Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vaporization (or vaporisation) of an element or compound is a phase transition from the liquid phase to vapor. There are two types of vaporization: evaporation and boiling. Evaporation is a surface phenomenon, whereas boiling is a bulk phenomenon.

Composite air-conditioning system combining air source heat pump system and rotating wheel dehumidification system

InactiveCN102384539AReduce energy consumptionImprove thermal comfortLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

The invention relates to a composite air-conditioning system combining an air source heat pump system and a rotating wheel dehumidification system. The composite system comprises a heat pump system and a rotating wheel dehumidification system; the dehumidifier unit consists of a dehumidification rotating wheel, a heat exchange rotating wheel, an evaporator, a heater, an air refreshing machine andan exhaust fan; and the heat pump unit consists of equipment such as a frequency conversion compressor, an outdoor heat exchanger, an indoor heat exchanger, a gas-liquid separator, a four-way change valve and the like. The composite air-conditioning system is combined with indoor radiant heating and cooling, and by means of controlling an electronic expansion valve, an electromagnetic valve, a one-way valve and a constant pressure valve, two vaporization temperature operation conditions are realized; and a dehumidification rotating wheel, a heat exchange rotating wheel, and the outdoor heat exchanger and the indoor heat exchanger of the heat pump unit are combined, the high temperature waste heat of the exhaust air of the compressor is used as the renewable energy for the dehumidificationrotating wheel, and part of cold of the heat pump is used for cooling the refreshed air, thus the performance of the dehumidifier unit is improved.

Owner:JIANGSU UNIV

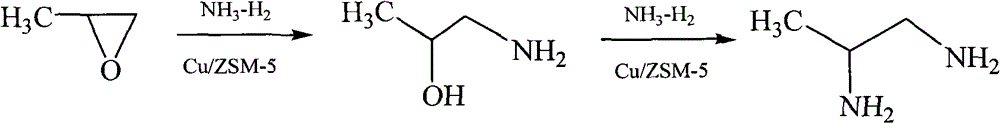

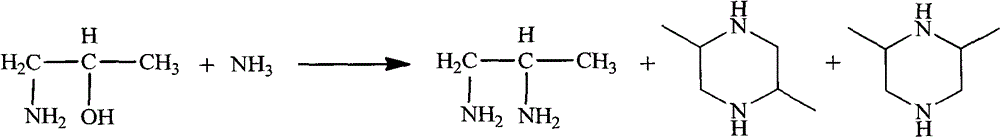

Coproduction method of 1, 2-propanediamine and dimethyl piperazine

InactiveCN102718661AReduce consumptionLow costOrganic compound preparationAmino compound preparationPorosityContact time

Owner:XIAN MODERN CHEM RES INST

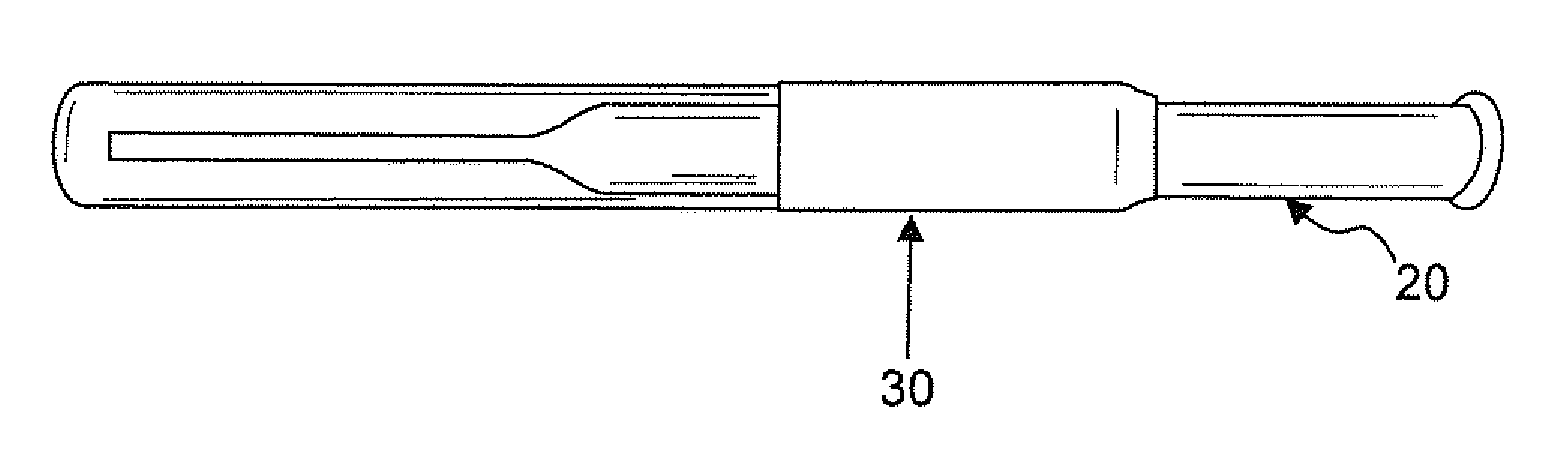

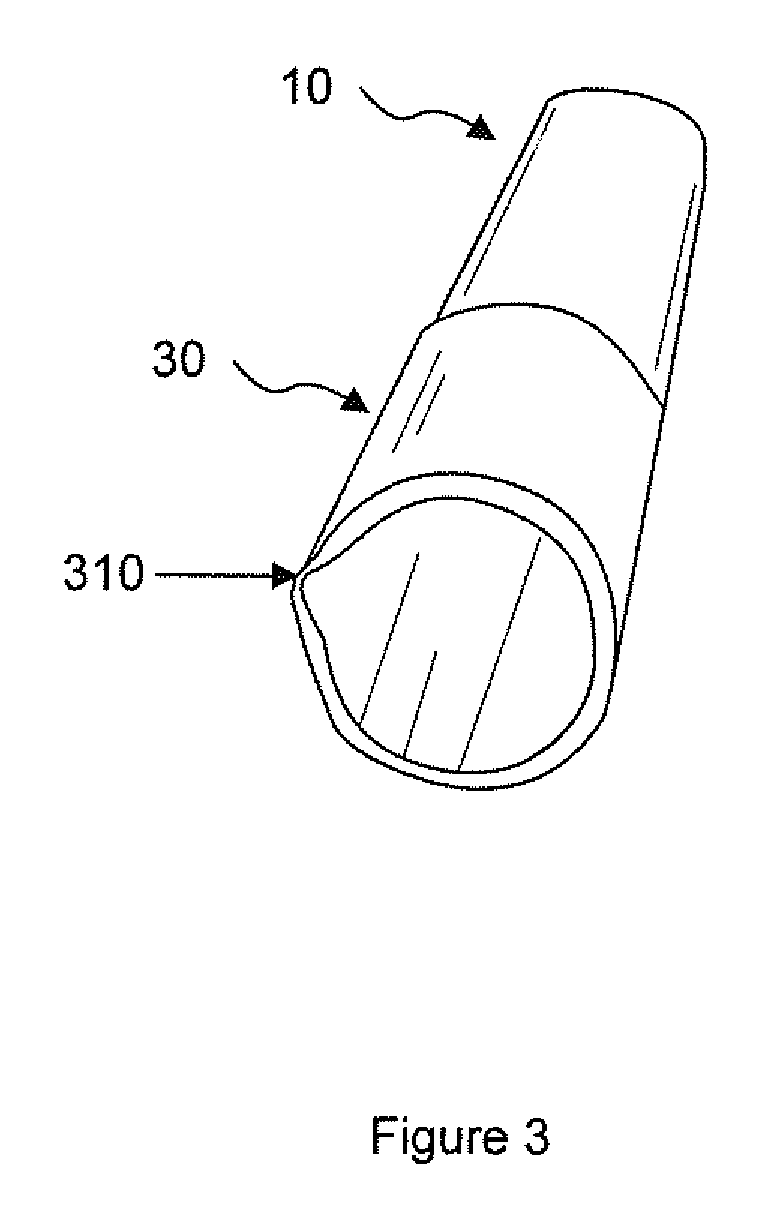

Portable Sublimation Device

Owner:COHN HARRIS

Preparation method for micron-size carbonyl iron and nickel alloy powder

ActiveCN105965033AReduce carbon and oxygen impurity contentEven distribution of iron and nickelEvaporationHigh pressure

Owner:JIANGYOU HEBAO NANO MATERIAL CO LTD

Low temperature plasma grafting vaporization method and apparatus

InactiveCN102744024AEasy to cleanEasy to replaceChemical/physical/physico-chemical processesTemperature controlVaporization

The invention provides a low temperature plasma grafting vaporization method and its apparatus, the apparatus comprises a material storing can, a heating device, a temperature control apparatus, a cleaning device and a flow regulator. The material storing can is composed of a material storing chamber, a top cover and a sealing ring, the material storing chamber is connected to a top cover by a screw, a feed inlet, a gas outlet and a temperature control probe installation port are provided on the top cover, the feed inlet, the gas outlet and the temperature control probe installing port are connected to the top cover by sealing with an O-shaped sealing ring, The heating device comprises the heating of the material storing can and a conveying pipeline. The invention has the advantages of simple operation, easy vaporization amount control, difficult condensation and easy cleaning, and provides convenience for usage, and the raw material scope is wide.

Owner:SUZHOU OPS PLASMA TECH

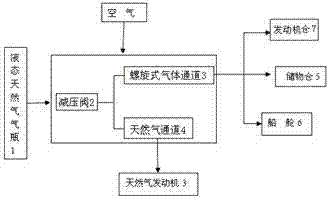

Liquefied natural gas latent heat energy reuse system of liquefied natural gas boat

InactiveCN103043204AIncrease resistanceImprove heat transfer coefficientAuxillariesVessel ventillation/heating/coolingGas solidHot weather

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap