Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combustion in a fire produces a flame, and the heat produced can make combustion self-sustaining. Combustion is often a complicated sequence of elementary radical reactions. Solid fuels, such as wood and coal, first undergo endothermic pyrolysis to produce gaseous fuels whose combustion then supplies the heat required to produce more of them. Combustion is often hot enough that incandescent light in the form of either glowing or a flame is produced. A simple example can be seen in the combustion of hydrogen and oxygen into water vapor, a reaction commonly used to fuel rocket engines. This reaction releases 242 kJ/mol of heat and reduces the enthalpy accordingly (at constant temperature and pressure)...

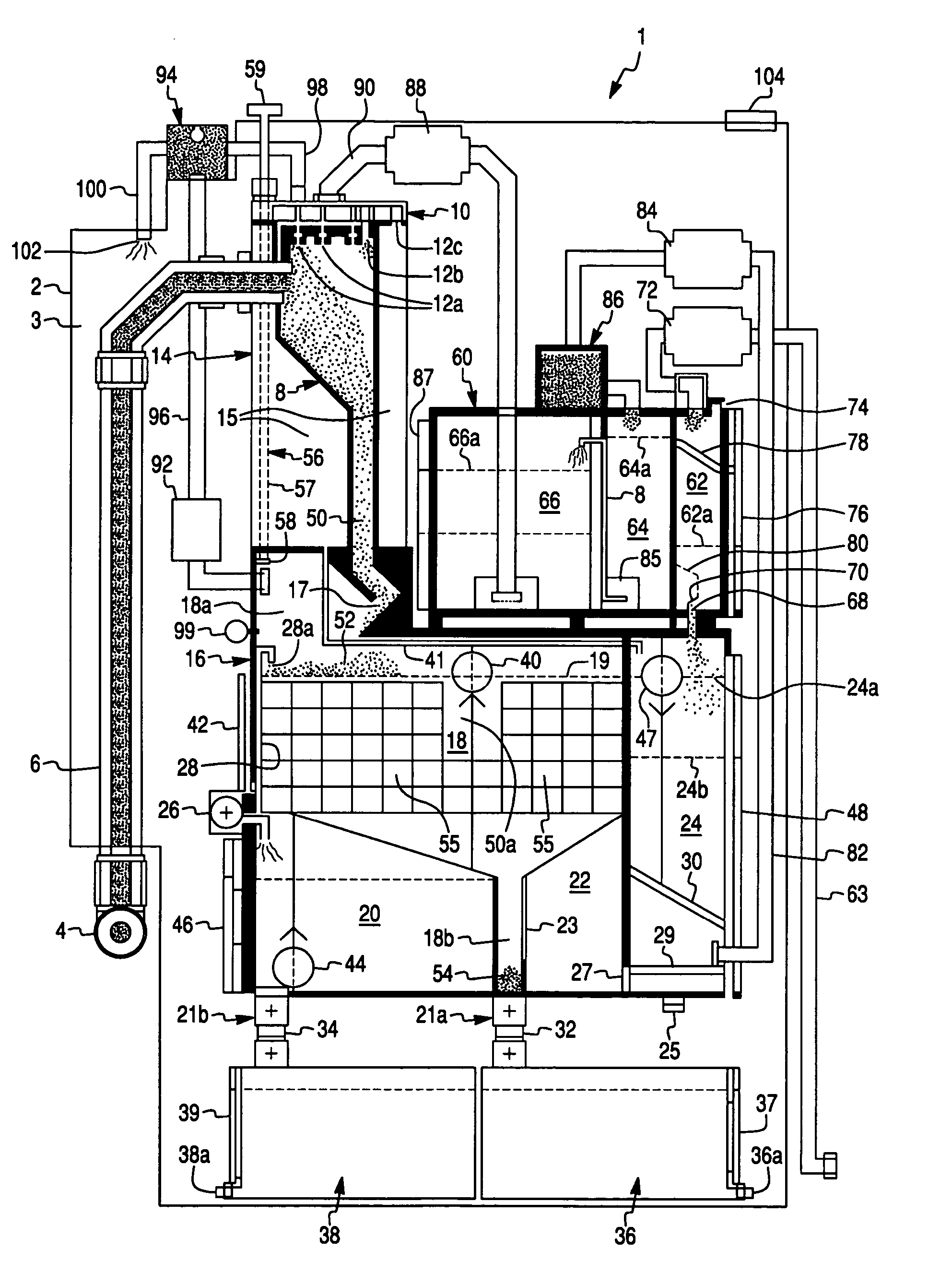

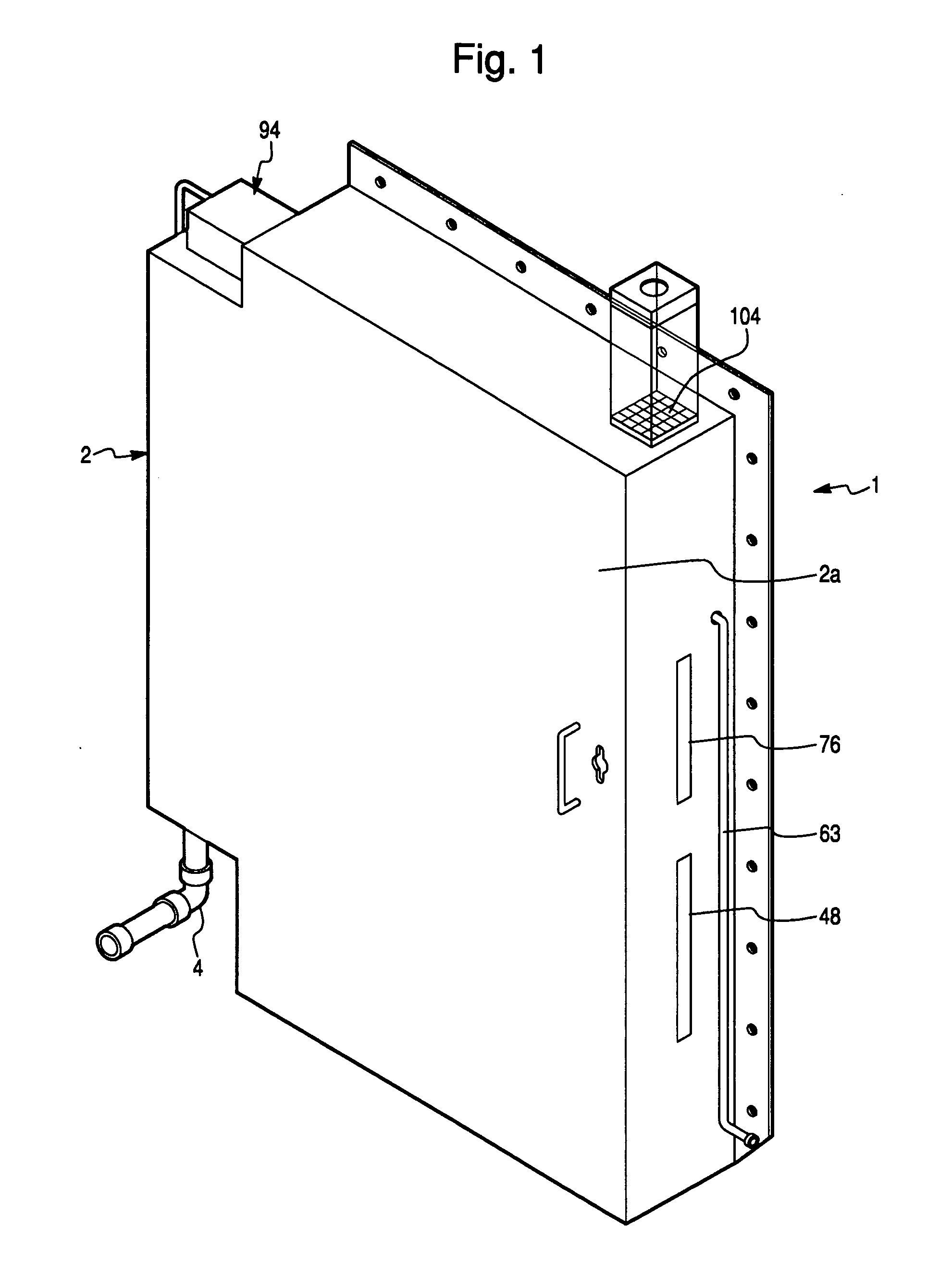

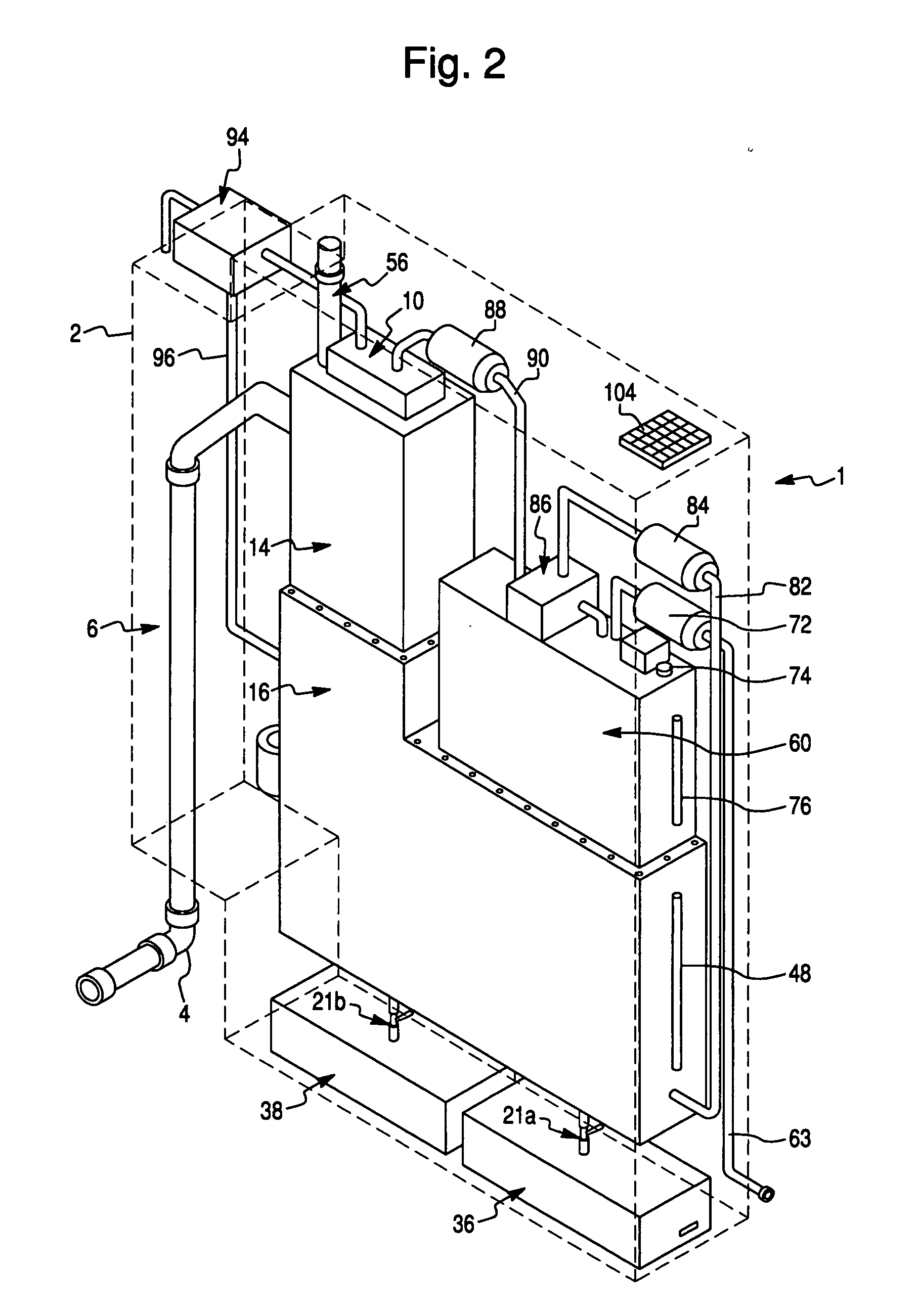

Apparatus for generating freshwater

InactiveUS20060000355A1Solve problemsSeawater treatmentGeneral water supply conservationSeawaterCombustion

Owner:MITSUBISHI HEAVY IND LTD

Electrically controlled solid propellant

Owner:DIGITAL SOLID STATE PROPULSION

Detection device

InactiveUS20120237402A1Improve accuracyImprove operational reliabilityInternal-combustion engine testingThermometer detailsCombustionEngineering

Owner:ELTEK

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

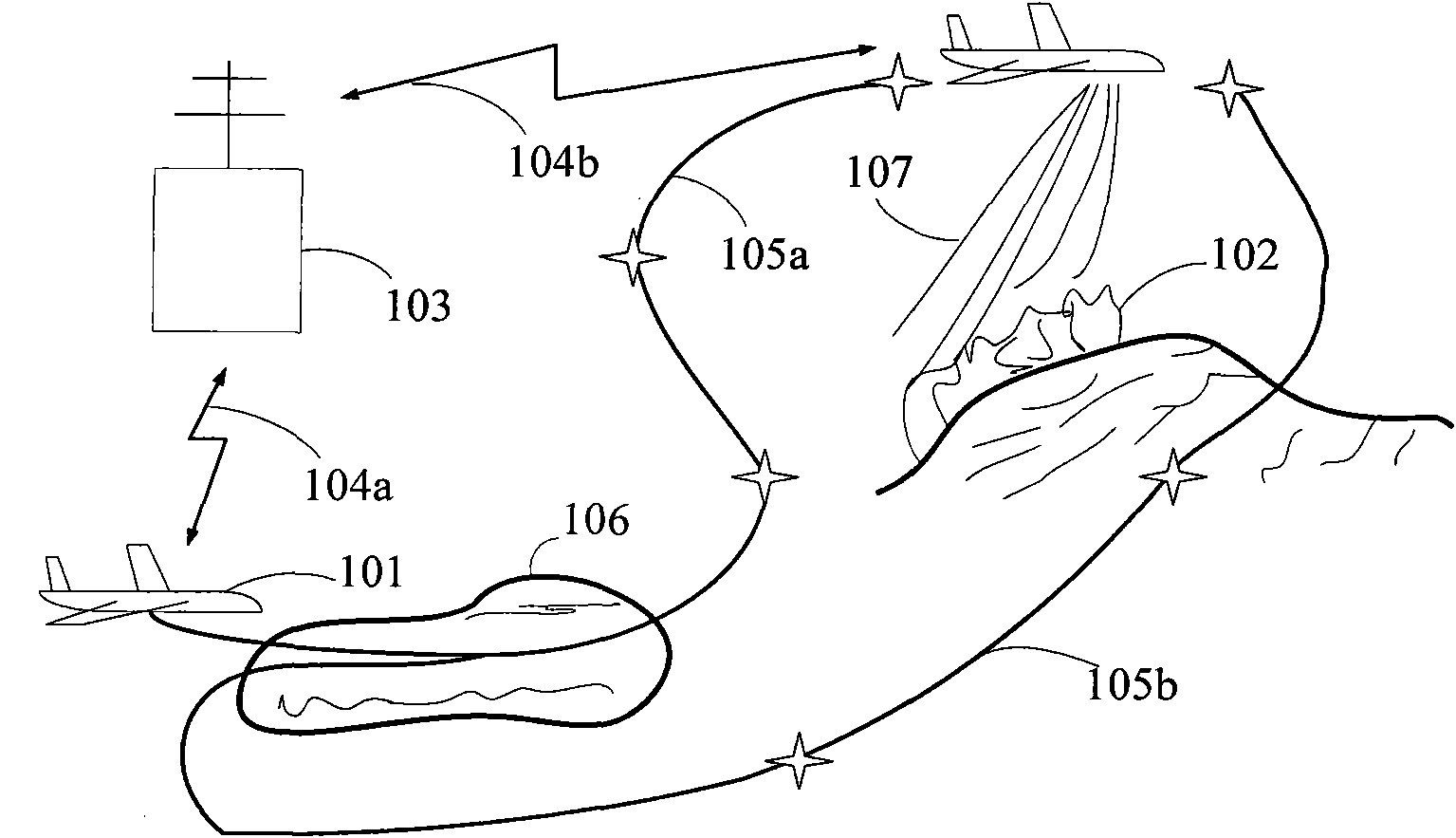

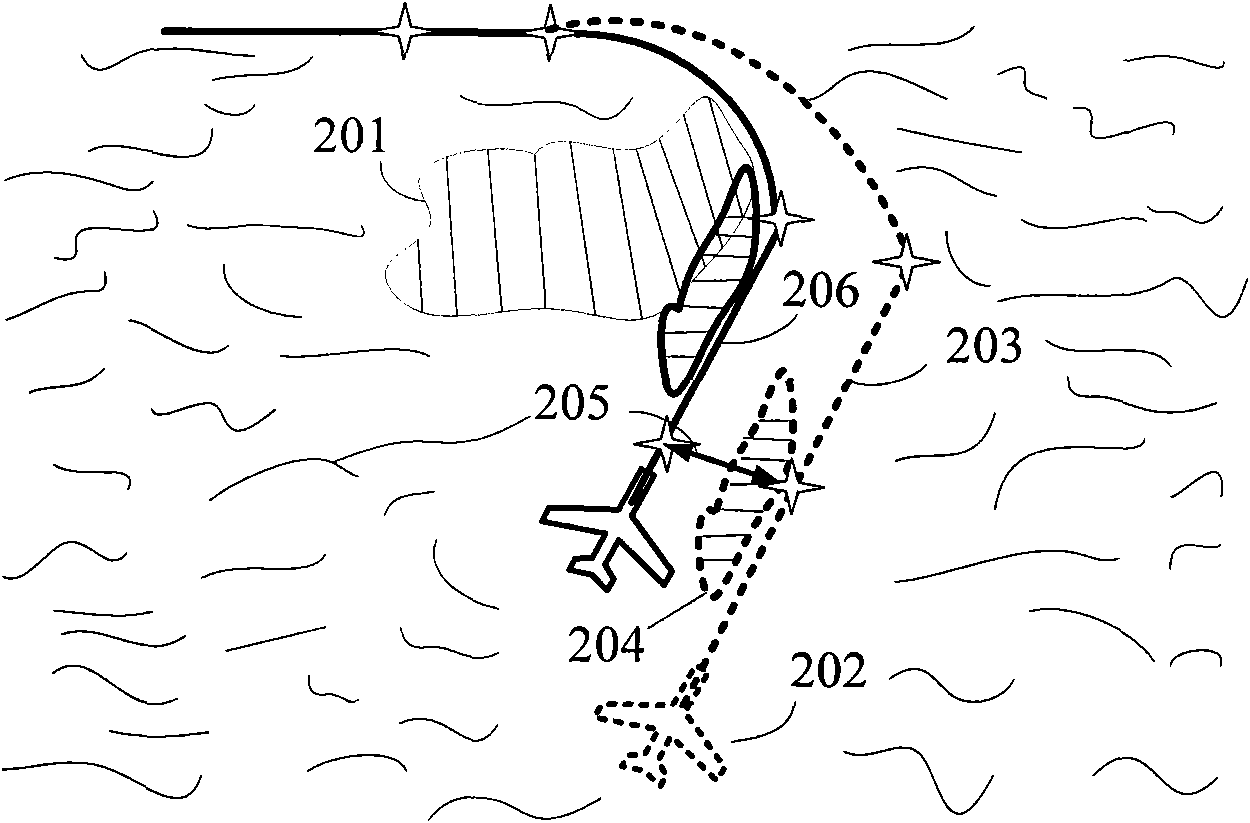

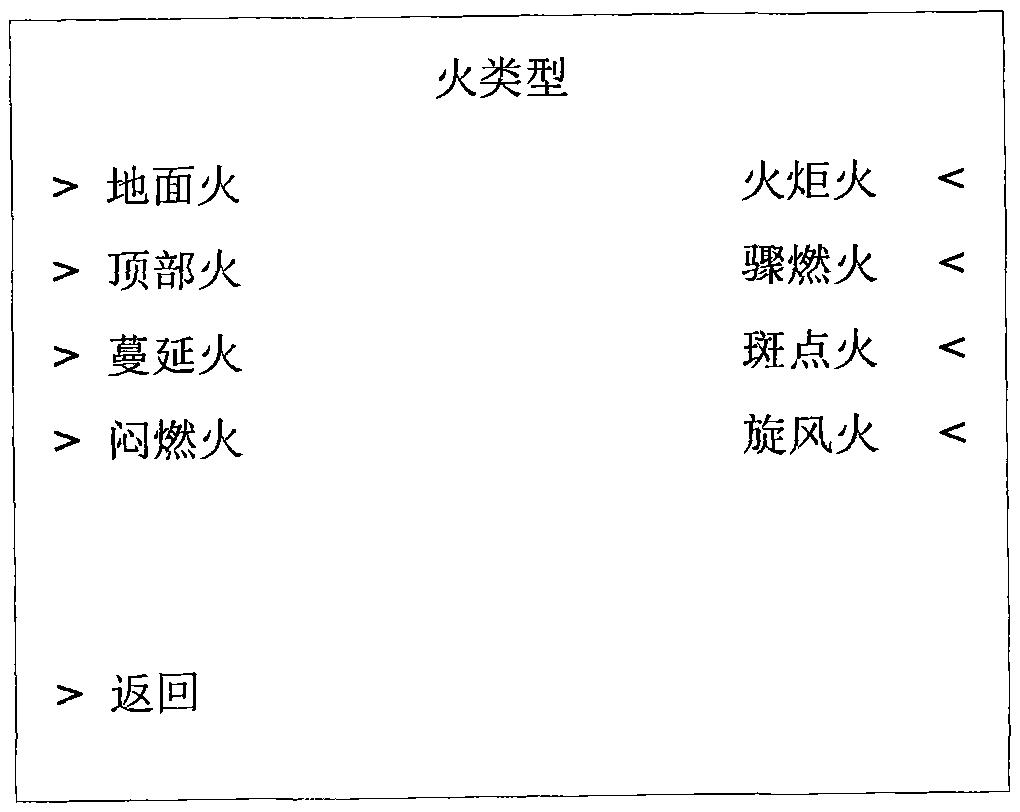

Airline extinguishment auxiliary device and airline extinguishment method

ActiveCN101927068ARapid change of flight planImprove securityAircraft componentsFire rescueAviationCombustion

Owner:上海航空电子有限责任公司

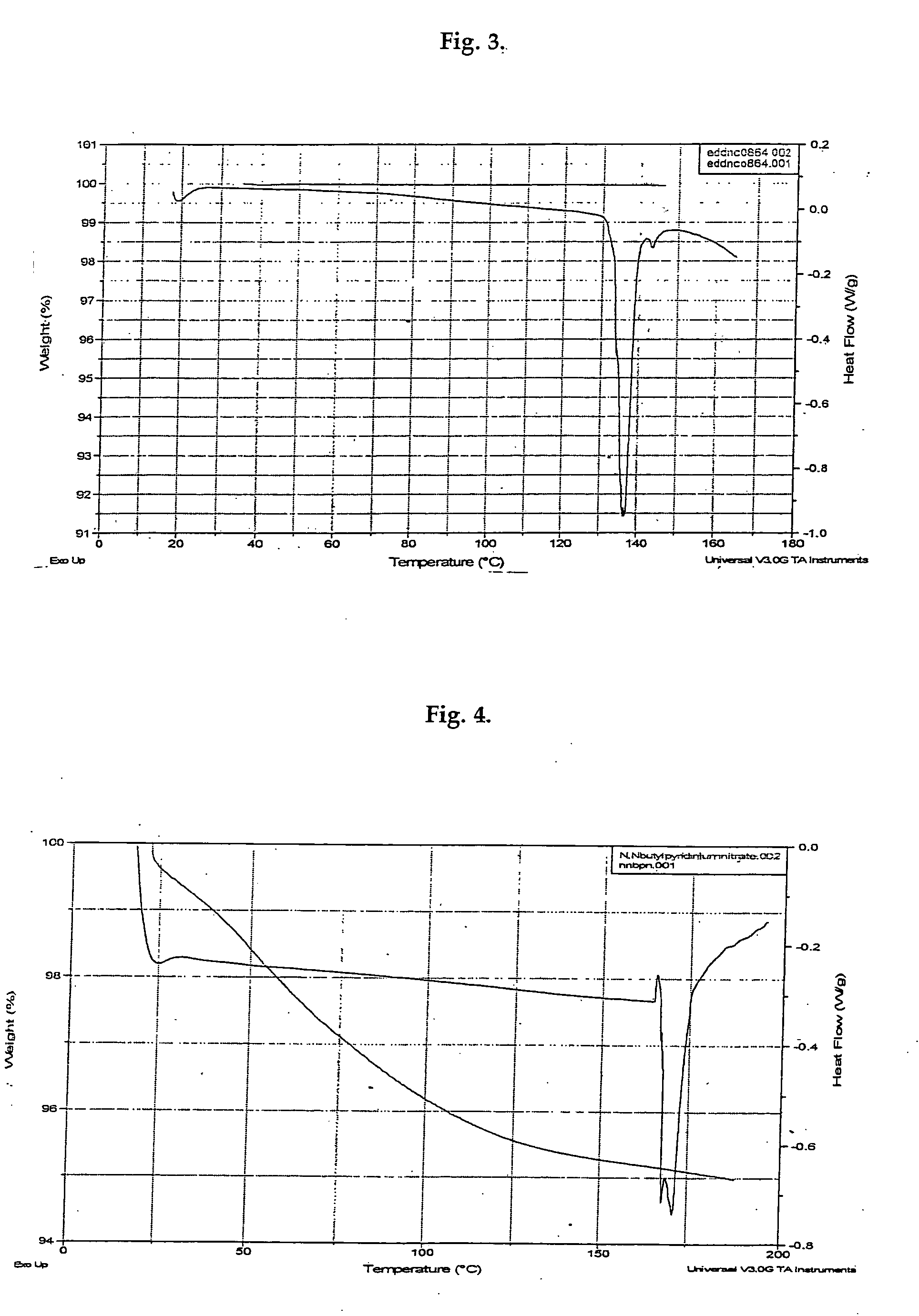

Aftertreatment system and control strategy for internal combustion engine

ActiveUS20120260633A1Shorten speedBreakage of the DPFElectrical controlNon-fuel substance addition to fuelExternal combustion engineLow load

In an exhaust gas treatment device in which a diesel oxidation catalyst and a DPF are provided in an exhaust pipe of an internal combustion engine, abnormal combustion in the DPF, occurring when the internal combustion engine varies from a high load condition to a low load condition, poses a problem. To solve this problem, in the present invention, a DPF abnormal combustion causing operation is determined to have occurred when the internal combustion engine shifts from a high rotation or high load operation region α to a low rotation, low load operation region β within a set time T1. When it is determined that a DPF abnormal combustion causing operation has occurred, abnormal combustion of PM collected in the DPF is suppressed by fully opening an intake throttle valve 44 in order to increase an exhaust gas flow so that heat is removed by sensible heat of the exhaust gas, thereby cooling a DPF device 52, and continuing a late post-injection in order to reduce an oxygen concentration of the DPF. As a result, an abnormal temperature increase in the DPF device 52 can be suppressed early.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

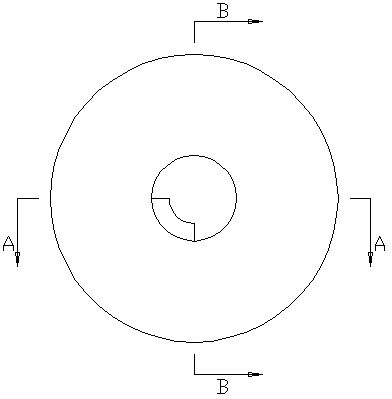

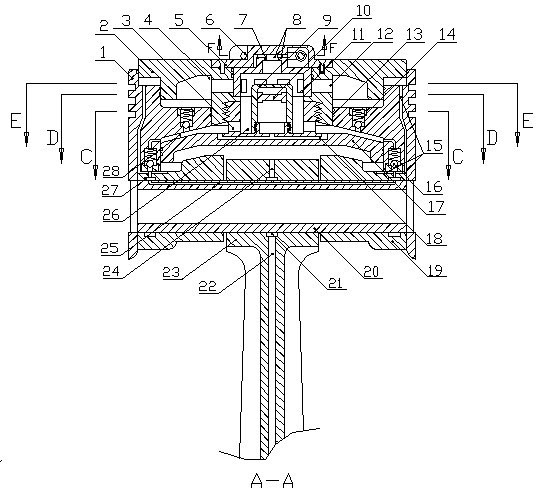

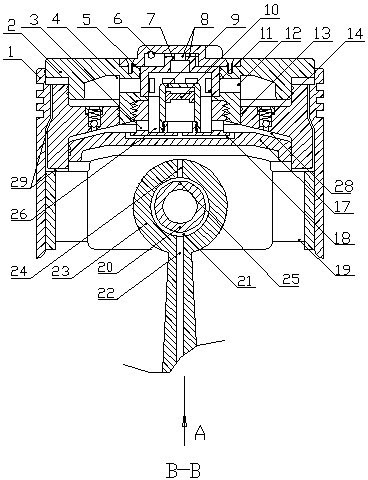

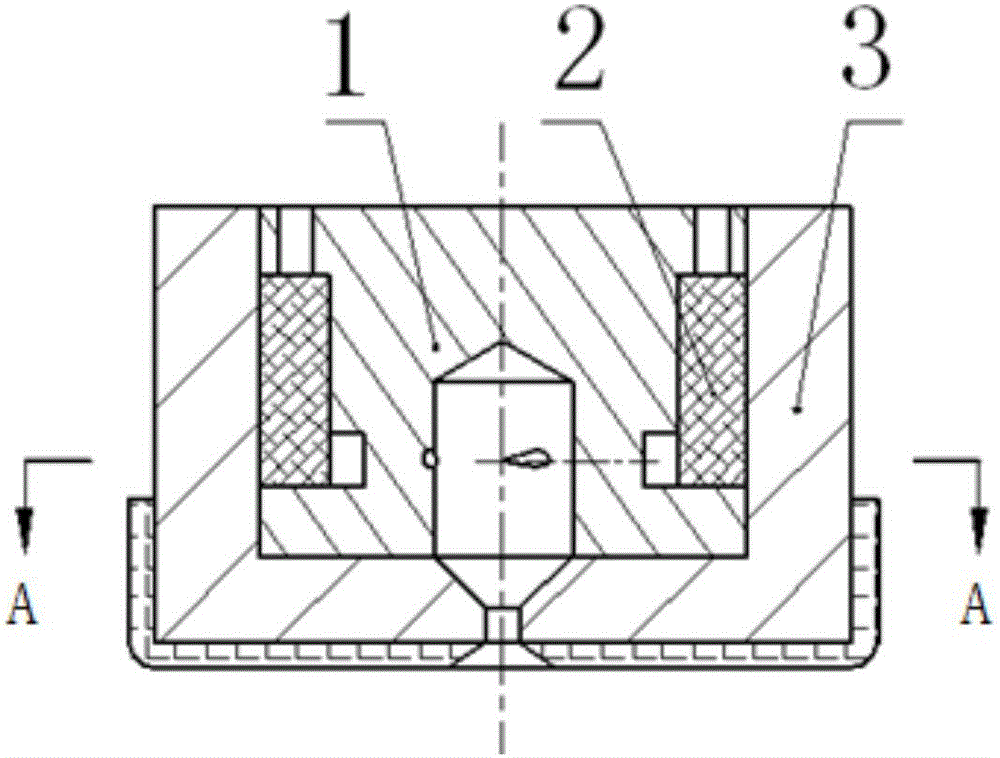

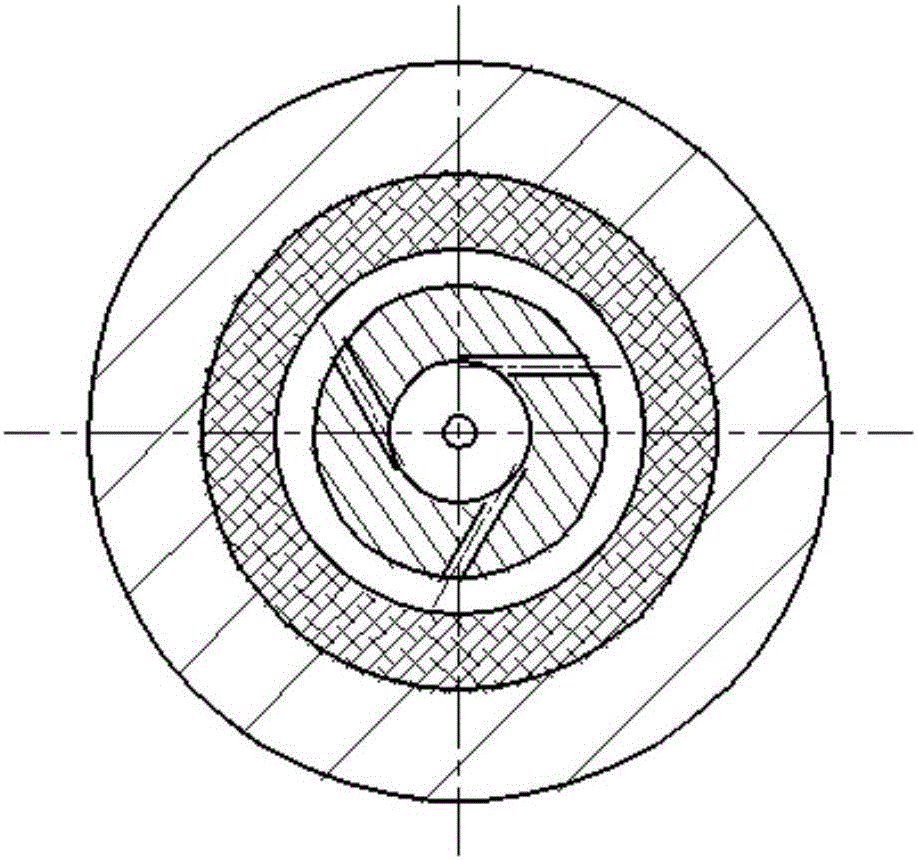

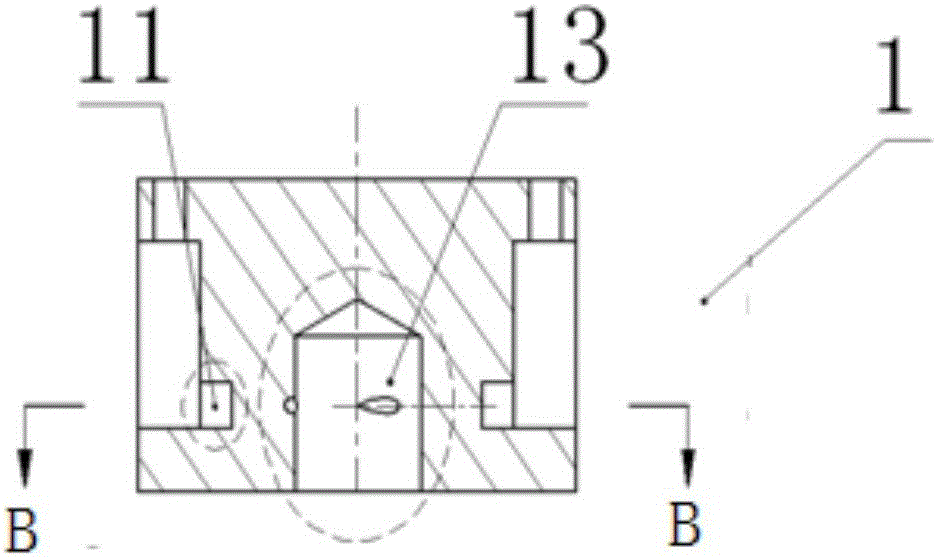

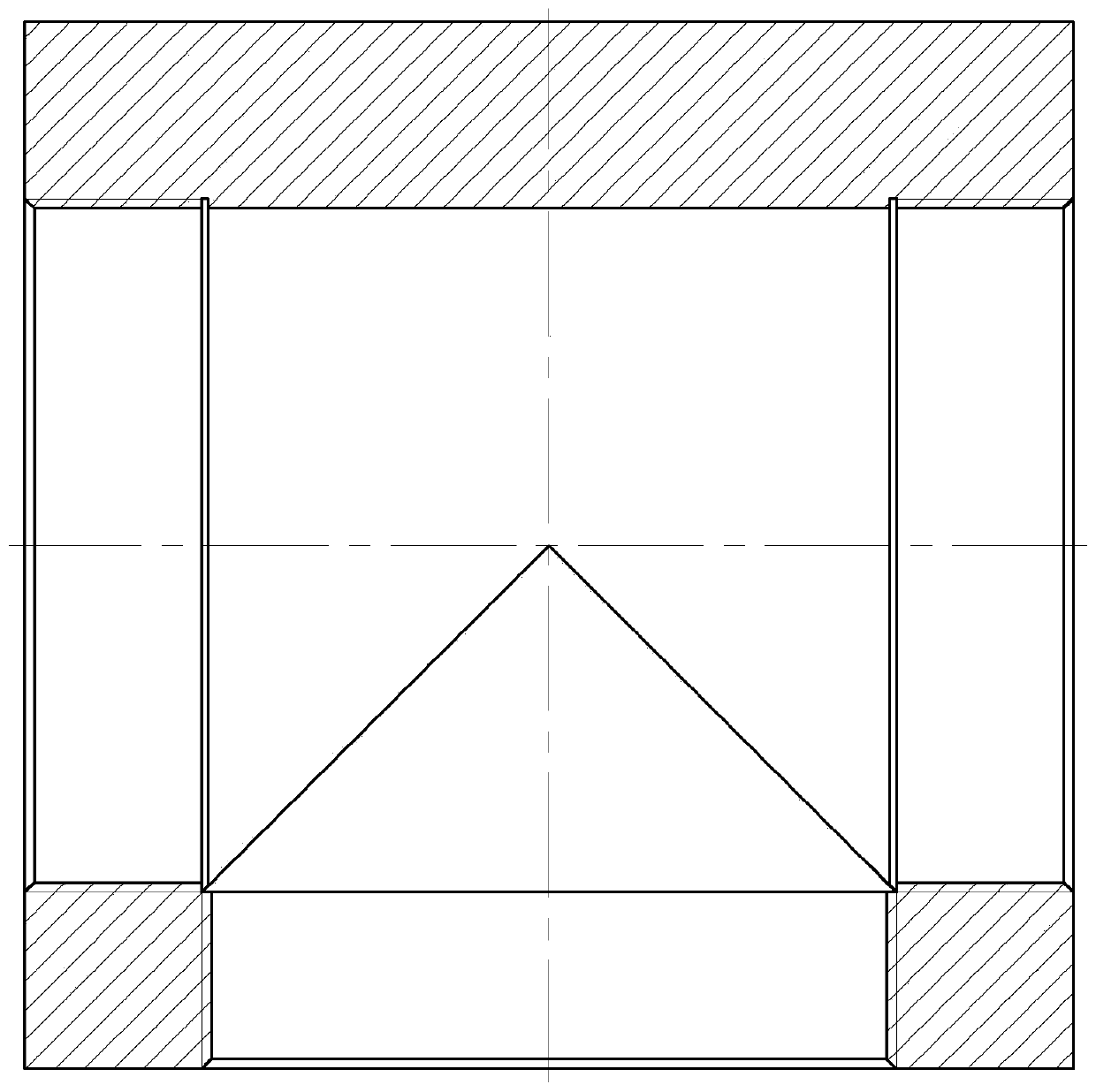

Adaptive variable compression engine piston

ActiveCN102330617ANo significant volume changeActual replacement installationEngine controllersMachines/enginesCombustionCheck valve

Owner:安徽格太信控科技有限公司

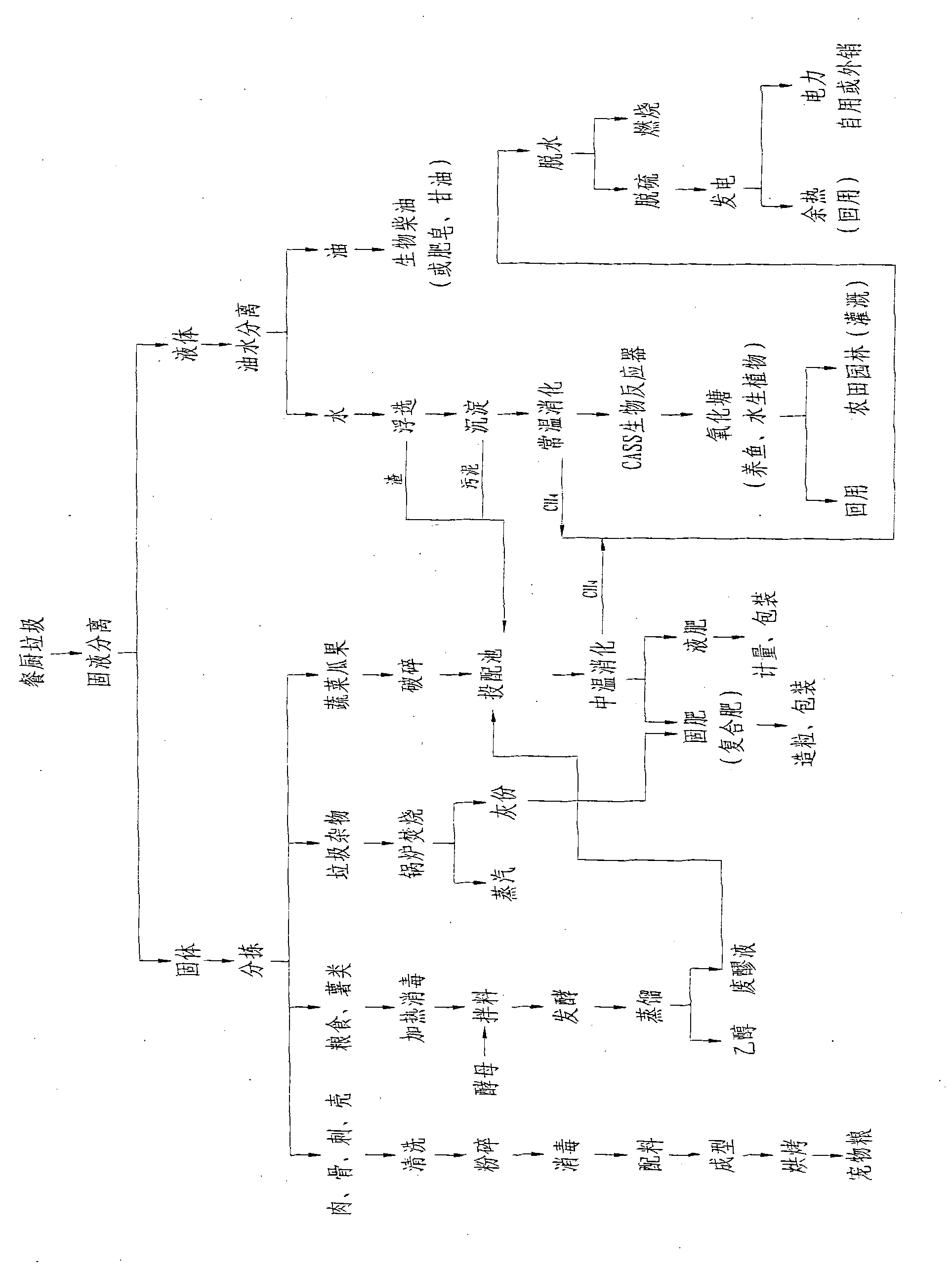

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

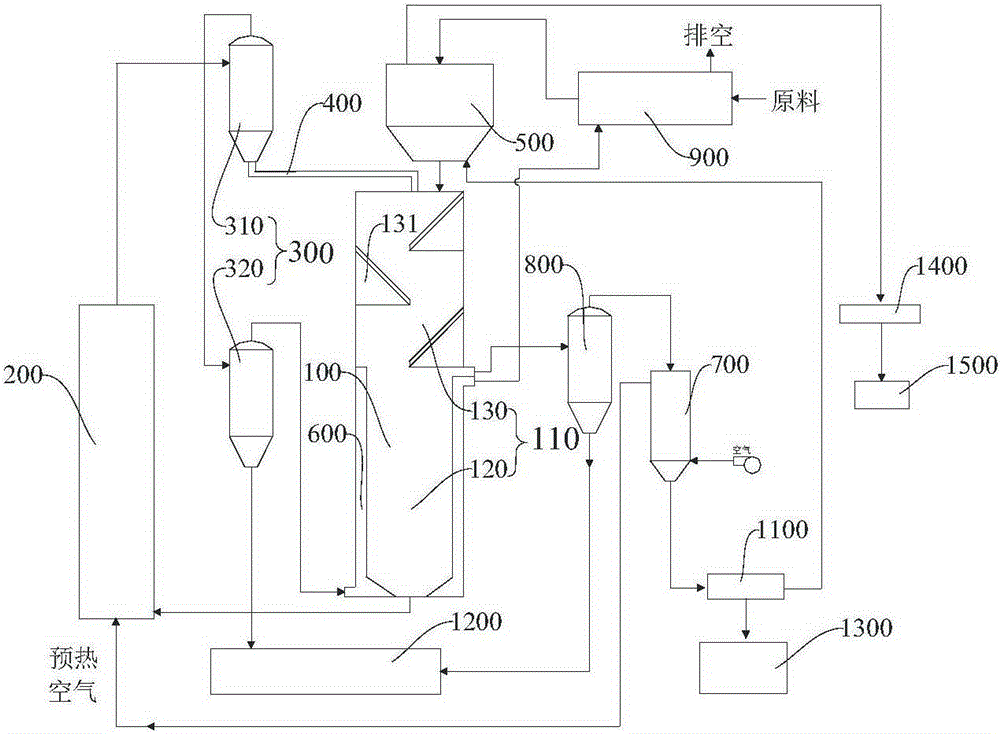

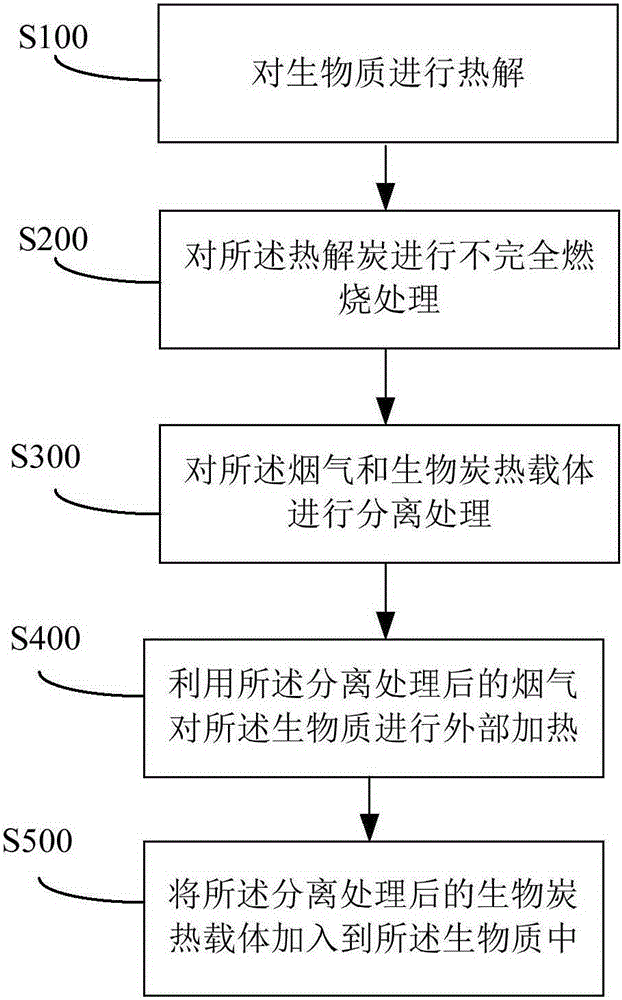

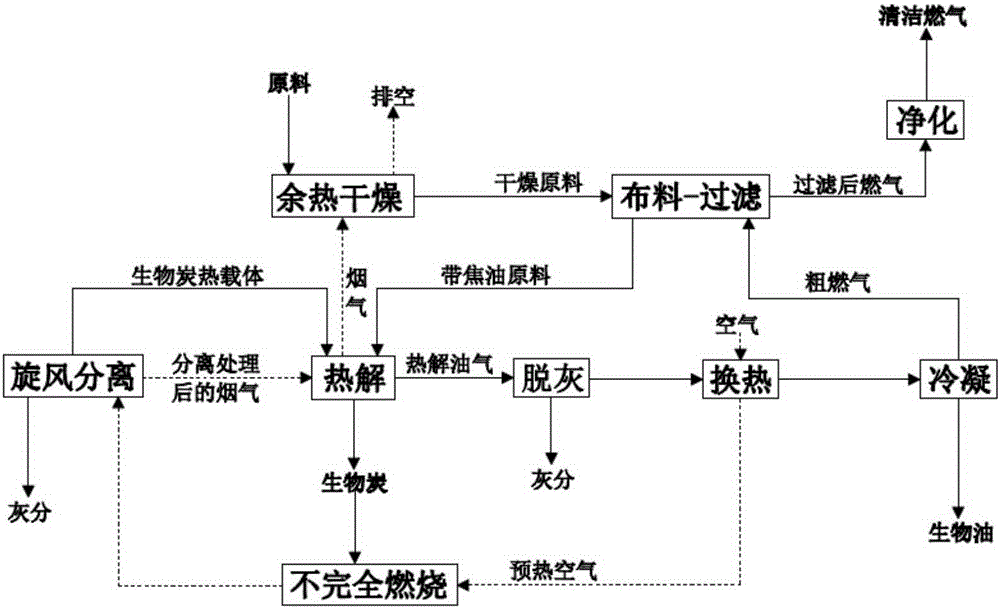

Biomass pyrolysis system and biomass pyrolysis method

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

Method and composition for improving fuel combustion

InactiveUS20050081430A1Promote combustionLighting and heating apparatusGaseous fuelsCombustionMethyl isobutyl ketone

Owner:CARROLL & ASSOC LLC

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

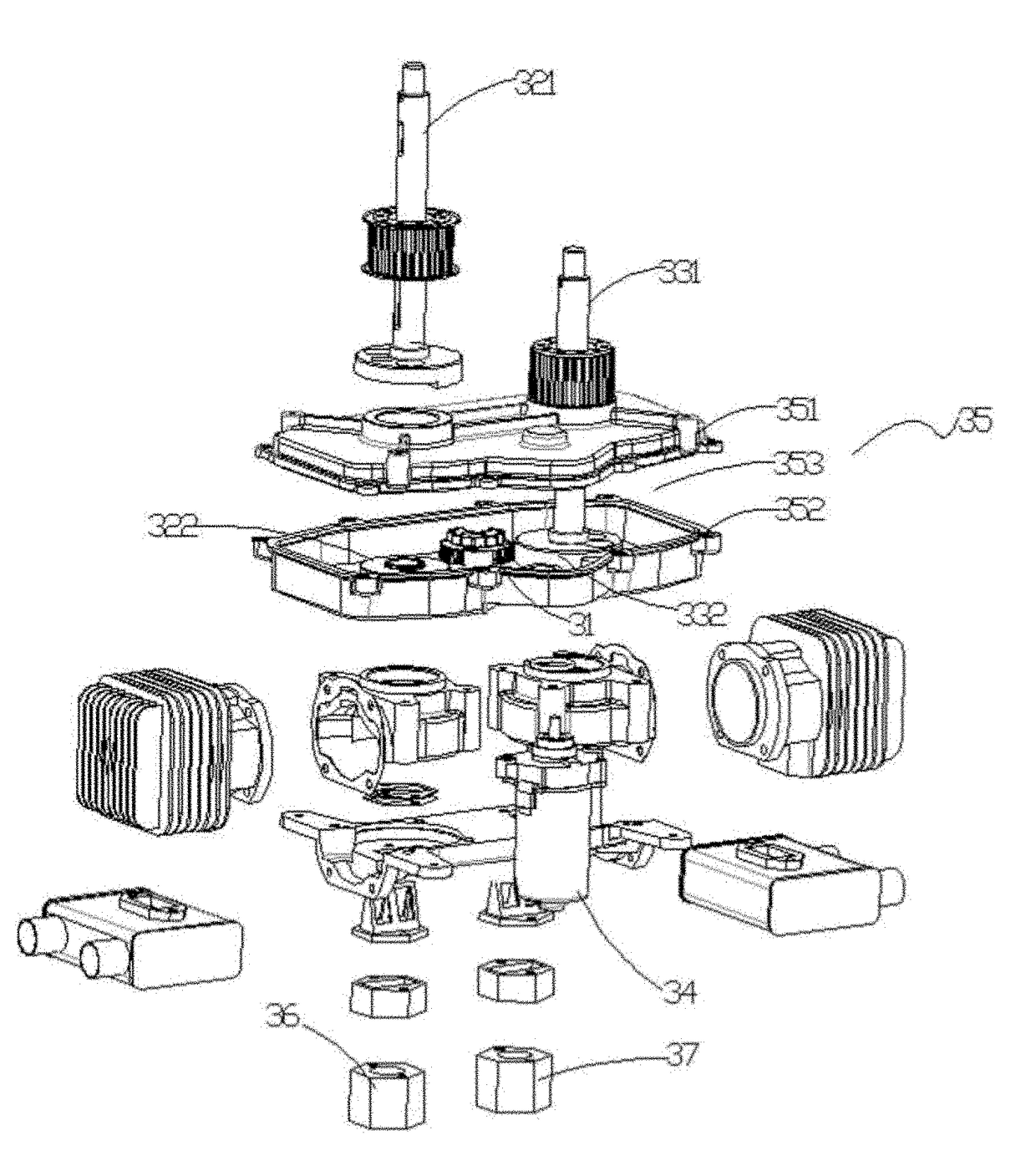

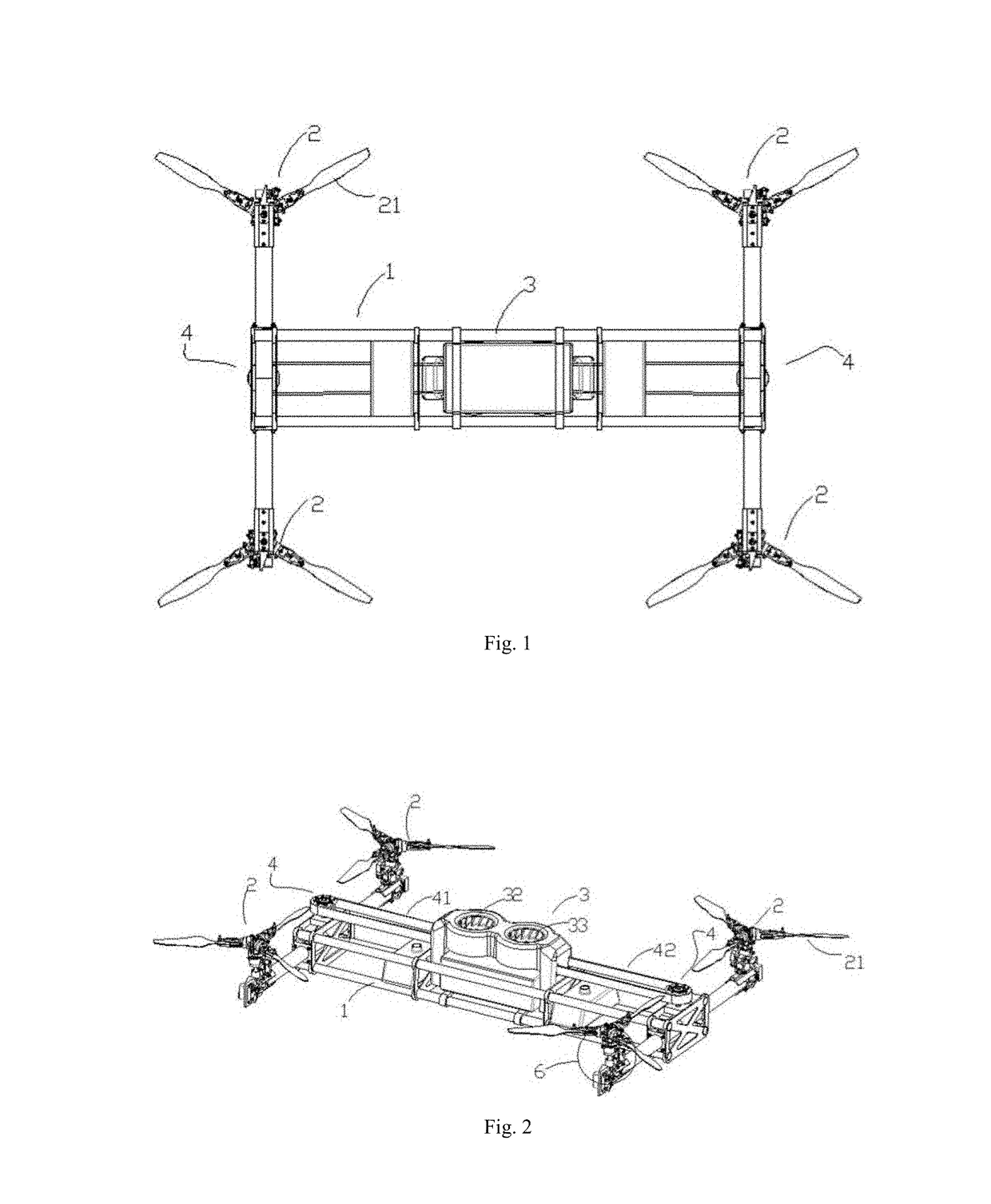

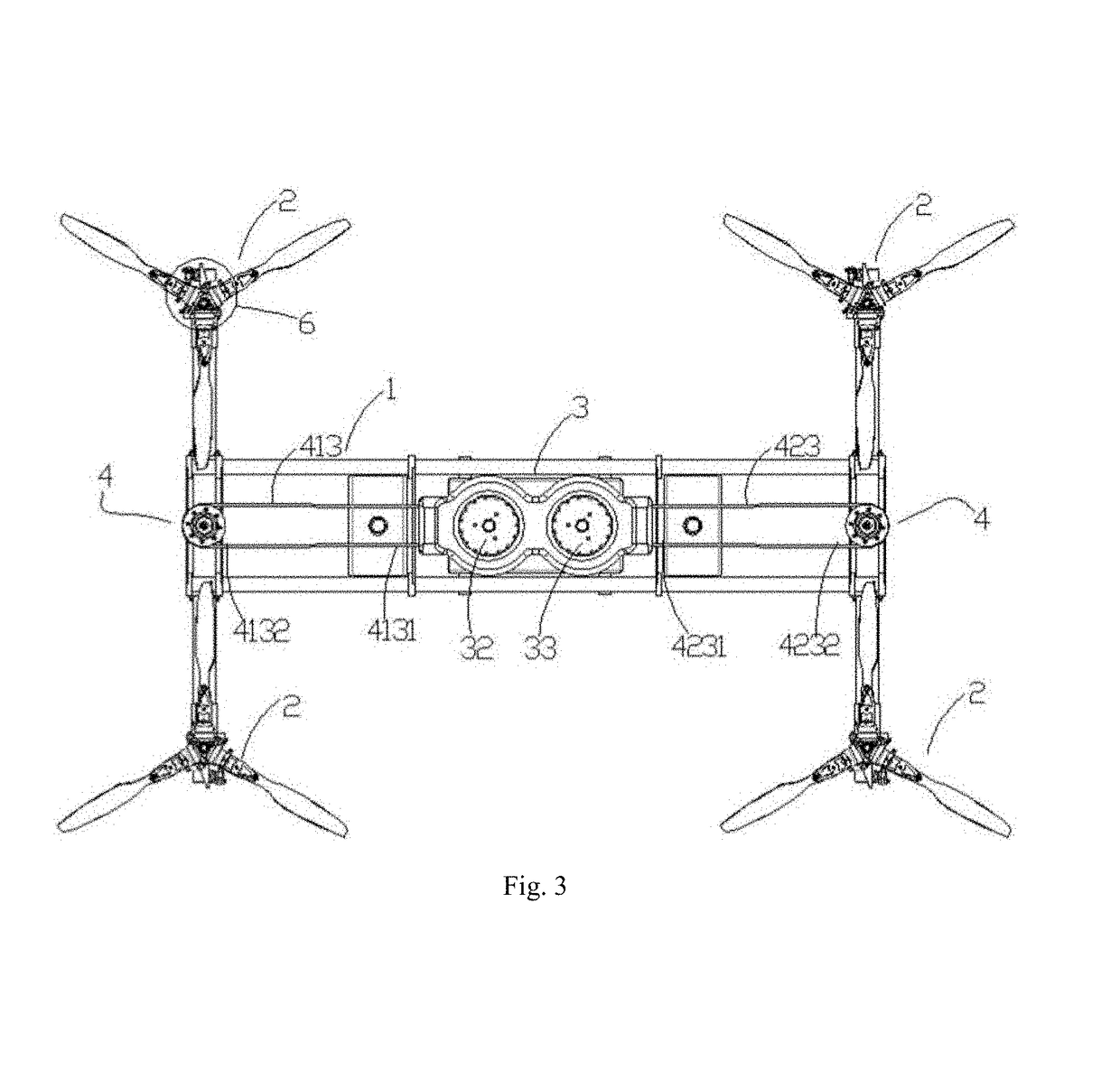

Multi-shaft power source unmanned flight equipment

InactiveUS20180030887A1Extended durationIncrease load capacityUnmanned aerial vehiclesCombination enginesCombustionUncrewed vehicle

Owner:EWATT TECH CO LTD

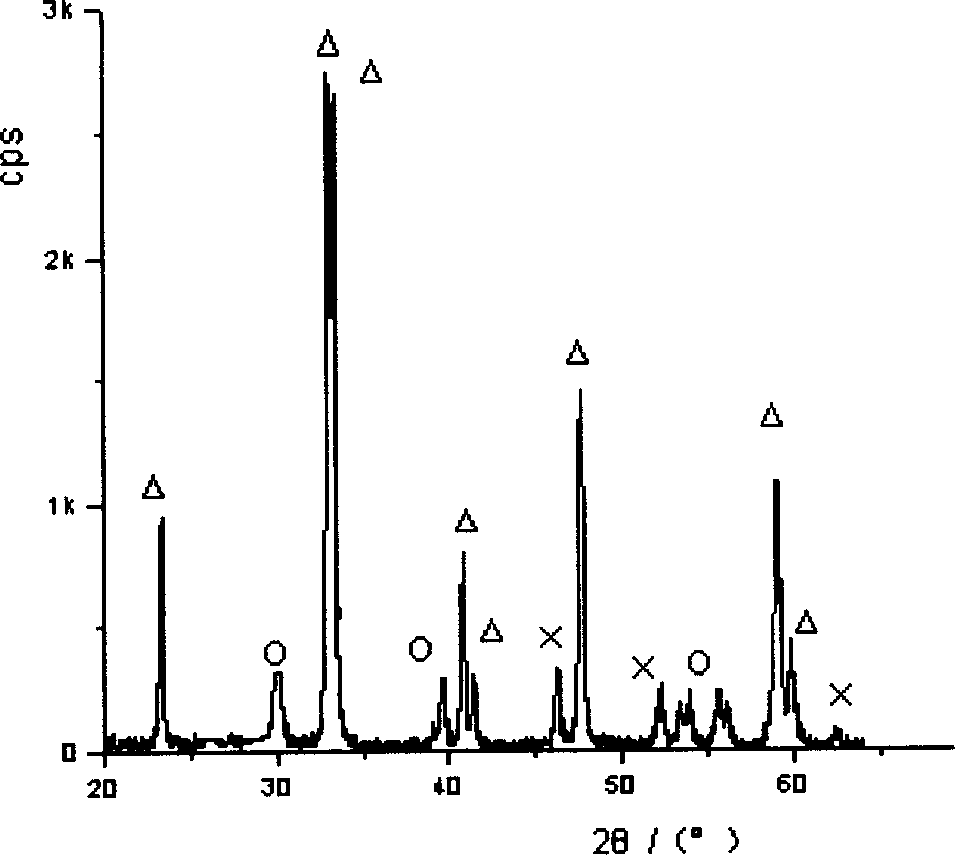

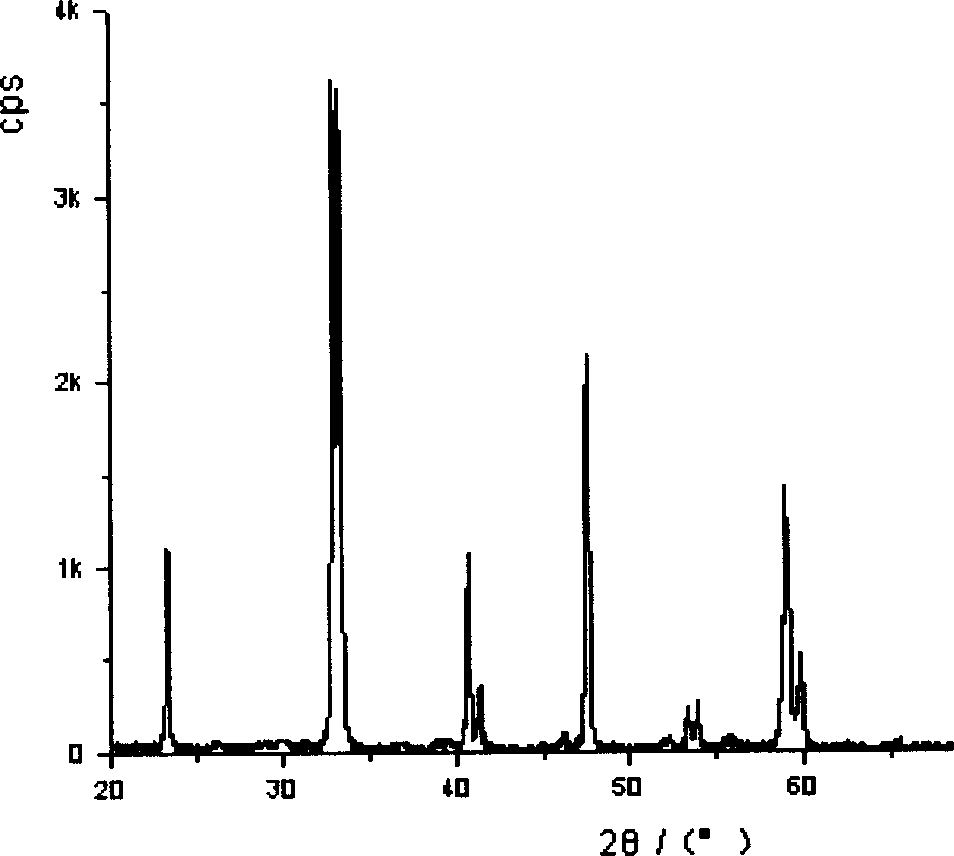

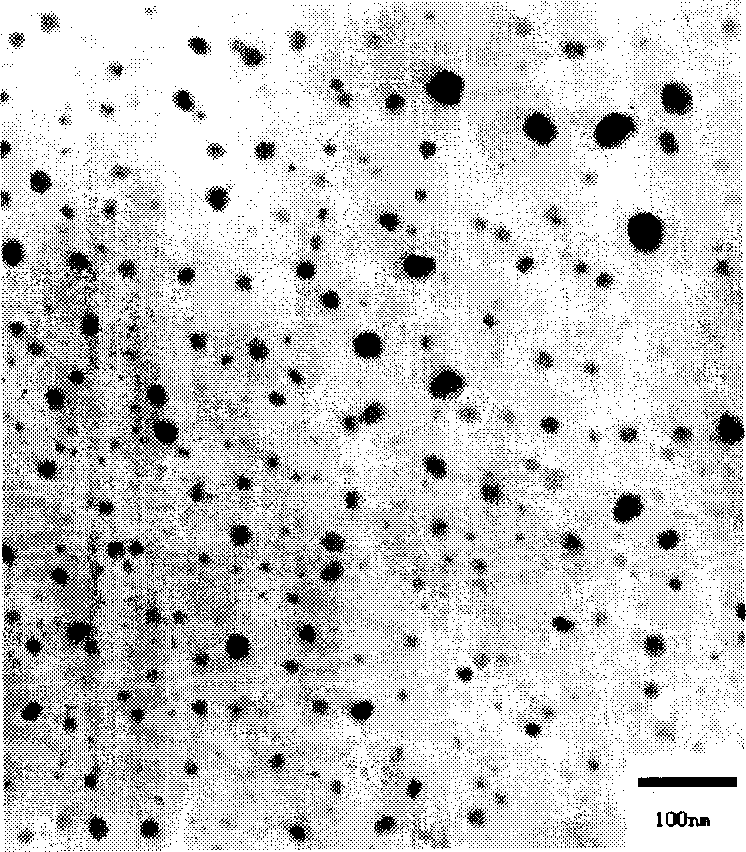

Method of burning gel of stearic acid for preparing Nano LaCo03 in type of perovskite

InactiveCN1915839AOvercome the shortcomings of large particle size and uneven distributionRaw materials are easy to getLithium compoundsCobalt compoundsCombustionNitrate

Owner:ZHONGBEI UNIV

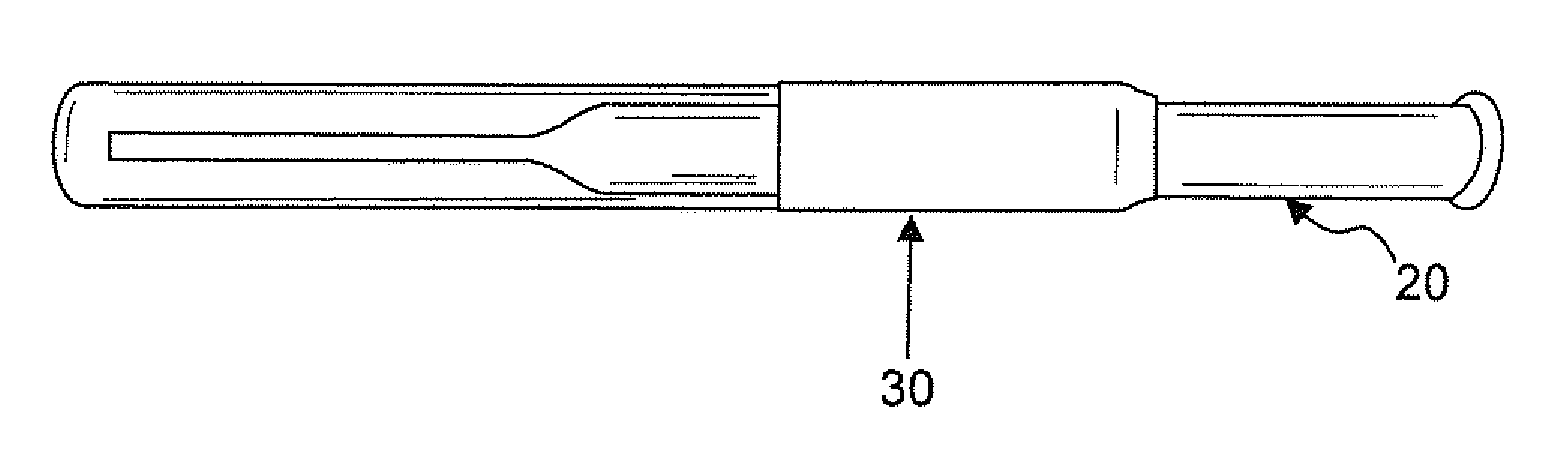

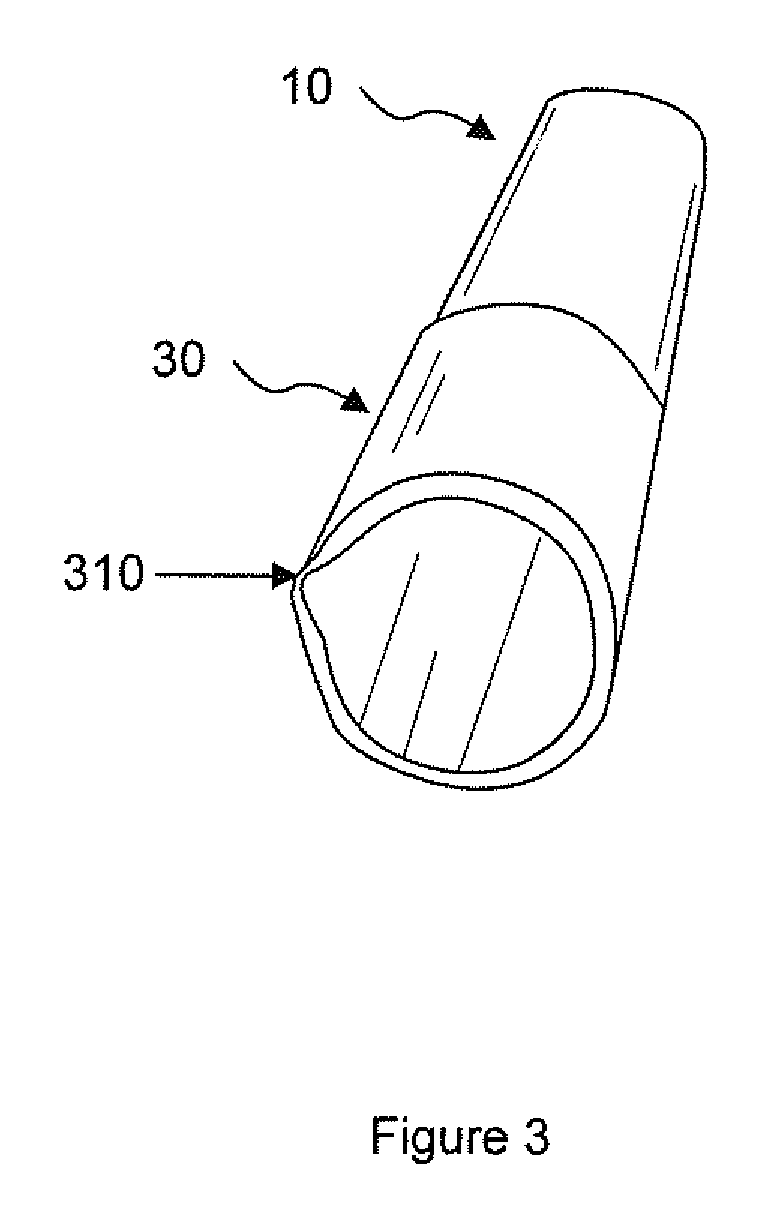

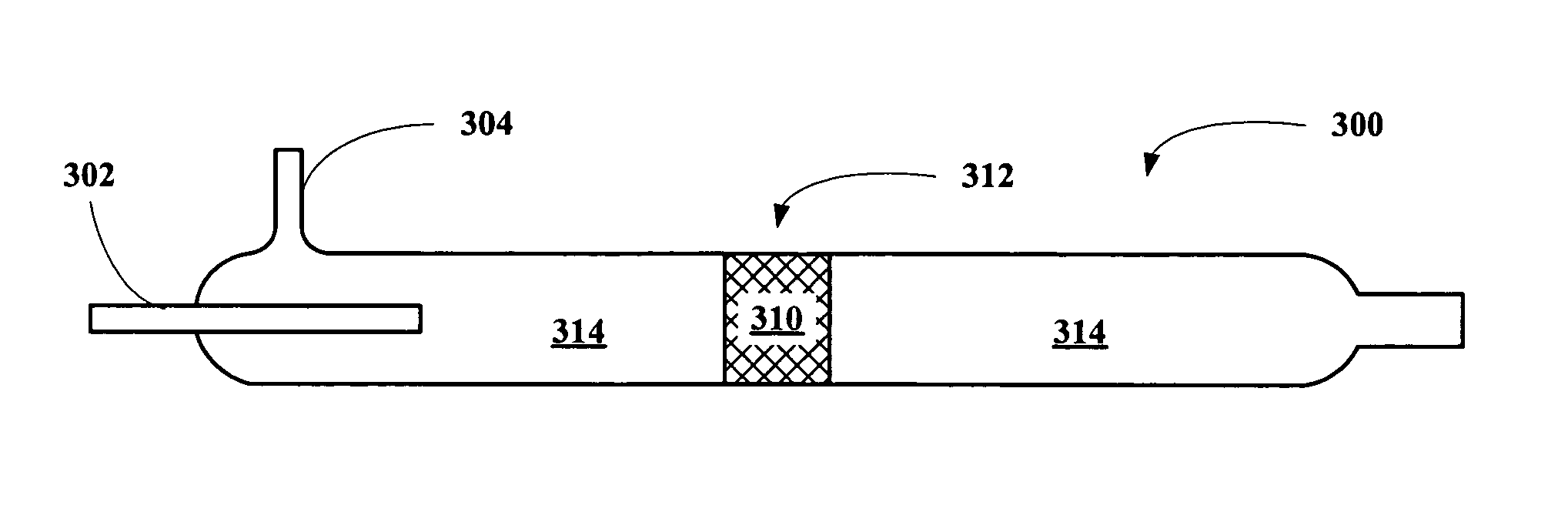

Portable Sublimation Device

Owner:COHN HARRIS

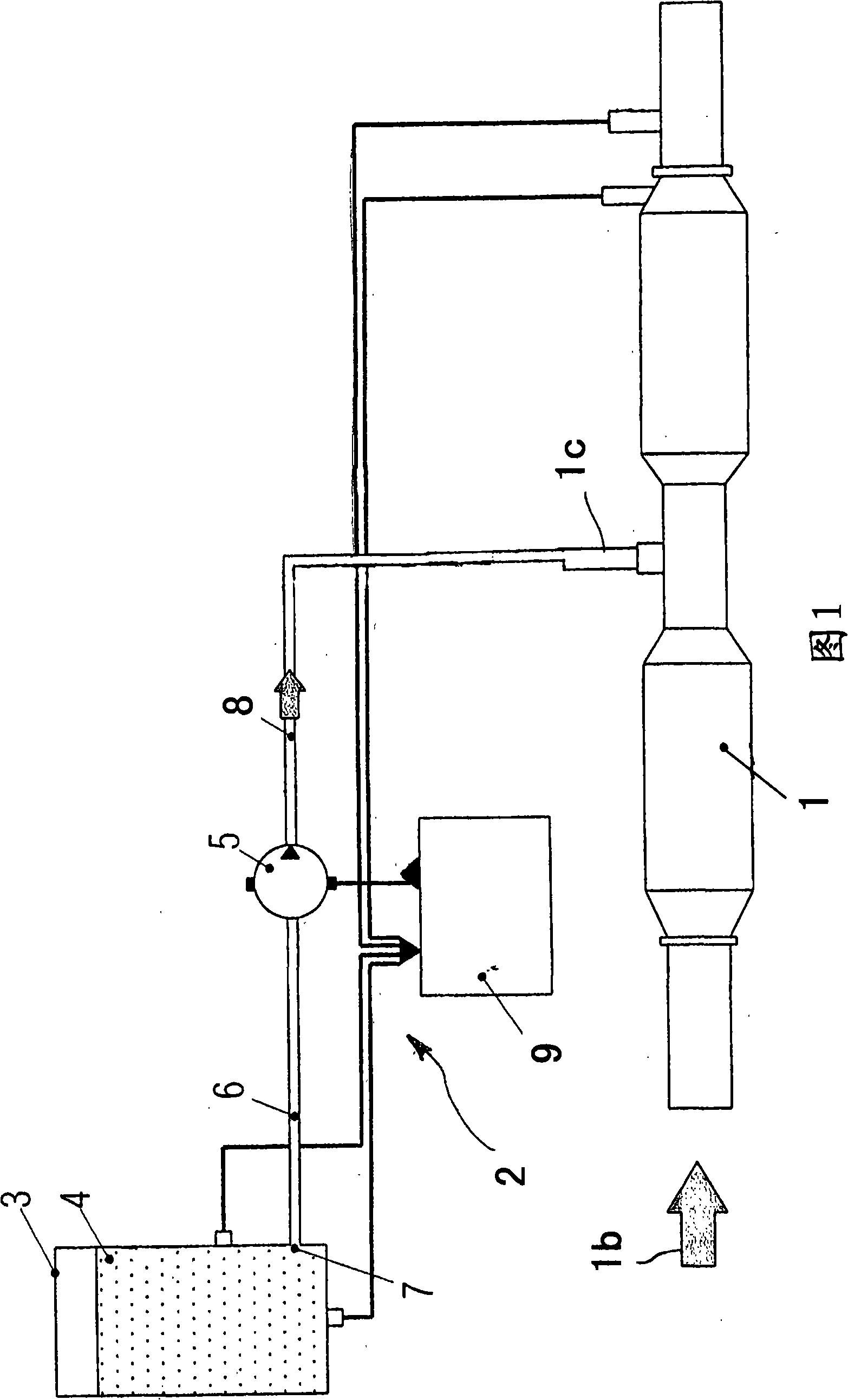

Acquisition system for collecting particles of different particle size discharged by fire coal

InactiveCN103323292AEasy to carryGood effectWithdrawing sample devicesPreparing sample for investigationParticulatesCombustion

The invention relates to an acquisition system for collecting particles of different particle size discharged by fire coal. The acquisition system comprises a flue gas collecting box, a flue gas pipeline, a slide plate with wheels, a civil coal-fired furnace, a blower, a frequency converter, a condenser tube, a temperature sensor, a MCI sampler and a MOUDI sampler. The flue gas collecting box, the flue gas pipeline and the slide plate with wheels are made of stainless steel; the civil coal-fired furnace is put inside the flue gas collecting box; the blower can blow air into the flue gas collecting box to dilute flue gas and provide oxygen for combustion; and the particles in the air are filtered by a filter cloth of 120 meshes at the blower air inlet. The apparatus in the invention avoids the defects that original particles in the air cannot be purified to enter the acquisition system, dilution multiple of fire coal flue gas cannot be calculated and flue gas temperature cannot be adjusted, the original apparatus is not convenient for carrying and condensation enters into sampler flue gas etc. The experiment result shows that the effect of collecting particles of different particle size that are discharged by fire coal is obvious and the sampling operation is simple.

Owner:SHANGHAI UNIV

Large casting lost-foam resin sand casting process

The invention provides a large casting lost-foam resin sand casting process which comprises steps of mould manufacturing, mould assembling, paint spraying and drying, resin sand vibration-filling, bottom-injection type semi-closed casting system applying, a casting clearing process and the like. A large casting lost-foam model is processed in a programmed and digital manner; the mould material replace rare korean pine wood with reproducible low-cost EPS foam, so that a great deal of non-renewable resources are saved; meanwhile, the processing performance and efficiency are greatly improved. A pouring system is designed with a gas exhaust channel, so that complex operations such as operation of eliminating a mould cavity lost mould by adopting methods such as combustion, and the like are avoided, limit in aspect of a metal material of a lost-foam casting process is further broken through, and therefore, the application field is wider.

Owner:YANTAI RUISHENG AUTOMOBILE MOULD CO LTD

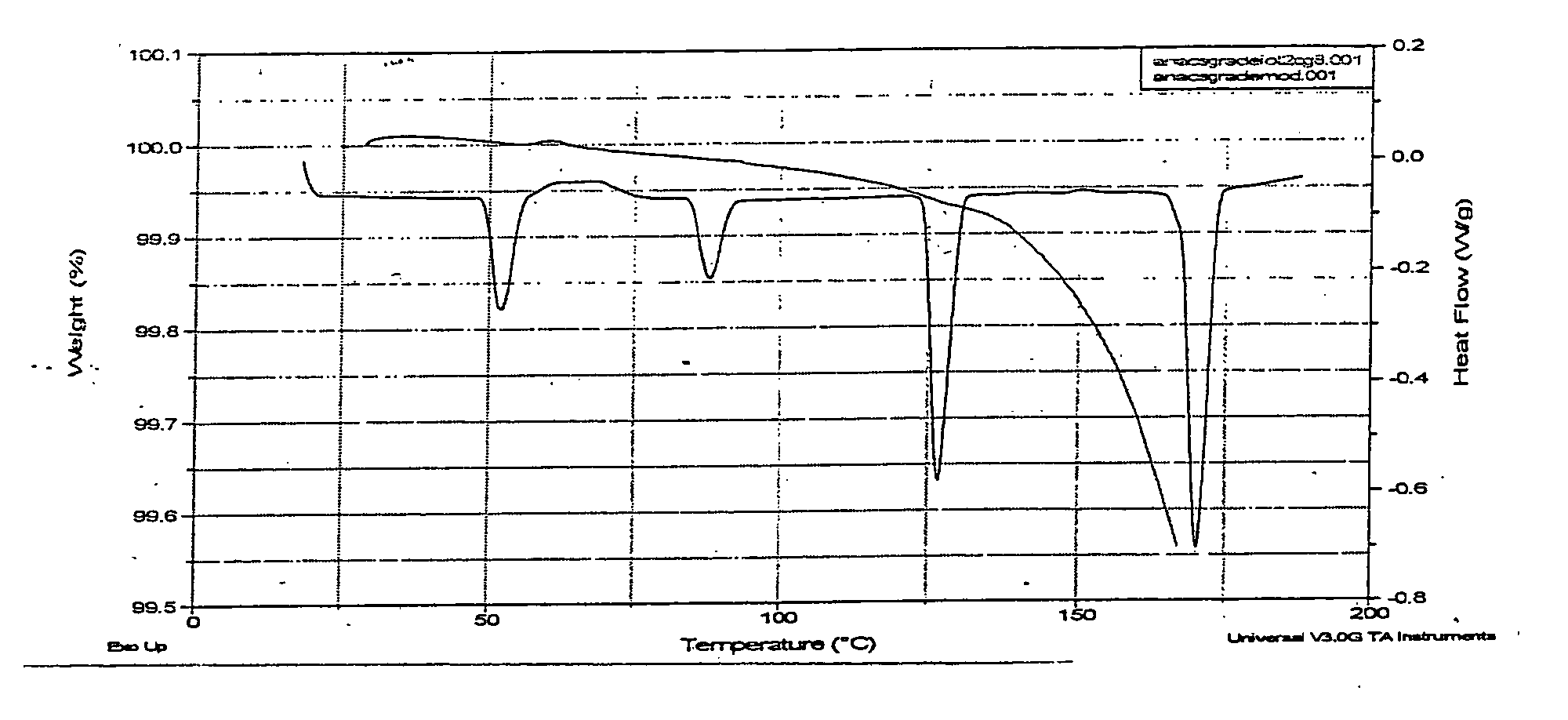

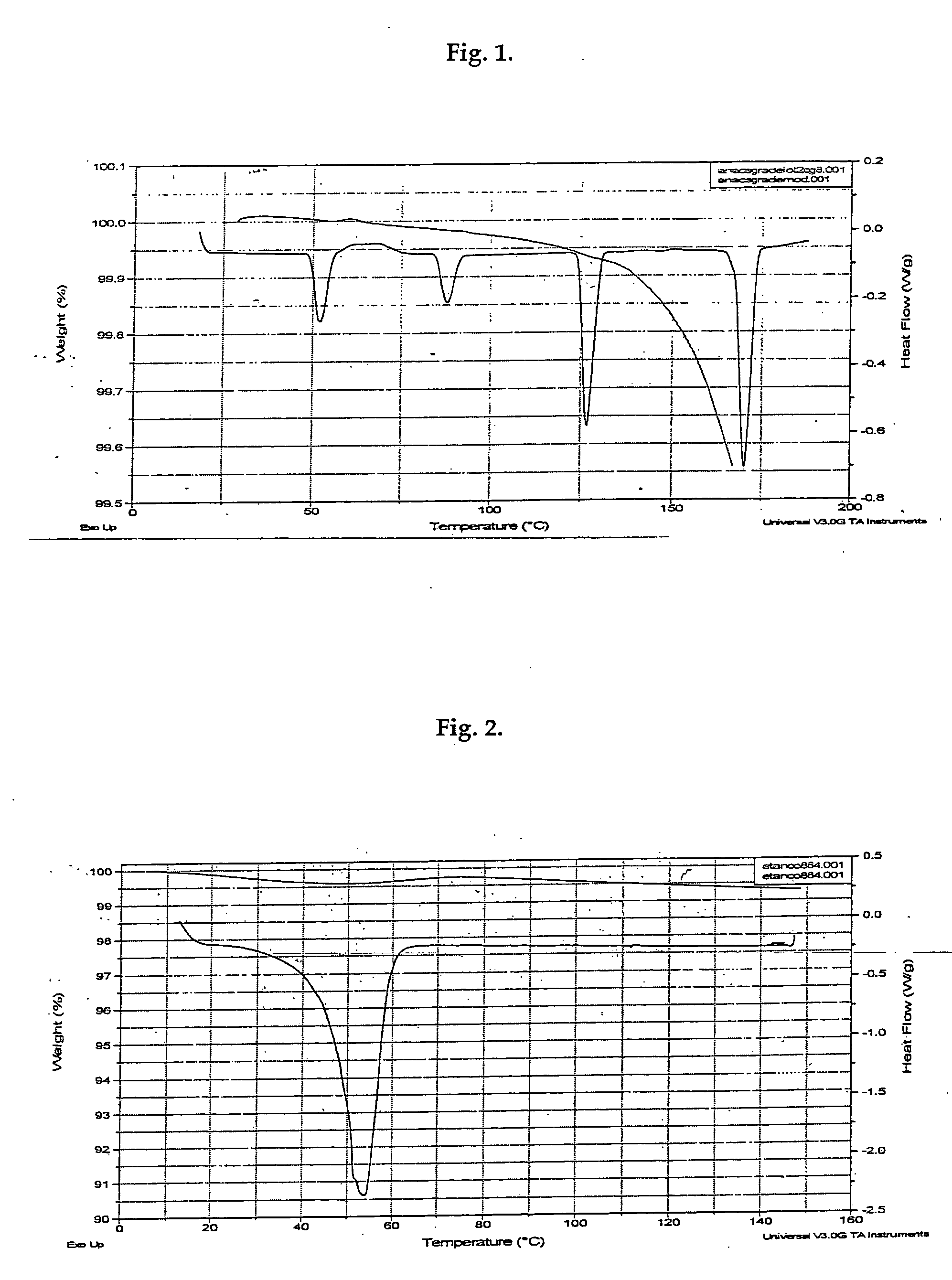

Basic metal nitrate, process for producing the same and gas generating agent composition

InactiveUS20070119530A1Enhanced interactionDecrease in decomposition temperatureNitrogen-metal/silicon/boron binary compoundsExplosivesGuanidine derivativesSlag

Owner:ZHOU XINGXI +5

Shale-sintered hollow ganged brick

Owner:陈振杰

Dry recycling technology for MOX fuel pellet waste

ActiveCN106782736AHigh recovery rateShort recycling processRadioactive decontaminationLiquid wasteCombustion

The invention belongs to the field of nuclear fuel. In order to solve the problem that an MOX fuel pellet waste wet recycling technology has many defects, the invention provides a dry recycling technology for MOX fuel pellet waste. The technology comprises the following steps of 1, burning MOX fuel pellet waste; 2, crushing by using a crusher; 3, screening; 4, ball milling; and 5 recycling. According to the technology provided by the invention, powdering of the MOX fuel pellet waste is achieved by crushing-ball milling technologies, so that the technology is fundamentally different from a dry recycling technology for UO2 fuel pellet waste using an oxidized crushing technology. Practical application shows that the MOX fuel pellet waste wet recycling technology provided by the invention has the advantages of high recycling rate, short recycling technical process, high in speed, simple in equipment, low in cost, and being free from generating radioactive liquid waste, and can be recycled in an MOX combustion manufacturer; the recycled power has similar sintering performance with the common MOX raw material powder, and can be mixed with common raw materials for preparing MOX fuel pellets.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

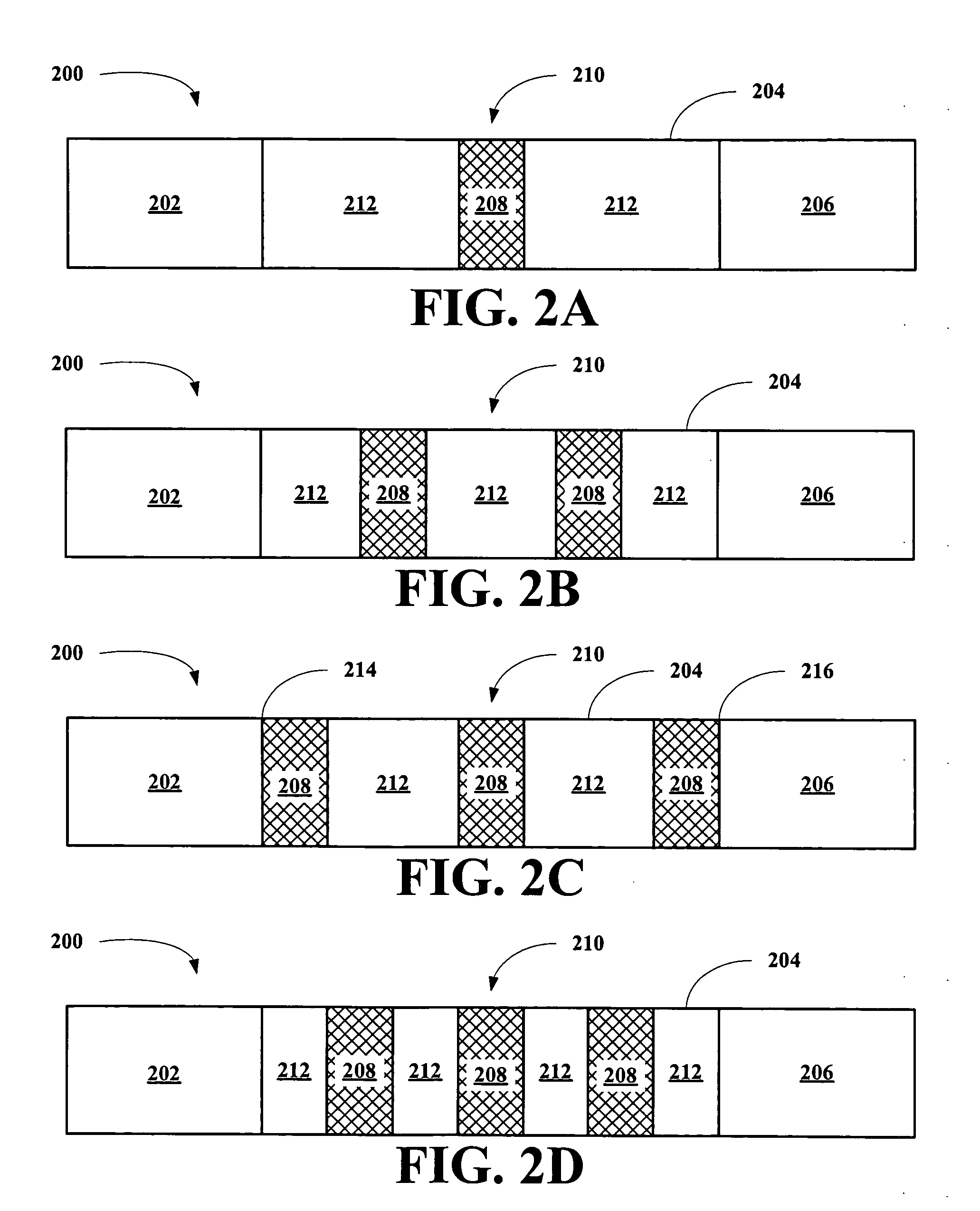

Combustion apparatus and methods for making and using same

ActiveUS20050153253A1Extended stayImprove combustion efficiencyMechanical apparatusGaseous fuel burnerCombustionEngineering

Owner:COSA XENTAUR CORP

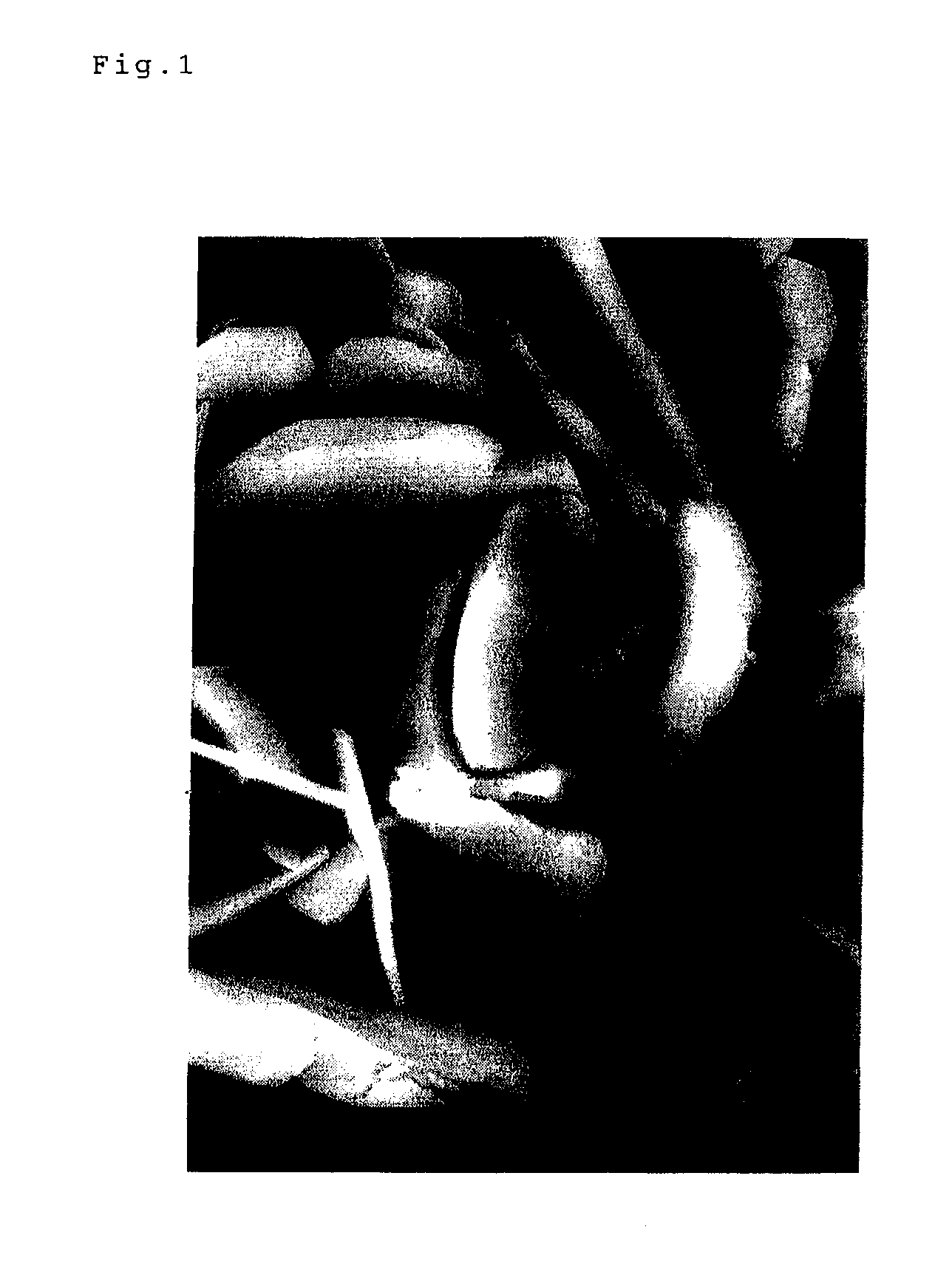

Anti-backfire nozzle for rocket engine

ActiveCN106762225AStop the spreadAnti-tempering functionRocket engine plantsCombustionThermal insulation

Owner:SHANGHAI INST OF SPACE PROPULSION

Dual-pulse solid rocket engine soft interlayer ablation test device

ActiveCN110425058ANo accelerationReal-time monitoring of flow fieldRocket engine plantsThroatCombustion

Owner:NANJING UNIV OF SCI & TECH

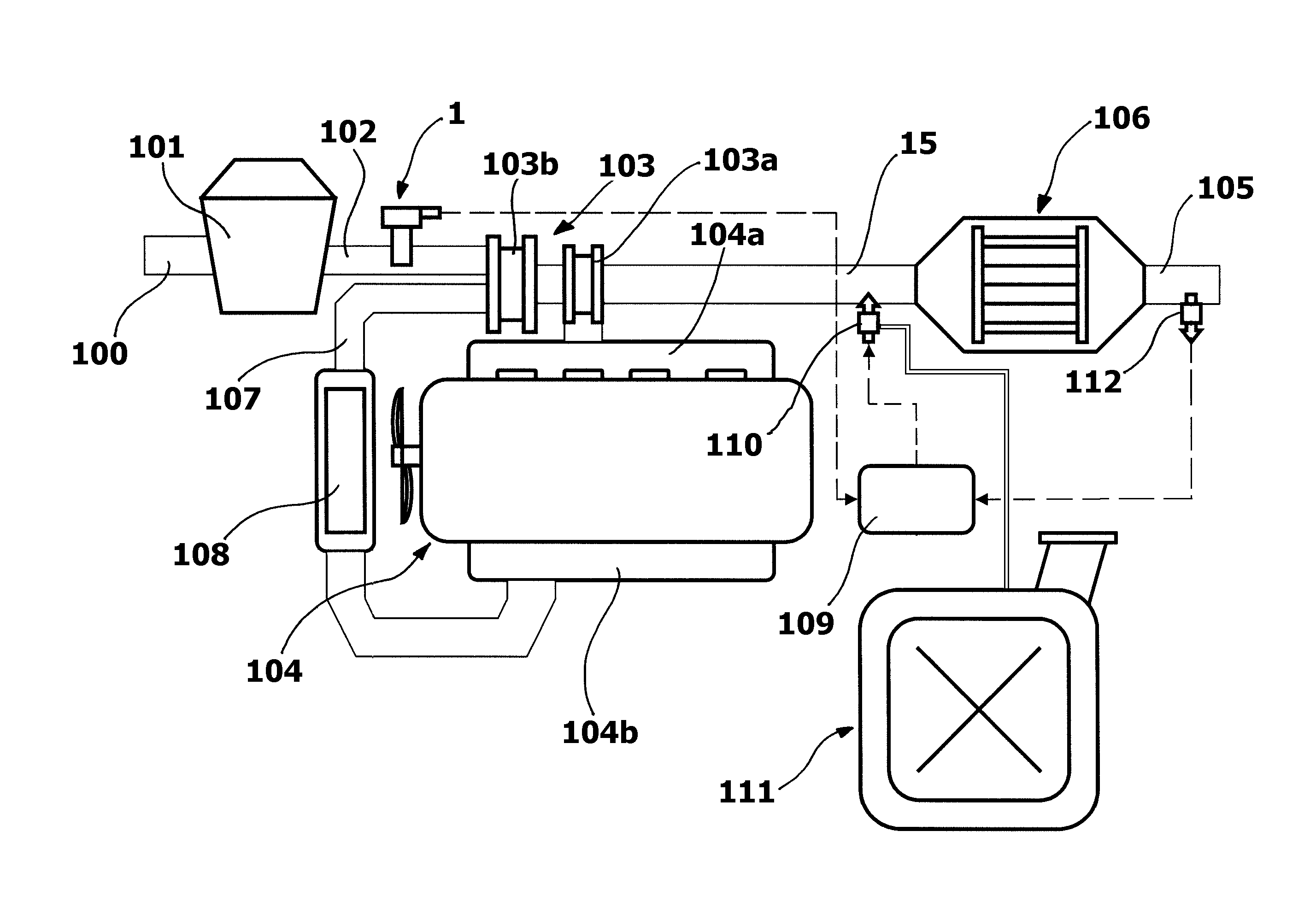

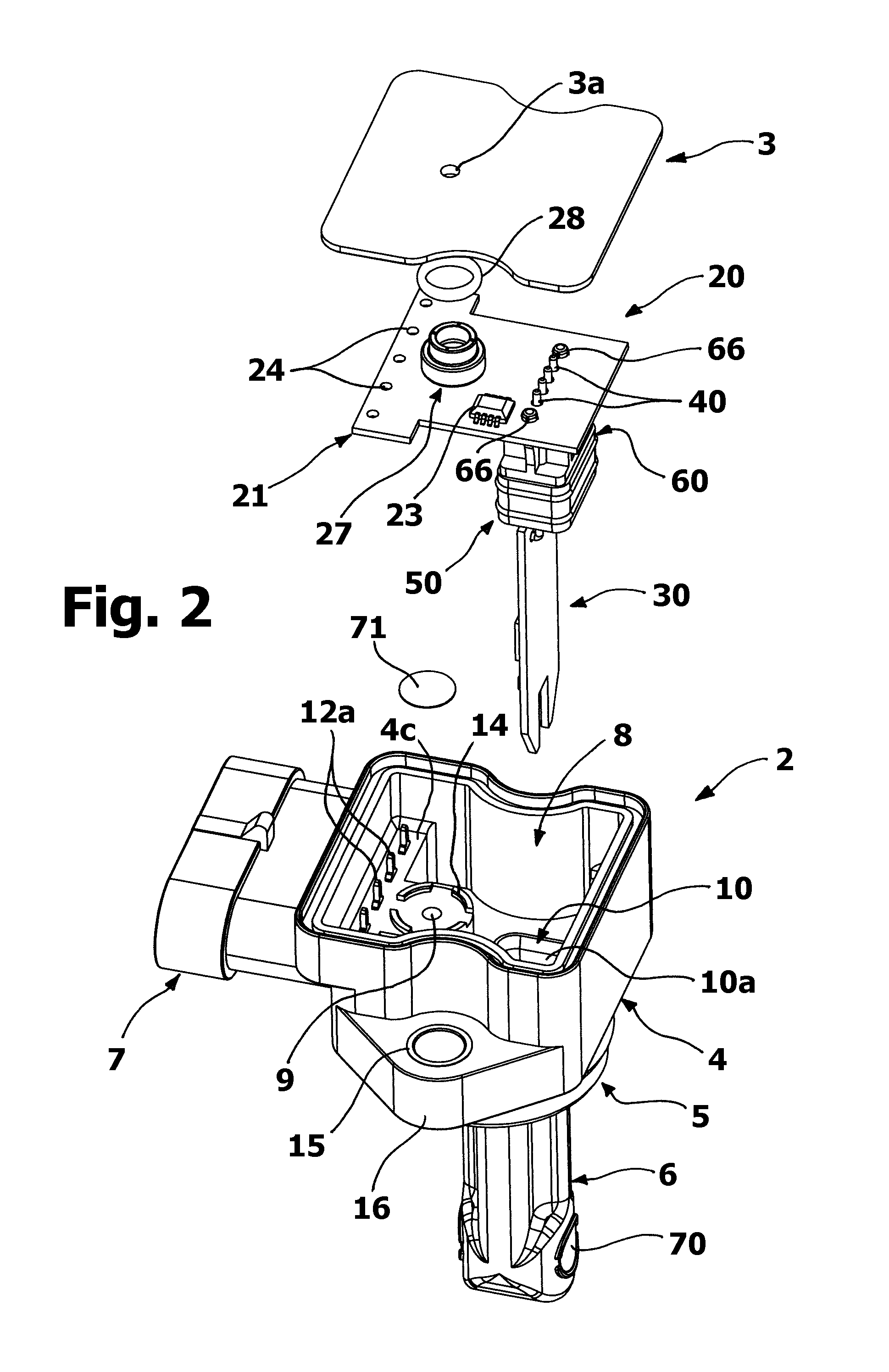

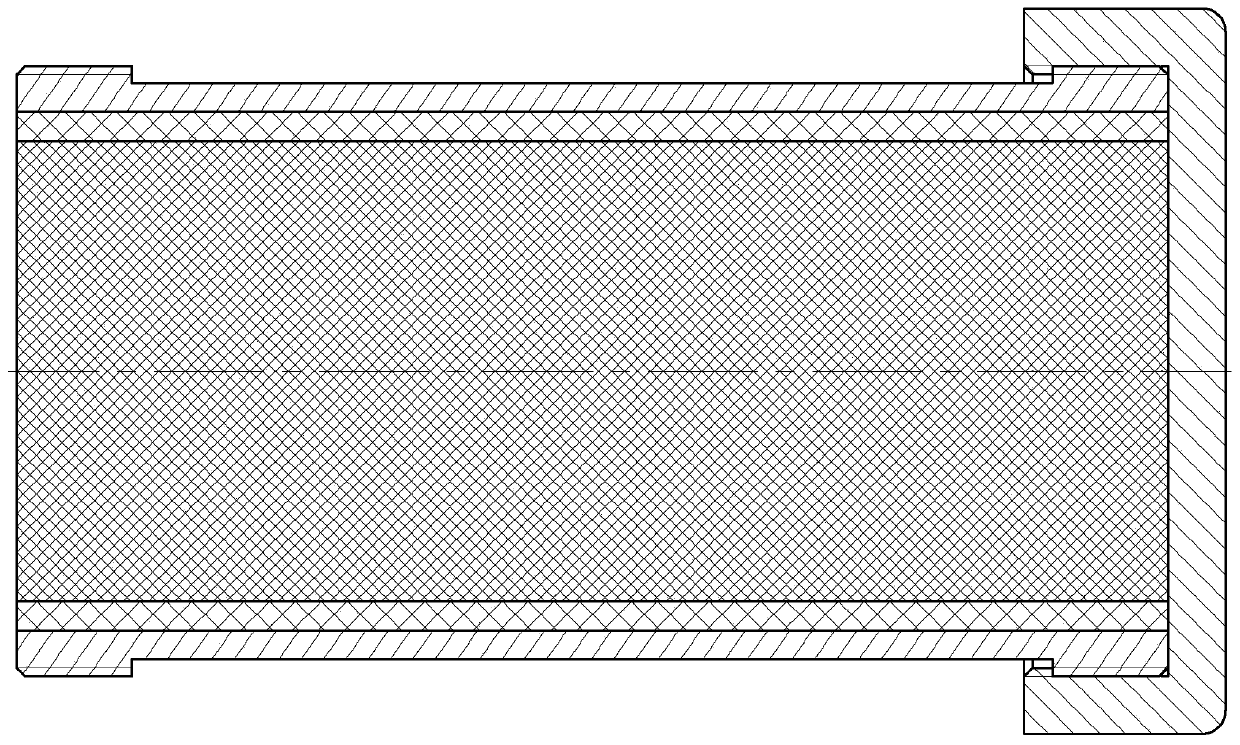

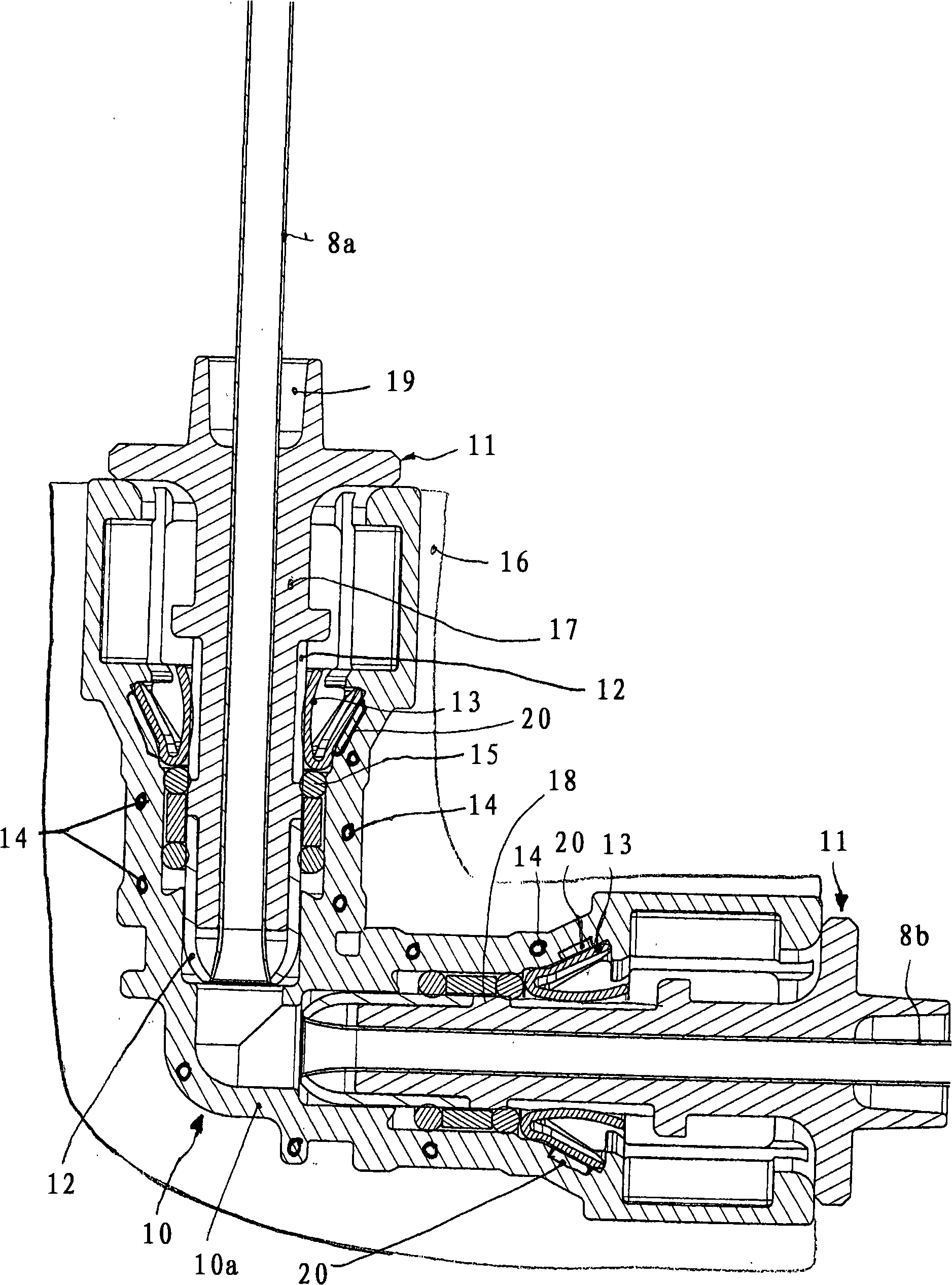

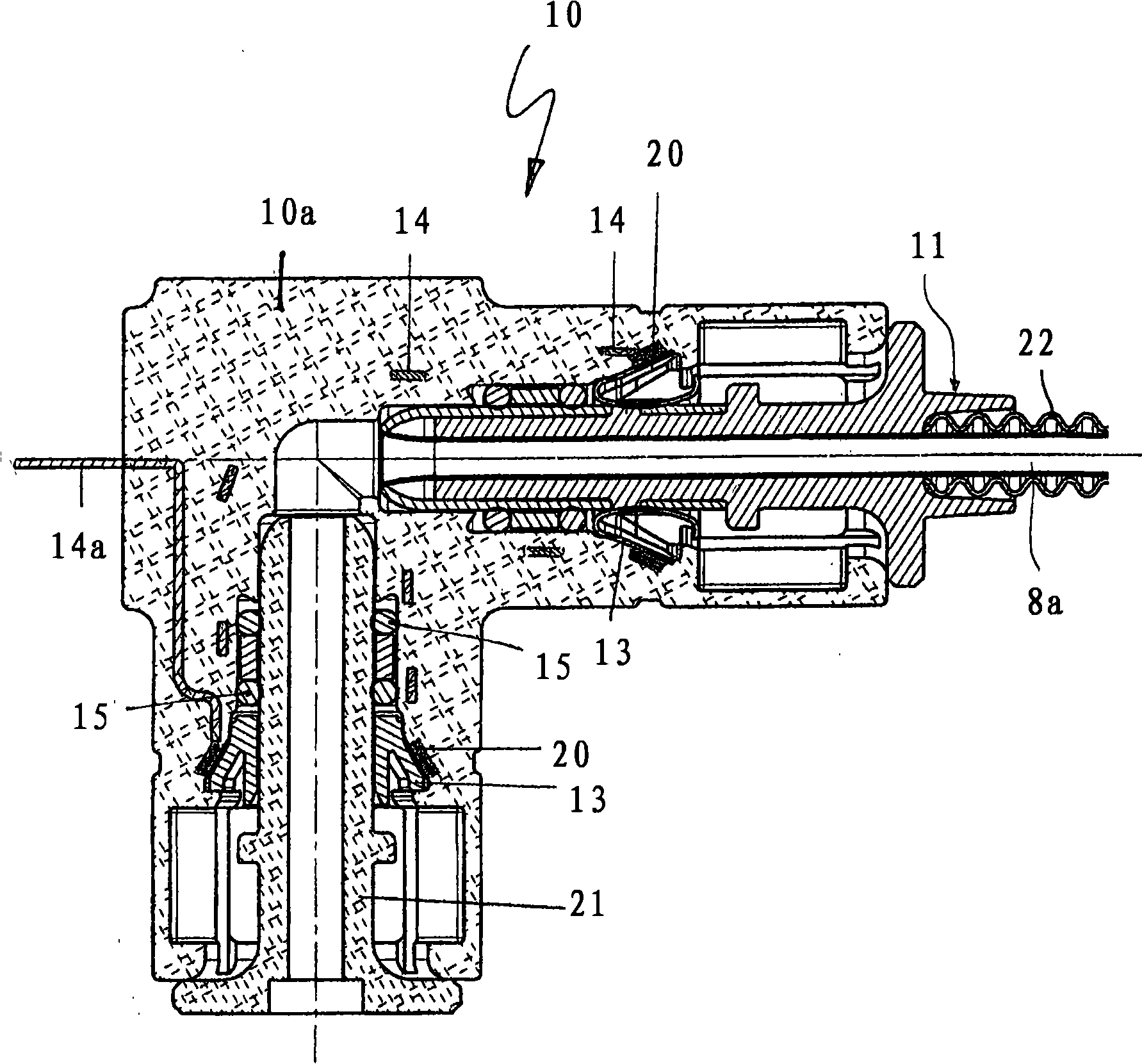

Reducing reagent supply system of internal-combustion engines and connecting component for connecting heating liquid conduit pipe thereof

InactiveCN101255812AEasy to installEasy to assembleExhaust apparatusDispersed particle separationElectricityCombustion

Owner:EICHENAUER HEIZELEMENTE

Tunnel kiln brick-making method

ActiveCN104279865AReduce pollutionReduce consumptionFurnace typesIncreasing energy efficiencyAlkaneTunnel kiln

The invention provides a tunnel kiln brick-making method. A tunnel kiln comprises a preheating section, a sintering section, a cooling section, a fuel and combustion-assisting air conveying system, a temperature control system, a heat exchange system and a smoke discharging system. The tunnel kiln brick-making method includes that a mixture of smoke containing polluting gas like pyrolytic gas, volatile gas gas and alkane generated by the preheating section and combustion-assisting air is fed into the sintering section to be mixed with fuel for mixed combustion, wherein the polluting gas is fully oxidized and finally generate carbon dioxide, water and the like along with combustion smoke to be cooled through a heat exchanger and then discharged. Hot air generated by the cooling section directly enters the preheating section to serve as preheated air, or the hot air generated by the cooling section together with normal-temperature air is heated through the heat exchanger to be preheated air so as to achieve the objective of waste heat recycling. By the tunnel kiln brick-making method, energy utilization rate of the tunnel kiln in the prior art is increased further, pollution, to surrounding environment, of discharged smoke is reduced, and effect of energy conservation and emission reduction is realized.

Owner:DALIAN UNIV OF TECH

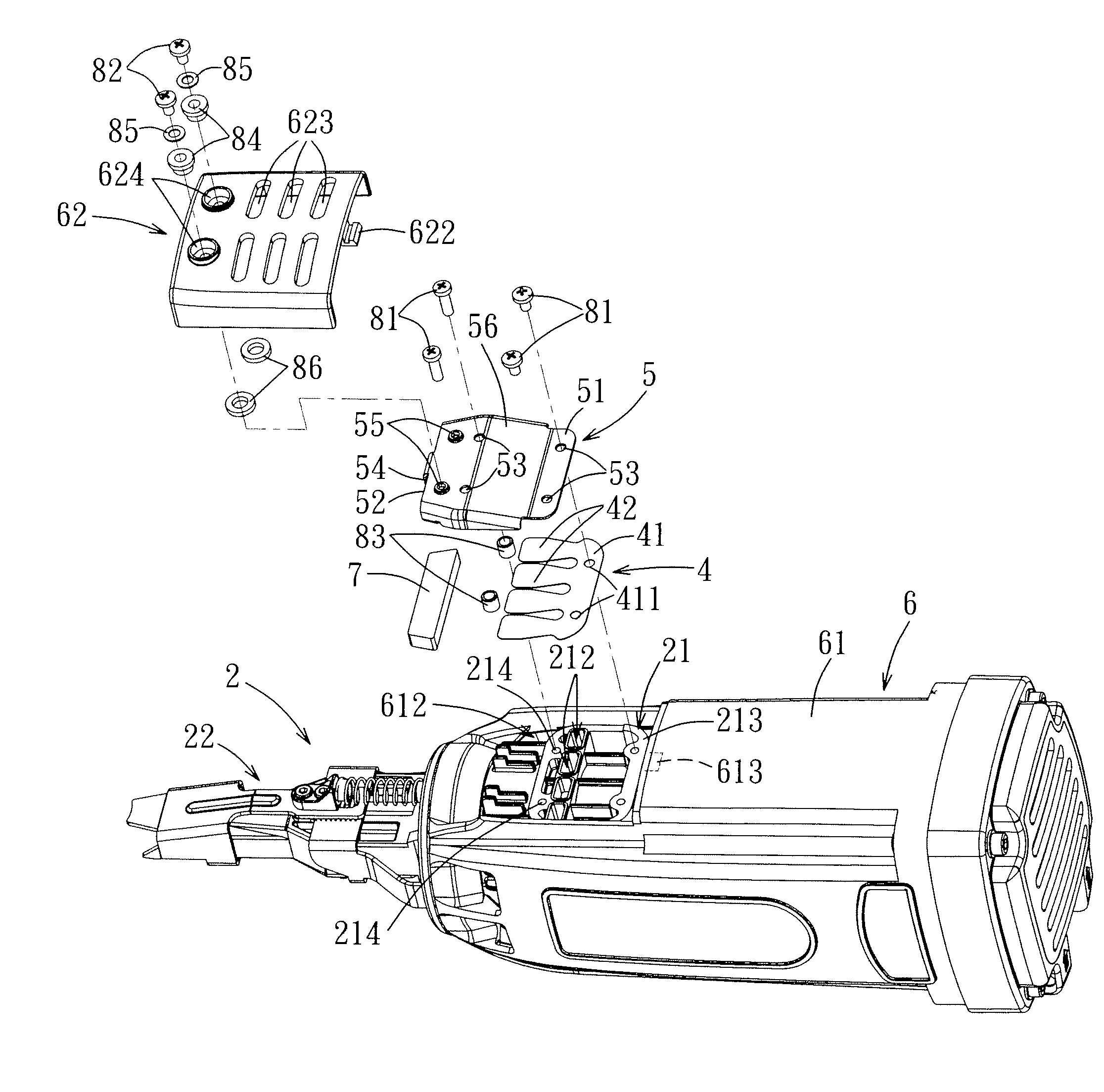

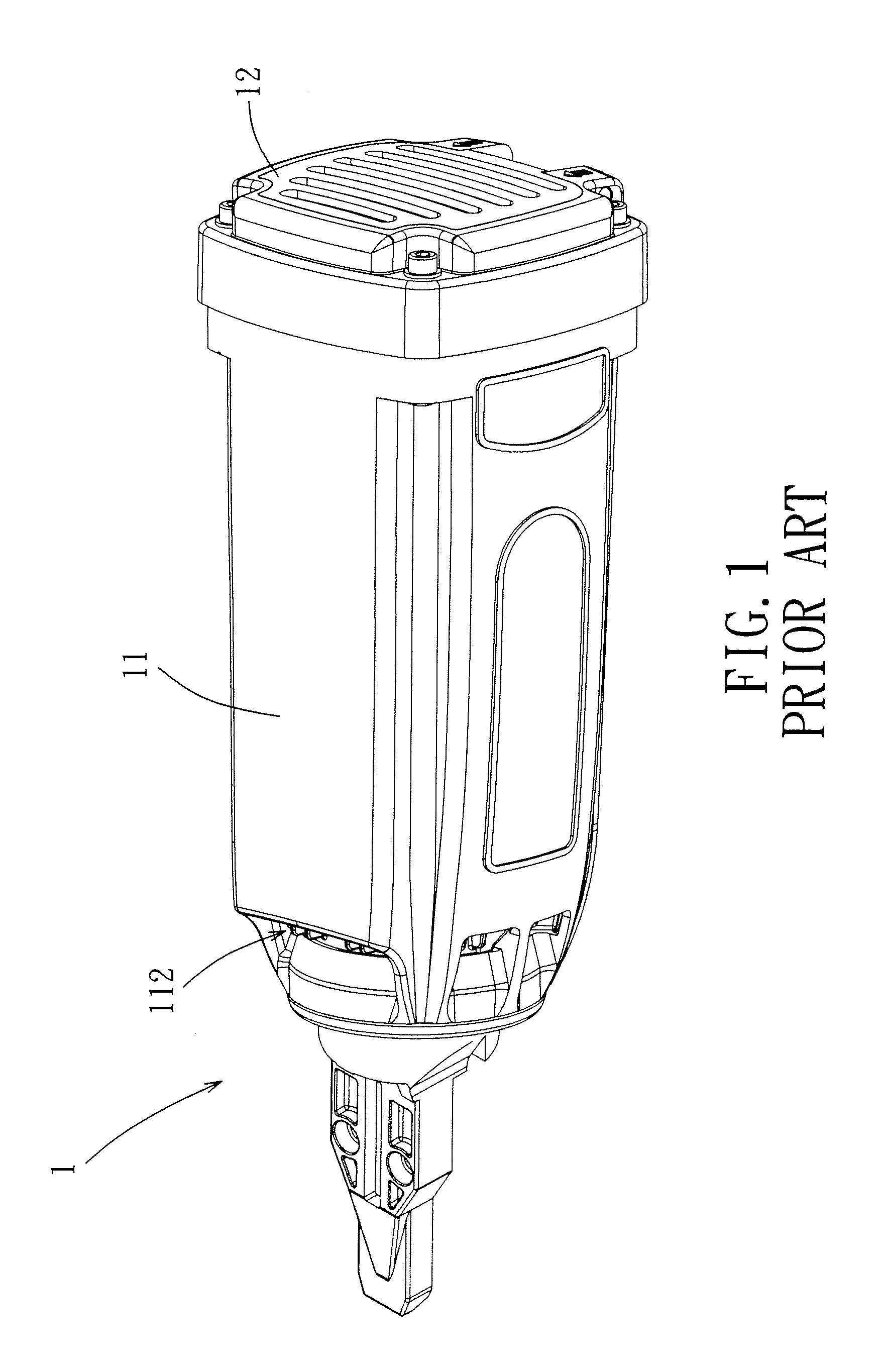

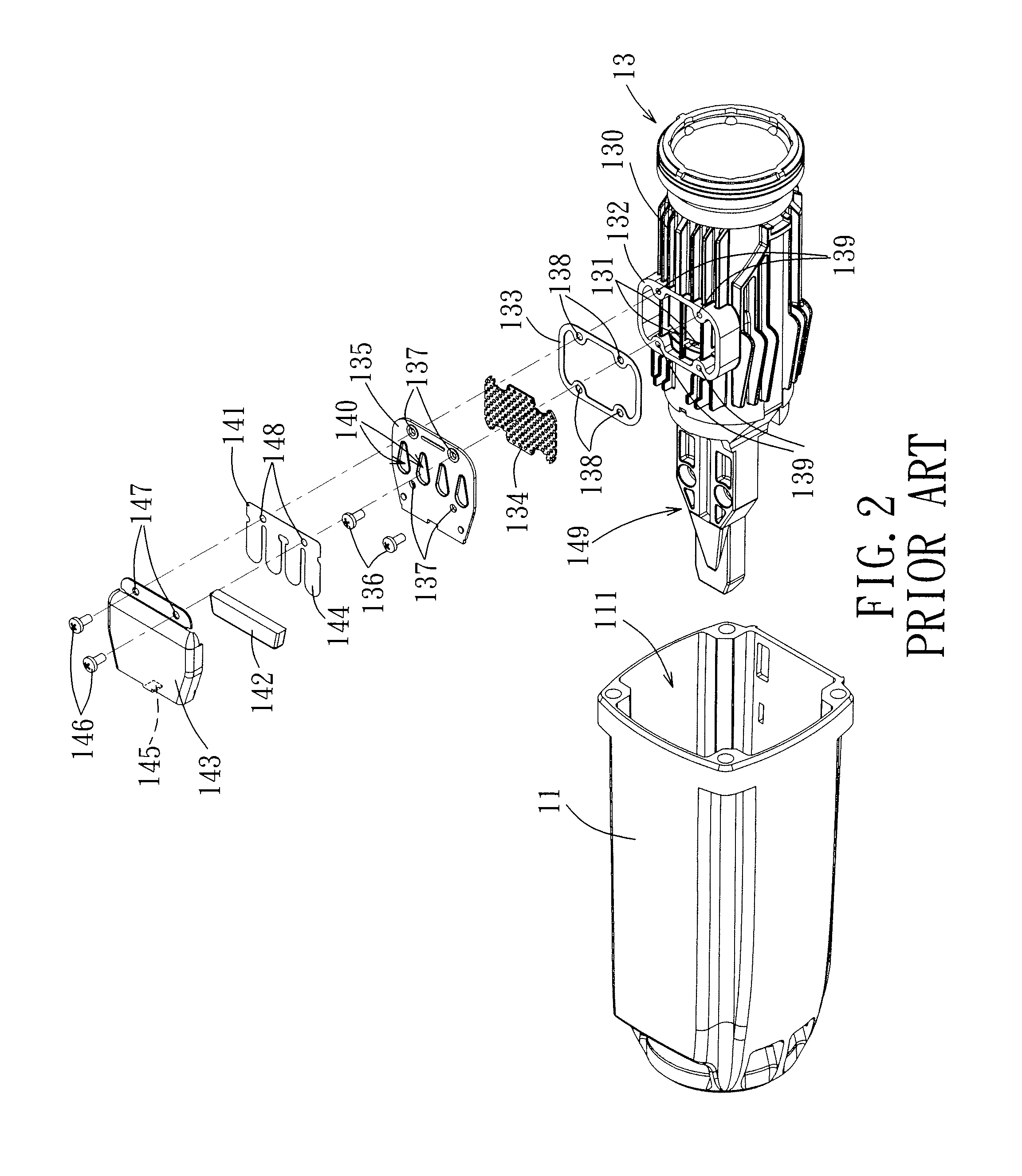

Combustion Nailing Tool

Owner:ZHU YIMIN

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

Device for connecting smoking machine and cigarette combustion and smoking appearance testing cavity, and testing method for device

InactiveCN102565276AEffective connectionReduce the differenceChemical analysis using combustionCombustionEngineering

Owner:中烟摩迪(江门)纸业有限公司

Method and device for improving output of coal mill based on lignite coal pulverizing system

InactiveCN111167566AImprove drying outputReduce power consumptionGrain treatmentsBrown coalCombustion

The invention relates to a method and device for improving the output of a coal mill based on a lignite coal pulverizing system. The device for improving the output of the coal mill based on the pulverizing system comprises that a grinding disc is arranged in the coal mill; nozzles are arranged on the periphery of the grinding disc; a grinding roller is arranged at the upper end of the grinding disc; one end of a high-temperature superheated steam pipeline is connected with a steam turbine, the other end of the high-temperature superheated steam pipeline penetrates through the cylinder wall ofthe coal mill, and then the other end of the high-temperature superheated steam pipeline is introduced into a grinding area of the grinding disc through a grinding roller gap; a valve is arranged onthe high-temperature superheated steam pipeline; and a primary fan conveys hot primary air into the coal mill through a primary air duct. According to the method and the device, raw coal is instantlyheated by using high-temperature superheated steam, and the temperature of the raw coal can be increased by 10-20 DEG C. Under the premise of ensuring the normal air-powder ratio, the outlet temperature can also be ensured, so that the drying output problem of burning lignite is solved. The combustion efficiency of a boiler is improved, meanwhile, the abrasion of related equipment of the pulverizing system and a pulverized coal pipeline is reduced, and the operation safety of the pulverizing system is improved.

Owner:BEIJING LAD ELECTRIC POWER TECH CO LTD

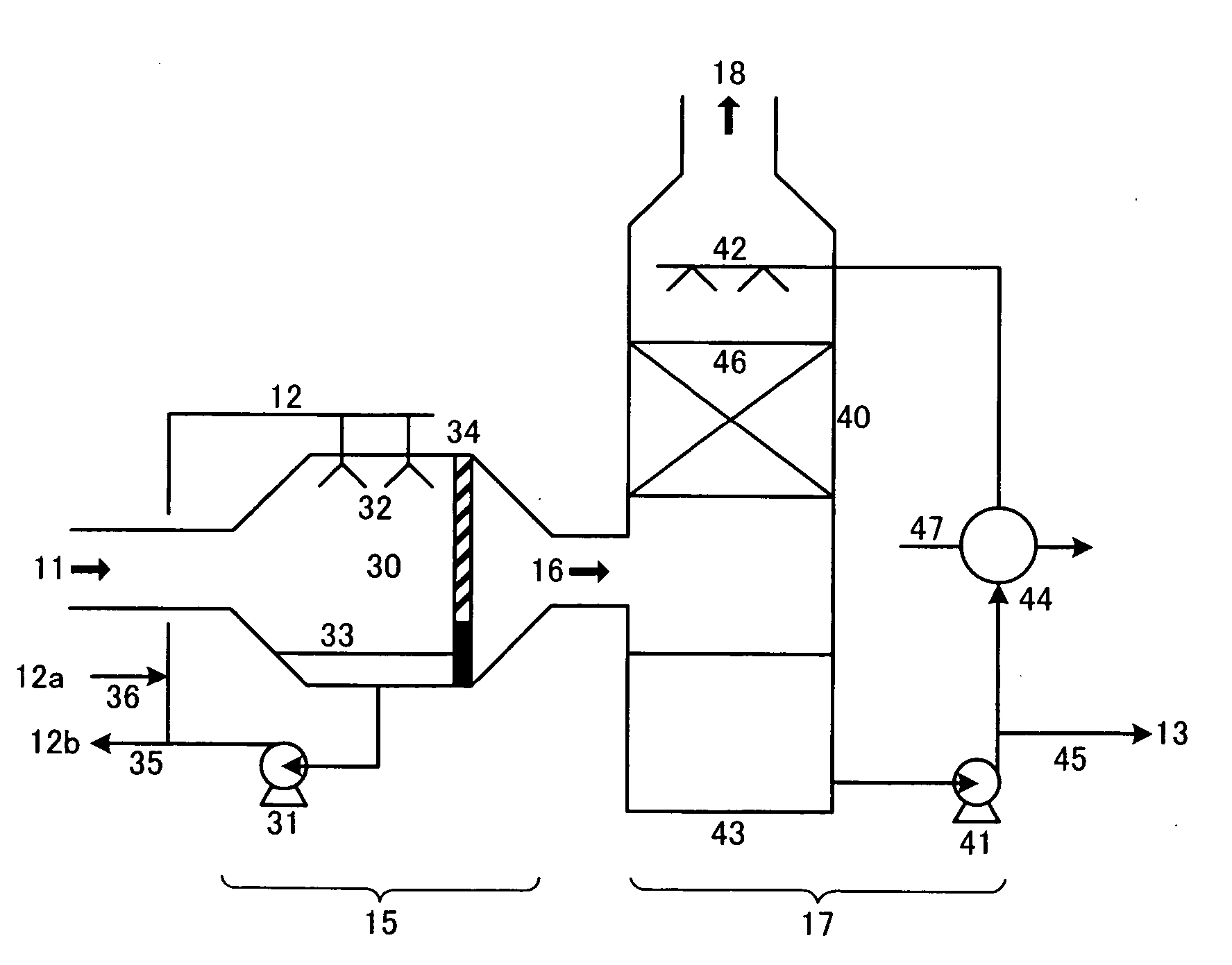

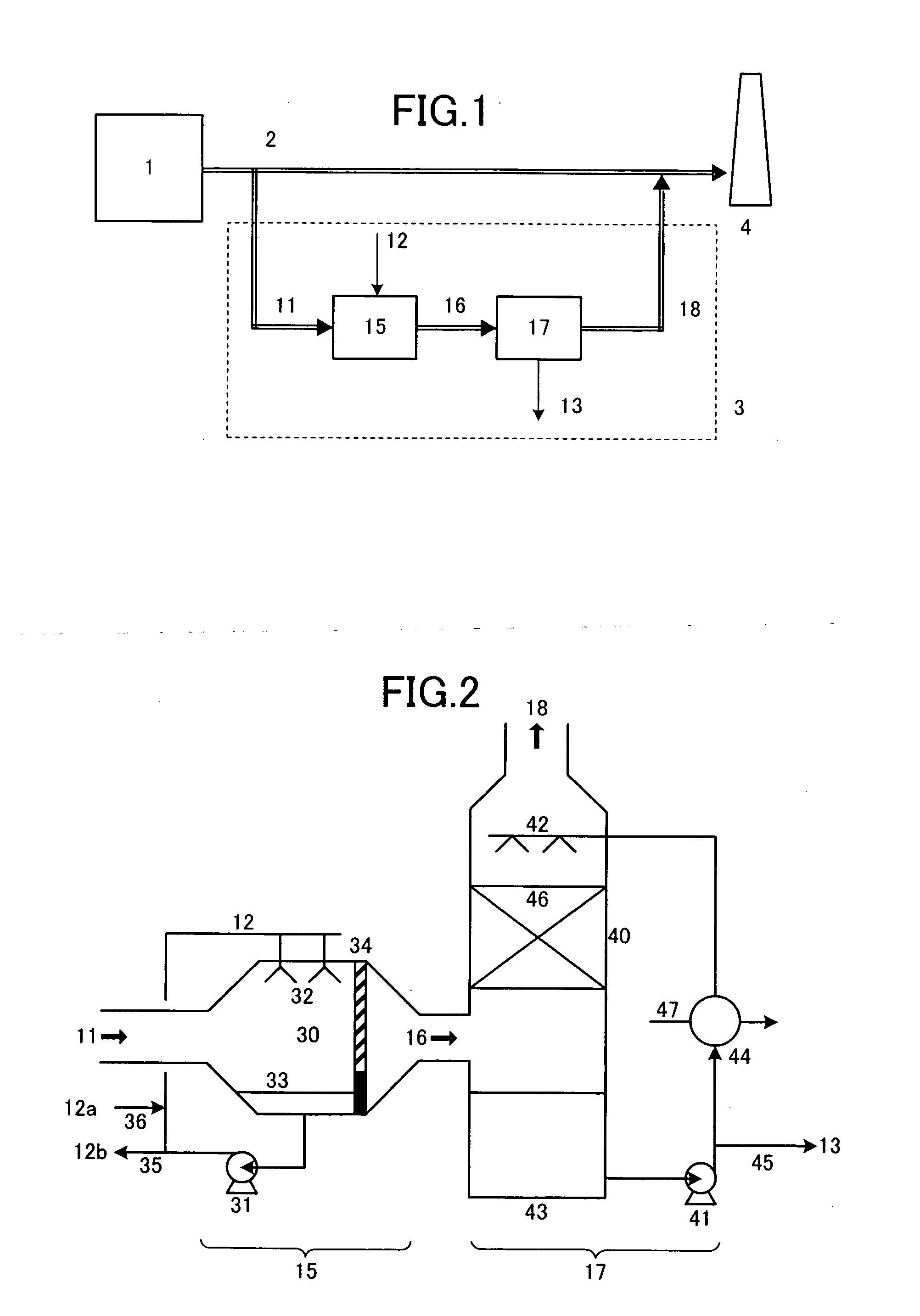

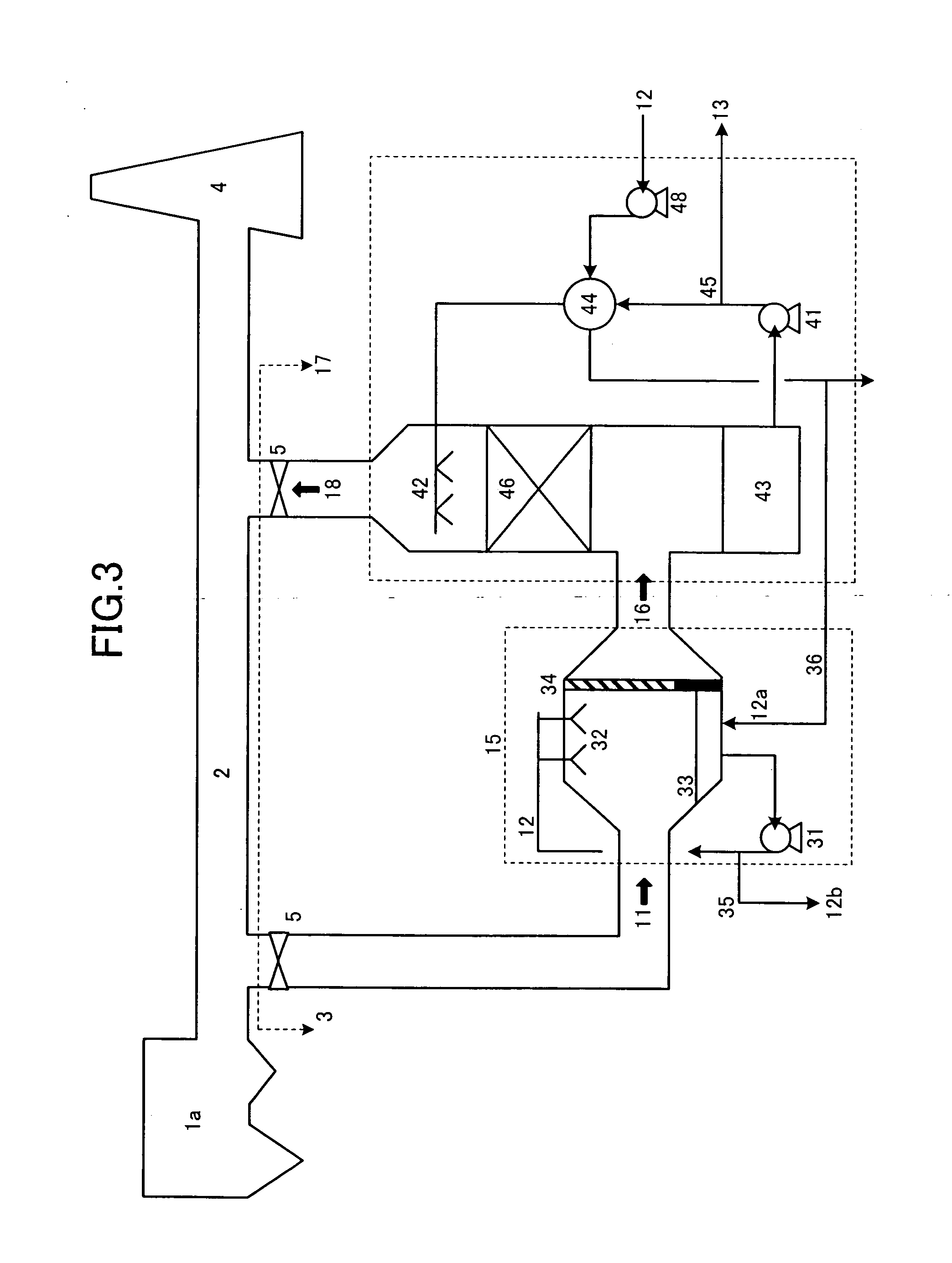

Exhaust gas purifying system

InactiveUS20050138922A1Liquid degasificationInternal combustion piston enginesCombustionSpray nozzle

Owner:BONCODIN FRANZ B

Production raw material for preparing calcium oxide by using calcium carbide furnace gas purified ash and preparation process thereof

InactiveCN109179468AEasy to operateSave energyCalcium/strontium/barium oxides/hydroxidesCombustionCoal dust

Owner:石嘴山市鹏盛化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap