All-solid-state lithium ion battery and integrated composite sintering preparation process thereof

A lithium-ion battery, all-solid-state technology, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problem of affecting the electrochemical performance of the battery, affecting the performance of the charge and discharge rate of the battery, the energy density of the battery, and the particle size of the material. The interface contact area is small and other problems, to achieve the effect of enhancing the interface stability and interface transport performance, suitable for large-scale industrial production and application, and the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

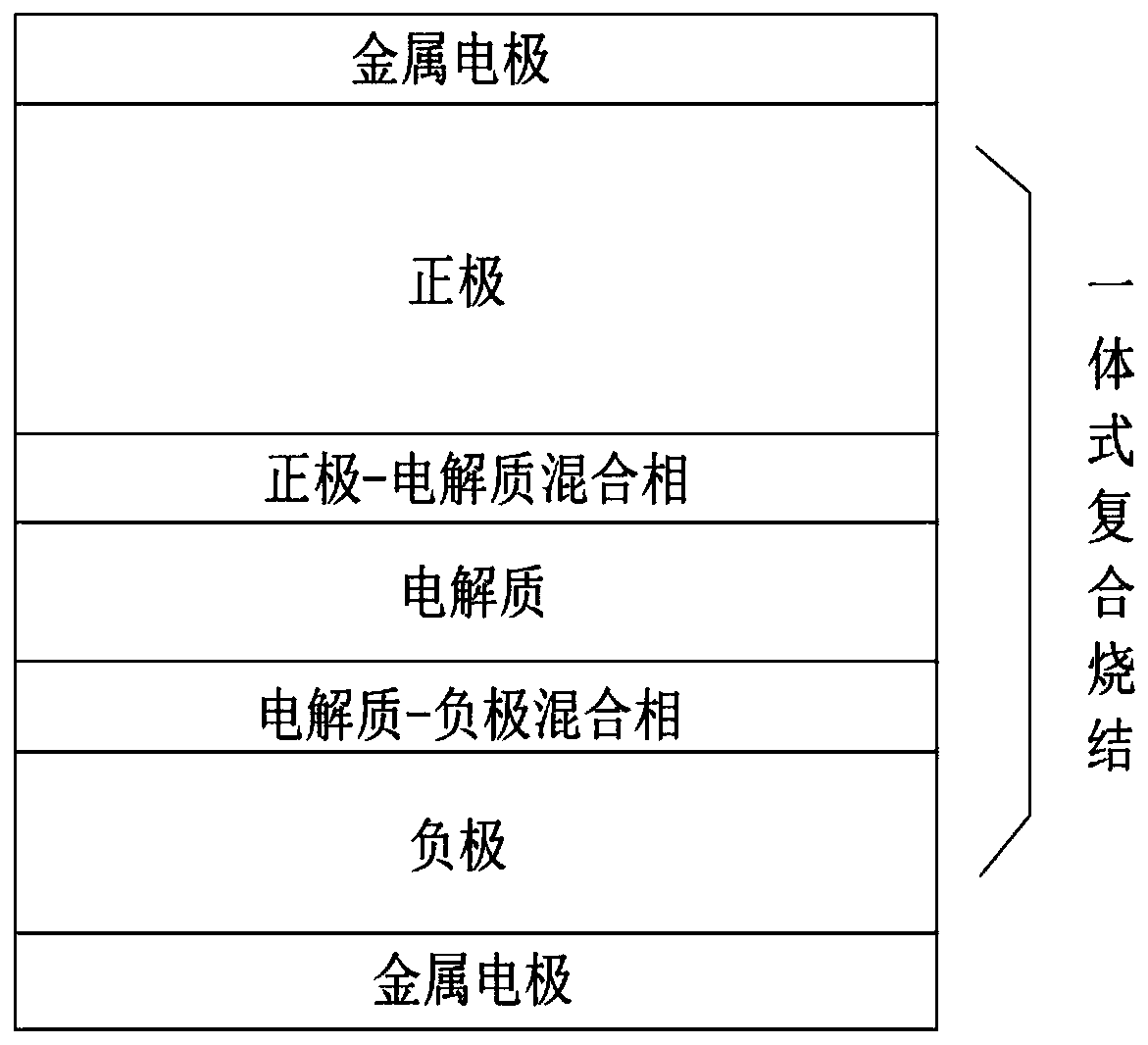

[0028] Such as figure 1 as shown,

[0029] An all-solid-state lithium ion battery provided in this embodiment includes an electrode-electrolyte composite electrode sheet and a metal electrode, the metal electrode is arranged at both ends of the electrode-electrolyte composite electrode sheet, and the electrode-electrolyte composite electrode sheet is composed of Positive electrode / positive electrode-electrolyte mixed phase / electrolyte / electrolyte-negative electrode mixed phase / negative electrode are sequentially superimposed and compacted by cold isostatic pressing, and the negative electrode material is Li 4 Ti 5 o 12 , the cathode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , the electrolyte is Li 0.33 La 0.56 TiO 3 .

Embodiment 2

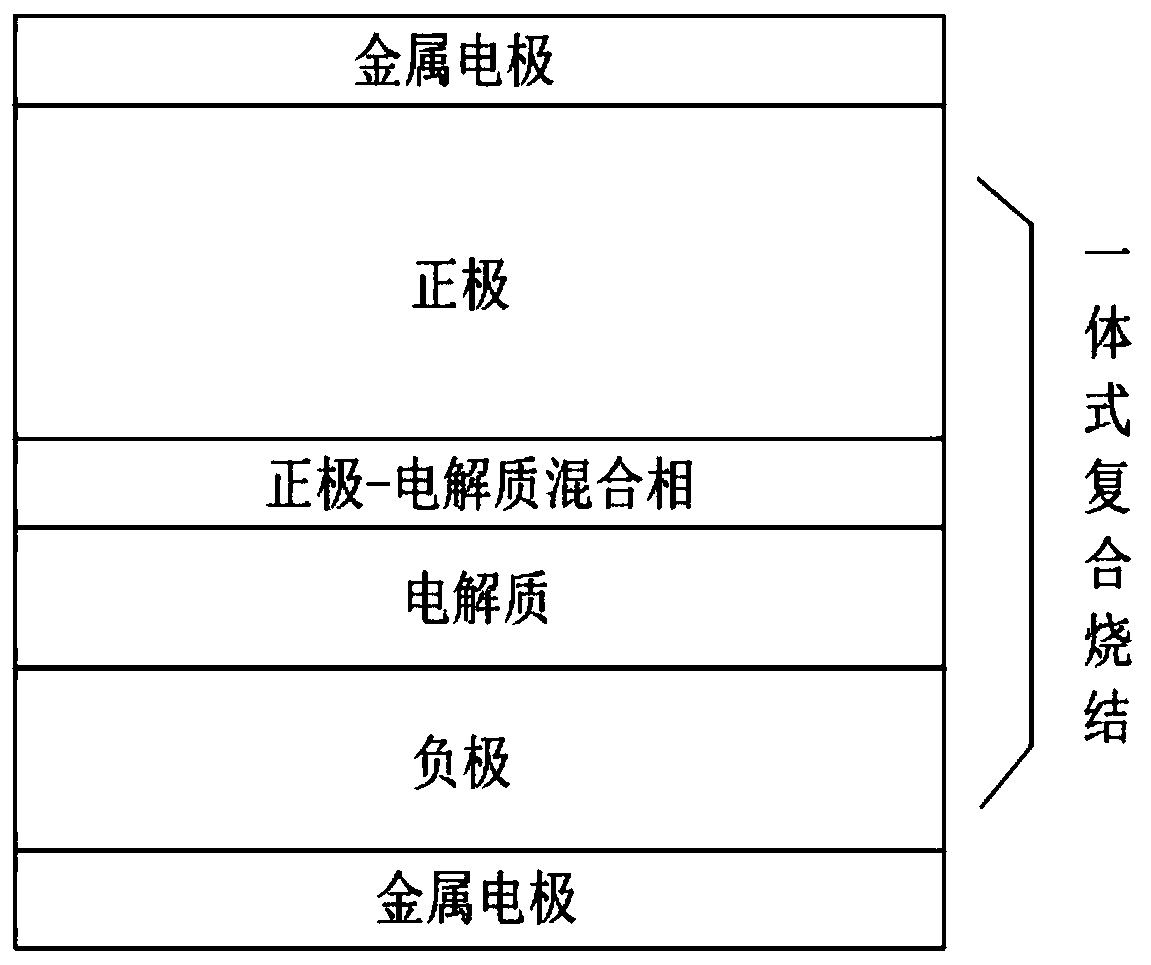

[0031] Such as figure 2 as shown,

[0032] An all-solid-state lithium ion battery provided in this embodiment includes an electrode-electrolyte composite electrode sheet and a metal electrode, the metal electrode is arranged at both ends of the electrode-electrolyte composite electrode sheet, and the electrode-electrolyte composite electrode sheet is composed of Positive electrode / positive electrode-electrolyte mixed phase / electrolyte / negative electrode are sequentially stacked and compacted by cold isostatic pressing. The negative electrode material is a non-oxide, which is a silicon-carbon composite material in this implementation, and the positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , the electrolyte is Li 7 La 3 Zr 2 o 12 .

Embodiment 3

[0034] An all-solid-state lithium ion battery provided in this embodiment includes an electrode-electrolyte composite electrode sheet and a metal electrode, the metal electrode is arranged at both ends of the electrode-electrolyte composite electrode sheet, and the electrode-electrolyte composite electrode sheet is composed of Positive electrode / positive electrode-electrolyte mixed phase / electrolyte / electrolyte-negative electrode mixed phase / negative electrode are sequentially superimposed and compacted by cold isostatic pressing, and the negative electrode material is Li 4 Ti 5 o 12 , the cathode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , the electrolyte is Li 7 La 3 Zr 2 o 12 .

[0035] The content that is not described in detail in the present invention can adopt the prior art, so it will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap