Display substrate and manufacturing method thereof, and display device

A technology for a display substrate and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve the problems of increasing the frame of OLED devices, unfavorable narrow frame of OLED devices, and reducing the yield of OLED devices, etc. Achieve the effect of reducing the frame, improving the yield, and avoiding short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following detailed description will be given in conjunction with the accompanying drawings and specific embodiments.

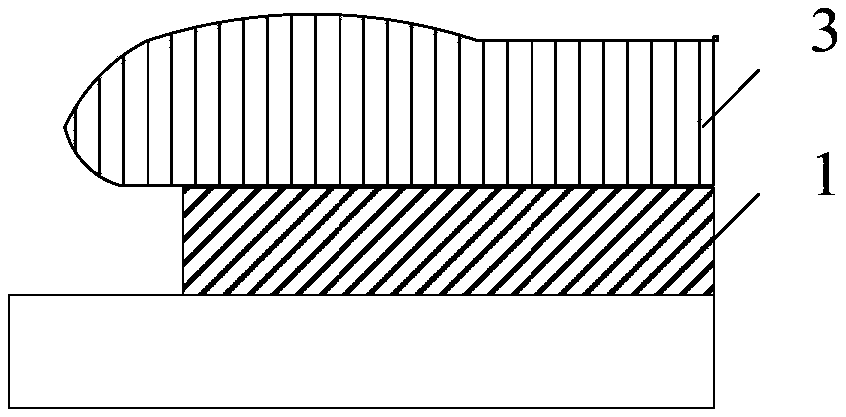

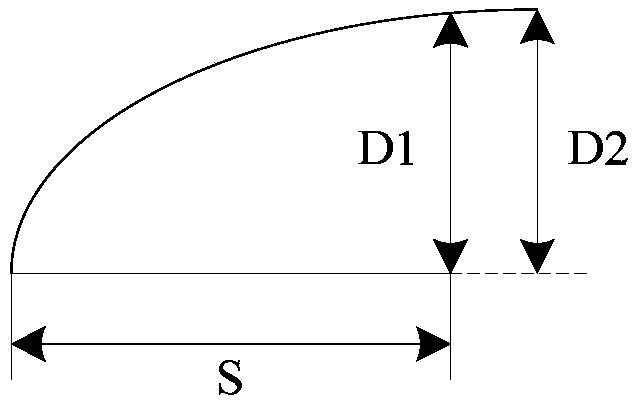

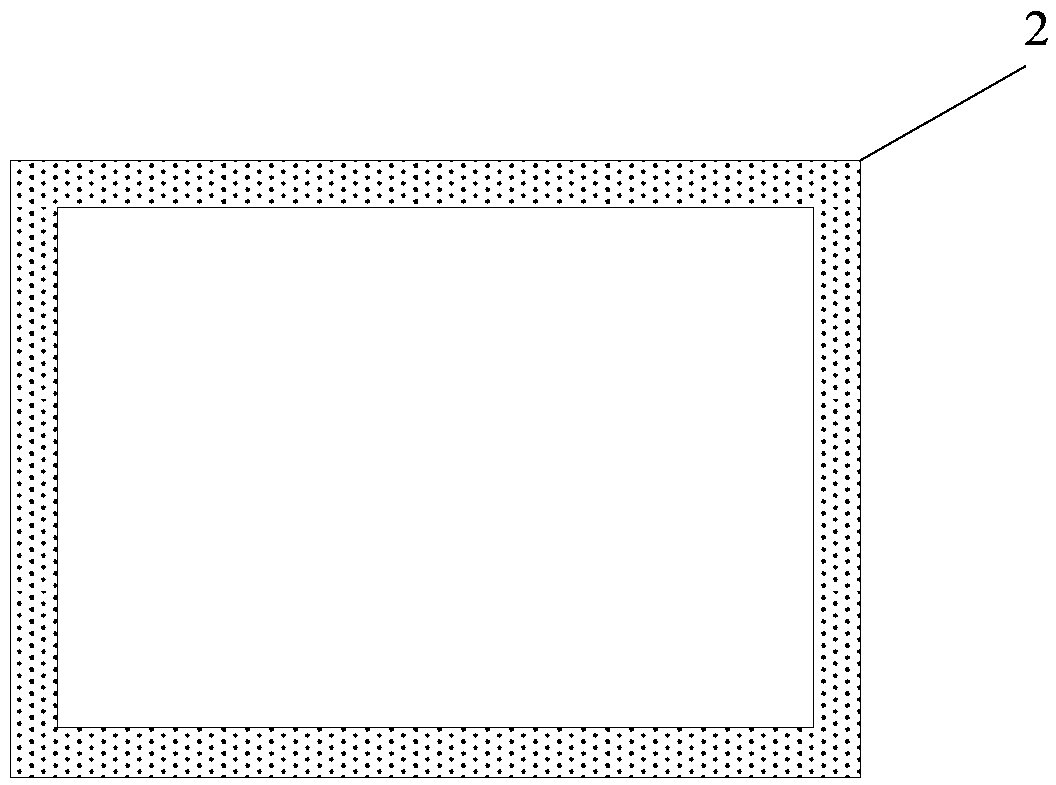

[0036] The embodiments of the present invention are aimed at preparing the cathode in the prior art, the cathode formed by sputtering often exceeds the display area, on the one hand, short circuit is prone to occur, which reduces the yield of the OLED device; on the other hand, the frame of the OLED device becomes larger. , which is not conducive to the realization of the narrow frame of the OLED device, and provides a display substrate, a manufacturing method thereof, and a display device, which can improve the yield of the display substrate and at the same time facilitate the realization of the narrow frame of the display device.

[0037] Embodiments of the present invention provide a method for fabricating a di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap