Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213results about "Dispersed particle separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

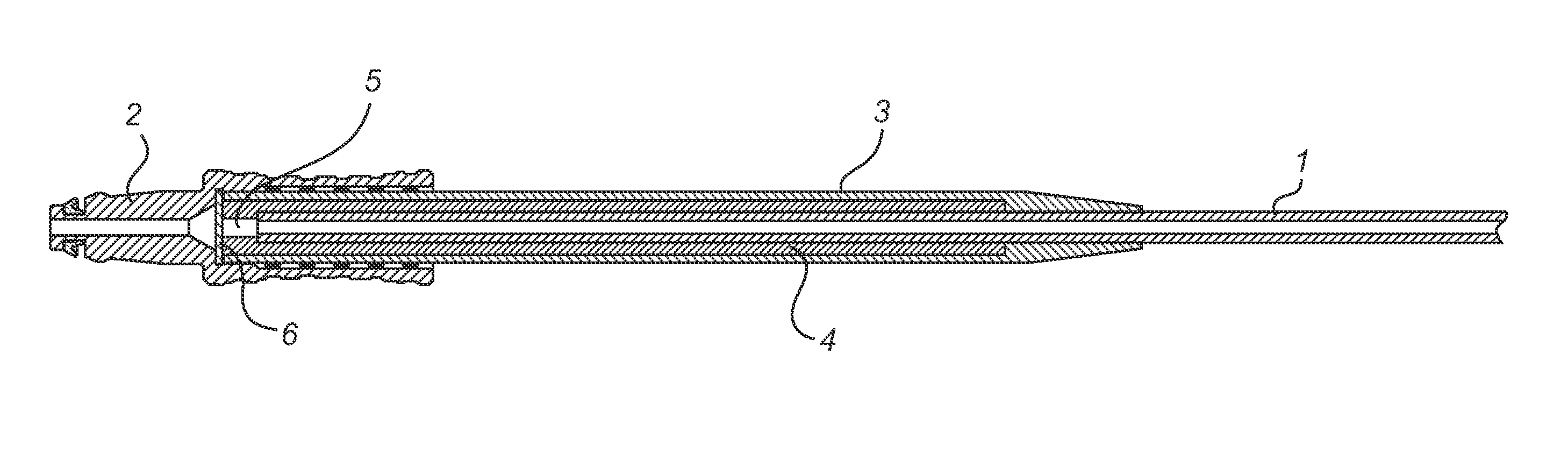

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

Detection device

InactiveUS20120237402A1Improve accuracyImprove operational reliabilityInternal-combustion engine testingThermometer detailsCombustionEngineering

Owner:ELTEK

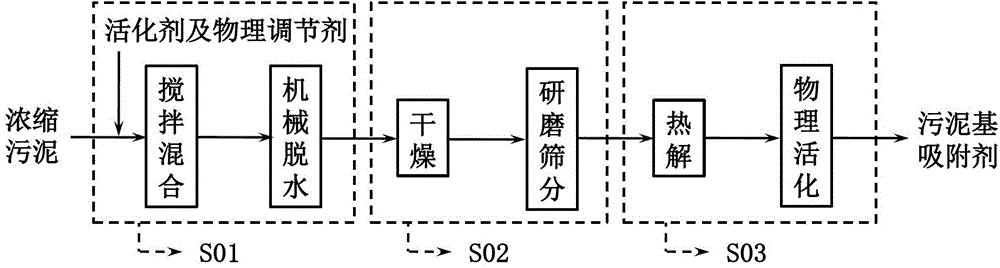

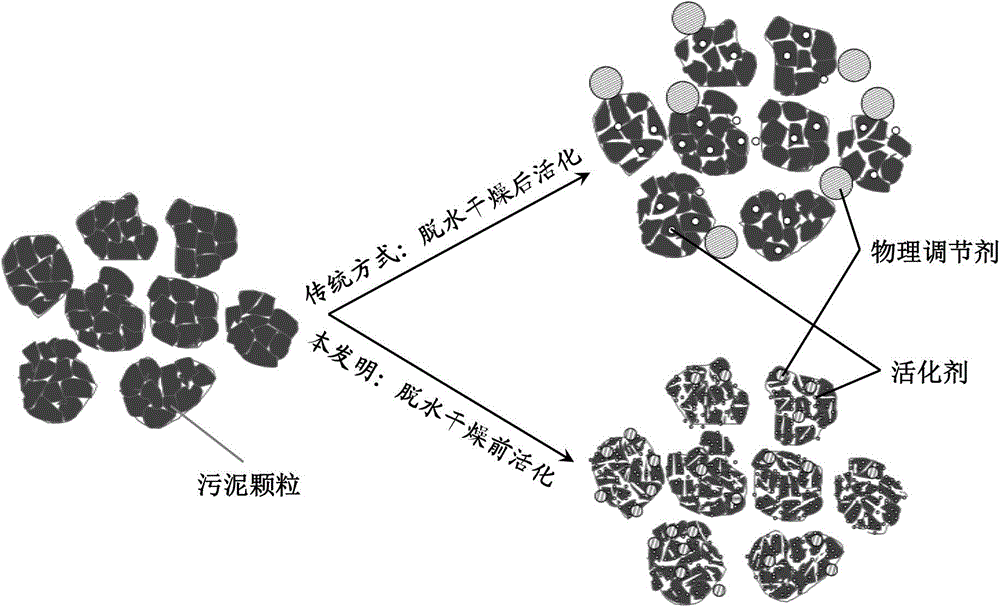

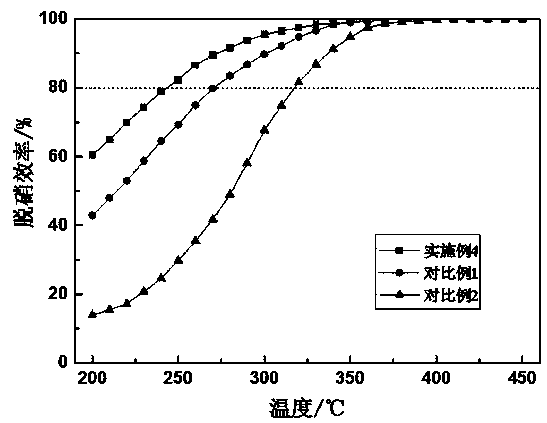

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

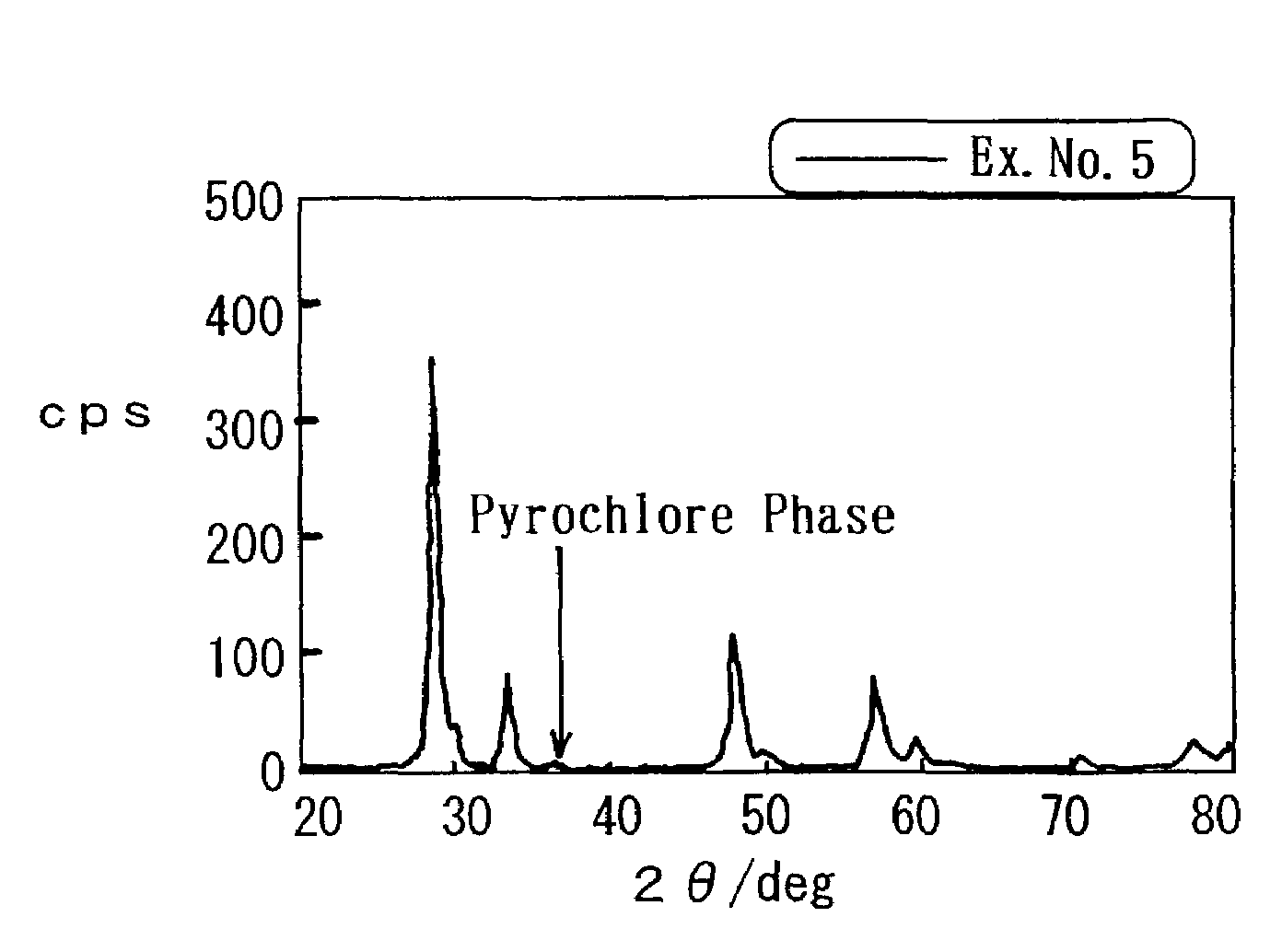

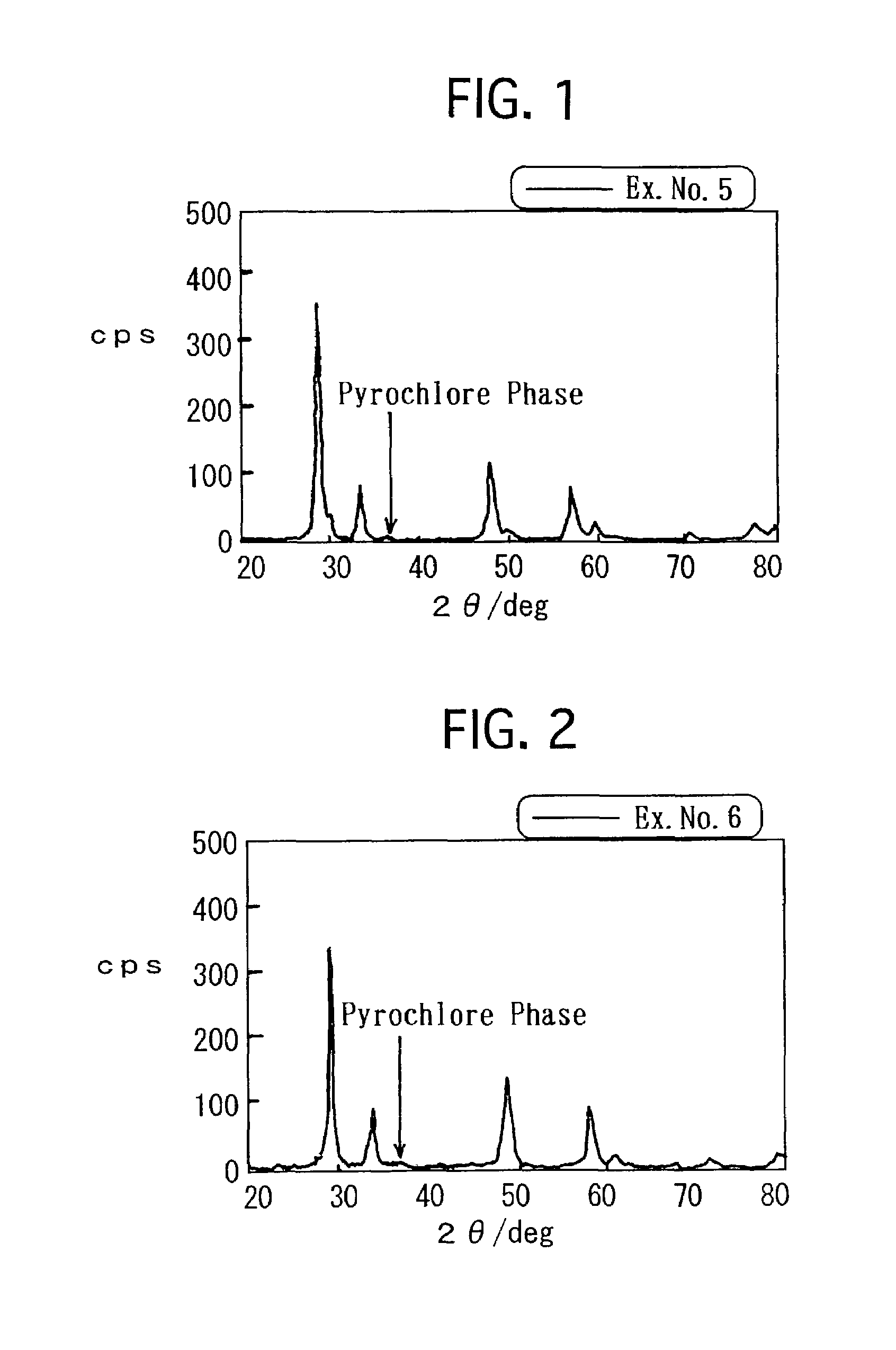

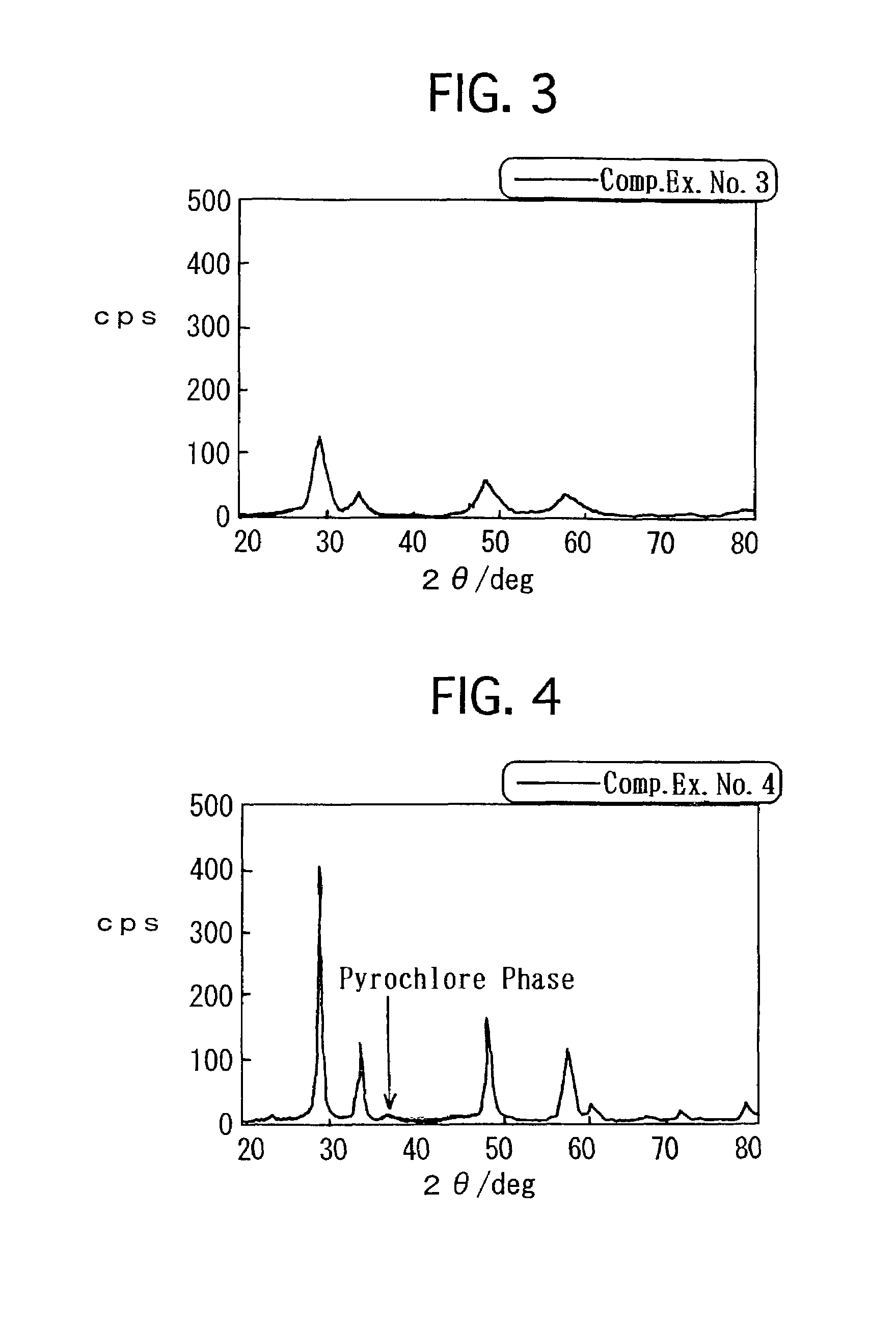

Composite oxide, process for producing the same, and exhaust gas reducing co-catalyst

ActiveUS7247597B2Lack of durabilityUpgrade heat resistanceDispersed particle separationCatalyst activation/preparationExhaust gasComposite oxide

Owner:TOYOTA CENT RES & DEV LAB INC

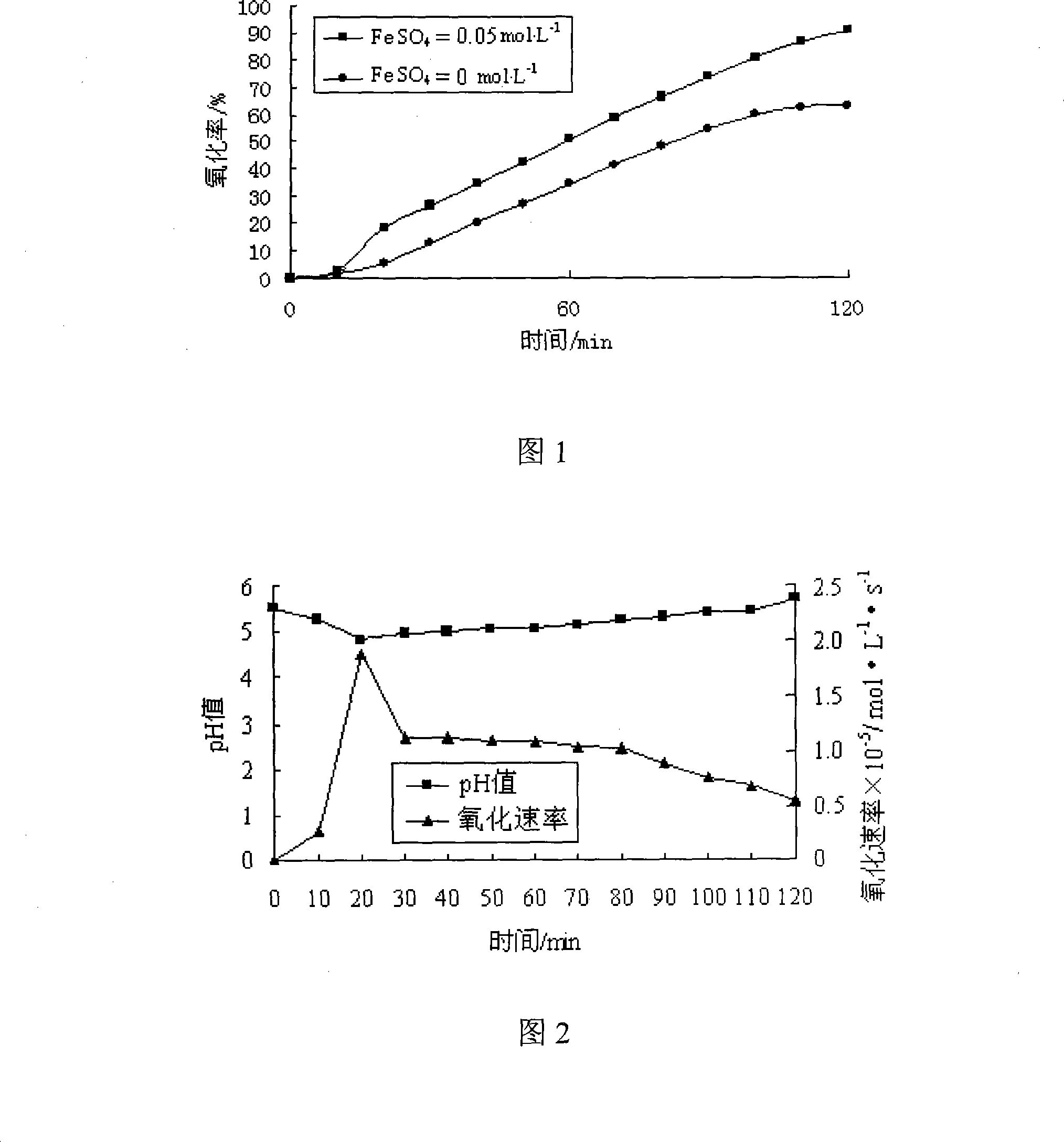

Catalytic oxidation technique for calcium sulfite

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Method for degrading malodorous gas by coupling biotrickling filter with dielectric barrier discharge

ActiveCN104128083AIncrease concentrationEasy to handleDispersed particle separationAir quality improvementProduct gasEnvironmental engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Zoning oxidation ozone distributor, and arrangement mode and applications thereof

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of manganese-based composite metal oxide ozonolysis catalyst

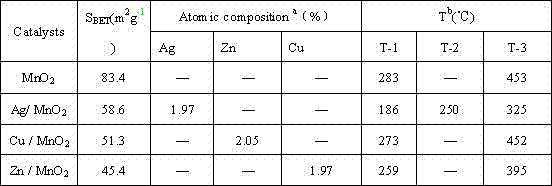

InactiveCN109833868AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOzonolysis

The invention provides a preparation method of a manganese-based composite metal oxide ozonolysis catalyst, and belongs to the fields of catalysis and environmental protection. The method uses a redoxprecipitation process to synthesize the nano-fibrous manganese-based composite transition metal oxide catalyst. The preparation method of the catalyst has the advantages of simple process, mild conditions, and realization of high stability of catalytic ozonolysis. The catalyst prepared by the method disclosed in the invention has a high ozone removal catalysis activity, and can realize complete removal of ozone at normal temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Chlorination aromatic hydrocarbon waste gases catalytic purification method

Owner:EAST CHINA UNIV OF SCI & TECH

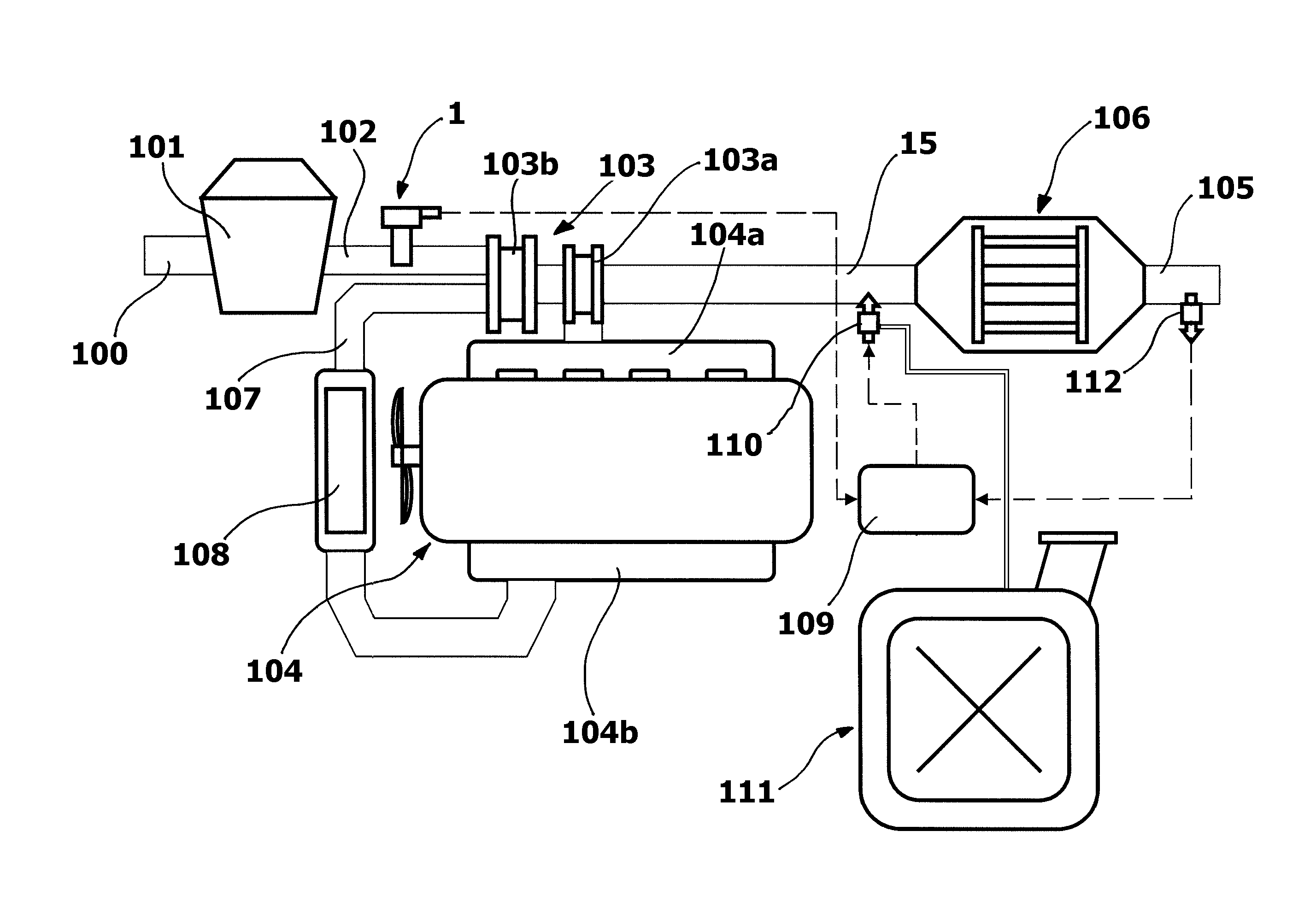

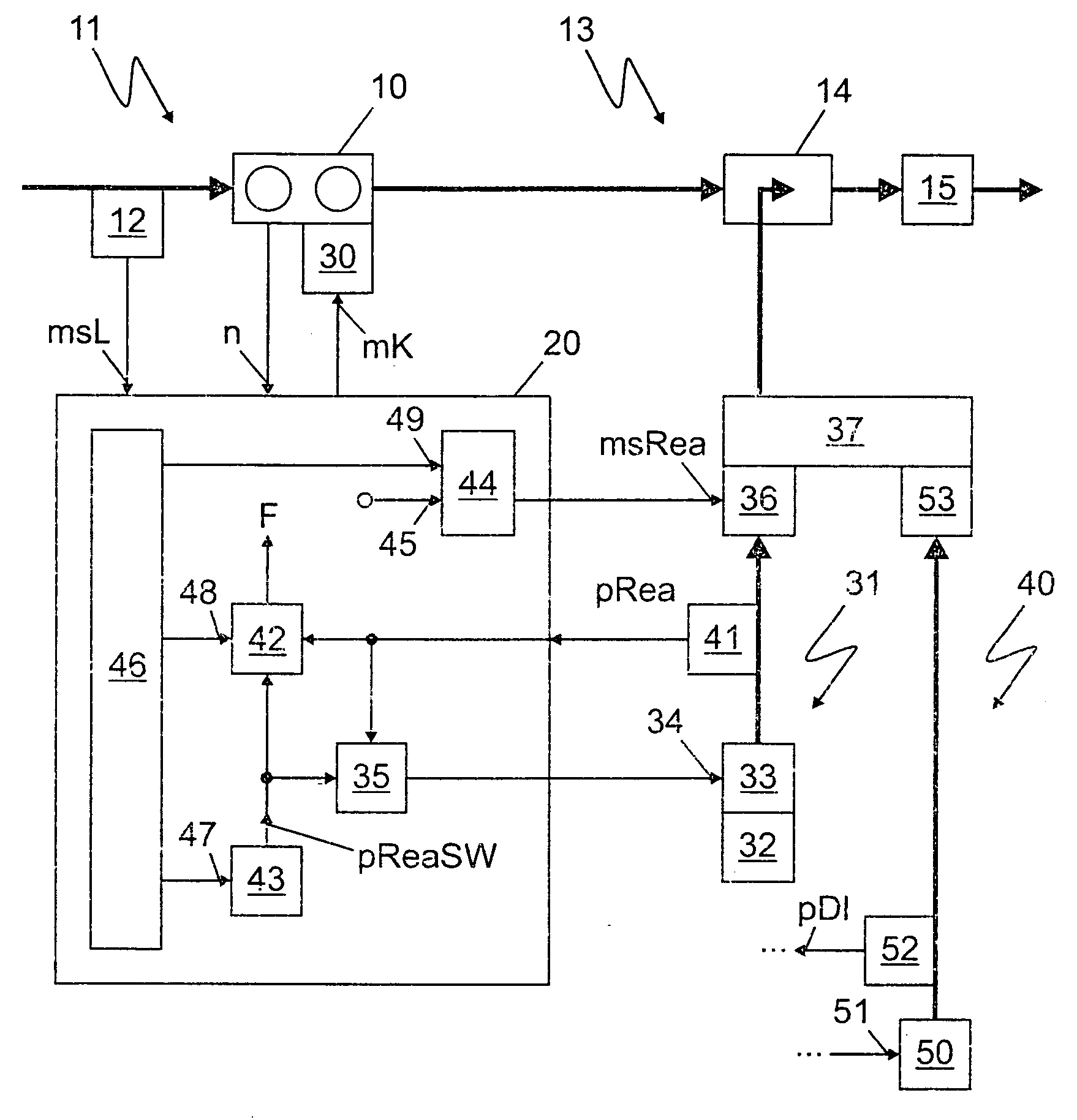

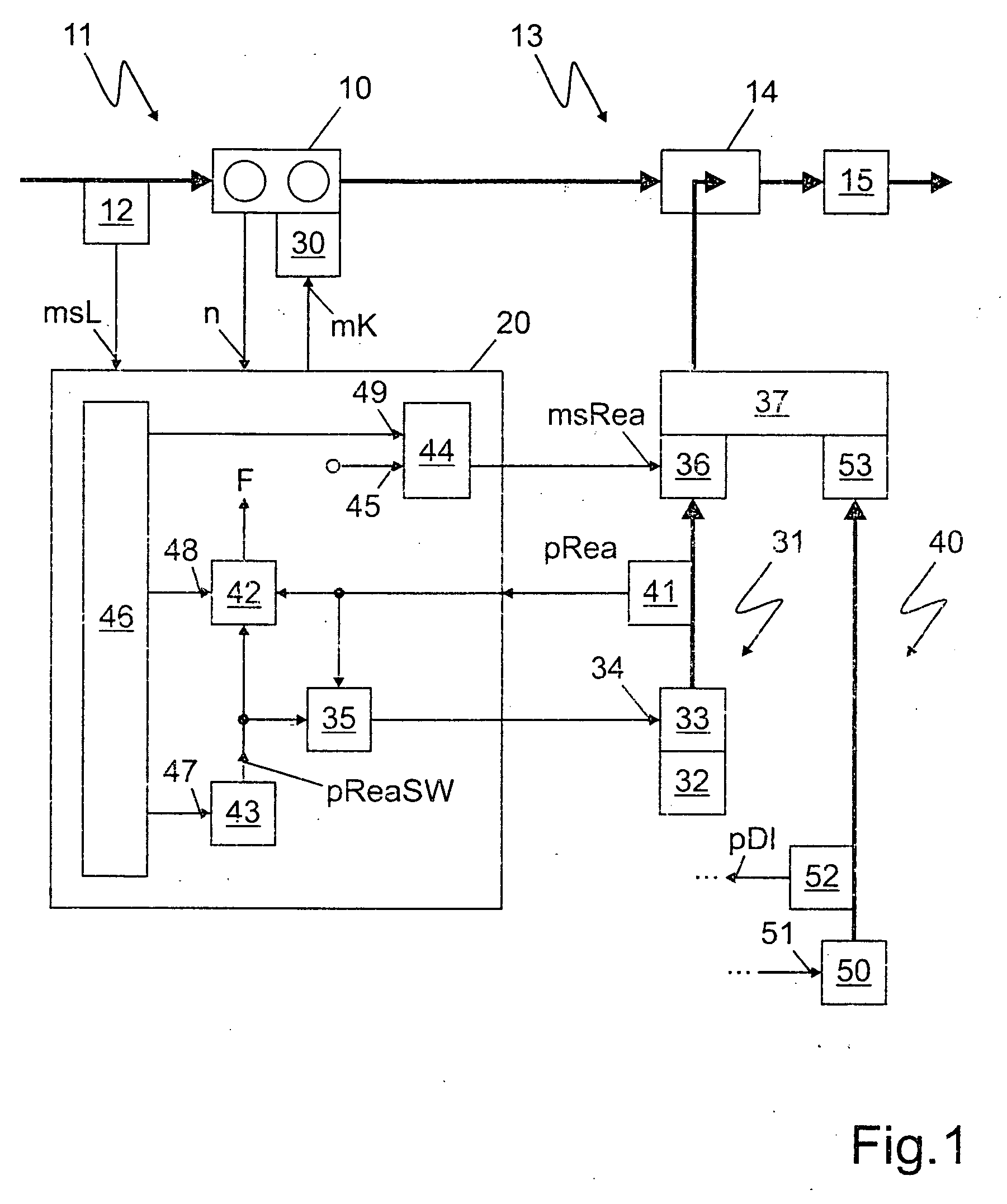

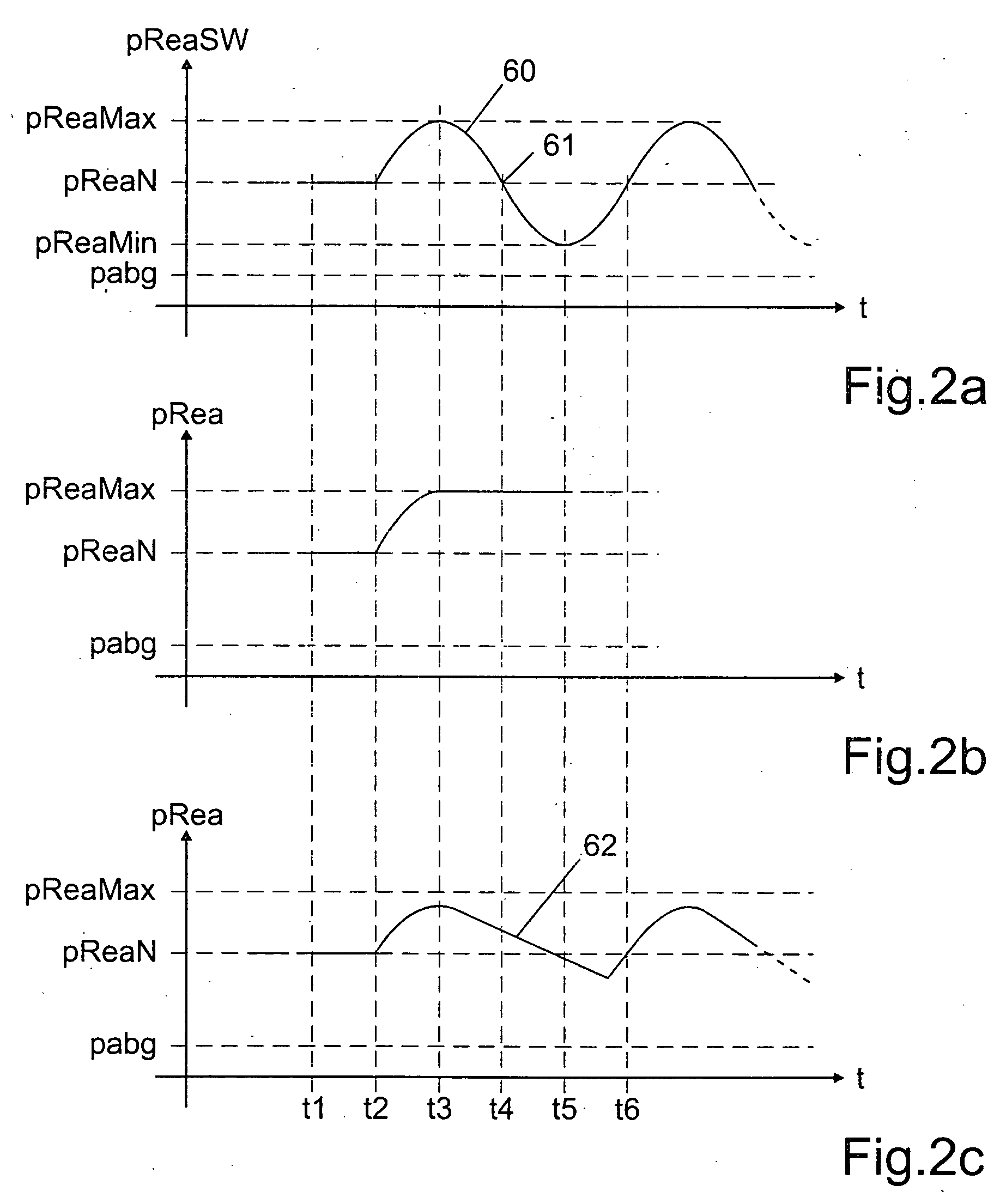

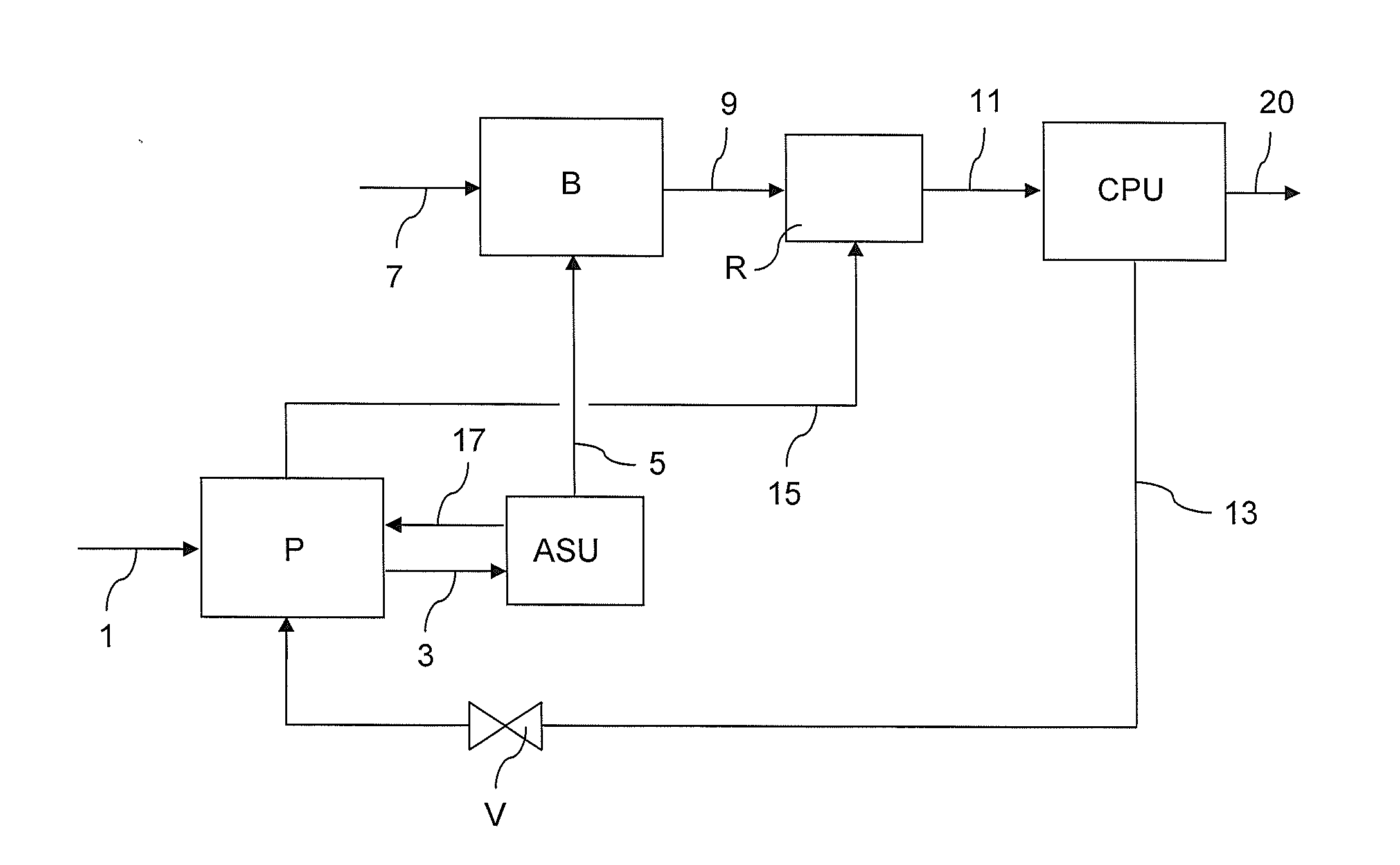

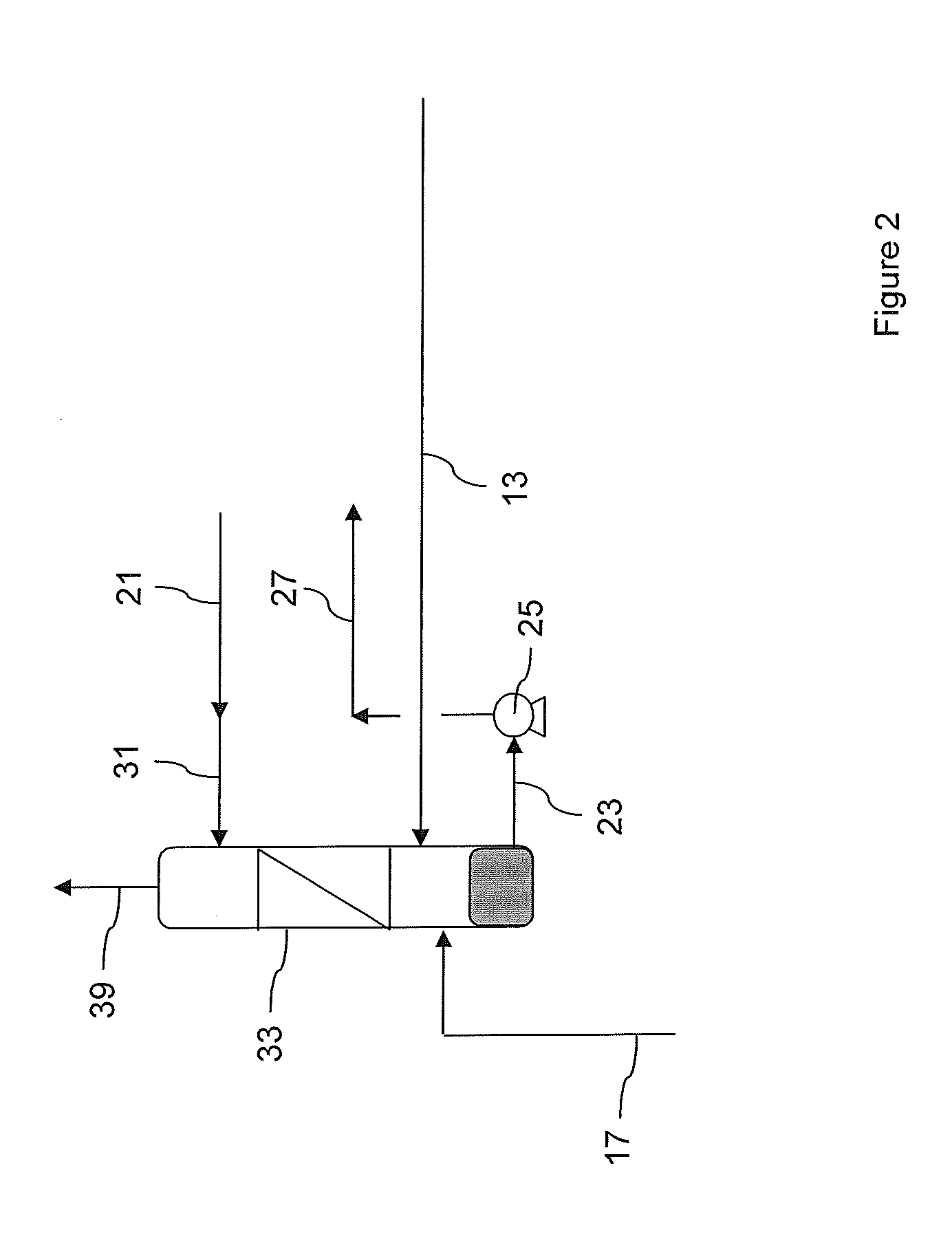

Method for operating an internal combustion engine and device for executing the method

InactiveUS20060196170A1Improve reliabilityEasily flammableInternal combustion piston enginesLighting and heating apparatusEngineeringInternal combustion engine

Owner:ROBERT BOSCH GMBH

Copper and iron compound honeycomb coating type denitrification catalyst as well as preparation method and application thereof

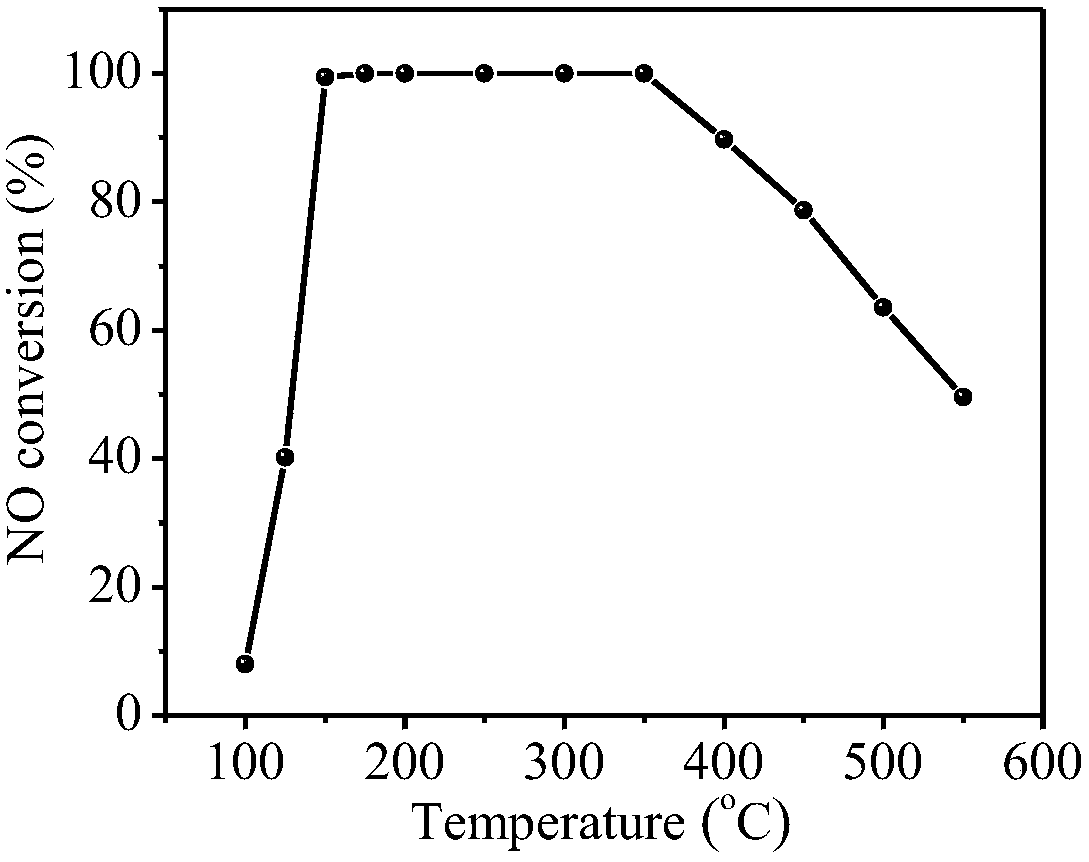

InactiveCN109499607AImprove thermal stabilityImprove anti-sulfur poisoning performanceMolecular sieve catalystsDispersed particle separationIon exchangeVacuum coating

Owner:VALIANT CO LTD

Phosphor-doped CHA molecular sieve, and preparation method and application thereof

ActiveCN108083292AGood activity at low temperatureMolecular sieve catalystsDispersed particle separationPotassium hydroxideCrystallinity

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

Method for synchronously removing sulfur dioxide and fine particles in smoke through electrical charge and mist spray

InactiveCN104162486ADispersed particle separationExternal electric electrostatic seperatorSulfur dioxideFlue gas

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

Method of recovering and regenerating waste gas desulfurizing and defluorinating absorbent liquid continuously

ActiveCN1974430ALow investment costLow running costDispersed particle separationWater/sewage treatmentSulfite saltSodium bisulfite

The method of recovering and regenerating waste gas desulfurizing and defluorinating absorbent liquid continuously includes absorbing SO2 and / or fluoride from waste gas with alkaline absorbent to generate desulfurizing and defluorinating absorbent liquid containing sodium sulfite, sodium bisulfite and / or fluoride; the subsequent reacting the desulfurizing and defluorinating absorbent liquid with magnesium-base suspension or solid to obtain magnesium sulfite and / or magnesium fluoride precipitate; filtering to eliminate magnesium sulfite and / or magnesium fluoride precipitate, and recovering the filtrate at pH 6.5-9.5 for reuse. The said method has fast regeneration reaction speed, low cost and complete reaction.

Owner:陆泳凯 +1

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

Method for recovering oil gas and device

InactiveCN102441309AImprove purification effectReduce the temperatureDispersed particle separationVapor condensationRecovery methodGas emissions

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel method for removing indoor formaldehyde by nano manganese dioxide

Owner:TIANJIN CITY CENTSTAGE TECH INCUBATOR COMPANY

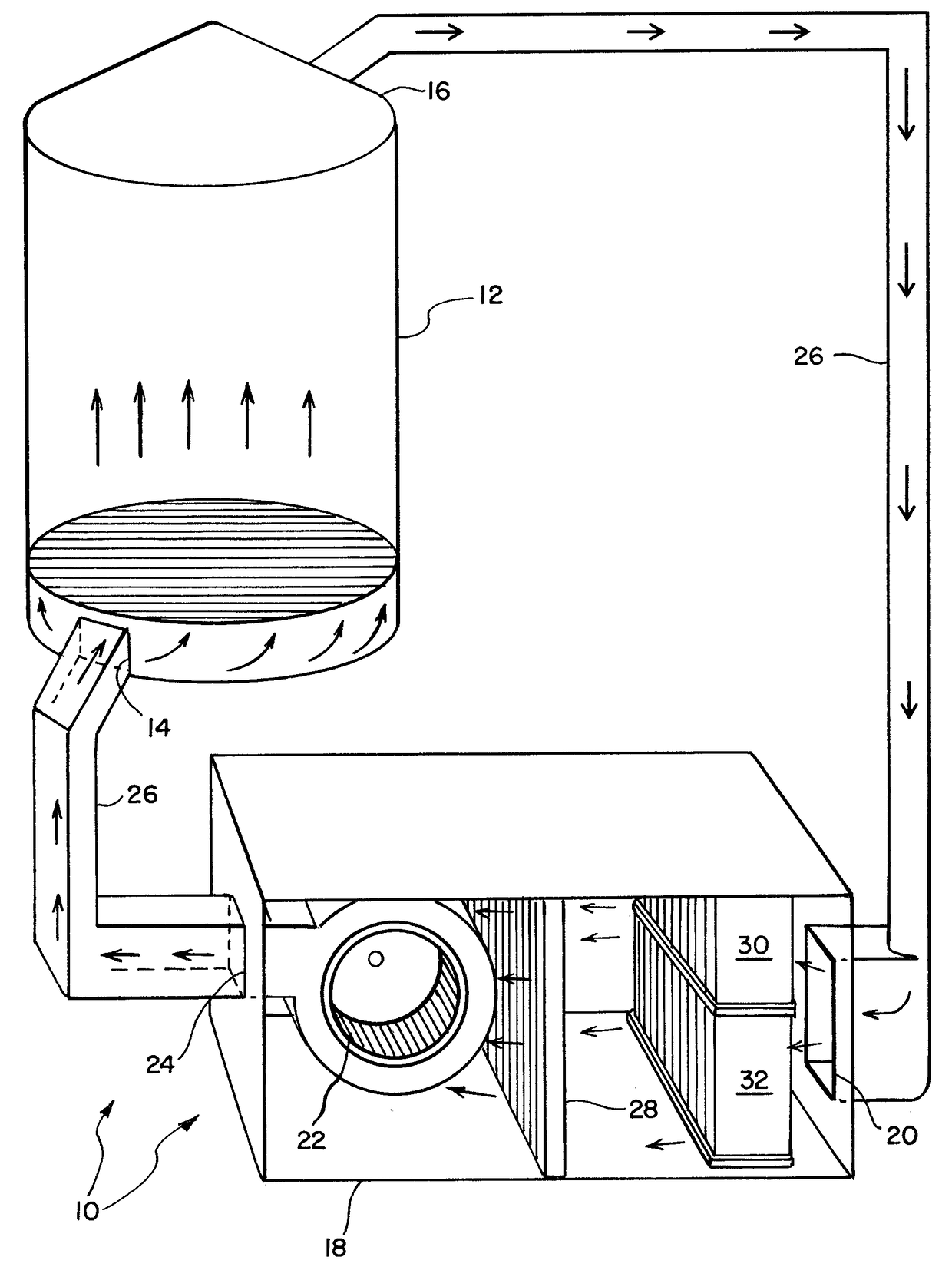

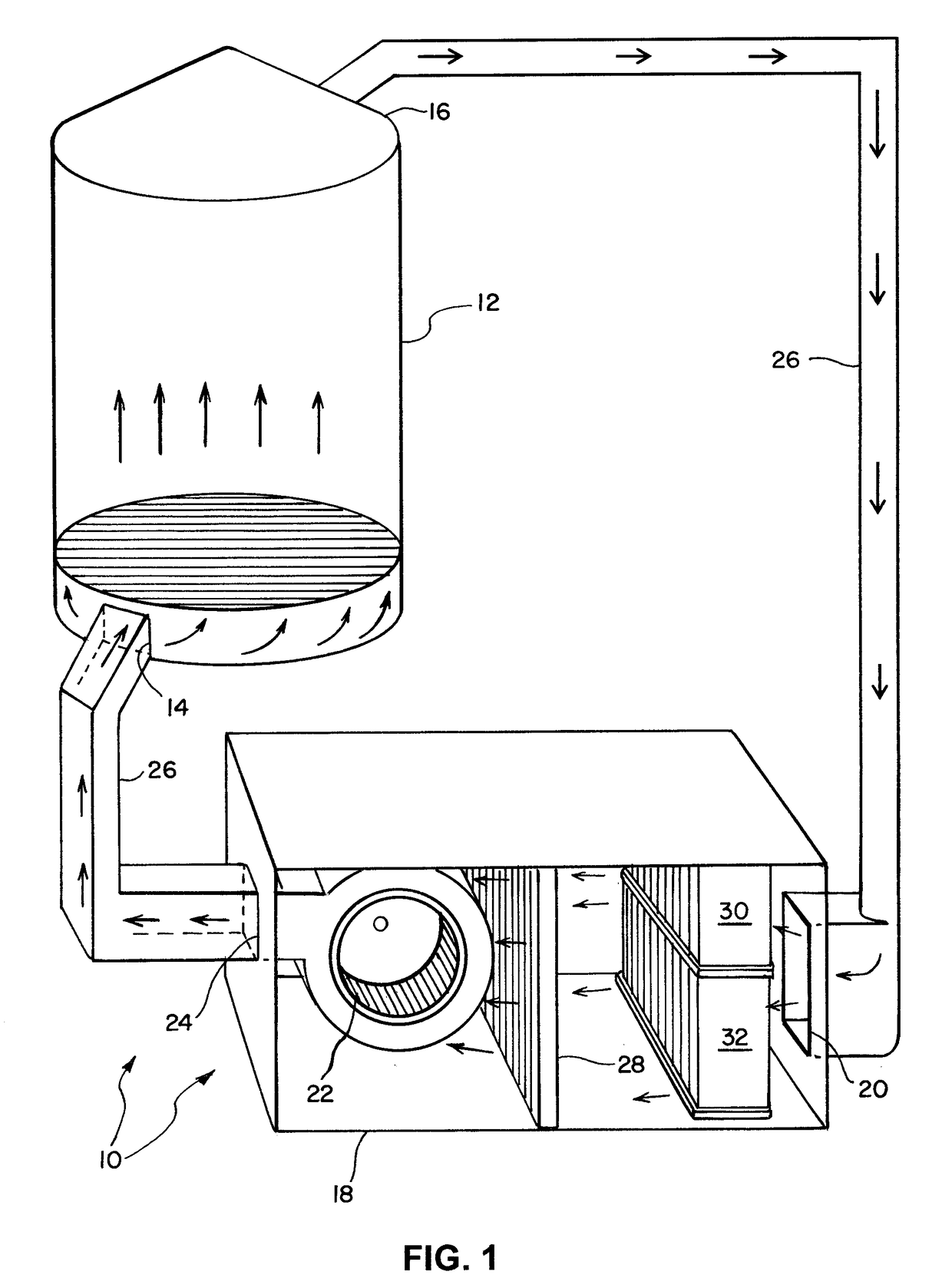

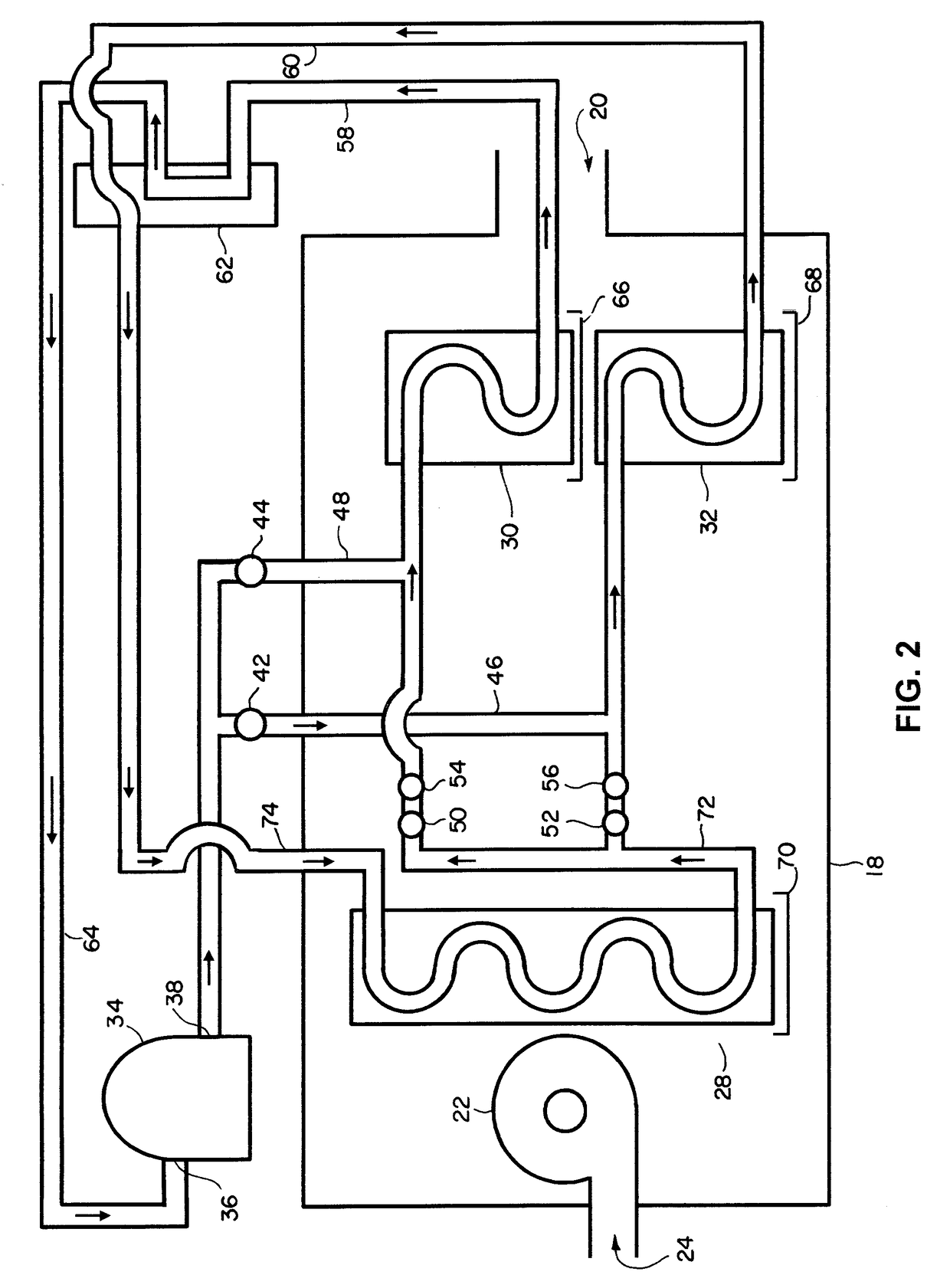

Crop drying system

ActiveUS20170115061A1Increase the ambient temperatureQuantity minimizationFruit and vegetables preservationGas treatmentClosed loopMoisture

Owner:LOEBACH DAVID R

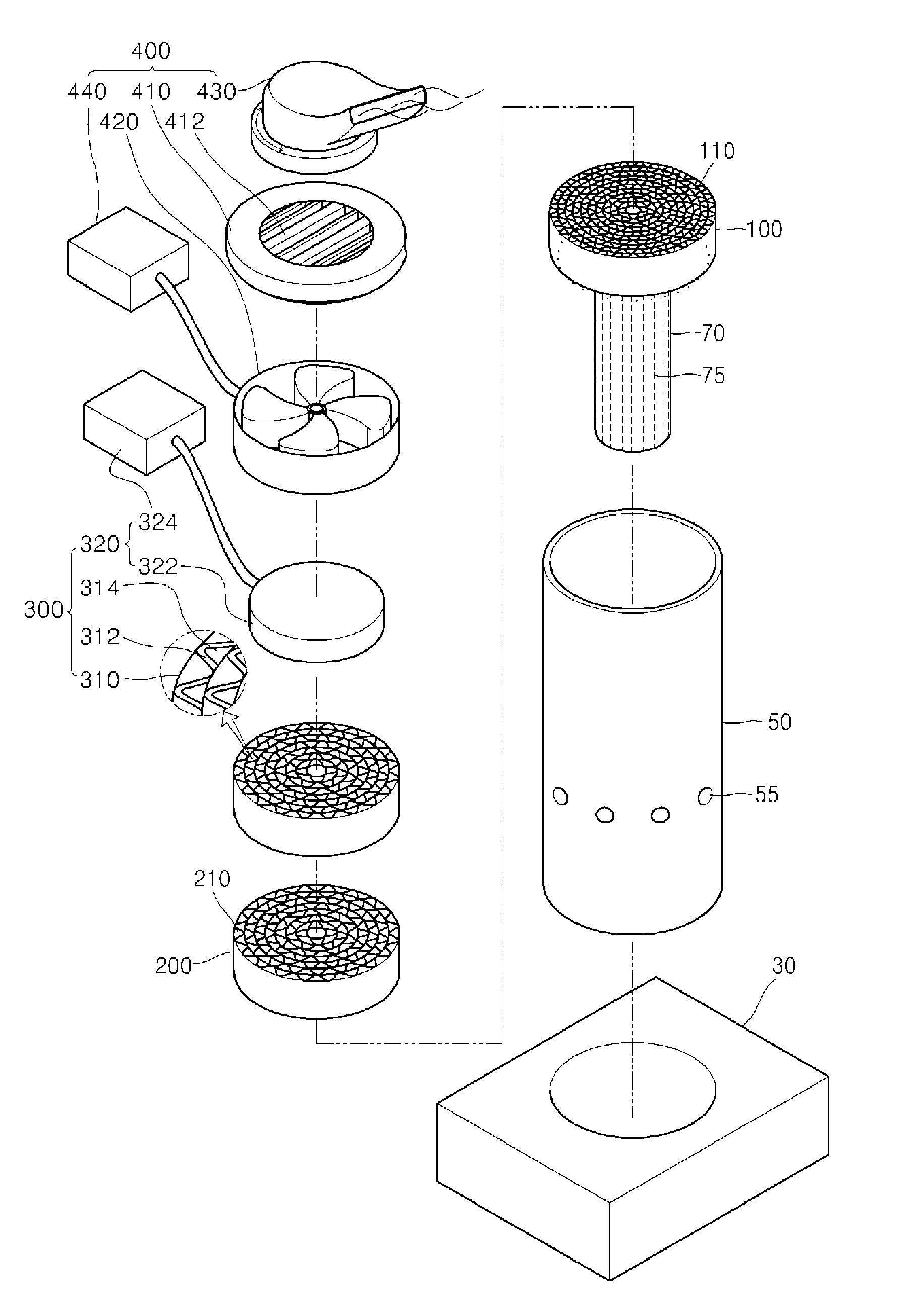

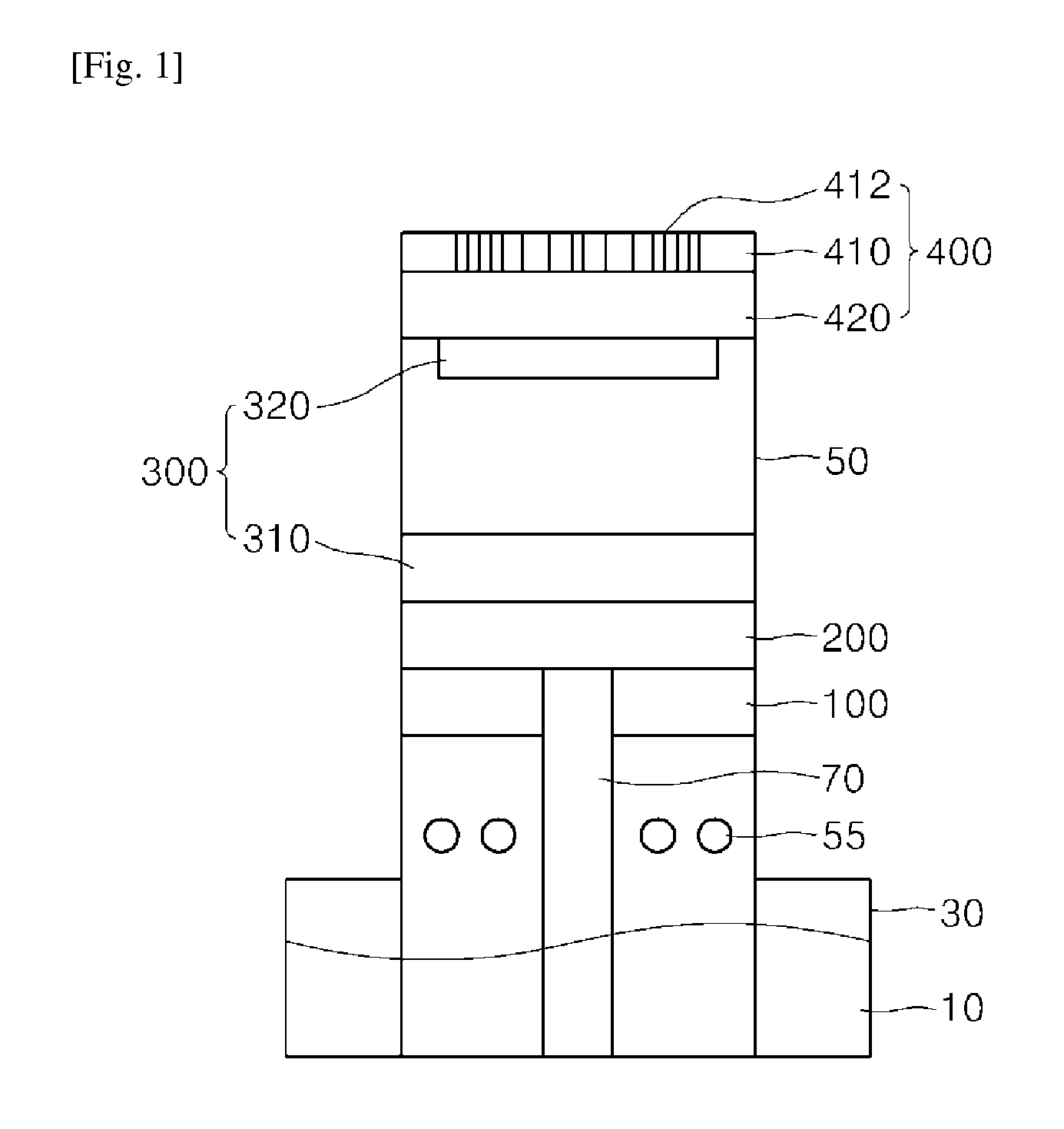

Humidifier apparatus using a photocatalyst having an air-cleaning function

ActiveUS20130330238A1Improve energy efficiencyReduce operating costsGas treatmentMechanical apparatusAir cleaningEngineering

Owner:LG HAUSYS LTD

Apparatus and Integrated Process for Separating a Mixture of Carbon Dioxide and at Least One Other Gas and for Separating Air by Cryogenic Distillation

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

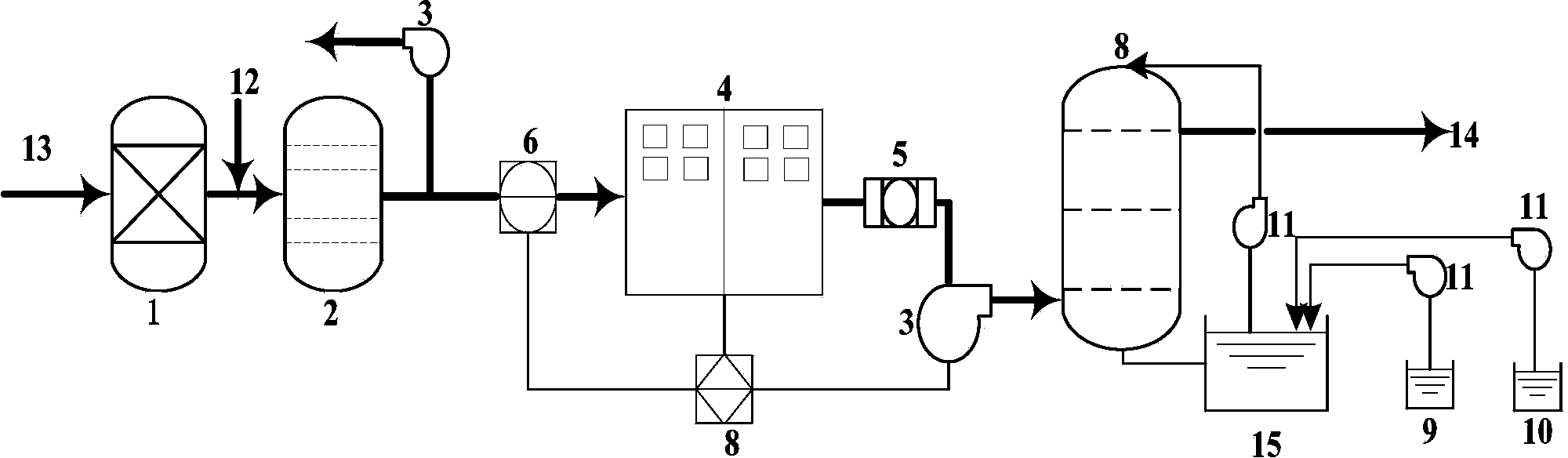

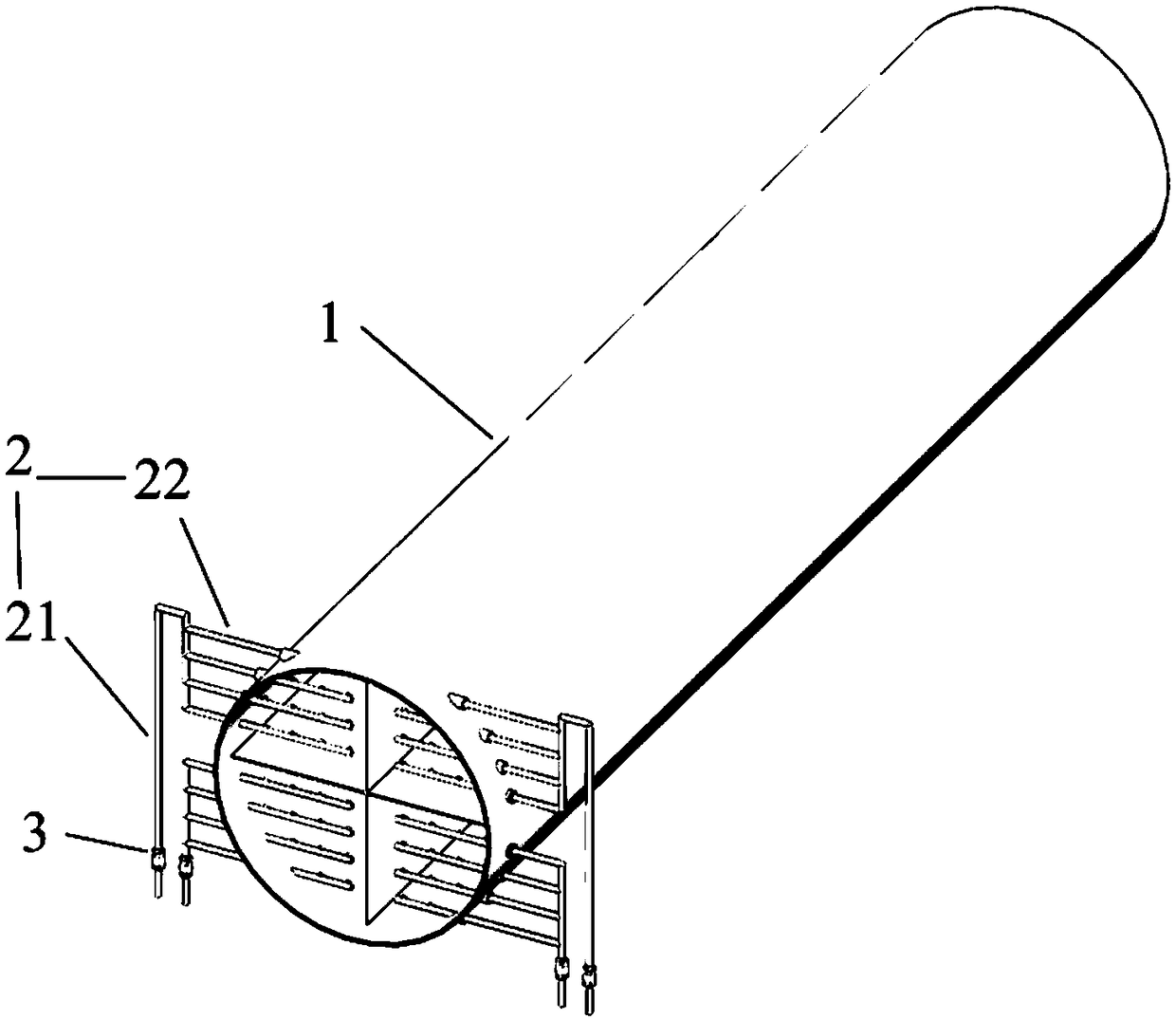

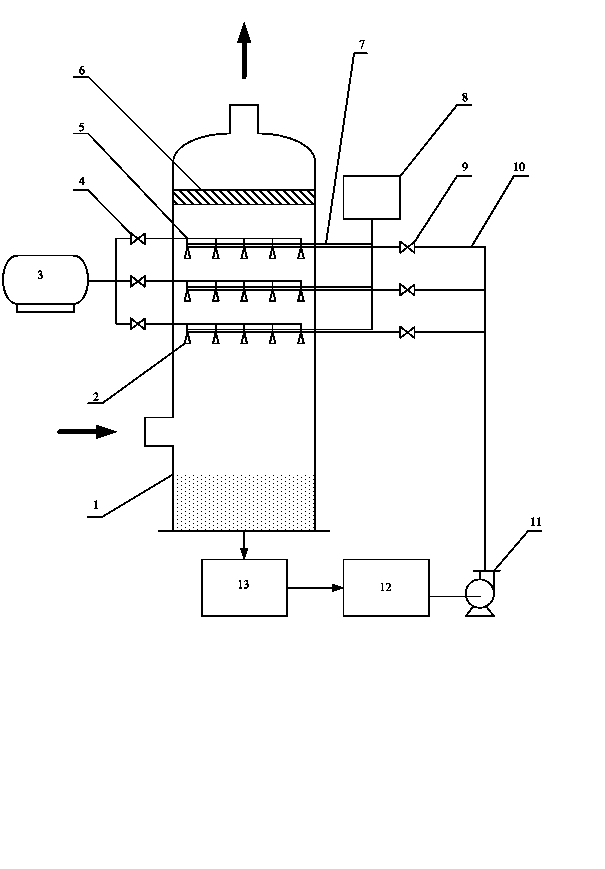

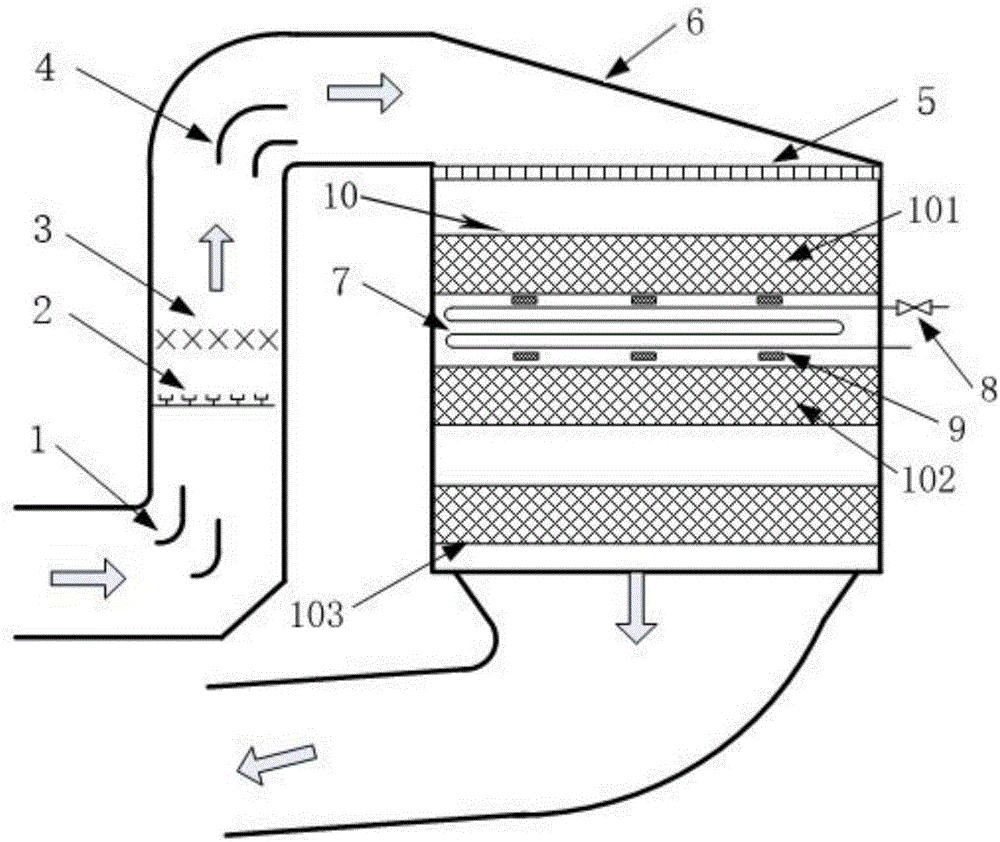

Cascading type rectifier used for SCR denitration device

ActiveCN101642678AReduce weightSave materialDispersed particle separationEngineeringMechanical engineering

The invention discloses a cascading type rectifier used for SCR denitration device, comprising an upper rectifying plate and a lower rectifying plate that are laminated together; wherein the upper rectifying plate is provided with a plurality of regular spread rectifying holes I penetrating the upper rectifying plate body, the lower rectifying plate is provided with rectifying holes II which correspond to the rectifying holes I and penetrates the lower rectifying plate body, the rectifying holes I and the rectifying holes II are partially laminated in vertical direction, and the laminated partforms a plurality of rectifying channels vertically penetrating the rectifier body. The rectifier is formed by adopting the upper and lower rectifying plates, and a plurality of rectifying channels are formed through overlap of the rectifying holes opened on the upper and lower rectifying plates in different directions, thus not only the effect of uniform smoke movement is achieved but also manufacturing cost can be saved.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Method for increasing concentration of carbon dioxide in tail gas of lime rotary kiln

InactiveCN110683544AIncrease concentrationHigh purityCalcium/strontium/barium carbonatesMaterial nanotechnologyCo2 absorptionDust control

The invention discloses a method for increasing the concentration of carbon dioxide in tail gas of a lime rotary kiln. The method is characterized by comprising the following steps: (1) the tail gas of the lime kiln passes through dedusting equipment to remove dust particles; (2) the dedusted tail gas is sprayed through a washing tower, the sprayed tail gas is desulfurized through a desulfurizingtower; (3) the desulfurized tail gas passes through a booster fan to enter a surge flask and then is conveyed into a carbon dioxide absorption tower, alkanolamine in the absorption tower absorbs the carbon dioxide, and the tail gas is metered and then emptied; (4) a carbon-dioxide-absorbed alkanolamine solution is pressurized through a rich solution pump to enter a regeneration tower; (5) the carbon-dioxide-absorbed alkanolamine solution is heated in the regeneration tower to desorb the carbon dioxide, the desorbed carbon dioxide is cooled, dried, analyzed and stored; and (6) a regenerated barren solution is cooled by a barren solution cooler and then pressurized through a barren solution pump to enter an absorption tower, and the carbon dioxide is absorbed again. An enrichment technologyfor the carbon dioxide in the tail gas of the lime rotary kiln brings certain economic benefits for enterprises while according with national industrial structure adjustment and environmental protection.

Owner:HUBEI UNIV

Sewage treatment integrated equipment

ActiveCN109876599AEasy dischargeEasy to collectDispersed particle separationWater/sewage treatmentFixed frameEngineering

The invention discloses sewage treatment integrated equipment, which structurally comprises a compression tank device, a controller, a wire, a hydraulic rod, a compressor and a supporting frame. Sewage is guided onto an odor-backflow-preventing device, a floating block is pushed through buoyancy of the sewage to move upwards, and then a flow-stop block is driven to move upwards to open a sewage discharging channel to discharge the sewage; after no sewage flows into the channel, the flow-stop block and a semicircular connecting block are connected to close the channel so as to avoid backflow ofodor in the sewage; when the compressor is pressed to the compression tank device, a movable plate extrudes an airbag to guide an air flow into a pneumatic rod, thus the pneumatic rod pushes a deodorization filter net device to rotate around a return rod, and the air flow is blown onto a deodorization filter net to be deodorized; and when the compressor moves upwards, a fixing frame is provided with restoration power by arranging a return spring in the return rod, and the compressor moves upwards and makes contact with the fixing frame to provide the fixing frame restoration power.

Owner:ANHUI BAIBANG ENVIRONMENTAL ENG CO LTD

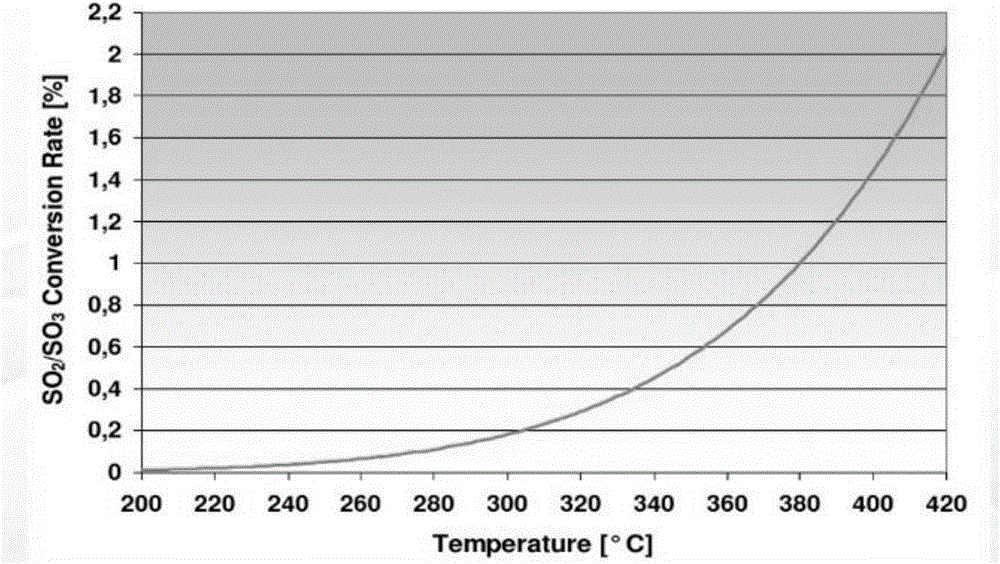

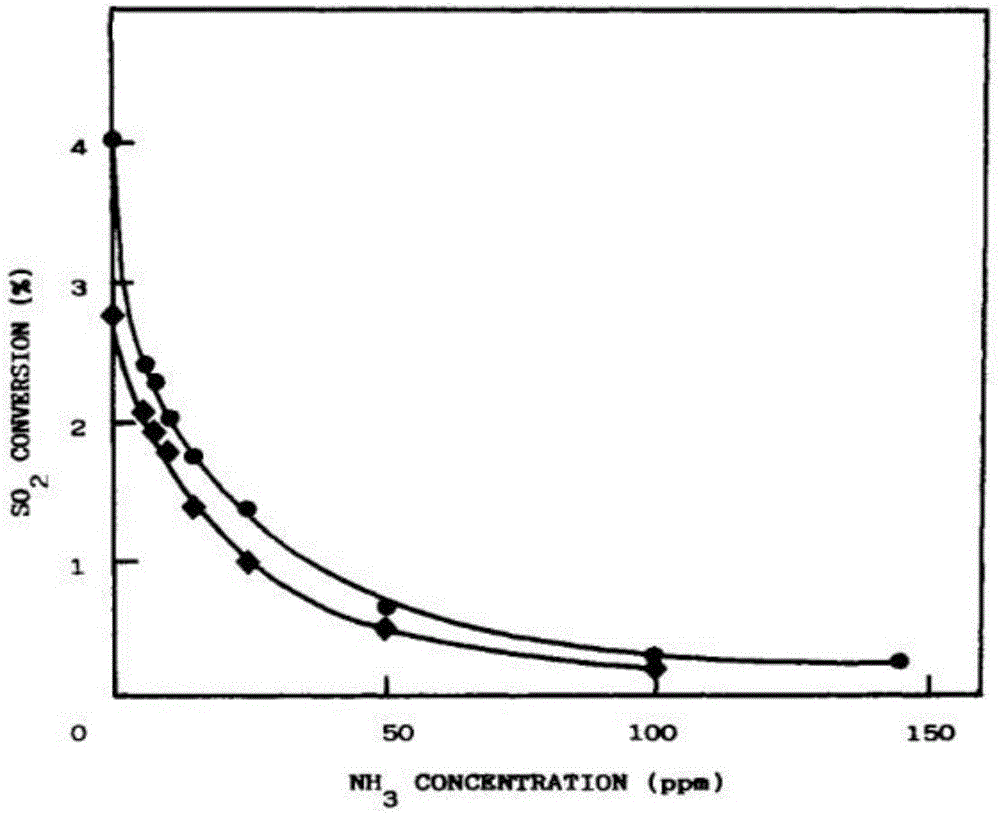

SCR denitration system with low SO2/SO3 conversion rate

InactiveCN106178950AReasonable structureEasy to installDispersed particle separationFlue gasEngineering

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

Method for controlling discharge of dioxins in burning process using sulfurous iron ore

Owner:ZHEJIANG UNIV

Methods and apparatus for improving the sensitivity of capillary zone electrophoresis

InactiveUS20070014699A1Analysis using chemical indicatorsComponent separationElectrophoresisAnalytical chemistry

The present invention relates to novel methods and apparatus for improving the sensitivity of capillary zone electrophoresis (CZE). The invention particularly concerns devices comprising a channel that contains an in-line sol-gel column to concentrate samples being subjected to capillary zone electrophoresis, and the use of such devices to enhance the sensitivity of capillary zone electrophoresis.

Owner:BECKMAN COULTER INC

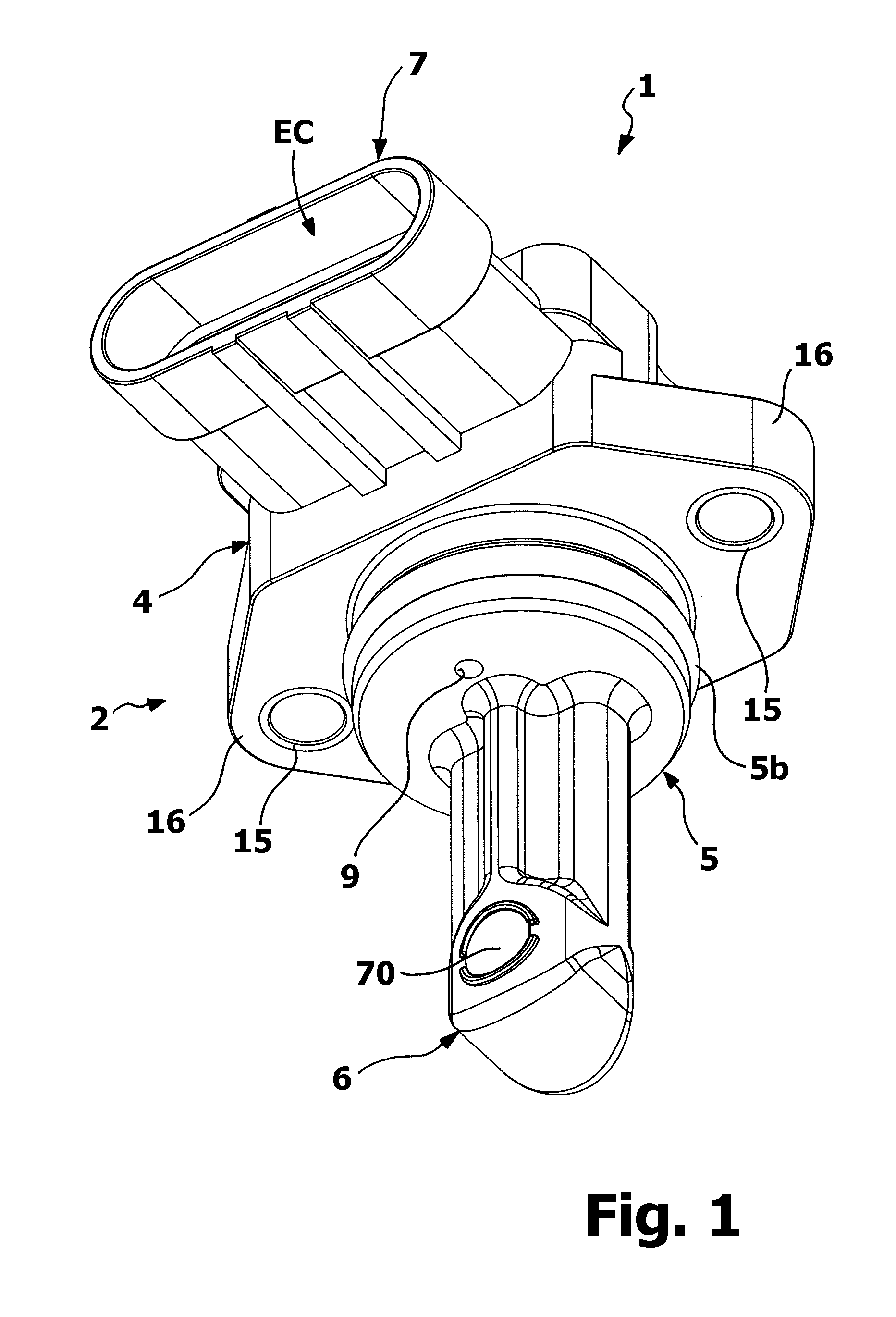

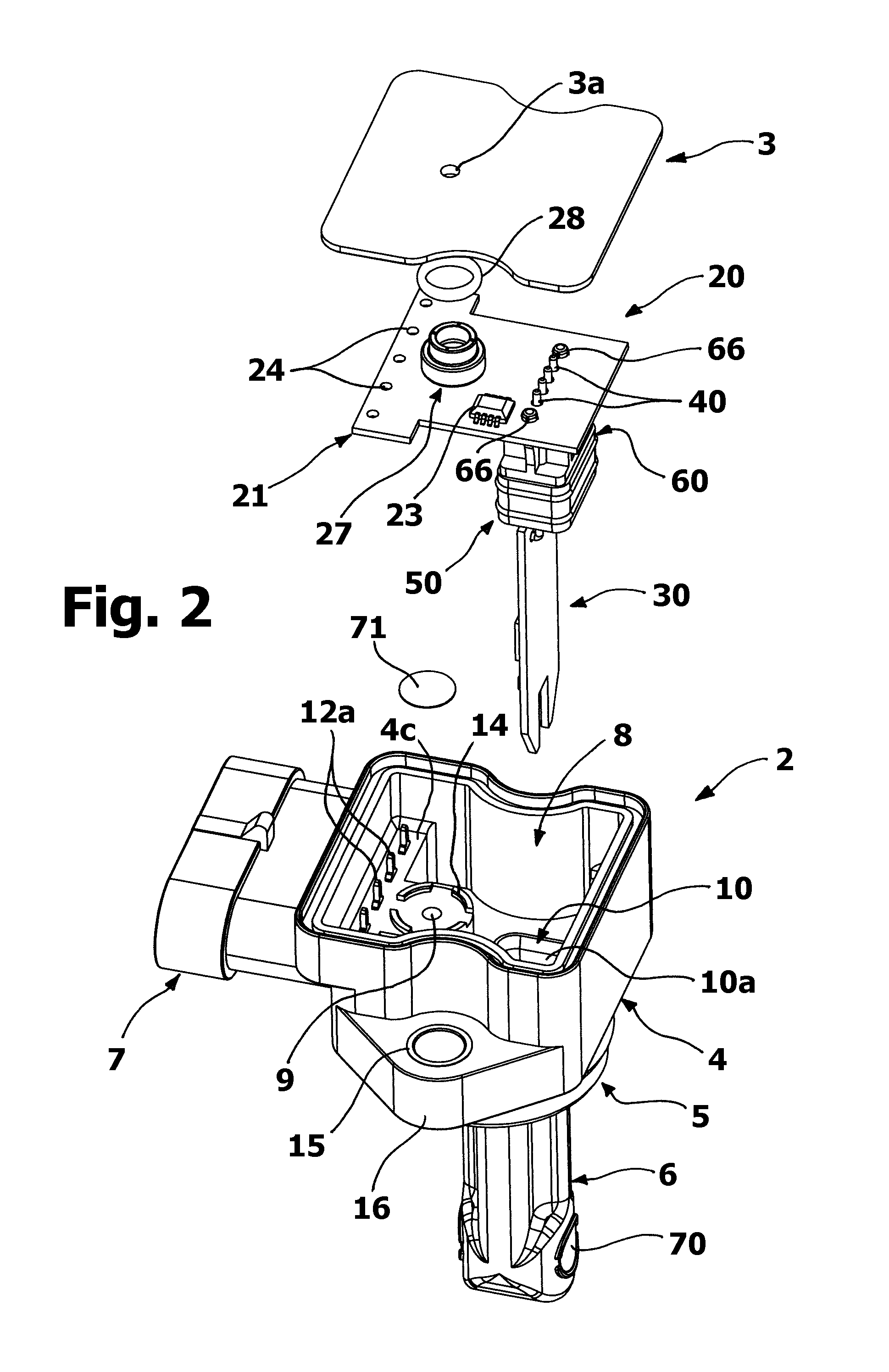

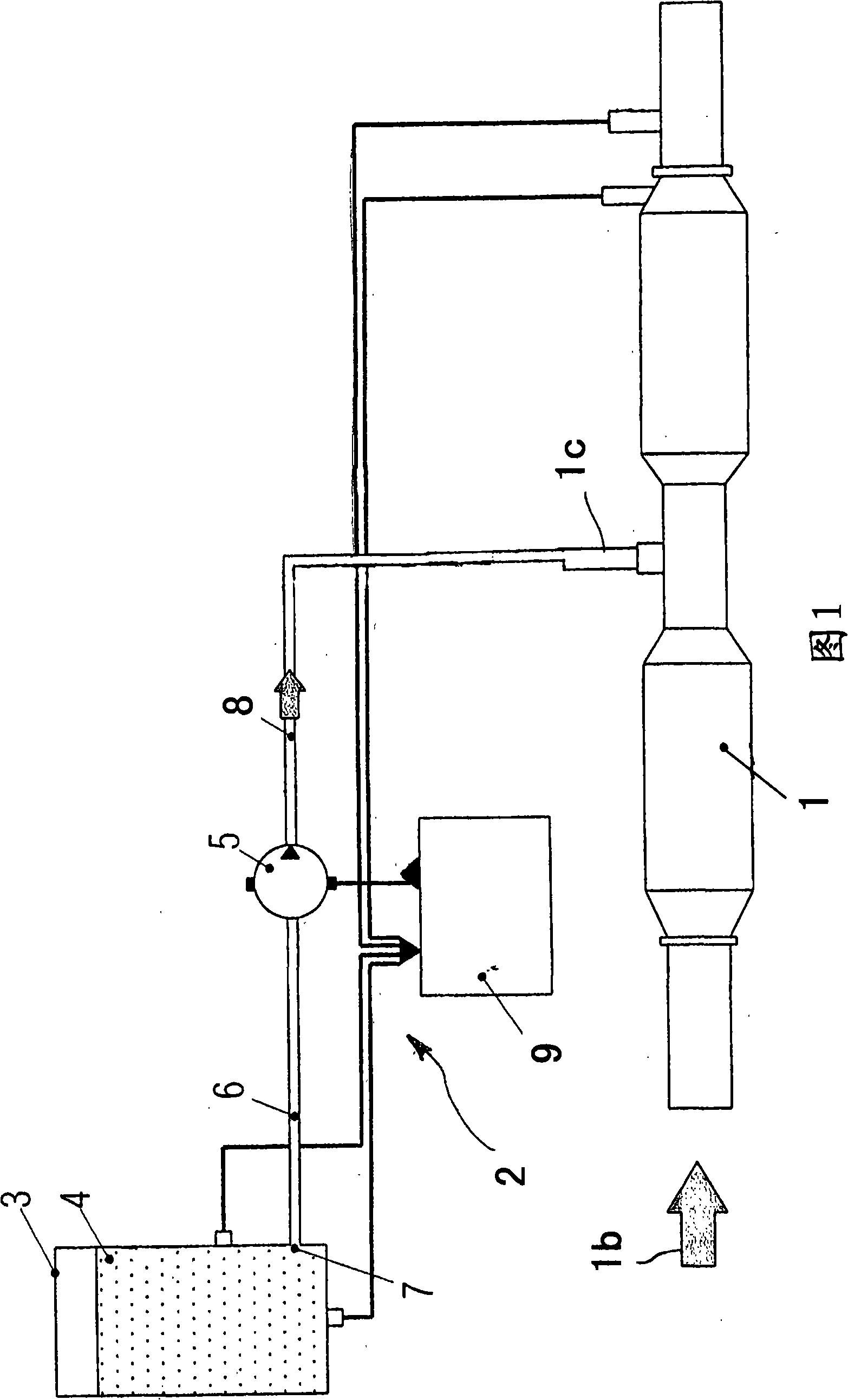

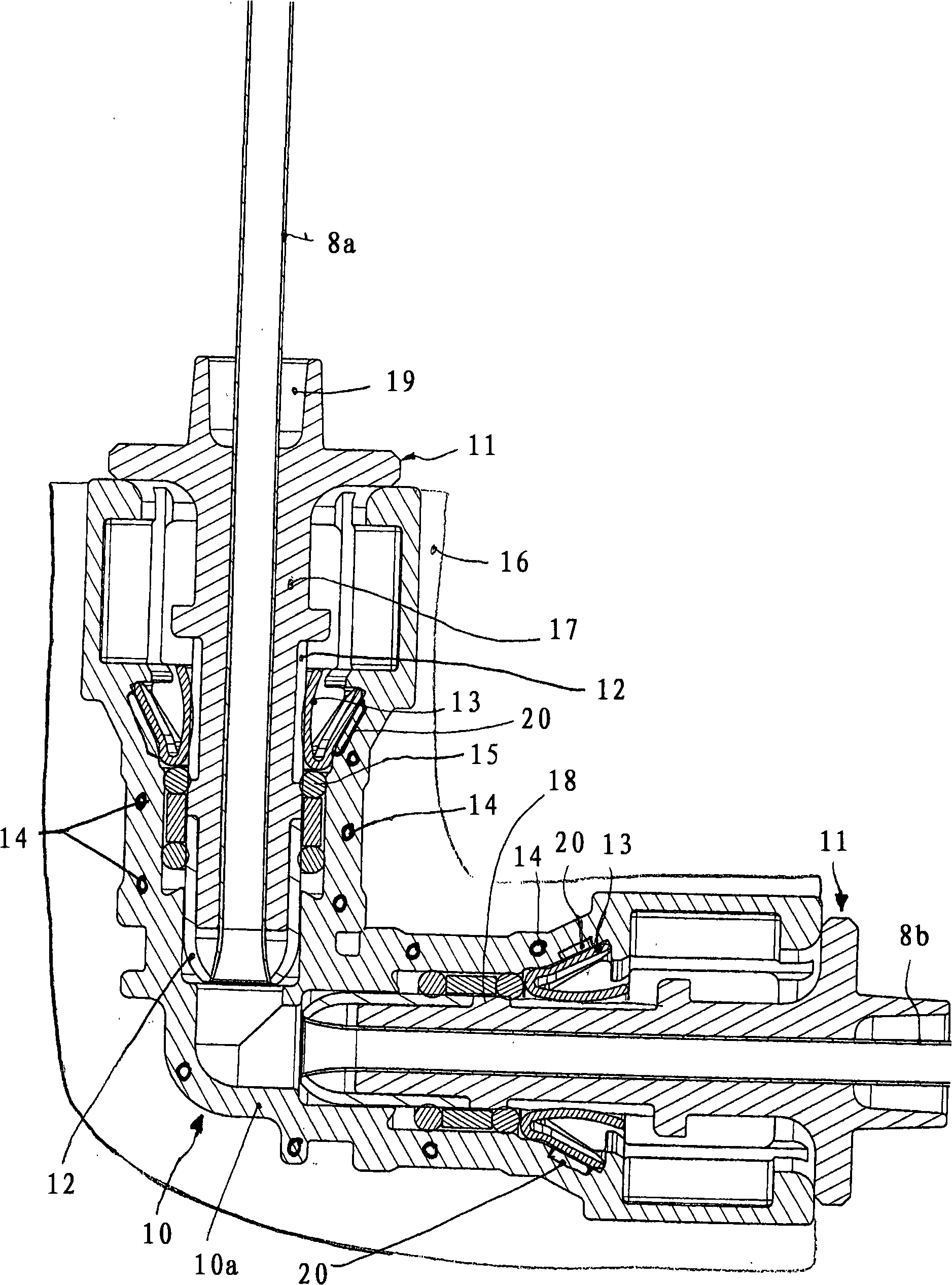

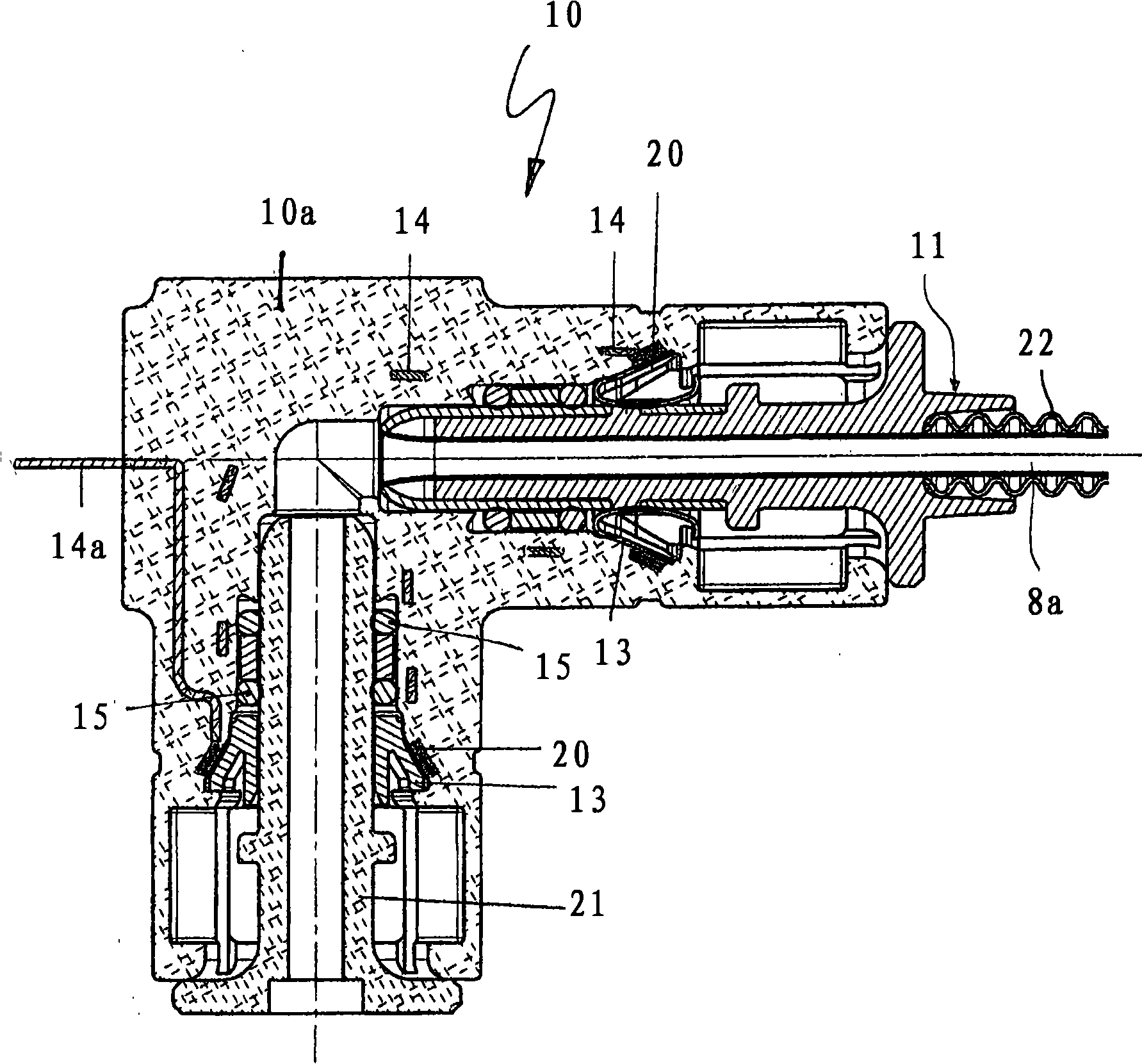

Reducing reagent supply system of internal-combustion engines and connecting component for connecting heating liquid conduit pipe thereof

InactiveCN101255812AEasy to installEasy to assembleExhaust apparatusDispersed particle separationElectricityCombustion

Owner:EICHENAUER HEIZELEMENTE

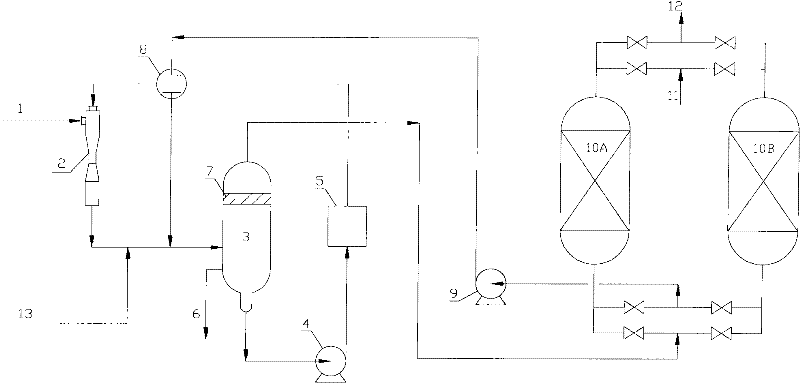

Hydrogen-peroxide high-efficiency utilization method and apparatus for desulphurization and denitration of low-temperature flue gas

InactiveCN106853328AIncrease profitReduce usageDispersed particle separationAir quality improvementFlue gasPhysical chemistry

The invention provides a hydrogen-peroxide high-efficiency utilization method and apparatus for desulphurization and denitration of low-temperature flue gas. According to the method, hydrogen peroxide is fed in the form of gas in the process of desulphurization and denitration of low-temperature flue gas via hydrogen peroxide. The apparatus comprises a hydrogen peroxide storage tank, a feed pump, a flue and an absorbing tower. The apparatus is characterized in that hydrogen peroxide is converted to a gaseous state after treatment by a device for feeding liquid hydrogen peroxide after direct heating and vaporization of liquid hydrogen peroxide, or a device for feeding hydrogen peroxide after bubbling of hot carrying gas in hydrogen peroxide, or a device for feeding hydrogen peroxide carried by hot carrying gas or a device for feeding atomized hydrogen peroxide carried by hot carrying gas; the gaseous hydrogen peroxide then enters the flue; and the gaseous hydrogen peroxide and hydroxyl radicals therein are used for desulphurization and denitration reactions. The method and apparatus provided by the invention changes a conventional liquid-gas mixed reaction into a gas-gas mixed reaction. Compared with liquid hydrogen peroxide, more hydroxyl radicals can be produced through decomposition in the process of vaporization of hydrogen peroxide, so the utilization rate of hydrogen peroxide and the removal rate of NOx are improved, and the usage amount of hydrogen peroxide is reduced.

Owner:UNIV OF JINAN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap