Natural bamboo fibers modified by nano-cellulose whiskers and preparing method of natural bamboo fibers

A technology of nano-cellulose and cellulose whiskers, which is applied in fiber raw material treatment, fiber chemical post-treatment, and microbial/enzymatic cellulose treatment, etc., can solve the problems of rare bamboo fiber performance improvement, bamboo fiber performance and Efficiency can not be balanced and other issues, to achieve the effect of improving comprehensive economic value, improving work efficiency, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

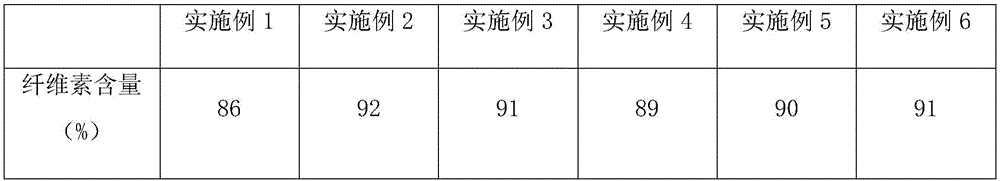

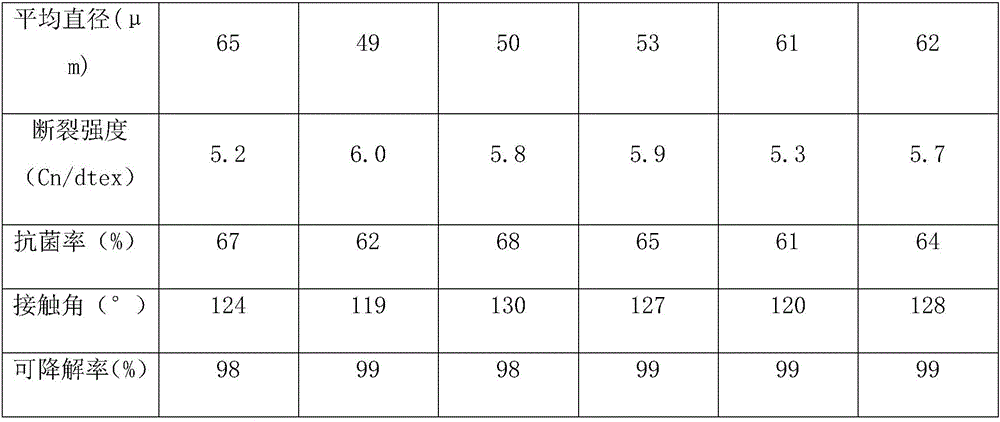

Examples

Embodiment 1

[0028] (1) fresh bamboo is cut into slices to form a length of 3cm and a bamboo chip of 2mm in thickness. With a bath ratio of 1:30, the bamboo chip is immersed in the lye of 3% cellulase in a mass fraction, the pH of the lye The value is 8.5, boiled for 20 minutes, taken out, rolled for 3 minutes, and dried to obtain pretreated bamboo fiber.

[0029] (2) the pretreated bamboo fiber bundle is placed in the steam explosion treatment device, gas explosion treatment 5min under 2MPa pressure, take out, wash with water, filter to obtain the bamboo fiber bundle, through carding, the length is greater than 5cm to be the original long fiber of bamboo, and the rest is Bamboo staple fiber.

[0030] (3) With a material ratio of 1g:8ml, place bamboo short fibers in an acetic acid solution, take out and wash with water to take out the acetic acid, then add a deionized aqueous solution, and ultrasonically pulverize for 10 minutes to form fibers with a mass fraction of 0.5% and a particle size

Embodiment 2

[0033] (1) fresh bamboo is cut into slices to form a length of 5cm and a bamboo chip of 3mm in thickness. With a bath ratio of 1:40, the bamboo chip is immersed in the lye of 5% cellulase in a mass fraction, the pH of the lye The value is 9, boiled for 30 minutes, taken out, rolled for 5 minutes, and dried to obtain pretreated bamboo fiber.

[0034] (2) the pretreated bamboo fiber bundle is placed in the steam explosion treatment device, gas explosion treatment 10min under 3MPa pressure, take out, wash with water, filter to obtain the bamboo fiber bundle, through carding, the length is greater than 5cm to be the original long fiber of bamboo, and the rest is Bamboo staple fiber.

[0035] (3) With a material ratio of 1g:10ml, place bamboo short fibers in acetic acid solution, take out and wash with water to take out acetic acid, then add deionized aqueous solution, and ultrasonically pulverize for 10 minutes to form fibers with a mass fraction of 3% and a particle size of 30nm Ve

Embodiment 3

[0038](1) fresh bamboo is cut into slices to form a length of 4cm, a thickness of 2.5mm bamboo chips, with a bath ratio of 1:35, the bamboo chips are immersed in the lye that the mass fraction is 4% cellulase, the lye The pH value is 8.7, boiled for 25 minutes, taken out, rolled for 4 minutes, and dried to obtain pretreated bamboo fiber.

[0039] (2) The pretreated bamboo fiber bundle is placed in a steam explosion treatment device, and is subjected to gas explosion treatment under a pressure of 2.2MPa for 6 minutes, taken out, washed with water, and filtered to obtain the bamboo fiber bundle, and after carding, the length is greater than 5cm to be the original long fiber of bamboo, and the rest It is bamboo staple fiber.

[0040] (3) With a material ratio of 1g:9ml, place bamboo short fibers in acetic acid solution, take out and wash with water to take out acetic acid, then add deionized aqueous solution, and ultrasonically pulverize for 10 minutes to form fibers with a mass fra

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap