Battery positive electrode composite pole piece, preparation method thereof and solid-state battery comprising battery positive electrode composite pole piece

A battery positive electrode, solid electrolyte technology, applied in battery electrodes, positive electrodes, secondary batteries and other directions, can solve problems such as being unsuitable for large-scale industrialization and application, complex operation procedures, etc., and achieve mass production, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

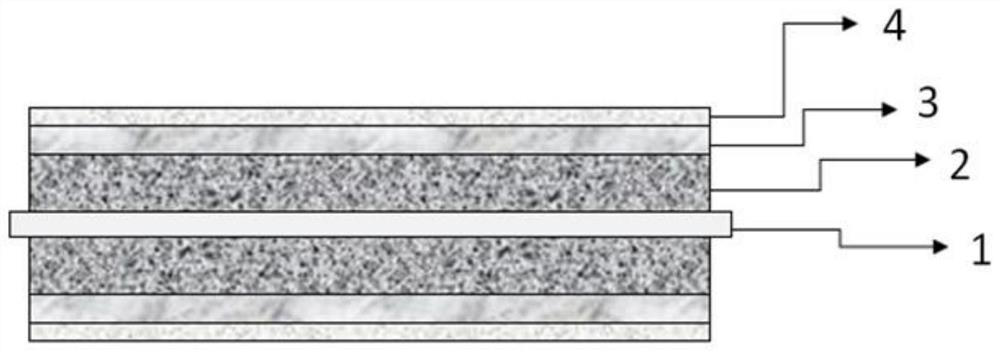

[0094] This embodiment provides a battery positive composite pole piece, the battery positive composite pole piece includes an aluminum layer, and a composite active material layer, a solid electrolyte layer and a polymer lithium salt that are sequentially stacked from opposite sides of the aluminum layer Floor. The thickness of the composite active material layer is 100 μm, including polyvinylidene fluoride, lithium hexafluoroarsenate, lithium cobaltate, polyacrylonitrile and carbon fiber; the lithium hexafluoroarsenate and lithium cobaltate in the composite active material layer The mass ratio is 5:85; the mass proportion of carbon fiber in the composite active material layer is 3%; the mass proportion of polyvinylidene fluoride in the composite active material layer is 5%; the polyvinylidene fluoride in the composite active material layer The mass proportion of acrylonitrile is 2%; the thickness of the solid electrolyte layer is 40 μm, including polyvinylidene fluoride, lithiu

Embodiment 2

[0105] This embodiment provides a battery positive composite pole piece, the battery positive composite pole piece includes an aluminum layer, and a composite active material layer, a solid electrolyte layer and a polymer lithium salt that are sequentially stacked from opposite sides of the aluminum layer Floor. The thickness of the composite active material layer is 50 μm, including polyethylene oxide, lithium bisfluorosulfonimide, lithium nickel manganese oxide, polyacrylonitrile and graphene; the lithium bisfluorosulfonimide in the composite active material layer The mass ratio of lithium nickel manganese oxide is 8.4:80; the mass proportion of graphene in the composite active material layer is 1%; the mass proportion of polyethylene oxide in the composite active material layer is 5.6%; the The mass proportion of polyacrylonitrile in the composite active material layer is 5%; the thickness of the solid electrolyte layer is 20 μm, including polyethylene oxide, lithium bisfluoro

Embodiment 3

[0114] This embodiment provides a battery positive composite pole piece, the battery positive composite pole piece includes an aluminum layer, and a composite active material layer, a solid electrolyte layer and a polymer lithium salt that are sequentially stacked from opposite sides of the aluminum layer Floor. The thickness of the composite active material layer is 200 μm, including polyacrylonitrile, lithium tetrafluoroborate, lithium iron phosphate, polyvinylidene fluoride and carbon nanotubes; in the composite active material layer, lithium tetrafluoroborate and lithium iron phosphate The mass ratio is 1.1:81; the mass proportion of carbon nanotubes in the composite active material layer is 5%; the mass proportion of polyacrylonitrile in the composite active material layer is 9.9%; The mass proportion of polyvinylidene fluoride is 3%; the thickness of the solid electrolyte layer is 60 μm, including polyacrylonitrile, lithium tetrafluoroborate and aluminum oxide; the mass rat

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap