Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Electrode material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrodes and electrode materials are metals and other substances used as the makeup of electrical components. They are used to make contact with a nonmetallic part of a circuit, and are the materials in a system through which an electrical current is transferred. ... Electrode Materials Some of the most prominent alloys and materials used as electrode materials are copper, graphite, titanium, brass, silver, and platinum.

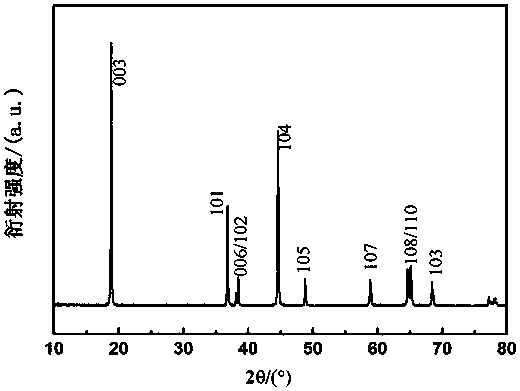

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

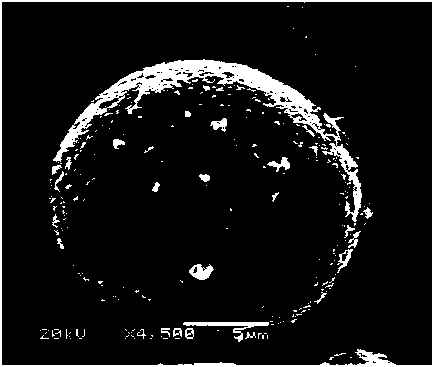

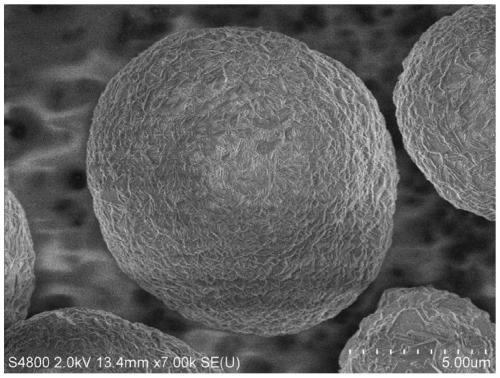

Process For Producing Spherical Carbon Material

InactiveUS20070212610A1High yieldGood spherical shapeAlkali metal halidesSecondary cellsNon aqueous electrolytesElectrode material

Owner:KUREHA KAGAKU KOGYO KK

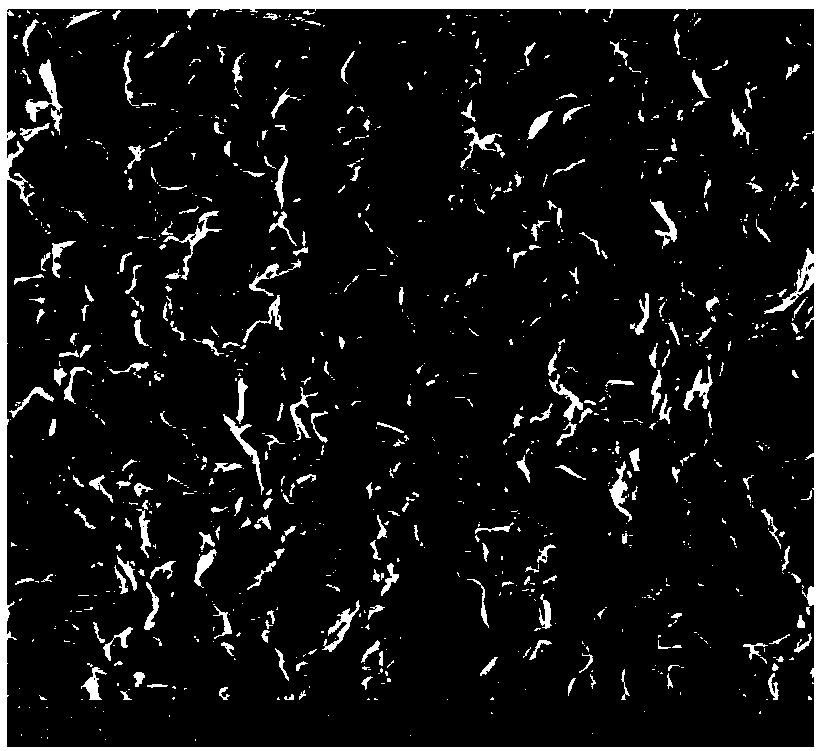

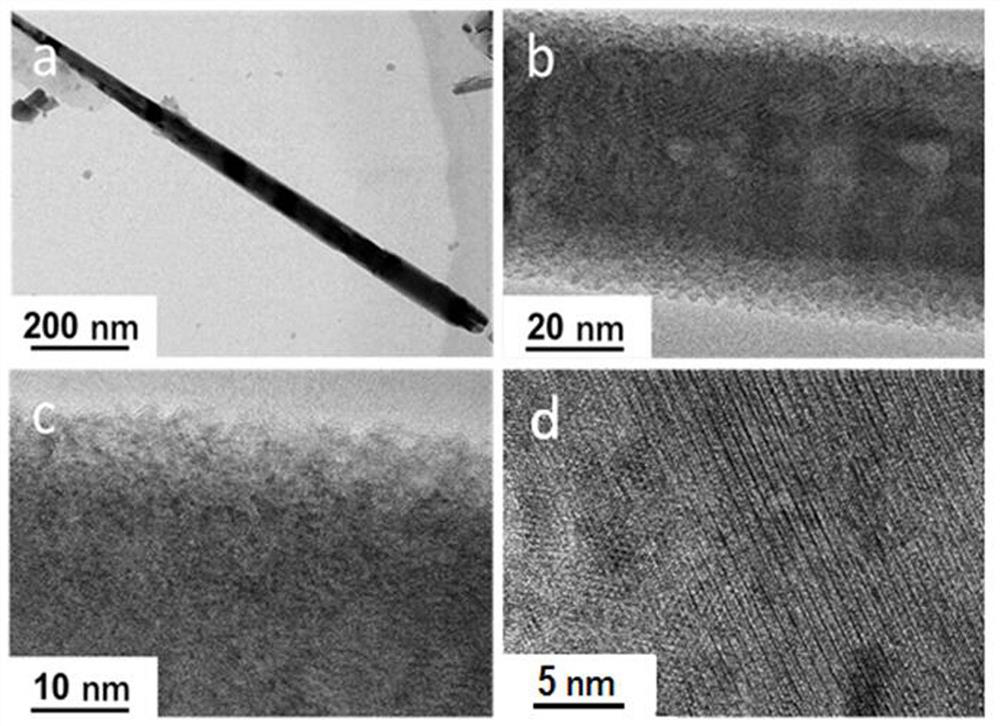

Conductive composite fiber and preparation method thereof

The invention relates to a conductive composite fiber and a preparation method thereof. The conductive composite fiber comprises a skin core structure including conductive particles and organic fibers, wherein the mass percentage composition of the conductive particles is 0.5-10%, and the mass percentage composition of the organic fibers is 90-99.5%. The preparation method comprises the following steps: (1) pre-treating the organic fibers in pretreatment liquid, and blowing; (2) soaking the fibers into water dispersion liquid of the conductive particles, ultrasonically assisting the conductive particles to outer layers of the fibers in ice water bath, soaking, drying, and soaking, cleaning and drying through hydrochloric acid solution to obtain the conductive composite fiber. According to the invention, the conductive composite fiber has the advantages of no organic solvent in preparation, greenness and environmental friendliness, simple process, low cost, continuous large-scale production, high conductivity of a product, difficulty in falling conductive components, durable conductive performance, soft hand feel and capability of being knitted; and the conductive composite fiber is used as an antistatic and electromagnetic shield material and an energy storage electrode material.

Owner:DONGHUA UNIV

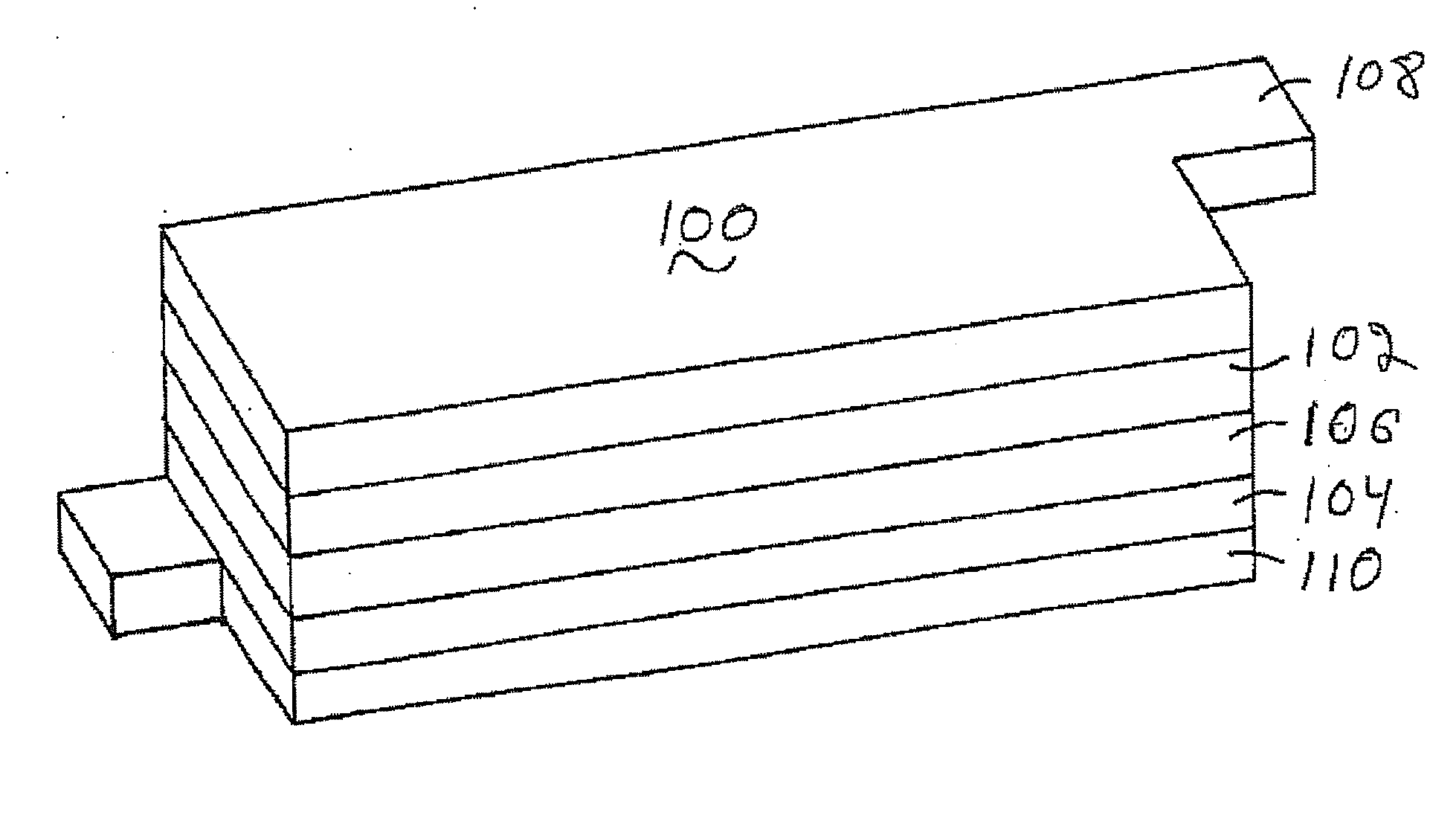

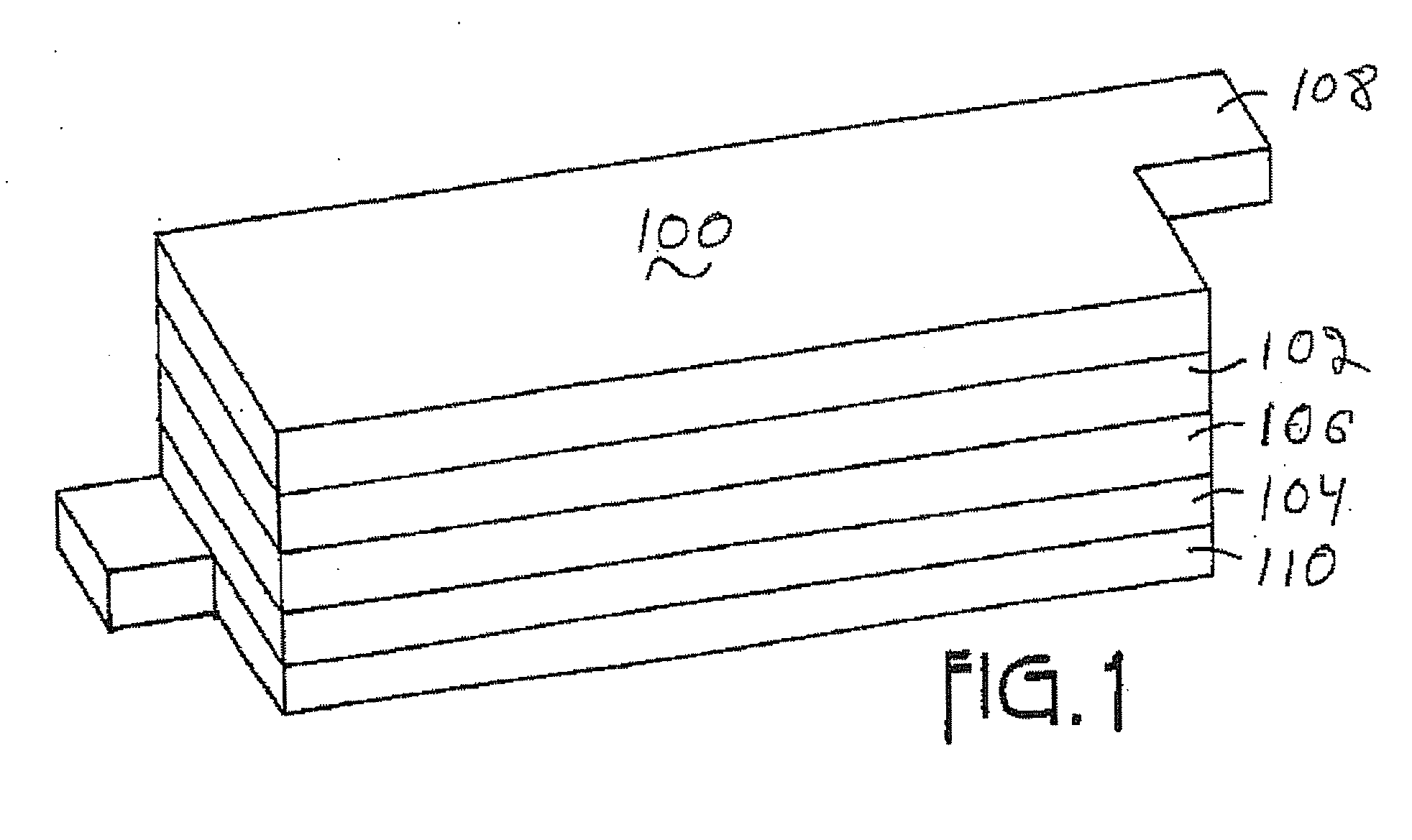

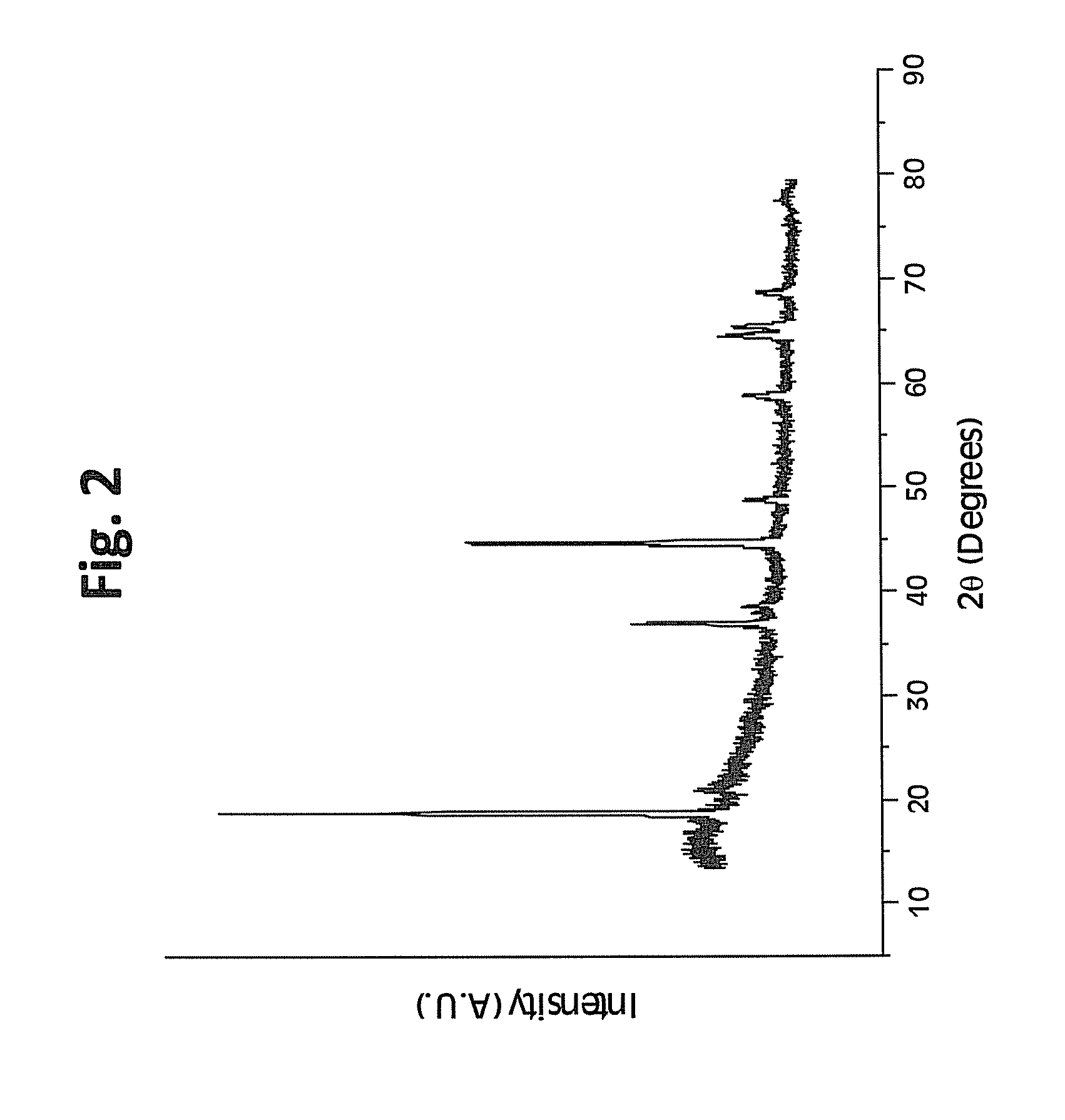

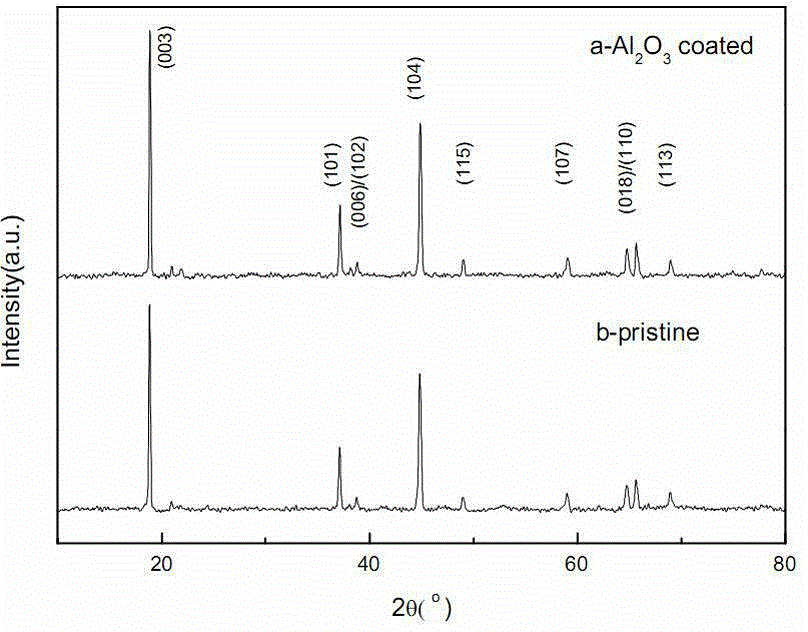

Alumina coating method of lithium ion battery positive electrode material

InactiveCN104577128AImprove cycle stabilitySmall capacity attenuationCell electrodesSecondary cellsAir atmosphereLithium-ion battery

Owner:WUXI XINGBO ENERGY TECH

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

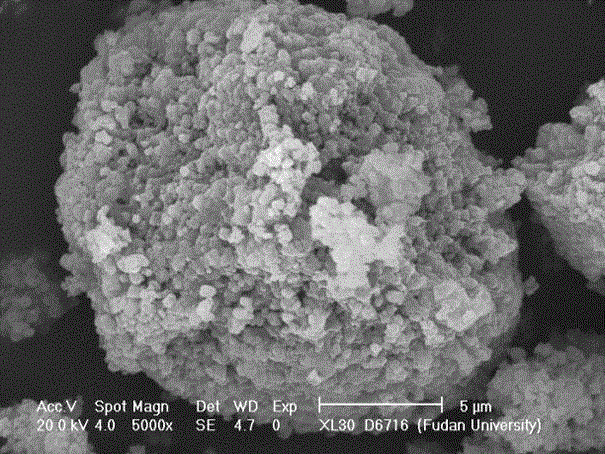

Preparation method of positive electrode material of lithium-ion battery

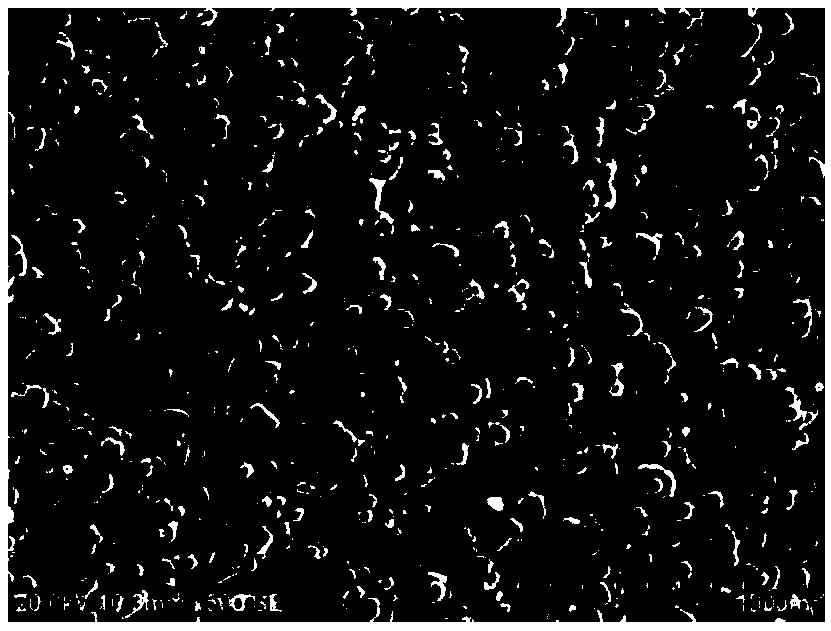

InactiveCN106207167AObvious lamellar structureUniform sizeElectrode manufacturing processesSecondary cellsUltrasonic cavitationLithium-ion battery

The invention discloses a preparation method of a positive electrode material of a lithium-ion battery. The method comprises the specific steps of dropwise adding a metal salt solution and a mixed solution of a precipitant and a complexing agent to a surfactant solution; controlling a pH value and a temperature under a synergistic effect of an inert atmosphere, ultrasonic cavitation and stirring dispersion until the metal salt solution is dropwise added; carrying out spray drying and roasting to obtain a spherical product, mixing the spherical product with a lithium source and roasting the mixture again to obtain the positive electrode material of the lithium-ion battery. The crystalline morphology can be effectively controlled by using a surfactant; the early synthesized material has an obvious sheet structure; particles agglomerated by a spray-dried product are uniform in size; a foundation is laid for later roasting to obtain the spherical particles with uniform sizes; and meanwhile, another foundation is laid for a relatively good morphology of the final product positive electrode material.

Owner:KUNMING UNIV OF SCI & TECH

LiAlO2 coated LiNi1-xCoxO2 lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105185954AImprove thermal stabilityGood discharge specific capacityCell electrodesSecondary cellsPower batteryElectrical battery

The present invention belongs to the field of lithium-ion batteries, and provide a modified lithium-ion battery positive electrode material LiNi1-xCoxO2@LiAlO2 with high thermal-stability LiAlO2 coated on the LiNi1-xCoxO2 surface, and a preparation method thereof. A purpose of the present invention is to overcome the disadvantages of overcharging intolerance and pool thermal-stability of the lithium-ion battery LiNi1-xCoxO2 (x is more than 0 and is less than or equal to 0.5) positive electrode material. According to the present invention, the positive electrode material of the present invention has characteristics of good thermal-stability, good discharge specific capacity and excellent cycle stability compared with the LiNi1-xCoxO2 positive electrode material, can meet the large rate charge and discharge requirements, and is especially suitable for the positive electrode material of the electric vehicle power battery; and the product prepared through the preparation method has characteristics of high purity, high chemical uniformity, good coating effect, high crystal quality, fine particle, uniform distribution, excellent electrochemical performance and low manufacturing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for treating lithium metal with fluoroethylene carbonate and application of lithium metal in solid-state batteries

ActiveCN108468042AEasy to prepareLow costCell electrodesMetallic material coating processesMetallic lithiumElectrical battery

The invention relates to a method for treating the surface of lithium metal with fluoroethylene carbonate and an application of the lithium metal in solid-state batteries, and belongs to the technicalfield of preparation of negative electrode materials for lithium batteries. The method comprises that a lithium negative electrode is immersed in fluoroethylene carbonate, and then taken out and subjected to drying treatment to volatilize a residual liquid on the surface. The method is simple and easy to operate and easy to control, has obvious effect on solving the problems of poor compatibilityof lithium metal / solid electrolyte interfaces and lithium dendrite growth in conventional solid-state batteries, and is suitable for large-scale commercialized production.

Owner:SHANDONG UNIV

Electric storage device

InactiveUS20100291423A1Improve securityInhibition releaseProtecting/adjusting hybrid/EDL capacitorSmall-sized cells cases/jacketsInternal pressureElectricity

A substantially U-shaped sealing strip and a sealing strip are formed on an outer container of the electric storage device as first sealing strips by heat sealing processing so as to surround an electrode housing portion. Further, a safety valve portion having a narrower sealing width than other sites is formed in the center of the substantially U-shaped sealing strip. Furthermore, a second sealing strip is formed on the outer container to oppose the safety valve portion at a predetermined distance. When an internal pressure of the electrode housing portion exceeds a prescribed value due to overcharge, etc., a sealing surface of the safety valve portion peels away, thereby opening the safety valve portion such that gas in the electrode housing portion is discharged from the opened safety valve portion. Electrode material and an electrolyte are also discharged, but trapped by the second sealing strip.

Owner:SUBARU CORP

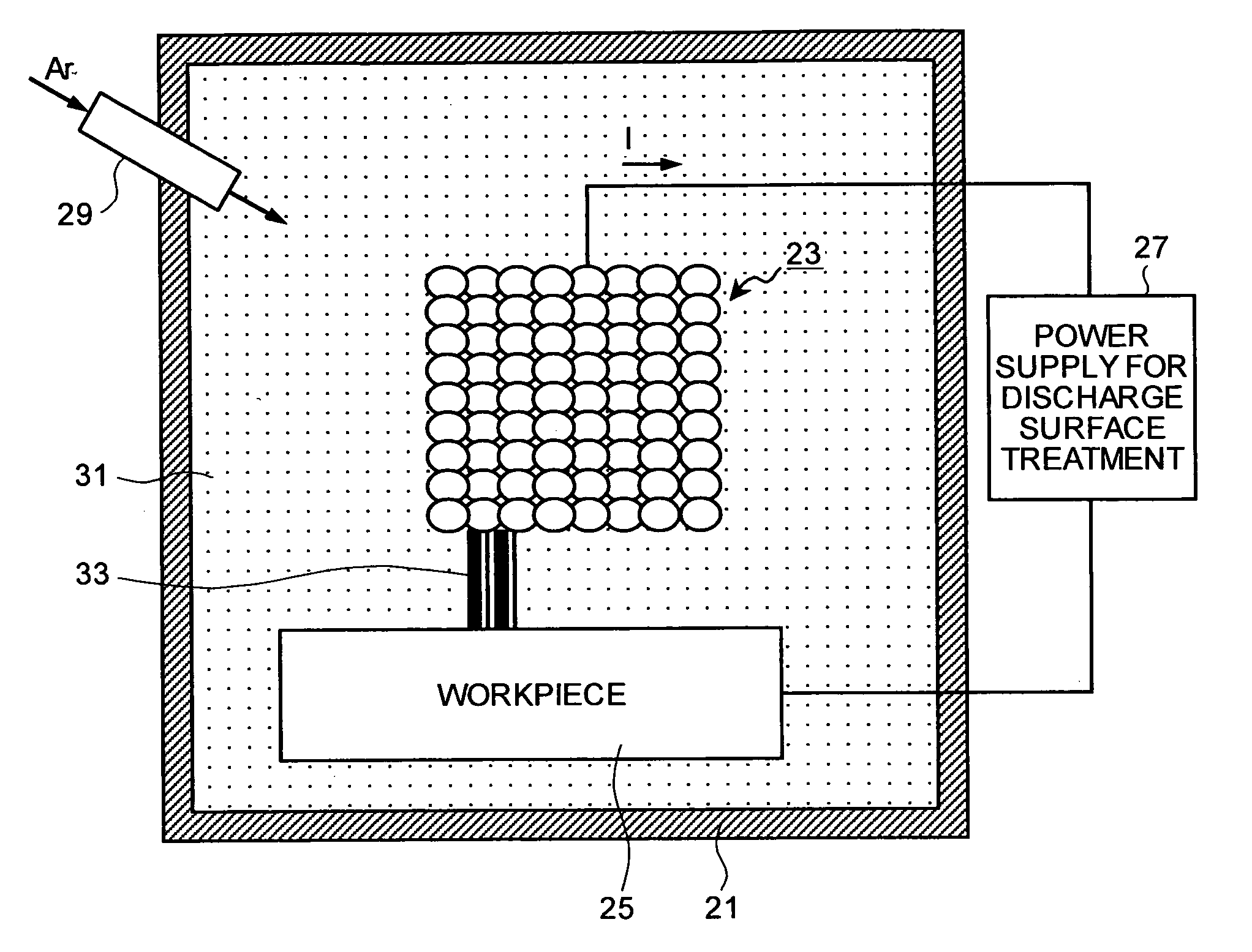

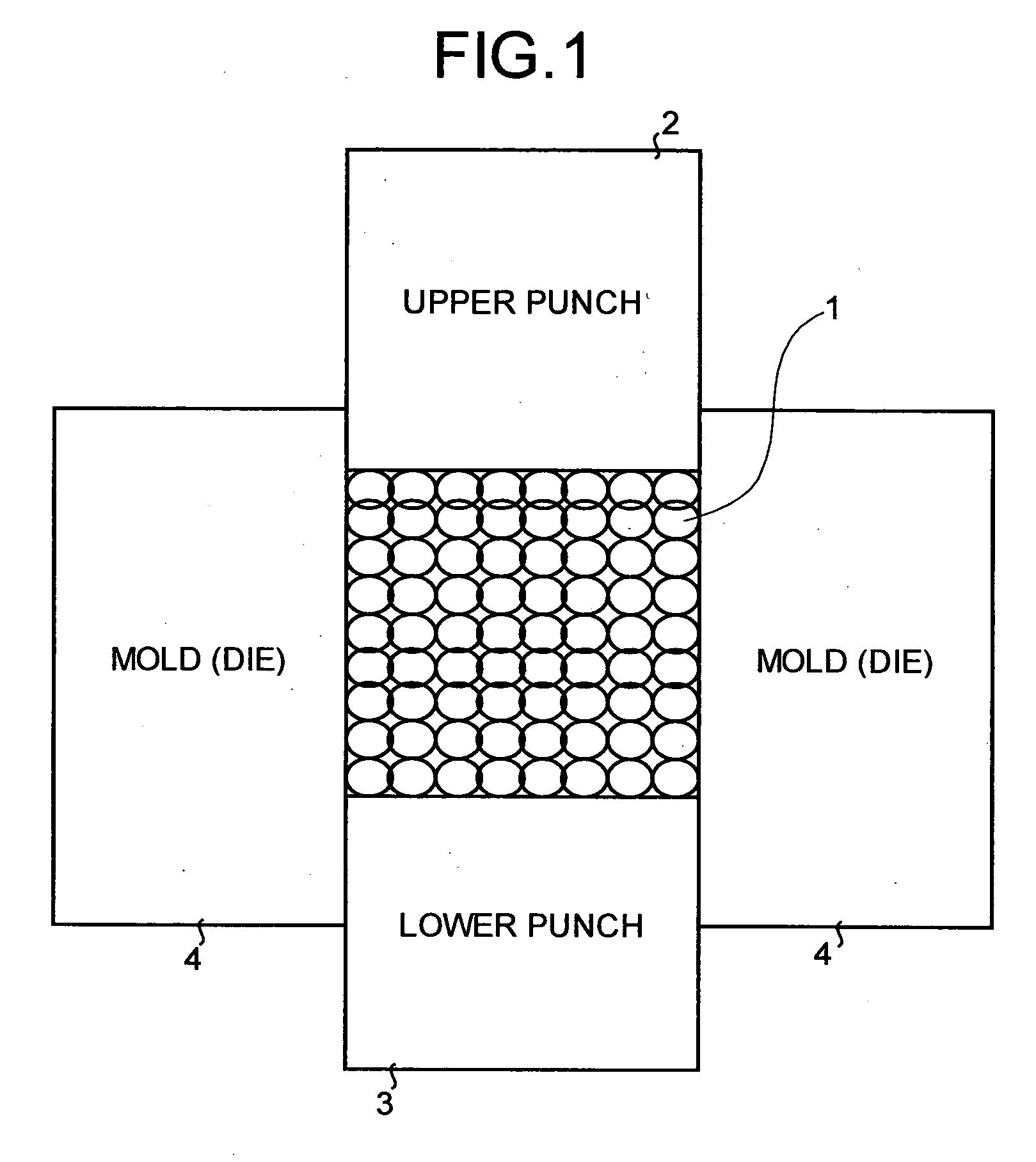

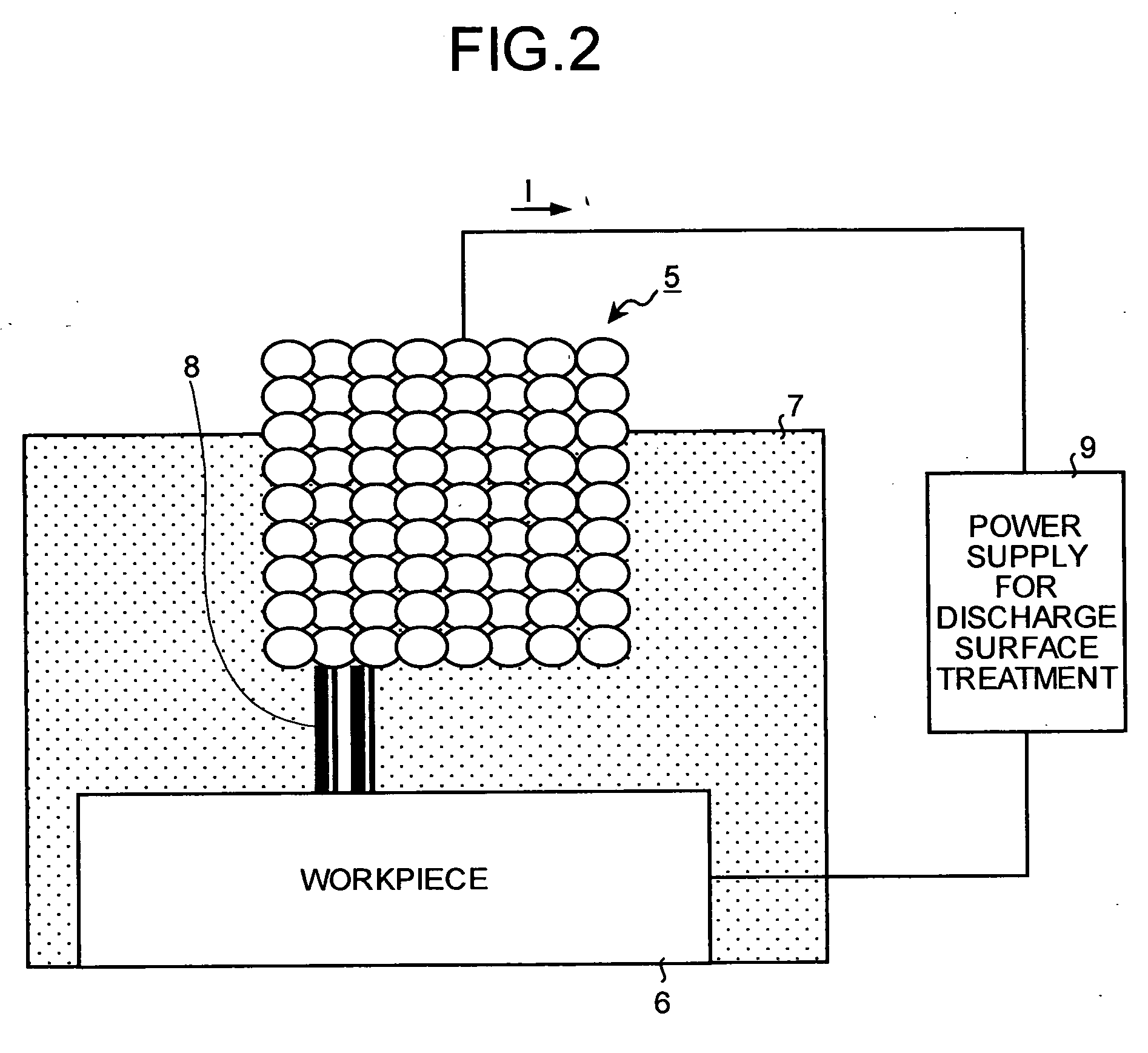

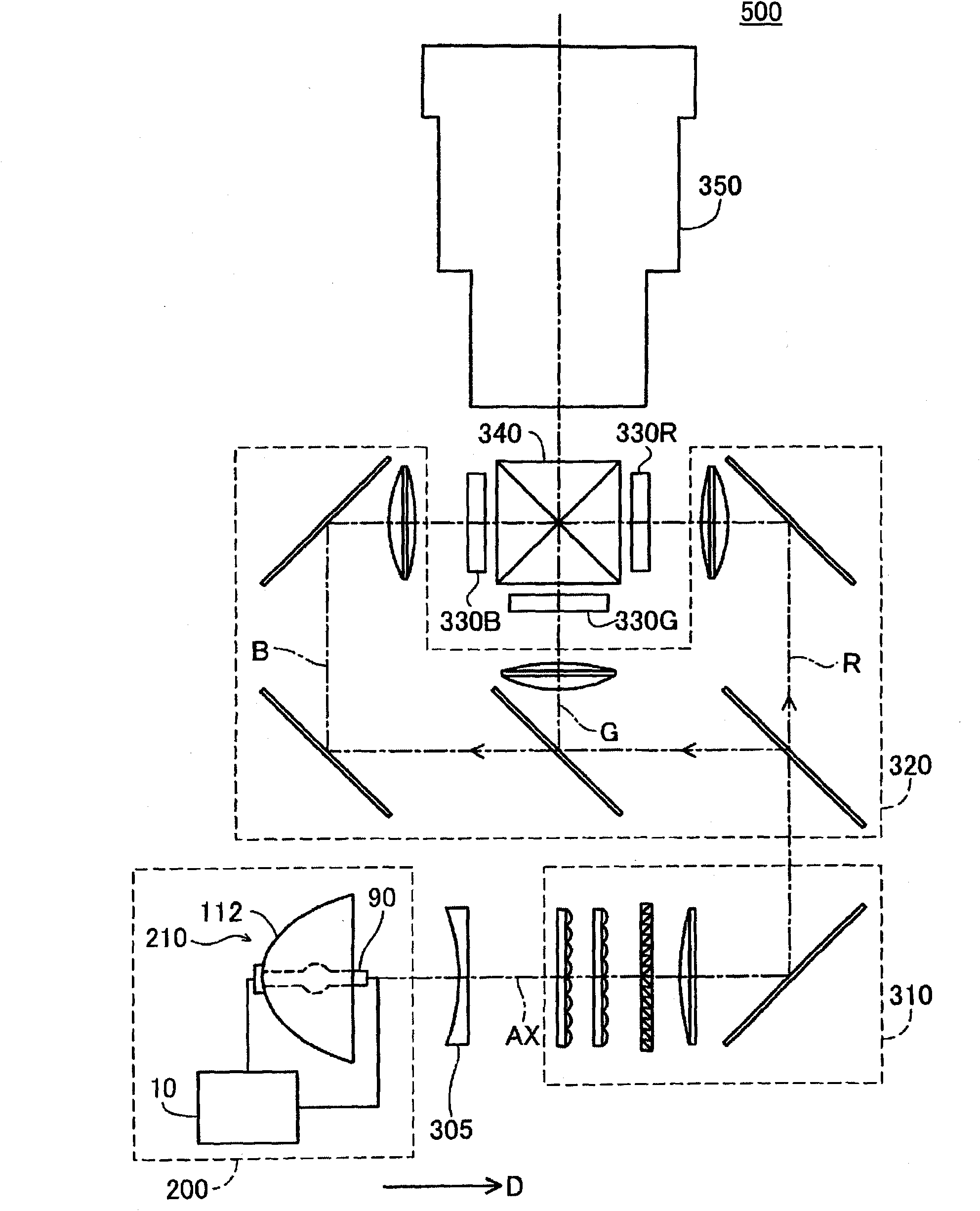

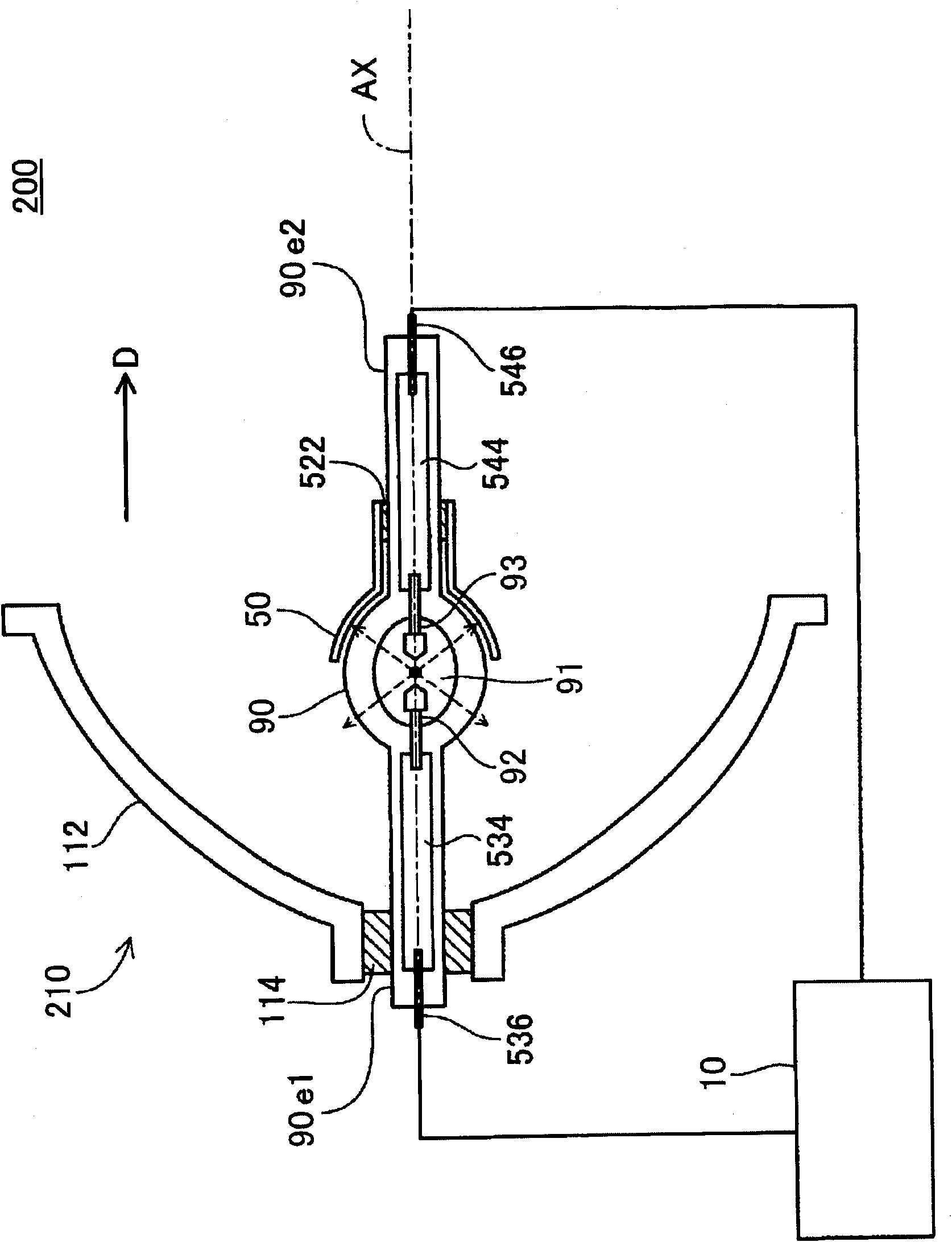

Discharge surface-treatment method and discharge surface-treatment apparatus

InactiveUS20060090997A1Metallic material coating processesEnergy based chemical/physical/physico-chemical processesMetal powderMaterials science

Owner:MITSUBISHI ELECTRIC CORP +1

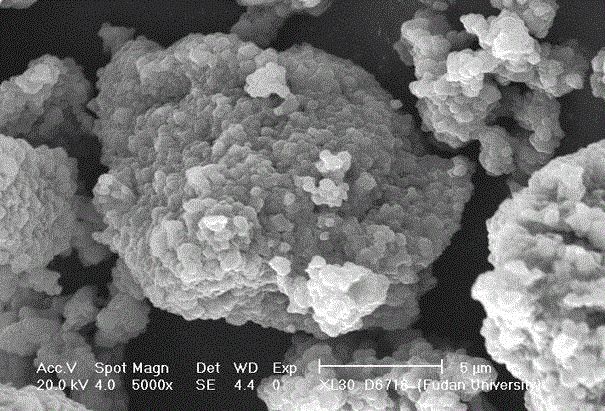

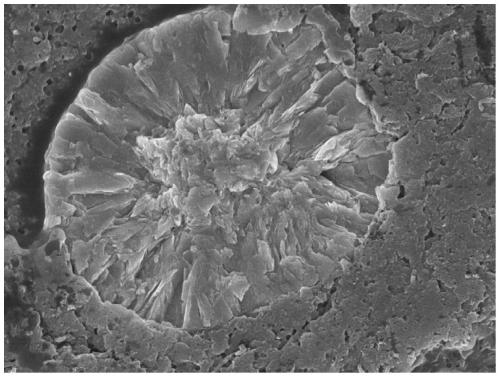

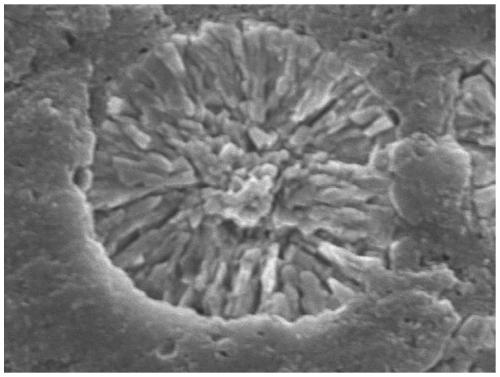

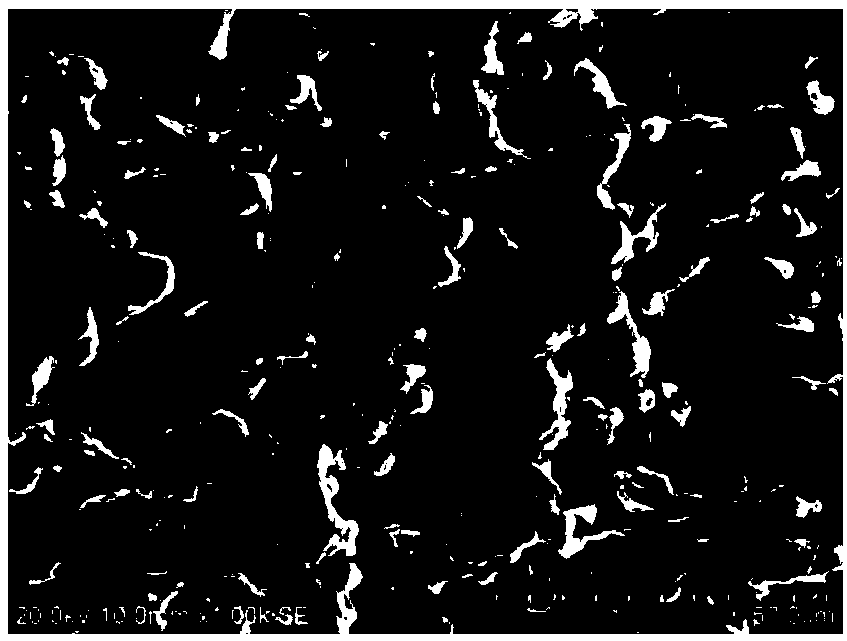

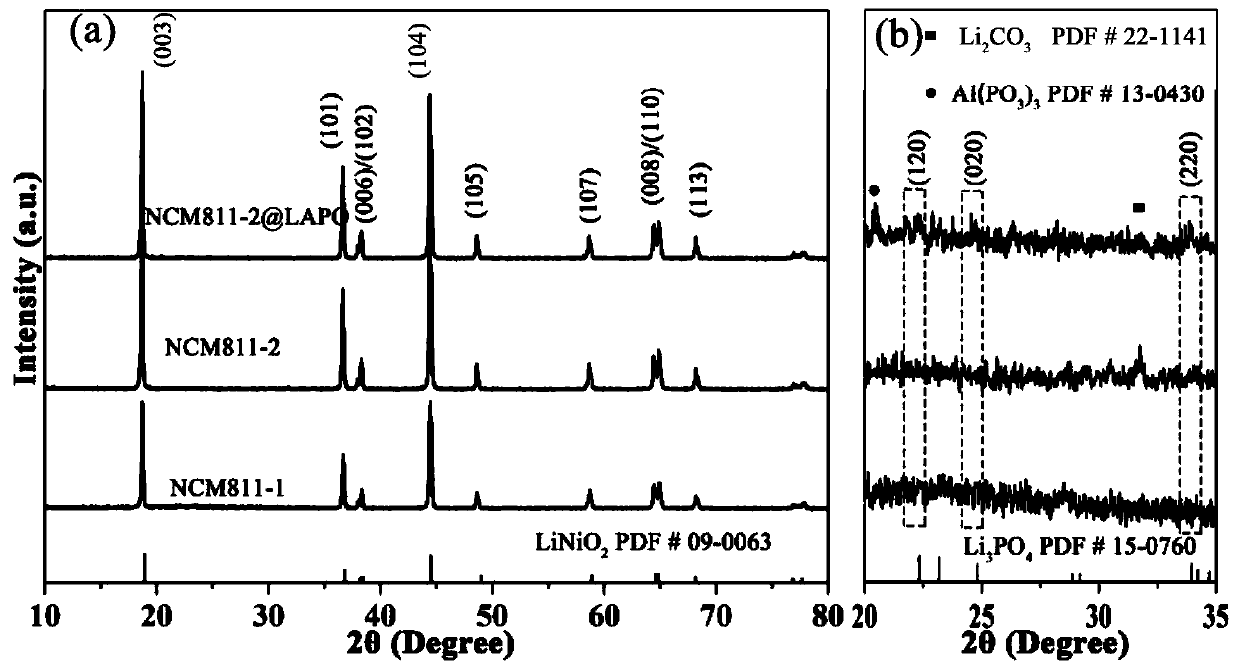

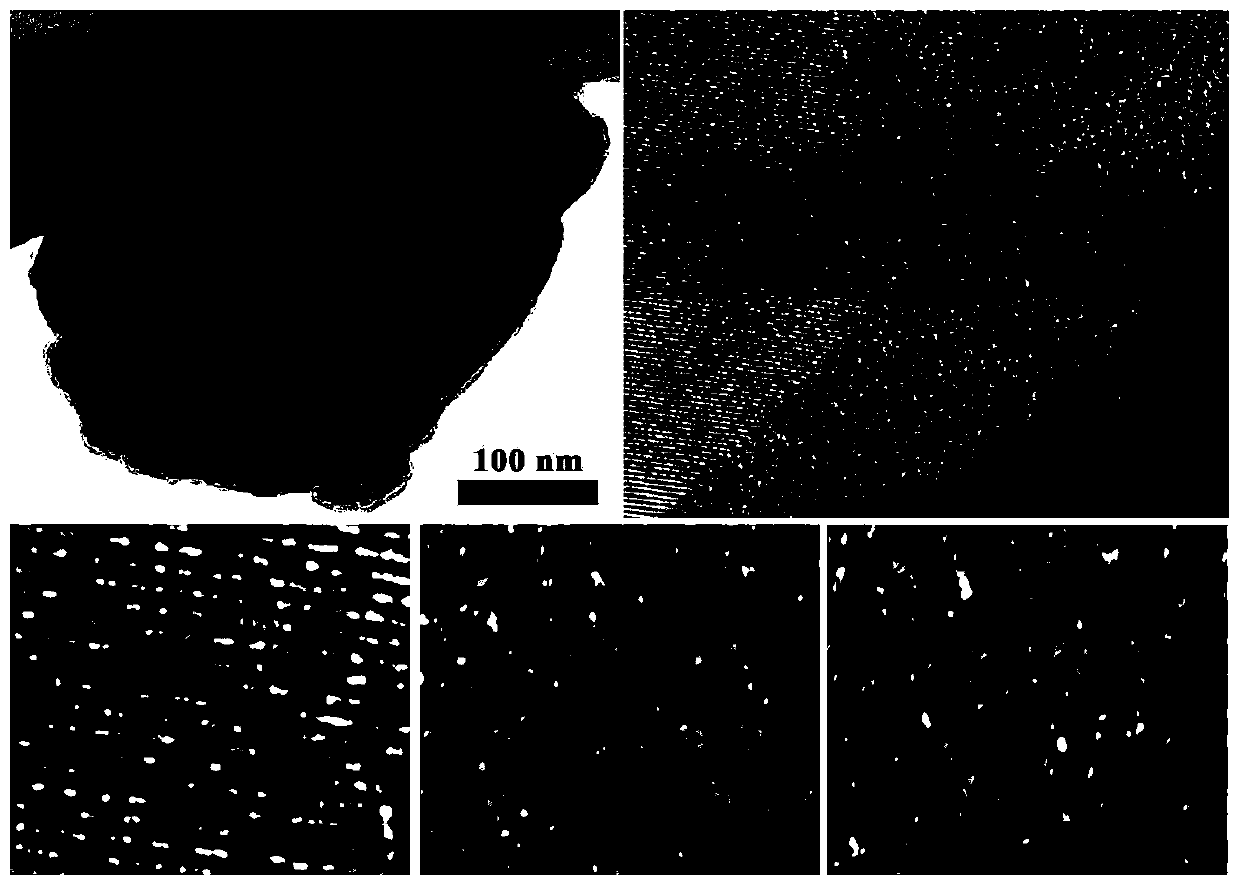

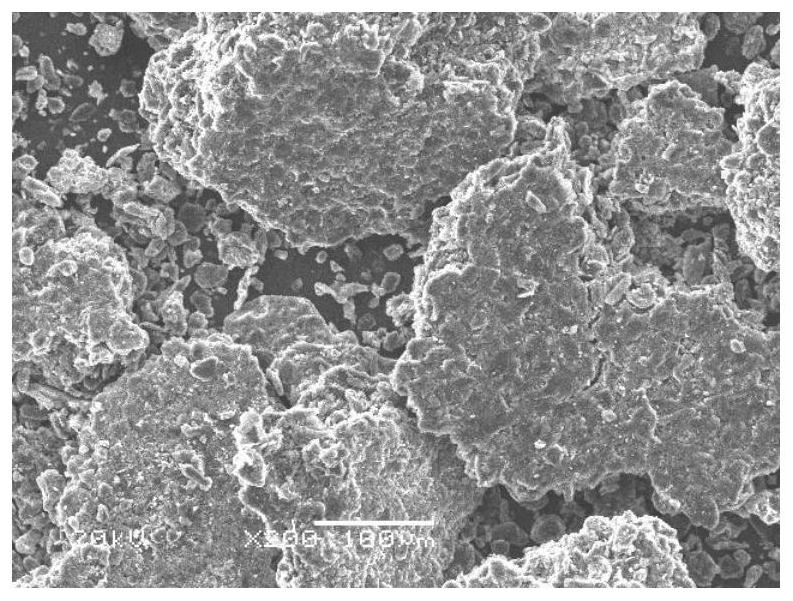

Preparation method of radial structure spherical NCM811 type ternary positive electrode material

ActiveCN110330060AReduced anisotropic volume changeHigh tap densityCell electrodesSecondary cellsNickel saltFiltration

Owner:HAINAN UNIVERSITY

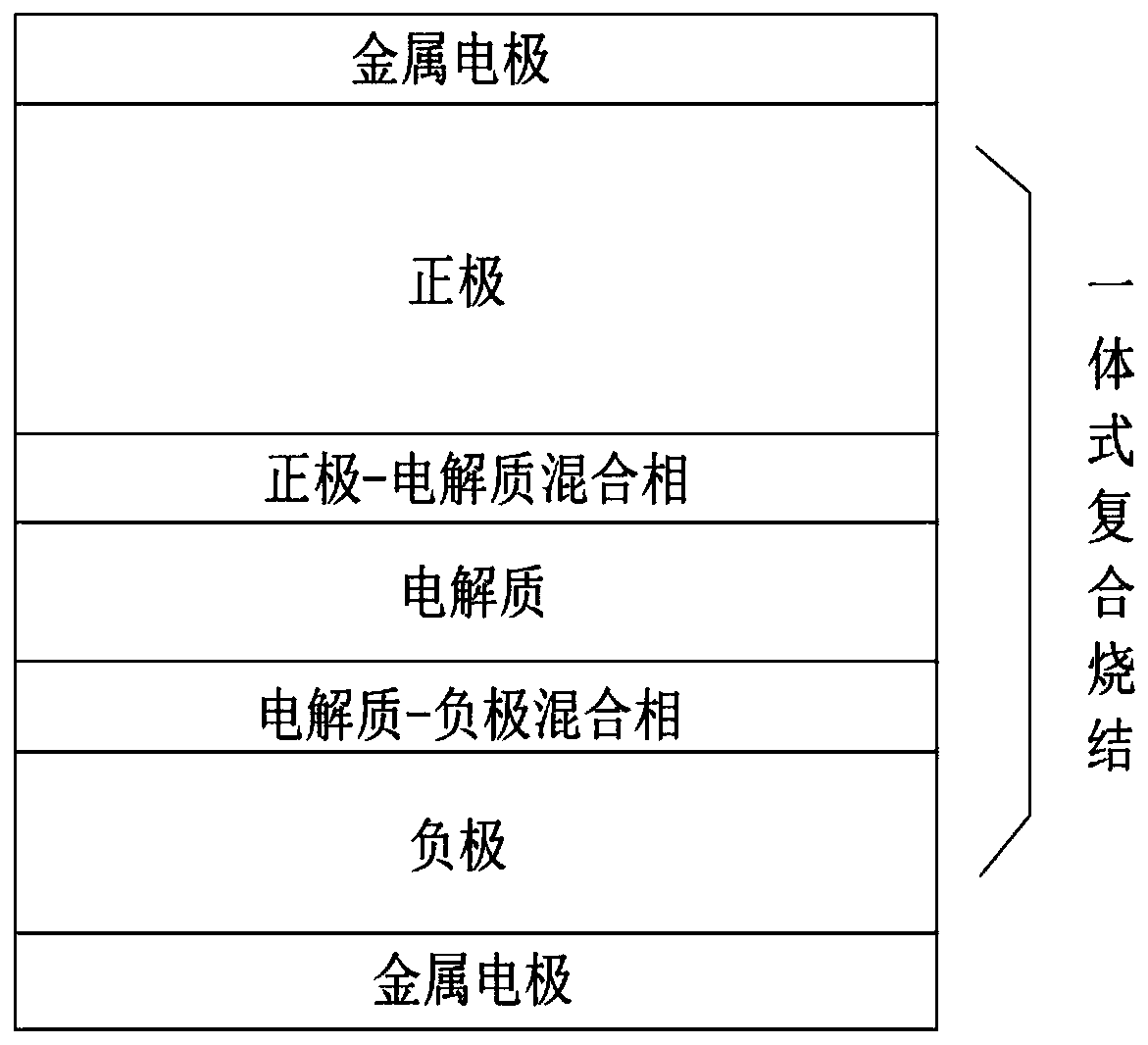

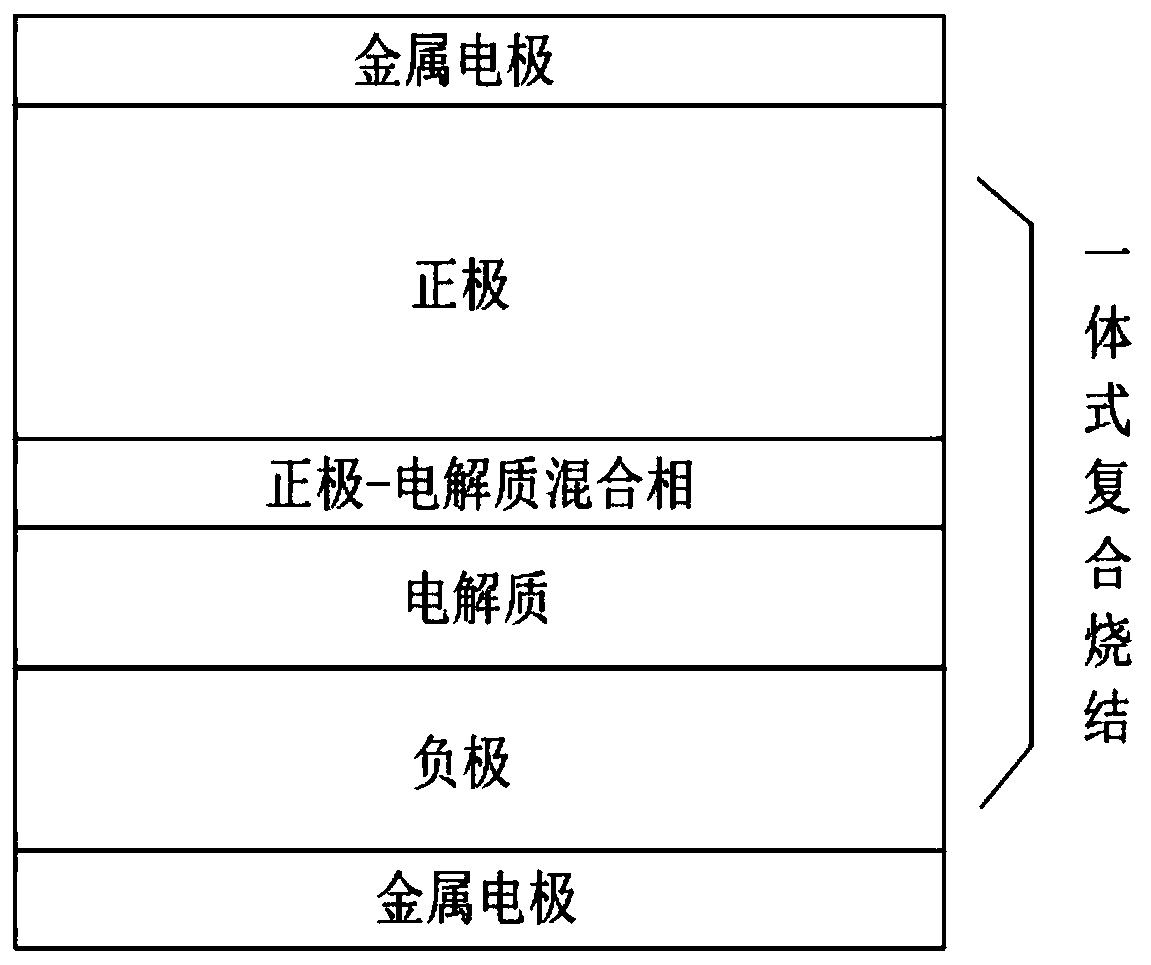

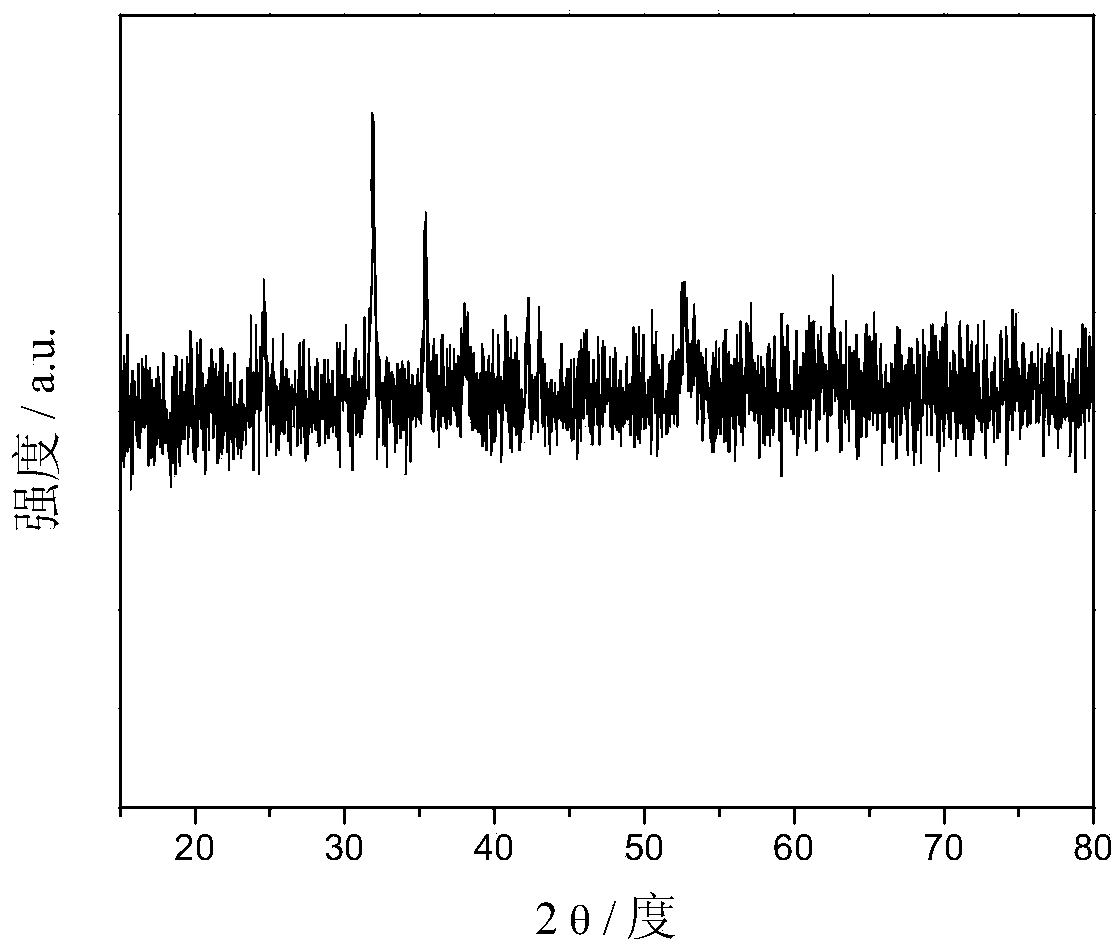

All-solid-state lithium ion battery and integrated composite sintering preparation process thereof

InactiveCN110165286AImprove Interface StabilityEnhanced interfacial transport propertiesFinal product manufactureSecondary cells manufactureLithium oxideSolid state electrolyte

Owner:浙江国能锂业有限责任公司

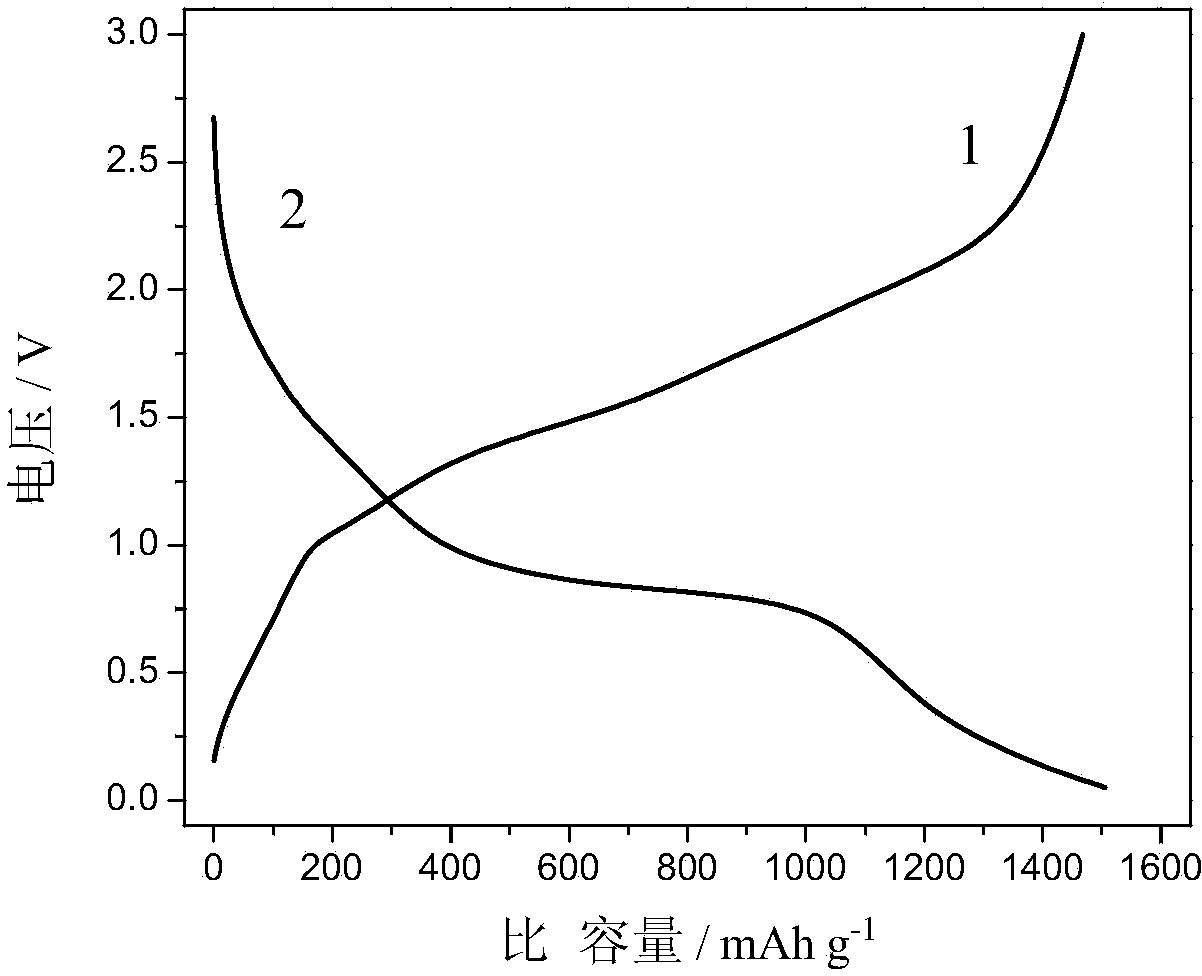

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

High-thermal-conductivity pure porous silicon carbide material, preparation method and application thereof

ActiveCN110746192AImprove thermal conductivityAdjustable volumeCeramicwareElectromagnetic shieldingGrain boundary

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

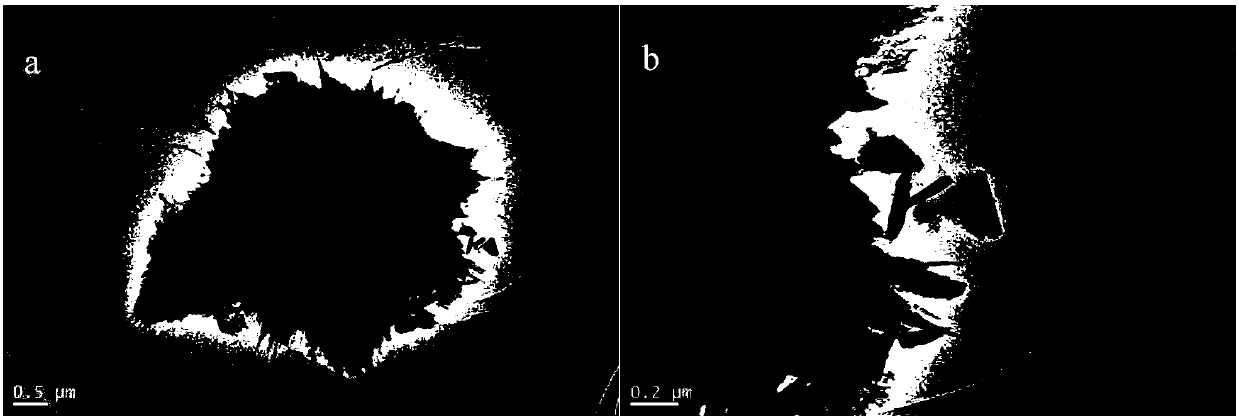

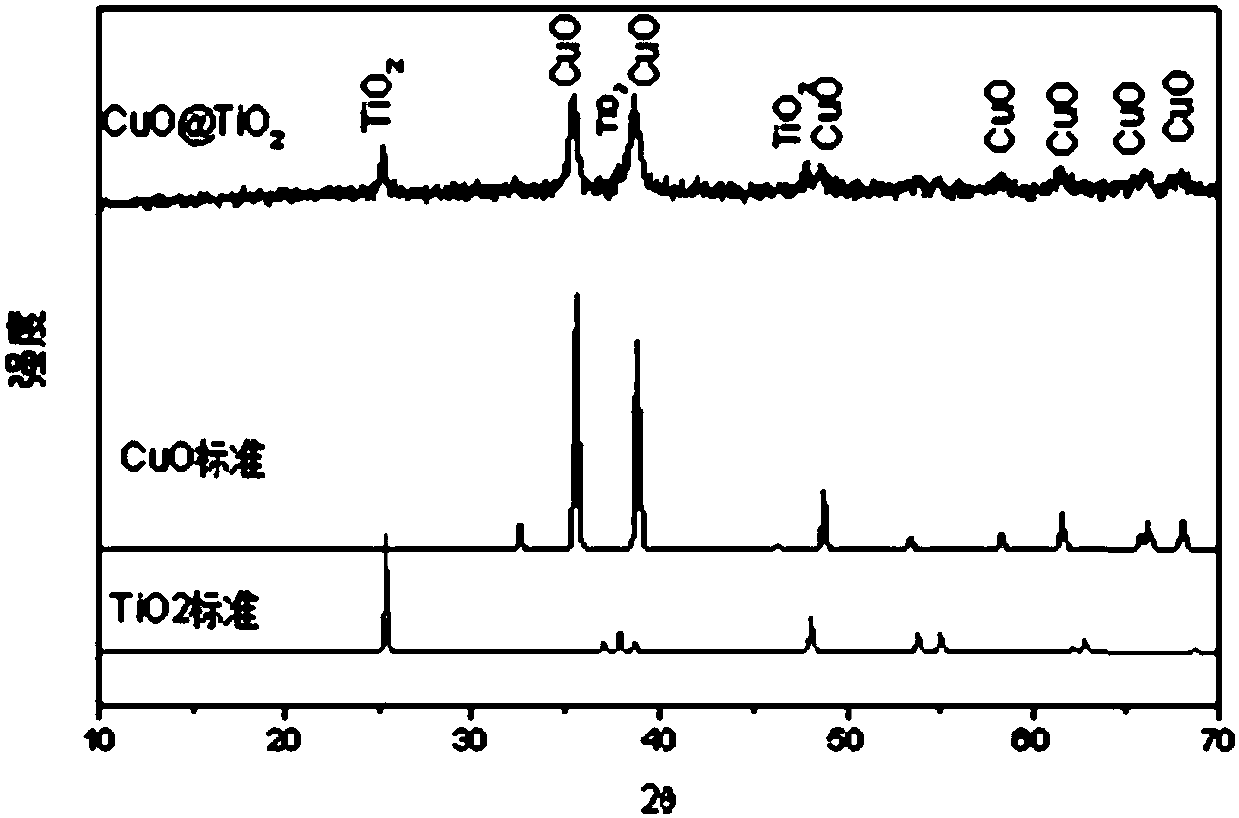

Titanium dioxide-copper oxide nano compound and preparation method and application thereof

ActiveCN107799744ARaw materials are easy to obtainSimple processMaterial nanotechnologyCell electrodesAir atmosphereFree cooling

Owner:SOUTH CHINA NORMAL UNIVERSITY

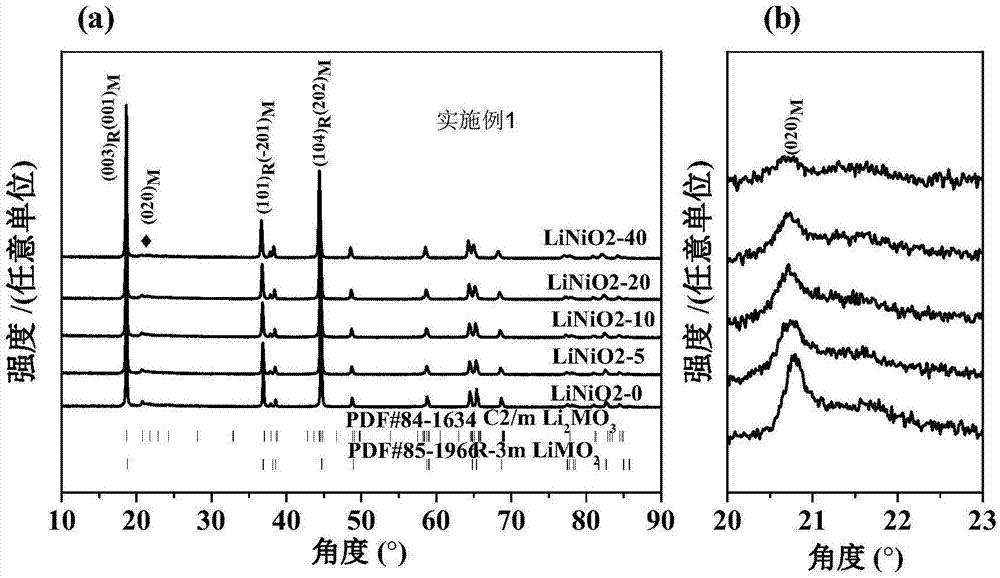

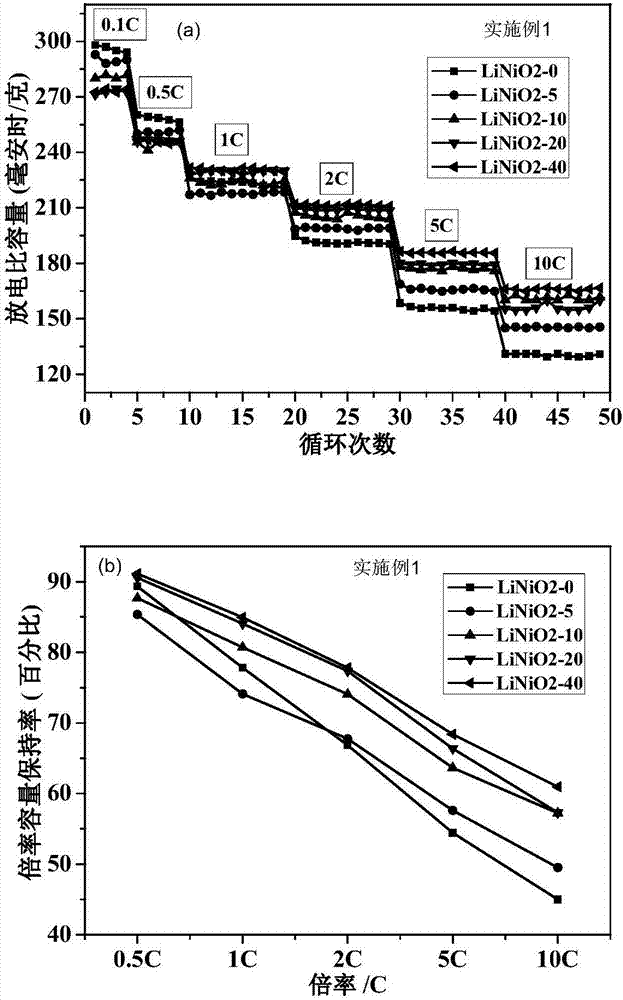

Layered lithium-rich manganese oxide positive electrode material suppressing capacity/voltage attenuation during circulation process effectively and preparation method therefor and application thereof

InactiveCN107069026AIncrease energy densityImprove cycle stabilityCell electrodesSecondary cellsCyclic processHigh energy

Owner:ZHEJIANG UNIV

Discharge lamp lighting device, method of driving discharge lamp, and projector

InactiveCN101801149AAvoid consumptionPrevent precipitationElectrical apparatusElectric lighting sourcesTime conditionDriving current

Owner:SEIKO EPSON CORP

Fabrication method of Ag/ZnO core-shell structure nanorod array electrode material

ActiveCN108878660AIncreased efficiency of transport to electrodesBlock holesSolid-state devicesSemiconductor/solid-state device manufacturingMetal electrodesCore shell

The invention discloses a fabrication method of an Ag / ZnO core-shell structure nanorod array electrode material. The fabrication method comprises the steps of (1) electrically depositing a silver nanorod array on a conductive glass substrate; (2) fabricating pinhole-free conformal ZnO coating layer; (3) spinning a polymer; and (4) evaporating a buffer layer and a metal electrode. With the Ag / ZnO core-shell structure nanorod array electrode material fabricated by the method, the efficiency of transmitting charges in a solar cell to an electrode can be substantially improved, the electron-hole recombination rate is effectively reduced, and the photoelectric conversion efficiency is favorably improved; and the fabrication method is simple to operate, is suitable for production on a large scale and is relatively low in production cost, the process is easy to control, and thus, the fabrication method is suitable for industrial protection on a large scale.

Owner:BEIJING INST OF TECH

Method for repairing ternary positive electrode material with deteriorated performance and acquired ternary positive electrode material

ActiveCN110534721ASolve dropSimple processSecondary cellsPositive electrodesOrganic solventUltrasonic dispersion

Owner:CENT SOUTH UNIV

Silicon-based negative electrode material and preparation method thereof, lithium ion battery and electric appliance

InactiveCN112820847AImprove cycle stabilityHigh reversible capacityElectrode thermal treatmentNegative electrodesElectrical batteryCopper foil

The invention discloses a silicon-based negative electrode material and a preparation method thereof, a lithium ion battery and an electric appliance and relates to the technical field of battery electrode material preparation. The preparation method of the silicon-based negative electrode material comprises the following steps: annealing a primary negative electrode material which is obtained by cold spraying and is loaded with a Si-Cu coating on the surface in an inert gas atmosphere at the temperature of 500-800 DEG C, and preserving heat for 7-9 hours. The silicon-based negative electrode material is prepared by the preparation method. The lithium ion battery adopts the silicon-based negative electrode material as a negative electrode. The electric appliance takes the lithium ion battery as a power supply. After the primary negative electrode material of the Si-Cu coating is obtained through cold spraying on the copper foil, the Si-Cu3Si-Cu composite material obtained through annealing treatment at the proper temperature and the proper heat preservation time is used as the negative electrode material of the lithium ion battery and has good cycle stability and reversible capacity.

Owner:GUANGDONG INST OF NEW MATERIALS

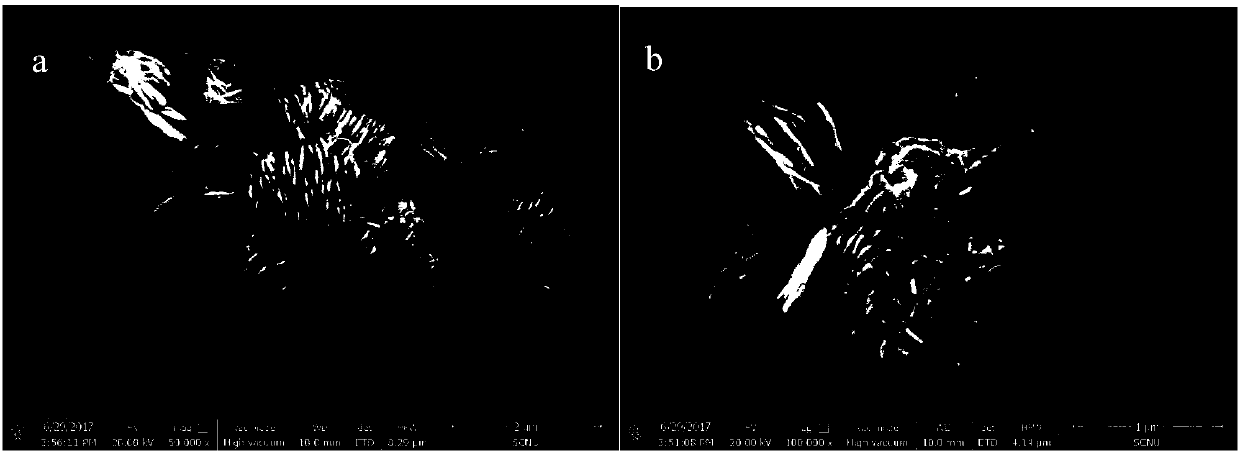

Method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles

ActiveCN112010305AReduce energy consumptionSimple and time-saving operationCarbon compoundsNegative electrodesAl powderArgon atmosphere

The invention relates to a method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles. The method comprises: mixing dried V powder, Ti powder, Al powder, Sn powder and C powder according toa molar ratio of (1.8-1): 1, (0.2-1): (0.2-1): (1-1.5): (0-0.35): (0.85-1.2), grinding in a ball mill, carrying out high-temperature self-propagating synthesis on the obtained powder in an argon atmosphere, so that (V, Ti) 2AlCMAX phase materials are obtained, crushing and grinding the (V, Ti) 2AlCMAX phase materials, carrying out solvent ultrasonic treatment, carrying out standing precipitation on a solution obtained after ultrasonic treatment for 2-5 days, taking an upper-layer solution, and carrying out centrifugation, wherein a lower-layer precipitate comprises (V, Ti) 2AlC submicron sheets, and the supernatant comprises a colloidal solution of (V, Ti) 2AlC nanoparticles. The method is low in energy consumption, safe, environmentally friendly, easy to operate, capable of saving time and low in cost, and the prepared (V, Ti) 2AlC submicron sheets and nanoparticles are suitable for being used as lithium ion battery negative electrode materials.

Owner:YANCHENG INST OF TECH

Electrode material for secondary battery and secondary battery

ActiveUS20190305357A1Improve stabilityLarge capacityCell electrodesLi-accumulatorsEngineeringElectrolyte

Owner:NATIONAL TSING HUA UNIVERSITY

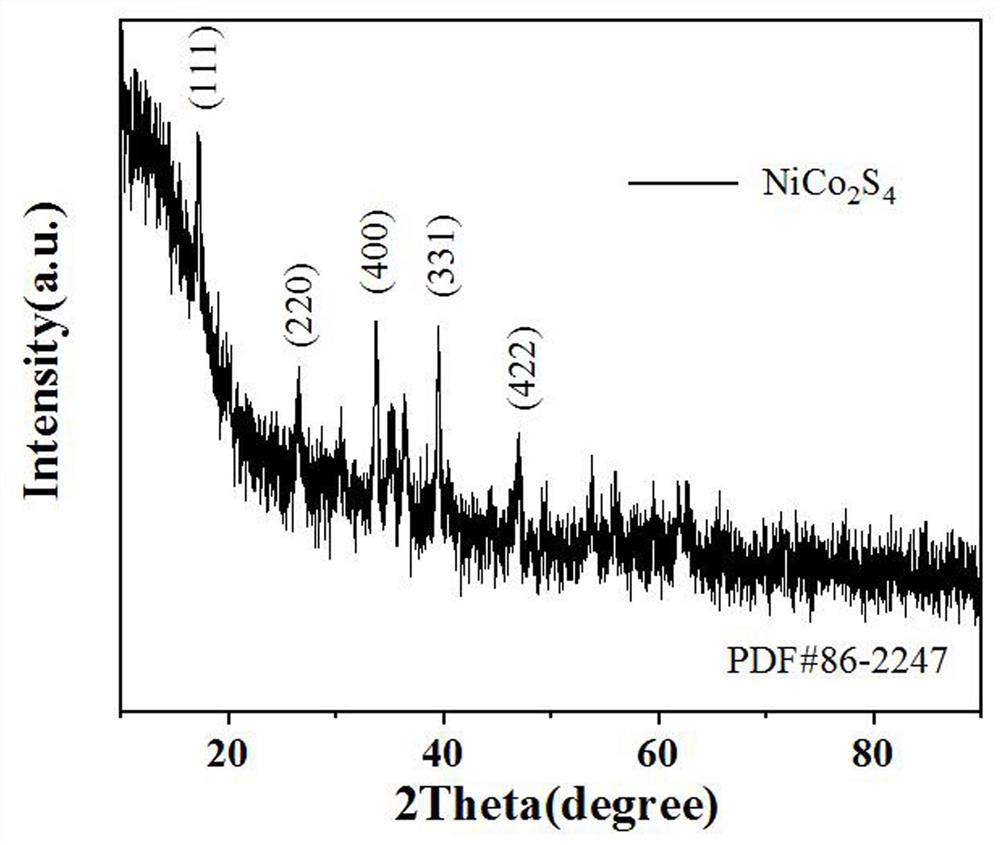

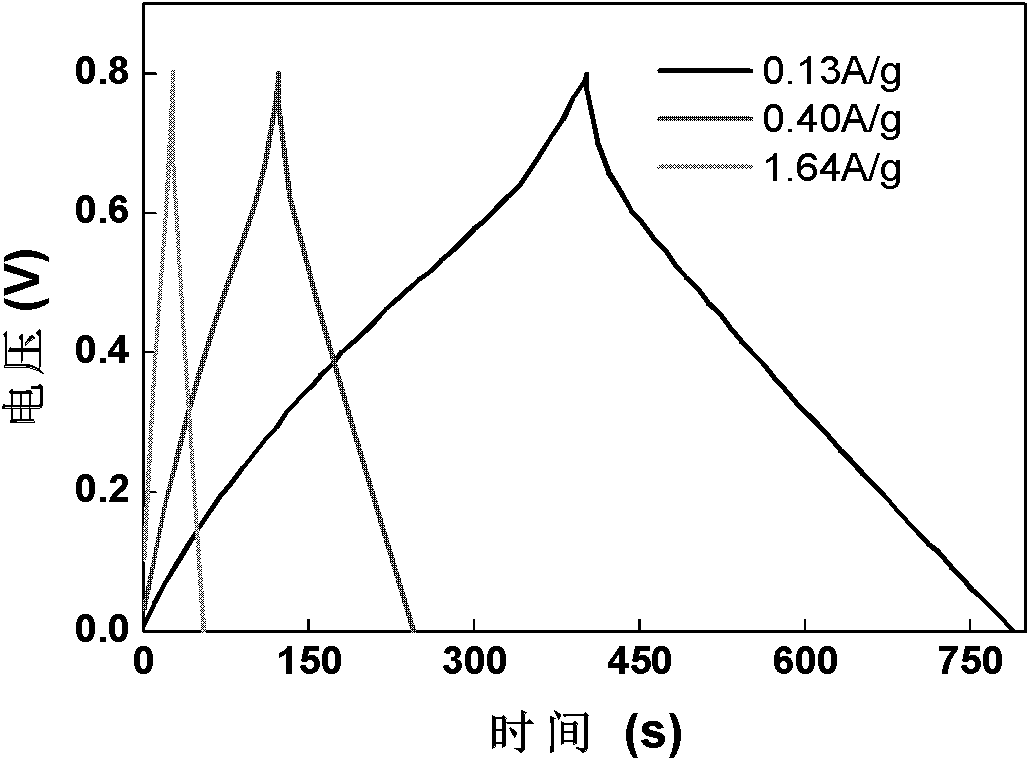

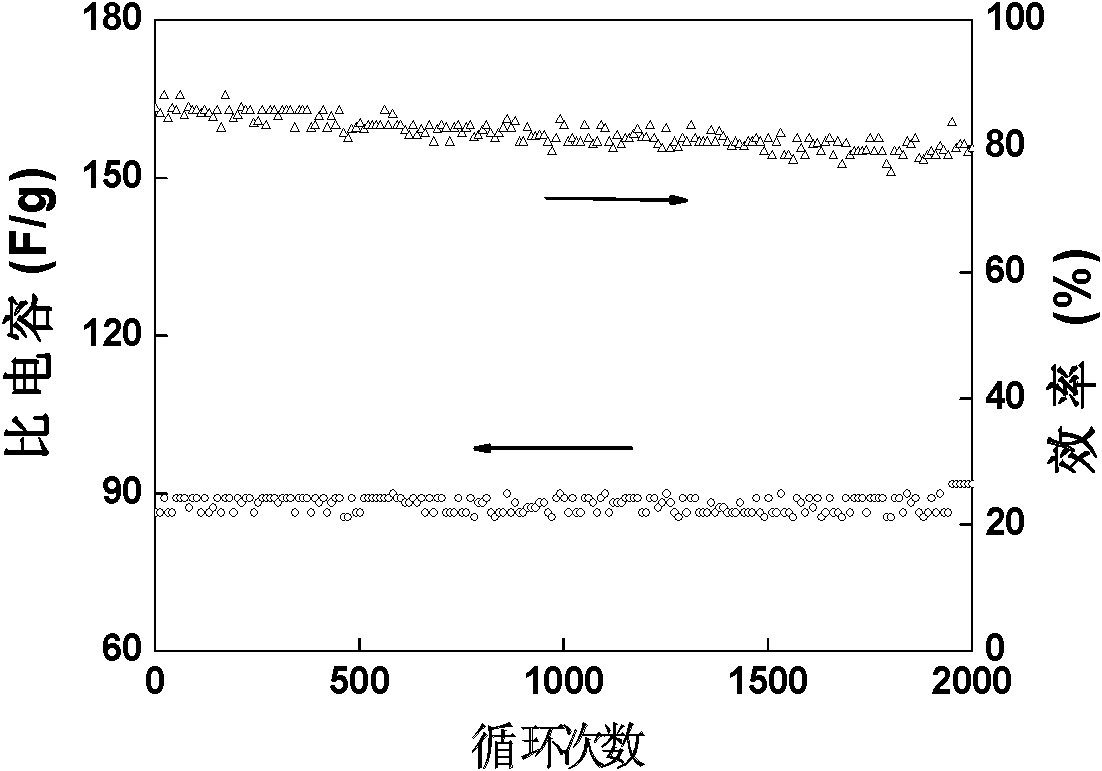

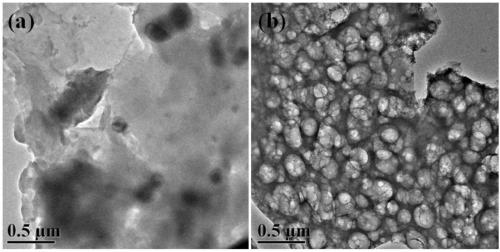

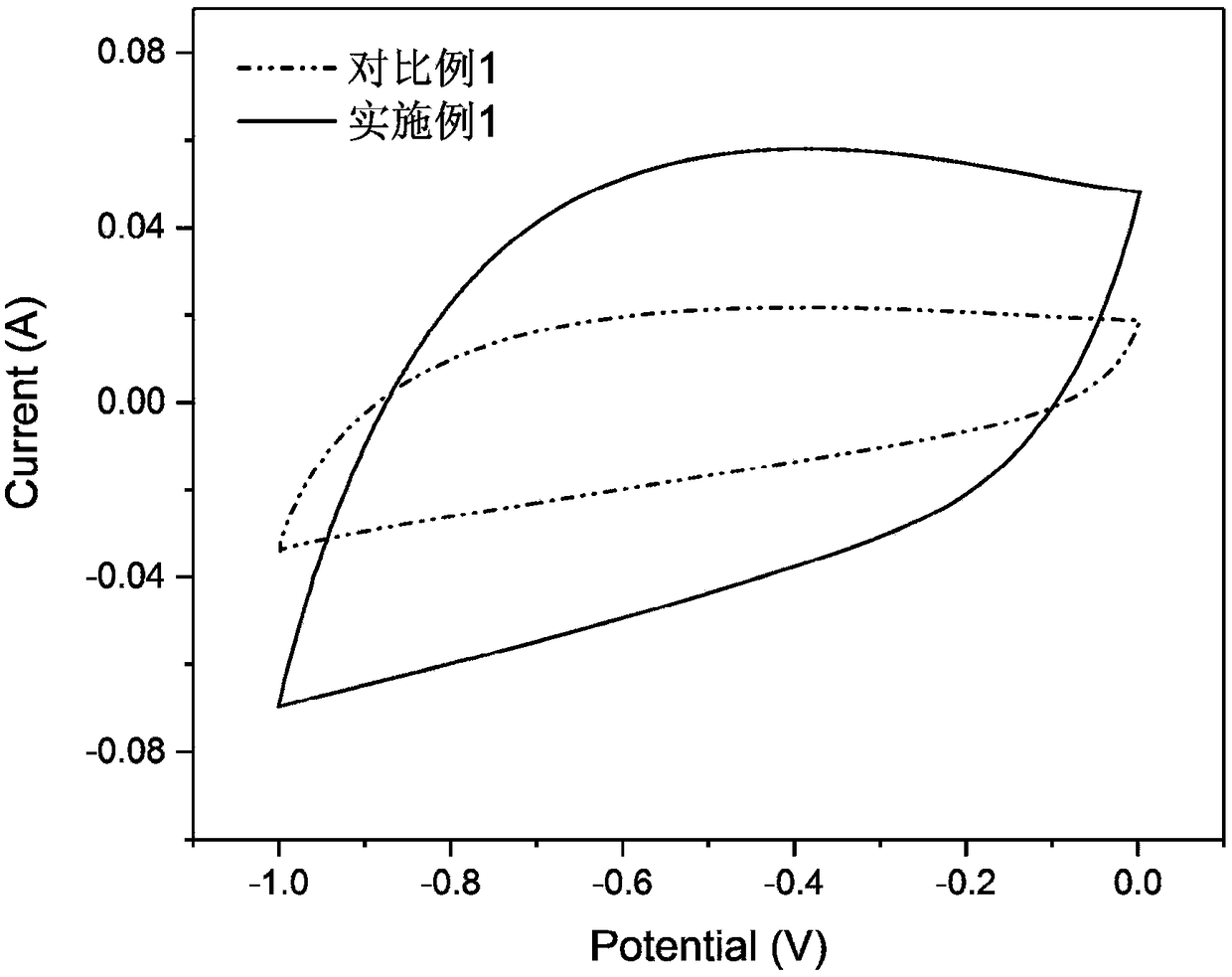

Composite electrode material and preparation method thereof, and super capacitor

PendingCN110970226ALarge specific surface areaHigh specific capacitanceHybrid capacitor electrodesElectrolytic agentCapacitance

Owner:EAST CHINA UNIV OF SCI & TECH

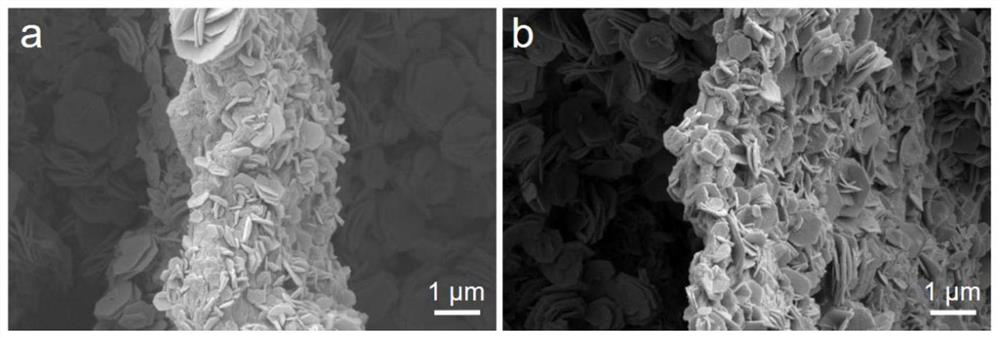

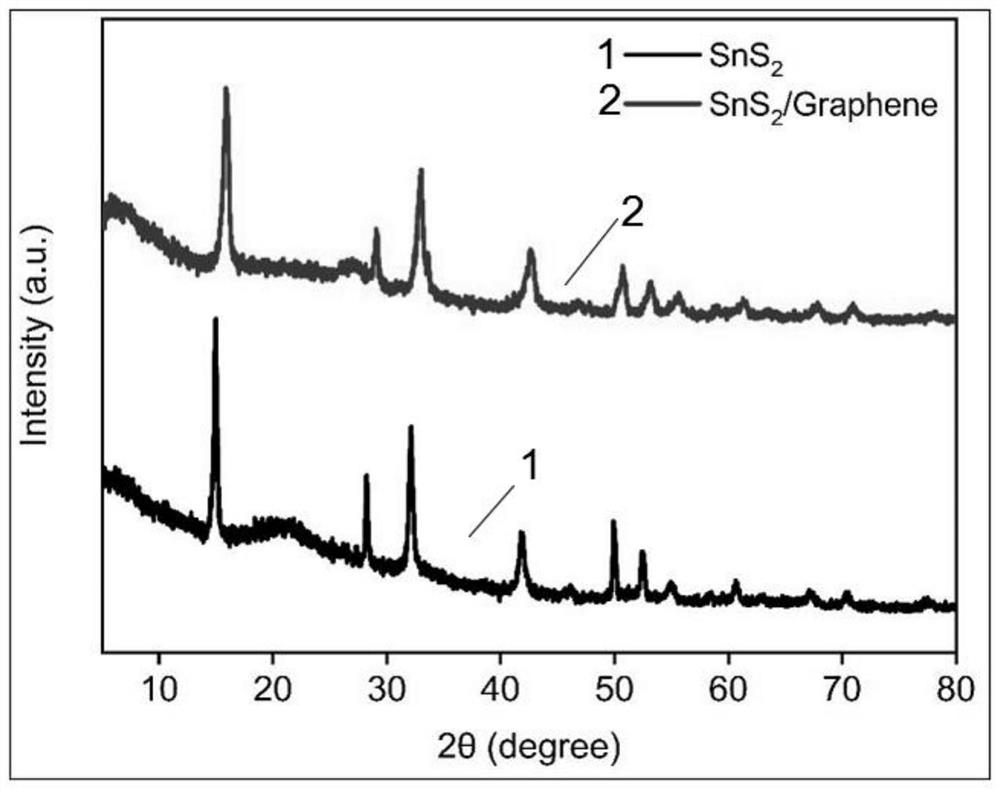

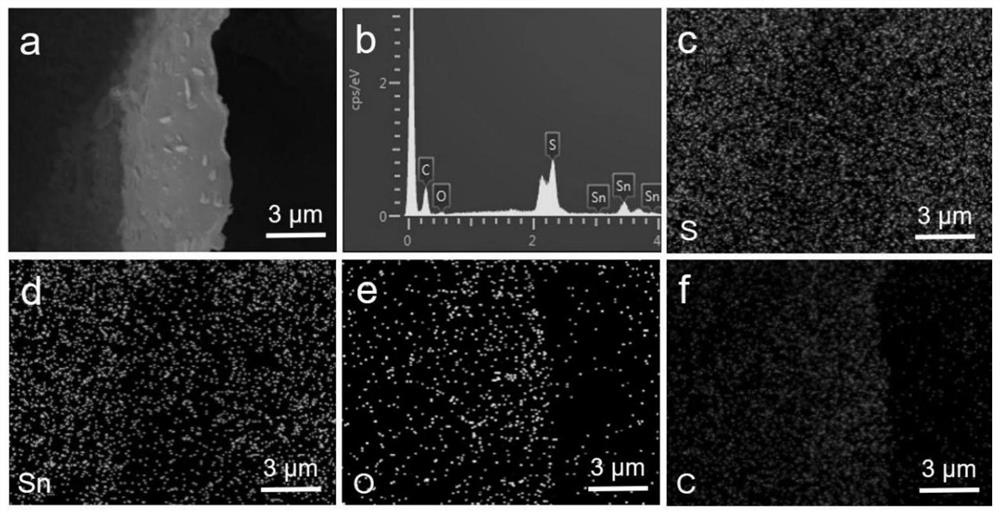

Preparation method of SnS2 nanosheet loaded graphene-based nanocomposite

Owner:安徽光特新材料科技有限公司

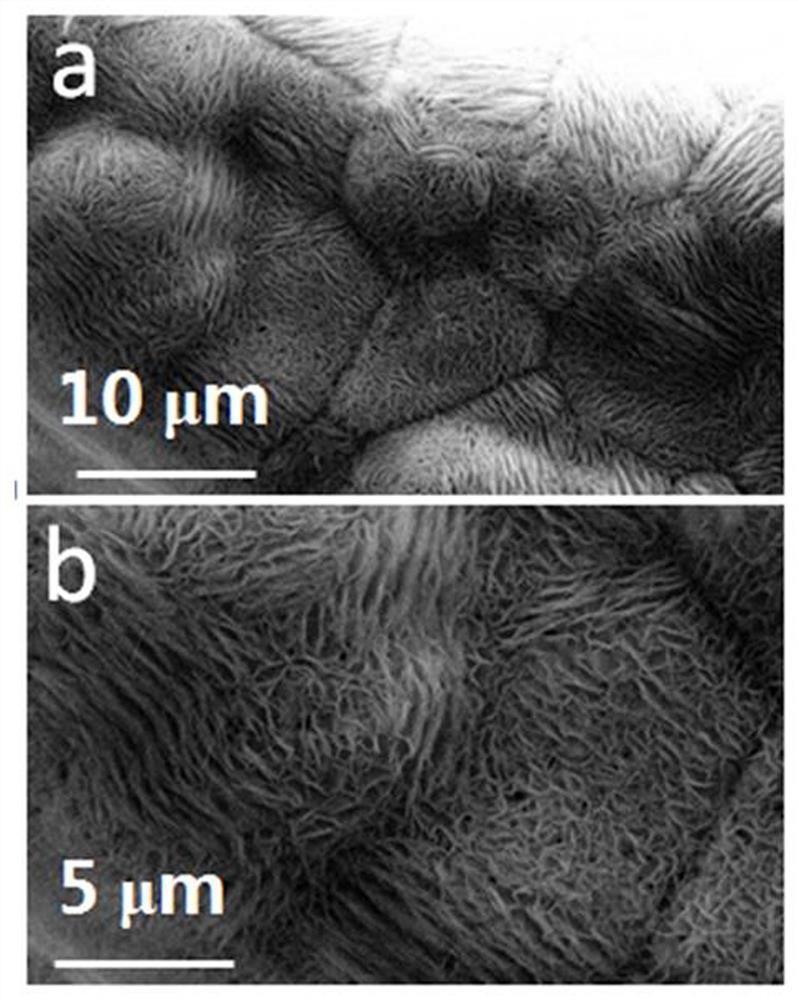

Polypyrrole coated Ni-Co-S nanoneedle array composite material and preparation method and application thereof

ActiveCN111785526AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceConductive polymer

Owner:GUILIN UNIV OF ELECTRONIC TECH

Combined treatment method of waste lithium ion battery black powder

ActiveCN112047335AImprove electrochemical performanceImprove fast charging performanceGraphiteCell electrodesElectrical batteryFast charging

Owner:湖南宸宇富基新能源科技有限公司

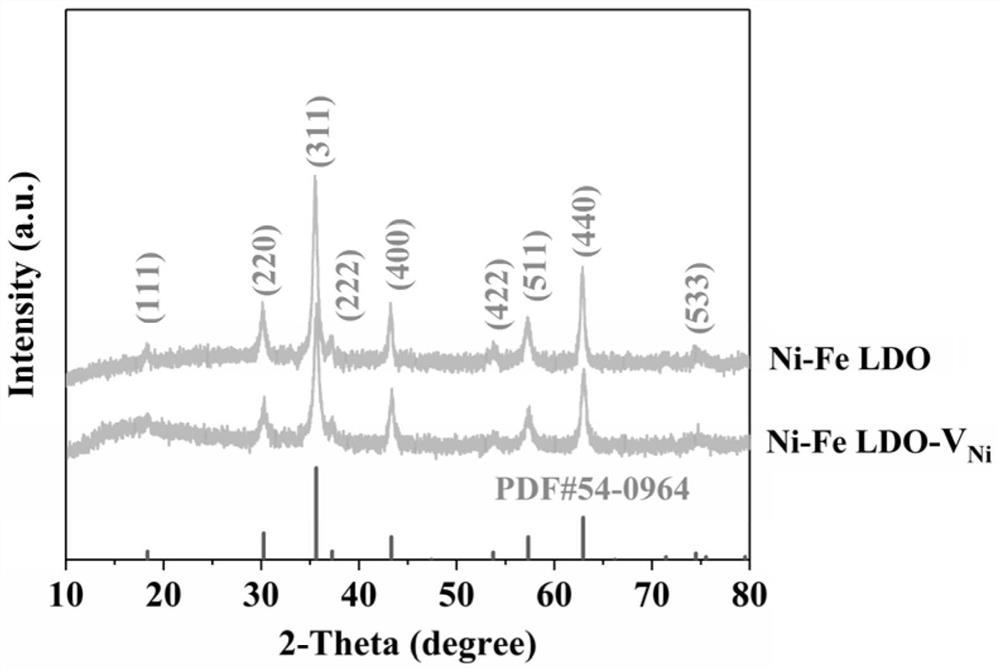

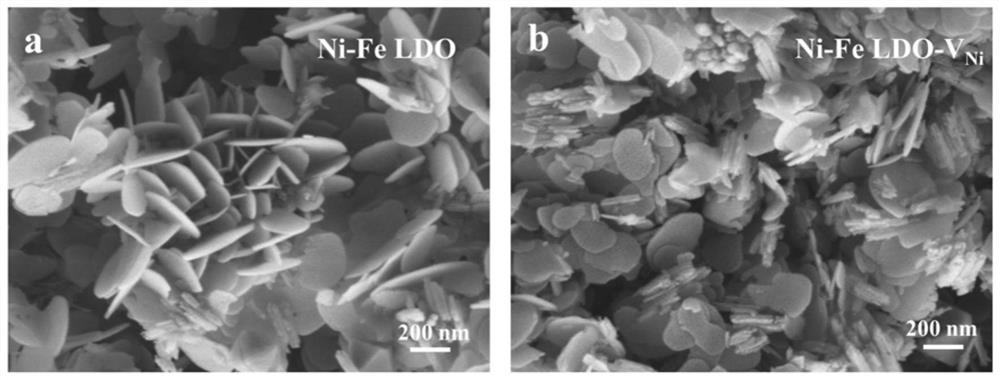

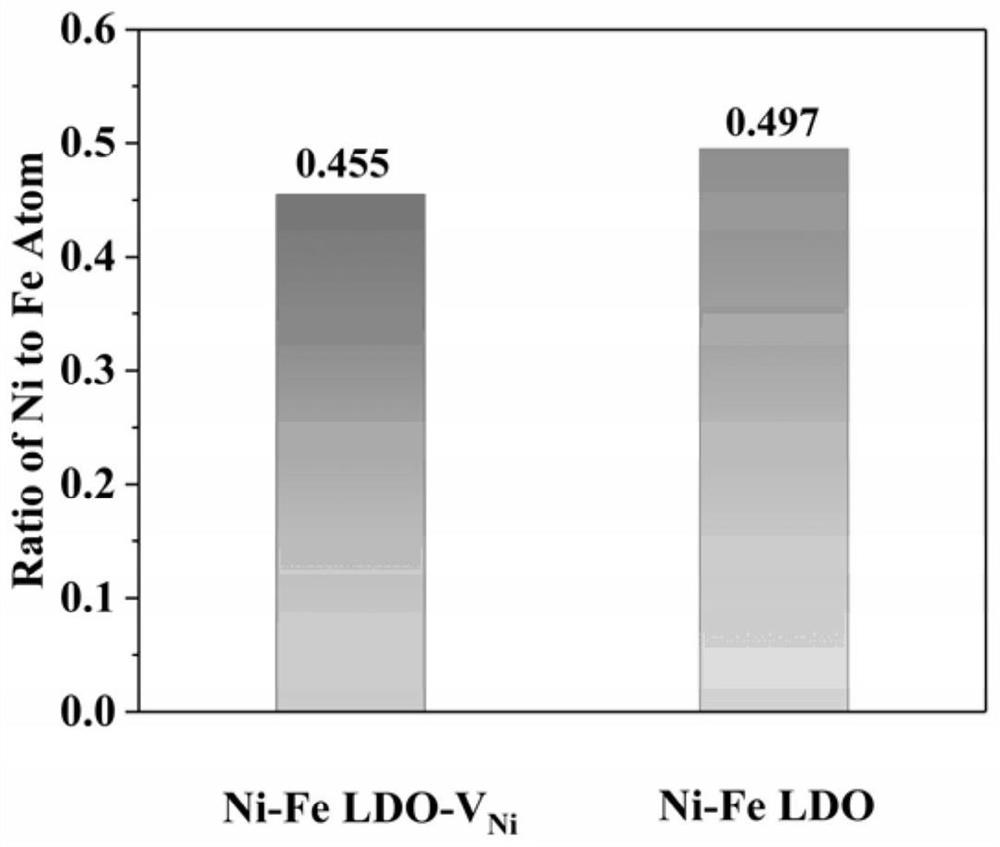

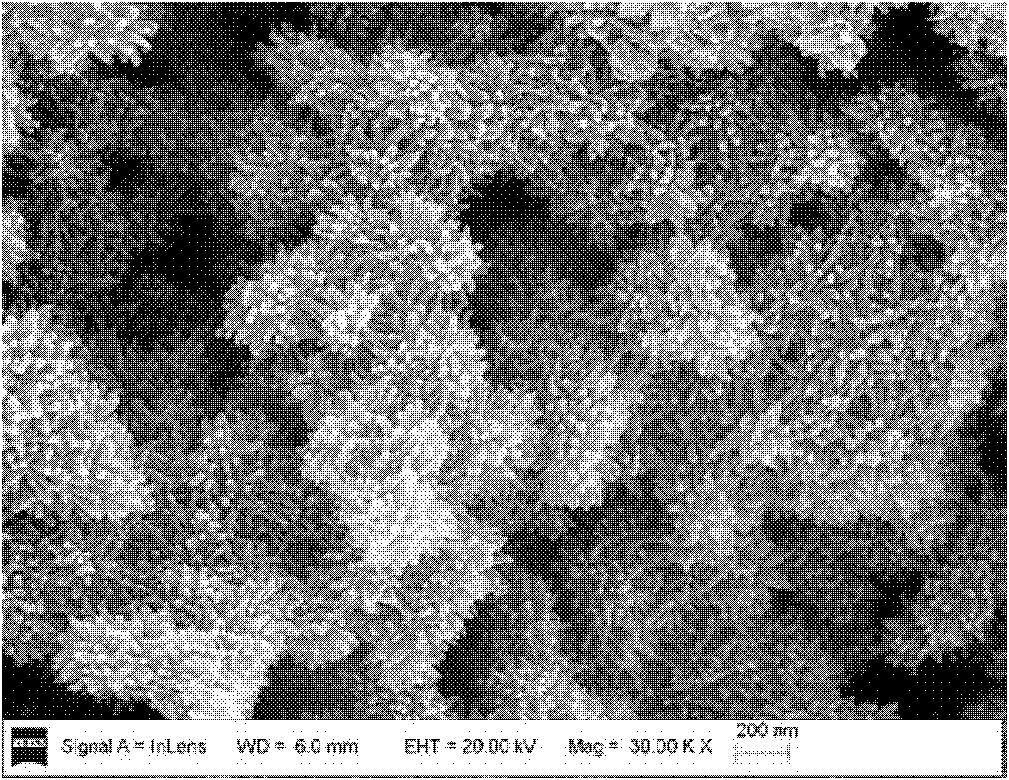

Layered bimetallic oxide negative electrode material and preparation method and application thereof

PendingCN114824331AImprove electrocatalytic activityIncrease working current densityMaterial nanotechnologyCell electrodesHigh current densityElectrical battery

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A preparation method of nanometer metatitanic acid doped polyaniline composite electrode material for supercapacitor

ActiveCN102280265AIncrease capacitance densityIncrease energy densityElectrolytic capacitorsCyclic processCapacitance

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

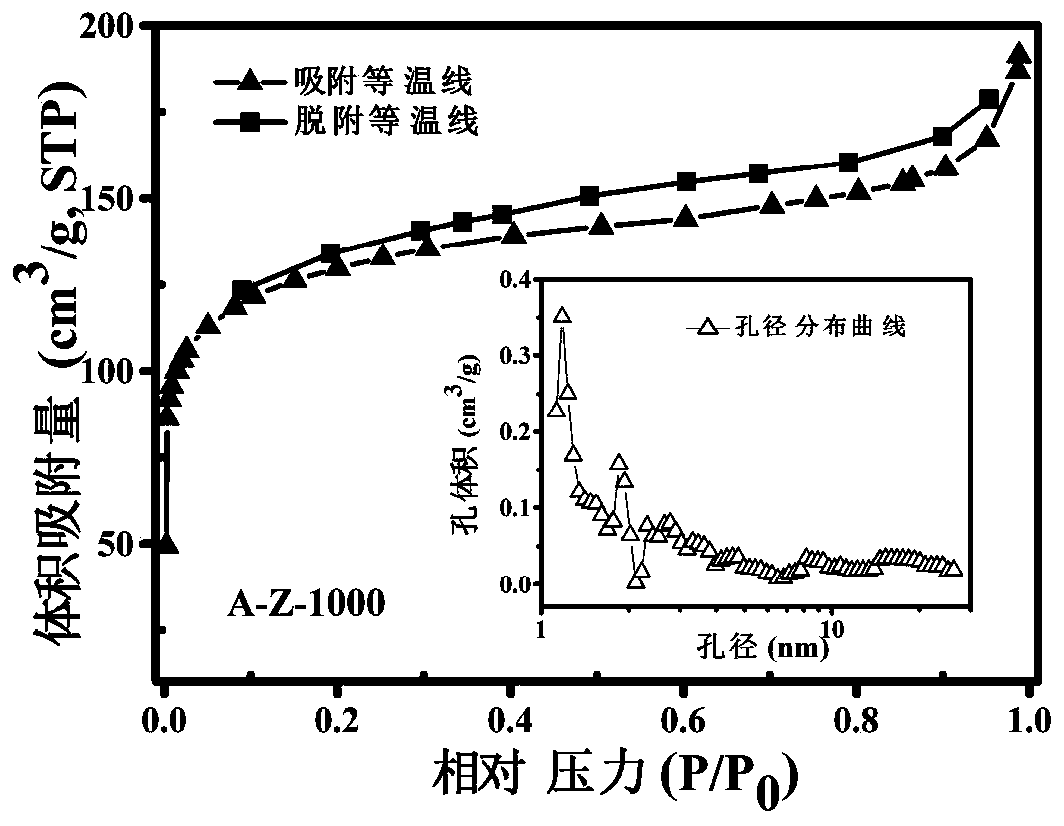

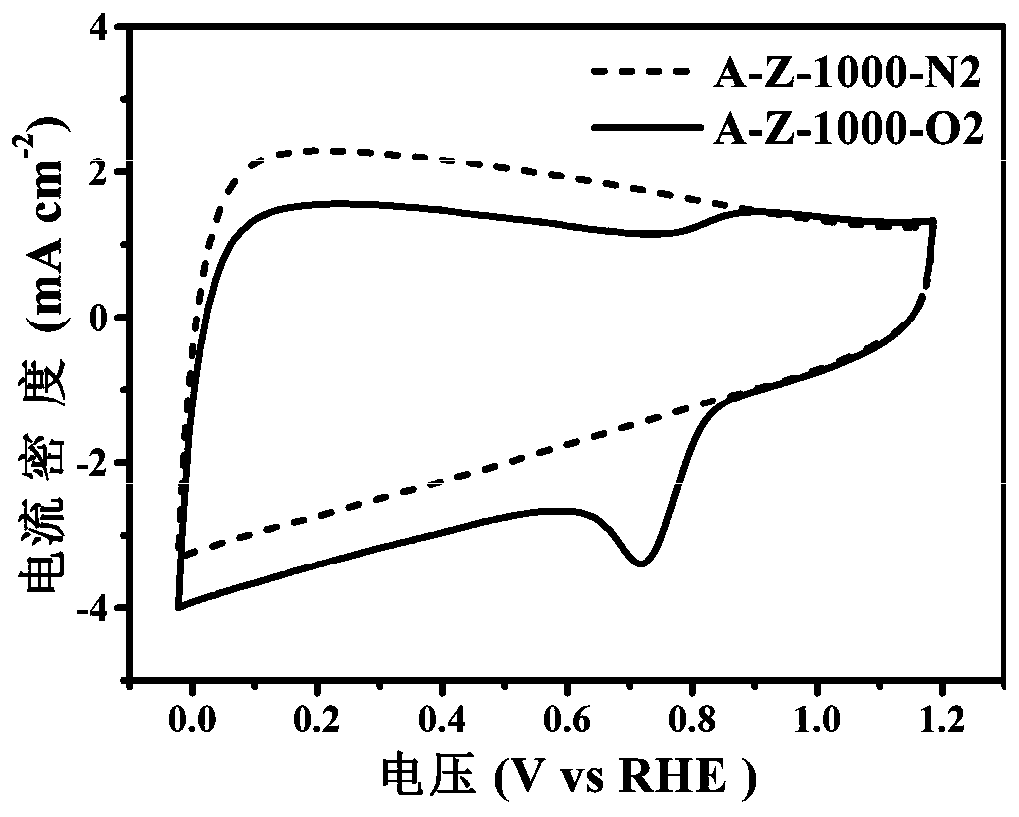

Method for preparing micro-mesoporous carbon anode material from amino acid modified metallic organic framework and application

ActiveCN109745950AIncrease aperture sizeGood effectOther chemical processesCell electrodesPorous carbonCarbonization

Owner:XIANGTAN UNIV

Porous carbon material prepared by using self-modification of pseudomonas putida and preparation method and application thereof

ActiveCN109399604AShorten the growth cycleIncrease added valueHybrid capacitor electrodesCarbon preparation/purificationPorous carbonPseudomonas putida

Owner:CENT SOUTH UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap