Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Good mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast aluminum alloy high in thermal conductivity

Owner:天津凯鑫程铝业股份有限公司

Method for preparing high-performance regenerated aluminum alloy with target components from waste aluminum

ActiveCN112921194ABroad market application prospectsGood mechanical propertiesProcess efficiency improvementAluminium alloyIron removal

Owner:佛山市辰辉金属科技有限公司

Electrolyte for manufacturing electrolyte copper foil and application of electrolyte

PendingCN114182310AEasy to operateGood mechanical propertiesElectroforming processesAlkyl sulfonateAlkylbenzenes

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Polymer cement waterproof coating and preparation method thereof

InactiveCN109554054AExcellent tensile bond strength and elongation at breakGood mechanical propertiesCoatingsAcrylic acidCalcium carbonate

Owner:东联北方科技(北京)有限公司

Tungsten-cobalt-nickel alloy and preparation method and application thereof

InactiveCN111763869AEliminate porosity and shrinkageGood mechanical propertiesCobalt nickel alloyElectrode

Owner:UNIV OF SCI & TECH BEIJING

Method for adsorbing uranyl ions

ActiveCN108404888AGood mechanical propertiesHigh adsorption capacityOther chemical processesRadioactive decontaminationAcrylonitrileFiber

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Epoxy resin composition with high elongation at break and high temperature resistance

Owner:WELLS ADVANCED MATERIALS SHANGHAI

Metal plate strip production method for forming U-shaped material through continuous extrusion and flattening U-shaped material on line

Owner:大连康丰科技有限公司

High-strength heat-resistant concrete and preparation method thereof

Owner:西安新意达建筑制品有限公司

Nail-like-graphite-free nodular cast iron for wind power equipment and preparation method thereof

ActiveCN113106326AGood mechanical propertiesGuaranteed physical propertiesFoundry coresFoundry mouldsDuctile ironMold filling

Owner:宁波明凌科技有限公司

Method for preparing 316 stainless steel complex thin-wall pipeline through selective laser melting forming technology

InactiveCN106493365AGood digital-to-model consistencyGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceSelective laser melting

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

Dealcoholized silicone rubber sealant

ActiveCN106957631AGood flexibilityGood mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilicone sealantMoisture

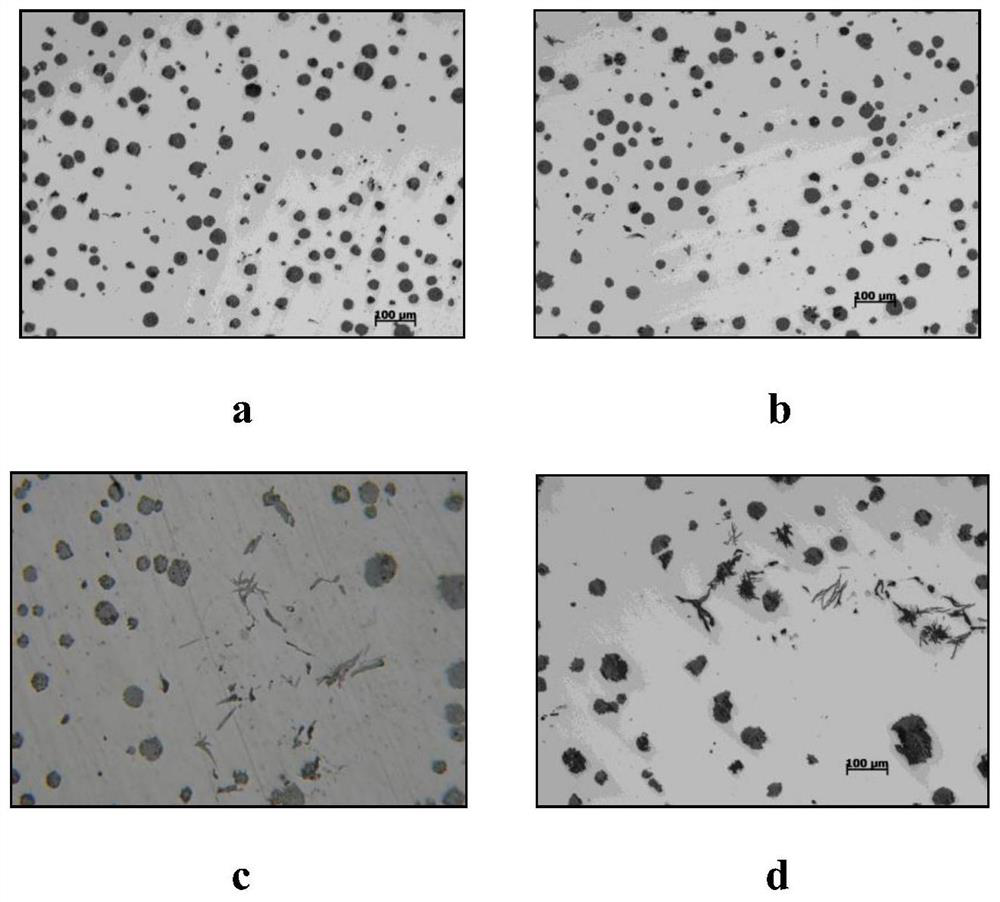

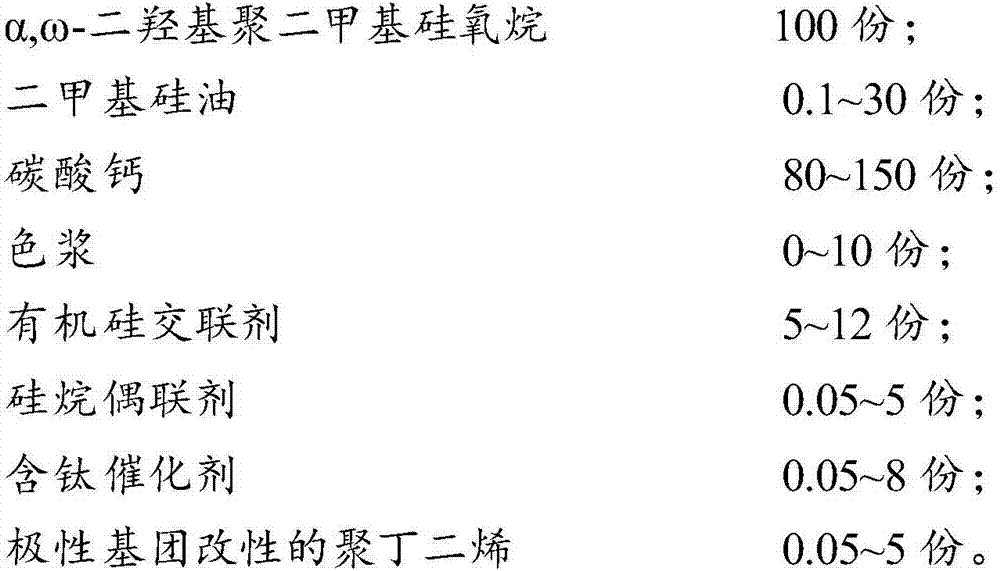

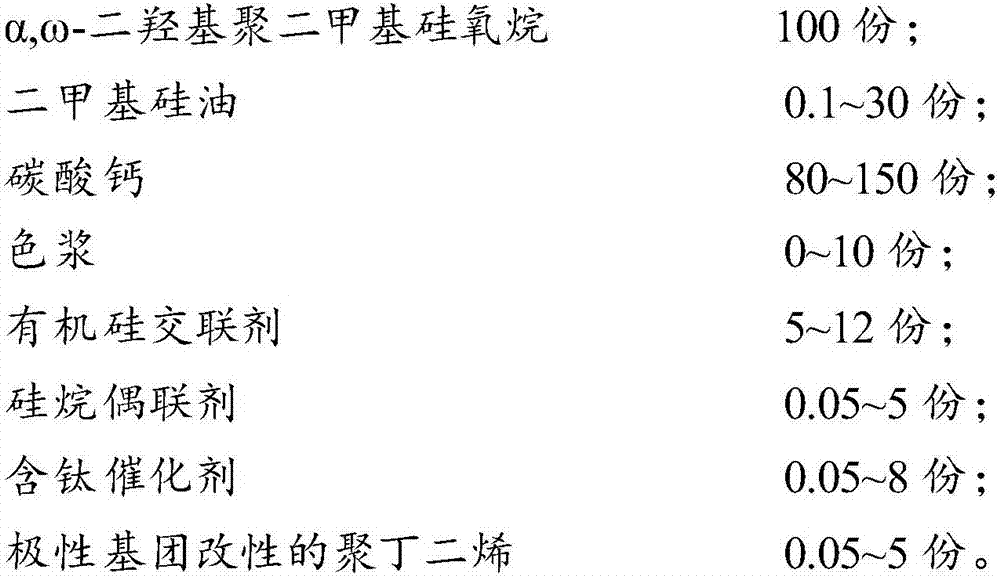

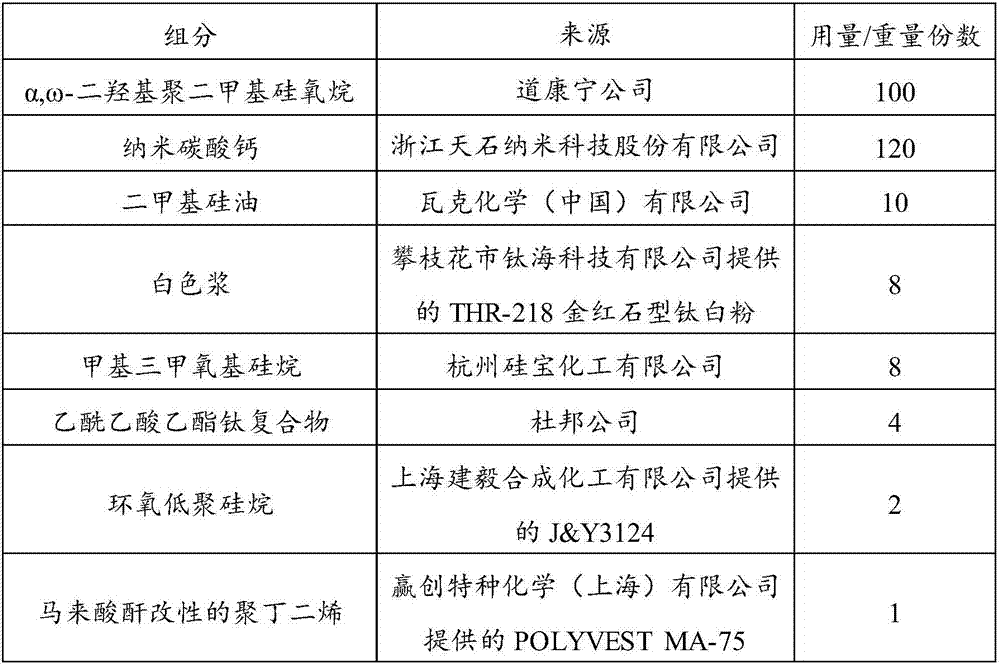

The invention provides a dealcoholized silicone rubber sealant, which is prepared from the following components in parts by weight: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 0.1 to 30 parts of simethicone, 80 to 150 parts of calcium carbonate, 0 to 10 parts of mill base, 5 to 12 parts of silicone cross-linking agent, 0.05 to 5 parts of silane coupling agent, 0.05 to 8 parts of titanium-containing catalyst, and 0.05 to 5 parts of polar group modified polybutadiene. According to the dealcoholized silicone rubber sealant provided by the invention, the polar group modified polybutadiene is adopted, and a polar group is contained, so that the moisture introduction in air is increased, and the initial curing speed and the initial strength of the sealant are improved. According to the dealcoholized silicone rubber sealant provided by the invention, through reasonably controlling the components in the sealant and adjusting the content of each component, so that the sealant has the advantages of fast initial curing speed, high shearing strength, and excellent cohesiveness under the combined action of the components.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

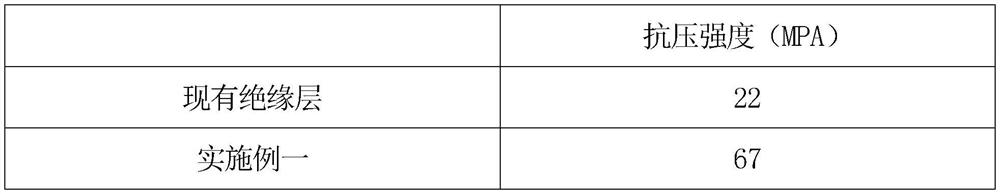

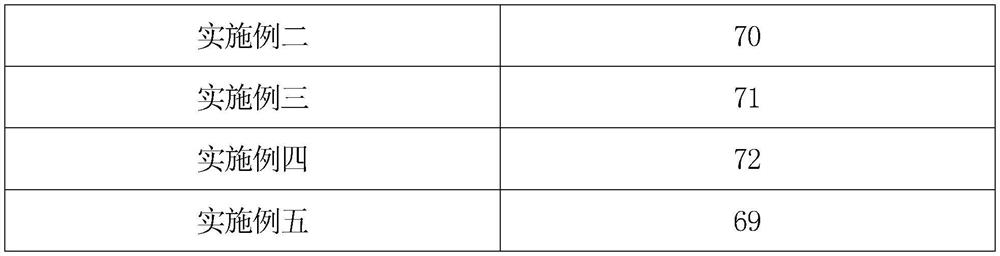

Manufacturing process of ultra-large low-temperature liquid-filled insulating layer

PendingCN112555672AGood mechanical propertiesImproves Strength and ToughnessNon-pressured vesselsVessel manufacturingAerogelManufacturing engineering

Owner:酷泰克保温科技江苏有限公司

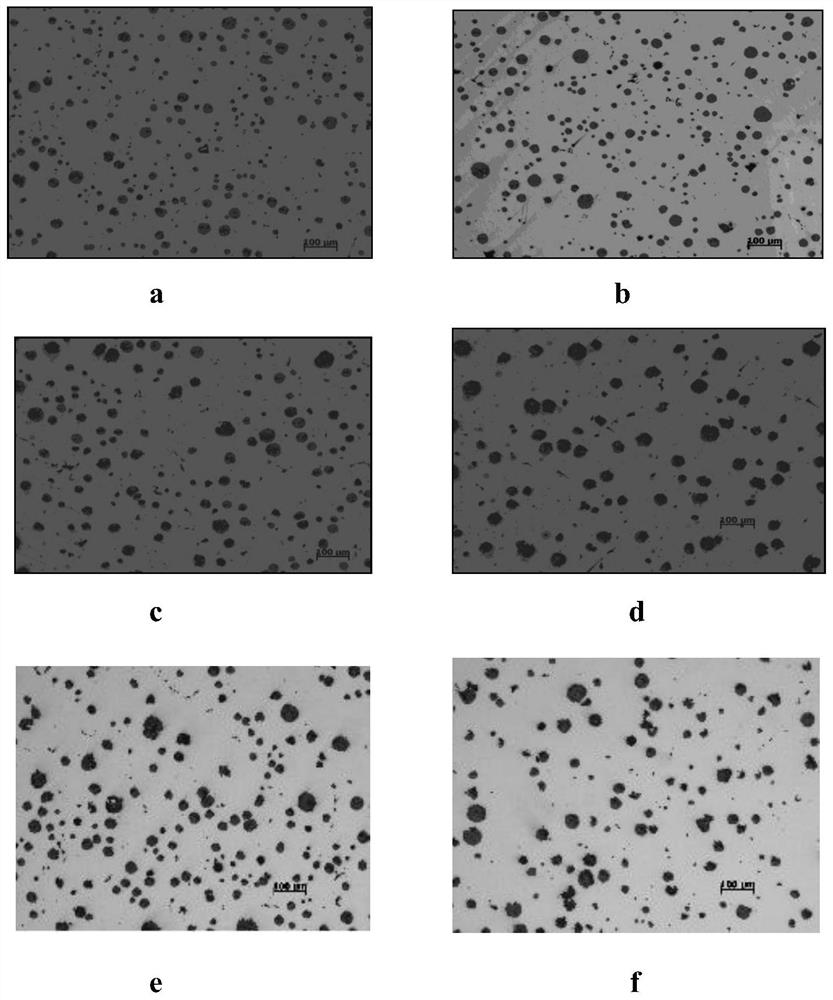

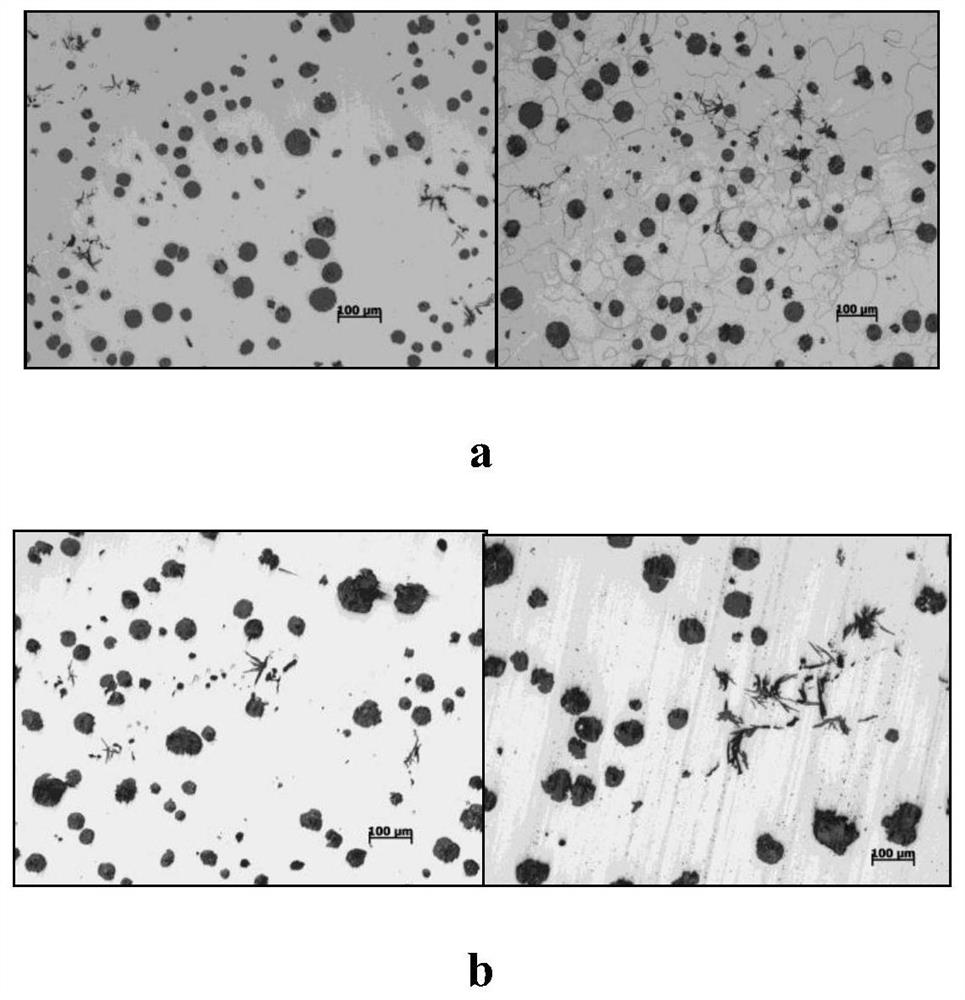

Free-cutting aluminum alloy and preparation method thereof

InactiveCN110358938AGood mechanical propertiesHigh elastic modulusFurnace typesHeat treatment furnacesAluminium alloyInternal energy

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

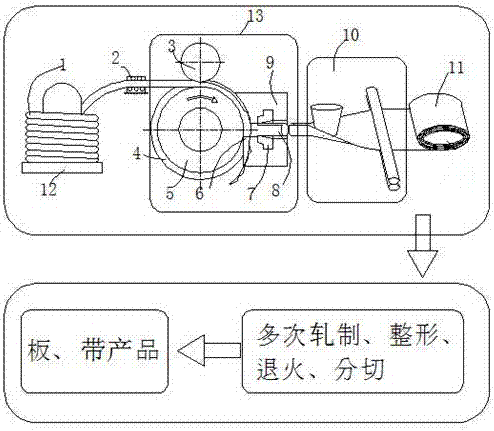

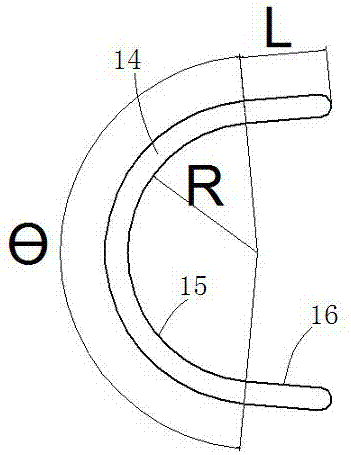

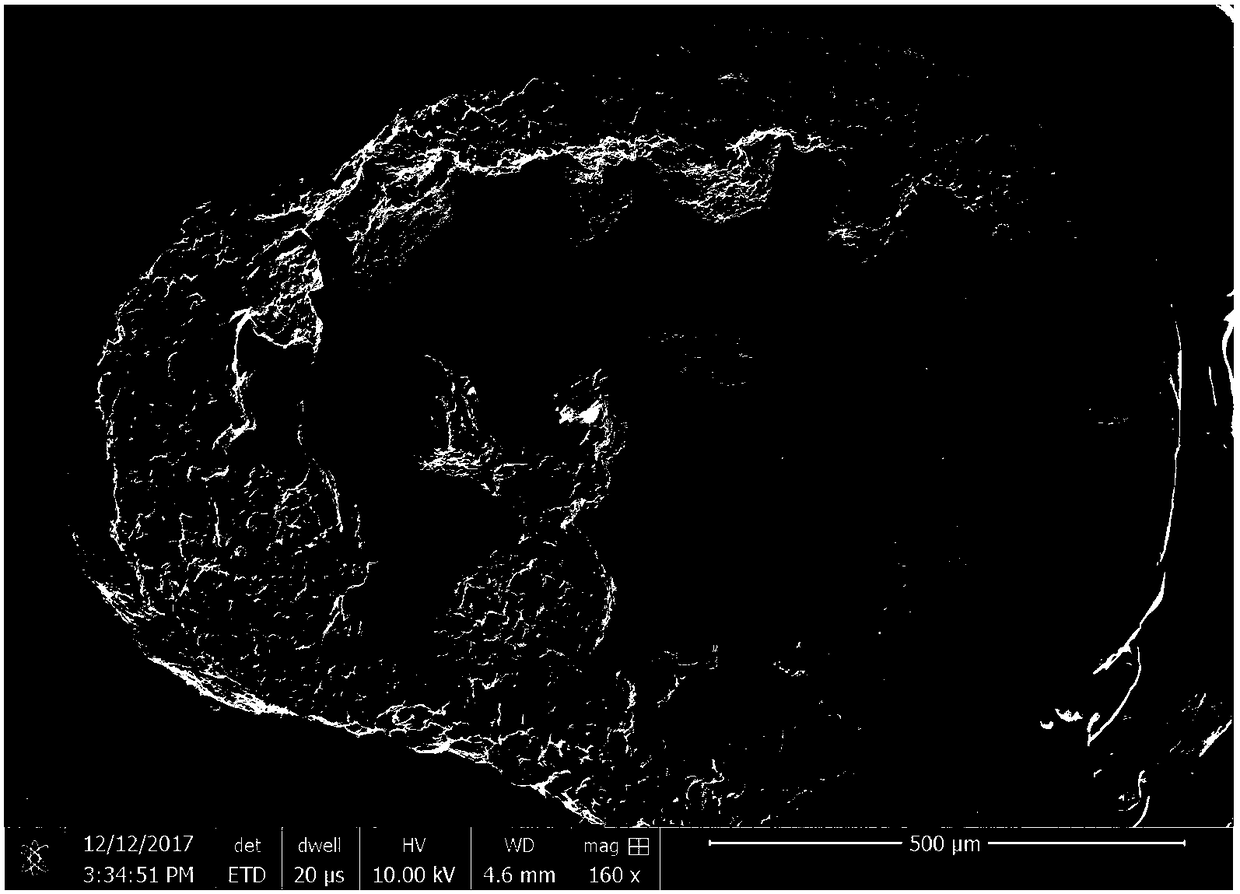

Preparation method of aluminum and aluminum alloy busbar for electrician

ActiveCN104307920BDense internal organizationGood mechanical propertiesExtrusion diesRams/plungersAluminium alloyClutch

Owner:广西百金铝业有限公司

High-performance rubber material for external windshield of high-speed rail and compression molding preparation method of high-performance rubber material

ActiveCN107603112AGood high and low temperature resistanceGood mechanical propertiesCeramicCompression molding

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Impact needle of spray head of large character code spraying machine

Owner:HANGZHOU WISDOM TECH

3D printing tissue engineering scaffold and preparation method thereof

Owner:深圳市晶莱新材料科技有限公司

Antistatic electronic jacquard trademark machine and preparation method thereof

InactiveCN108610723AGood antistatic propertiesGood mechanical propertiesElectrically-conductive paintsPolycarbonate coatingsAgricultural engineeringCoating

Owner:芜湖衣码通信息科技有限公司

System and method for preparation of ultrahigh vacuum electromagnetic suspension material

ActiveCN110252986AEffective controlGood mechanical propertiesElectric heating for furnacesRadiation pyrometryAlloyCollection system

Owner:NORTHWESTERN POLYTECHNICAL UNIV

3D printing polystyrene resin and preparation method thereof

ActiveCN108299753A3D printing polystyrene resin products are pureGood mechanical propertiesAdditive manufacturing apparatus3d printer3D printing

Owner:NORTH HUAJIN CHEM IND CO LTD

Reinforced flame-retardant low-warpage PBT alloy material and preparation method thereof

Owner:中广核瑞胜发(厦门)新材料有限公司

Preparation method of cellulose acetate nanofiber composite aerogel for heat preservation

PendingCN113024880AGood mechanical propertiesGood application prospectArtificial filaments from cellulose derivativesChemistryCellulose acetate

Owner:DONGHUA UNIV

High-strength aluminum alloy and production process thereof

Owner:烟台三和新能源科技股份有限公司

Preparation method of polyolefin nanometer composite material

ActiveCN108467528AGood mechanical propertiesUniform dispersion of nanofillersEthanolHydrochloric acid

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Grape skin edible food packaging material and preparation method thereof

InactiveCN105924680AExtended shelf lifeGood mechanical propertiesBio-packagingClimate change adaptationAgarCitric acid

Owner:SUZHOU DINGLI PACKAGING

Olanzapine oral instant film and preparation method thereof

ActiveCN110251489AGood mechanical propertiesGreat tasteNervous disorderOrganic active ingredientsBuccal administrationDibasic acid

Owner:SHENYANG PHARMA UNIVERSITY

Flame-retardant polyester adhesive tape base material

ActiveCN106221143AGood mechanical propertiesGood molding processabilityFilm/foil adhesivesChemistryHeat resistance

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Preparation method of silver nanowire/PBAT (poly(butyleneadipate-co-terephthalate)) nanometer fiber/polyvinyl alcohol composite conductive hydrogel

ActiveCN108794770AGood biocompatibilityGood mechanical propertiesBiocompatibility TestingComposite hydrogels

Owner:ZHONGYUAN ENGINEERING COLLEGE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap