Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Hydrothermal synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term "hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase equilibria since the beginning of the twentieth century. George W. Morey at the Carnegie Institution and later, Percy W. Bridgman at Harvard University did much of the work to lay the foundations necessary to containment of reactive media in the temperature and pressure range where most of the hydrothermal work is conducted.

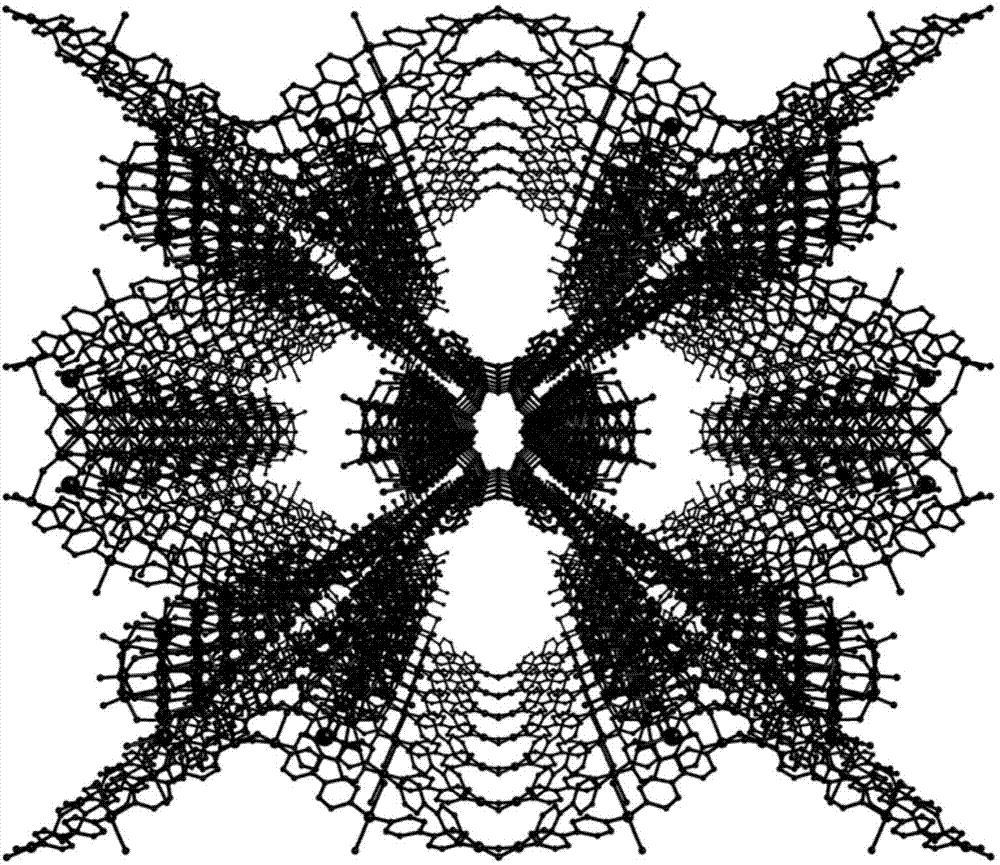

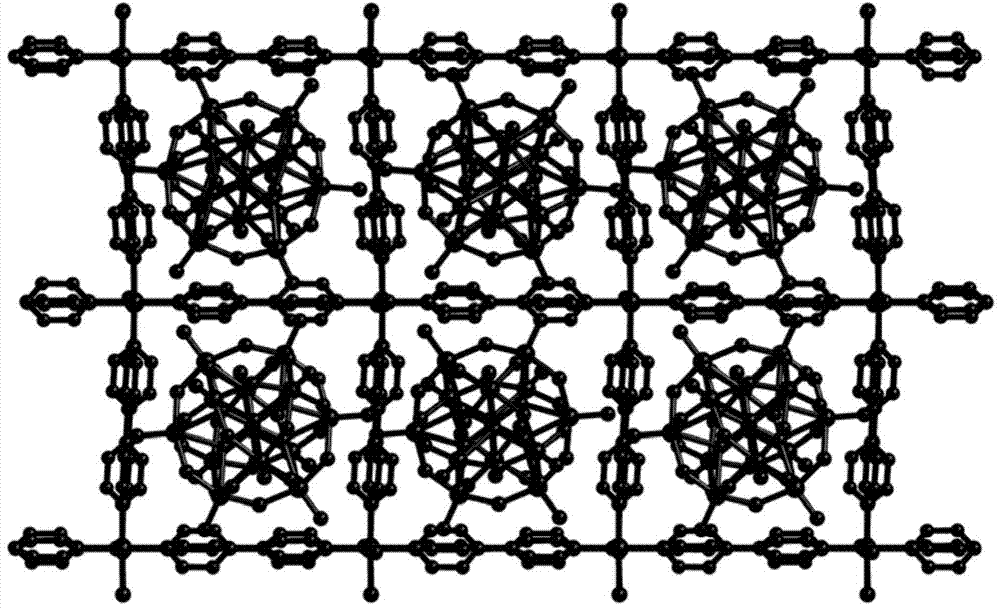

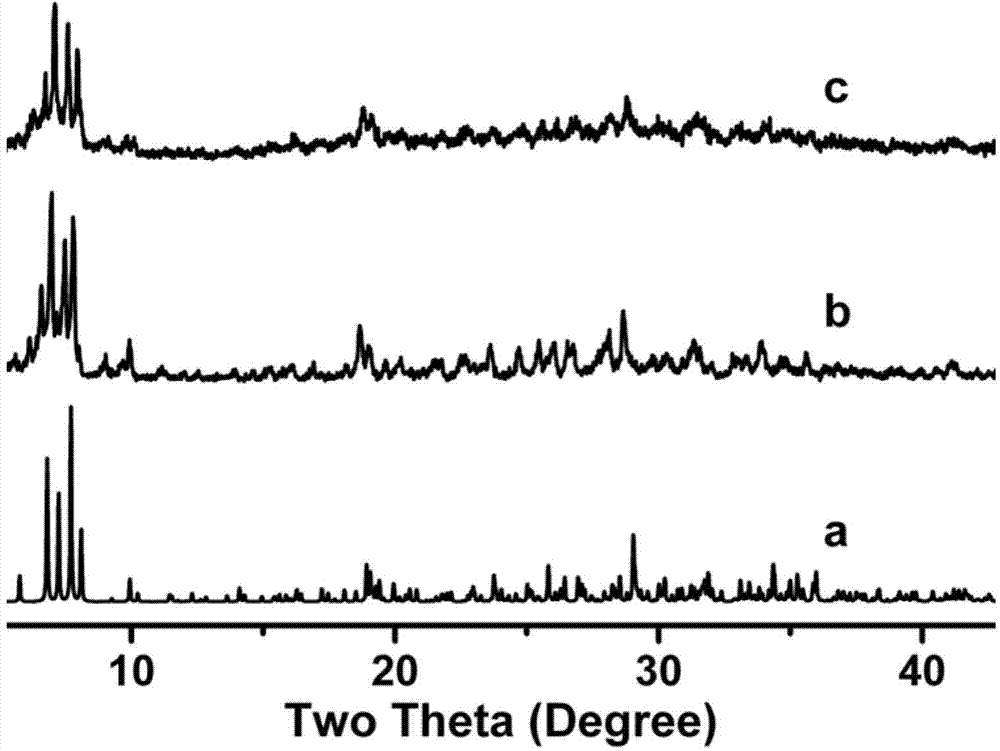

Preparation method and application of bimetallic photocatalytic functional POM/MOFs

ActiveCN104324754AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDiffusionReusability

Owner:DALIAN UNIV OF TECH

A kind of preparation method of chabazite and chabazite membrane

The invention provides a method for preparing chabazite and a chabazite film in the absence of a template agent. Pure chabazite is formed through induction of out-of-phase crystal nucleus T-shaped zeolite under the condition of not adding an organic template agent. The chabazite molecular sieve film is formed through induction by loading formed chabazite on the outer surface of a porous support as a crystal seed. The method is characterized in that: silicon powder and sodium metaaluminate are used as a silicon source and an aluminum source; based on the molar ratio of oxides, the ratios of components which are prepared into sol are that: the molar ratio of SiO2 to Al2O3 is equal to 15-30, the molar ratio of OH<-> to SiO2 is equal to 0.9-1.5, the molar ratio of Na<+> to K<+> is equal to 0.1-1, and the molar ratio of H2O to SiO2 is equal to 18-40; the sol for coating the crystal seed is subjected to hydrothermal synthesis at the temperature of 100-160 DEG C for 16-72 hours; and a compact chabazite film is synthesized on a porous carrier. Through the method for preparing the chabazite and the chabazite film, the expensive organic template agent is prevented from being added, the synthesis process is simple, and the repeatability is high. The synthesized film shows better stability in an inspection acid medium and can be widely applied to a pervaporation separation process and a pervaporation film reactor of an acidic system.

Owner:JIANGXI NORMAL UNIV

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

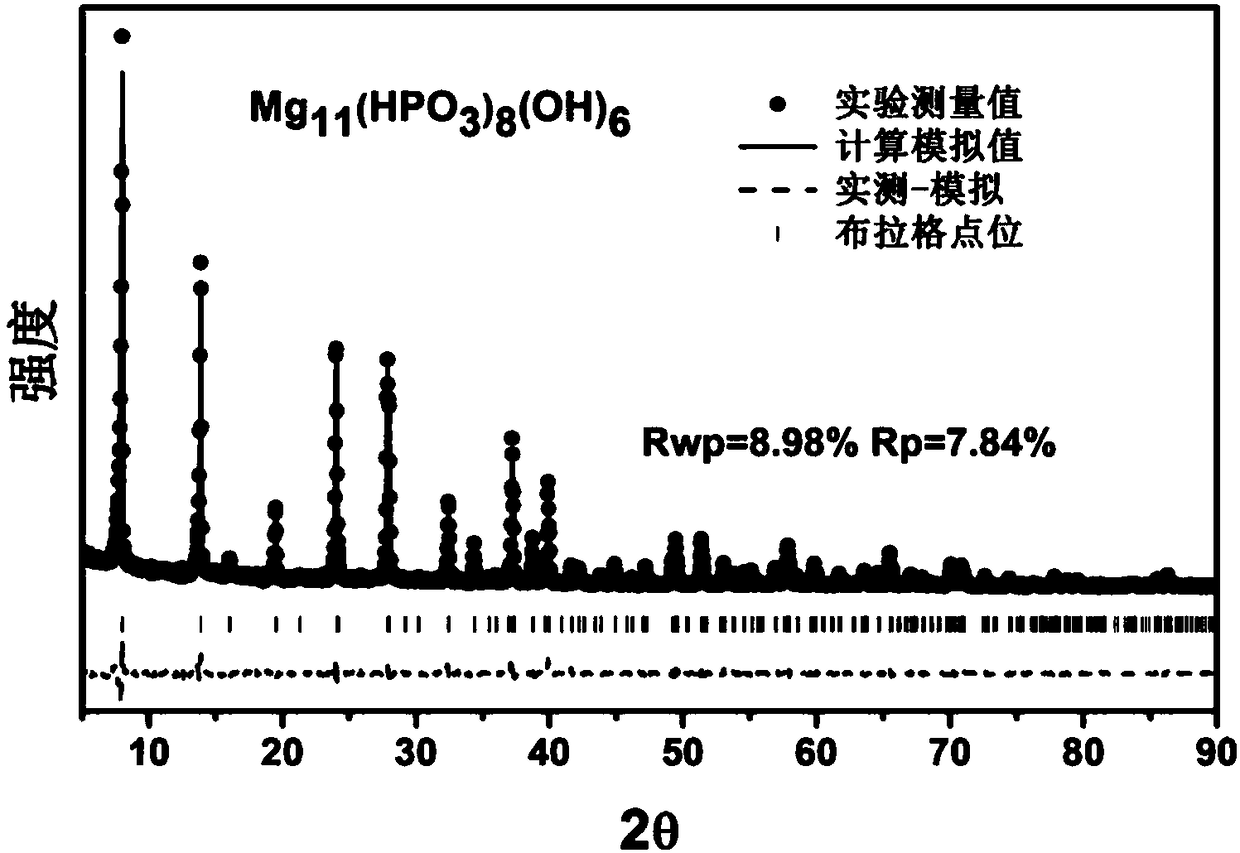

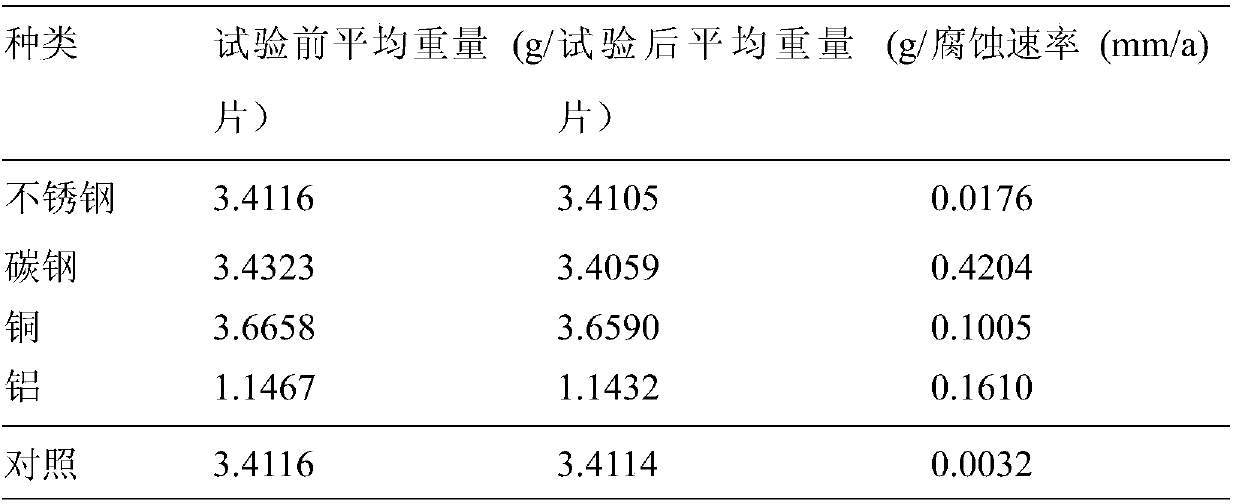

Crystal material, and preparation method and application thereof

ActiveCN108193268AHigh UV-Vis-NIR high reflectivityImprove performancePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidMagnesium Acetate Tetrahydrate

Owner:SOUTH CHINA UNIV OF TECH

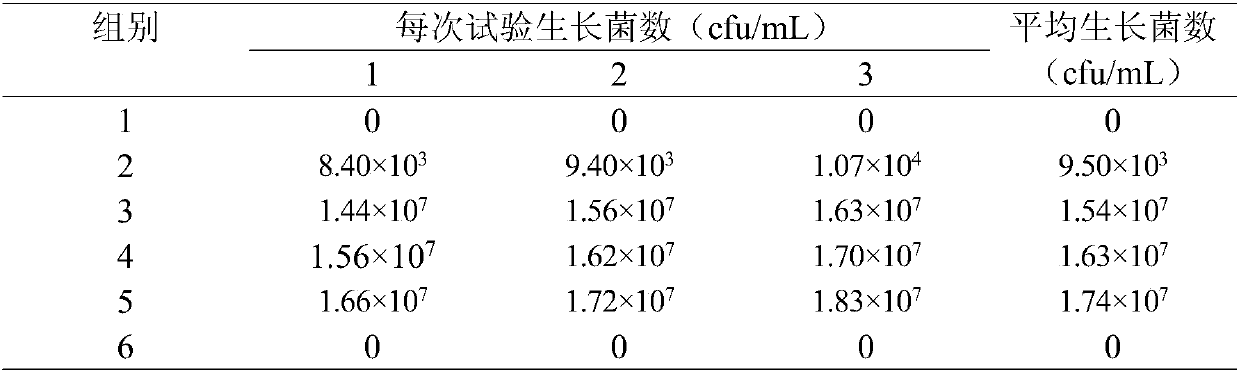

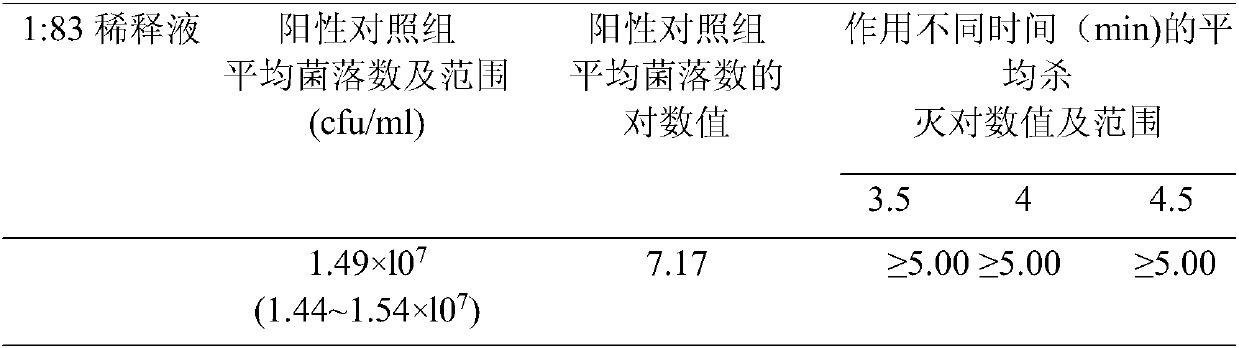

Preparation method of beer bottle sterilizing detergent based on microcrystalline cellulose/silver composite material

ActiveCN107699392AGood ability to remove dirtImprove the bactericidal effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydrothermal synthesisBottle

Owner:ANHUI SCI & TECH UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap