Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about "Decorative surface effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

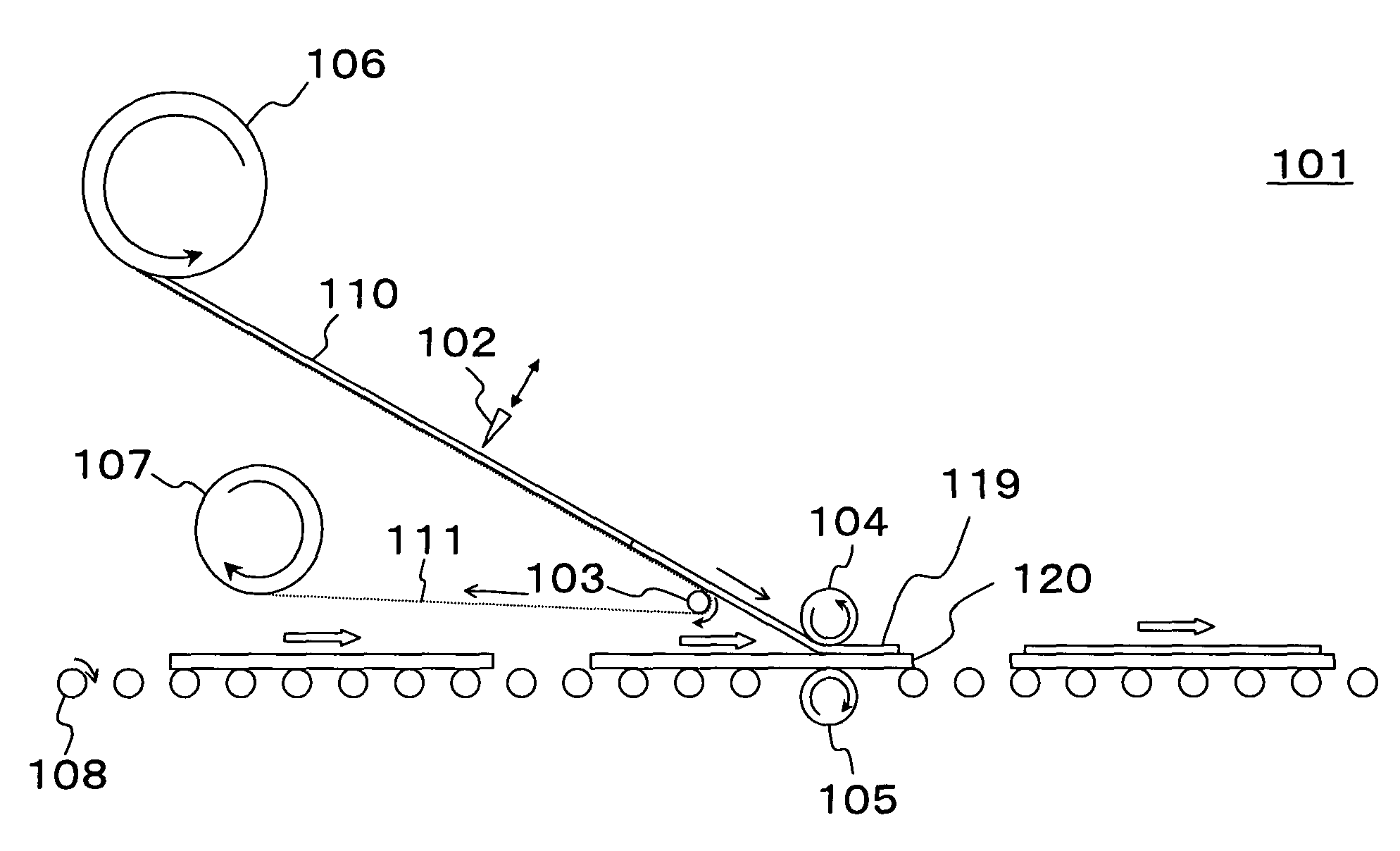

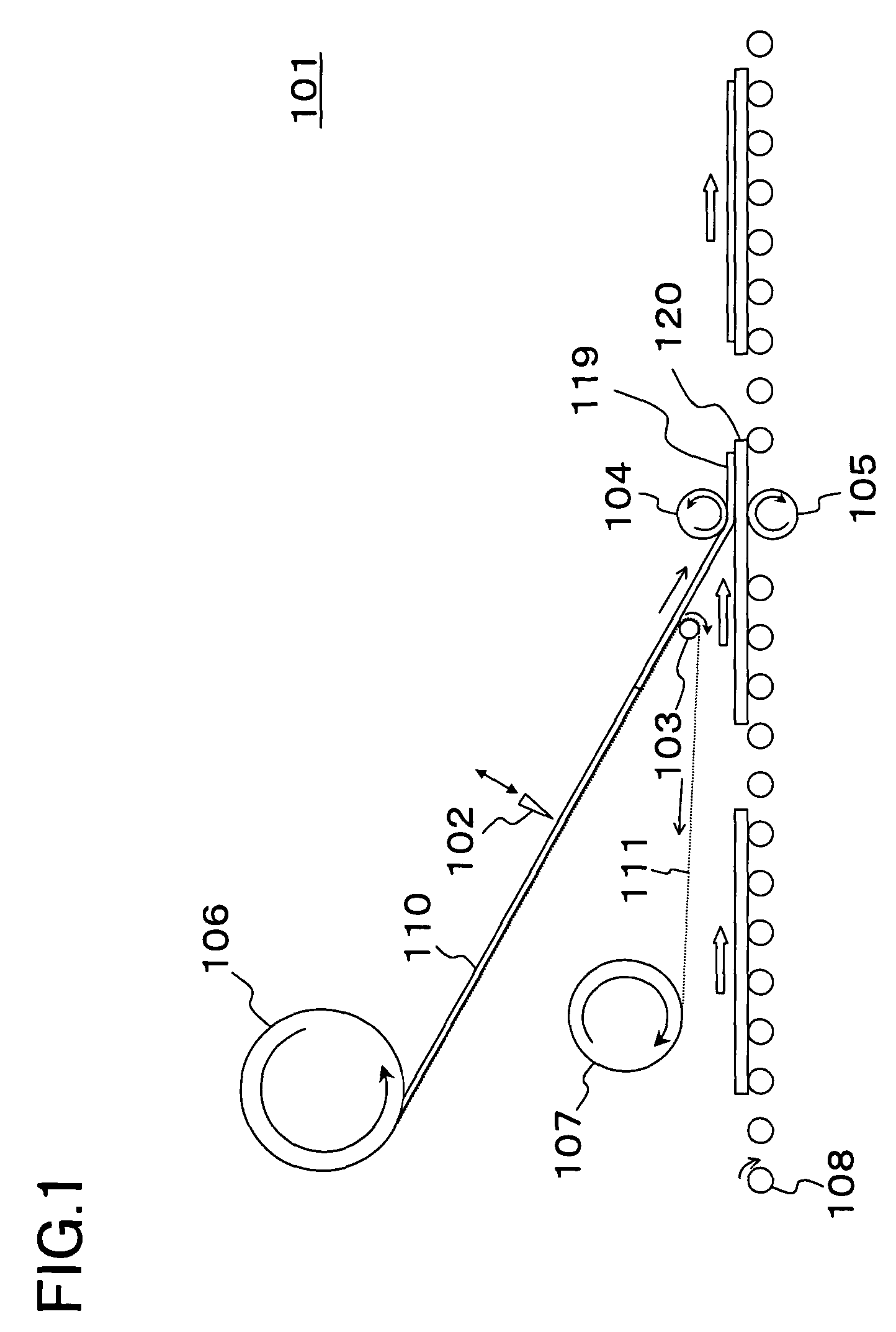

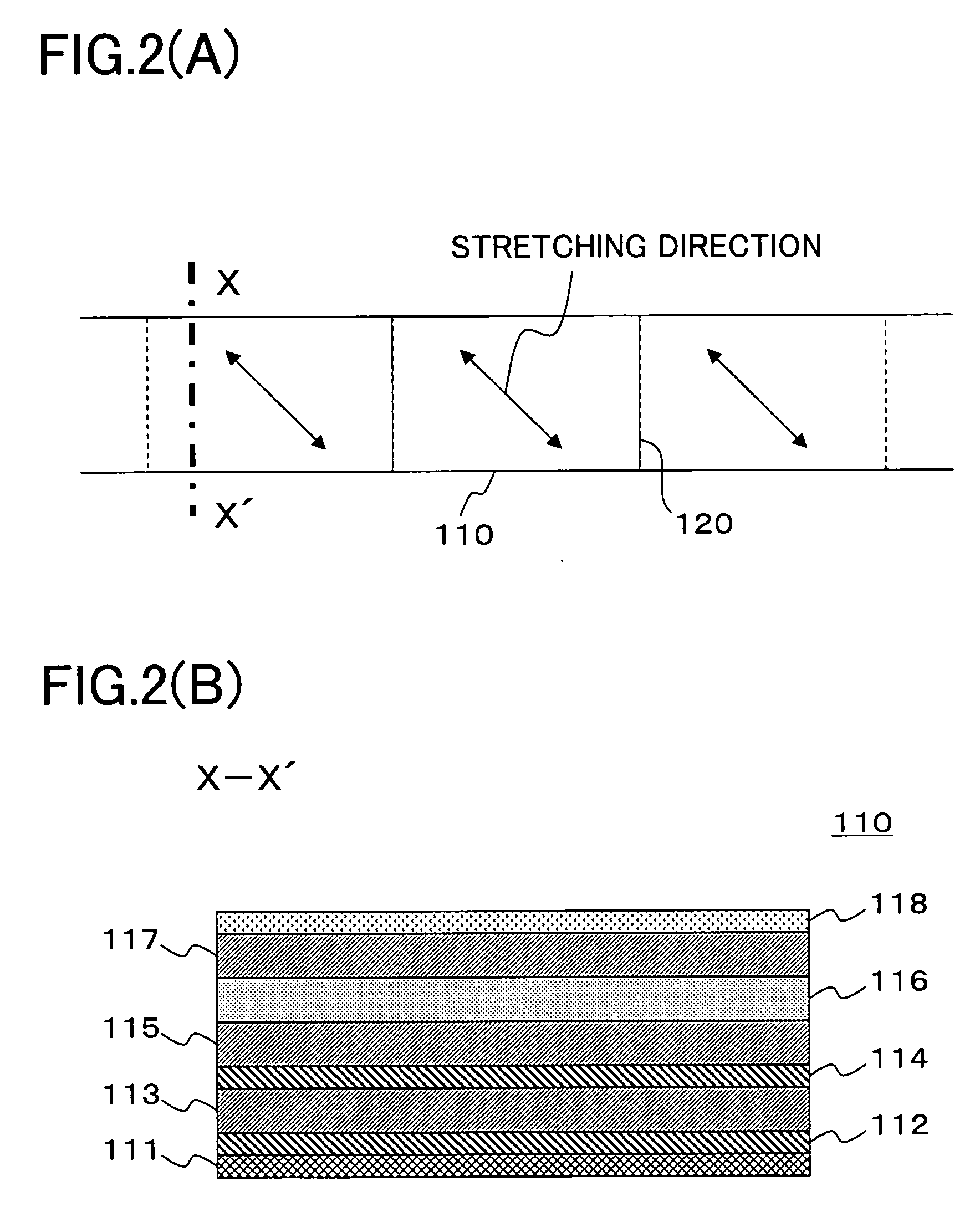

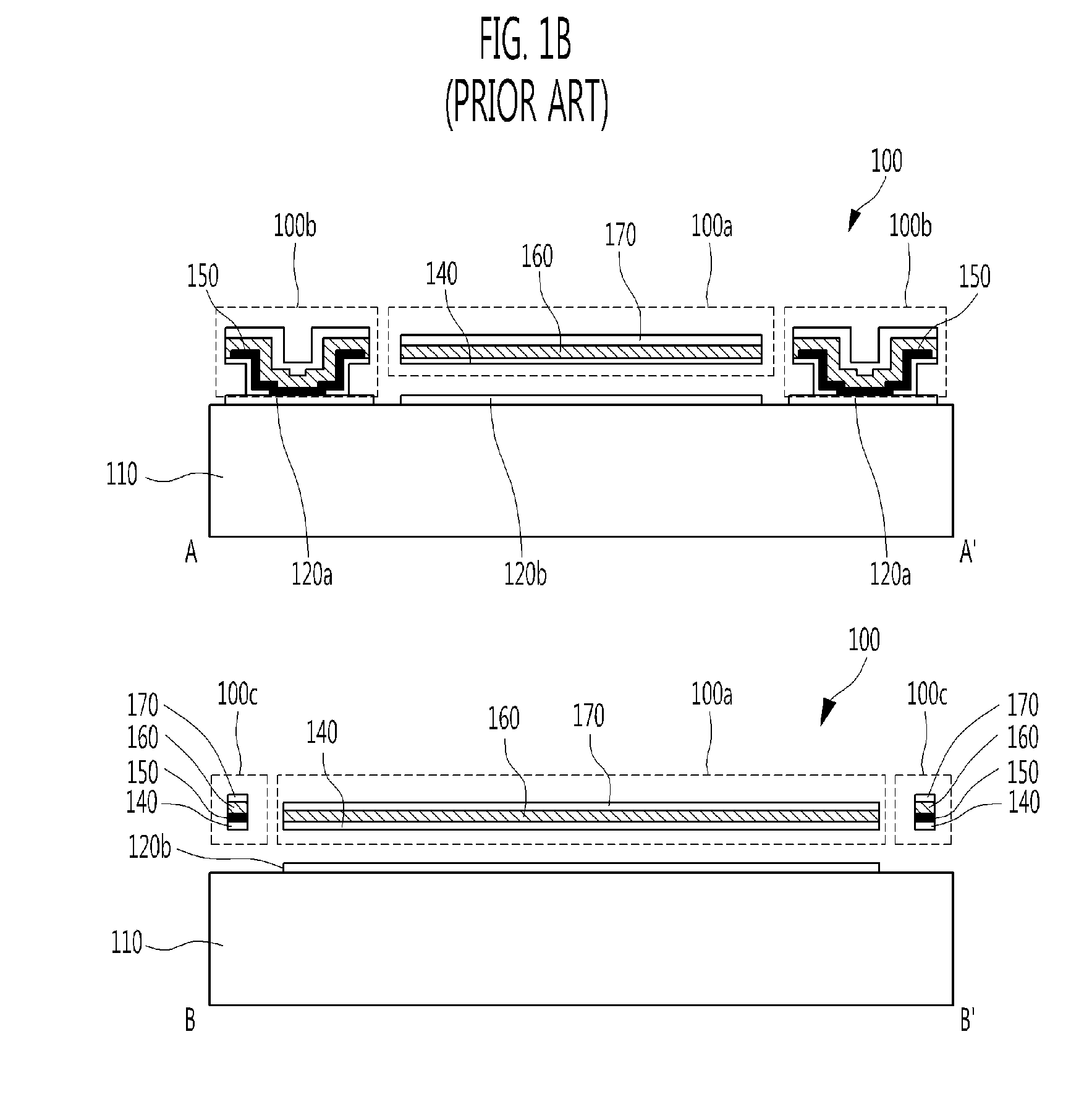

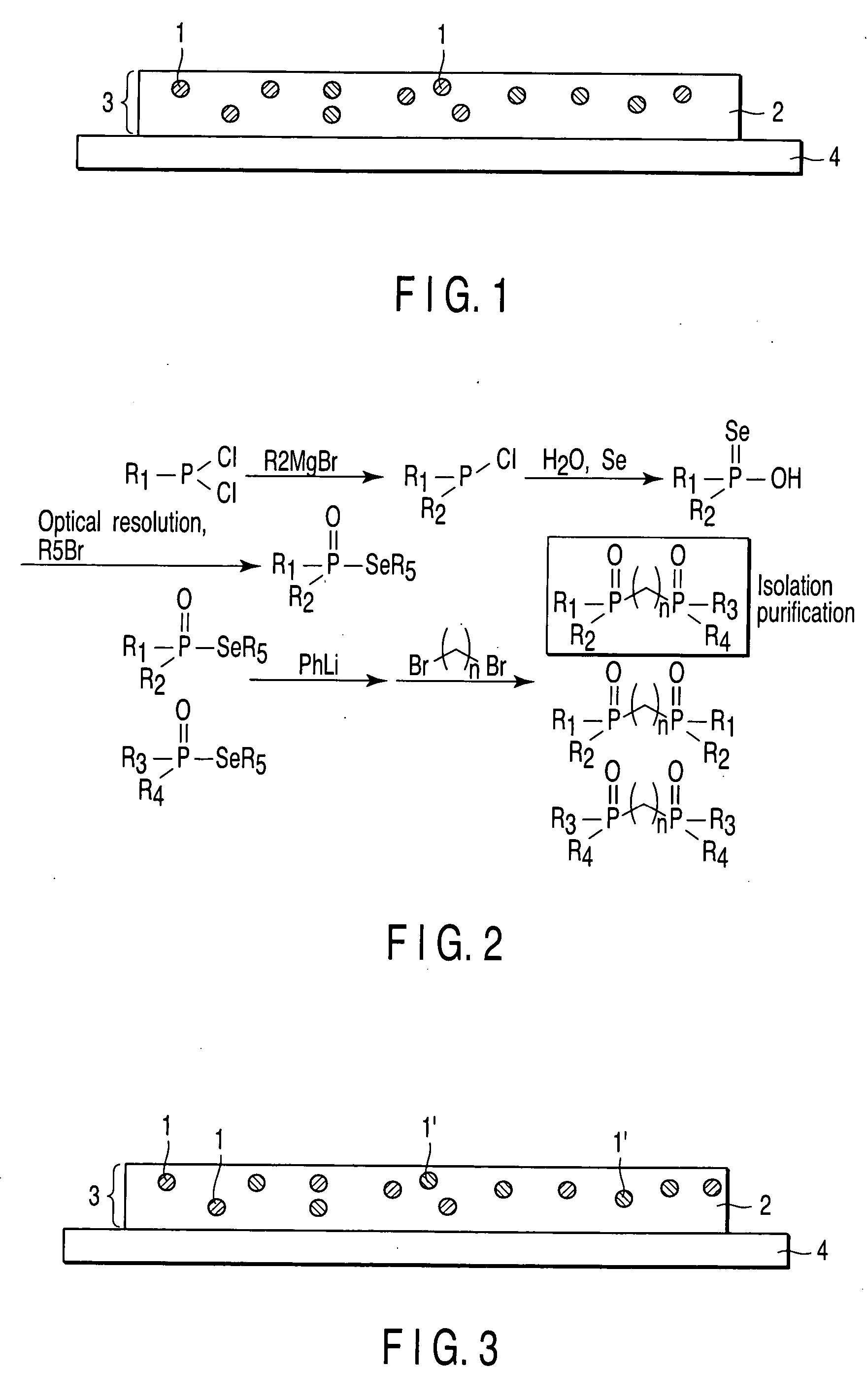

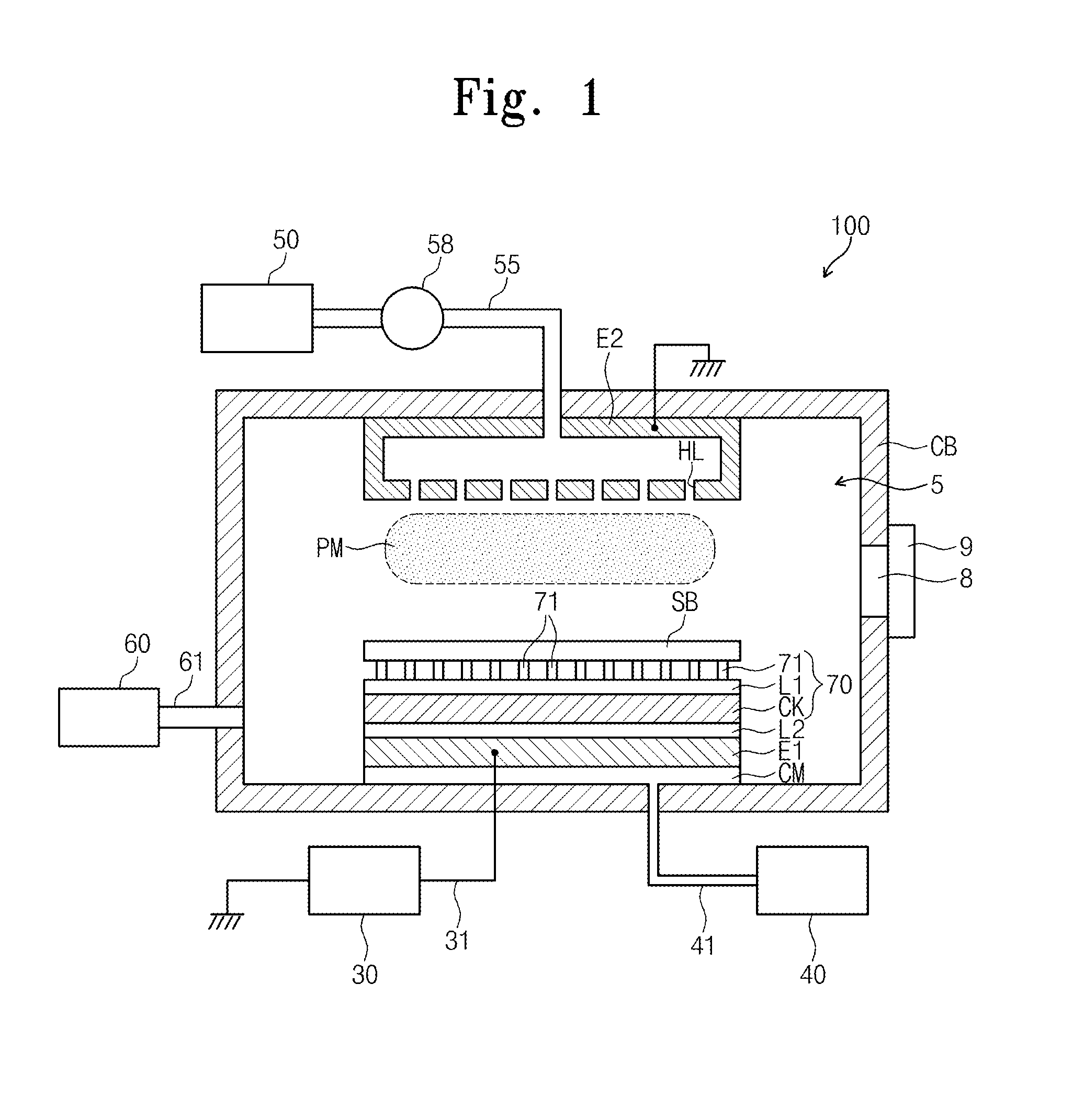

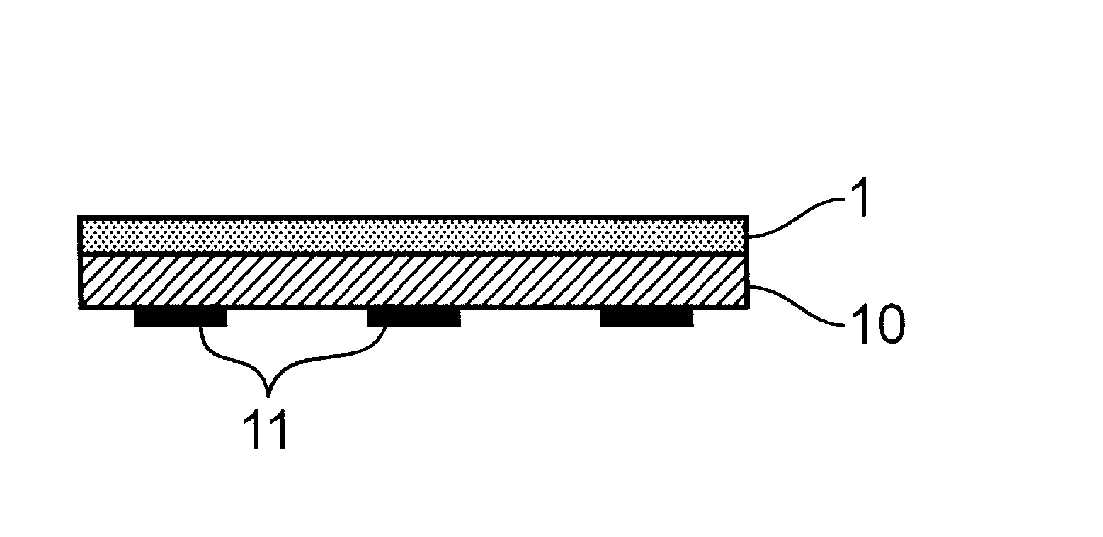

Method and apparatus for bonding polarizing plate

ActiveUS20050016670A1Easy to controlProhibit stop markLamination ancillary operationsDecorative surface effectsPolarizerEngineering

Owner:FUJIFILM CORP +1

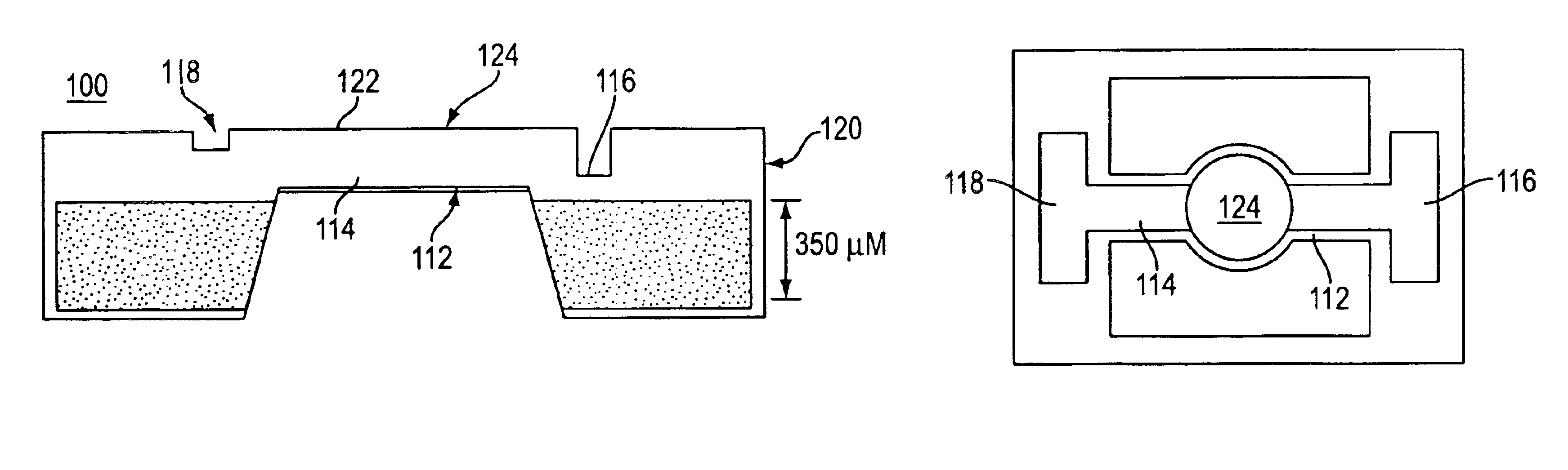

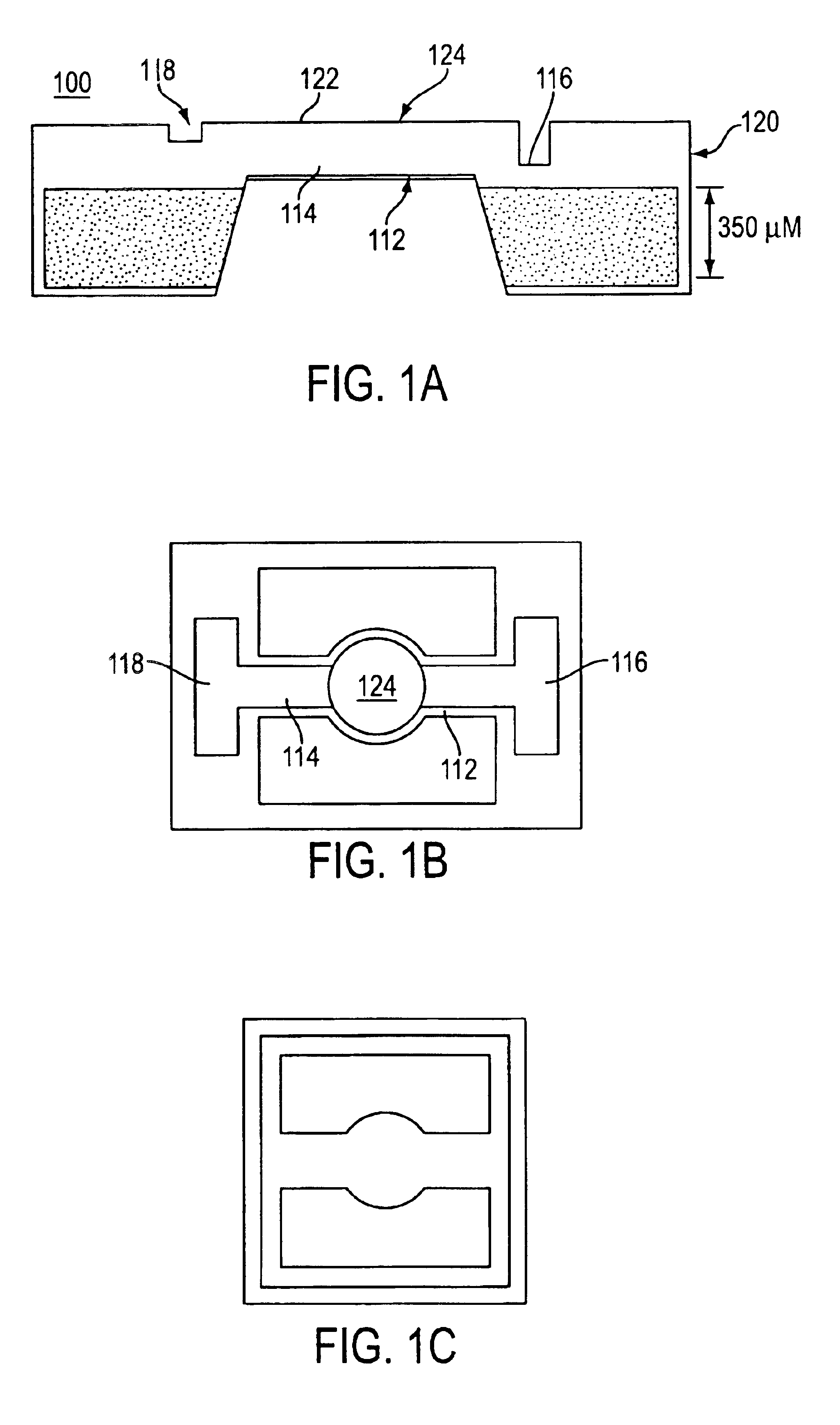

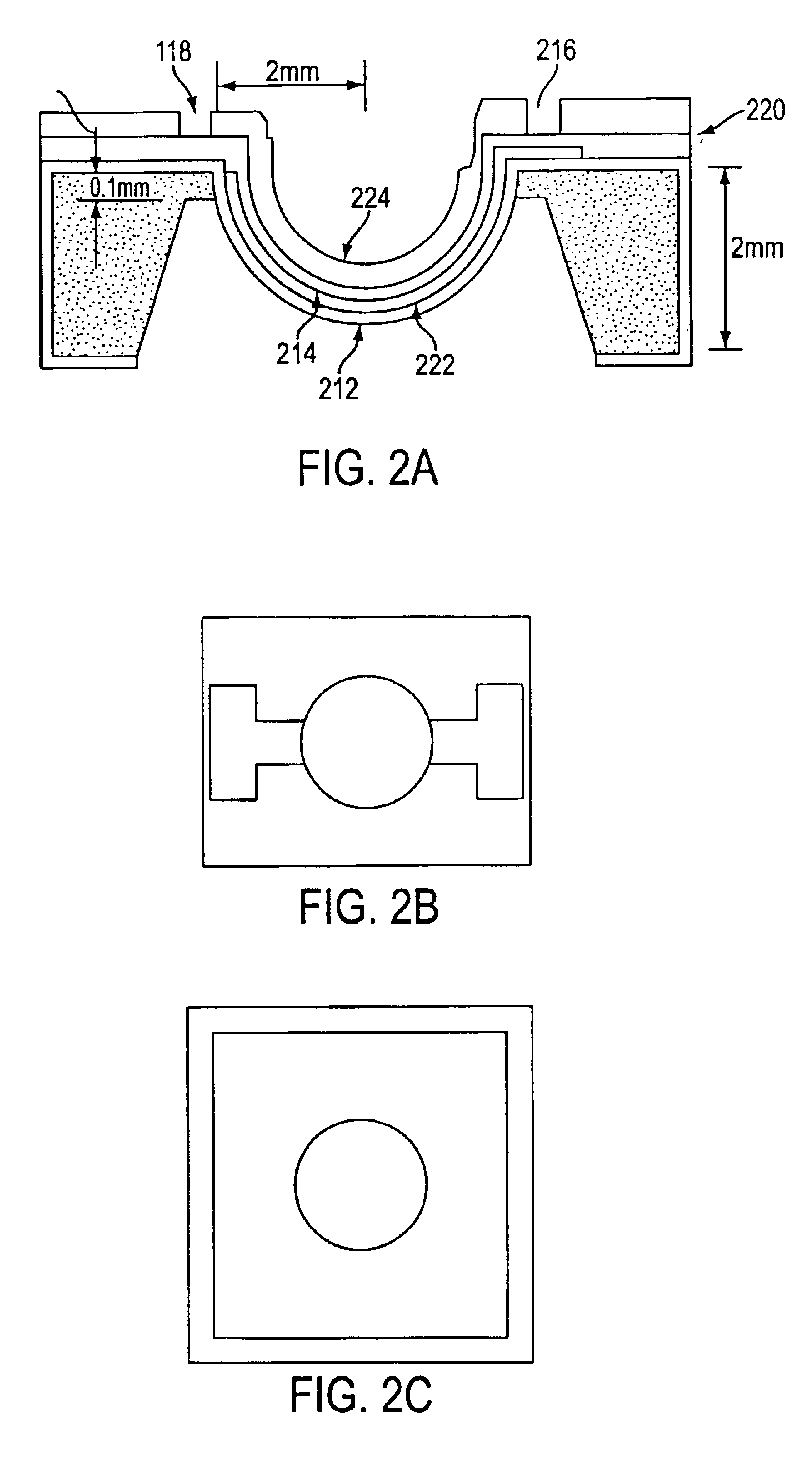

Method of forming parylene-diaphragm piezoelectric acoustic transducers

InactiveUS6857501B1Improve structural qualityTransducer detailsDecorative surface effectsParyleneTransducer

Owner:UNIV OF HAWAII

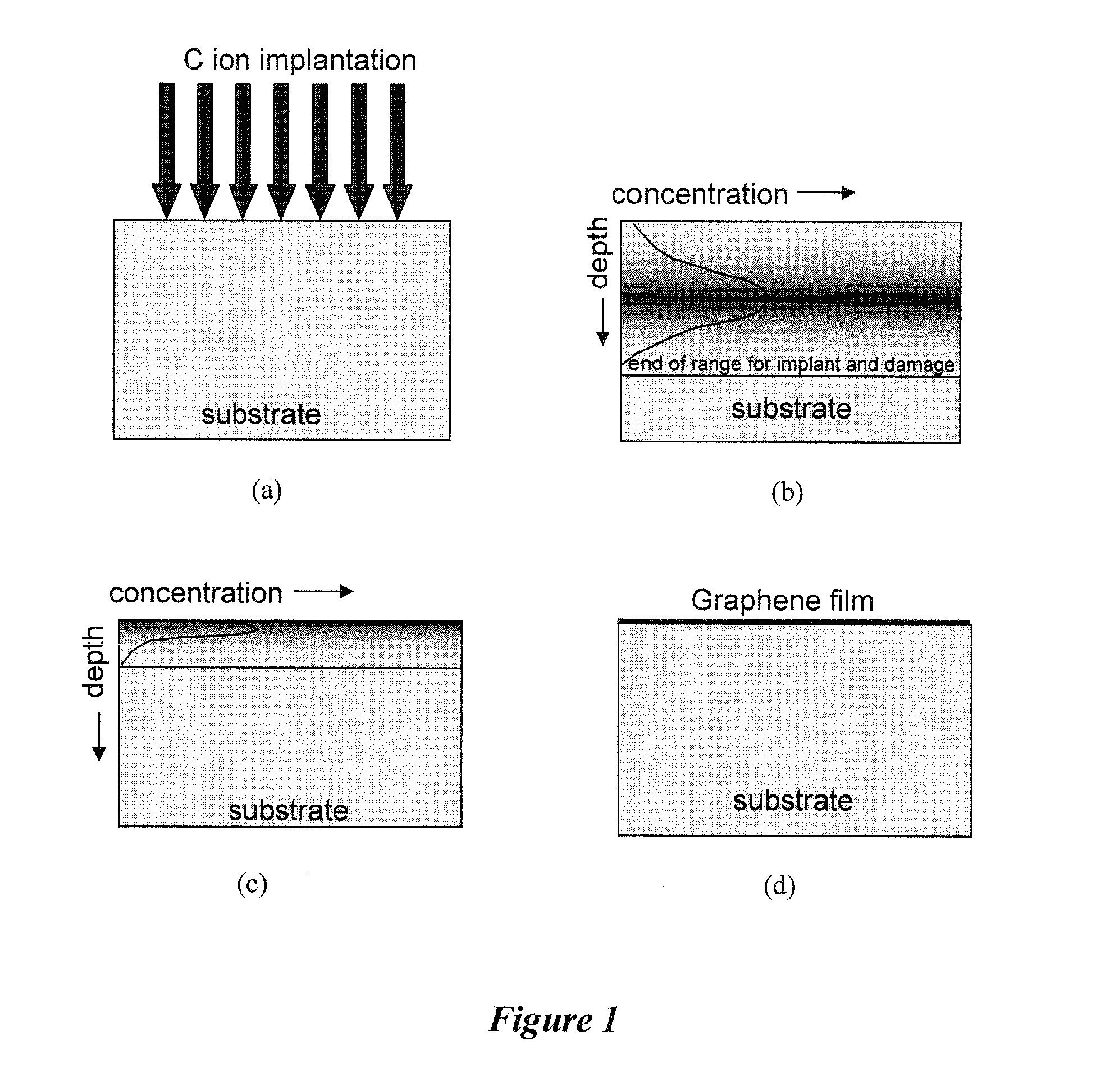

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

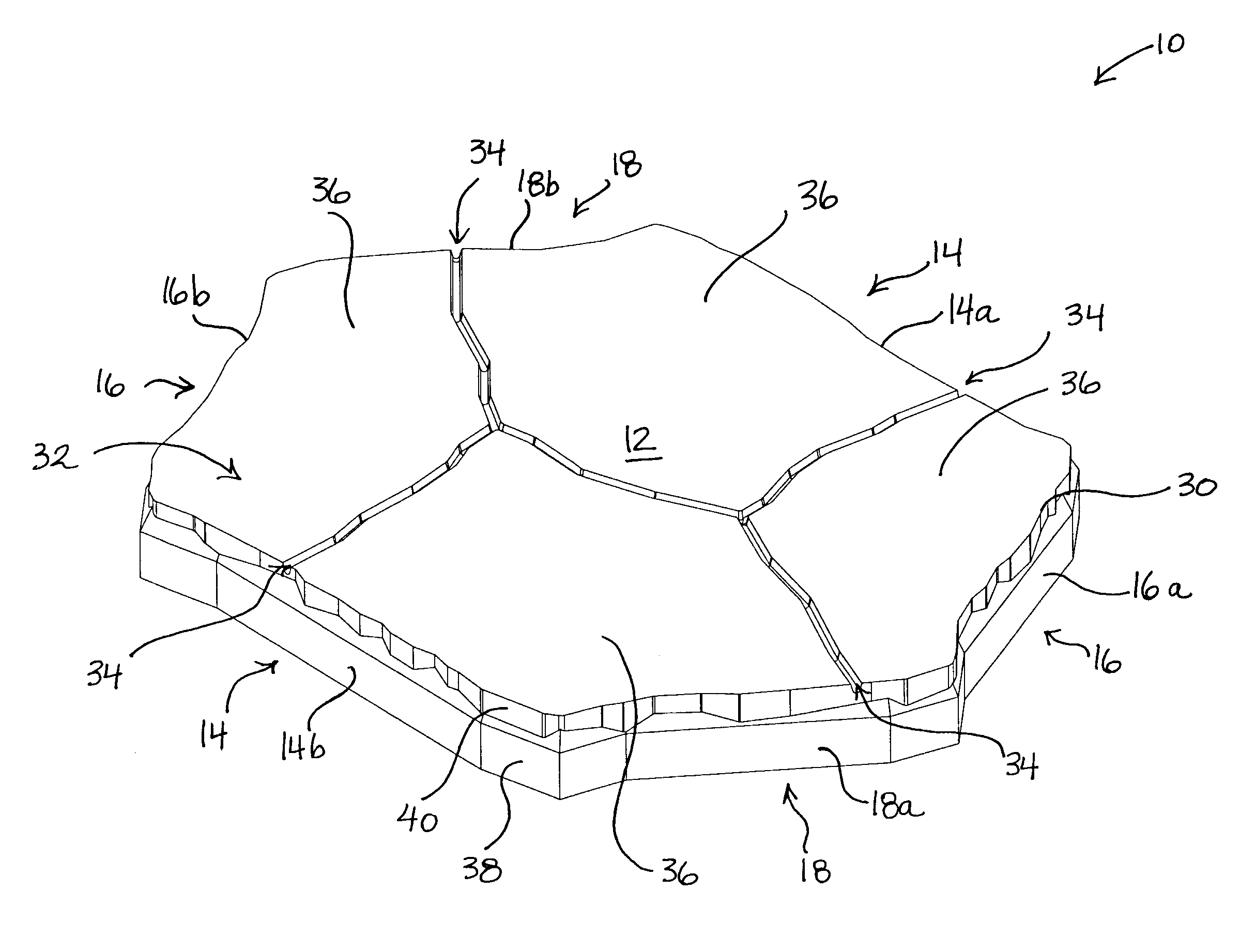

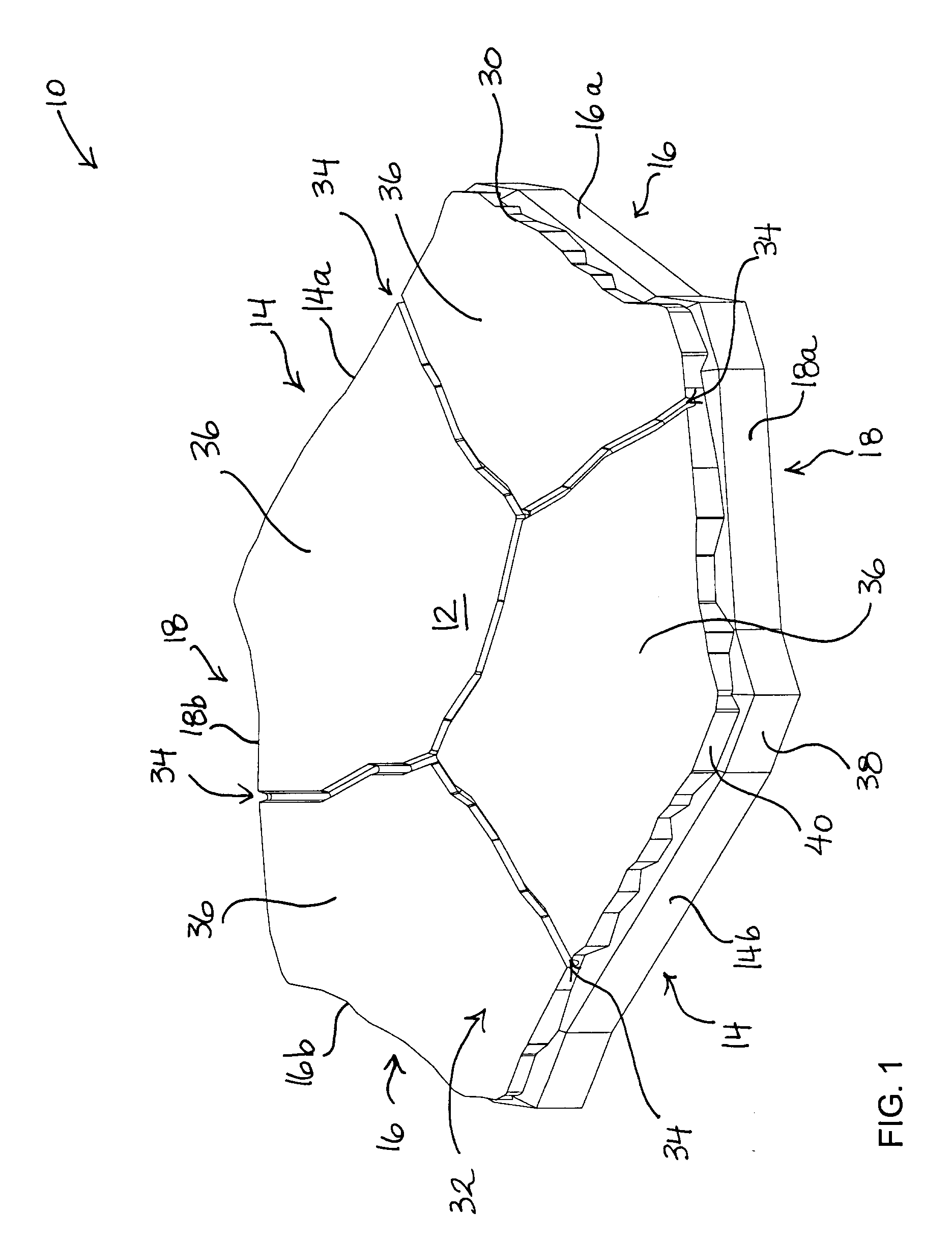

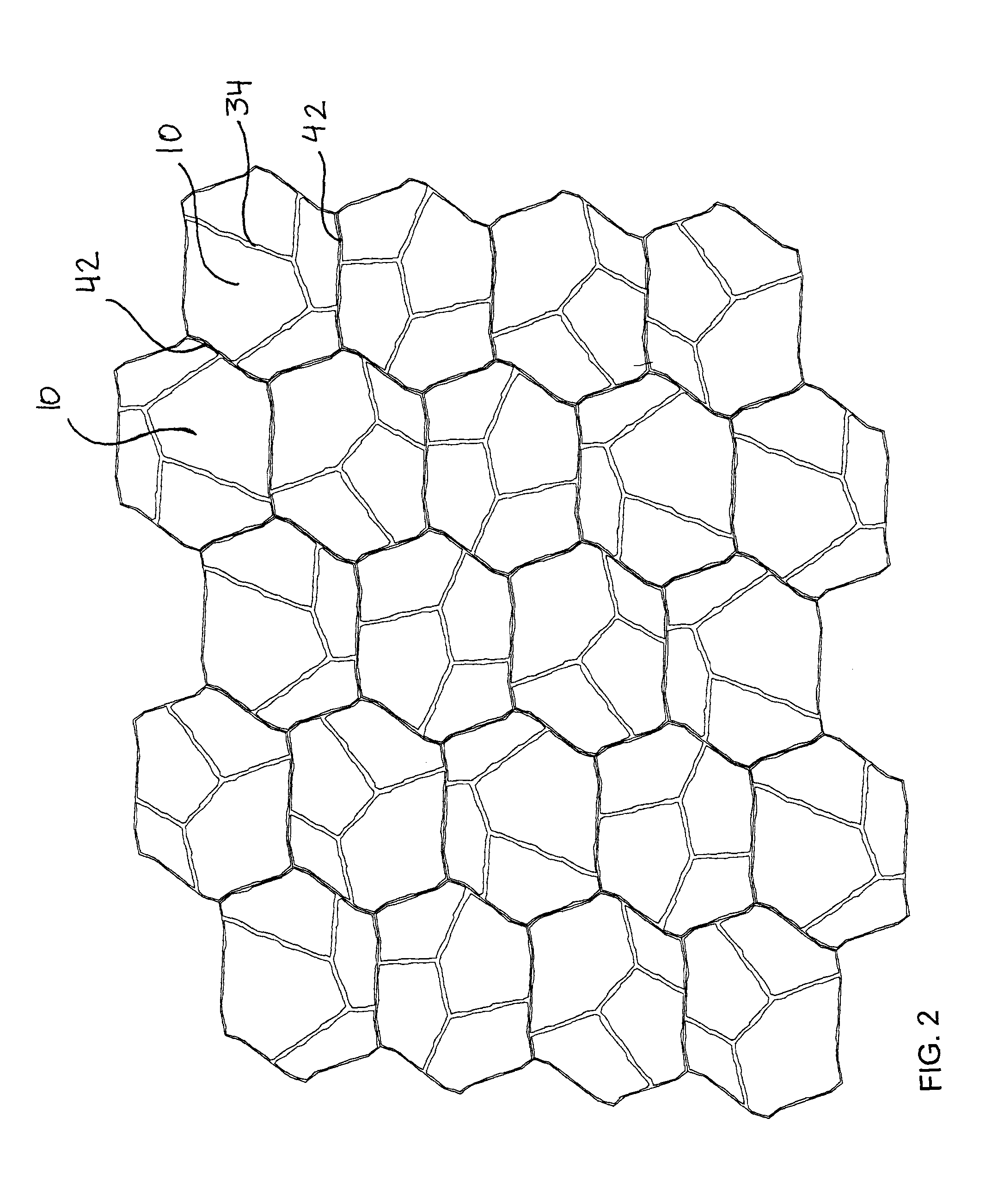

Covering Unit

Owner:OLDCASTLE BUILDING PROD CANADA INC

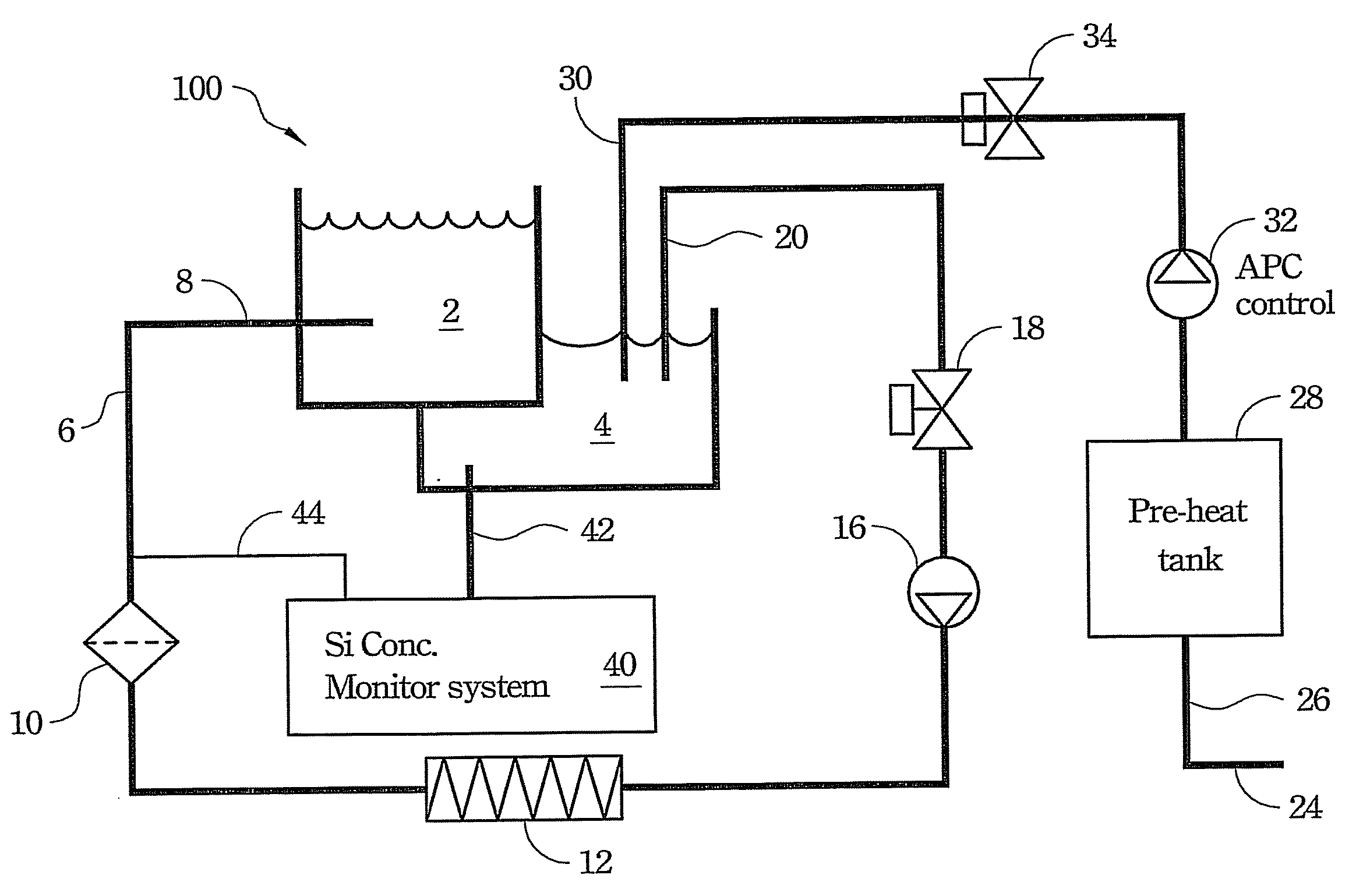

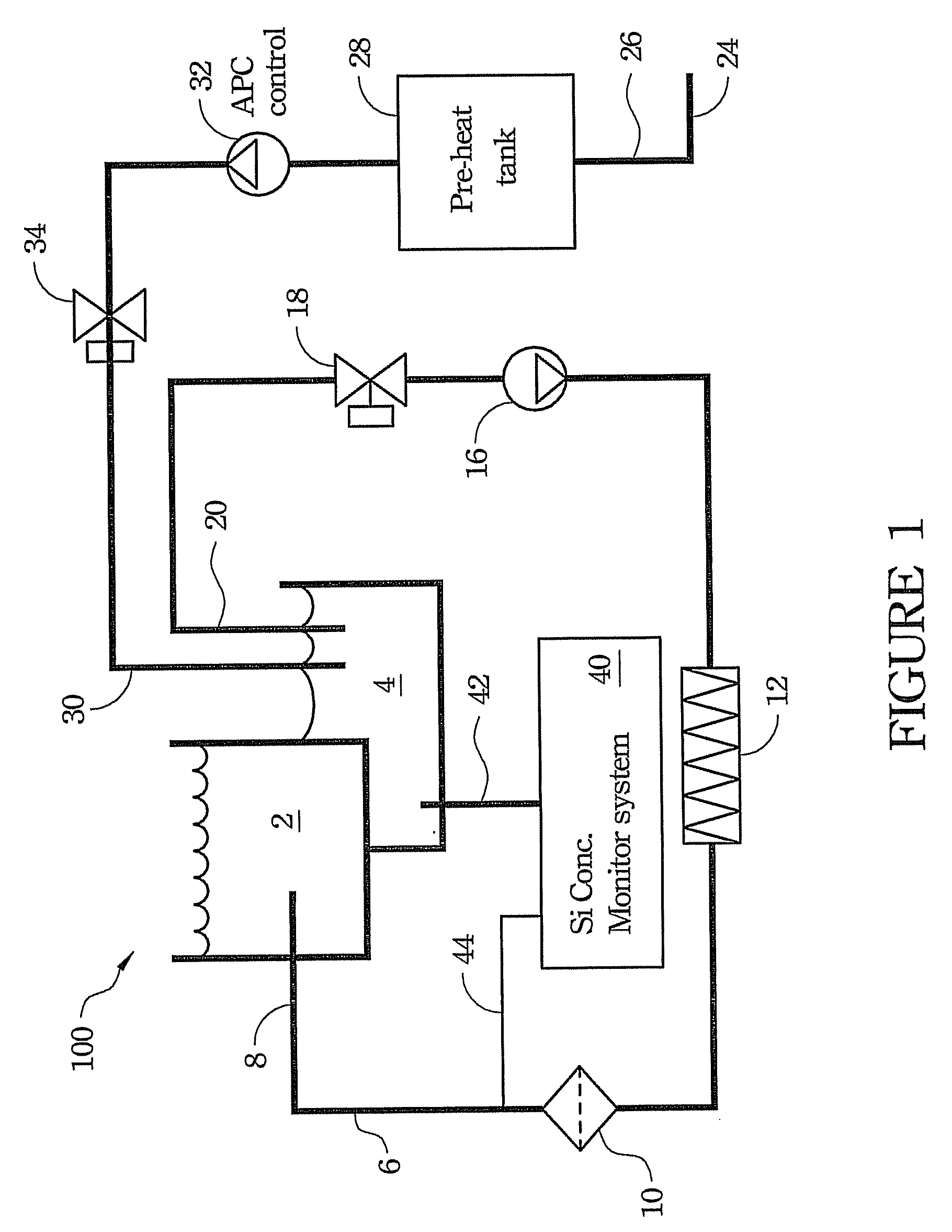

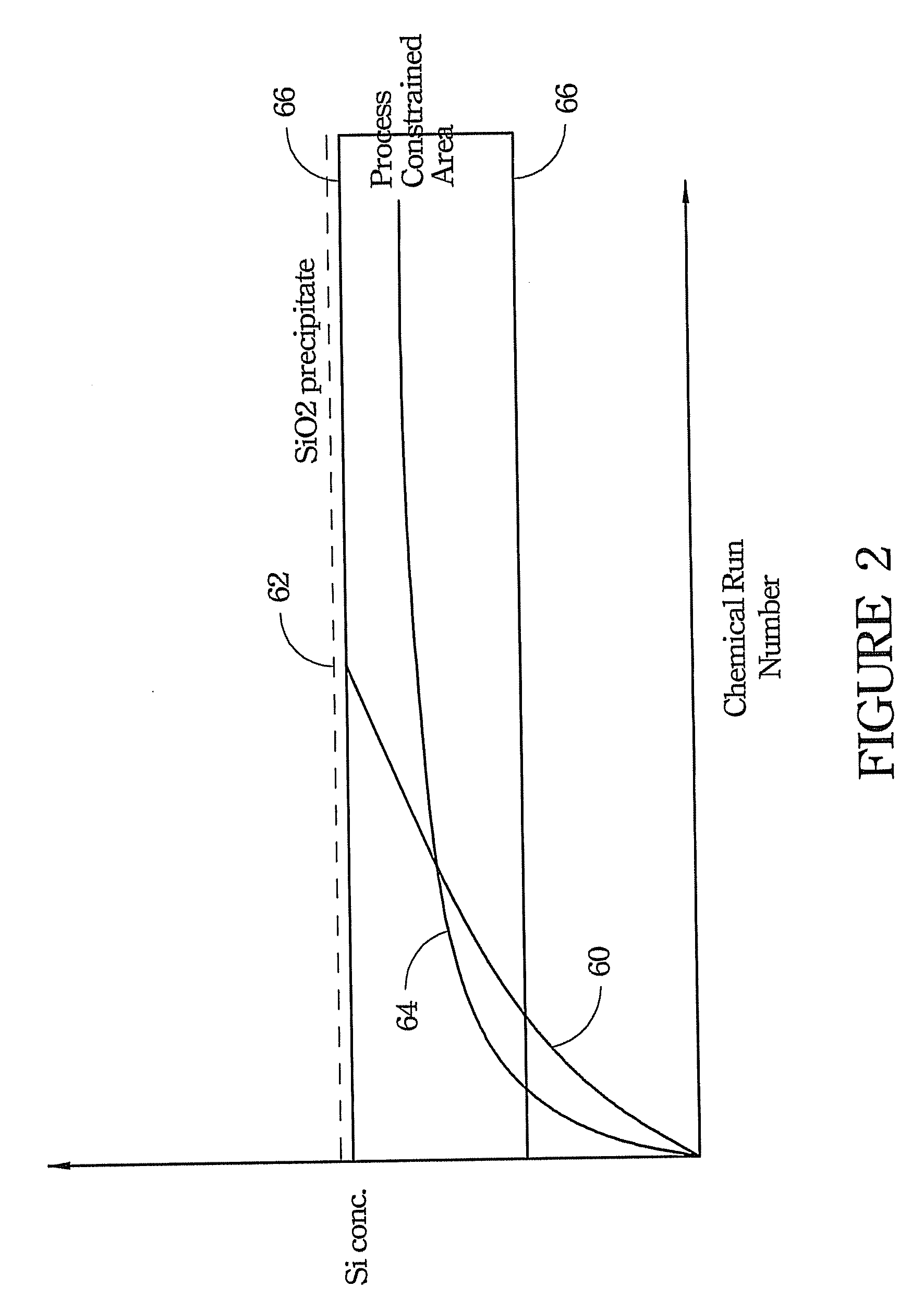

Apparatus and method for controlling silicon nitride etching tank

ActiveUS20080179293A1Semiconductor/solid-state device testing/measurementDecorative surface effectsO-Phosphoric AcidSteady state temperature

Owner:TAIWAN SEMICON MFG CO LTD

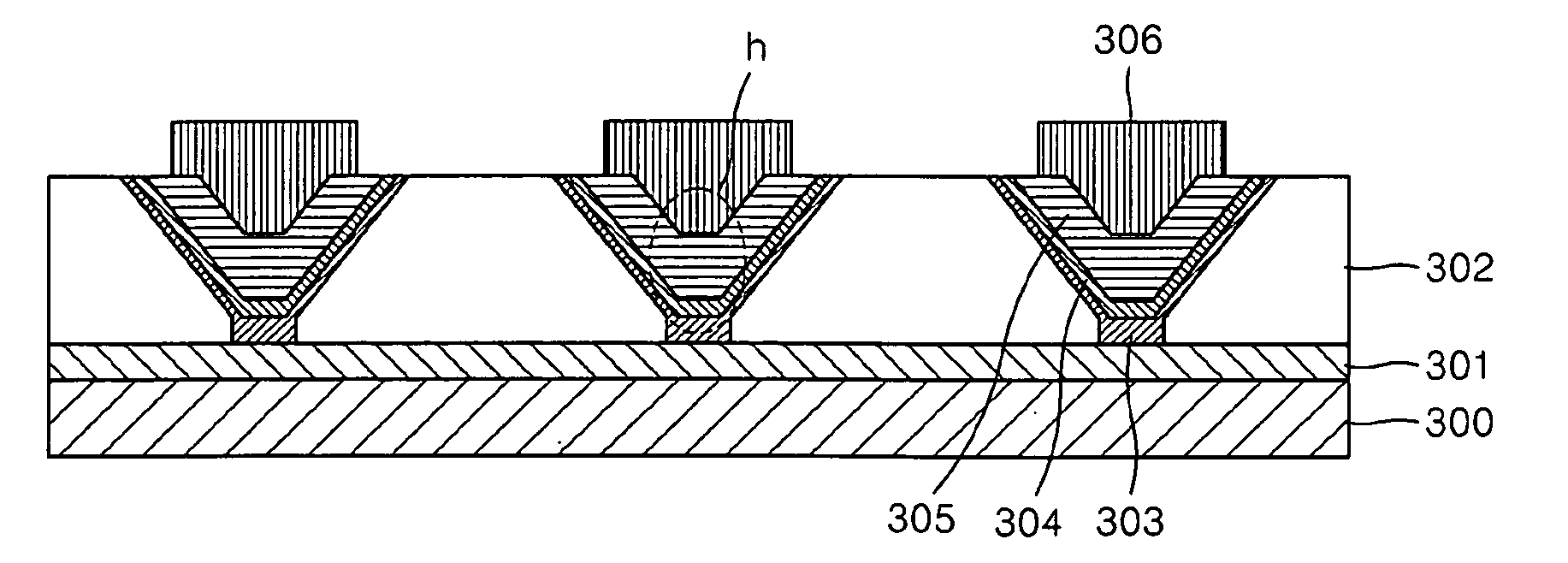

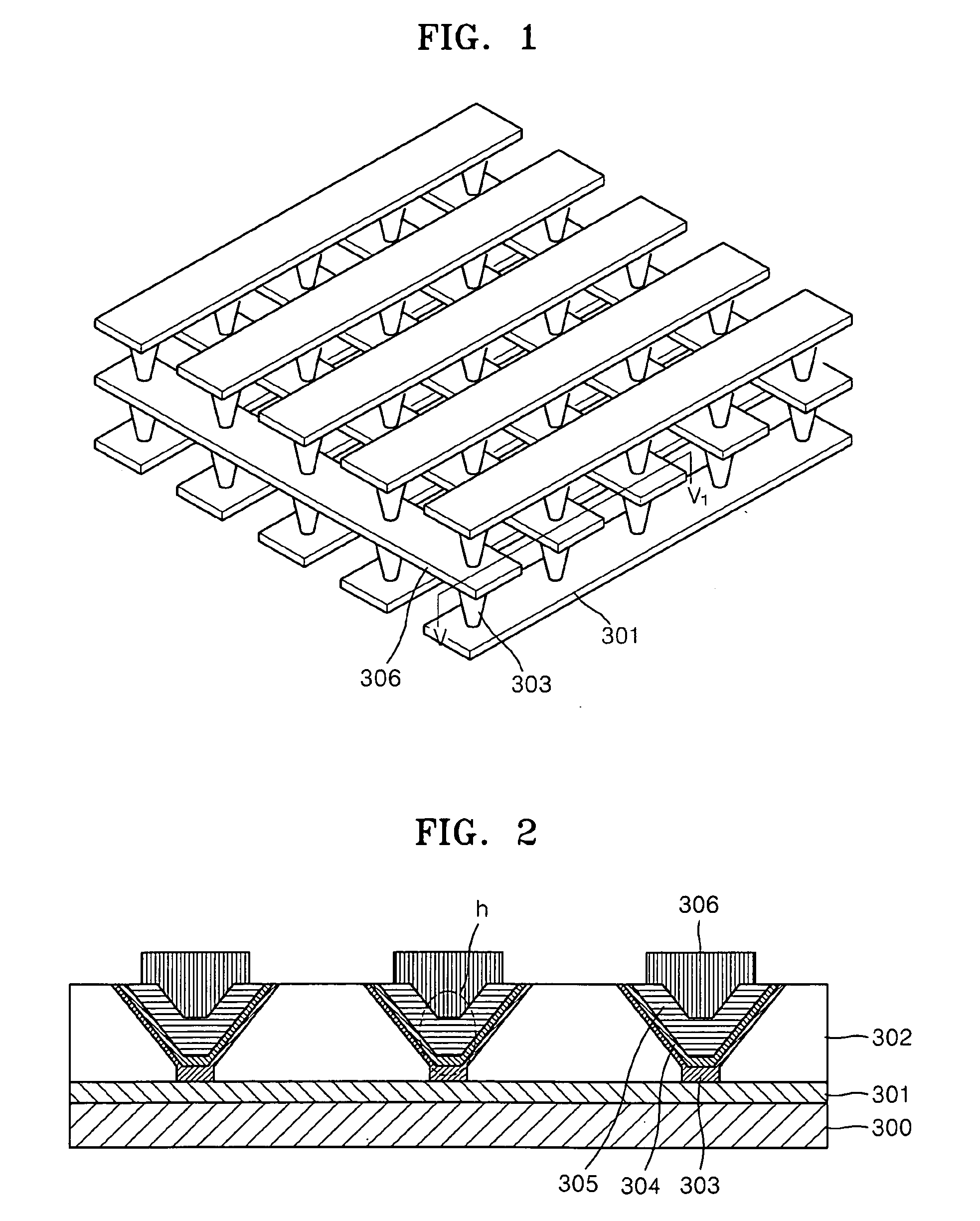

Cross point memory arrays, methods of manufacturing the same, masters for imprint processes, and methods of manufacturing masters

Owner:SAMSUNG ELECTRONICS CO LTD

Multilayer thin film OTFT (organic thin film transistor) formaldehyde gas sensor and preparation method thereof

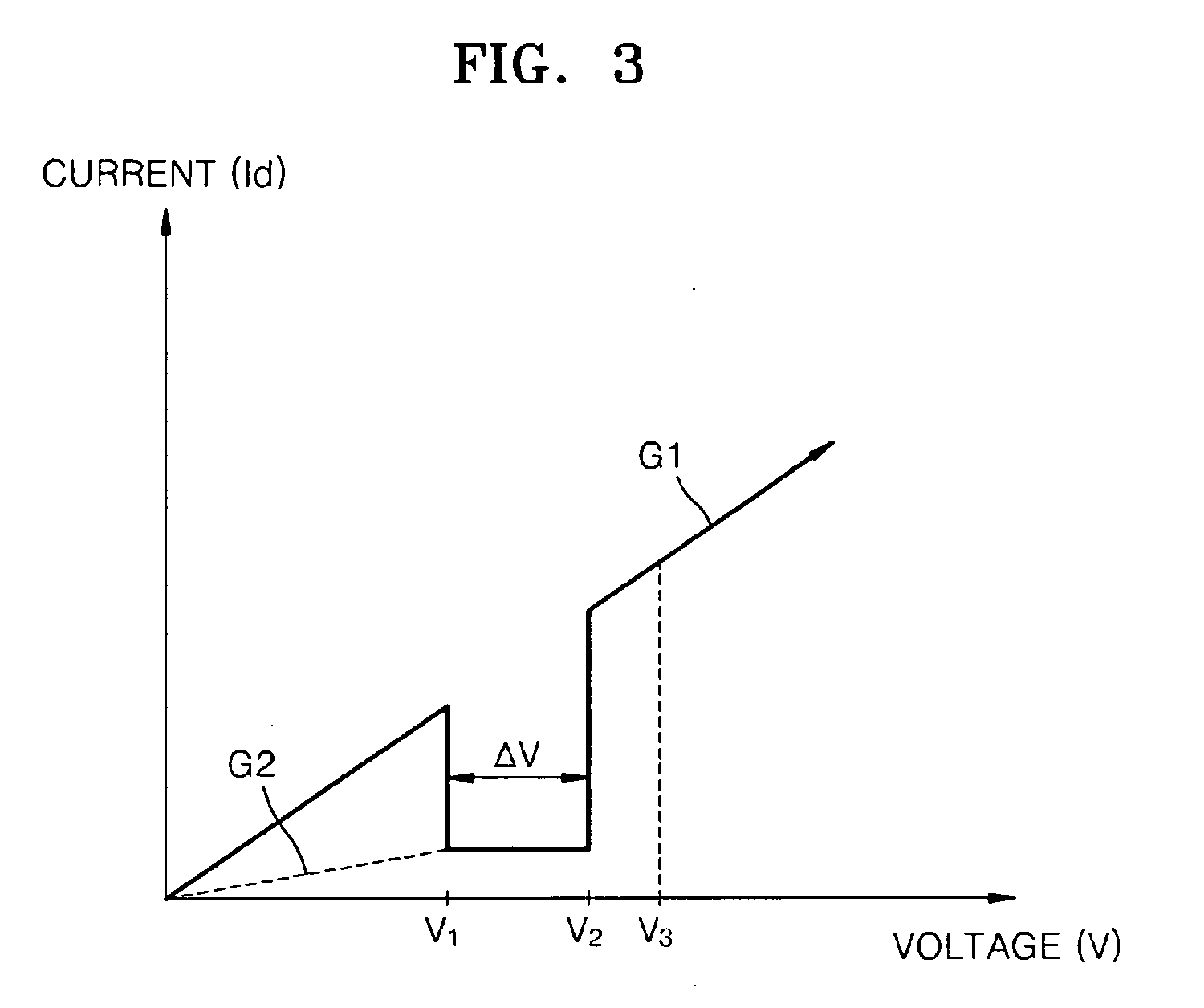

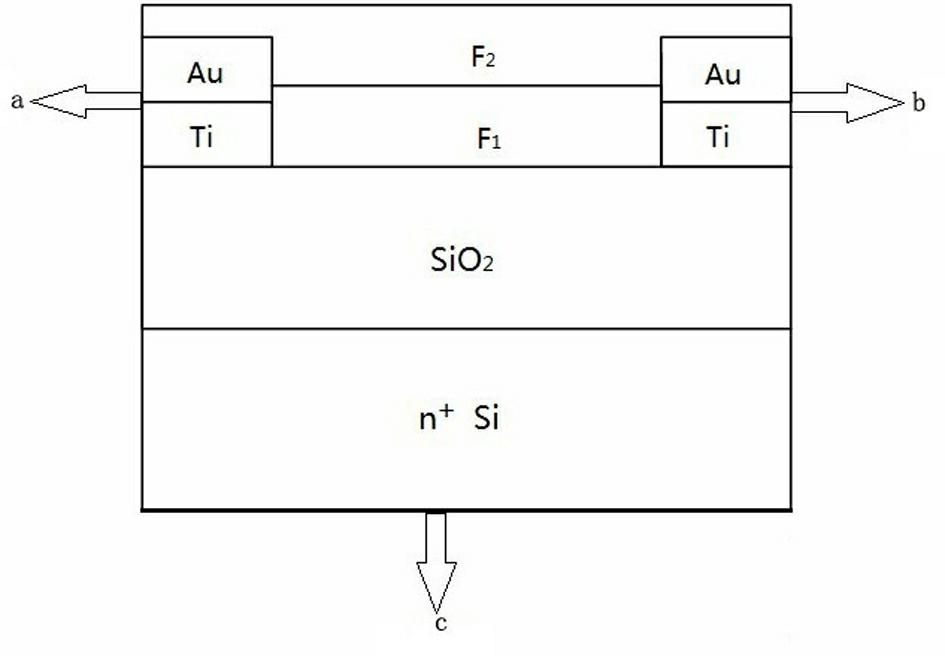

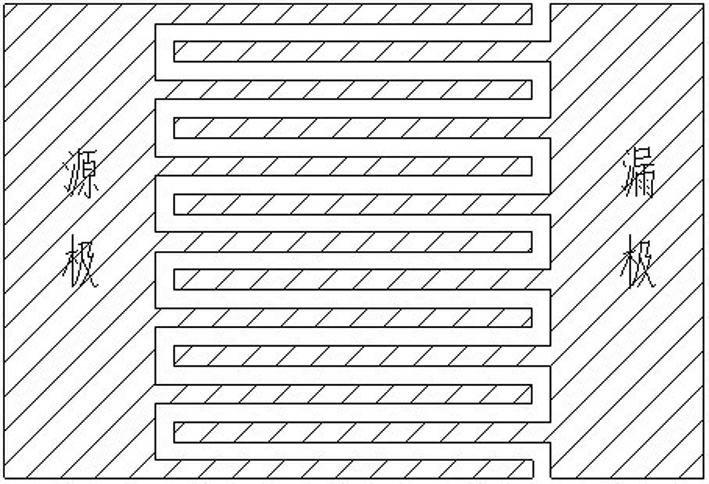

InactiveCN102636544ADecorative surface effectsMaterial analysis by electric/magnetic meansTitaniumOxide

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Mirror process using tungsten passivation layer for preventing metal-spiking induced mirror bridging and improving mirror curvature

InactiveUS20060037933A1Prevent metal-spiking induced mirror bridgingImprove mirror curvatureDecorative surface effectsMicroelectromechanical systemsOptoelectronicsTungsten

A mirror process uses a tungsten passivation layer to prevent metal-spiking induced mirror bridging and improve mirror curvature. A mirror structure is patterned on a first sacrificial layer overlying a substrate. A tungsten passivation layer is then blanket deposited to cover the top and sidewalls of the mirror structure. A second sacrificial layer is formed overlying the tungsten passivation layer. A releasing process with an etchant including XeF2 is performed to remove the second sacrificial layer, the tungsten passivation layer and the first sacrificial layer simultaneously.

Owner:TAIWAN SEMICON MFG CO LTD

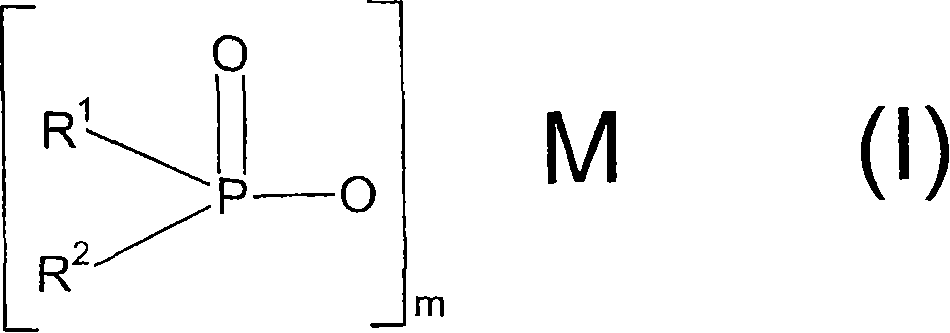

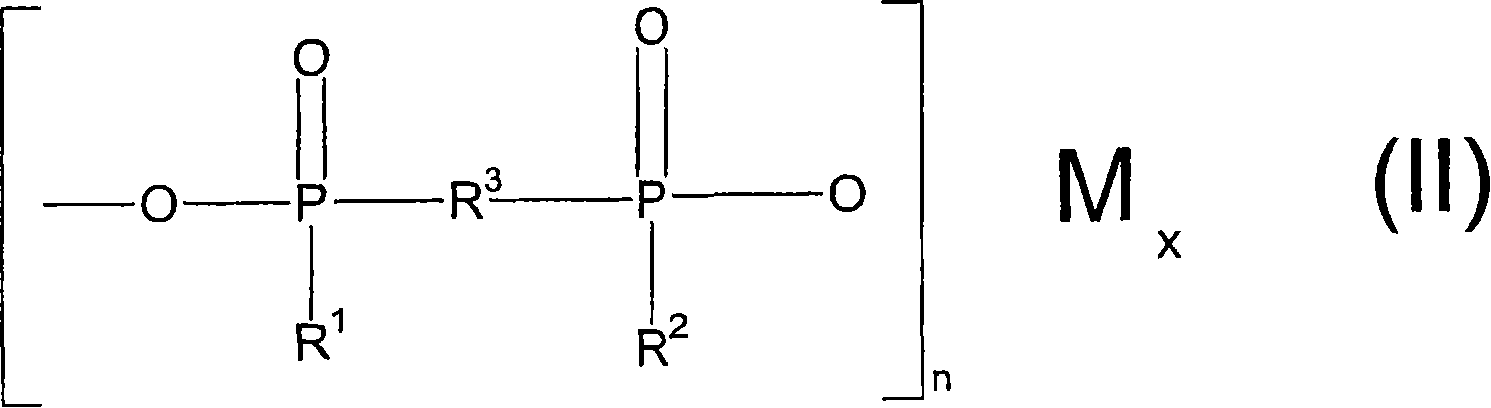

Laser-markable flameproof molding compounds and laser-markable and laser-marked products obtained from said molding compounds

The subject invention discloses a variety of different maintenance devices for use with a filling valve apparatus. The maintenance devices each include a movable component and a locking mechanism. An actuator of the locking mechanism is coupled to a caming section of the movable component for moving the movable component between a release position with a rim of the movable component spaced from fingers of the locking mechanism and an engaged position with the rim abutting the fingers. The fingers are wedged between the movable component and the filling valve apparatus when the movable component is in the engaged position for securing the device to the filling valve apparatus.

Owner:TICONA GMBH

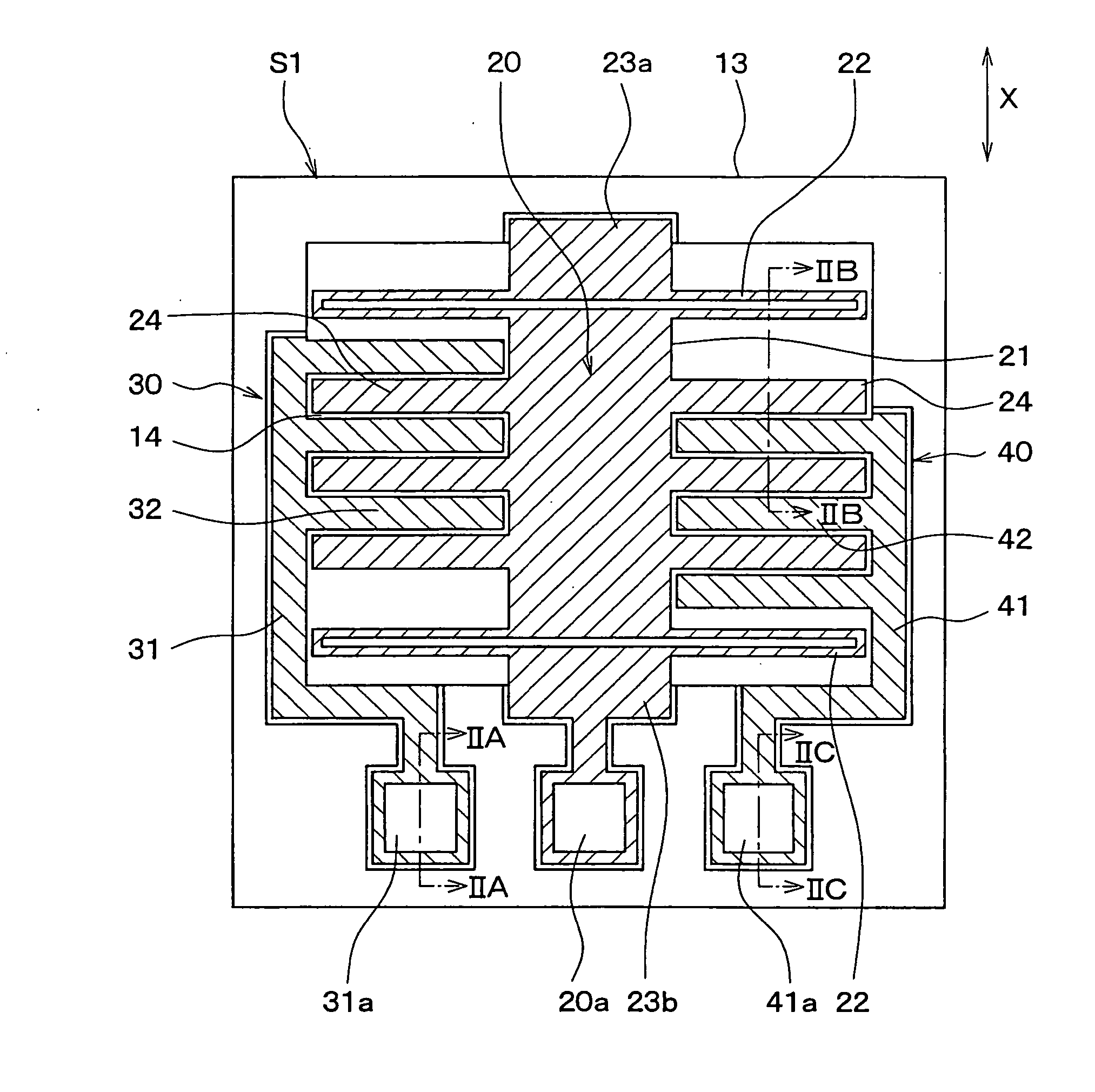

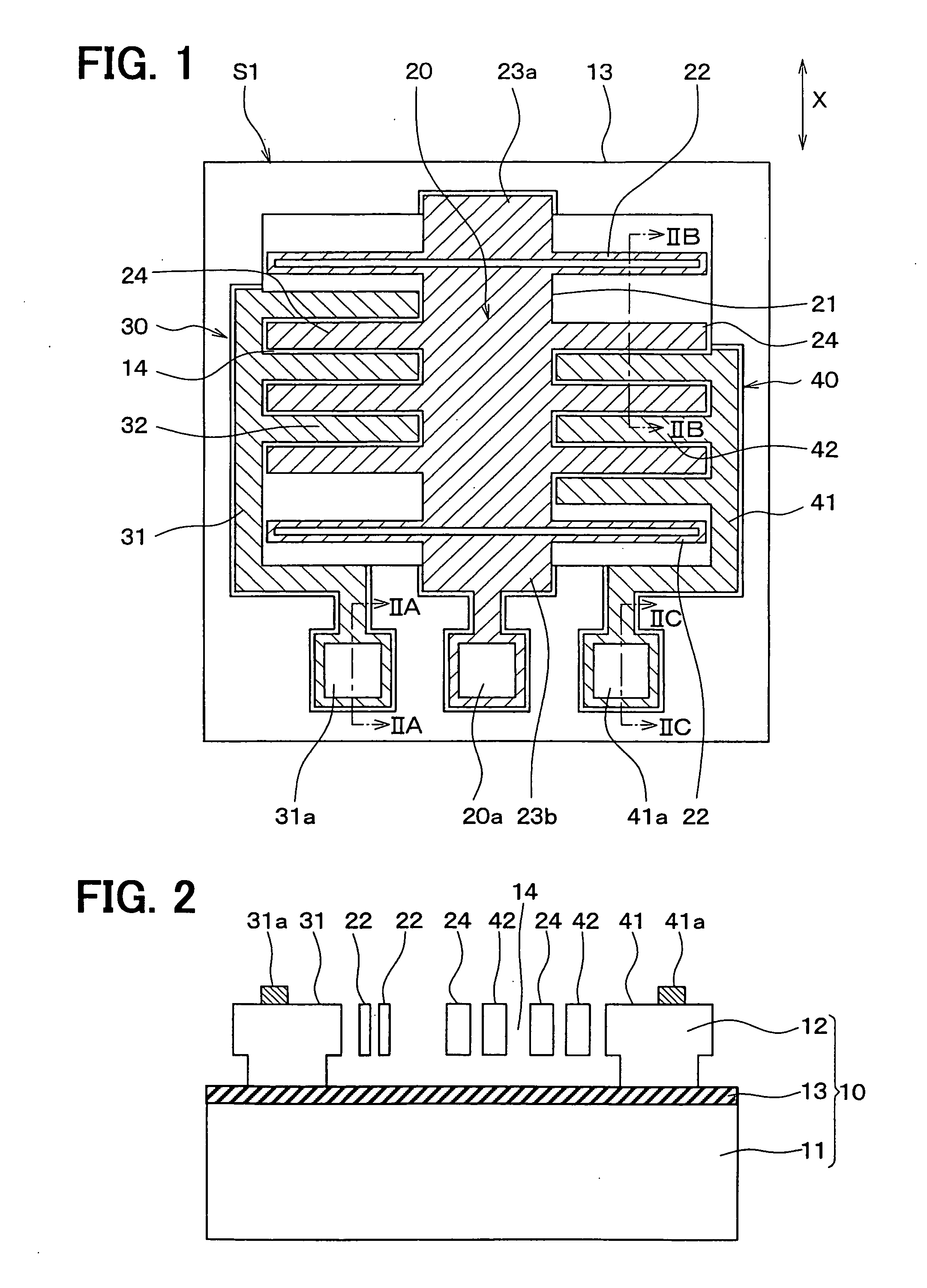

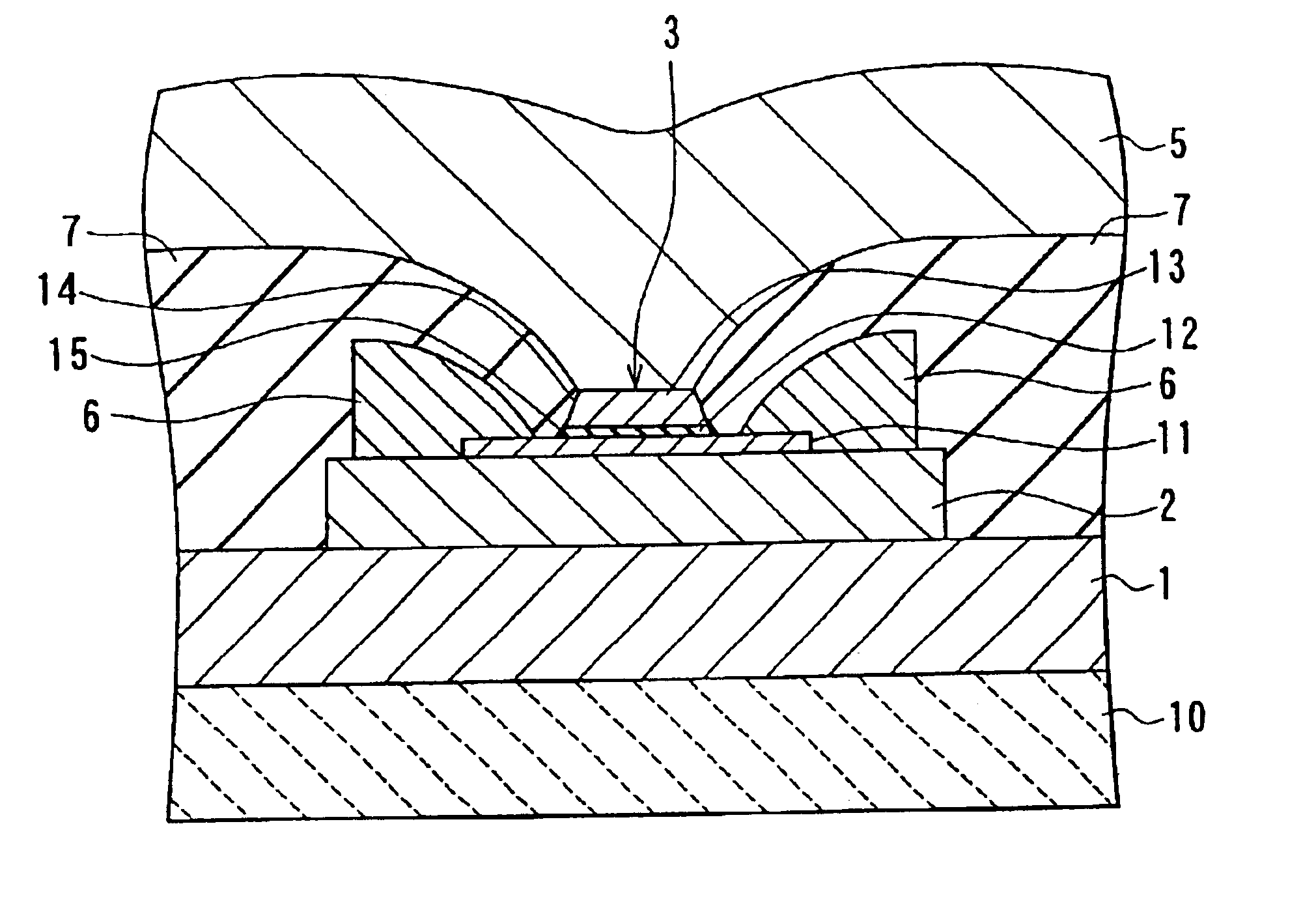

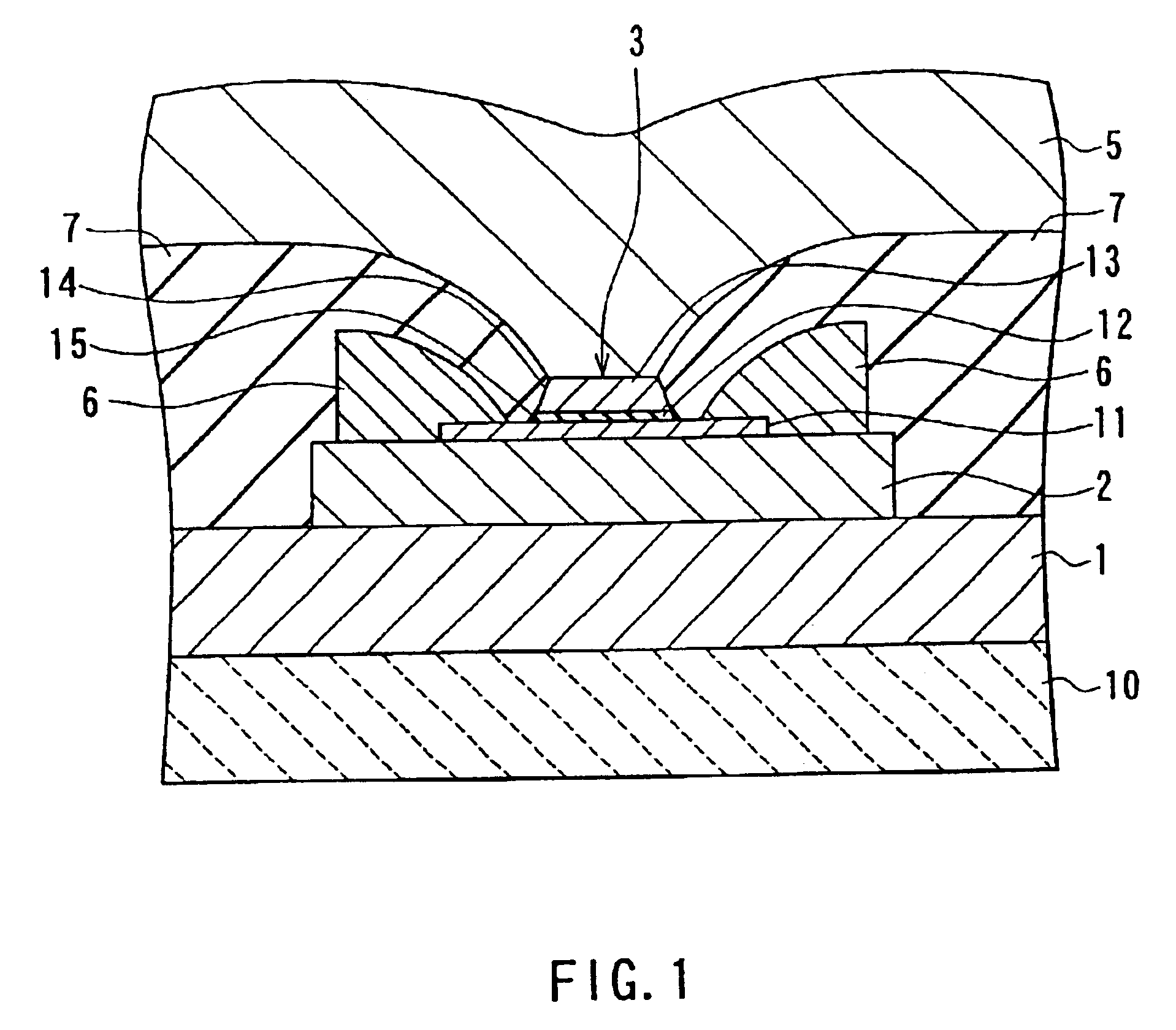

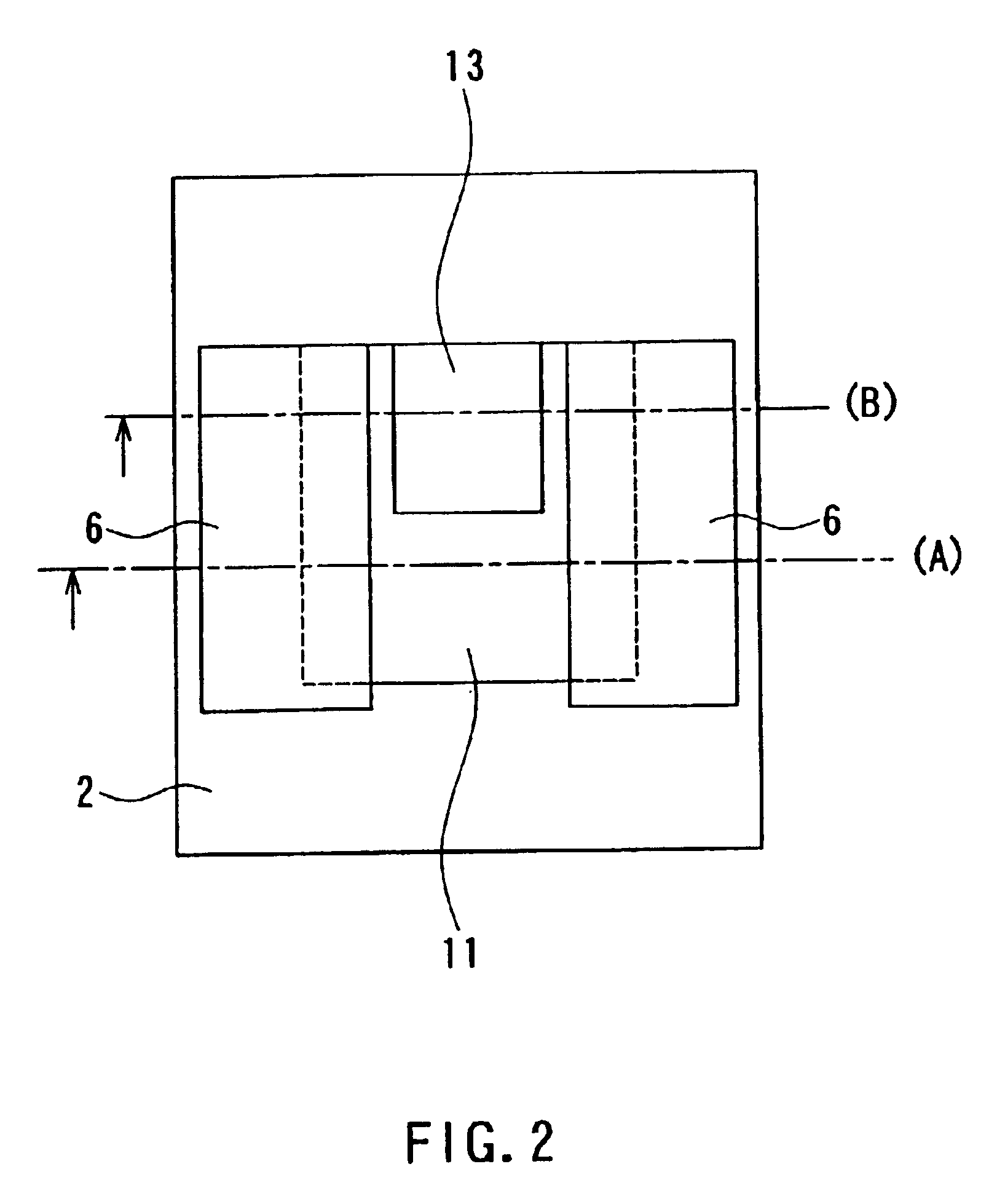

Infrared detection sensor and method of fabricating the same

InactiveUS20110042569A1Decorative surface effectsMaterial analysis by optical meansPhysicsThermal conductivity

Owner:ELECTRONICS & TELECOMM RES INST

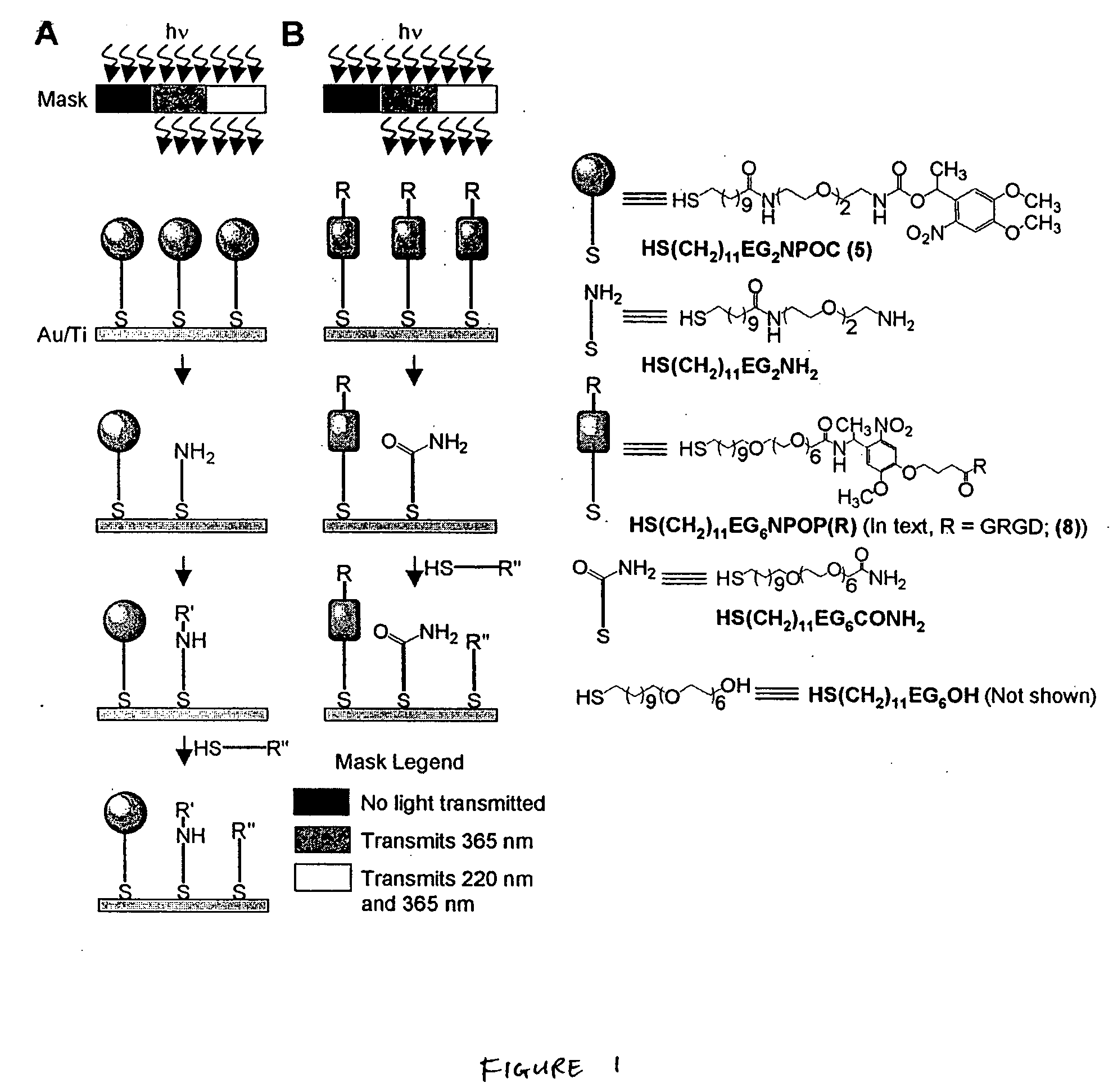

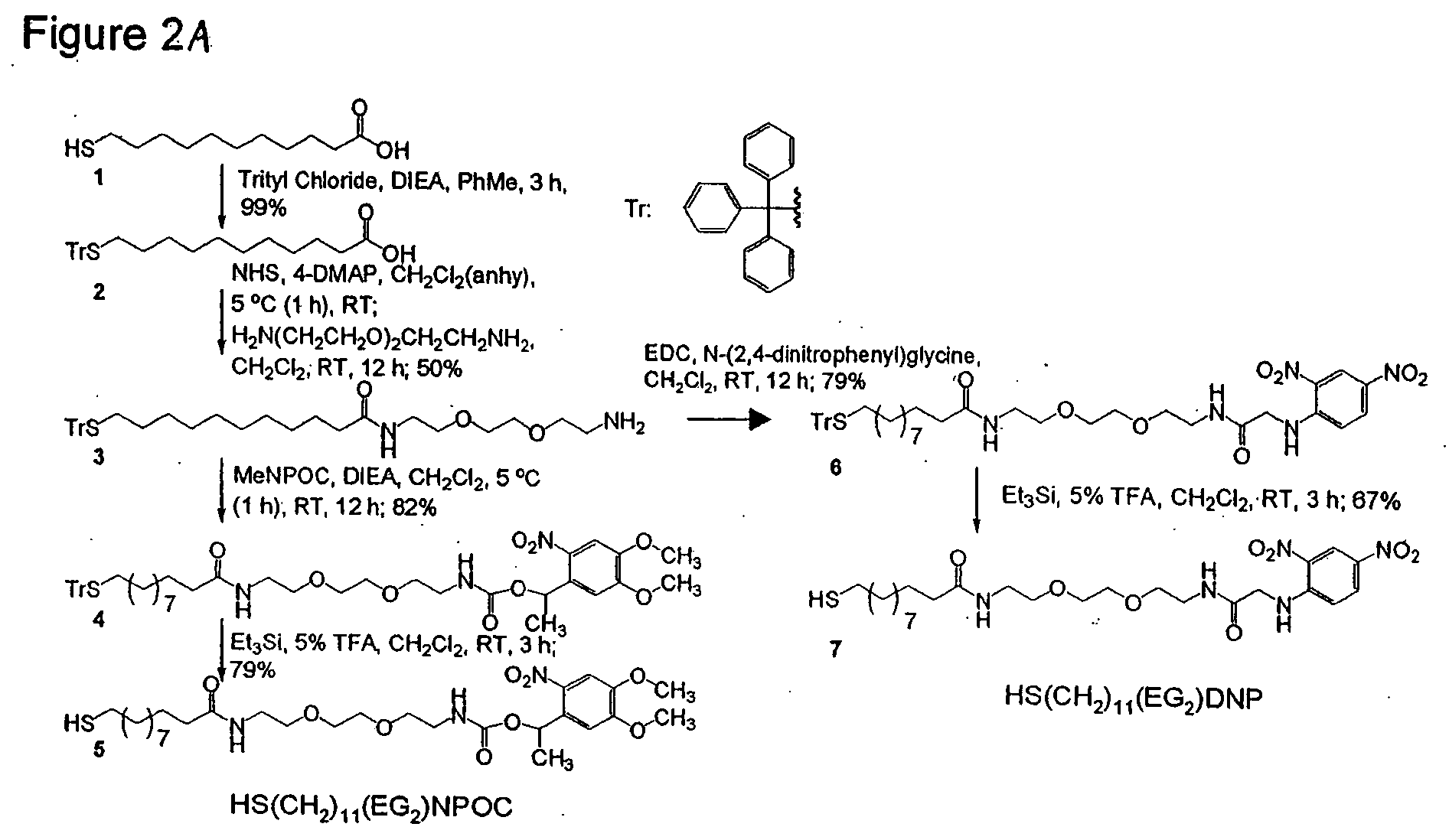

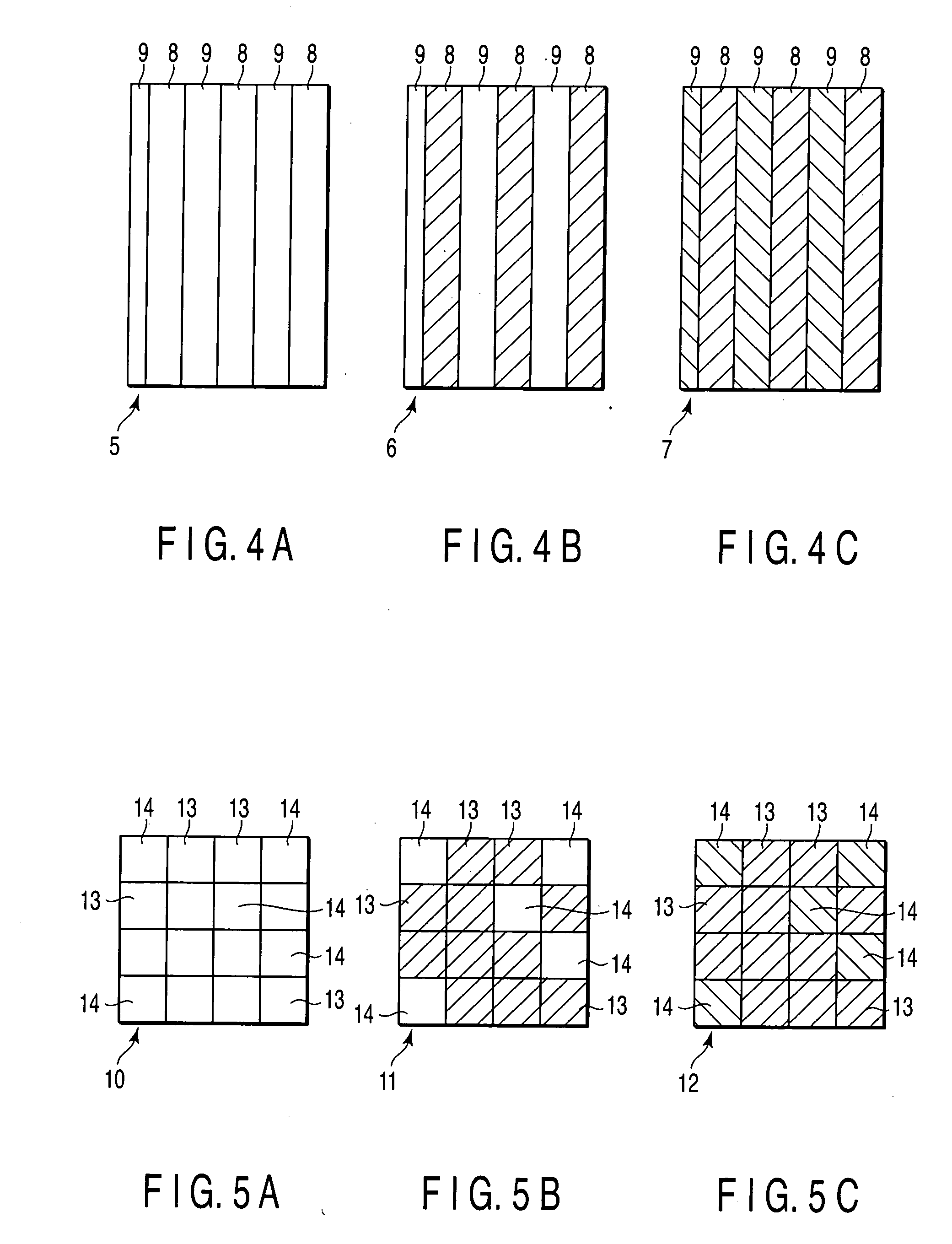

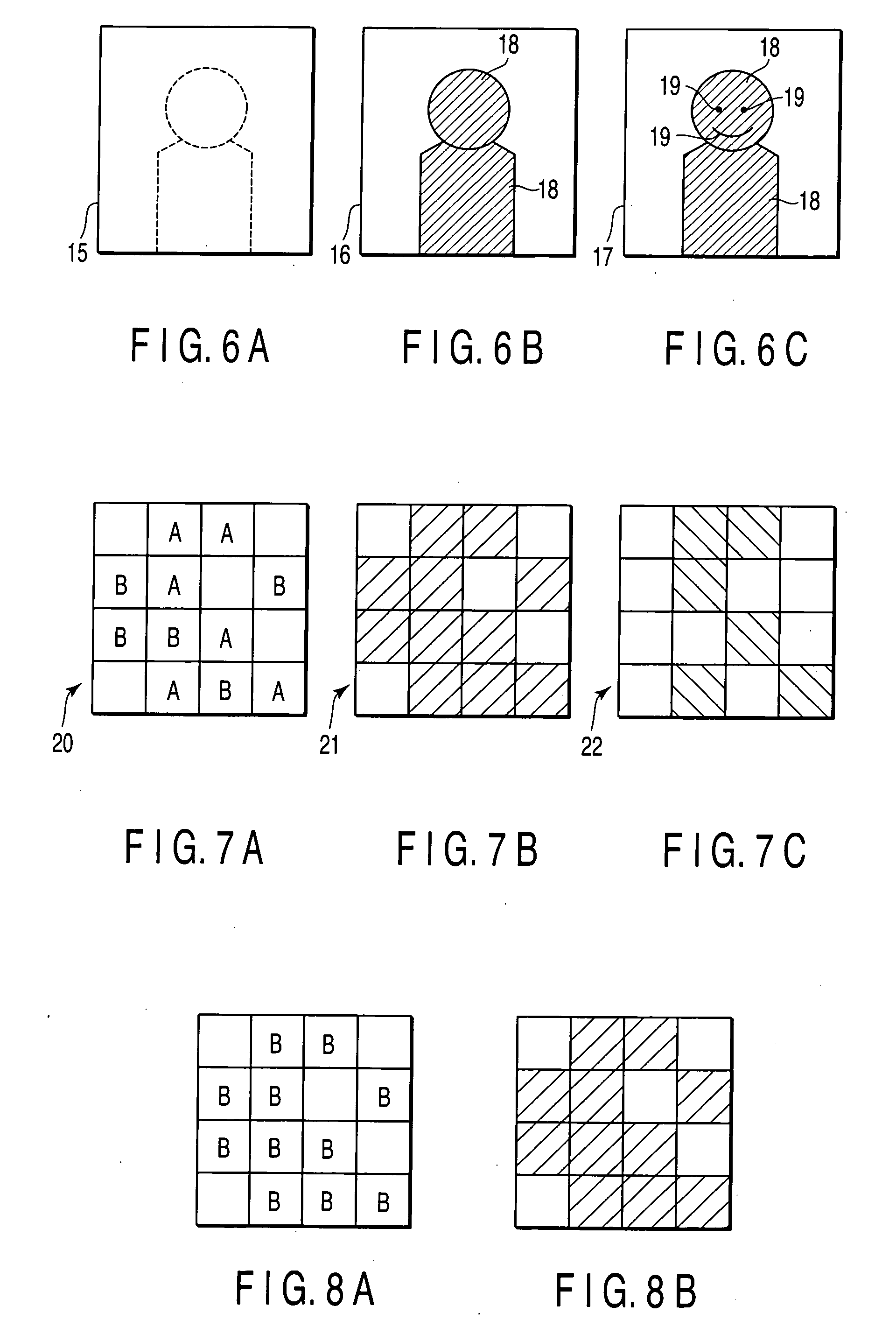

Patterning and alteration of molecules

Owner:RYAN DECLAN +7

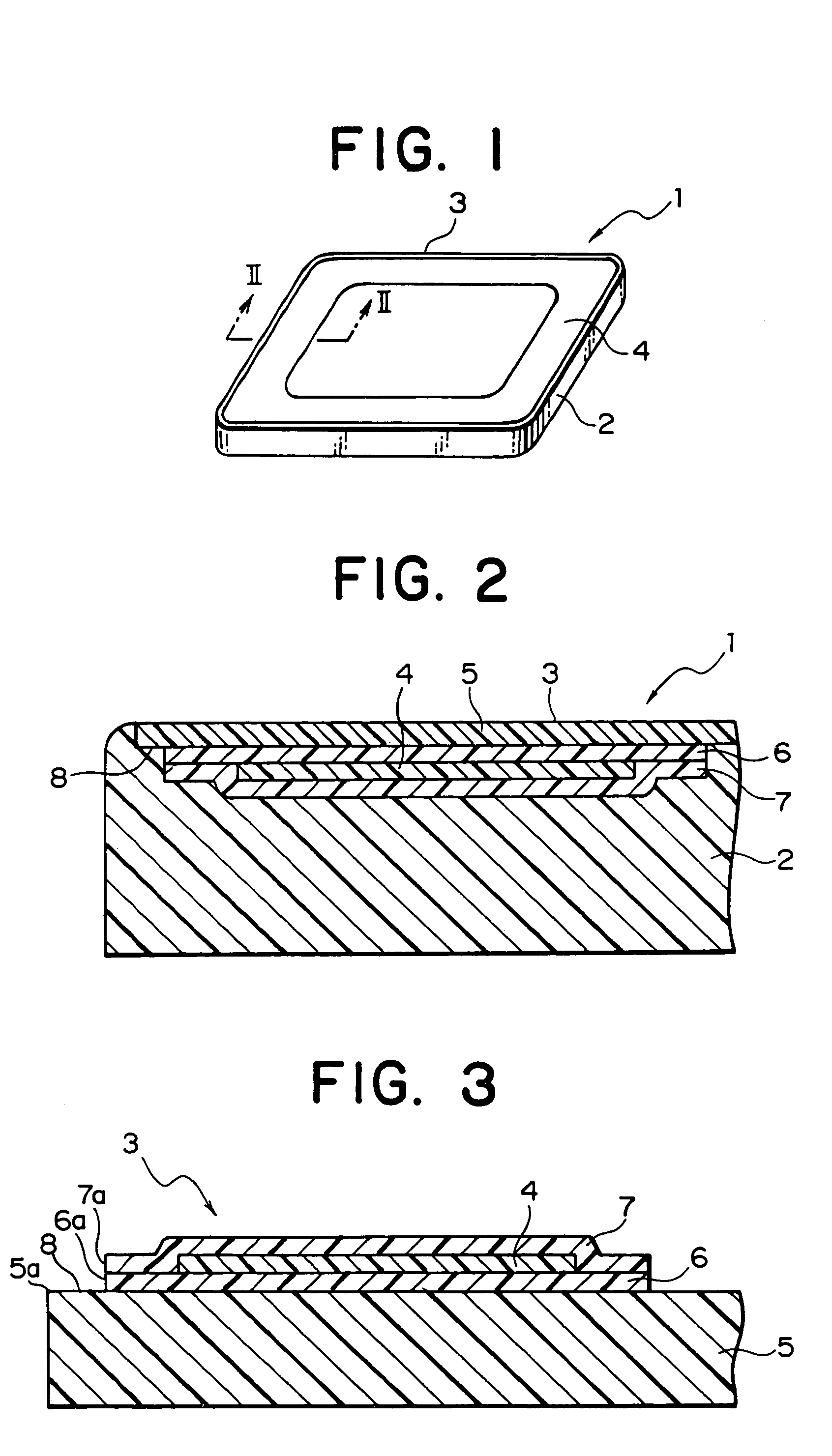

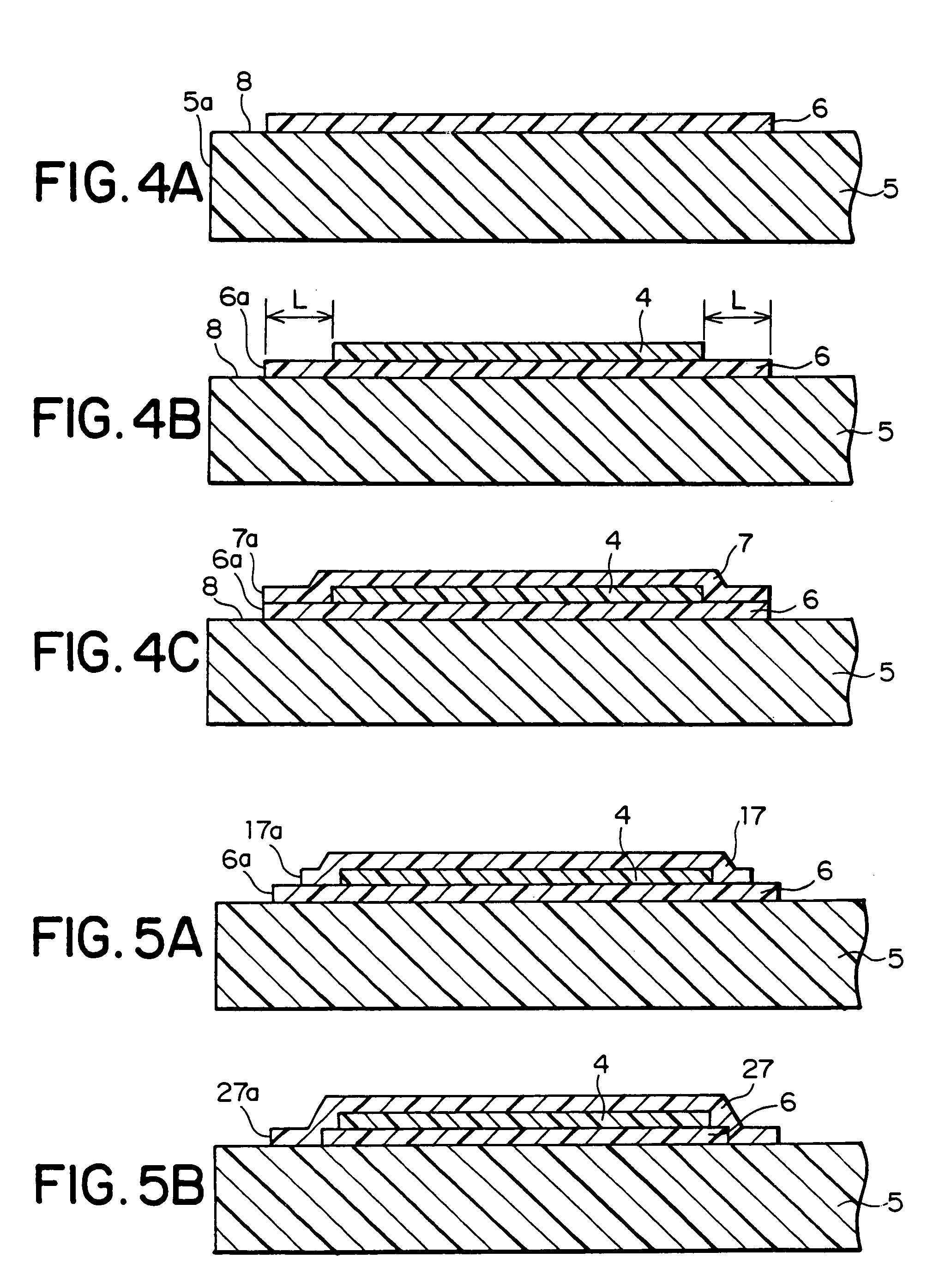

Insert film used for forming resin panel, process for producing the film and resin panel using the film

InactiveUS7220471B1Prevent ink from flowingSimple structurePicture framesDecorative surface effectsEngineeringSurface plate

Owner:TOYOTA IND CORP

High surface area and low structure carbon blacks for energy storage applications

ActiveUS20120214000A1Increase capacitanceEfficient separationPigmenting treatmentCapacitor and primary/secondary cellsApparent densityElectrochemical double layer capacitor

The present invention, in part, relates to a carbon black having a) a nitrogen BET surface area (BET) of from about 600 m2 / g to about 2100 m2 / g, b) a CDBP value in mL / 100 g of from about (−2.8+(b*BET)) to about (108+(b*BET)), where b is 0.087 and BET is expressed in m2 / g, and c) an apparent density (p, g / cm3) of at least about 0.820+q*BET, where q=−2.5×10−4, as determined at a compressive force (P) of 200 kgf / cm2 on dry carbon black powder. Energy storage devices, such as electrochemical double layer capacitors (EDLC's), containing the carbon black are also disclosed. Methods for making the carbon blacks and EDLC's made with them are also provided.

Owner:CABOT CORP

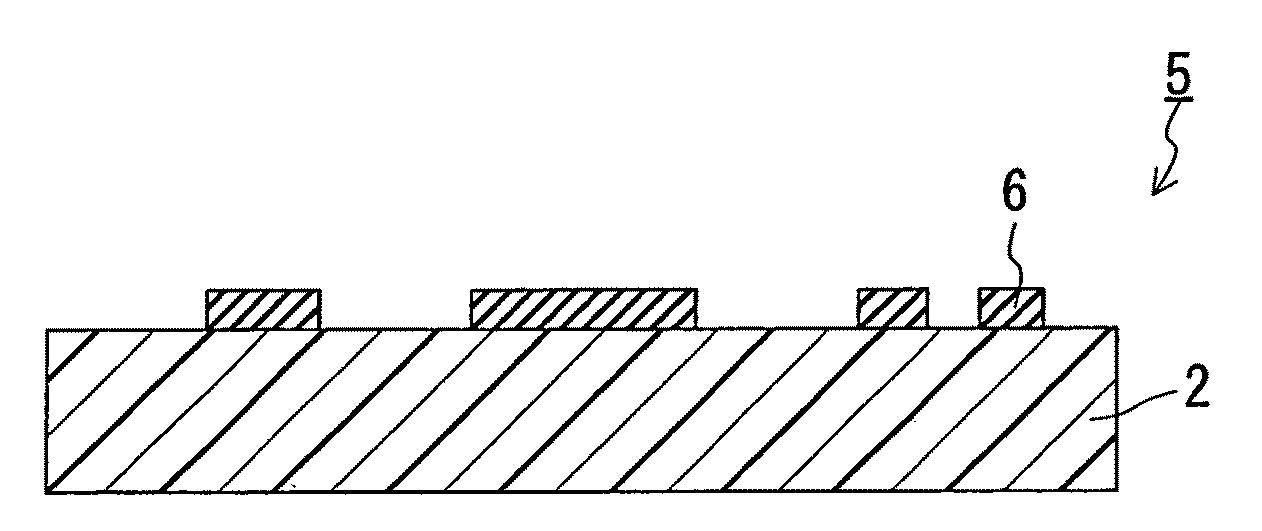

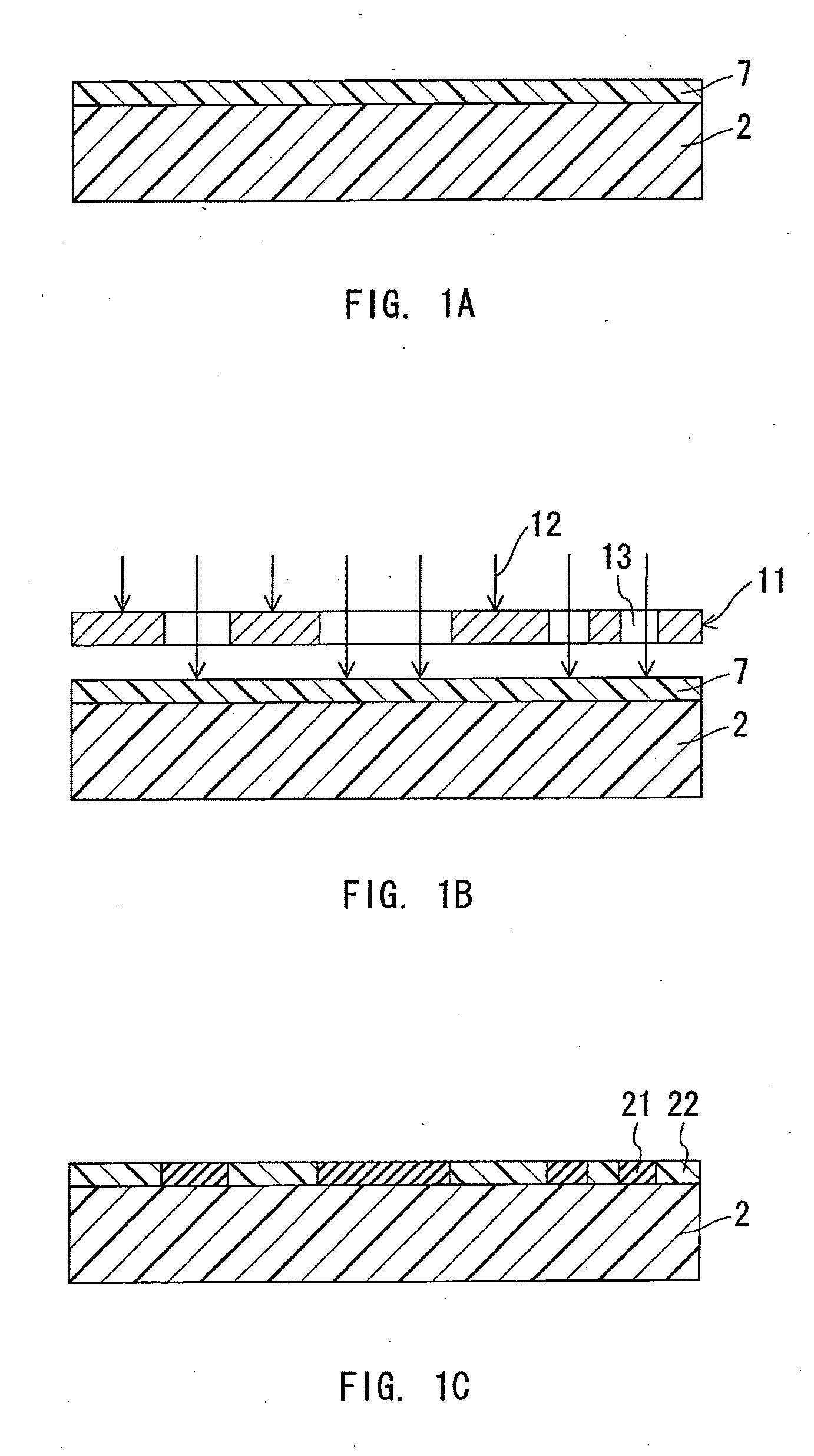

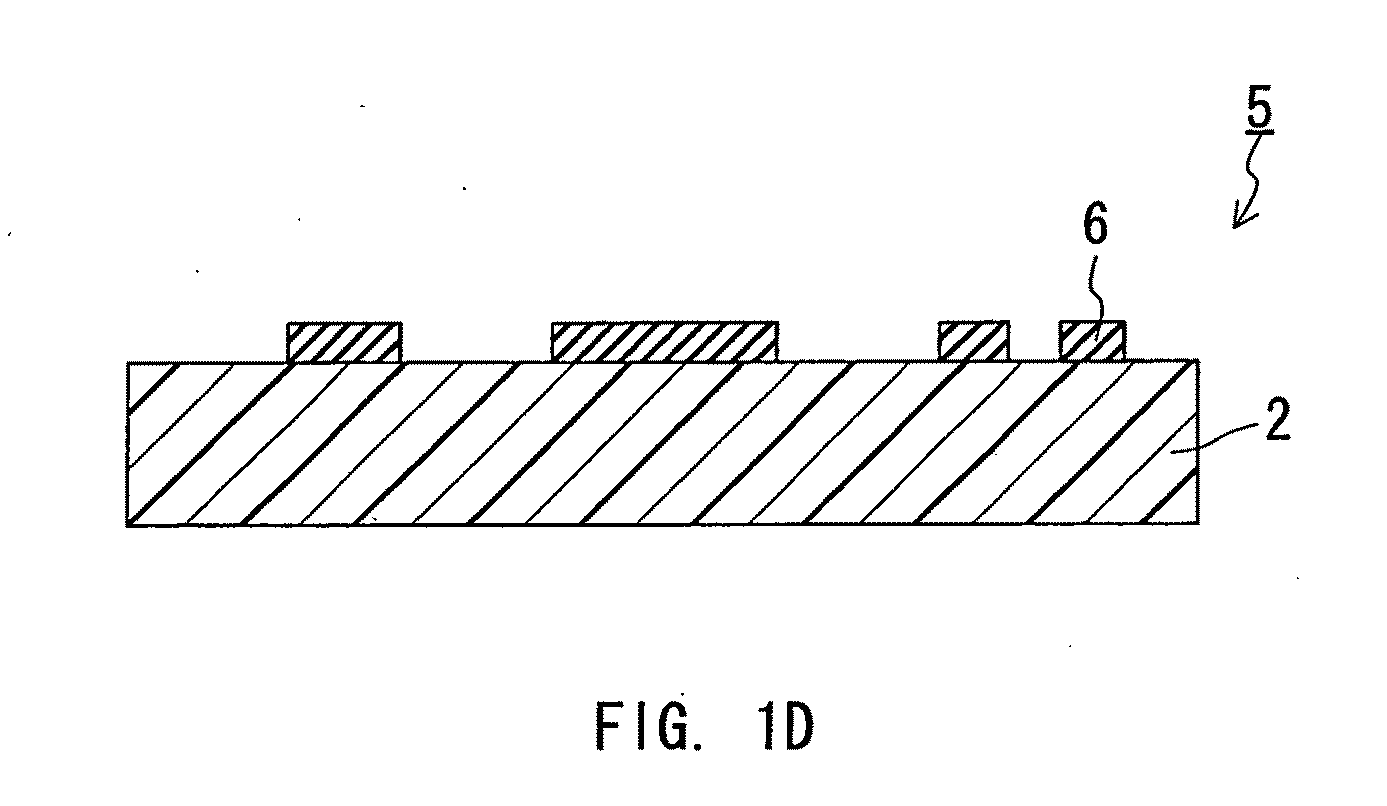

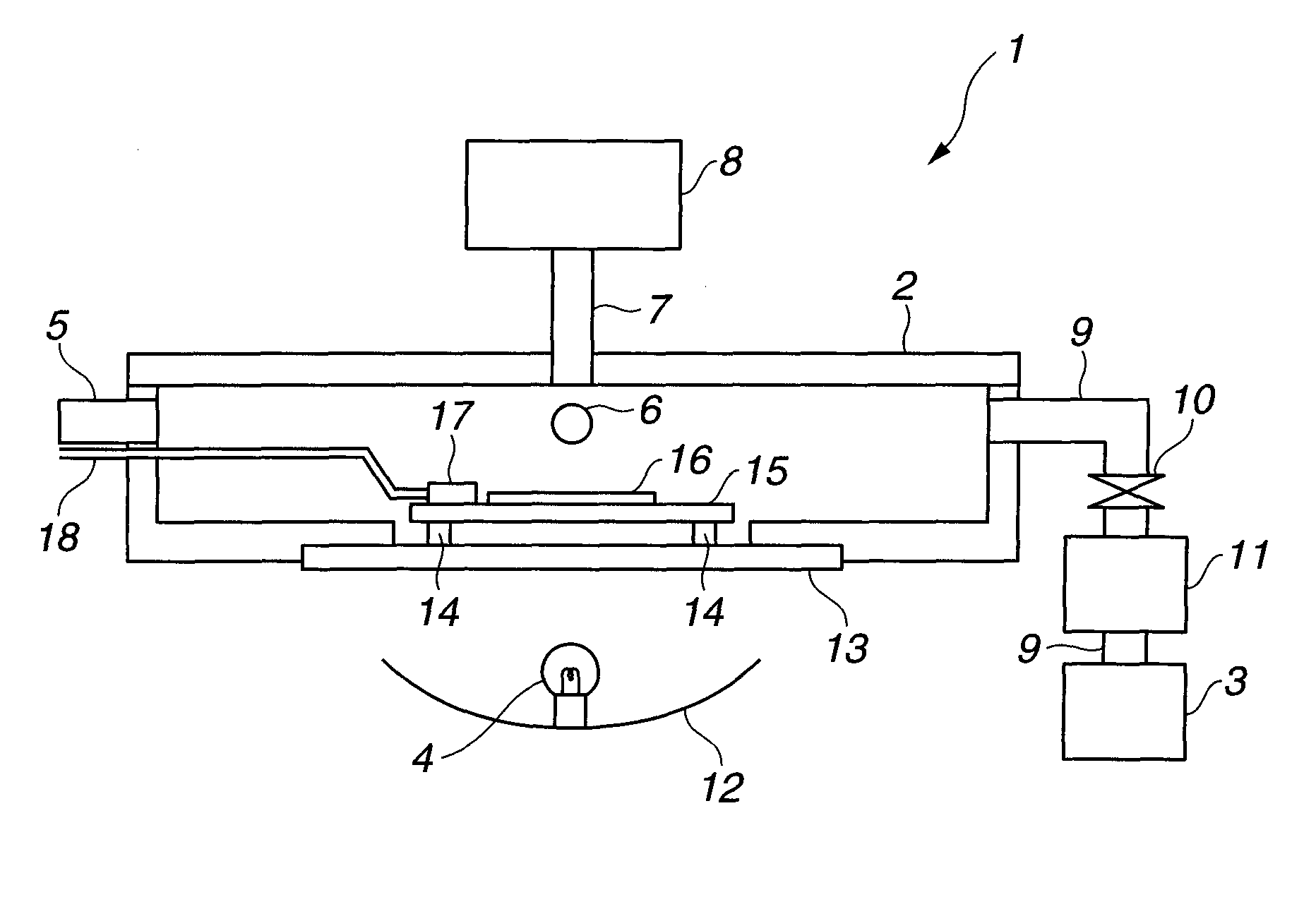

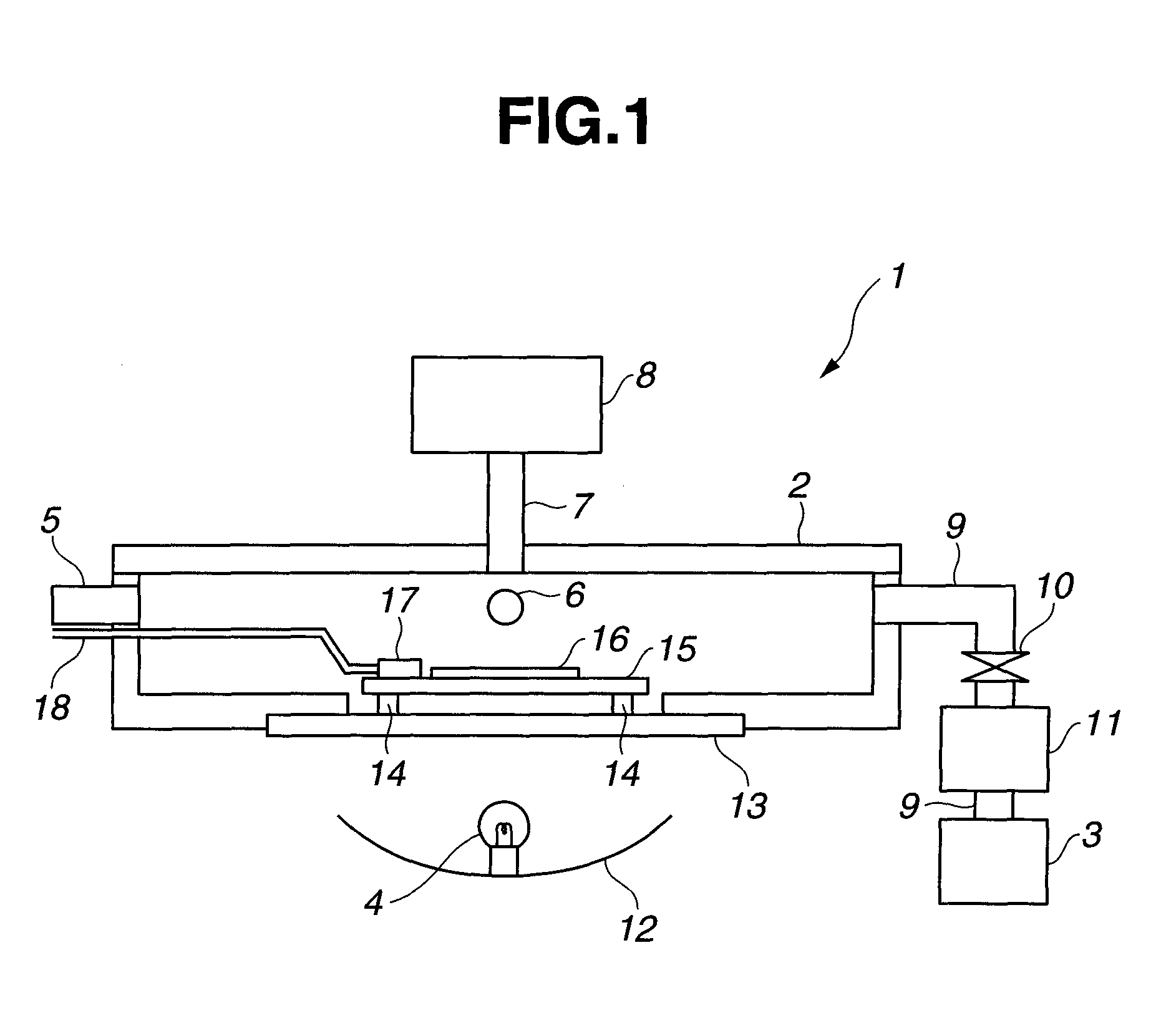

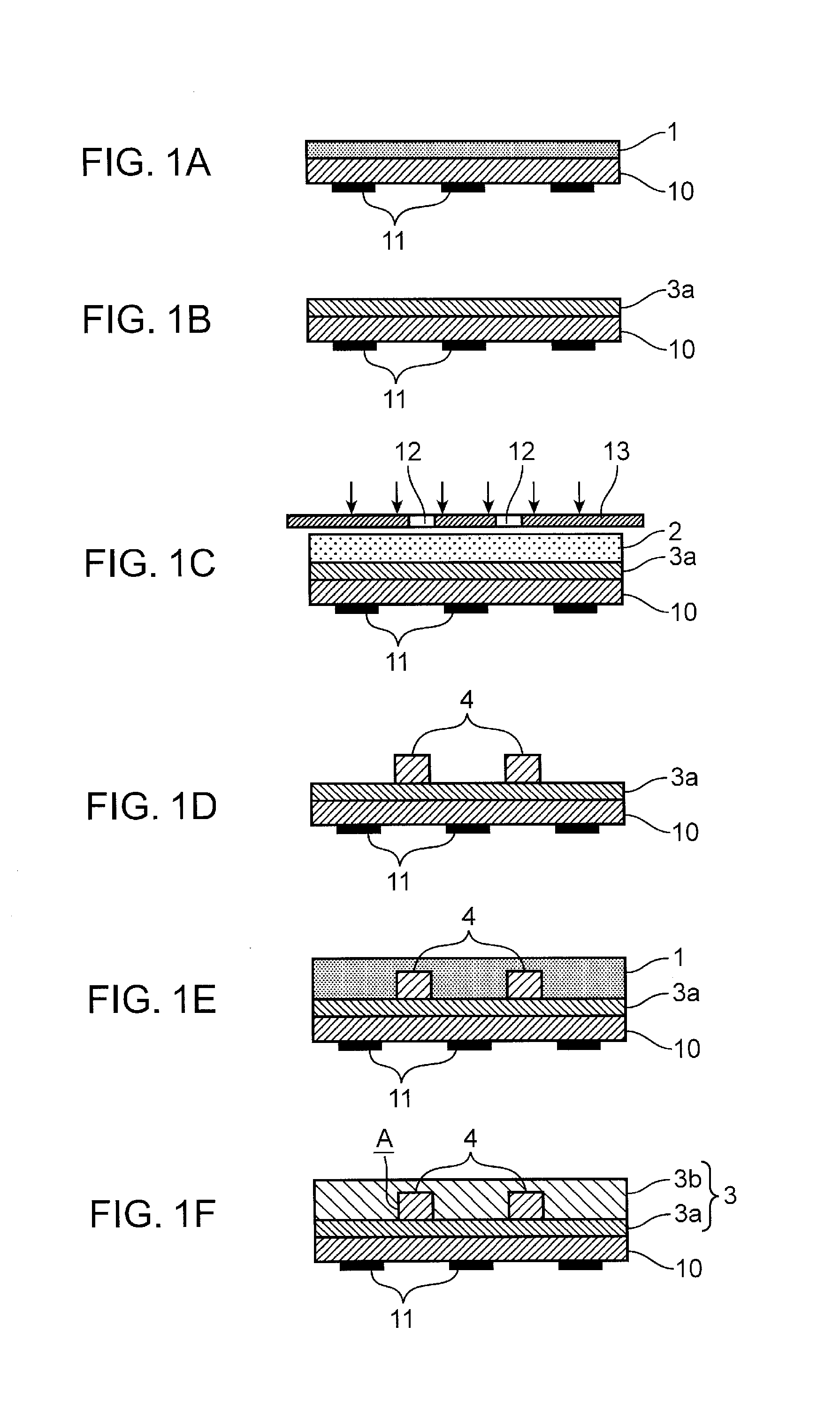

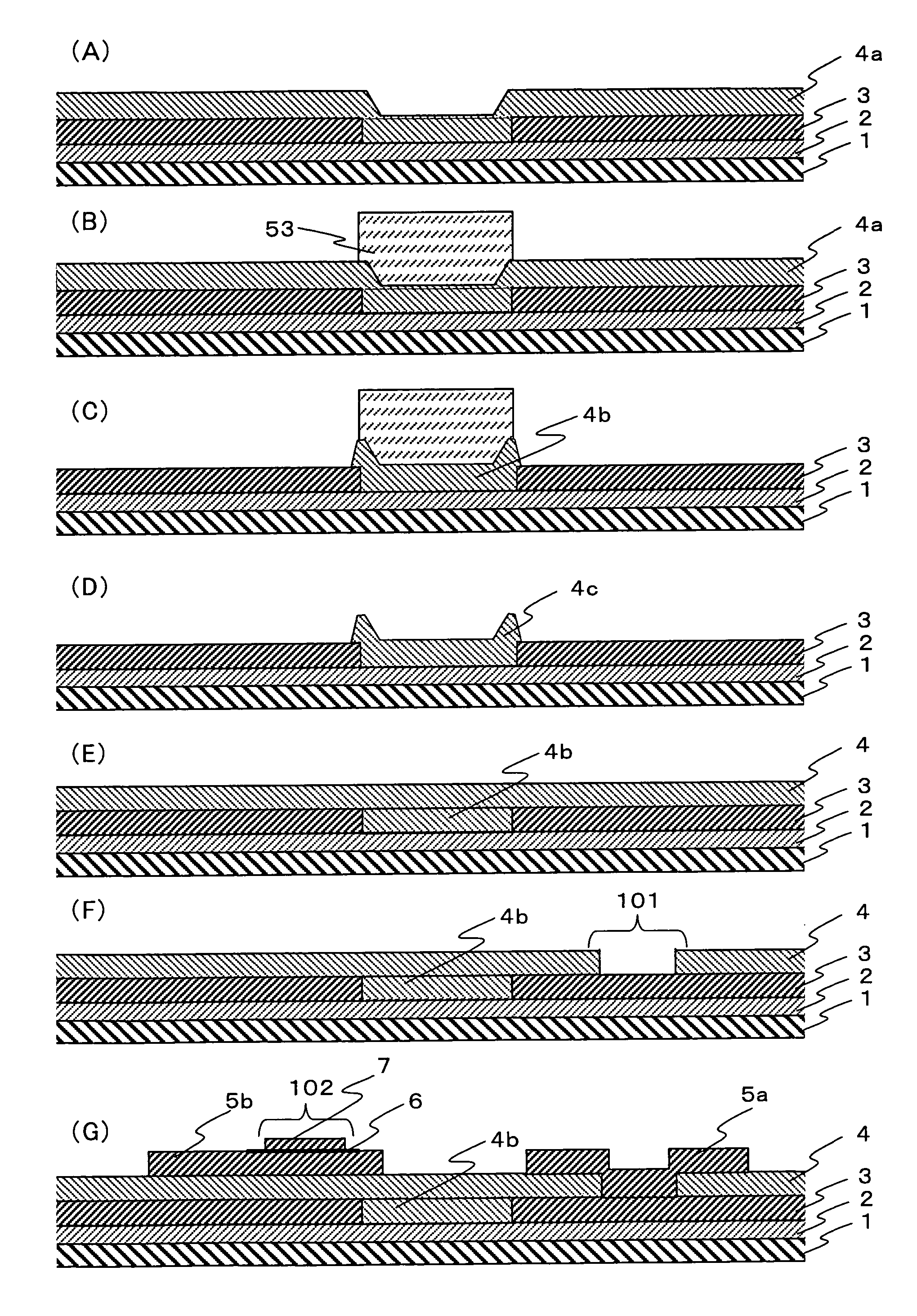

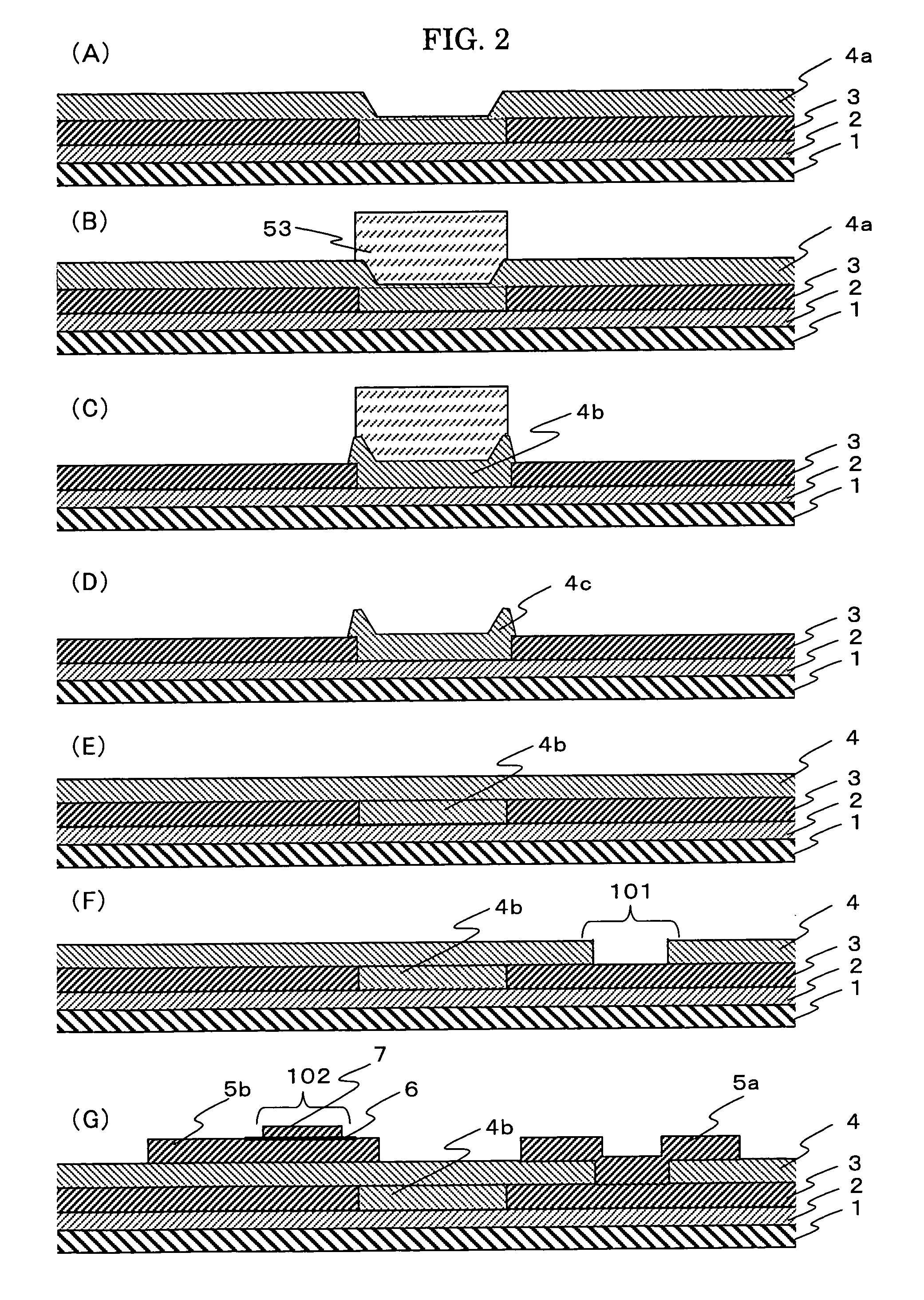

Method for manufacturing movable portion of semiconductor device

ActiveUS20050054153A1Short processing timeEasy to disassembleTransistorDecorative surface effectsInsulation layerDevice material

Owner:DENSO CORP

Fluorescent image-printed article and fluorescent ink

ActiveUS20060063036A1Improve security levelOther printing matterDuplicating/marking methodsFluorescenceRare earth

Owner:KK TOSHIBA

Printing superimposed layers

An apparatus and method for making a panel with superimposed layers of marking material in substantially exact registration is provided. An assembly includes a stencil layer sandwiched between a substrate and a transparent coating. The stencil includes a release surface. The coating tends to secure the stencil layer to the substrate, e.g., for storage and / or transport, and may protect the stencil layer from marking materials that might otherwise penetrate the stencil layer. A design and background layers are then printed onto the coating. A force is then applied to remove the background layer, design layer, and coating that are disposed on the stencil layer, leaving the remainder of the background layer, design layer, and coating adhered to the substrate in substantially exact registration within portions of the substrate that are devoid of the stencil layer. The design layer is right-reading visible through the substrates.

Owner:CONTRA VISION

Method for producing resin porous membrane with adhesive layer, resin porous membrane with adhesive layer, and filter member

Owner:NITTO DENKO CORP

Methods of manufacturing a tunnel magnetoresistive element, thin-film magnetic head and memory element

InactiveUS6895658B2Inhibition formationNanomagnetismDecorative surface effectsTunnel barrierTunnel magnetoresistance

Owner:TDK CORPARATION

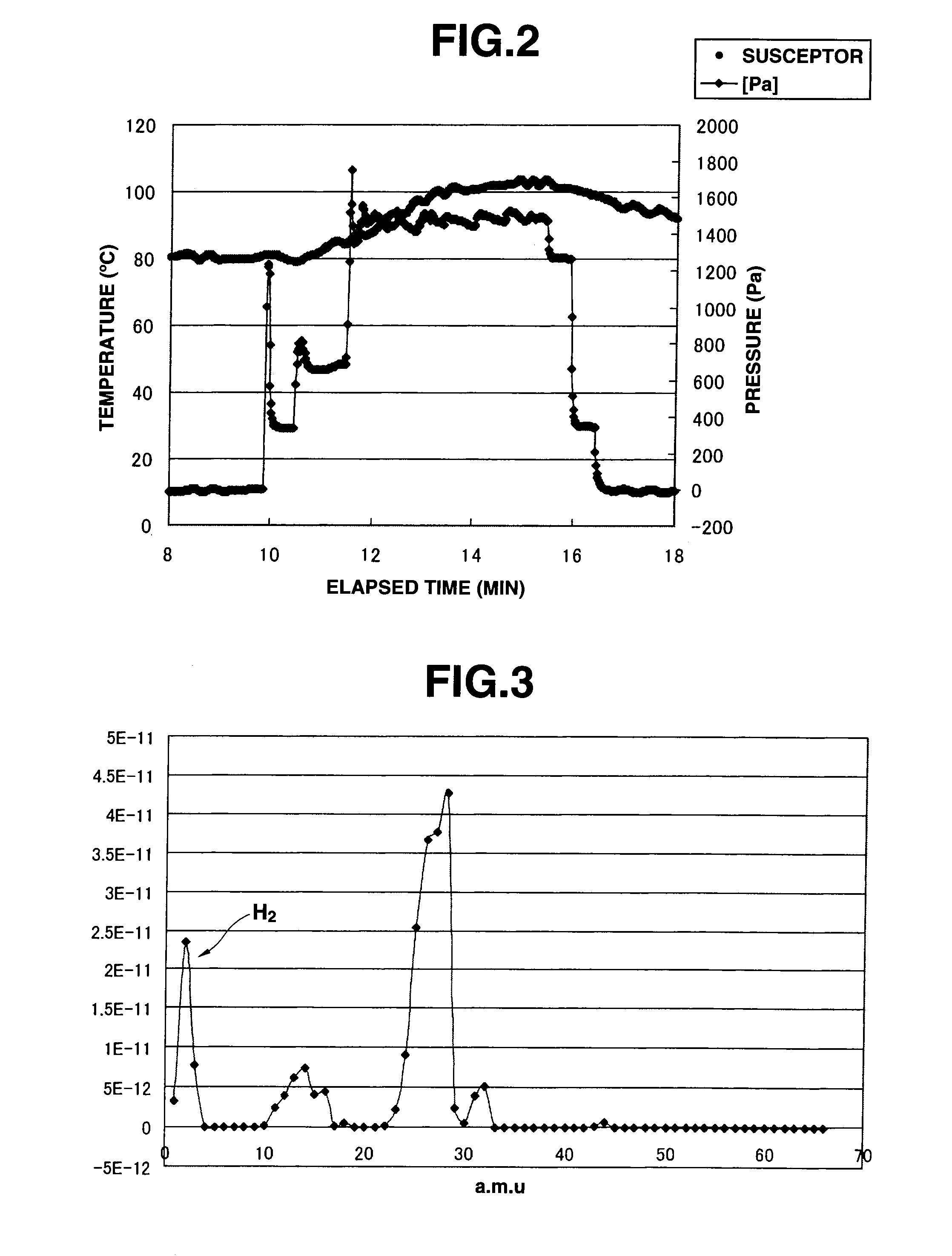

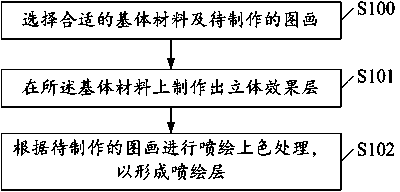

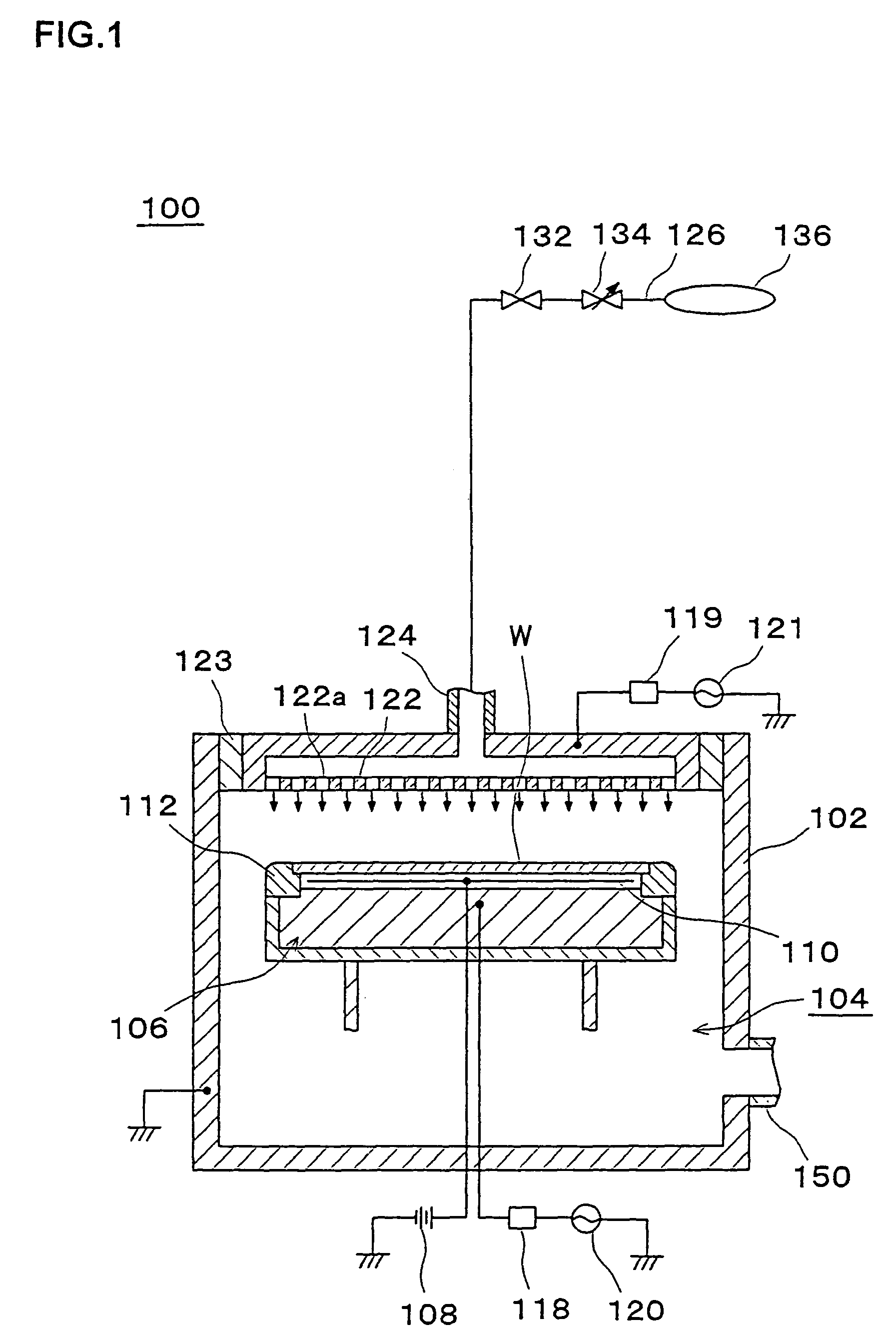

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

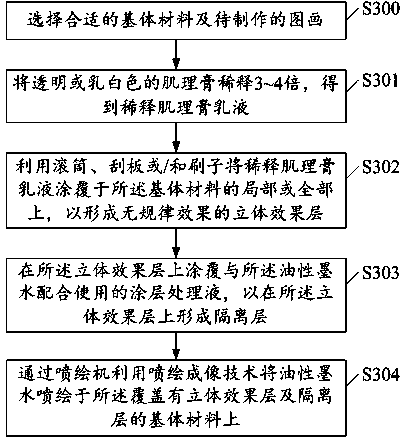

Method for manufacturing three-dimensional craft painting

ActiveCN103407319AImprove waterproof performanceGood sun protectionDecorative surface effectsSpecial ornamental structuresHigh volume manufacturingEngineering

Owner:XIAMEN HAOSHIDUO IND & TRADE CO LTD

Watercolor block printing blanked stamping process

InactiveCN103587328AImprove the three-dimensional effectDecorative surface effectsPattern printingStamping processComputer engineering

The invention discloses a watercolor block printing blanked stamping process, which comprises the following steps of 1) preparing watercolor block printing base timber; 2) drawing needed patterns on the upper surface of the watercolor block printing base timber; 3) etching to remove the surface base timber except the lines of patterns; 4) cutting the surplus base timber of the base timber with the three-dimensional patterns obtained in step 3) along the outer edge of each pattern to the position which is 1cm away from the outer edge of the pattern, thus obtaining a watercolor block printing version; 5) selecting the needed watercolor block printing version from step 4), printing colors corresponding to the patterns on the watercolor block printing version, and covering the watercolor block printing version by utilizing a piece of wetted Chinese art paper; 6) covering the Chinese art paper in step 5) by utilizing a felt, and brushing the felt for 3 to 5 times along a single oblique direction by utilizing a brush rake; 7) removing the felt in the step 6), lifting the Chinese art paper to be away from the watercolor block printing version, and airing the Chinese art paper for three hours; 8) mounting. The pattern indentation on the watercolor block printing version is pressed onto the wetted Chinese art paper through the brush rake, so that the colorful and fluctuated patterns can be formed.

Owner:HANGZHOU SHIZHUZHAI PRINT ART

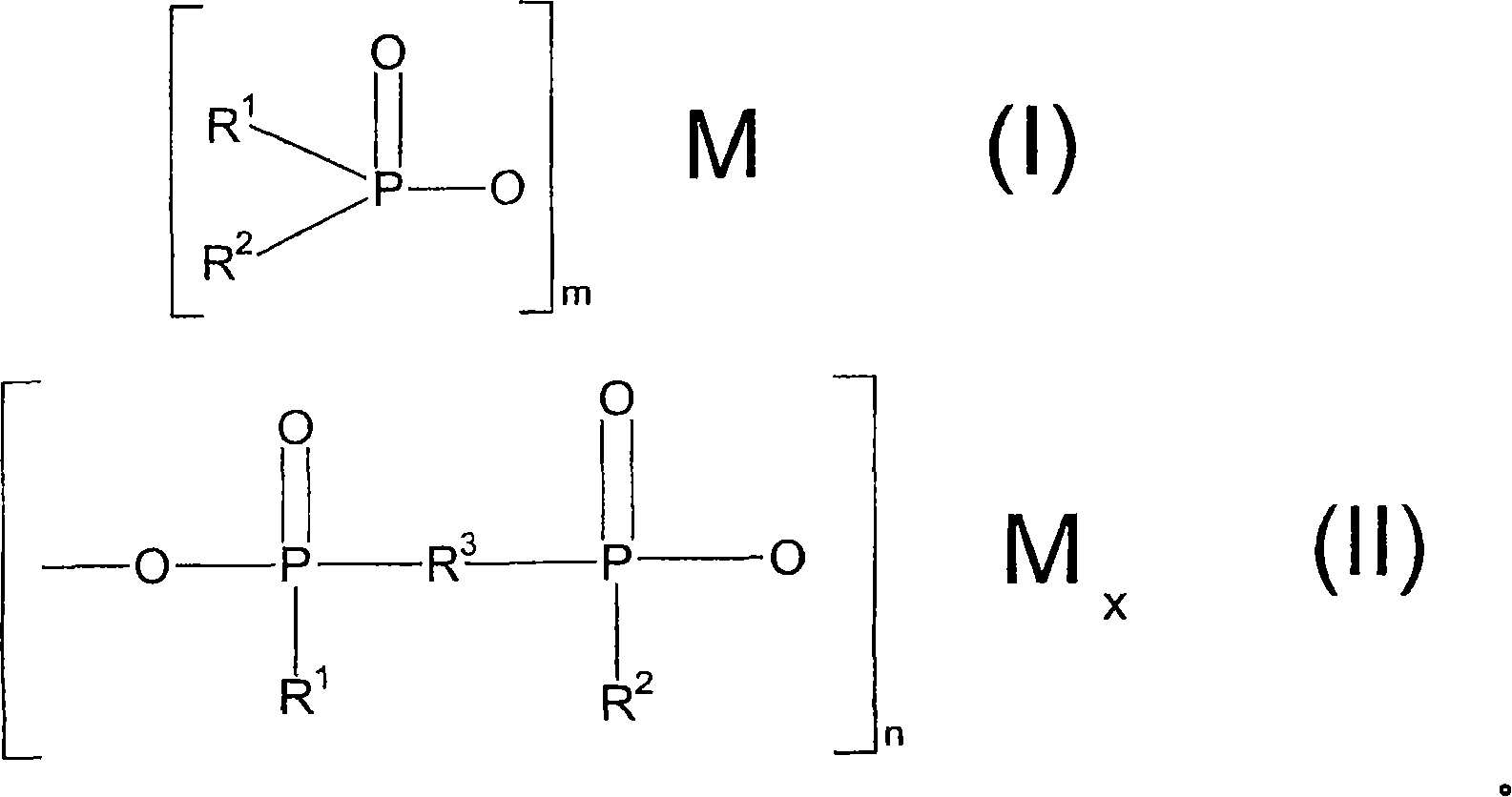

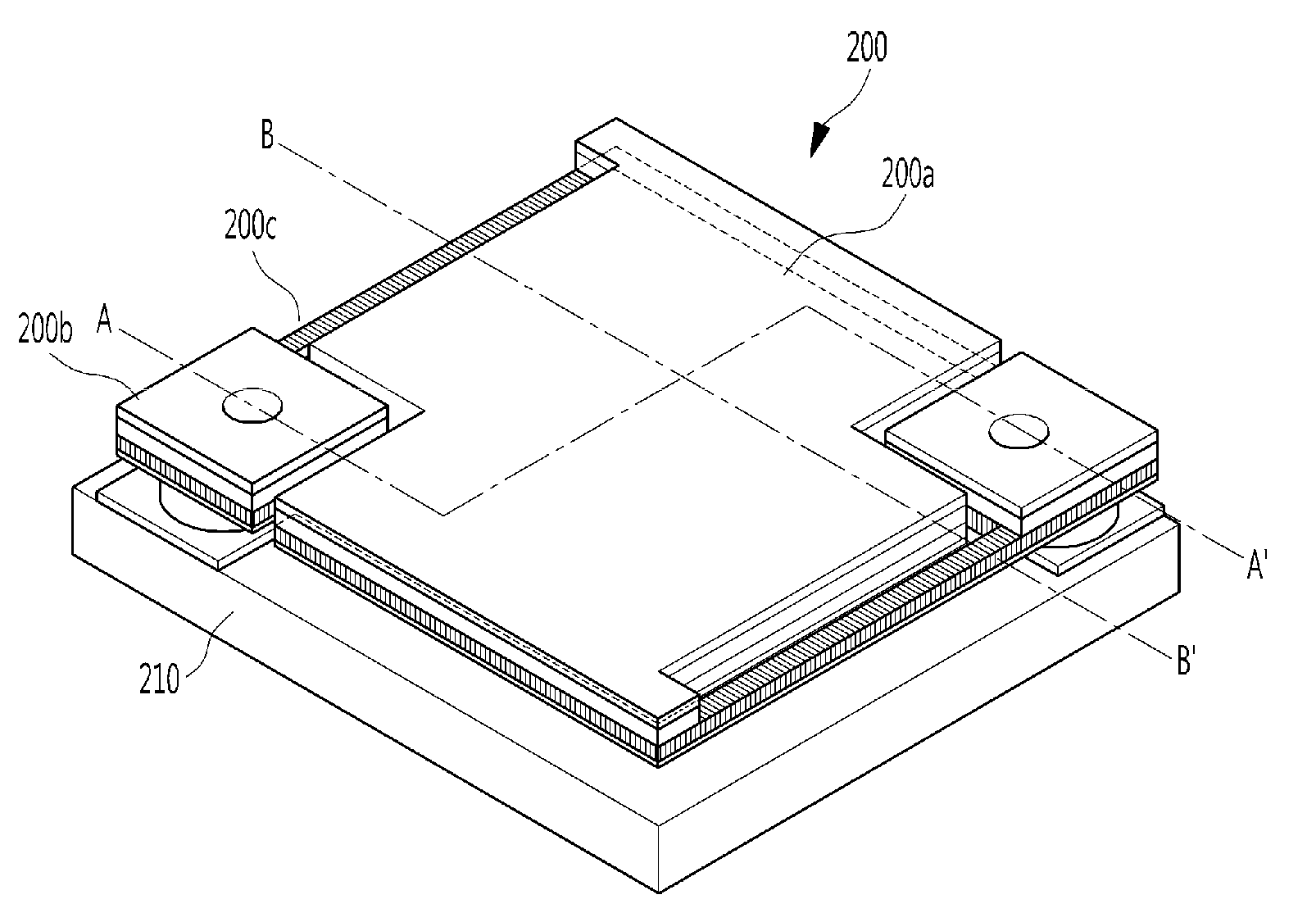

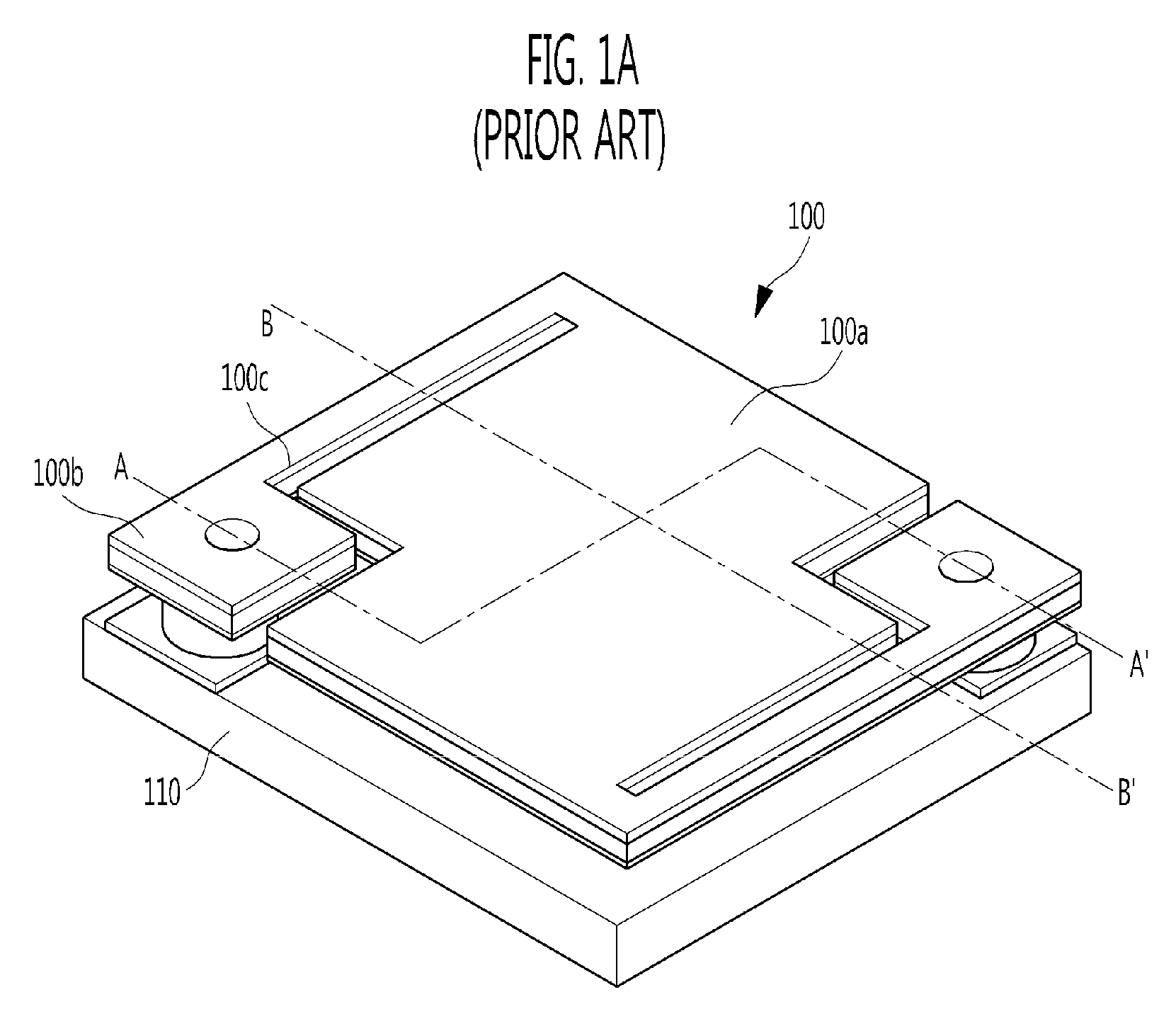

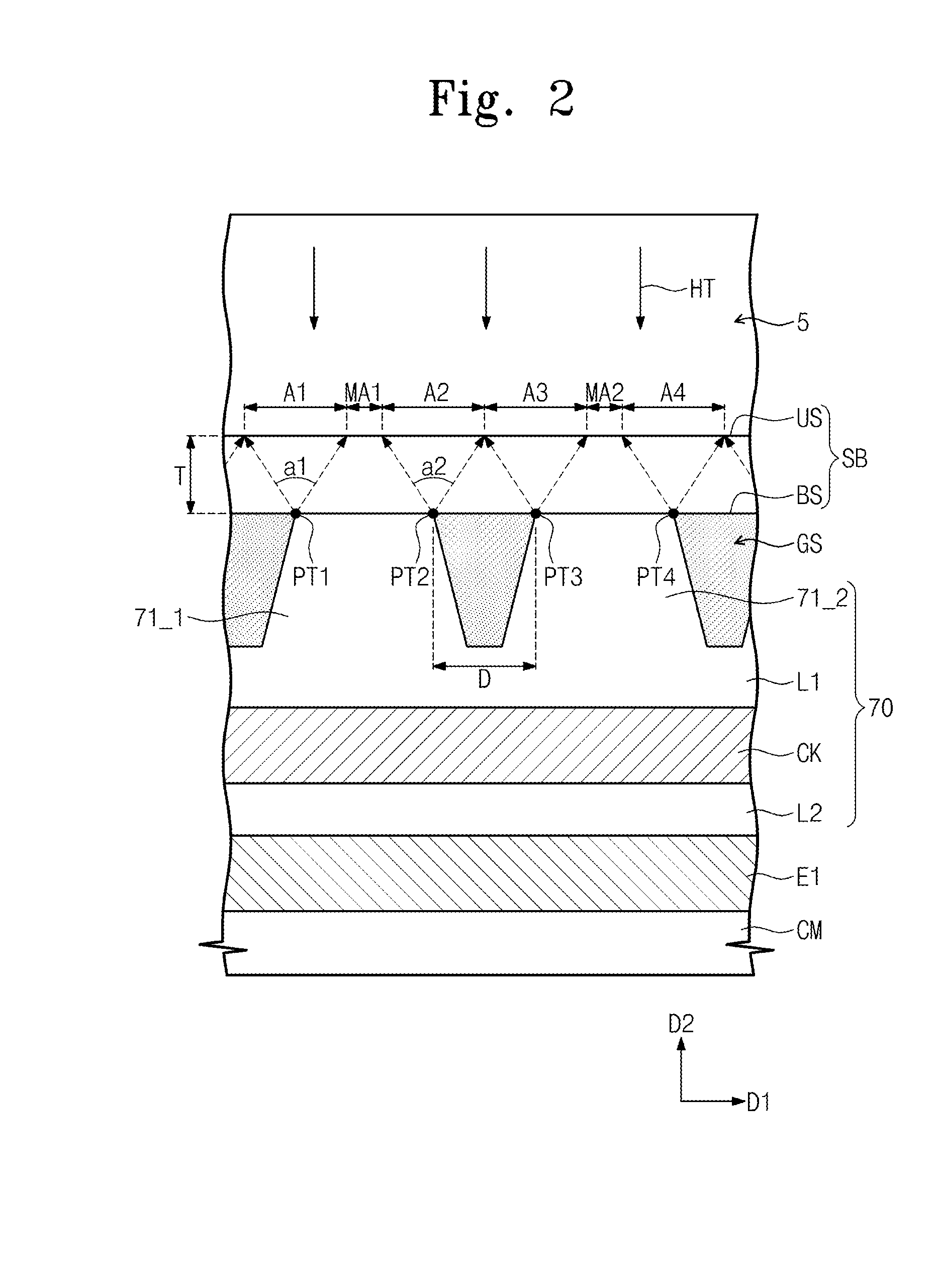

Substrate supporting unit and substrate treating apparatus and method

InactiveUS20140151332A1Electric discharge tubesDecorative surface effectsMechanical engineeringDielectric layer

Owner:SAMSUNG DISPLAY CO LTD

Bonding method of pecan artware

InactiveCN103042870APrecise positioningEasy positioning and bondingDecorative surface effectsScotch tapeEngineering

The invention belongs to the technical field of pecan artware making, and particularly relates to a bonding method of pecan artware. The bonding method mainly overcomes the defects that positioning on a wood pattern is difficult, adjustment is difficult, bonding operation is inconvenient, the efficiency is low, the technology cost is high, and the product quality is difficult to control in the existing pecan bonding technology. The bonding method adopts the technical scheme that the bonding method of the pecan artware comprises the steps that a pecan artware model is made with rigid foam; a layer of scotch tape is pasted on the surface of the pecan artware model; pecan pieces are arranged sequentially and fixed on the pecan artware model made by the rigid foam with a pin; and then glue is injected into mutual joints of the pecan pieces outside the pecan artware; stripping is conducted after the glue is dried; glue is injected into joints of the pecan pieces inside the pecan artware; and then the pecan artware is made through routine closure and polishing. The bonding method has the advantages that the bonding method is simple and convenient in bonding technology, rapid, low in cost and stable in quality.

Owner:上官建云

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS20140004321A1High transparencyLow coefficient of linear expansionDuplicating/marking methodsDecorative surface effectsEpoxyPolymer science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

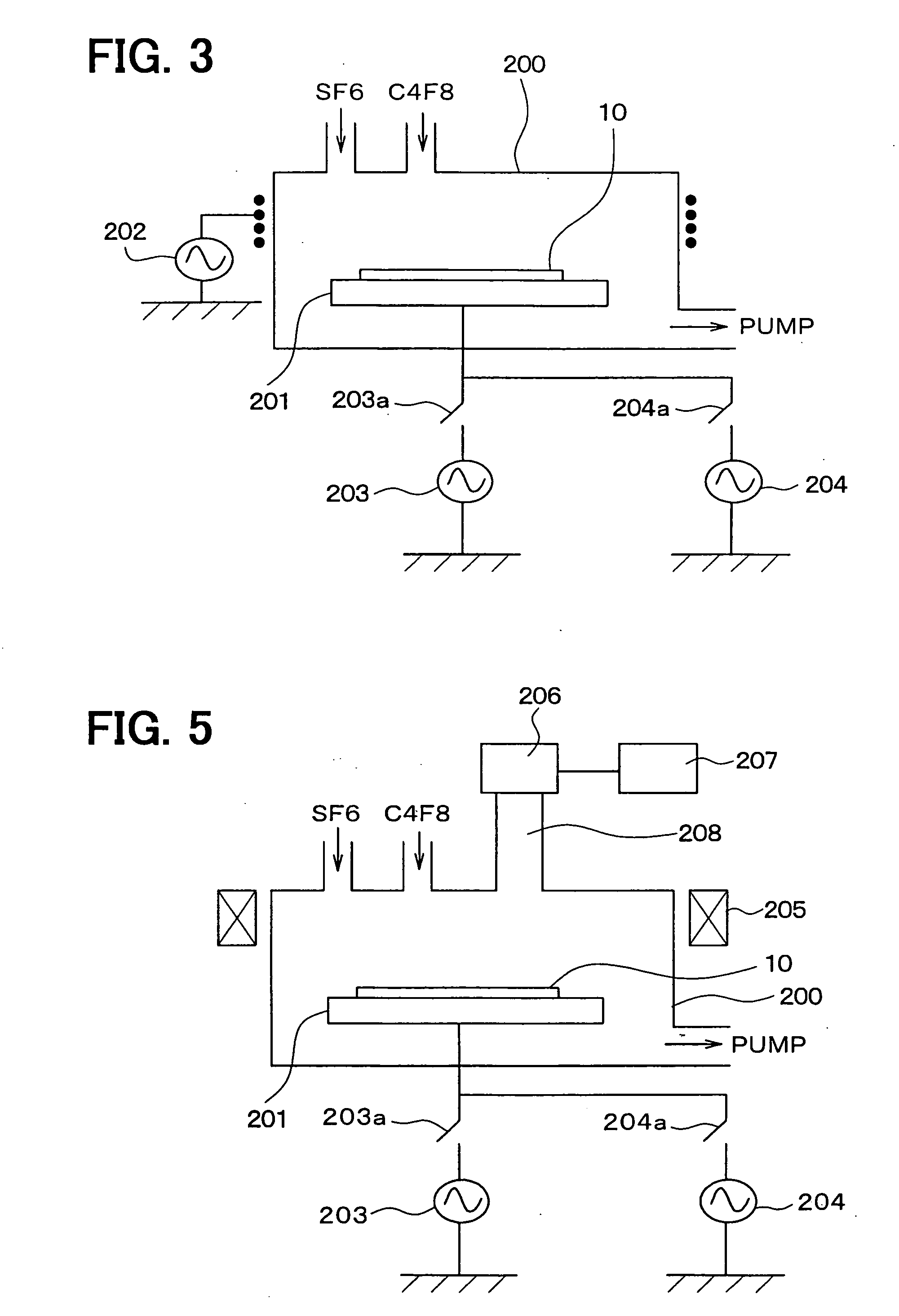

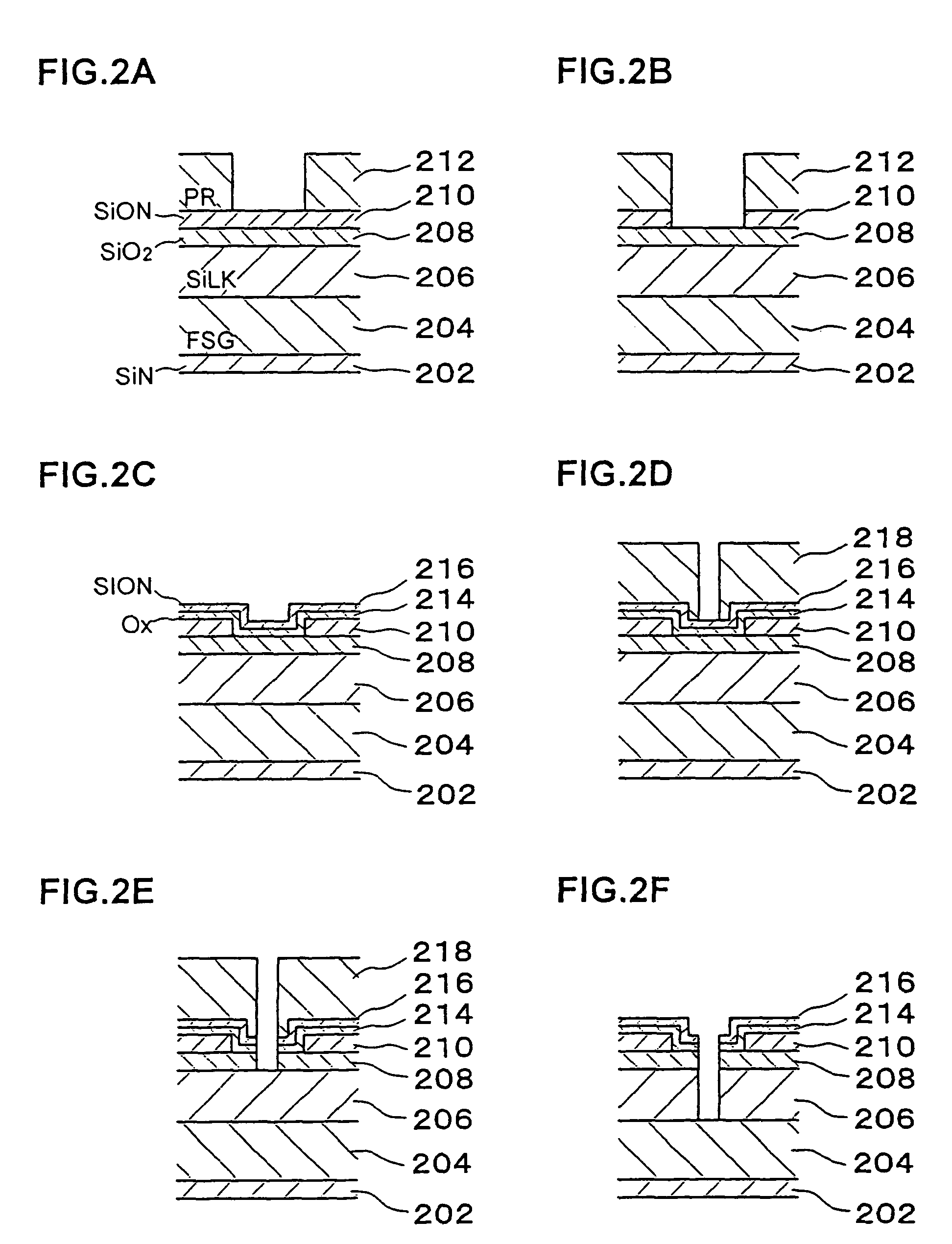

Method of etching dual damascene structure

InactiveUS7326650B2Maintain dimensional stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingHard maskPhysics

Owner:TOKYO ELECTRON LTD

Resin composition for laser engraving, relief printing plate precursor for laser engraving, relief printing plate and method of producing the same

The present invention provides a resin composition for laser engraving, including at least a complex between a layered inorganic compound and a cationic organic compound, and a binder polymer that is insoluble in water and soluble in an alcohol having 1 to 4 carbon atoms; a relief printing plate precursor for laser engraving using the same, a relief printing plate; and a method of producing the relief printing plate.

Owner:FUJIFILM CORP

Muddy substrate simulation wall painting and manufacturing process thereof

InactiveCN102673284AMeet printable requirementsImprove manufacturing speedDecorative surface effectsSpecial artistic techniquesHigh volume manufacturingBuilding construction

Owner:王强

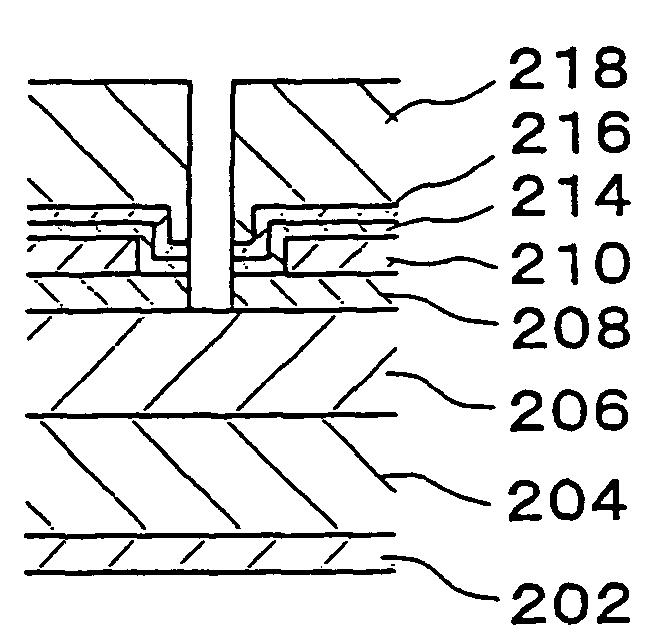

Manufacturing method for electronic device and multiple layer circuits thereof

InactiveUS7081417B2Large process marginRemarkable effectDecorative surface effectsSolid-state devicesInsulation layerMultiple layer

Owner:HITACHI LTD +2

Ink set for inkjet recording, recording method, and colored material produced using the ink set

InactiveUS20130328979A1Convenient lightingIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

An ink set for inkjet recording, which has excellent water resistance and light resistance in the hue range of yellow-orange-magenta. The ink set includes two-color ink compositions, i.e., a) a magenta ink composition and b) an yellow ink composition, each of which includes a dye, water and a water-soluble organic solvent, wherein the magenta ink composition a) contains a compound produced by sulfonating a compound represented by the formula (1), a salt of the compound, or a mixture thereof as a coloring agent.

Owner:NIPPON KAYAKU CO LTD

Method for manufacturing miniature spring mechanical sensor for film performance test

InactiveCN101343033AReduce tensionHigh resolutionDecorative surface effectsChemical vapor deposition coatingEngineeringLinearity

Disclosed is a manufacturing method of a micro spring mechanics sensor used for the film performance test in the testing technology field; the method includes the steps that: the metal Ti layer is sputtered on the glass sheet and processed with oxidation treatment; the whirl coating of negative photoresist, front drying and development are processed on the glass sheet after the sputtering and oxidation treatment; the graphical display of the photoresist structure is realized according to the shape of the micro spring mechanics sensor designed by the mask plate; the Ni spring layer is electroformed on the processed titanium oxides layer; the micro spring mechanics sensor is processed with flatness machining; the sedimentation of the aligning marking and the displacement marking is processed on the Ni electroplated coating through the electrodeposition technology; the micro spring mechanics sensor is finally obtained after negative photoresist, the residual glass and the Ti sputtering layer are removed. The micro spring mechanics sensor prepared by the manufacturing method in the invention has the advantages of good linearity, simple process, high resolution, low cost and being easy to be integrated with the film mechanics performance test system.

Owner:SHANGHAI JIAOTONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap