Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219results about "Microorganism based processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing ethanol from crop straw

ActiveCN101186943AEasy to separateTake advantage ofBiofuelsMicroorganism based processesSolid componentFiltration

The invention provides a process for producing ethanol with raw materials of straws. The process comprises preliminary treatment to crops straws, solid-liquid separation, hydrolyzed solid components and fermentation with yeasts after hyperfiltration and filtration enrichment by RO combination. The invention can simultaneously conduct evaporating concentration to liquid components, and produce corresponding by-product of lignosulfonate by adding sulfonating agent. The ethanol producing process of the invention greatly decreases the cost of industrial production which ferments straws to produce ethanol, and efficiently utilizes all the ingredients of crops straws.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

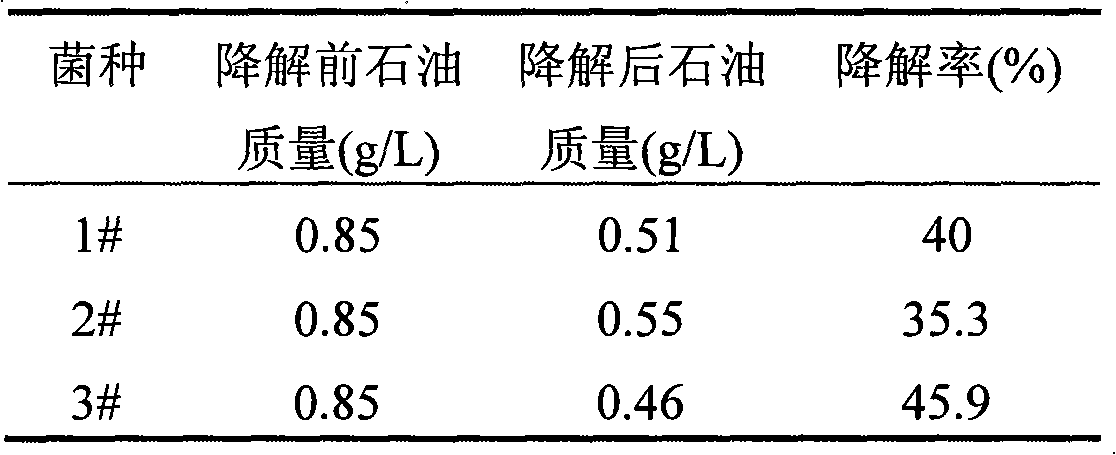

Solid microbial agent to remedy soil contaminated by petroleum, preparation method thereof and application

InactiveCN101597576AHigh organic contentImprove micro-ecological environmentBacteriaContaminated soil reclamationMicroorganismEcological environment

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

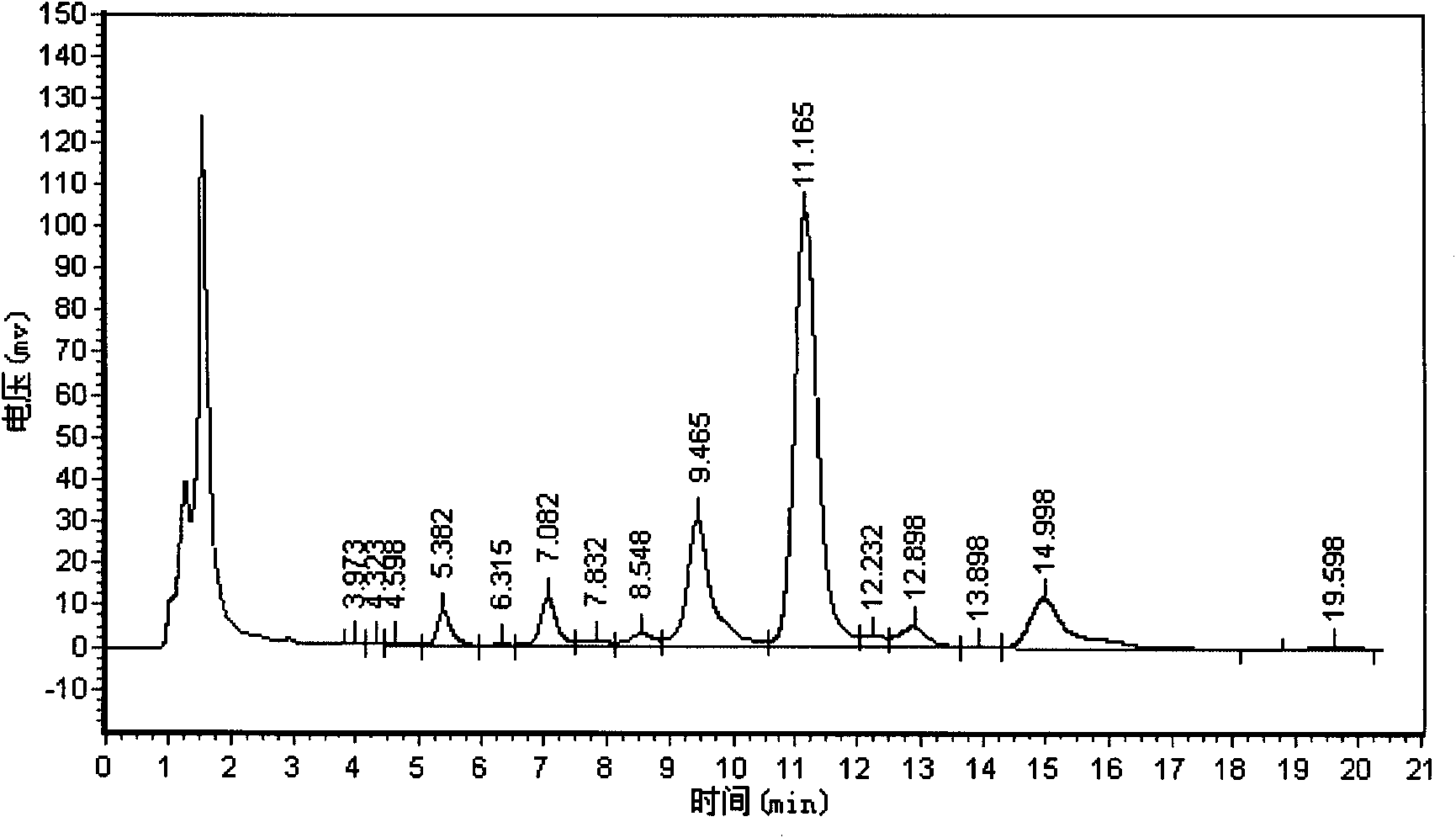

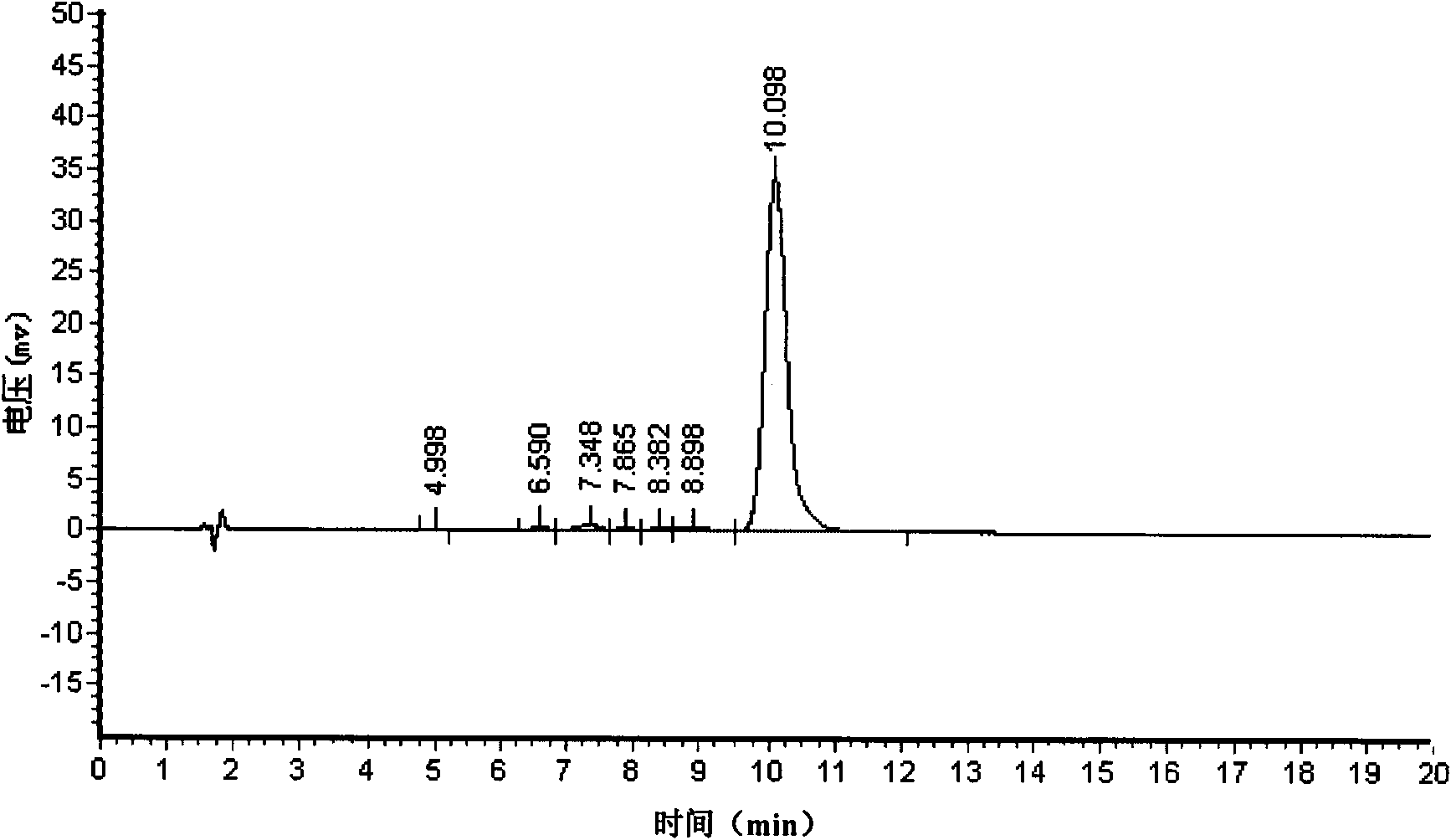

Preparation method of nemadectin

Owner:CHONGQING DAXIN PHARMA +2

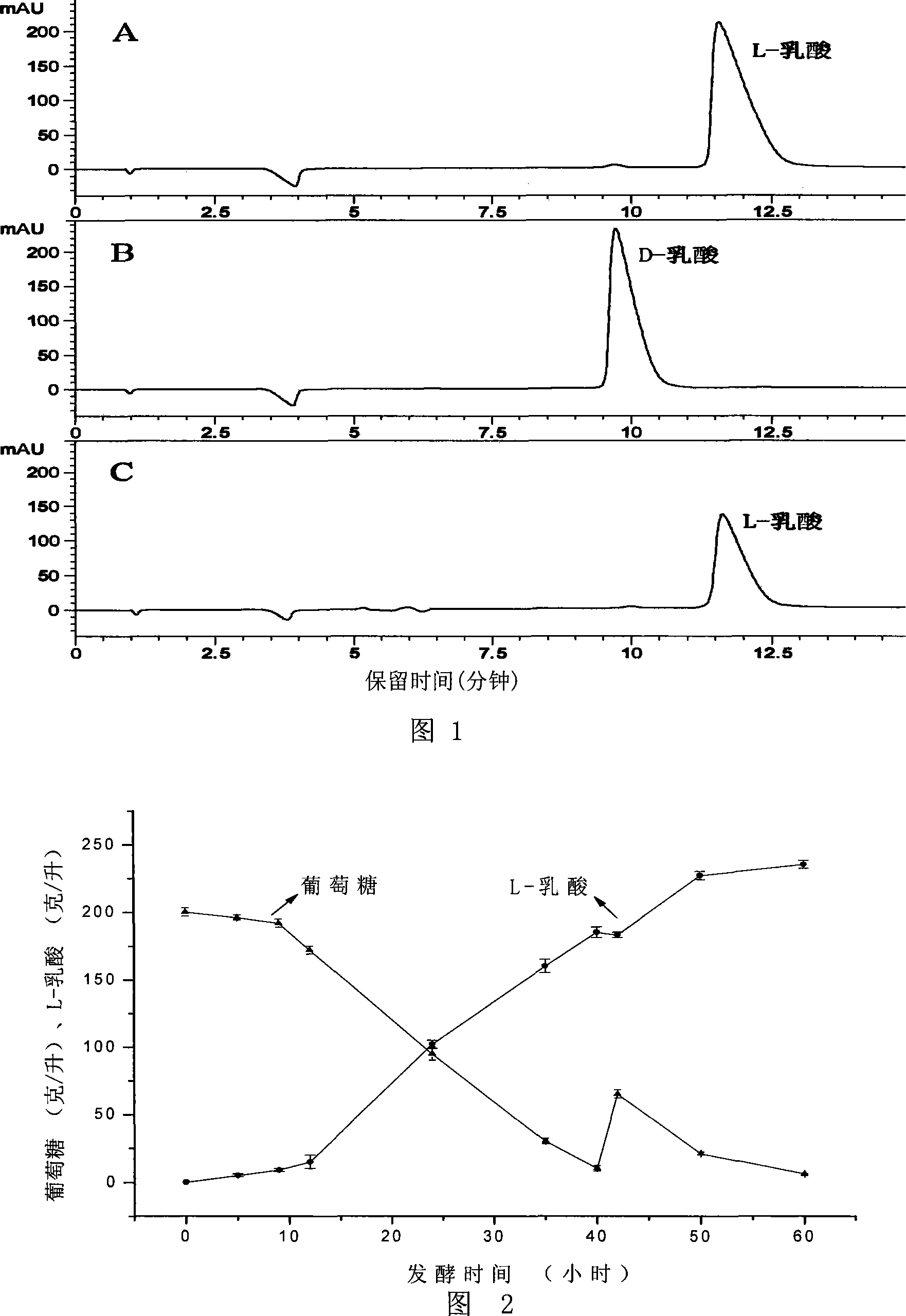

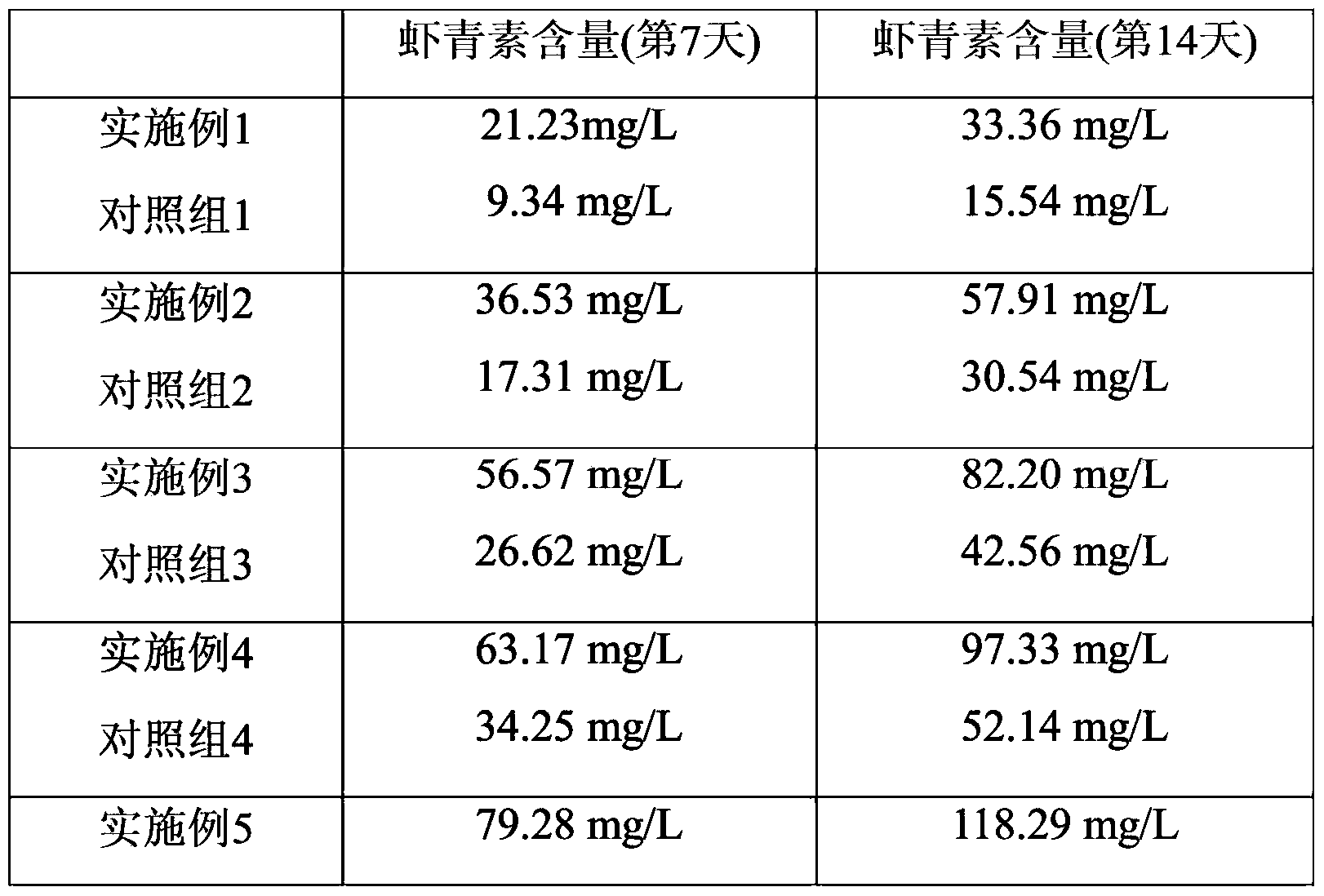

Method for producing L-lactic acid and isoduicitol lactobacillus special for the same

ActiveCN101173241AImprove utilization efficiencySimplify raw material handlingBacteriaMicroorganism based processesCarbon sourceHigh concentration

The invention discloses a method producing L-lactic acid and a special lactobacillus rhamnosus which is Lactobacillus rhamnosus CASL CGMCC No.2183. The L-lactic acid can be obtained by cultivating the Lactobacillus rhamnosus CASL CGMCC No.2183. The fermentation culture medium of the strains is provided with a carbon source, a nitrogen source and the neutralizer used for controlling the fermentation liquid pH; the carbon source is glucose of 150 to 200g / L (the initial fermentation concentration); the nitrogen source is soybean meal hydrolysate, soybean meal hydrolysate and corn steep liquor, or soybean cake powder, and can comprise protease by 0.05 to 0.1g / L when the nitrogen source is soybean cake powder; the neutralizer is the calcium carbonate of 75 to 100g / L, the rest is water and the pH of the fermentation culture medium is 5.5 to 7. With glucose as substrate and a transformation rate of 94.5% to 96.5%, the Lactobacillus rhamnosus CASL CGMCC No.2183 produces the L-lactic acid with an optical purity of 97.6% to 98.7% under the condition of 35 DEG C-45 DEG C, with a highest concentration of 235g / L.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

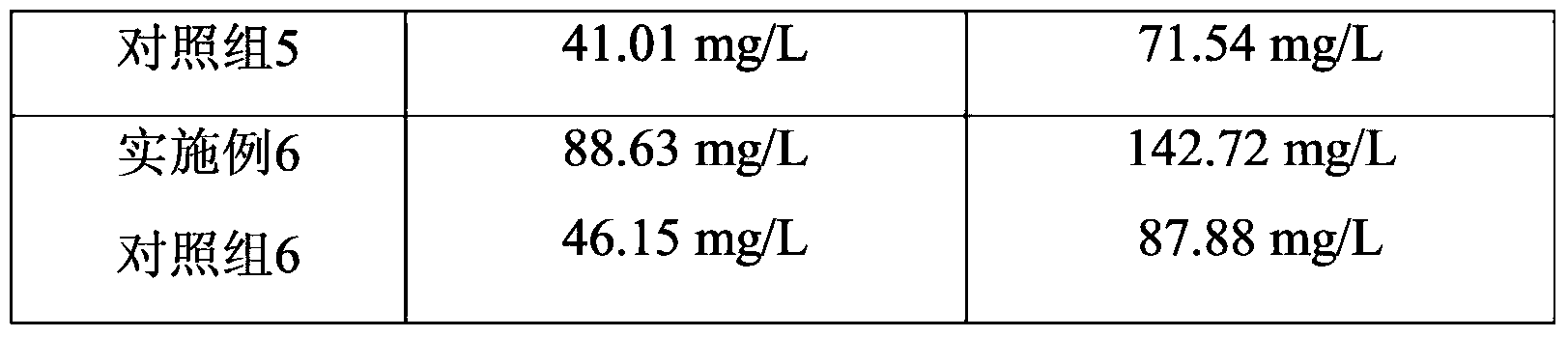

Method for producing astaxanthin by inducing Haematococcus pluvialis

ActiveCN104232720AIncrease carbon dioxide levelsPlay a stirring roleMicroorganism based processesFermentationGrowth phaseBetaxanthins

Owner:BIOALGO CY CO LTD +1

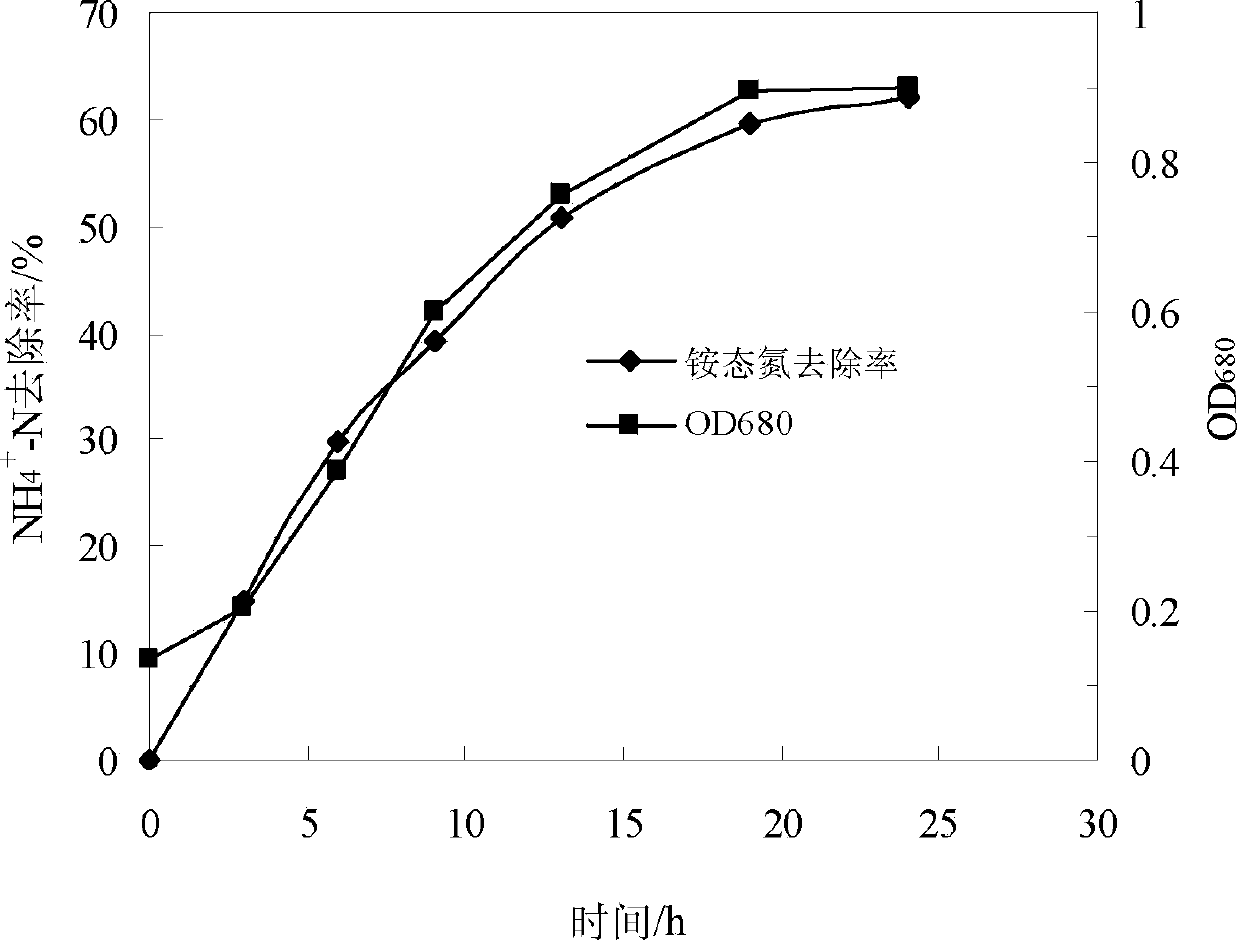

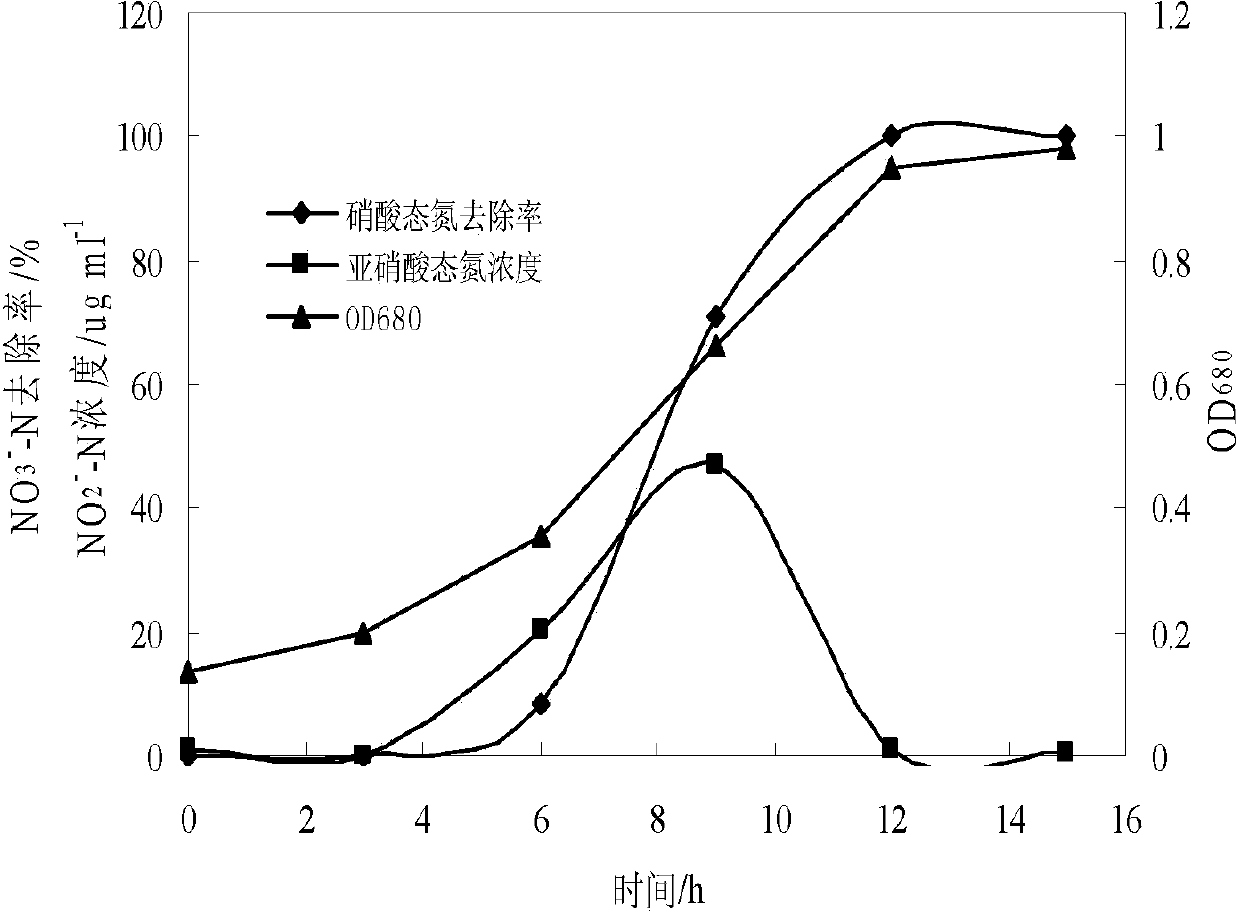

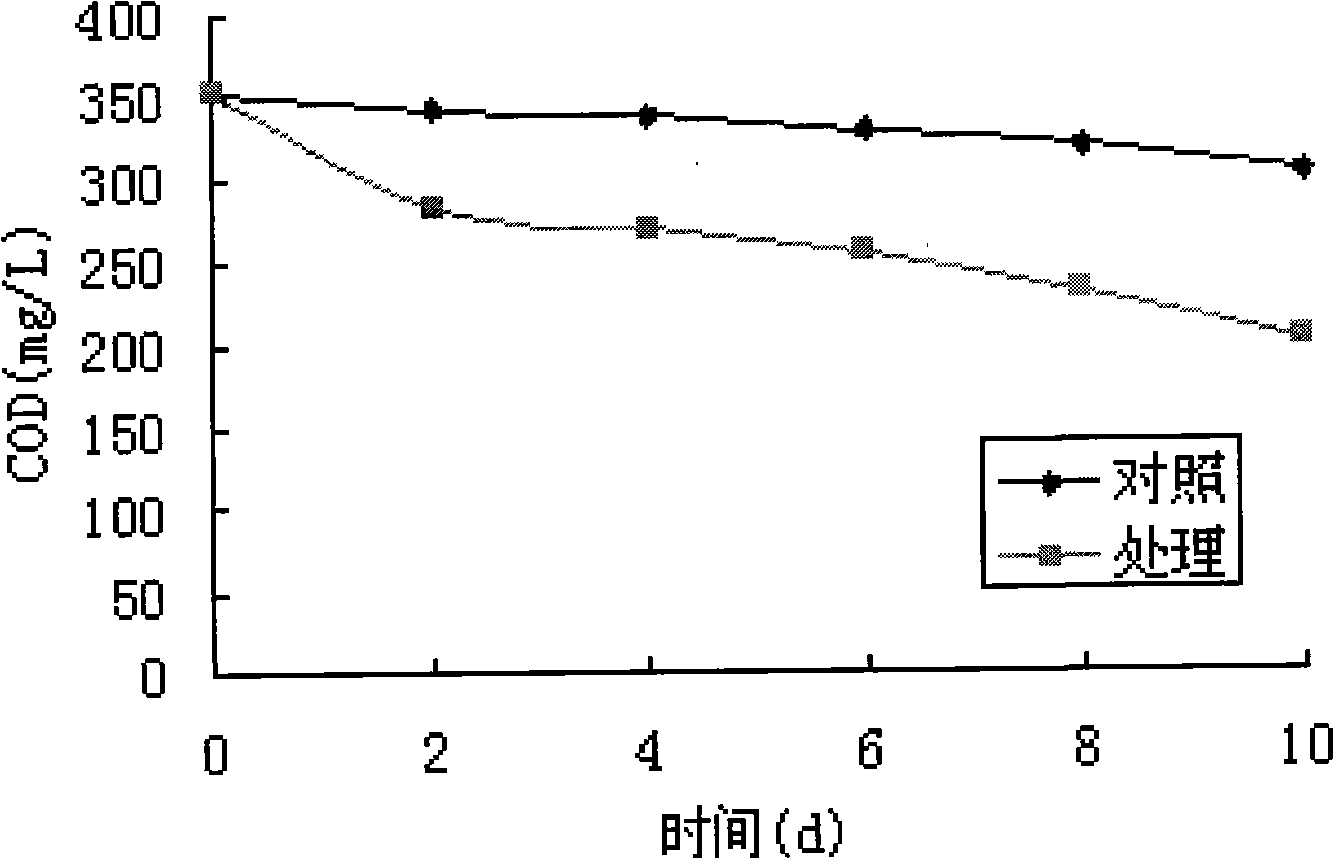

Alcaligenes faecalis and application thereof

InactiveCN103289939AEfficient removalReduced footprintBacteriaWater contaminantsMicroorganismWastewater

Owner:CHONGQING UNIV

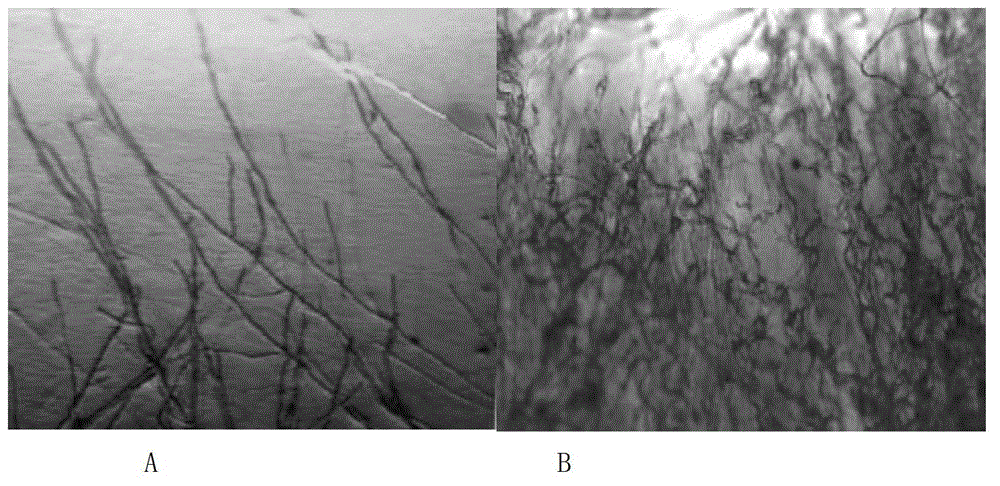

Biological control strain capable of preventing and curing root knot nematode disease for greenhouse vegetable

Owner:NANJING AGRICULTURAL UNIVERSITY

Industrial production method of lipopeptide bio-surfactant

InactiveCN102757994AOil displacement effect is goodMicroorganism based processesFermentationGlycolipidTernary complex

The invention relates to an industrial production method of a dry rat glycolipid bio-surfactant powder. The method comprises the following steps of: (1) breeding a strain; (2) slantly culturing the strain; (3) carrying out enlarged culture on the strain; (4) industrially fermenting and culturing the strain; and (5) centrifuging a produced lipopeptide bio-surfactant fermentation liquor by a high speed centrifugal machine at a rotation speed of 8000 rpm / min, so as to respectively obtain a lipopeptide separating liquor and bacillus subtilis. The surface tension of the stoste of the lipopeptide bio-surfactant fermentation liquor produced with the method provided by the invention is less than 26 mN / m; and after being centrifuged to remove thalli and then diluted by 500 times, the stoste of the lipopeptide bio-surfactant fermentation liquor obtains the surface tension of less than 34 mN / m. The separated lipopeptide separating liquor can be used for ternary complex flooding oil-extraction; and the flooding effect of the lipopeptide separating liquor can be improved by 8-16% on the basis of water flooding. It is detected that the bacterial count of the separated bacillus subtilis can reach more than 10 billions in every 6 ml of the fermentation liquor; and the bacillus subtilis can be used for producing and processing EM (E Mycin) bacterial liquids and is applied to the fields, such as agriculture, livestock breeding, and sewage treatment (industrial sewage and breeding sewage).

Owner:DAQING VERTEX CHEM

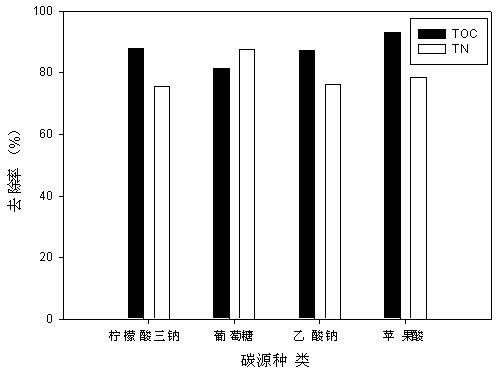

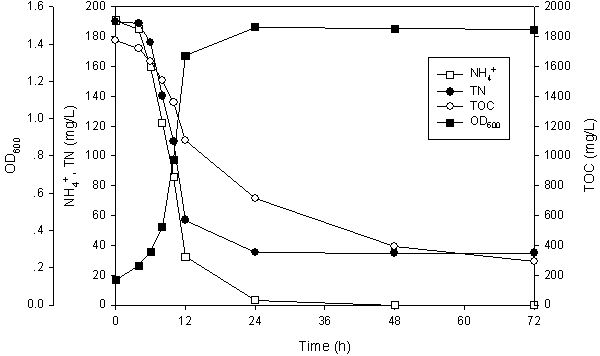

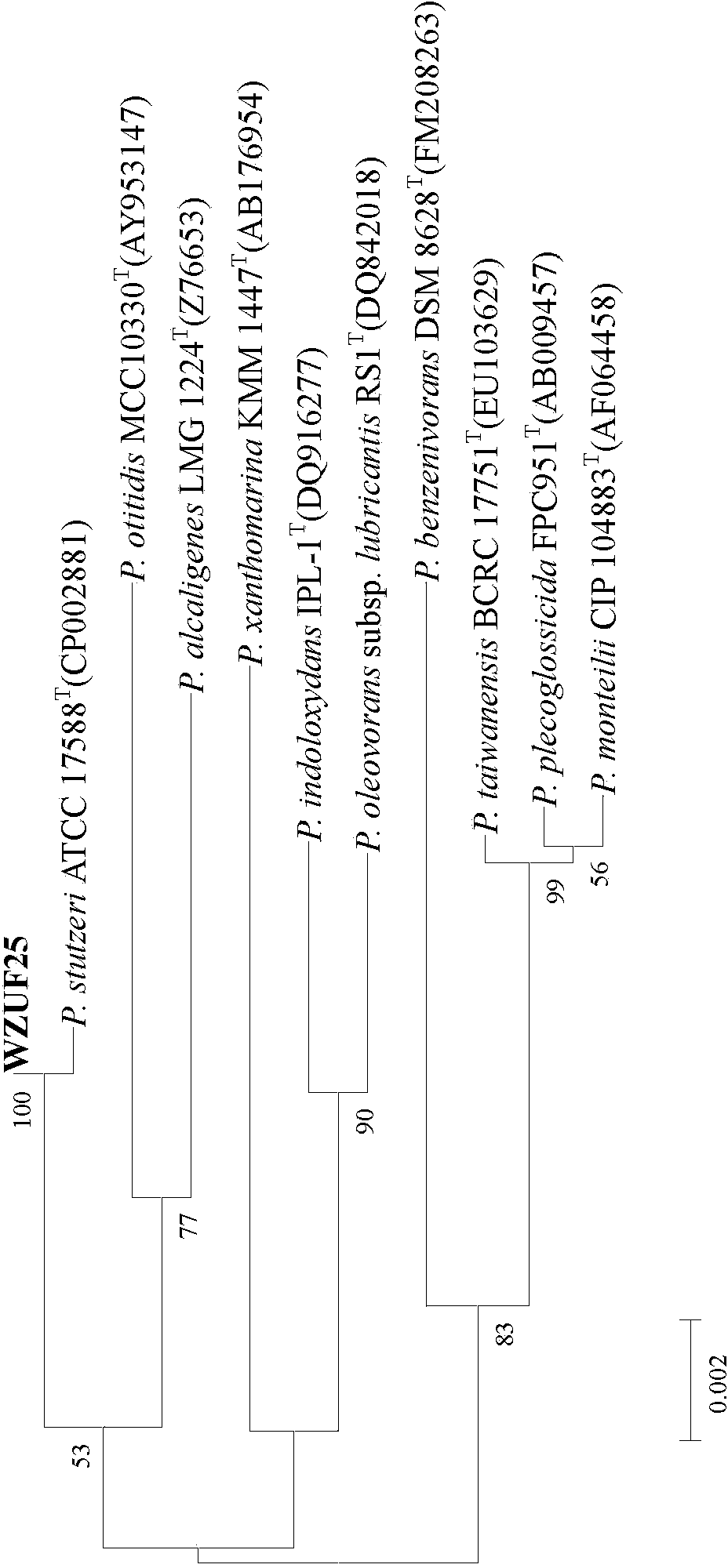

Pseudomonas stutzeri and its culture, immobilization and use

InactiveCN103497908AHigh removal rateWide pH rangeBacteriaWater contaminantsMicrobiological cultureDenitrification

Owner:WENZHOU UNIVERSITY

Bacillus subtilis and application thereof

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

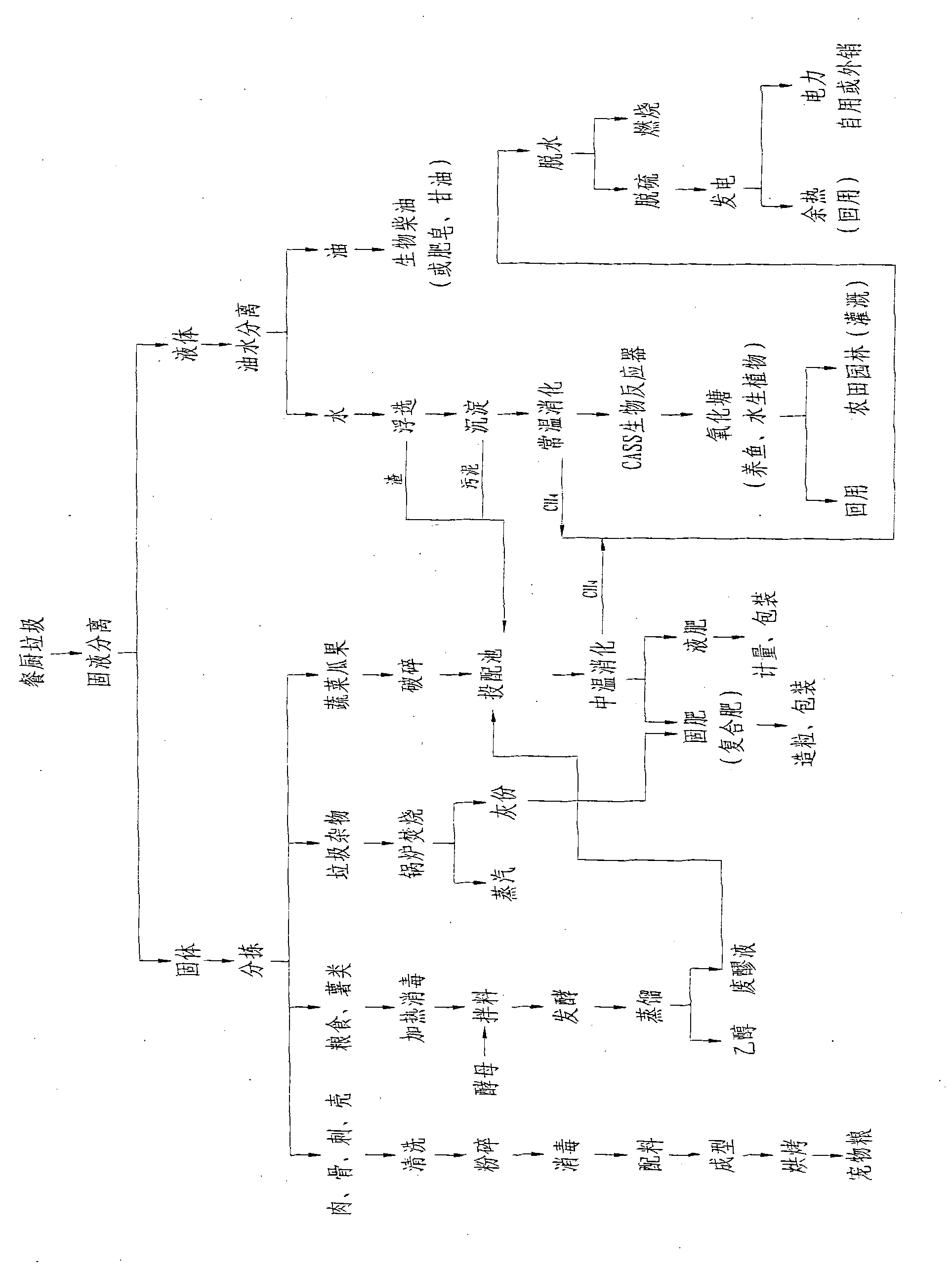

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

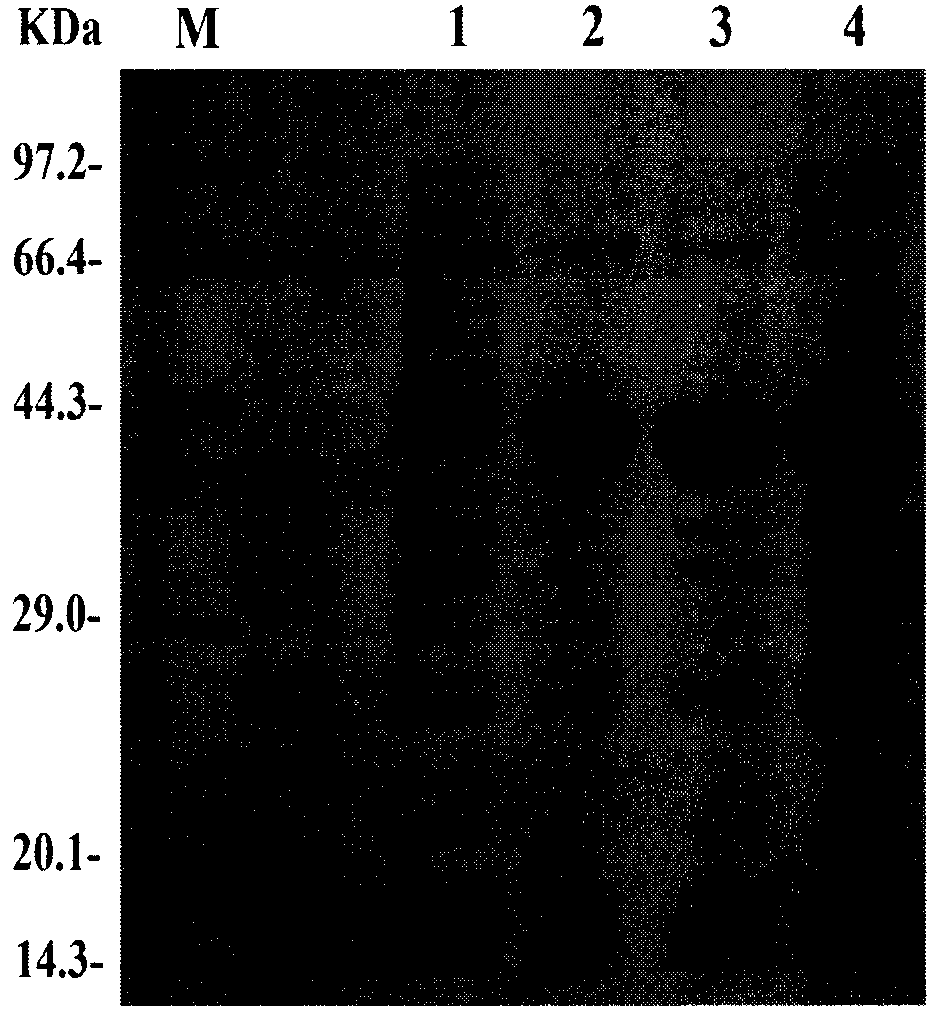

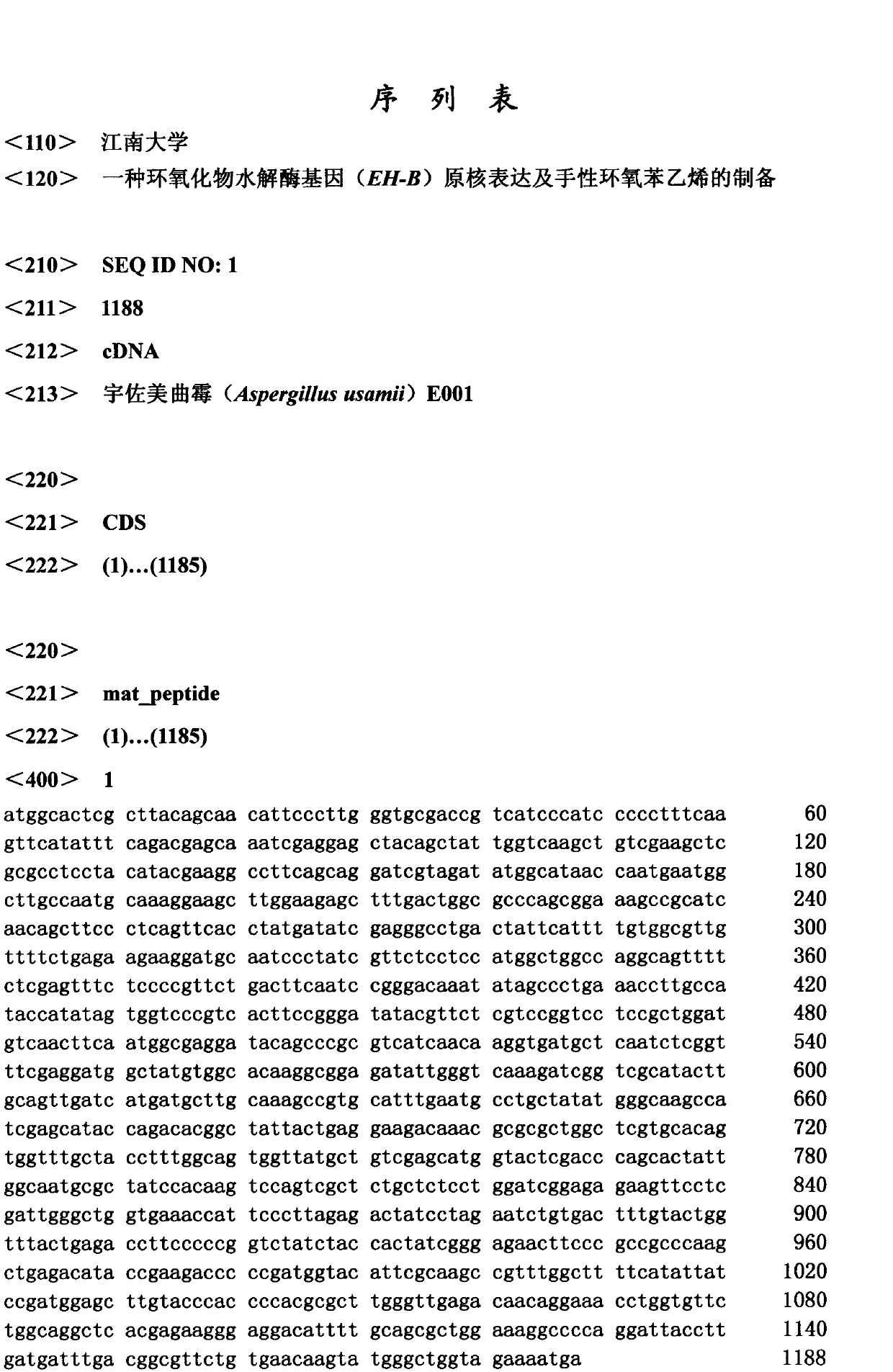

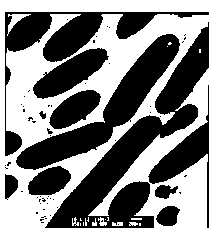

Pronucleus expression of epoxide hydrolase gene (EH-B) and preparation of chiral epichlorohydrin

Owner:JIANGNAN UNIV

Denitrifying phosphorus removal bacteria bacillus cereus H-hrb01 and screening method and application

ActiveCN102827787AEasy to waterExcellent water indicatorsBacteriaMicrobiological testing/measurementBiotechnologyChemical oxygen demand

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION

High-yield strain of high temperature resistant 1,4-beta-D-xylanase, method for producing high temperature resistant 1,4-beta-D-xylanase through fermentation of high-yield strain, and high temperature resistant 1,4-beta-D-xylanase

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Application of mycoplasma bovis MbovP730 protein in natural infection and vaccine immunity identification

Owner:HUAZHONG AGRI UNIV

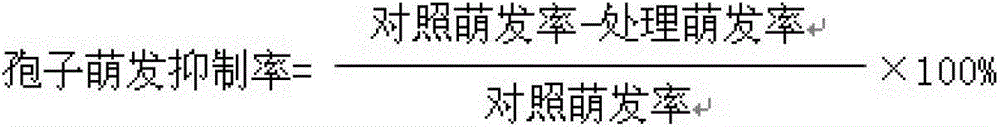

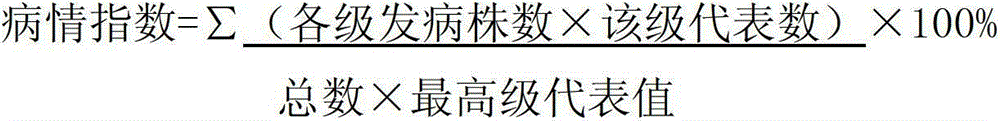

Preparing method and application of composite biological agent for agricultural root-knot nematodes

ActiveCN105316243AImprove physiological activityPromote growthBiocideFungiBiotechnologyPaecilomyces lilacinus

The invention relates to a preparing method and application of a composite biological agent for agricultural root-knot nematodes. The biological agent is obtained through solid fermentation of paecilomyces lilacinus YT08 with the preservation number of CG MCC No.10026 and has a powerful inhibitory effect on the agricultural root-knot nematode disease. A preferred culture medium involved in solid fermentation is prepared from 17-30% of dried brewer grain, 4-8% of bran, 3-6% of smashed peanut shells, 2-5% of soy peptone, 2.55-7.5% of powder chitosan (with the deacetylation degree larger than or equal to 90%), 1-2.25% of crab shell meal, 0.2-0.5% of NaCl, 0.1-0.3% of CaCl2, 0.1-0.3% of MgSO4, 0.05-0.15% of FeSO4 and 40-70% of water. The preparing method has the advantages of being easy to operate and control and suitable for industrial production, the raw materials are low in cost, and the composite biological agent has the powerful effect.

Owner:LUDONG UNIVERSITY

Escherichia coli and method for preparing L-cysteine by using same

ActiveCN101831397APromote accumulationHigh activityBacteriaMicroorganism based processesEscherichia coliSerine acetyltransferase

Owner:HANGZHOU BIOKING BIOCHEM ENG

Microorganism water purifying assistant, and preparation and use thereof

Owner:东莞市华中生物科技有限公司

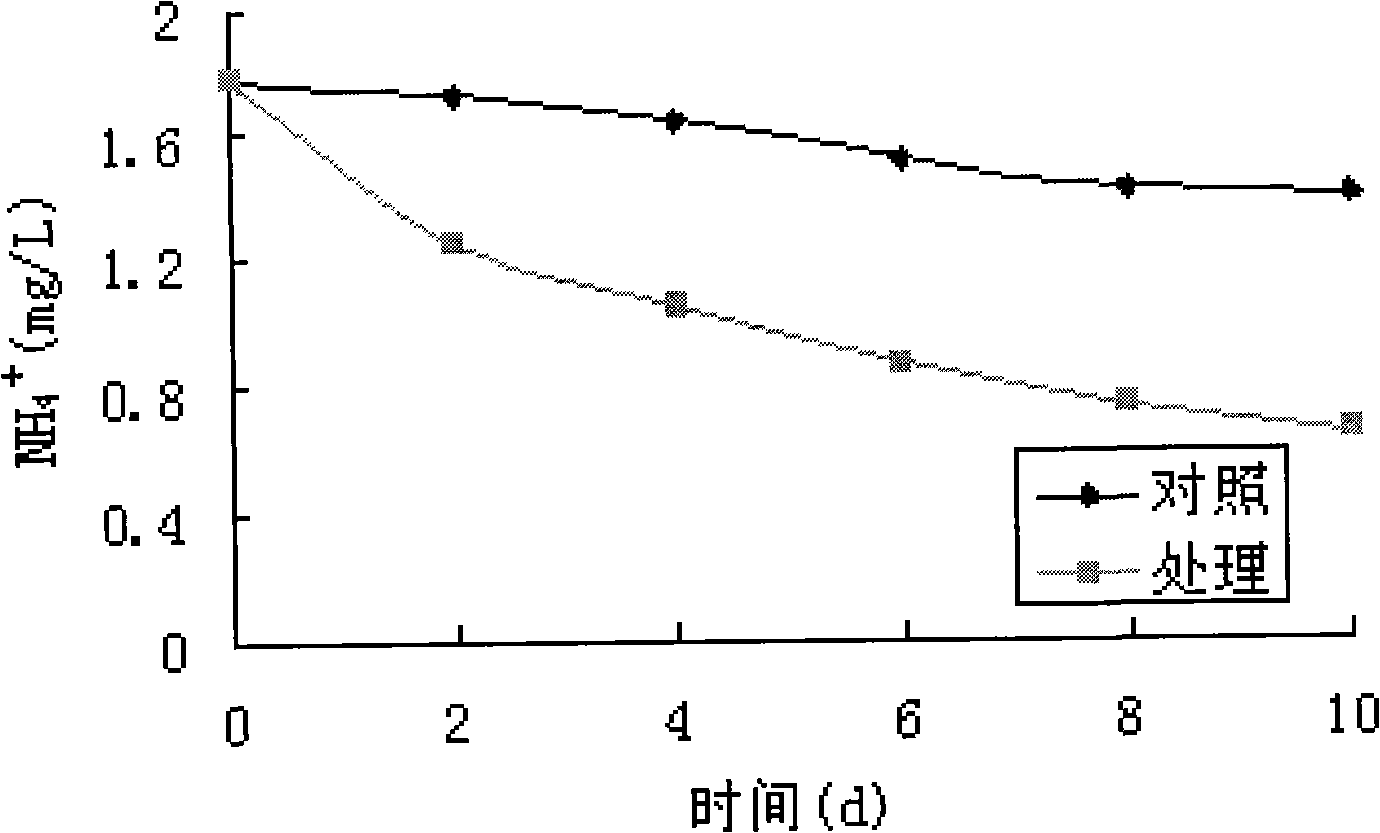

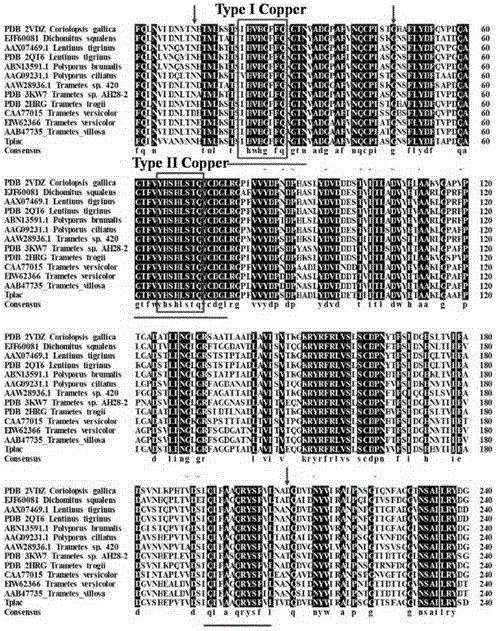

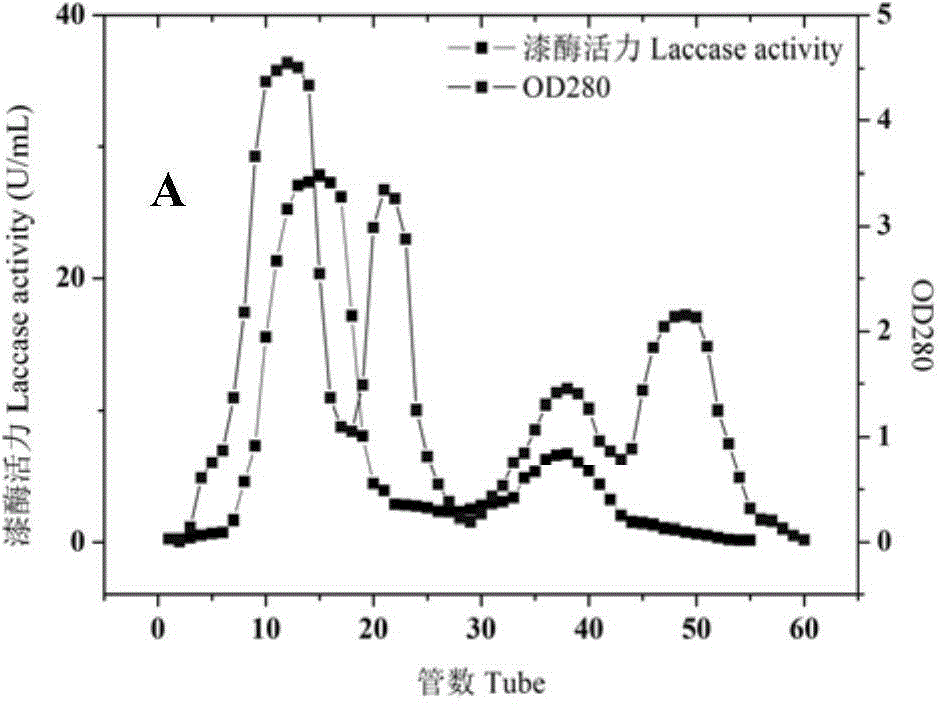

Bacterial strain for producing laccase, method for producing laccase by bacterial strain, produced laccase and application of laccase

InactiveCN104611235ASimple production methodMild culture conditionsFungiMicroorganism based processesMicroorganismCongo red

Owner:BEIJING FORESTRY UNIVERSITY

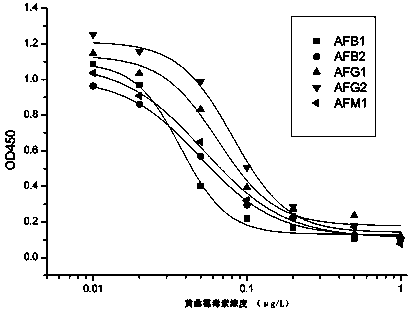

Anti-aflatoxin general type monoclonal antibody hybridoma cell line and application thereof

ActiveCN104004717AHigh detection sensitivityHigh affinityMicroorganism based processesImmunoglobulins against fungi/algae/lichensBALB/cPolyethylene glycol

Owner:无锡迪腾敏生物科技有限公司 +1

Cell isolation method

InactiveCN1395620AUniversal binding ability is beneficialAdvantages FlexibilityBacteriaMicrobiological testing/measurementMicrobiologyIsolate - microorganism

Owner:挪威诊断联合股份有限公司

Method for producing microbial grease by fermenting inulin serving as raw material

InactiveCN102417915AExpand sourceLow costBiofuelsMicroorganism based processesBiodiesel feedstockBiodiesel

Owner:HENAN UNIV OF SCI & TECH

Recomposed escherichia coli base cell for efficient synthesis of terpene chemical compounds as well as preparation method and application thereof

ActiveCN103773729AAbundant resourcesGood synthesis effectBacteriaMicroorganism based processesEscherichia coliLycopene

The invention relates to a recomposed escherichia coli base cell for efficient synthesis of terpene chemical compounds as well as a preparation method and application thereof. Particularly, an escherichia coli endogenous 2-C-methyl-D-erythritol-4-phosphoric acid (MEP) precursor pathway is reconstructed; the reconstructed escherichia coli base cell is utilized to perform the efficient biological synthesis of the terpene chemical compounds; the reconstruction of the precursor pathway mainly comprises the steps of fully digging the MEP precursor pathway gene modules of the sources of other natural microorganisms, screening gene modules with excellent characteristics to be expressed in the escherichia coli, and at the same time, performing the downstream synthesis pathway for integrally assembling the colibacillus chemical compounds in the reconstructed base cell, wherein the colibacillus chemical compounds include sesquiterpene chemical compounds such as amorphadiene, diterpene chemical compounds such as shell alkene, tetraterpenes chemical compounds such as lycopene, polyterpene chemical compounds, other terpene alkaloid chemical compounds and the like. The escherichia coli base cell can remarkably facilitate the synthesis of the terpene chemical compounds.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

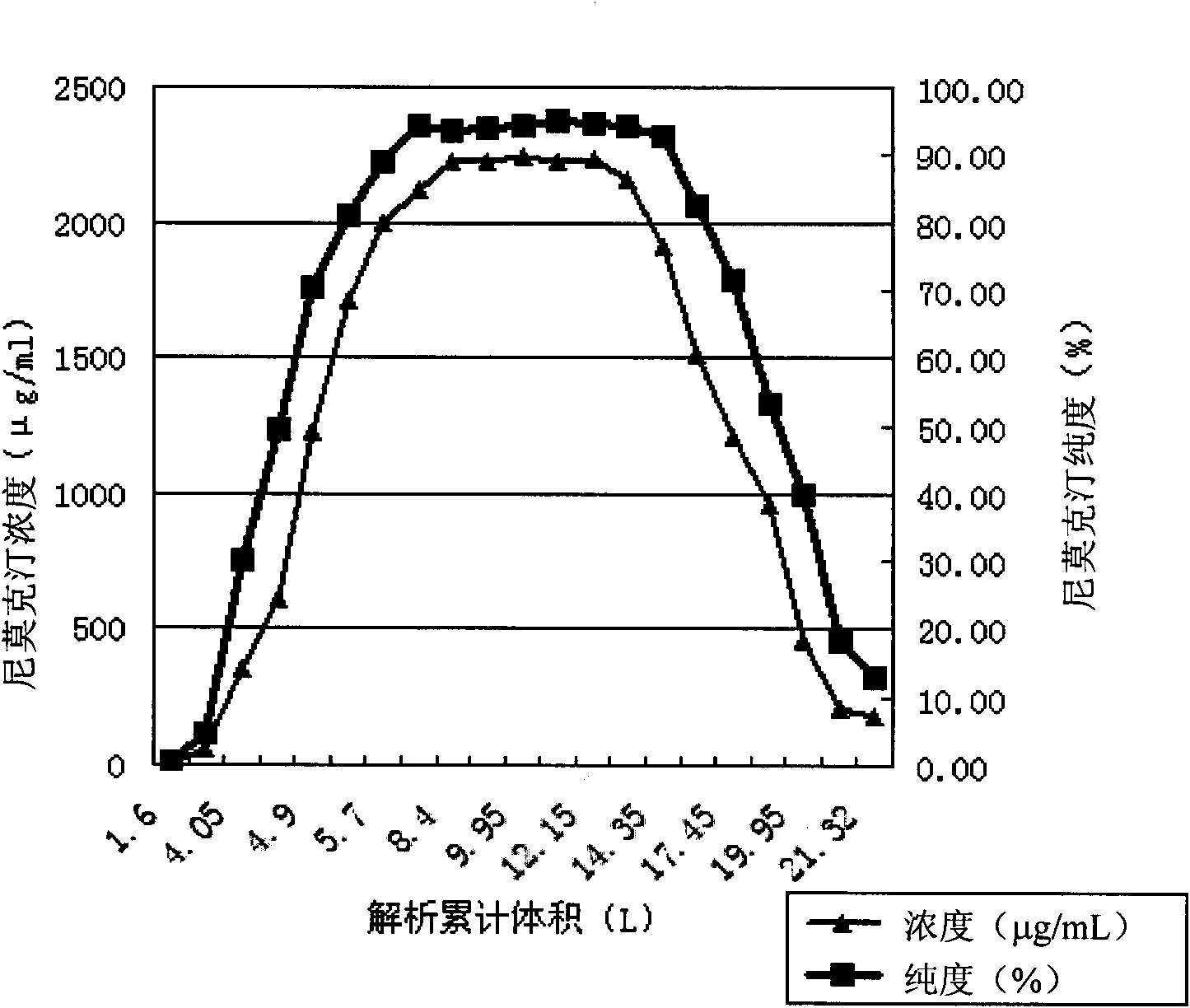

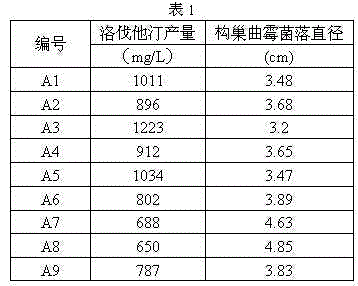

High-yield production method of lovastatin

ActiveCN104561166AIncrease production capacityQuality improvementMicroorganism based processesFermentationBiotechnologyMicroorganism

Owner:山东中惠生物科技股份有限公司 +1

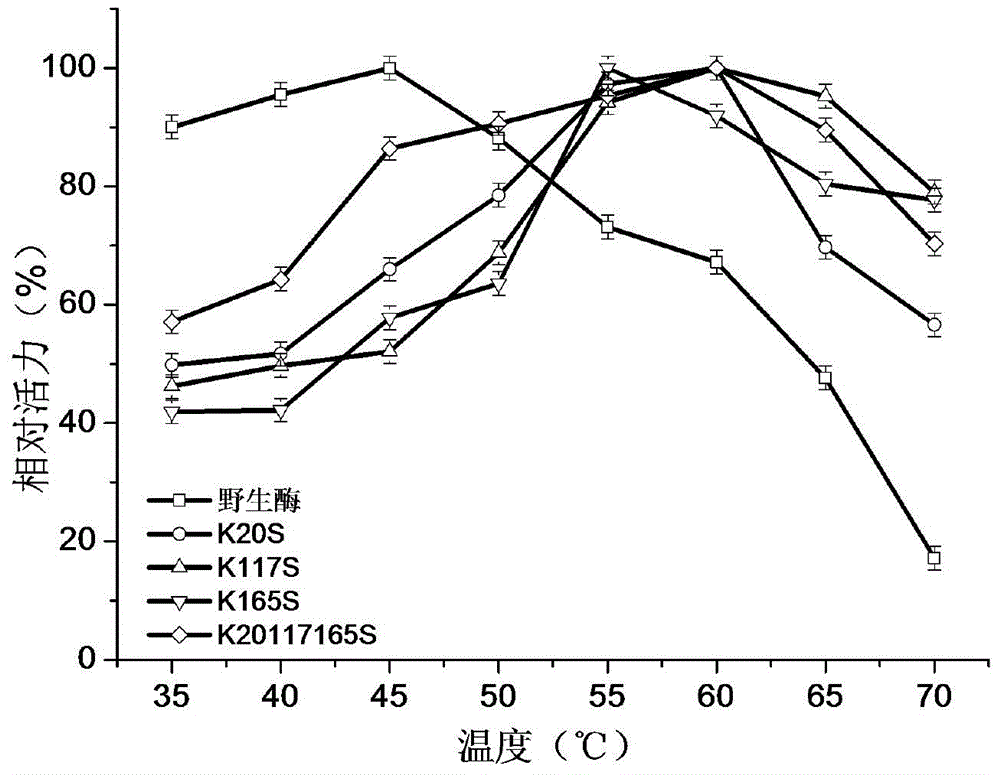

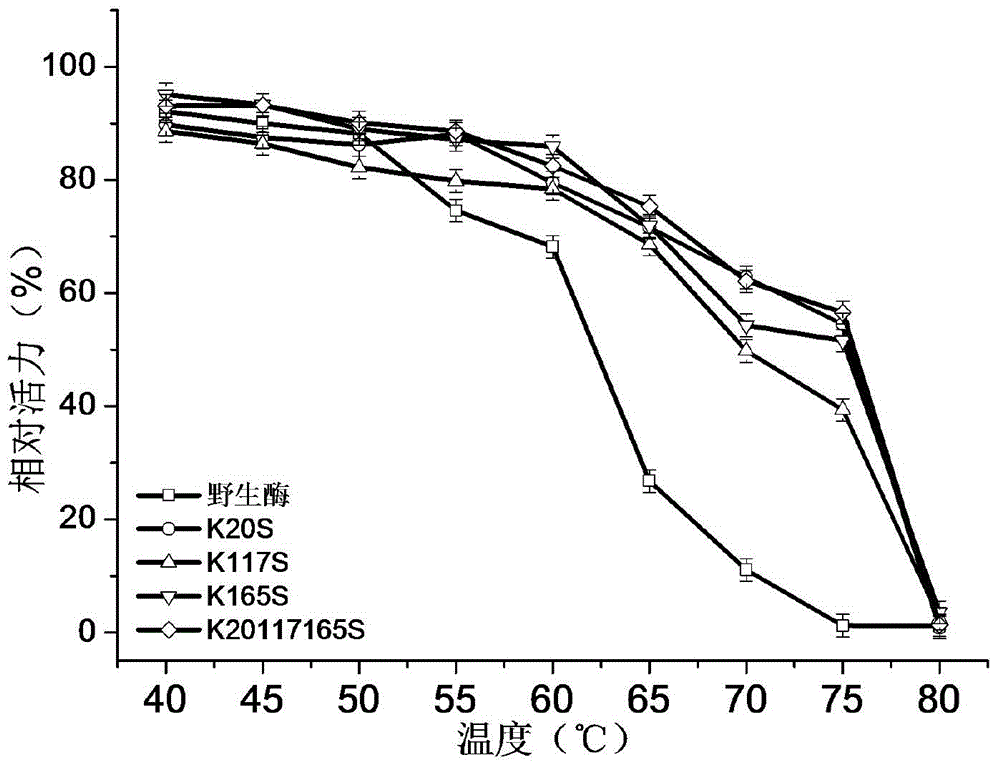

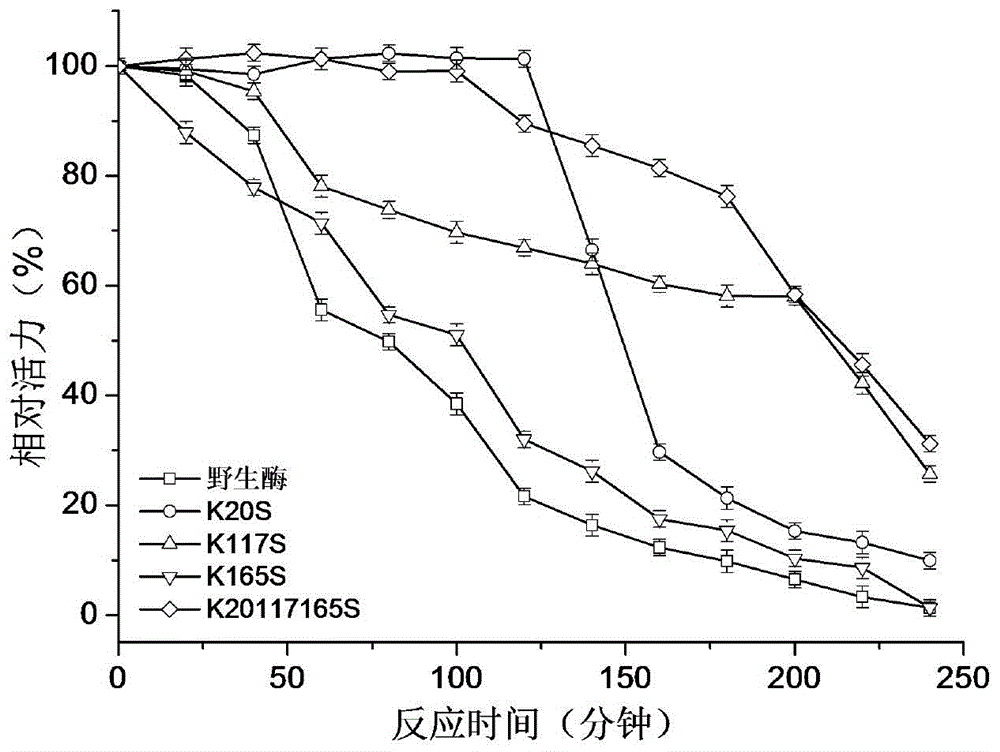

1,3-1,4-Beta-glucanase mutant

ActiveCN104130988AImprove activity stabilityImprove thermal stabilityBacteriaWort preparationMutaseGlucanase

Owner:无锡正元生物科技有限公司

Culturing method for mycelia of Antrodia camphorata

InactiveCN107586724AOvercome the cycleOvercoming success rateFungiMicroorganism based processesHyphaHyphomycetes

Owner:殷东林 +1

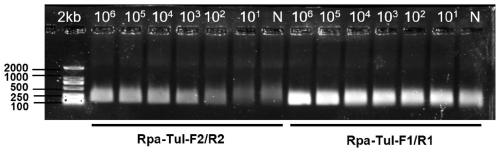

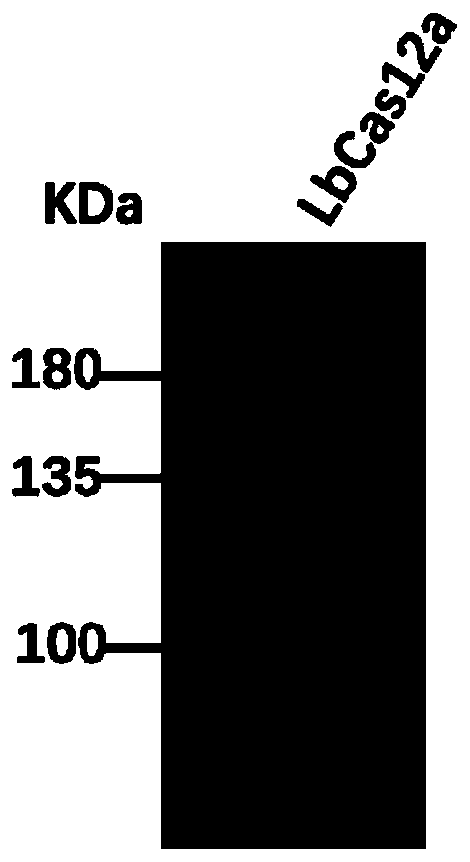

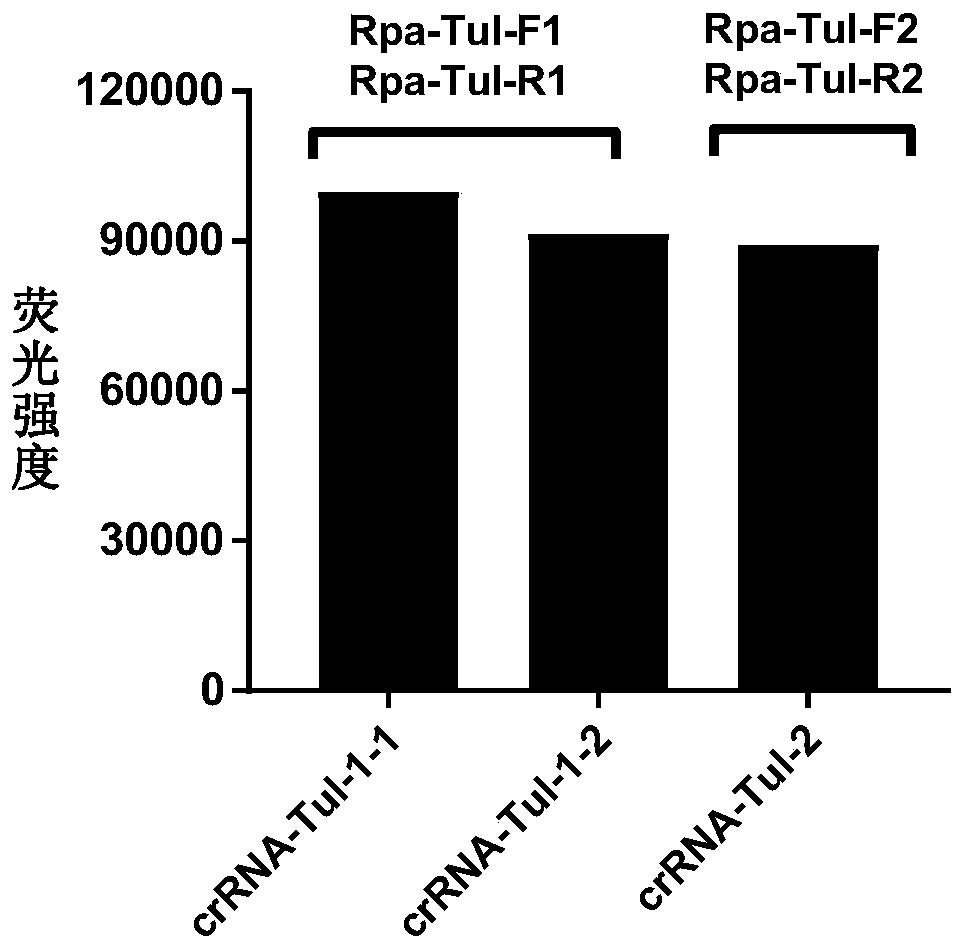

CRISPR-Cas12a detection primer group for francisella tularensis and application thereof

ActiveCN111394490AShort detection timeHigh amplification efficiencyMicrobiological testing/measurementMicroorganism based processesGeneticsNucleotide sequencing

Owner:ACADEMY OF MILITARY MEDICAL SCI

Methods for producing fuel ethanol by using cellulosic waste plants

InactiveCN101613723AReduce removalEliminate omissionBiofuelsMicroorganism based processesChemistryEthanol fuel

The invention provides methods for producing fuel ethanol by using cellulosic waste plants. One method comprises the following steps of: cleaning and grinding the waste plants, adding dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, adding lime in filtrate, and removing precipitation; and carrying out delignification treatment on residue, adding sulfuric acid, heating to lead cellulose to be hydrolyzed, diluting till the weight percentage concentration of the sulfuric acid is 30-40%, recycling the sulfuric acid, heating acidiferous sugar liquor again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate. The other method comprises the following steps of: cleaning and grinding the waste plants, adding waste dilute sulfuric acid to lead hemicellulose to be hydrolyzed, filtering, then adding lime in filtrate, and removing precipitation; adding waste concentrated sulfuric acid in residue, heating, cooling, diluting, heating again, hydrolyzing, adding calcium oxide for neutralization, and removing calcium sulfate; and adding yeast in the product obtained by the method for fermentation, distilling, and dehydrating to obtain the finished product of the fuel ethanol. The methods greatly reduce the cost, have simple process, and are convenient for wide range of generalization and application.

Owner:张羡信

Strain for generating pullulan and method for producing pullulan by fermenting strain

Owner:SHIHEZI UNIVERSITY

Culture medium and culture method for culturing haematococcus pluvialis by using brewery wastewater

The invention relates to a culture medium for culturing haematococcus pluvialis by using brewery wastewater, of which the formula is as follows: 80 ml of brewery wastewater, 28 mg of sodium citrate, 20 mg of urea, 12 mg of potassium dihydrogen phosphate, 150 mg of fructose, 45 mg of yeast extract powder, 50 mg of casein tryptone, 12 mg of ammonium citrate, 25 mg of whey powder, 30 mg of lactose, 60 mg of glucose, 1.8 ml of horse manure leachate, 2 ml of fermented soya-bean milk, 100 mg of sorbitol, 24 mg of soluble starch, 25 mg of soytone, 28 mg of beta-sodium glycerophosphate, 12 mg of an edetic acid, 10 mcg of vitamin B1, 21 mcg of vitamin B1, 1.8 ml of soil extract, 1.5 ml of human urine, 2.4 ml of chicken manure leachate, and 1000 ml of pure fresh water disinfected by sodium hypochlorite. An important bioactive substance-astaxanthin can be obtained. The culture medium is low in cost, uneasily polluted, and can be reused; and due to the mixed utilization of organic fertilizers and inorganic fertilizers, the growth rate and astaxanthin content of haematococcus pluvialis are significantly increased, and the yield is increased by 270%.

Owner:LINYI UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap