Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Improve yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for casting rotary axis casts of aerogenerators

ActiveCN101618425AImprove yieldReduce manufacturing costFoundry mouldsFoundry coresMetallurgyBlock effect

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove water resistanceImproves breakage resistanceFluid removalBreakage rateResin coating

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

Compressed flame retardant section bar

InactiveCN102922583AReduce manufacturing costImprove yieldWood compressionWood layered productsChemistryPolymer chemistry

Owner:张新宇 +4

Method for processing two-dimensional code on laser film

InactiveCN104318855AImprove yieldSimple processDuplicating/marking methodsIdentification meansCompound aHot-melt adhesive

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Plate tapping equipment

ActiveCN104647465AImprove processing efficiencyImprove yieldDrilling machinesMetal working apparatusCamConical surface

Owner:XINGHUA GUANGFU METAL PROD

Automatic sealing equipment for medical children capsules

PendingCN114084442AImprove work efficiencyImprove yieldWrapper twisting/gatheringEngineeringHeater Rod

Owner:陈永娴

Dual-side SiP three-dimensional package structure

ActiveCN107768349AImprove high frequency performanceImprove yieldSemiconductor devicesSemiconductor/solid-state device detailsElectromagnetic interferenceElectromagnetic shielding

Owner:JCET GROUP CO LTD

Method for producing cold-rolled steel strip used for high-carbon saw blade

Owner:ANGANG STEEL CO LTD

Preparation method of refining agent for melting aluminum alloy section doped with plant ash

Owner:邹学千

Copper pin automatic inlaying and inserting device

ActiveCN105846285AFacilitate subsequent installationImprove yieldContact member assembly/disassemblyCopperElectrical and Electronics engineering

Owner:深圳华阳华科技有限公司

Organic light-emitting display device and manufacturing method thereof

ActiveCN103928493AImprove yieldSemiconductor devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Wiring structure, display substrate and display device

ActiveCN106971671AGuaranteed yieldImprove yieldDigital data processing detailsIdentification meansDisplay device

Owner:BOE TECH GRP CO LTD +1

Forging method of nickel base alloy containing copper and nickel base alloy containing copper

ActiveCN104741494AImprove plasticityAvoid defects such as cracking and scrappingMetal-working apparatusIngotHeating furnace

The invention provides a forging method of nickel base alloy containing copper and the nickel base alloy containing copper and belongs to the technical field of forging technologies. The forging method overcomes the defects that because copper is added to the nickel base alloy, the hot working character is poor, and forge cracking is caused, and the yield can be effectively improved. The forging method comprises the steps of conducting billet forging, wherein preprocessed nickel base alloy ingots containing copper are placed in a heating furnace, the nickel base alloy ingots containing copper are heated to the temperature T1, the temperature T1 is kept, forging is conducted according to the forging ratio y1, so that forging stocks are obtained, the temperature T1 is 1120+ / -10 DEG C, and y1 is smaller than or equal to 1.4; conducting initial forming, wherein the forging stocks are arranged in the heating furnace to be heated, the temperature is kept, and forged pieces which are initially formed are obtained through forging; conducting final forging, wherein the initially formed forged pieces are arranged in the heating furnace to be heated to the temperature T3, the temperature T3 is kept, forging is conducted according to the forging ratio y3, so that finished forged pieces are obtained, the temperature T3 is higher than 1000 DEG C and lower than 1080+ / -10 DEG C, and y3 is larger than 1.5 and smaller than 2. The forging method can be used for forging of the nickel base alloy containing copper.

Owner:ENN ENVIROTECH CO LTD

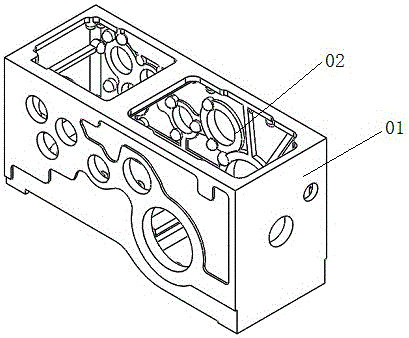

Manufacturing method of tractor transmission blank

InactiveCN106270387AImprove yieldRealize automated productionFoundry coresFoundry mouldsAgricultural machineryManufacturing engineering

Owner:李向阳

Optical waveguide lens overlapping structure and manufacturing method thereof

InactiveCN112965254AParallelism of lifting surfaceGuaranteed thicknessOptical elementsAdhesiveUltraviolet lights

The invention discloses an optical waveguide lens overlapping structure and a manufacturing method thereof, wherein the optical waveguide lens overlapping structure comprises a first lens and a second lens which are overlapped, and an ultraviolet light curing adhesive layer is clamped between the first lens and the second lens; and the ultraviolet light curing adhesive layer comprises a base adhesive and particles filled in the base adhesive, and the ultraviolet light curing adhesive layer is used for bonding the first lens and the second lens. According to the technical scheme, the surface parallelism of the optical waveguide lens overlapping structure is good, and the reduction contrast performance is good.

Owner:GOERTEK INC

Sagger with high-yield for lithium battery cathode material and manufacturing method thereof

The invention discloses a sagger with high-yield for a lithium battery cathode material. The sagger comprises a sagger body and a protective coating, wherein the sagger body comprises: 50-70% of mullite, 10-30% of alpha-alumina, 5-15% of an organic metal salt, and 1-5% of a binder; and the protective coating comprises: 30-40% of silicon carbide coarse powder, 30-40% of silicon carbide fine powder,10-20% of polyacrylate, 1-10% of methanol, and 0.1-0.5% of attapulgite. A manufacturing method of the sagger comprises the following steps: weighing the raw materials constituting the sagger body, and adding water to form a slurry; placing the slurry in a mold, and performing press-forming to obtain a blank material; performing demoulding on the blank material after curing to obtain a blank body,and oven-drying the blank body after demoulding and then performing firing to obtain the sagger body; weighing the raw materials of the protective coating, and adding water to form a coating; covering the coating on the inner surface of the sagger body, and performing natural drying; and performing firing. The disclosed sagger for the lithium battery cathode material has high yield, high servicelife and corrosion resistance.

Owner:HUNAN TAIZI NEW MATERIAL TECH CO LTD

Method for preparing mechanical coating powder through slurry coating, heating and curing

ActiveCN111496246AImprove yieldShort preparation timeMetal-working apparatusTransportation and packagingAero engineCeramic materials

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

UV curing adhesive glue, solar reflective strip and solar reflective strip seamless film connecting production process

ActiveCN111440585AGood weather resistanceImprove yieldPhotovoltaic energy generationPolyureas/polyurethane adhesivesAcrylic acidAcrylic resin

Owner:NINGBO EXCITON TECH

Production method for 5182 aluminum alloy cover base material

InactiveCN105618482AAvoid poor lubricationImprove yieldMetal rolling arrangementsRoll speed control deviceAluminium alloyContinuous rolling

Owner:SHANDONG NANSHAN ALUMINUM

Miniature microphone and manufacturing method of miniature microphone

InactiveCN111770423AHigh sensitivityImprove yieldMicrophonesSemiconductor electrostatic transducersParasitic capacitorEngineering

The invention discloses a miniature microphone and a manufacturing method of the miniature microphone. The miniature microphone comprises a substrate which comprises a first cavity; a first sacrificial layer which is located on the substrate, wherein the first sacrificial layer comprises a second cavity; a vibrating diaphragm layer of which at least one part is supported by the first sacrificial layer, wherein the vibrating diaphragm layer located above the second cavity forms a vibrating diaphragm; a second sacrificial layer which is located on the vibrating diaphragm layer, wherein the second sacrificial layer comprises a third cavity; a back polar plate layer which is located on the second sacrificial layer of which at least one part is supported by the second sacrificial layer, whereinthe back polar plate layer located above the third cavity forms a back polar plate, and the back polar plate comprises at least one sound hole; a first passivation layer which is located between thevibrating diaphragm layer and the back polar plate layer, wherein the first passivation layer surrounds the inner side wall of the second sacrificial layer. According to the miniature microphone provided by the embodiment of the invention, the parasitic capacitance is reduced, and the problem of adverse influence of process deviation on the device performance is solved.

Owner:HANGZHOU SILAN MULTICHIP CO LTD

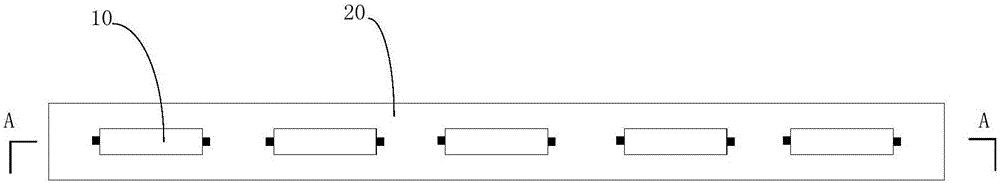

Packaging device, LED lamp strip, backlight module, display device and packaging method

InactiveCN106298750AAvoid leaningImprove yieldElectric lightingPrinted circuit non-printed electric components associationConvex structureDisplay device

Owner:BOE TECH GRP CO LTD +1

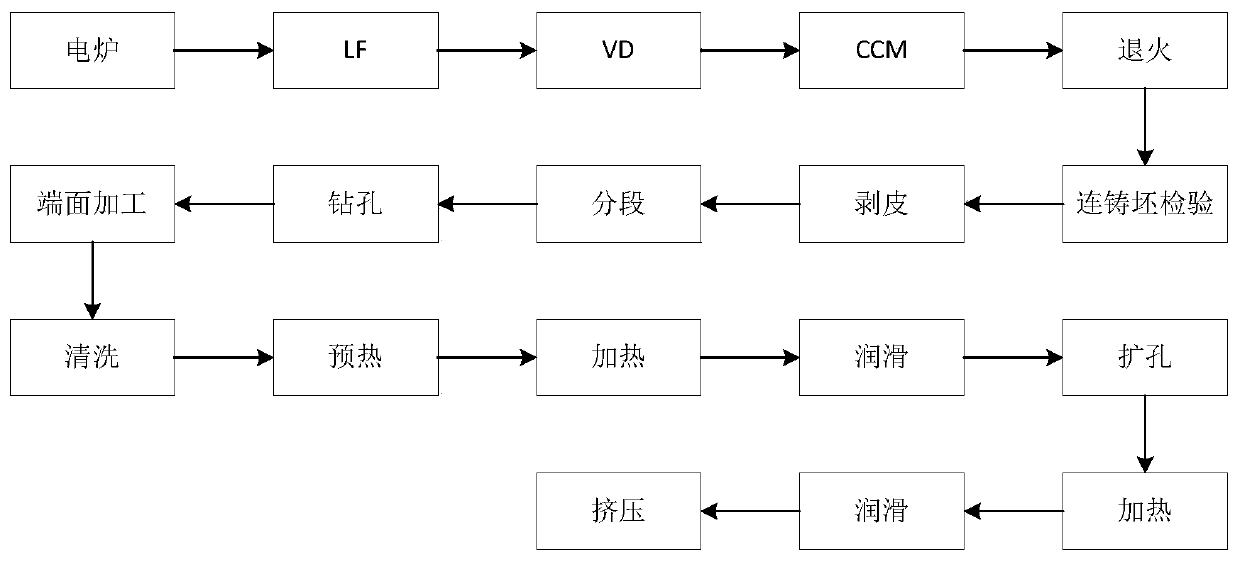

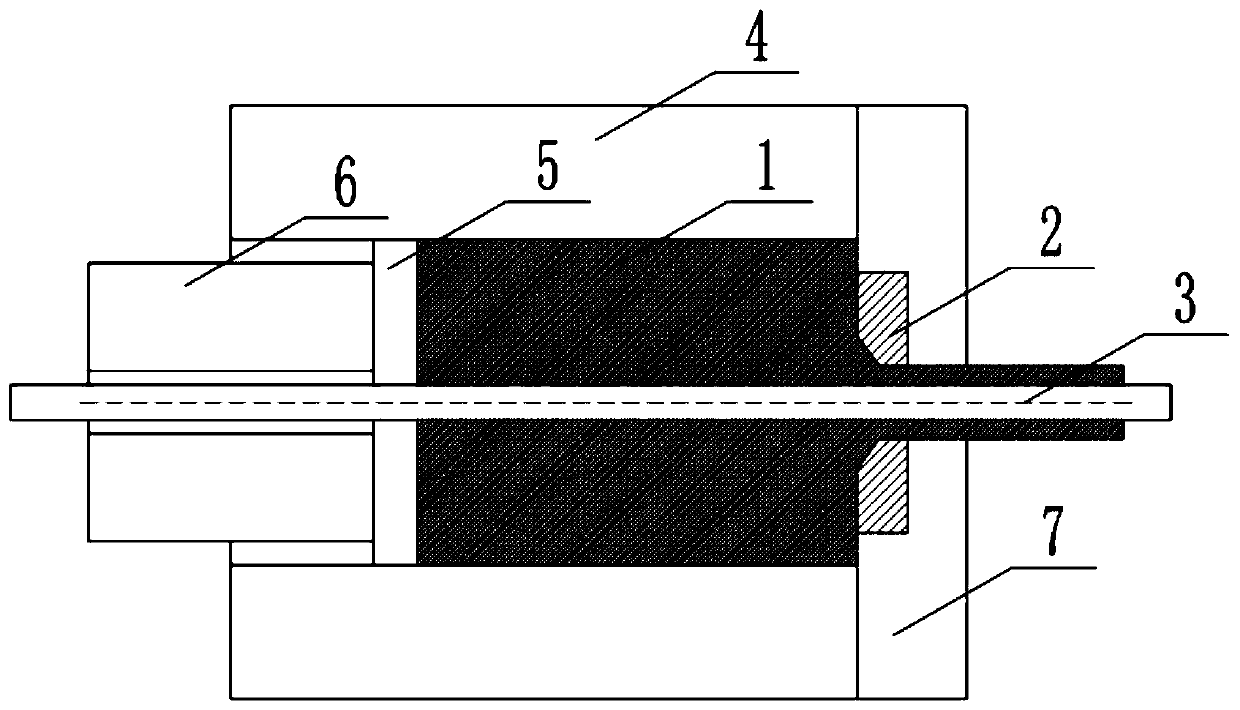

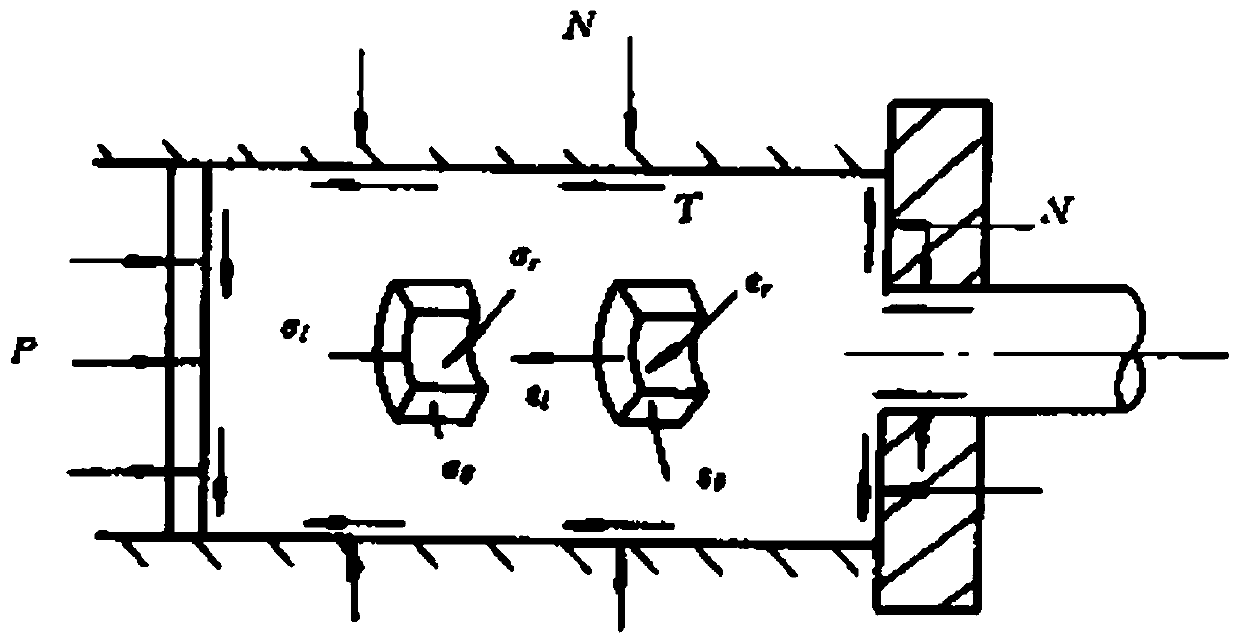

Method for manufacturing martensitic stainless steel continuous casting billet extruded seamless pipe

Owner:江阴华润制钢有限公司

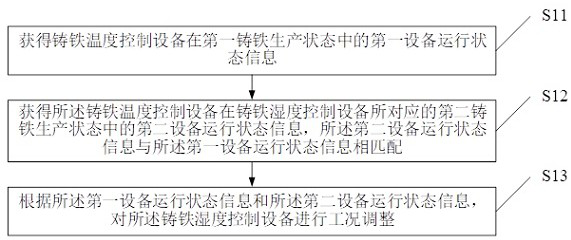

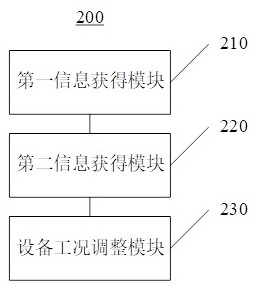

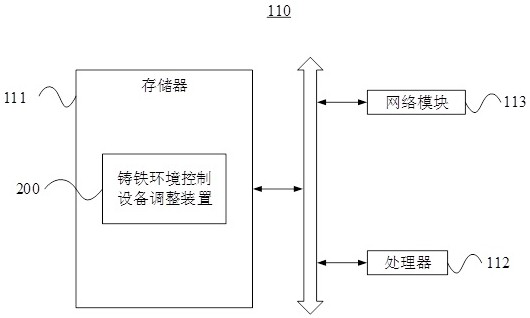

Cast iron environment control equipment adjusting method and device

InactiveCN112181033AImprove yieldSimultaneous control of multiple variablesProcess engineeringCast iron

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Automatic COF coil punching device

InactiveCN109109089ARealize automatic punchingImprove yieldCleaning using toolsCleaning using gasesPunchingEngineering

The invention provides an automatic COF coil punching device. The automatic COF coil punching device comprises a COF material strip, a rack, a cabinet and a UPS, and is characterized by further comprising a new material wheel, a protective film recycling wheel, a waste recycling wheel, ratchet wheels, a punching mechanism and a plurality of guide wheels, wherein the two ratchet wheels are vertically arranged on the portion, between the new feeding wheel and the protective film recycling wheel, of the rack; the punching mechanism is arranged between the two ratchet wheels; the punching mechanism comprises a mounting block, a Z-direction servo motor, a screw rod, a horizontal correction block, a finished product box and a punching die; the mounting block is vertically arranged on the rack; the Z-direction servo motor is vertically arranged on the mounting block; one end of the screw rod is connected with the output end of the Z-direction servo motor; the other end of the screw rod penetrates through a supporting block of the punching die; the other end of the screw rod and the supporting block of the punching die form a screw rod transmission structure; the horizontal correction block is horizontally connected to the rack and is rectangular; the punching die penetrates through the horizontal correction block and can move in the vertical direction through the screw rod transmission structure; and the finished product box is arranged below the punching die.

Owner:ZHEJIANG SEMIPEAK TECH CO LTD

Short-process decarburization process of powdered rock phosphate for yellow phosphorus production

ActiveCN104261367AEnvironmental safety risk reductionImprove yieldPhosphorus compoundsAdhesiveChemistry

Owner:YUNNAN TIANAN CHEM CO LTD

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

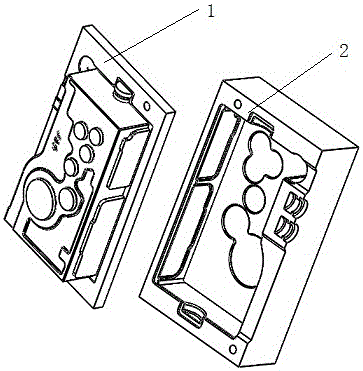

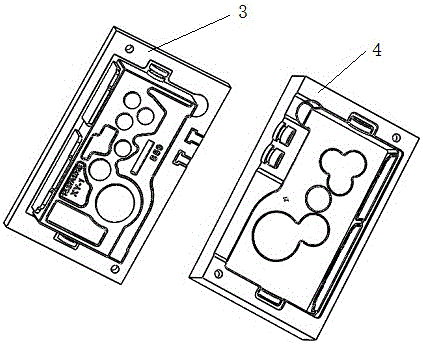

Rapid forming mold for resin-based wax pattern

ActiveCN107538662AAchieve shockAvoid premature coolingFoundry moulding apparatusRapid prototypingLost-wax casting

The invention relates to the field of lost wax casting, in particular to a rapid forming mold for a resin-based wax pattern. The rapid forming mold comprises an upper mold shell, a lower mold shell, an upper mold body, a lower mold body, casting tubes, vibration modules, a turnover module, heating modules and a controller; the left end of the upper mold shell and the left end of the lower mold shell are hinged together through a hinge pin; the upper mold body and the lower mold body are located inside the upper mold shell and the lower mold shell correspondingly and are elastically connected to the upper mold shell and the lower mold shell correspondingly through the vibration modules; the upper mold body and the lower mold body are connected through connecting pieces in a sealed mode; thevibration modules can vibrate the upper mold body and the lower mold body under the action of the turnover module; the turnover module can shake the upper mold body and the lower mold body; the two casting pipes are arranged, are connected to the upper mold body and the lower mold body separately in a threaded mold and penetrates upwards or downwards out of the upper mould shell or the lower mould shell; and the heating modules are arranged on the inner wall of the upper mold shell and the inner wall of the lower mold shell. The rapid forming mold has the advantages that air in the complex mold can be discharged, and the pattern forming rate can be effectively increased.

Owner:QINGDAO HISWELL ENVIRONMENTAL PROTECTION TECH CO LTD

Antibacterial anti-glare glass and preparation method thereof

InactiveCN108439815AImproved anti-glare performanceUniform thicknessCoatingsUltraviolet lightsSpray coating

An antibacterial anti-glare glass includes glass and an antibacterial anti-glare layer coating the surface of the glass. The antibacterial anti-glare layer includes an anti-glare material comprising 1-2 mass% of nano TiO2. In the antibacterial anti-glare glass, the glass is coated with the antibacterial anti-glare layer formed by the anti-glare material comprising nano TiO2, wherein the TiO2 is harmless to human body and can be activated to perform a reaction under a weak ultraviolet light, thus killing bacteria. The glass has effects of sterilization, antifouling, deodorization and self-cleaning; meanwhile, the antibacterial anti-glare glass has excellent anti-glare effect. The invention also provides a preparation method for the antibacterial anti-glare glass by the steps of: bombardingsurface of the glass by plasma to activate the surface, and spray-coating the activated surface of the glass with the antibacterial anti-glare material; then curing the coating to form the antibacterial anti-glare glass. The preparation method is simple in operation, is high in yield and is environment-friendly.

Owner:HENAN ZHUOJIN PHOTOELECTRIC TECH CO LTD

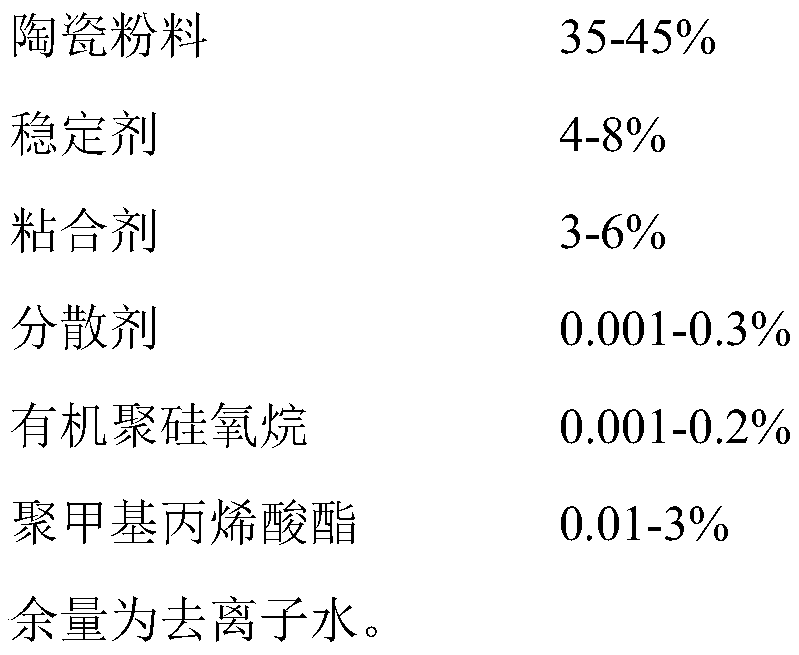

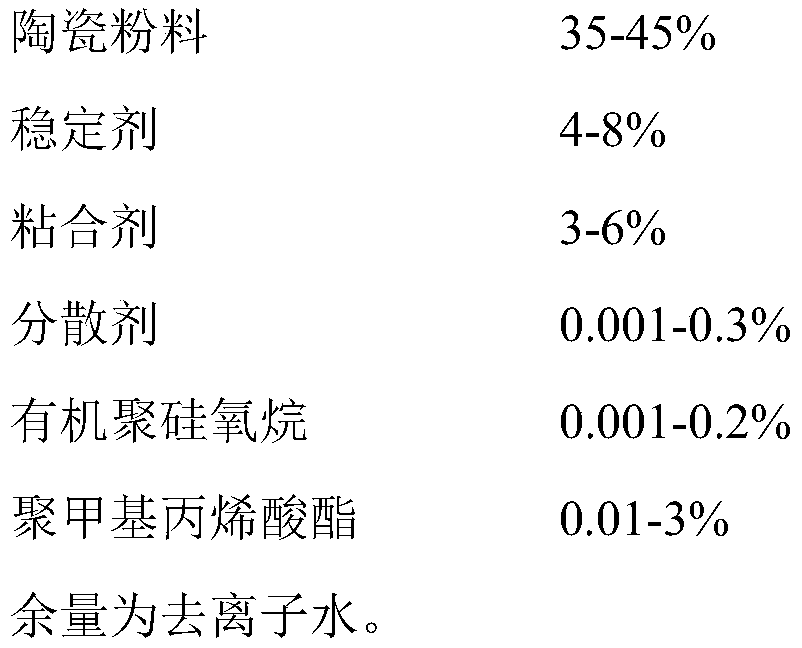

Preparation and applications of ultralow-water-content ceramic slurry for lithium ion battery

ActiveCN110643207AImprove yieldReduce surface tensionCell component detailsCoatingsLithium electrodeAdhesive

Owner:DONGGUAN ADVANCED ELECTRONICS TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap