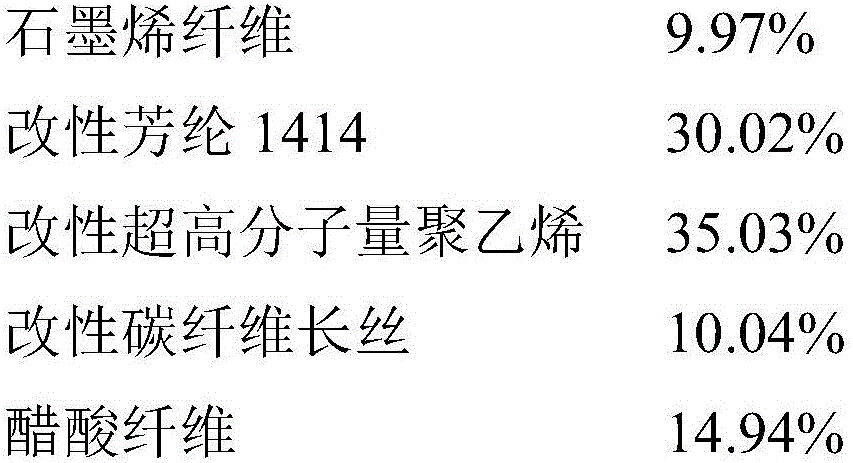

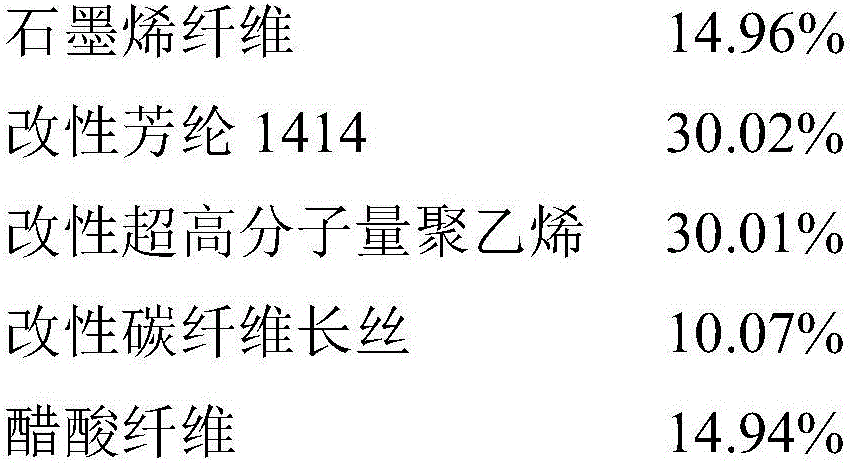

Flame-retardant yarn/fabric/clothing

Owner:SINOPPE BEIJING CO LTD

Polyester viscose blended fabric

Owner:QINGDAO TOPLINK INFORMATION TECH

Underwear fabric capable of promoting blood circulation and stopping pain

Owner:TAICANG SIXIN TEXTILE

Fibers and Nonwovens Made from uncross-linked alkyd oligomers

Owner:THE PROCTER & GAMBLE COMPANY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap