High-temperature zone track of nitrogen atmosphere protection pushed slab kiln

A pusher kiln and high temperature zone technology, applied in the track field of pusher kiln, can solve problems such as unsafe accidents, reduce nitrogen atmosphere protection pusher kiln production efficiency, easy loosening of refractory bricks, etc., achieve less maintenance and repair, reduce economic The effect of burden and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

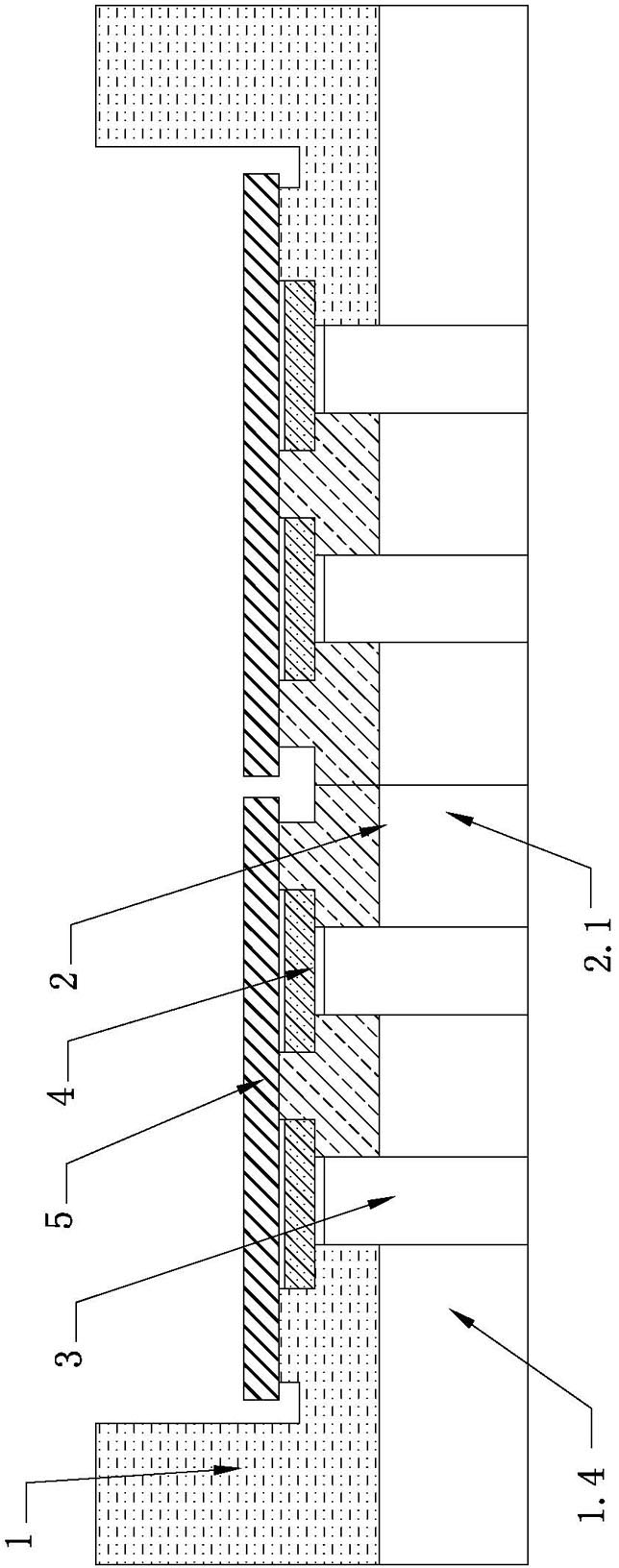

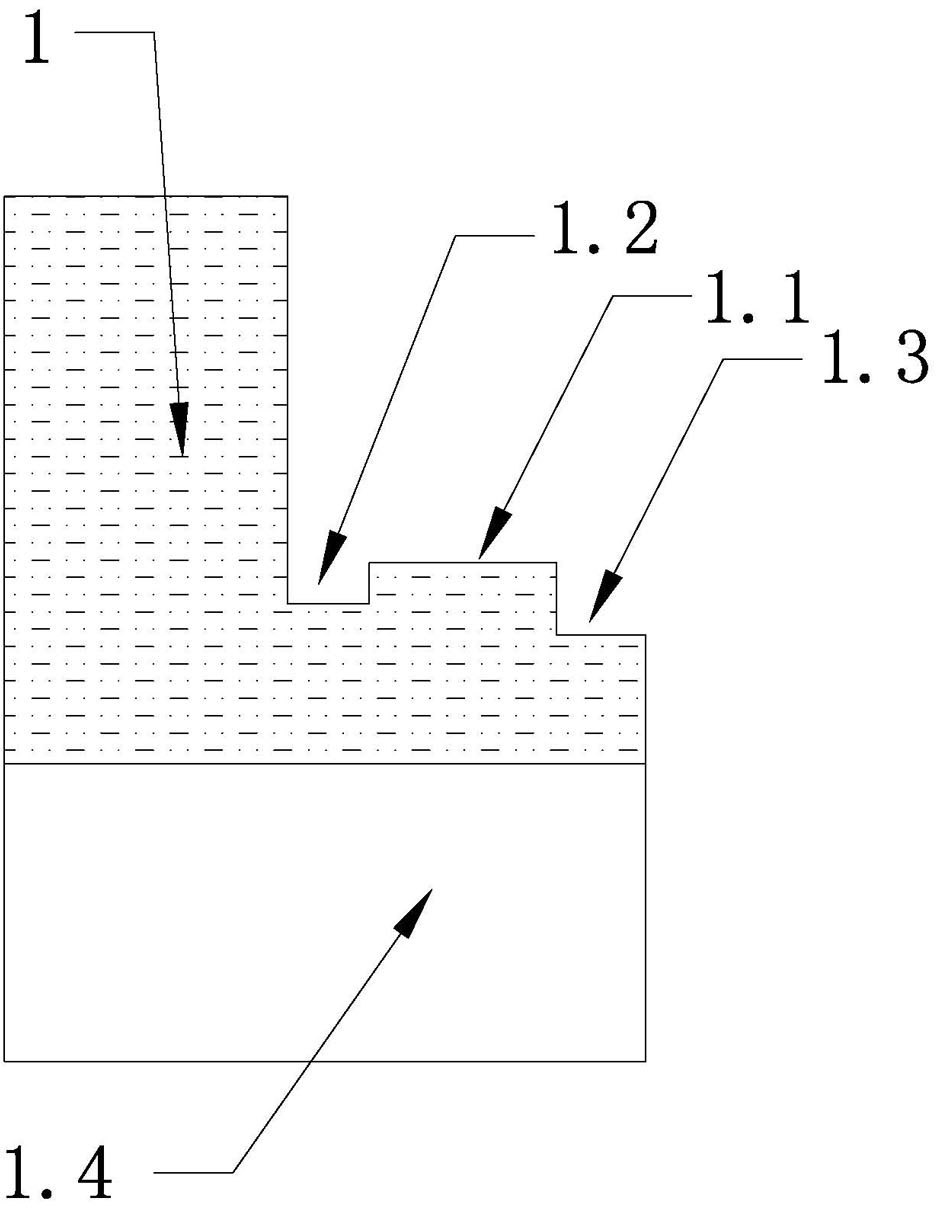

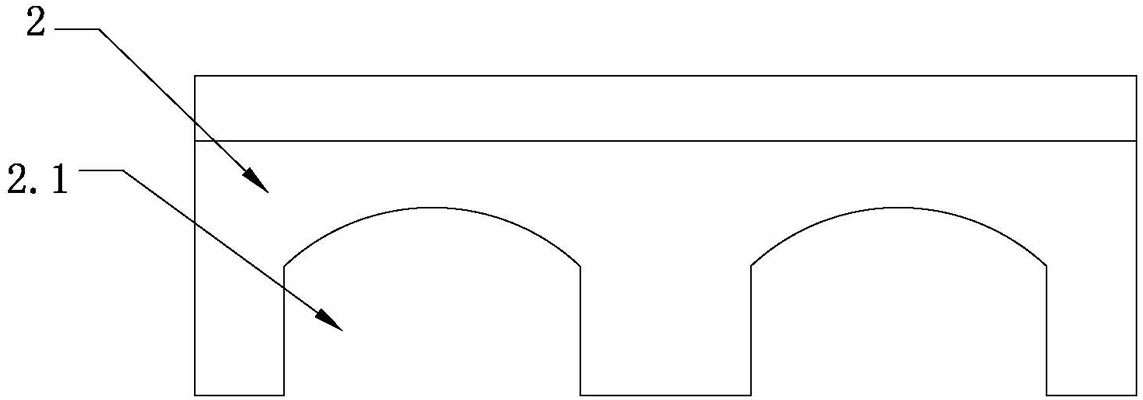

[0012] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a nitrogen atmosphere protects the track in the high temperature zone of the pusher kiln, which is characterized in that it includes a side rail 1, a middle rail 2, a spacer 3 and a partition 4; the side rail 1 is L-shaped, and the side rail 1 transverse base 1.1 has a groove 1.2 and a notch 1.3, and two arched notches 1.4 are arranged at the lower end of the side rail 1; the middle rail 2 is an inverted T shape, and two arched notches 2.1 are arranged at the lower end of the middle rail 2; The side rails 1 are installed on both sides respectively, and the four middle rails 2 are installed between the two side rails 1, and spacers 3 and partitions are installed between the side rails 1 and the middle rail 2, and between the middle rail 2 and the middle rail 2. 4. The middle two middle rails 2 are installed close to each other. Push plate 5 is placed on side rail 1, middle rail 2, and heating pipe can be insta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap