Enzymatic Digestion of Microalgal Biomass for Lipid, Sugar, and Protein Recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

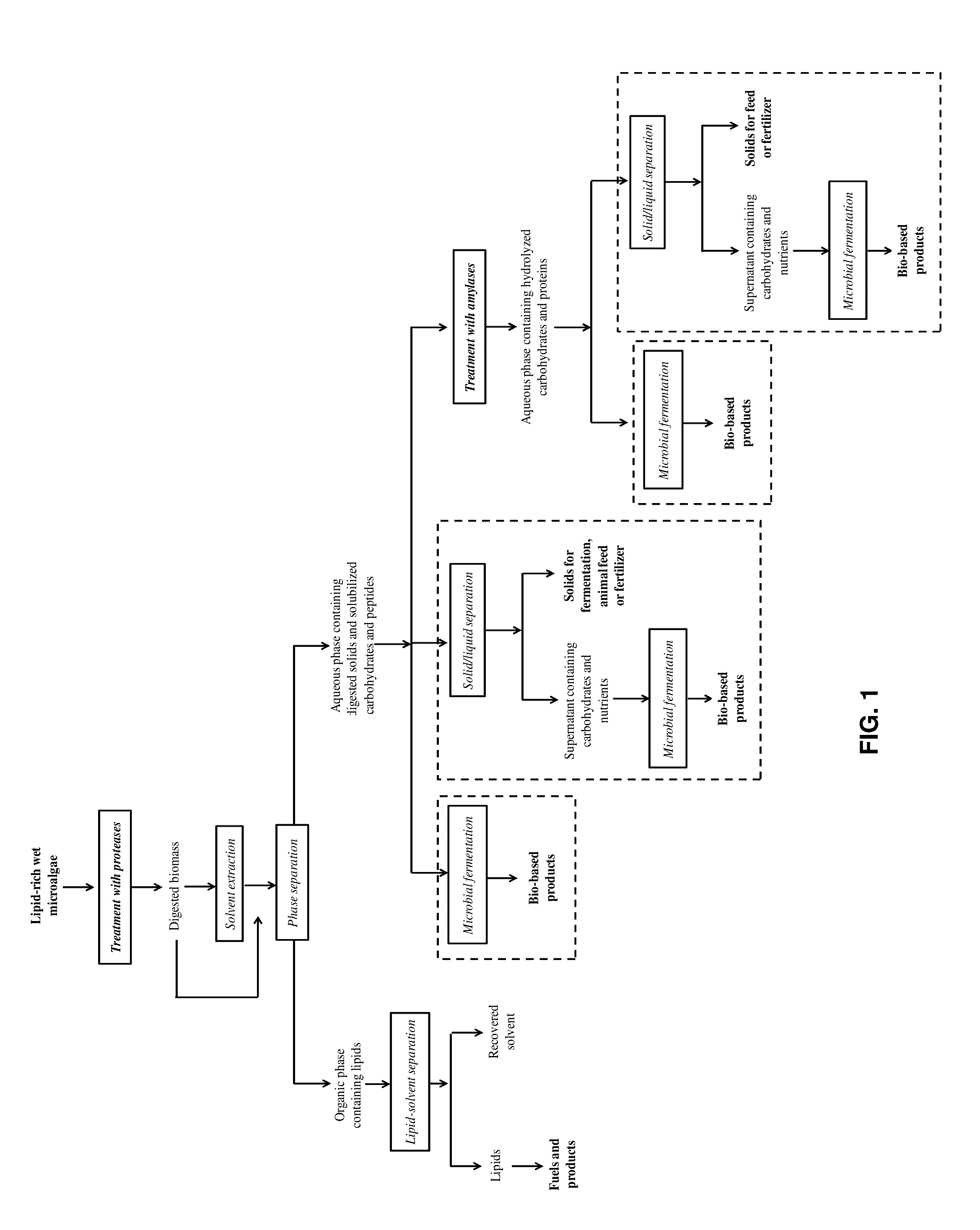

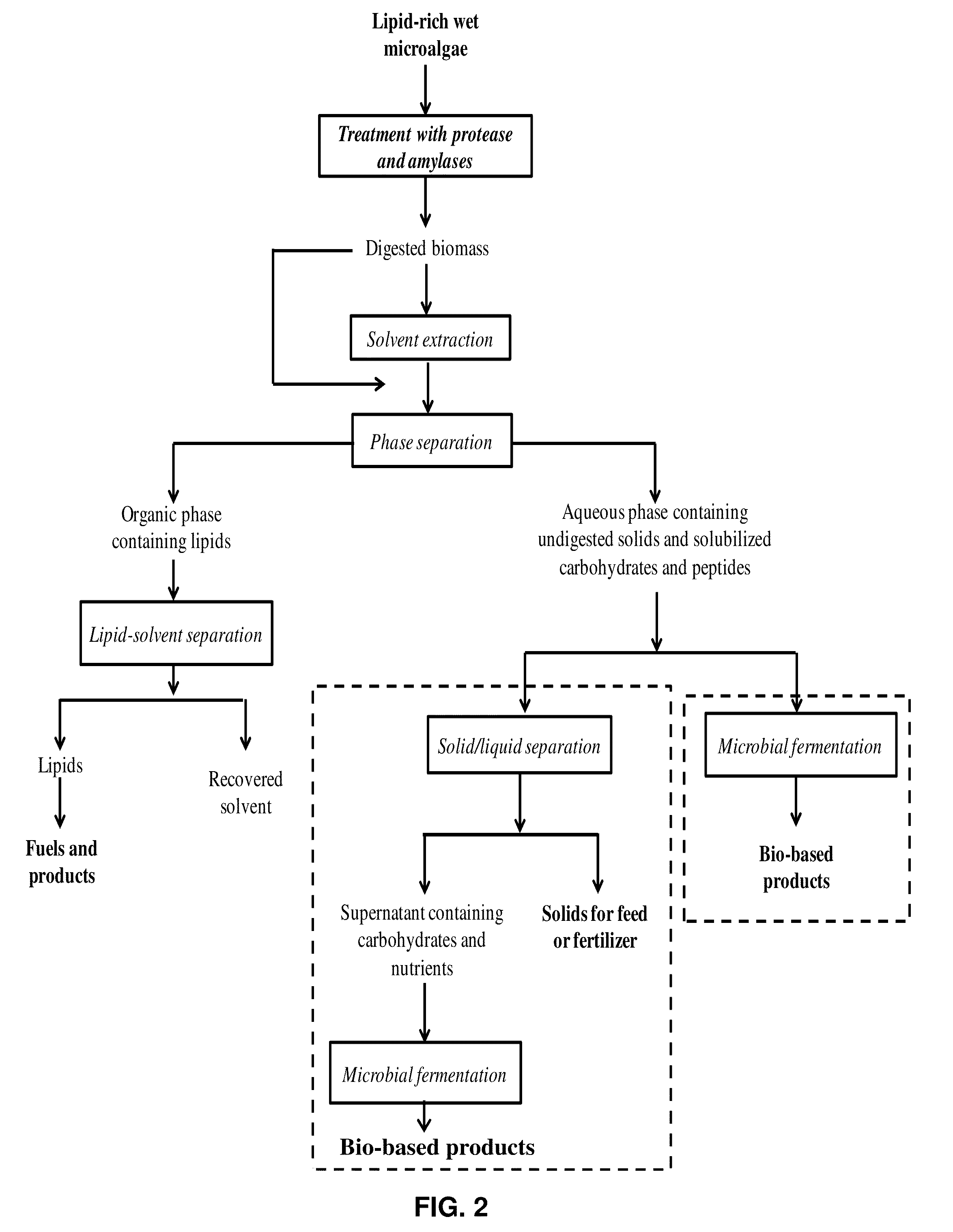

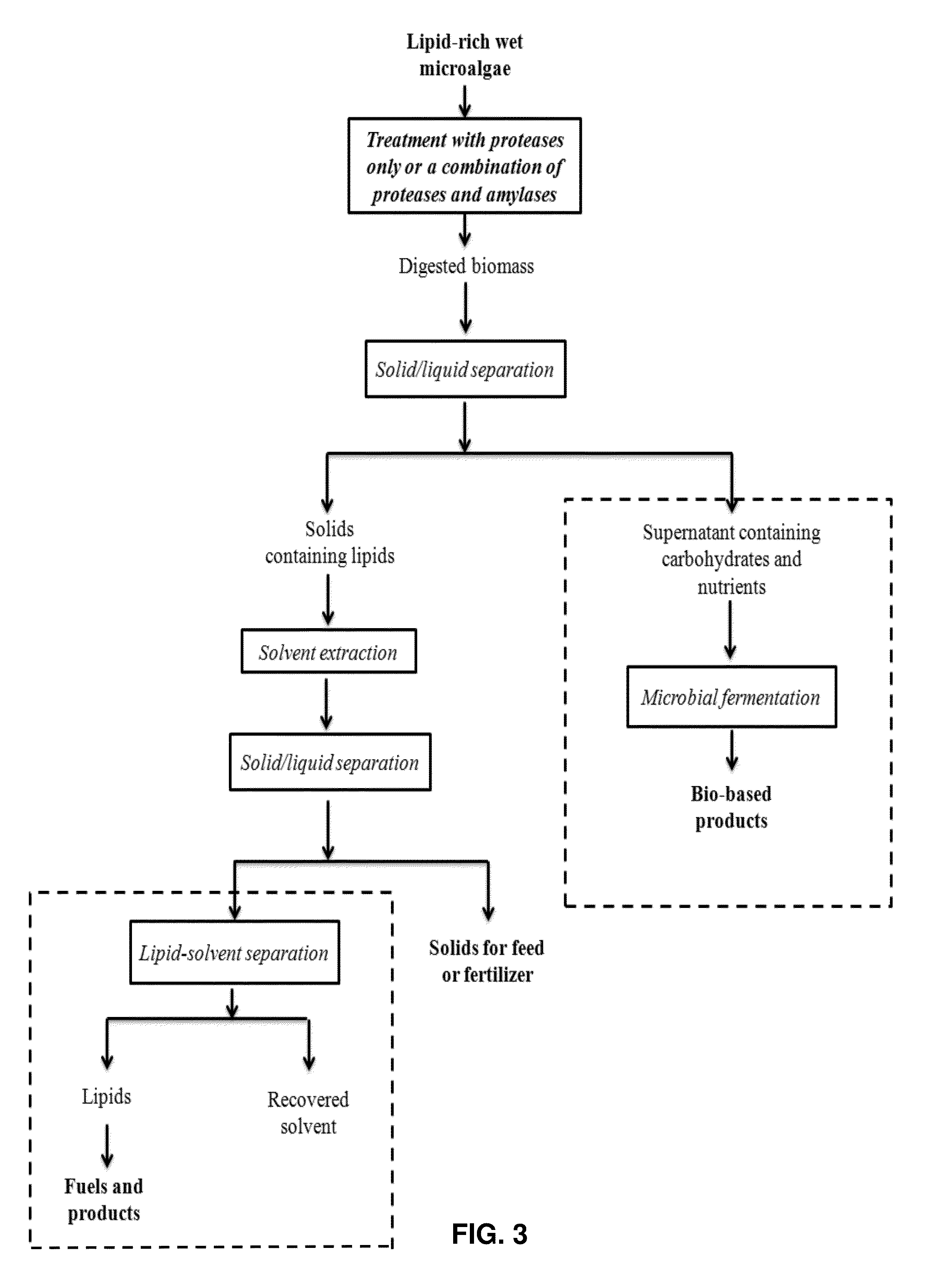

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Recovery of Lipids and Monomeric Sugars from Wet Algal Biomass Using Enzymatic Treatment Methods

[0069]Two strains of algae were used in these experiments: a) Chlorella sp. SLA-04, and b) Schizochitrium limacium SR21, obtained from ATCC (MYA 1381).

[0070]Biomass digestions were performed at a solid concentration of 10% (w / v) in 50 mM citrate buffer adjusted to a pH of 4.5. Protease alone or a mixture of protease with α-amylase and amyloglucosidase (all purchased from Sigma) were added to the biomass slurries. Enzyme loadings (per g-biomass) used were as follows—(a) protease 312 U / g; (b) α-amylase 1875 U / g; and (c) glucoamylase 18.75 U / g. 1 α-amylase unit is defined as the amount of enzyme that liberates 1 μmol maltose per minute at pH 6.0 and 25° C.; 1 glucoamylase unit is defined as the amount of enzyme which cleaves 1 μmol of maltose per min at pH 4.3 and 25° C.; and 1 protease unit is defined as the amount of enzyme which hydrolyzes 1 μmol of L-leucine-p-nitroanilide per min.

[

example 2

Sugar Recovery from Microalgal Biomass by Enzymatic Digestion

[0077]Enzymatic hydrolysis experiments were conducted using protease, α-amylase, and glucoamylase, and their combinations. A mixed culture of lipid-lean algal biomass (lipid content <5% (w / w)) was obtained from a commercial wastewater treatment facility. The biomass had a carbohydrate content of 24.5% (w / w). The digestion experiments were performed at a solids' loading of 16% (w / v) at a pH of 4.5. The amount of each enzyme was fixed as follows: 2.5 kU protease, 5 kU of α-amylase, and 150 U of glucoamylase. Enzymatic hydrolysis reactions were performed in sealed serum vials agitated at 200 rpm for 2 h at 55° C. Samples were collected at the end of the incubation period and analyzed by HPLC using a Shodex SH1011 ion exchange column with refractive index (RI) detector.

[0078]The results (FIG. 11) show that treatments with protease alone resulted in the release of a significant amount of monomeric sugars. Without wishing to

example 3

Sugar Recovery from Microalgal Biomass by Hydrothermal Pretreatment Followed by Enzymatic Digestion

[0081]Hydrothermal pretreatment was used in combination with enzymatic digestion to evaluate the potential for lowering enzyme requirements for sugar recovery. For the hydrothermal treatment, algal slurries (16% w / w) were loaded into sealed serum bottles and autoclaved at 120° C. for 30 minutes. After cooling to room temperature, the pretreated slurries were digested at 55° C. for 6 h using a mixture of α-amylase and glucoamylase (pH=4.5). A series of digestions were performed with α-amylase loadings between 0.5 and 15 kU while maintaining a glucoamylase loading of 150 U. Monomeric sugar release was measured at the end of the experiments. As seen from FIG. 15, the pretreatment improved enzymatic digestibility relative to controls which were not thermally pretreated. As a result, up to 90% sugar recovery was able to be achieved at α-amylase loadings as low as 5 kU.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap