Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Active agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

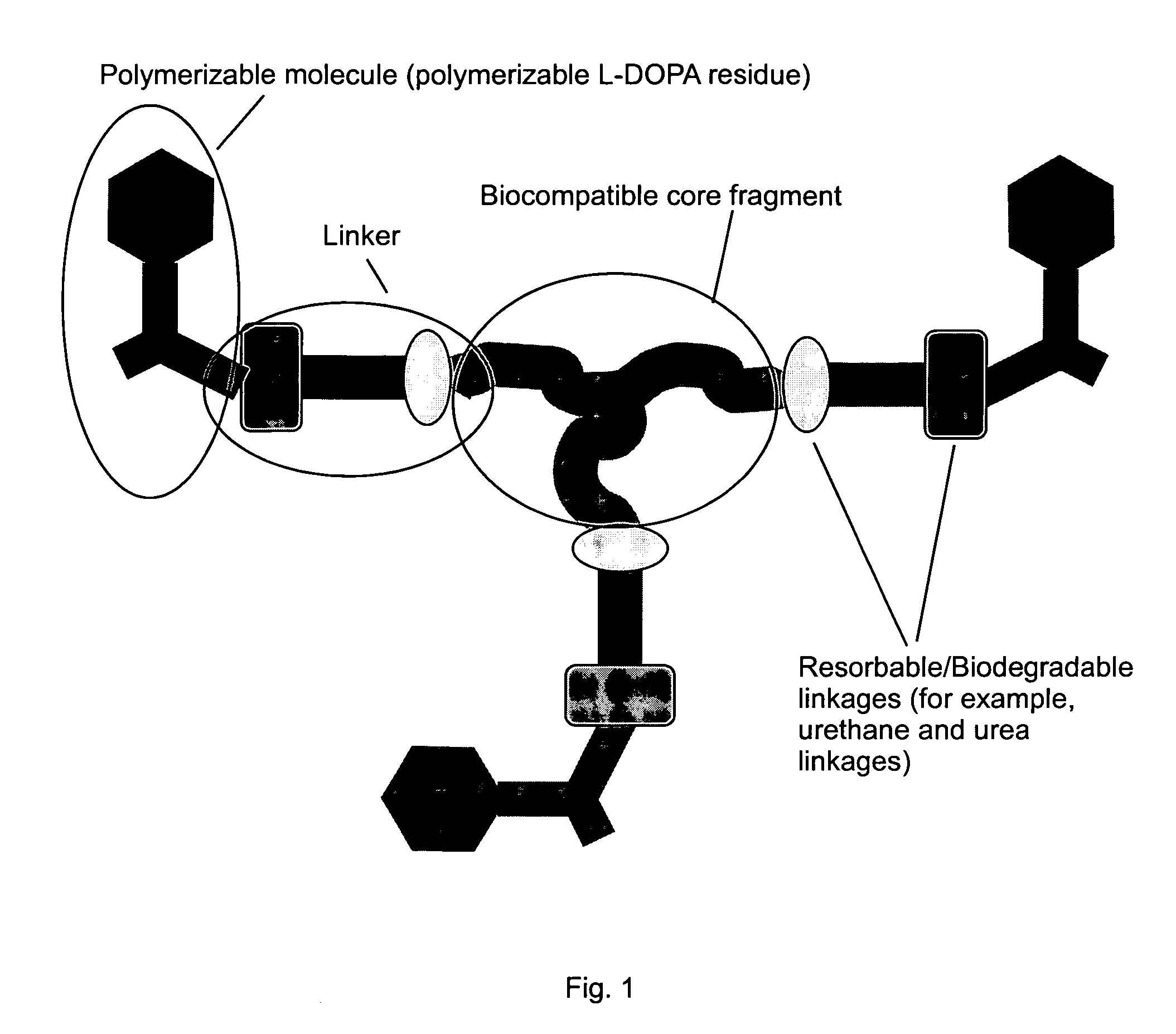

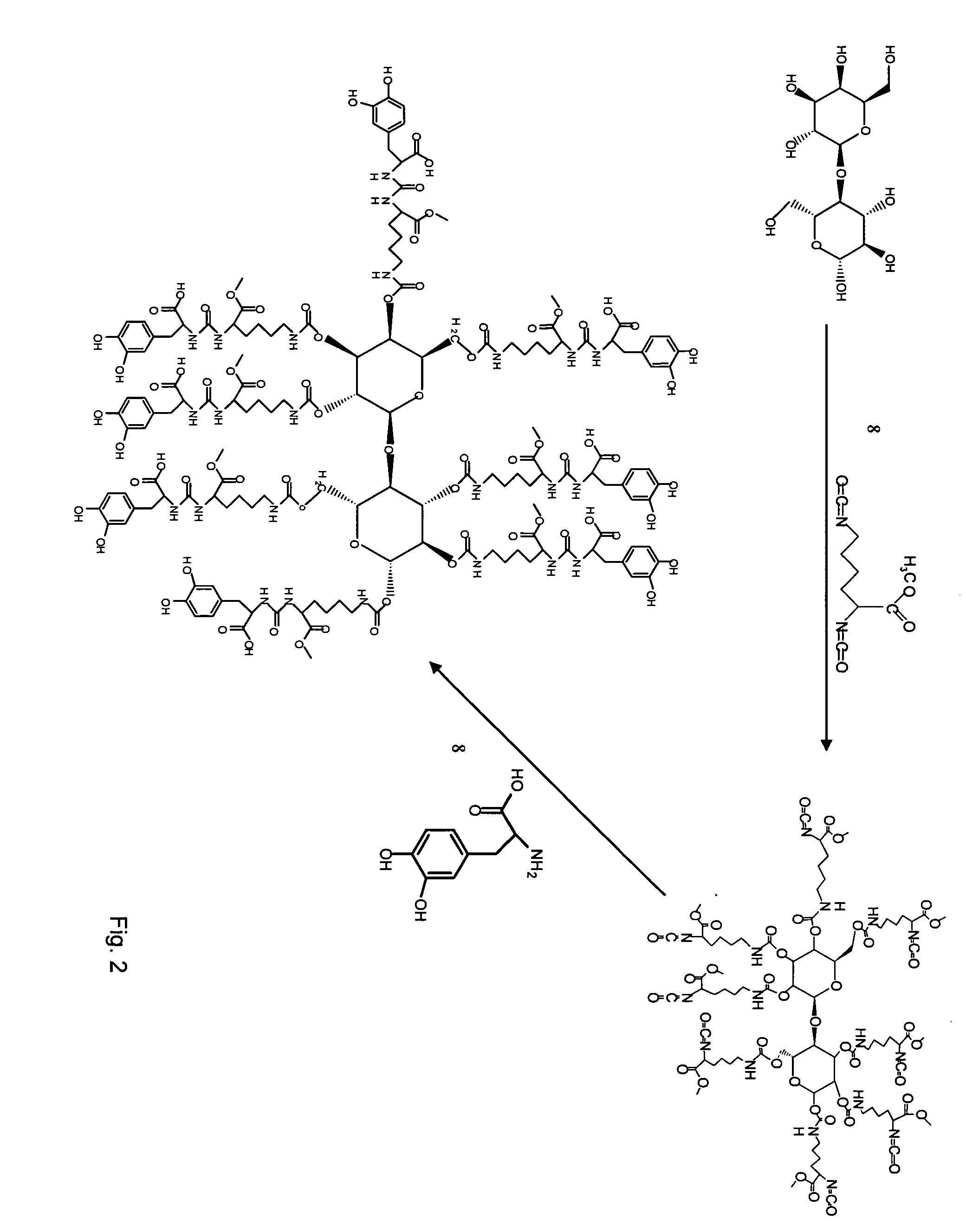

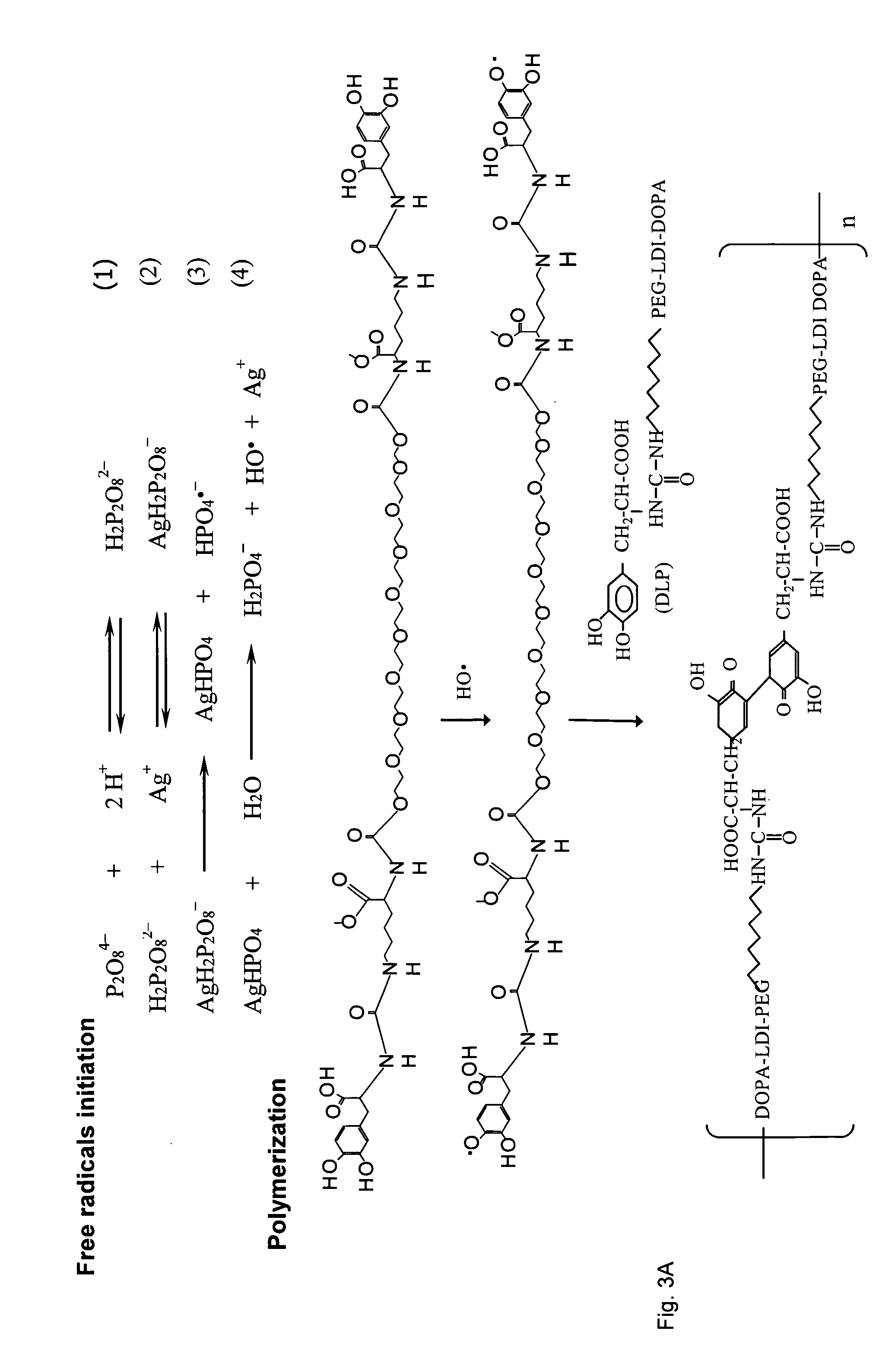

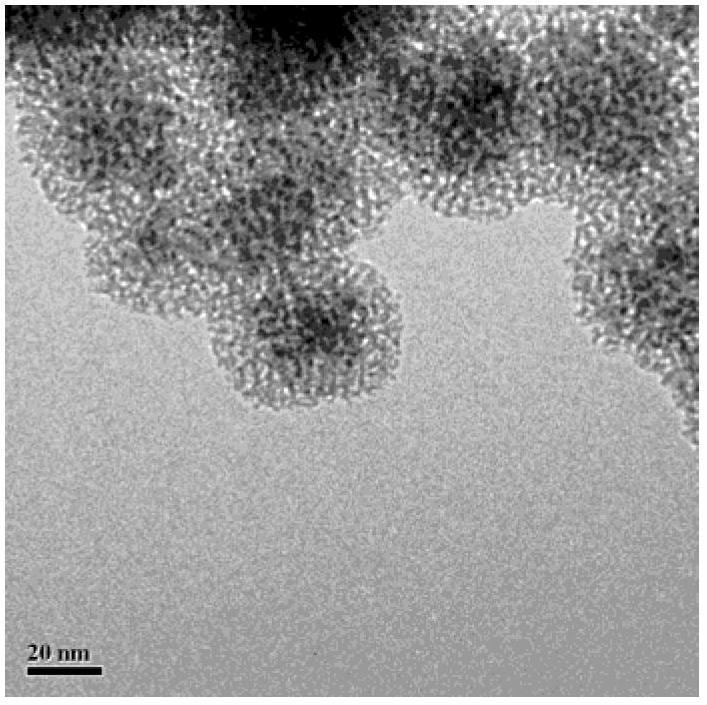

Wound healing polymeric networks

Owner:UNIVERSITY OF PITTSBURGH

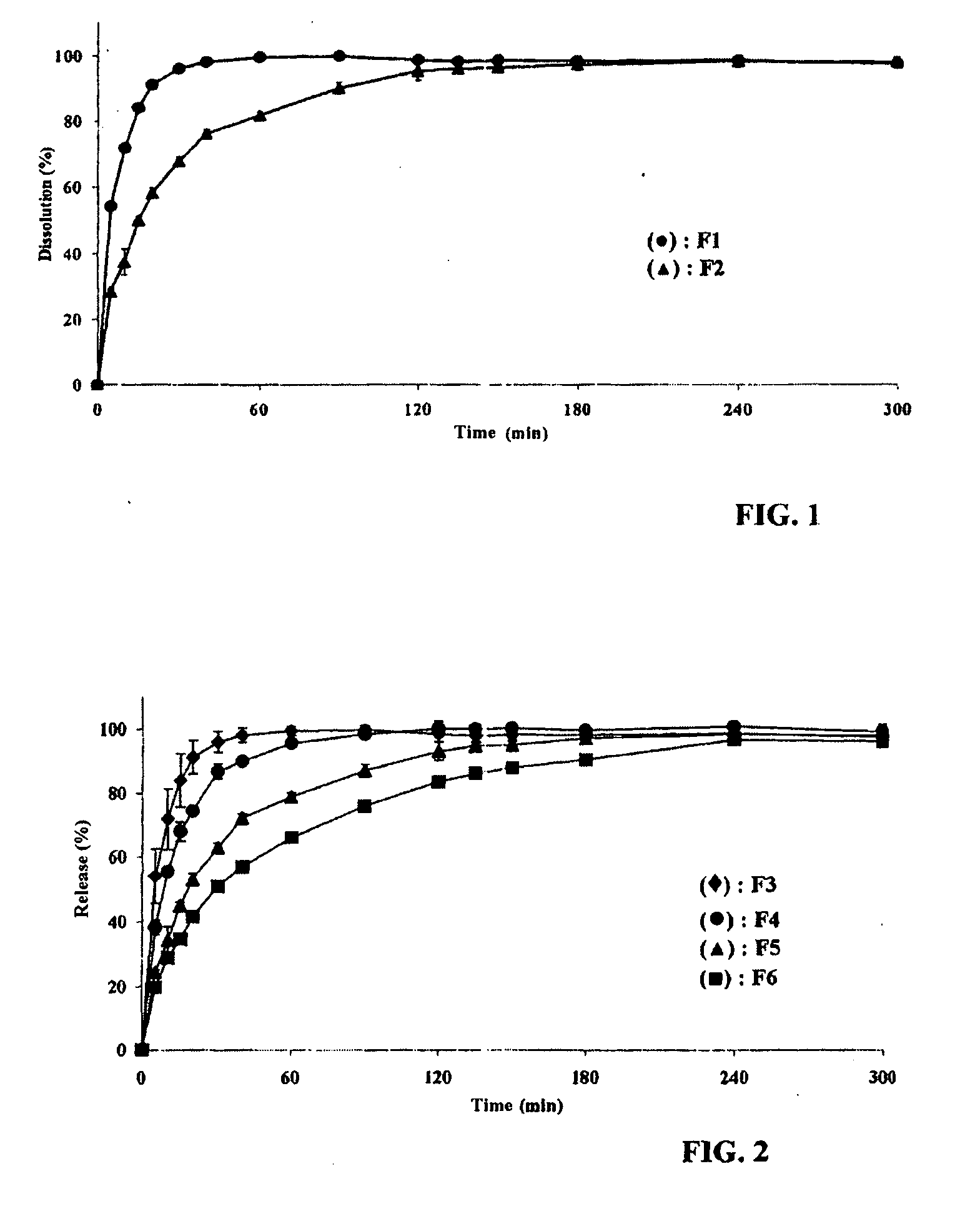

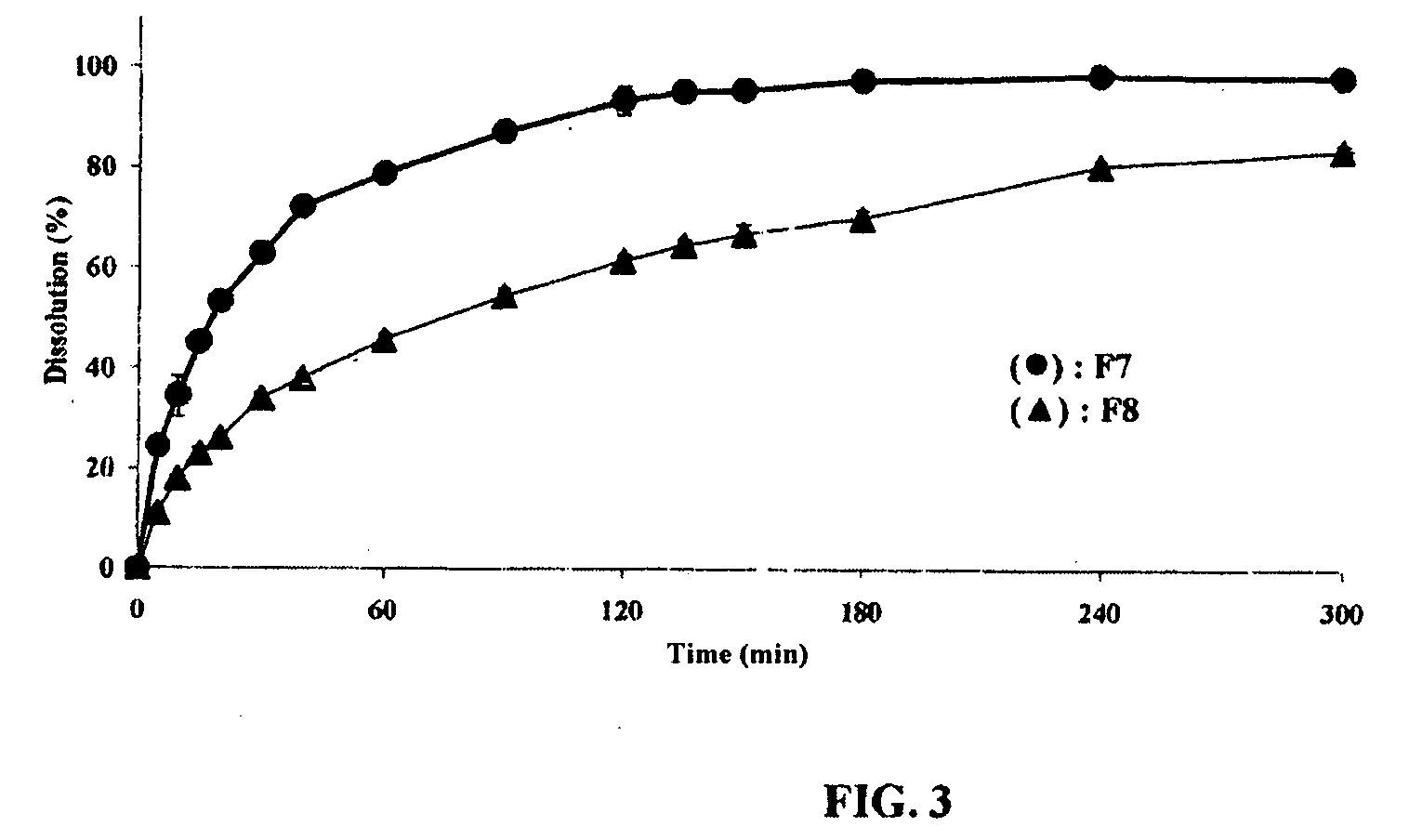

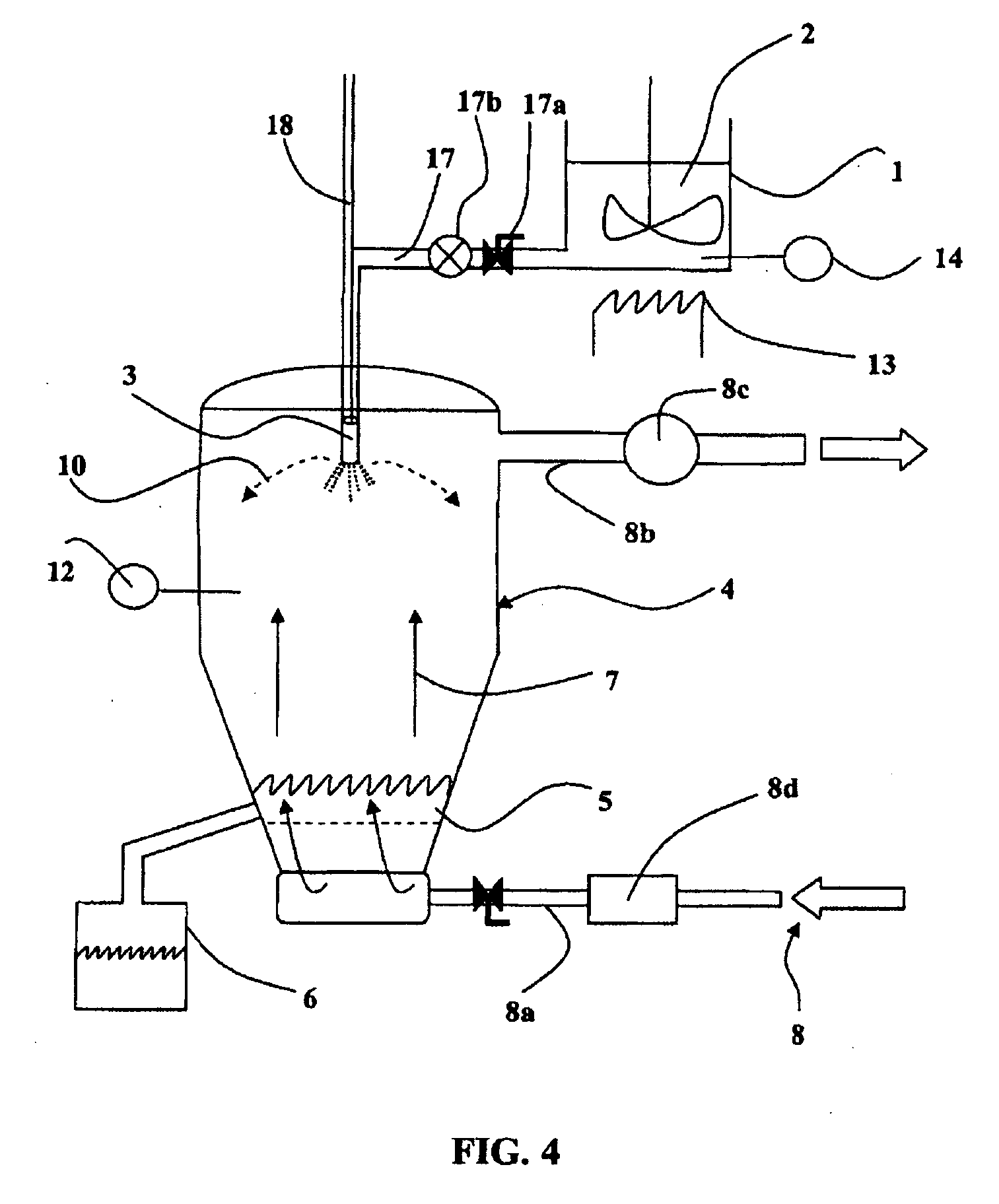

Controlled-release formulations, method of manufacture, and use thereof

Owner:SUN PHARMA IND INC

Surface protection film for polarizer film

InactiveUS20080166549A1Low costGood antifoulingLiquid surface applicatorsSynthetic resin layered productsActive agentWater vapor

The present invention provides a film for the protection of the surface of polarizer film. Said film surface has anti-static coated layer. The coating solution contains polythiophene, surfactant, binding resin and water. According to the present invention, said protection film on the surface on the polarizer film has the excellent anti-static, transmittance, anti-foul and water repellence. It is able to prevent the invasion of imbuing with dust, accumulative anti-static and water vapor from the processing of assembling and transportation so as to influence the quality of polarizer film.

Owner:NANYA PLASTICS CORP

Fe3O4/CuO/pSiO2 catalyst and preparation method thereof

InactiveCN102688760AEfficient separation and recoveryReduce churnOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemistryActive agent

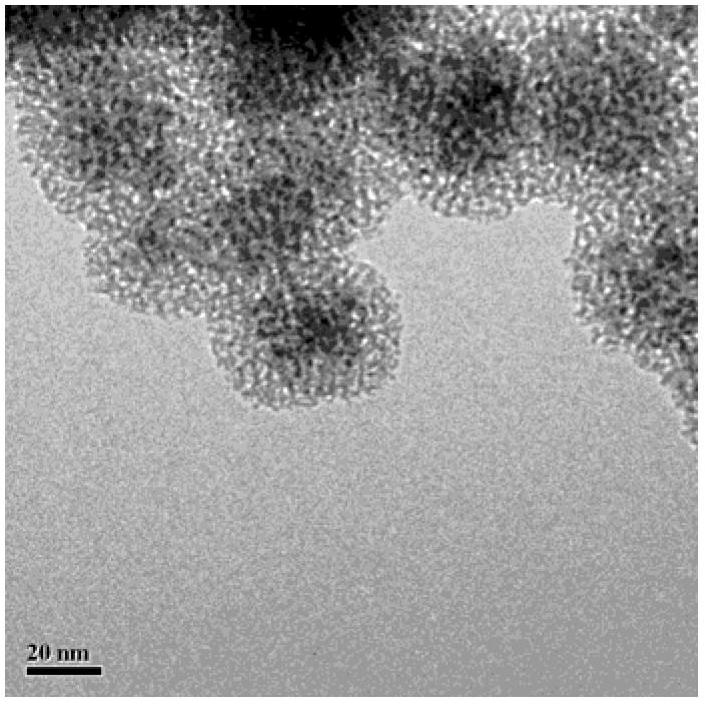

The invention relates to a Fe3O4 / CuO / pSiO2 (porous silica) catalyst, a preparation method thereof and application thereof in olefin epoxidation reaction. The preparation method comprises the following processes of: obtaining Fe3O4 microspheres serving as magnetic cores by adopting a co-precipitation method, and modifying the surfaces of the Fe3O4 microspheres by using polyvinyl pyrrolidone (PVP) in order to improve the adsorption effect of the surfaces of the Fe3O4 microspheres on metal cations; coating a CuO nano shell layer on the surfaces of the Fe3O4 microspheres by using copper acetate as a copper source through hydrothermal synthesis; and finally, coating the porous silicon dioxide shell layer by using cetyl trimethyl ammonium bromide (CTAB) as a surfactant and using ethyl orthosilicate as a silicon source, and thus obtaining a composite catalytic material with a magnetic Fe3O4 / CuO / pSiO2 core-shell structure. The catalytic performance of the composite material is researched by respectively using epoxidation reaction of styrene and cyclooctene as probe reaction, and the results prove that the catalytic material has high reaction activity and selectivity, and the catalytic material is easy to separate and recover by introducing the magnetic ores; and the catalytic material has a good circulating effect, still can keep excellent catalytic performance by dozens of times of circulation, and has a great application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

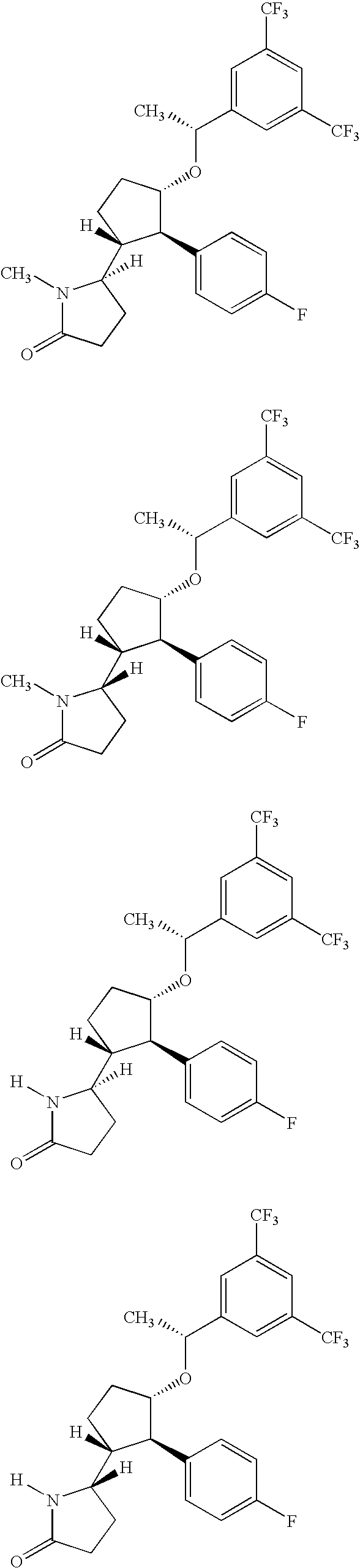

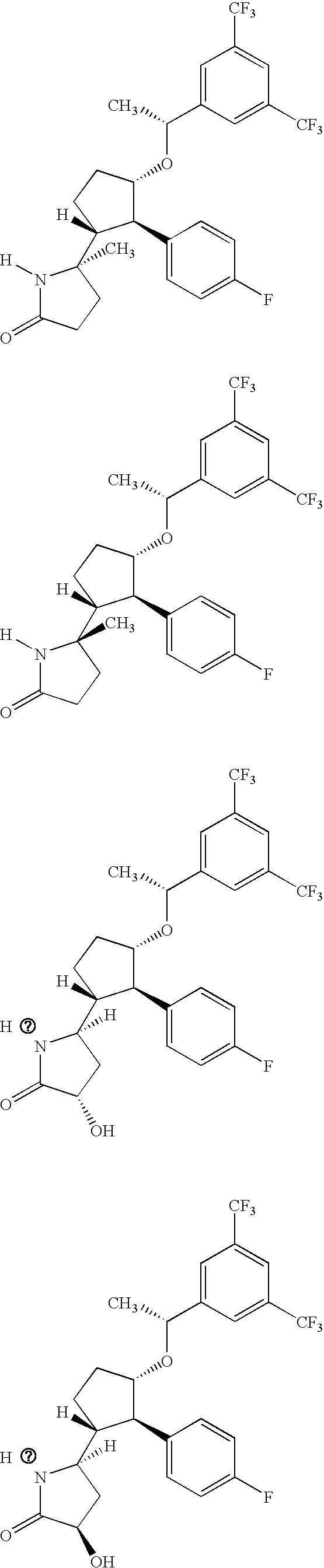

Combination therapy for the treatment-of lower urinary tract symptoms

Owner:MERCK SHARP & DOHME CORP

Micro-encapsulated capsicum, method for preparing the same and use thereof

InactiveUS20100055253A1Improve concentrationLimiting irritant effectConfectioneryAnimal feeding stuffActive agentChemistry

A food additive or feed ration for an animal contains an active agent including at least one capsaicinoid. The additive or ration is prepared by a method which includes the step of cold-state atomizing of granulating a liquid mixture containing an encapsulation fat, the active agent including at least one capsaicinoid. Solid particles of the mixture are thus produced. The cold-state atomization or the granulation act on the nature of the encapsulating fat, on the particle size, and on the temperature of the atomization step in order to control the capsaicinoid release kinetics in the digestive tract of animals.

Owner:AXISS FRANCE

Composite underwater sound transmission rubber material and preparation method thereof

Owner:TIANJIN RUBBER IND RES INST

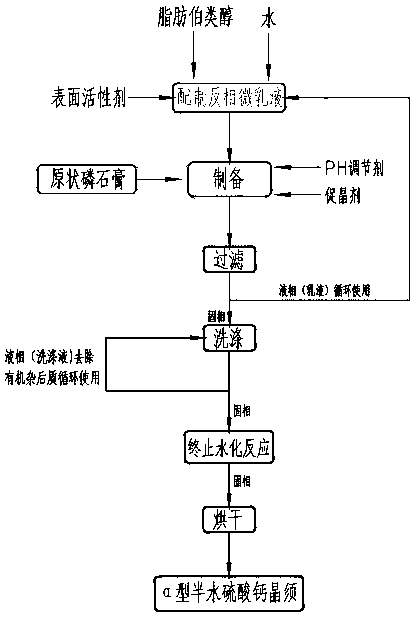

Method for preparing nano-scale alpha-type calcium sulfate hemihydrate whiskers from phosphogypsum in reverse microemulsion system

ActiveCN110835780APolycrystalline material growthFrom normal temperature solutionsActive agentCalcium Sulfate Hemihydrate

Owner:KUNMING UNIV OF SCI & TECH

Compositions comprising multiple bioactive agents, and methods of using the same

Owner:DEBIOPHARM INTERNATIONAL SA

Methods and compositions for promoting localization of pharmaceutically active agents to bone

Owner:AFFINERGY INC +1

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

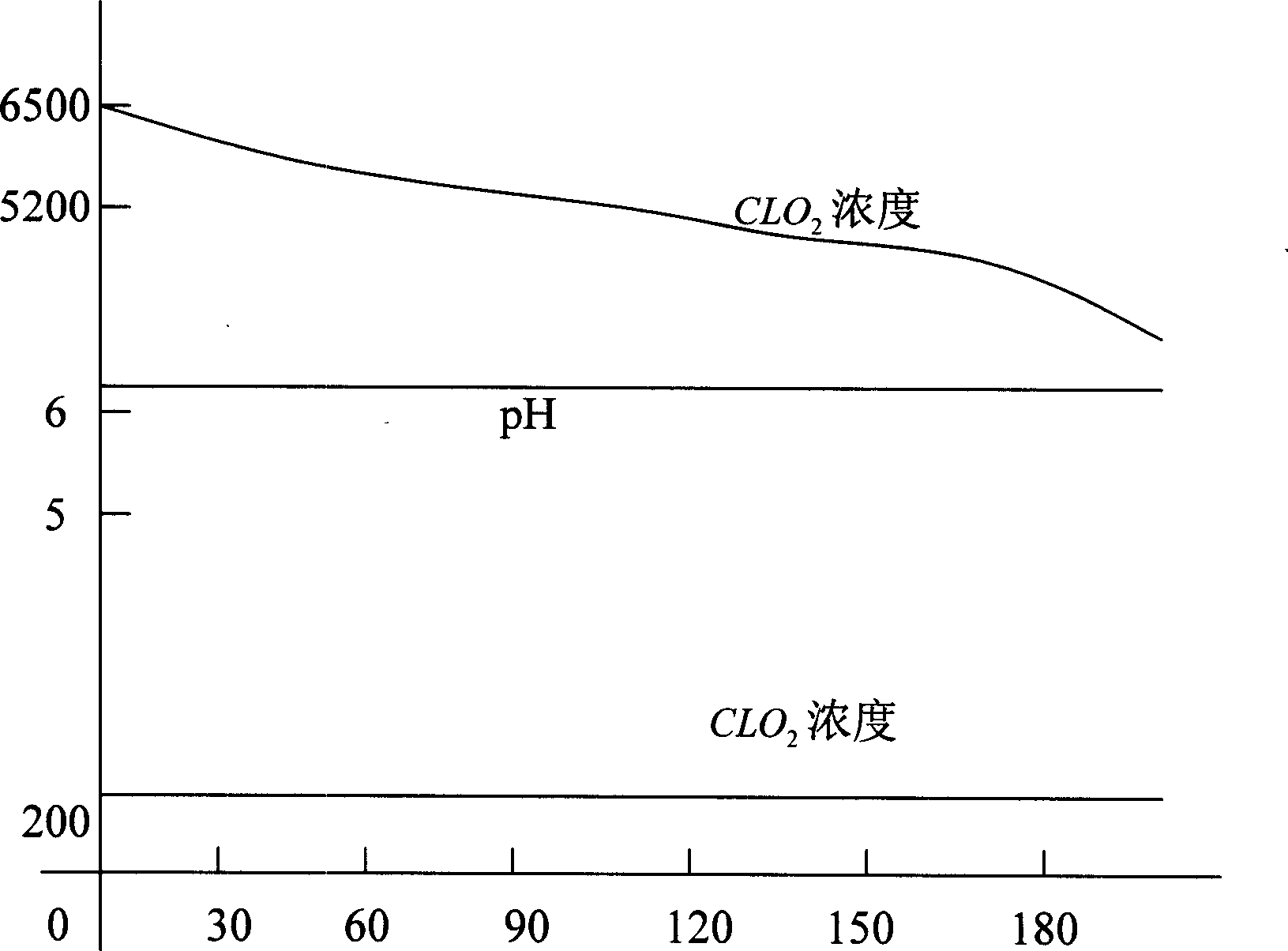

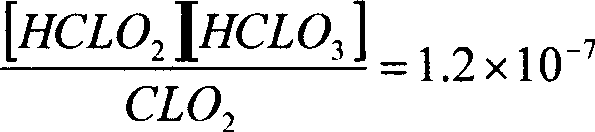

Chlorine dioxide sterilization foreign taste removing liquor

InactiveCN101380031AActivation withoutUse low concentrationBiocideDisinfectantsHigh concentrationStable state

Owner:吴予奇

W/O/W type multi-emulsion water plugging system and preparation method thereof

ActiveCN112210357AGood selective blocking abilityWater blocking will notDrilling compositionActive agentOil phase

The invention relates to a W / O / W type multi-emulsion water plugging system which is composed of a W / O type initial phase and an outer water phase, the volume ratio of the W / O type initial phase to theouter water phase is (3-0.5:7-9.5), the W / O type initial phase comprises an oil phase and an inner water phase, and the volume ratio of the oil phase to the inner water phase is (4-2:6-8). The oil phase comprises the following components in percentage by mass: 1%-5% of an oil-soluble surfactant, 0.1%-0.5% of nano silicon dioxide sol and the balance of oil. The W / O / W type multi-emulsion water plugging system is injected into an oil well, the W / O / W type multi-emulsion firstly utilizes the Jacquard effect of multiple interfaces to plug a water layer along with the gradual rising of the temperature in the oil well from top to bottom and the entering of the system into the stratum, and meanwhile, the adsorption of an emulsifying agent and a stabilizing agent of a water phase in the W / O / W typemulti-emulsion on the rock surface is realized; and the W / O / W type multiple emulsion outer phase loses stability, the high-viscosity W / O type emulsion is separated out, and a water layer is further blocked.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Iron and steel product surface treating agent and preparation method thereof

InactiveCN105256321AReduce productionReduce wasteMetallic material coating processesIndustrial waste waterO-Phosphoric Acid

The invention provides an iron and steel product surface treating agent and a preparation method thereof, and relates to the technical field of metal surface treating agents. The surface treating agent comprises, by weight, 12%-17% of phosphoric acid with the concentration of 85%, 3%-8% of composite phosphate, 7%-12% of nitric acid with the concentration of 65%, 5%-10% of corrosion inhibitor(s), 1%-3% of aqueous surface active agent(s), 3%-6% of zinc chrome, 4%-7% of polyol ester, and the balance water. The iron and steel product surface treating agent can be used for carrying out derusting, deoiling and phosphating on iron and steel products at the same time, and the generation amount of industrial waste water in the production process can be greatly reduced; the iron and steel product surface treating agent can be stored for a long time without lowering of the effectiveness, and uniform and compact phosphating films still can be formed on the surfaces of the iron and steel products even if the iron and steel product surface treating agent is stored for a long time; in addition, when the iron and steel product surface treating agent is used for carrying out comprehensive surface treating on the iron and steel products, the replacement frequency of bath solutions is low, the utilization rate of acid liquor is high, and the production cost of enterprises is low.

Owner:NANHUA UNIV +1

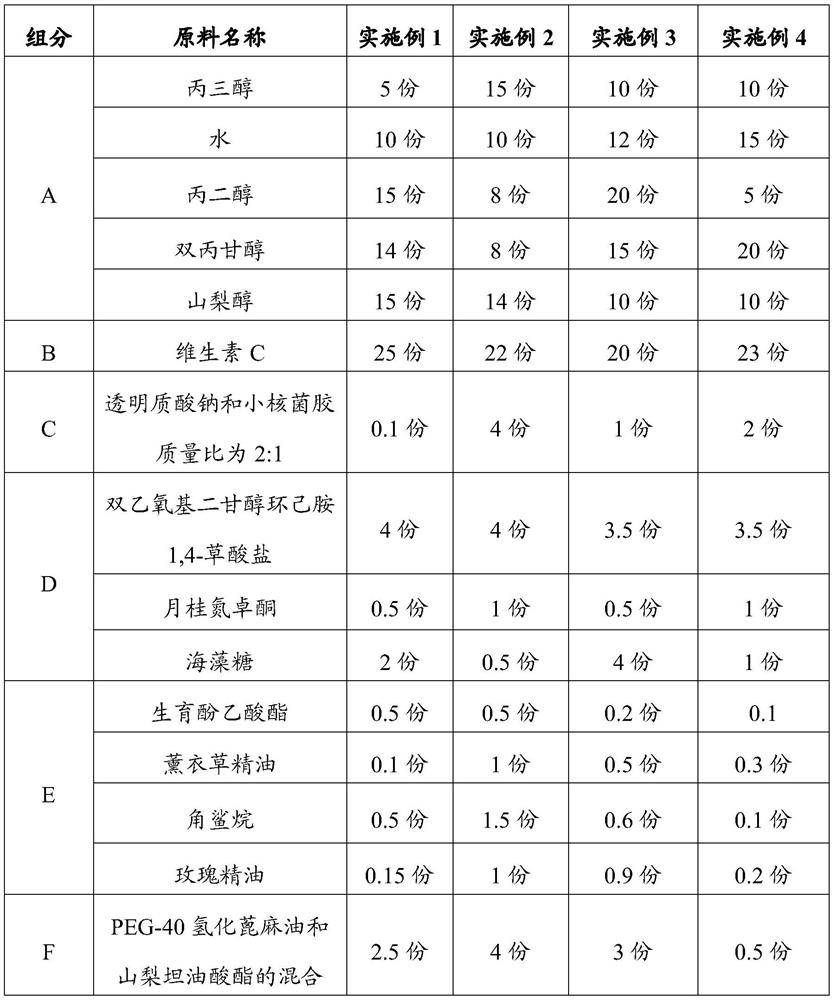

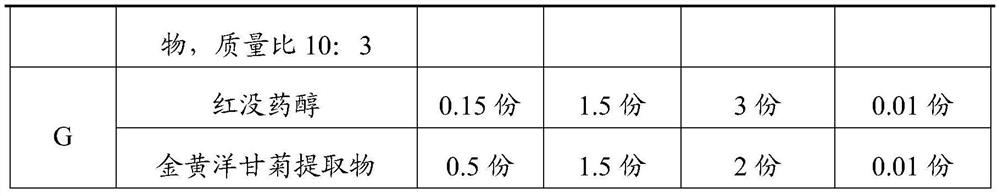

Cosmetic composition with high vitamin C content as well as preparation method and application thereof

ActiveCN112587438AHigh in Vitamin CImprove solubilityCosmetic preparationsToilet preparationsBiotechnologyVitamin C

Owner:彭氏(惠州)实业发展有限公司

Fabric conditioning compositions

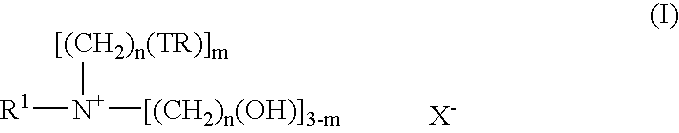

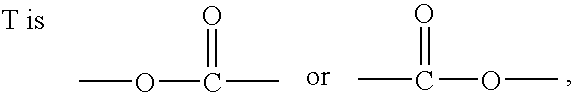

InactiveUS20040048770A1Control viscosityLow viscosityCationic surface-active compoundsDry-cleaning apparatus for textilesIodine valueNonionic surfactant

An aqueous fabric conditioning composition comprises (a) 7.5 to 60% by weight of a cationic fabric softening compound of a quaternary ammonium softening compound, the compound having one or more hydrocarbyl chains formed from parent fatty acyl compounds or fatty acids having an iodine value of between 0 and 20, (b) 0.01%-1.5% by weight of a nonionic surfactant viscosity modifier and (c) optionally up to 1.4% by weight of a fatty alcohol wherein the combination of (b) and (c) is no more than 1.5% by weight of the composition and the composition comprises particles having a mean diameter of from 0.3 to 7 microns, measured using a Malvern Mastersizer.

Owner:HENKEL IP & HOLDING GMBH

Soft solder for SnAgCuNiGe alloy solder paste

InactiveCN101176957AWeldablePrintableWelding/cutting media/materialsSoldering mediaActive agentMetallurgy

Owner:东莞市特尔佳电子有限公司

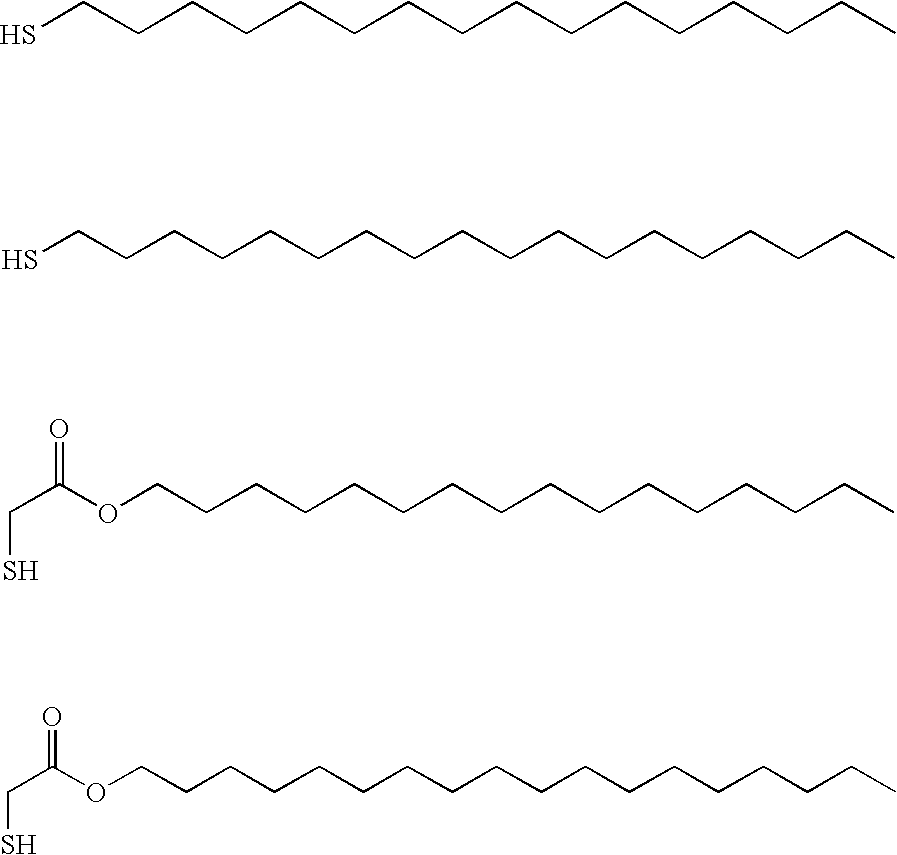

Water-Based Metal Treatment Composition

InactiveUS20070277906A1Organic detergent compounding agentsDetergent mixture composition preparationThio-Active agent

Owner:MIDDLESEX SILVER CO LTD

Antibacterial easy-to-clean water-soluble drawing oil and preparation method thereof

PendingCN111763552AImprove the lubrication effectImprove surface qualityLubricant compositionBacteriostatic agentActive agent

The invention relates to the technical field of stretching lubricating oil and preparation thereof, in particular to antibacterial easy-to-clean water-soluble drawing oil and a preparation method thereof. The water-soluble drawing oil is prepared from the following components in parts by weight: 25-50 parts of synthetic oil, 10-15 parts of base oil, 5-10 parts of an emulsifier, 8-10 parts of a reinforcing agent, 7-10 parts of a surfactant, 1.5-3.0 parts of a bacteriostatic agent, 16-20 parts of an extreme pressure anti-wear agent, 6-10 parts of a metal cleaning agent and 4-5 parts of a rapid defoaming agent. The water-soluble drawing oil is prepared by mixing and stirring the components and heating. The problems that in the prior art, water-soluble drawing oil is prone to bacteria generation, large in foam and poor in cleaning effect are solved, and the provided water-soluble drawing oil has the advantages of being good in compression resistance and abrasion resistance, good in antibacterial effect, capable of achieving rapid defoaming and easy to clean.

Owner:昆山泰诺得润滑科技有限公司

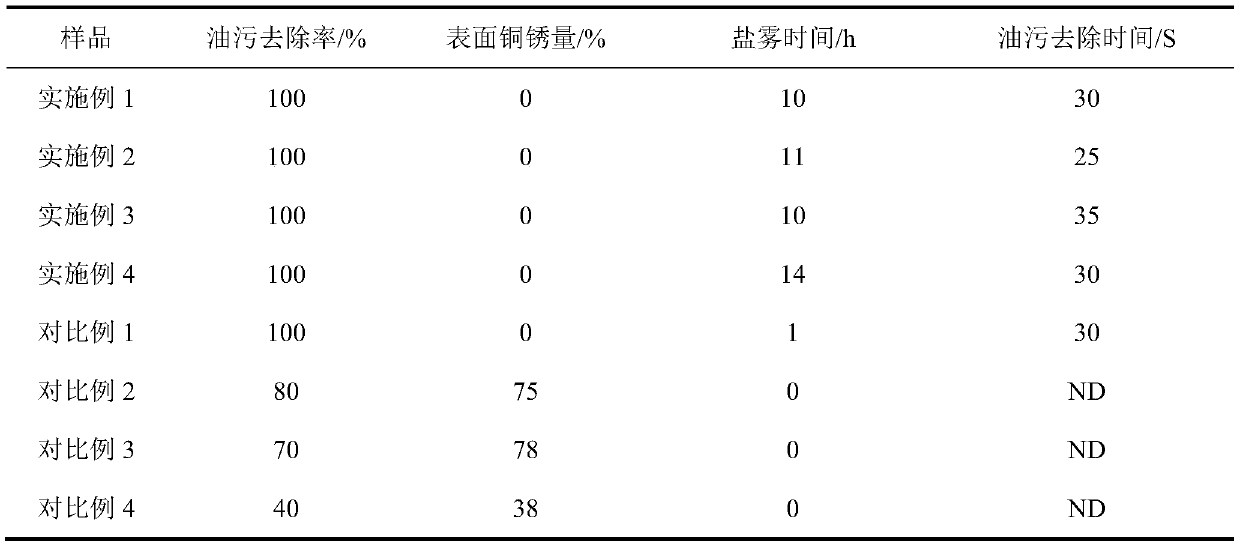

Copper cleaning agent and preparation method thereof

Owner:JIANGNAN UNIV

High-activity multifunctional laundry bead and preparation method thereof

InactiveCN111234967AIncrease contentImprove solubilityOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentHigh activity

Owner:JIANGNAN UNIV

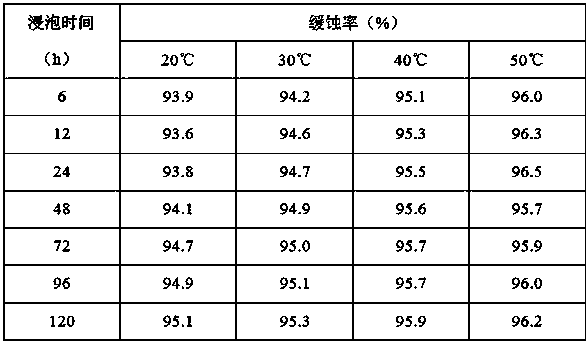

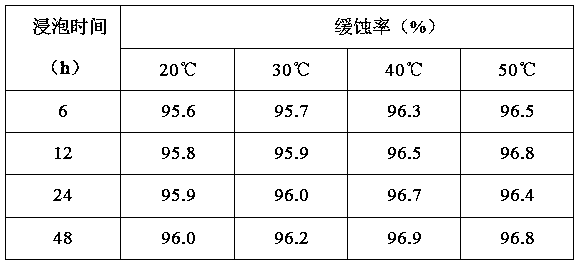

Camellia oleifera abel shell compound corrosion inhibitor and preparation method and application thereof

Owner:SOUTHWEST FORESTRY UNIVERSITY

Super absorbent resin and preparation method thereof

The invention provides super absorbent resin and a preparation method thereof. The preparation method comprises the steps of: mixing and heating a dispersion medium, a surfactant and a dispersing agent to obtain a substrate solution; mixing the substrate solution with a certain amount of an initiator-based mixed solution A and an acrylic acid solution A, heating, carrying out primary polymerization reaction, and evaporating out part of water; and then mixing the substrate solution with a certain amount of an initiator-based mixed solution B and an acrylic acid solution B to carry out secondary polymerization reaction, then evaporating out part of water, and carrying out post-crosslinking, distillation treatment, solid-liquid separation and drying to obtain spherical resin particles. According to the preparation method, complete interface fusion or partial interface fusion among the spherical resin particles can be avoided, the particle size of the synthesized spherical resin particles can be controlled within a certain distribution range, meanwhile, the synthesized resin does not have a special shape, and the water absorption effect of the resin is improved.

Owner:YANKUANG COAL WATER SLURRY GASIFICATION & COAL CHEM NAT ENG RES CENT CO LTD

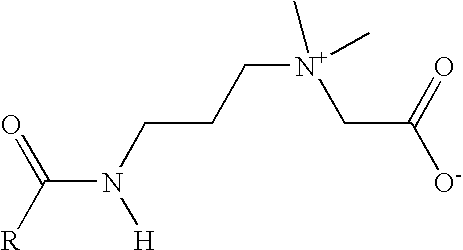

Chemical sensors for detecting hydrogen and methods of use

InactiveUS20100224507A1Weather/light/corrosion resistanceVolume/mass flow measurementChemical physicsNanoparticle

The presently-disclosed subject matter provides sensors and methods for detecting hydrogen by determining the conductivity of a chemiresistant film upon exposure to hydrogen, including for example chemiresistant films comprised of alkylamine-, alkylthiolate-, and / or surfactant-coated metal alloy nanoparticles.

Owner:UNIV OF LOUISVILLE RES FOUND INC

Plating solution formula for continuously electroplating satin nickel and process

InactiveCN112680754AWon't decomposeIncrease the frequency of maintenanceActivated carbonActive agent

The invention relates to the field of nickel electroplating, and discloses a plating solution formula for continuously electroplating satin nickel and a process.The satin nickel plating solution formula comprises the following components in proportion by weight: 500-560g / L of nickel sulfate pentahydrate, 25-35g / L of nickel chloride, 40-50g / L of boric acid and a non-ionic surfactant; and the non-ionic surfactant comprises the components in proportion by volume: 32-36 ml / L of a cylinder opening agent, 4.0-6.0 ml / L of an auxiliary agent and 0.8-1.2 ml / L of a sand agent. The process comprises the steps of pretreatment->nickel pre-plating-> satin nickel plating->semi-gloss nickel plating->water repelling. Compared with the prior art, the formula of the satin nickel plating solution formula and a saltin nickel plating layer electroplated by the electroplating process have the advantages that the glossiness of the saltin nickel plating layer is stabilized at 40-80, the appearance is uniform, yellow spots are avoided when the saltin nickel plating layer is exposed in air, the maintenance period of the saltin nickel plating solution is obviously prolonged, and the saltin nickel plating layer is treated and maintained once a month by activated carbon.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Skincare cosmetic containing self-repairing active agent and preparation method of skincare cosmetic

Owner:CHENDU NEW KELI CHEM SCI CO LTD

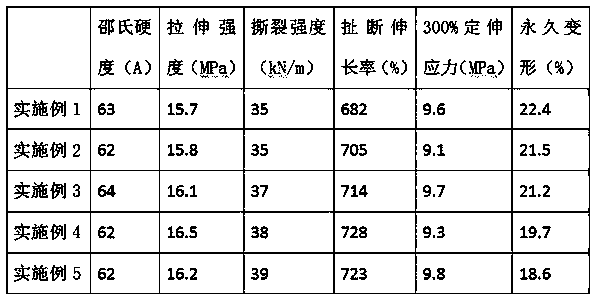

Preparation method of high-strength tire curing bladder

InactiveCN110698776AStrong responsivenessImprove adhesionDomestic articlesPolymer scienceActive agent

Owner:YONGYI RUBBER CO LTD

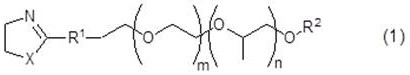

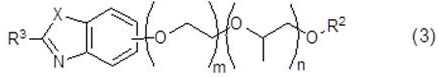

PEG coupled heterocyclic compound and application thereof in acidic bright copper plating

Owner:WENZHOU INST UNIV OF CHINESE ACAD OF SCI

UV frosted ink

The invention discloses UV frosted ink which comprises the following raw material components in parts by weight: 30-40 parts of cured resin, 10-15 parts of UV gloss oil, 40-55 parts of an active agent, 2-5 parts of a photoinitiator and 10-15 parts of an additive. The active agent is formed by mixing an active diluent and a surfactant. The weight percentages of the active diluent and the surfactantare 87% and 13% respectively. The UV frosted ink is high in adhesive force, can be well attached to a printing stock, and is high in drying speed, high in flexibility and smooth and bright in surface, and the problems of cracking and air holes do not occur after curing is completed.

Owner:洪浪

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap