Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Filtration separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

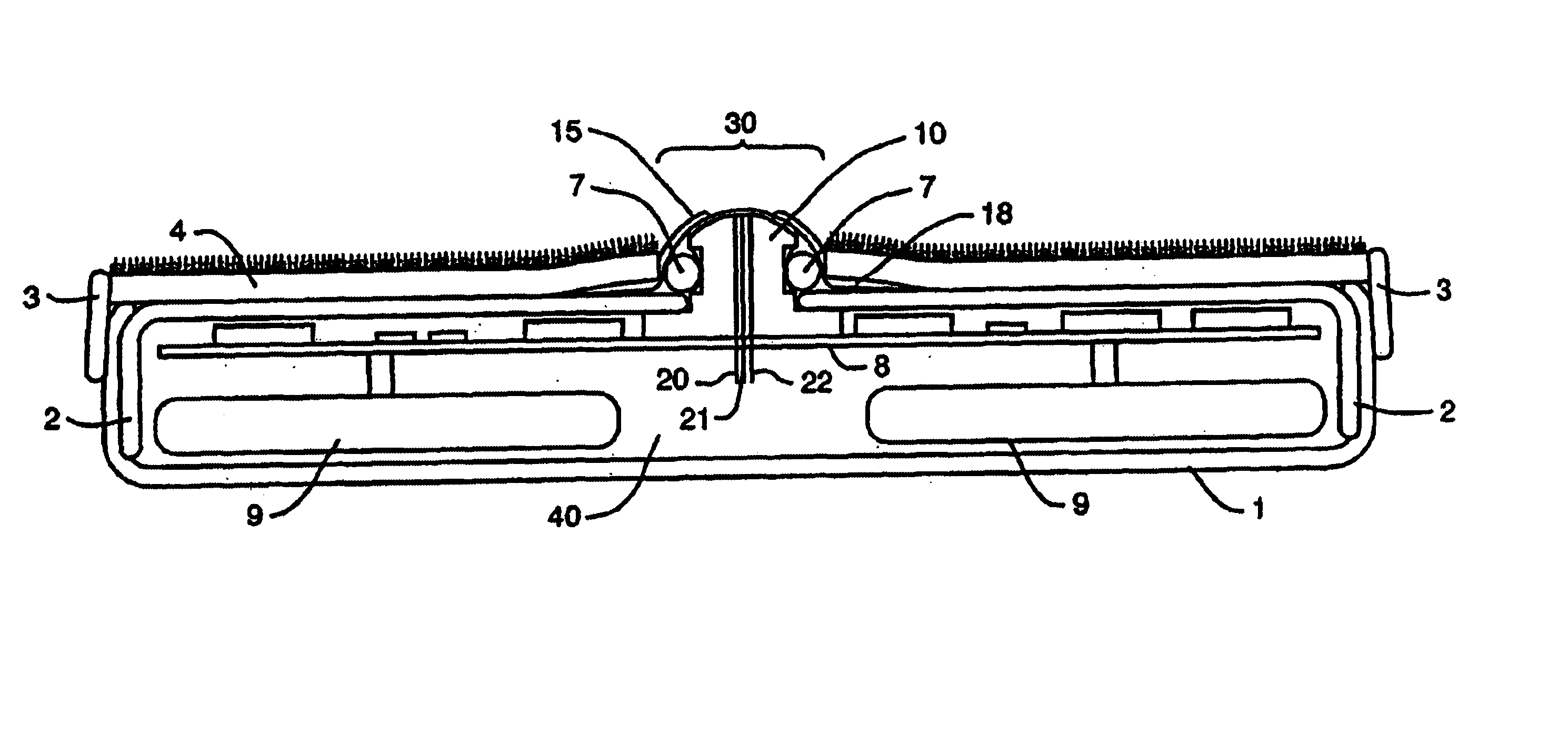

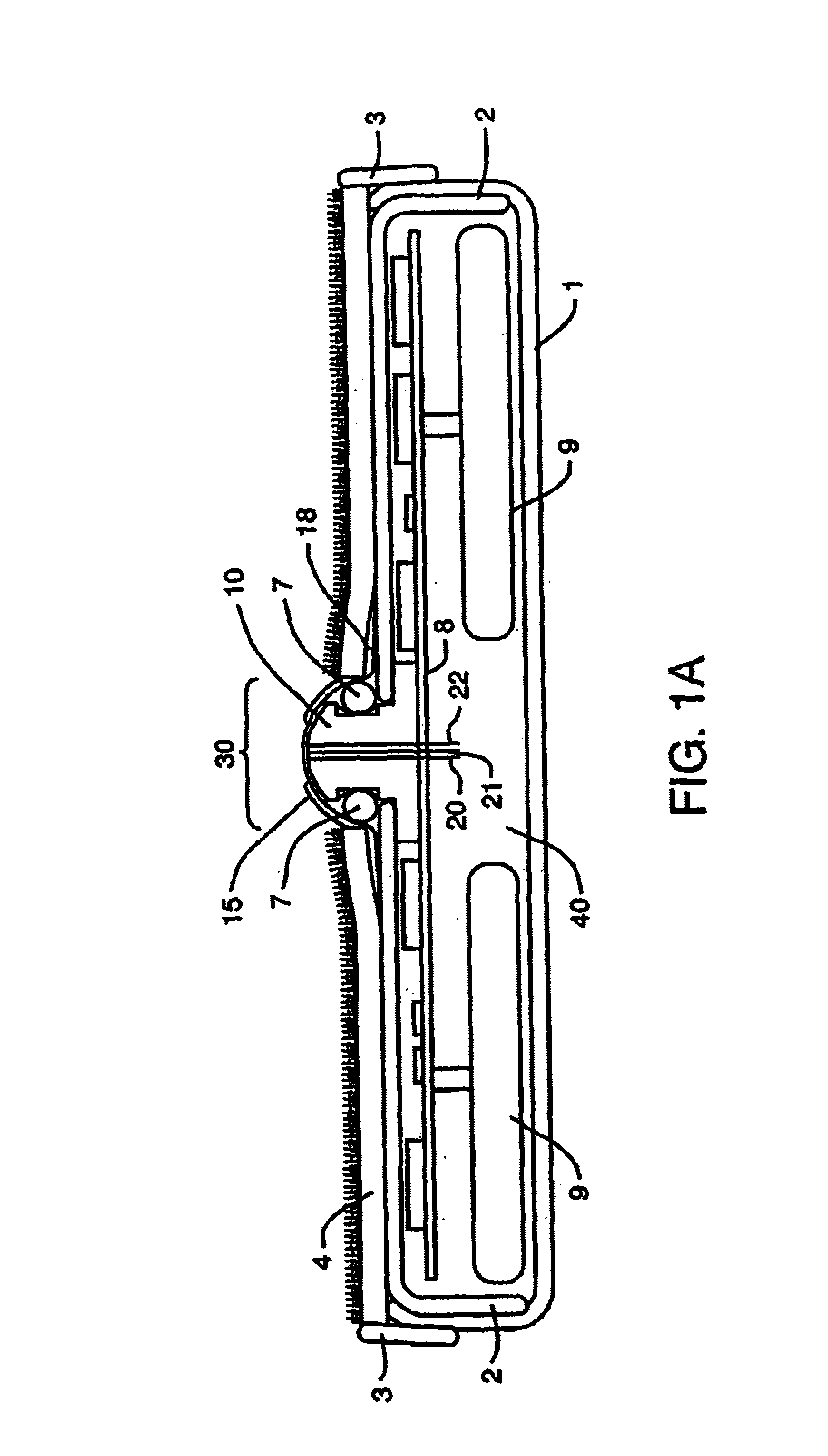

Device and method for determining analyte levels

InactiveUS7110803B2Reducing and eliminating phenomenonEliminate and significantly delay environmental stress crackingWithdrawing sample devicesMicrobiological testing/measurementAnalyteImplanted device

Owner:DEXCOM

Ionic solvents used in ionic polymer transducers, sensors and actuators

InactiveUS20050103706A1Stable responseSolve the stability is not highMaterial nanotechnologySemi-permeable membranesIonomerTransducer

Ionic liquids are incorporated into transducers, actuators or sensors which employ the ionic polymer membranes. The ionic liquids have superior electrochemical stability, low viscosity and low vapor pressure. The transducers, actuators and sensors which utilize ionic polymer membranes solvated with ionic liquids have long term air stability. Superior results are achieved when a conductive powder and ionomer mixture is applied to the ionic polymer membrane to form the electrodes during or after the ionic liquid is imbibed into the ionic polymer membrane.

Owner:VIRGINIA TECH INTPROP INC +1

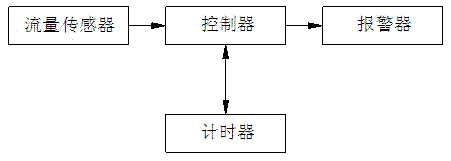

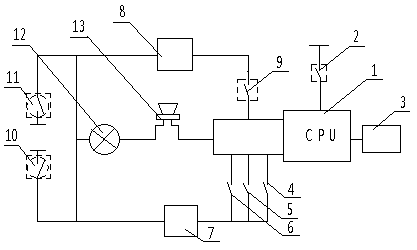

Alarm device used for filter core replacing

InactiveCN102728137AReplace scienceGuaranteed water purification effectFiltration separationWater channelWater flow

Owner:WUXI LAIJITE INFORMATION TECH

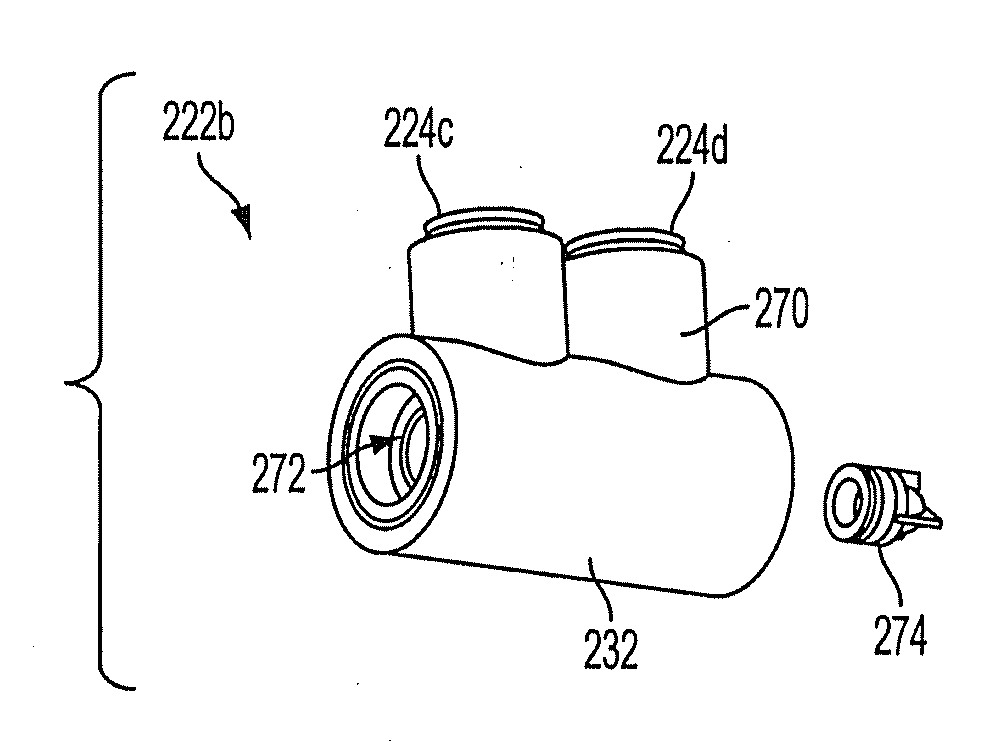

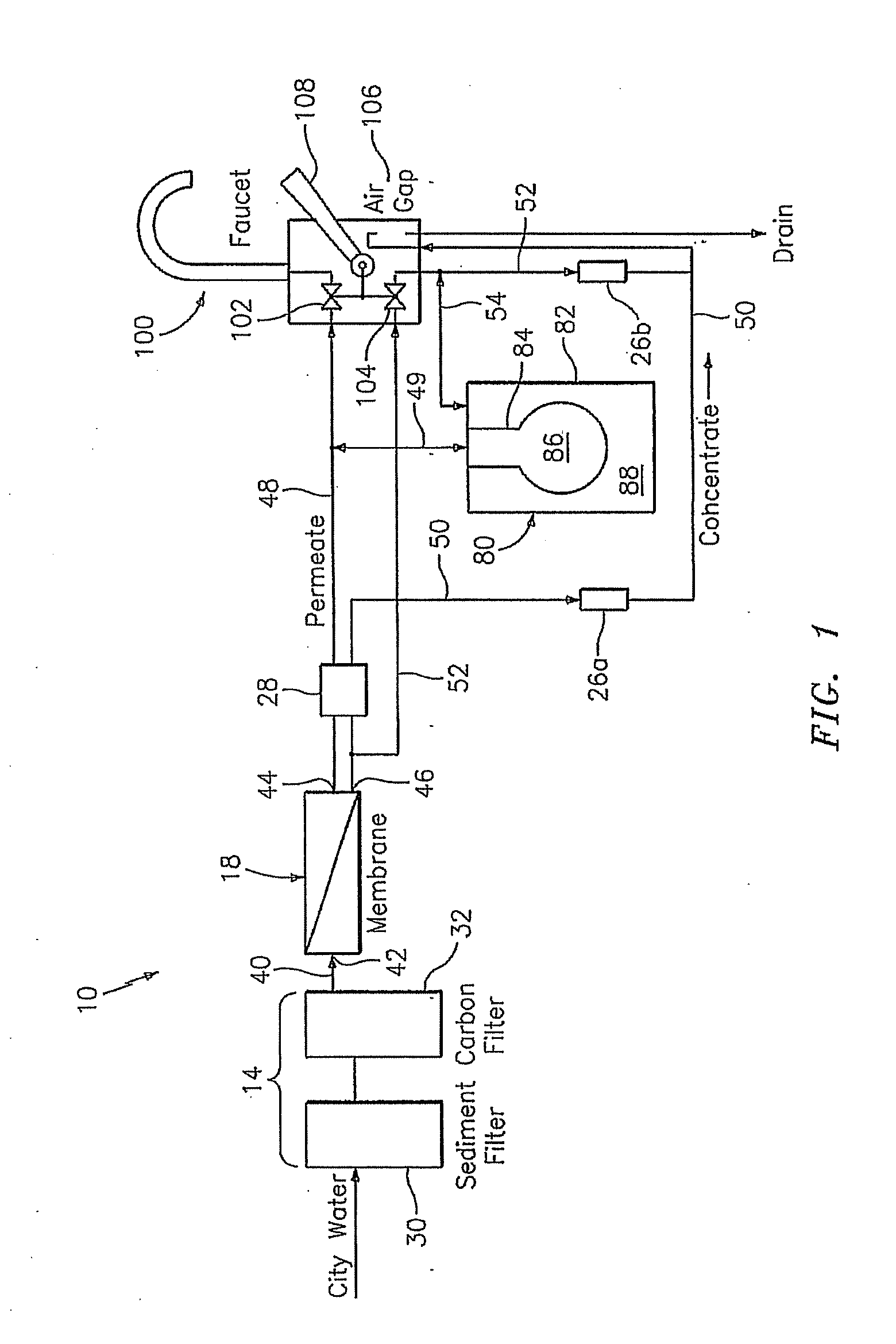

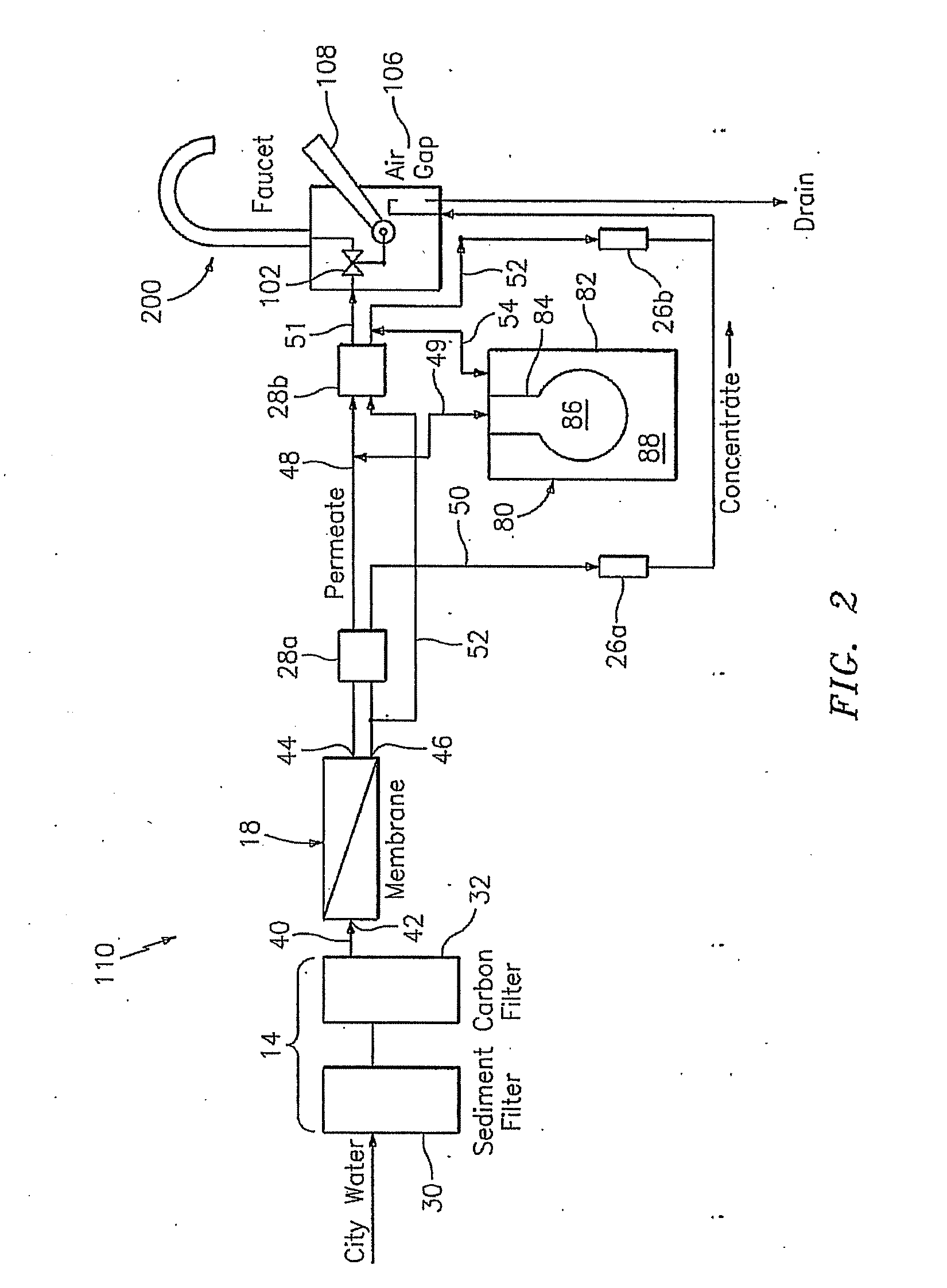

Reverse osmosis water filtering system

ActiveUS20100116724A1Reduce backpressureReduce back pressureServomotor componentsTreatment involving filtrationEngineeringMechanical engineering

A valve assembly having a first valve defining an inlet connected to the inlet supply and an outlet connected to the concentrate chamber, a second valve defining an inlet connected to the permeate chamber and an outlet connected to the faucet, and a third valve defining an outlet connected to drain, a port connected to the concentrate chamber, and an inlet connected to the inlet supply. The port is selectively in fluid communication with the third valve outlet and inlet. When the faucet opens, the first valve opens, the second valve has permeate flowing, and the third valve opens a flowpath between the third valve port and the inlet due to pressure dropping in the second valve. When the faucet closes, the first valve closes and the third valve opens another flowpath between the third valve port and outlet due to pressure created in the second valve.

Owner:WATTS REGULATOR

Using asymmetrical flow focusing to detect and enumerate magnetic particles in microscale flow systems with embedded magnetic-field sensors

InactiveUS20090001024A1Water/sewage treatment by magnetic/electric fieldsFiltration separationMagnetic markerAnalyte

Improved detection and enumeration of magnetic particles in a flowing stream by enveloping the particle-containing sample stream with buffer streams from the sides and from the top, thus individualizing the particles and navigating the sample stream as a single-file flow into the proximity of sensors embedded underneath the flow channel. At the same time, larger physical size of the flow channel alleviates problems such as channel clogging. Magnetic particles can represent any analyte of interest, such as biomolecules or bacterial cells, which are labeled with magnetic labels.

Owner:IOWA STATE UNIV RES FOUND INC

Binchotan-added activated carbon filter material for air conditioners and preparation method thereof

InactiveCN104324699AGood health effectImprove adsorption efficiencyOther chemical processesFiltration separationIonActivated carbon

The invention discloses a Binchotan-added activated carbon filter material for air conditioners. The Binchotan-added activated carbon filter material is characterized by being prepared from the following raw materials, by weight, 135-145 parts of cocoanut active charcoal, 10-15 parts of Binchotan, 2-3 parts of potassium hydroxide, 3-4 parts of brown sugar, 12-14 parts of zeolite powder, 7-9 parts of meerschaum powder, 3-5 parts of seaweed meal, 1-2 parts of sodium alginate, 1-2 parts of D-sodium erythorbate, 4-6 parts of sodium chloride, 4-6 parts of an adsorbent-aid and a proper amount of water. Apart from the addition of components such as zeolite powder, meerschaum powder and the like that enhance the adsorbing effect, the component Binchotan is also added, enhancing adsorptivity of activated carbon, releasing negative ions, blocking electromagnetic wave and appropriately adjusting indoor humidity. The component Binchotan has an excellent health-care effect. In cooperation of the adsorbent-aid, adsorption efficiency is enhanced, and indoor harmful gases are removed rapidly to make the air indoors fresh and pleasant. The preparation process is simple, and the activated carbon filter material has long service life and can repeatedly be used.

Owner:MINGGUANG JIAYI ELECTRIC CONTROL TECH

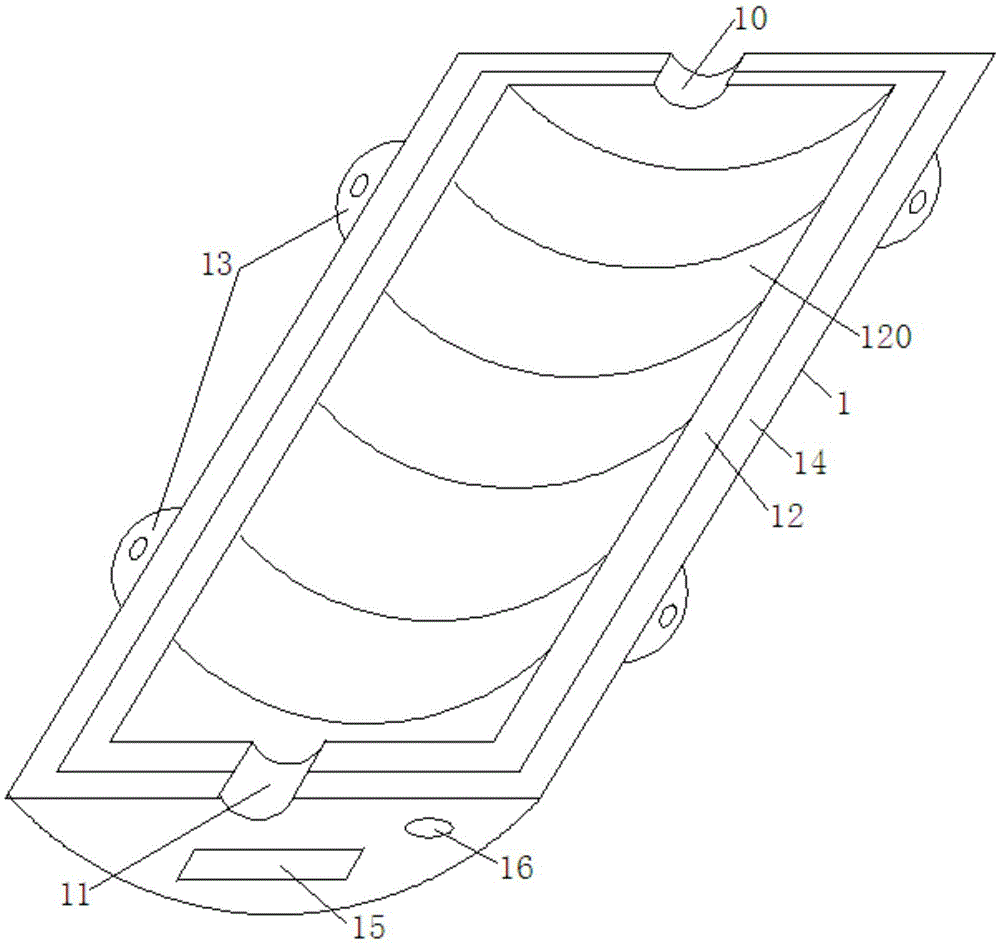

Water purifying device capable of rapidly replacing filter element

InactiveCN105585164AEasy to installEasy to disassembleTreatment involving filtrationMultistage water/sewage treatmentWater leakageEngineering

Owner:胡秀娟

Microbe filter made from micropore ceramics

InactiveCN1727032AIncrease killEnhanced inhibitory effectSemi-permeable membranesFiltration separationCalcium biphosphateAntibiotic Agents

Owner:TSINGHUA UNIV

Liquid treatment cartridge, set of such cartridges and method of manufacturing it

ActiveCN105753207AWater distributersWater/sewage treatment by ion-exchangeEngineeringTreatment system

Owner:BRITA GMBH

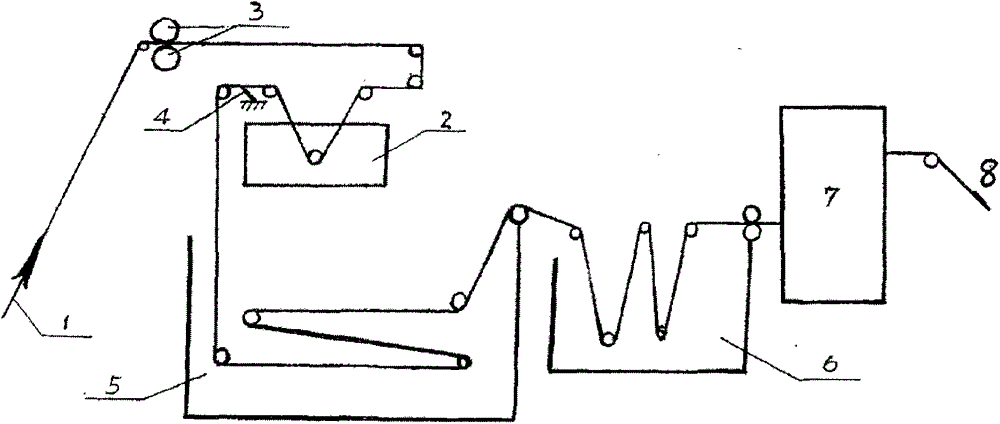

Method for making coated filter cloth through wet process

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

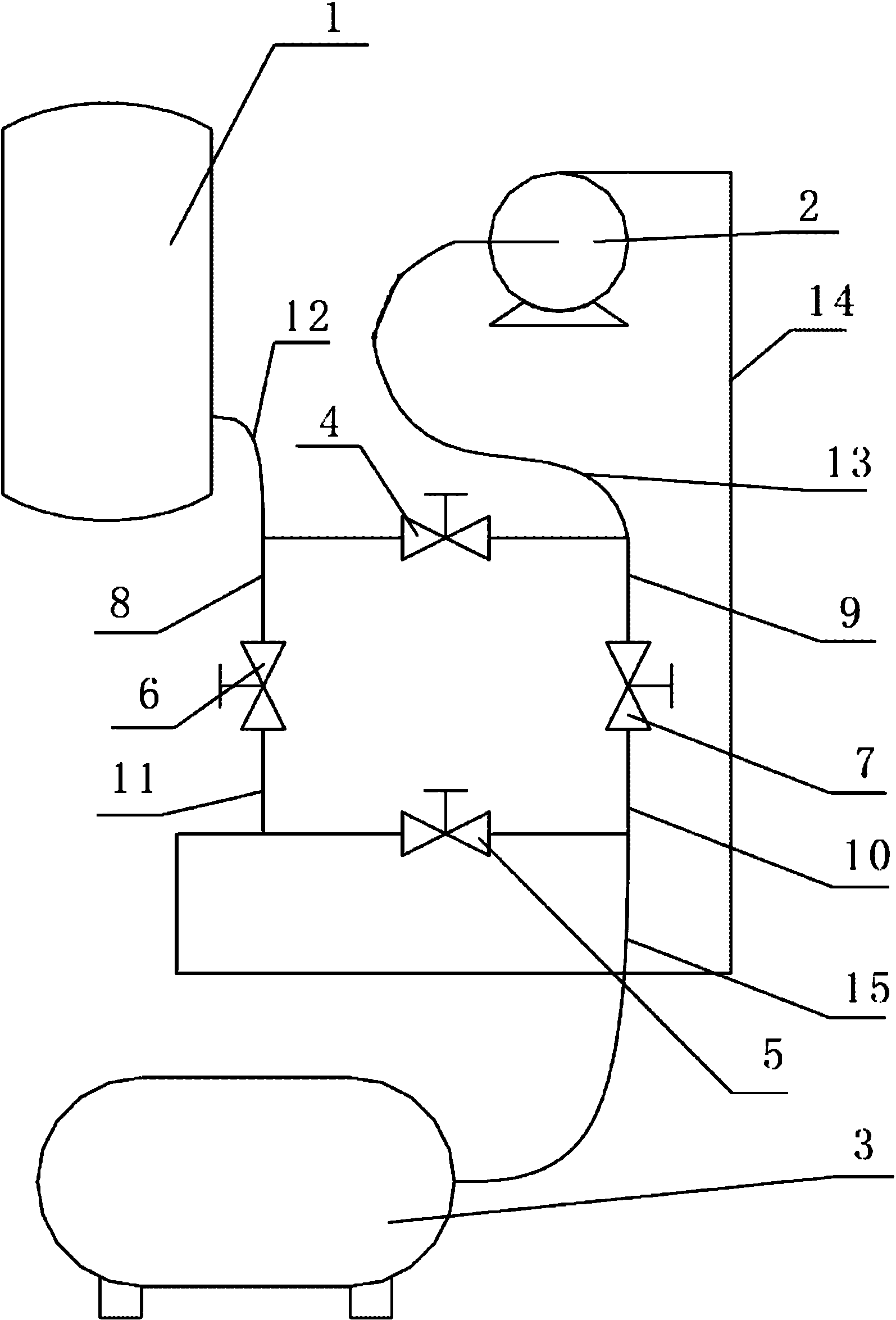

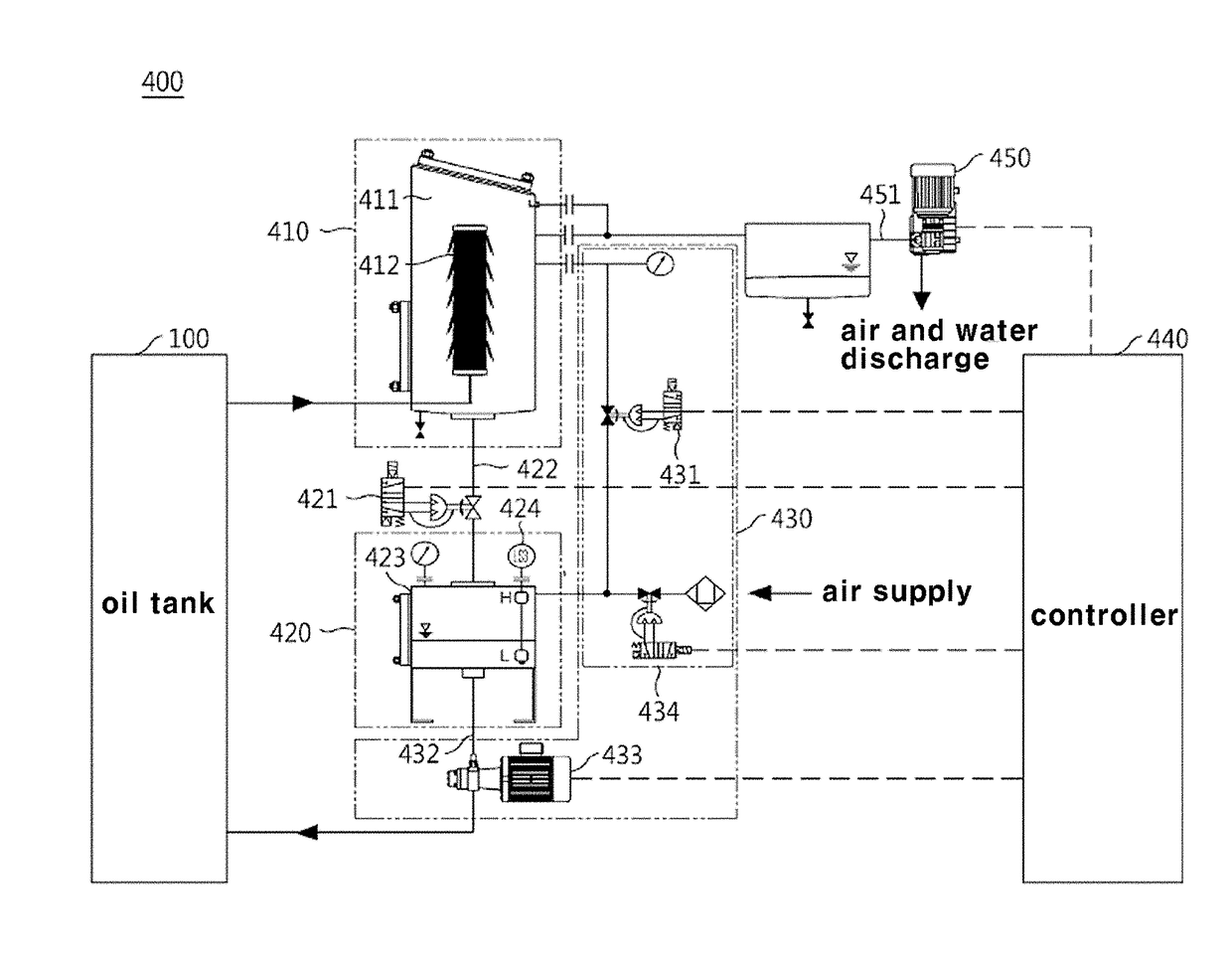

Filtering method for transformer oil

InactiveCN102426903AAvoid frequent openingSave energyTransformers/inductances coolingFiltration separationWork periodTransformer oil

Owner:CHINA FIRST METALLURGICAL GROUP

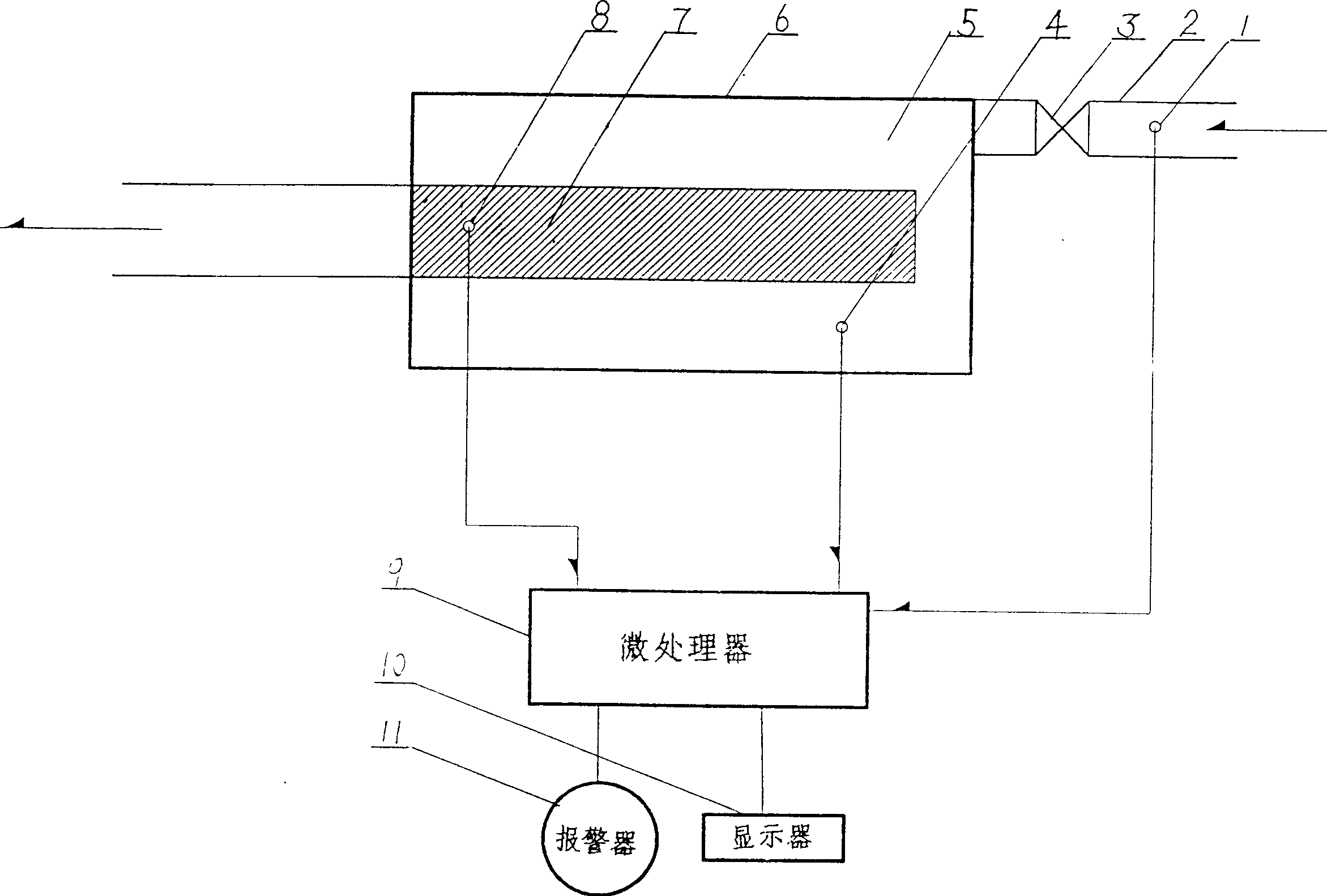

Apparatus for monitoring blockage status of mechanical filter

InactiveCN1736540ABlockage MonitoringAccurate judgmentFiltration separationDisplay deviceEngineering

Owner:王惠生

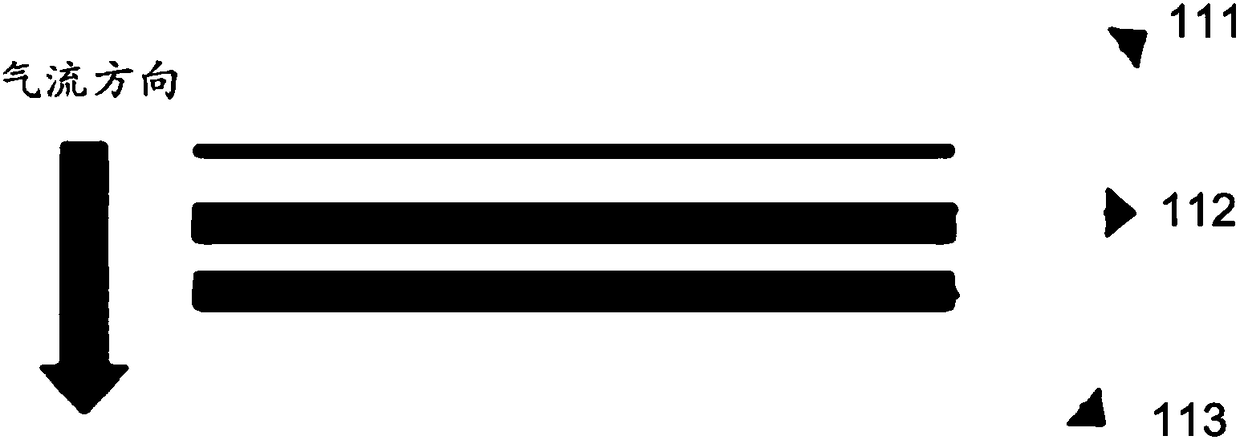

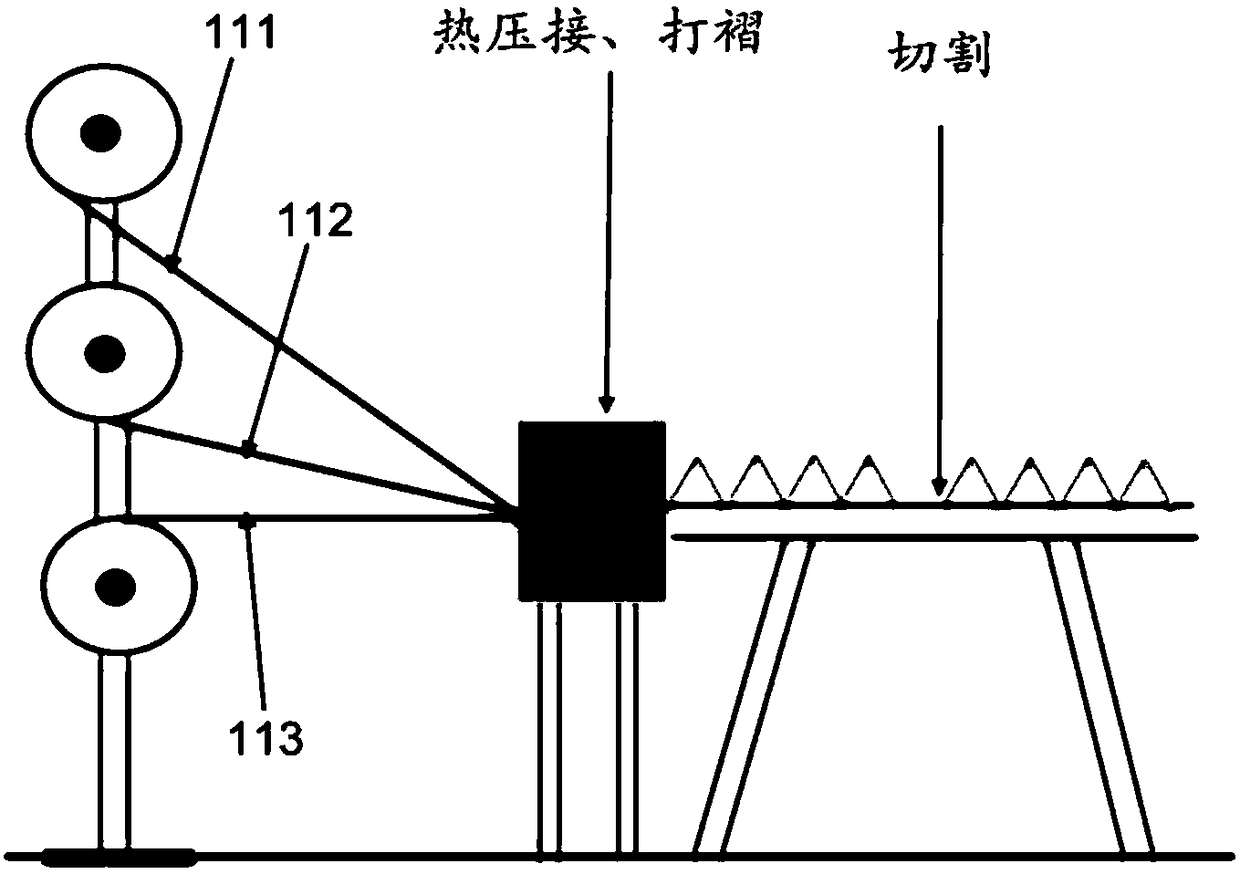

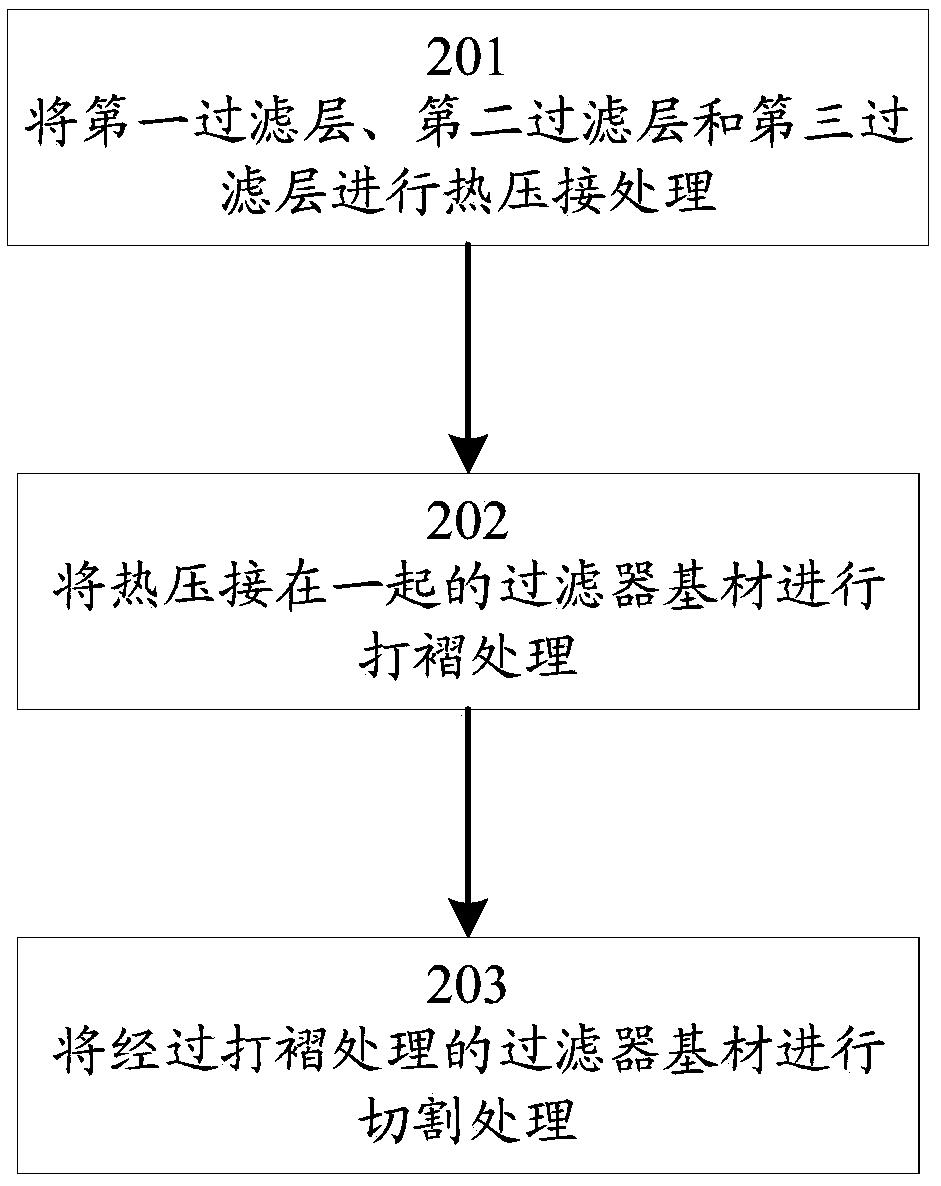

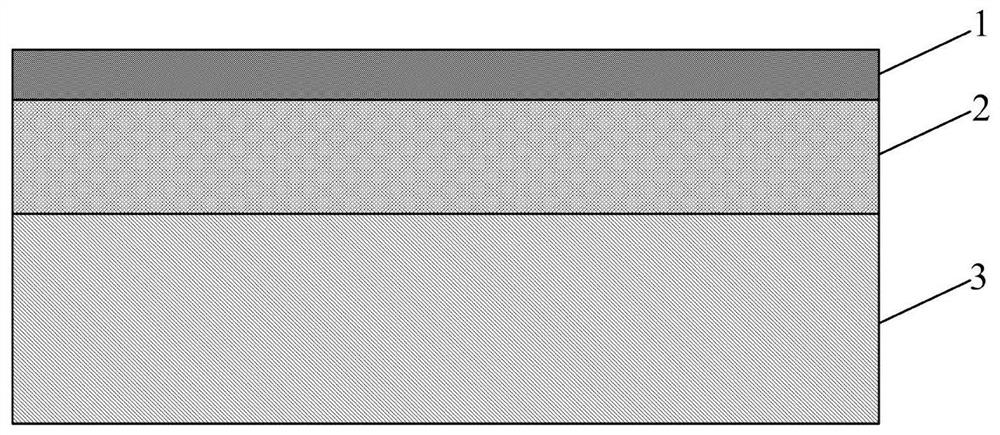

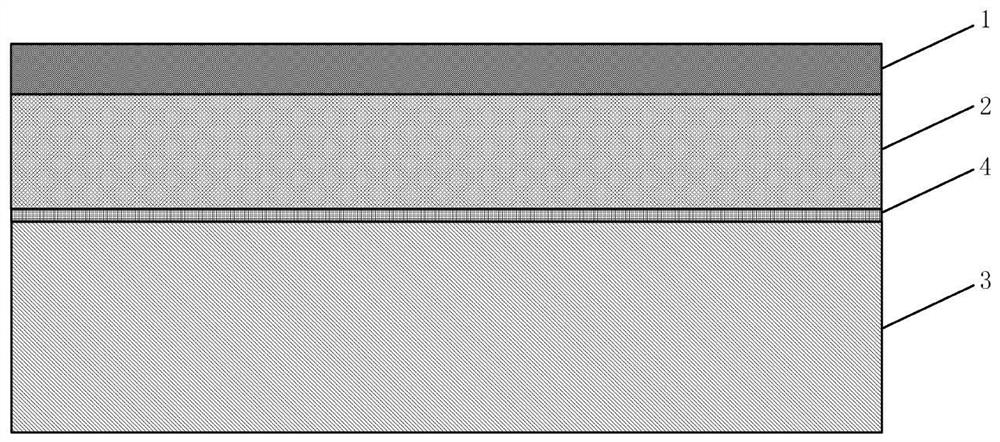

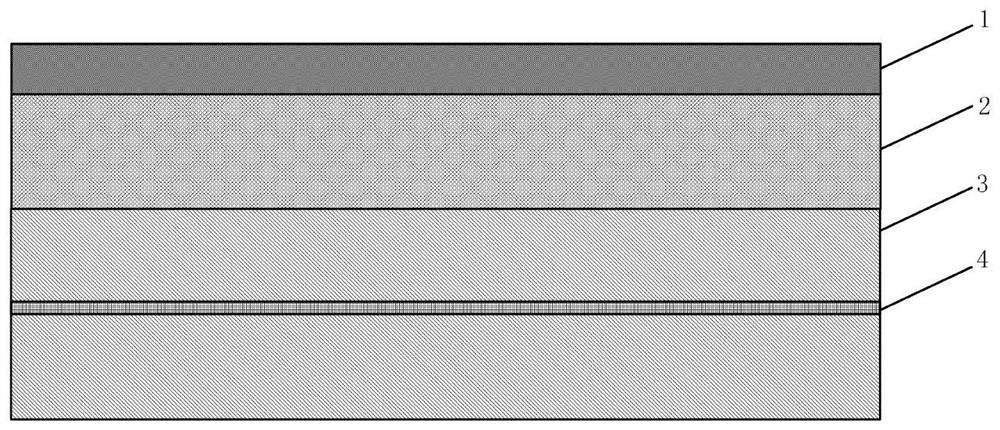

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

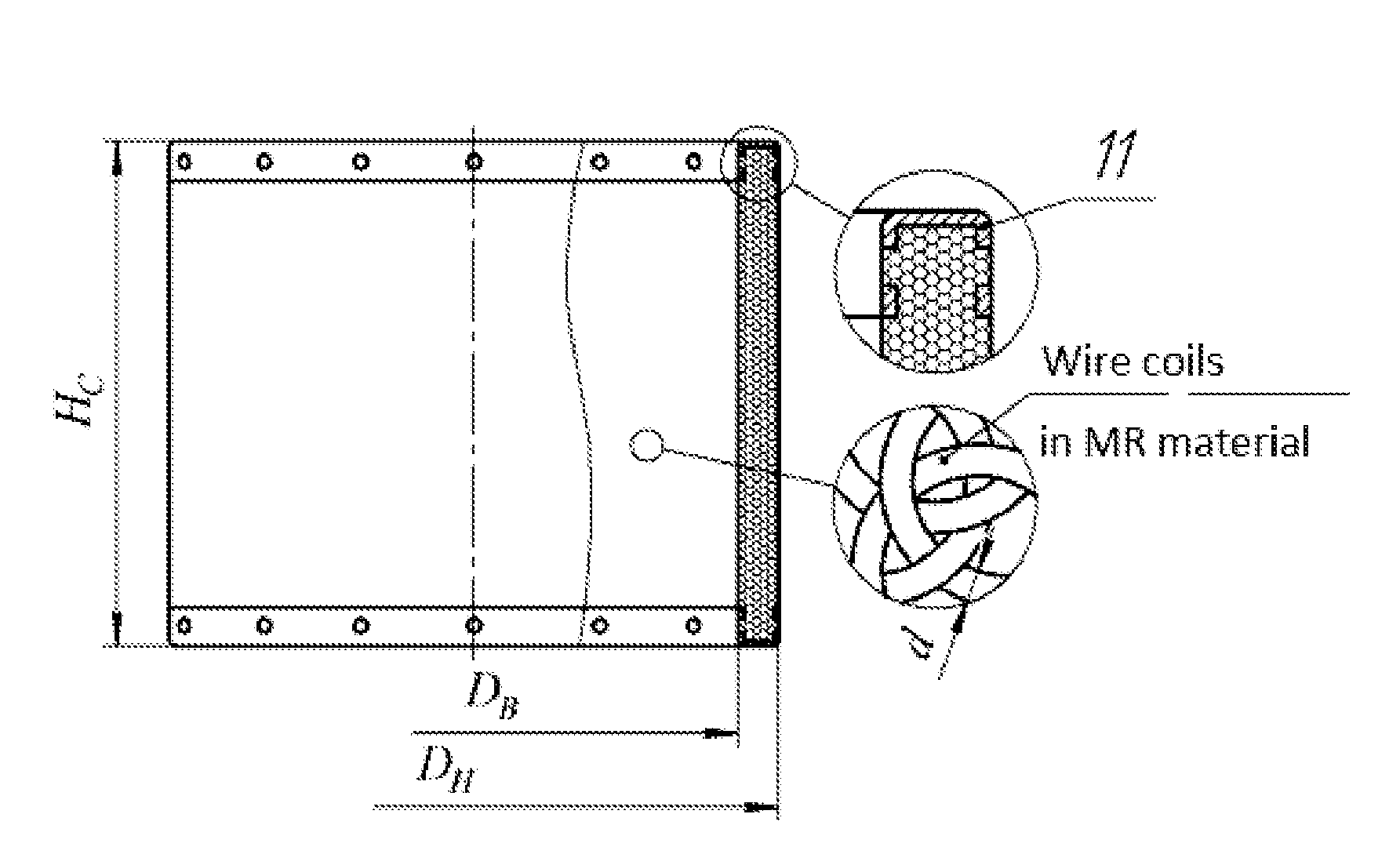

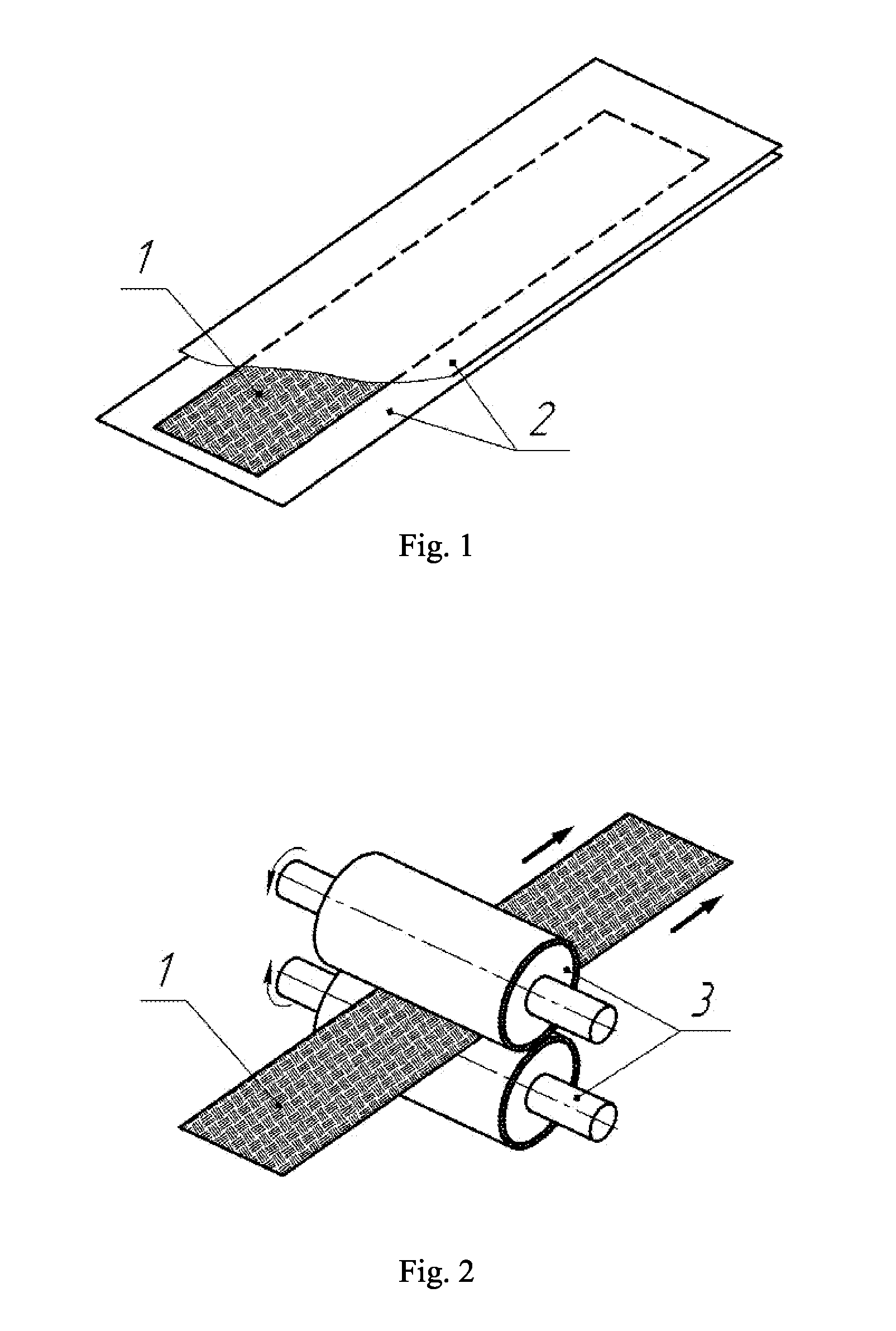

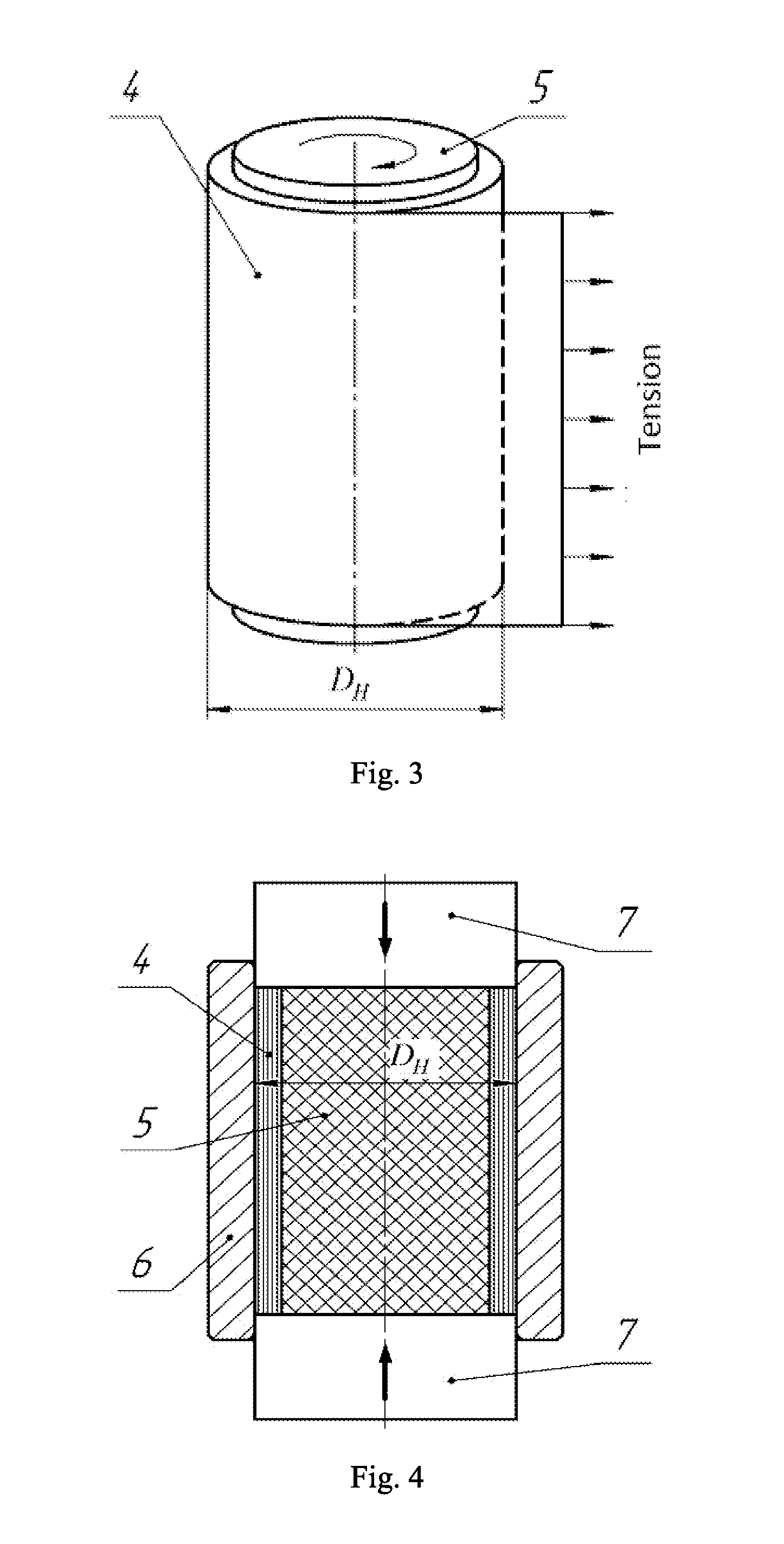

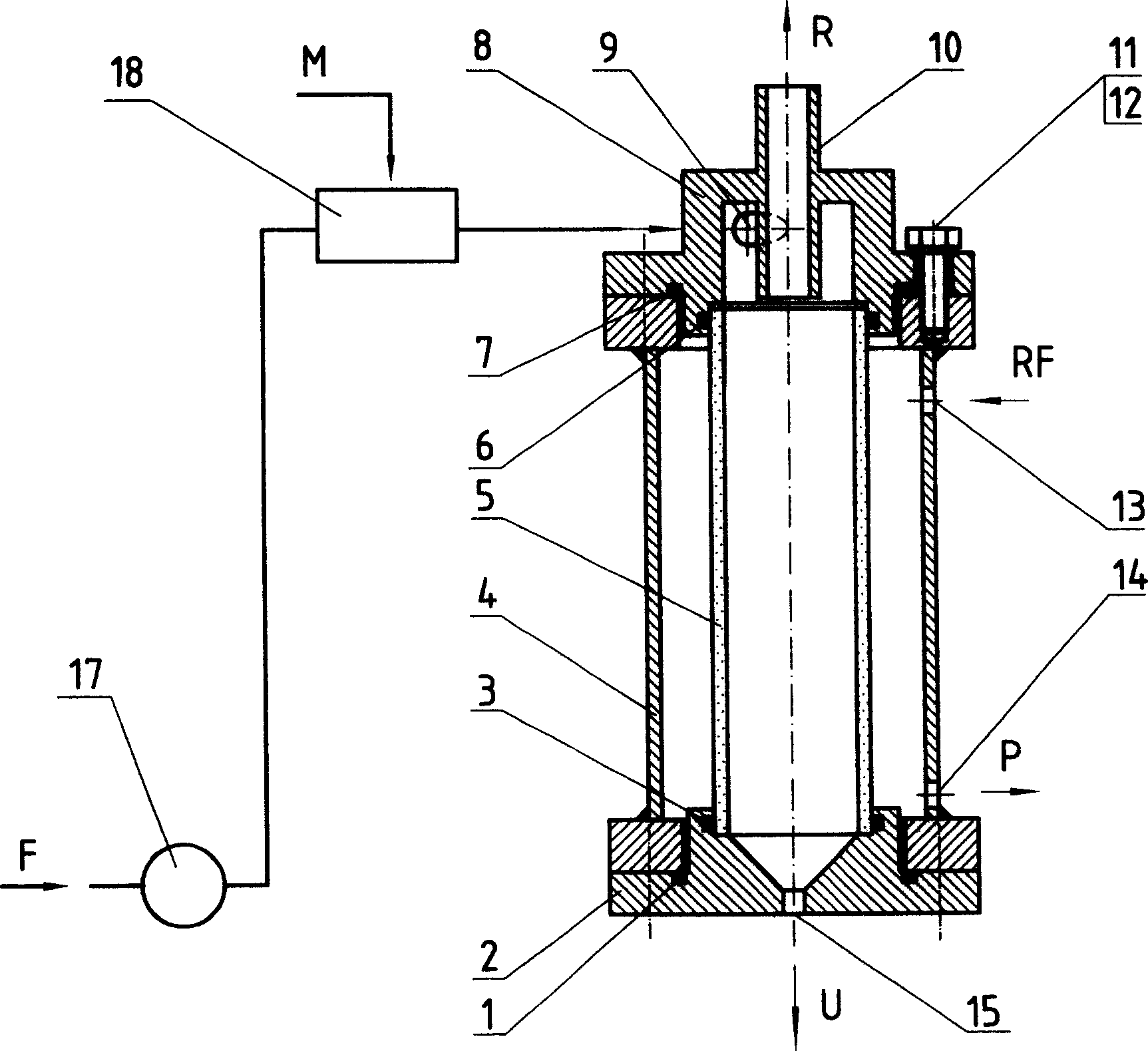

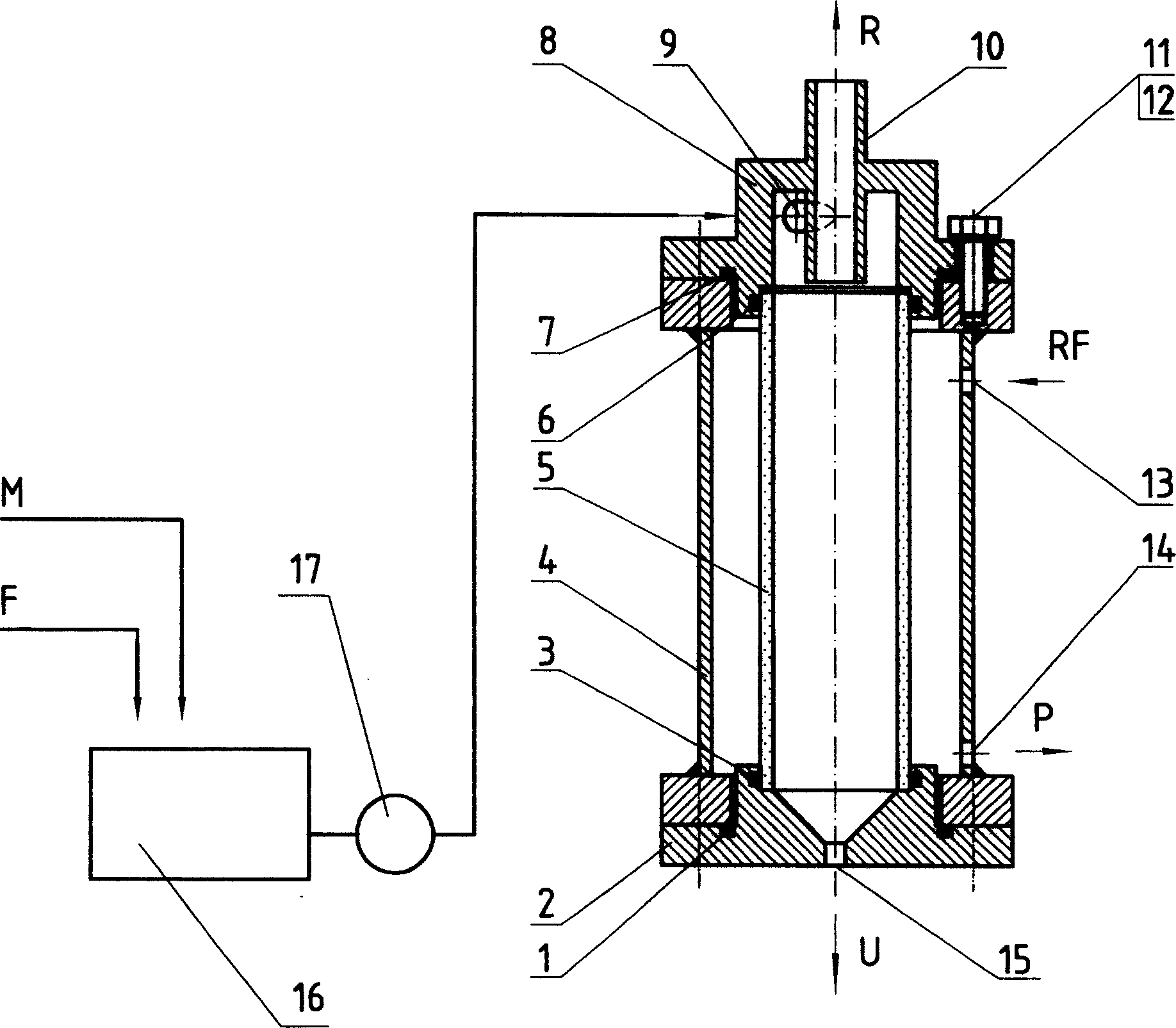

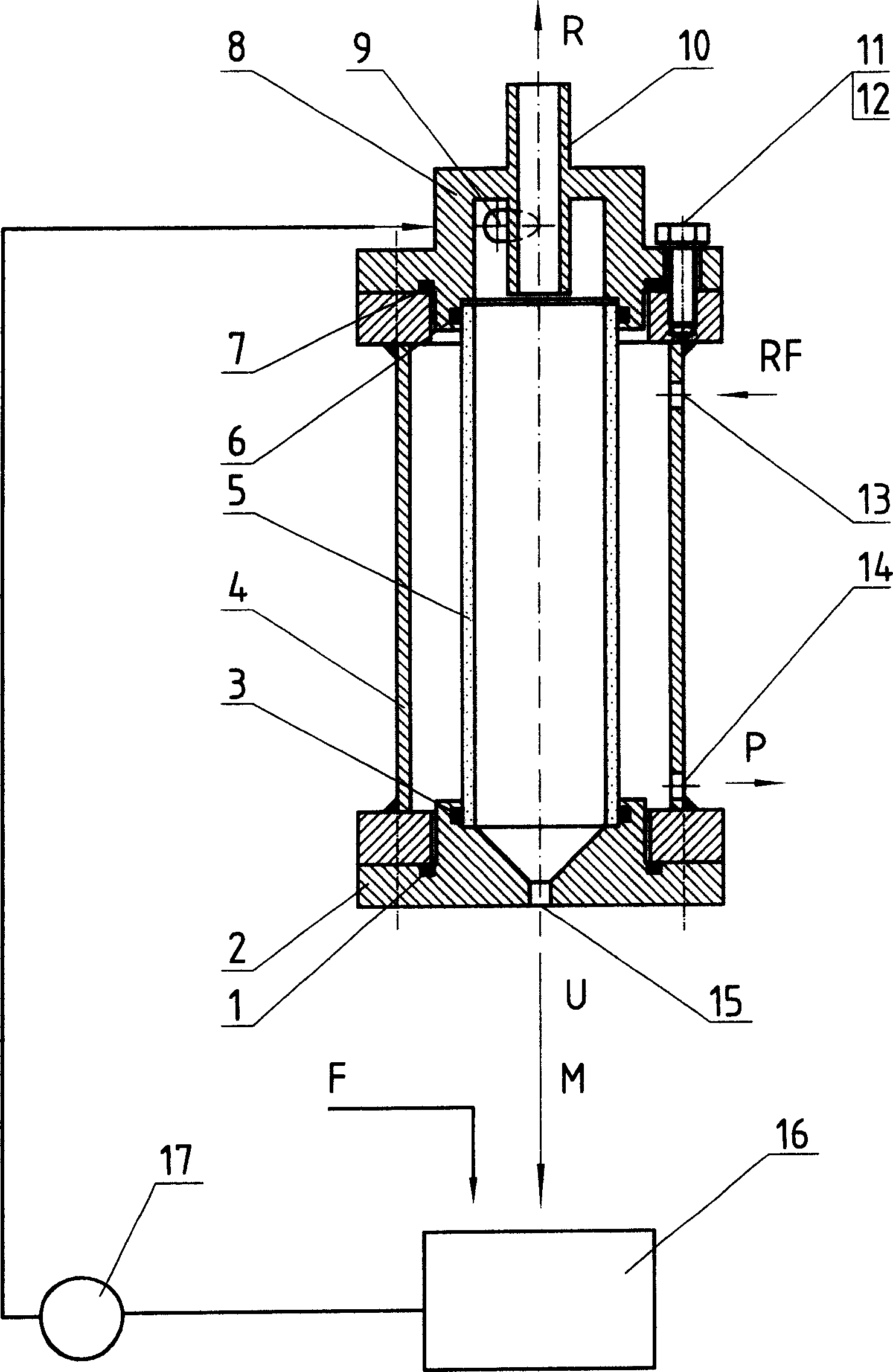

Process for the manufacture of thin-walled elastoporous parts in the form of bushings in metal-rubber (MR)

InactiveUS20150343677A1Improve reliabilityWire networkFiltration separationRubber materialPolymer science

Owner:SAMARA STATE AEROSPACE UNIVERSITY

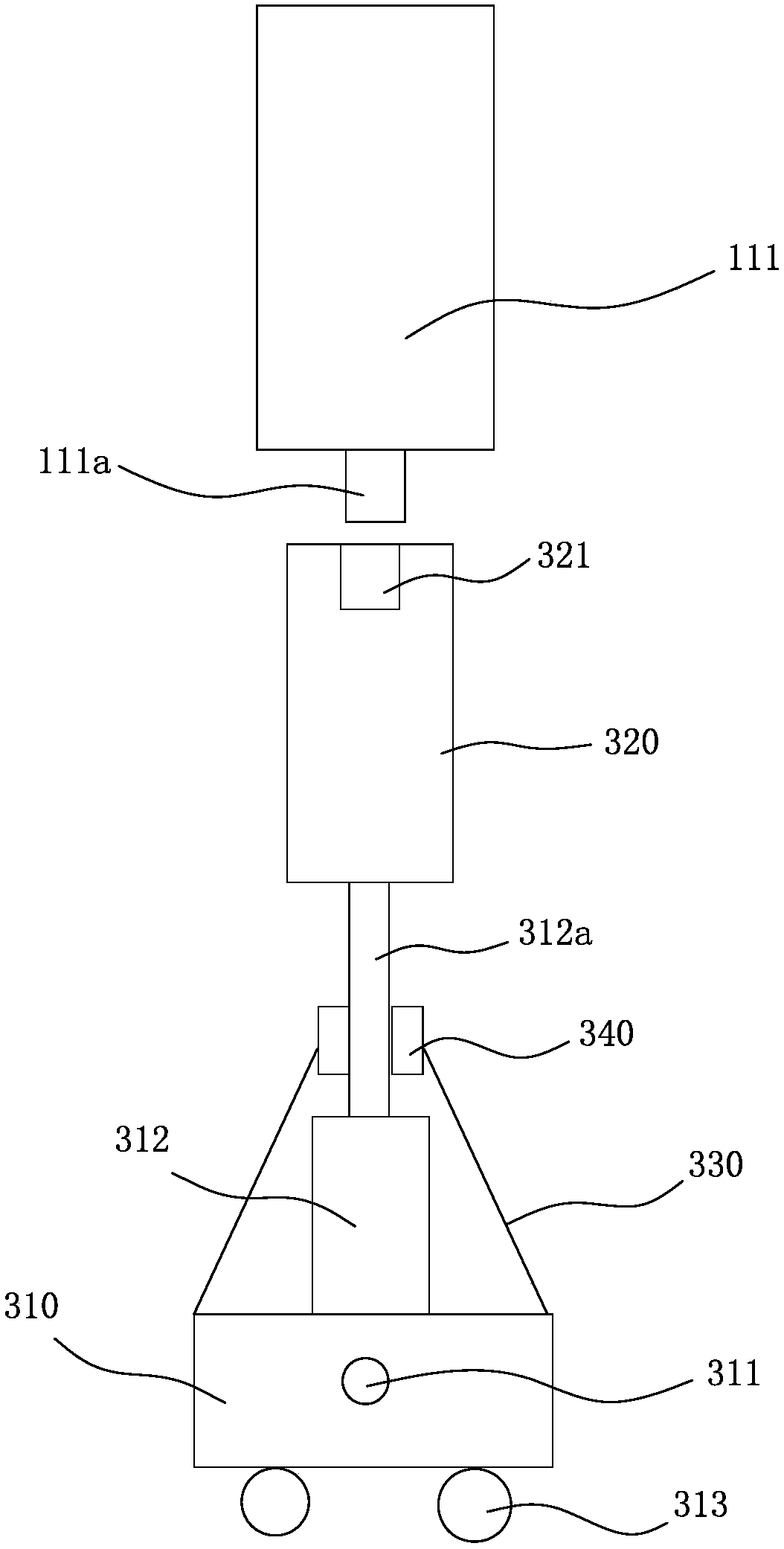

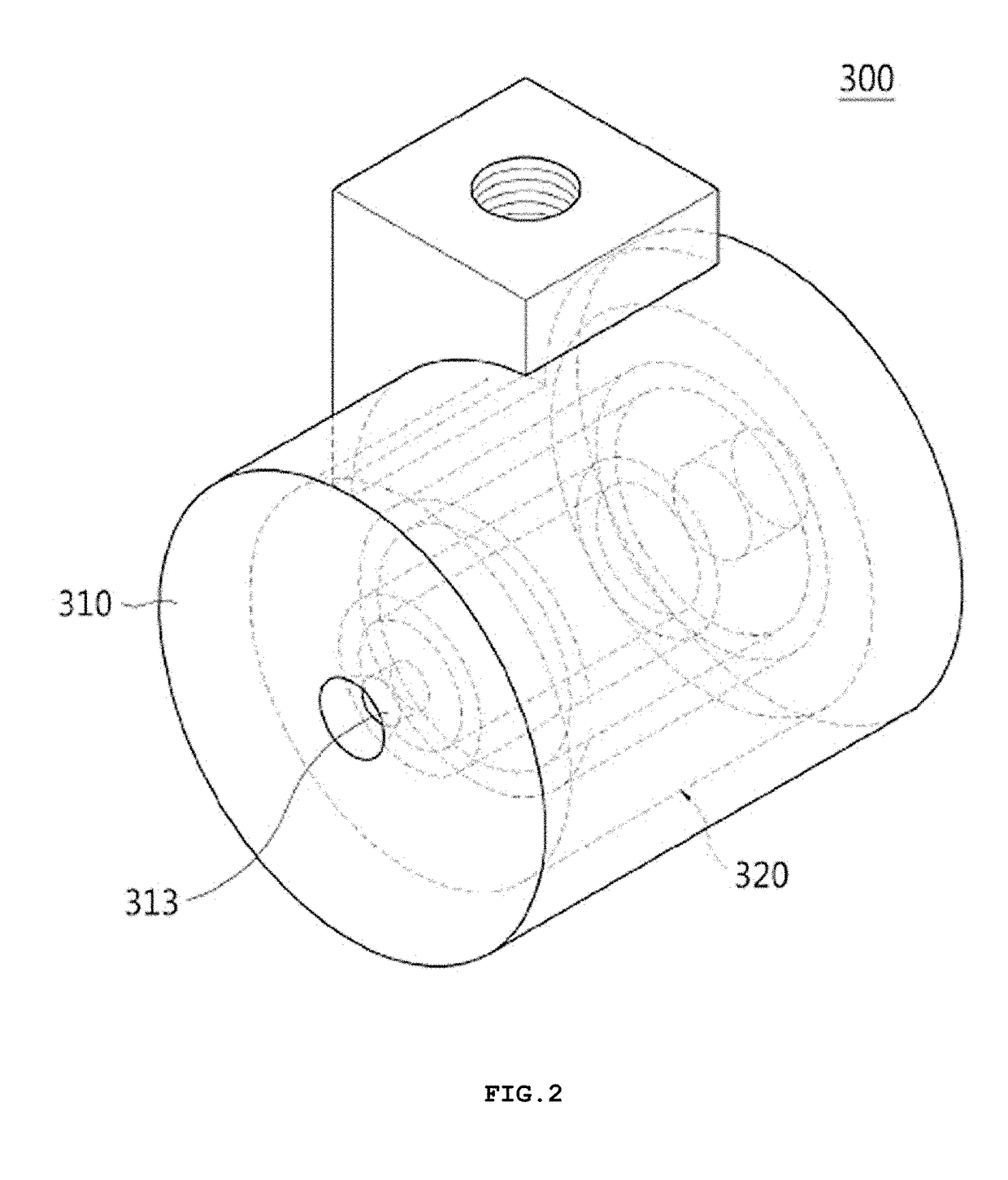

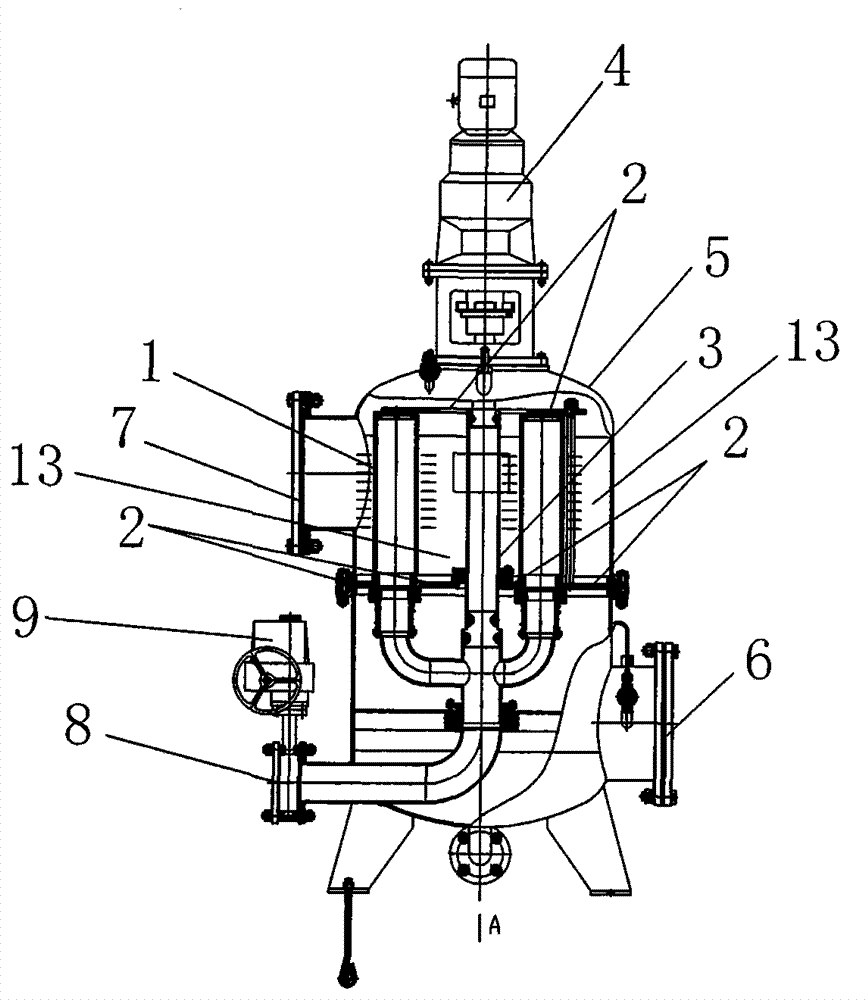

Self cleaning type internal rotation flow membrane separating device

InactiveCN1631548ASimple structural designEasy to replaceVortex flow apparatusFiltration separationEngineeringElectrical and Electronics engineering

Owner:SICHUAN UNIV

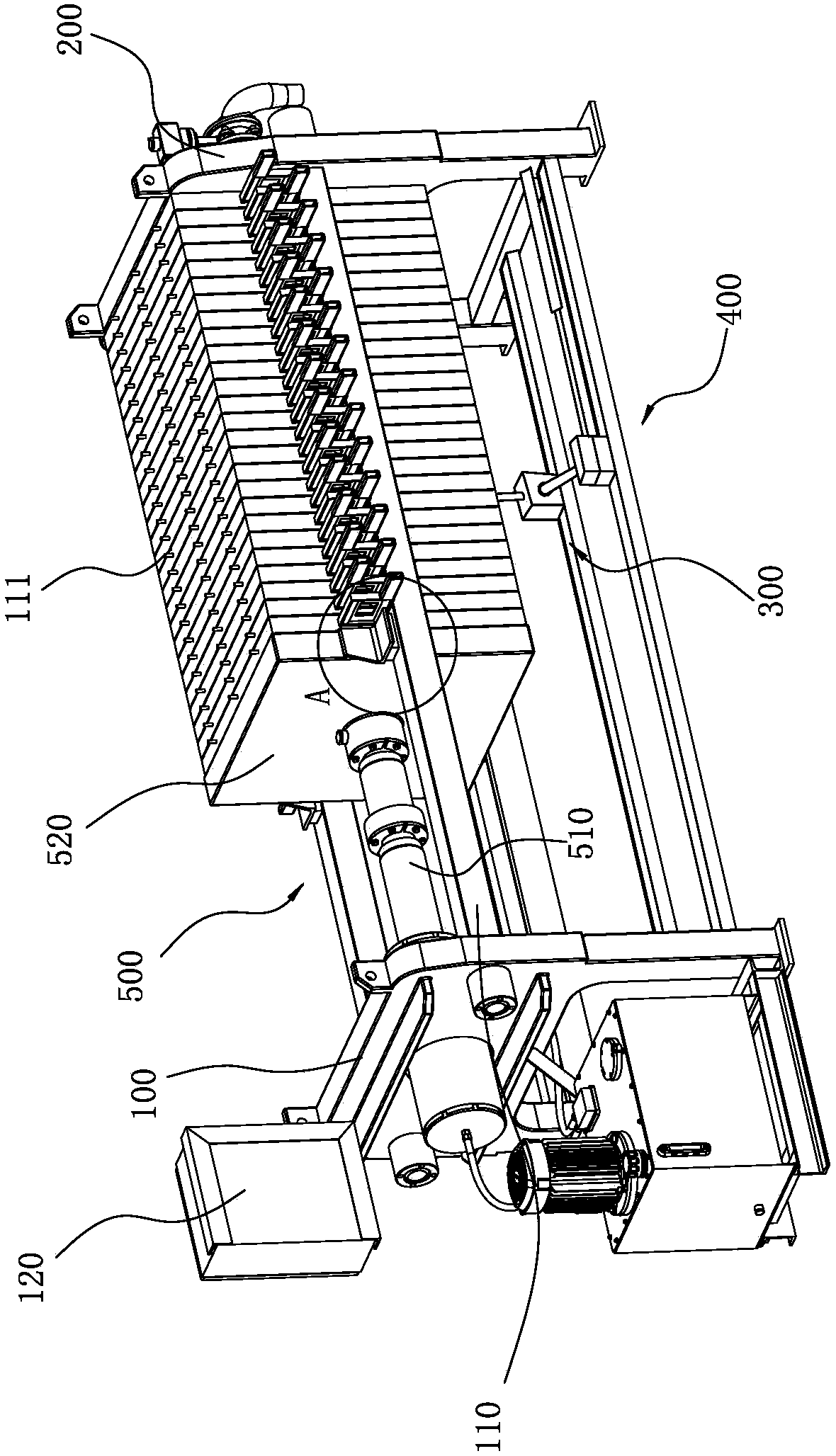

Multifunctional filter press

PendingCN108144335ASludge treatment by de-watering/drying/thickeningFiltration separationElectricitySewage treatment

Owner:浙江精鼎电力设备有限公司

Squeezing safety and automatic alarm device of diaphragm filter press

PendingCN111298490AImprove the safety requirements of automatic control operationEasy to useAlarmsElectric transmission signalling systemsText displayAutomatic control

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AEvenly distributedFacilitate cross-linkingSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberFiltration

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

Automobile air conditioner filter

InactiveCN108211554AWide range of specific surface areaSmall filter resistanceGas treatmentDispersed particle filtrationFiberCarbon fibers

Owner:VALEO AUTOMOTIVE AIR CONDITIONING HUBEI CO LTD

Lubricating oil filtering device

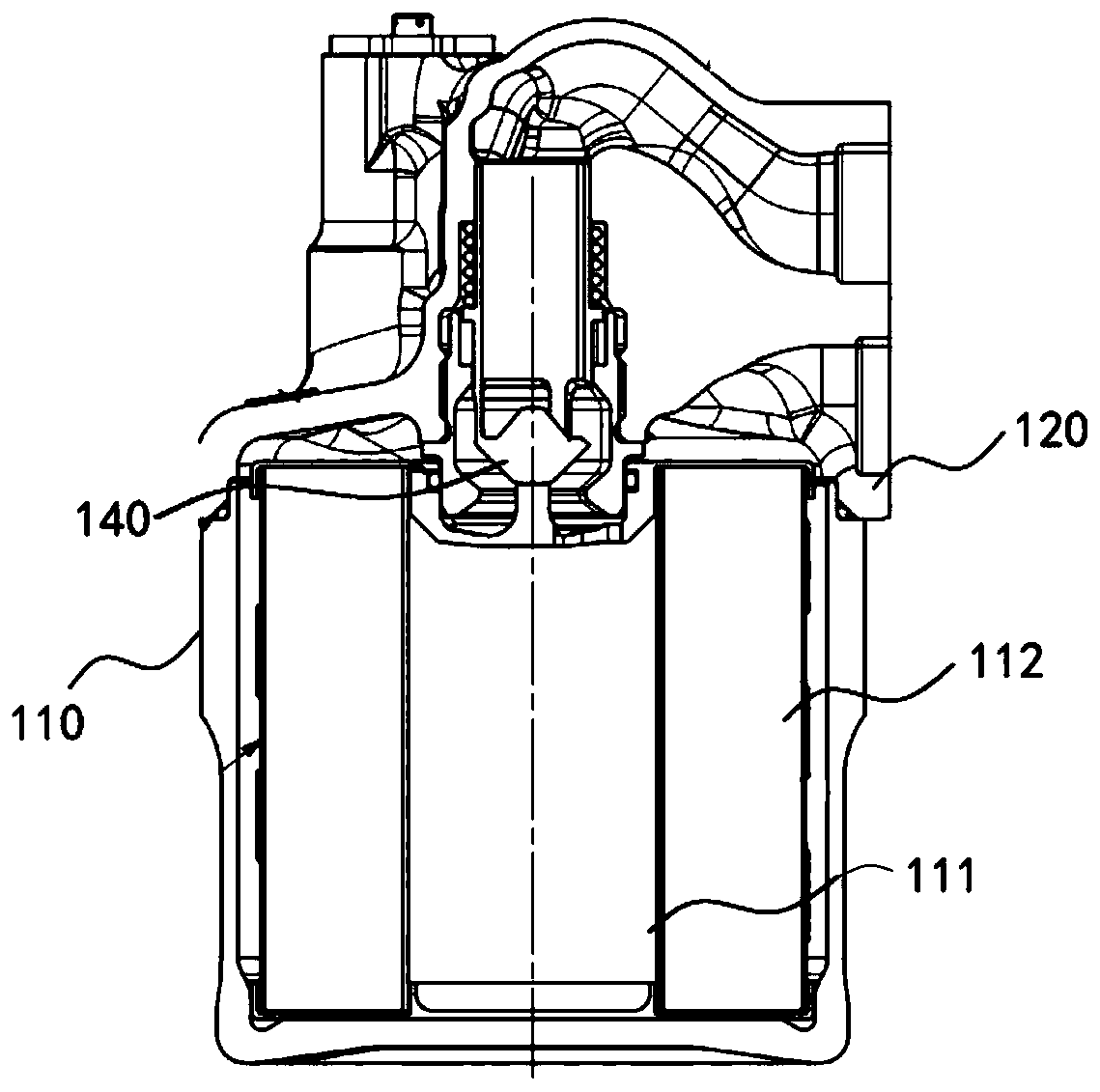

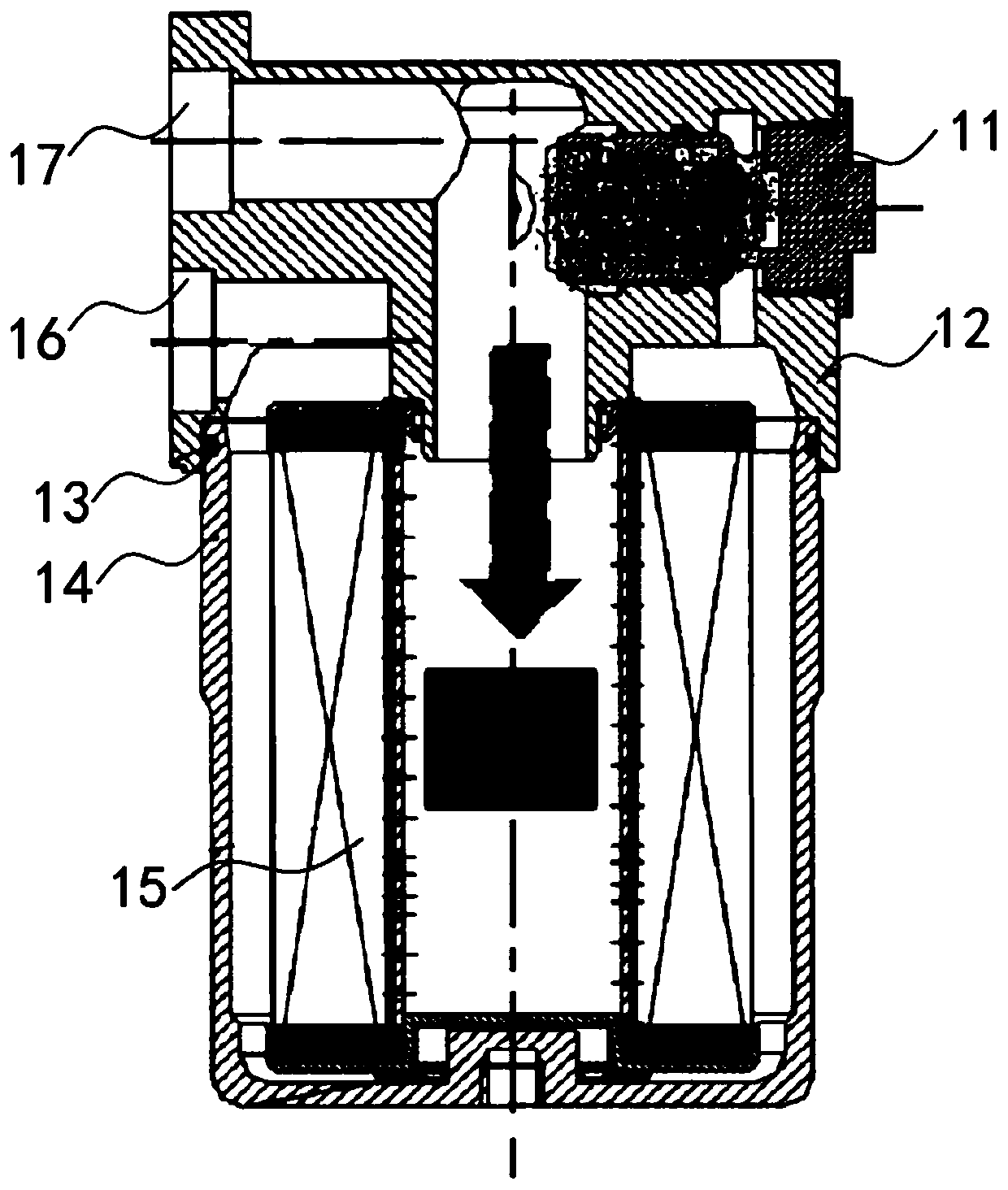

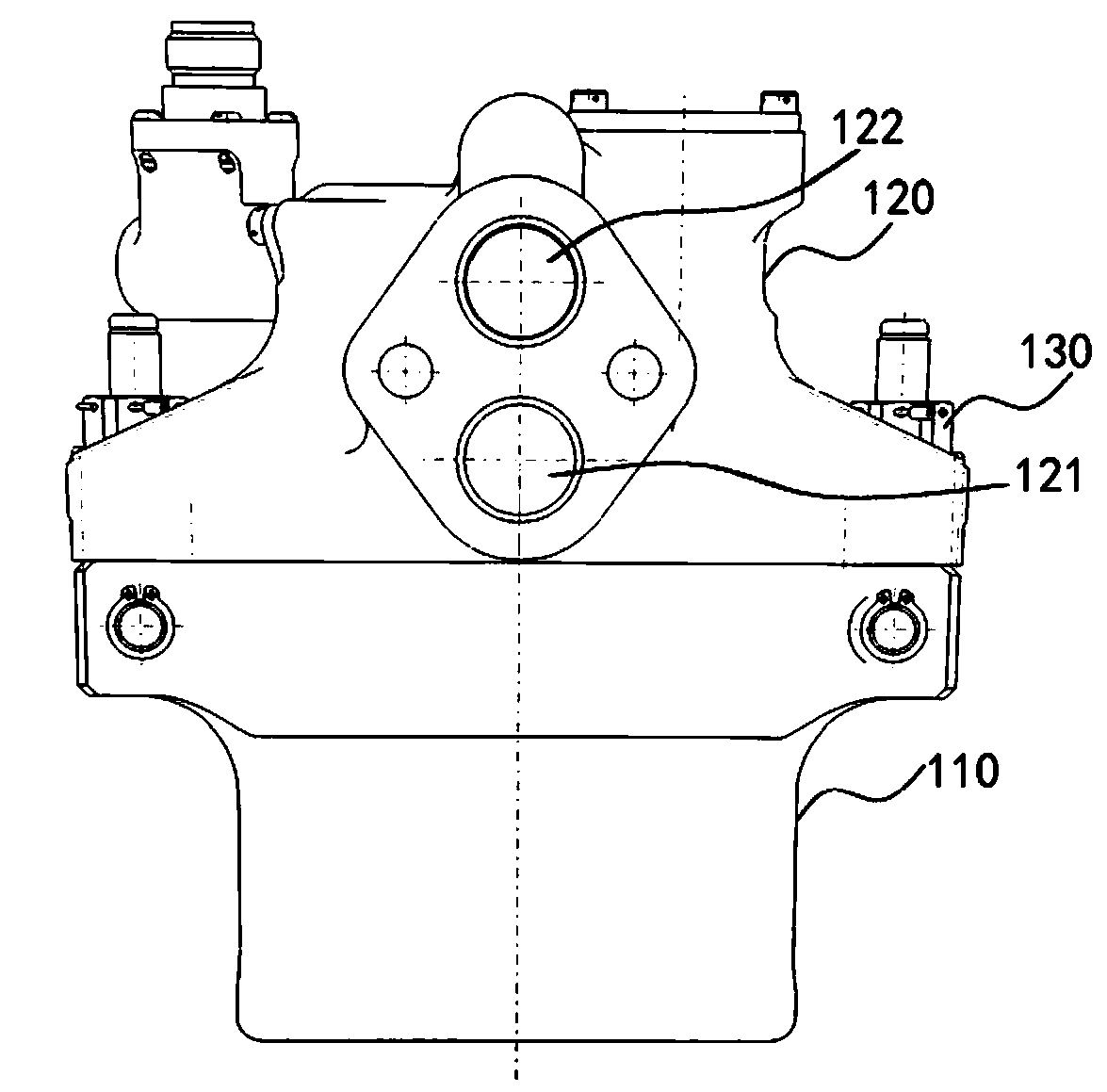

ActiveCN110242737AQuick installationQuick releaseGear lubrication/coolingFiltration separationInlet channelEngineering

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Belt edge

InactiveUS20170362748A1Low tensile strengthAvoid wear and tearSelvedgesMembrane filtersEngineeringWeft yarn

Owner:CLEAR EDGE GERMANY

Water purifying filter material with strong absorption capacity

Owner:SUZHOU TENGNA GREEN TECH

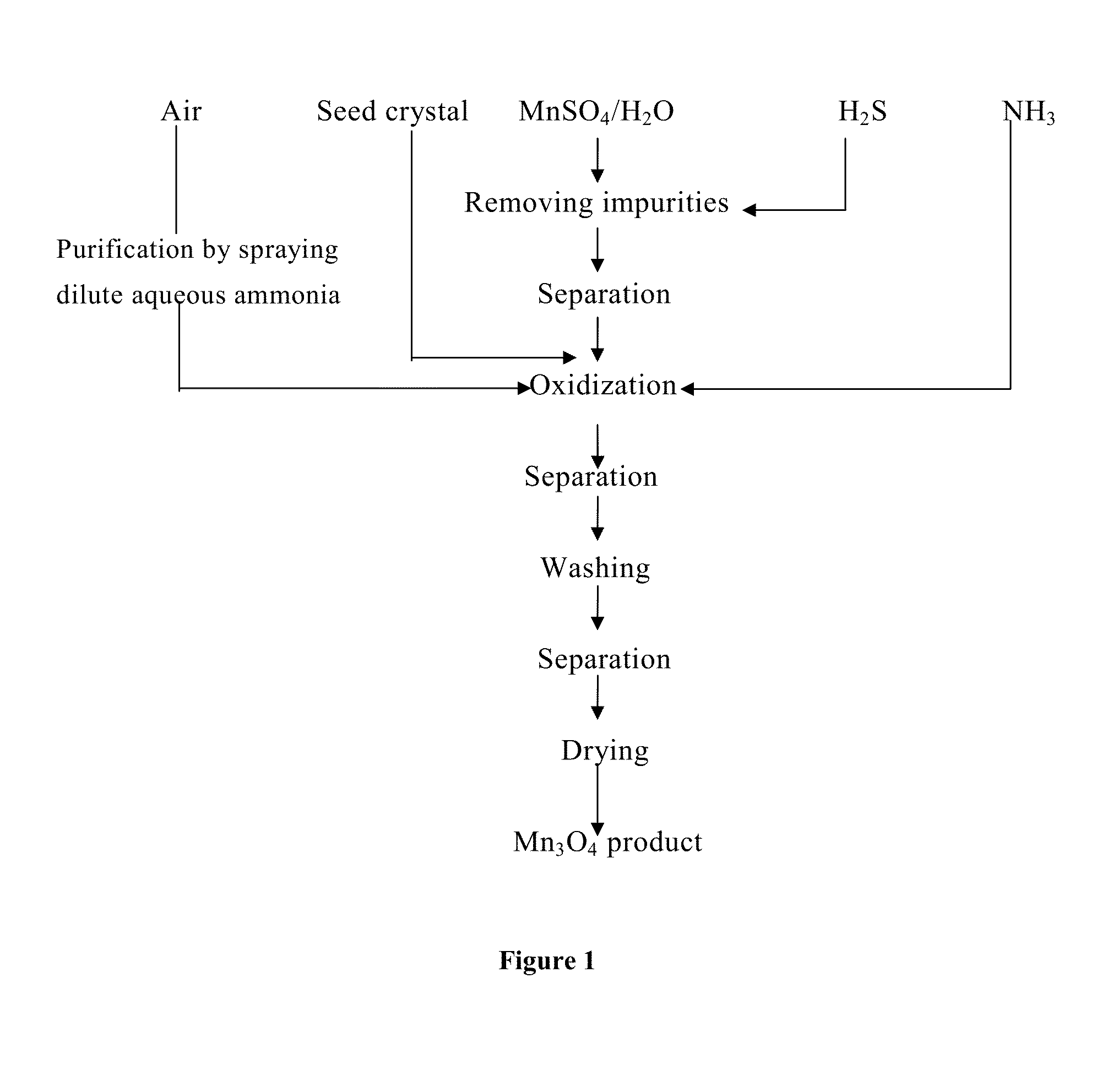

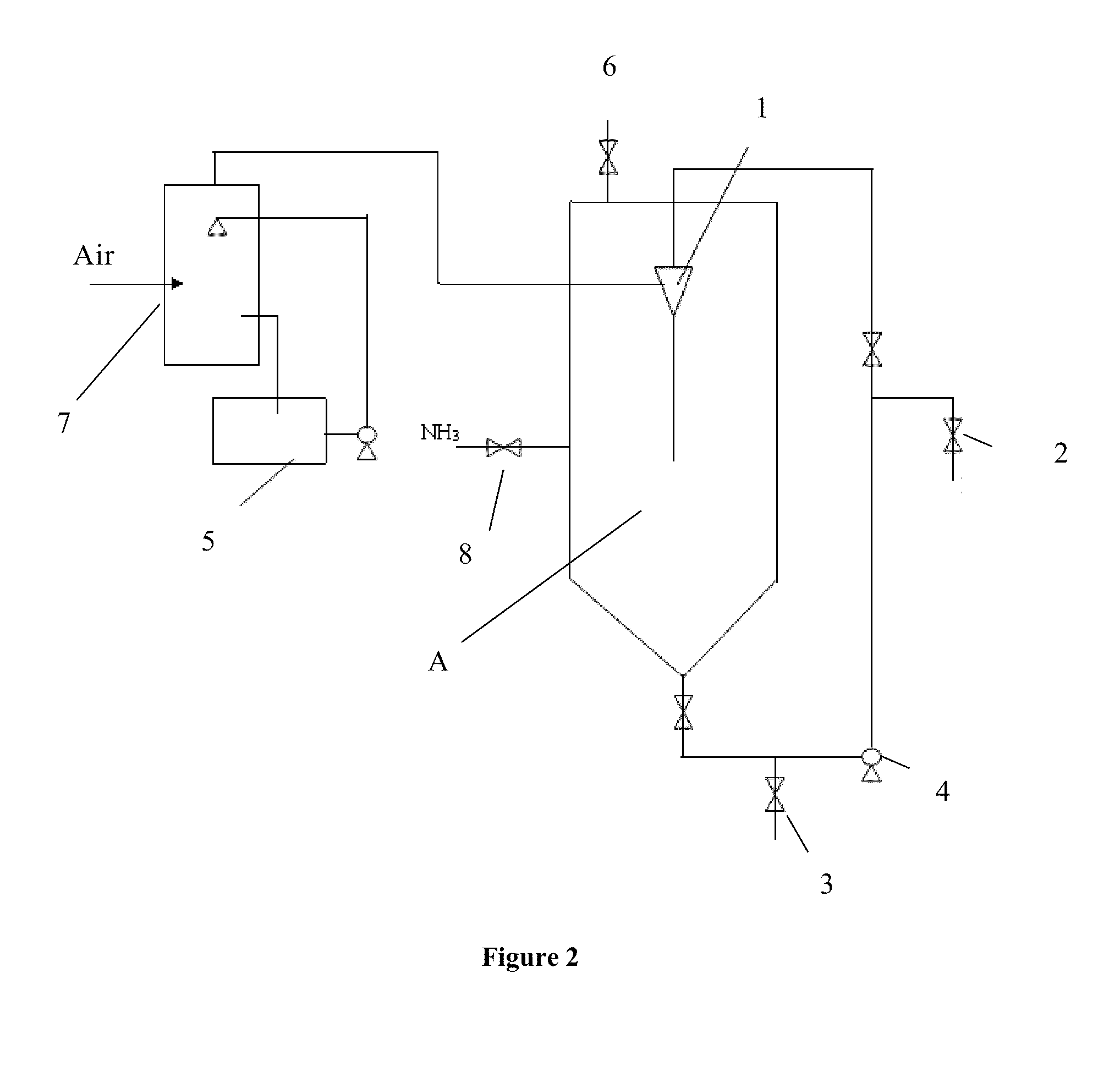

Methods for preparing trimanganese tetroxide with low bet specific surface area, methods for controlling particle size of trimanganese tetroxide and trimanganese tetroxide product

InactiveUS20130344333A1Improve battery cycle performanceReduce the presence of impuritiesFrom normal temperature solutionsManganese oxides/hydroxidesManganese(II,III) oxideChemistry

Owner:GUIZHOU REDSTAR DEVING

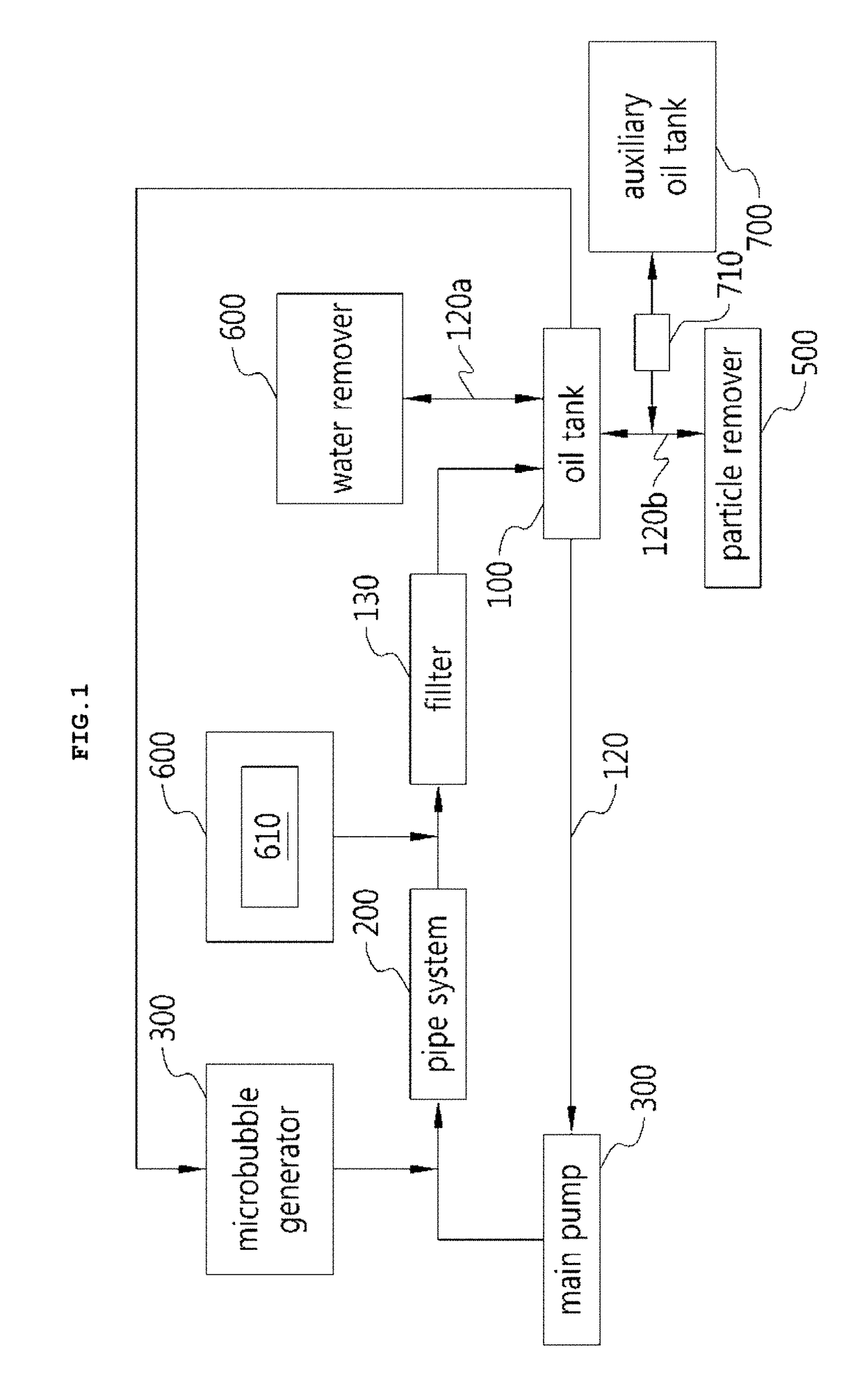

System for flushing pipe plumbing using microbubbles, method therefor, and ship or maritime plant having same

InactiveUS20180078978A1Good removal effectIncrease the Reynolds numberVessel cleaningLiquid separation auxillary apparatusElectricityMicrobubbles

Owner:SAM YOUNG TECH +1

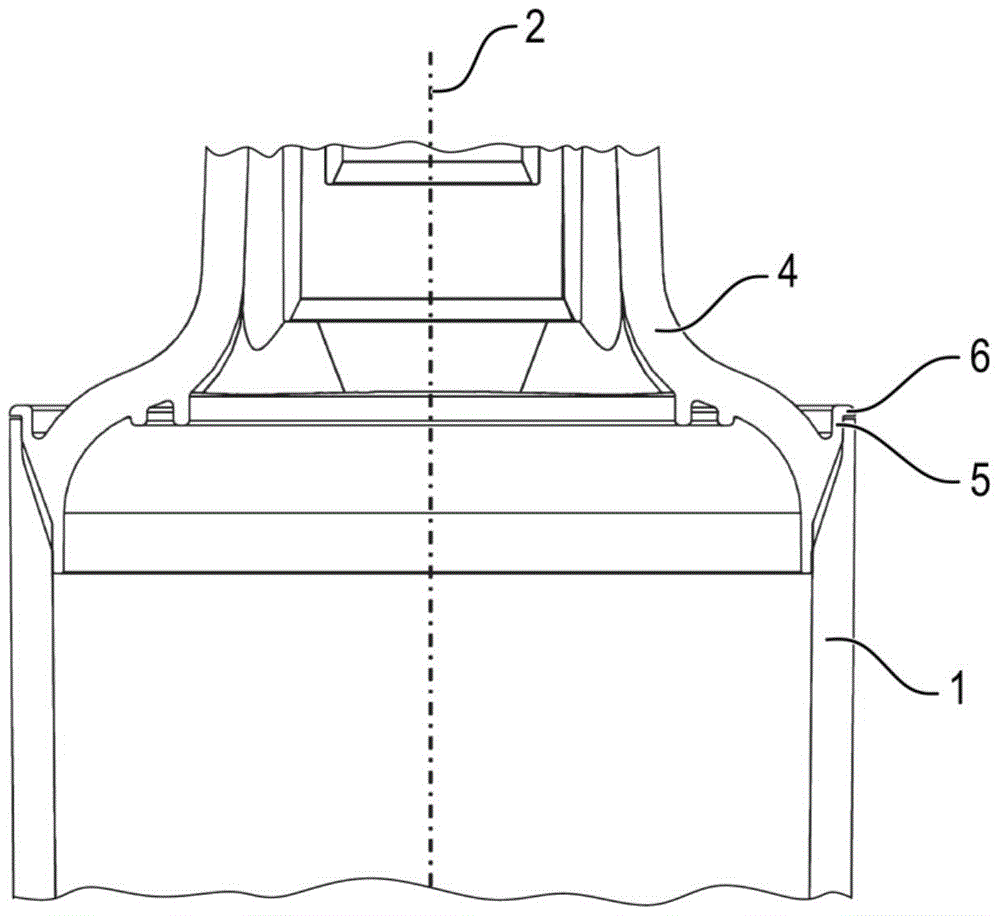

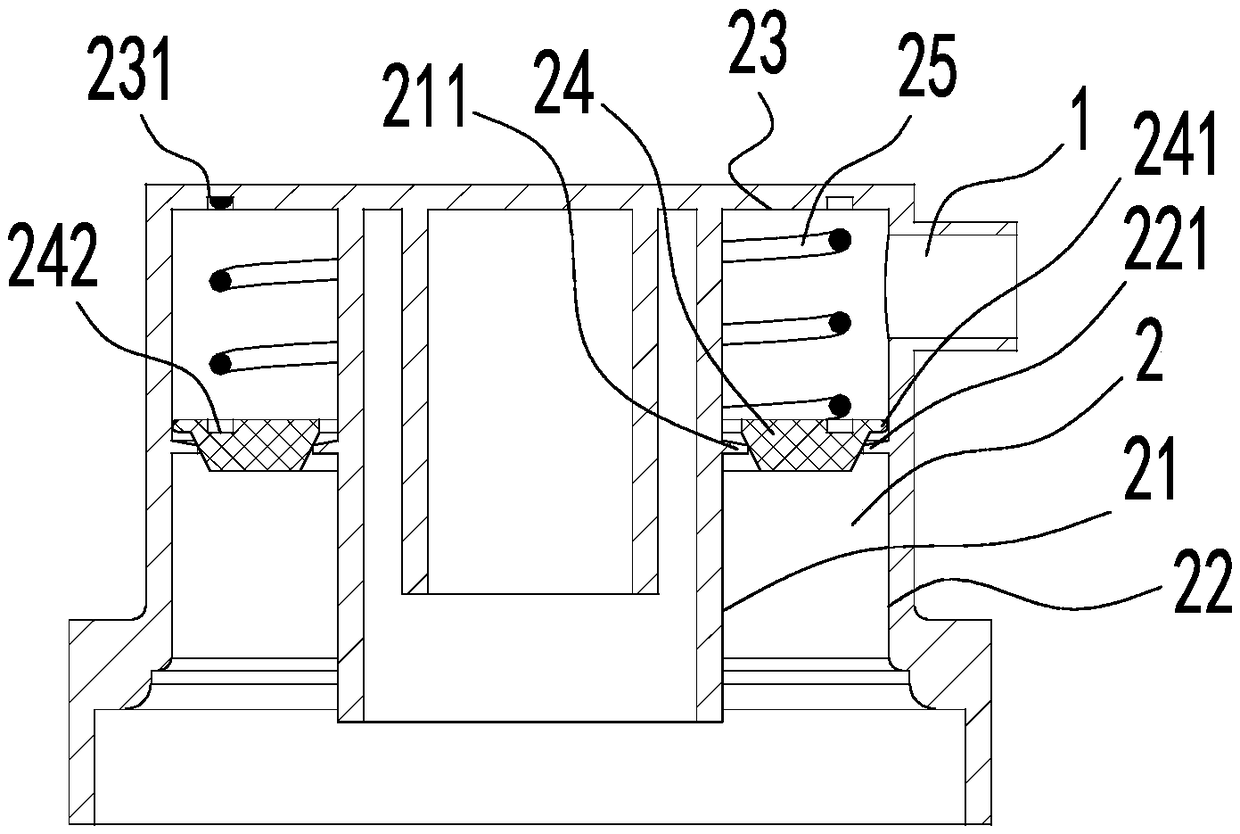

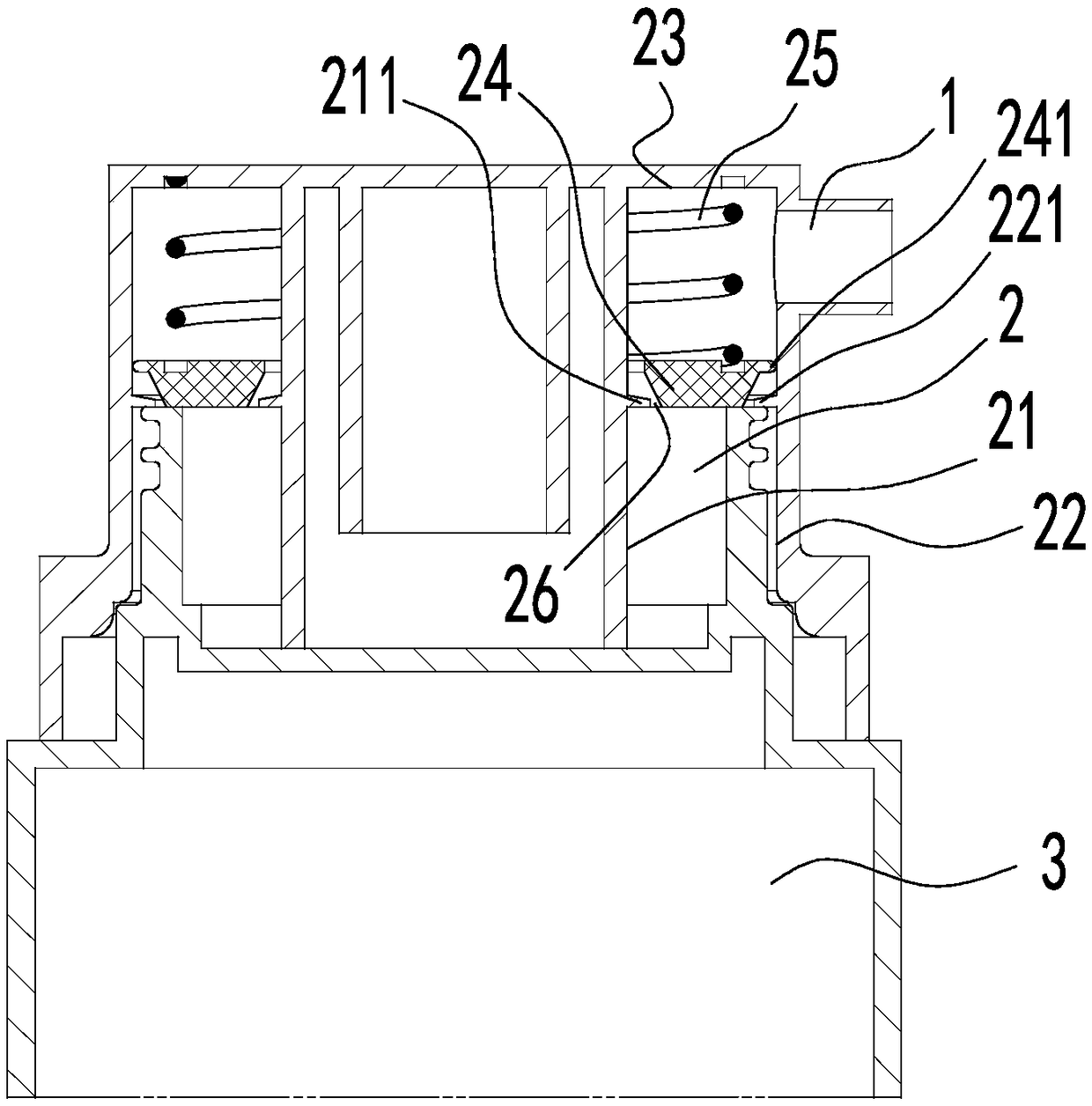

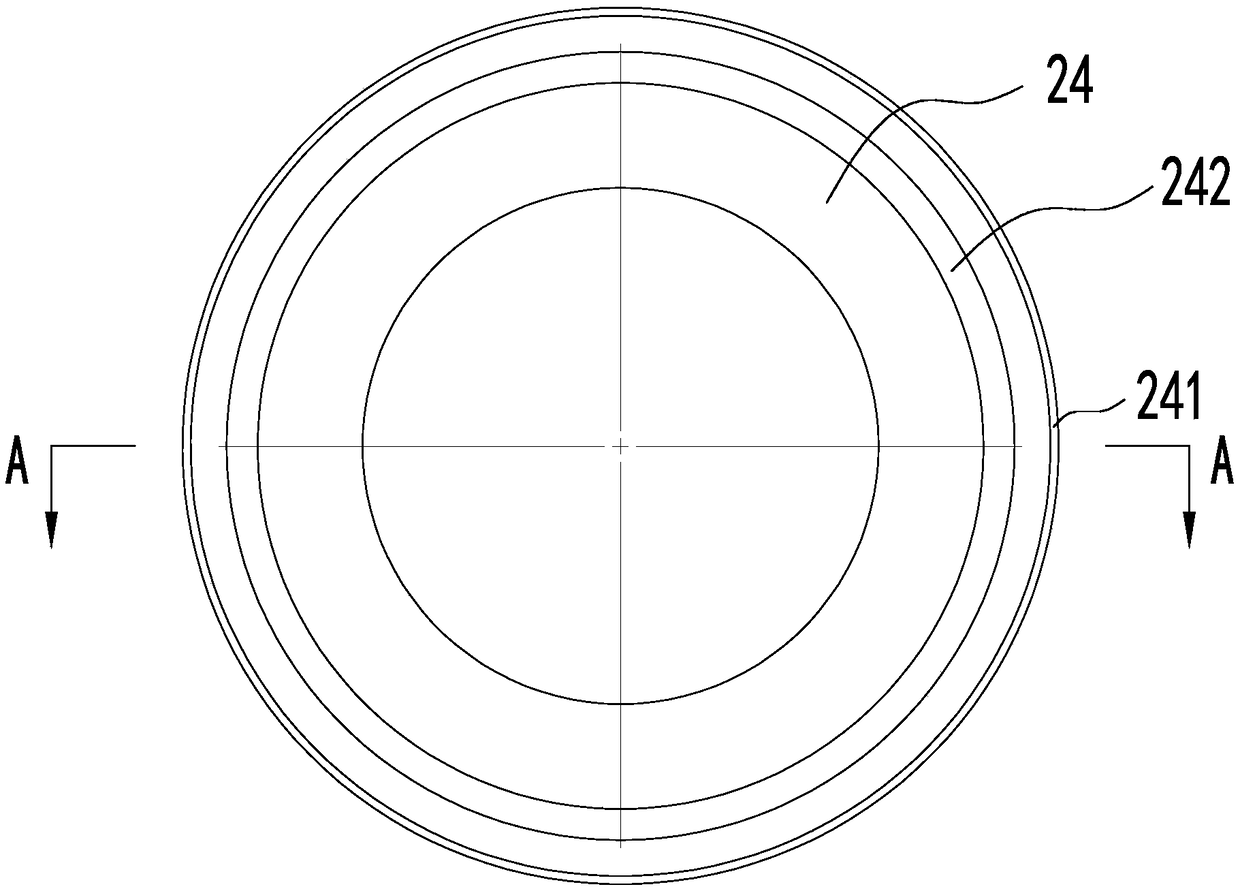

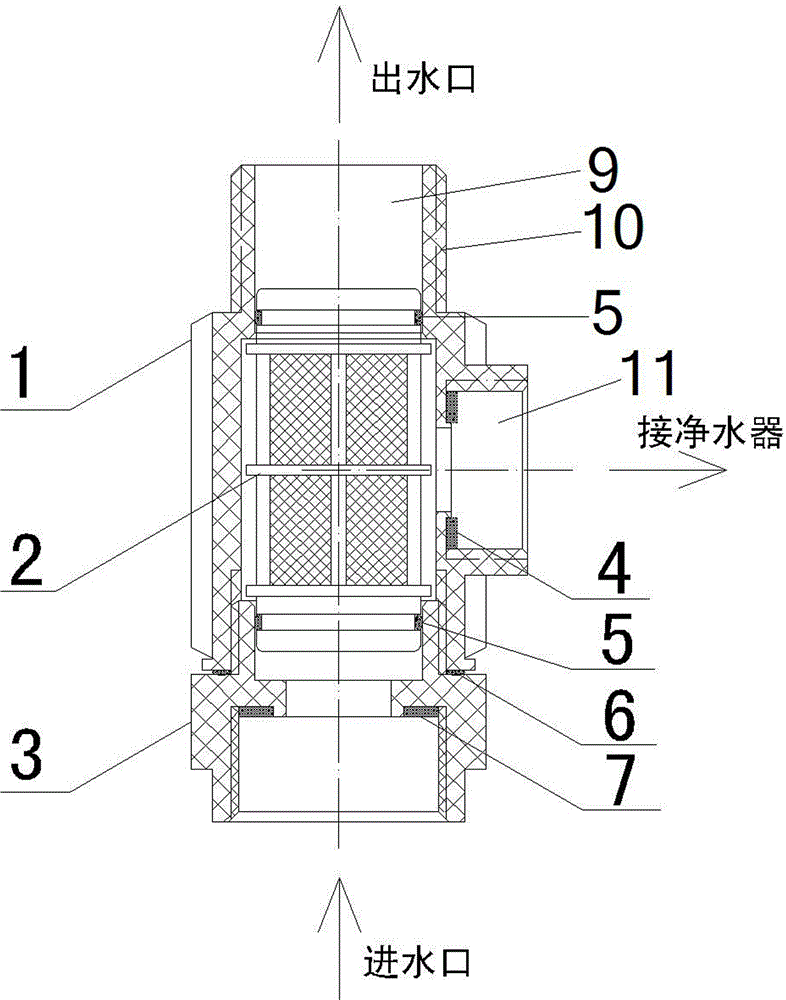

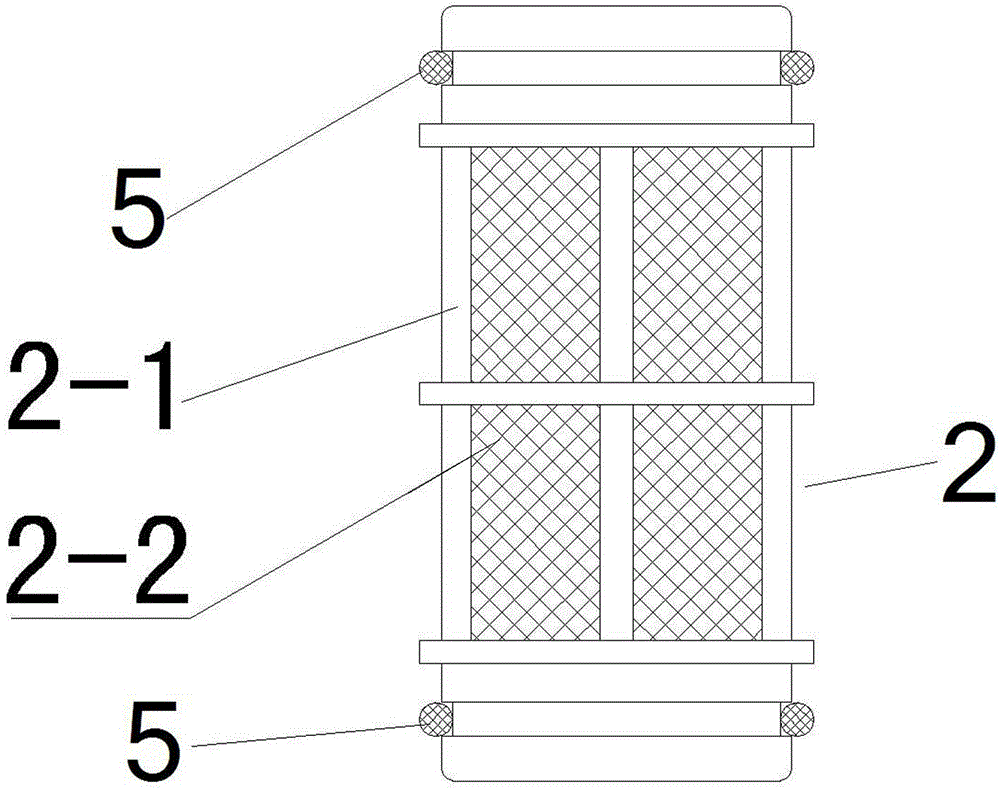

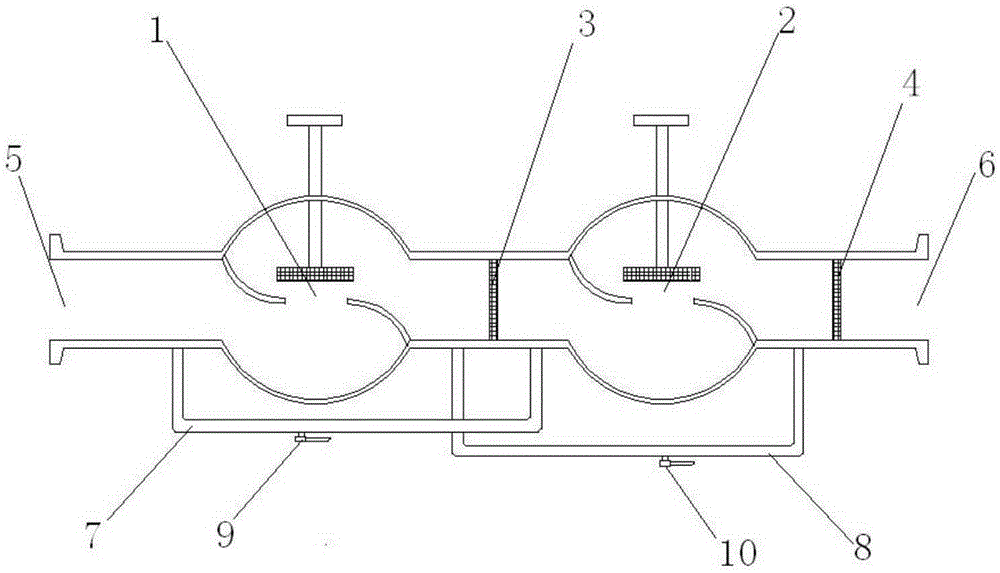

Automatic water-stopping filter element holder

PendingCN109107263ATo achieve the purpose of automatic water stopImprove replacement efficiencyFiltration separationInlet valveEngineering

Owner:广州共盈信息科技有限公司

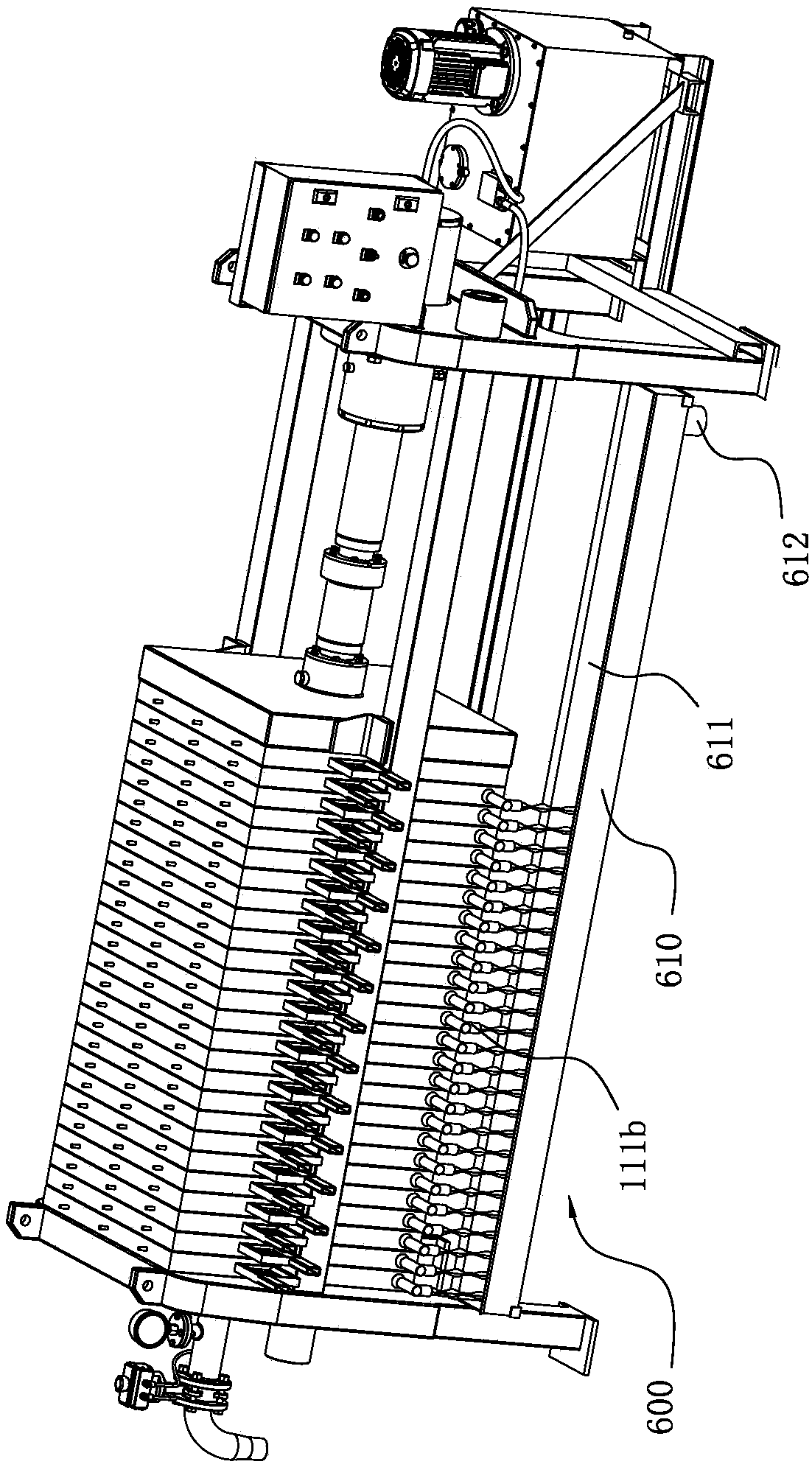

Filter press for preparing nano cerium oxide

InactiveCN113082801AGuarantee the effect of crushing and dispersingMeet needsFiltration separationGrain treatmentsElectric machinePhysical chemistry

The invention discloses a filter press for preparing nano cerium oxide. The filter press comprises a rack and a filter press body installed on the rack. A crushing frame is fixed between the inner walls of the rack, the bottom of the crushing frame is connected with a hopper, and a crushing assembly driven by a motor is arranged in the crushing frame. A centrifugal disc is in transmission connection with the crushing assembly, crushing rods which are uniformly arranged are connected to the outer side of the centrifugal disc, and centrifugal rods which are arranged at equal intervals are fixed to the outer side of the bottom surface of the centrifugal disc. A material receiving hopper is restrained below the rack. According to the device, on the basis of a traditional filter press, materials subjected to filter pressing are further crushed, the crushing and dispersing effects can be guaranteed through crushing, and then the recycled raw materials can better meet the actual requirements.

Owner:SHENZHEN GEMINI MICROELECTRONICS CO LTD

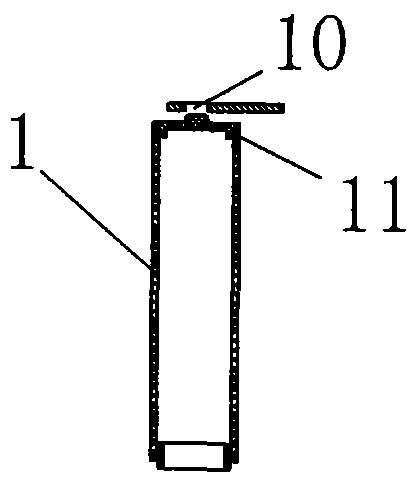

Water purifier water inlet joint with filtering function

InactiveCN104976469AReduce use costReduce maintenance costsBranching pipesFiltration separationUpper jointEngineering

Owner:YUYAO HAIDI WATER PURIFICATION TECH CO LTD

Filter core-replaceable filter

InactiveCN104722124AEasy to replaceFor quick replacementFiltration separationSolenoid valveScrew thread

Owner:SICHUAN FINE PURIFICATION EQUIP

Permeable filtering sound insulation material and manufacturing method thereof, tray, decorative brick and filtering equipment

PendingCN111746064ALow costAbrasion resistance is not affectedCovering/liningsDomestic upholsteryEpoxyCompression molding

Owner:河南英煌匠新科技有限公司

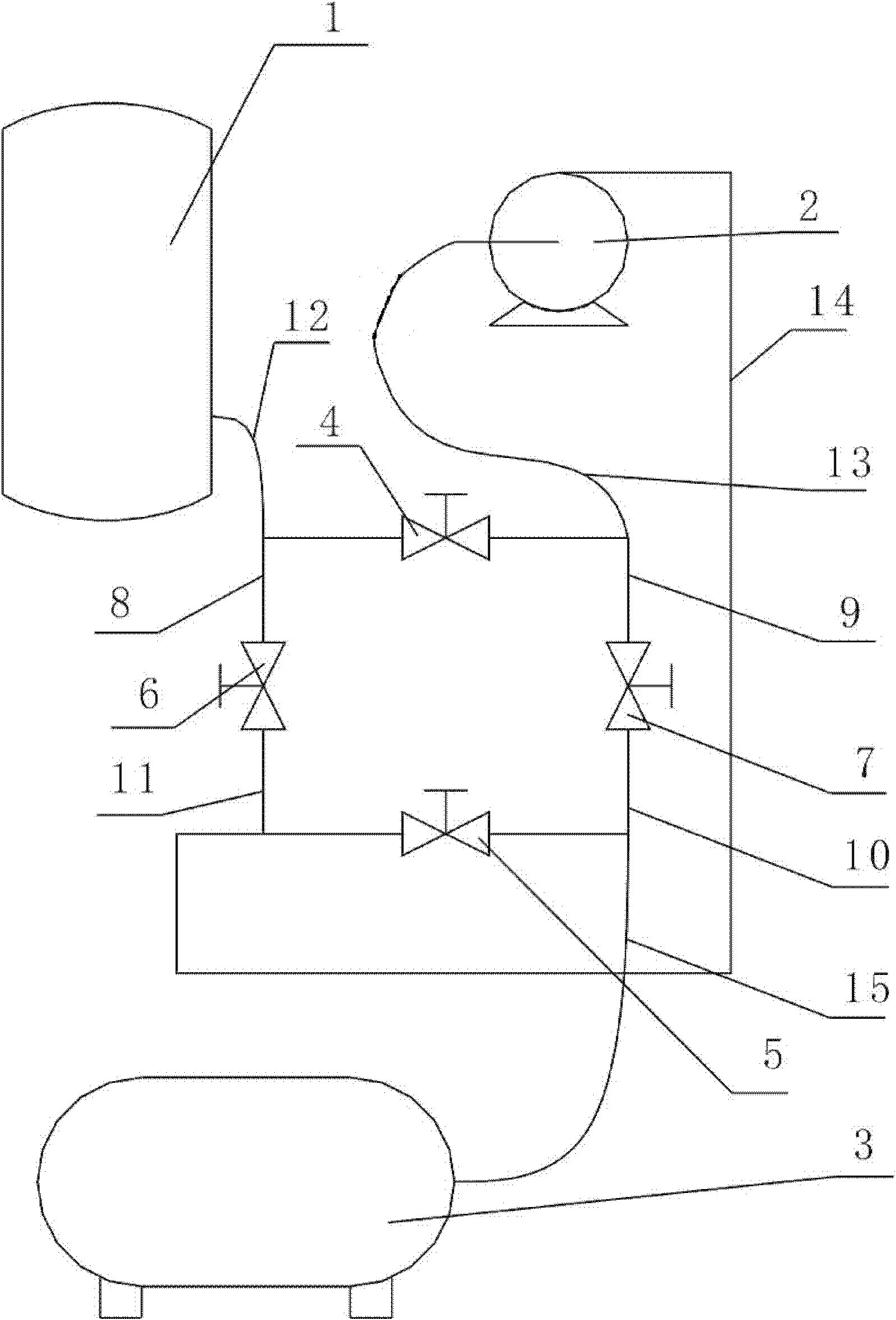

Anti-blockage backflush double-valve device

Owner:天津市盟特电气仪表配件制造股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap