System for flushing pipe plumbing using microbubbles, method therefor, and ship or maritime plant having same

a technology of microbubbles and flushing pipes, which is applied in the direction of separation processes, vessel construction, filtration separation, etc., can solve the problems of pipe damage, scale removal cost increase, and pipe cannot perform the function as designed, so as to increase the flow rate, increase the reynolds number, and increase the removal efficiency of foreign substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Hereinafter, the present invention will now be described in detail with reference to the attached drawing.

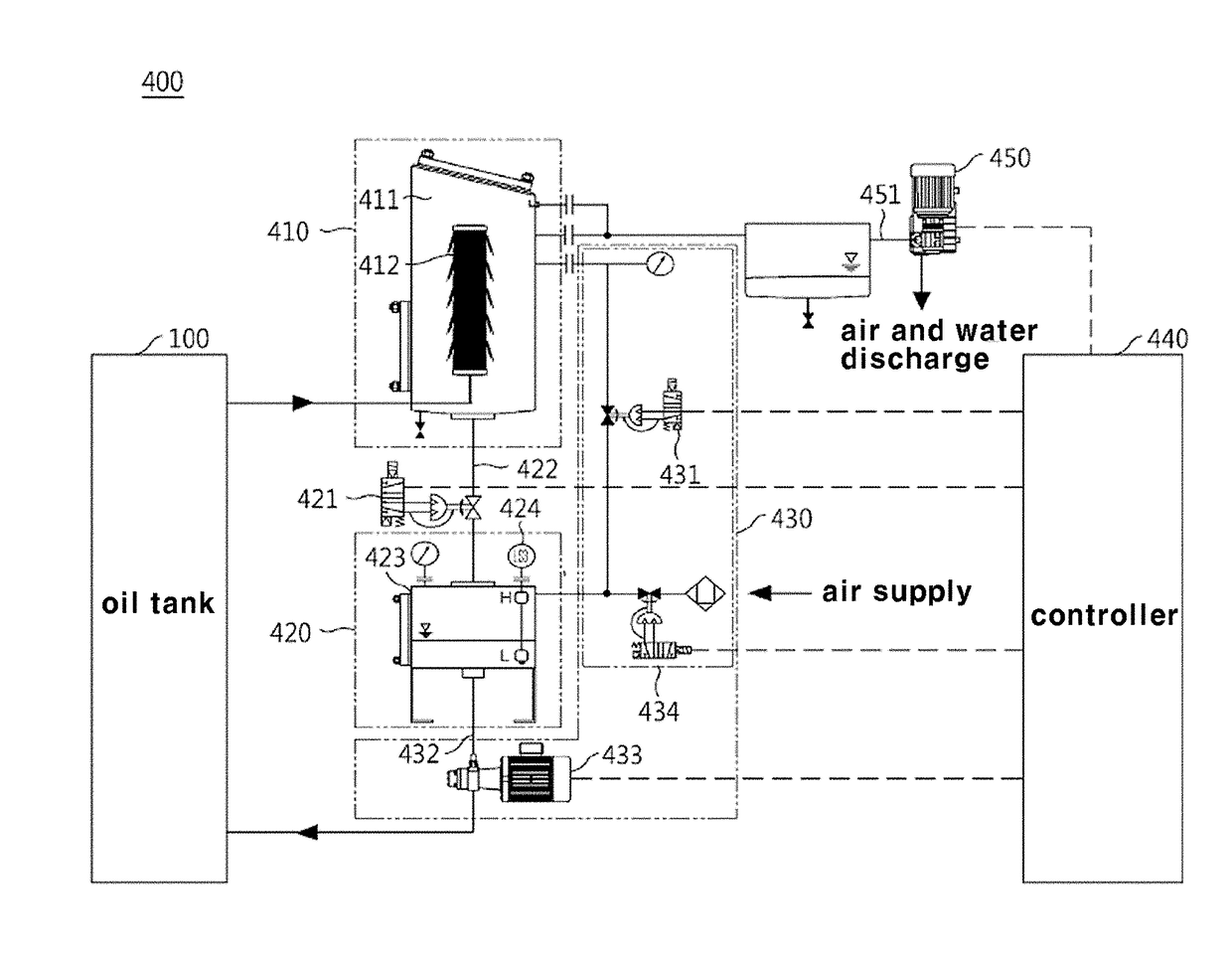

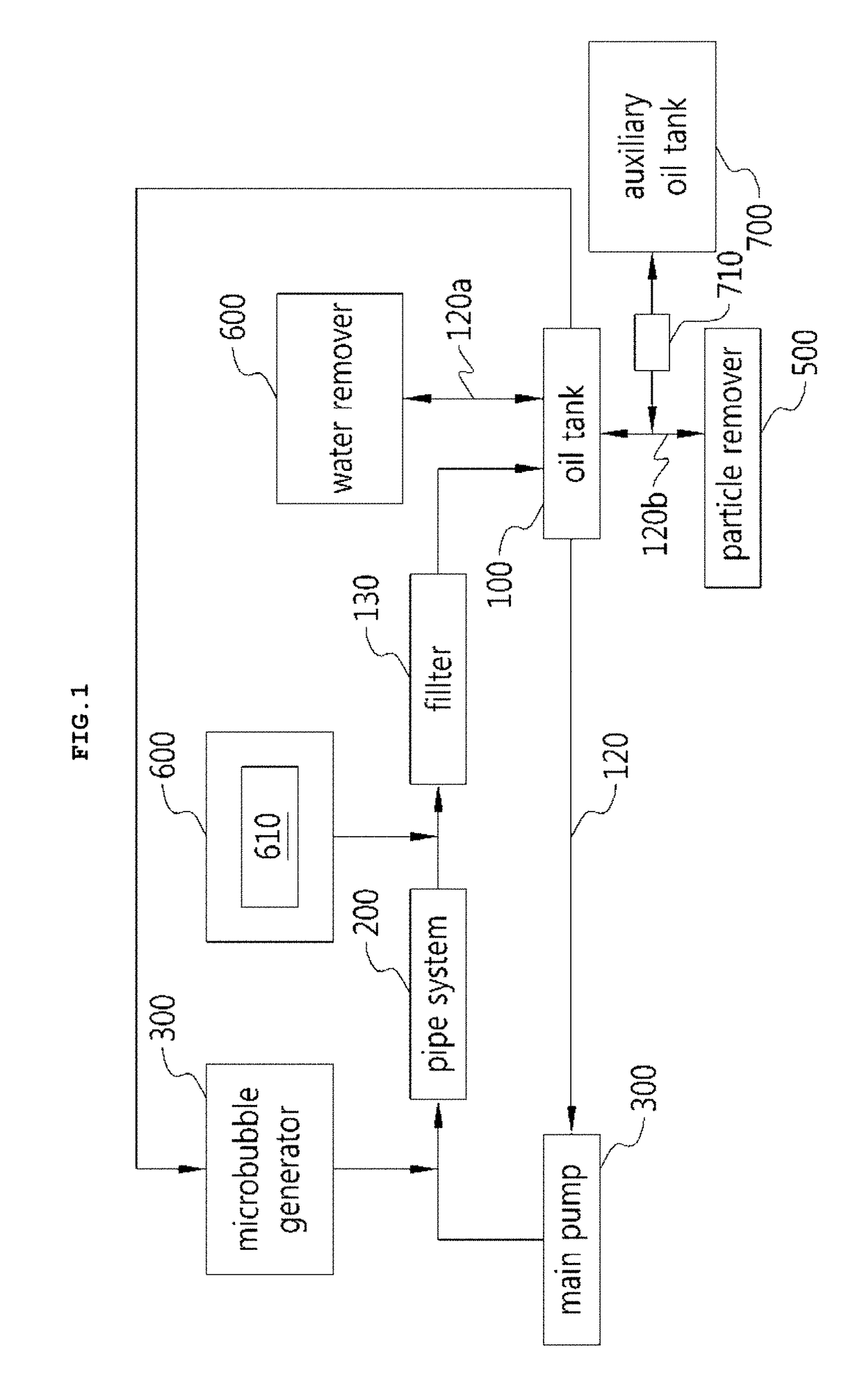

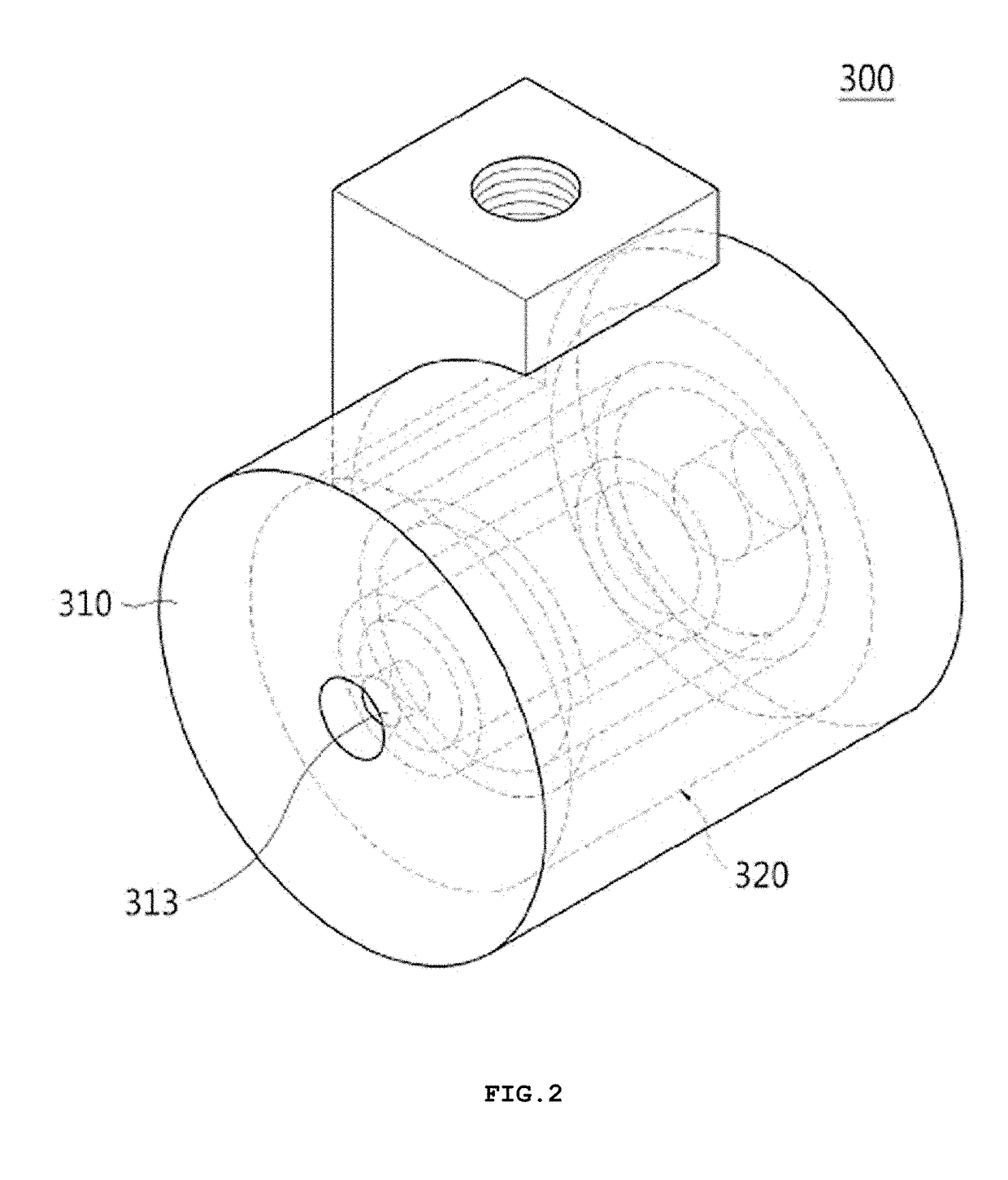

[0044]FIG. 1 is a block diagram showing a system for flushing a pipe using microbubbles according to the present invention, FIG. 2 is a perspective view showing the interior of a microbubble generator in the system according to the present invention, FIG. 3 is a sectional view showing the microbubble generator of FIG. 2, FIG. 4 is a block diagram showing a water remover in the system according to the present invention, FIG. 5 is a block diagram showing the internal structure of a particle remover in the system according to the present invention, and FIG. 6 is a sectional view showing the electrodes of the particle remover of FIG. 5.

[0045]FIG. 7 is a flowchart showing a method for flushing a pipe using microbubbles according to the present invention, FIG. 8 is a flowchart showing the step of generating the microbubbles in the method according to the present invention, and FIG.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Adsorption entropy | aaaaa | aaaaa |

| Electric force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap