Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically polishing refers to processes that use an abrasive that is glued to the work wheel, while buffing uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process while buffing is less harsh, which leads to a smoother, brighter finish. A common misconception is that a polished surface has a mirror bright finish, however most mirror bright finishes are actually buffed.

Stainless steel plate 8K mirror surface processing method

ActiveCN102962731AImprove the finishImprove anti-corrosion performancePolishing machinesFlexible-parts wheelsRough surfacePolishing

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Automatic fire polishing machining device

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Screw polishing machine

Owner:海盐天奇标准件股份有限公司

Shaft cleaning and polishing device

Owner:云和县达祥凯机械设计工作室

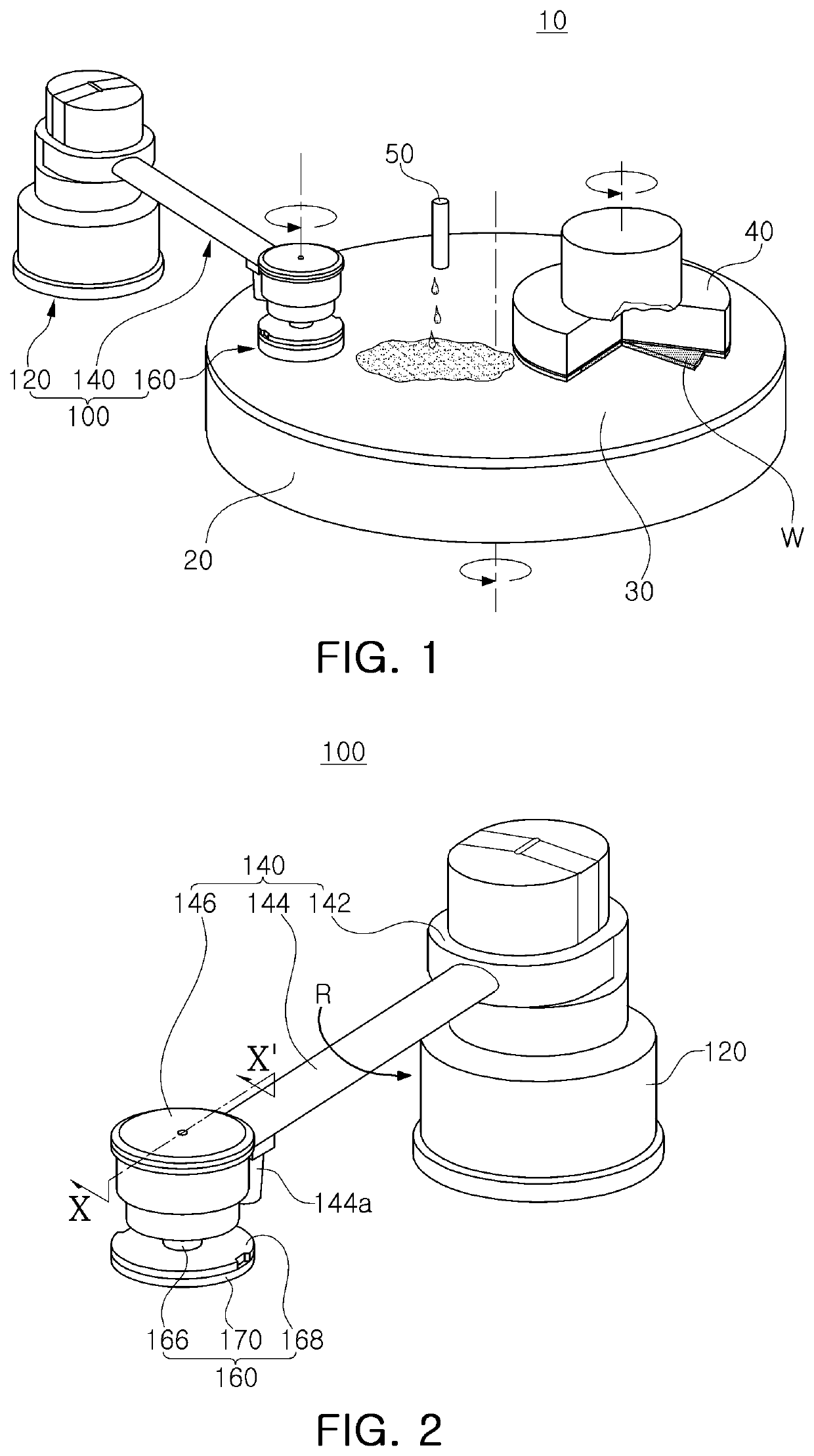

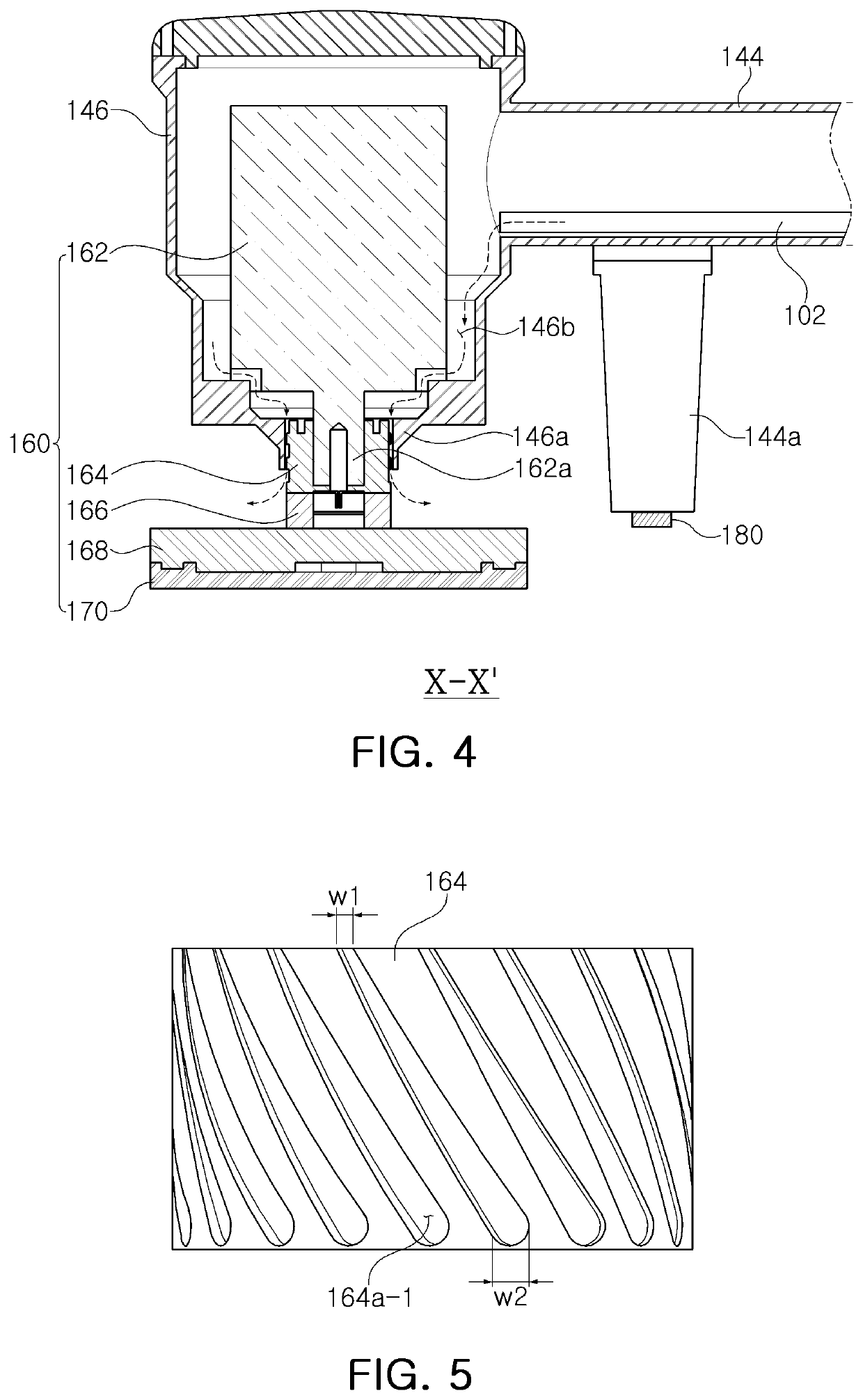

Polishing pad conditioning apparatus

ActiveUS20200206870A1Reduce deformation stressBelt grinding machinesFlexible-parts wheelsRotational axisForeign matter

Owner:SAMSUNG ELECTRONICS CO LTD

Surface polishing and grinding system for forging and casting part and machining process

ActiveCN113635189AAchieve angle adjustmentRealize replacement workPolishing machinesBelt grinding machinesRobot handPolishing

Owner:江苏和昌重工科技有限公司

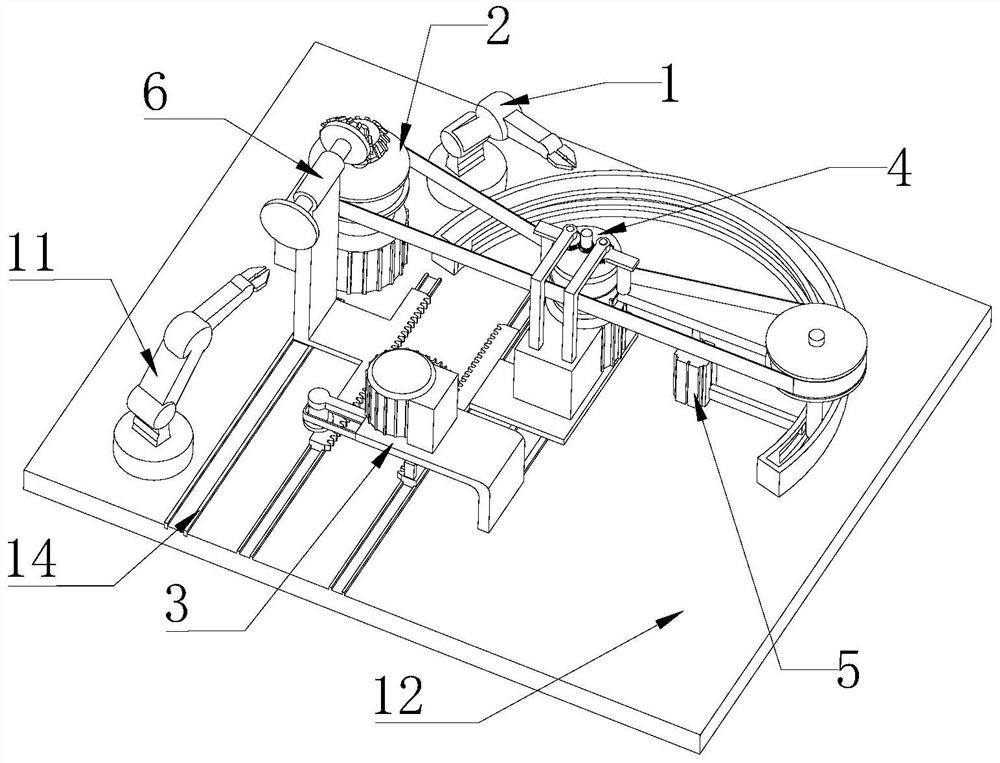

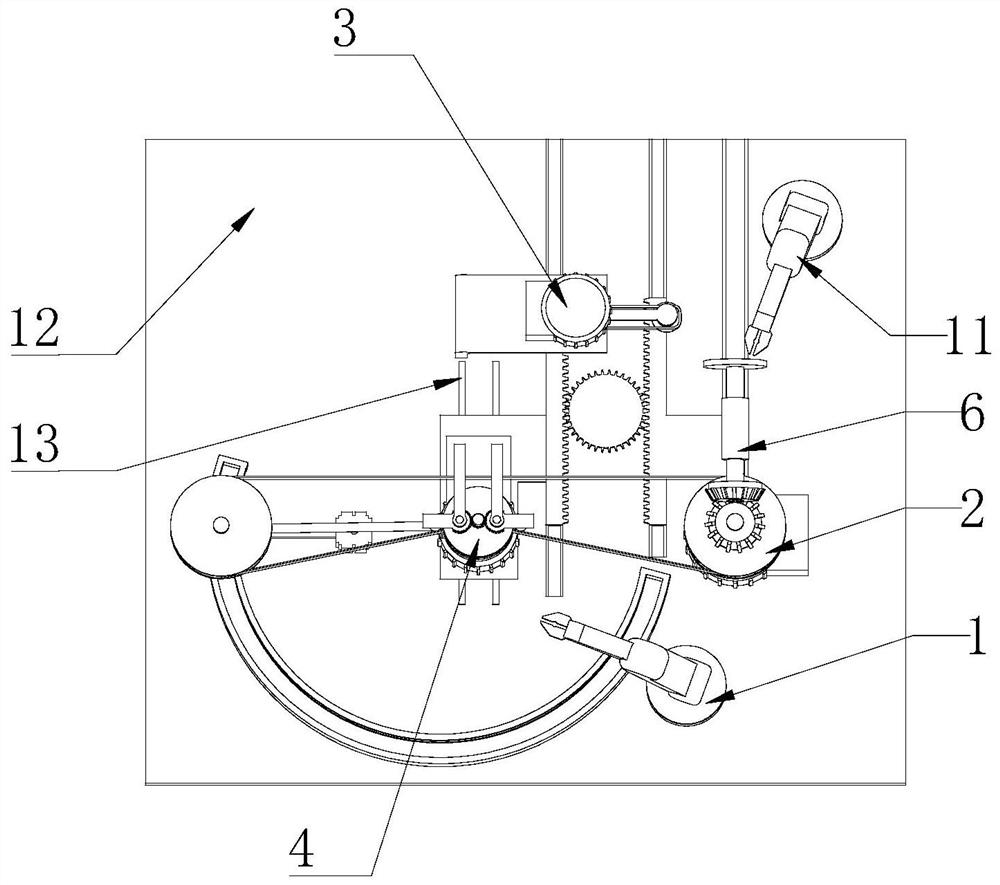

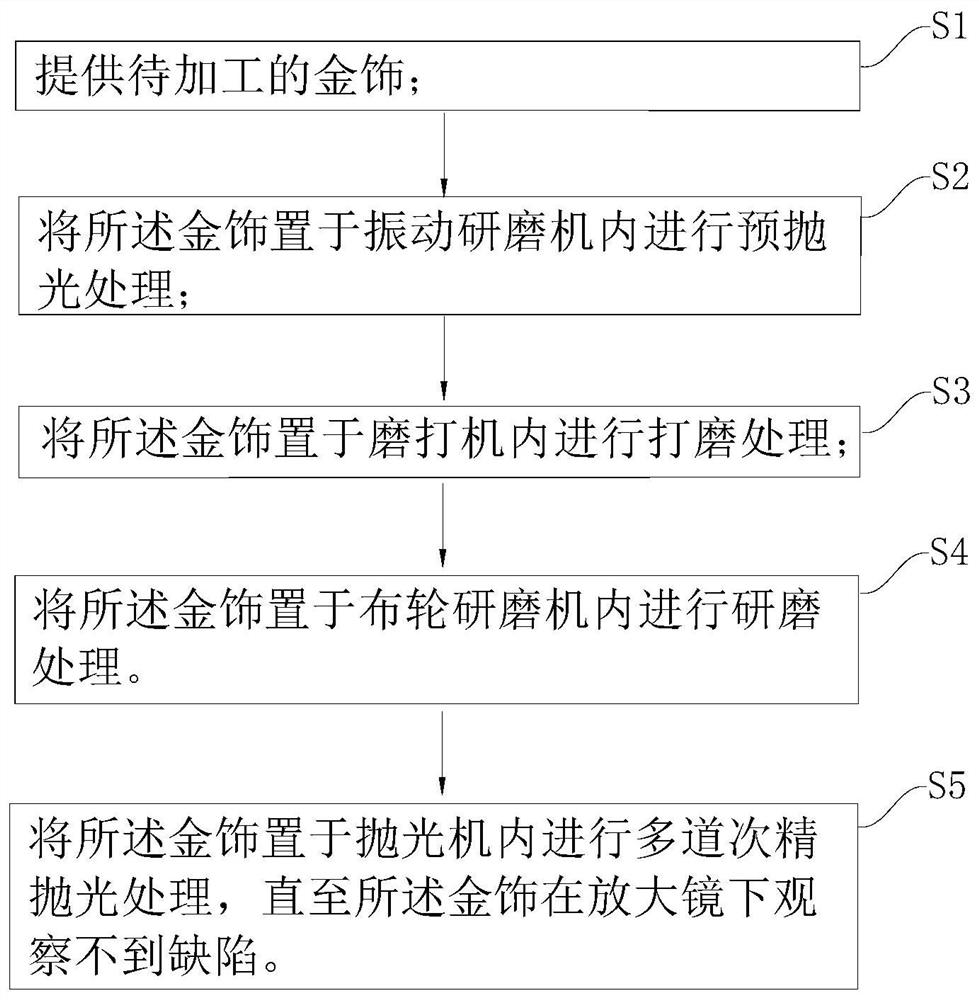

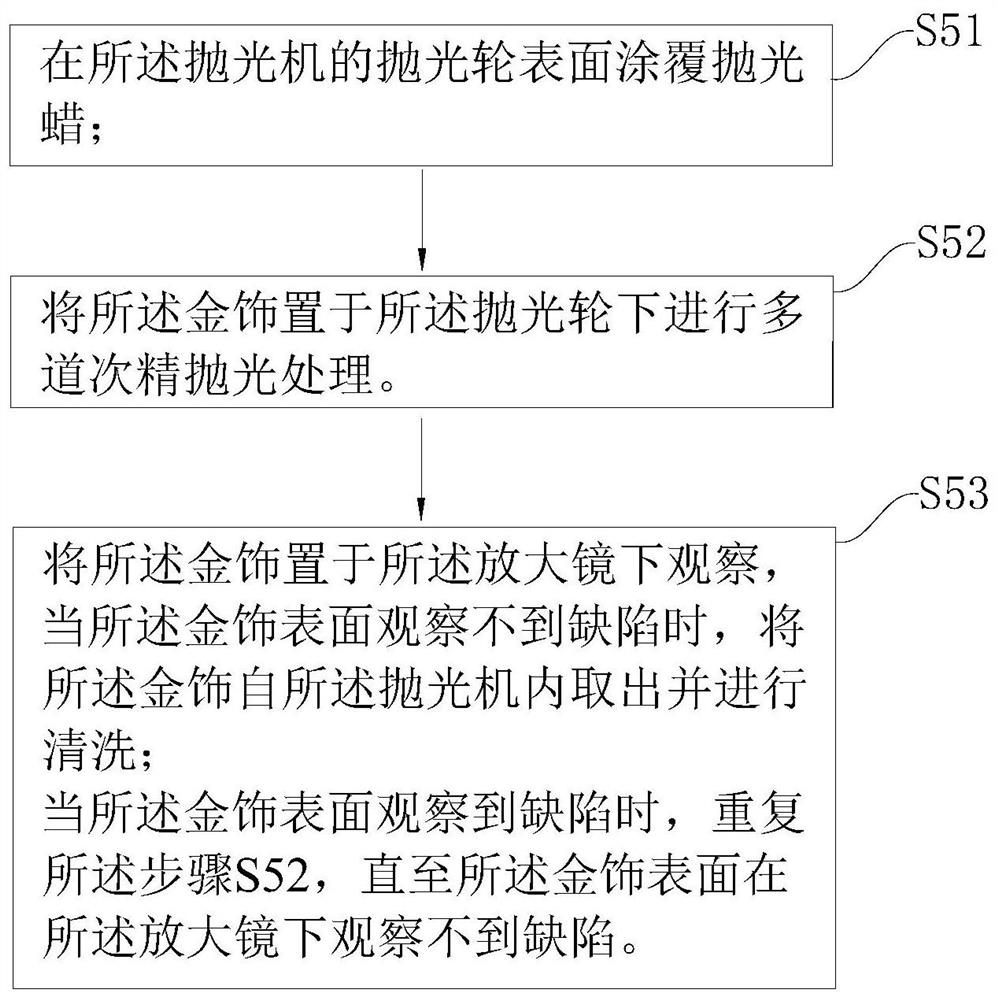

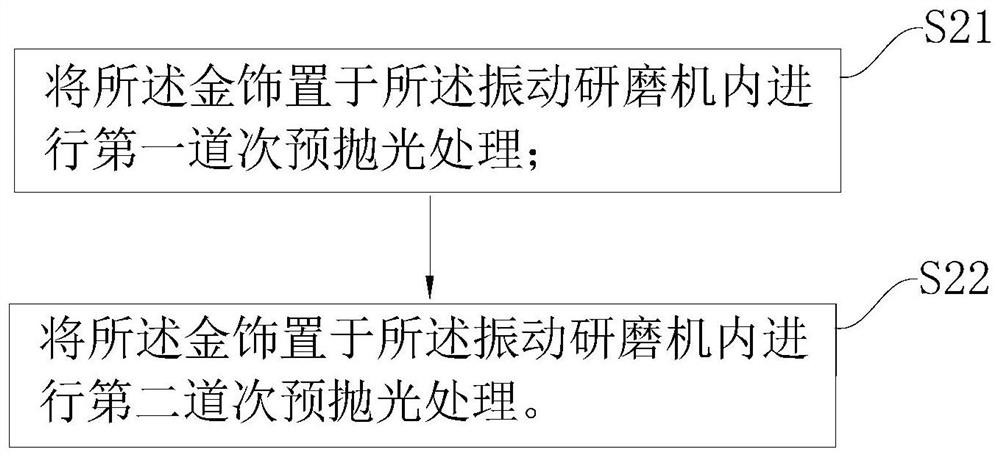

Processing method of high-brightness gold ornament and high-brightness gold ornament

Owner:SHENZHEN JINBAITAI JEWELRY IND CO LTD

Multi-surface guide polishing equipment based on hardware machining

Owner:杭州昕华信息科技有限公司

Billiard table stone plate corner polishing device with automatic adjustment function

Owner:JIUJIANG JINYING TECH

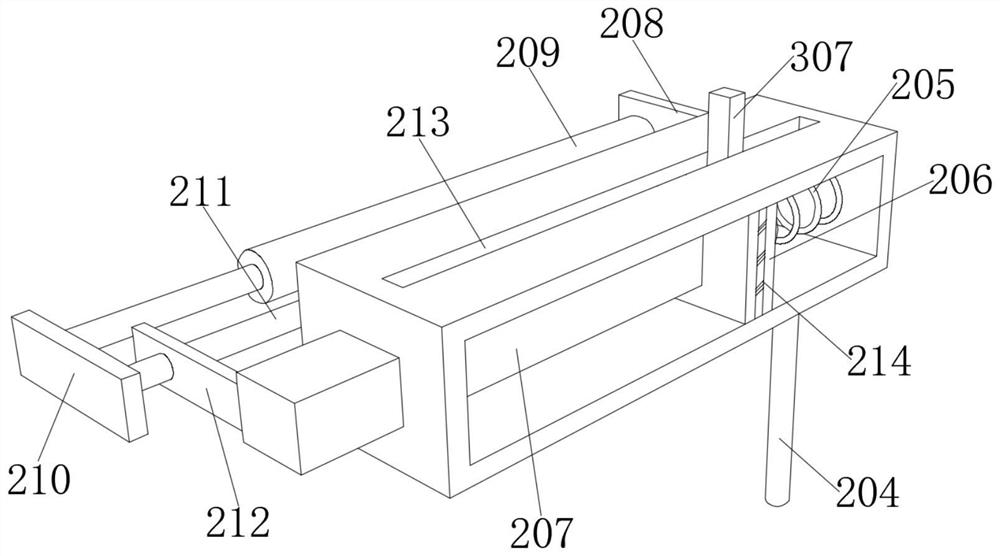

Grinding and polishing device and method based on glass machining

ActiveCN113696004AChange heightReduce the difficulty of manual cleaningGrinding carriagesRevolution surface grinding machinesPolishingEngineering

Owner:湖北浠玻实业有限公司

Preparation method and application of wafer bonding wax sheet

Owner:江苏聚冠新材料科技有限公司

Equipment suitable for ceramic rear cover automatic polishing

InactiveCN111571392AEasy to disassembleEasy to replaceGrinding carriagesGrinding bedsPolishingMachine

Owner:陕西励峰德精密陶瓷科技有限公司

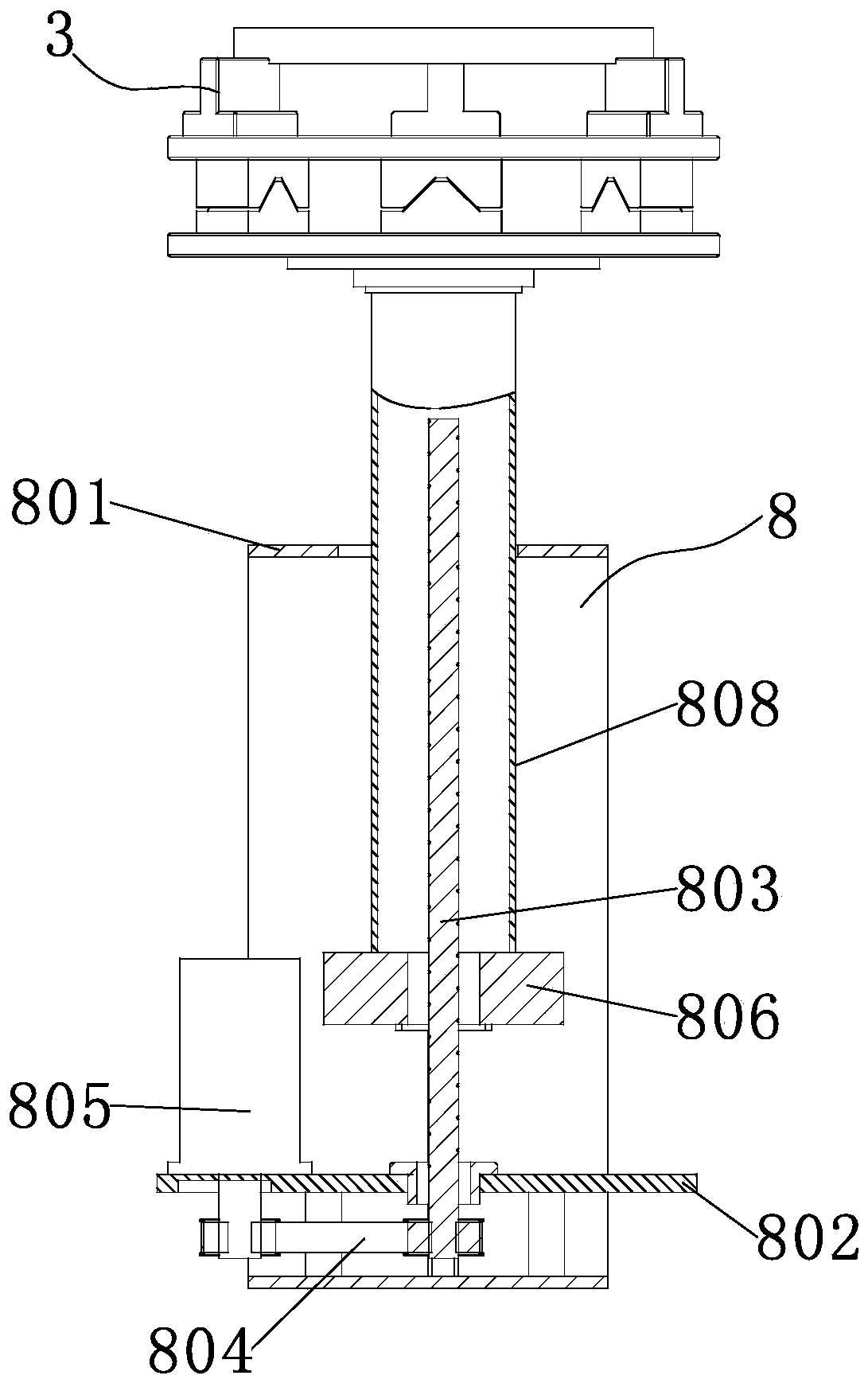

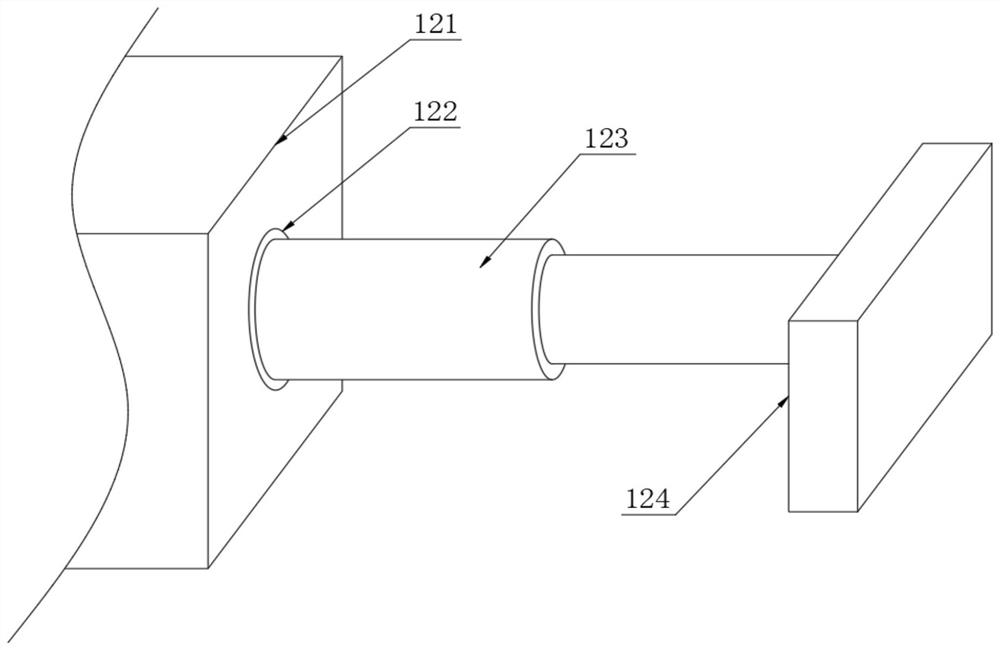

Inner wall polishing device for deep-hole precision part

InactiveCN114800091AEasy to grindReasonable structural designRevolution surface grinding machinesGrinding drivesDrive shaftPolishing

Owner:南通凯石机电科技有限公司

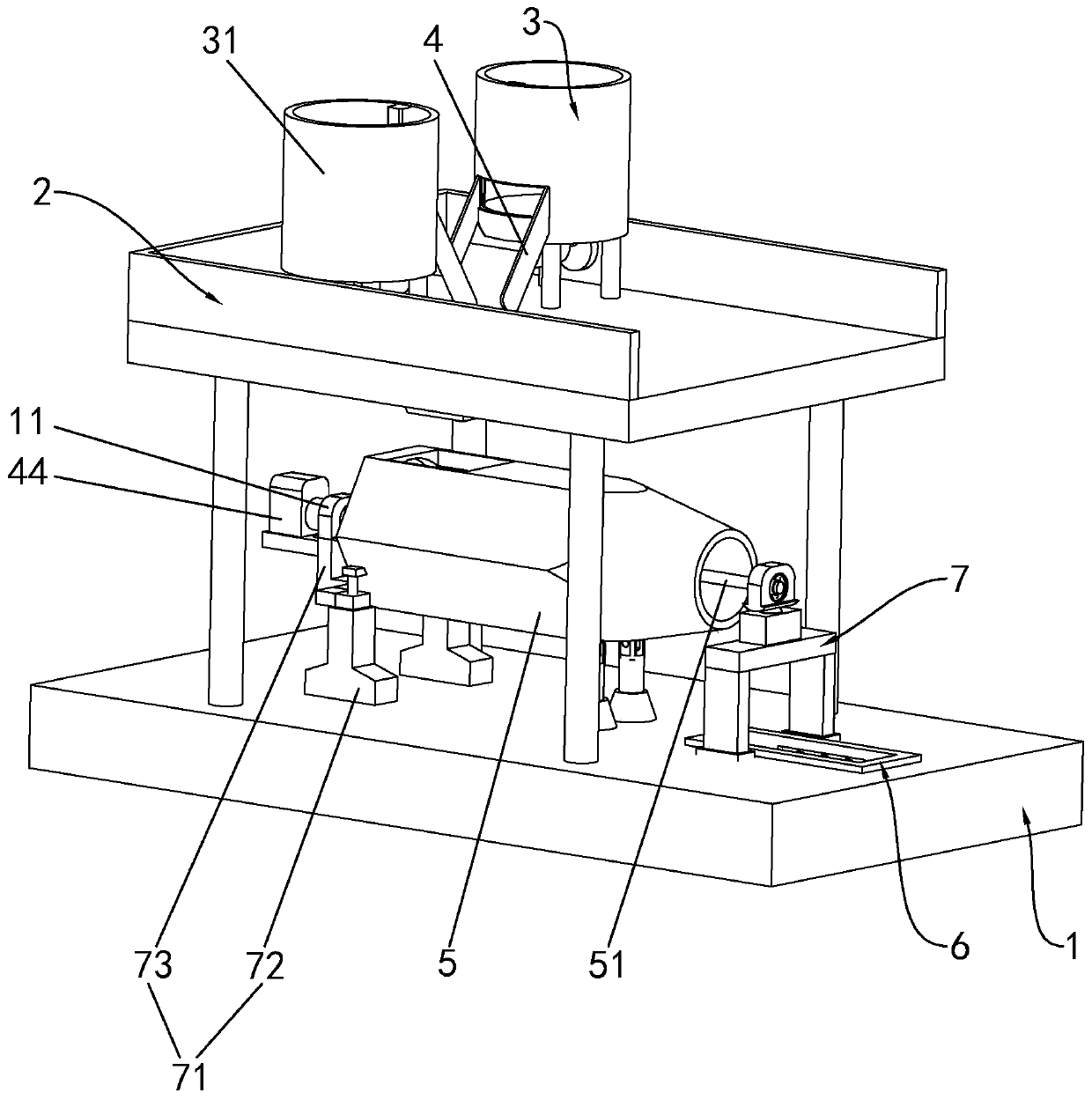

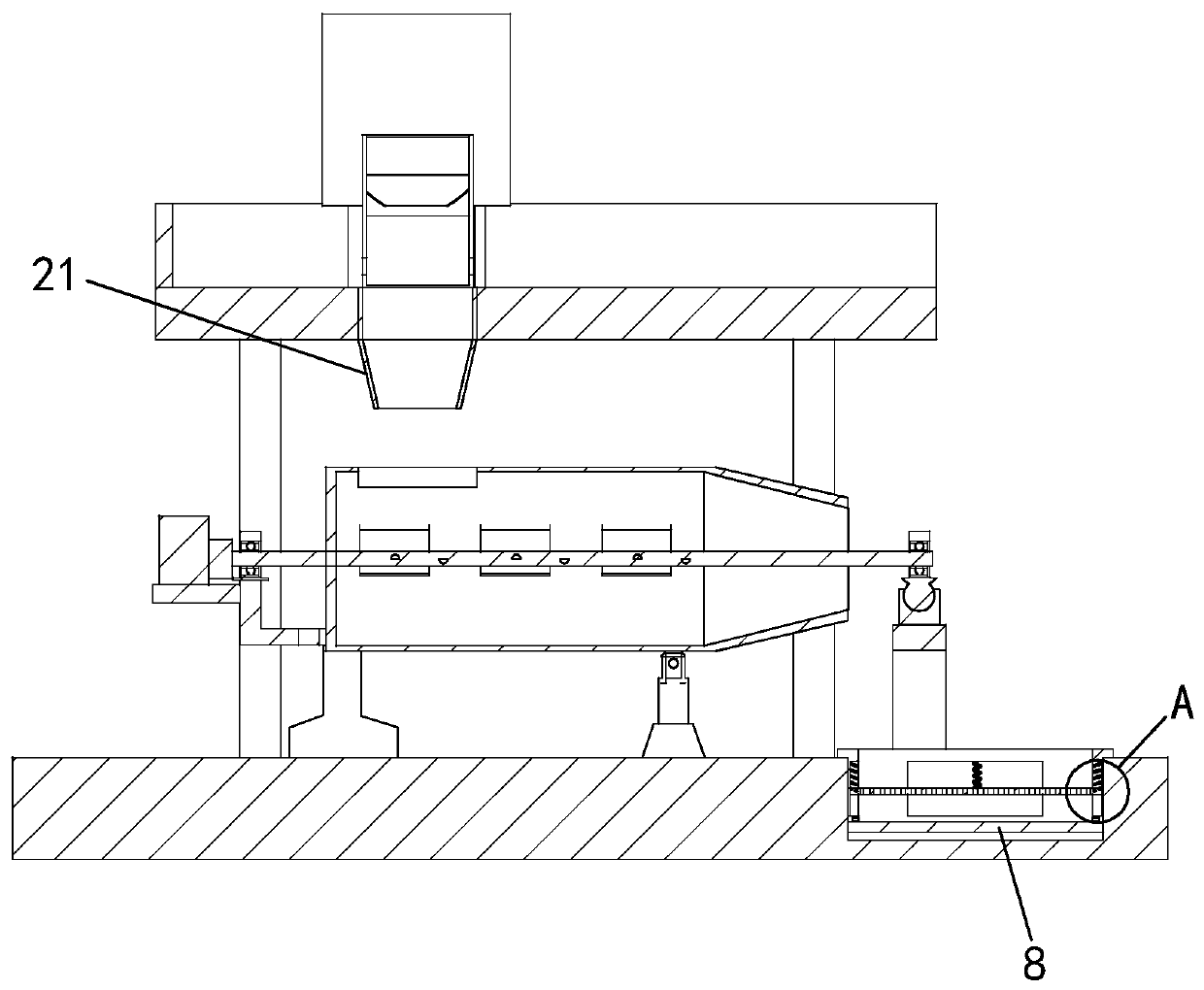

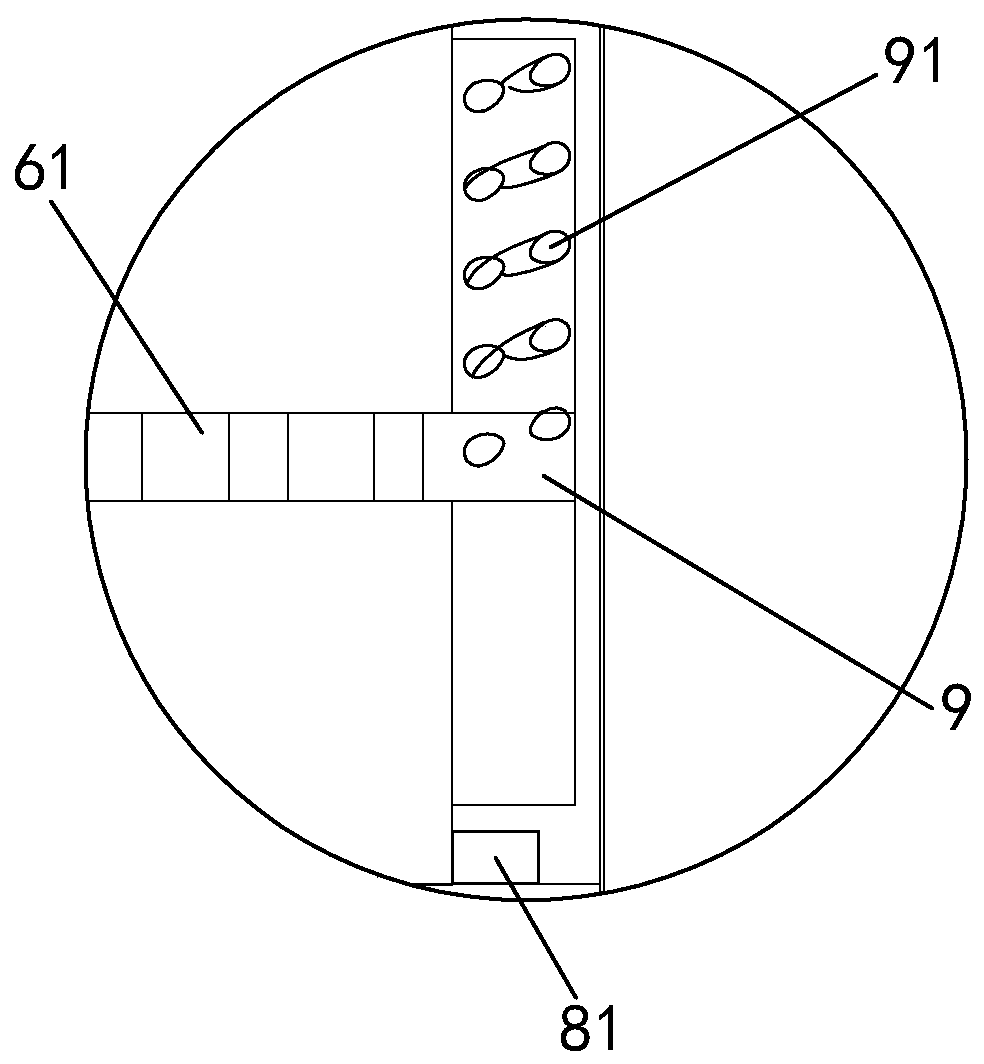

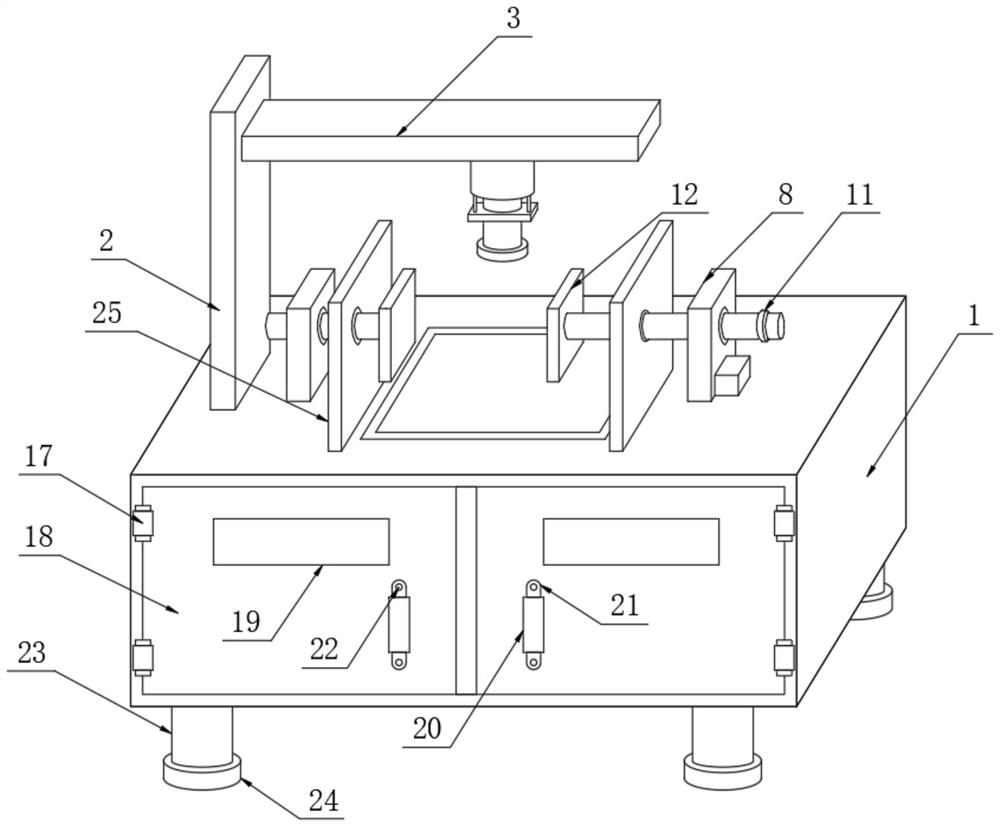

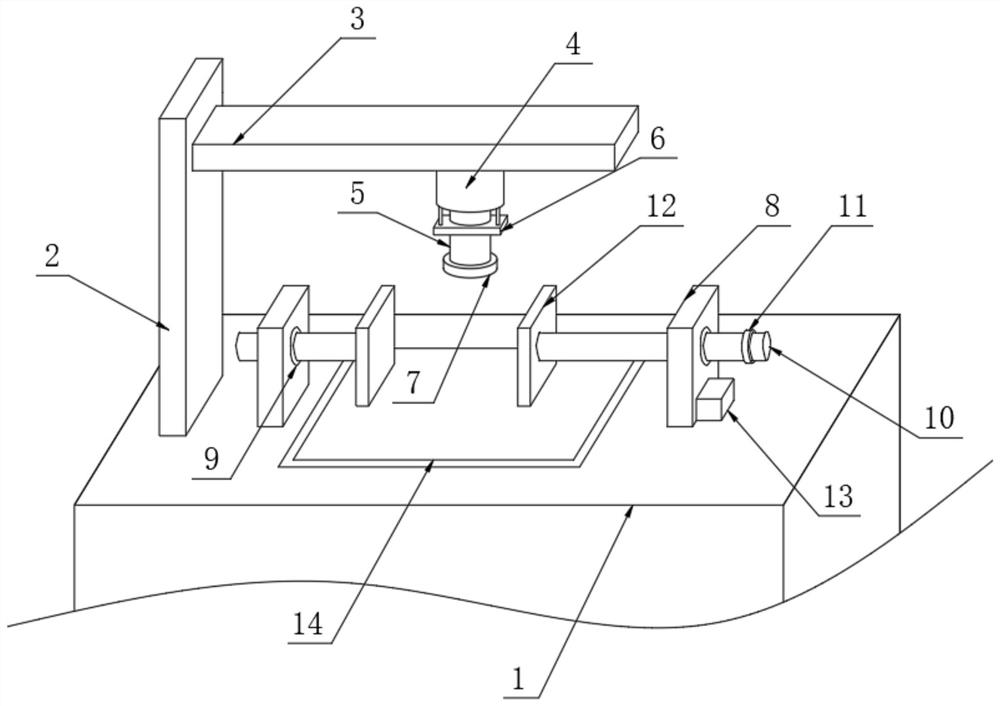

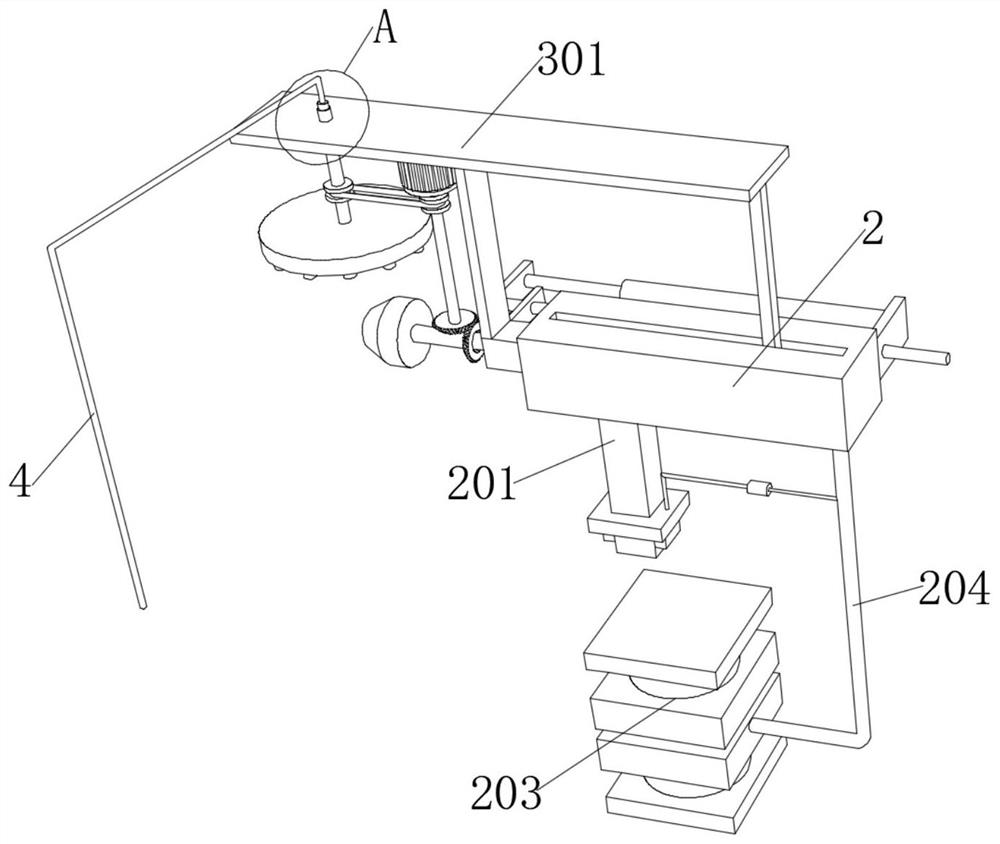

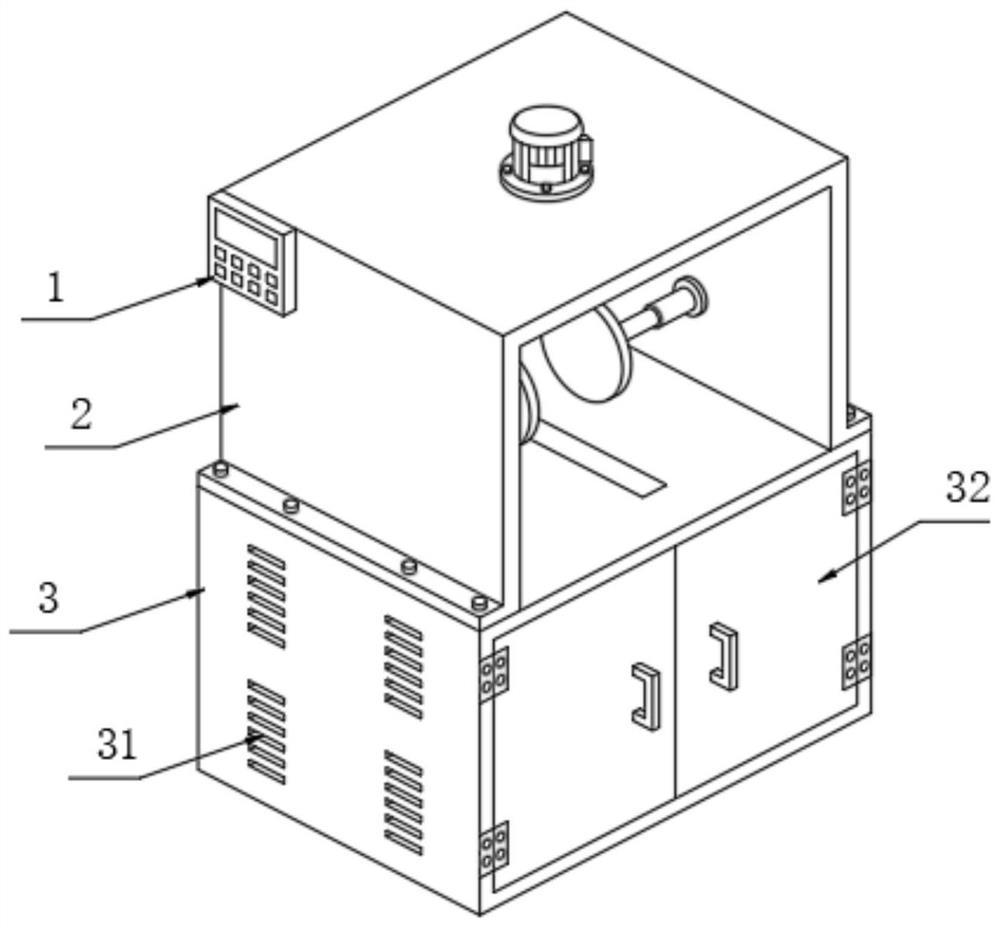

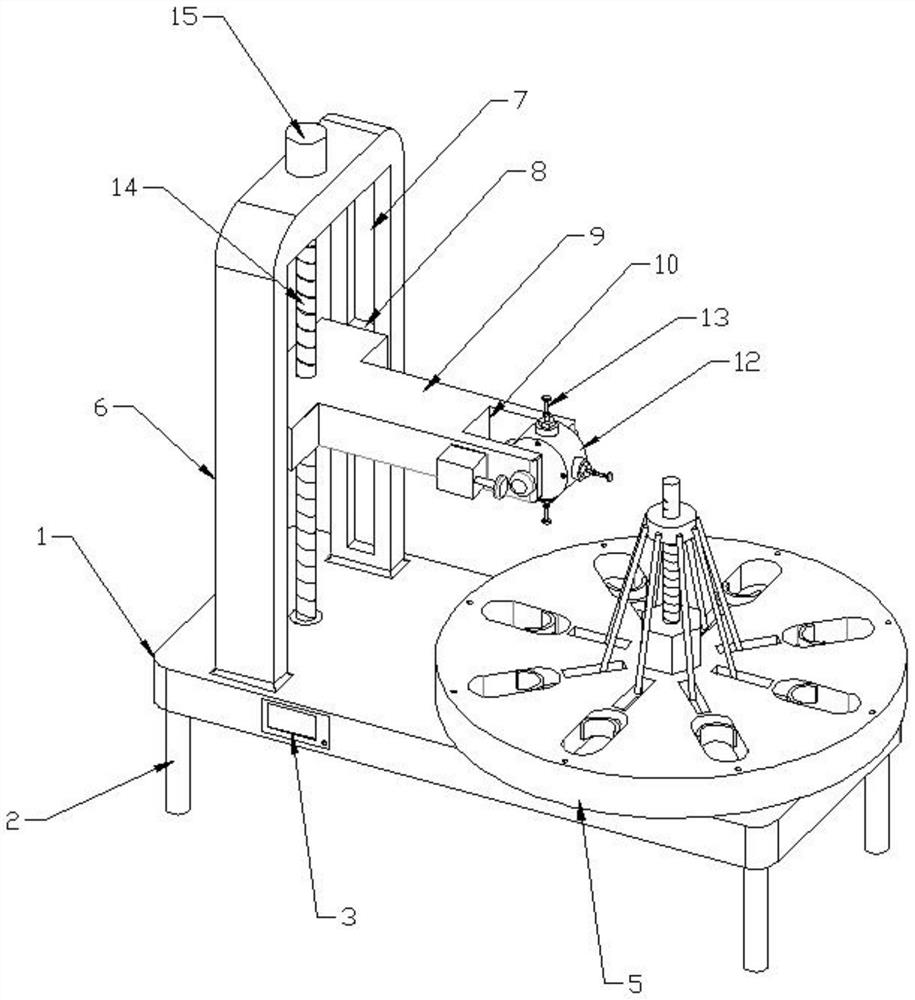

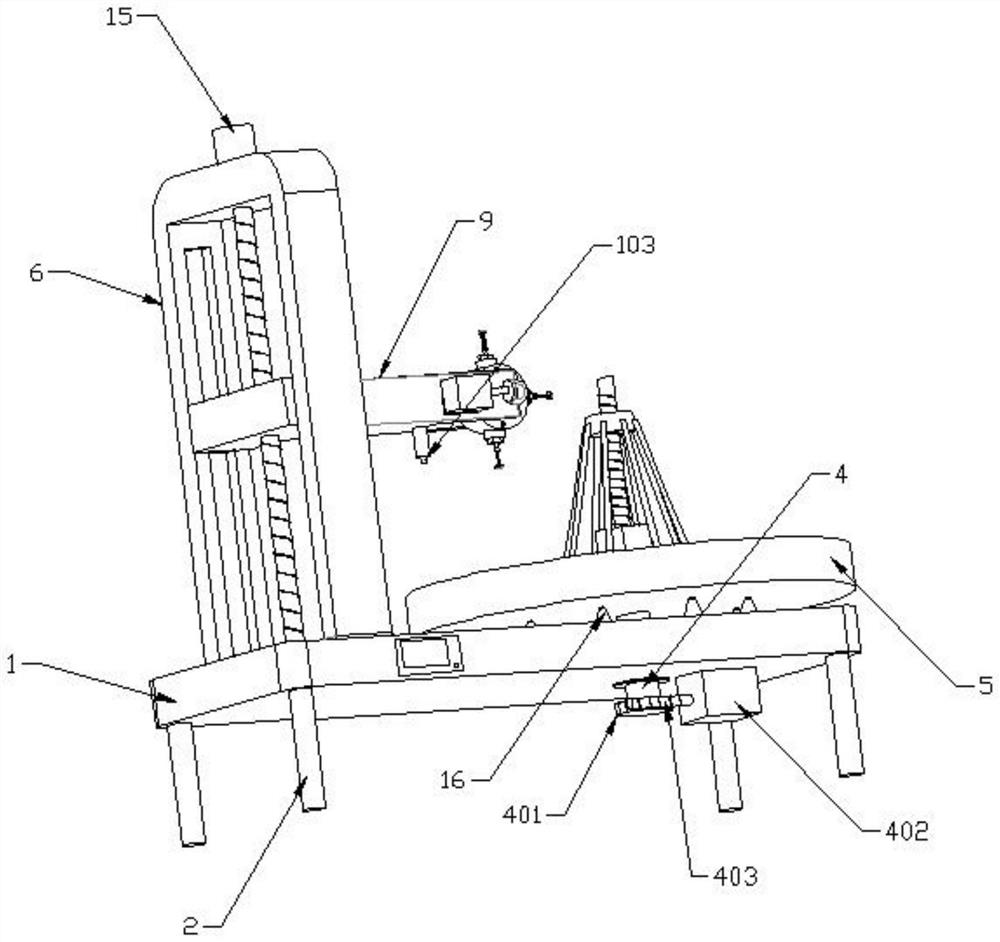

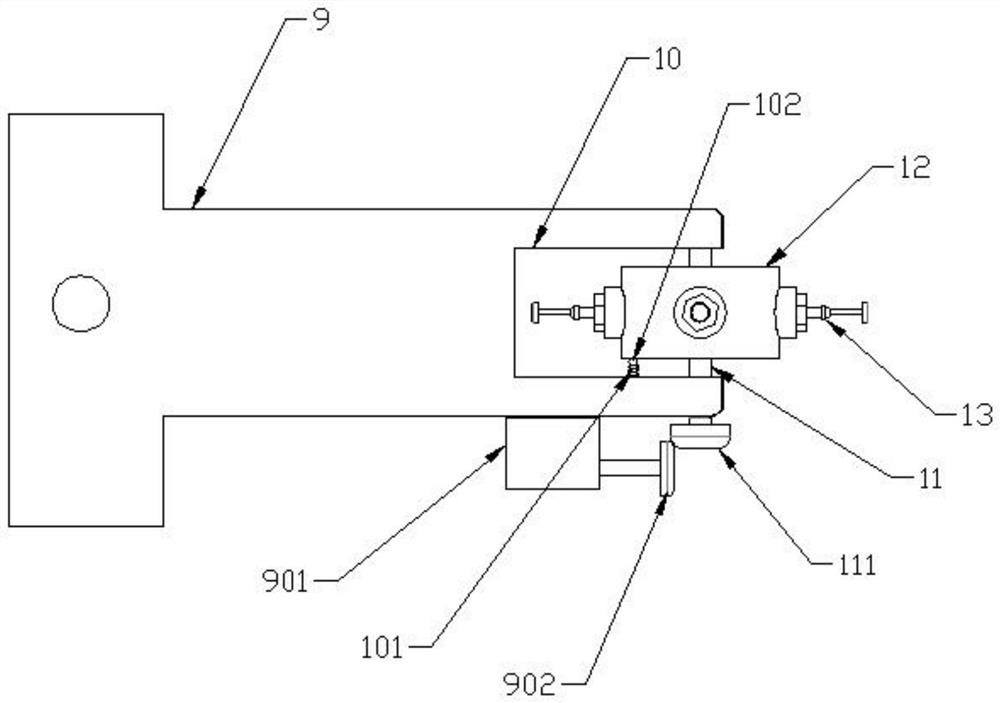

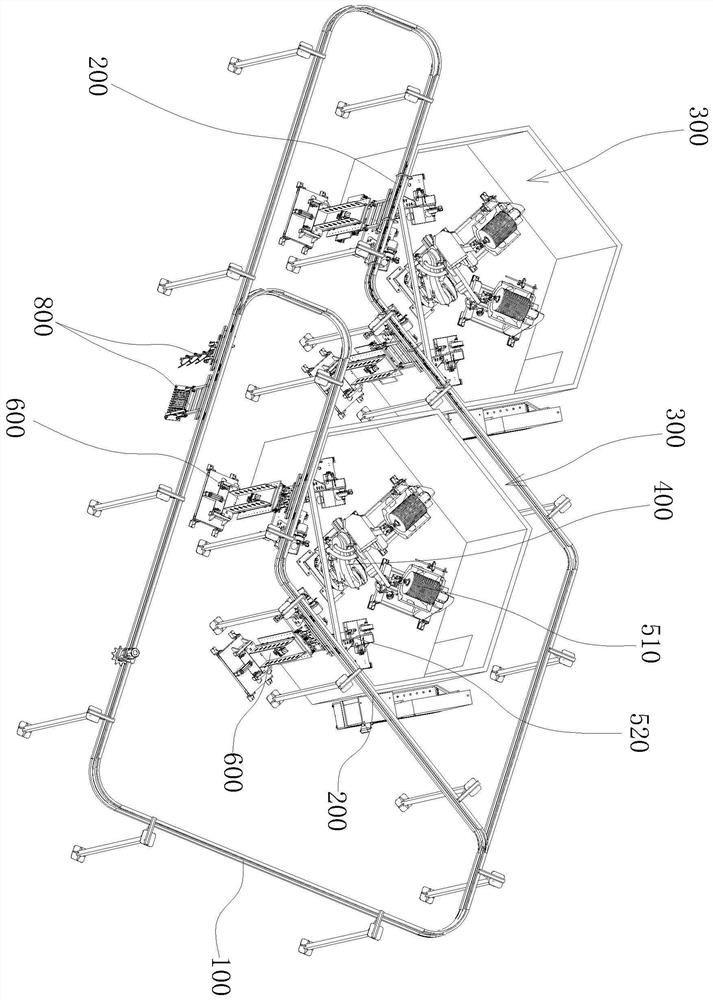

Four-station wet-type anti-explosion dust removal equipment

InactiveCN113752140ASmall footprintImprove space utilizationDirt cleaningGrinding machinesPolishingDust control

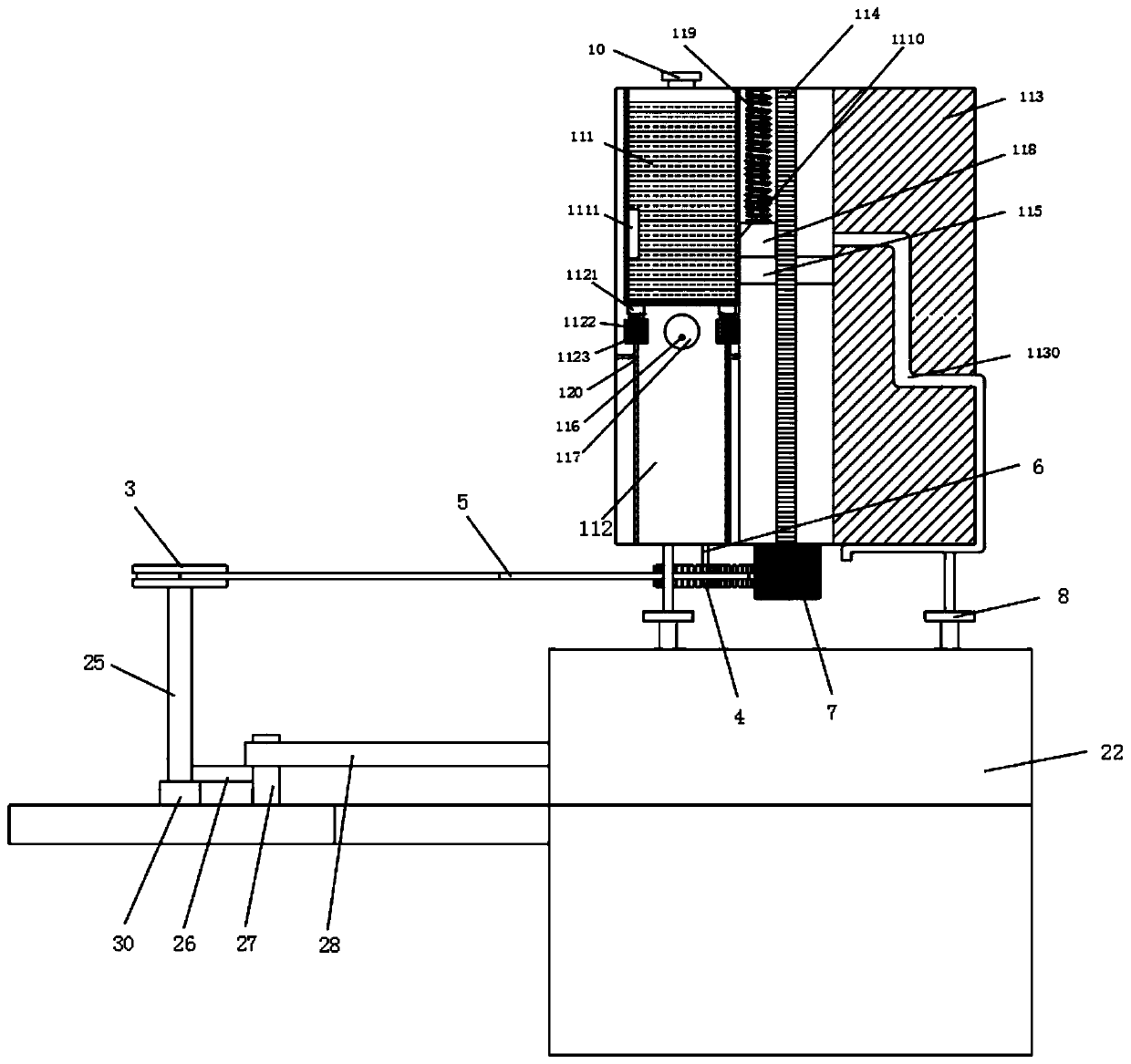

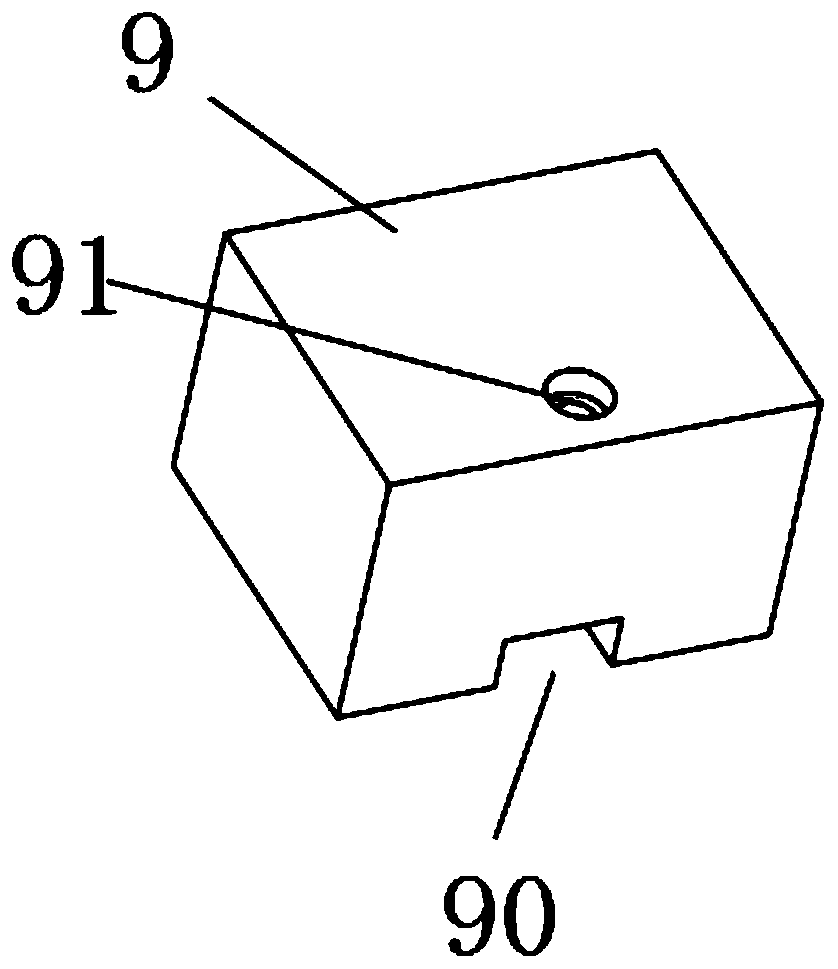

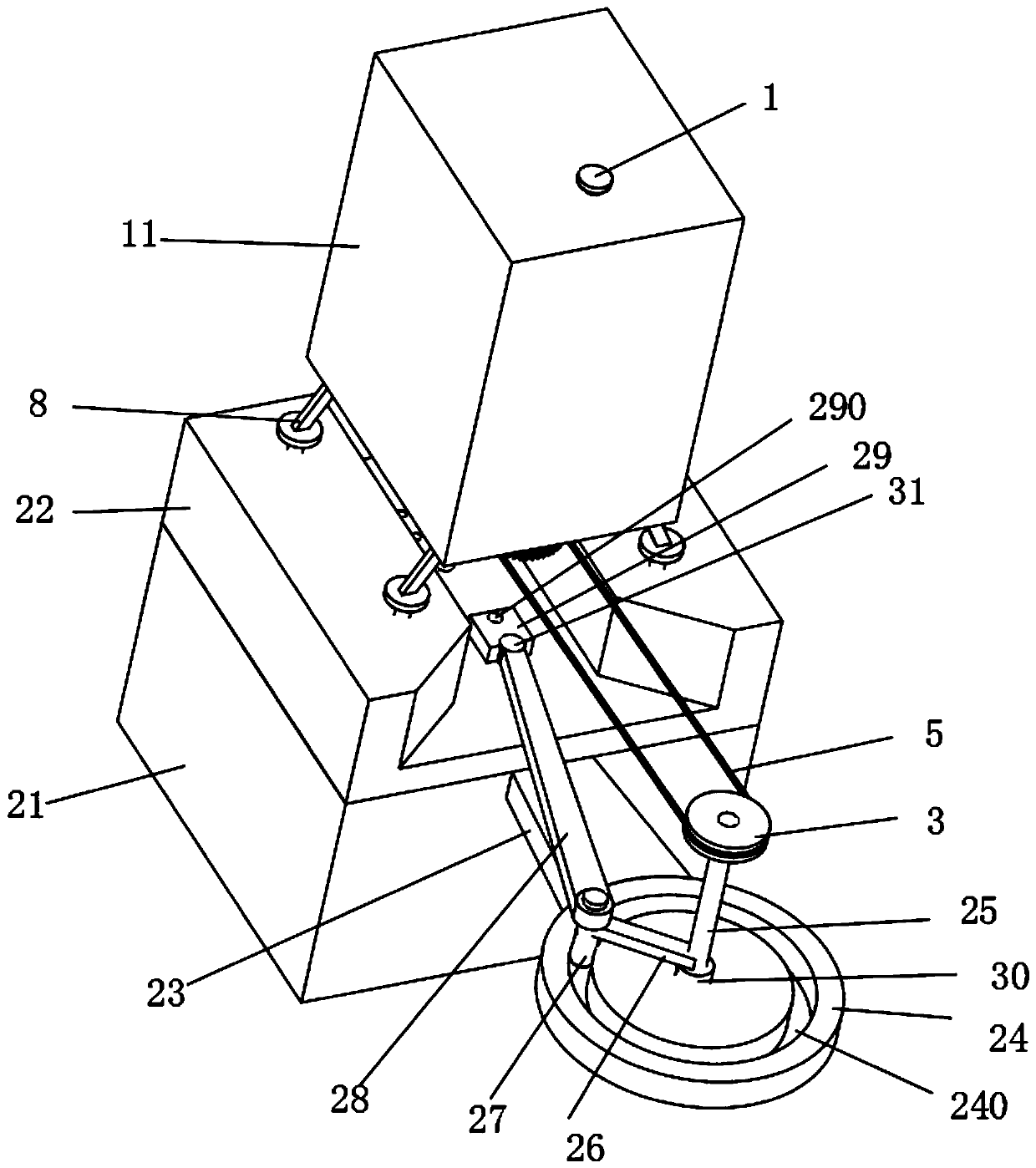

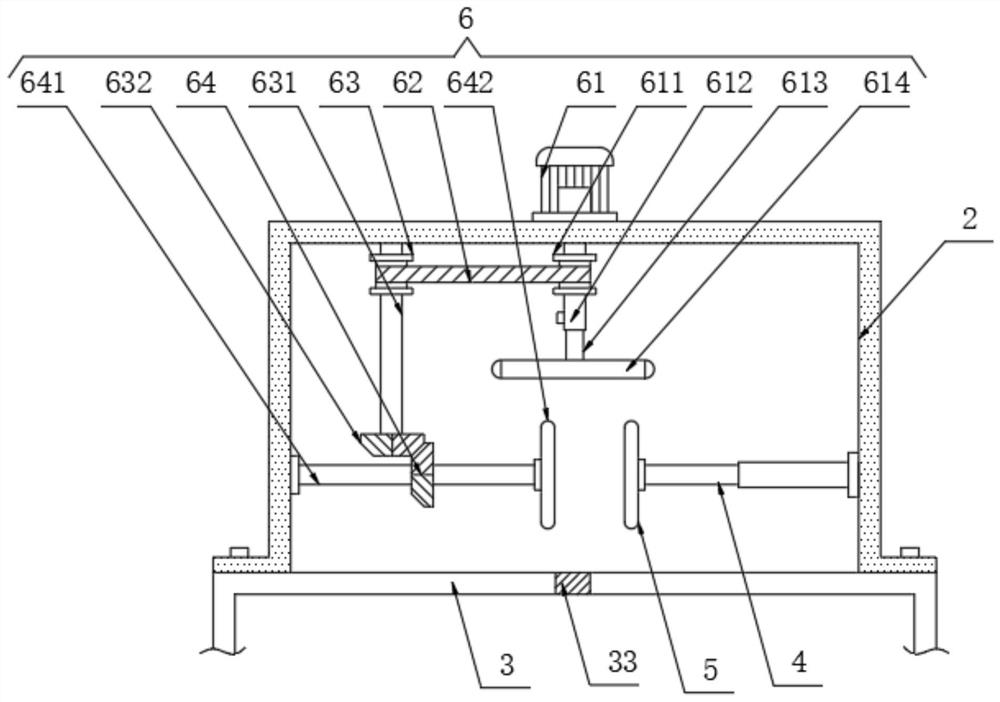

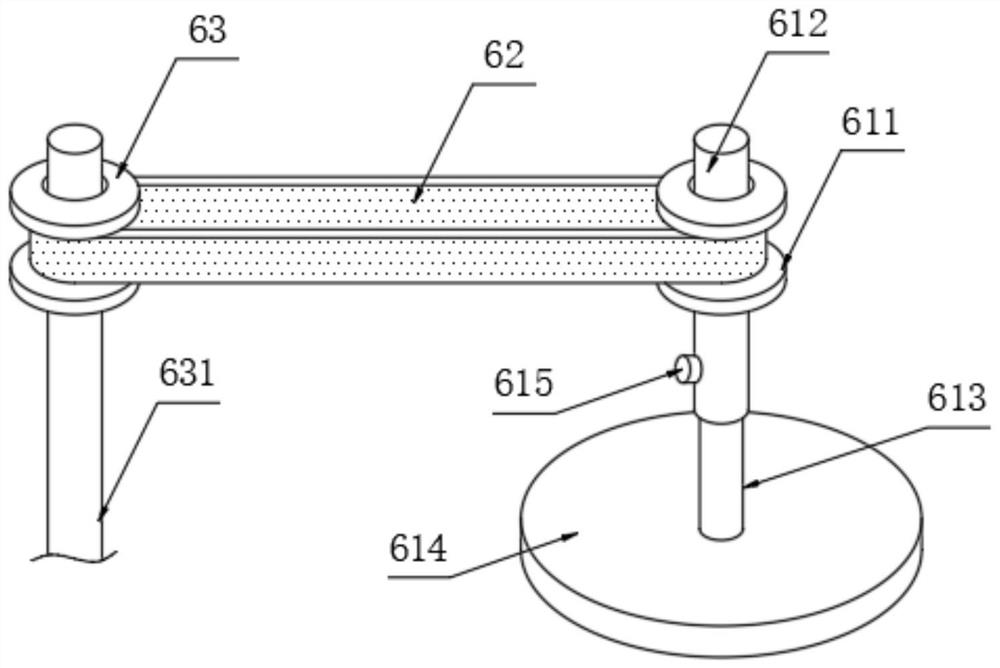

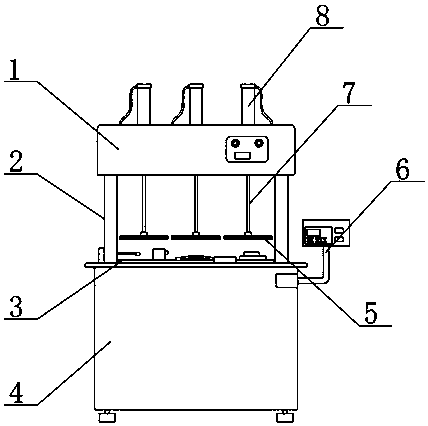

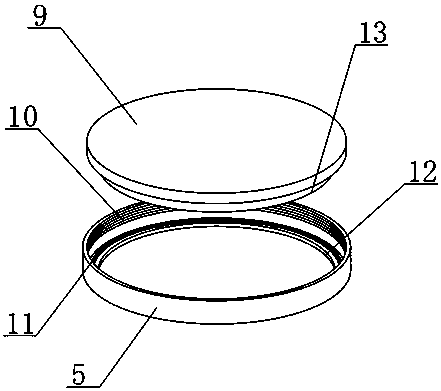

The invention discloses four-station wet-type anti-explosion dust removal equipment. The four-station wet-type anti-explosion dust removal equipment comprises a machine body and a plurality of polishing stations which are arranged on the front side and / or the rear side of the machine body respectively and provided with polishing devices, a cabinet barrel provided with a dust collection assembly is arranged at the bottom of each polishing station, and a wet-process dust collection mechanism or a dry-process dust collection mechanism is arranged in each dust collection assembly. Compared with the prior art, the dust-removing explosion-proof equipment has the advantages that by providing the plurality of polishing stations with dust-removing mechanisms, the occupied area of a workshop is reduced as much as possible, and the space utilization rate of the workshop is increased; and switching use of wet-process dust removal and dry-process dust removal is achieved through the replaceable dust collection assemblies, so that the equipment adapts to polishing and dust removal work of different workpieces or different materials, and the practicability of the equipment is improved.

Owner:GUANGDONG SENHAO DUST REMOVAL EQUIP CO LTD

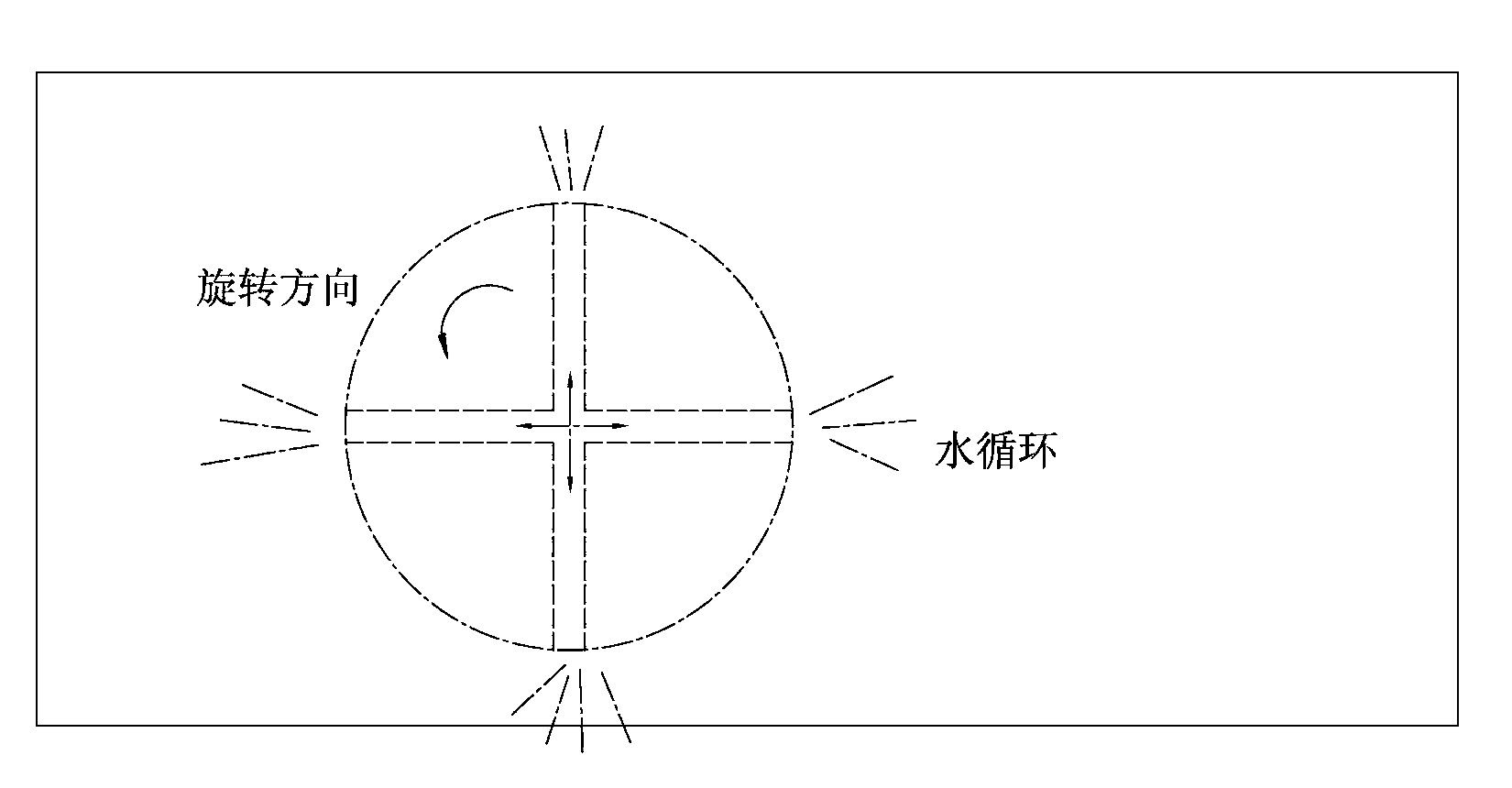

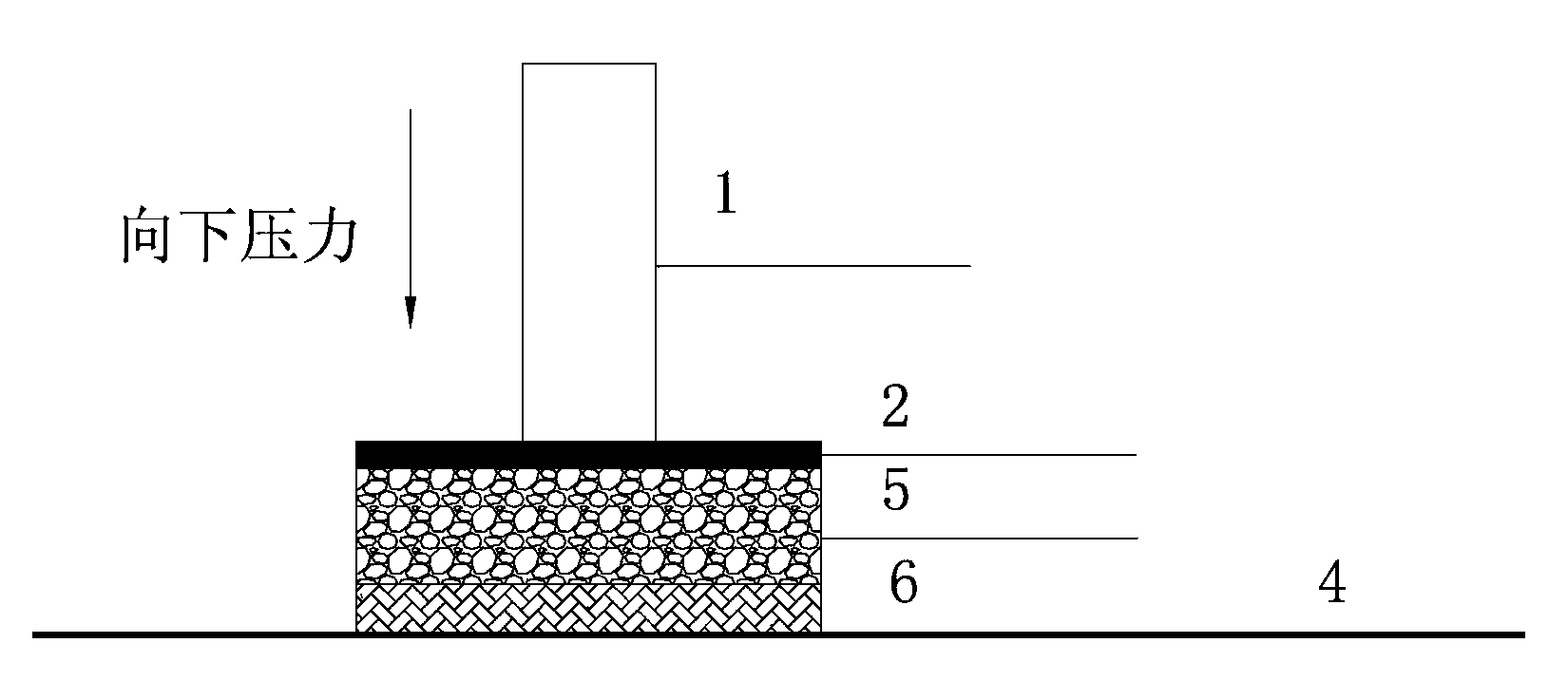

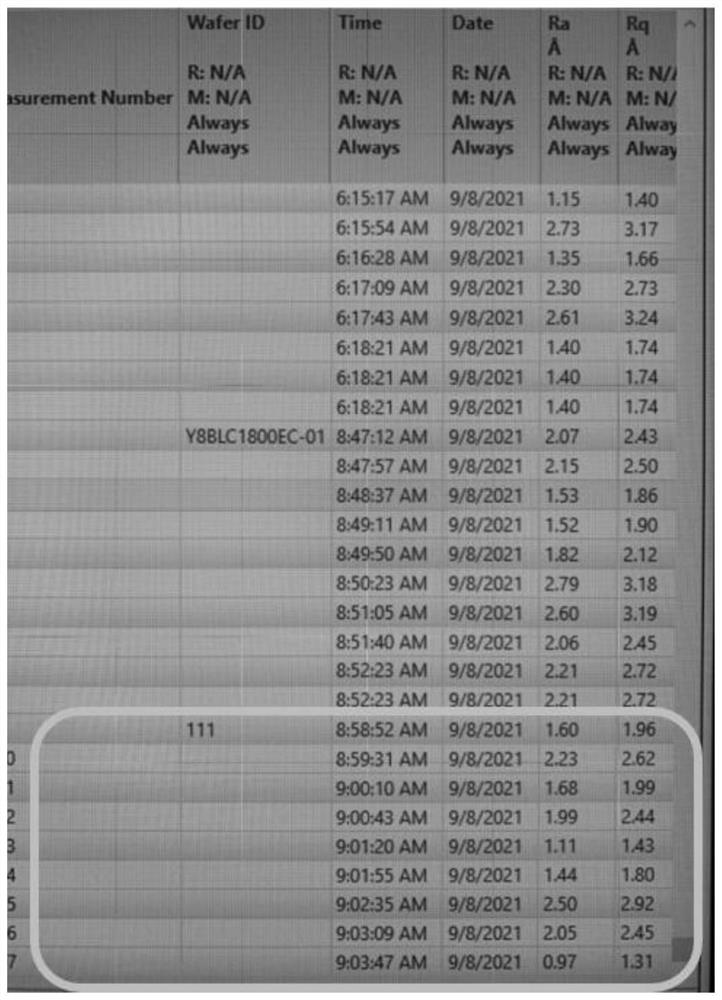

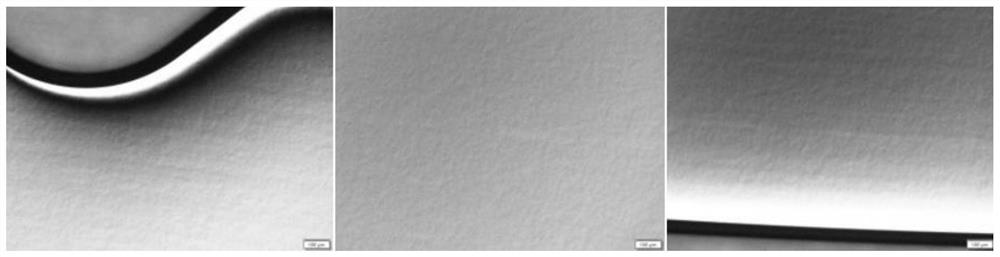

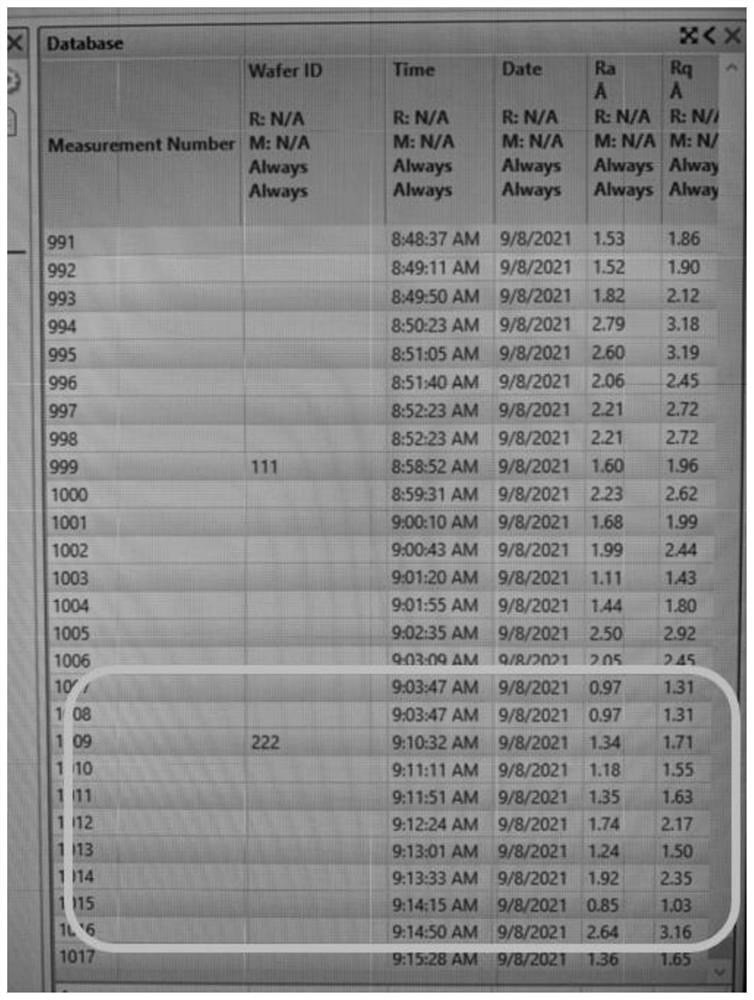

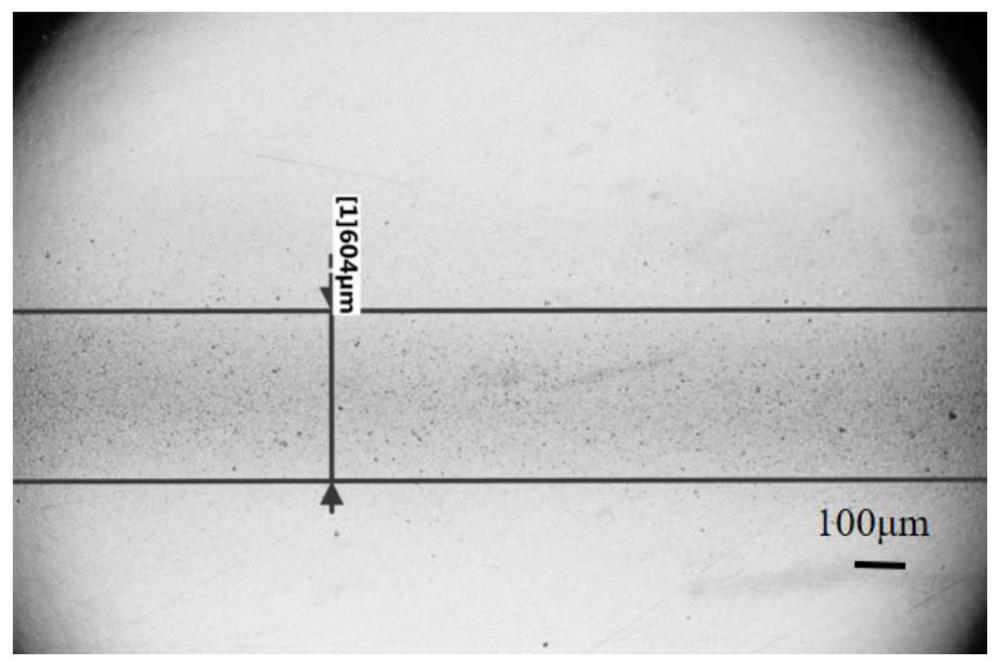

Polishing process for improving surface roughness of silicon wafer

The invention provides a polishing process for improving surface roughness of a silicon wafer. The process comprises the steps that S1, a crystal bar with the diameter being 200 mm and without single crystal defects (COP-Free) is selected, the equipment state is checked before polishing, and process adjustment is conducted after it is guaranteed that no abnormity exists; S2, the rotating speed of a large disc, the rotating speed of a center guide wheel and the temperature of a polishing ice maker are set; S3, a rough polishing pad is FPK660C2, an intermediate polishing pad is 7355-000FE, and a fine polishing pad is a 275NX flat pad; S4, the coordination of FFU setting and air exhaust setting in a feeding wax sticking machine of a polishing machine is guaranteed, the working state of an electrostatic ion rod is checked, and it is guaranteed that the internal environment of the wax sticking machine reaches the first-level particle standard; S5, the wax dripping amount is calibrated; S6, the polishing solution processing flow and the cooling water flow are calibrated; and S7, after polishing is finished, pre-washing feeding is conducted, and after a wax layer and surface particles on the back face of the product are washed up, the surface roughness of the product is measured. The processed silicon wafer has the advantage of low roughness.

Owner:中环领先半导体材料有限公司

Oxygen-free copper microstructure functional surface jet flow polishing solution and polishing method

InactiveCN113956797AImprove the efficiency of ultra-precision machiningPrevent oxidationPolishing compositions with abrasivesPolishingUltra precision

The invention provides an oxygen-free copper microstructure functional surface jet flow polishing solution and a polishing method. The polishing solution comprises the following components in percentage by mass based on the total mass of the polishing solution: 1%-20% of particles, 0.1%-10% of an oxidizing agent, 0.01%-1% of a complexing agent, 0.1%-1% of a pH regulator, 0.001%-0.1% of an oxidation balance agent and the balance of deionized water. Therefore, by adopting the polishing solution, the ultra-precision machining efficiency of the surface of the oxygen-free copper microstructure can be remarkably improved, and meanwhile oxidation of the oxygen-free copper after machining is avoided.

Owner:TSINGHUA UNIV

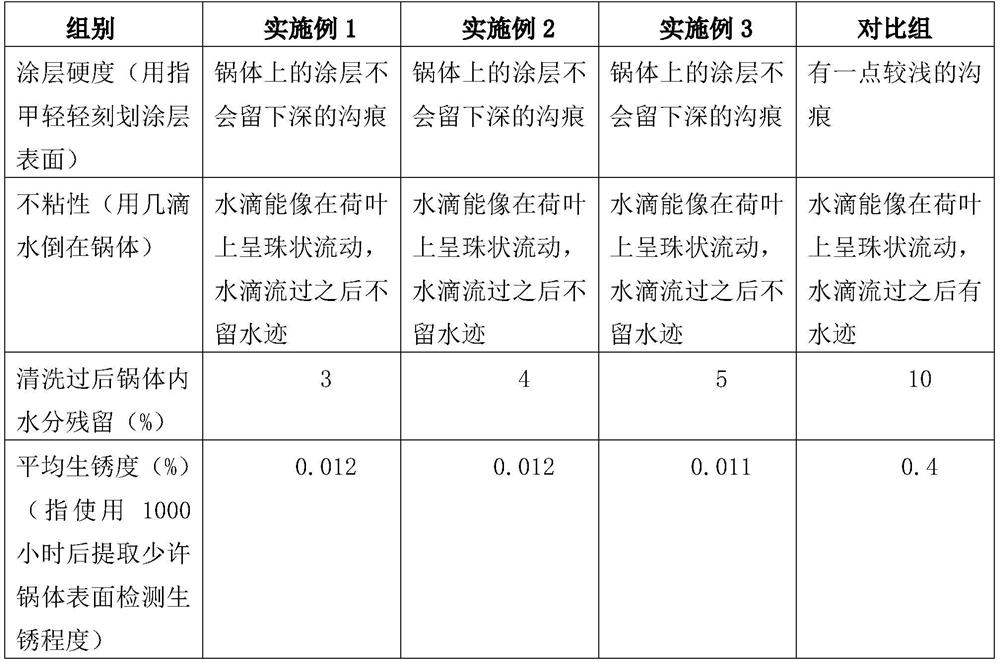

Manufacturing process suitable for pure iron or composite iron non-stick pan

ActiveCN111633381AGood non-stickExtended service lifeCooking-vessel materialsPolishing machinesPunchingManufacturing technology

Owner:ZHEJIANG FOSCOM KITCHENWARE CO LTD

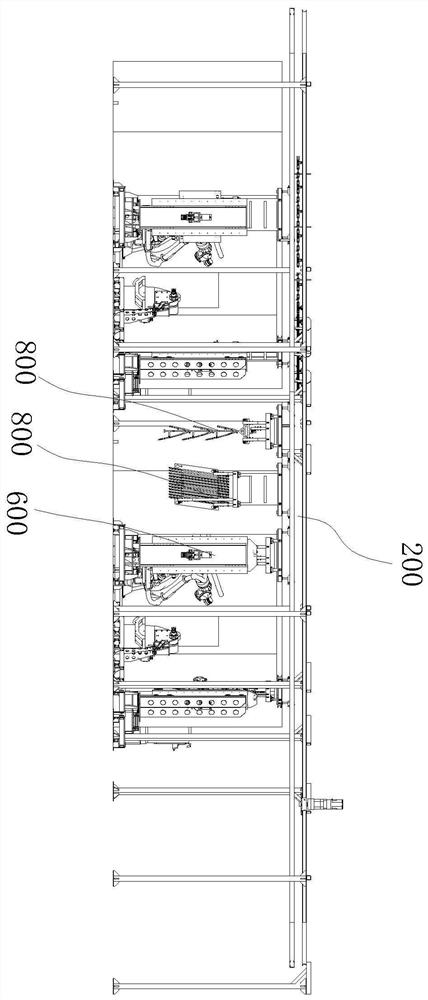

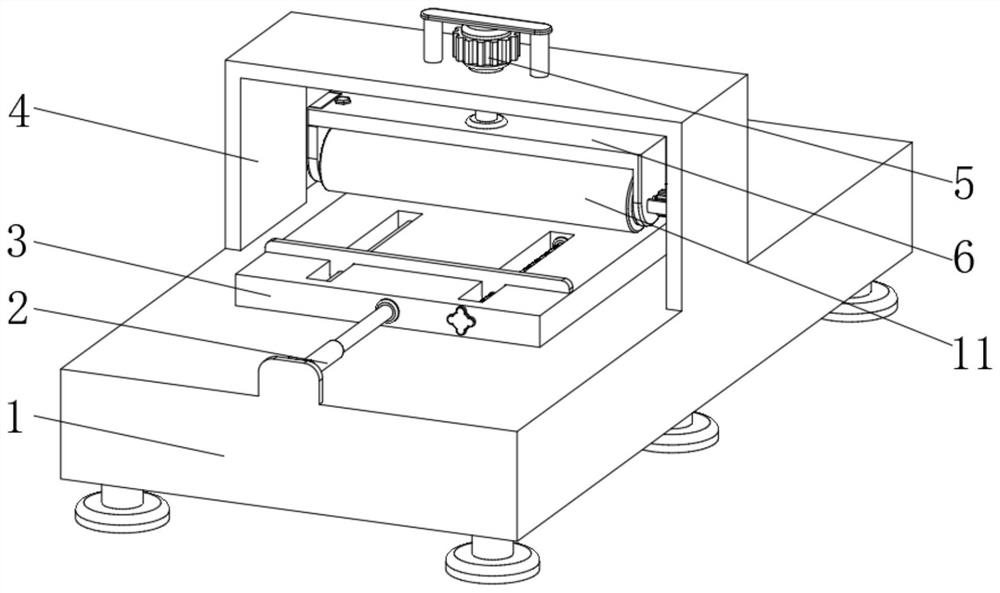

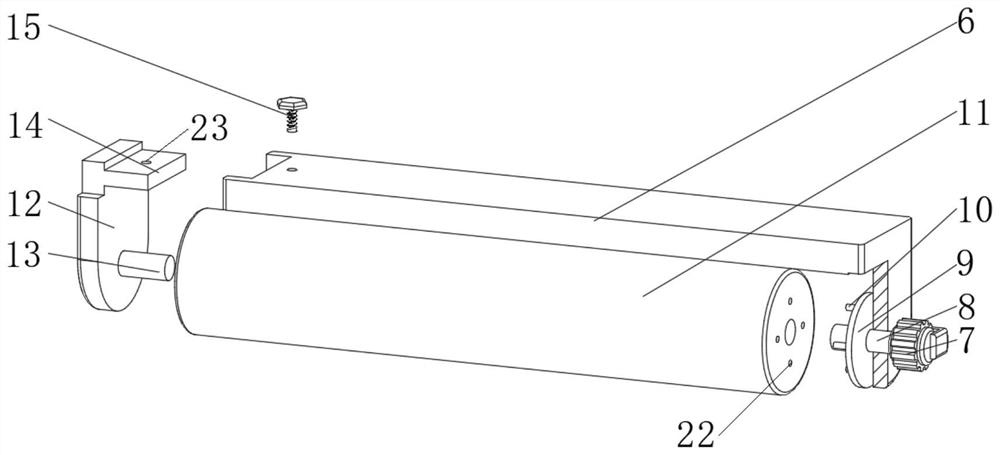

Unmanned automatic polishing system

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Polishing machine for polishing surface of metal plate

Owner:新余钢铁股份有限公司

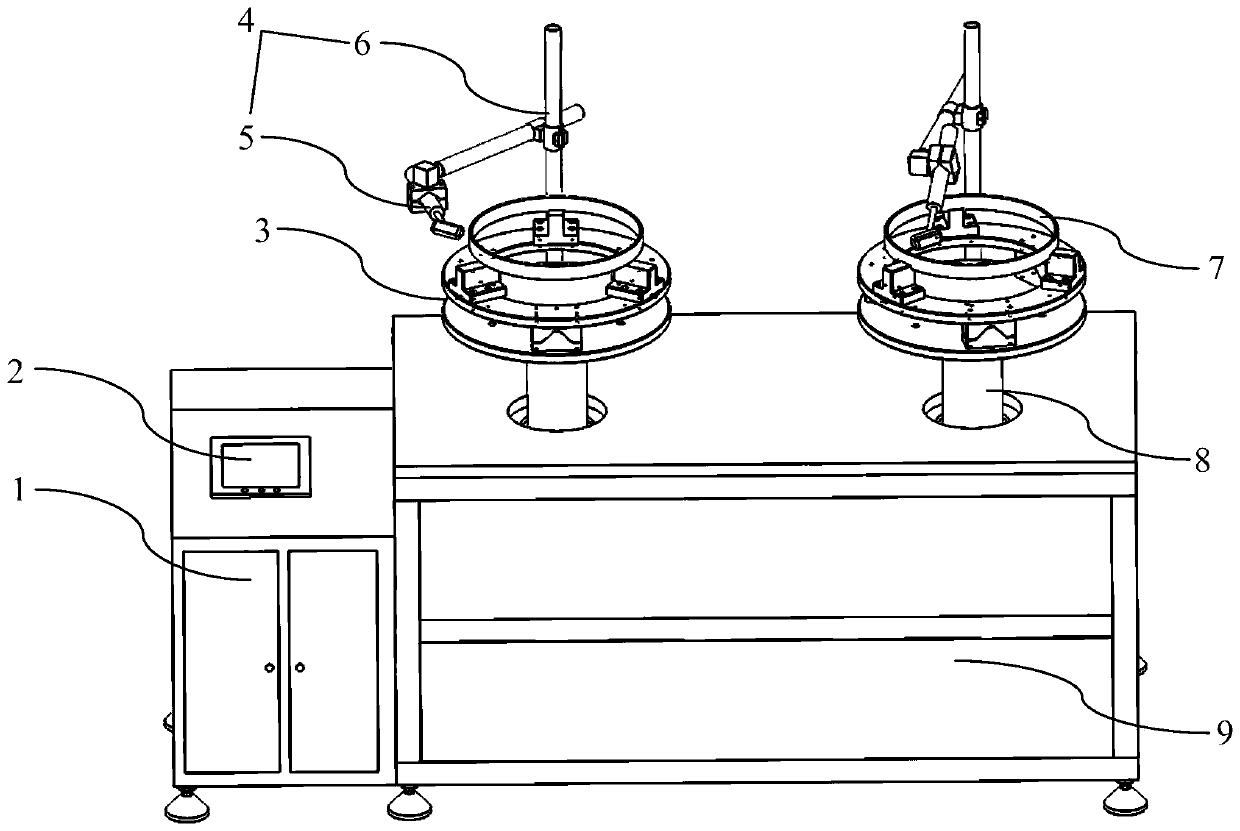

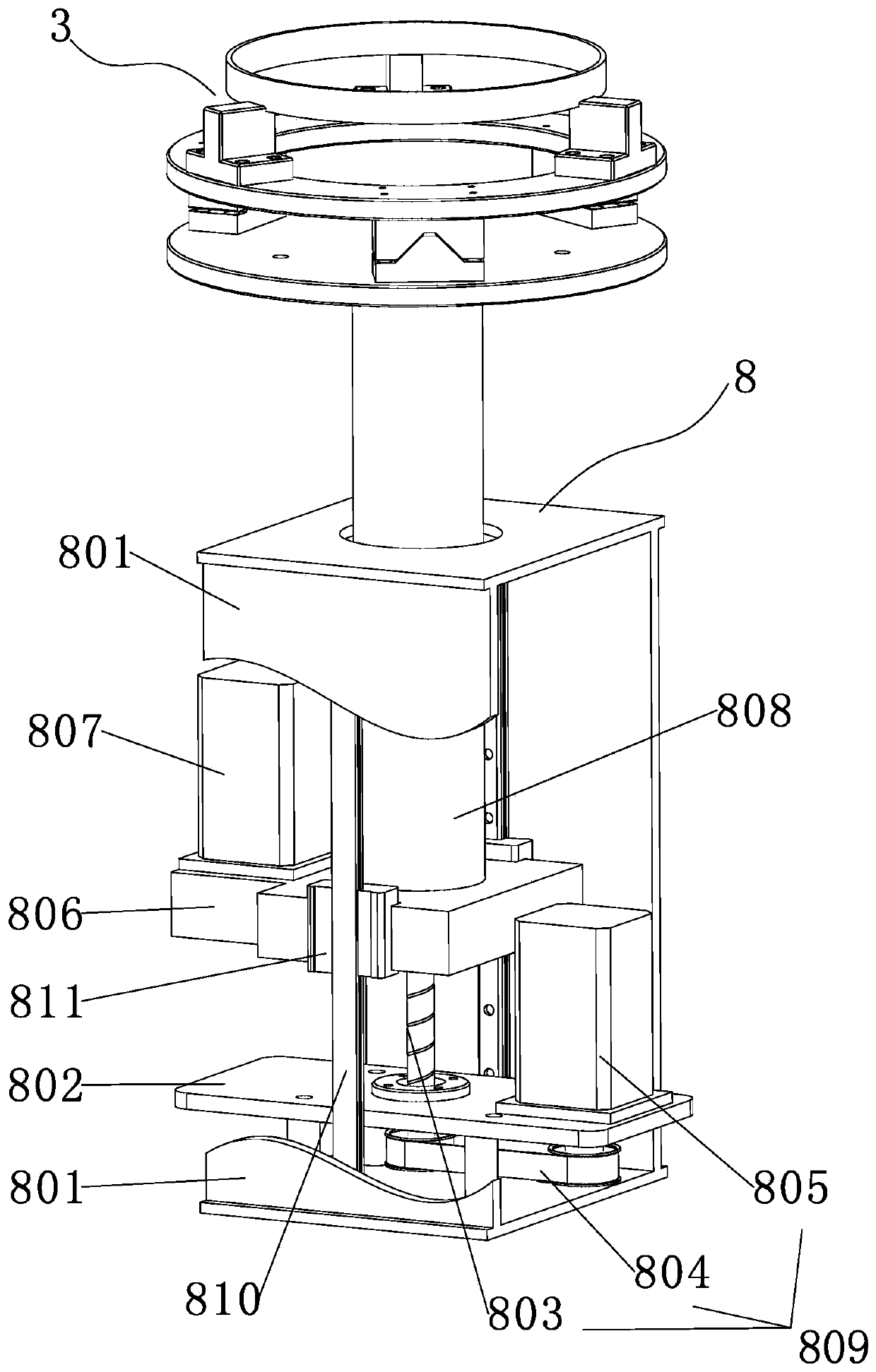

Polishing method of box dam layer, box dam and ceramic substrate

ActiveCN113380633AAchieving acceptable polishingPolishing machinesSemiconductor/solid-state device detailsPolishingEngineering

The invention discloses a polishing method of a box dam layer. The method comprises the following steps that supplementary electroplating is conducted on the box dam layer, the front face of a substrate of the box dam layer subjected to supplementary electroplating faces upwards, the back face of the substrate is embedded into a wax-free pad, polishing is conducted twice through a wandering star wheel, the rotating speed of the high-speed stage of each time of polishing is 28 rpm, and the box dam layer with the qualified leveling effect is obtained. The polishing method has the beneficial effects that qualified polishing of the front face of the box dam can be achieved by improving the polishing technology, adopting the mode of the wandering star wheel and the wax-free pad and adjusting the polishing rotating speed.

Owner:CERATRON ELECTRIC (TONGLING) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap