Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

290 results about "Oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oxide /ˈɒksaɪd/ is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O²⁻ atom. Metal oxides thus typically contain an anion of oxygen in the oxidation state of −2. Most of the Earth's crust consists of solid oxides, the result of elements being oxidized by the oxygen in air or in water. Hydrocarbon combustion affords the two principal carbon oxides: carbon monoxide and carbon dioxide. Even materials considered pure elements often develop an oxide coating. For example, aluminium foil develops a thin skin of Al₂O₃ (called a passivation layer) that protects the foil from further corrosion. Individual elements can often form multiple oxides, each containing different amounts of the element and oxygen. In some cases these are distinguished by specifying the number of atoms as in carbon monoxide and carbon dioxide, and in other cases by specifying the element's oxidation number, as in iron(II) oxide and iron(III) oxide. Certain elements can form many different oxides, such as those of nitrogen. other examples are silicon, iron, titanium, and aluminium oxides.

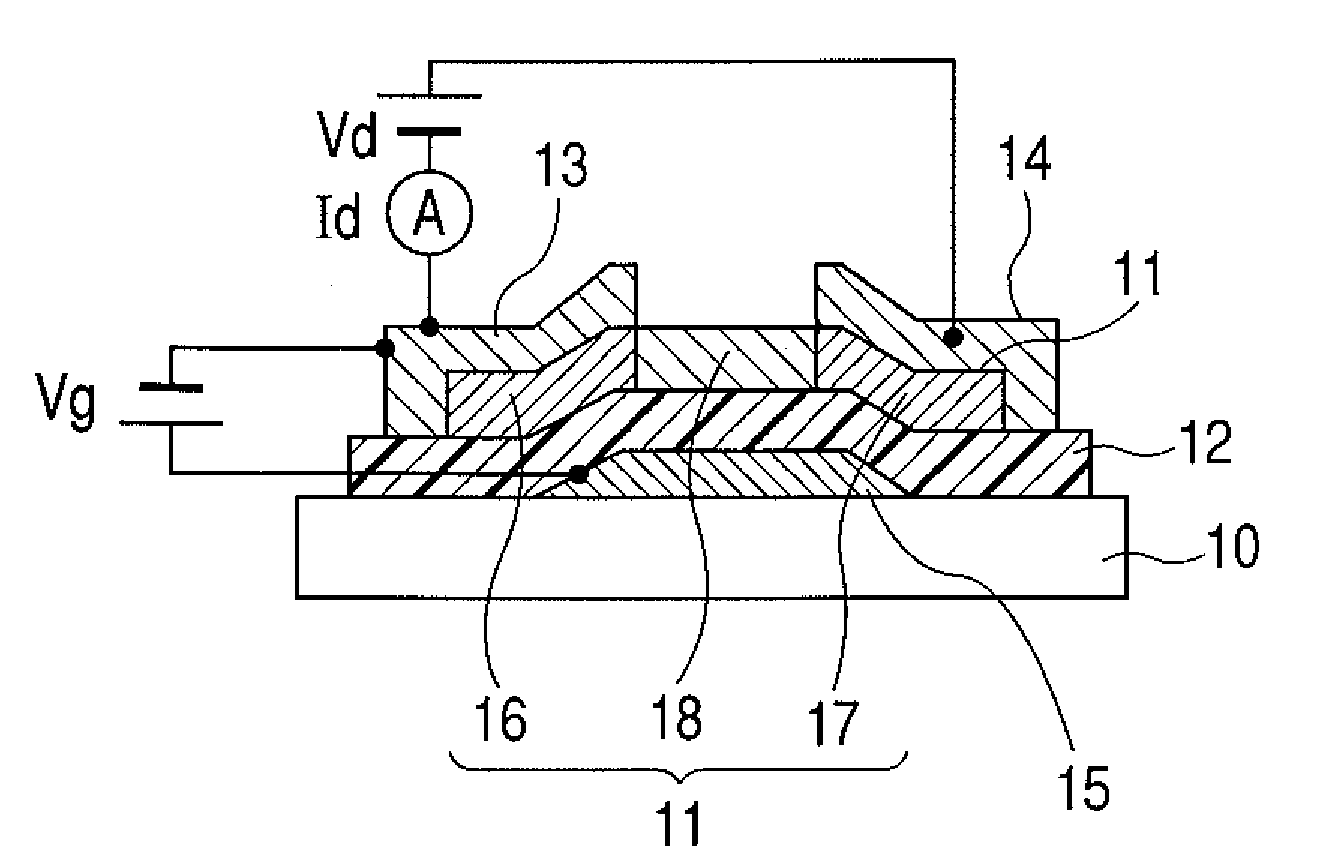

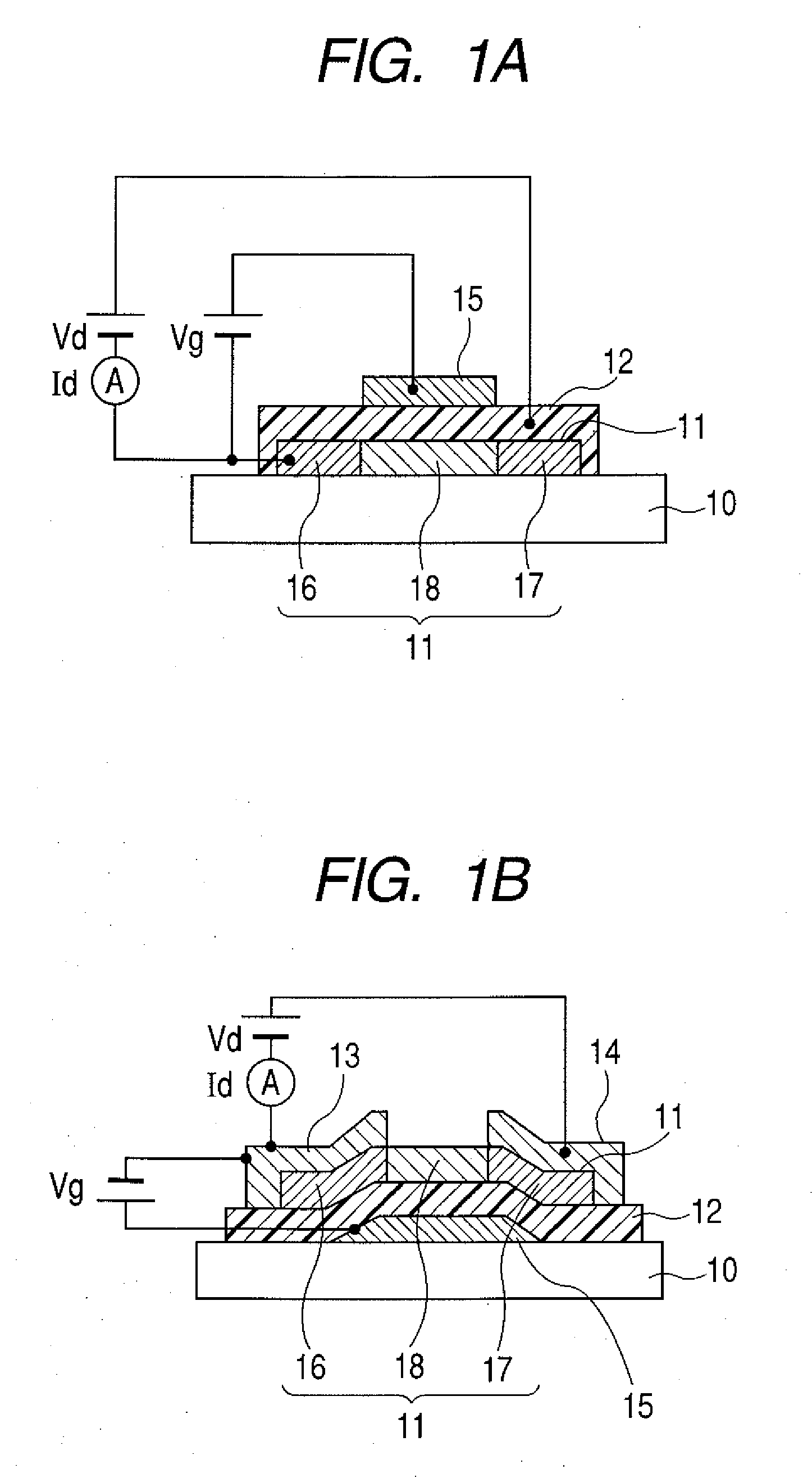

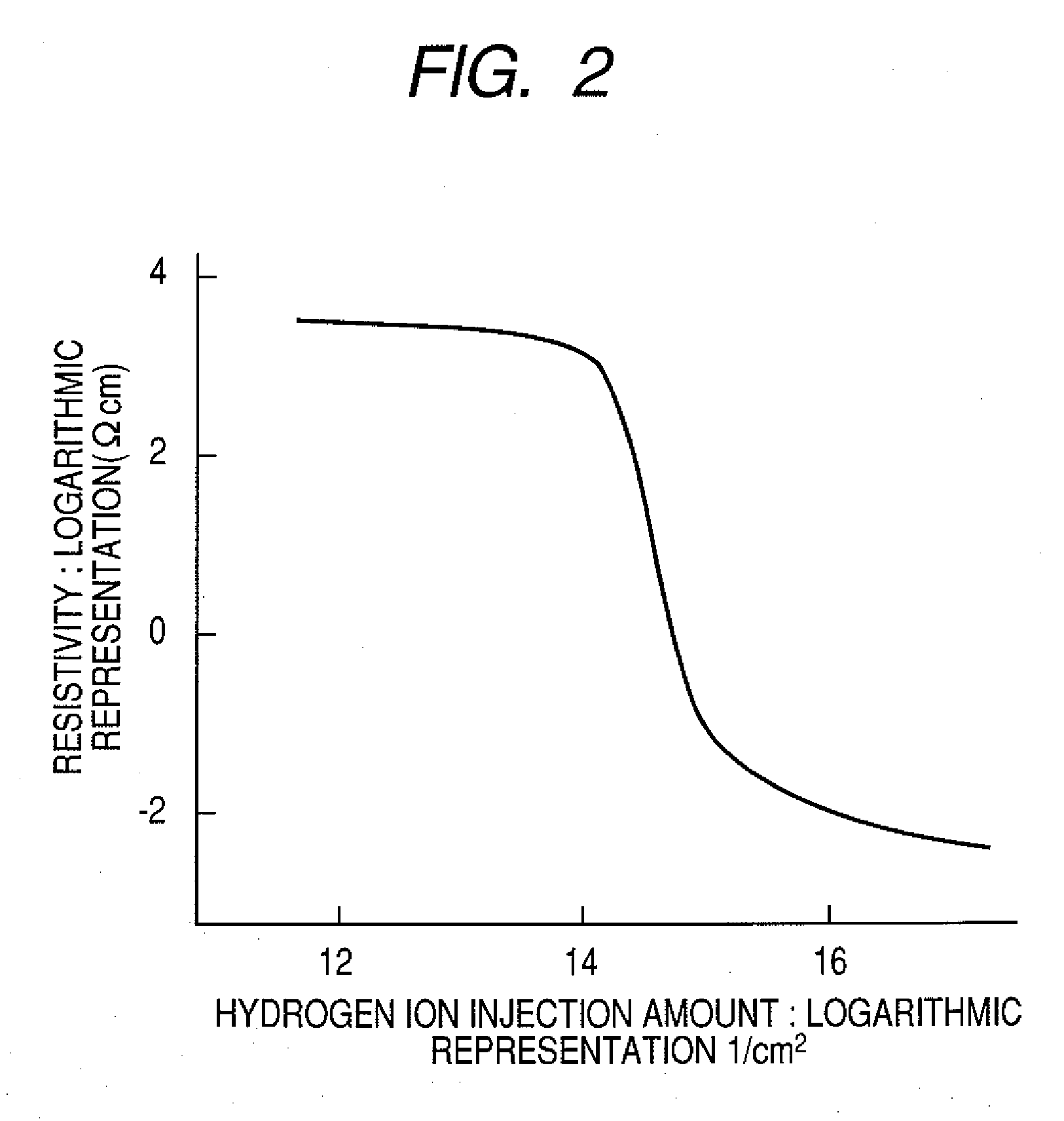

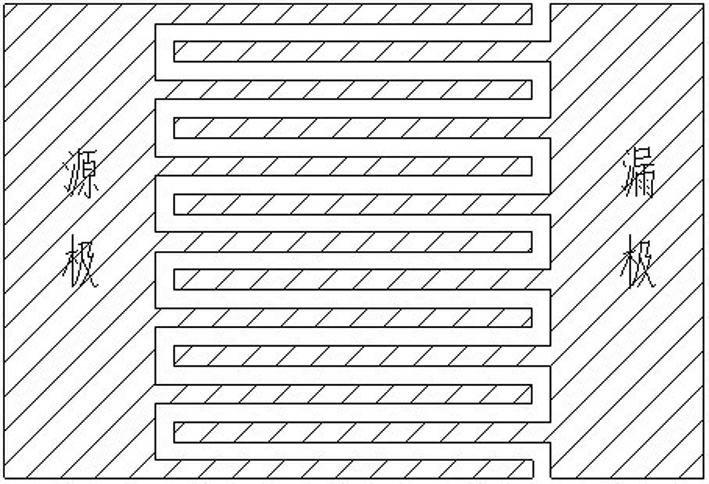

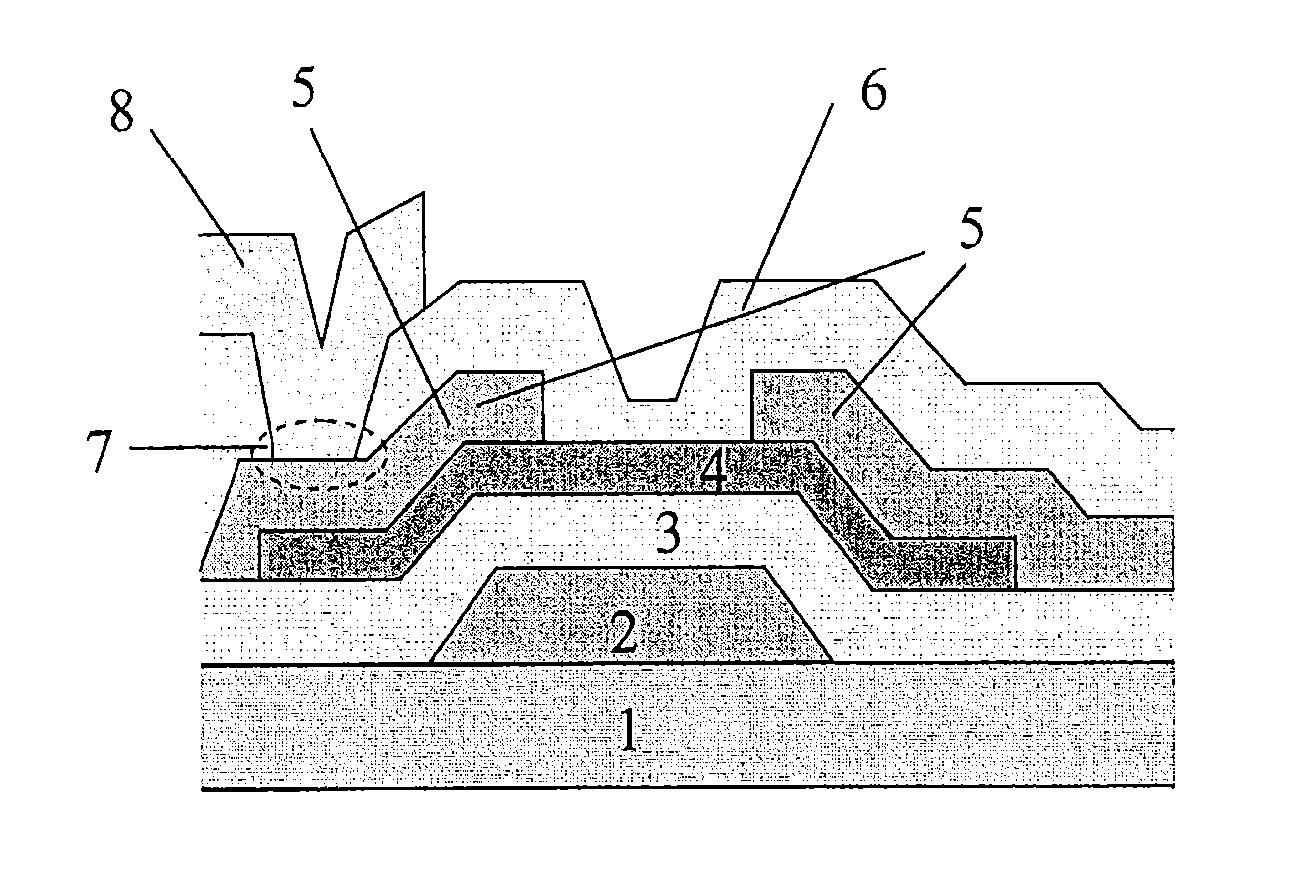

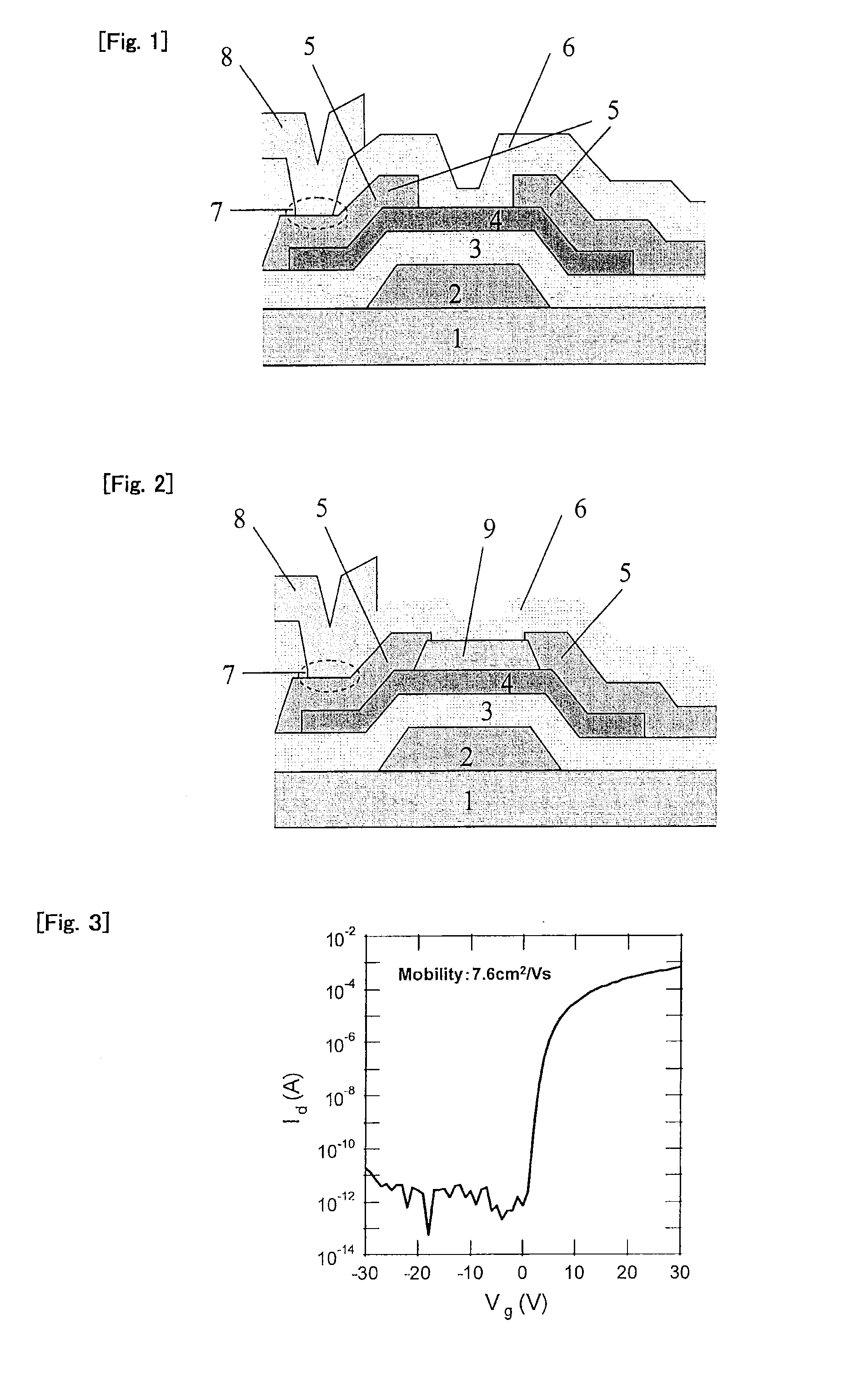

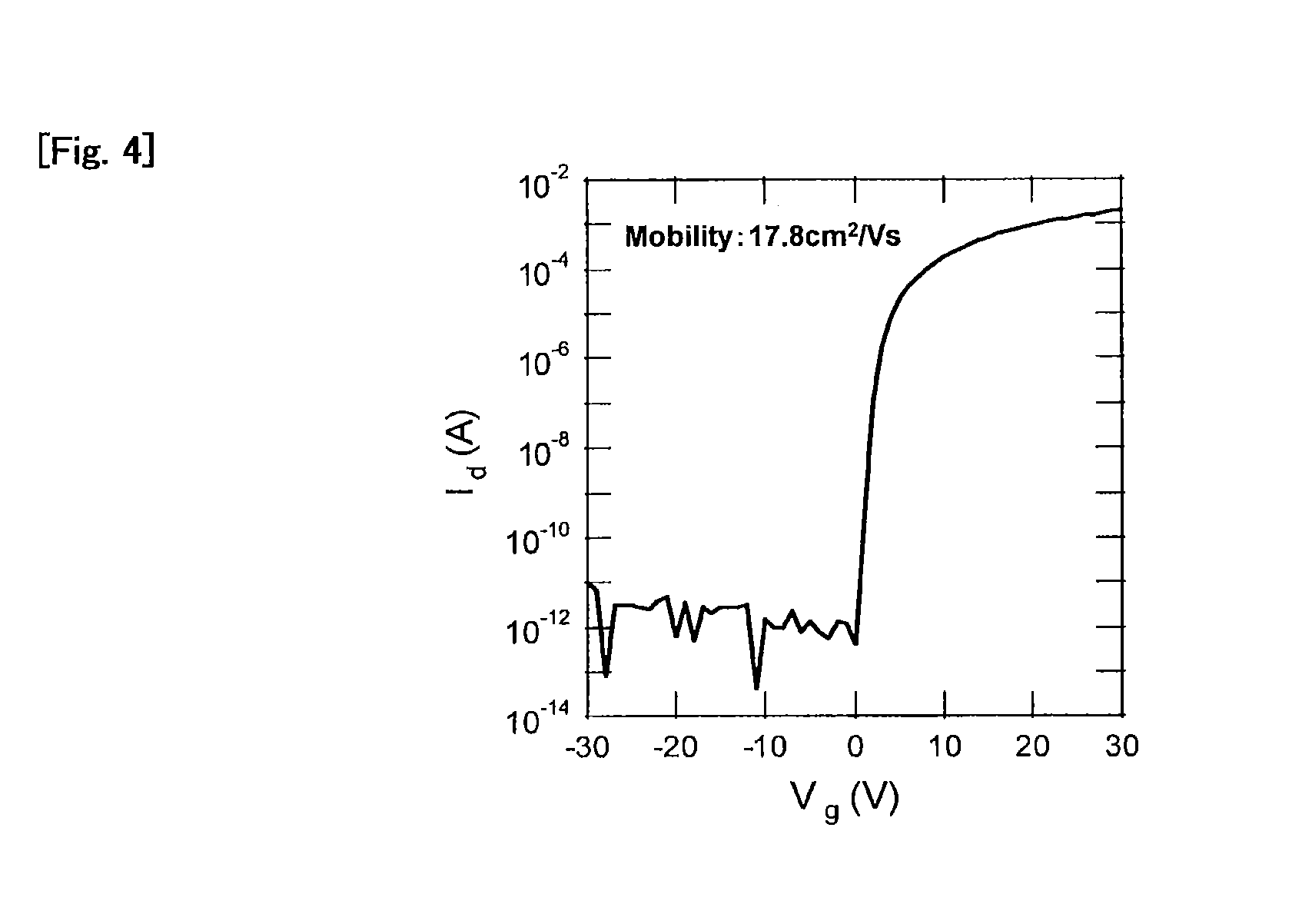

Field effect transistor using oxide film for channel and method of manufacturing the same

ActiveUS20090065771A1Reduce variationImprove accuracyTransistorSemiconductor/solid-state device manufacturingHydrogenField-effect transistor

Owner:CANON KK

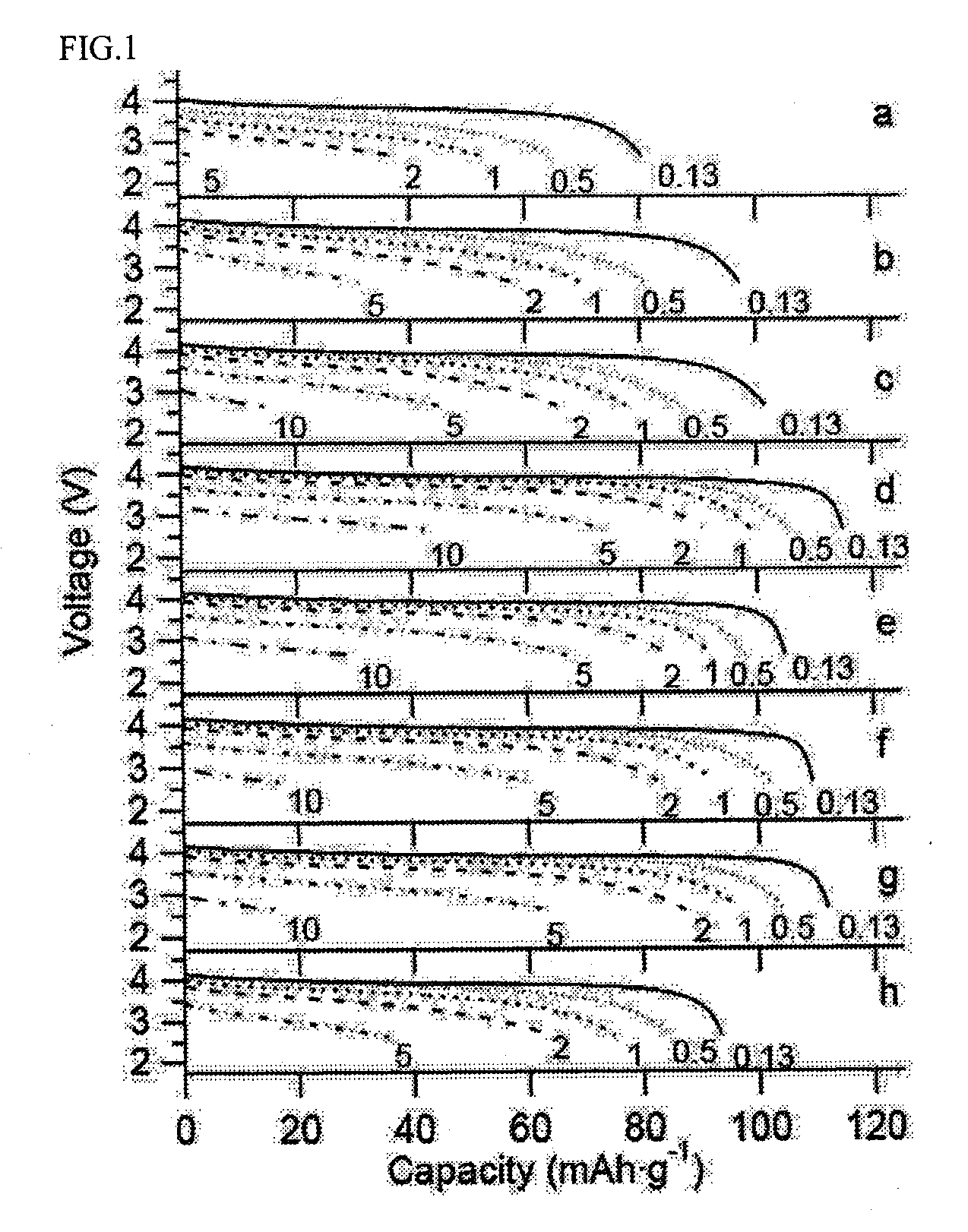

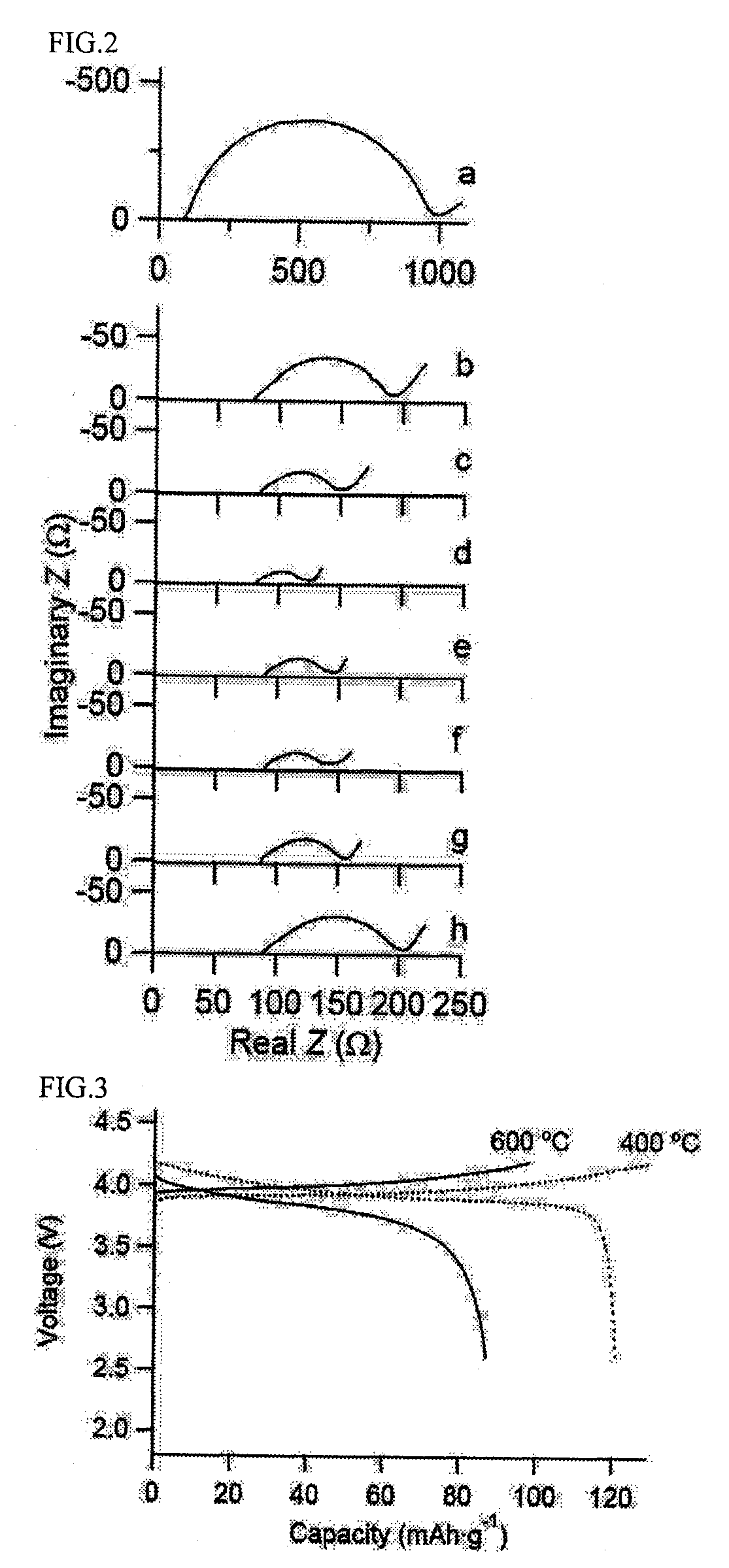

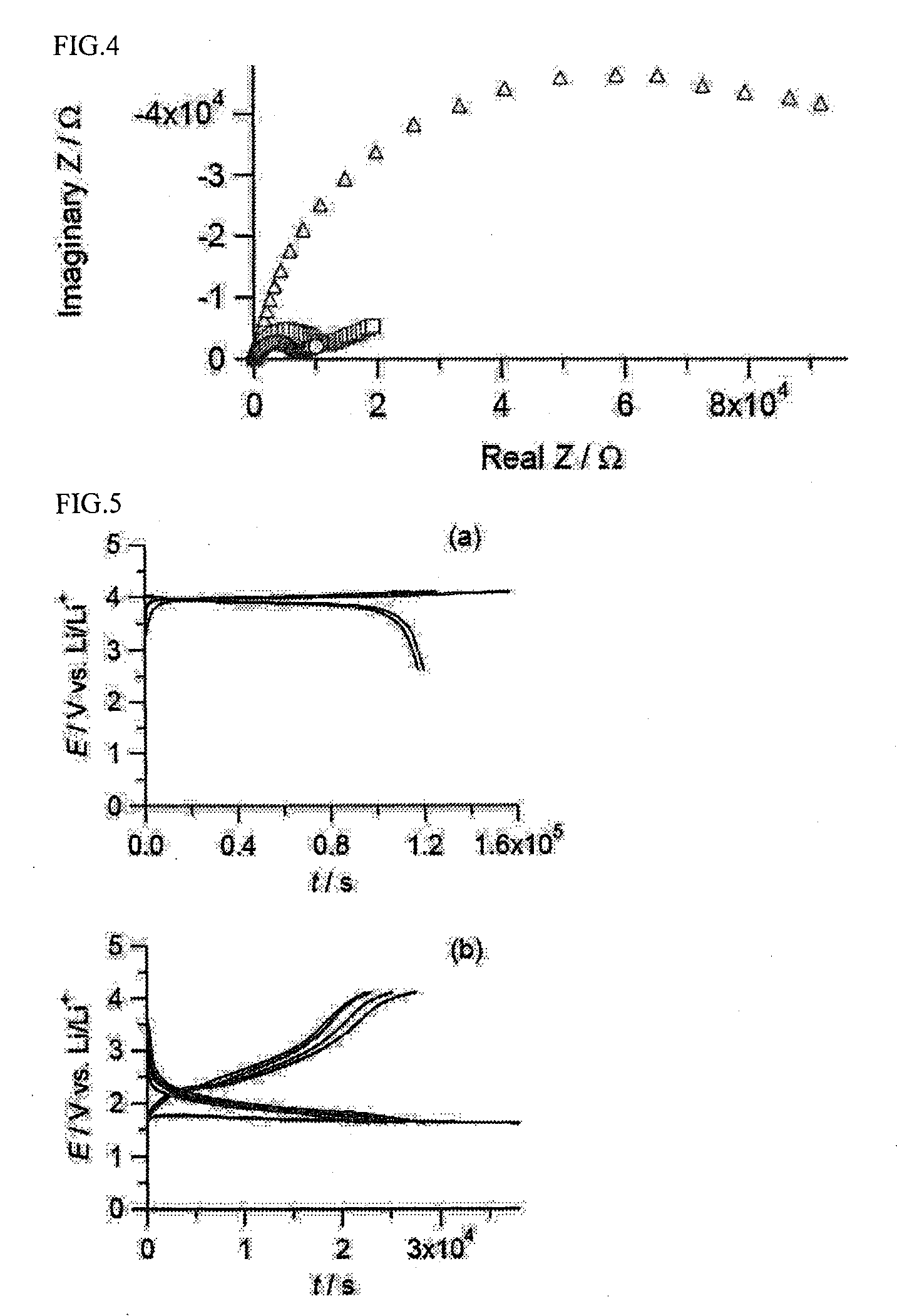

All-solid lithium battery

ActiveUS20090081554A1Improve output performanceLayer formationSolid electrolytesElectrode carriers/collectorsRedoxSulfide

Owner:NAT INST FOR MATERIALS SCI

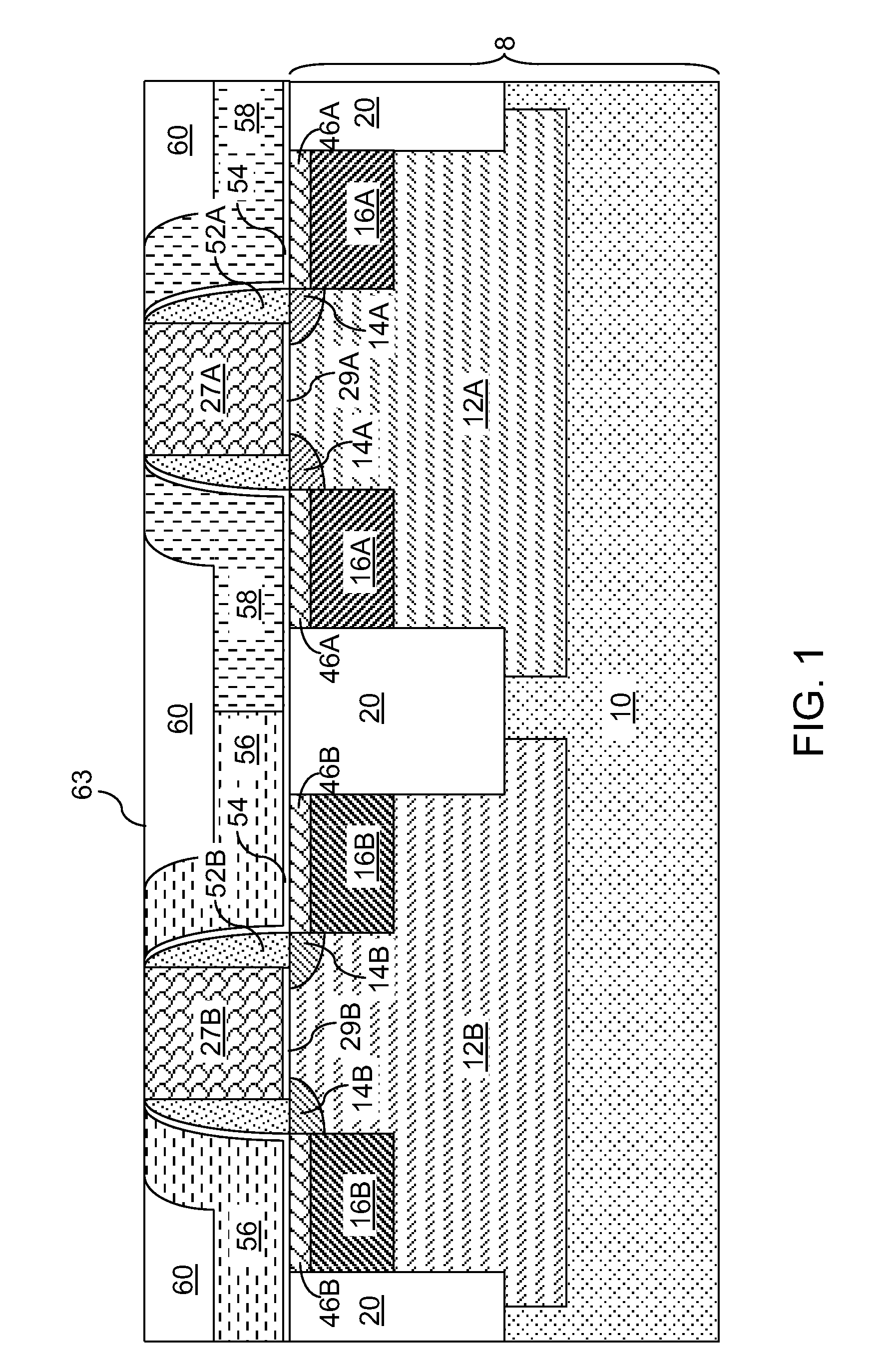

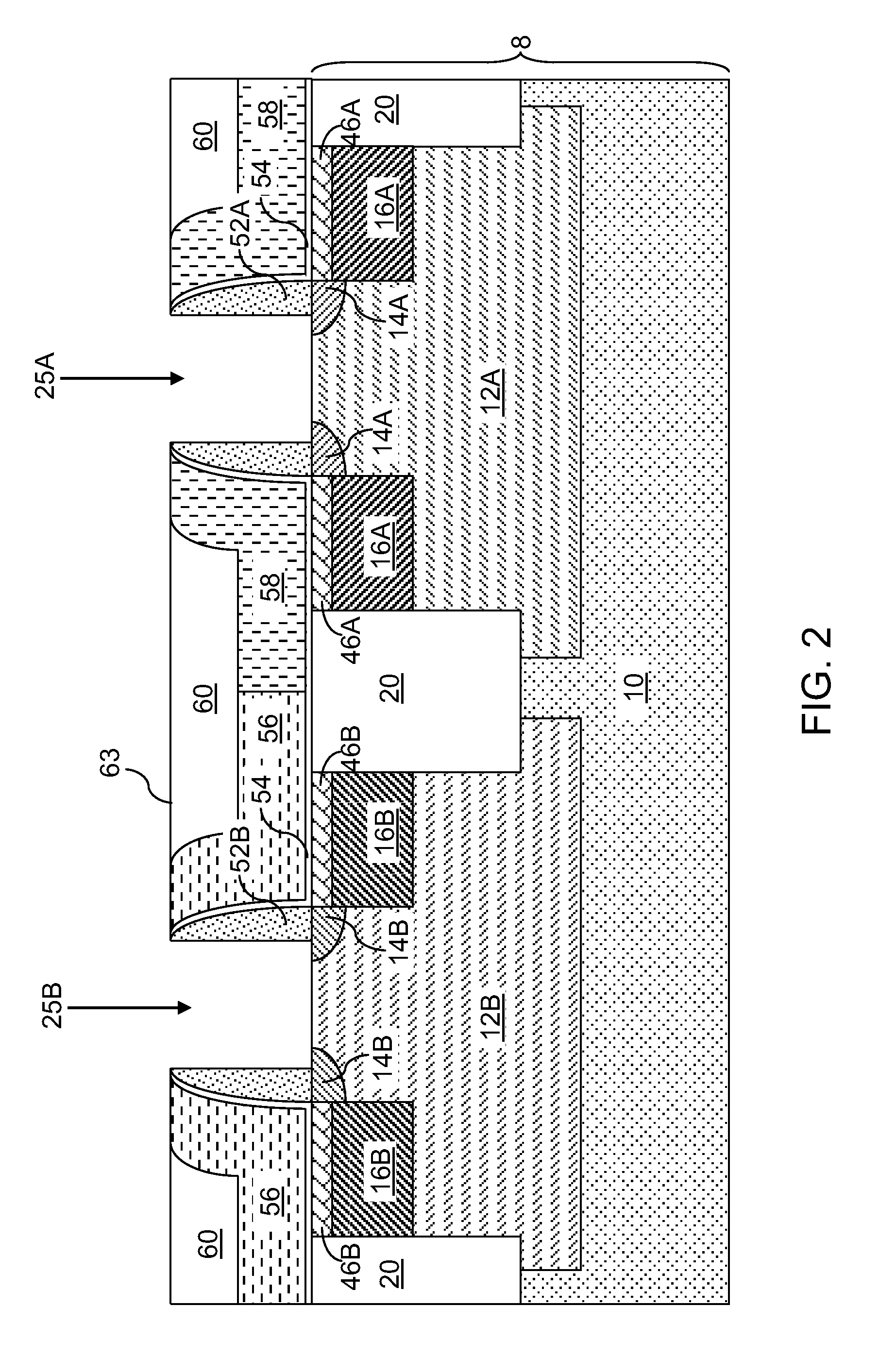

Fabrication of graphene nanoelectronic devices on SOI structures

ActiveUS20110114918A1Eliminates thermal budget limitationGood substrateSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureGraphene

A semiconductor-on-insulator structure and a method of forming the silicon-on-insulator structure including an integrated graphene layer are disclosed. In an embodiment, the method comprises processing a silicon material to form a buried oxide layer within the silicon material, a silicon substrate below the buried oxide, and a silicon-on-insulator layer on the buried oxide. A graphene layer is transferred onto the silicon-on-insulator layer. Source and drain regions are formed in the silicon-on-insulator layer, and a gate is formed above the graphene. In one embodiment, the processing includes growing a respective oxide layer on each of first and second silicon sections, and joining these silicon sections together via the oxide layers to form the silicon material. The processing, in an embodiment, further includes removing a portion of the first silicon section, leaving a residual silicon layer on the bonded oxide, and the graphene layer is positioned on this residual silicon layer.

Owner:GLOBALFOUNDRIES U S INC

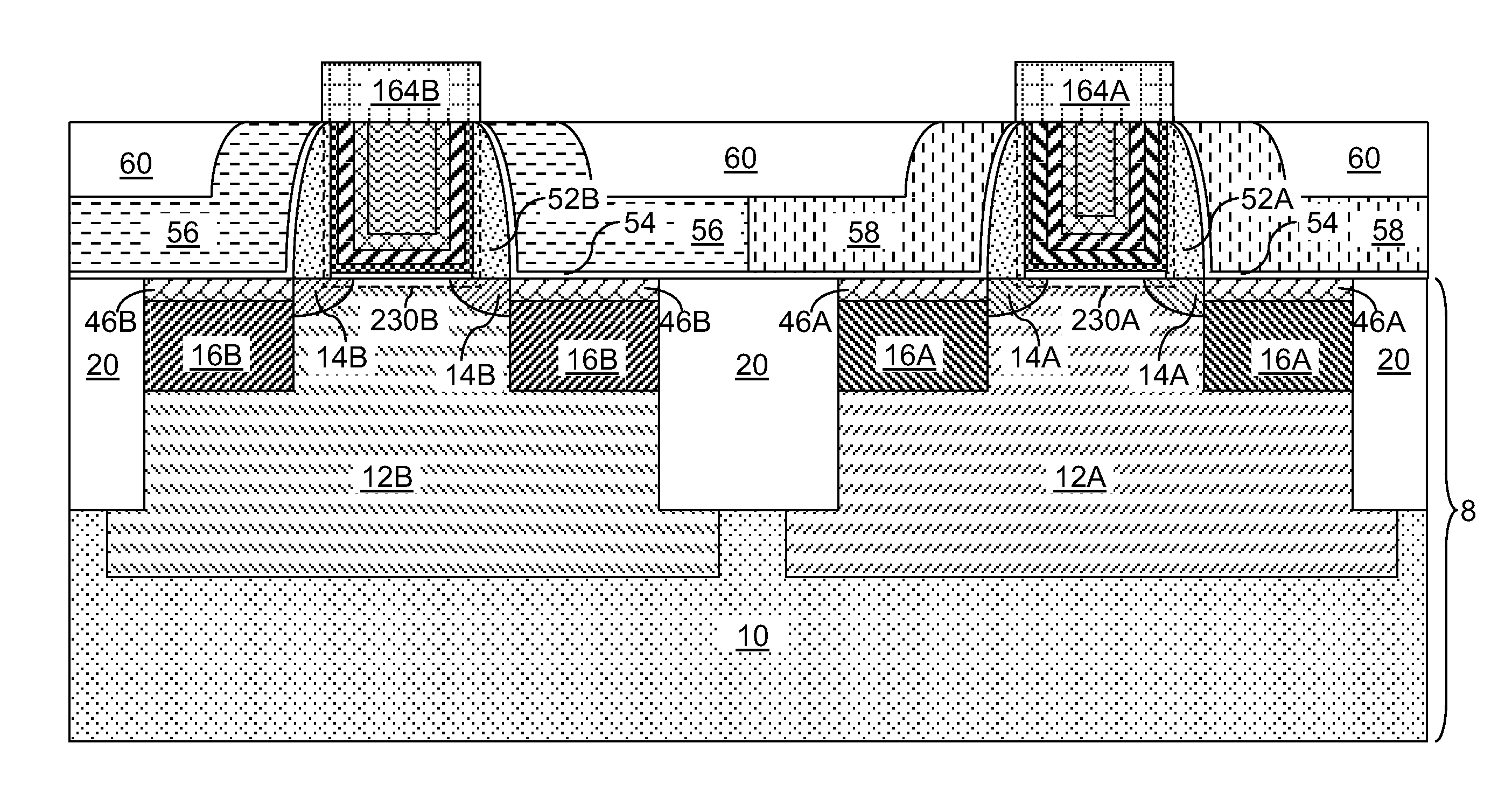

Borderless contact for replacement gate employing selective deposition

ActiveUS20120126295A1TransistorSemiconductor/solid-state device manufacturingElectrical ShortingOxide

Owner:AURIGA INNOVATIONS INC

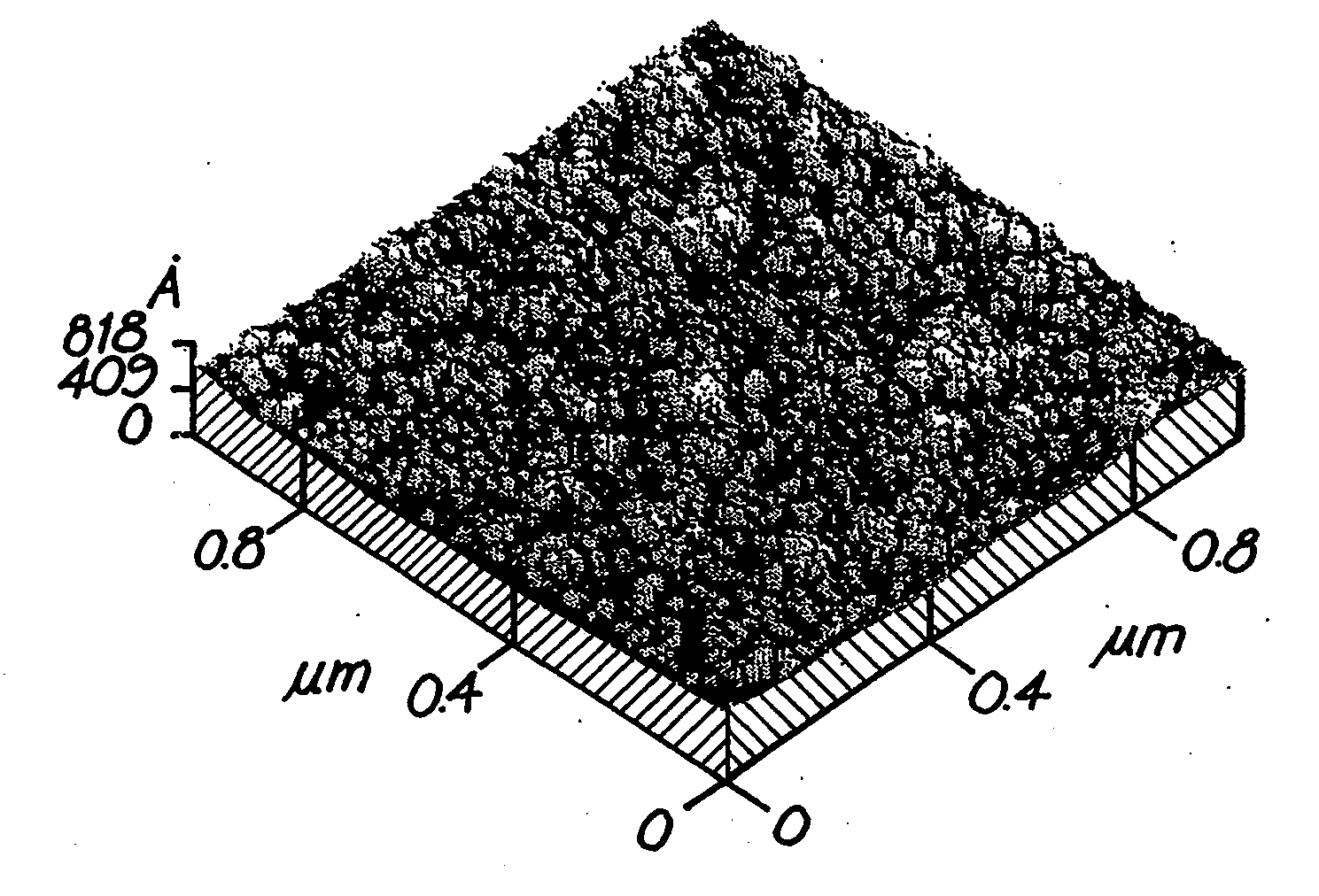

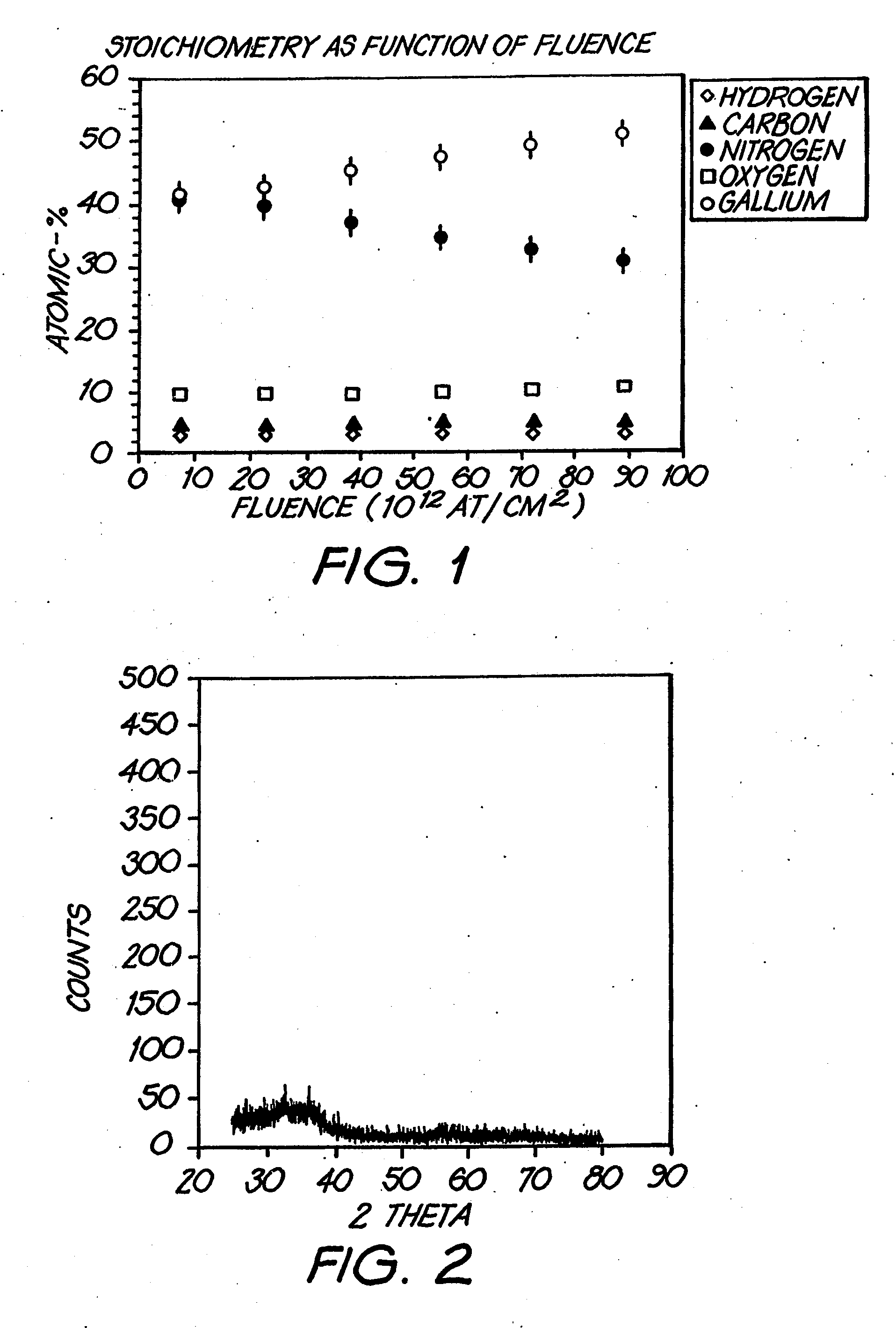

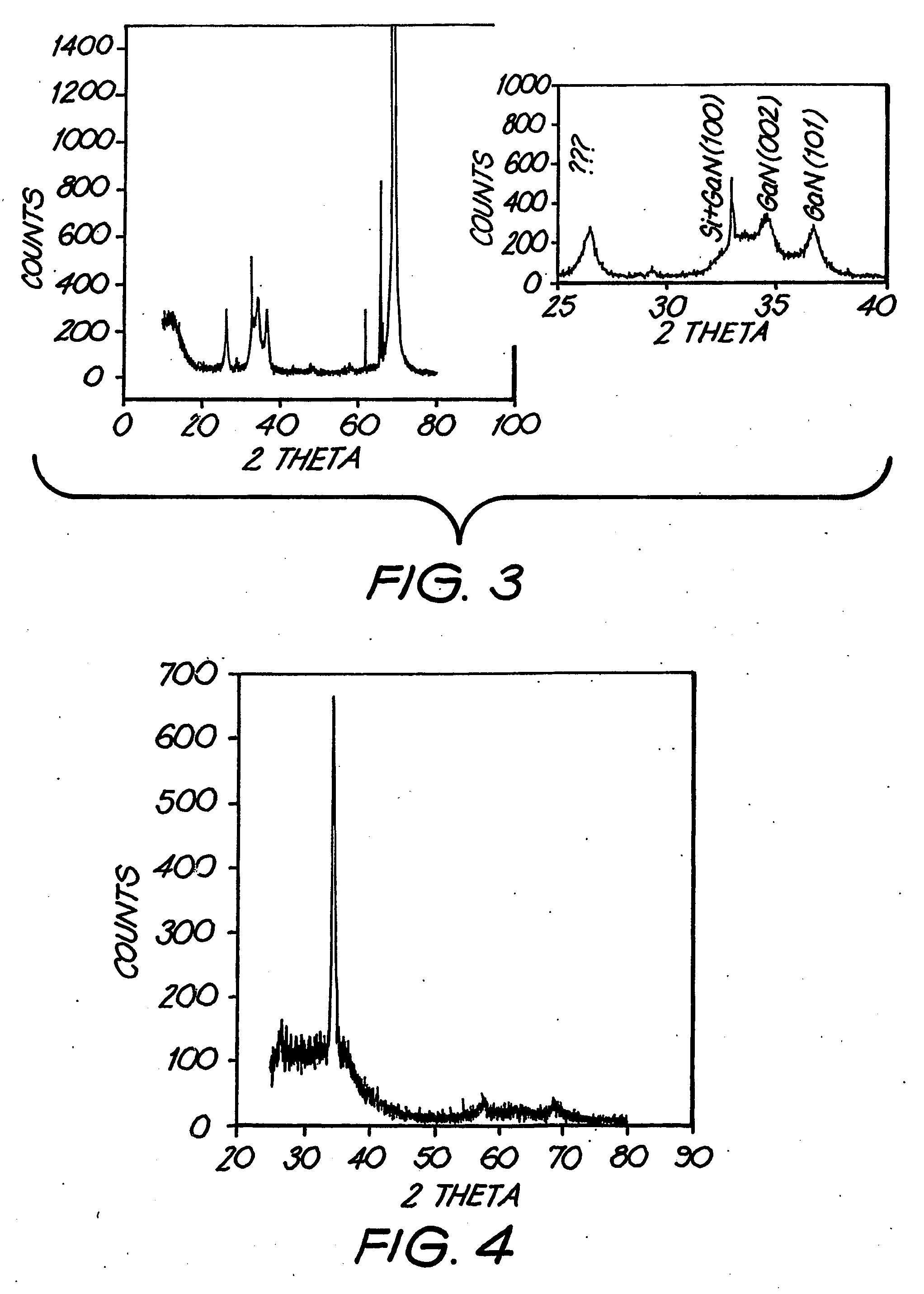

Process for manufacturing a gallium rich gallium nitride film

Owner:GALLIUM ENTERPRISES

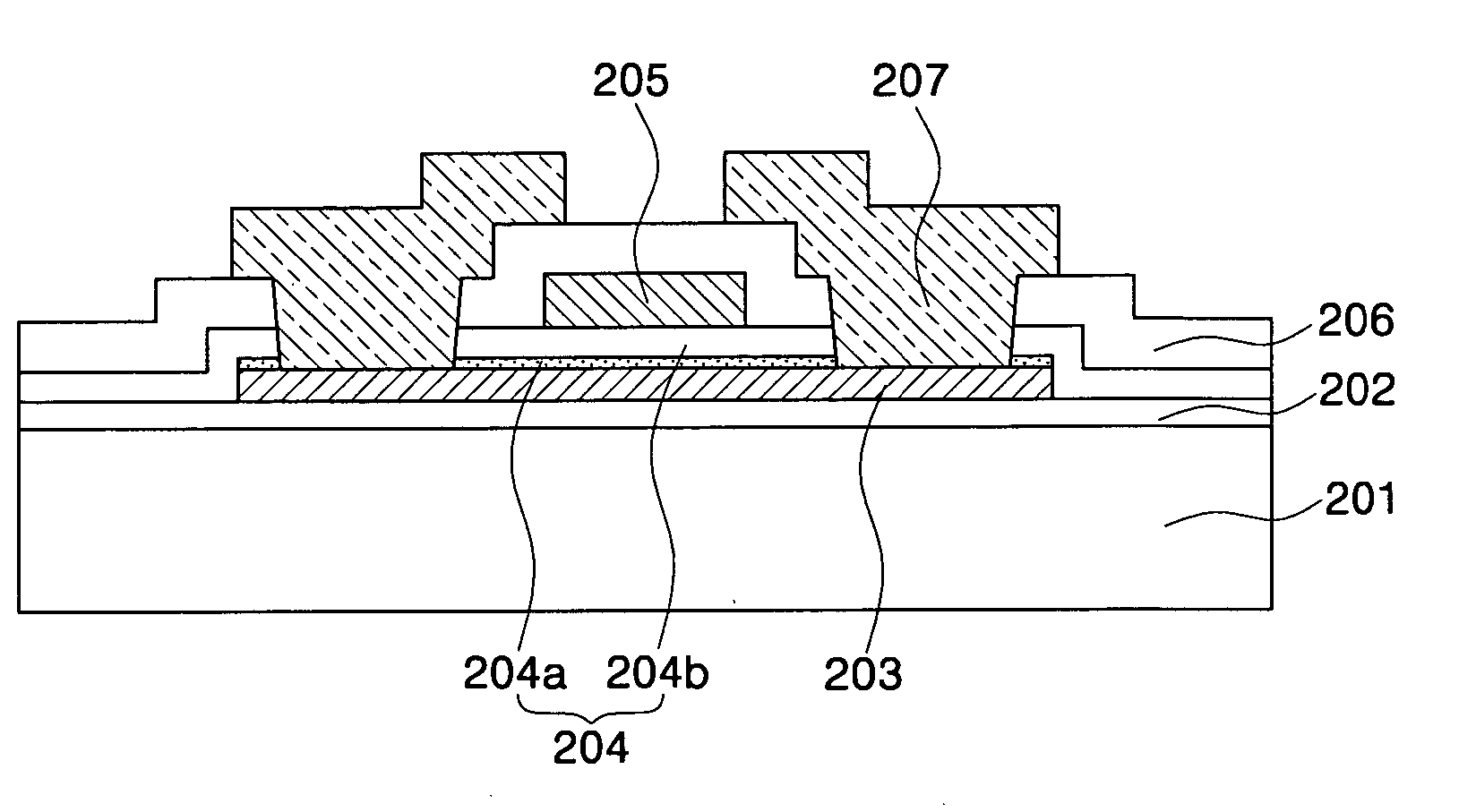

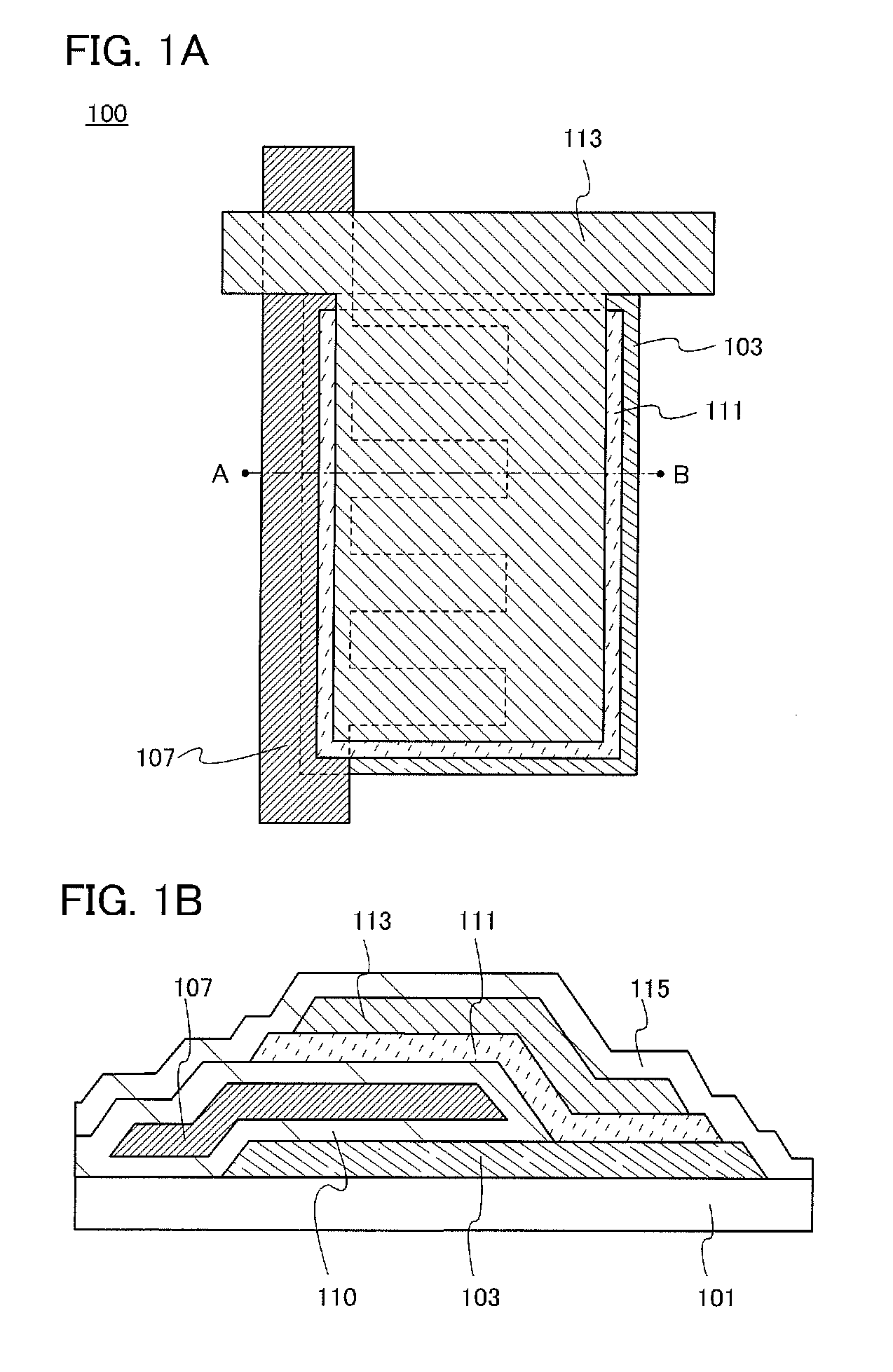

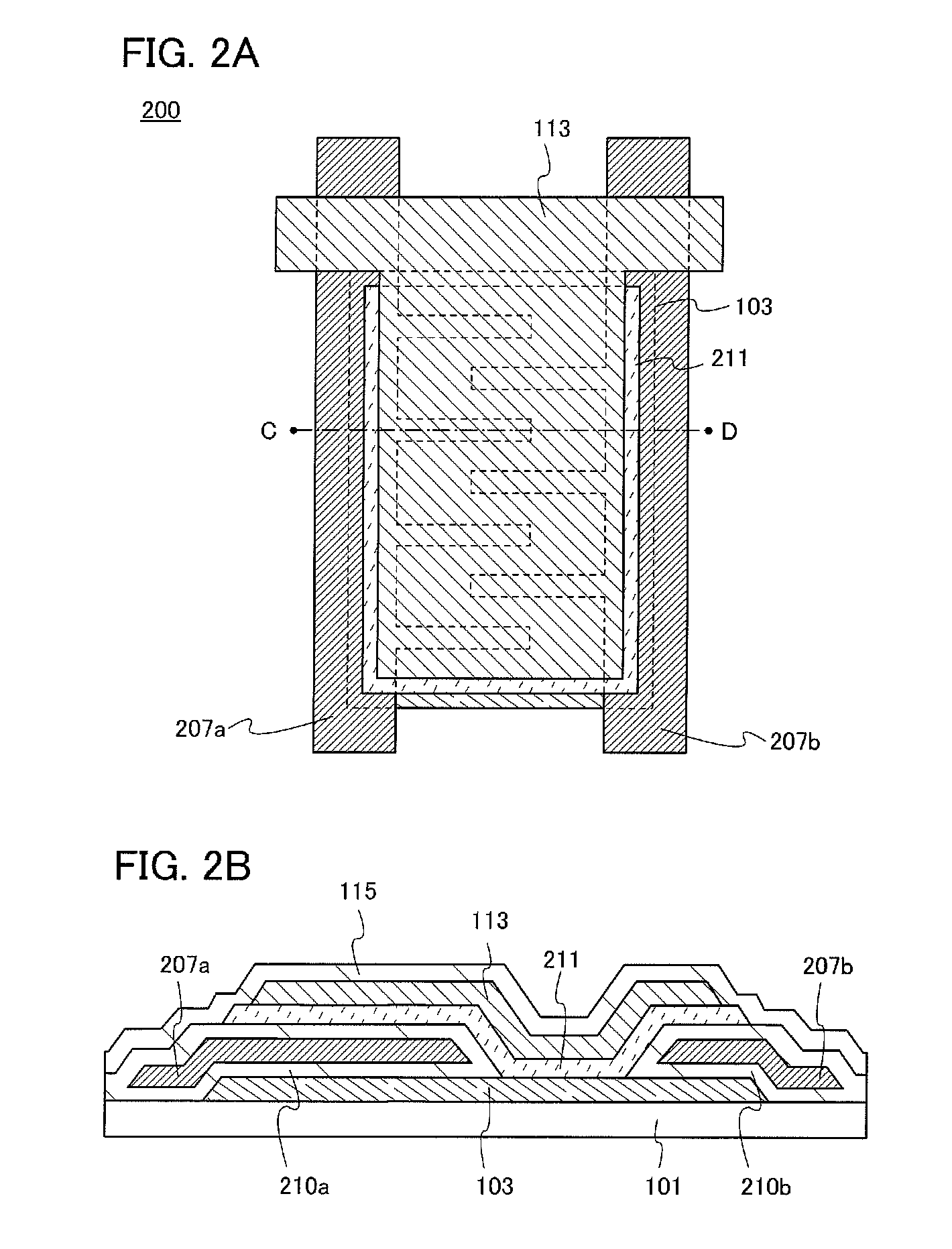

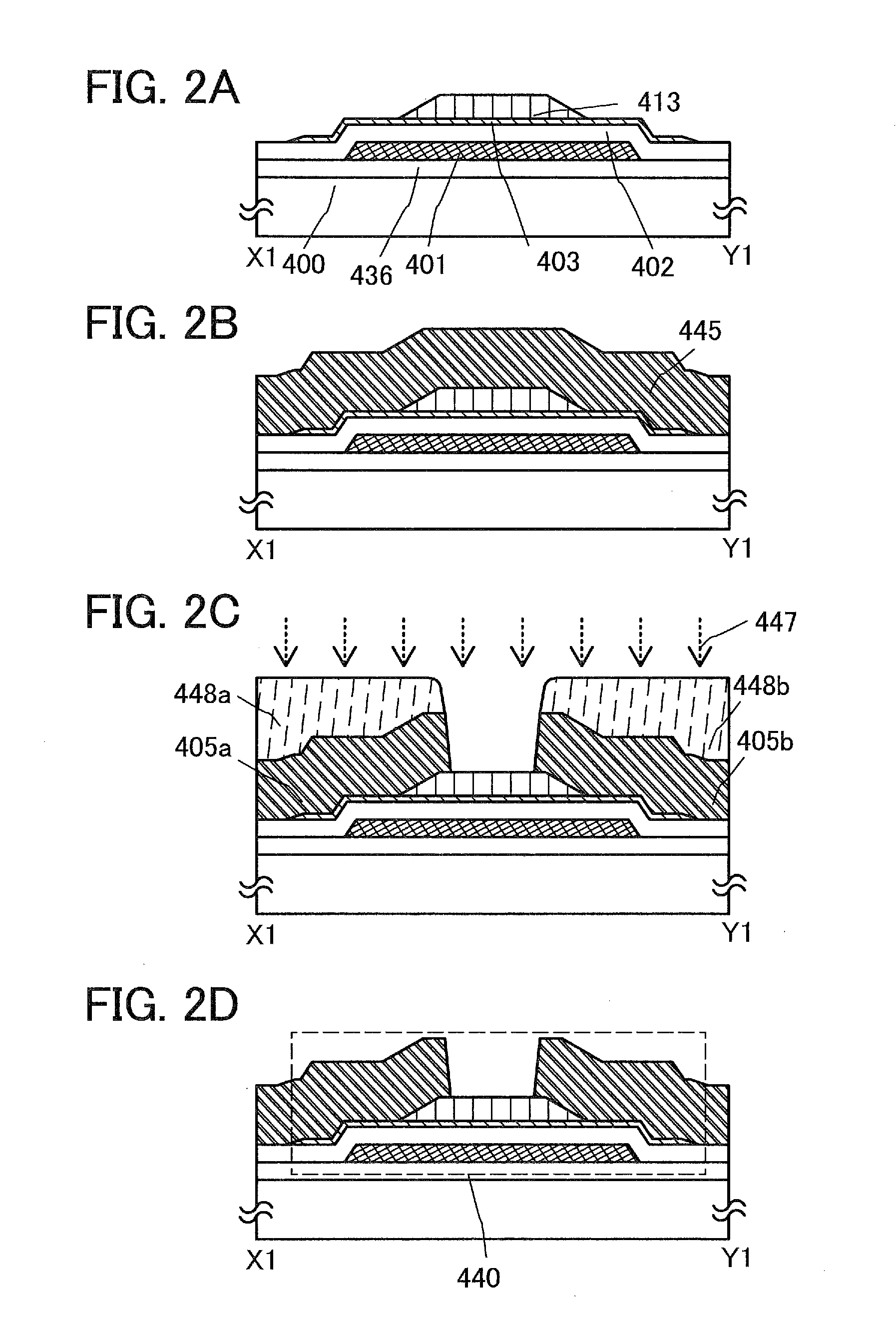

Thin film transistor and method of fabricating the same

ActiveUS20060033107A1Improve featuresRemain very smallTransistorSemiconductor/solid-state device manufacturingSemiconductorTransistor

Owner:SAMSUNG DISPLAY CO LTD

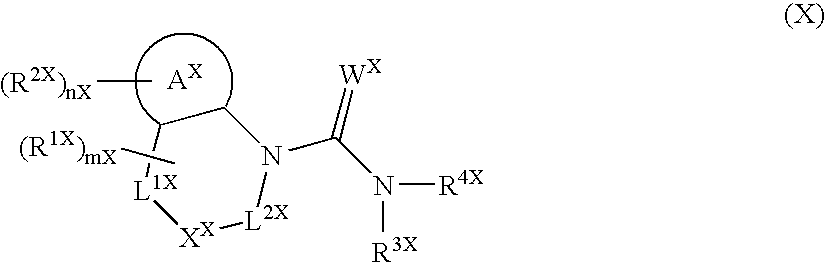

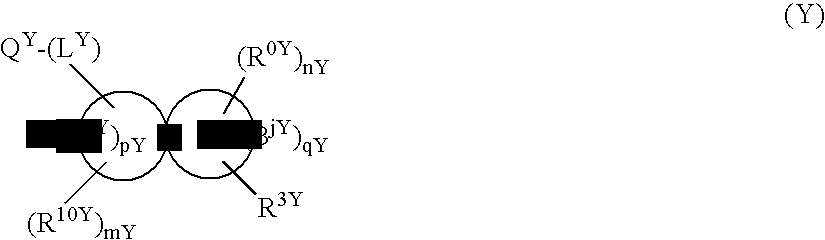

Heterocyclic Spiro Compound

Owner:ONO PHARMA CO LTD

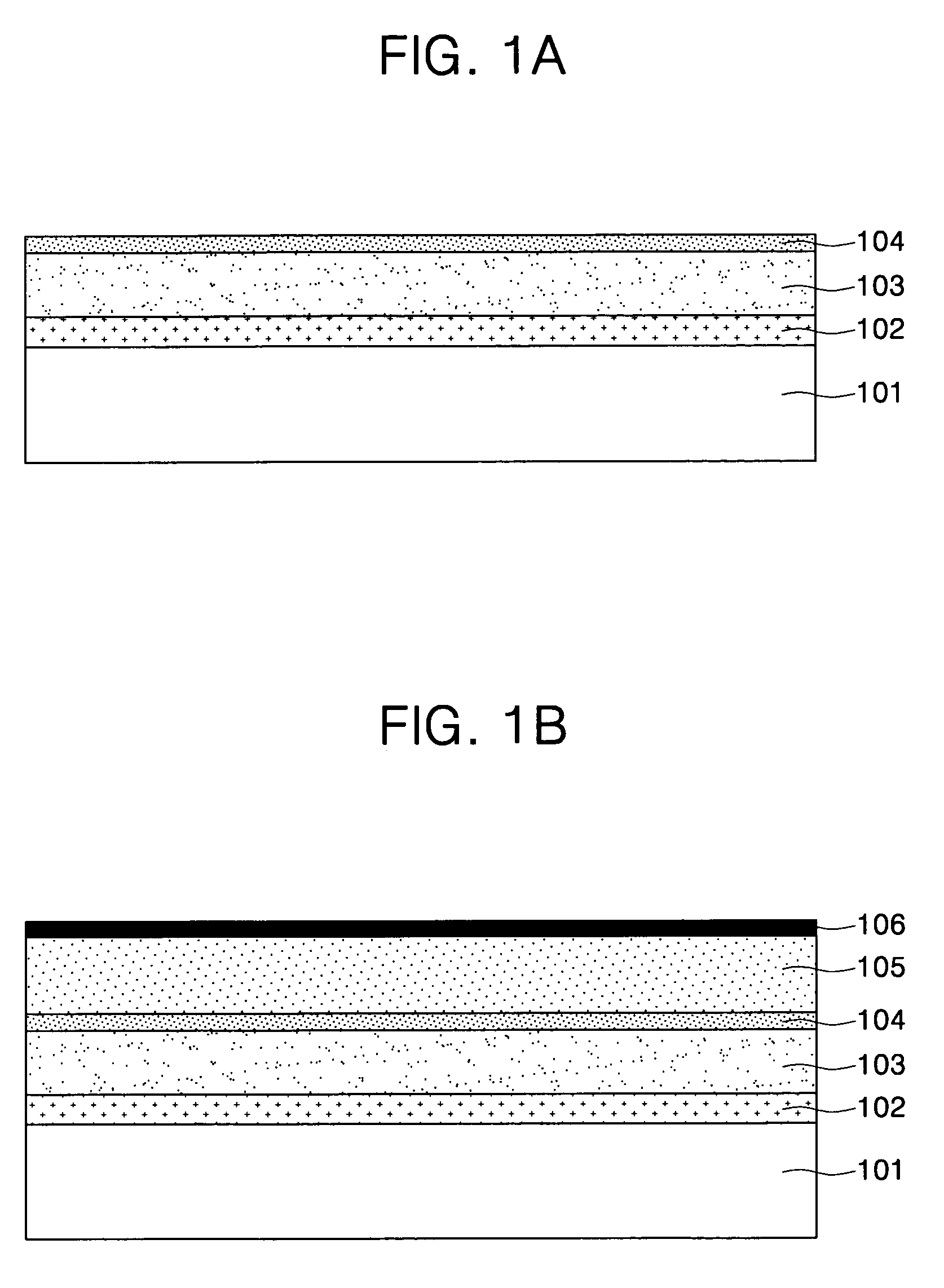

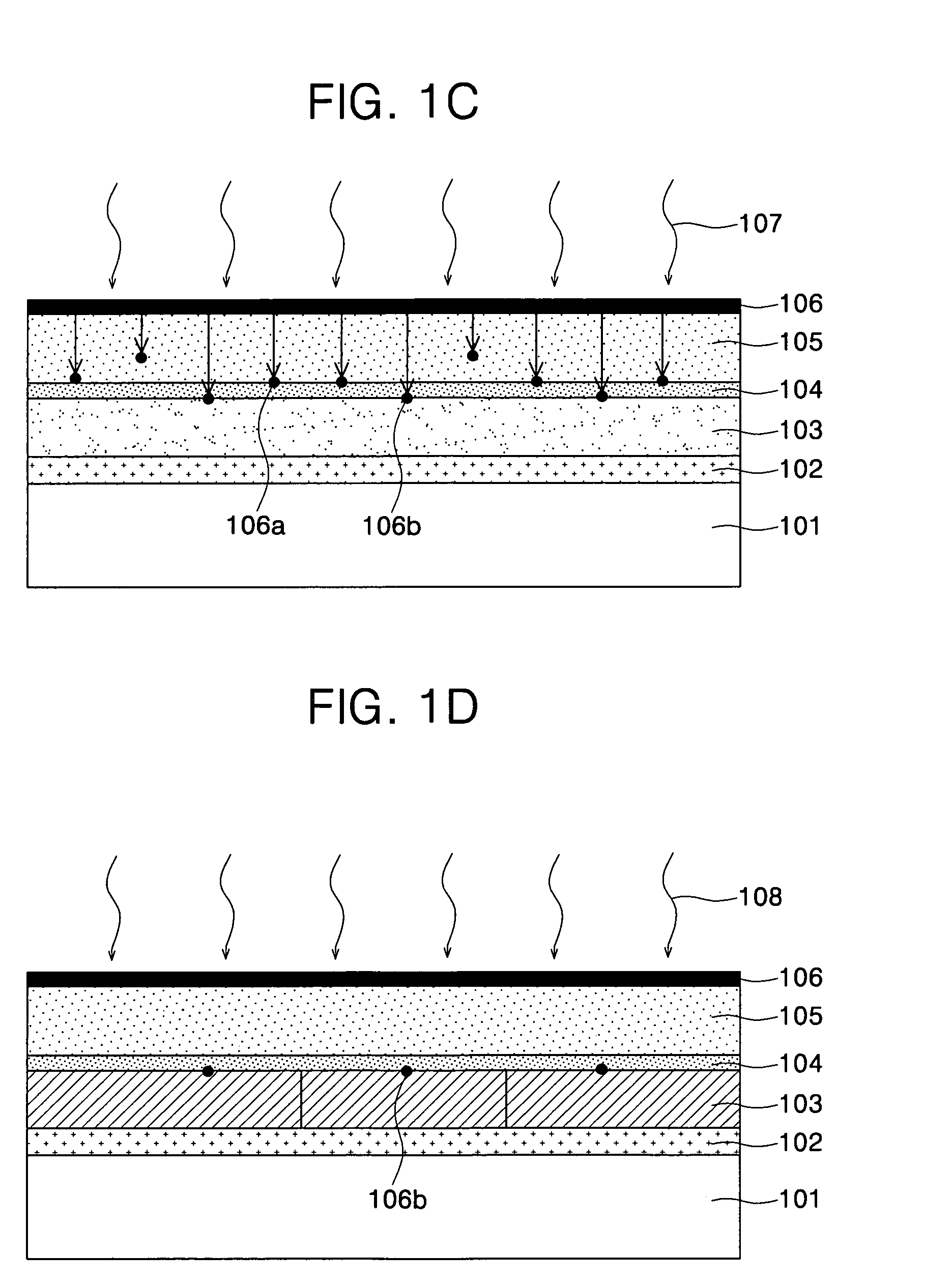

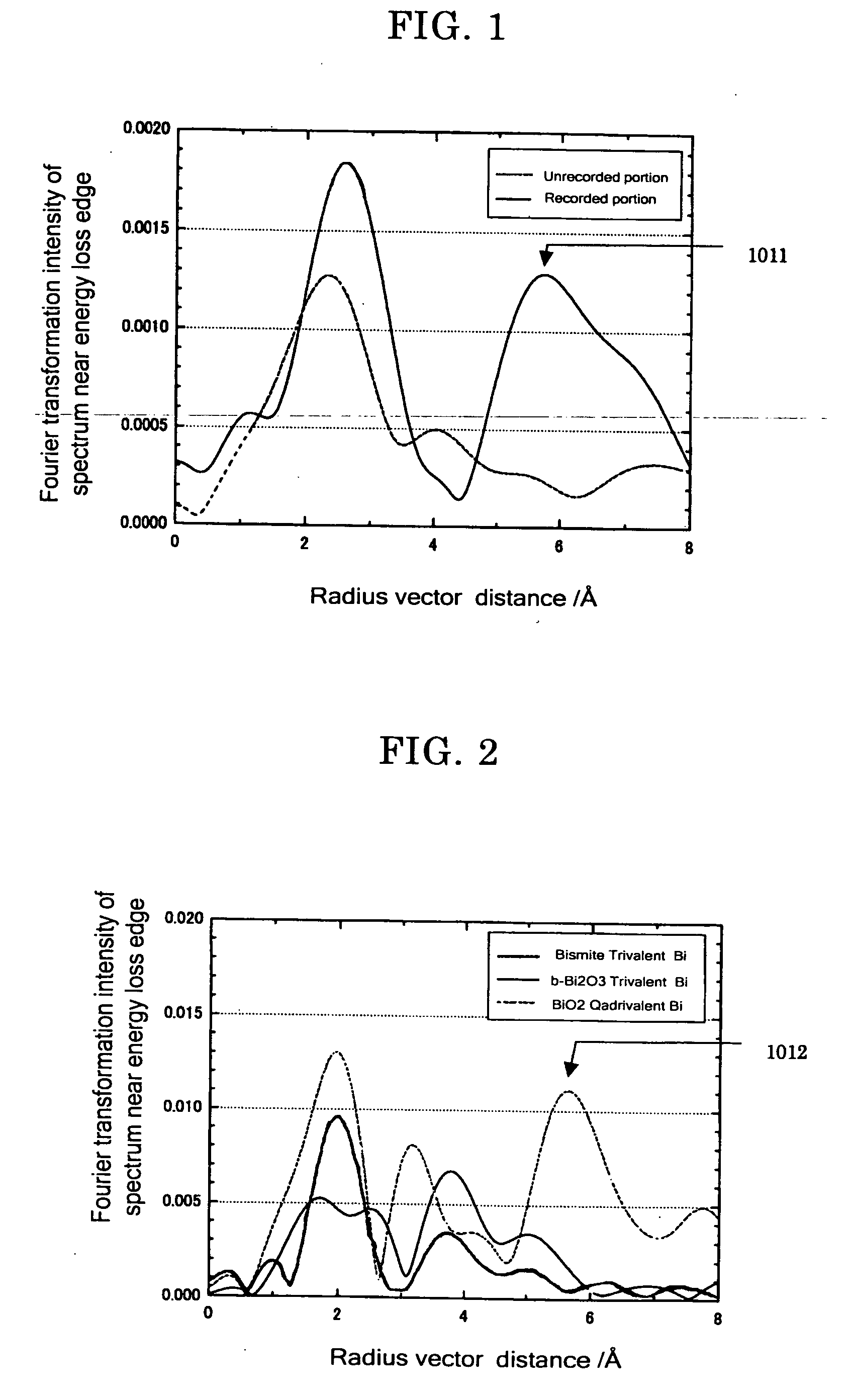

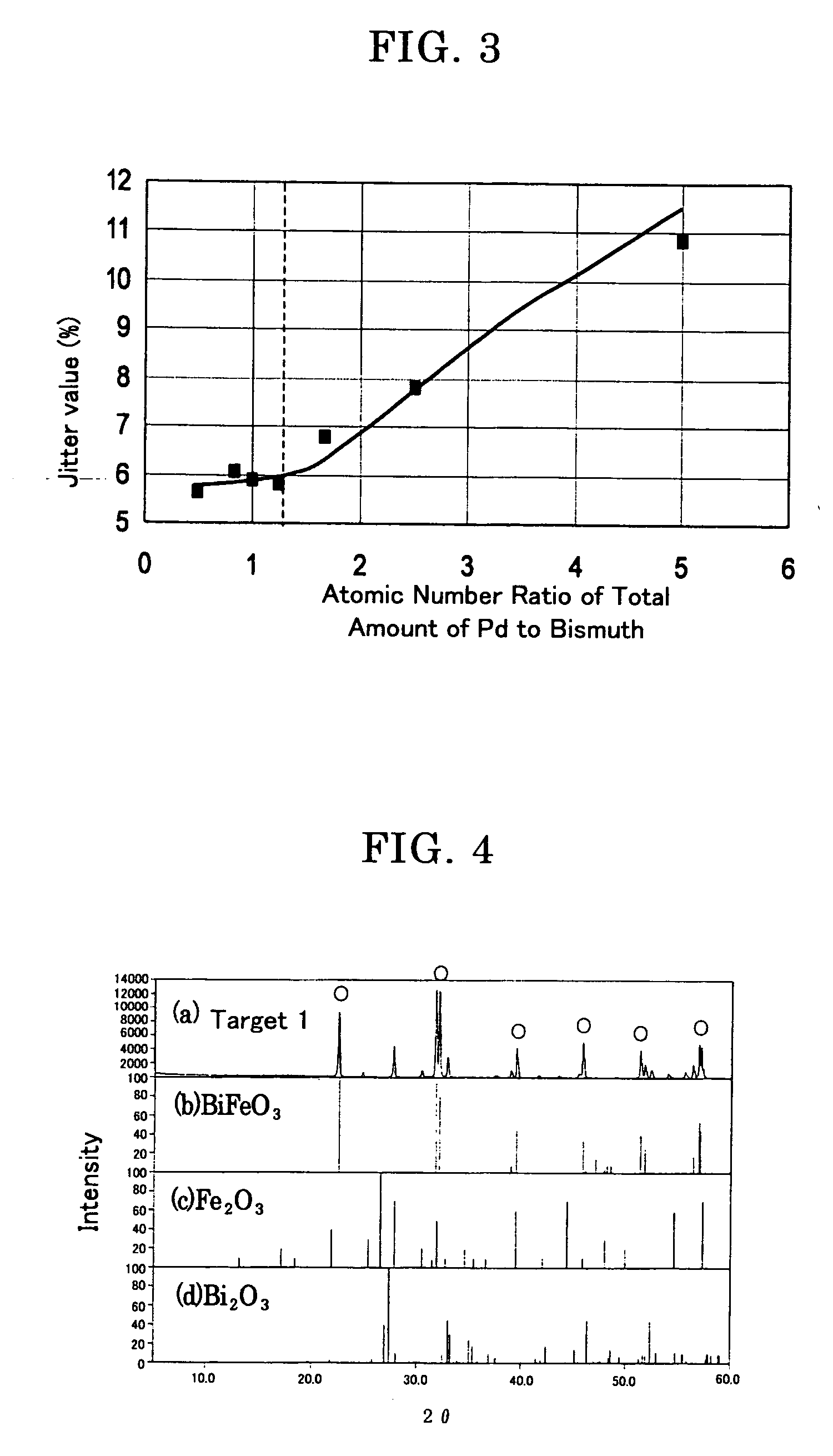

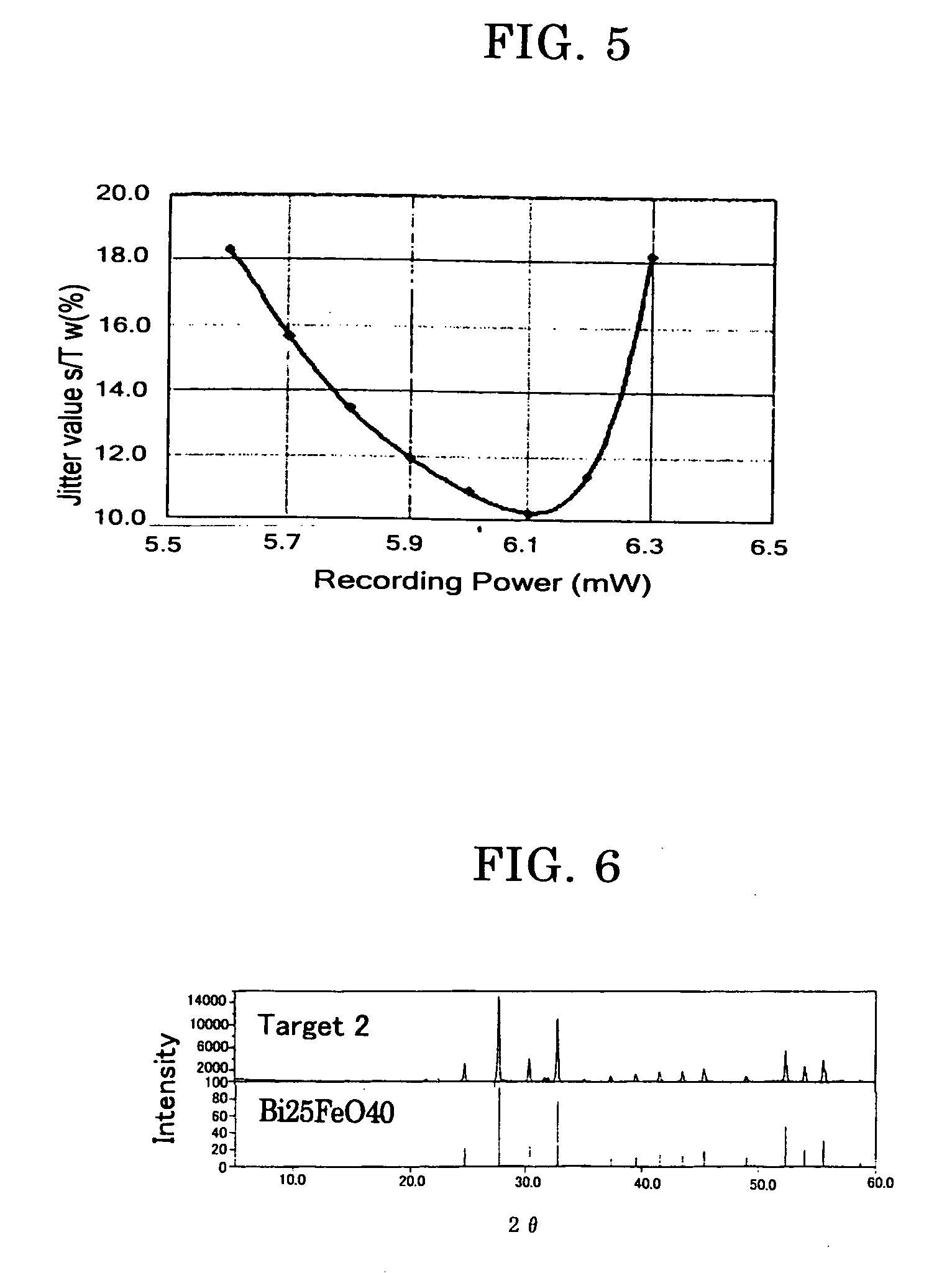

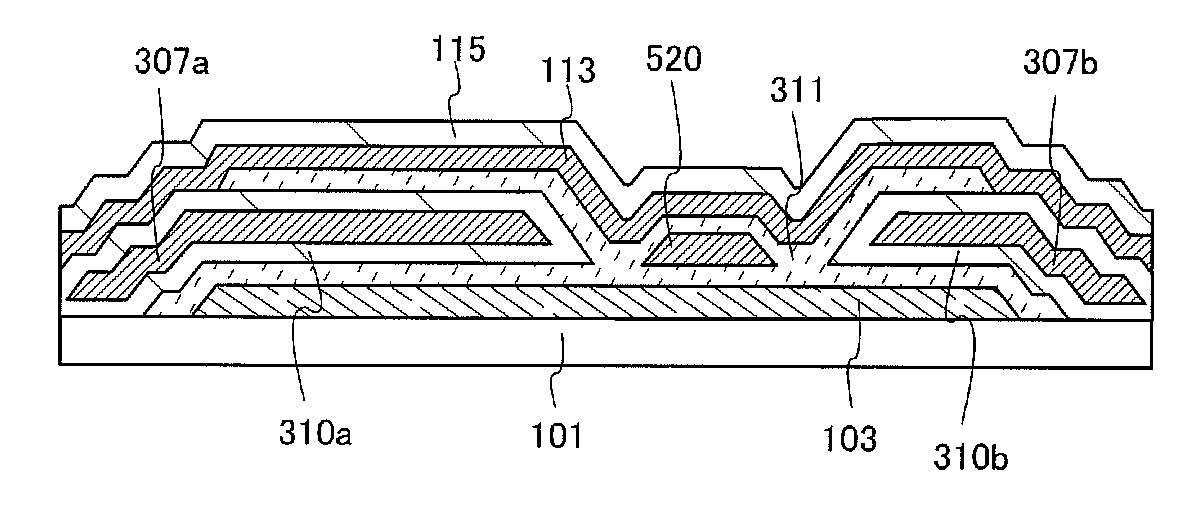

Write-onece-read-many optical recording medium, sputtering target and the production method thereof

InactiveUS20060222810A1High density recordingLayered productsVacuum evaporation coatingHigh densityOxygen

Owner:RICOH KK

A kind of preparation method of chabazite and chabazite membrane

The invention provides a method for preparing chabazite and a chabazite film in the absence of a template agent. Pure chabazite is formed through induction of out-of-phase crystal nucleus T-shaped zeolite under the condition of not adding an organic template agent. The chabazite molecular sieve film is formed through induction by loading formed chabazite on the outer surface of a porous support as a crystal seed. The method is characterized in that: silicon powder and sodium metaaluminate are used as a silicon source and an aluminum source; based on the molar ratio of oxides, the ratios of components which are prepared into sol are that: the molar ratio of SiO2 to Al2O3 is equal to 15-30, the molar ratio of OH<-> to SiO2 is equal to 0.9-1.5, the molar ratio of Na<+> to K<+> is equal to 0.1-1, and the molar ratio of H2O to SiO2 is equal to 18-40; the sol for coating the crystal seed is subjected to hydrothermal synthesis at the temperature of 100-160 DEG C for 16-72 hours; and a compact chabazite film is synthesized on a porous carrier. Through the method for preparing the chabazite and the chabazite film, the expensive organic template agent is prevented from being added, the synthesis process is simple, and the repeatability is high. The synthesized film shows better stability in an inspection acid medium and can be widely applied to a pervaporation separation process and a pervaporation film reactor of an acidic system.

Owner:JIANGXI NORMAL UNIV

Cement composition

InactiveUS20050016421A1High strengthImprove abilitiesOrganic fertilisersSoil conditioning compositionsPhosphateSilicic acid

To provide a novel cement which is alkalescent, capable of solidifying a wide range of soil and applicable to biological environment. That is, a cement composition comprising 100 parts by weight of magnesium oxide comprising 5 to 25% by weight of at least any one of silicic acid, alumina and iron oxide, 3 to 35 parts by weight of a phosphate, 2 to 30 parts by weight of gypsum and 0.005 to 7 parts by weight of an oxycarboxylic acid or a ketocarboxylic acid.

Owner:NAT AGRI & FOOD RES ORG +1

A production method for copper-coated aluminum material

InactiveCN101123129AAvoid high temperature oxidationAvoid lubricationCable/conductor manufactureCelsius DegreeMaterials science

Owner:丹阳市中信化工电器设备有限公司

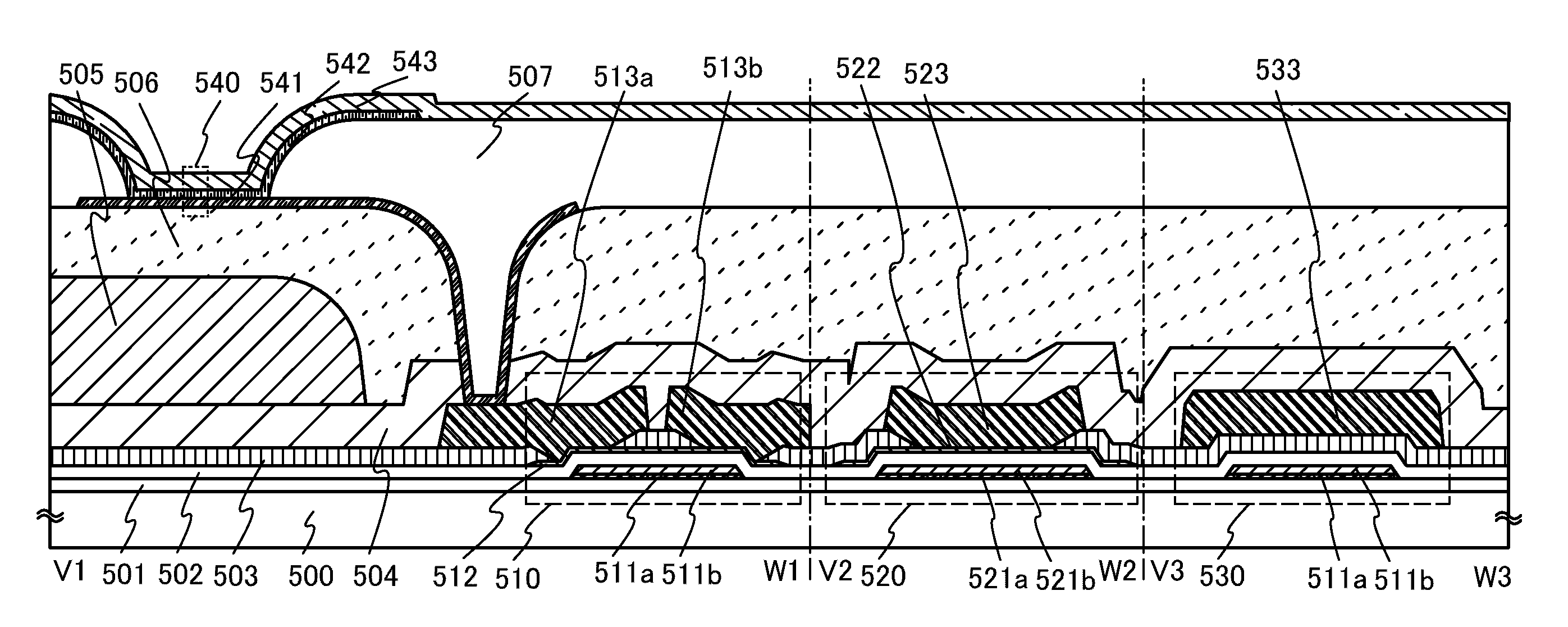

Semiconductor device

ActiveUS20110233555A1High drain-breakdown-voltage characteristicMaintain good propertiesTransistorSemiconductorSemiconductor device

Owner:SEMICON ENERGY LAB CO LTD

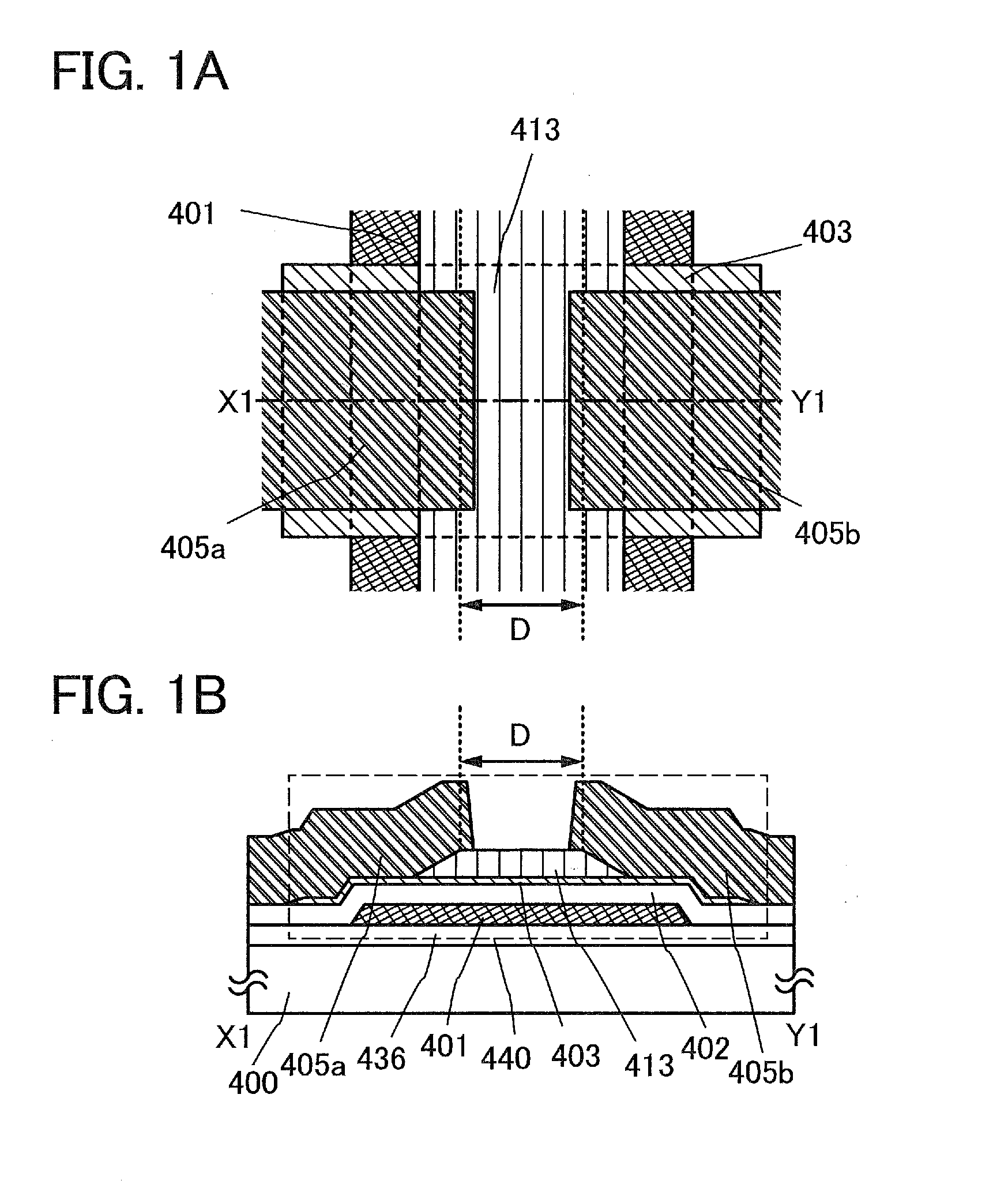

Semiconductor device and method for manufacturing the same

ActiveUS20130082252A1Improve reliabilityHigh yieldTransistorSemiconductor/solid-state device manufacturingProduction rateIndium

Owner:SEMICON ENERGY LAB CO LTD

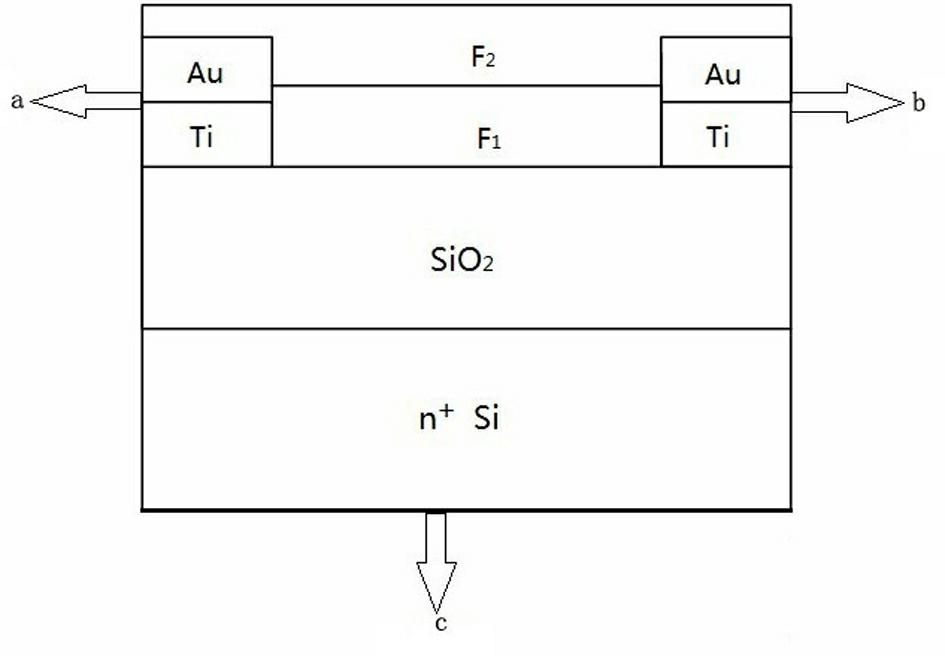

Multilayer thin film OTFT (organic thin film transistor) formaldehyde gas sensor and preparation method thereof

InactiveCN102636544ADecorative surface effectsMaterial analysis by electric/magnetic meansTitaniumOxide

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsGas phaseAging resistance

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:JIAXING JUNHONG OPTICAL CO LTD

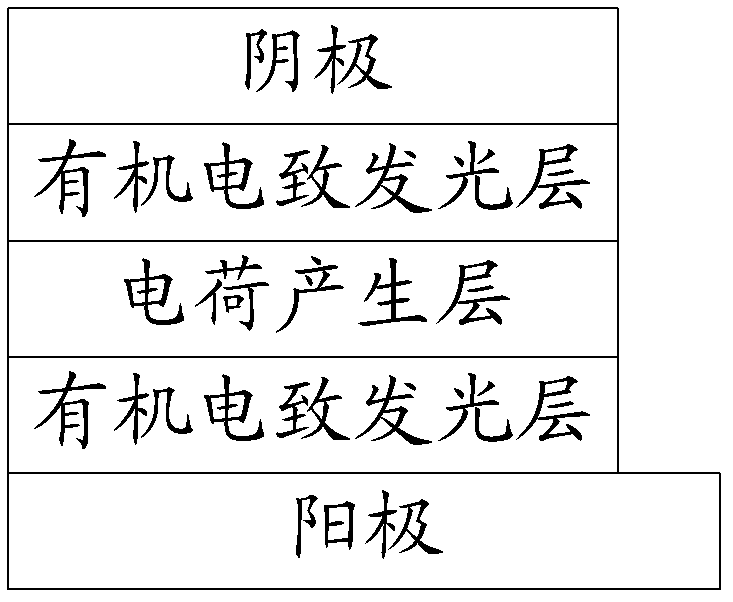

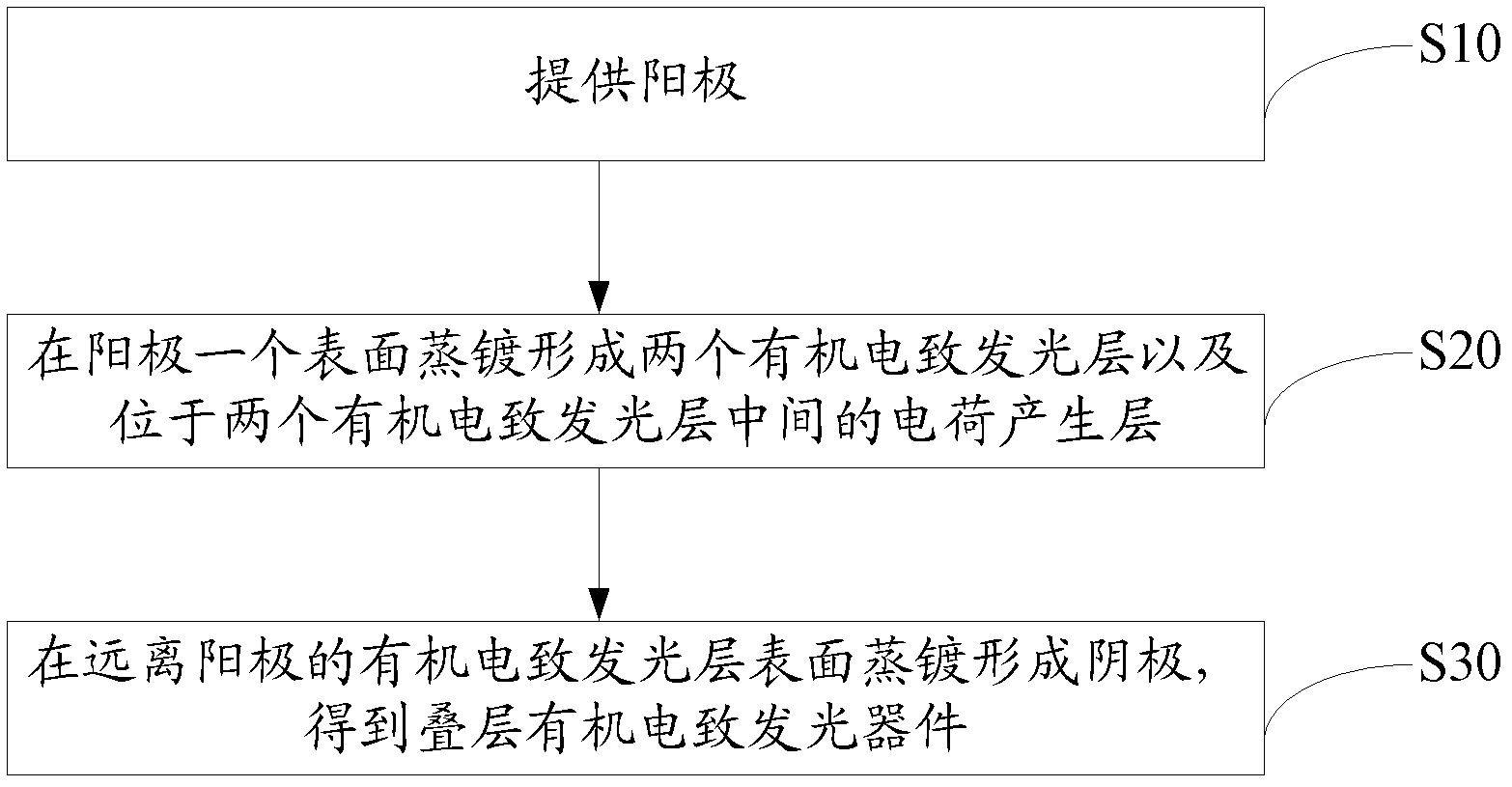

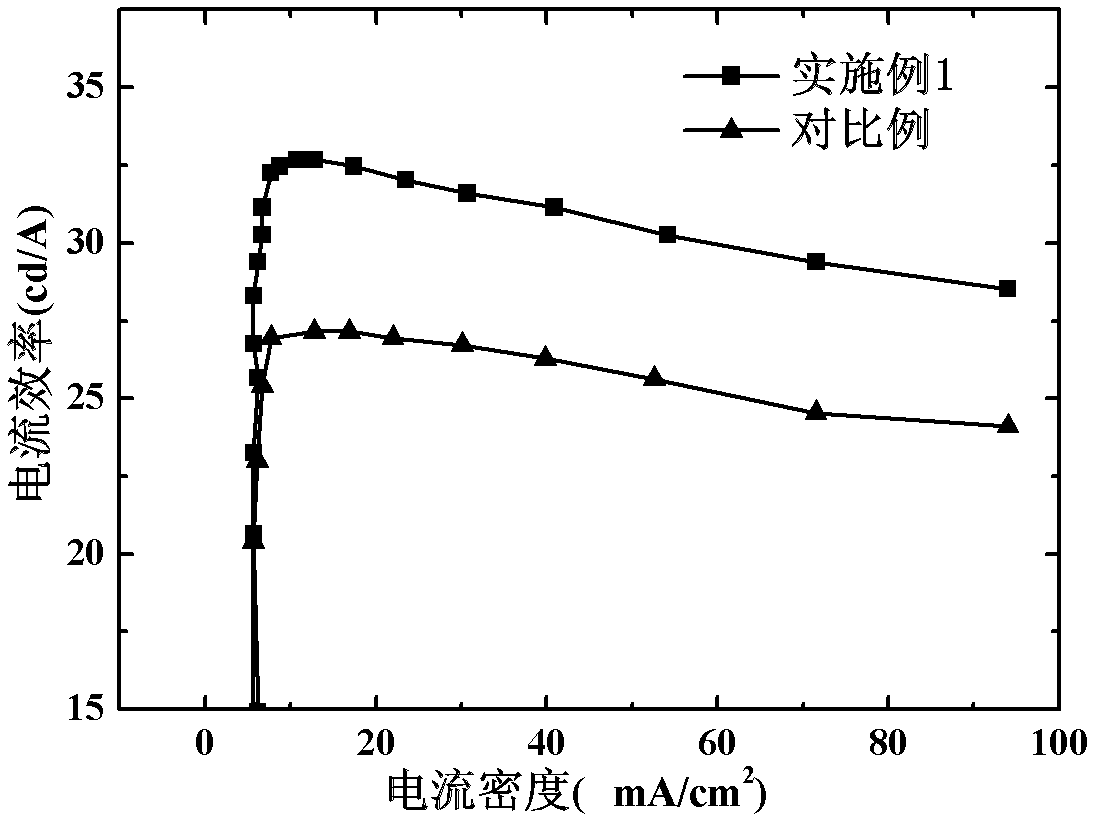

Laminated organic electroluminescent device and preparation method thereof

InactiveCN102810644ASolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOxide

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Oxide for semiconductor layer of thin-film transistor, sputtering target, and thin-film transistor

Owner:KOBE STEEL LTD

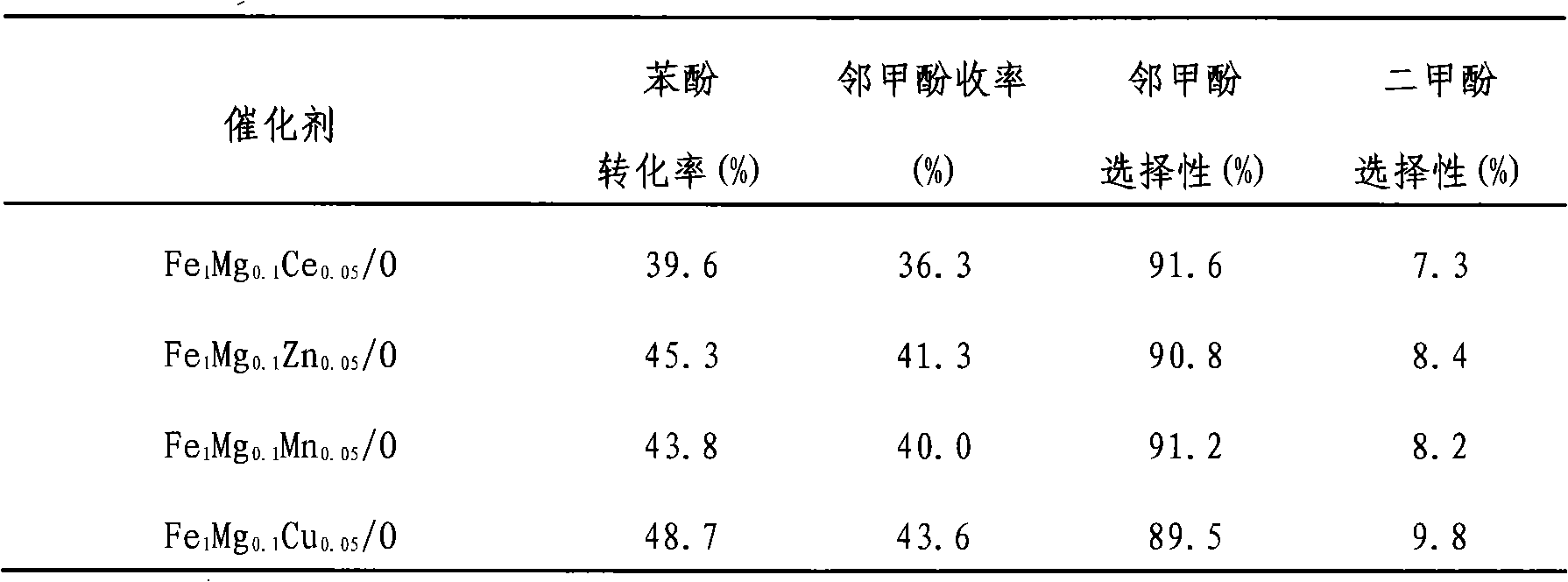

Phenol ortho-methylation catalyst and preparation method thereof

ActiveCN101513614AEasy to makeLow reaction temperatureOrganic chemistryOrganic compound preparationMagnesium saltOrtho position

Owner:HUNAN XINLING CHEM CO LTD

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

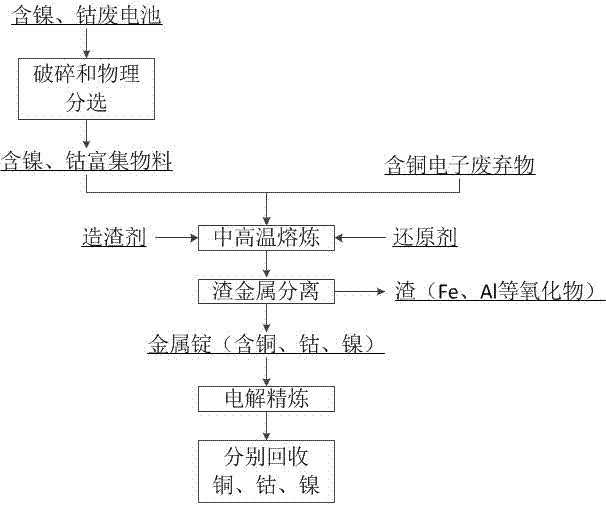

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Laser-markable flameproof molding compounds and laser-markable and laser-marked products obtained from said molding compounds

The subject invention discloses a variety of different maintenance devices for use with a filling valve apparatus. The maintenance devices each include a movable component and a locking mechanism. An actuator of the locking mechanism is coupled to a caming section of the movable component for moving the movable component between a release position with a rim of the movable component spaced from fingers of the locking mechanism and an engaged position with the rim abutting the fingers. The fingers are wedged between the movable component and the filling valve apparatus when the movable component is in the engaged position for securing the device to the filling valve apparatus.

Owner:TICONA GMBH

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

Catalyst for selective hydrogenation and olefin removal of reformed generated oil as well as preparation method and application

ActiveCN104014337AReduce dosageIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationActive componentHigh activity

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

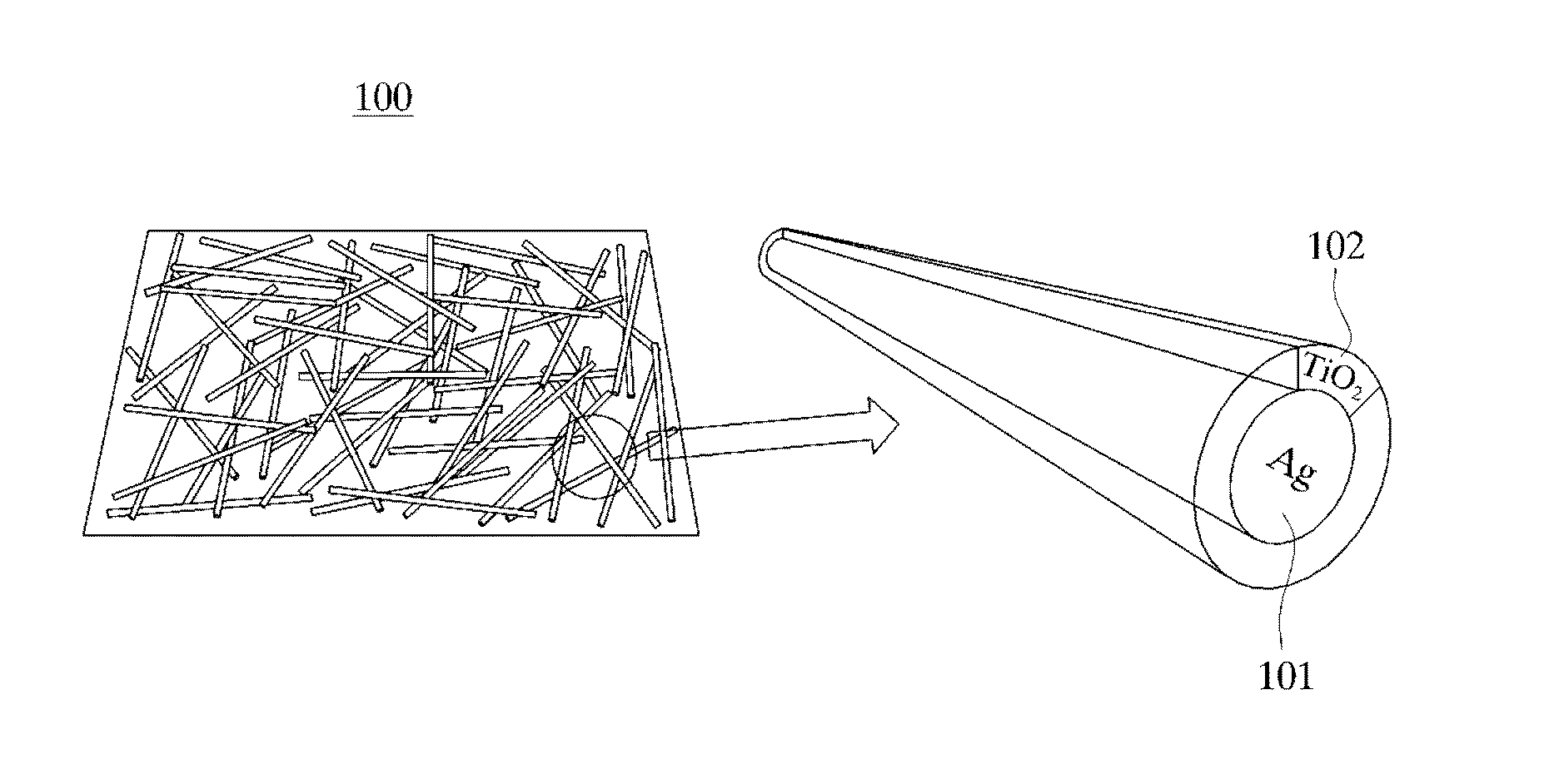

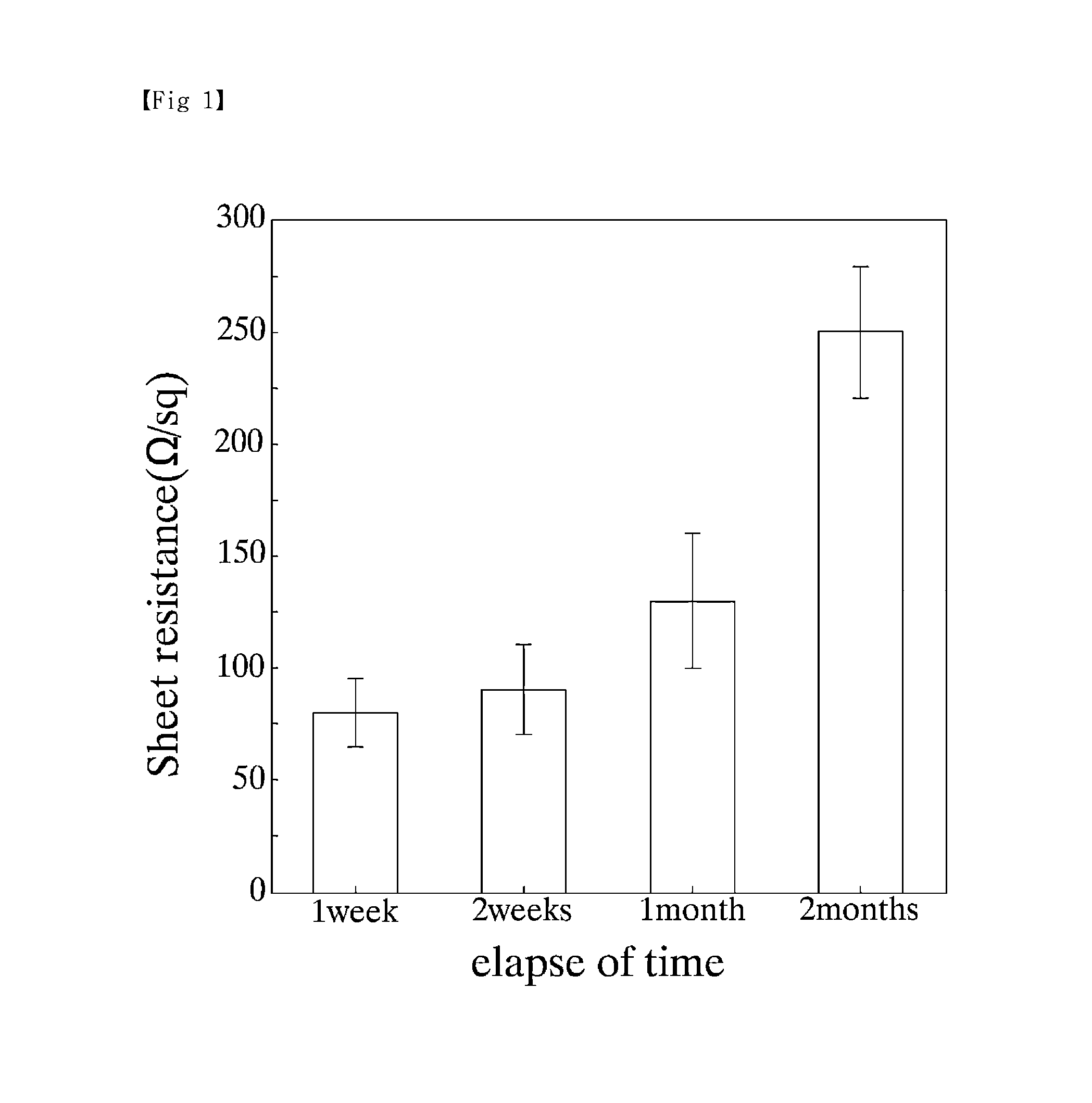

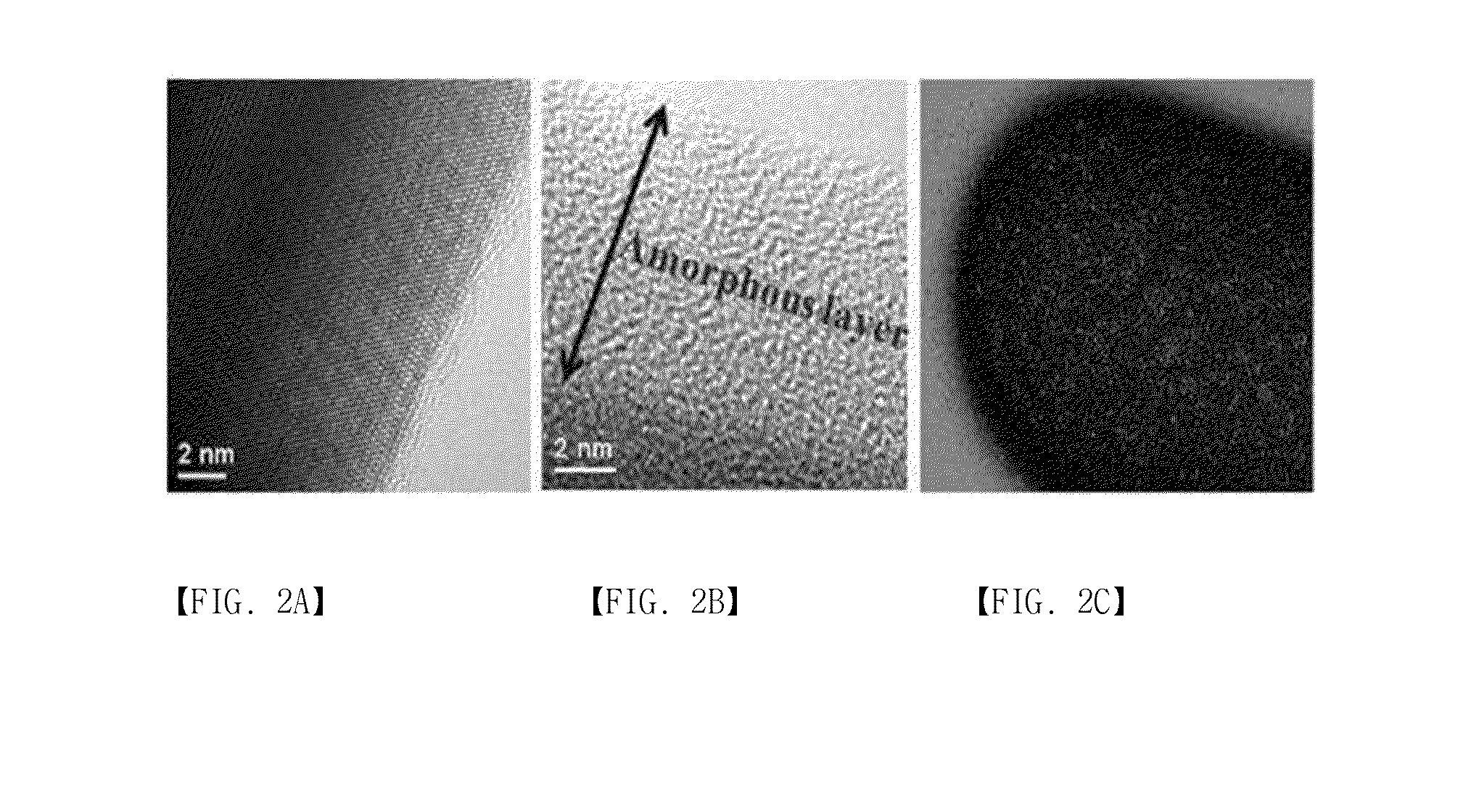

Silver nanowire conductive film and method of fabricating the same

ActiveUS20140020737A1Conductive layers on insulating-supportsSynthetic resin layered productsProtection layerSilver nanowires

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

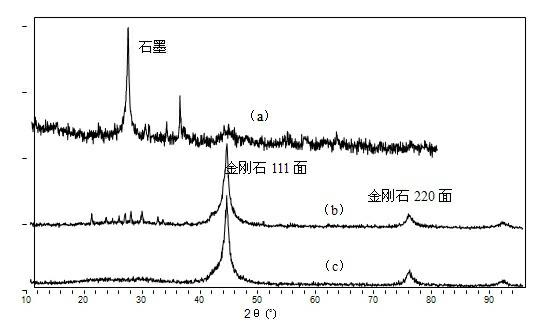

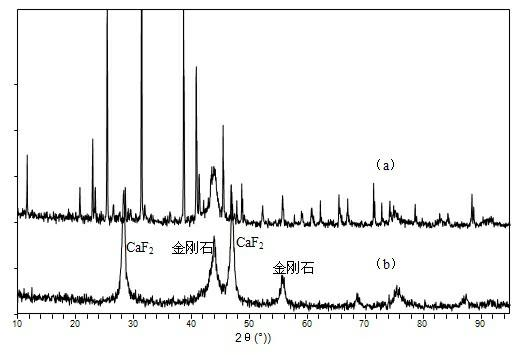

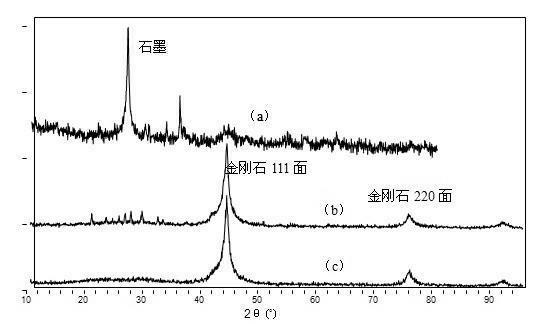

Purification method of nano diamond ash material

Owner:江苏金海丰硬质材料科技有限公司

Method of manufacturing semiconductor device capable of sensing dynamic quantity

InactiveUS20020177252A1Avoid stickingEfficient removalSemiconductor/solid-state device manufacturingAcceleration measurementElectricitySilicon on insulator

A method of manufacturing a semiconductor device is provided. The device is manufactured with use of an SOI (Silicon On Insulator) substrate having a first silicon layer, an oxide layer, and a second silicon layer laminated in this order. After forming a trench reaching the oxide layer from the second silicon layer, dry etching is performed, thus allowing the oxide layer located at the trench bottom to be charged at first. This charging forces etching ions to impinge upon part of the second silicon layer located laterally to the trench bottom. Such part is removed, forming a movable section. For example, ions to neutralize the electric charges are administered into the trench, so that the electric charges are removed from charged movable electrodes and their charged surrounding regions. Removing the electric charges prevents the movable section to stick to its surrounding portions.

Owner:DENSO CORP

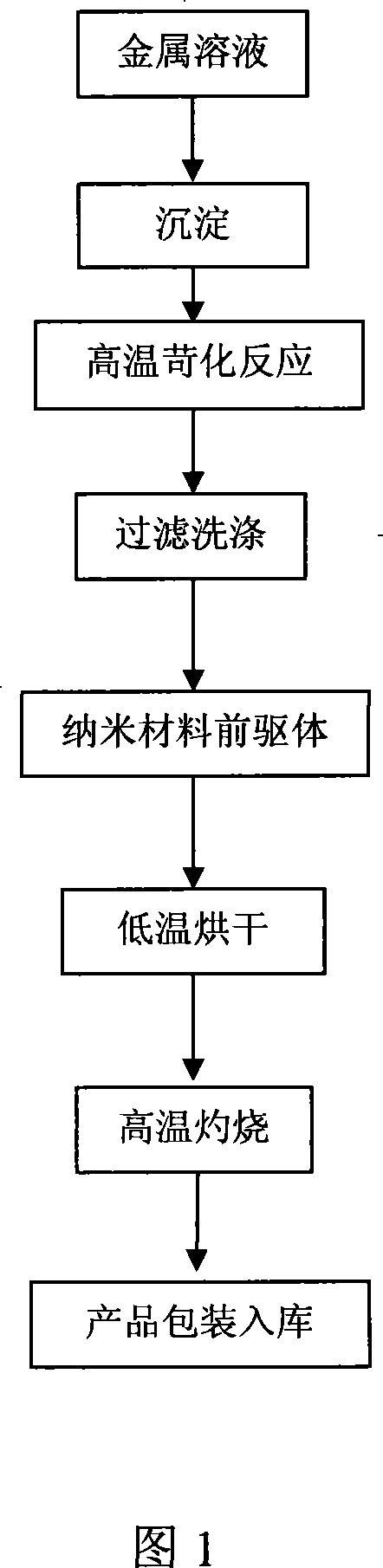

Method of preparing superfine micro-particle and nano granule

Owner:CHINA MINMETALS BEIJING RES INST OF RE

Infrared Reflecting Black Pigment, Paint and Resin Composition

InactiveUS20080134941A1Good infrared reflection performanceGood blacknessMaterial nanotechnologyPigmenting treatmentLength waveCopper

Owner:TODA IND

Transparent anti-static polyvinylidene fluoride piezoelectric material and preparation method thereof

InactiveCN103102623AImprove antistatic performanceExcellent piezoelectric propertiesCarbon nanotubePolyvinylidene difluoride

The invention relates to a transparent anti-static polyvinylidene fluoride piezoelectric material and a preparation method thereof. The filler is very difficult to uniformly disperse by adding carbon nano-tubes, graphene or zinc oxide to PVDF (Polyvinylidene Fluoride) material in the prior art; and the material is directly transmitted to be conductive from insulating, and is not attractive. The polyvinylidene fluoride piezoelectric material is a mixture of polyvinylidene fluoride and ionic liquid. The preparation method of the transparent anti-static polyvinylidene fluoride piezoelectric material comprises the following steps of: drying the polyvinylidene fluoride and the ionic liquid for 24 hours to 48 hours at 80 DEG C to 110 DEG C in a vacuum environment; adding the dried polyvinylidene fluoride and ionic liquid in a mass ratio of 100:(0.5-40) to a fusion smelting device for melting-blending at 180 DEG C to 200 DEG C to obtain a mixture; and discharging the mixture from the melting-blending device, cooling the mixture to normal temperature and crystallizing the cooled mixture to obtain the polyvinylidene fluoride piezoelectric material. The polyvinylidene fluoride piezoelectric material disclosed by the invention has good antistatic property, good piezoelectricity and excellent transparency. According to the preparation method of the polyvinylidene fluoride piezoelectric material disclosed by the invention, the normal melting-blending device is only needed to be used, and the industrial preparation is simple.

Owner:HANGZHOU NORMAL UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap