Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kiln (/kɪln/ or /kɪl/) is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone to lime for cement, and to transform many other materials.

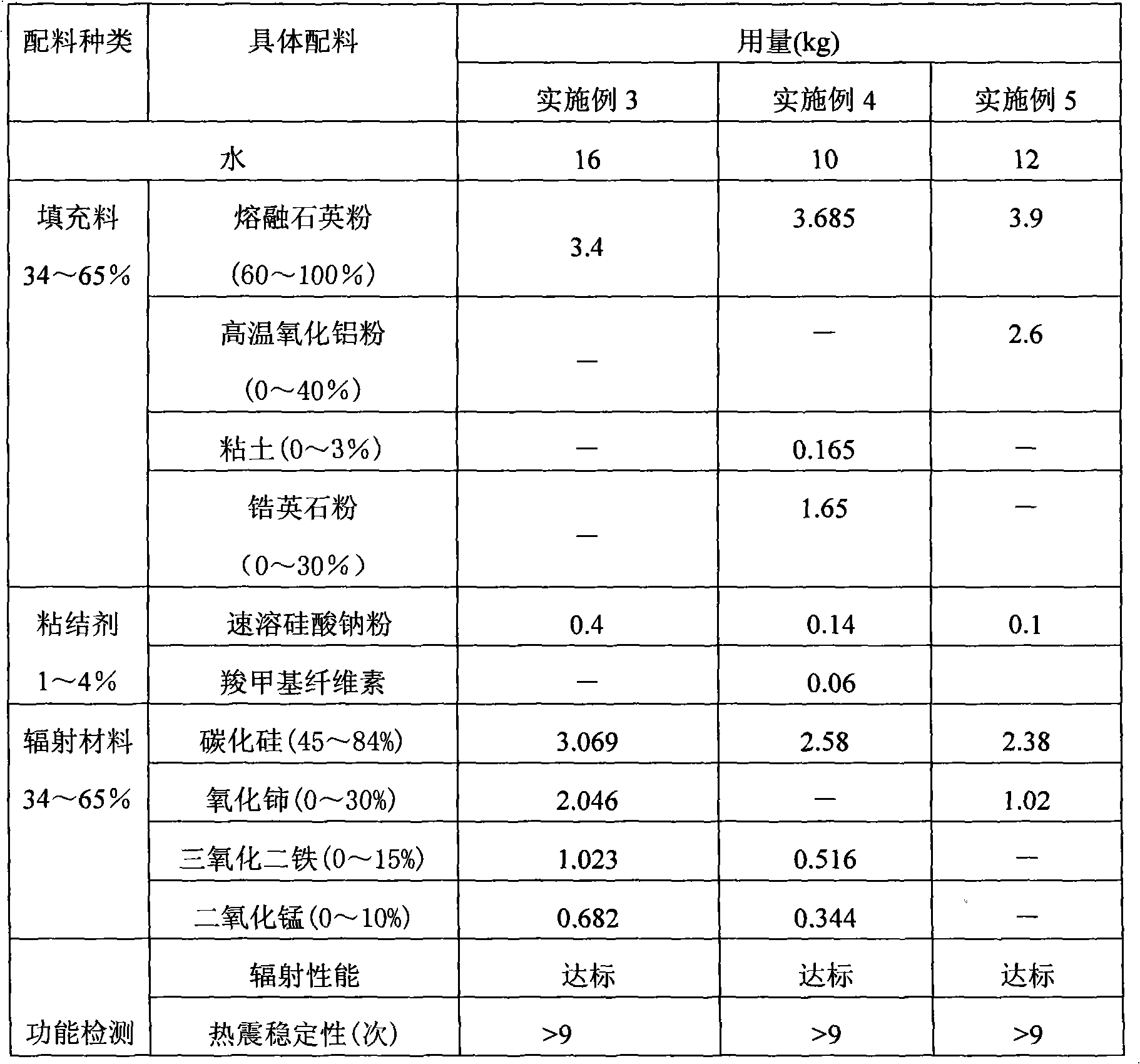

Inorganic radiation paint for inner lining of kiln

InactiveCN101343427AImprove thermal shock resistanceReduce the probability of cracking and falling offChemical industryReflecting/signal paintsCarboxymethyl celluloseFilling materials

Owner:CHINA BUILDING MATERIALS ACAD

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

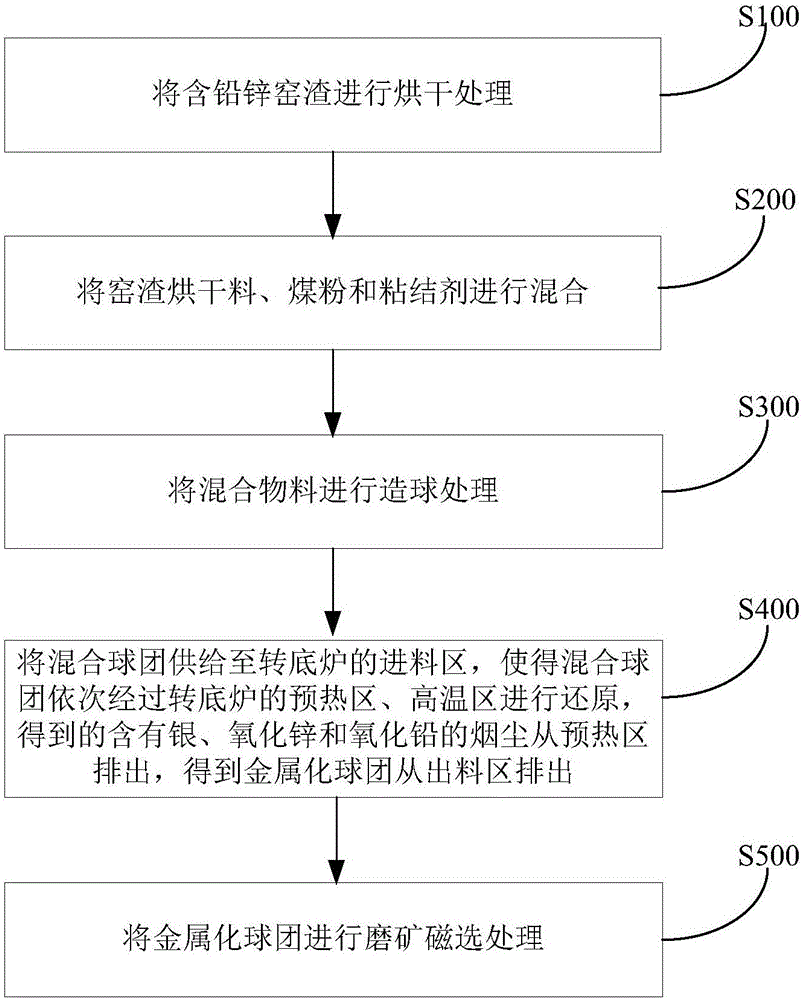

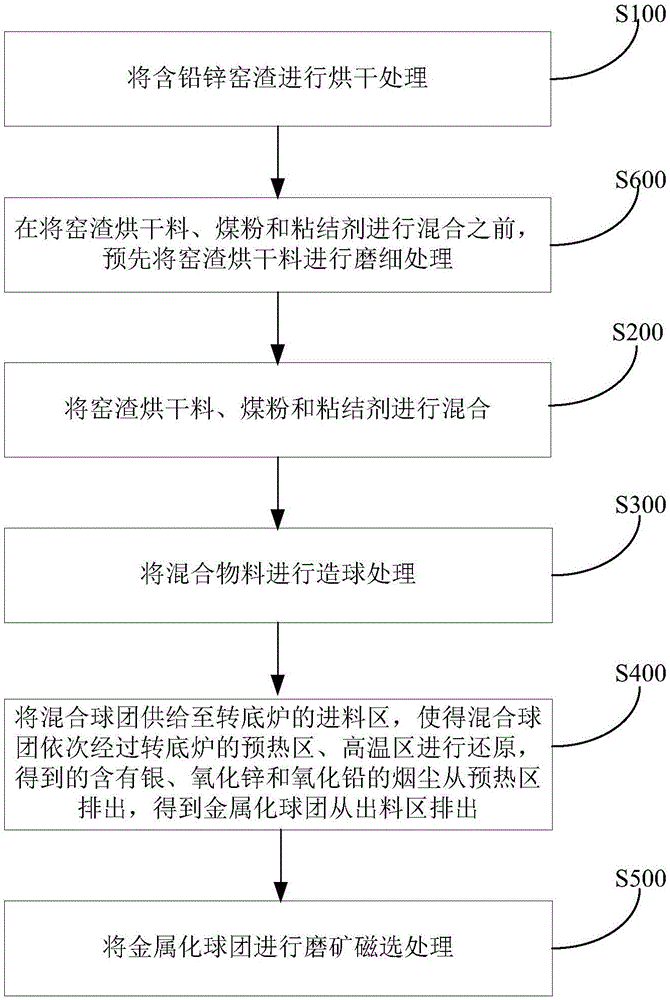

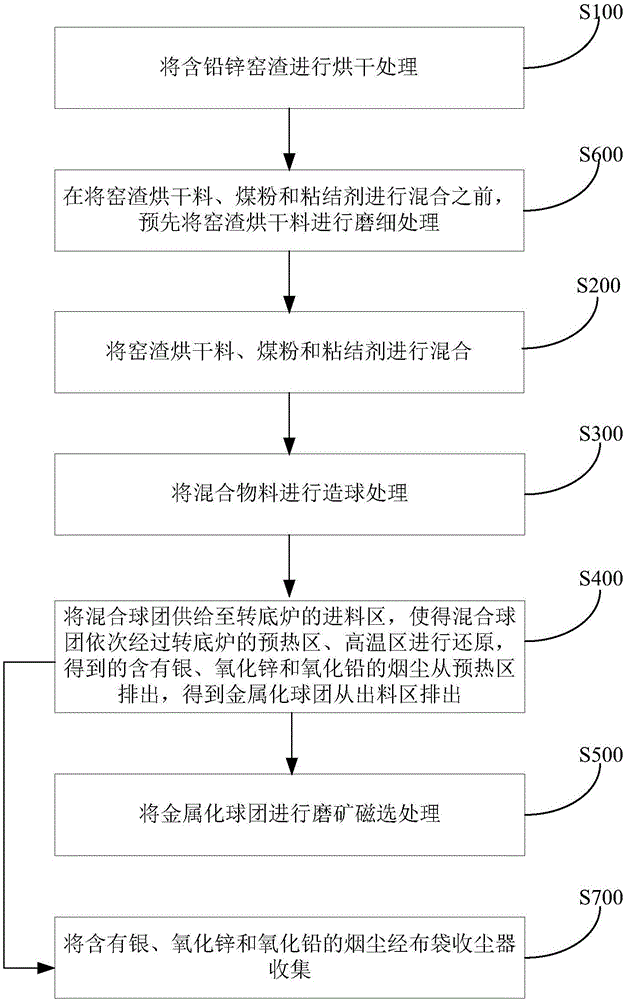

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

Kiln cleaning apparatus

Owner:MARTIN ENG

Method for preparing lithium manganate by wet-doping method

InactiveCN103337619AIncrease the average oxidation stateSuppress purityCell electrodesManganates/permanganatesOxidation stateManganate

Owner:HUNAN DAHUA NEW ENERGY

Surface concave-convex pattern sculpturing molding method for Jianshui purple pottery white mud device

InactiveCN110078474AStrong three-dimensional senseStrong light and shadow effectDecorative surface effectsClaywaresSurface patternKiln

Owner:方志坚

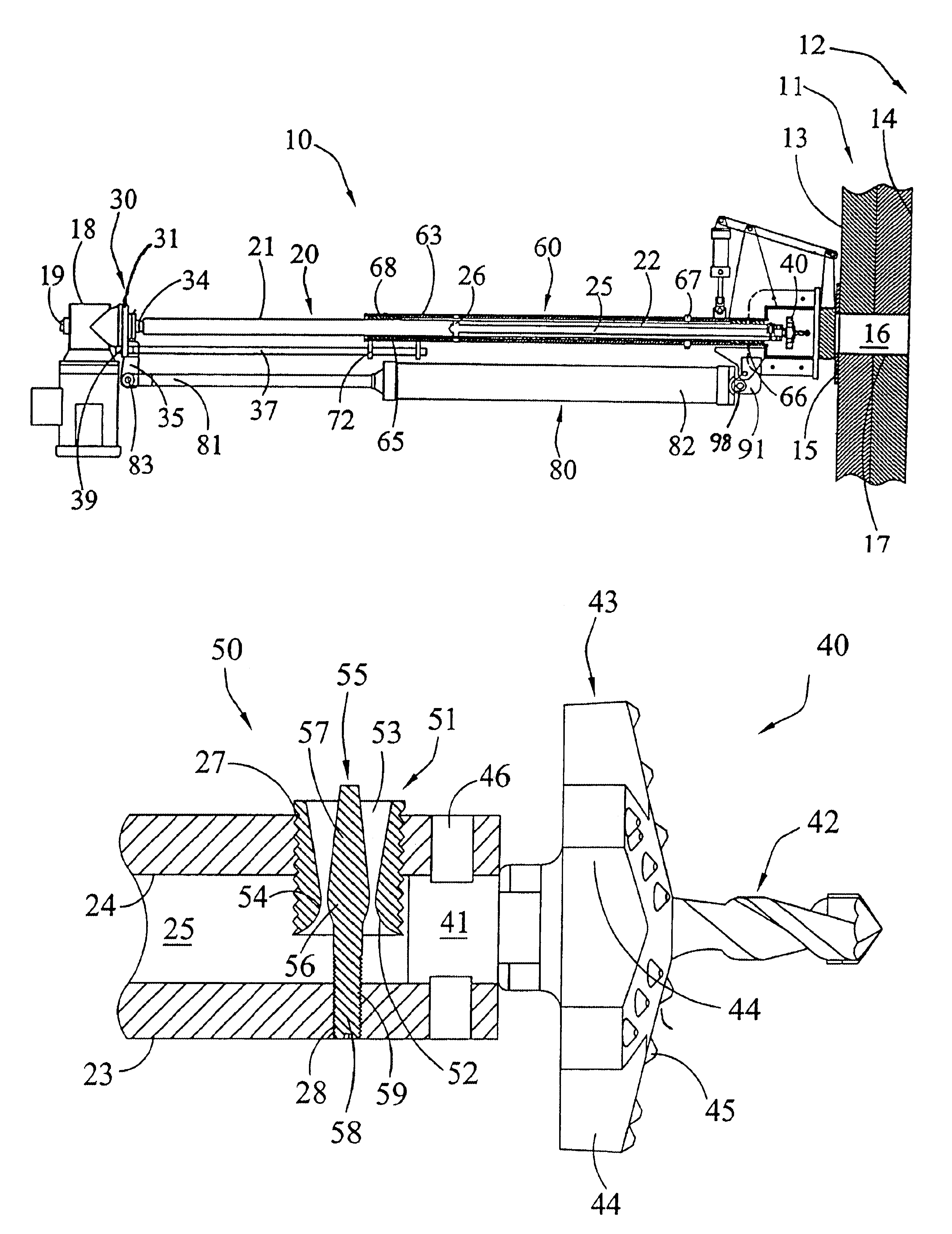

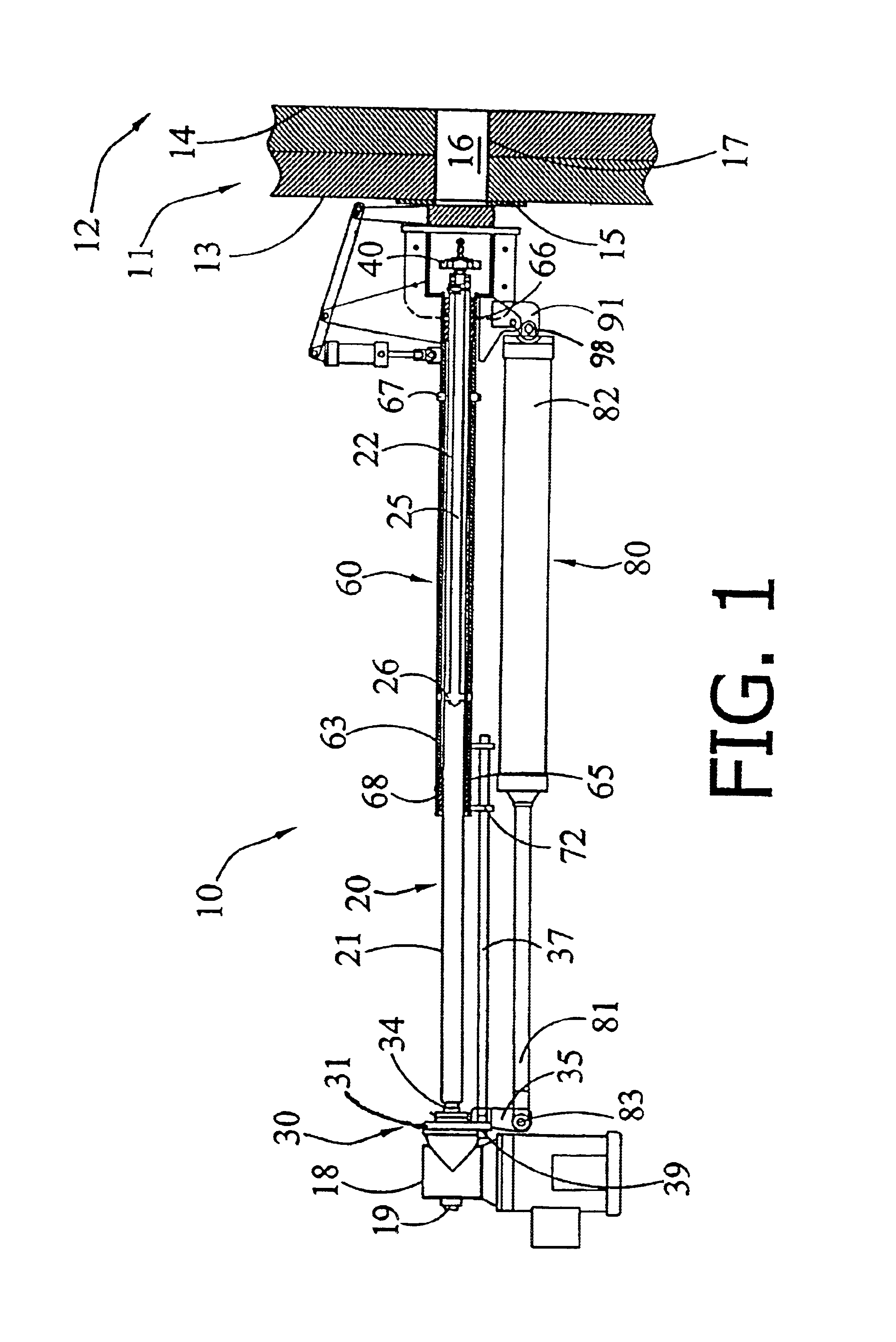

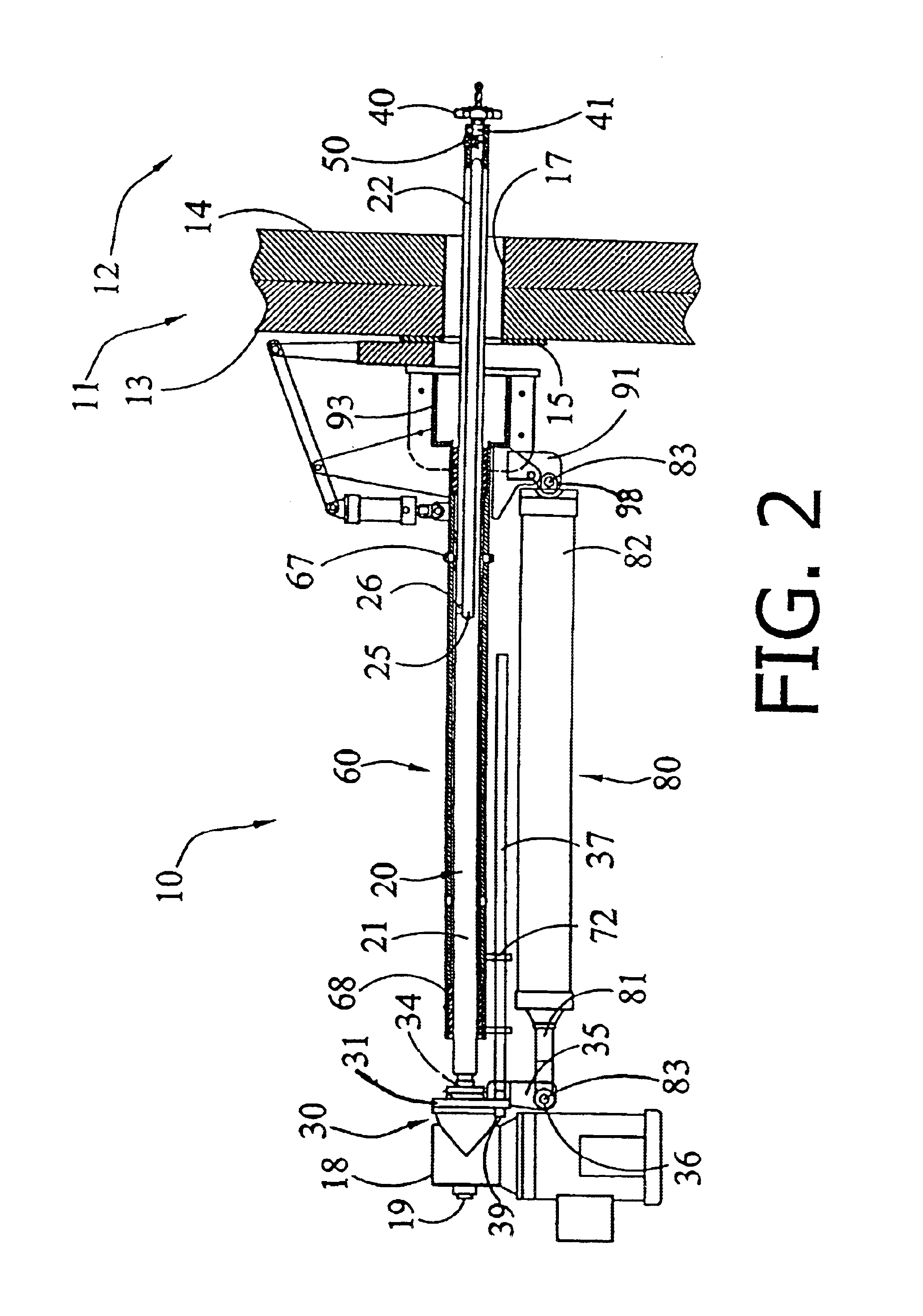

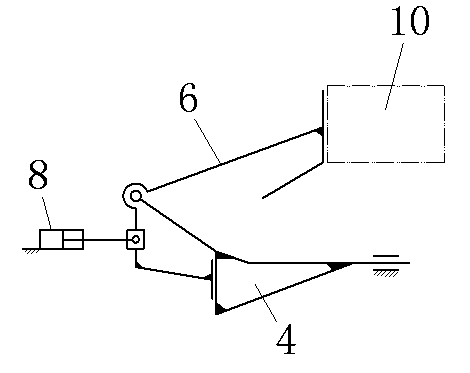

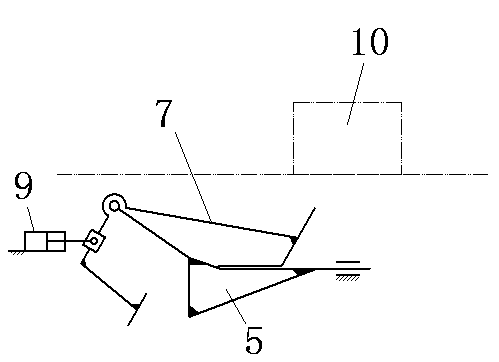

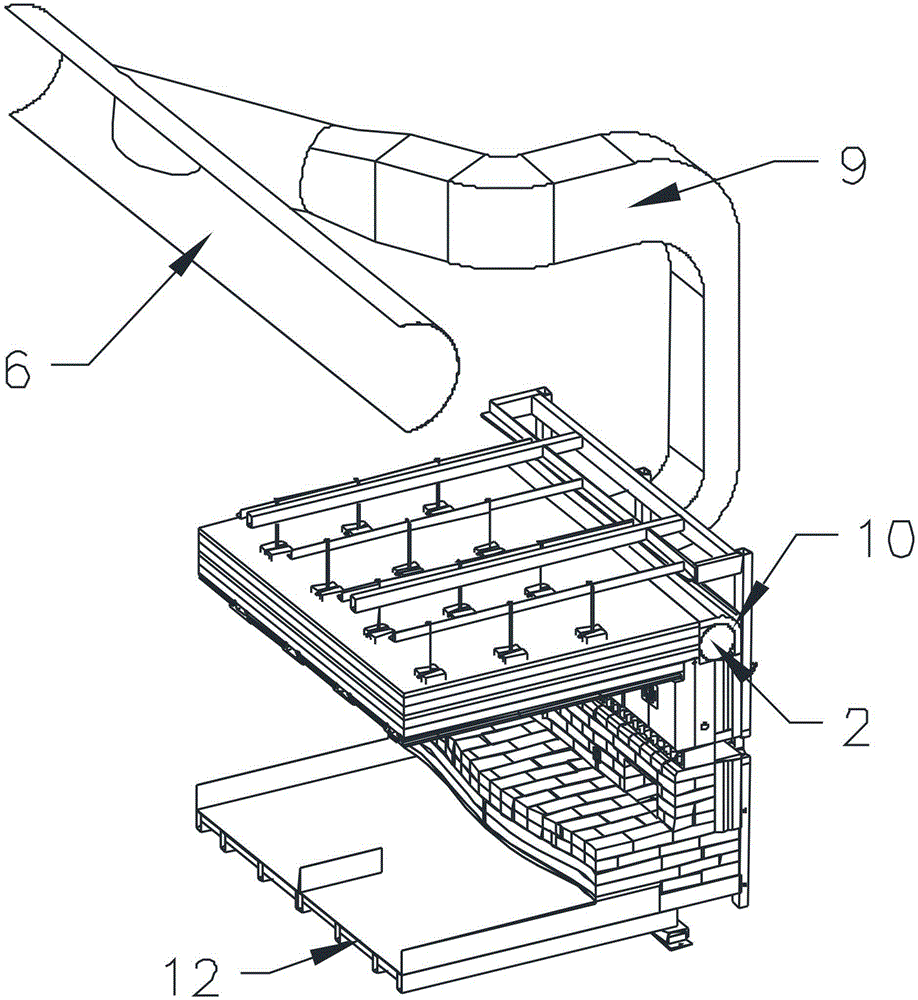

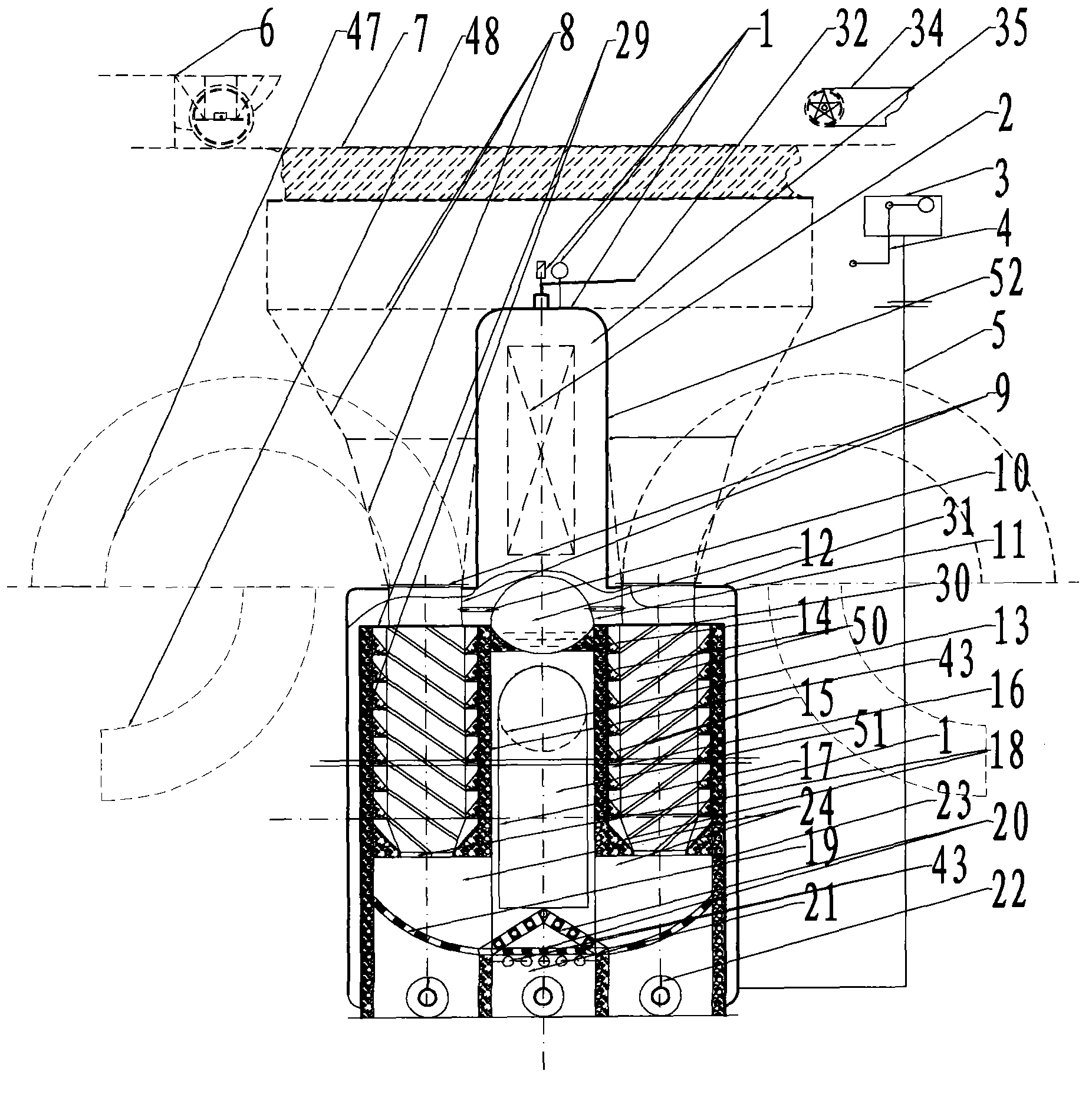

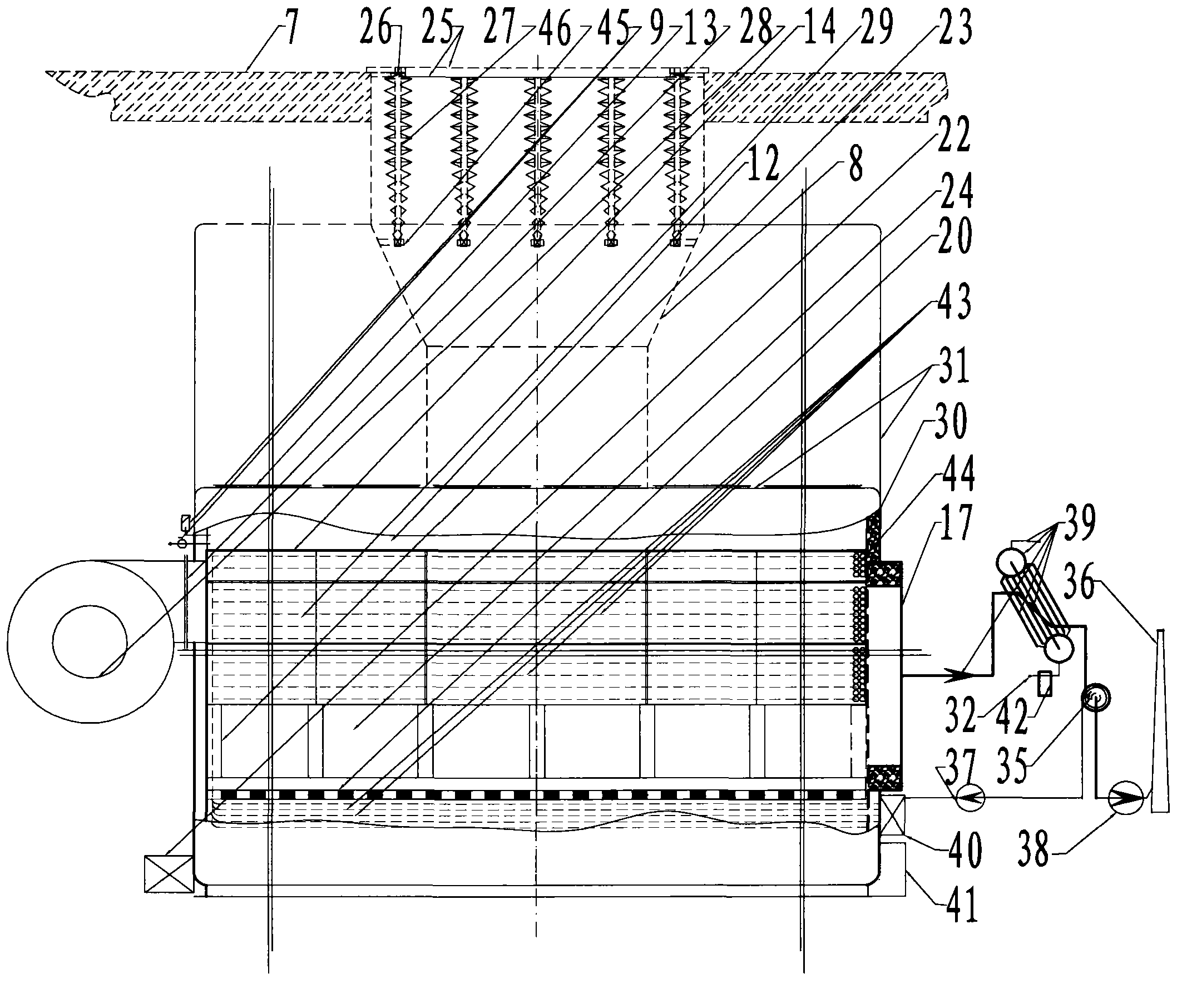

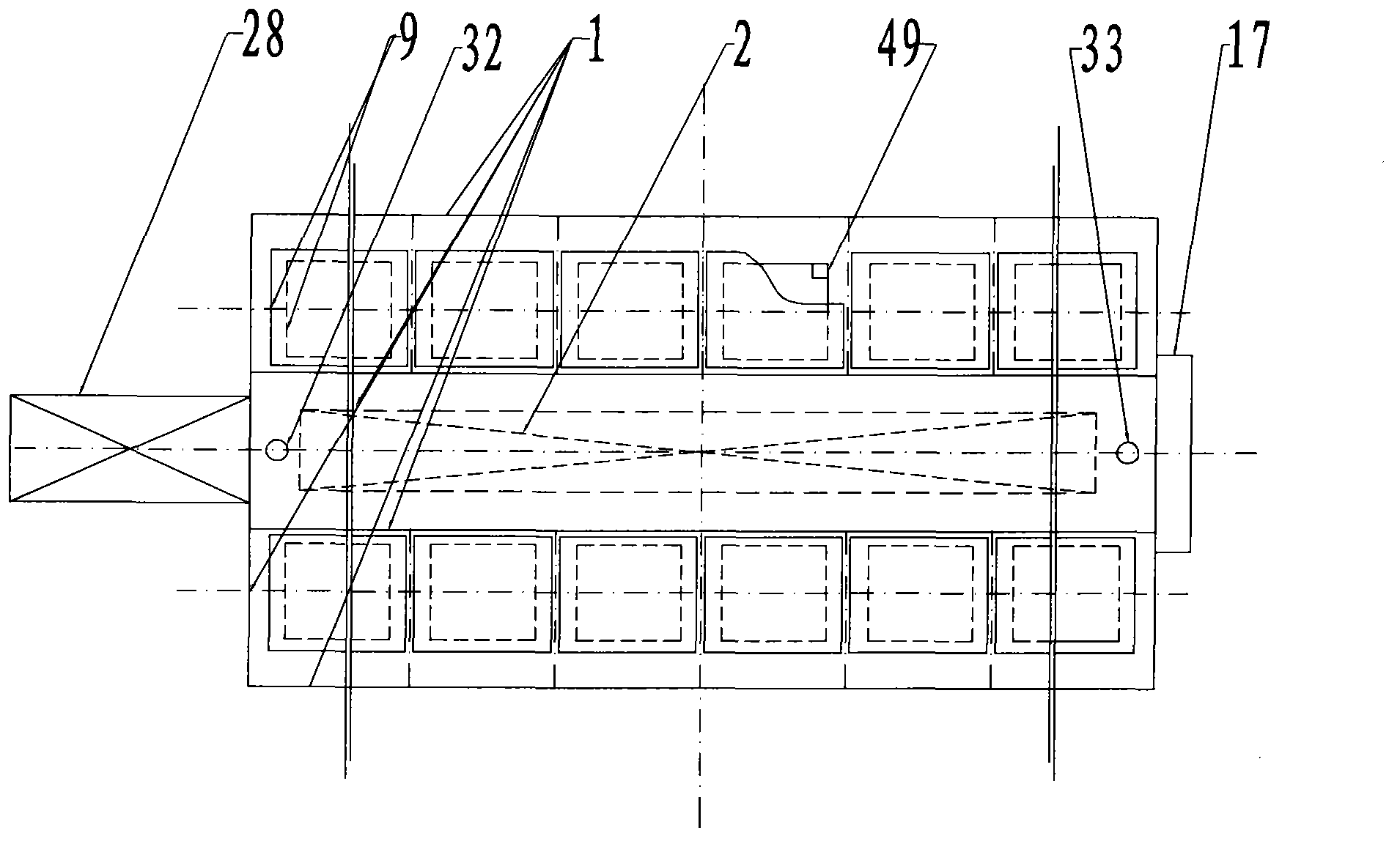

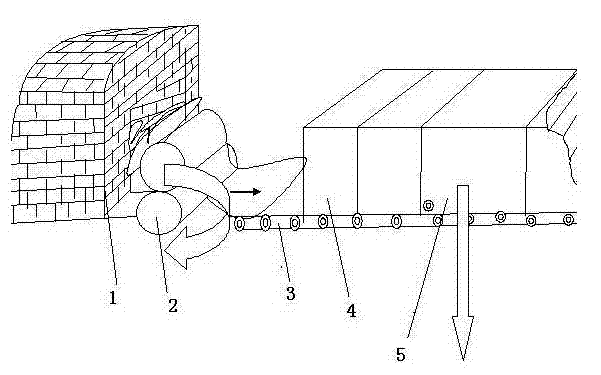

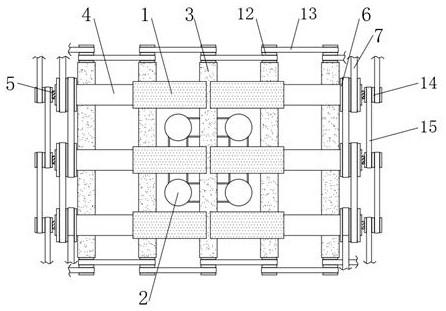

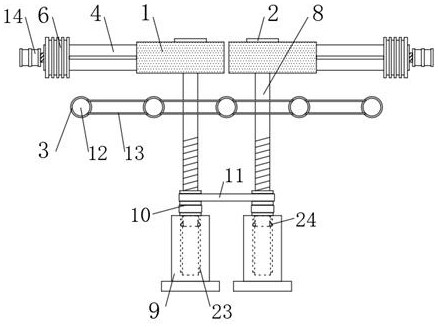

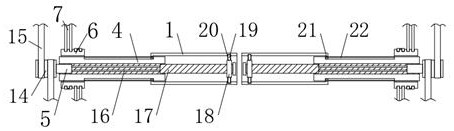

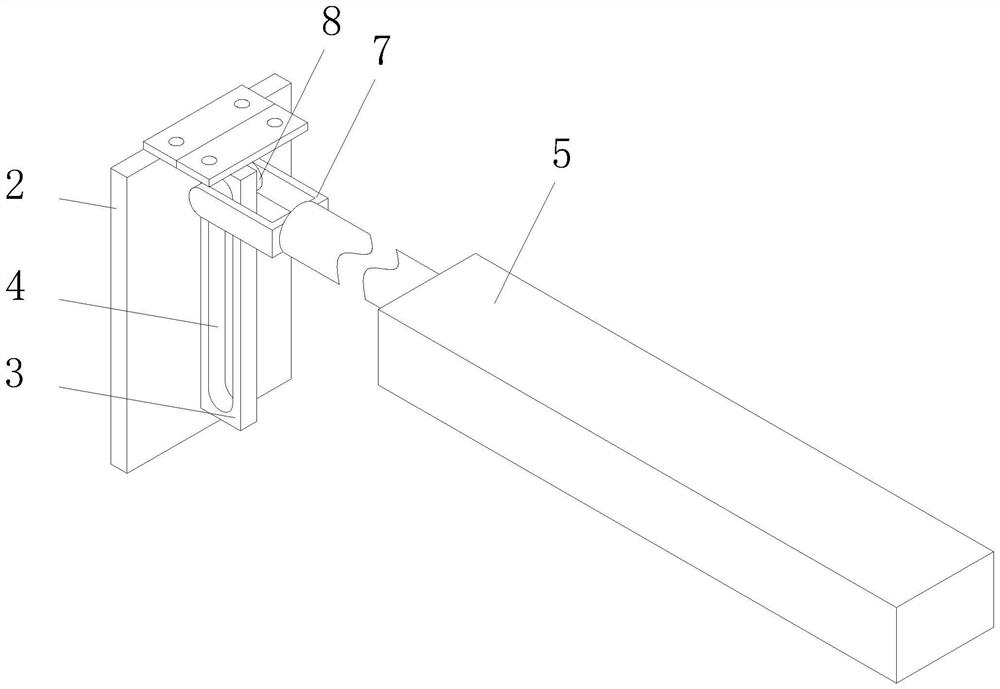

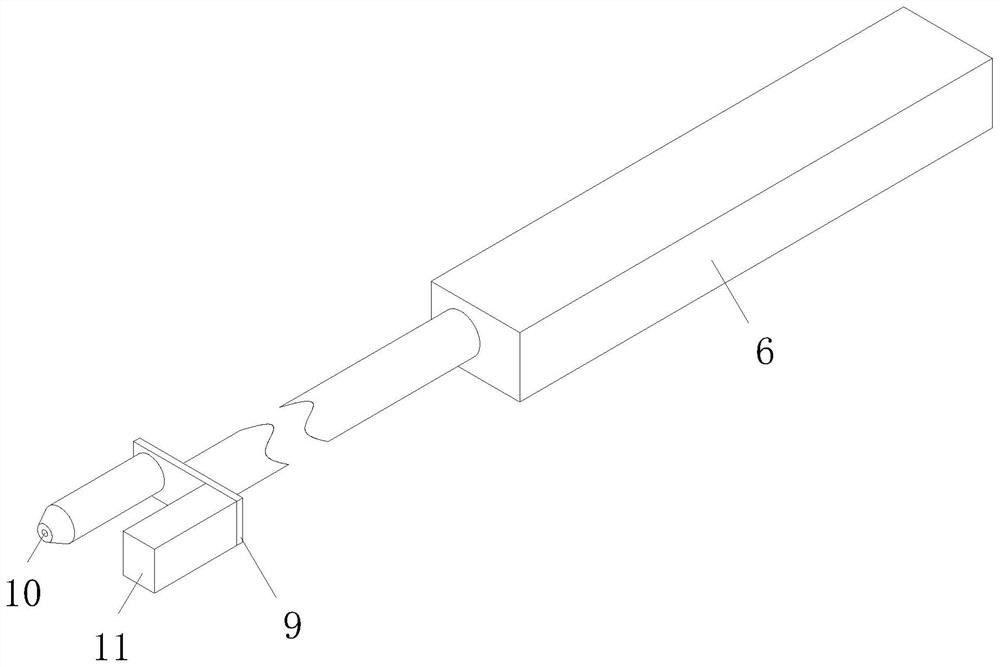

Method and device for achieving bi-directional stepping of kiln car on assembling and disassembling rail

ActiveCN103808138AReduce labor intensityIncrease productivityCharge manipulationFurnace typesHydraulic cylinderMechanical engineering

Owner:GUIYANG AL-MG DESIGN & RES INST

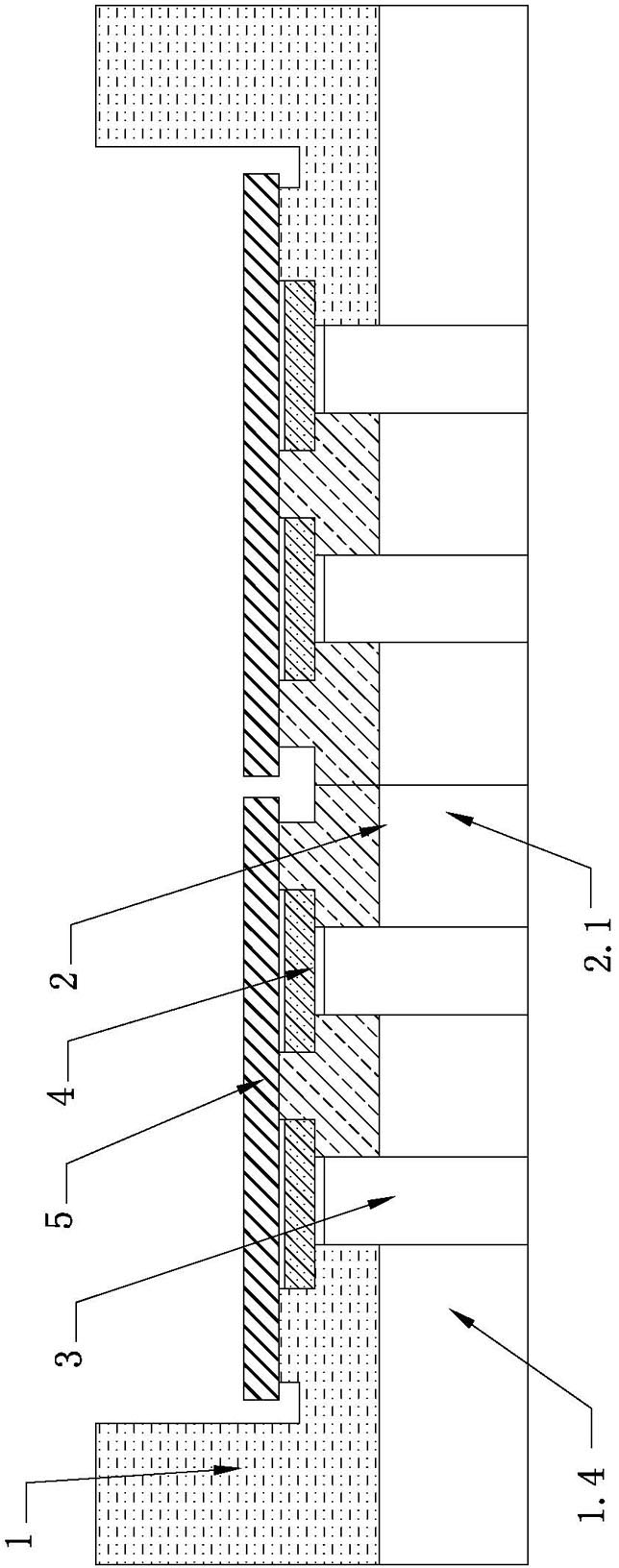

Combustion supporting air heating and energy storing energy-saving roller kiln

InactiveCN105403037AReduce lossReduce energy consumptionFurnace typesWaste heat treatmentCombustionInsulation layer

Owner:MODENA TECH LTD

Water-based combustion-supporting straw particle boiler-kiln universal burner with fuel such as coal, gas and oil

InactiveCN104235832AKeep aliveResponse is continuous and stableCombustion using multiple fuelsCombustion using catalytic materialWater basedBrick

Owner:管理

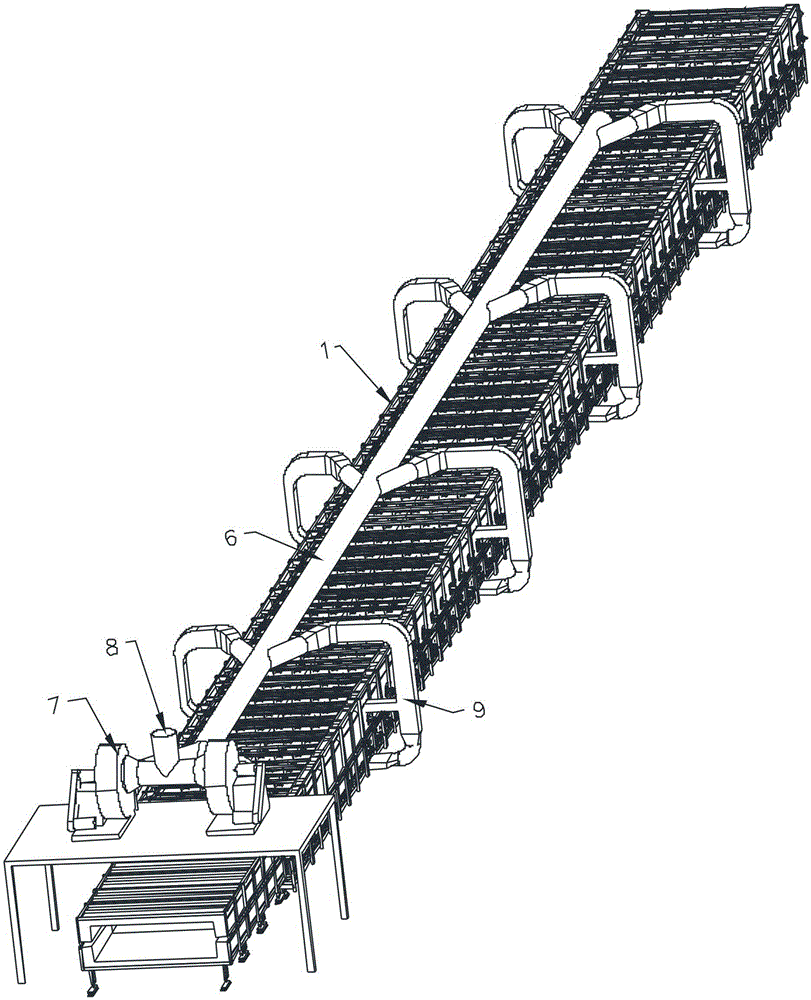

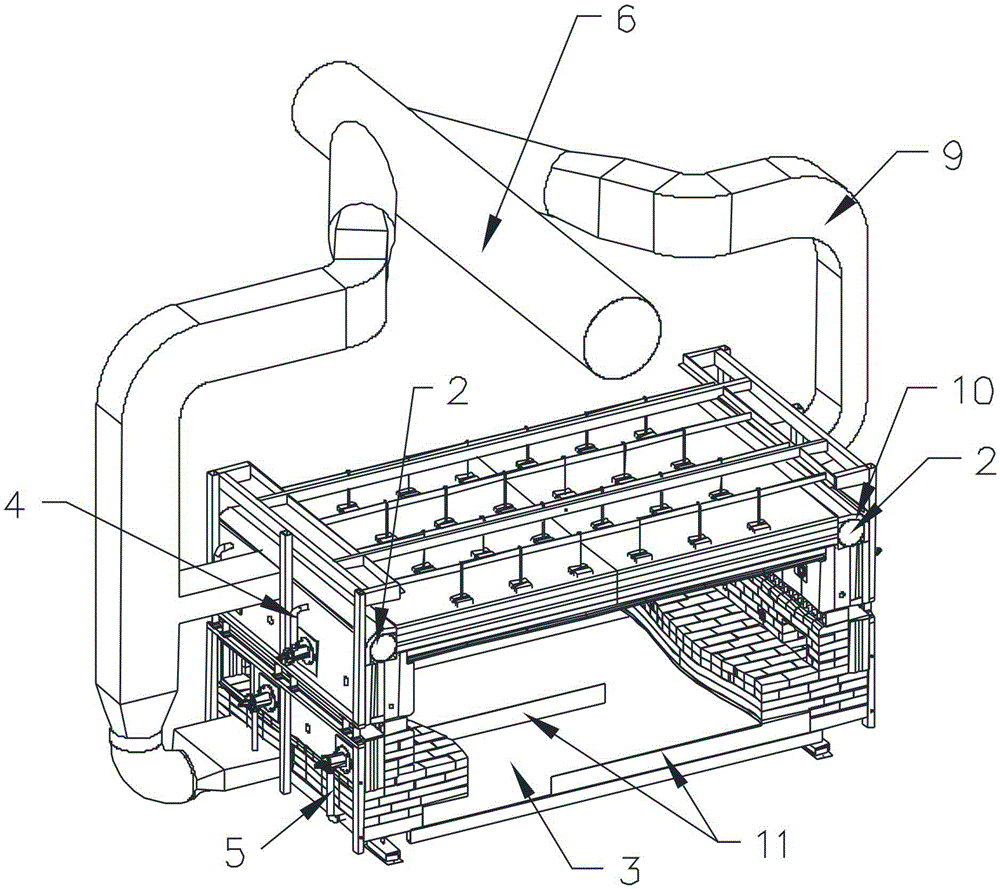

Lumber drying kiln

InactiveCN101144685AImprove thermal conductivityTemperature safetyHeating arrangementCombustion chamberHeat conducting

Owner:李祥文

Method for preparing green glaze ceramic cup artwork

Owner:ANHUI HONGFU CRAFTS

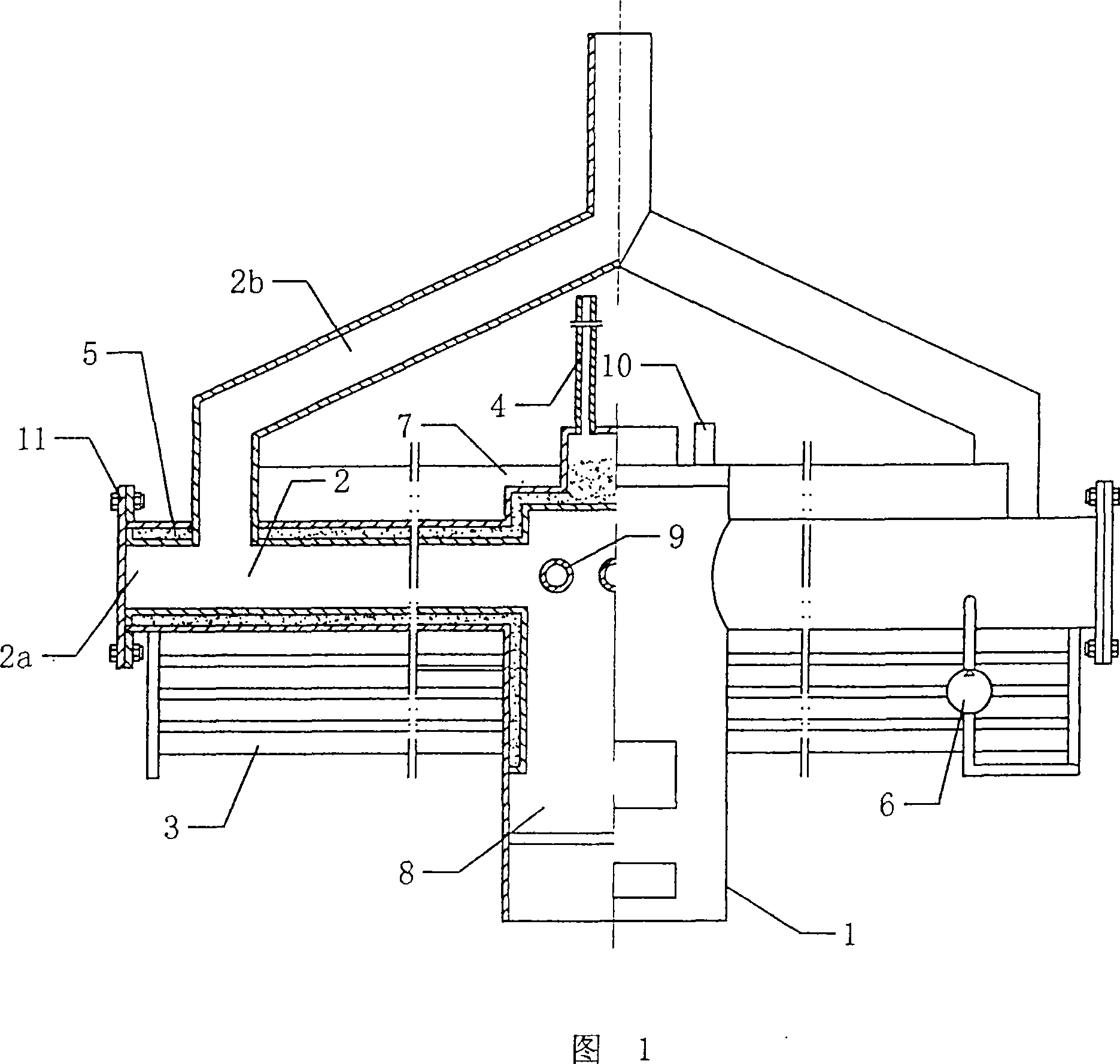

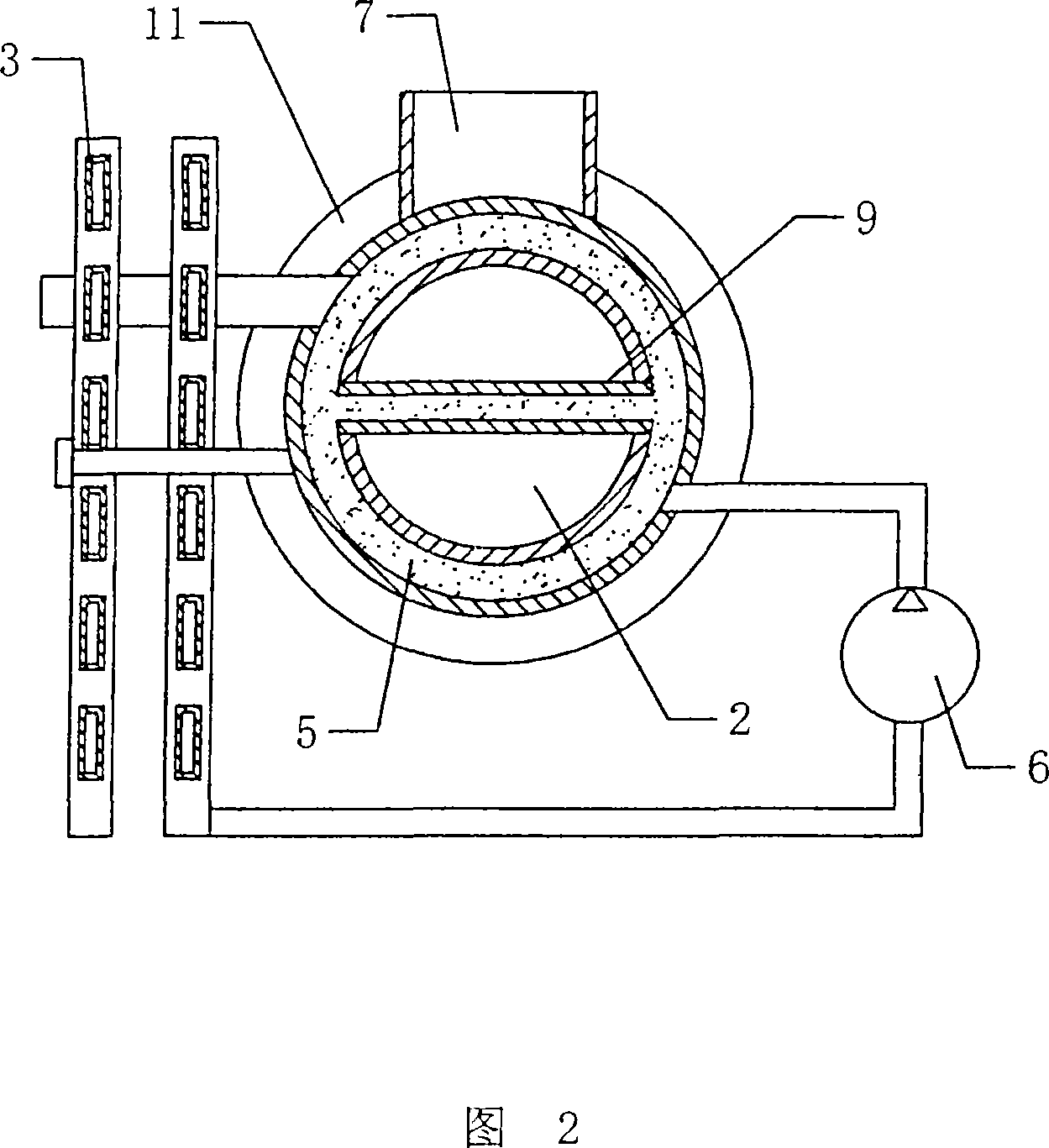

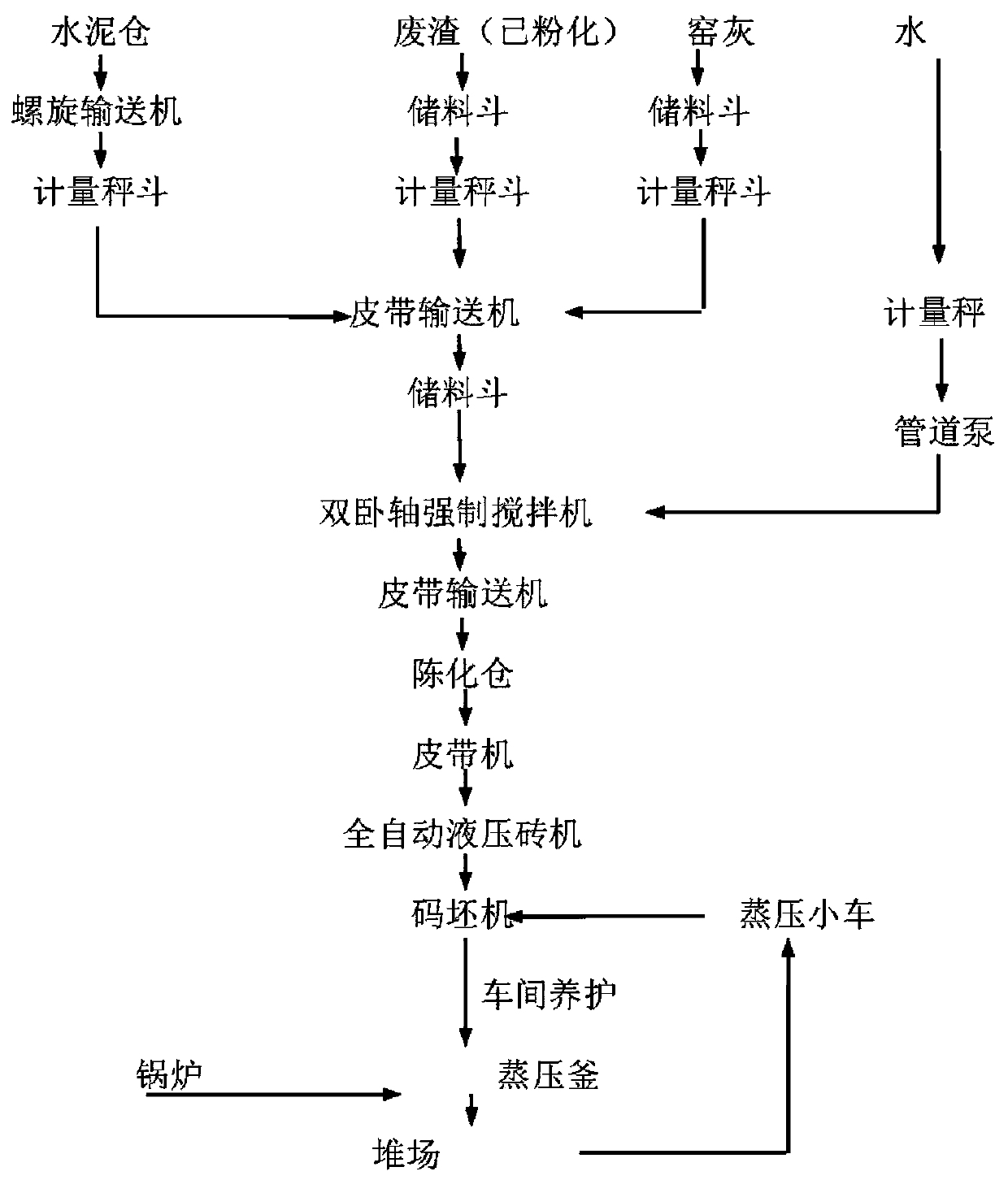

Technology for making bricks from aggregate waste residues

Owner:华新新型建筑材料有限公司

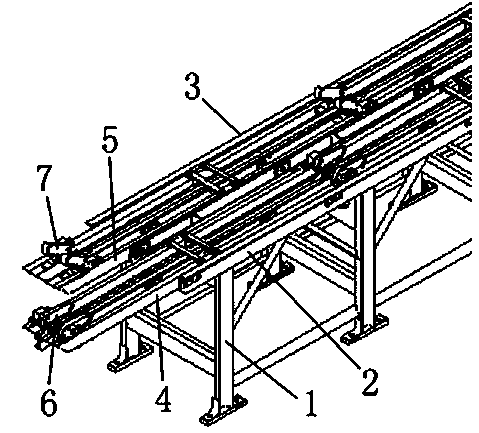

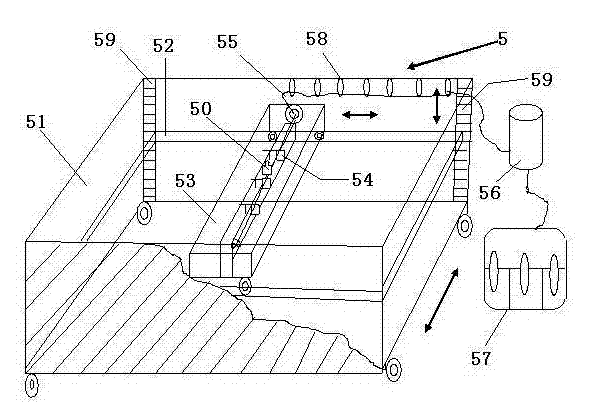

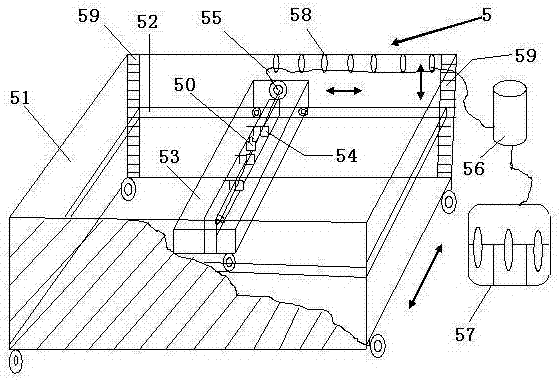

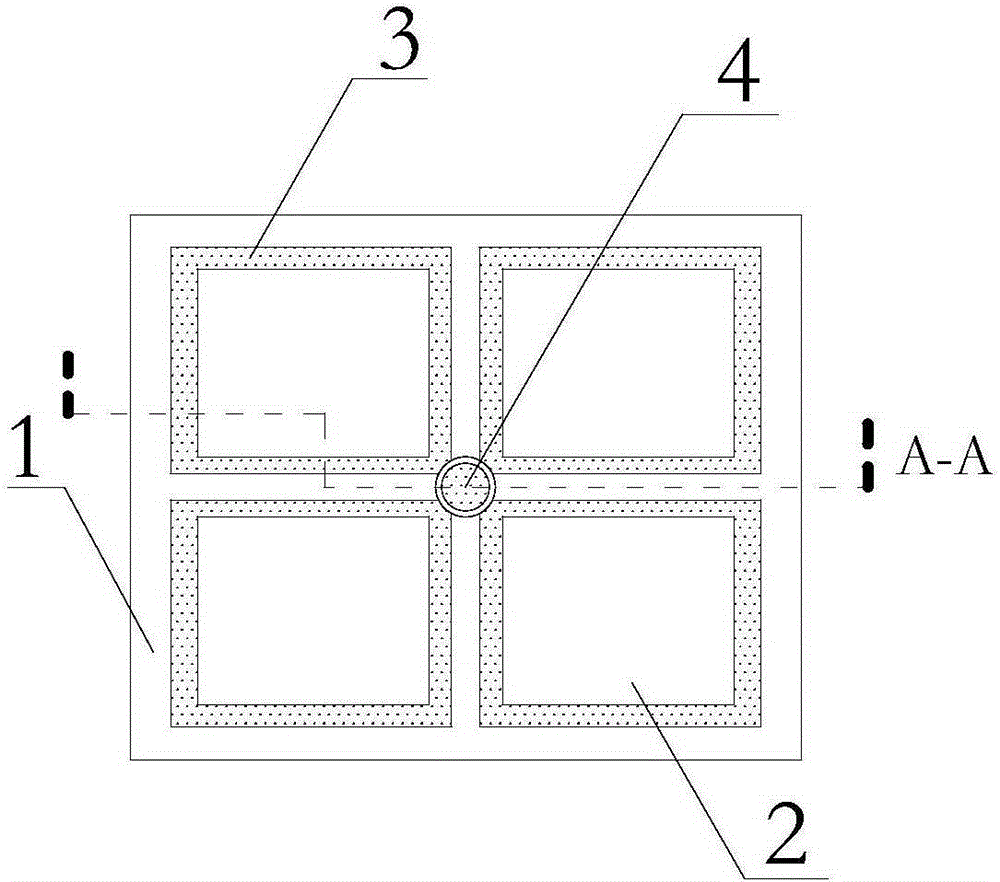

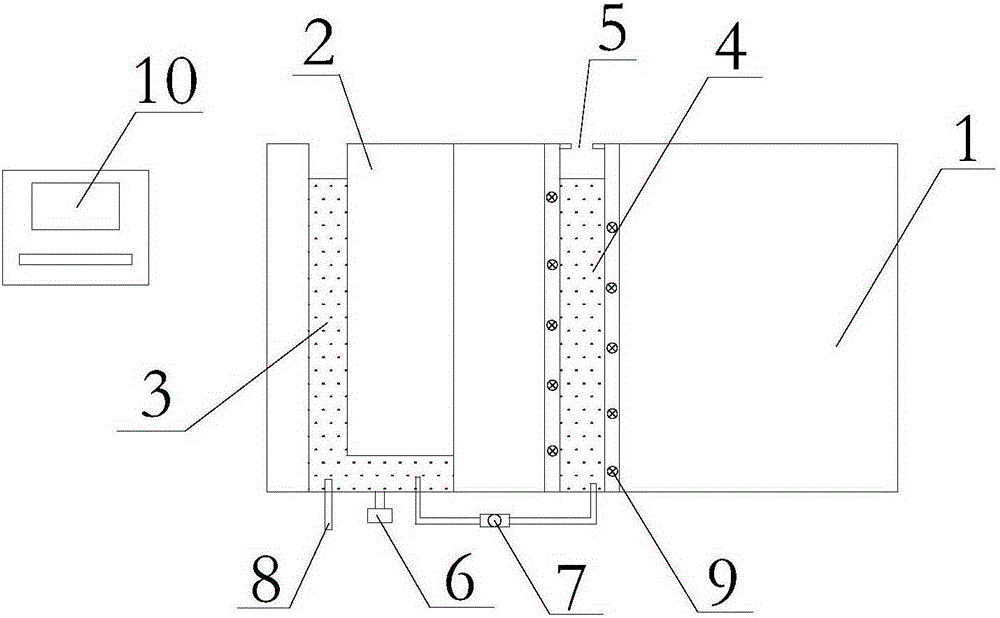

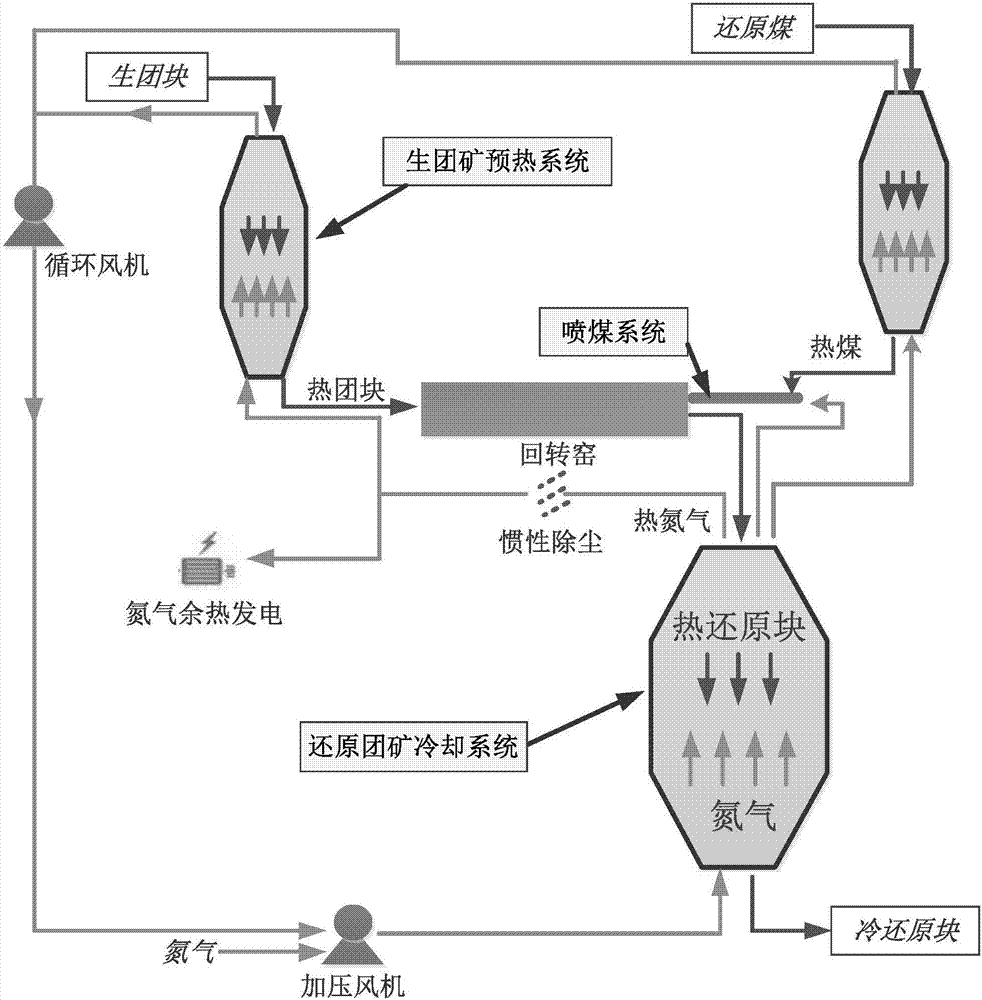

Accelerating separation device, leveling device and roller kiln

The invention discloses an accelerating separation device, a leveling device and a roller kiln. The accelerating separation device comprises a plurality of roller bars which are sequentially arranged at intervals to form a conveying line, the conveying line is provided with a low-speed section and a high-speed section which are sequentially connected in the conveying direction, and the low-speed section and the high-speed section are each provided with the more than two roller bars; at least one roller bar, closest to the high-speed section, in the high-speed section is a composite roller, each composite roller comprises more than one annular rotating piece used for supporting materials and a mandrel driven by a second driving device to rotate, and the annular rotating pieces are installed on the mandrels in a sleeving mode in the mode that the annular rotating pieces can rotate on the mandrels and generate resistance during rotation to hinder rotation of the annular rotating pieces. The leveling device comprises the accelerating separation device and a material blocking and leveling mechanism. The roller kiln comprises a furnace body with a hearth and a roller bar type conveying line, and the roller bar type conveying line is provided with the accelerating separation device or the leveling device. The accelerating separation device, the leveling device and the roller kiln have the advantages of being simple in structure, low in cost, easy to manufacture and implement, capable of reducing the possibility of material disorder and jamming and the like.

Owner:HUNAN JINLU TECH CO LTD

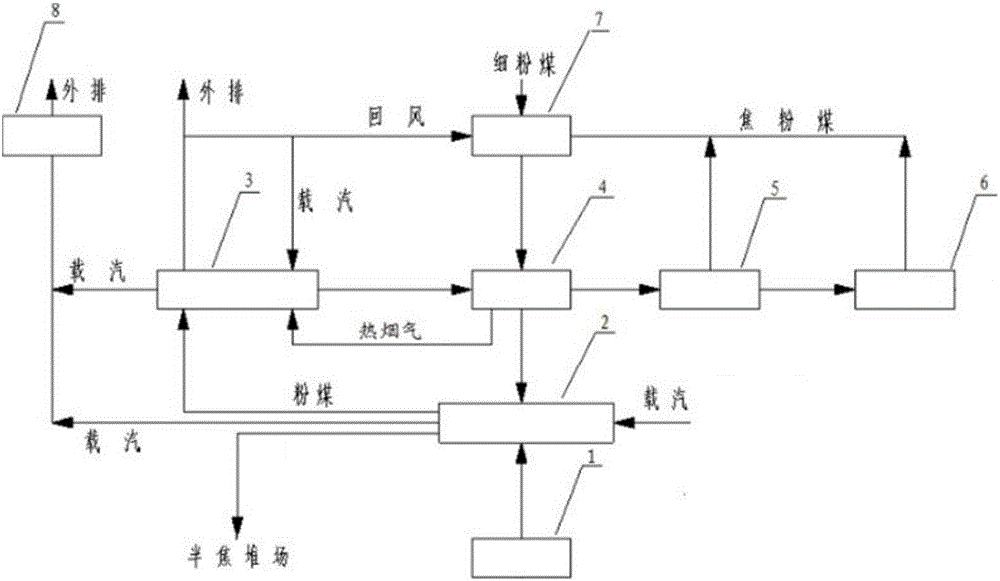

Pyrolytic process method for directly drying pulverized coal through semicoke

InactiveCN106190205AReduced risk of cloggingSimple processEnergy inputSpecial form destructive distillationProcess engineeringHeat energy

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

An online coating system for solar ultra-clear embossed glass

Owner:FLAT GLASS GROUP CO LTD +1

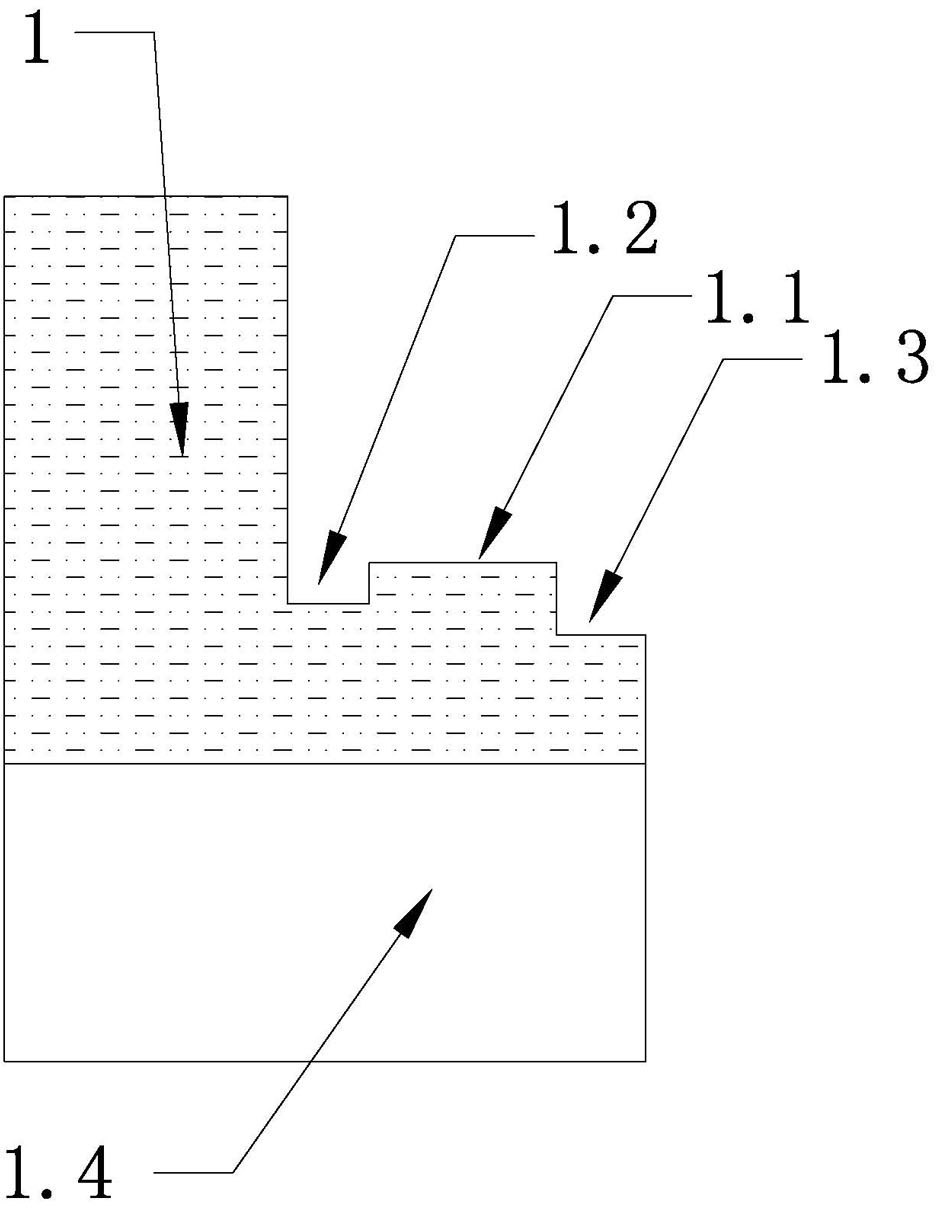

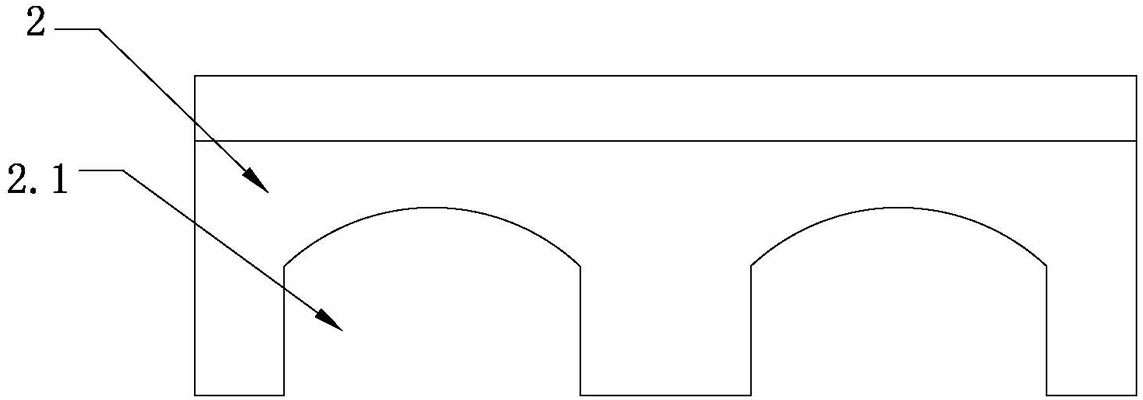

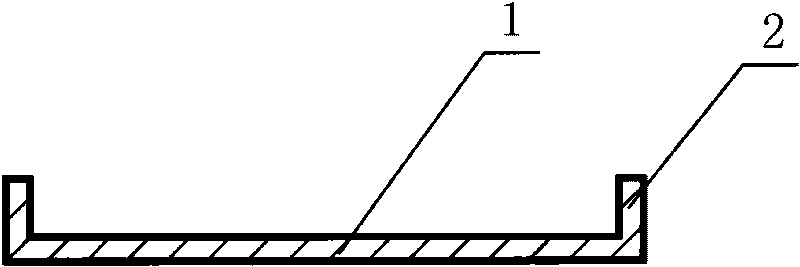

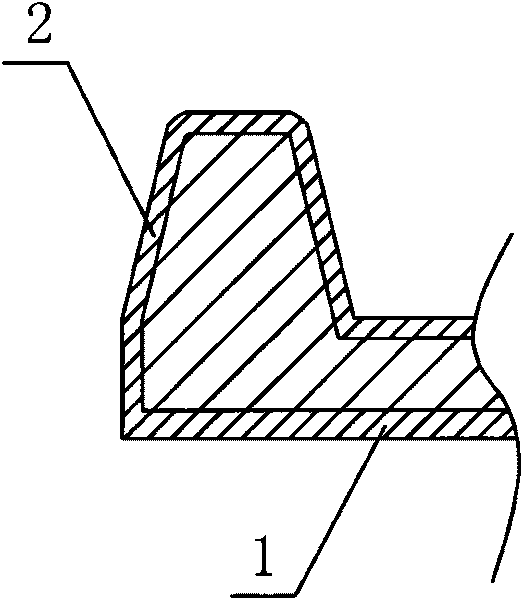

Sandwich setter plate

Owner:冯维银

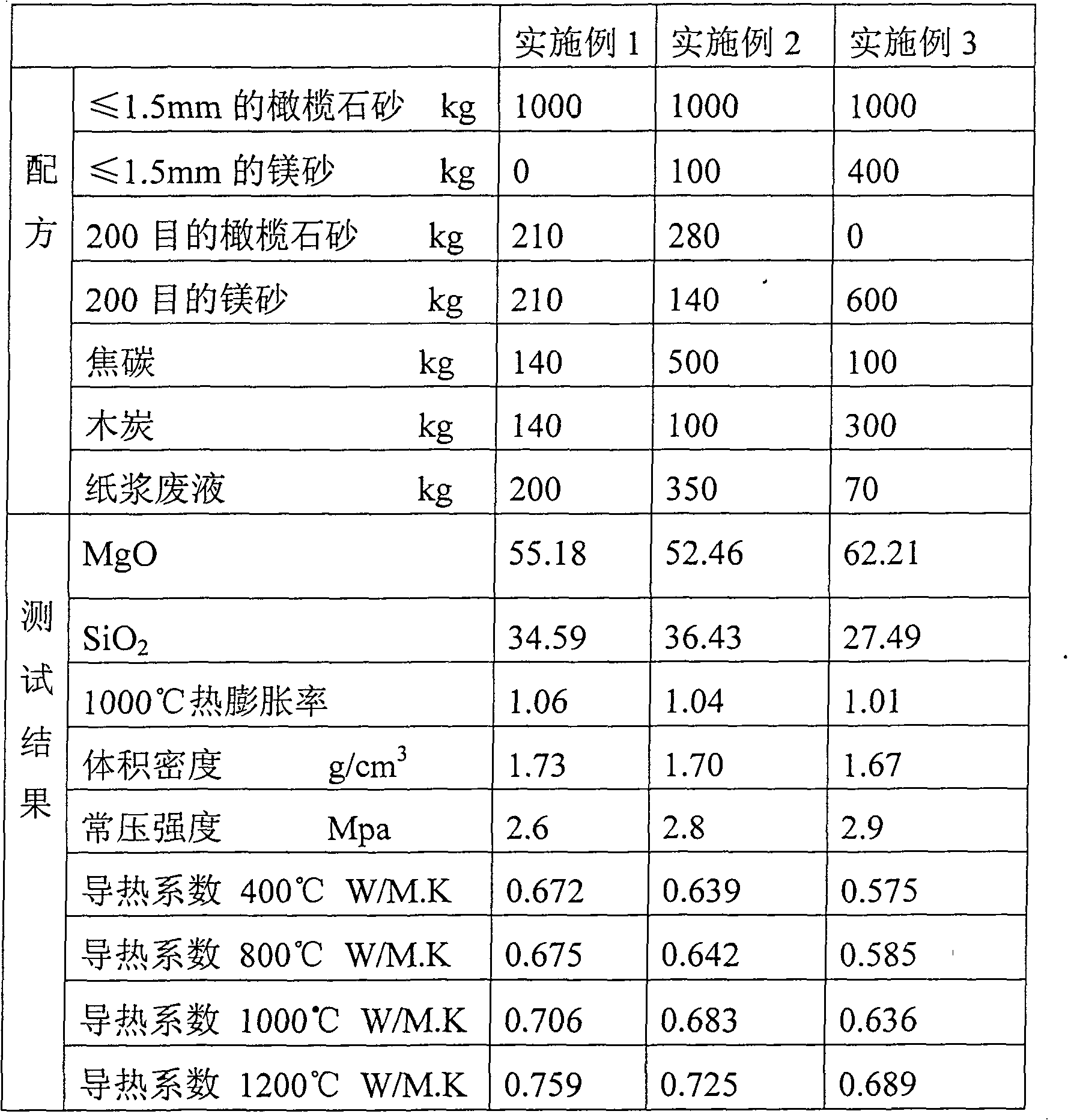

Lightweight forsterite brick and manufacturing method thereof

Owner:中国建筑材料科学研究院大石桥镁砖厂

Integrated float glass production device

InactiveCN112479583AImprove annealing efficiencyGlass transportation apparatusProduction lineElectric machine

Owner:合肥加拓宝商业管理有限公司

Fermented soybean fermentation tank

Owner:CHONGQING YONGCHUAN FERMENTED SOY BEAN FOOD CO LTD

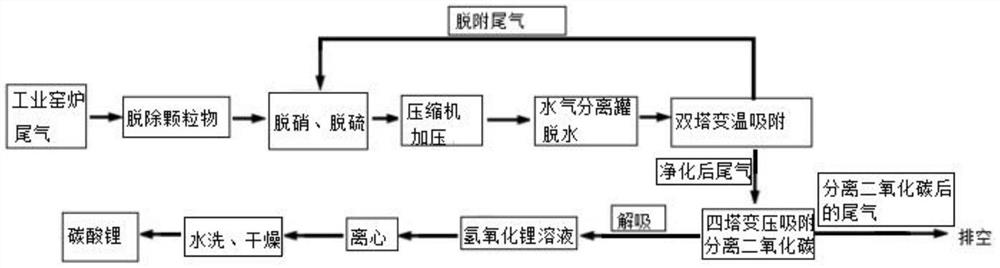

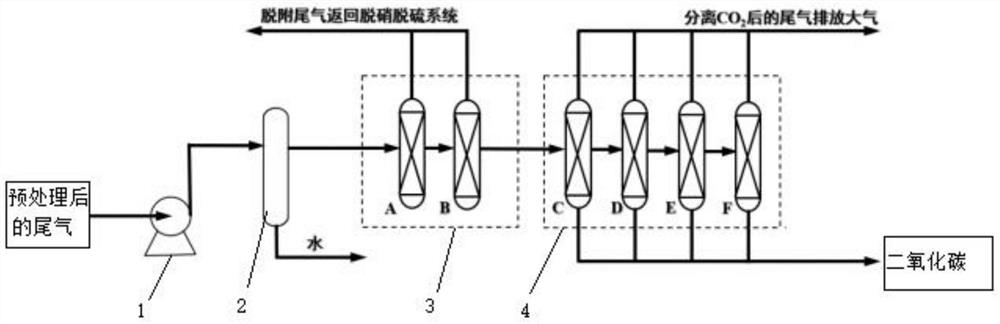

Method for recovering carbon dioxide from tail gas of industrial kiln and producing lithium carbonate

ActiveCN114835142AHigh gas purityHigh recovery rateProductsCarbon compoundsParticulatesLithium hydroxide

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD +1

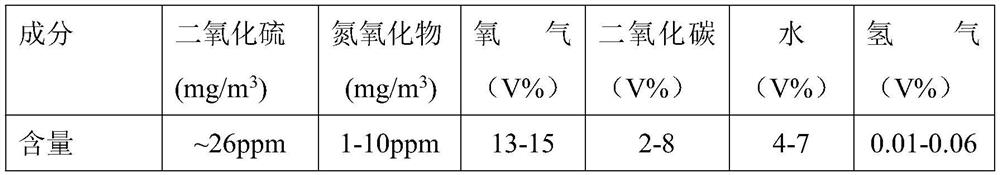

Laterite-nickel-ore reduction and cooling method

Owner:CENT SOUTH UNIV

Automatic flameout and ignition device for kiln

PendingCN114034195APlay a protective effectCombustion ignitionControl devices for furnacesFlameoutEngineering

Owner:佛山市凌赫热能科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap