Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Water washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

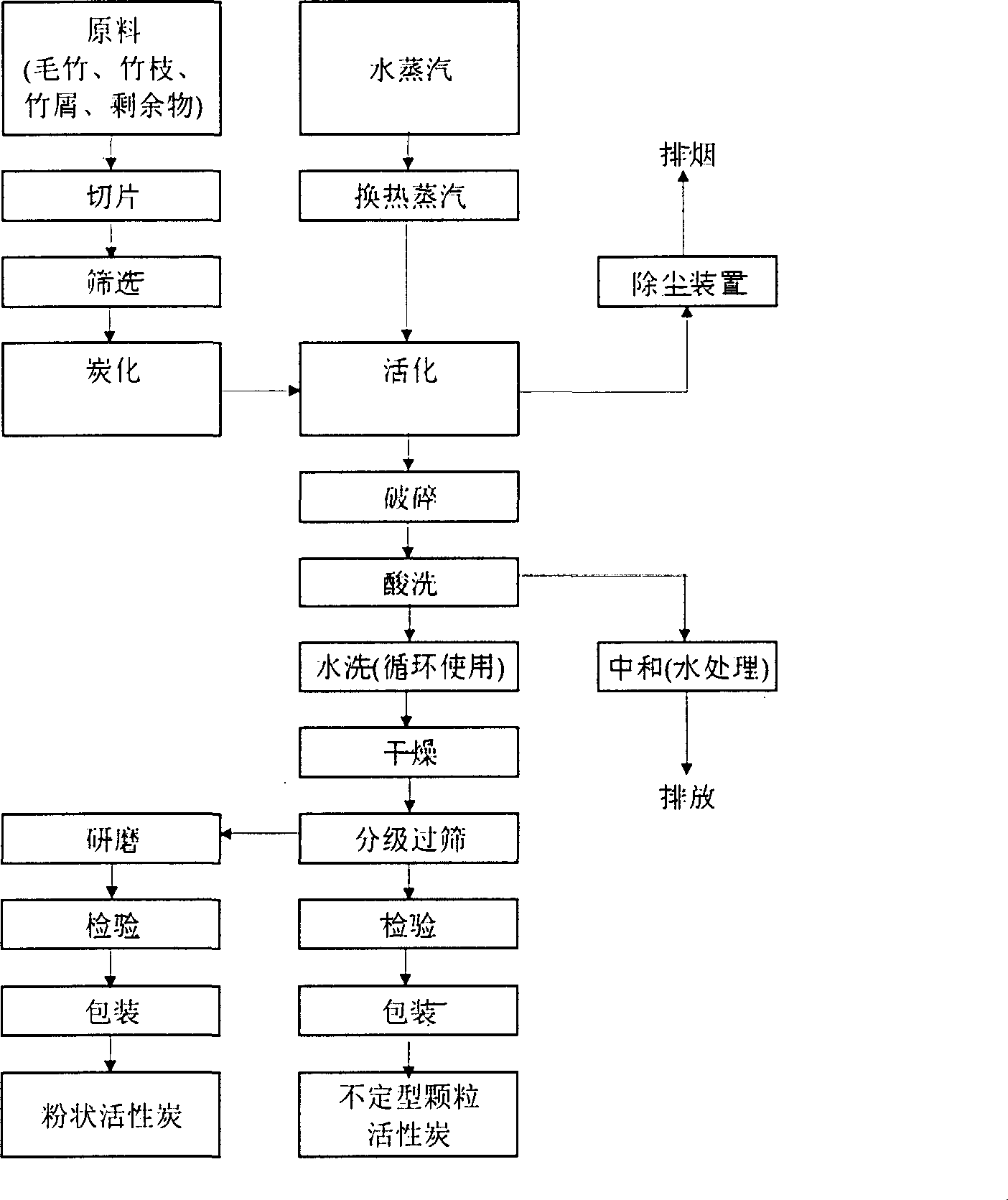

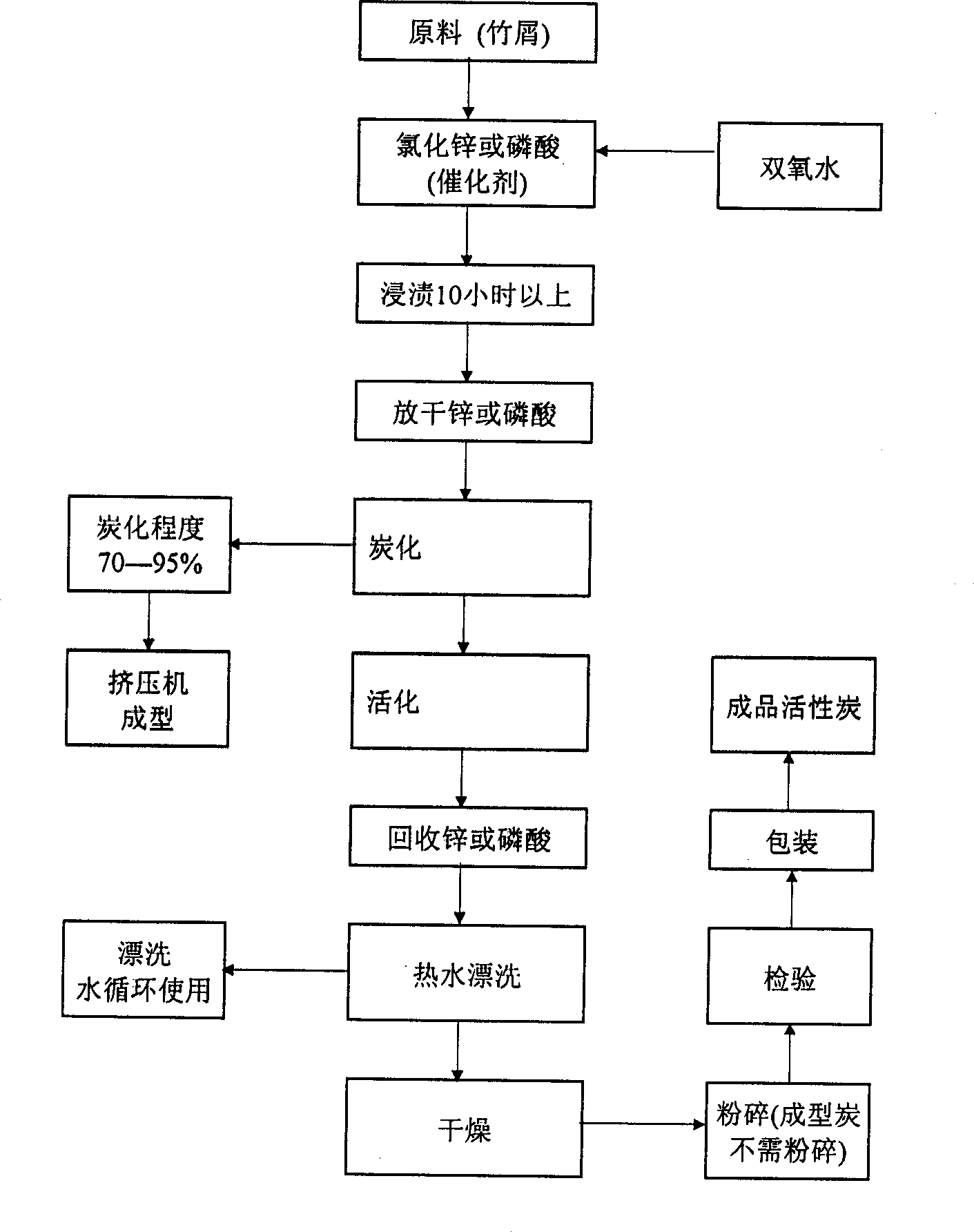

Method for preparing activated char from bamboo material

InactiveCN1333180AImproved decolorizationMesopore developedCarbon compoundsDistillationPhosphoric acid

Owner:尤匡银

Stainless steel plate 8K mirror surface processing method

ActiveCN102962731AImprove the finishImprove anti-corrosion performancePolishing machinesFlexible-parts wheelsRough surfacePolishing

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

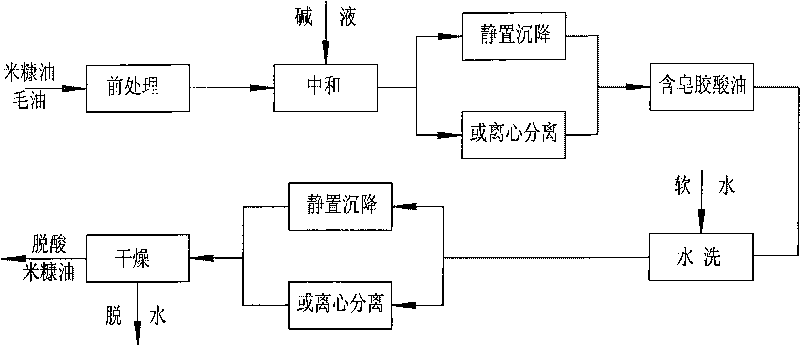

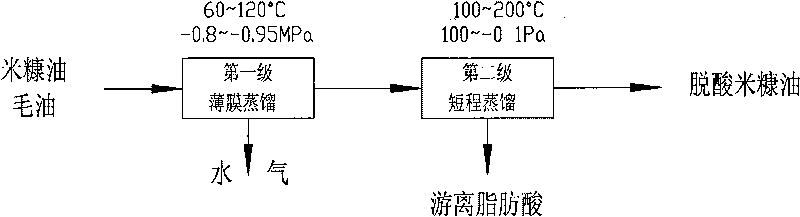

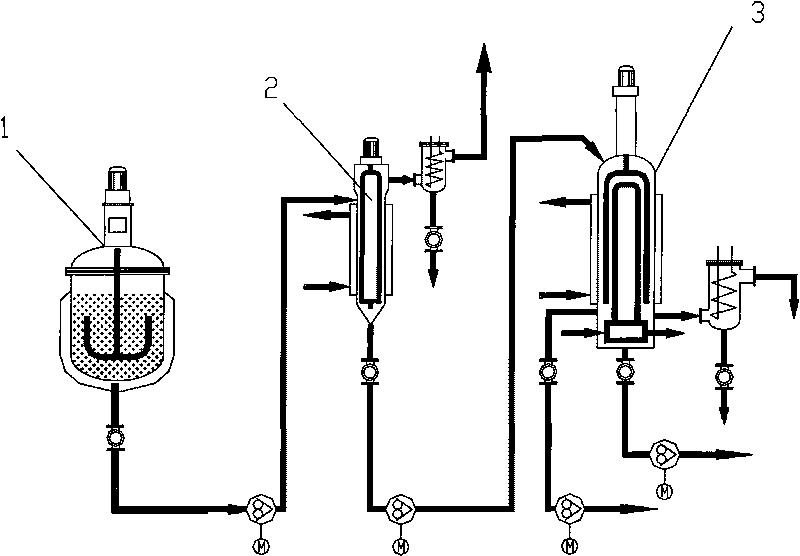

Method for refining rice bran oil by using short distance distillation

InactiveCN101705148ANo effectNo pollution in the processFatty-oils/fats refiningDistillationOleic Acid Triglyceride

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of sheepskin collagen casing

The invention discloses a preparation method of a sheepskin collagen casing. The preparation method comprises raw sheepskin immersion in water and washing, liming hair removal, hydrogen peroxide treatment, primary pickling, mincing and beating, compounding, secondary pickling, homogenization and filtration, extrusion and curing, water washing and plastification, UV crosslinking, drying and humidification. The preparation method realizes the comprehensive utilization of bur sheepskin, prevents the waste of resources and the pollution of the environment and can produce huge economic and social benefits.

Owner:INNER MONGOLIA QIUSHI BIOLOGICAL CO LTD

Preparation method of silicon dioxide used for tooth paste

The invention discloses a preparation method of silicon dioxide used for tooth paste. According to the invention, a two-stage alkali-adding method is adopted, and the method comprises the steps that: a certain amount of sodium silicate water solution and a certain amount of sulfuric acid water solution are prepared firstly; the sulfuric acid water solution is added into a reaction kettle at ordinary temperature, wherein the adding amount is 50% of needed sulfuric acid; the sodium silicate water solution is added until the pH reaches 7-8; the temperature is increased to 70-80 DEG C; mixing is performed for 1-2 h; the rest sodium silicate solution is added into the reaction slurry; the temperature is increased to 70-80 DEG C; the sulfuric acid water solution is added until the pH reaches 4-5; the heat temperature is preserved for 20-30 min; water washing, drying and smashing are conducted to obtain tooth-paste-used silicon dioxide. The silicon dioxide has proper abrasion amount and good thickening property.

Owner:FUJIAN SANMING TONGSHENG CHEM

Preparation method of polyacrylonitrile-based hollow carbon fibers

InactiveCN109576824AMake up for the vacancyEfficient use ofWet spinning methodsConjugated synthetic polymer artificial filamentsCarbon fibersCarbonization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Resin adsorption treatment process of high-salt wastewater containing amine system

PendingCN109912098AEfficient removalBiotoxicMultistage water/sewage treatmentWater/sewage treatment by sorptionAdditive ingredientDesorption

The invention discloses a resin adsorption treatment process of a high-salt wastewater containing an amine system. The resin adsorption treatment process mainly comprises the following specific steps:adjusting the pH value of raw water, feeding the adjusted raw mater into a raw water pool, pumping the raw water into a precise filter and filtering out mechanical impurities; enabling outlet water to enter a resin adsorption tower; enabling outlet water after resin adsorption to enter a resin outlet water tank, performing triple effect evaporation for evaporative crystallization and enabling mother liquid to return to a raw water buffer tank; performing desorption after adsorption, washing with water and enabling washing water to enter the raw water pool; performing desorption with methanol,evaporating desorption liquid and enabling evaporated methanol to enter a rectifying tower for refining; washing with water, feeding washing water into the rectifying tower for refining, recycling methanol at the top of the tower and feeding kettle residues into a dehydrogenation tower; enabling an ingredient at the top of the dehydrogenation tower to return to the rectifying tower and feeding kettle residues into the raw water pool. Compared with the prior art, the resin adsorption treatment process has the advantages of being low in operating cost, low in investment cost of equipment and high in removal rate, causing no secondary pollution, being cleaner, being high in selectivity and good in regeneration of the equipment and having reusability.

Owner:NANJING JIANDI ENVIRONMENTAL ENG CO LTD

Preparation method of rice hull carbon based solid sulfoacid

InactiveCN103157512AHigh densityEasy to dehydrateOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholAcid catalyzed

Owner:TIANJIN POLYTECHNIC UNIV

Particle-size-controllable nano and sub-micron CeO2 preparation method

InactiveCN103145168AGranularity controllableSave washingMaterial nanotechnologyRare earth metal compoundsCerium nitrateCerium nitrate hexahydrate

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

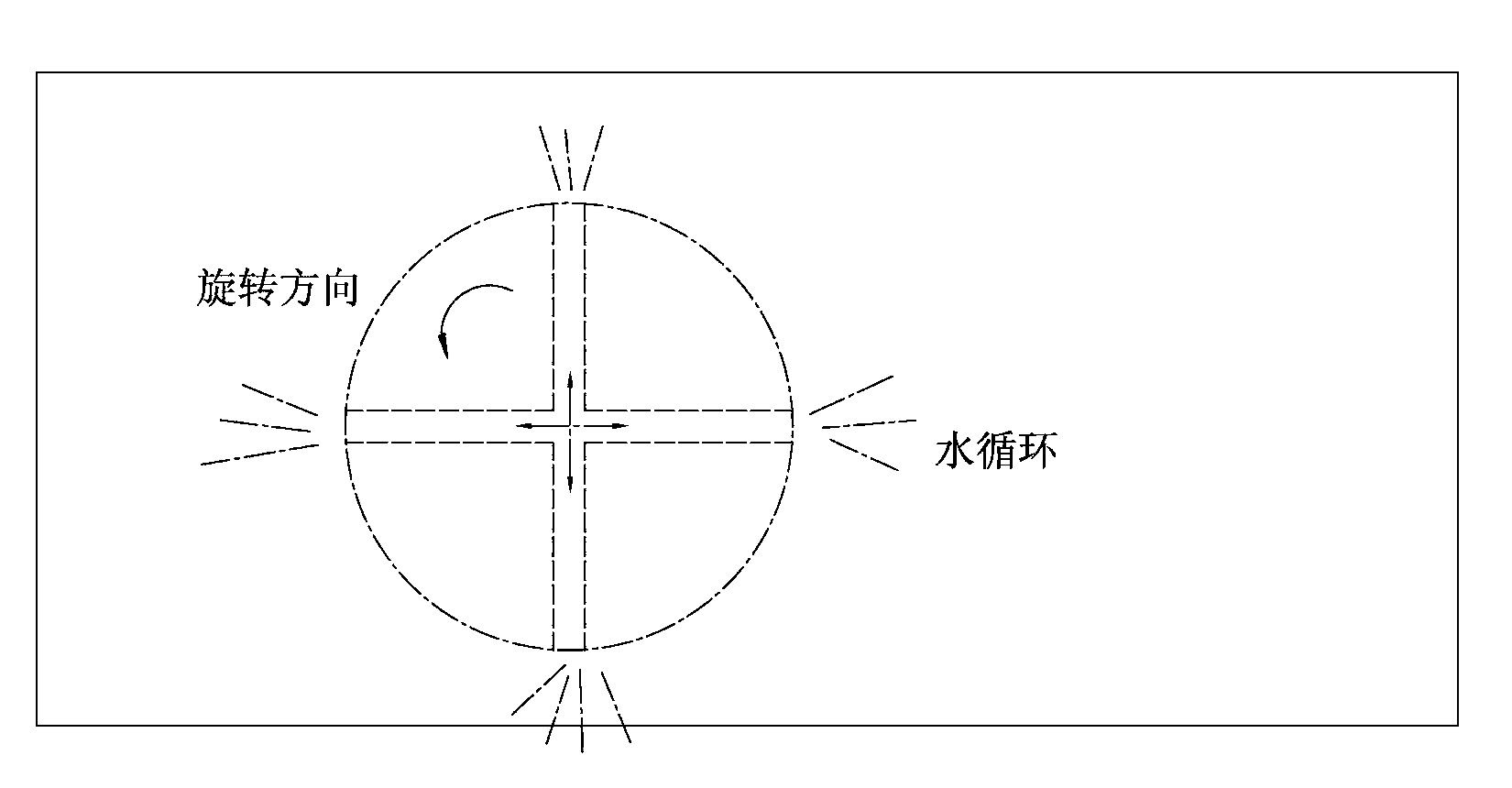

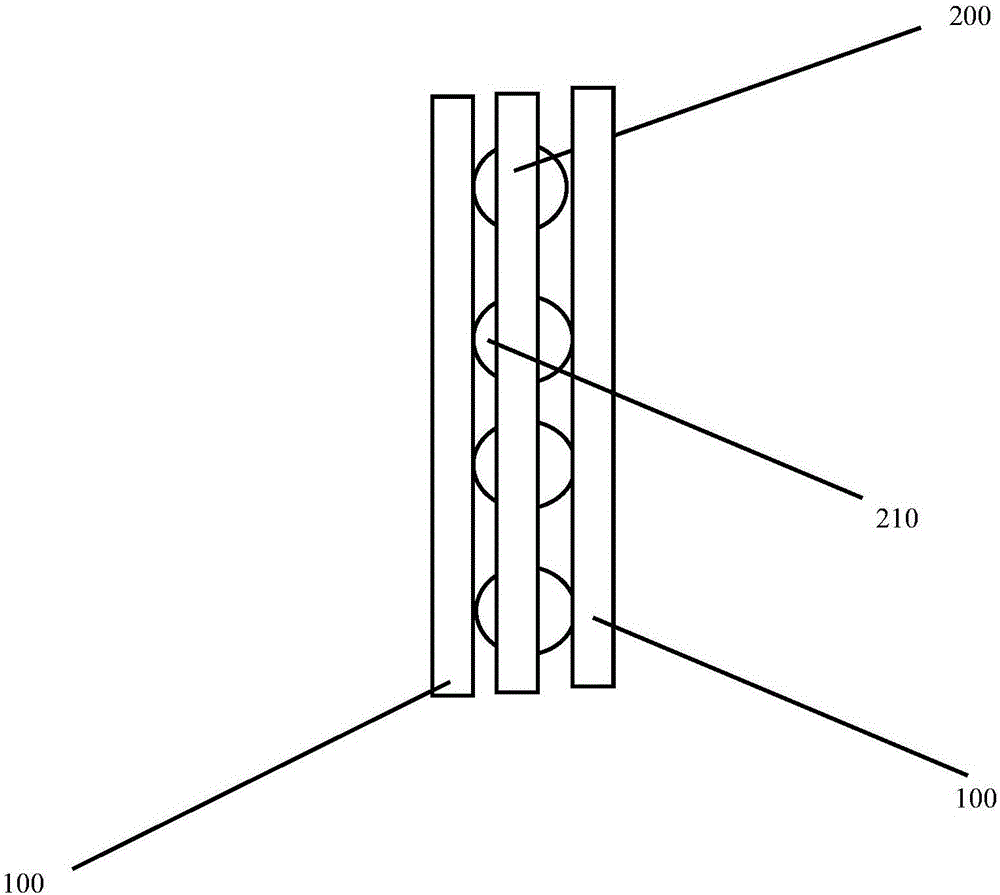

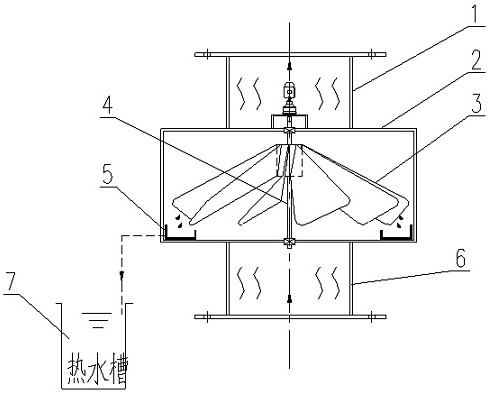

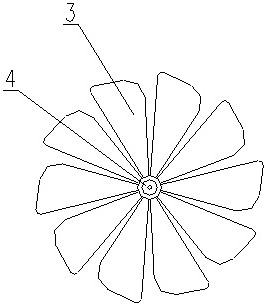

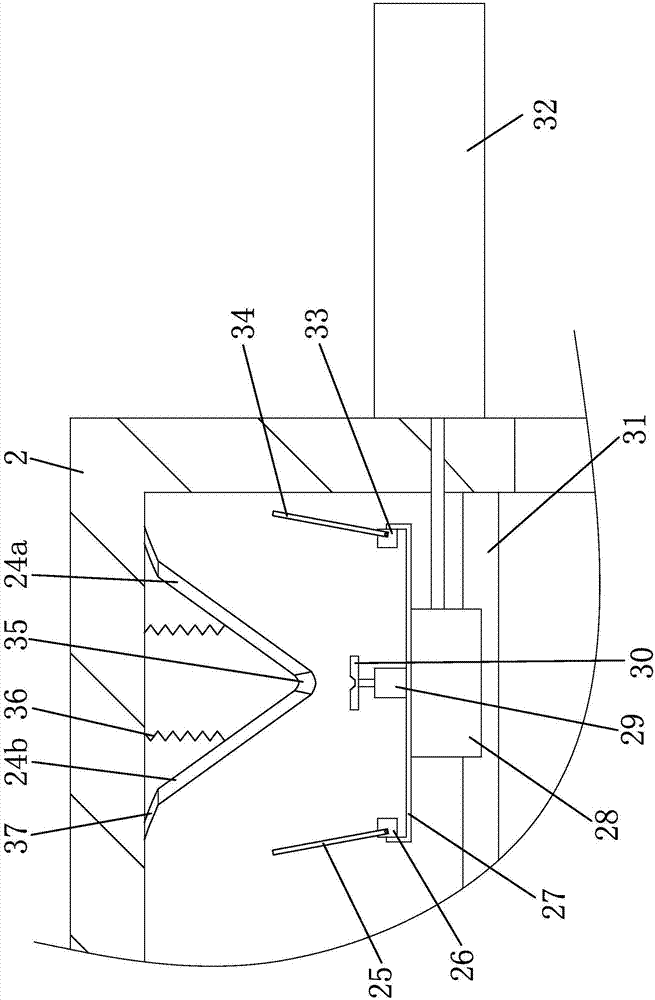

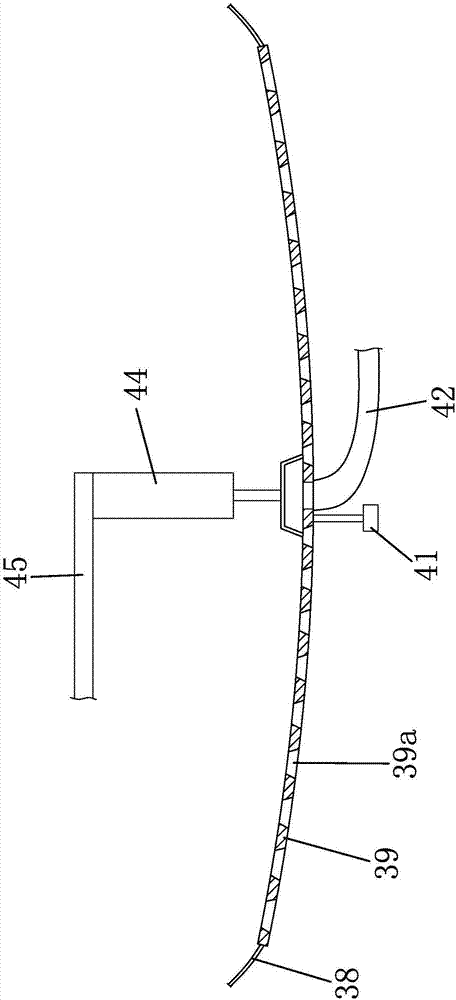

Water-washing dust-cleaning horizontal type mesh cage dust removing machine

InactiveCN102728175AMake sure it's cleanExtended service lifeCombination devicesSewage treatmentWater tanks

The invention discloses a water-washing dust-cleaning horizontal type mesh cage dust removing machine, which mainly comprises a plurality of parts, i.e., a horizontal type rotary mesh cage, a sealed type dust accumulating chamber, an automatic water mist spraying device and a helix sewage disposal device, wherein the horizontal type rotary mesh cage is a filtering unit main body which can be composed of one to more mesh cages; the mesh cages are arranged in parallel inside the dust accumulating chamber; one or more layers of filtering cloth wrap on the mesh cages; and the mesh cages are driven to rotate slowly by a transmission device. The dusty gas is led into the sealed dust accumulating chamber by a fan or a draught pipe; and during the process that the dusty gas penetrates through the filtering cloth on the mesh cages and is discharged out from a discharge port, the dust is captured by the filtering cloth, while the clean air permeates through the filtering cloth and is discharged out from ports of the mesh cages. A V-shaped water tank is arranged at the lower part of the dust accumulating chamber; a water level of certain height is maintained; and the dust accumulated on the filtering cloth is washed when the mesh cages swashes with water while rotating backwards, so that the purpose of automatic dust cleaning is achieved.

Owner:YUEYANG FOREST & PAPER CO LTD

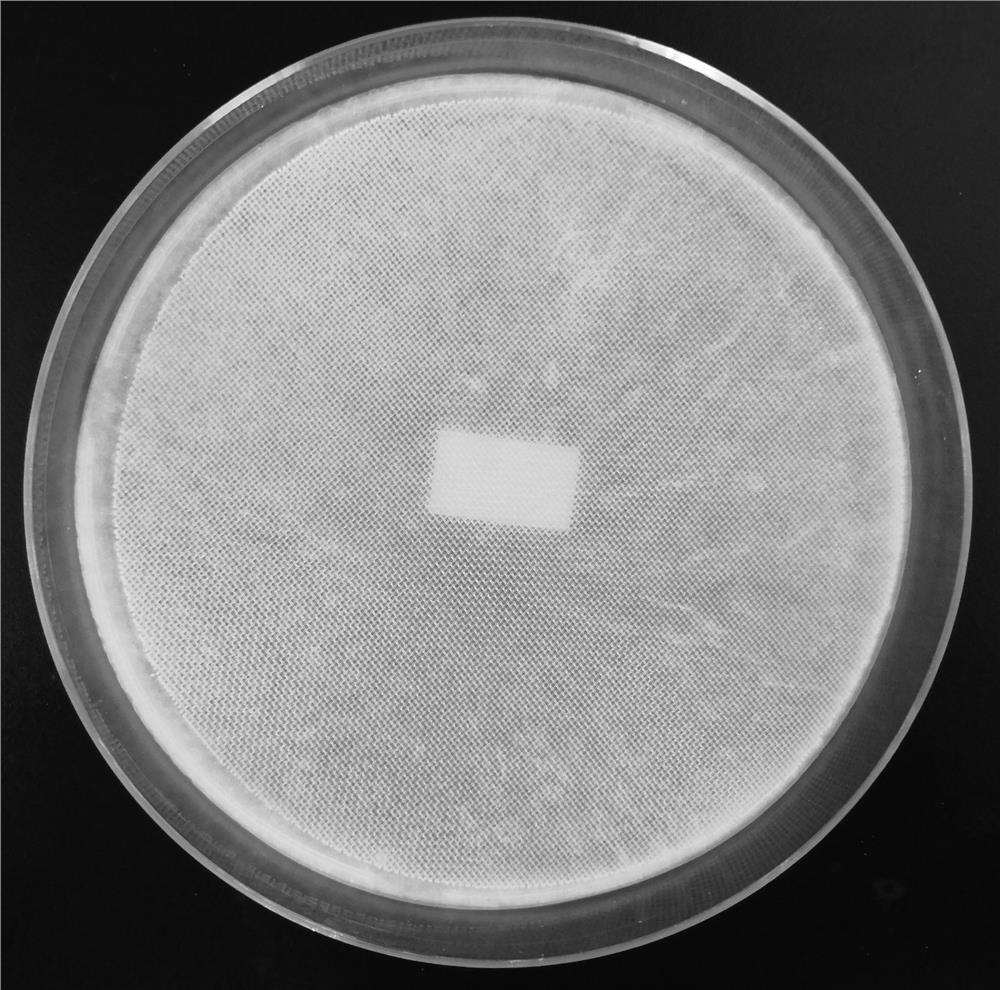

Method for making coated filter cloth through wet process

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

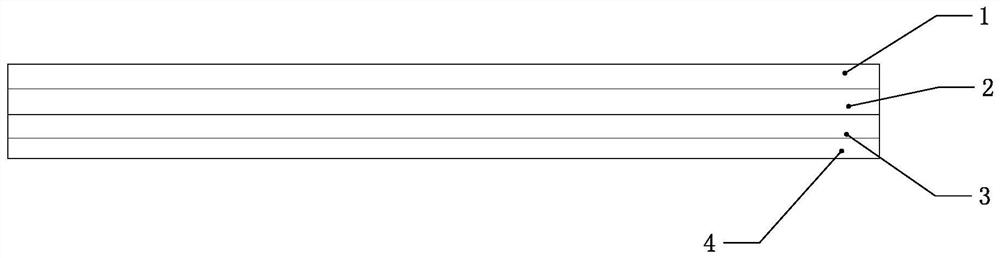

Preparation method of chemically-silvered active carbon as composite conductive filler

ActiveCN104152882AReduce usageLight in massInorganic pigment treatmentLiquid/solution decomposition chemical coatingActivated carbonGrey substance

Owner:广东致卓环保科技有限公司

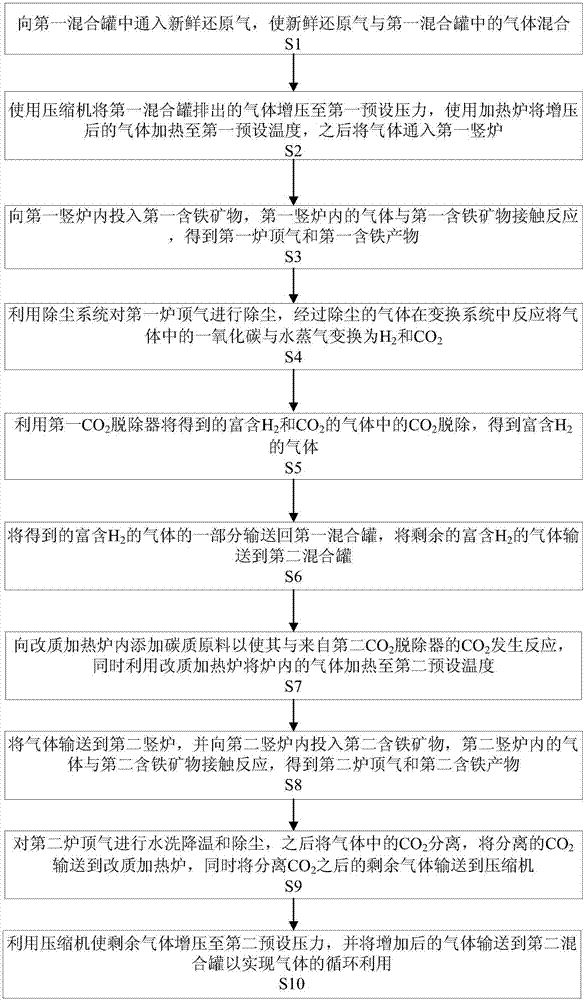

Double shaft furnace system and method for joint production

PendingCN107513596AEfficient use ofAchieve productionShaft furnaceProcess efficiency improvementShaft furnaceMixing tank

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

High-efficiency and environmental-protection dyeing post-processing method of medium or dark terylene knitted fabric

InactiveCN106758412AAchieve dyeing effectShorten the timeDyeing processTime efficientNuclear engineering

Owner:SHANGHAI JIALE

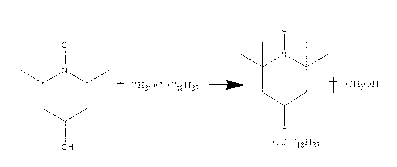

Preparation method of 2, 2, 6, 6-tetramethyl-piperidinooxy stearate

InactiveCN103274994AEmission reductionLow priceOrganic chemistryManufacturing technologyWater discharge

Owner:南通市振兴精细化工有限公司

Aluminum alloy and preparation method thereof

Owner:CHANGCHUN UNIV OF TECH

Online wet and hot water vapor recovery device for electroplating treatment

InactiveCN113398714AReduce heating energy consumptionCapture implementationCellsGas treatmentWater vaporEnvironmental engineering

Owner:中航长沙设计研究院有限公司

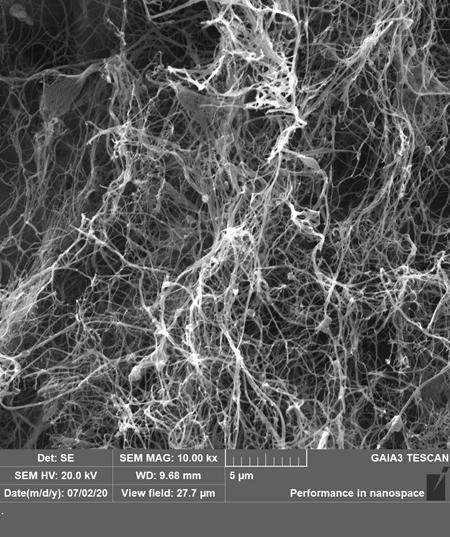

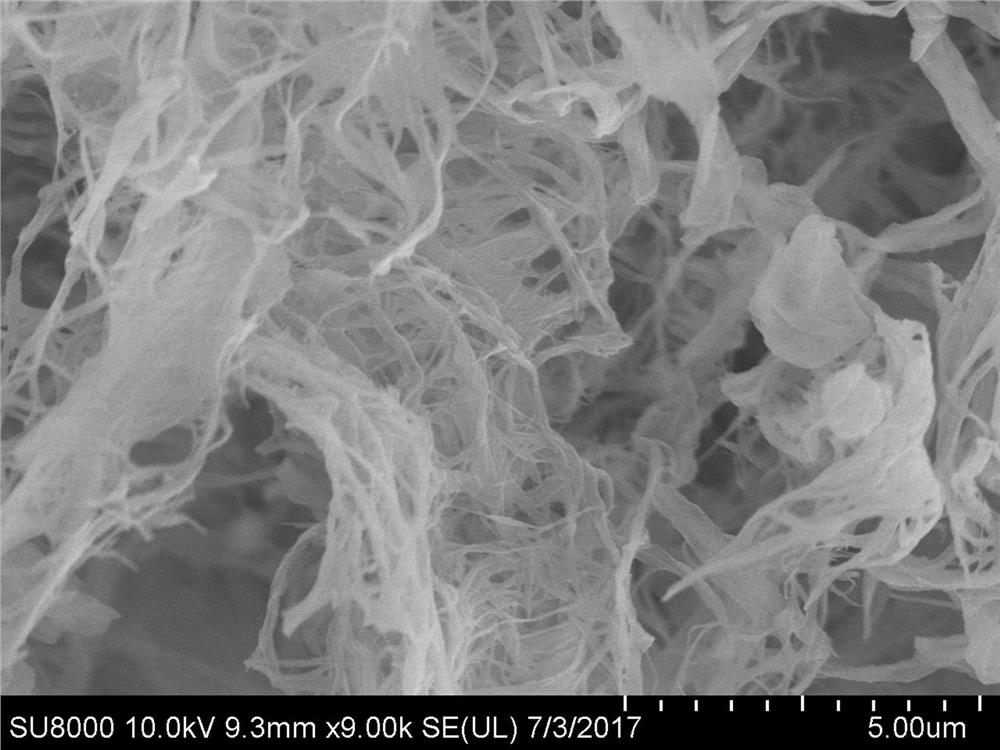

Preparation method of cellulose aerogel-based efficient air filtering membrane

ActiveCN112876713AImprove mechanical propertiesSimple processSemi-permeable membranesHuman health protectionAir filtrationFreeze-drying

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Cotton imitation wax printing process

InactiveCN107604691AConsistent positive and negative effectsSimple processDyeing processDisperse dyeWax

Owner:宣城凯欧纺织有限公司

Dyeing and finishing long vehicle finishing method of bio-enzyme treatment

ActiveCN111394917AIncrease productivityImprove quality stabilityTextile storage in superimposed formSucessive textile treatmentsTextile printerProcess engineering

Owner:鲁丰织染有限公司

Manufacturing method of weft knitting polyester velvet blanket

PendingCN114381849ASimple processRealize development and utilizationWeft knittingBlanketPolyesterTextile printer

Owner:连云港飞雁毛毯有限责任公司

Sewage pretreatment process used during organic product preparation

ActiveCN109896684APromote precipitationReduce saltOrganic compound preparationMultistage water/sewage treatmentOrganic layerSolvent

An embodiment of the invention discloses a sewage pretreatment process used during organic product preparation. The process includes: (a), adding a nonpolar solvent, sodium alcoholate and main and auxiliary raw materials into a synthesis kettle for reaction; (b), adding a saturated sodium salt solution into a water-washing neutralization kettle, cooling, adding reaction liquid in the synthesis kettle into the water-washing neutralization kettle, and titrating till being slightly acidic; (c), standing a solution in the water-washing neutralization kettle to obtain a lower-layer solid-liquid mixture and an upper-layer organic layer; (d), performing suction filtering on the lower-layer solid-liquid mixture to obtain sodium salt and a mixed solution; (e), taking the mixed solution in the step(d) as the solution added into the water-washing neutralization kettle in the step (b) for reutilization; (f), using water to wash the organic layer, and distilling or rectifying to obtain an organicproduct. The process can promote recycling of sodium salt and reutilizing of sewage, reduce salt in the sewage and substantially lower sewage yield, thereby reducing COD in the sewage and sewage treatment energy consumption and treatment cost.

Owner:ZHANGJIAJIE HONGYAN NEW MATERIAL TECH DEV CO LTD

Method for removing metal from hydrocarbon oil by using by product generated in producing fatty acid through oxidizing paraffin

InactiveCN1431278ALow costImprove removal efficiencyRefining with acid-containing liquidsParaffin waxFatty acid

Owner:CHINA PETROLEUM & CHEM CORP +1

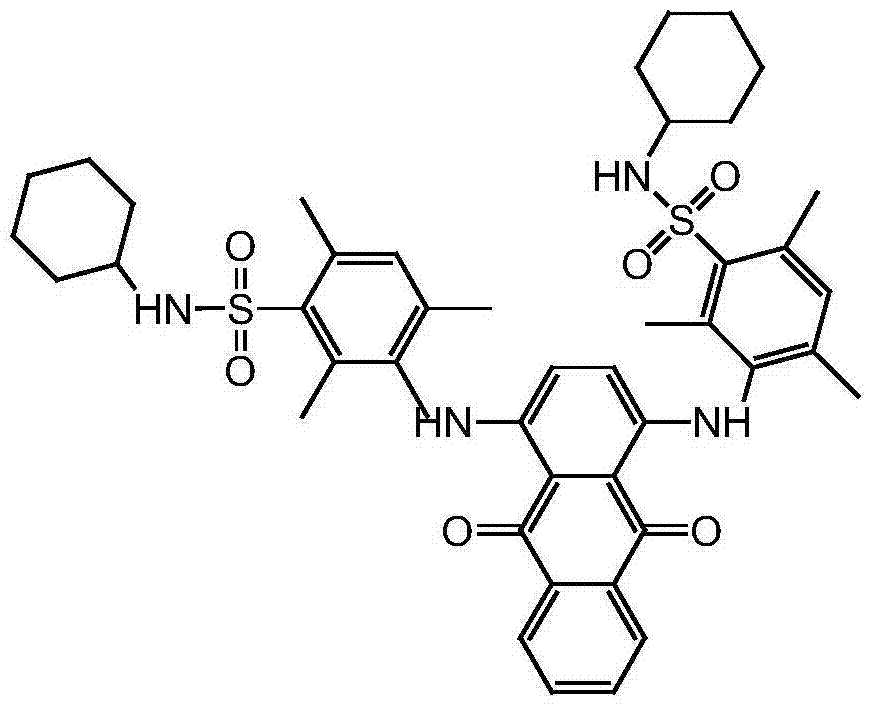

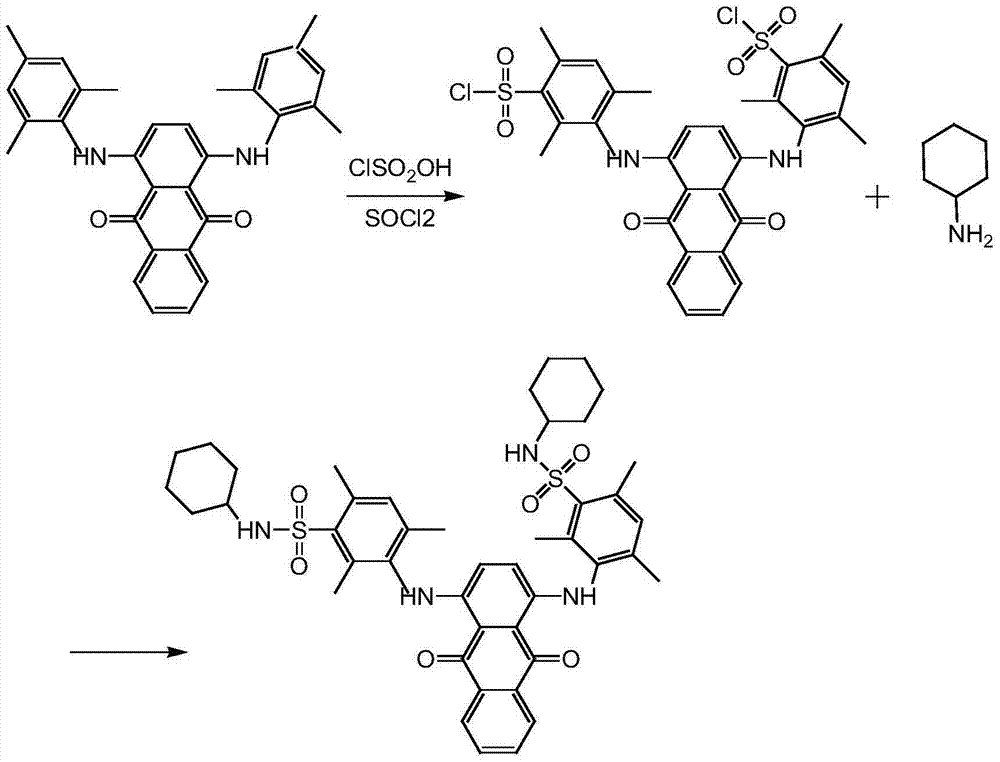

Preparation method of dye

ActiveCN104725891ALittle effect on responseBig impact on qualityAnthracene dyesHydrogenReaction temperature

Owner:JIANGSU DAOBO CHEM

Novel water-washing protection oil and preparation method thereof

InactiveCN104927559AGood film formingLow viscosityEpoxy resin coatingsDiethylene glycol monobutyl etherWater based

Owner:SHENZHEN GLITER PRINTING MATERIALS & EQUIP

Denim fabric printing and dyeing process

ActiveCN107254786AFast coloringNot easy to fadeLiquid/gas/vapor removalTextile treatment machine arrangementsSodium bicarbonateDenim

Owner:上海宛林服装有限公司

Preparation method of officinal nano-zinc oxide

ActiveCN104843767ALow costReduce consumptionMaterial nanotechnologyZinc oxides/hydroxidesZinc hydroxideAlcohol

Owner:HUNAN ER KANG PHARMA

Method for preparing magnesium sulfate from byproduct sulfuric acid of benzene sulfone chloride

PendingCN111977675AIncrease concentrationEasy to separateSulfur compoundsMagnesium sulfatesSulfonyl chlorideChlorosulfuric acid

The invention discloses a method for preparing magnesium sulfate from byproduct sulfuric acid of benzene sulfone chloride. The method comprises the following steps: (1) sulfonation reaction: chlorosulfonic acid and pure benzene are taken as raw materials; firstly, the chlorosulfonic acid is added into a reaction kettle; then, the reaction kettle is heated, and the reaction kettle is started; afterstarting, under the stirring state that the stirring rate is 100-150r / min, the pure benzene is dropwise added by employing a constant-pressure dropping funnel; and after being dropwise added, the pure benzene and the chlorosulfonic acid react for 2-3h to produce hydrogen chloride gas; then the produced hydrogen chloride gas is condensed and is absorbed by a secondary falling film to prepare a hydrochloric acid solution with mass concentration of 38%-45%; after the solution is obtained, 10-15g of sulfonation additive is added into the solution; then the reaction kettle is restarted for reaction; and after the reaction ends, cooling, hydrolyzing, crystallization, suction filtration, water washing and drying are performed to obtain the benzene sulfone chloride and by-products thereof; the sulfuric acid can be separated very conveniently, and the magnesium sulfate can be quickly prepared by using the sulfuric acid.

Owner:JIANGSU KANGXIANG GRP CORP +1

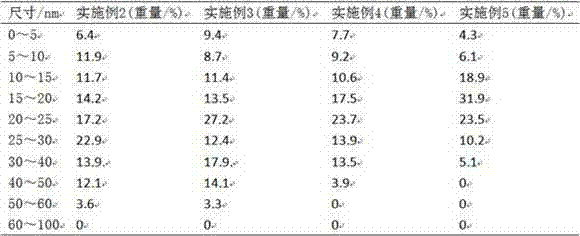

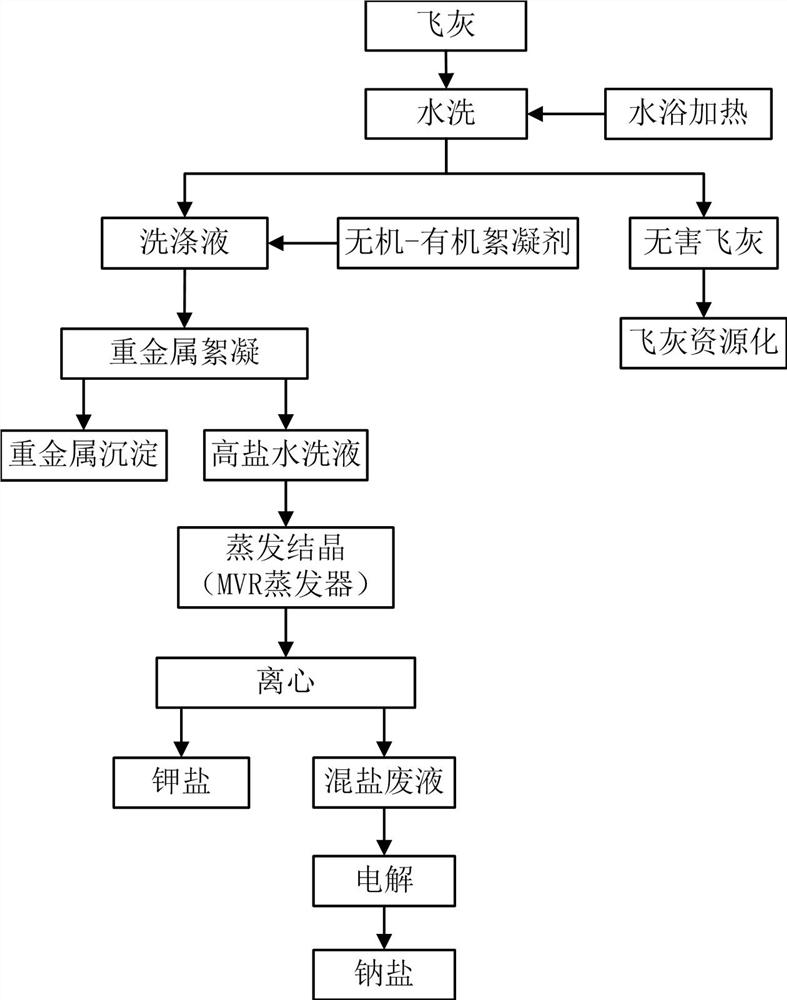

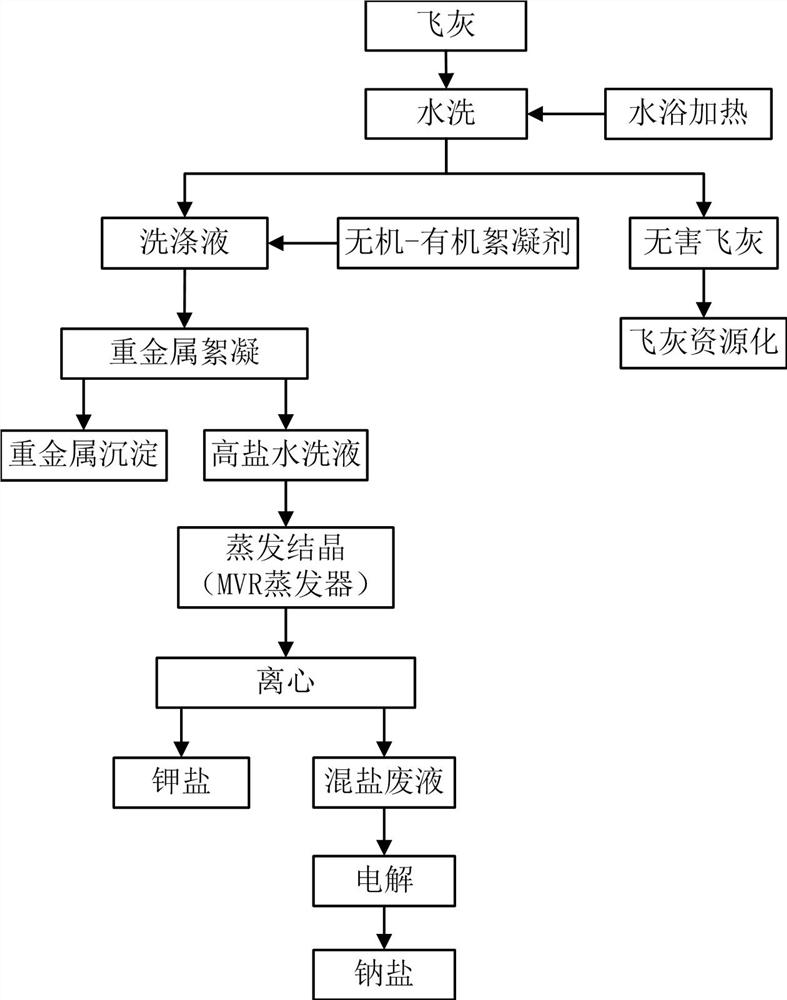

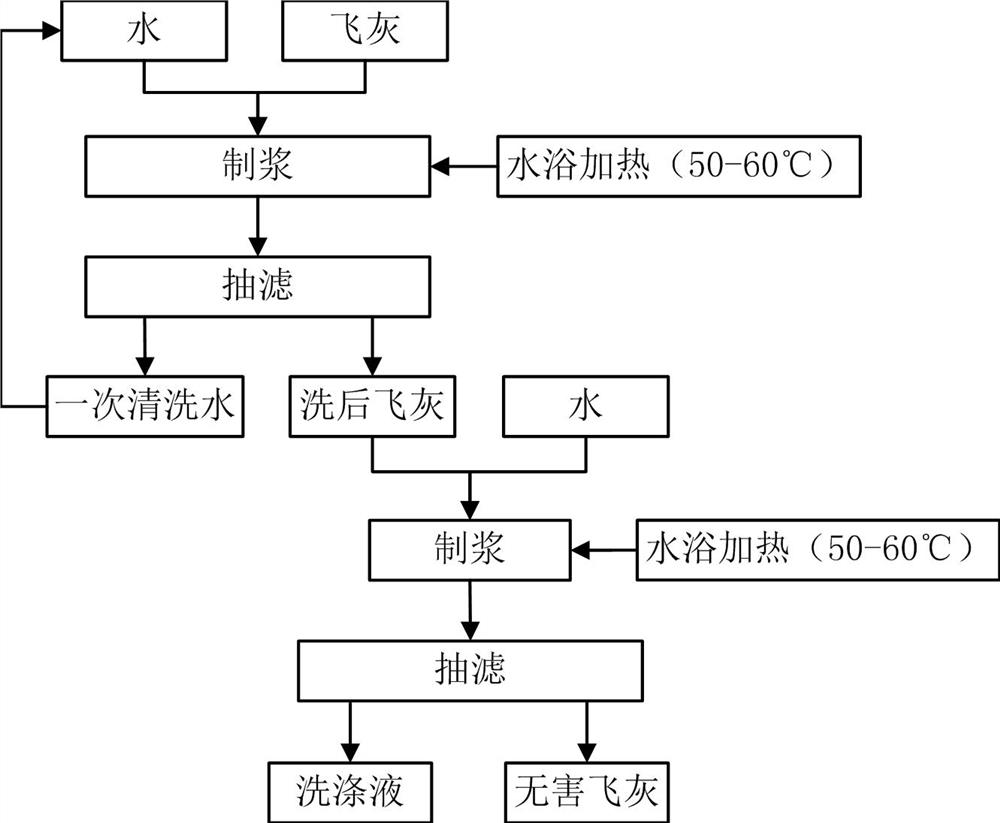

Fly ash enhanced washing and high-salinity wastewater resource utilization method

PendingCN113953303AAchieve harmlessReach resourcesSolid waste disposalWater contaminantsSaline waterSalt water

Owner:JIANGXI GAIA ENVIRONMENTAL SCI & TECH CO LTD +1

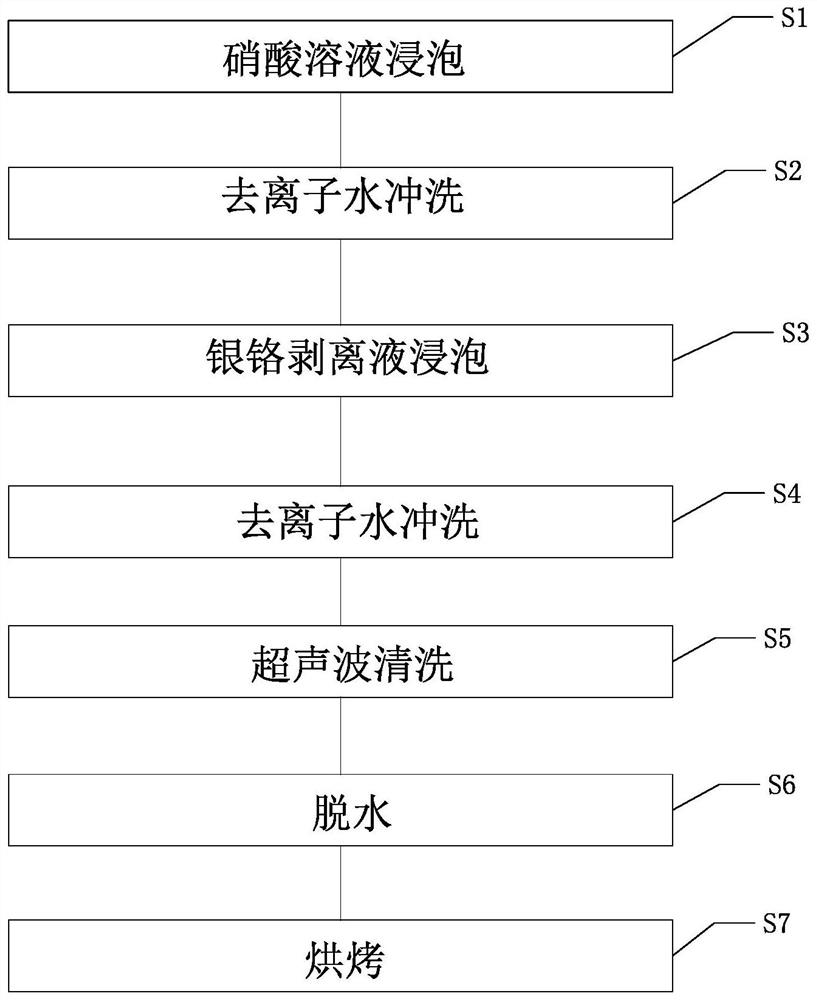

Wafer clamp and cleaning method thereof

PendingCN112547667ACleans fully and effectivelyClean upDrying solid materials without heatDrying machines with local agitationWaferingPhysical chemistry

Owner:CHENGDU KINGBRI FREQUENCY TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap