Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoride (/ˈflʊəraɪd, ˈflɔːr-/) is an inorganic, monatomic anion with the chemical formula F⁻ (also written [F]⁻), whose salts are typically white or colorless. Fluoride salts typically have distinctive bitter tastes, and are odorless. Its salts and minerals are important chemical reagents and industrial chemicals, mainly used in the production of hydrogen fluoride for fluorocarbons. Fluoride is classified as a weak base since it only partially associates in solution, but concentrated fluoride is corrosive and can attack the skin.

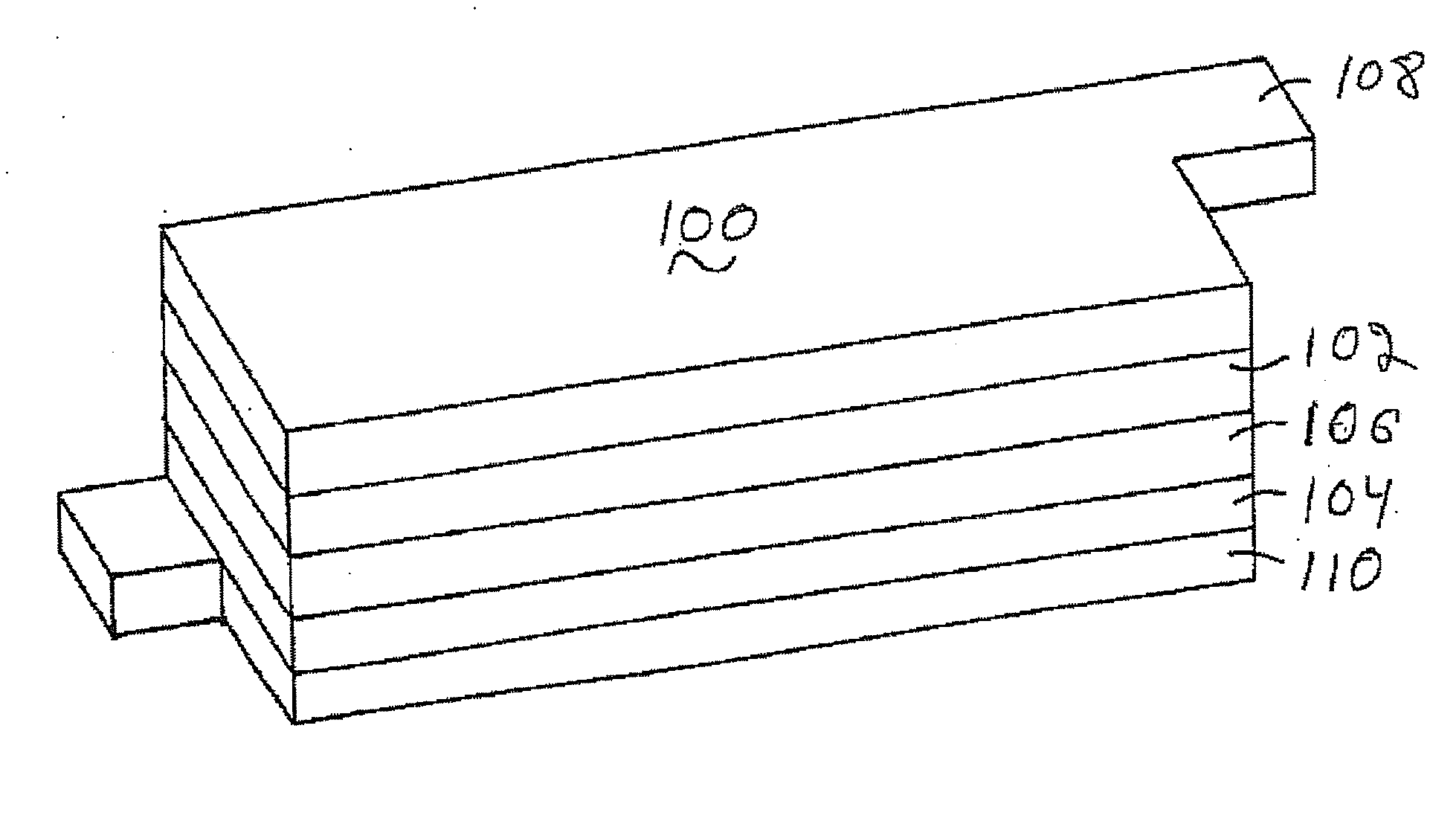

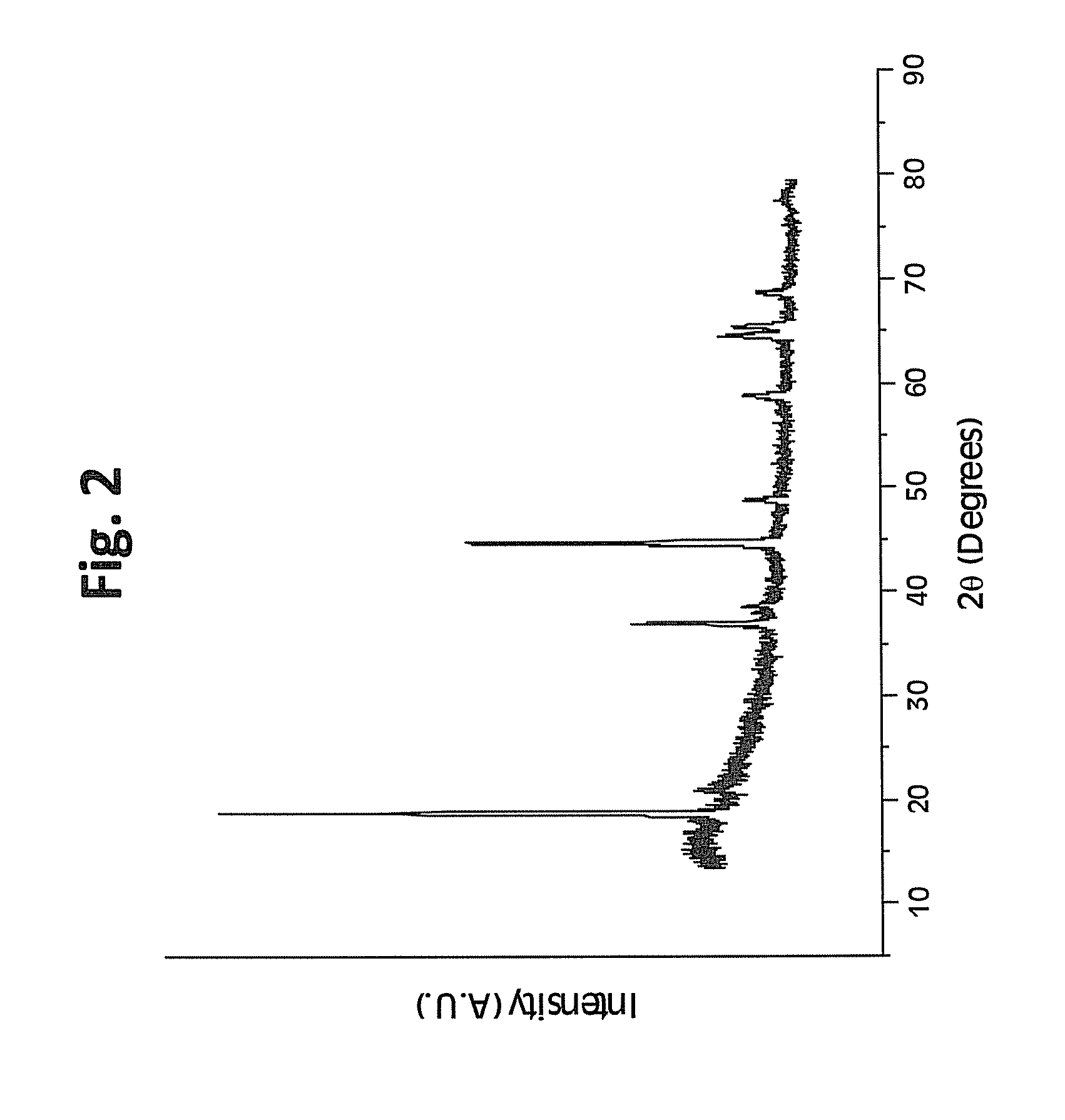

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

Method and apparatus for the production of nitrogen trifluoride

InactiveUS20020127167A1Nitrogen and non-metal compoundsHydrogen fluorideReaction zone

The present invention provides a method and apparatus for producing nitrogen trifluoride. The method comprises contacting a fluorine-containing feed stream with liquid ammonium acid fluoride in a reaction zone for time and under conditions sufficient to produce nitrogen trifluoride. During the contacting step, the effective melt acidity value of the liquid ammonium acid fluoride is decreased and a reaction product stream is removed. In one embodiment, a gaseous mixture of elemental fluorine and hydrogen fluoride is contacted with a bulk liquid ammonium acid fluoride, such that the initial effective melt acidity value is greater than the melt acidity value of the bulk liquid ammonium acid fluoride in the reaction zone.

Owner:BOC GRP INC

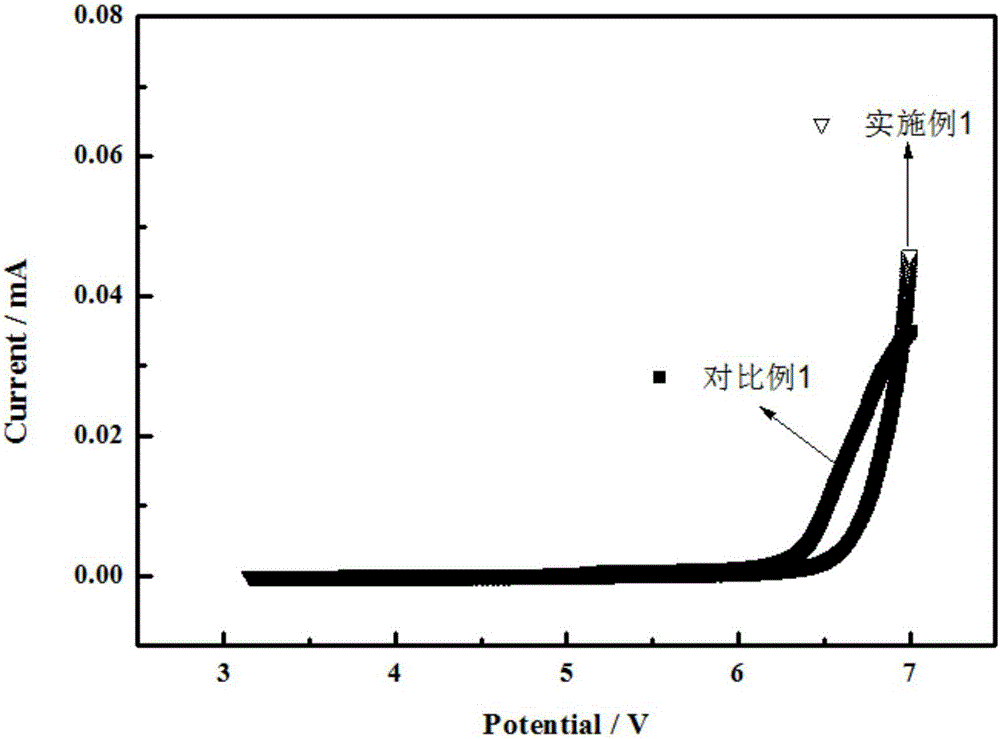

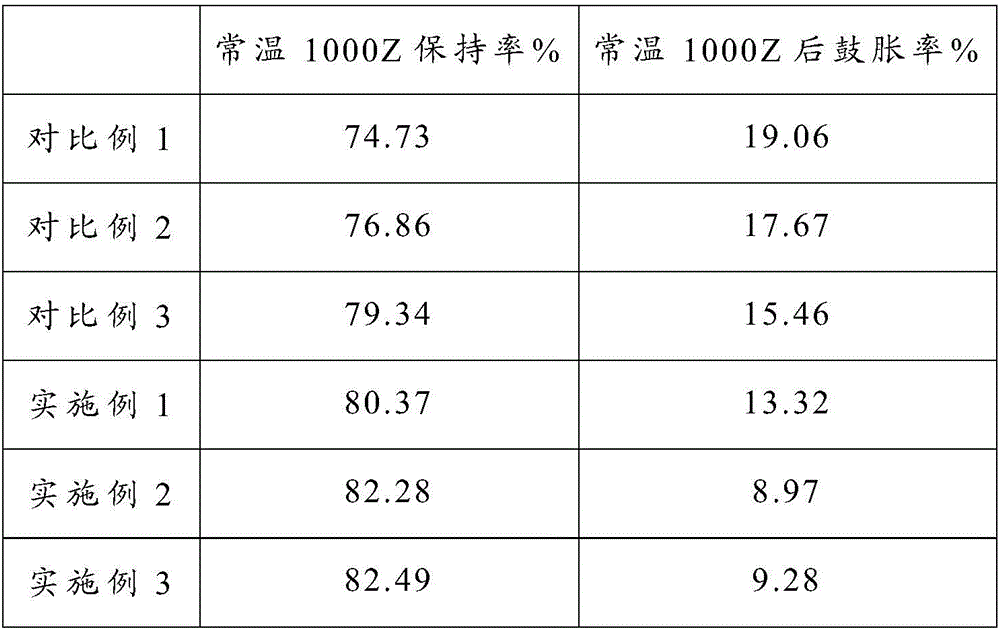

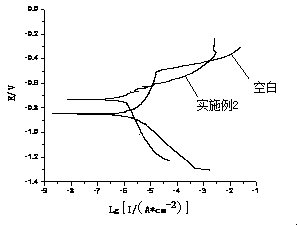

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Method of recovering and regenerating waste gas desulfurizing and defluorinating absorbent liquid continuously

ActiveCN1974430ALow investment costLow running costDispersed particle separationWater/sewage treatmentSulfite saltSodium bisulfite

The method of recovering and regenerating waste gas desulfurizing and defluorinating absorbent liquid continuously includes absorbing SO2 and / or fluoride from waste gas with alkaline absorbent to generate desulfurizing and defluorinating absorbent liquid containing sodium sulfite, sodium bisulfite and / or fluoride; the subsequent reacting the desulfurizing and defluorinating absorbent liquid with magnesium-base suspension or solid to obtain magnesium sulfite and / or magnesium fluoride precipitate; filtering to eliminate magnesium sulfite and / or magnesium fluoride precipitate, and recovering the filtrate at pH 6.5-9.5 for reuse. The said method has fast regeneration reaction speed, low cost and complete reaction.

Owner:陆泳凯 +1

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

Aluminum alloy surface titanium dioxide conversion coating solution and using method thereof

InactiveCN103924229AUniform colorImprove corrosion resistanceMetallic material coating processesTitanium oxideConversion coating

Owner:无锡铱美特科技有限公司 +1

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Novel rubber good in oil resistance and preparation method thereof

InactiveCN105061953AMethacrylateRubber material

Owner:苏州凯欧曼新材料科技有限公司

Preparation method of polyvinylidene fluoride resin

ActiveCN104558306AIncrease responsivenessShorten the polymerization reaction timeParaffin waxOrganic solvent

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Method for treating or pretreating containers

InactiveUS7344757B2Simpler and cost-effective processIncrease chanceHot-dipping/immersion processesPretreated surfacesBottleAluminium alloy

Owner:CHEMETALLGMBH

Composition comprising a semi-crystalline vdf polymer and a fluorinated thermoplastic elastomer block copolymer

InactiveUS20200095415A1Improved resistance to stainingEasy to adjustInsulatorsElastomerPolymer science

Owner:SOLVAY SOLEXIS

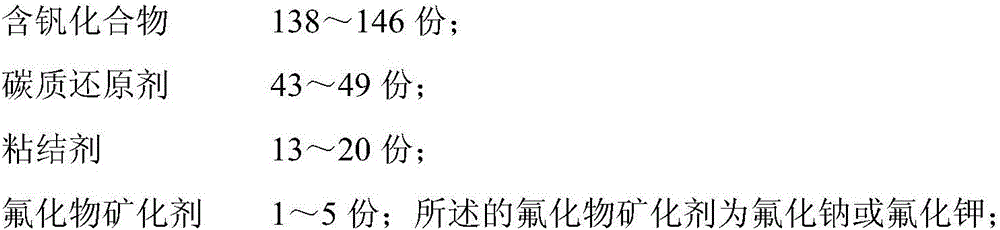

Production method of vanadium nitrogen alloy

InactiveCN103014345BIncreased vanadium contentHigh apparent densityApparent densityVanadium nitride

Owner:HUNAN HONGYUAN RARE METAL MATERIALS

Setting agent used after wool stretch and refinement

InactiveCN106702736AGuaranteed stabilityImprove oxidation efficiencyAnimal fibresPolystyreneButanone

Owner:HUZHOU PINCHUANG INCUBATOR

Combination material of fluorine-free flux and cadmium-free silver solder for copper-brass brazing

InactiveCN106342015BNot corrosiveImprove wettabilityWelding/cutting media/materialsSoldering mediaCeriumCadmium Cation

The invention relates to a composite material of fluorine-free brazing flux and cadmium-free silver brazing filler metal for copper-brass brazing, belonging to brazing materials. This brazing material is a combination of fluorine-free flux and cadmium-free silver solder, wherein the fluorine-free flux includes 2% to 8% boric acid (H3BO3), 28% to 38% boric anhydride (B2O3), 5% to 15% % carbonate (K2CO3 or Na2CO3), 0.1% to 1.0% nitrate (KNO3 or NaNO3), the rest is borate (K2B4O7 or Na2B4O7); cadmium-free silver solder includes 15% to 45% silver (Ag) , 3% to 10% of phosphorus (P), 0.001% to 0.030% of zirconium (Zr), 0.001% to 0.010% of cerium (Ce), and the rest is copper (Cu). The composite material has good wettability when brazing copper-copper, brass-brass, and copper-brass, and the brazing joint has good plasticity and comprehensive mechanical properties, and there is no residual fluorine ion at all. It is especially suitable for brazing copper materials that are used in harsh environments (high humidity, high temperature, high salt spray, etc.).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

High-strength foam aluminum material and preparation method thereof

The invention discloses a high-strength foam aluminum material and a preparation method thereof and belongs to the technical field of aluminum materials. The foam aluminum material is prepared with aluminum powder and aluminum alloy powder as a base material and includes, by weight, 30-50 parts of aluminum powder, 15-30 parts of aluminum alloy powder, 5-15 parts of a foamer, 10-20 parts of asbestos fiber, 2-8 parts of potassium hexafluorozirconate, and 5-10 parts of silicon nitride. The aluminum alloy powder is Al / Mg alloy powder. The foamer is CaCO3 modified by a fluoride. The preparation method includes adding a dispersant to the components for dispersion and uniform mixing, and ball-milling, drying and sintering the mixture to obtain the material. By adding the silicon nitride and compounding the CaCO3 modified by a fluoride, the potassium hexafluorozirconate and the like with the base material, the foam aluminum material is high in strength, is high in porosity and small in pore diameter, and is low in density.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Anti-wear electrical ternary fluororubber nonmetal compensator and preparation method thereof

InactiveCN106566140AHigh bonding strengthImprove heat resistancePipeline expansion-compensationYarnPolymer science

The invention discloses a wear-resistant electrical ternary fluororubber nonmetal compensator, which is prepared from the following raw materials in parts by weight: a proper amount of ternary fluorubber, 100-110 of alkali-free bulked yarn fiberglass fabric, 50-55 of vinylidene fluoride-hexafluoropropylene copolymer, 200-220 of acetone, 2-2.5 of TEBA, 80-85 of 5-5.5 wt% potassium hydroxide aqueous solution, 110-120 of 30-31 wt% hydrogen peroxide aqueous solution, a proper amount of 36-38 wt% hydrochloric acid aqueous solution, 3-3.5 of zinc oxide crystal whiskers, 0.5-0.7 of zirconium oxychloride, 2.5-3 of PPS micron powder, and 0.3-0.5 of trifluoroethyl acrylate. According to the technical scheme of the invention, the compatibility and the heat resistance of PPS micron powder and rubber are improved. Meanwhile, the PPS micron powder can improve the toughness and the wear resistance of the rubber. Therefore, the toughness and the wear resistance of the compensator are improved.

Owner:DANGTU JINLONGFENG TECH CO LTD

Environment-friendly water-based shaping lubricant

InactiveCN111154531AImprove the lubrication effectImprove wear resistanceLubricant compositionCelluloseStearic acid

The invention discloses an environment-friendly water-based shaping lubricant. The technical scheme of the invention comprises that the environment-friendly water-based shaping lubricant is prepared from the following components in parts by weight: 67-135 parts of neutral base oil, 1-3 parts of fumed silica, 2.6-3.5 parts of cellulose, 0.2-0.5 part of a de-foaming agent, 2-3 parts of graphite fluoride, 5.0-6.0 parts of sodium polyacrylate, 4-7 parts of a surface modifier, 55-60 parts of ethylene glycol, 2-8 parts of a viscosity index improver, 0.8-1.3 parts of high-fine graphite powder, 4-7 parts of an antioxidant, 0.2-0.3 part of polyvinyl alcohol, 3-5 parts of a dispersing aid, 5-10 parts of sorbitol, 2-8 parts of glyceryl monostearate, 2-6 parts of a metal deactivator and 0.2-1 part ofa preservative. Compared with the prior art, the environment-friendly water-based shaping lubricant provided by the invention is safe and environment-friendly.

Owner:JIAHONG AUTO PARTS TECH (SUZHOU) CO LTD

Velocit cracking method

InactiveCN1552807AImprove wear resistanceOvercome the disadvantages of poor anti-wear performanceCatalytic crackingMolecular sieveGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap