Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Calcium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to prevent or treat low blood calcium levels in people who do not get enough calcium from their diets. It may be used to treat conditions caused by low calcium levels such as bone loss (osteoporosis), weak bones (osteomalacia/rickets), decreased activity of the parathyroid gland (hypoparathyroidism), and a certain muscle disease (latent tetany). It may also be used in certain patients to make sure they are getting enough calcium (e.g., women who are pregnant, nursing, or postmenopausal, people taking certain medications such as phenytoin, phenobarbital, or prednisone).

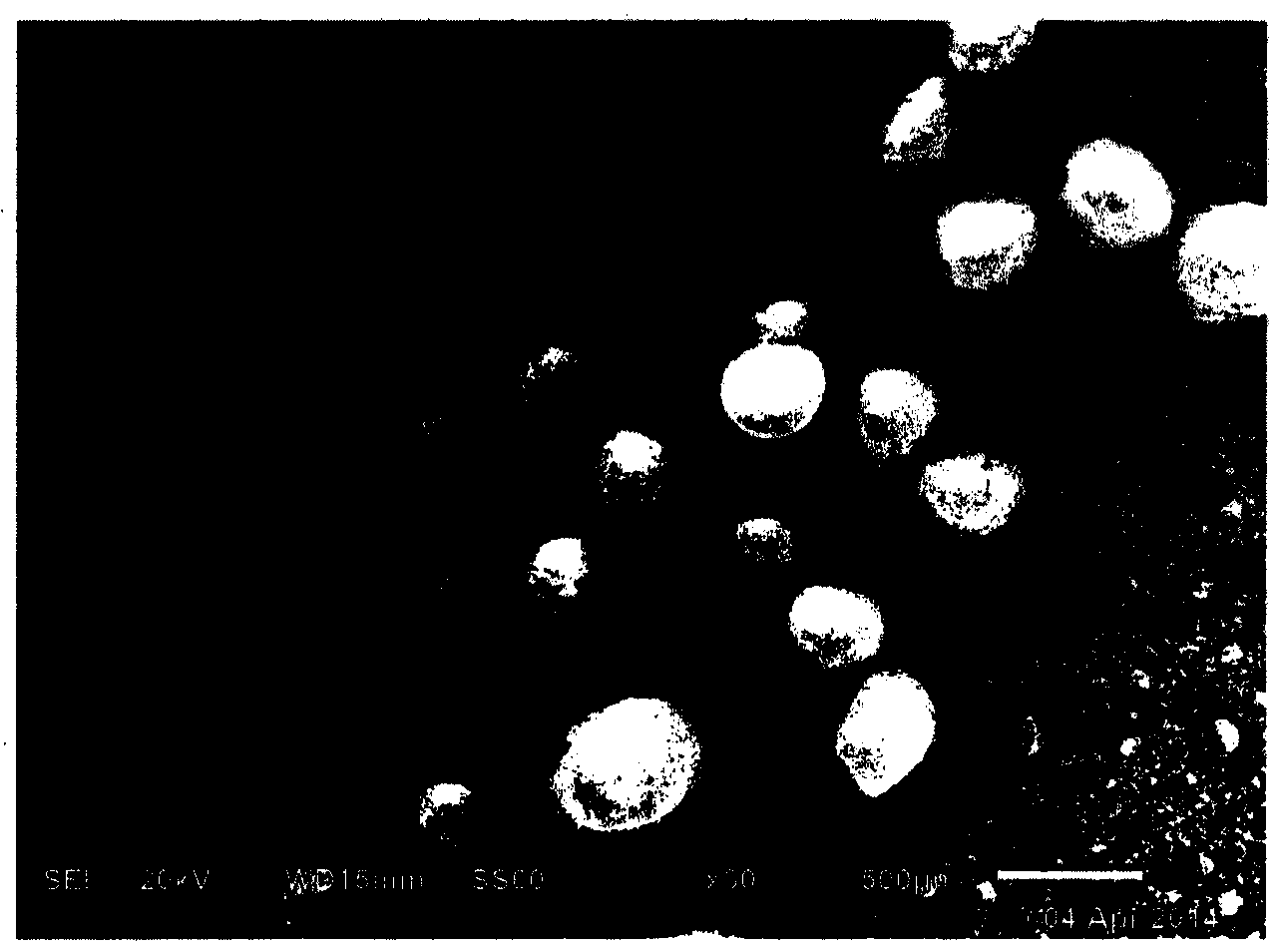

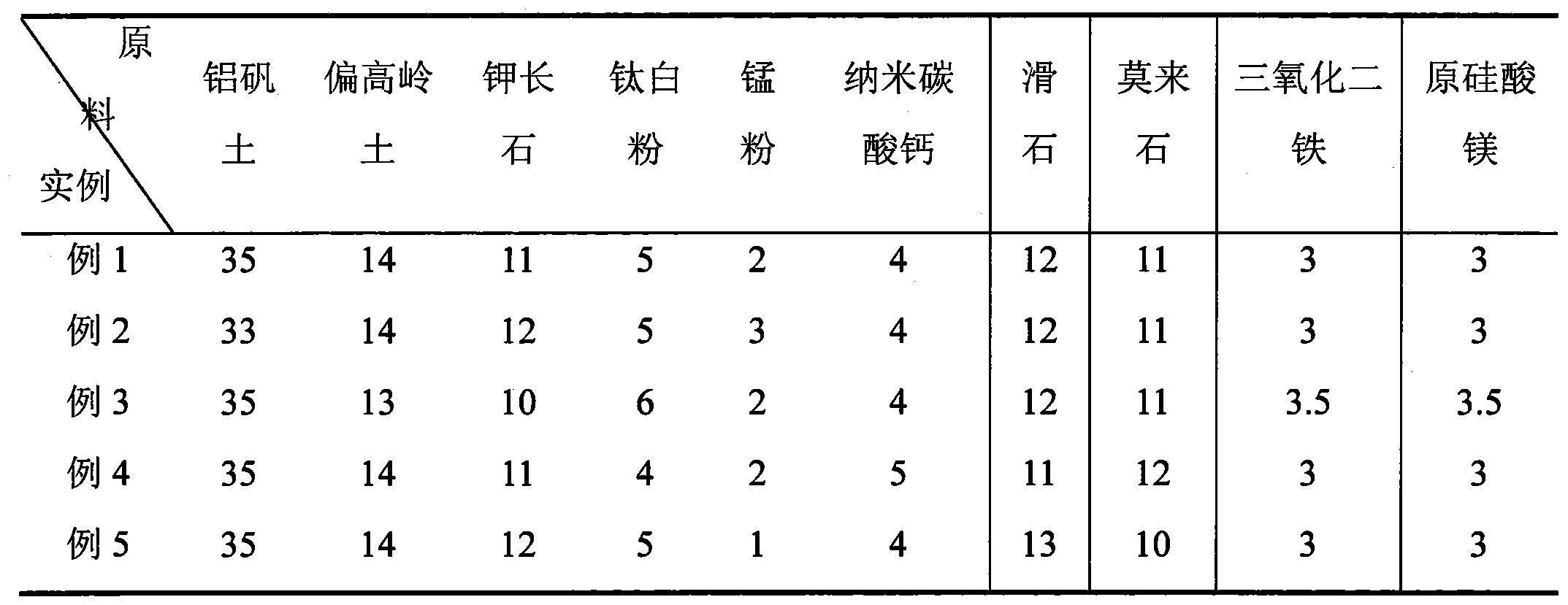

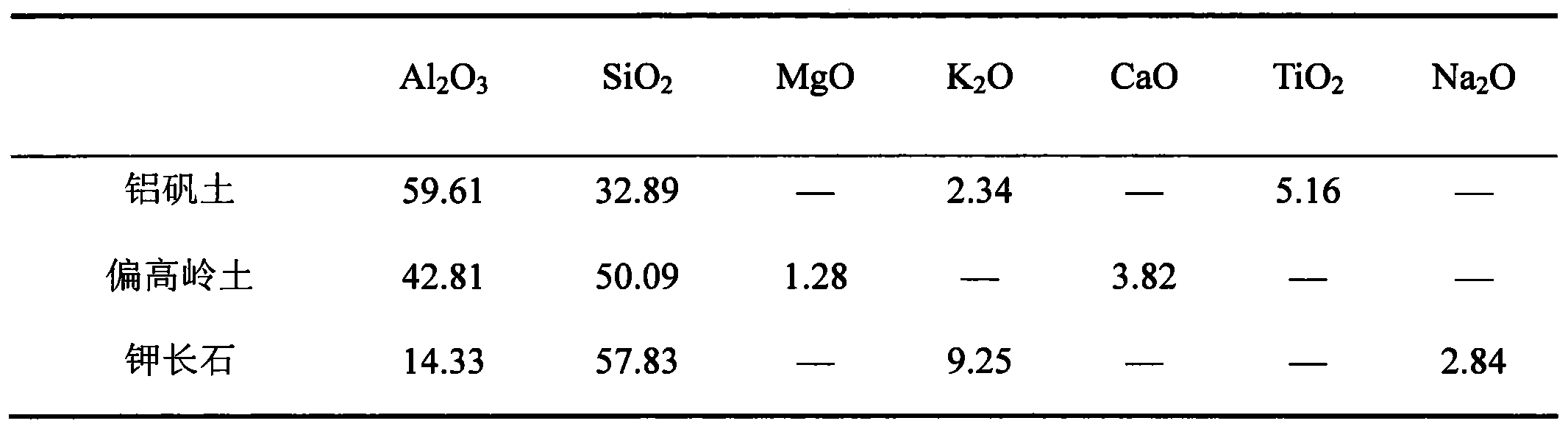

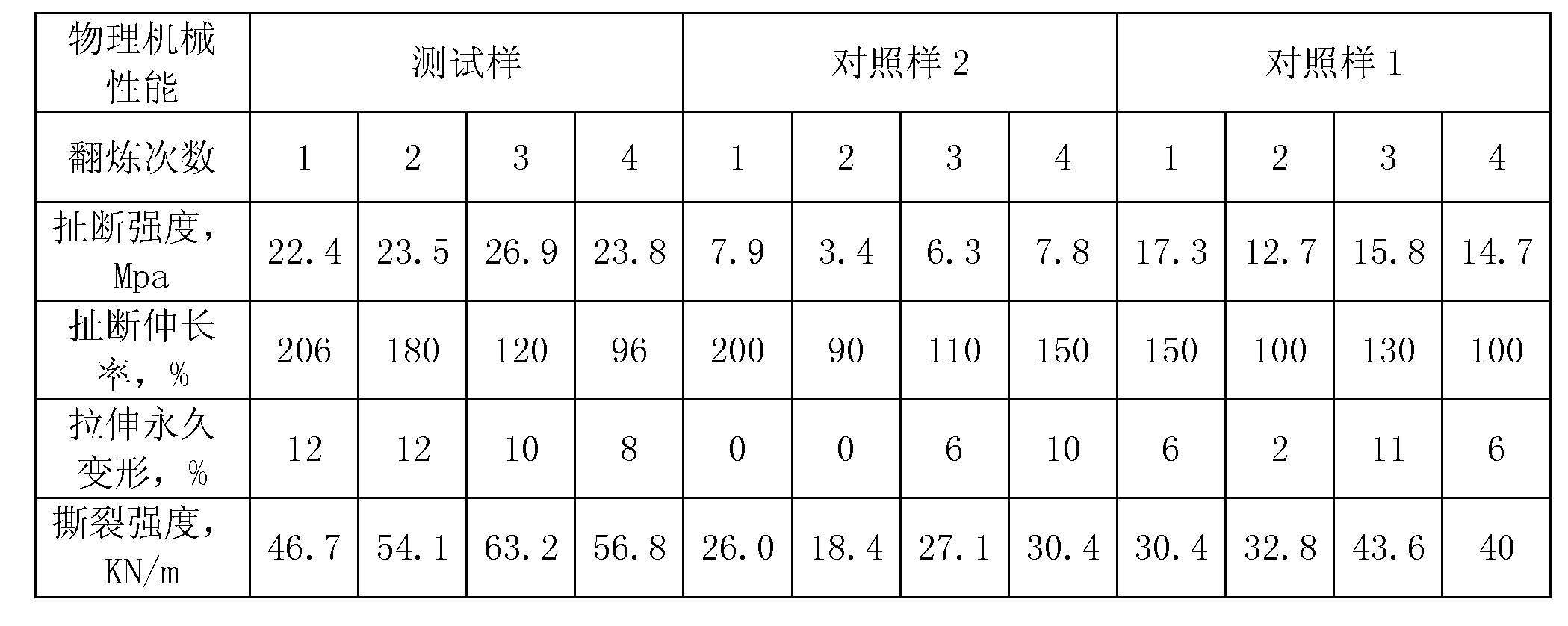

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Oil resistant rubber

The invention discloses an oil resistant rubber, which is composed of the following components by weight: 40-60 parts of fluorine rubber, 20-30 parts of natural rubber, 10-15 parts of nitrile rubber, 20-40 parts of carbon black, 15-30 parts of white carbon black, 0.5-2 parts of antioxidant RD, 1-2 parts of antioxidant 4010 Na, 2-4 parts of paraffin, 25-35 parts of light calcium carbonate, 2-3 parts of eleaostearic acid, 3-5 parts of zinc oxide, 5-10 parts of magnesium oxide, 1-2 parts of 2, 2'-dibenzothiazyl disulfide, 3-4 parts of coumarone and 0.2-0.8 parts of vulcanizing agents. The oil resistant rubber provided by the invention has the advantages of oil resistance, airtight and good high temperature resistance.

Owner:GUANGZHOU CHONGQI IND CO LTD

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

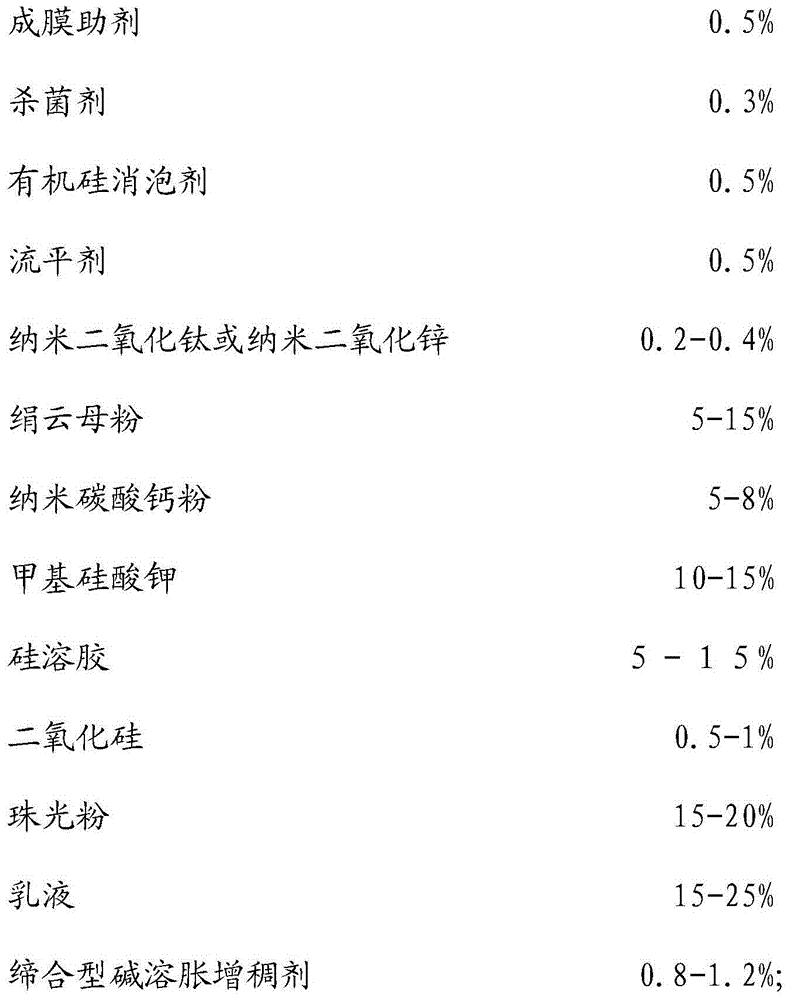

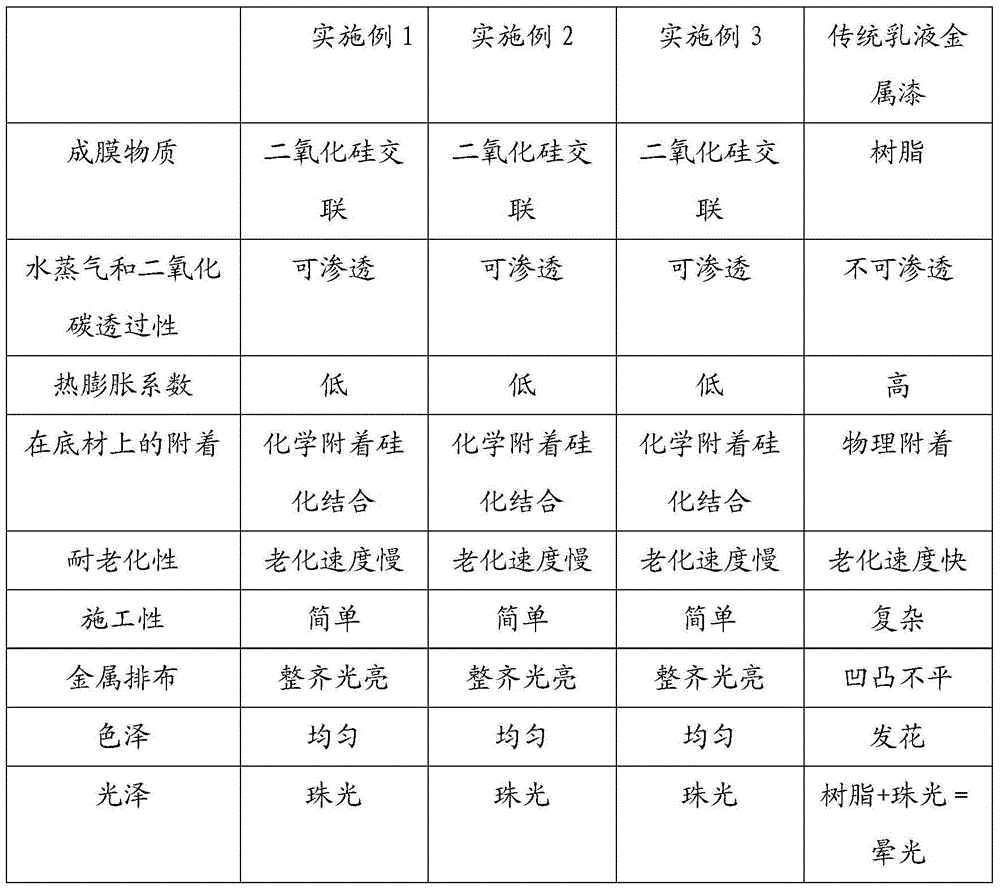

Inorganic water-based metallic paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateLow melting pointGlass shaping apparatusFoaming agentSodium phosphates

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

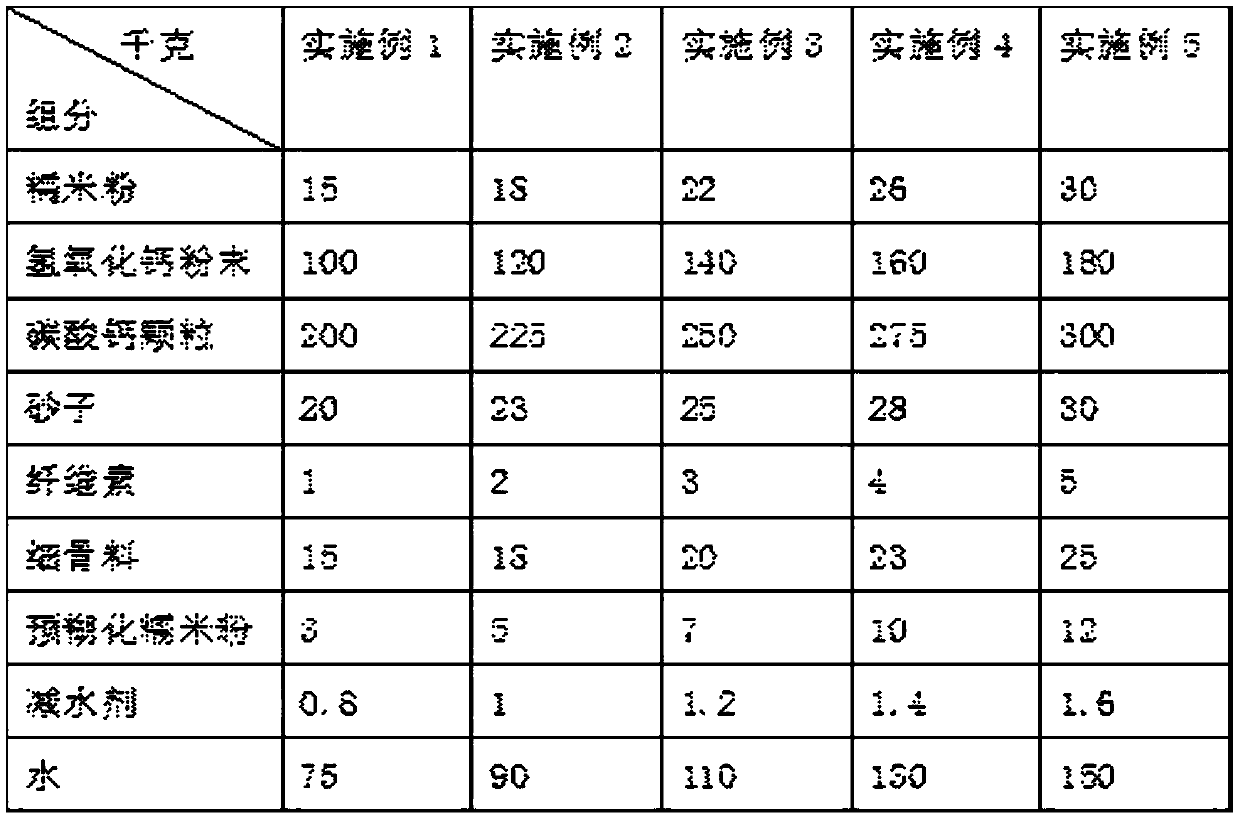

Sticky-rice mortar and preparation method thereof

Owner:中兴文建工程集团有限公司

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

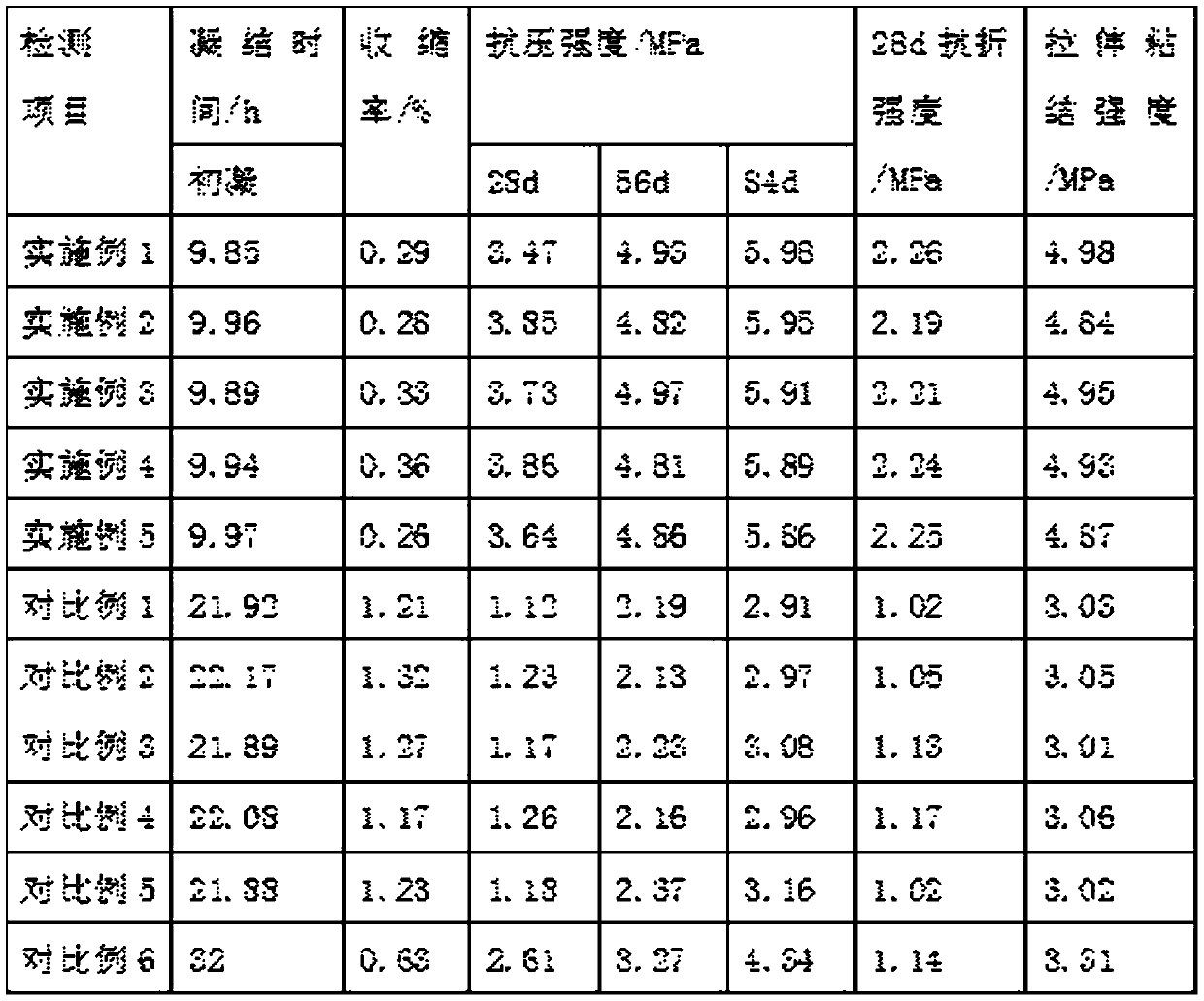

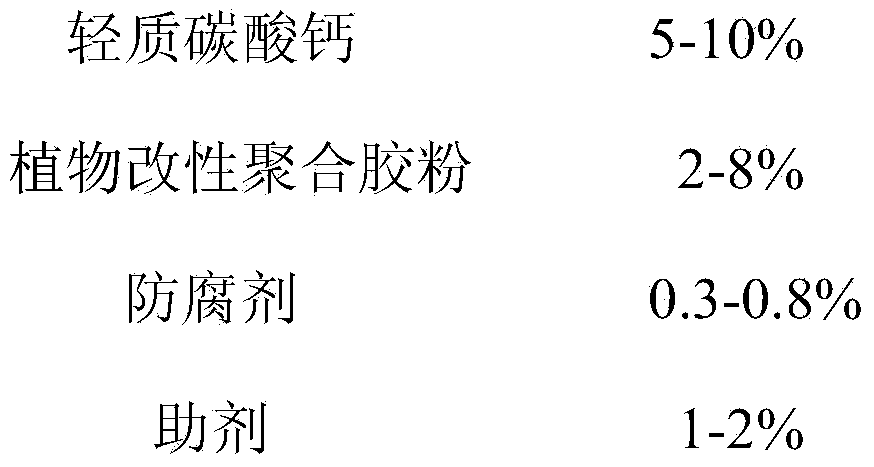

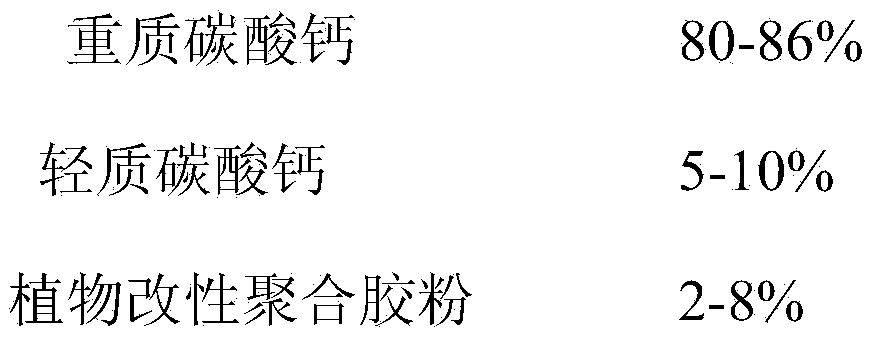

Environment-friendly spackling compound and preparation method thereof

InactiveCN103804975ANot easy to layerHigh in plant polysaccharidesFilling pastesSolid componentAdhesive

Owner:WUHAN YOUBANG NEW MATERIAL CHEM

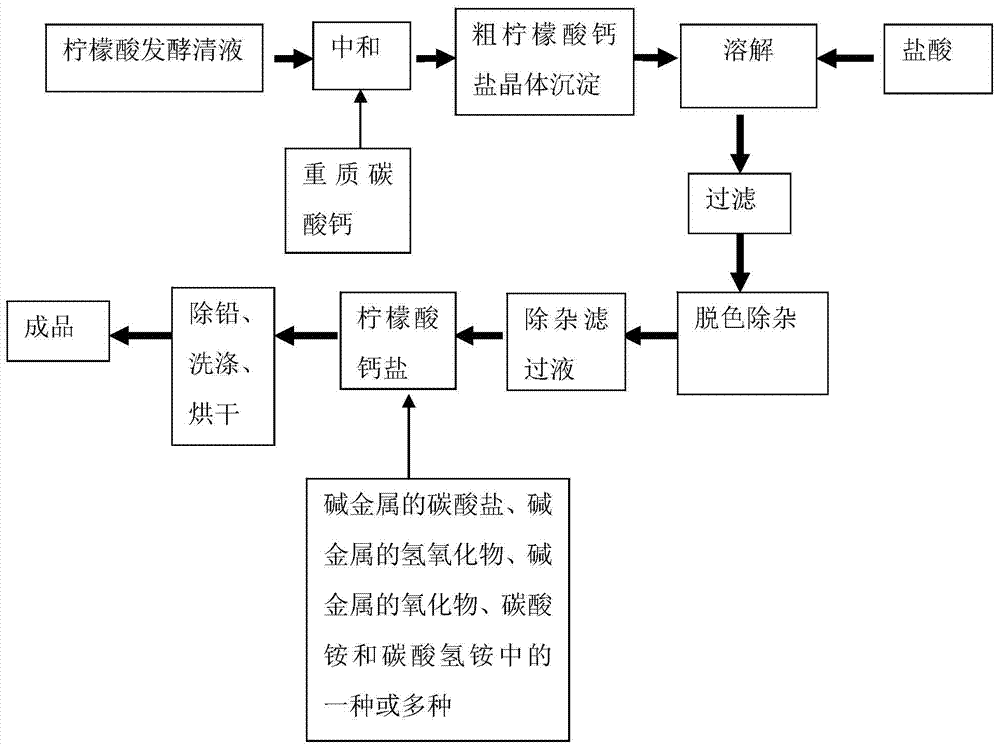

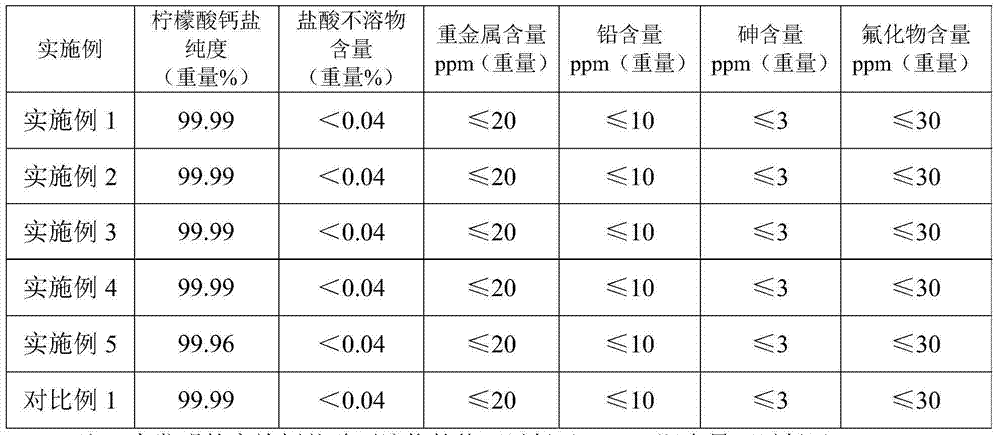

Calcium citrate producing method

ActiveCN104513154AHigh purityOrganic compound preparationCarboxylic acid salt preparationFood additiveImpurity

Owner:COFCO BIOTECHNOLOGY CO LTD

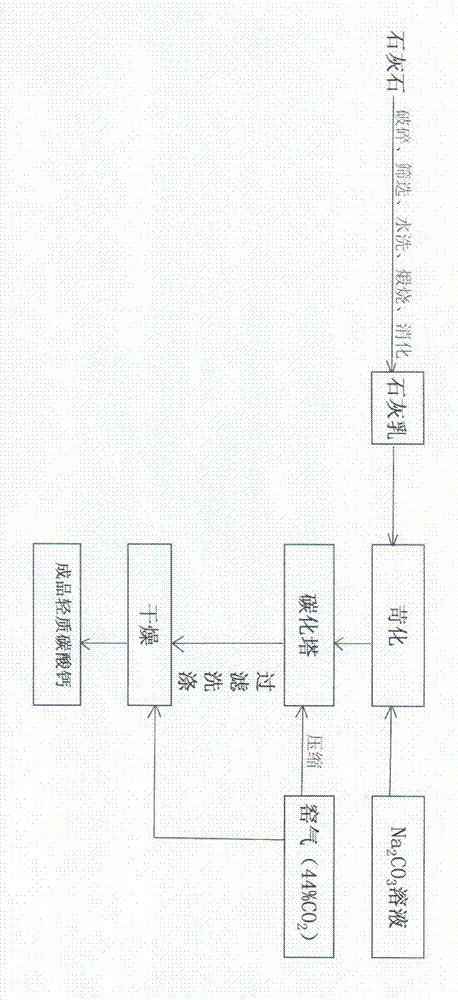

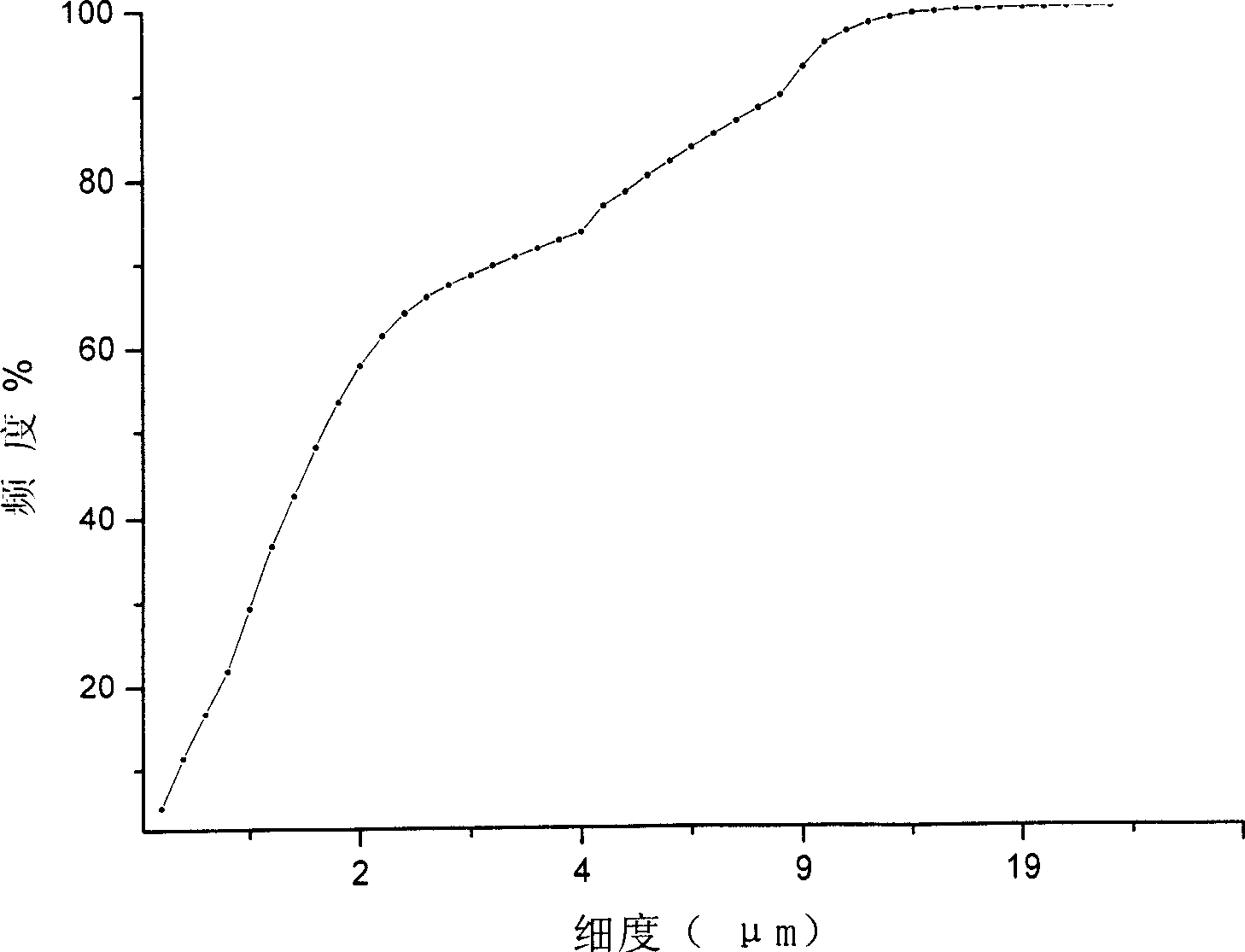

Preparation method of light calcium carbonate

InactiveCN104261452AImprove qualityHigh oil absorption valueCalcium/strontium/barium carbonatesCalcium carbonateCarbon dioxide

The invention discloses a preparation method of light calcium carbonate. The preparation method comprises the following steps: crushing a limestone raw material in a crusher; screening the crushed limestone, and washing the screened limestone by water; calcining the screened and washed limestone to generate quick lime (CaO) and carbon dioxide (CO2); digesting: adding the quick lime generated by calcining the limestone into hot water, and constantly stirring to generate lime milk; sieving the generated lime milk with a 120-mesh sieve, and concocting the lime milk by filtering till the effective CaO concentration is larger than 170g / L; transferring the lime milk at the concocted concentration into a stirring reactor, causticizing by adding a NA2CO3 solution; inflating kiln gas CO2 into a causticized CaCO3 solution for carbonizing in a carbonizing tower; filtering, washing, drying and grinding a carbonized CaCO3 slurry to obtain a light calcium carbonate product. The light calcium carbonate prepared by the preparation method is relatively high in quality.

Owner:山西玉竹活性石灰制造有限公司

Pharmaceutical premixed agent for disease resistance and growth promotion and application thereof

InactiveCN101011107AIncrease profitImprove qualityOrganic active ingredientsDigestive systemDigestive canalDisease

The invention relates to a method for preparing quinsadu premixed agent which can resist illness and accelerate the growth of animal. The inventive premixed agent comprises 5 deals of quinsadu and 95 deals of carrier, wherein, the carrier can be one or the combination of zeolite powder, talcum powder, calcium carbonate powder, degreased rice bran powder, corn powder or amidon. The inventive premixed agent can be used in the forage additive of pig, chicken, duck, fish, calf and lamb, while the relative contents are 25-100mg, 25-200mg, 25-100mg, 25-200mg, 25-150mg, and 25-100mg. The invention can accelerate the growth, reduce the forage cost and improve the animal quality, while it can control the infection of digestive canal.

Owner:HUAZHONG AGRI UNIV

Concrete expansive agent

Owner:王嘉文

Acrylate damping coating and preparation method thereof

The invention discloses an acrylate damping coating and a preparation method thereof. The acrylate damping coating comprises, by weight, 20-35 parts of water, 1-3 parts of an aqueous disperser, 10-18 parts of calcium carbonate, 20-35 parts of talcum powder, 7-11 parts of a fire retardant, 0.5-2 parts of an aqueous antifoaming agent, 50-110 parts of a propionate emulsion, 0.1-1.5 parts of a thickener, 0.1-3.3 parts of a damping pigment filler and 0.5-1.8 parts of a film forming assistant. The propionate emulsion is adopted in the preparation process of the acrylate damping coating, so the damping performance of the coating in high and low temperature state is improved, and the coating also has the advantages of good noise reduction effect, non-toxicity, no peculiar smell, hard film, good gloss retention, good durability and good pollution resistance.

Owner:郭小曼

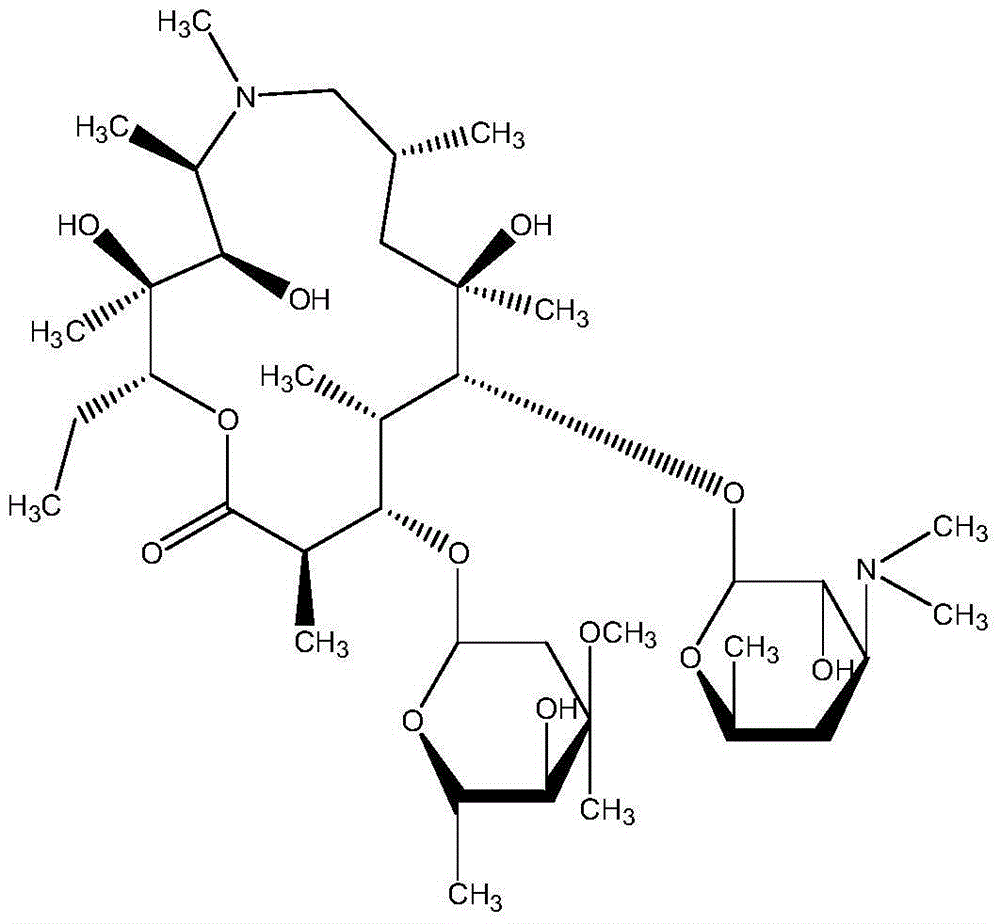

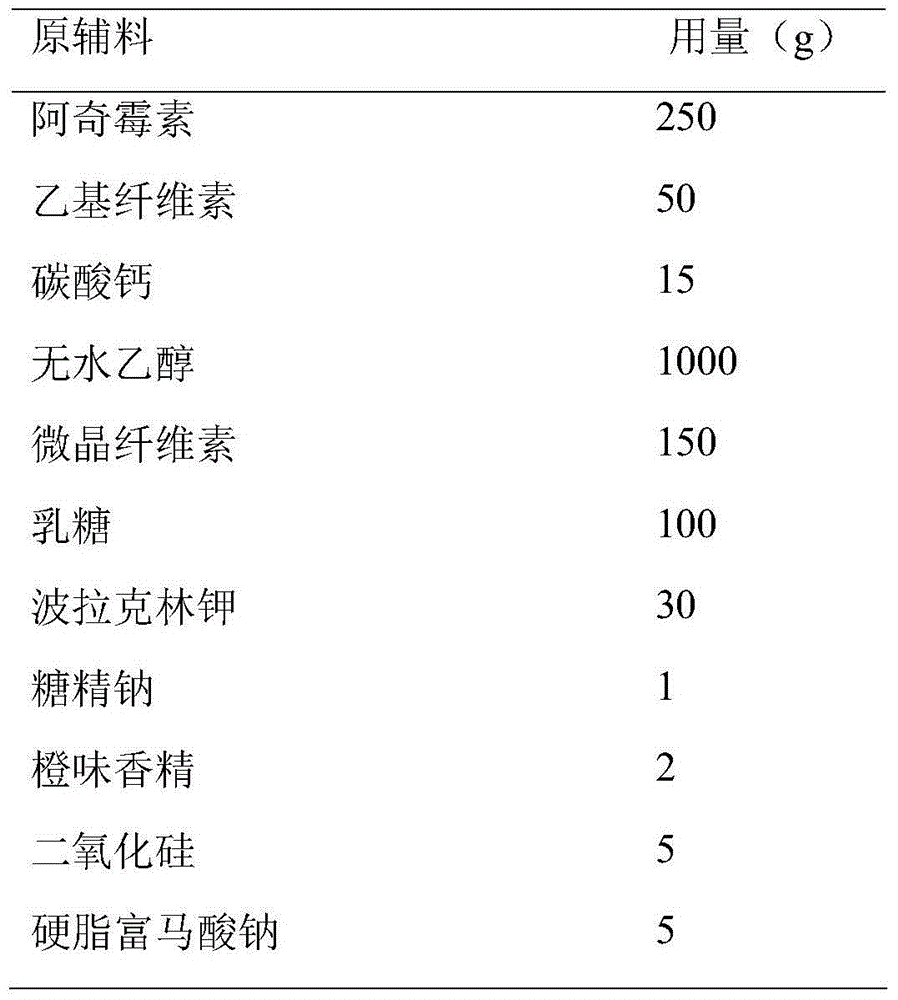

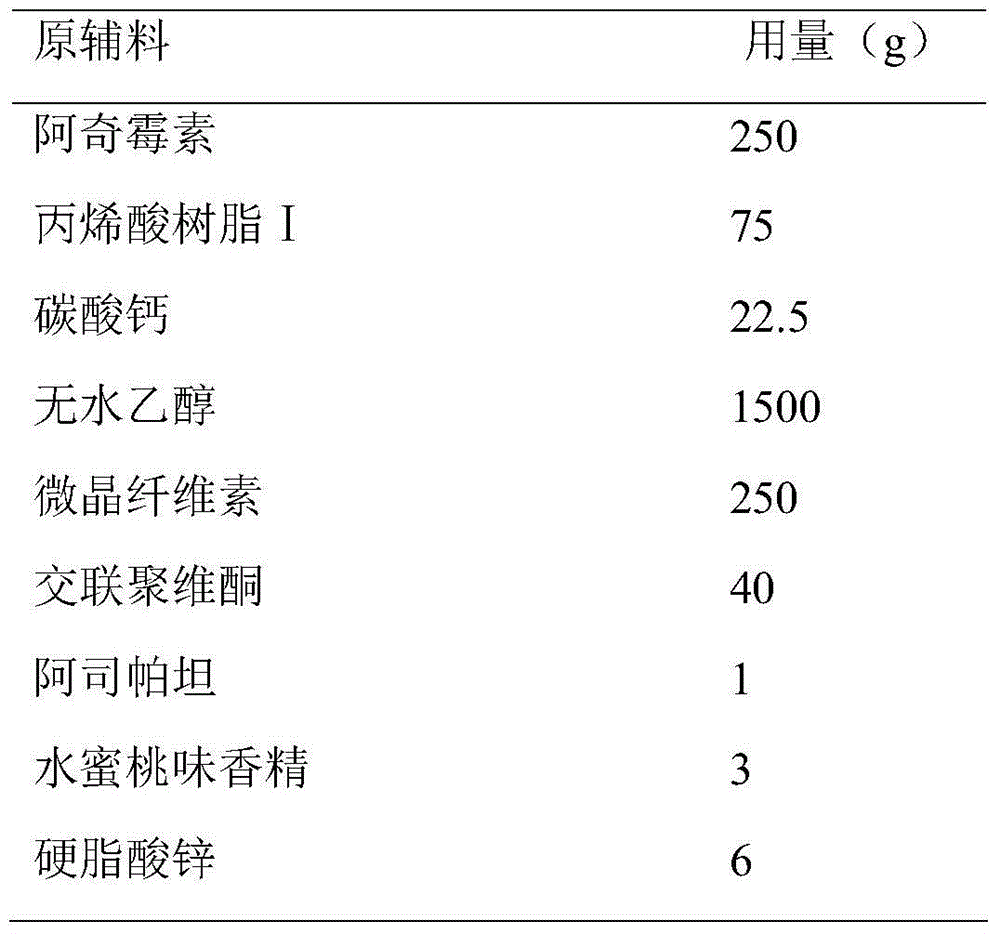

Azithromycin dispersible tablet

Owner:LUNAN BETTER PHARMA

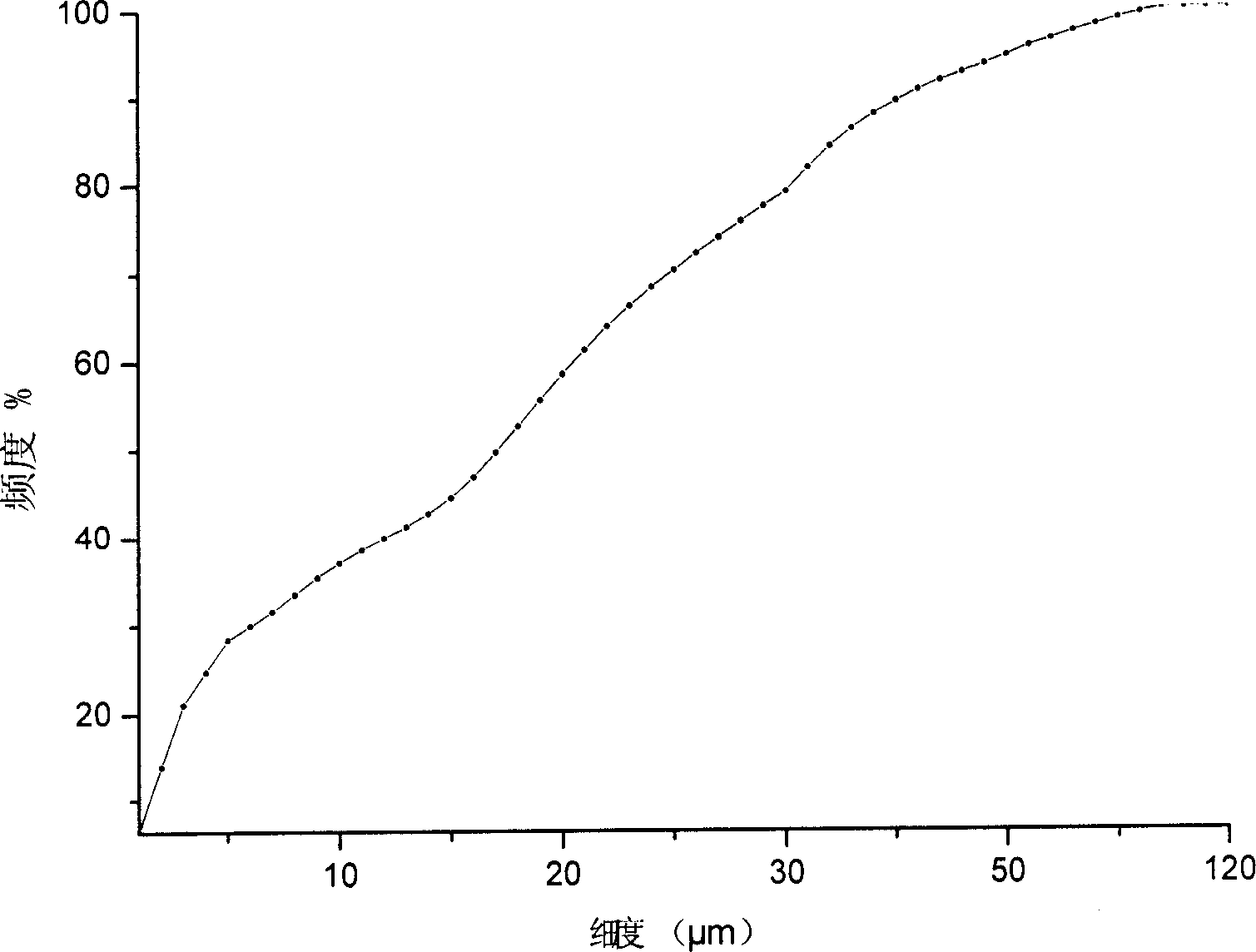

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

Tilapia feed

InactiveCN105010892AIncrease growth rateImprove disease resistanceAnimal feeding stuffVerbenaGLYCYRRHIZA EXTRACT

Owner:陶建壮

BMC material for molding decorative plate and preparation method thereof

The invention discloses a BMC material for a molding decorative plate. The BMC material comprises the following components: unsaturated polyester resin, calcium carbonate, aluminium hydroxide, zine stearate, potato starch, a low shrinkage agent, a curing agent, chopped glass fiber and stone toner. A preparation method of the BMC material comprises the following steps: (1) calcium carbonate, aluminium hydroxide, zine stearate and potato starch are added into a kneader to be mixed; (2) unsaturated polyester resin, the low shrinkage agent and the curing agent are mixed by a high-speed mixer; (3) a resin solution from the step (2) is added into the powder from the step (1) to be kneaded; (4) the stone toner is added into the mixture from the step (3) to be mixed and kneaded; and (5) chopped glass fiber is added into the pellet material from the step (4) to be kneaded, and discharging is carried out after kneading. The prepared BMC material for the decorative plate is fire retardant, has high plasticity, is easy to process, has good dimensional stability and has bright and lasting color.

Owner:GAOGANG DISTRICT DEYI NEW MATERIALS FACTORY

Thin-film capacitor housing heat dissipation coating and preparation method thereof

A thin-film capacitor housing heat dissipation coating is prepared from, by mass, 35 parts of resol, 3 parts of gelatin, 5 parts of glycidyl methacrylate, 3 parts of sodium dodecyl benzene sulfonate, 3 parts of gloss oil, 5 parts of dimethyl dicarbonate, 3 parts of olive oil, 3 parts of colored glaze carbylic acid, 3 parts of olive oil, 3 parts of graphene, 5 parts of pigment, 50 parts of distilled water, 3 parts of benzoyl paeoniflorin, 3 parts of sodium hypochlorite, 5 parts of a modifying agent, 3 parts of calcium carbonate, 3 parts of glacial acetic acid, 3 parts of magic acid, 5 parts of polyester resin, 3 parts of potassium dihydrogen phosphate, 1 part of sodium phosphate, 3 parts of aluminum silicate, 3 parts of imidazole, 3 parts of cohesive soil, 3 parts of polyvinyl alcohol and 3 parts of sodium borohydride. The modifying agent is added in a traditional formula to perform modification processing, the coating coated on a capacitor housing can effectively guide capacitor inside temperature rising due to work to the housing and convert heat into infrared radiation waves, and the working voltage of a capacitor can be also in a stable state in addition to prolonging of the service life of the capacitor.

Owner:HUAIAN SHENGYU ELECTRONICS

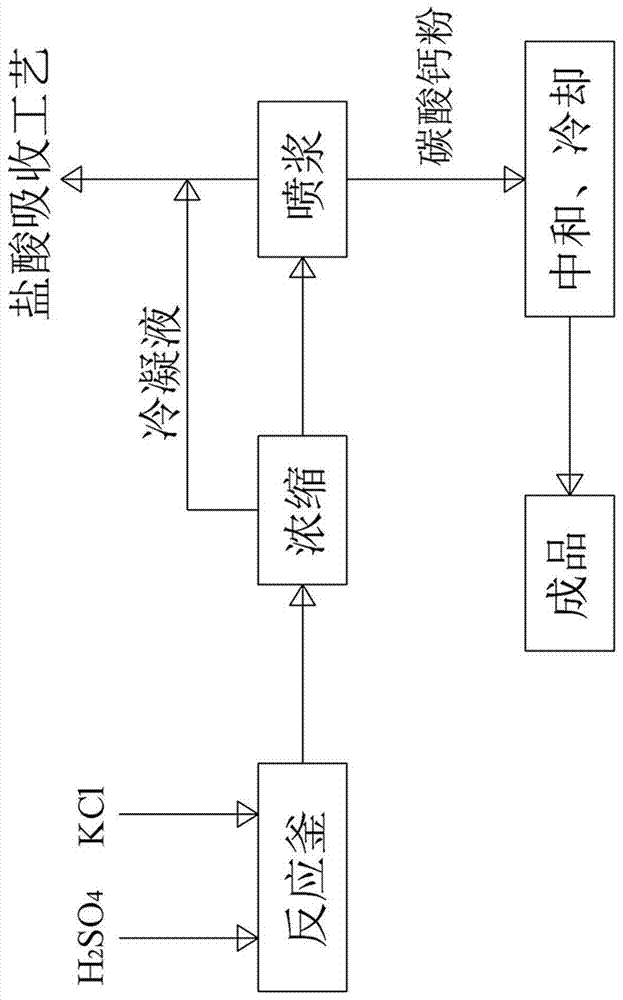

Technology for producing potassium sulphate by liquid-phase grouting method

InactiveCN107032834AImprove product qualitySolve complexityCalcareous fertilisersSulfate/bisulfate preparationHigh energyDecomposition

Owner:KAIFENG UNIV

Gas producing agent for fire extinguisher

The invention discloses a gas producing agent for a fire extinguisher. The gas producing agent comprises, by weight, 40-80 parts of a strontium salt oxidant, 10-20 parts of a combustible agent, 2-10 parts of an additive which is a mixture of one or more of carbon powder, magnesium carbonate, calcium carbonate and potassium feldspar. The strontium salt oxidant is continuously reacted with the combustible agent, wherein the carbon in the additive also participates in the reaction to provide continuous pushing force for a fire extinguishing agent, thereby improving fire extinguishing effect. One part of the fire extinguishing agent in the fire extinguisher, under the effect of air pressure, is pushed out by pressure, and the other one part is siphoned and is entrained out by air flow under the effect of subsequent air flow, thereby reducing residue of the fire extinguishing agent and improving the fire extinguishing effect.

Owner:YANGZHOU KAILUNDA TECH CO LTD

Composite desulfurizer of iron and steel and its preparing process

Owner:TAIYUAN UNIV OF TECH

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Insulated fireproof coating for optical cables

InactiveCN105567024AExcellent physical and chemical propertiesDry fastFireproof paintsEpoxy resin coatingsFiberEpoxy

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

Polyvinyl alcohol water-based architectural paint

Owner:苏州市超邦涂料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap