Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Protease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A protease (also called a peptidase or proteinase) is an enzyme that catalyzes (increases the rate of) proteolysis, the breakdown of proteins into smaller polypeptides or single amino acids. They do this by cleaving the peptide bonds within proteins by hydrolysis, a reaction where water breaks bonds. Proteases are involved in many biological functions, including digestion of eaten proteins, protein catabolism (breakdown of old proteins), and cell signalling.

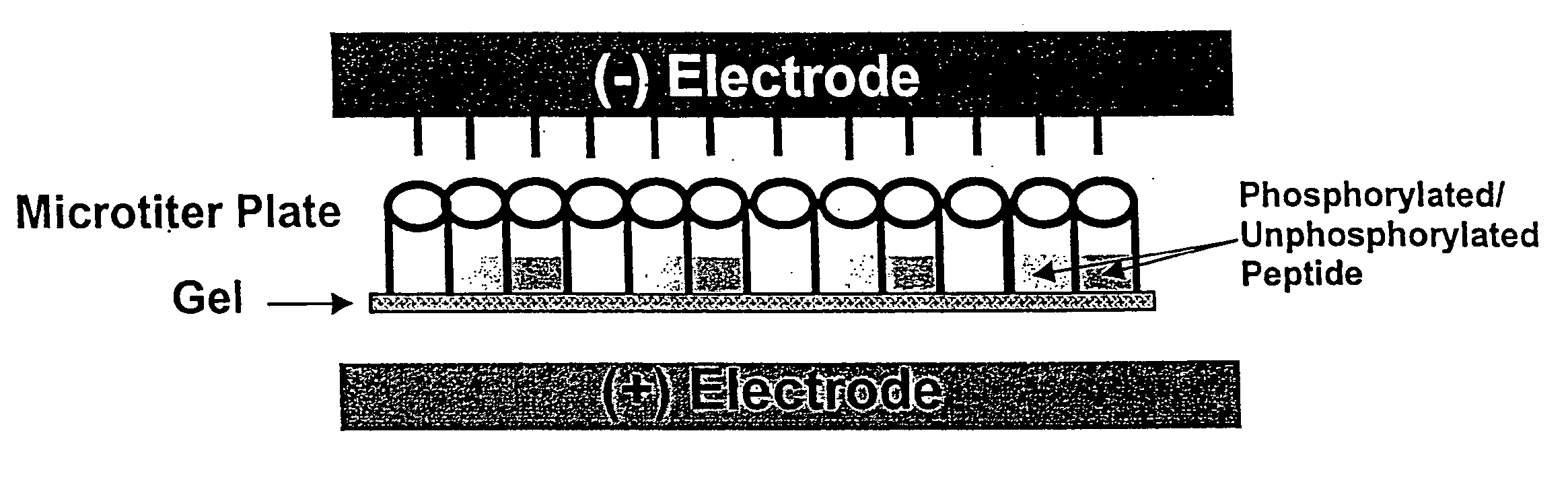

Microtiter plate format device and methods for separating differently charged molecules using an electric field

InactiveUS20050173247A1Easy to adaptSludge treatmentVolume/mass flow measurementHigh-Throughput Screening MethodsProteinase activity

Owner:NANOGEN INC

Method for producing peanut beverage

Owner:汤花荣

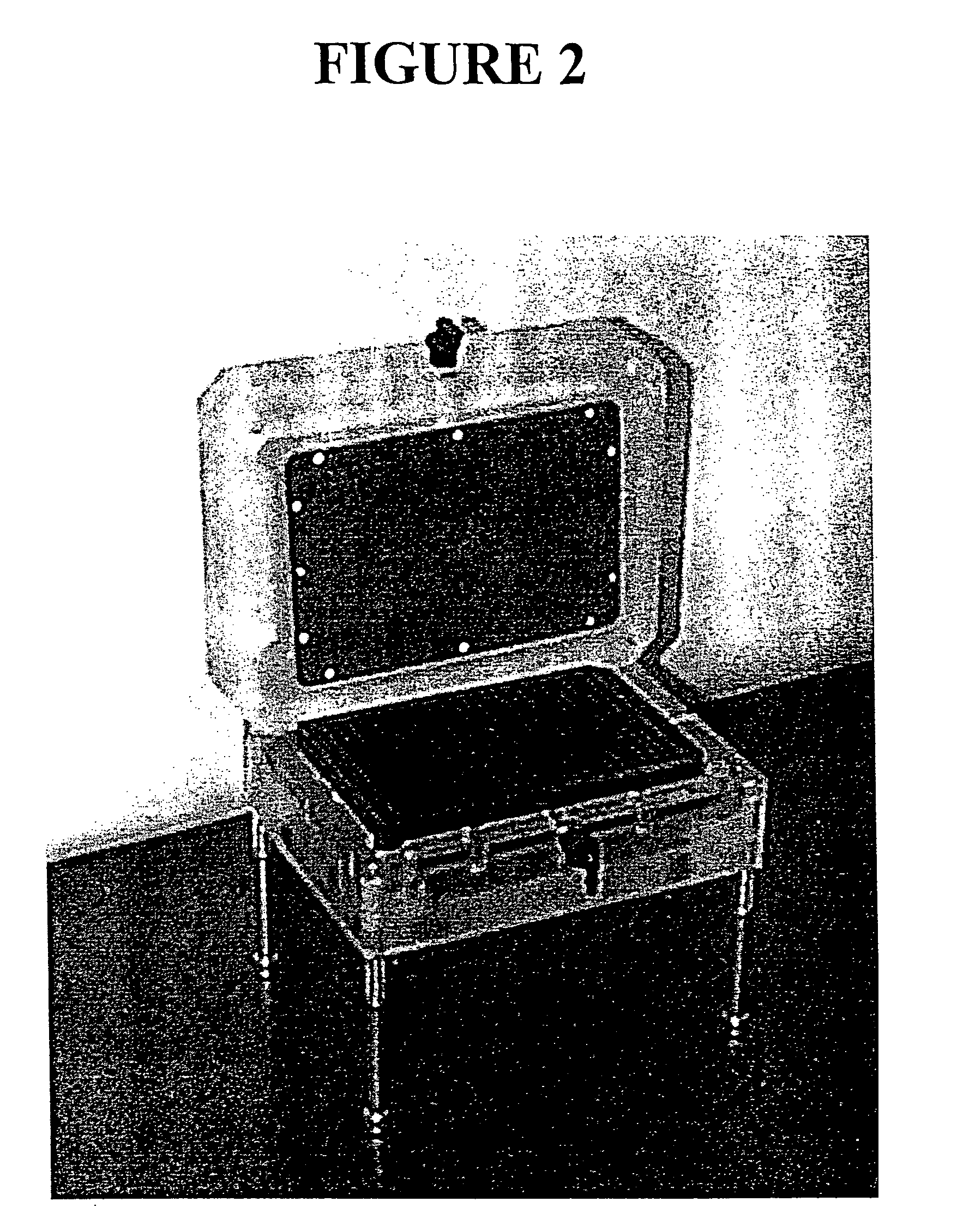

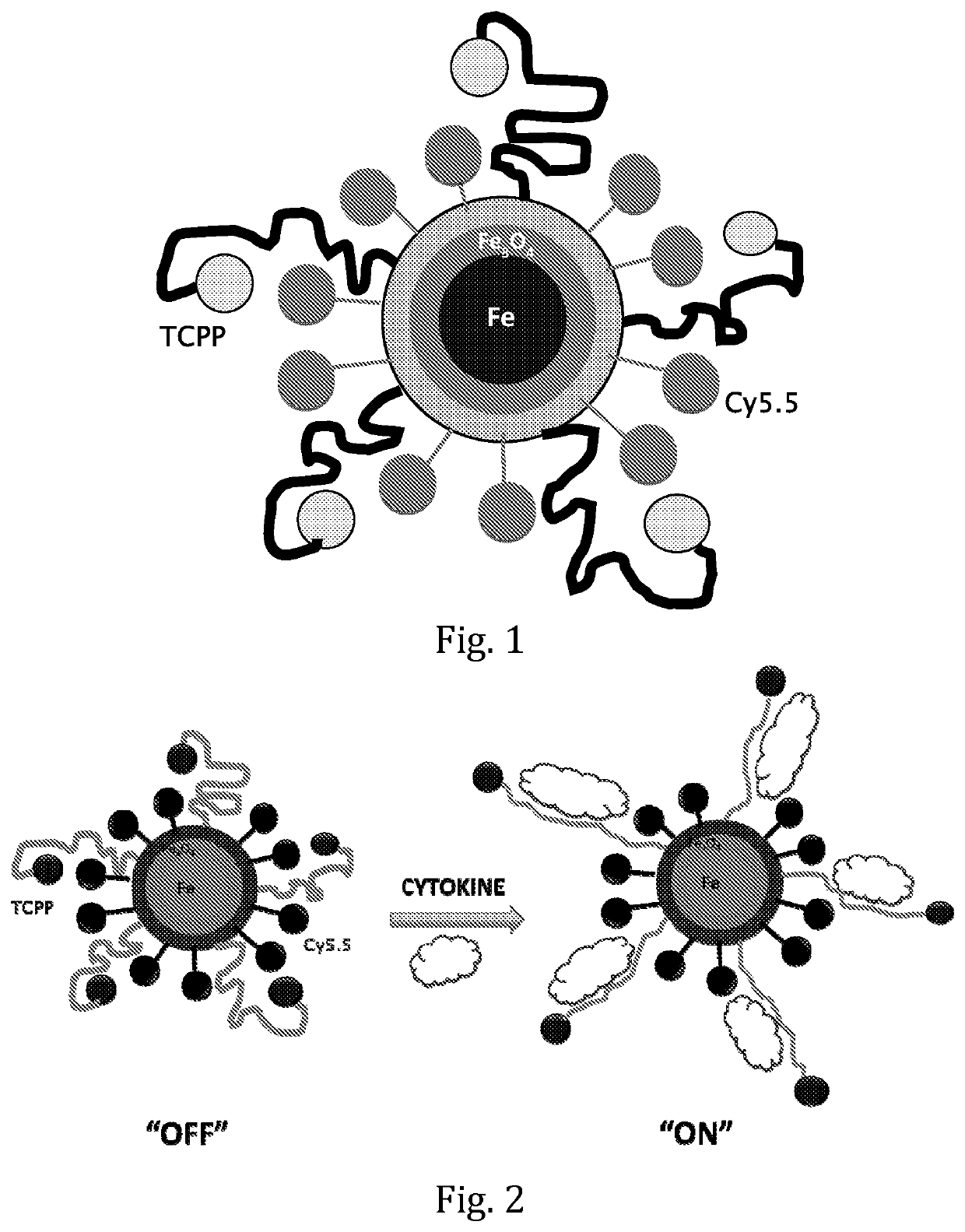

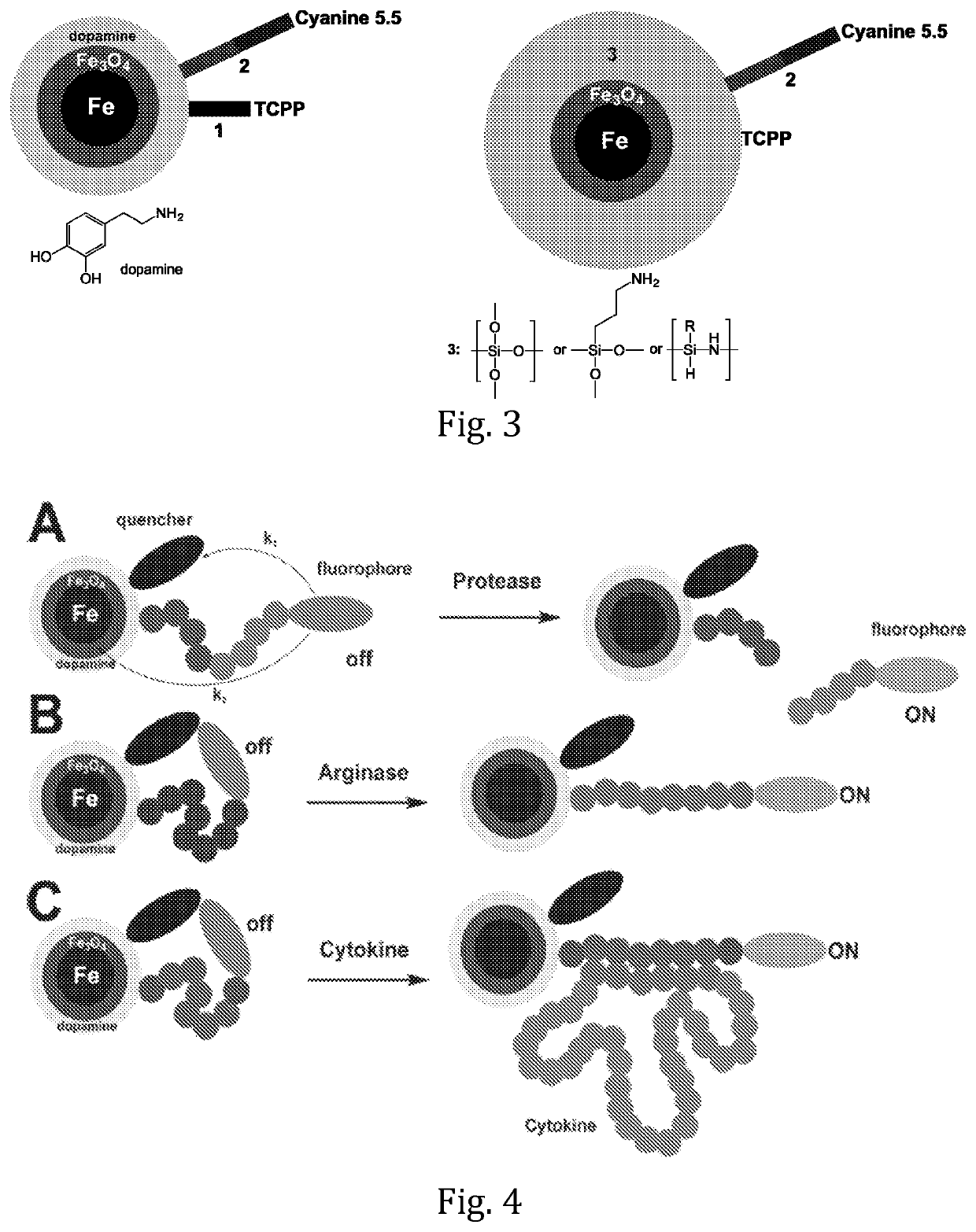

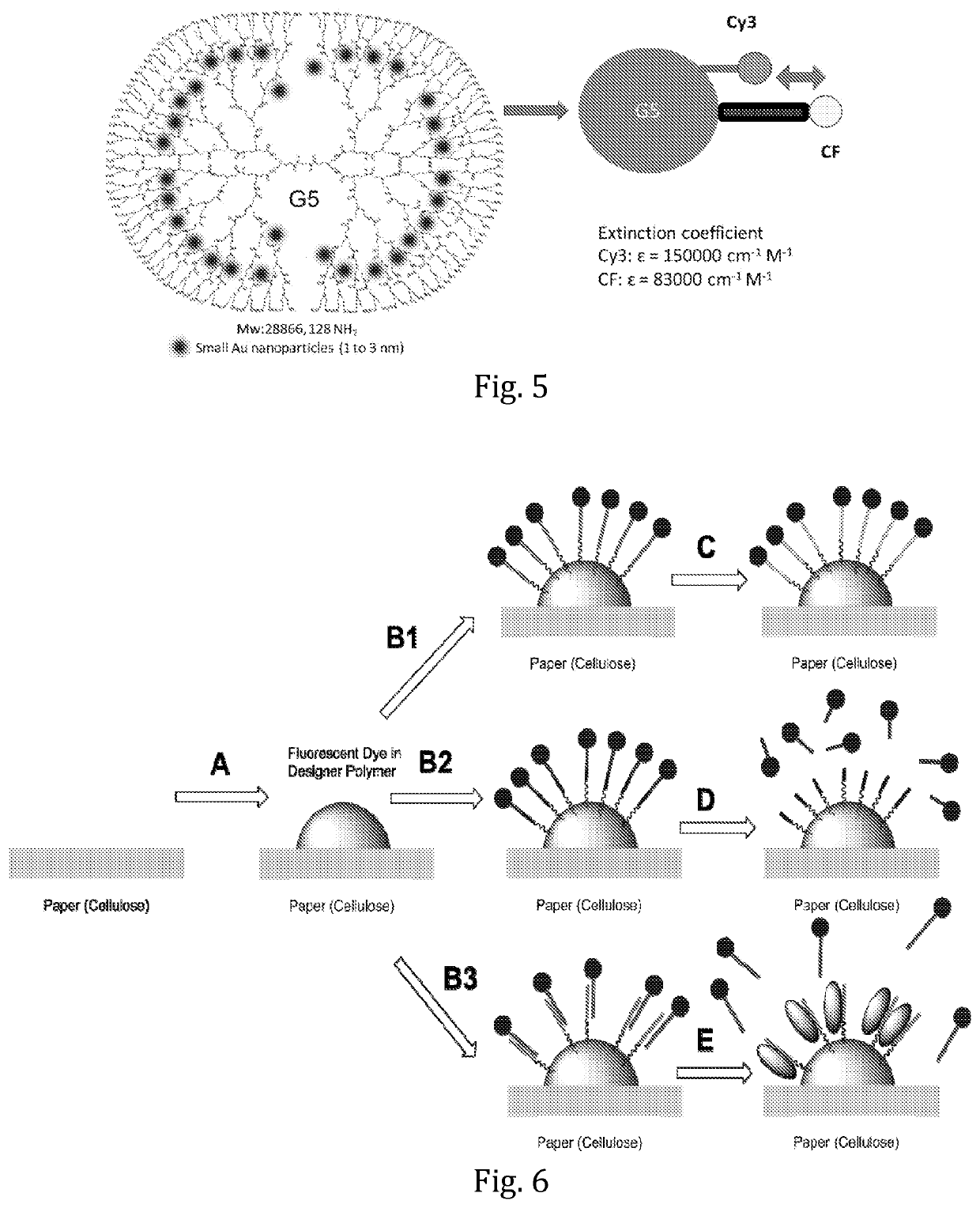

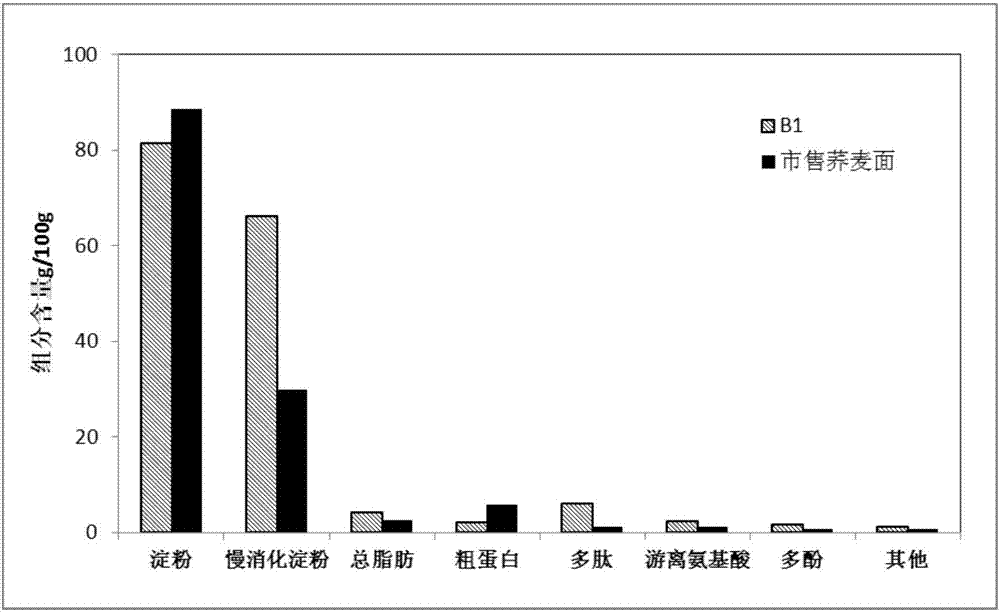

Nanosensors and methods for detection of biological markers

PendingUS20200300849A1Easy to moveBiological material analysisLaboratory glasswaresPost translationalCytokine

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

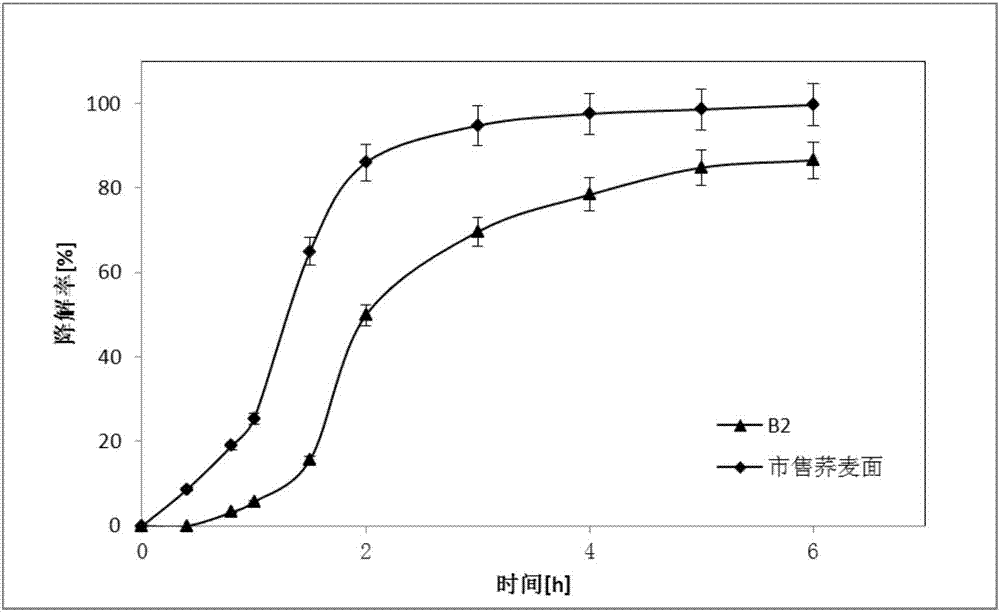

Integrated plant enzyme and application of integrated plant enzyme in good and health food

InactiveCN106993804AThe improvement effect is sufficientComprehensive improvement effectFood ingredient functionsBiotechnologyProtease

Integrated plant enzyme relates to the field of enzymes and comprises, by weight, 35-45 parts of pancreatin replacement enzyme, 0.5-1.5 parts of protease 3.0, 0.5-1.5 parts of protease 4.5, 0.5-1.5 parts of protease 6.0, 0.5-1.5 parts of bromelain, 8-10 parts of carbohydrate hydrolytic enzyme and 0.5-1.5 parts of fat hydrolytic enzyme, wherein the protease 3.0 is protease with the optimum pH value being 3; the protease 4.5 is protease with the optimum pH value being 4.5; and the protease 6.0 is protease with the optimum pH value being 6. The integrated plant enzyme can take effect on human bodies with different pH values, has a full effect of improving the function of human body, has the function of pancreatin, and has an integrated effect of improving the function of human body. In addition, the invention also designs the application of the integrated plant enzyme in food and health food.

Owner:WUHAN BENHE BIOTECHNOLOGY CO LTD

Plant activation of insect toxin

Owner:PIONEER HI BRED INT INC +1

New method for extracting plant essential oil by aqueous enzymatic method

Owner:TIANJIN NAER BIOTECH

Skincare cosmetic containing self-repairing active agent and preparation method of skincare cosmetic

Owner:CHENDU NEW KELI CHEM SCI CO LTD

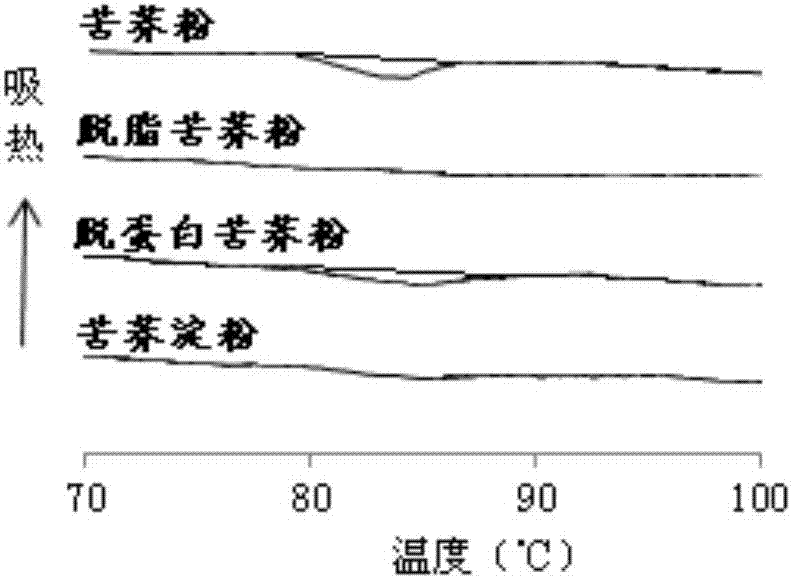

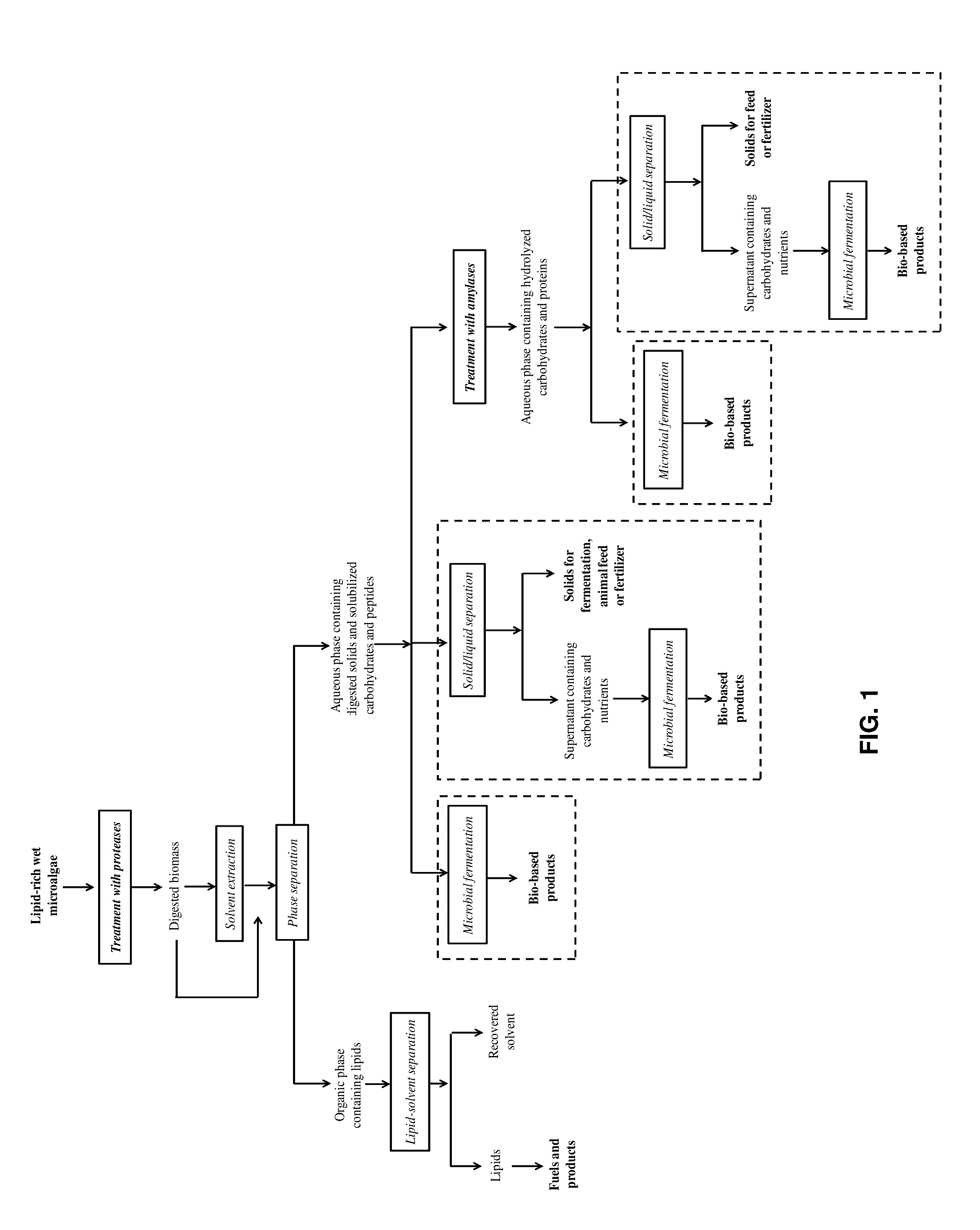

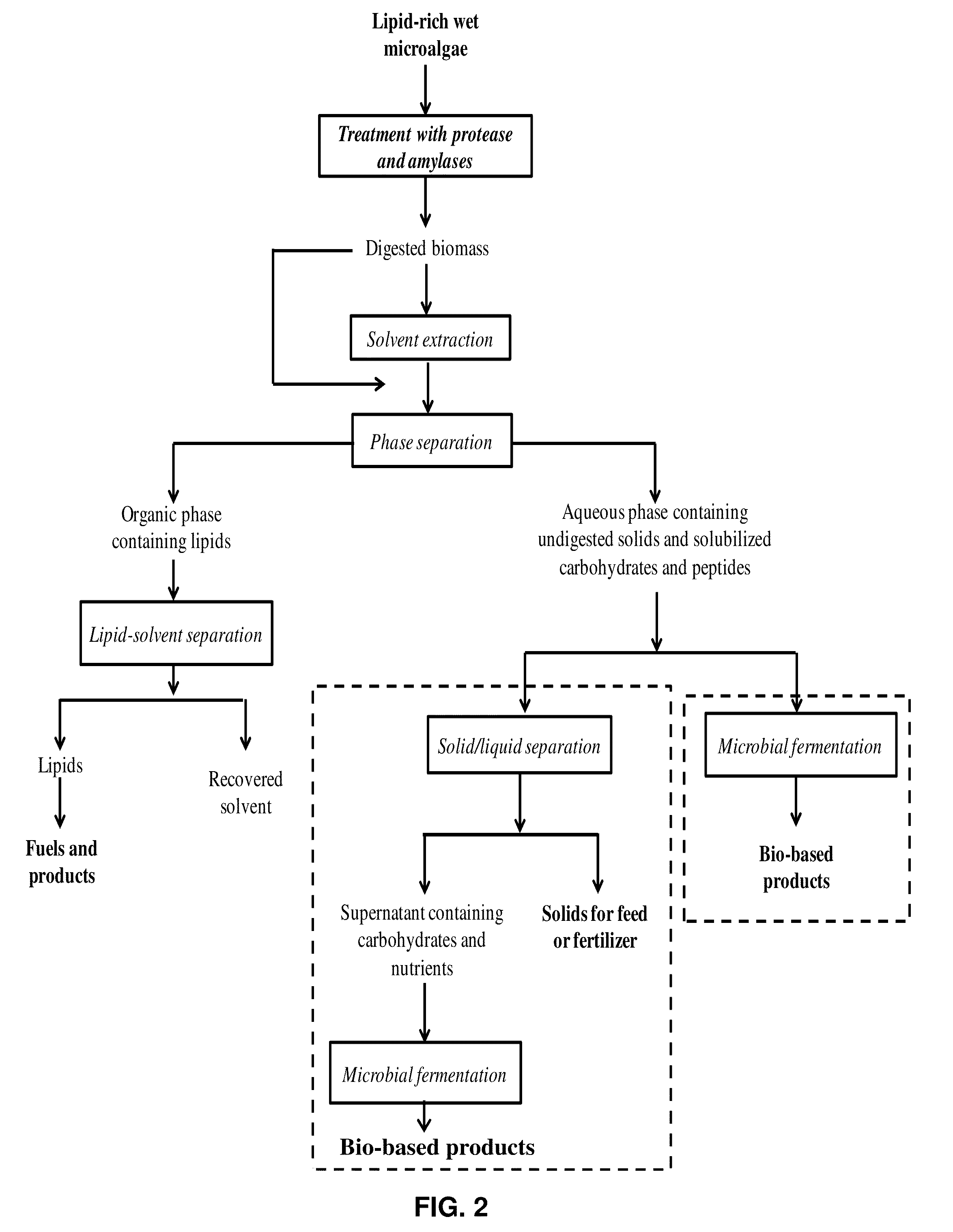

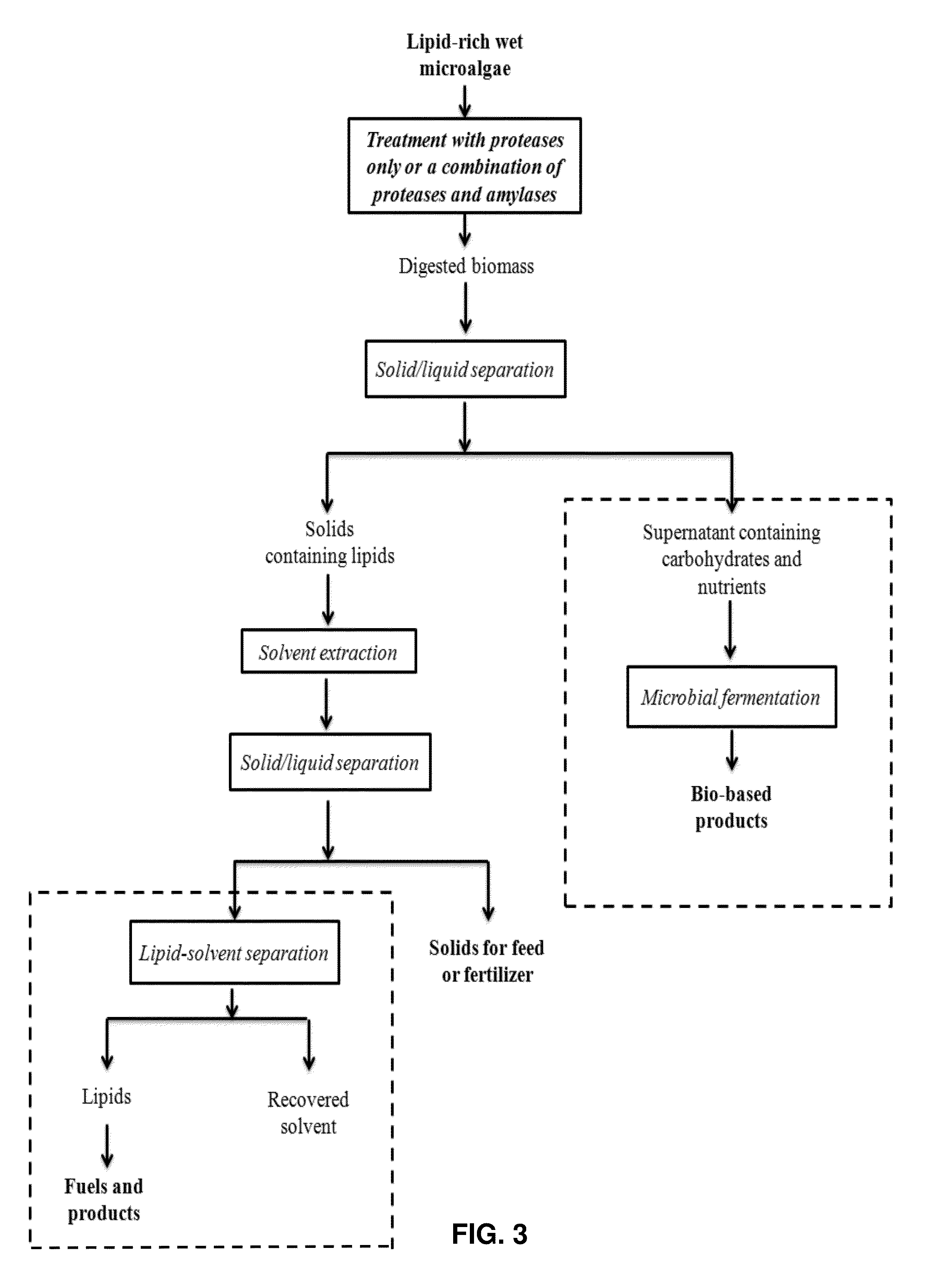

Enzymatic Digestion of Microalgal Biomass for Lipid, Sugar, and Protein Recovery

Owner:UNIVERSITY OF TOLEDO

Production process of braised chicken paste in brown sauce

The invention provides a production process of a braised chicken paste in brown sauce. The production process comprises the following steps: scalding, enzymolysis, stirring, heating, grinding and the like, and the production process specifically comprises the following steps: crushing chicken into granules with particle sizes of 3-7mm, and scalding for 5-15 minutes in water which accounts for 3-5 times of the weight of the chicken at 70-80 DEG C to ensure that the fishy smell of the chicken can be preliminarily removed on the one hand, the growth and propagation of most microorganisms can be inhibited on the other hand, and thus the content of harmful substances can be reduced, and the safety and sanitation of the chicken can be ensured; and adding a corn liquid and protease to perform thermal reaction, then matching with raw materials such as spices, table salt and the like, and then grinding for 2-3 hours at 70-80 DEG C. By adopting the production process provided by the invention, nutrient substances in the chicken can be better protected and cannot be damaged, and realistic effects of natural meat flavor can be generated; and moreover, the braised chicken paste in brown sauce provided by the invention has the natural fragrance and nutritional components of corns, and the prepared braised chicken paste in brown sauce is good in taste, rich and natural in meat flavor and attractive in color, is easier to be absorbed by the intestines, and can be used for better meeting the needs of a human body on nutrient balance.

Owner:叶县伊帆清真食品有限公司

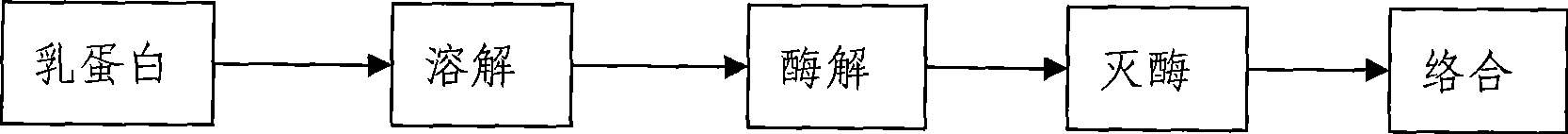

Enzymatic hydrolysis lactoprotein zinc complex compound and preparation thereof

InactiveCN101475628ASafe preparationReduce solubilityPeptide/protein ingredientsMetabolism disorderIntestinal structureMilk protein

Owner:CHINA AGRI UNIV

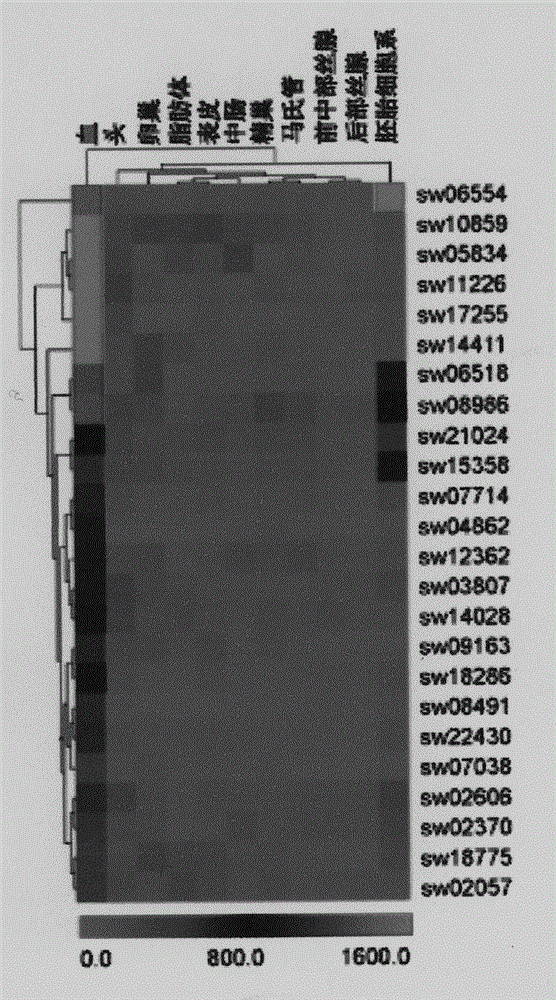

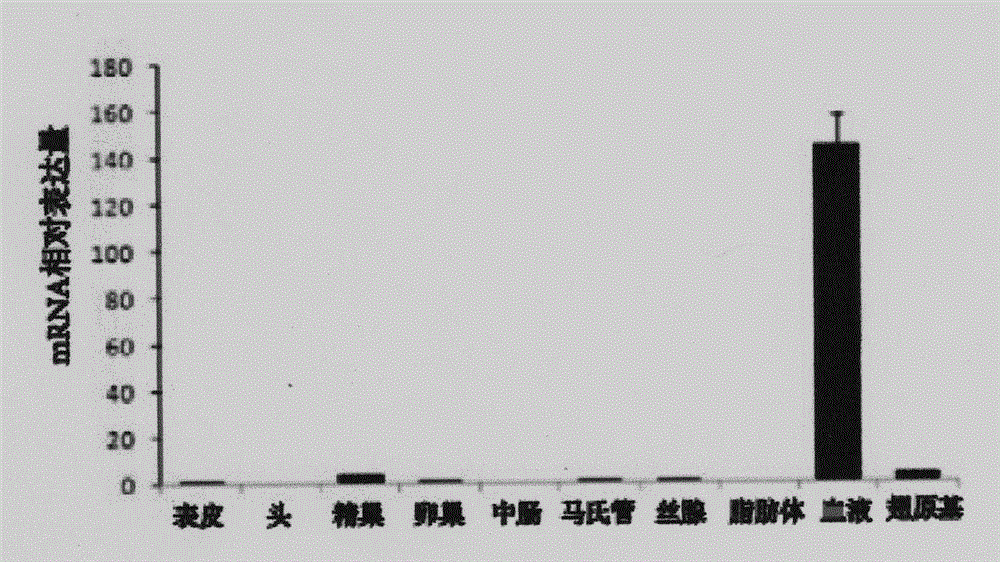

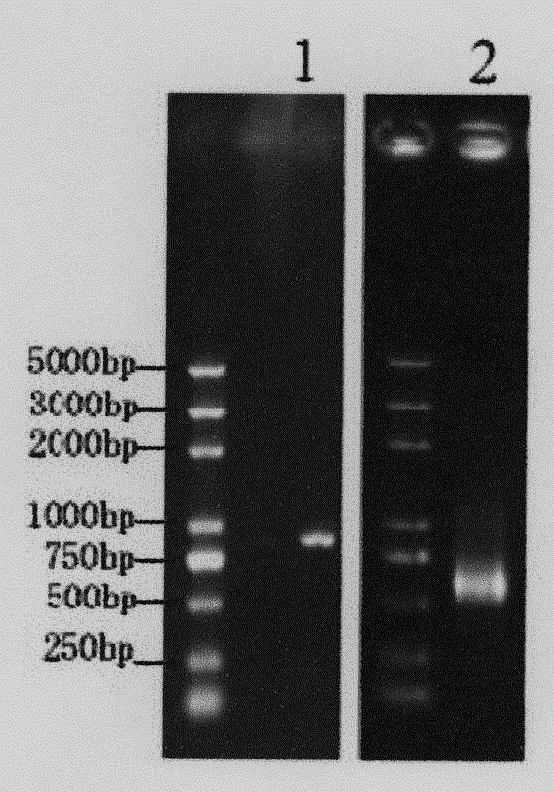

Identification of silkworm hemocyte specific expressed gene cathepsin O regulation element

Owner:SOUTHWEST UNIVERSITY

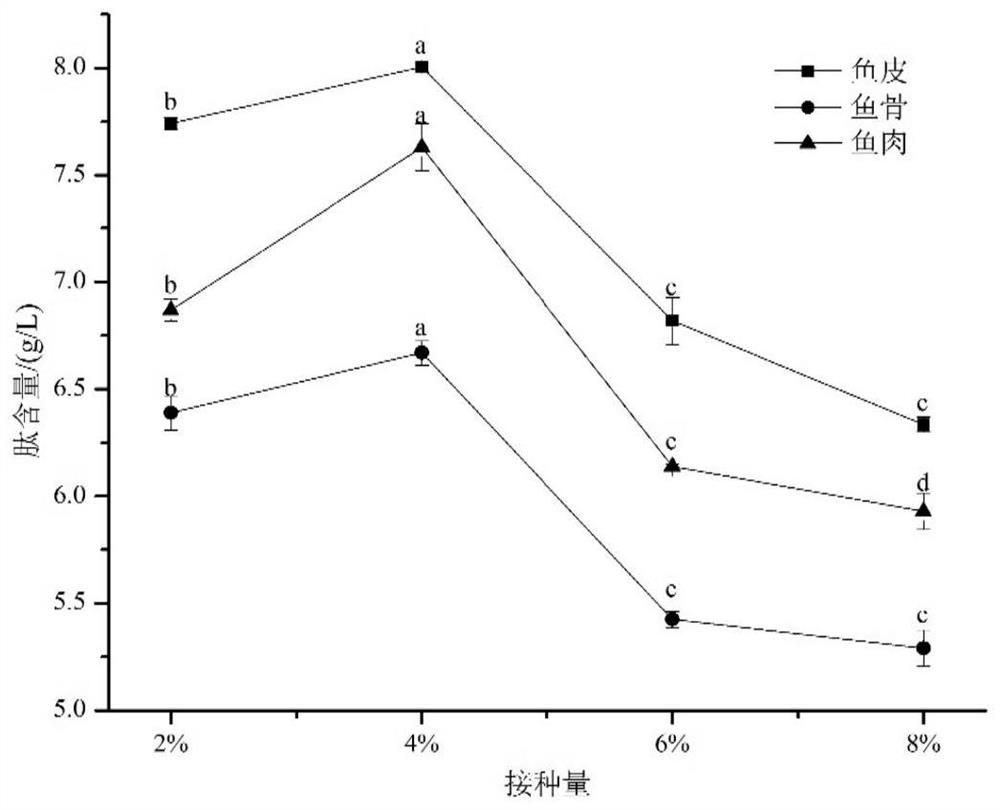

Nutritional noodles added with fish polypeptide powder and preparation method of nutritional noodles added with fish polypeptide powder

PendingCN112544874ATake advantage ofRich tasteProtein composition from fishBacteriaBiotechnologyAlkaline proteinase

Owner:QINGDAO AGRI UNIV

Special feed additive for animal intestines

InactiveCN112006185AReduce manufacturing costEasy to adjustAnimal feeding stuffAccessory food factorsBiotechnologyBenzoic acid

The invention discloses a special feed additive for animal intestines. The feed additive is prepared from the following raw materials in percentage by weight: 15-20% of an enzyme preparation, 30-60% of a fermentation material, 10%-20% of bentonite, 0.5%-1% of multi-vitamin, 1%-5% of multi-mineral, 0.5%-2% of a mildew preventive, 0.5%-2% of an antioxidant, 2%-20% of zeolite powder, wherein the enzyme preparation is a plurality of compound enzymes such as protease, cellulase, glucolase and xylanase, the fermentation material is a substrate for fermentation of a microecological preparation, the multi-vitamin comprises vitamin A, vitamin D3, vitamin E, vitamin B1 and vitamin B2, the multi-mineral comprise a plurality of trace elements: copper glycinate, zinc glycinate and iron glycinate, the main components of the mildew preventive are propionic acid, calcium propionate and benzoic acid, and the main components of the antioxidant are ethoxyquinoline and butylated hydroxytoluene. The special feed additive for animal intestines is high in overall utilization rate, improves the egg laying efficiency of old laying hens, and can be widely popularized and used.

Owner:KUNMING YUNNAN NONGDA BIOLOGICAL TECH CO LTD

Automatic dishwashing detergent composition

InactiveUS20180179475A1Organic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsAmino acid substitutionPhosphate

A phosphate-free automatic dishwashing cleaning composition comprising a protease wherein the protease is a variant of a parent protease, the parent protease having the amino acid sequence of SEQ ID NO:1 and the variant protease has at least 90% identity with the amino acid sequence of SEQ ID NO:1 wherein the variant protease comprises at least an amino acid substitution in position 167 and / or 170 (BPN′ numbering) and wherein the variant protease is free of aspartic acid and / or glutamic acid in any of the positions 95 to 103 (BPN′ numbering).

Owner:PROCTER & GAMBLE CO

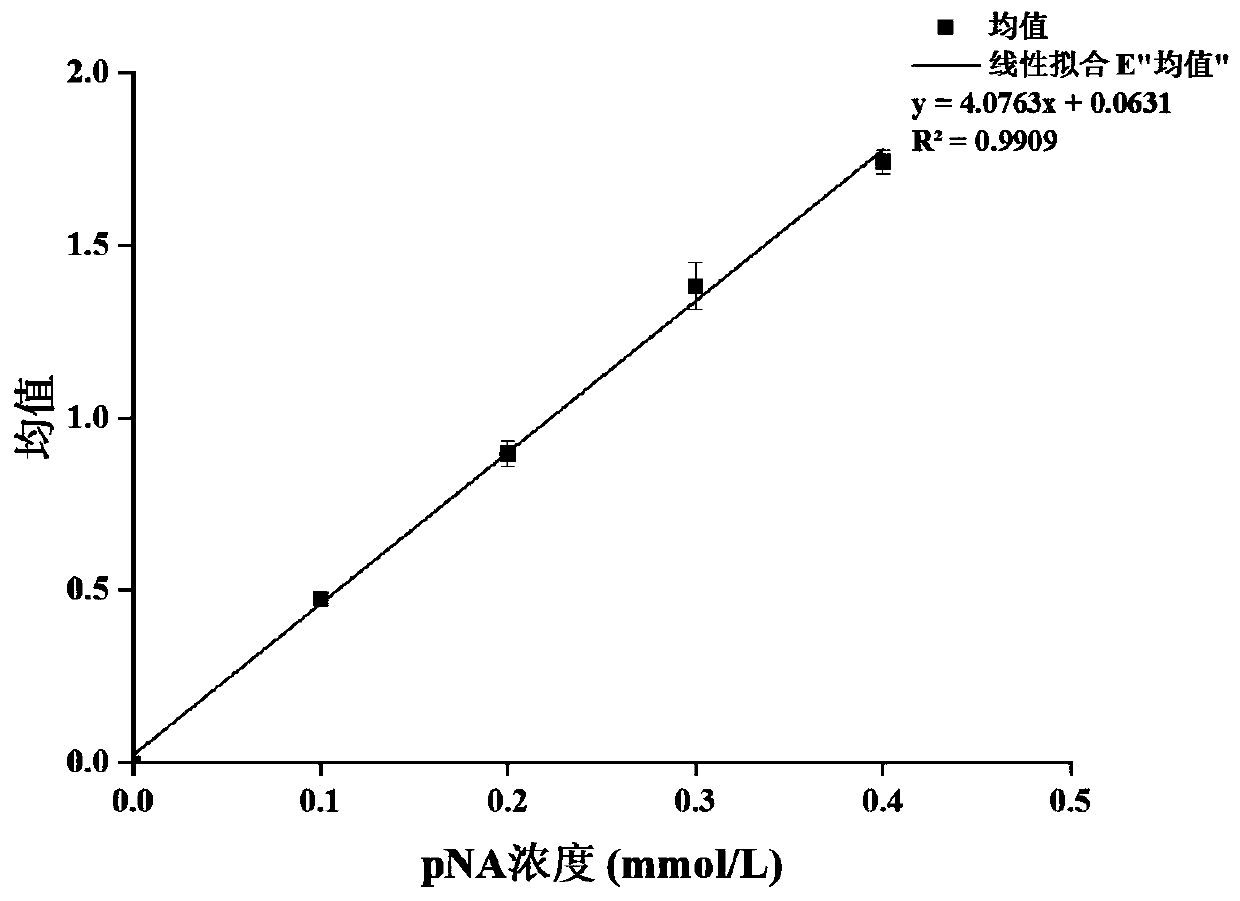

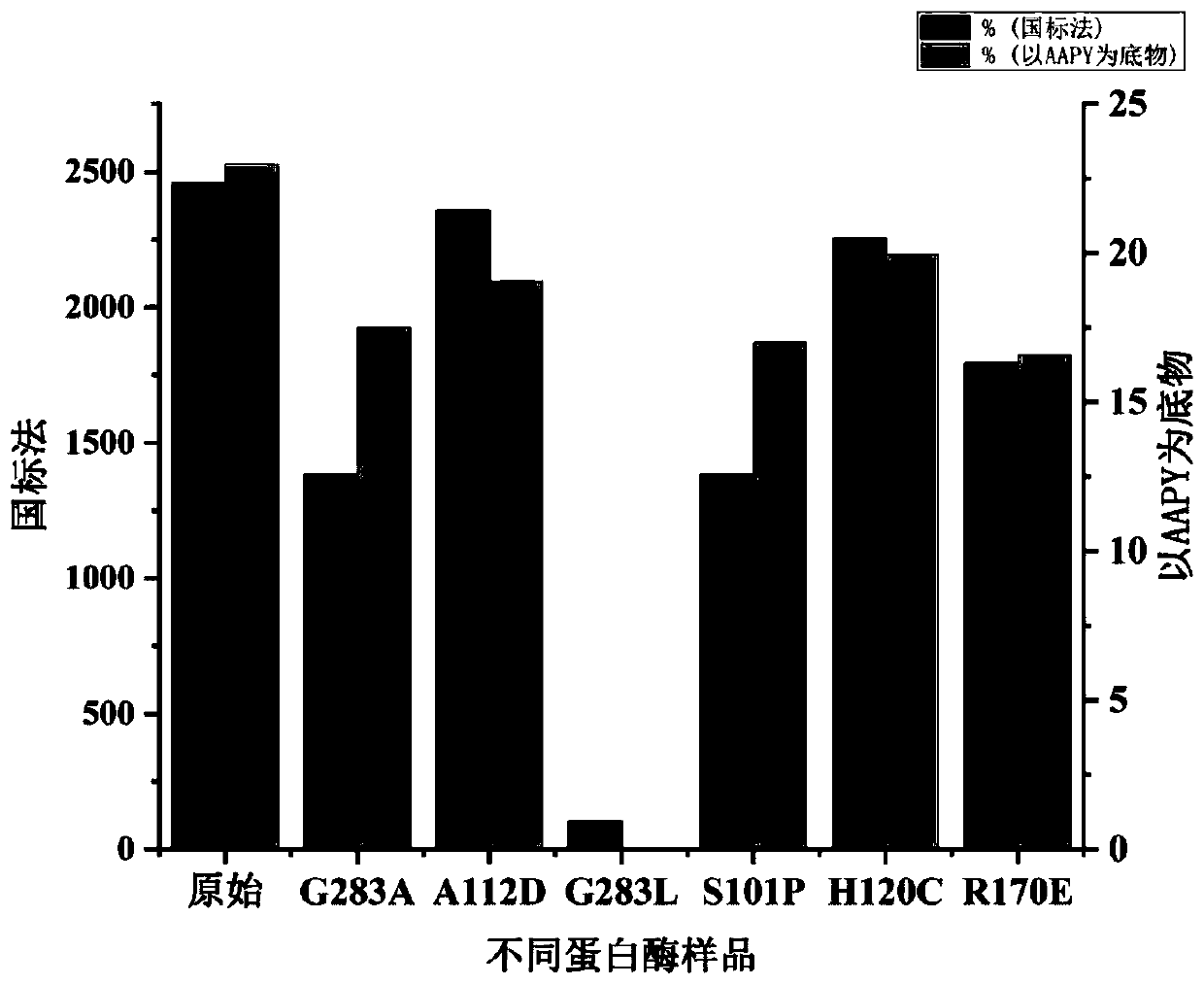

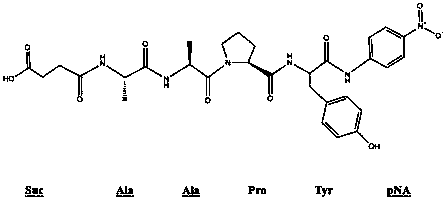

Method of simply, conveniently and quickly measuring protease activity

PendingCN110305934AReduce demandMeet needsMicrobiological testing/measurementPeptidesProteinase activityTyrosine

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Water purifier for production of rubber accelerator DZ and wastewater treatment method

InactiveCN105967449AImprove water qualityEmission reductionWater/sewage treatmentMultistage water/sewage treatmentChemical treatmentMicrobial agent

The invention belongs to the technical field of rubber chemical wastewater treatment and particularly relates to a water purifier for production of a rubber accelerator DZ and a wastewater treatment method. The water purifier for production of the rubber accelerator DZ comprises a solid adsorption material, a microbial water purifier and an enzyme preparation. The solid adsorption material is prepared from, by weight, 10-25 parts of medical stone, 5-20 parts of active coke and 5-15 parts of slag; the microbial water purifier is prepared from, by weight, 0.5-2.0 parts of phosphorus-accumulating bacteria powder, 0.4-1.4 parts of geotrichum candidum powder, 0.2-0.8 part of white rot fungi powder and 0.3-1.2 parts of microbacterium powder; the enzyme preparation comprises, by weight, 0.05-0.1 part of manganese catalase, 0.04-0.12 part of oxidoreductase, 0.03-0.08 part of streptomyces protease and 0.02-0.1 part of nitrile hydratase. By joint action of the solid water purifier, the composite microbial agent and the enzyme preparation to wastewater, secondary pollution caused by chemical treatment is avoided, sewage discharging amount is decreased, and quality of treated wastewater is improved. In addition, by the wastewater treatment method, CODcr discharging amount reaches national specified standards.

Owner:SHANDONG YONGTAI CHEM GROUP

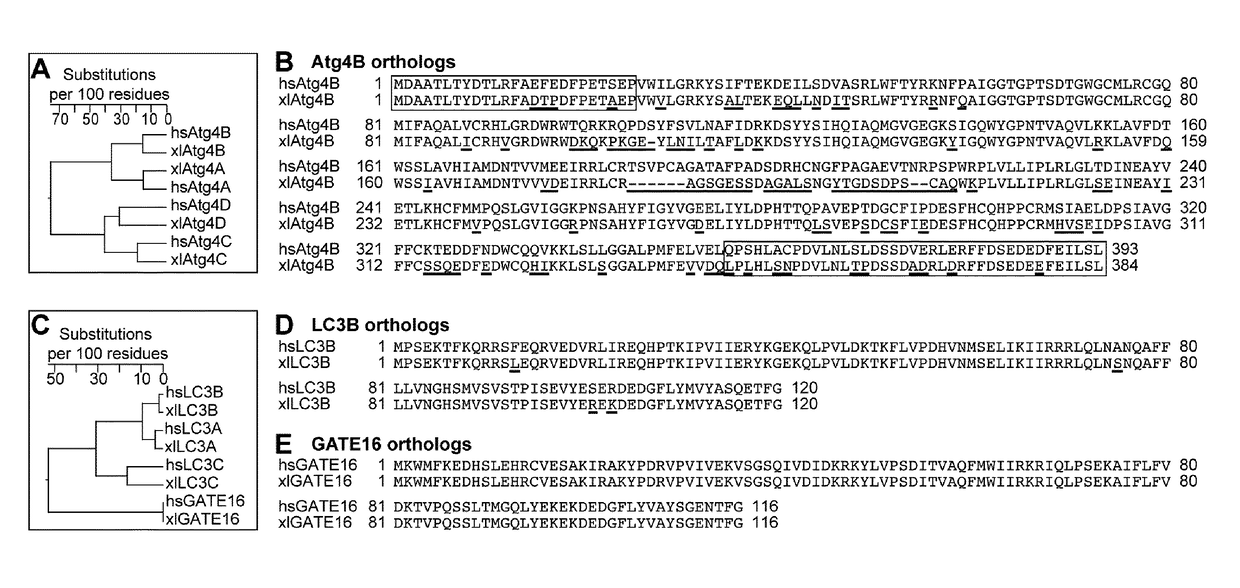

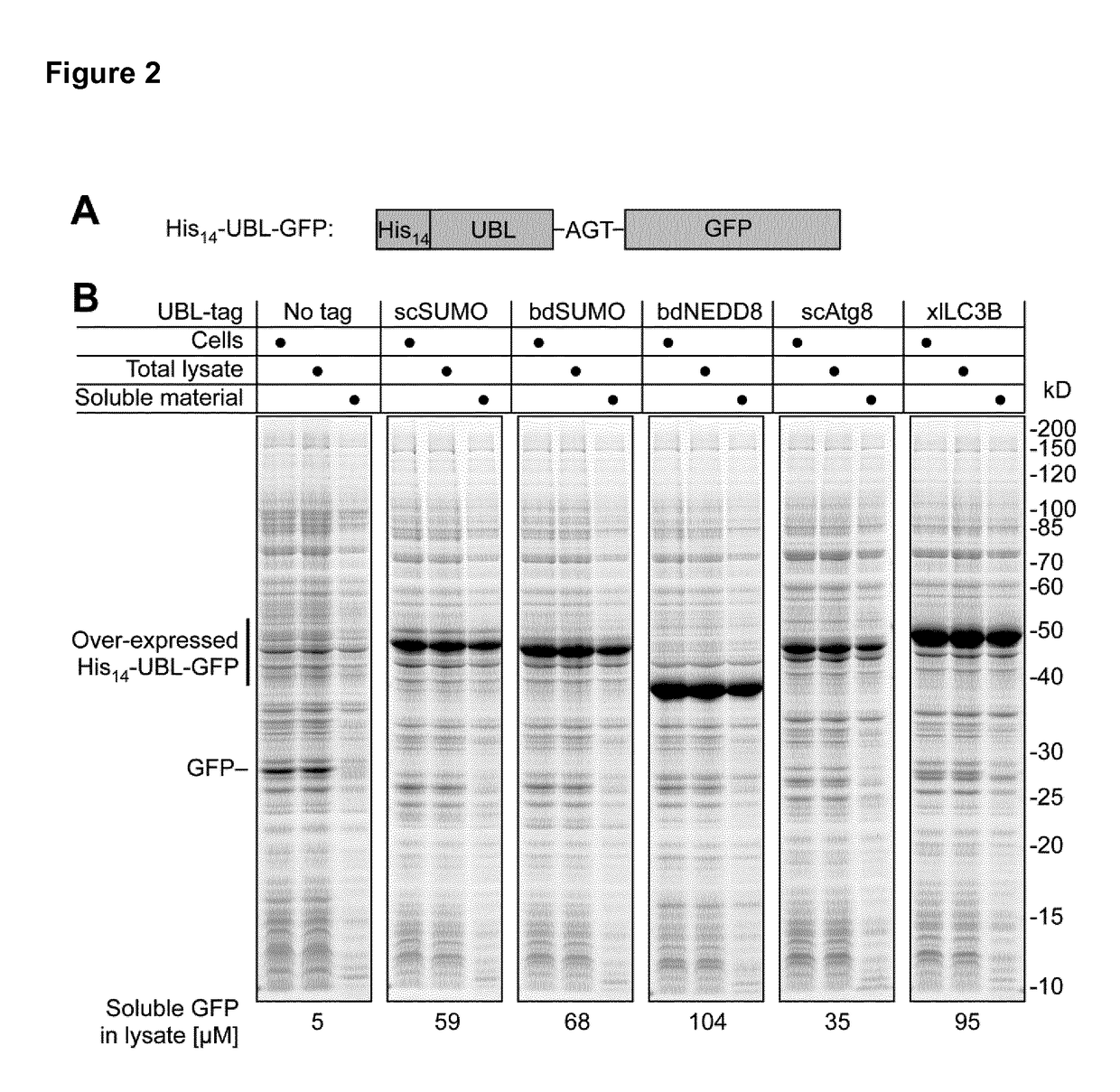

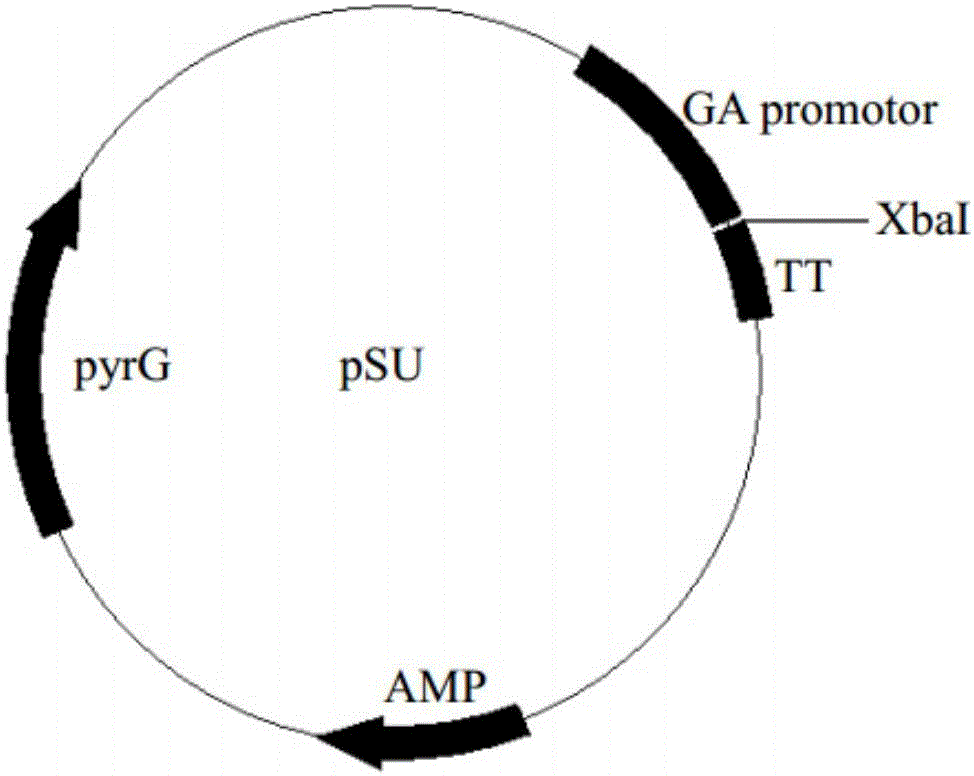

Tag removal from proteins expressed in pro- and eukaryotic hosts

ActiveUS20180195056A1High expressionImprove solubilityHydrolasesPeptide preparation methodsHost cell filopodiumProtease

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

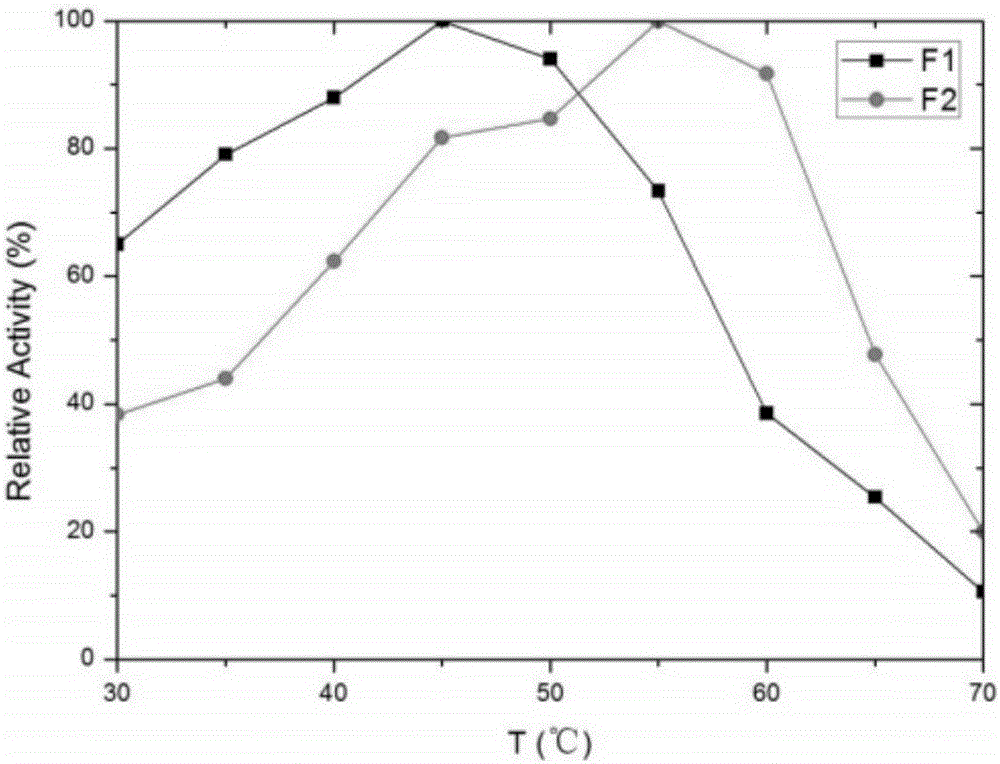

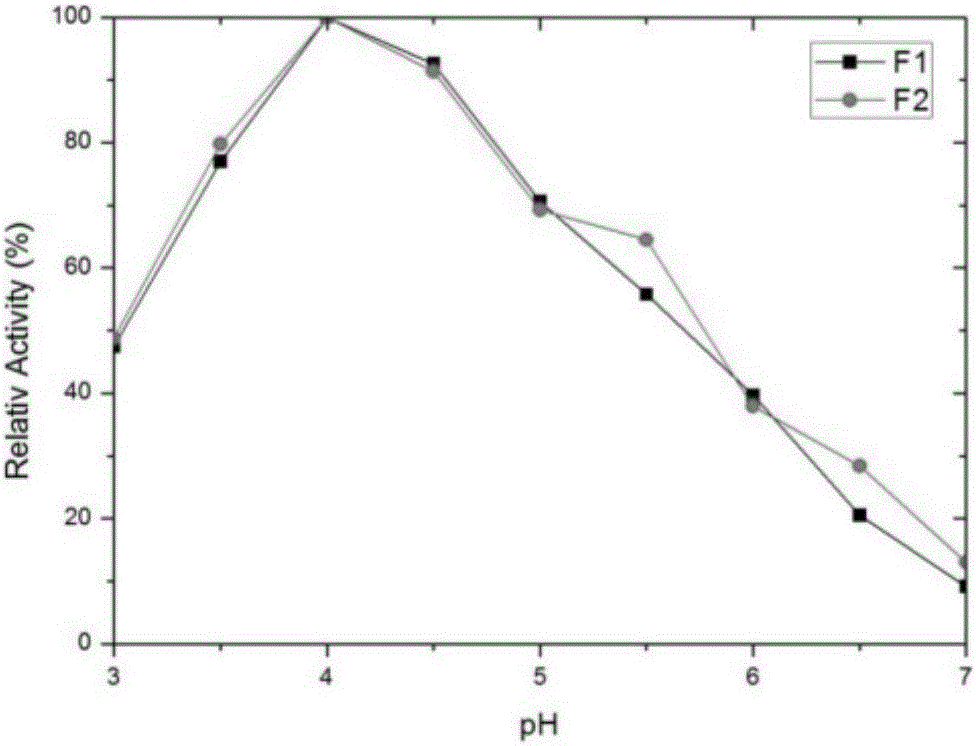

Proline protease mutant and application thereof

ActiveCN106754837AReduce turbidityGood enzymatic effectFermentationGenetic engineeringProteinase activityHeat resistance

Owner:QINGDAO VLAND BIOTECH GRP +1

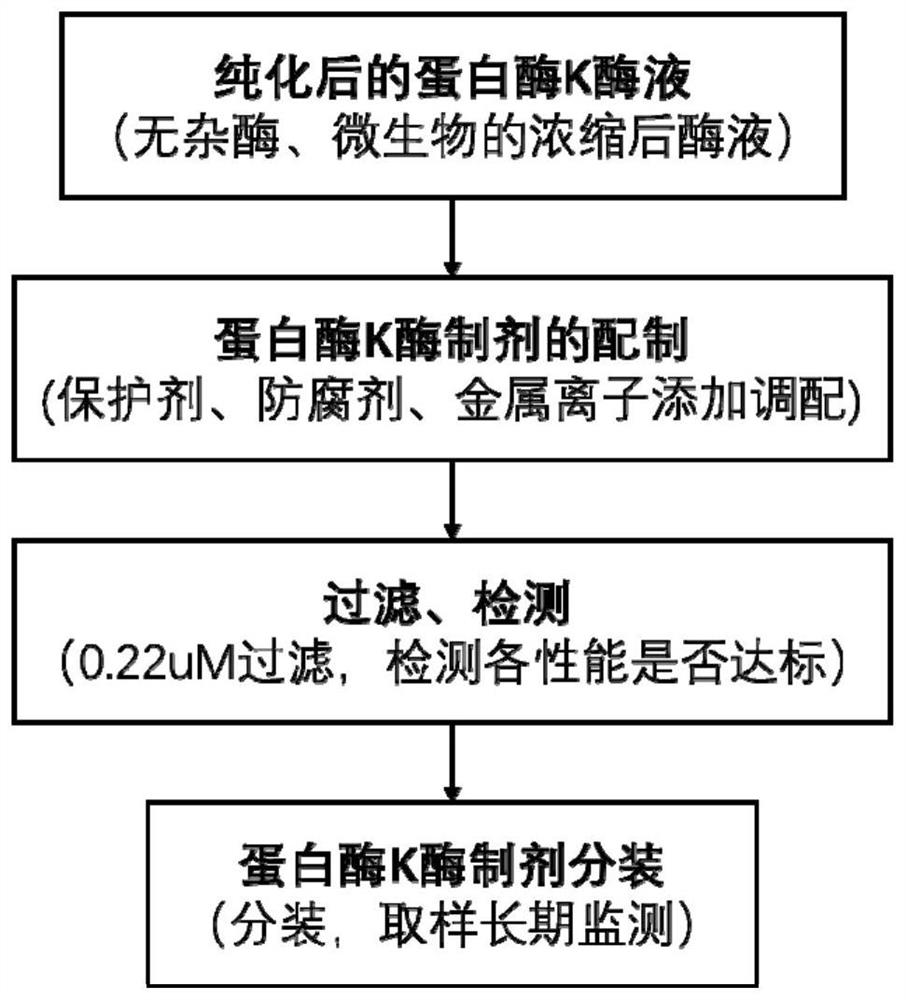

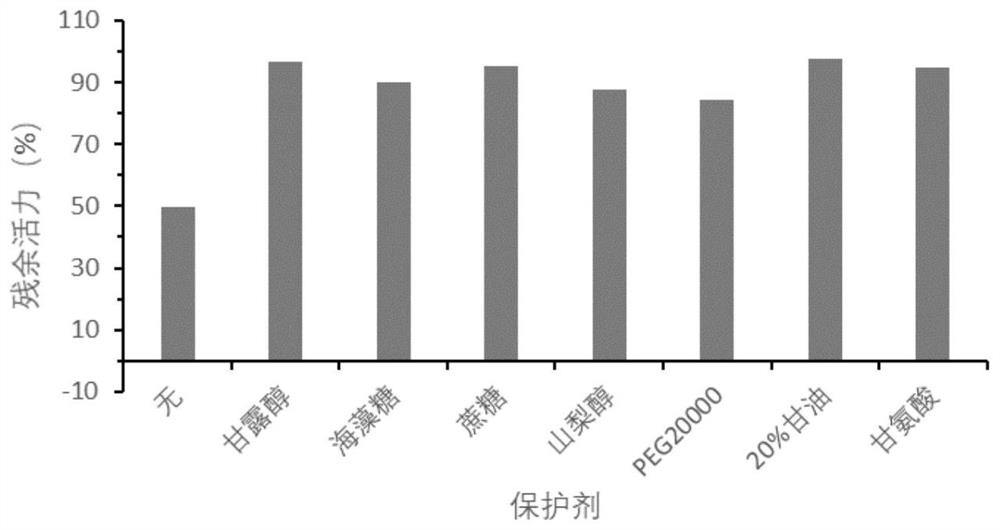

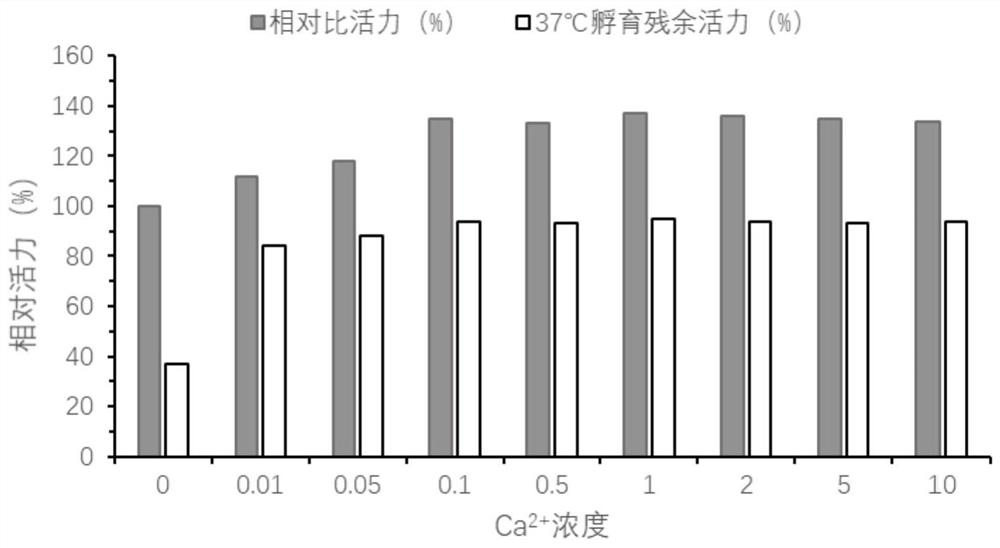

Protease k liquid enzyme preparation for molecular biology and in vitro diagnostics

PendingCN113416723AMicrobiological testing/measurementBiological material analysisProtein proteinProtease

Owner:WUHAN HANHAI NEW ENZYMES BIOLOGICAL TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap