High-efficiency and environmental-protection dyeing post-processing method of medium or dark terylene knitted fabric

A technology for knitted fabrics and polyester, which is applied in the field of high-efficiency and environmentally friendly post-dyeing treatment of medium-dark polyester knitted fabrics. It can solve the problems of production efficiency and production cost limitations, increase the pressure of sewage treatment, and long process cycle, so as to save time and reduce sewage. The effect of processing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

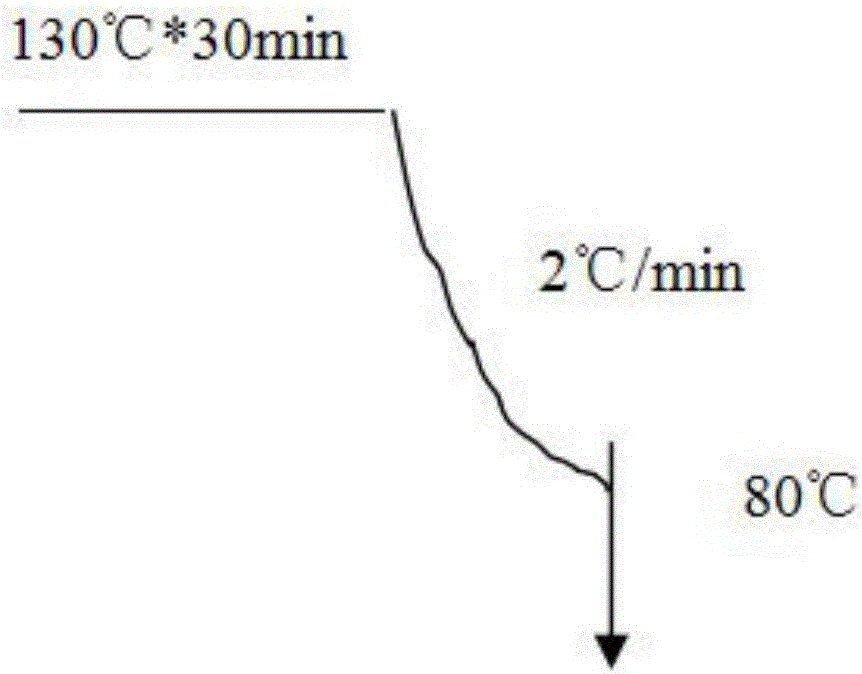

[0031] Such as figure 1 As shown, during the dyeing and cooling process, the high-temperature dyeing residue is discharged under high pressure, and the heat conduction of the residue is used to heat the water injected into the dyeing vat, and the discharged dyeing residue can reduce the temperature to 70°C and discharge it at once. .

[0032] The above-mentioned thermal energy conduction process using residual liquid is realized by using a heat exchanger;

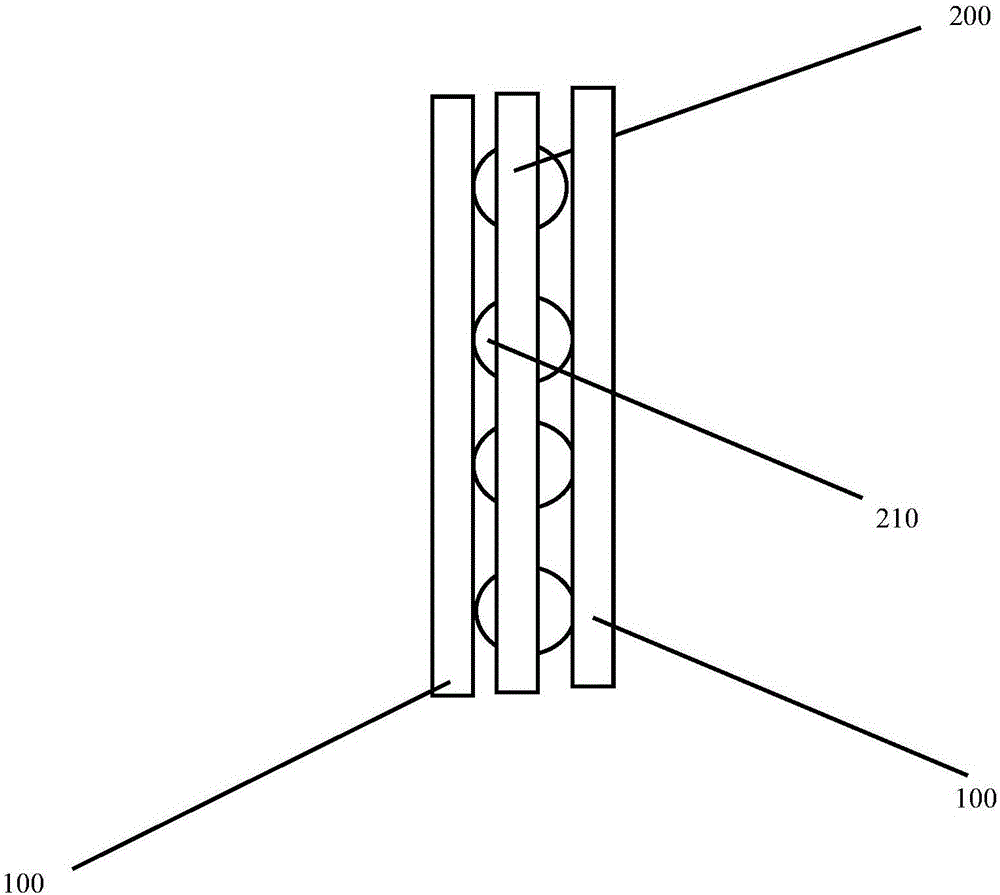

[0033] Such as figure 2 As shown, in this embodiment, the heat exchanger is composed of several water inlet plates 100 and water outlet plates 200;

[0034] The plurality of water inlet plates 100 and the water outlet plates 200 are arranged at intervals; the water inlet plates 100 and the water outlet plates 200 are installed in the middle of the fixed compression plate and the movable compression plate in a superimposed form, and then tightened with tightening bolts.

[0035] The water outlet plate 200 is provided with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap